MTS Sensors Temposonics R, Temposonics RP, Temposonics RH Datasheet

Temposonics

®

SENSORS

Magnetostrictive, Absolute, Non-contact

Linear-Position Sensors

R-Series Models RP and RH

DeviceNet Output

Data Sheet

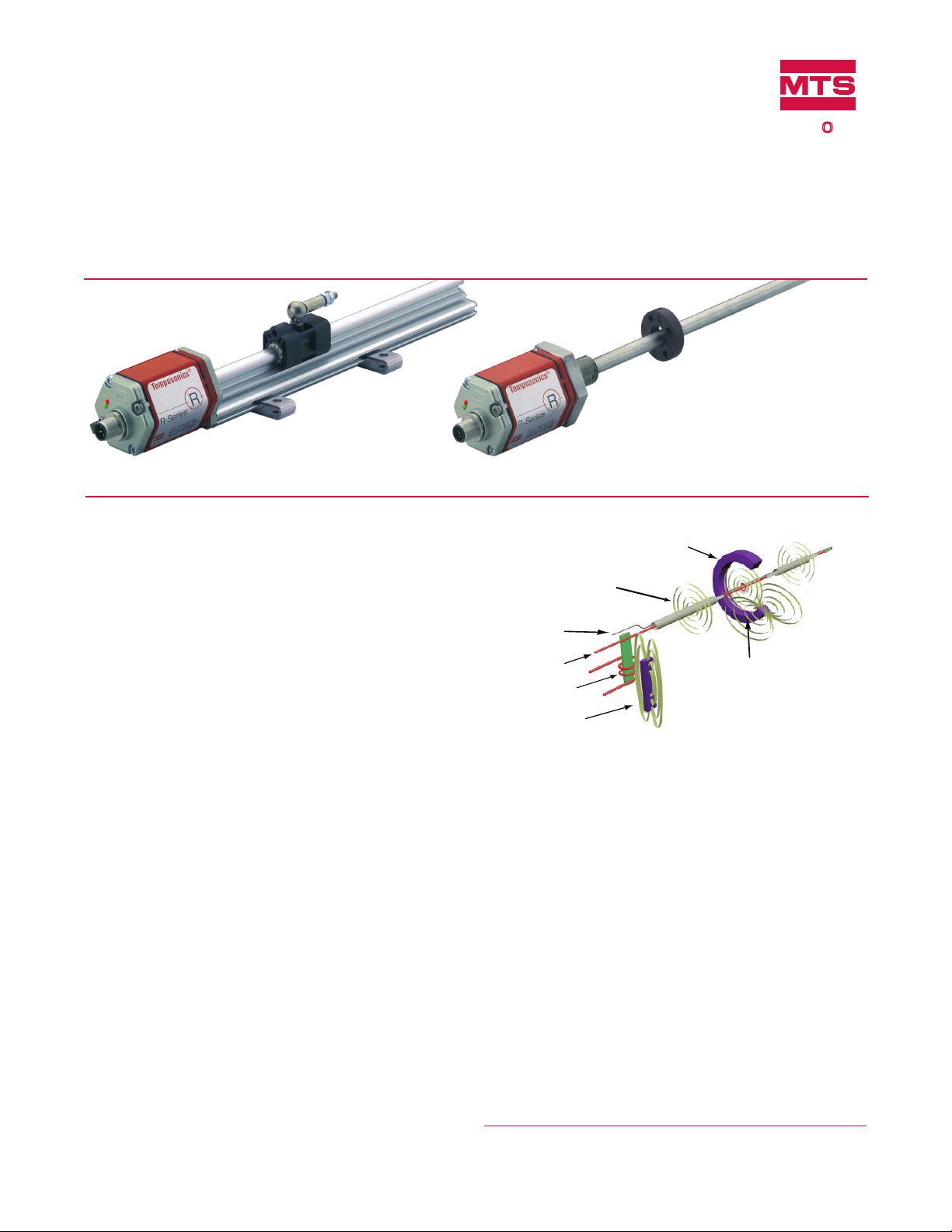

Model RP Prole-style position sensor

FEATURES

Linear, Absolute Measurement

LEDs For Sensor Diagnostics

Superior Accuracy, Resolution down to 2 µm

Non-Contact Sensing Technology

Linearity Deviation Less Than 0.01%

Repeatability Within 0.001%

Direct DeviceNet Output

BENEFITS

Rugged Industrial Sensor

Cost-effective Communications Network linking Industrial

Measurement and Control Devices

Interface Up to 64 Devices using one cable

APPLICATIONS

Continuous Operation In Harsh Industrial Conditions

High Pressure Conditions

TYPICAL INDUSTRIES

Factory Automation

Fluid Power

Plastic Injection and Blow Molding

Material Handling and Packaging

Document Part Number

550651 Revision F

Model RH Rod-style position sensor

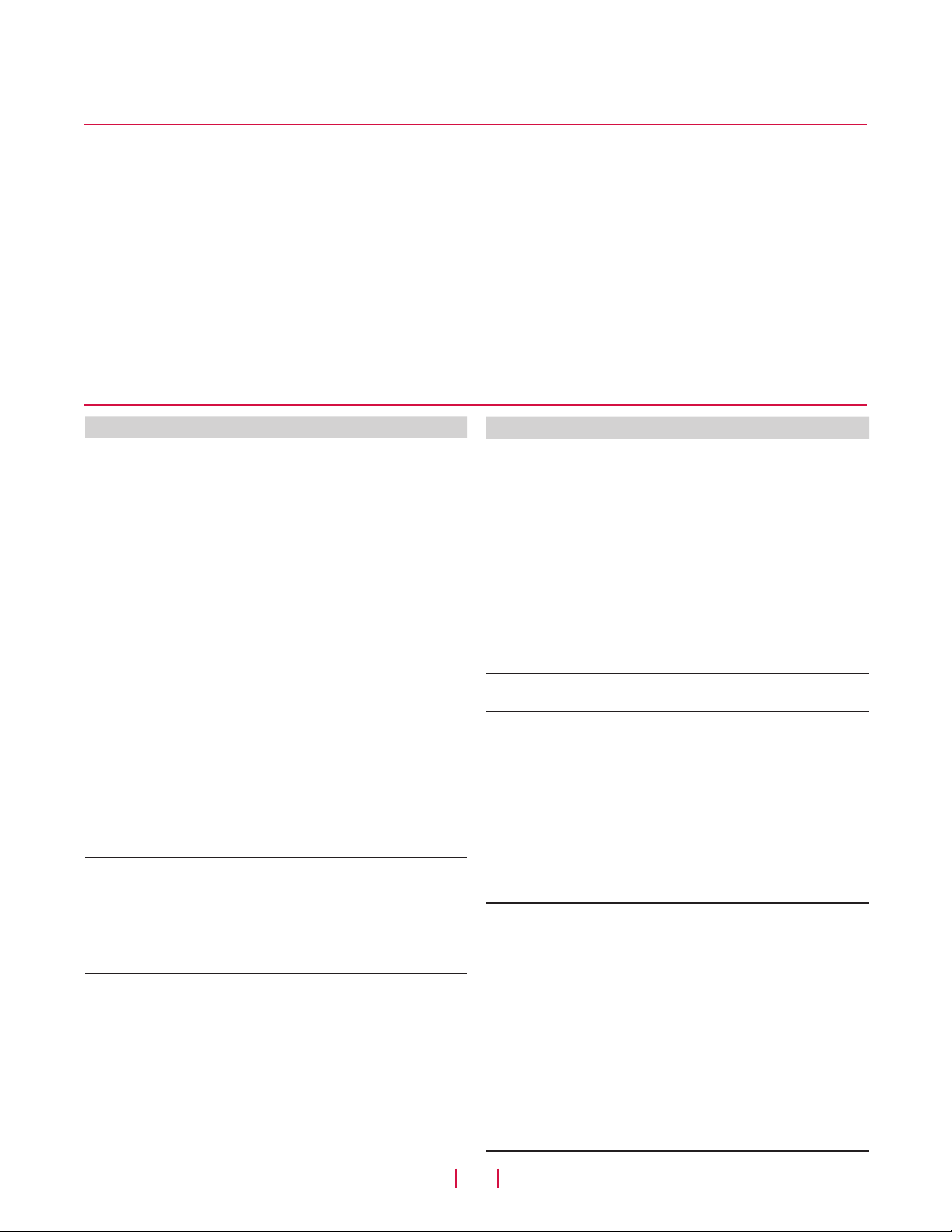

Time-based Magnetostrictive position sensing principle

Movable position magnet

Magnetic field encompasses

entire waveguide - generated

by the interrogation pulse

Interrogation

Return wire

Waveguide

Strain-Pulse detector

Bias magnet

Benefits of Magnetostriction

Temposonics linear-position sensors use the time-based

magnetostrictive position sensing principle developed by MTS.

Within the sensing element, a sonic-strain pulse is induced in a

specially designed magnetostrictive waveguide by the momentary

interaction of two magnetic fields. One field comes from a moveable

permanent magnet that passes along the outside of the sensor. The

other field comes from an “interrogation” current pulse applied along

the waveguide. The resulting strain pulse travels at sonic speed along

the waveguide and is detected at the head of the sensing element.

The position of the magnet is determined with high precision and

speed by accurately measuring the elapsed time between the application of the interrogation pulse and the arrival of the resulting strain

pulse with a high-speed counter. The elapsed time measurement is

directly proportional to the position of the permanent magnet and is

an absolute value. Therefore, the sensor's output signal corresponds

to absolute position, instead of incremental, and never requires

recalibration or re-homing after a power loss. Absolute, non-contact

sensing eliminates wear, and guarantees the best durability and

output repeatability.

All specifications are subject to change. Contact MTS for specifications and

engineering drawings that are critical to your application. Drawings contained

in this document are for reference only. Go to http://www.mtssensors.com for

the latest support documentation and related media.

Magnetic field from

position magnet

Interaction of magnetic

fields causes waveguide to

generate a strain pulse

®

Product Overview and Specifications

Product overview

R-Series model RH and RP sensors are extremely robust and are

ideal for continuous operation under harsh industrial conditions.

MTS offers two standard sensor housings, rod and profile extrusion.

The rod housing is capable of withstanding high pressures such as

those found in hydraulic cylinders.

The profile extrusion housing provides convenient mounting options

and captive sliding magnets which utilize slide bearings of special

material that reduce friction, and help mitigate dirt build up. The

sensor head contains the active signal conditioning and a complete

integrated electronics interface. Double shielding is used to ensure

EMI protection for unsurpassed reliability and operating safety.

Product specifications

Parameters Specifications

OUTPUT

Measured output

variable: Position

Resolution: 2 µm or 5 µm

Update times: 0.5 ms up to 1200 mm,

1.0 ms up to 2400 mm,

2.0 ms up to 4800 mm,

4.0 ms up to 7600 mm stroke length

Linearity

deviation: < ± 0.01% full stroke (minimum ± 40 µm)

Repeatability: < ± 0.001% full stroke

(minimum ± 2.5 µm)

Hysteresis: < 4 µm

Output:

Baud rate, kBit/s:

Cable length, m:

Stroke length:

ELECTRONICS

Operating voltage: +24 Vdc nominal: -15% or +20%*

* UL Recognition requires an approved power supply with energy limitation UL 61010-

1), or Class 2 rating according to the National Electrical Code (USA) / Canadian

Electrical Code.

** The IP rating is not part of the UL Recognition.

Interface:

CAN-Fieldbus system ISO DIS 11898

Data protocol DeviceNet release 2.0

500 250 125

<100 <250 <500

Sensors will be supplied with ordered Baud rate

which can be changed by the customer.

Range (Profile style):

25 mm to 5080 mm (1 in. to 200 in.)

Range (Rod style):

25 mm to 7620 mm (1 in. to 300 in.)

Polarity protection: up to -30 Vdc

Overvoltage protection: up to 36 Vdc

Current drain: 90 mA typical

Dielectric withstand voltage: 500 Vdc

(DC ground to machine ground)

Controller Area Network (CAN) is a standard for device level communications and the foundation of fieldbus systems like DeviceNet,

CANopen and CANbus.These fieldbus systems can provide high

speed transmission appropriate for position indication and for motion control in industrial applications.

DeviceNet allows users to interface up to 64 devices using a single

cable, thus eliminating the need for conventional methods of multiple

wire runs. DeviceNet provides a way to define how, and in which

priority, data will be transmitted over the network. The result is a

lower complexity, cost-effective communications network linking

industrial measurement and control devices. Together, the open

DeviceNet protocol and the MTS “smart” R-Series sensors offer an

effective, high-precision data transfer system that is well suited for

industrial automation.

Parameters Specifications

ENVIRONMENTAL

Operating

conditions:

Operating temperature:

-40 °C (-40 °F) to +75 °C (+167 °F)

Relative humidity: 90% no condensation

Temperature coefficient: 15 ppm/ °C

EMC test: Electromagnetic emission:

IEC/EN 50081-1

Electromagnetic susceptibility:

IEC/EN 50082-2, IEC/EN 61000-4-2/3/4/6,

level 3/4 criterium A, CE qualified

Shock rating: 100 g (single hit)/IEC standard 68-2-27

(survivability)

Vibration rating: 15 g / 10 to 2000 Hz / IEC standard 68-2-6

WIRING

Connection type: 5-pin male D51 DeviceNet connector

PROFILE STYLE SENSOR (MODEL RP)

Electronic head: Aluminum housing with diagnostic LED

display (LEDs located beside connector/

cable exit)

Sealing: IP 65**

Sensor extrusion: Aluminum (Temposonics profile style)

Mounting: Any orientation. Adjustable mounting

feet or T-slot nut (M5 threads) in bottom

groove

Magnet types: Captive-sliding magnet or open-ring

magnet

ROD STYLE SENSOR (MODEL RH)

Electronic head: Aluminum housing with diagnostic LED

display (LEDs located beside connector/

cable exit)

Sealing: IP 67 or IP 68 for integral cable models**

Sensor rod: 304L stainless steel

Operating

pressure:

350 bar static, 690 bar peak

(5000 psi static, 10,000 psi peak)

Mounting: Any orientation. Threaded flange M18 x 1.5

or 3/4 - 16 UNF-3A

Typical

mounting torque: 45 N-m (33 ft. - lbs.)

Magnet types: Ring magnet, open-ring magnet, or

magnet float

R-Series Models RP and RH Temposonics® Linear-Position Sensors - DeviceNet Output

Product Data Sheet, Document Part No.: 550651 Revision F (EN) 05/2014 2

MTS Sensors

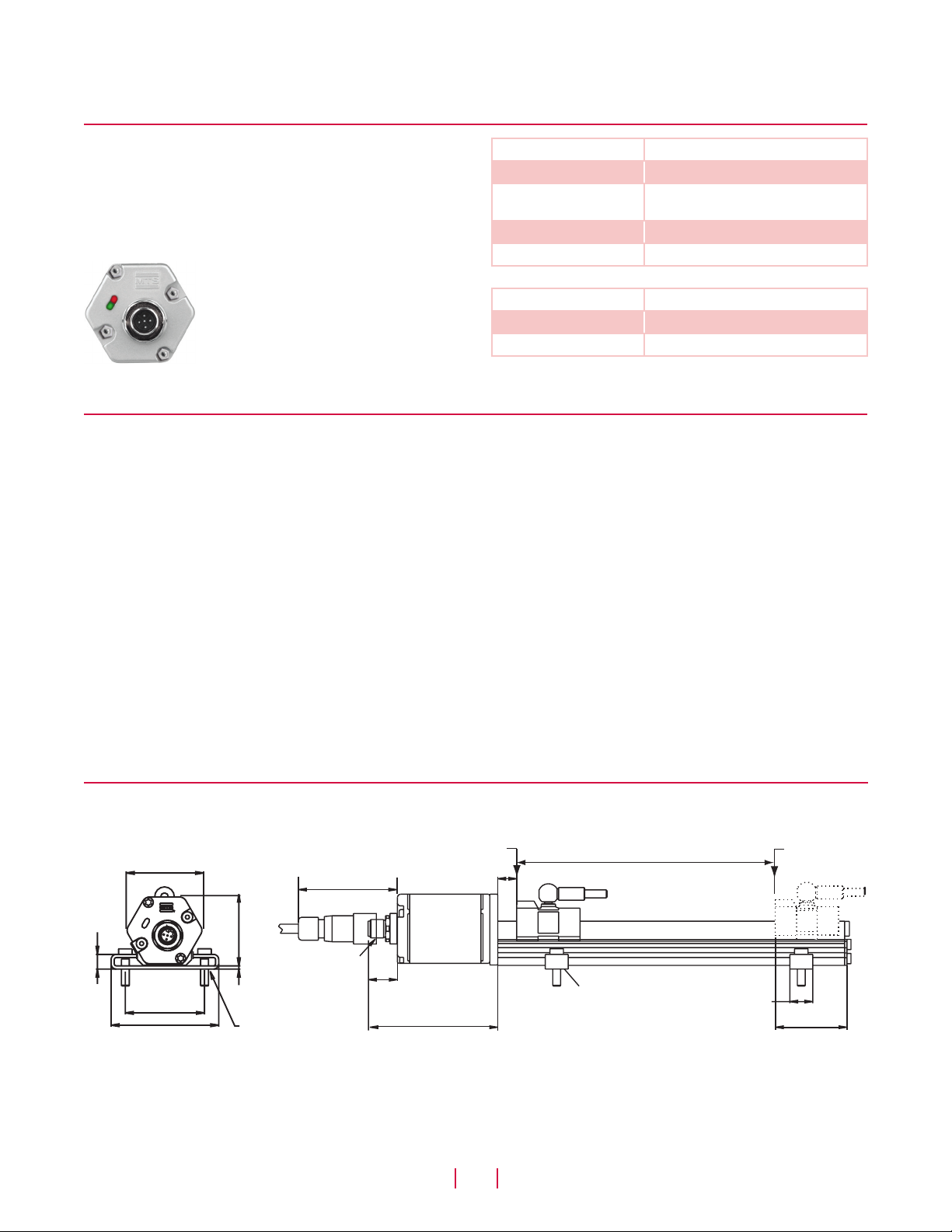

Enhanced monitoring and diagnostics

9 mm

DeviceNet Protocol, Programmability, Enhanced Monitoring,

Diagnostics and Model RP sensor dimension references

SENSOR STATUS AND DIAGNOSTIC DISPLAY

Integrated diagnostic LEDs (green/red), located beside sensor connector (see ‘Figure 1’), provide basic visual monitoring

for normal sensor operation and DeviceNet communications.

Diagnostic display LEDs indicate two modes, Network and Module

status as described in ‘Table 1’.

Figure 1. R-Series sensor Integrated diagnostic LEDs

DeviceNet protocol

R-Series models RP and RH linear-position sensors as slave devices

fulfill all requirements of the CANbus (ISO 11898) standard. The sensors electronics and integrated software implement the DeviceNet

protocol to convert the displacement measurements into bus

oriented outputs and transfer this data directly to the controller.The

DeviceNet protocol is appropriate for serial data transfer up to 500

kBit/sec.

When using the DeviceNet protocol with R-series sensors, functionality always includes but is not limited to the following:

• Position

• Error Detection

• Polling & bit-strobe communications modes

PLUG AND PLAY

R-Series sensors with DeviceNet output can be directly connected

to a DeviceNet network. The plug and play design makes installation

quick and easy. The sensor acts as a “slave” device that transmits

Network Status LED Operation status/mode

Green Normal function (operation mode)

Green Flashing Waiting for instructions from

DeviceNet master

Red Initialization error

Red Flashing No answer from DeviceNet master

Module Status LED Operation status/mode

Green Normal function (operation mode)

Red Magnet not detected

Table 1. Diagnostic display indicator modes

its position and status data upon request to the “master” device

such as a PLC or IPC. After initial system configuration, the user is

not required to have extensive knowledge concerning network timing and sensor technology to execute operations within DeviceNet

environment. Sensor-specific parameters are installed into the

network using the Electronic Data Sheet (EDS). To obtain the EDS,

go to www.mtssensors.com.

There are only two programmable parameters, which are, the node

identifier and the baud rate. If desired, a PC programming tool,

such as DeviceNet Manager offered by Allen Bradley, can be used

to change their values. The node identifier is factory set at node 63.

The selected baud rate is shown in the sensor's model number.

Note that the sensor will only be recognized on a network running

at the same baud rate.

Model RP profile-style sensor dimension references

MODEL RP, PROFILE-STYLE SENSOR WITH CAPTIVE-SLIDING MAGNET

Drawing is for reference only, contact applications engineering for tolerance specific information.

Beginning of stroke - ‘Null’ position

(0.36 in.)

50 mm (1.97 in.)

68 mm (2.68 in.)

49 mm

(1.9 in.)

D51

45 mm

(1.77 in.)

Metal connector

2 mm

(0.07 in.)

5.5 mm (0.21 in.)

for M5 or #10 screw

63 mm

(2.5 in.)

12 mm (0.47 in.)

Sensor head

18 mm

(0.7 in.)

81 mm

(3.2 in.)

integral connector option

Figure 2. R-Series Model RP Profile-style sensor dimension reference (Shown with the D51 integral connector option)

MTS Sensors

3

R-Series Models RP and RH Temposonics® Linear-Position Sensors - DeviceNet Output

Stroke length

Captive-sliding magnet

Mounting foot, moveable

(part no.: 400802)

Product Data Sheet, Document Part No.: 550651 Revision F (EN) 05/2014

14.5 mm

(0.57 in.)

End of stroke

‘Span’ position

Dead zone

82 mm

(3.2 in.)

Loading...

Loading...