MTS Sensors Temposonics M, Temposonics MH Datasheet

®

Temposonics

Magnetostrictive, Absolute, Non-contact

Linear-Position Sensors

®

SENSORS

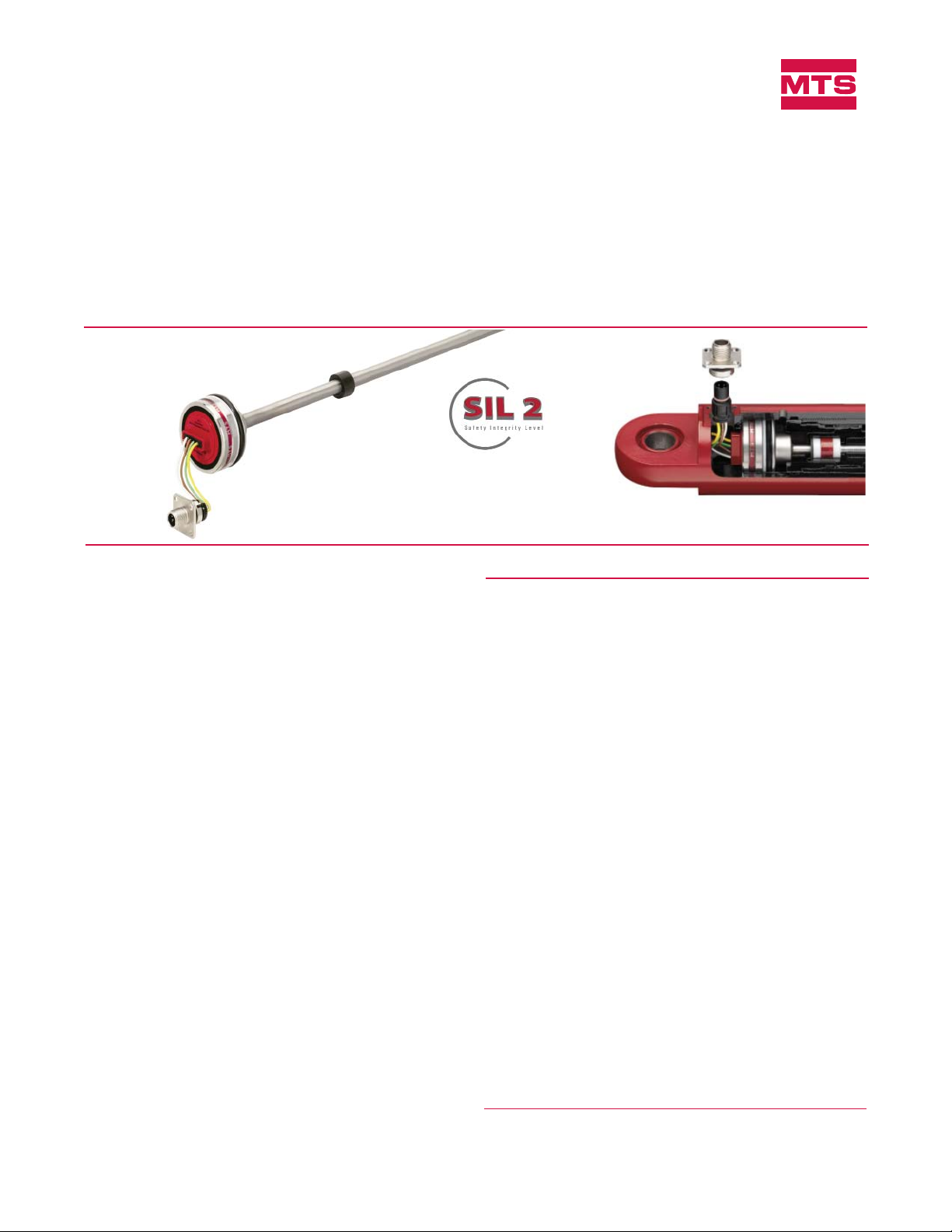

M-Series Mobile Hydraulic

In-Cylinder Sensor

Model MH CAN Safety (SIL 2)

FEATURES

Linear, Absolute Measurement in Hydraulic Cylinders

Non-Contact Sensing Technology

Superior Accuracy, < ± 0.04% F.S.

Hysteresis < ± 0.1 mm

Repeatability, < ± 0.005% F.S.

Compact Design for Embedded Cylinder Applications

Direct CAN Safety Output:

Displacement + Velocity

Stroke length: 50 mm (2 in.) to 2500 mm (98 in.)

Voltage input: 12/24 Vdc

Shock Rating: 100 g (single hit) / IEC 68-2-27

Vibration Rating 25 g / 10-2000 Hz/IEC 68-2-6

200 V/m EMI Immunity

BENEFITS

Rugged Mobile Sensor

SIL2 Safety Integrity Level

CAN Safety (SIL 2) Output

Data Sheet

Document Part Number

551194 Revision B

Cylinder Application ExampleM-Series Model MH Sensor

Product overview

The M-Series Model MH sensor is designed with the “mobile” world

in mind. The Model MH sensor is validated in the field by customers

worldwide. Performance is second-to-none with high EMI resistance

of 200 V/m. Ruggedness is “designed in”; 100 g shock and 25 g vibration rating. The model MH CAN Safety sensor can be fully sealed and

embedded in a cylinder to ensure a long operating life.

The absolute, non-contact Temposonics position sensor with CAN

Safety reaches a level of 95% for SFF at a fault to ground of 0 for the

hardware. Since they are approved for SIL 2 level, they have an average probability for Failure (PFH) in the range of ≥10

A SIL Safety manual and direct connection to the Temposonics

M12x1 connector system and other proven mobile connectors are

available.

-7

to <10-6 per year.

®

APPLICATIONS

Continuous Operation In Harsh Mobile Conditions

High Pressure Conditions

For Welded and Tie-rod Cylinder Applications

TYPICAL INDUSTRIES

Construction

Agriculture

Off-highway Machinery

All specifications are subject to change. Contact MTS for specifications and

engineering drawings that are critical to your application. Drawings contained

in this document are for reference only. Go to http://www.mtssensors.com for

the latest support documentation and related media.

M-Series Model MH CAN Safety Sensor

Product Overview and Specification

Product specifications

Parameters Specifications

INPUT/OUTPUT

Measured

variable: Linear position and velocity

Output: Direct CAN Safety acc. CiA DS-304

Resolution: Consistent: > 1 mm/s

CAN Safety ≤ ± 0.1 mm

Signal output frequency:

CAN Safety adjustable 1 ms to 65535 ms or

Sync. mode

Velocity: Typical 1 m/s

Stroke length: 50 mm to 2500 mm (2 in. to 98 in.)

Measured in 5 mm (0.20 in.) increments

Linearity

uncorrected:

50 to 250 mm ≤± 0.1 mm

255 to 2000 mm < ± 0.04% full stroke

(minimum ± 0.100 mm 0.003 in.)

< ± 0.08% full stroke (for short damping zone)

500 mm ≤± 0.2 mm

750 mm ≤± 0.3 mm

1250 mm ≤± 0.5 mm

2005 to 2500 mm ≤± 0.8 mm

Hysteresis: ± 0.1 mm (0.003 in.)

Cycle time: 1 ms

Setpoint

tolerance: ± 0.2 mm (0.007 in.)

Operating

voltage:

12/24 Vdc (8-32 Vdc)

Voltage supply ripple: <1 % p-p

Power drain: < 1.5 W

ELECTRONICS

Electrical

isolation: 500 Vdc (DC ground to machine ground)

Polarity

protection: Up to -36 Vdc

Overvoltage

protection: Up to 36 Vdc

Parameters Specifications

ENVIRONMENTAL

Operating

conditions:

Operating: any orientation, -40 °C (-40 °F) to

+105 °C (221 °F)

Storage: -30 °C (-22 °F) to +105 °C (221 °F)

90% relative humidity, no condensation

EMC test: 200 V/m

ISO 11452-5

ISO 14982: Agriculture and forest machinery

Shock rating: 100 g (single hit)/IEC standard 68-2-27

(survivability)

25 g / 10 to 2000 Hz /IEC standard 68-2-6

Vibration

rating:

Sensor rod, 10 mm (0.39 in.): 25 g

Sensor rod, 7 mm (0.27 in.): 15 g

WIRING

Connection

type:

One 5-wire with the M12x1 connector

and flange (provides IP69K environmental

protection when installed in a cylinder).

ROD STYLE SENSOR (Model MH)

Material: Sensor rod: Stainless steel 1.4306 / AISI

304L

Housing: Stainless steel 1.4305 / AISI 303

Mechanical assembly: Flange housing 48 mm

(1.89 in.) dia., O-ring 40.87 x 3.53 mm NBR

80, backup ring 42.6 x 48 x 1.4 PTFE

Sealing: IP67 (IP69k when installed inside a cylinder

with M12 x 1 in. connection type)

Pressure

rating:

Sensor rod, 10 mm (0.39 in.):

Operating, 350 bar (5076 psi)

Peak, 450 bar (6615 psi)

Sensor rod, 7 mm (0.27 in.):

Operating, 300 bar (4350 psi)

Peak, 400 bar (5800 psi)

Pressure pulse test acc.: DIN EN ISO 19879

Magnet type: Ring magnet (see standard magnet selections)

M-Series Model MH Temposonics® Position Sensor for Mobile Hydraulics, CAN Safety (SIL 2)

Product Data Sheet, Document Part No.: 551194, Revision B 02/12, 05/12, 08/12

2

MTS Sensors

M-Series Model MH CAN Safety Sensor

Output, Dimension and Magnet References

Output options

The M-Series Model MH position CAN Safety sensor provides direct CAN Safety output.

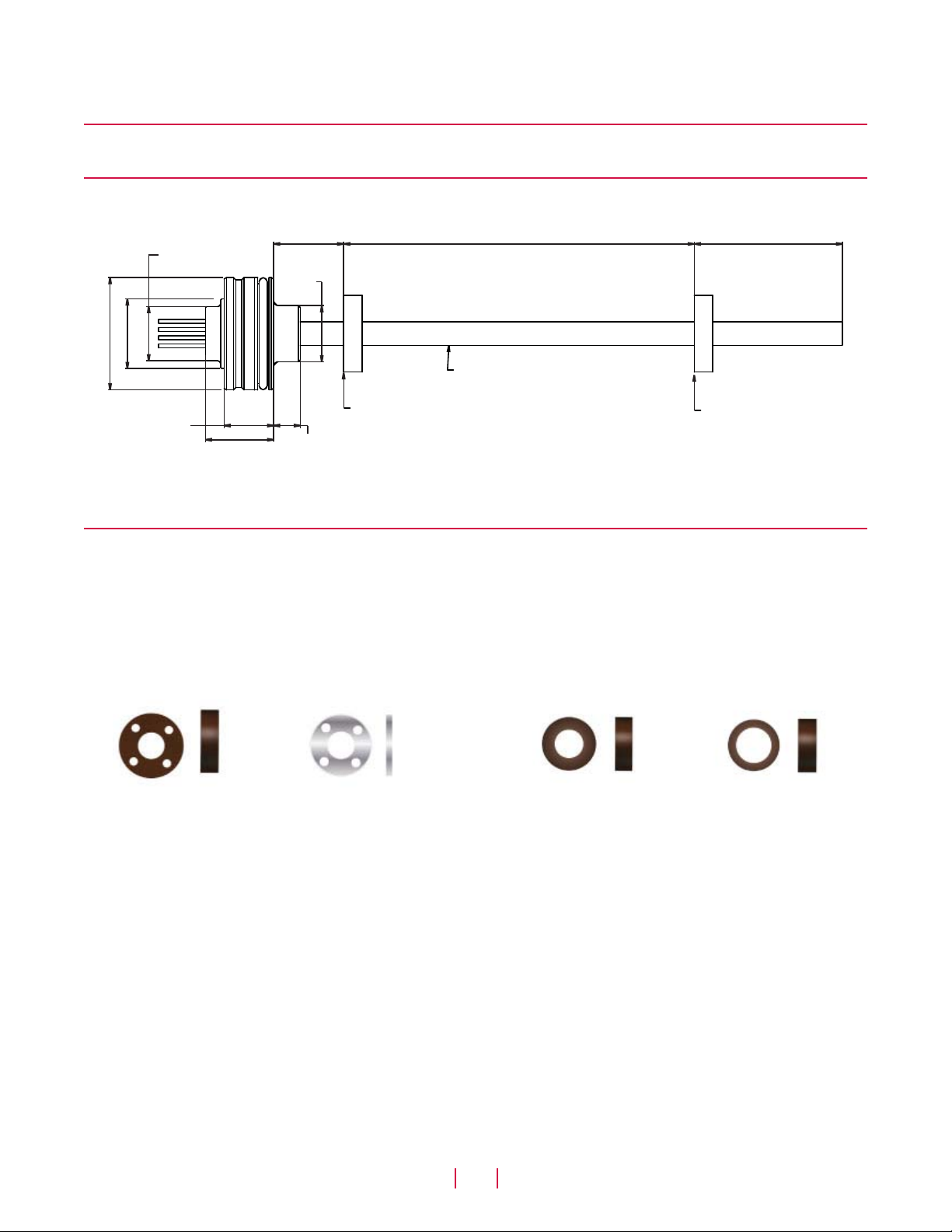

Model MH sensor dimension references

Model MH, rod-style Redundant Sensor Drawing is for reference only, contact applications engineering for tolerance specific information.

Null

23 mm

(0.9 in.) dia.

30 mm

(1.18 in.) dia.

48 mm (1.88 in.) dia.

21.2 mm

(0.83 in.)

+0 / -0.2

+0 / -0.007

30 mm

(1.18 in.)

30 mm

(1.18 in.)

24 mm

(0.94 in.)

dia.

11.5 mm

(0.45 in.)

50 mm (1.96 in.) to 2500 mm (98.42 in.)

Stroke length

7 mm (0.27 in.) dia. or

10 mm (0.39 in.) dia.

Stroke length start ‘Null’ position

Dead zone

63.5 mm (2.49 in.) or

36.5 mm (1.44 in.)

Stroke length end ‘Span’ position

Figure 1. M-Series Model MH rod-style sensor dimension reference

Standard magnet selections (Model MH)

SELECTION OF POSITION MAGNETS (MAGNET AND MAGNET SPACER MUST BE ORDERED SEPARATELY)

A choice of three magnets are available with the Model MH rod-style sensor. Magnets must be ordered separately with Model MH position

sensors. The standard ring magnet (part number 201542-2) is suitable for most applications.

STANDARD RING MAGNET

Part number 201542-2

(used with magnet part no.: 201542-2)

Material: Ferrite PA

I.D.: 13.5 mm (0.53 in.)

O.D.: 33 mm (1.3 in.)

Thickness: 8 mm (0.3 in.)

Operating temperature:

- 40 °C (-40 °F) to

- 105 °C to (221 °F)

MAGNET SPACER

Part number 400633

Material: Non-ferrous

Used with ring magnet (part no.:

201542-2)

I.D.: 14 mm (0.56 in.)

O.D.: 32 mm (1.25 in.)

Thickness: 3.2 mm (0.125 in.)

RING MAGNET

Part number 400533

Material: Ferrite PA

I.D.: 13.5 mm (0.53 in.)

O.D.: 25.4 mm (1 in.)

Thickness: 8 mm (0.3 in.)

Operating temperature:

- 40 °C (-40 °F) to

- 105 °C to (221 °F)

RING MAGNET

Part number 401032

Material: Ferrite PA

I.D.: 13.5 mm (0.53 in.)

O.D.: 17 mm (0.68 in.)

Thickness: 8 mm (0.31 in.)

Operating temperature:

- 40 °C (-40 °F) to

- 105 °C to (221 °F)

MTS Sensors

3

M-Series Model MH Temposonics® Position Sensor for Mobile Hydraulics, CAN Safety (SIL 2)

Product Data Sheet, Document Part No.: 551194, Revision B 02/12, 05/12, 08/12

Loading...

Loading...