MTM 52 Original Manual

UNIVERSAL OIL HEATER

TYPE MTM 52 kW

ORIGINAL MANUAL

v. 08/2015

MTM DARIUSZ SEFERYŃSKI

t

EC DECLARATION OF CONFORMITY

HEATING, VENTILATION, AIR CONDITIONING

04-239 WARSAW, ul. MŁODNICKA 52 C

I hereby declare that the oil air heater intended for heating industrial rooms

without central heating systems:

model MTM 52, serial no. ............................ manufactured in the year 20…….

Rated power of 30-52 kW

Due to its design and structure, meets the basic safety and health requirements set forth in

the Directive 2006/42/EC on machinery and has been manufactured according to the directives as follows:

• Directive 2006/42/EC - on machinery (MD)

• Directive 2006/95/EC - on electrical equipment designed for use within certain voltage limits (LVD)

• Directive 2004/108/EC - on electromagnetic compatibility (EMCD)

• Directive 89/106/EEC - on construction products (CPD)

and the following norms:

• EN 1:1998+A1:2007 Fuel oil stoves with vaporising burners and chimney

connection

• EN 303-5:1999 Heating boilers - Part 5: Solid fuel heating boilers with manual and automatic fuel charge

with rated power of max. 300 KW - Definitions, requirements, testing and marking and labelling.

• EN 953:1997+A1:2009 Safety of machinery - Guards - General requirements for the design and

construction of fixed and movable guards

• EN 60204-1:2006+A1:2009+AC:2010 Safety of machinery - Electrical equipment of machines - Part 1:

General requirements

• EN ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and

risk reduction

• EN ISO 13732-1:2008 Ergonomics of the thermal environment - Methods for the assessment of human

responses to contact with

surfaces - Part 1: Hot surfaces

• EN ISO 13857:2008 Safety of machinery - Safety distances to prevent hazard zones being reached by

upper and lower limbs

• EN ISO 14159:2008 Safety of machinery - Hygiene requirements for the design of machinery

• EN 60335-1:2002+A14:2010 Household and similar electrical appliances - Safety - Part 1: General

requirements

• EN 55014-1:2006+A1:2009 Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus - Part 1: Emission

• EN 55014-2:1997+A2:2008 Electromagnetic compatibility (EMC) - Requirements for household

appliances, electric tools and similar apparatus - Immunity - Product family standard

• EN 61000-6-1:2007 Electronic compatibility (EMC) - Part 6-1: Generic standards - Immunity for residential,

commercial and light-industrial environments

• EN 61000-6-3:2007 Electronic compatibility (EMC) - Part 6-3: Generic standards - Emission standard

for residential, commercial and light-industrial environments

The authorisation to compile the machine technical documentation has been given to the representative of the producer:

MTM DARIUSZ SEFERYŃSKI

HEATING, VENTILATION, AIR CONDITIONING

04-239 WARSAW, ul. MŁODNICKA 52 C

Contact person: Dariusz Seferyński

This declaration pertains only to the machine in condition in which it was launched on the market and does not cover componen

parts added by the end user or later actions performed by them. This declaration expires

if any changes are made to the device that have not been consulted with us.

Warsaw, on ............... 20.......... (full name and signature of the person authorised to make the declaration)

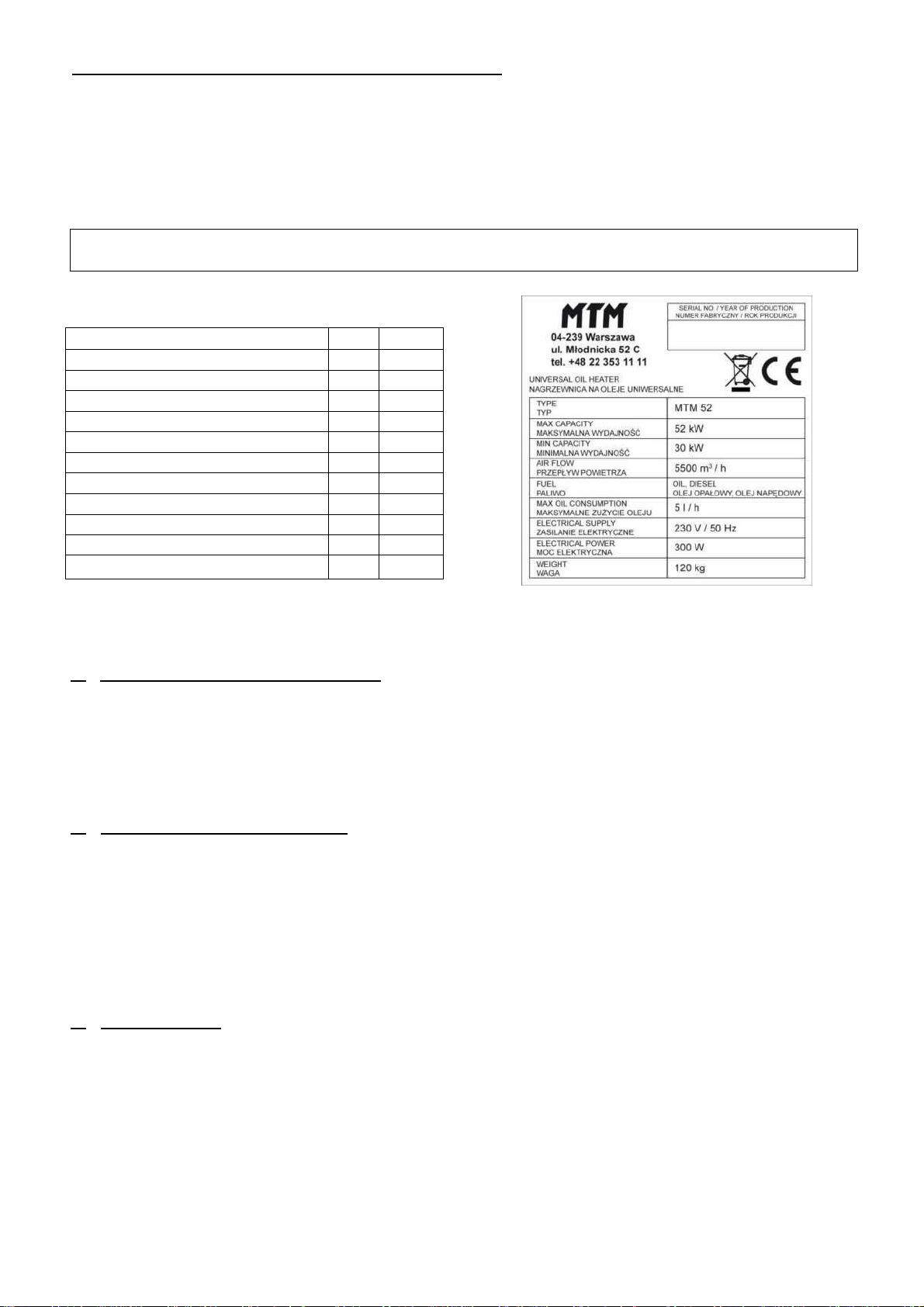

1. Heater intended application and technical data

The universal oil heater type MTM 52 is designed to heat up industrial

rooms not covered with central heating systems (workshops, car repair shops,

industrial shops, warehouses, storage buildings, basements, garages, etc.).

The stove can operate using most waste oils of mineral and plant origin,

e.g. engine, gear, hydraulic, fuel oil, with maximal density in temperature of 15°C

equal to 860 kg/m3 and with ignition temperature exceeding 56°C.

DO NOT USE TRANSFORMER OIL AS THEY CAN CONTAIN SUBSTANCES

AFFECTING STOVE OPERATION AND USER HEALTH

TECHNICAL DATA

Maximal thermal capacity* kW 52

Minimal thermal capacity* kW 30

Maximal fuel consumption l/h 5.2

Minimal fuel consumption l/h 3

Heated air flow m3/h 5500

Power supply V/Hz 230/50

Maximal power consumption W 300

Exhaust fumes outlet diameter mm 150

Device width cm 60

Device height cm 130

Device length cm 120

Device weight kg 120

* Calorific effect specified for fuel with the following parameters:

• calorific value = 42.6 MJ/kg.

• density at temp. max. 15°C = 860 kg/cm

In case of higher parameters, the calorific effect can be

increased even up to 55 kW.

3

.

PLACED ON THE REAR ENCLOSURE OF THE DEVICE

TEMPLATE OF THE RATING PLATE

2. Storage environmental conditions

The universal oil heater type MTM 52 must be stored in the following conditions:

• temperature from -20°C to 85°C

• relative humidity < 85%

• pressure < 1200 hPa

• no dusting

• environment free from chemical contamination.

3. Use environmental conditions

The universal oil heater type MTM 52 must be used in the following conditions:

• temperature

• relative humidity

• pressure

• IP protection level against environmental impact

• good ventilation of the heated room.

• device noise -

4. Safety aspects

from 0°C to 30°C

< 85%

< 1200

hPa

IP21

not exceeding 70Db

• It is inadmissible to use fuels other than specified in point 1. of the Original Manual.

In particular, it is forbidden to use such fuels as solvents or petrol!

• All activities regarding operation of the device must be performed in protective

gloves and by a person trained for operation.

• It is prohibited to put hands in the protective grids of the furnace or areas of the operating

fan.

• It is necessary to ensure efficient ventilation of the heated room in order to avoid carbon

monoxide poisoning.

• While cleaning the device or performing other maintenance activity, the device must be

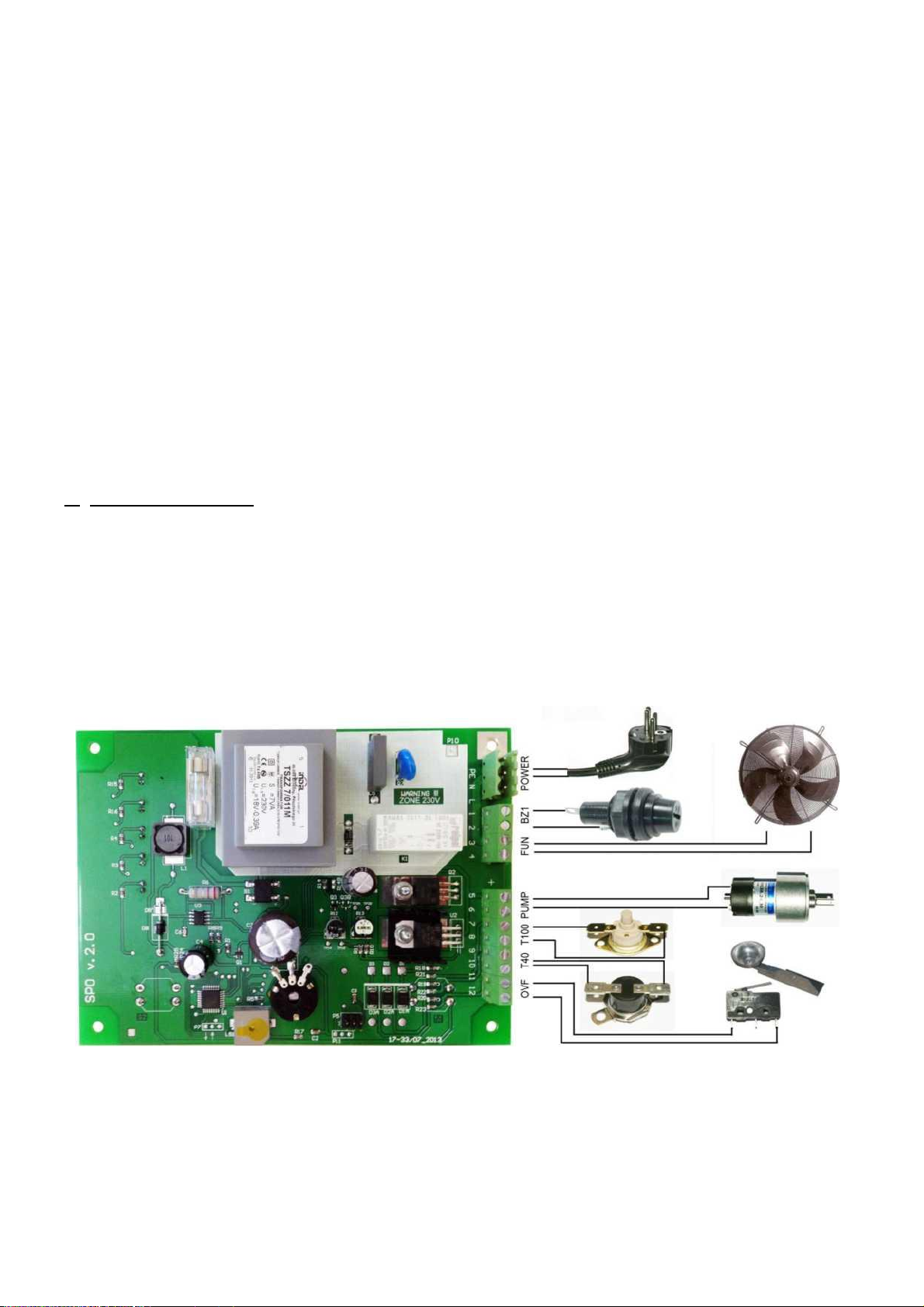

Fig. 1. The connection of the universal oil heater type MTM 52.

disconnected from the power network by removing the electrical plug from the power socket.

• While connecting the device to a power network, it must be made sure that the wiring is

operational and that it has differential current protection and earthing.

The MTM 52 universal oil heater is powered by the alternating current network of 230V, 50Hz.

It is equipped with two bimetallic sensors, ensuring safe and economic operation

of the device. The bimetallic sensor located on the heat exchanger reacts with contact shorting when

the temperature exceeds 40°C and with contact opening when the temperature drops below 35°C.

In emergency situations (overheating, oil overflow) the processor checks the bimetallic sensor signal

and maintains the fan operation until the furnace has cooled down to the temperature

below 35°C.

The other bimetallic sensor is located on the heat exchanger as well and its threshold temperature

equals 90°C. Its contact opening resulting from exceeding the threshold temperature causes the stove

to immediately enter the Overheating phase (see point 8. in this Manual). The heater is also equipped

with a weight sensor located under the combustion chamber (i.e. the so-called overflow cut-out).

When the tank of the above cut-out has filled up, the stove automatically switches to the phase

Overflow (see point 8. in this Manual).

5. Controller structure

The connection of the stove controlling panel to other system components (sensors, pump, fan)

is factory-made. During normal use, due to safety, under no circumstances should there be any

interference in the covered part of the stove controller or duct integrity. Any action by an unauthorised

person may result in electrocution (230V AC, 50Hz) and burning.

Loading...

Loading...