Page 1

MAINTENANCE

At intervals not exceeding two months, check:

1. Status indication lights

2. Conditions of connecting cables and terminals

Module Replacement

WARNING: Before opening the access panel, ensure

that the AC supply has been disconnected.

Unplug the remote contact connector at the top of the module.

Remove the mounting nuts at the top and bottom of the module.

The protection module can now be removed.

WARNING: Replace the defective module with a module

having the same model numbers.

ZONESENTINEL® SERIES

AC Panel Transient Voltage Surge Suppressors

Installation of the replacement module is the reverse of the above

procedure. Final step, check that all cable connections are secure

and nuts are tightened. Do not overtighten.

NOTE: No customer serviceable parts inside. Opening

module WILL void Warranty

For more information please contact your local MTL offi ce

or visit our web site at www.mtlsurge.com

The Americas: +1 800 835 7075

UK: +44 (0)1582 723633

Singapore: +65 6 487 7887

801481 Rev E 07/14/09

The Netherlands: +31 (0)481 450250

Italy: +39 (0)2 6180 2011

Australia: +61 (0)8 9455 2994

India: +91 (0)44 450 1660

Installation

Instructions

& User Manual

Page 2

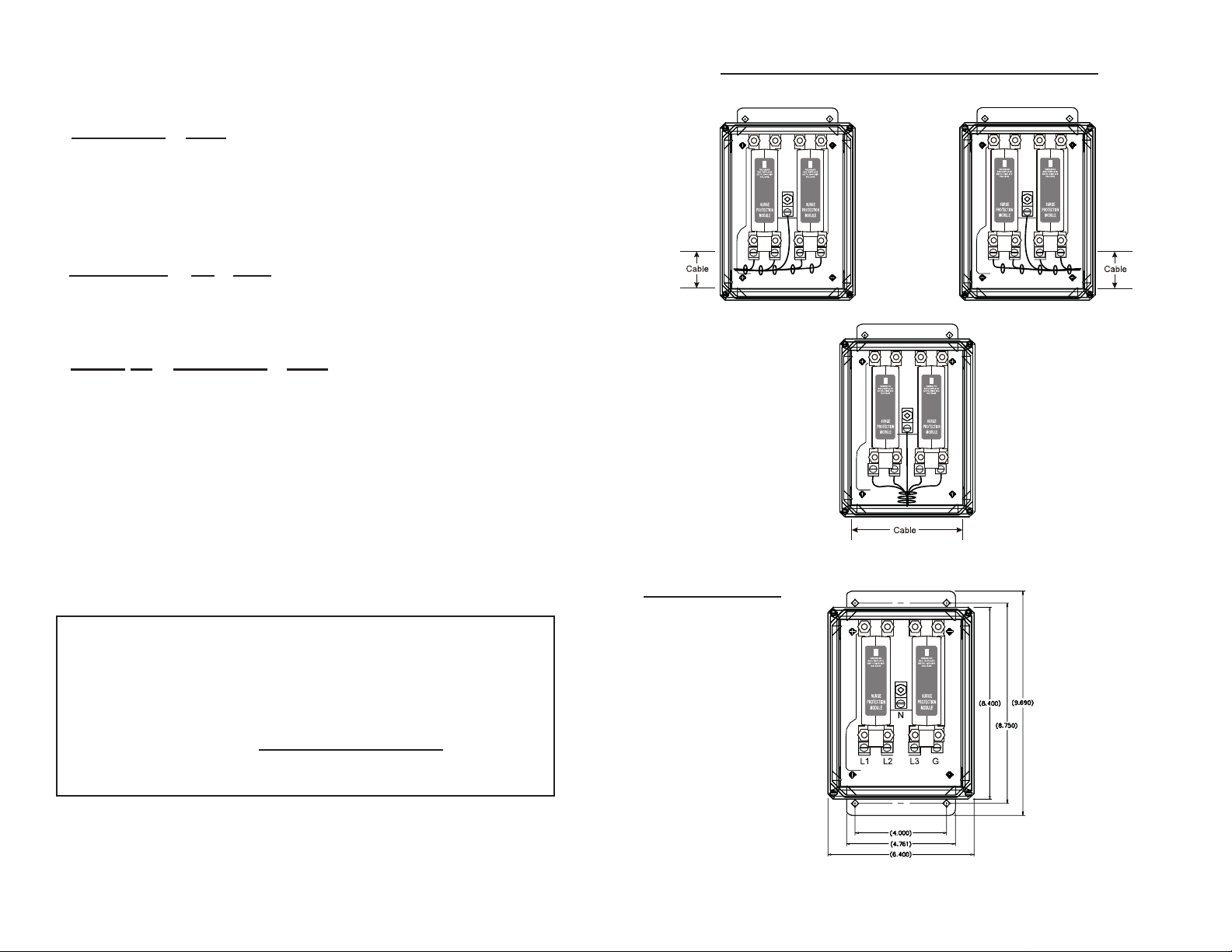

CONNECTING LEADS

Connect the suppressor as shown in the installation diagram.

Refer to page 5 for recommended cable dressing. Connect the

terminals within the suppressor to the load side of 30A breakers

within the panel.

RECOMMENDED WIRE GAUGE

Minimum of 10 AWG

Maximum of 4 AWG ( for ease of dressing)

LENGTH OF CONNECTING LEADS

The longer the connecting leads between the ZoneSentinel® and

power panel, the higher the residual transient

voltage.

RECOMMENDED MAXIMUM: 19” (500mm)

IDEALLY: 10” (250mm)

RECOMMENDED CABLE DRESSING

Each 10” (250mm) increase in cable length; increases clamping

voltage by 25V per 1000A surge current discharged.

• BIND THE PHASE NEUTRAL AND GROUND

CONDUCTORS TIGHTLY, OVER THE ENTIRE RUN

FROM THE SUPPRESSOR TO THE SERVICE PANEL.

• ALWAYS USE THE SHORTEST LENGTH OF

CONNECTING CABLE POSSIBLE.

4

DIMENSIONS

5

Page 3

INTRODUCTION

ZONESENTINEL

and Schematic Connection Diagrams

®

Confi guration

This document explains how to install the ZoneSentinel® Series

of AC Panel Surge Protective Devices.

INSTALLATION INSTRUCTIONS

Warning: Terminals marked L1, L2, L3, N, GND (where relevant)

must be connected respectively to phase(s) neutral and ground.

Failure to comply may result in danger or damage. See corresponding diagrams for proper connections.

INSTALLATION DESCRIPTION

ZoneSentinel® units are connected in parallel (or in “shunt” across)

the supply to be protected. The connecting cable does not carry

the supply current, only the current associated with suppressing

the transient overvoltage.

MOUNTING

120/240V SPLIT PHASE 3W

ZONESENTINEL

and Schematic Connection Diagrams

120/208V THREE PHASE 4W WYE

240/415V THREE PHASE 4W WYE

277/480V THREE PHASE 4W WYE

220/380V THREE PHASE 4W WYE

®

Confi guration

The units should be mounted as close as possible to the panel to be

protected. See Connecting Lead lenghts on page 4. Conduit, preferably metallic, is to be installed from the suppressor to the panel.

Drill holes in the ZoneSentinel® enclosure only in the designated

areas as shown in recommended cable dressing illustrations (page

5). Mount the unit in the appropriate location using the mounting

holes provided on the enclosure.

2

7

Page 4

STATUS INDICATORS

The ZoneSentinel® units have comprehensive, continuous visual status

monitoring present on each module.

Power/Protection

Indicator

Status Full Reduced No No Power to High N-G

Indicated Protection (Standby) Protection Protector Voltage*

Present Protection

LED Green Red Red Green Red & Green

Indicator LED Lit LED Lit LED Lit LED Out LED Lit

REMOTE INDICATORS

A remote indication of the reduced protection state is available as a normally open or normally closed dry contact

“Form C”. Rated maximum 1A at 30Vdc resistive and

maximum 0.3A at 125Vac (30VA dc or 37.5VA ac) general

use. Suitable for connection of AVLV2 18AWG to 20AWG

copper wire. Recommended tightening torque: 7 in - lbs.

Routing of these wires should be separate from the power

with a minimum of spacing of two inches.

Pluggable Connector

OVERCURRENT PROTECTION

The ZoneSentinel® can be installed on electrical services without overcurrent protection if the available SCCR is 100k AIC or less. If the SCCR

is greater than 100k AIC, coordinated overcurrent protection (30-60A)

must be installed.

FLUSH MOUNT

The fl ush mount ZoneSentinel® is installed into a suitably sized hole in

the wall. Remove the four snap-in screw covers and remove the cover,

temporarily disconnect the cover ground wire. Choose a location such

that the recessed part of the ZoneSentinel® enclosure can be fi xed to a

wall stud or suitable upper or lower support. Be sure that the ZoneSen-

tinel® enclosure is fl ush with the wall. Follow the standard instructions

for location and connecting leads. Reconnect the cover ground wire and

install the cover plate. Replace the four snap-in screw covers.

Customer

supplied wires

Common

Normally Closed

Normally Open

End view of

ZoneSentinel Module

*WARNING:

OF HIGH NEUTRAL TO GROUND VOLTAGE

On certain models, if both Red and Green lights are on, consult a qualifi ed

electrical contractor to check the integrity of the building wiring.

6 3

INCORRECT INSTALLATION WILL IMPAIR THE EFFECTIVENESS OF THE AC PANEL PROTECTORS. Particularly

important is the length of the connecting leads (page).

Loading...

Loading...