Page 1

US INSTALLATION NOTES

4. The apparatus is to be installed such that the fl ying leads are afforded a degree of protection of at least IP54.

5. Although all versions of the TP48-*-* and TP32-*-* Series Surge Protection Devices meet the 500V test to the

metal case the electrical circuit within the Surge Protection Devices are not capable of withstanding the 500V

voltage withstand test for one minute without breakdown to the Green/Yellow wire. This must be taken into con sideration in any installation.

6. These devices are not provided with an external connection facility for an earthing or bonding conductor. It is the

user’s responsibility to ensure adequate earth continuity via the mounting arrangement.

7. This apparatus is also afforded Flameproof Certifi cation to Baseefa04ATEX0053X and is dual marked. It is the

user’s responsibility to determine the relevant protection concept and to permanently mark the apparatus in the

space provided for guidance on installation and maintenance.

NOTE: Items 1-3 relate to installations to Baseefa04ATEX0053X and items 4-7 relate to installations to

Baseefa04ATEX0251X.

Ex ia: The three wires must be afforded a degree of protection of at least IP20 when the apparatus is installed.

Ex d: The fl ying leads must be suitably protected against mechanical damage and terminated in a suitable facility. The

device is not provided with an external earthing facility, adequate earthing should be ensured. Mounting directly in an

earthed metal enclosure should meet this requirement.

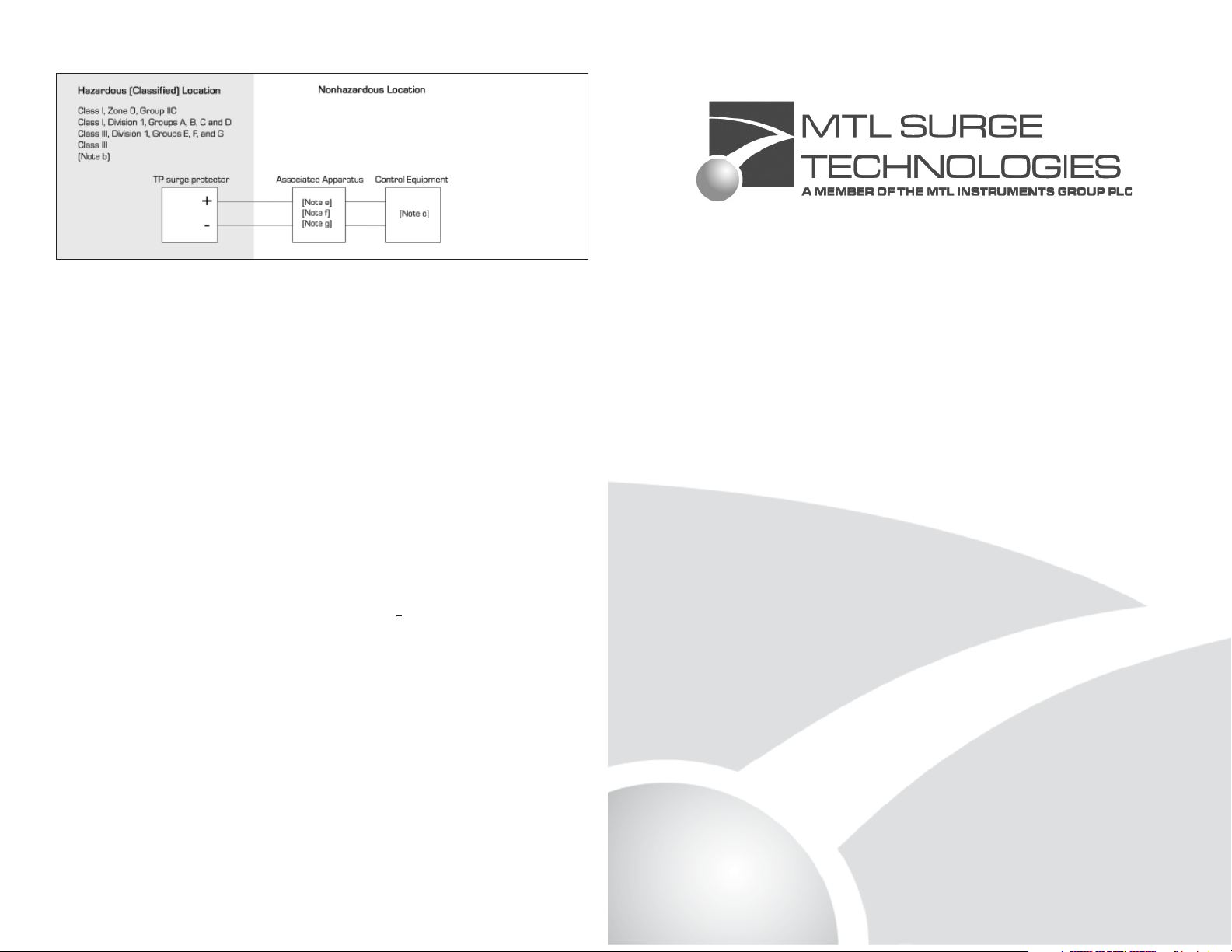

For U.S. installations, the TP Surge Protectors are Approved for Class I, Zone 0 applications. If connecting AEx[ib]

Associated Apparatus or AEx ib I.S. Apparatus to the TP Surge Protectors the I.S. circuit is only suitable for Class I,

Zone 1, or Class I, Zone 2,

Notes:

a) The Intrinsic Safety Entity concept allows the interconnection of two FM Approved Intrinsically Safe devices with

entity parameters not specifi cally examined in combination as a system when: Voc or Uo or Vt £ Vmax, Isc or Io or

It £ Imax, Ca or Co, Ci + Ccable, La or Lo, Li + Lcable, and for FM only: Po < Pi.

b) Dust-tight conduit seal must be used when installed in Class II and Class III environments.

c) Control equipment connected to the Associated Apparatus must not use or generate more than 250 Vrms or

Vdc.

d) Installation in the U.S. should be in accordance with ANSI/ISA RP12.6 “Installation of Intrinsically Safe Systems for

Hazardous (Classifi ed) Locations” and the National Electrical Code® (ANSI/NFPA 70) Sections 504 and 505.

e) The confi guration of associated Apparatus must be Factory Mutual Research Approved under Entity Concept.

f) Associated Apparatus manufacturer’s installation drawing must be followed when installing this equipment.

g) For U.S. installations, the TP Surge Protectors is Approved for Class I, Zone 0 applications. If connecting AEx[ib] As

sociated Apparatus or AEx ib I.S. Apparatus to the TP Surge Protectors the I.S. circuit is only suitable for Class I,

Zone 1, or Class I, Zone 2, and is not suitable for Class I, Zone 0 or Class I, Division 1, Hazardous (Classifi ed)

Location.

Installation Guide

TP Series

Transmitter Mounting Surge Protector

For more information please contact your local MTL offi ce

or visit our web site at www.mtlsurge.com

The Americas: +1 800 835 7075

UK: +44 (0)1582 723633

Singapore: +65 6 487 7887

801640 Rev B 10/15/08

The Netherlands: +31 (0)481 450250

Italy: +39 (0)2 6180 2011

Australia: +61 (0)8 9455 2994

India: +91 (0)44 450 1660

Page 2

1. INTRODUCTION

The TP Series surge protector provides surge protection for fi eld mounted process transmitters and is available for

1/2’’NPT, 20mm ISO and G1/2” threaded conduit entries. The TP Series is certifi ed and approved for use in hazardous areas. More details of this are shown throughout this installation guide.

2. IMPORTANT SAFETY INFORMATION

WARNING

In EEx d / explosionproof applications where explosive gases may be present, the loop must be

isolated before any EEx d / explosionproof covers are removed.

The TP Series must be installed, operated and maintained by trained competent personnel.

The TP unit must not be subjected to mechanical or thermal stresses in excess of those outlined in

the ATEX and FM specifi cations.

The TP range must not be installed in an area where it may be attacked by aggressive substances.

Where hazardous area protection concepts are being applied the product must be installed in

accordance with the requirements of the EC Type Examination and FM guidelines in this document.

The ‘transmitter’ must be electrically isolated during the installation procedure.

All installation and maintenance must be carried out in accordance with all appropriate interna tional, national and local standard codes of practice and site regulations and in accordance with

the instructions contained within this manual.

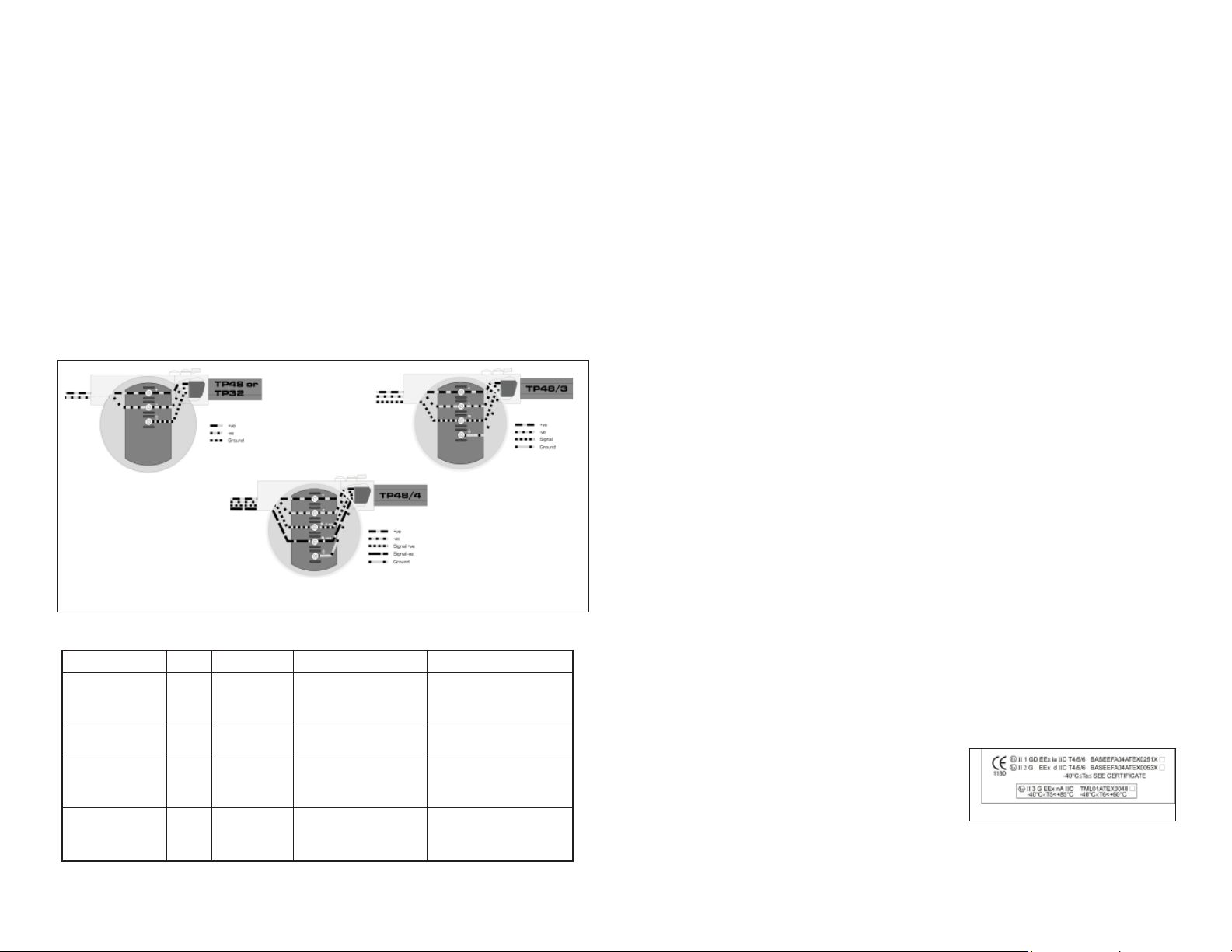

2 WIRE

3 WIRE

4 WIRE

Figure 1 Connection detail for typical process transmitter

3. INSTALLATION

+ve -ve Signal Earth/Ground

TP48, TP32 Red Black N/A Green/Yellow

or TP32-T

TP48-3 Blue Brown Black Green/Yellow

TP48-4 Blue Brown Black = Signal + Green/Yellow

White = Signal -

TP24/7 Red Black Blue = Signal + Green/Yellow

White = Signal -

WARNING: Ensure polarity is correct when connecting TP32-T.

3.1 Select conduit entry to be used for installation, and remove any blanking plug.

Note: If direct installation onto the apparatus itself is impossible e.g. because all conduit entries are in use al ready, an external junction box or conduit hub can be used. The TP Series is supplied with 300mm leads, which

should be suffi cient for them to reach the transmitter terminals from a junction box. If these leads are not long

enough then use supplementary terminals and wiring. Installation should be within 1m of, and bonded to, the

transmitter.

3.2 Ensure that the TP body thread matches the conduit entry. Thread types are not interchangeable, but adapt ers may be used where necessary. For explosionproof (EEx d) installations, only certifi ed or approved adapters

are permitted.

3.3 Remove apparatus terminal housing cover.

3.4 Insert connecting wires into apparatus body and start threading unit into conduit entry using moderate hand force, with lubricants as necessary.

3.5 Tighten fully (hand-tight plus 1/2 turn of 23mm A/F spanner). The steel body of the TP48 is not used as part of

the electrical circuit, therefore sealing of the thread with PTFE tape or other sealing compounds will not af fect

the performance of the TP48.

Note: In Explosionproof (EEx d) applications, sealing of the thread is not permitted - the TP should be

treated in the same way as any other cable gland/hub into similar equipment.

3.6 For effective protection, the leads of the TP should be as short as possible. Before wiring to the transmitter

terminals, cut the leads to the appropriate length and strip back 10mm of insulation. Do not try to coil excess

lengths of cable into the transmitter housing as this will degrade the protection given by the surge protector.

3.7 Connect the fl ying leads to the terminals indicated below;-

Note: The protection circuit needs to be connected in parallel with the transmitter 4-20mA current

loop, not in series. Many transmitters offer linked terminals to avoid installation with multiple wires in

each terminal. If your transmitter does not, then use an appropriate termination method e.g. ring-tag,

piggy-back Faston tab, split ferrule etc. to complete the connection satisfactorily.

3.8 Ensure that all connections are tight, particularly the earth bonding connection, which is likely to be via a stud

within the apparatus terminal housing.

3.9 Refi t apparatus terminal housing cover.

Reconnect circuit if it was previously isolated.

3.10 TP32-T ONLY: The TP32-T is a FISCO/Fieldbus terminator. It can be used as a spur terminator and surge

protective device. Make sure no other terminating blocks are in use for the spur.

4. EARTHING / GROUNDING

WARNING: The enclosure does not provide an external or internal connection for earthing or ground ing the enclosure. It is the user’s responsibility to provide adequate earth continuity via the mounting

arrangements for all locations and all protection methods.

The TP earth wire (Green/Yellow) should be connected to the earth terminal or stud usually provided inside the transmitter housing. In the unlikely event that no such stud exists, make the connection to a structural mounting part, such as a

terminal block fi xing screw.

5. MAINTENANCE

At intervals of not more than one year (more frequently for particularly harsh environments) visually check the instal lation and ensure that:

i) Device and/or enclosure is fi rmly attached to mounting

ii) There are no signs of external damage or corrosion

iii) Interconnecting cables are not frayed or otherwise damaged

iv) All connections are properly made with clear labelling

If this unit suffers damage send back to MTL Surge Technologies for evaluation which should only be carried out by

MTL Surge Technologies. This product is not fi eld repairable.

6. APPROVALS

In hazardous locations check the marking on the device to ensure that it is appropriate for the application. Mark

the appropriate box (fi gure 2) to indicate the type of protection being utilised. For marking use a punch mark. The

product range has been designed to meet the fault tolerant requirements of Electrical Apparatus for Category ‘ia’.

Entity parameters: See Certifi cate number Baseefa04ATEX0251X

ATEX Special Conditions for Safe Use:

1. The permanently attached cables shall be suitably protected against

pulling, mechanical damage and must be terminated within a ter-

minal or junction facility suitable for the conditions of use.

2. These devices are not provided with an external connection facility

for an earthing or bonding conductor. It is the user’s responsibility to ensure adequate earth continuity via the

mounting arrangements.

3. The equipment is also afforded Intrinsically Safe Certifi cation to BASEEFA04ATEX0251, and hence the equipment

is dual marked. It is the user’s responsibility to determine the protection concept to be applied and permanently

mark the equipment in the space provided for guidance in installation and maintenance.

WARNING: Ensure polarity is correct when connecting TP32-T.

Figure 2 ATEX certifi cation details

Loading...

Loading...