Page 1

SD ATEX Information

The Essential Health and Safety Requirements (Annex II) of the EU Directive 94/9/EC [the ATEX Directive - safety of

apparatus] requires that the installation manual of all equipment used in hazardous areas shall contain certain information.

This guide is included to ensure that this requirement is met. It compliments the information presented in this document and

does not confl ict with that information. It is only relevant to those locations where the ATEX directives are applicable.

1. General

a) In common with all other electrical apparatus installed in hazardous areas, this apparatus must only be installed, oper ated and maintained by competent personnel. Such personnel shall have undergone training, inculding instruction on

the various types of protection and installation practices, the relevant rules and regulations, and on the general prin ciples of area classifi cation. Appropriate refresher training shall be given on a regular basis. [See clause 4.2 of EN

60079-17].

b) The apparatus has been designed and manufactured to satisfy the “essential health and safety requirements” of Annex

II of the Directive.

c) This apparatus has been designed to meet the requirements of I.S. electrical apparatus in accordance with EN 50020

and EN50014 and is normally mounted in the hazardous area.

d) This apparatus requires additional protection for use in dust environments.

2. Installation

a) The installation should comply with the appropriate European, national and local regulations, which may include

reference to the IEC code of practice IEC 60079-14. In addition particular industries or end users may have specifi c

requirements relating to the safety of their installations and these requirements should also be met. For the majority of

installations the Directive 1999/92/EC [the ATEX Directive - safety of installations] is also applicable.

b) The apparatus must not be subjected to mechanical and thermal stresses in excess of those permitted in the certifi ca-

tion documentation, this manual and the product specifi cation. If necessary the product must be protected by an enclo-

sure to prevent mechanical damage.

c) The apparatus must not be installed in a position where it may be attacked by aggressive substances and must be

protected from excessive dust, moisture and other contaminants by an enclosure.

d) This apparatus is I.S. electrical apparatus and is normally mounted in a hazardous area. It meets the requirements of

Category 1 apparatus and may be installed in a Zone 0 location providing that the relevant installation conditions are

met.

3. Inspection and maintenance

a) Inspection and maintenance should be carried out in accordance with European, national and local regulations which

may refer to the IEC standard IEC 60079-17. In addition specifi c industries or end users may have specifi c require-

ments which should also be met.

b) If the outer enclosure of the apparatus needs to be cleaned, this should be done with a cloth lightly moistened by a

dilute mixture of detergent in water.

4. Special Conditions for Safe Use

a) The plastic enclosure may present an electrostatic risk and must not be rubbed in service.

b) The range of SD**XXX Series Surge Protection Devices will not meet

the 500V insulation requirements to earth, therefore suitable precau tions must be taken when installing the apparatus.

5. Repair

a) The products cannot be repaired by the user and must be replaced with

an equivalent certifi ed product. Repairs should only be carried out by

the manufacturer or his authorised agent.

6. Marking

a) The products each have their own markings, a sample of which is

reproduced to the right, along with indications of where the markings

for the variants differ. In addition the serial number and/or date of

manufacture are marked on the individual apparatus. This manual

applies to products manufactured and date marked during or after the

year 2003.

Notes:

1) The number and subsequent letters will change depending on the

product variant.

2) The electrical parameters and simplifi ed circuit diagram will change

depending on the product variant.

INSTALLATION INSTRUCTIONS

SD Series

Surge Protection Devices

For more information please contact your local MTL offi ce

or visit our web site at www.mtlsurge.com

The Americas: +1 800 835 7075

UK: +44 (0)1582 723633

Singapore: +65 6 487 7887

830-007 02 11/06/07

The Netherlands: +31 (0)481 450250

Italy: +39 (0)2 6180 2011

Australia: +61 (0)8 9455 2994

India: +91 (0)44 450 1660

Page 2

SD Series

The SD range of devices protects electronic circuits from high voltage transients and temporary overloads on

signal and power lines. This is achieved by diverting the transient current to earth and limiting the signal line

voltage for the duration of the surge. Earthing is provided simply by clipping the SD unit to an earthed DIN rail.

Screw terminals are provided to connect cable screens to earth.

Note: The overall earthing system is critical to effective op-

eration of the surge protector. This amy require re-routing of

the system earthing and the installation instructions should

be checked carefully. If the system requires the DIN rail to be

isolated from the mounting plate then use ISP7000 insulating

spacers (see Fig. 5).

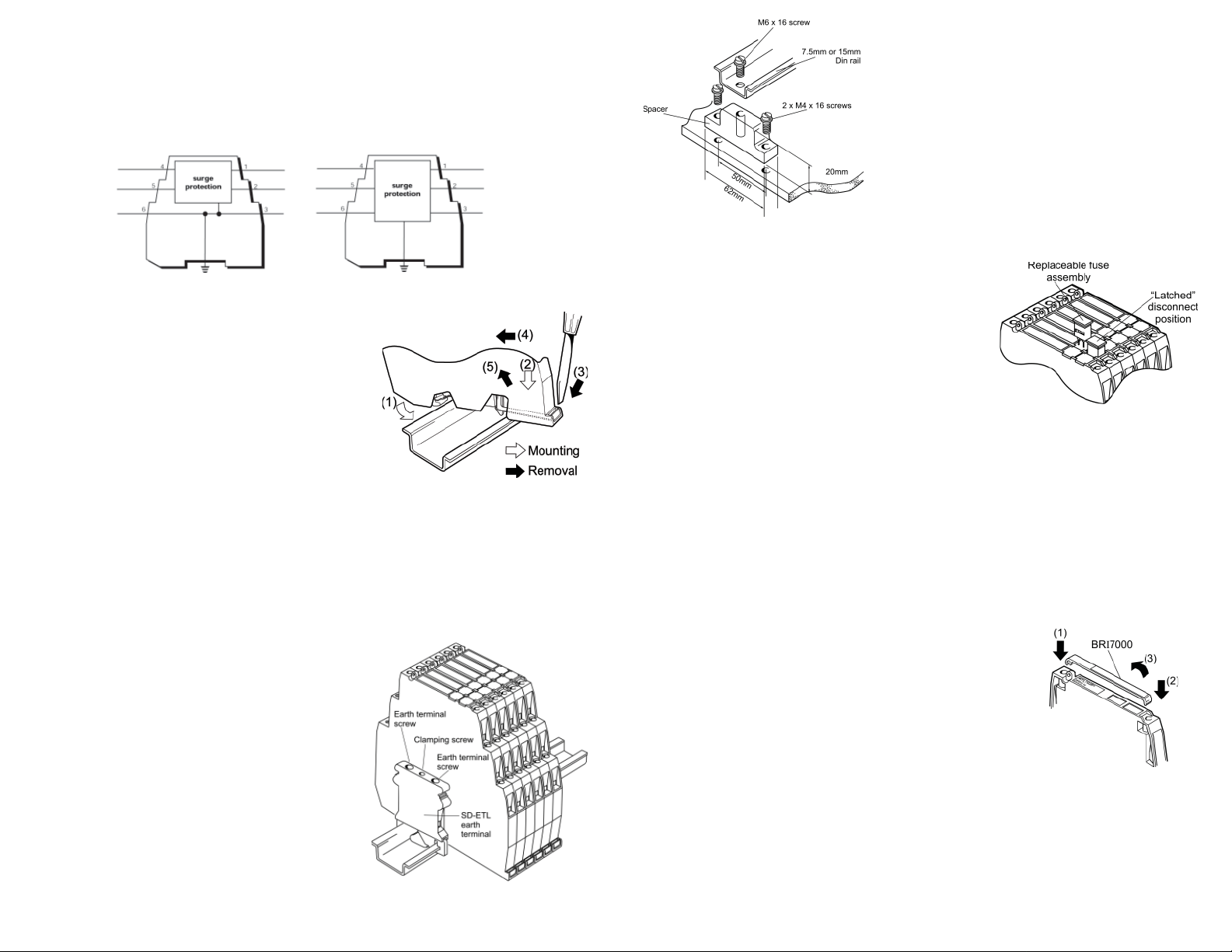

Fig. 1 Two wire SD

protection unit

Field

Wiring

Protected

Wiring

DIN Rail

Field

Wiring

Protected

Wiring

Fig. 2 Three wire SD

protection unit

DIN Rail

Installation

These units are suitable for use in hazardous area circuits as described in IEC/EN60079-14. Because of their intended safety function they must be removed when performing the 500V insulation

test.

SD devices are mounted as follows (see Fig. 3):

a) Hook the earthing clamp at the fi eld side of the base of the SD

unit over one fl ange of the DIN rail (1).

b) Press down the protected area end of the SD unit fi rmly until it

clicks into position (2).

c) Check that the SD unit is securely clamped into place on both

fi eld and protected sides

Fig. 3 Mounting/removing an SD unit

Note: it is essential to check that the earth connection has been

made securely.

d) To remove, insert the blade of a screwdriver down the protected side of the SD unit (3) and lever the handle

gently towards the SD unit (4) and upwards to disengage the spring, freeing the unit from the rail (5).

e) When connecting the signal wires, if using an electric screwdriver the torque setting should be between 0.2

and 0.4Nm maximum.

Earthing

Correct earthing procedures are essential for effective and safe

surge protection. Each SD unit has its earth connection made

onto the DIN rail. Connection to the surge earth is made using an

ETL7000 earth terminal clamped to the DIN rail at either, or preferably both, ends of a row of SD surge protectors. (See Fig. 4).

a) Locate the earth terminal next to the SDs at the end of the row.

b) Hook the earthing clamp over the fl ange of the DIN rail. Press

down the other end of the terminal until it locates over the

DIN rail. Firmly tighten the clamping screw in the central hole

on top of the terminal. Check that the earth terminal is pro perly clamped to ensure that the earth connection has been

made securely.

c) The earth connection of the SD should be made to the earth

reference of the equipment to be protected. In practice, the

earth connection (via ETL7000 terminals) is usually made

to the OV reference earth box in the equipment cubicle.

The earth connection should be 1 metre in length and use

wire size

3

2.5mm2.

Fig. 4 Fitting the earth terminal

Fig. 5 Mounting the ISP7000 insulated spacer

Replaceable fuses

(Only fi tted in selected versions)

See Fig. 6. SD replaceable fuses protect the SD unit and associated

circuitry against wiring errors and circuit faults that may develop

during operation. They also act as “disconnects” providing a useful

mechanism for breaking the circuit between the protected area and

the fi eld equipment during commissioning, maintenance or fault

fi nding. The 250mA fuses are packaged in plastic assemblies and

spare assemblies for replacement purposes are available in packs of

5 (SD-F25). In addition, packs of 50mA (SD-F05) fuses are available for cases where the lower current limit is more appropriate.

Fig. 6 Fuse replacement

The procedure for using and replacing a secondary fuse is

a) Raise the latched end of the plastic SD identifi er (if fi tted) and pivot it upwards to provide access to the top

of the barrier.

b) With the tip of a small screwdriver, gently lever the fuse package upwards until it can be gripped between

two fi ngers.

c) Pull it upwards until a slight resistance is felt – this is the “disconnect” position used to isolate protected

and fi eld equipment during commissioning, maintenance and fault-fi nding procedures.

d) Use slightly greater force to withdraw the fuse assembly completely.

e) Insert the replacement fuse and press down fi rmly into place (with the top of the package fl ush with the top

of the SD unit) or reset the latched assembly similarly.

Note: the replacement fuses are non-polarised and can be inserted either way round.

f) Carefully pivot the identifi er and clip it back into place.

Individual terminal identifi cation

See Fig. 7. BRI7000 identifi ers mount on top of individual SD units and are

supplied with adhesive labels for identifi cation – the latter also being supplied

in separate sheets (BIL7000L) for pre-printing by the user. The installation

procedure is:

a) Clip the rounded end of the identifi er fi rmly onto the horizontal pins at the

fi eld-side end of the SD unit to form a pivot (1).

b) Push the free end of the identifi er downwards until the fl ange latches into

the slot at the protected end of the SD (2).

Note: on SD units with replaceable fuses it is necessary to pivot the

identifi er upwards (3) to provide access to the fuse.

Fig. 7 Installing SD identifi er and

label

UL497B Listed

Voltage breakdown ratings:

9-10Vdc SDRTD, SD07, SD07X, SD07R, SD07R3, SD07T3, SD0RX3

21-23Vdc SD16, SD16X, SD16R, SD16R3, SD16T3, SD16X3

45-47Vdc SD32, SD32X, SD32R, SD32R3, SD32T3, SD32X3

65-80Vdc SD55, SD55X, SD55R, SD55R3, SD55T3, SD55X3

Loading...

Loading...