Page 1

MTL646

IS Panel Mounting Serial Text Display

Instruction Manual

INM646

Page 2

ii

Page 3

INM646-1

Contents July 2003

1. Description

2. Operation

2.1 MTL646/7 protocol

2.2 MTL643/4 protocol

3. Intrinsic Safety Certification

3.1 Apparatus certificate (ATEX)

3.2 System certificates

3.3 Zones, groups and T rating

3.4 Power supply

3.5 External switches

3.6 Switch outputs

3.7 Certification label information

4. System Design for Hazardous Area

4.1 Cable length

4.2 Two wire system

4.3 Three wire system

4.4 Four wire system

4.5 Switch outputs

5. Installation

5.1 Location

5.2 Installation procedure

5.3 EMC

6. Configuration

6.1 Default configuration

6.2 Accessing the configuration menus

6.3 Summary of configurable functions

6.4 Quick access menu

The MTL646 is CE marked to show compliance with the

European Explosive Atmospheres Directive 94/9/EC,

the European EMC Directive 89/336/EEC

and the European Low Voltage Directive 73/23/EEC

7. Programming

7.1 Summary of MTL646/7 protocol

7.2 Command format

7.3 Response format

7.4 Operational modes

7.5 Multidrop operation

7.6 Summary of commands

7.6.1 Screen handling & text

7.6.2 Attributes

7.6.3 System commands

7.6.4 Line graphics

7.6.5 Pixel graphics

7.7 Graphics download

7.7.1 <DL> command

7.7.2 <DG> command

7.8 Cyclic Redundancy Check

7.8.1 Procedure for generating

CRC.

8. Maintenance

8.1 Fault finding during commissioning

8.2 Fault finding after commissioning

8.3 Servicing

8.4 Routine maintenance

8.5 Guarantee

8.6 Customer comments

9. Accessories

9.1 Tag number

9.2 MTL646/647 Programming Guide.

10. Index

iii

Page 4

iv

Page 5

MTL646 INM646-1

IS PANEL MOUNTING SERIAL TEXT DISPLAY July 2003

1. DESCRIPTION

The MTL646 is an intrinsically safe instrument

that can display text and simple graphics in a

hazardous area. Incorporating six operator

switches, two solid state outputs and a backlit

graphical display, it forms a simple operator

interface for machine or process control

applications.

The MTL646 text display has been certified

intrinsically safe by European Notified Body

Intertek Testing Services (ITS) to the ATEX

Directive 94/9/EC.

Safety approvals from authorities outside

Europe are being obtained, please contact

MTL for the latest information.

Housed in a robust 144 x 72 panel mounting

DIN enclosure, the text display has an IP65

front panel and is supplied with a gasket to

seal the joint between the instrument and the

panel.

2. OPERATION

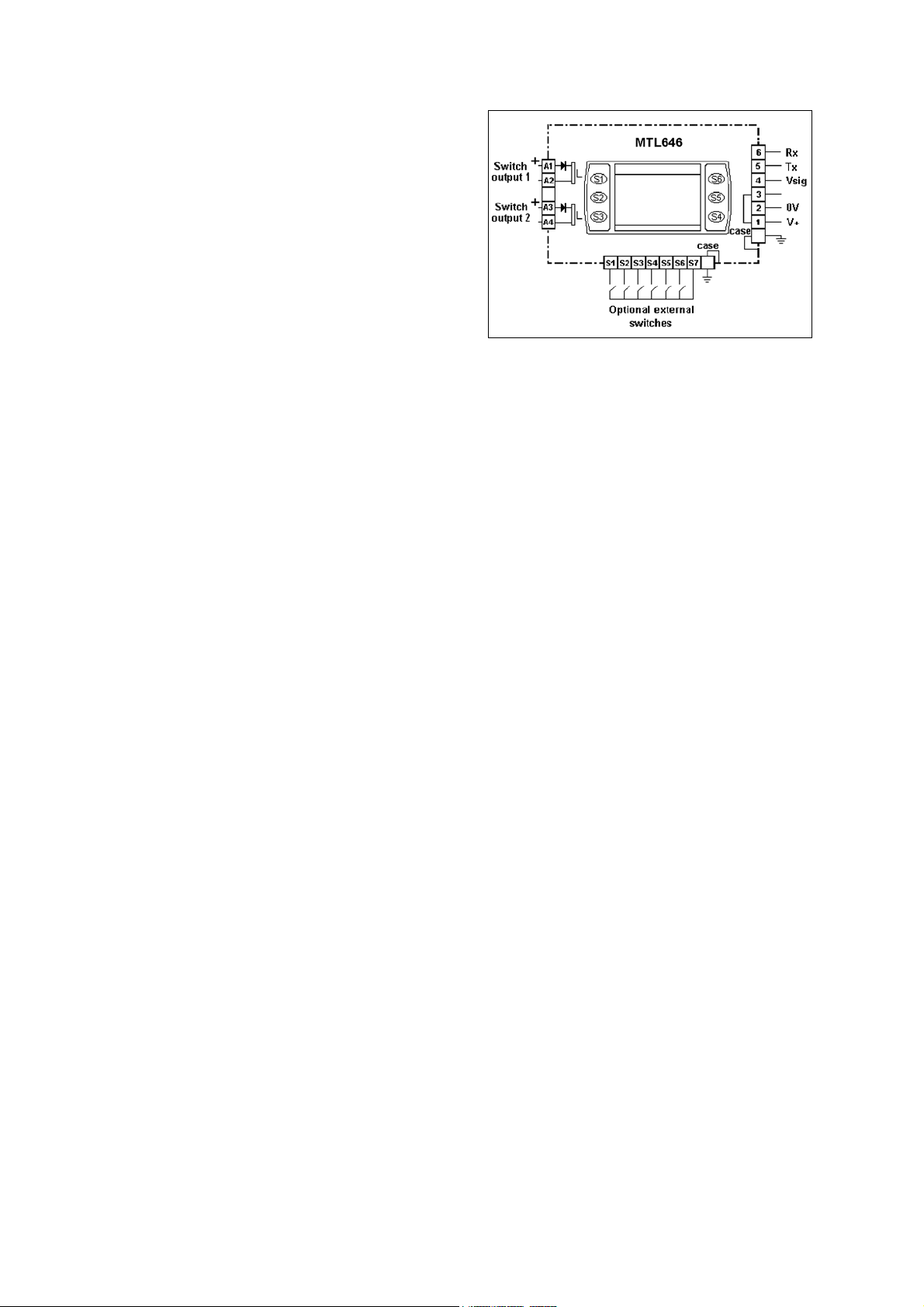

Fig 1 shows a simplified block diagram of a

MTL646 serial text display. The instrument is

connected to a serial data galvanic isolator in

the safe area via two, three or four wires that

carry both power and bi-directional

communication. The switch outputs may be

controlled and the operator switches

interrogated from the safe area via the serial

communication link.

The MTL646 serial text display has been

designed to operate with a certified galvanic

isolator that has an RS232 or RS422 safe area

port. This enables the MTL646 to be controlled

and interrogated by a process computer or a

dedicated instrument such as a PLC.

Installation and commissioning are simple. An

MTL646 serial text display may be operated on

a simple two-wire system that provides both

power and bi-directional communications. Two

MTL646 displays with separate addresses may

be multi-dropped from a two-wire system and

up to four displays from a three-wire system.

Up to 14 serial text displays may be address

from one RS232 or 422 port.

Section 7 of this manual includes a summary of

the MTL programming protocol and instruction

set. Detailed information is contained in the

Programming Guide, which may be

downloaded from the MTL web site

www.mtl-inst.com

Fig 1 Simplified block diagram of MTL646

2.1 MTL646/7 protocol

MTL646/7 protocol enables text to be written

anywhere on the screen in five different font

sizes, together with lines, boxes and

bargraphs. Simple bit map graphics may also

be downloaded to the display and all

characters can be reversed or flashed.

Information may also be written to a hidden

screen that may be displayed when required.

The protocol enables each of the six front

panel push-buttons to be interrogated so they

may be used for operator controls. By

displaying the switch function on the screen

adjacent to the button, ‘soft switches’ can be

created. If larger industrial size push-buttons

are required, these may be connected to the

MTL646 terminals. When external switches

are used the instrument front panel switches

are disabled.

Two single pole solid state outputs may be

used to switch certified hazardous area loads

such as sounders, beacons and valves.

2.2 Legacy protocol

The legacy protocol contained in the MTL646

allows the instrument to replace an MTL644 IS

text display. All the functions of an MTL644

are replicated, but with the advantage of a

backlit display and certification to the ATEX

Directive.

Legacy protocol only allows three external

switches S1, S2 & S3, not the front panel pushbuttons, to be used for operator inputs.

Similarly, the MTL644 only has one output

control, so the two switch outputs operate in

parallel.

When using the legacy protocol, the

configuration menus are only operational

between power being applied to the MTL646

and the first message being received.

1

Page 6

3. INTRINSIC SAFETY CERTIFICATION

3.1 Apparatus certificate (ATEX)

The MTL646 has been issued with EC-Type

Examination Certificate ITS03ATEX21172 by

Intertek Testing Services (ITS) confirming

compliance with the European ATEX Directive

94/9/EC for Group II, Category 1, gas

atmospheres, EEx ia IIC T5. The instrument

bears the Community Mark and, subject to

local codes of practice, may be installed in any

of the European Economic Area (EEA)

member countries, which currently comprise:

Austria, Belgium, Denmark, Finland, France,

Germany, Greece, Iceland, Ireland, Italy,

Liechtenstein, Luxembourg, The Netherlands,

Norway, Portugal, Spain, Sweden and the

United Kingdom. Certificates to the ATEX

Directive are also accepted in Switzerland and

the Czech Republic. This instruction manual

describes installations that conform with

PD60079-14:2000 Electrical Installation in

Hazardous Areas. When designing systems

for installation outside the UK, the local Code

of Practice should be consulted.

3.2 System certificates

In addition to the EC-Examination Certificate,

ITS have issued three system certificates of

conformity.

Ex03E21194 2 wire system SCI-976

Ex03E21195 3 wire system SCI-977

Ex03E21196 4 wire system SCI-978

3.3 Zones, groups and T rating

The MTL646 has been issued with EC-Type

Examination certificate ITS03ATEX21172

confirming that it complies with the

requirements for Group II Category 1 G EEx ia

IIC T5 (T

–40oC to +60oC) specified in the

amb

ATEX Directive. When connected to a suitable

system the MTL646 may be installed in:

Zone 0 explosive gas air mixture

continuously present

Zone 1 explosive gas air mixture

likely to occur in normal operation

Zone 2 explosive gas air mixture not likely to

occur, and if it does will only exist for

a short time,

for use with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

and having a temperature classification of:

T1 450

T2 300

T3 200

T4 135

T5 100

at an ambient temperature between –40

o

+60

C.

o

C

o

C

o

C

o

C

o

C

o

C and

Note: the guaranteed operating temperature

range of the text display is –20

o

C to +60oC

This allows the MTL646 to be installed in all

Zones and to be used with most common

industrial gases.

3.4 Power supply

When installed in a hazardous area the

MTL646 must be powered from an MTL5051

serial data galvanic isolator, or from an

MTL5051 plus an MTL5025 solenoid driver.

Although there are other certified barriers, or

galvanic isolators, with IS parameters

compatible with the MTL646, the MTL5051

must be used because it is the only one,

currently, providing the required data

conversion.

The maximum permitted cable parameters are

shown on the system certificates.

3.5 External switches

For applications requiring operator inputs to be

made by large industrial push-buttons,

terminals S1 to S7 allow external switches to

be connected to the text display. When the

external push-buttons are enabled in the

configuration menu, the front panel pushbuttons are automatically disabled.

Terminals S1 to S7 have the following

combined output safety parameters:

Uo = 14.7V dc

Io = 99mA dc

Po = 0.6W

The switches and associated wiring connected

to the terminals must comply with the

requirements for simple apparatus, i.e. they

must have IP20. Most industrial push-buttons

satisfy these requirements

2

Page 7

The total maximum permitted cable parameters

for all the cables connected to terminals S1 to

S7 in Group IIC must be less than:

Co = 0.22µF

Lo = 0.26mH

Although these are the lowest figures specified

by any of the three system certificates, they are

not restrictive and allow a significant distance

between the switches and the instrument. See

system certificates for maximum limits for each

of the three configurations

3.6 Switch outputs

Each of the two switch outputs is a separate,

galvanically isolated, solid-state switch. The

EC-Type Examination Certificate specifies that

under fault conditions the voltage, current and

power at each switch output will not exceed

those specified for simple apparatus in Clause

5.4 of EN50020:2002. This allows each of the

MTL646 switch outputs to be connected to any

intrinsically safe circuit protected by a certified

Zener barrier or galvanic isolator providing that

the output parameters of each circuit are less

than:

Uo 28V dc

Io 200mA

Po 0.85W

The two switch outputs are not shown on the

MTL646 system certificates because they will

be covered by the certificate for the system to

which the contacts are connected.

The maximum equivalent capacitance and

inductance of each MTL646 switch output is:

Ci = 40nF

Li = 20µH

To determine the maximum permissible cable

parameters, Ci and Li must be subtracted from

the maximum cable capacitance and

inductance specified by the system certificate

of the circuit connected to the switch.

3.7 Certification Label Information

The certification label is fitted in a recess on

the top outer surface of the enclosure. It shows

the certification information plus the MTL

name, location, instrument serial number and

year of manufacture. Other non-European

certification information may also appear on

this label.

S/No ??????/ ??/ ???

Measurement Technology Ltd

Luton England

1180 Ex II 1 G

ITS03ATEX21172

EEx ia IIC T5,

-40oC ≤ Ta ≤+60oC

Manufactured: ????

MTL646 SERIAL TEXT DISPLAY

3

Page 8

4. SYSTEM DESIGN FOR HAZARDOUS

AREAS

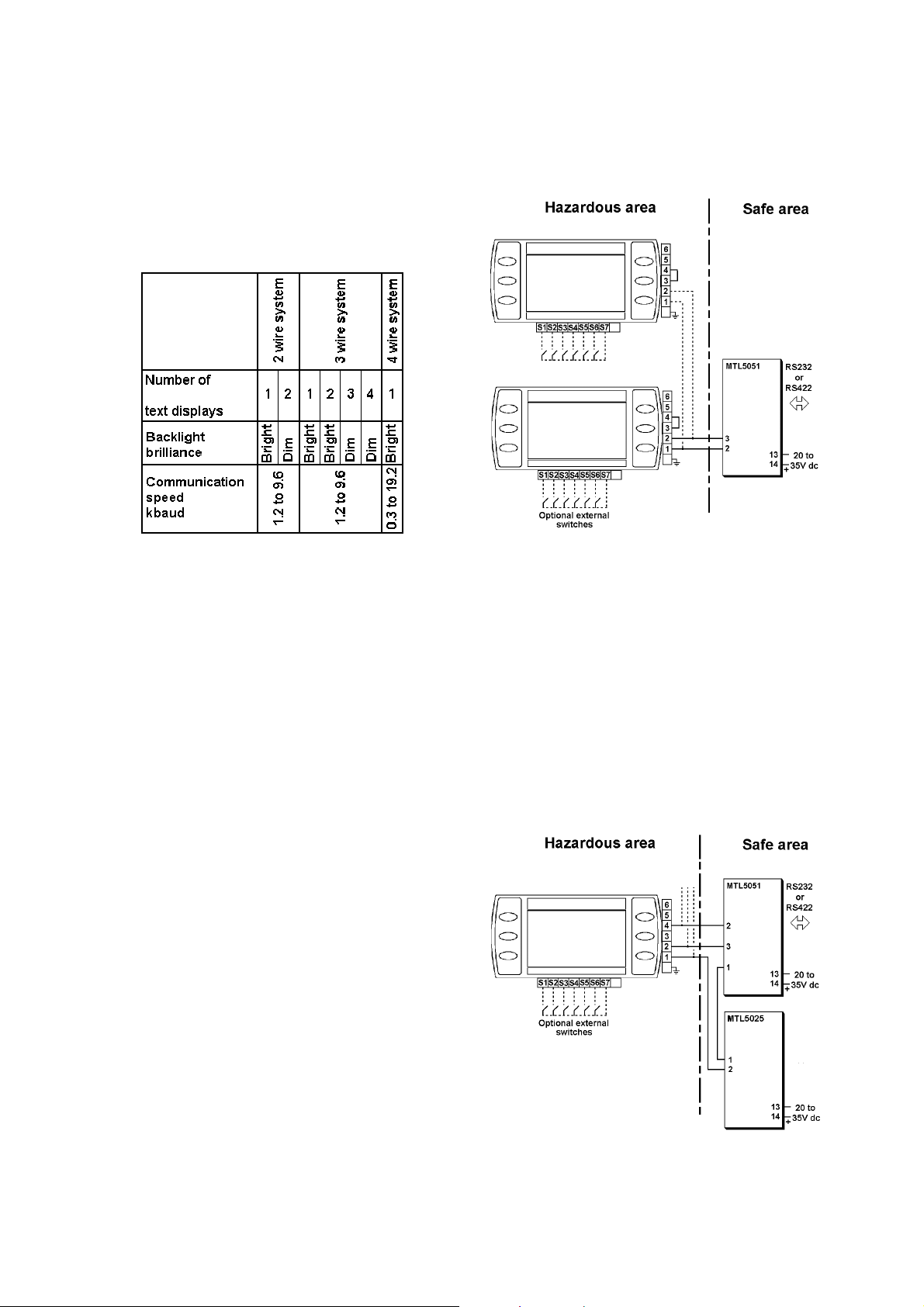

There are three configurations that may be

used for hazardous area installations. The

choice depends upon how many text displays

are required, the backlight brilliance and the

communication speed required. The following

table summarises the performance.

When two MTL646 text displays are multidropped from a common galvanic isolator the

brilliance of both display backlights will be

significantly reduced.

.

4.1 Cable length

The dc loop resistance of the cable between

the MTL646 and the associated galvanic

isolator in the safe area must not exceed 20Ω.

This applies for 2, 3 and 4 wire systems

irrespective of the number of text displays

connected to the loop. Most instrument cables

have a loop resistance of between 50 and

200mΩ per metre, thus limiting the maximum

cable length to between 100 and 400 metres.

The maximum permitted intrinsic safety cable

parameters specified on the system certificates

must also not be exceeded. However, in

practice only the capacitive limit in IIC gases is

likely to be restrictive.

Communication speed will also limit the

transmission distance. At 9.2k baud a

screened twisted pair should provide reliable

communication up to 100 metres. If data

corruption occurs the communication speed

should be reduced.

4.2 Two wire system

This is the simplest and probably the most

frequently used system. One or two MTL646

serial text displays are connected to a

MTL5051 in the safe area via two wires that

provide both power and bi-directional

communication.

Fig 2 shows the wiring diagram that is defined

by ITS System Certificate Ex03E21194.

With this configuration data may be transmitted

and received at 1.2, 2.4, 4.8 or 9.6kbaud.

Fig 2 Two wire system

4.3 Three wire system

The three-wire system illustrated in Fig 3 can

be used for multidrop applications. Up to four

MTL646 serial text displays may be powered

and addressed but, if more than two are used,

the backlight brilliance of all the displays will be

significantly reduced.

With this configuration data may be transmitted

and received at 1.2, 2.4, 4.8 or 9.6kbaud.

ITS System Certificate Ex03E21195 defines

this system.

Up to three

MTL646

Fig 3 Three wire system

4

Page 9

4.4 Four-wire system

The four-wire system, which is defined by ITS

System Certificate Ex03E21196, allows

communication at higher and lower rates than

the other two configurations. It should be used

for applications requiring fast display updates,

or with slow data rates when long cable runs

are required. The four-wire system does not

support multidrop operation.

Data may be transmitted and received at 0.3,

0.6, 1.2, 2.4, 4.8, 9.6 and 19.2kbaud.

MTL646

Fig 4 Four wire system

4.5 Switch outputs

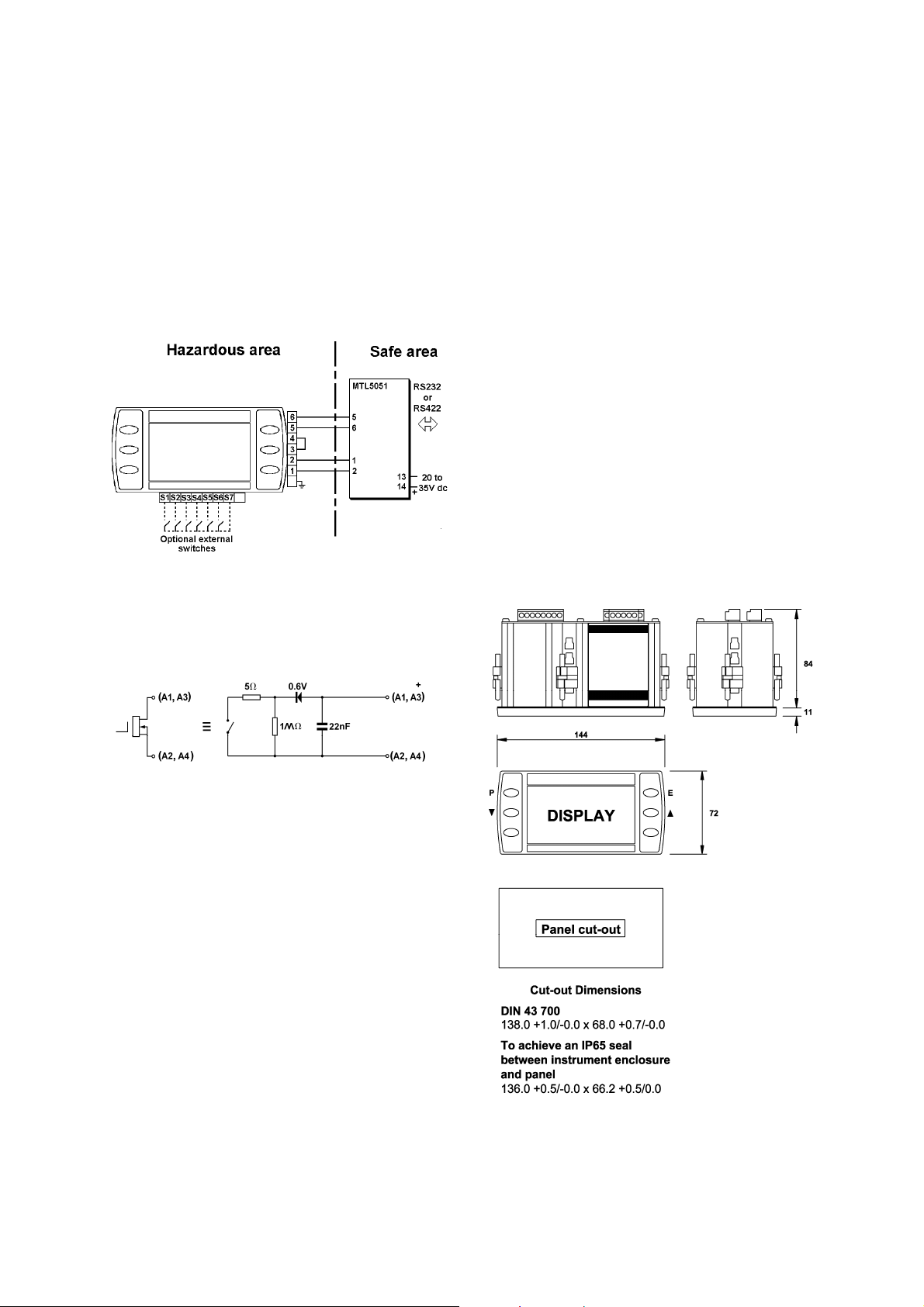

Each switch output is a galvanically isolated

single pole solid state switch output as shown

in Fig 5.

5. INSTALLATION

5.1 Location

The MTL646 is housed in a robust aluminium

enclosure with a toughened glass window

mounted in a Noryl bezel. The front of the

instrument provides IP65 protection and a

gasket seals the joint between the instrument

enclosure and the panel. The instrument may

be installed in any panel providing the

environmental limits shown in the specification

are not exceeded.

Fig 6 shows the overall dimensions of the

MTL646 and the panel cut-out. To achieve an

IP65 seal between the instrument enclosure

and the panel, the smaller cut-out must be

used and the instrument secured with four

panel mounting clips.

The MTL646 liquid crystal display has

maximum contrast when viewed from directly

ahead and slightly below the centre line of the

instrument.

Fig 5 Equivalent circuit of each switch output

The outputs are polarised and current will only

flow in one direction. Terminals A1 and A3

should be connected to the positive side of the

supply.

R

R

= 5Ω + 0.6V

on

= greater than 1MΩ

off

Note: Because of the series protection diode,

some test meters may not detect a closed

alarm output

WARNING

These switch outputs should not be

used for critical safety applications

such as an emergency shut down

system.

When the MTL646 power supply is turned off

or disconnected, both MTL646 switch outputs

will open irrespective of how they have been

programmed.

Fig 6 MTL646 dimensions

5

Page 10

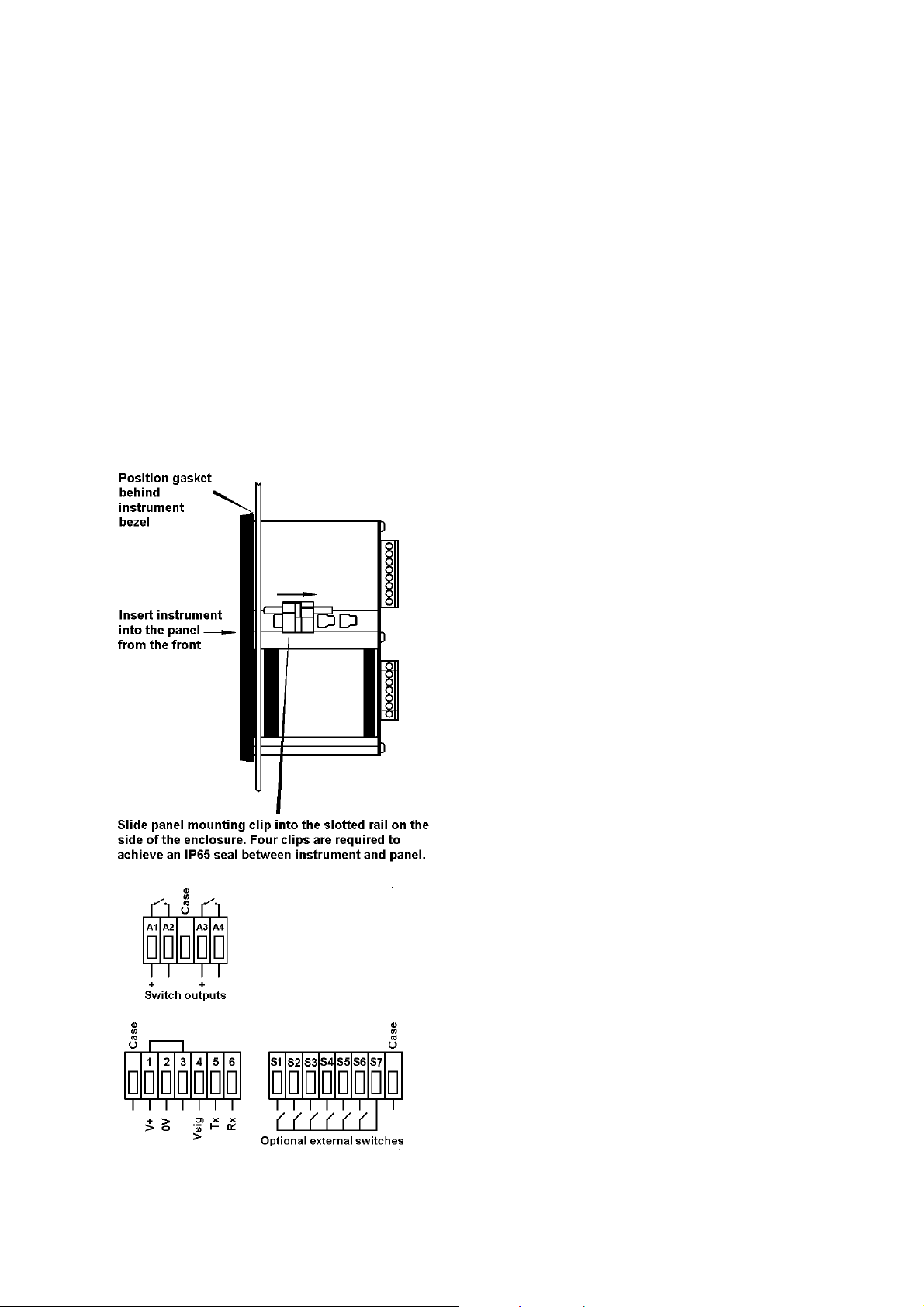

5.2 Installation Procedure

a. Insert the MTL646 into the instrument

panel cut-out from the front of the

panel.

b. Fix panel mounting clips to opposite

sides of the instrument and tighten until

the instrument is secure as shown in Fig

7. Four clips are required to achieve an

IP65 seal between the instrument

enclosure and the panel.

c. Connect the panel wiring to the rear

terminal block(s) as shown in Fig 7. To

simplify installation, the terminals are

removable so that panel wiring can be

completed before the instrument is

installed.

5.3 EMC

The MTL646 complies with the requirements of

the European EMC Directive 89/336/EEC. For

specified immunity all wiring should be in

screened twisted pairs.

To prevent circulating currents, cable screens

should only be earthed at one point in the safe

area.

Fig 7 Installation and terminal connections

6

Page 11

6. CONFIGURATION

Before the MTL646 can be commissioned it

must be configured to be compatible with the

host’s communications format and have the

required functions enabled.

The MTL646 is configured via four of the front

panel push-buttons. All the configuration

functions are contained in an easy to use menu

shown in Fig 8. Where necessary the submenus contain on-screen prompts to guide the

user through each adjustment.

When navigating through the configuration

menu, the push-button(s) should be held until

the required screen is displayed.

6.1 Default configuration

Unless otherwise requested at time of ordering,

MTL646 text displays will be supplied

configured as follows:

Baud rate 9.6k

Data bits 8

Stop bit 1

Parity None

Protocol MTL

Units Single

Address 0

Operational mode 1

Keypad Internal

Display brightness 50%

Display contrast 50%

Limit backlight On

Quick access menu On

Quick access menu code 0000

Configuration menu

access code. 0000

6.2 Accessing the configuration menus

Throughout this manual push-buttons are

shown in italics e.g. P or Up push-button, and

legends displayed by the instrument are shown

within inverted commas e.g. 'Please enter

code'.

The configuration menu is accessed by

operating the P and E push-buttons

simultaneously. Fig 6 shows the location of

these push-buttons. If the MTL646 is not

protected by an access code the main menu

will be displayed. If an access code other than

the default code 0000 has already been

entered, the MTL646 will request that the

access code be entered.

Using the Up or Down button set the first digit

of the code which will be flashing. Pressing P

will transfer control to the next digit, which

should be adjusted in the same way. When all

four digits have been set, pressing the E button

will enter the access code. If the code is

correct the main menu will be displayed, if the

code is incorrect ‘Invalid access code’ will be

displayed.

When entering an access code, timeout will

occur and the instrument will automatically

return to the operating mode ten seconds after

the push-buttons were last operated. In all

other menus timeout occurs after thirty

seconds.

When the main menu is displayed the required

sub-menu can be highlighted by scrolling

through the menu using the Up or Down pushbutton. Operating the P push-button will

display the highlighted sub-menu from which a

further selection may be made. After a

configuration parameter has been adjusted,

pressing the E button will enter the selection

and move the display up one level.

After configuration has been completed,

operating the E push-button repeatedly will

return the instrument display to the main menu.

One more operation of the E button will then

return the MTL646 to the operating mode.

6.3 Summary of configurable functions

This section provides a brief explanation of

each configurable function and should be read

in conjunction with Fig 8.

View settings

Displays the instruments main

communication settings.

Baud rate

Data rate may be set to seven speeds

between 0.3 and 19.2kbaud. Allowable

rates depend upon the system in which the

MTL646 is used.

Data bits

7 or 8 data bits may be selected. 8 bit data

is required in MTL mode for graphics and

error checked modes

Stop bits

1 or 2 stop bits may be selected.

Parity

An even, odd or no parity bit may be

selected.

Protocol

MTL646/7 or legacy MTL643/4 protocol

may be selected. The Legacy protocol is

compatible with the MTL644.

Units

Selects single or multiple MTL646 displays

connected to a single MTL5051.

7

Page 12

Address

For multidrop applications each text display

must be allocated a unique non-zero

address. Addresses may be set between 1

and 15. For single text display applications

the MTL646 address should be set to 0.

Operational mode

Five levels of communications security may

be selected, ranging from immediate

execution of a command with no

acknowledgement, to a requirement for a

16 bit cyclic redundancy check. See

section 7 and the programming guide for a

detailed explanation.

This function is not available when Legacy

protocol is selected.

Keypad

This function allows the instrument front

panel push-buttons or external pushbuttons to be used for operator inputs.

Whichever are selected, the instrument

front panel push-buttons are used for

configuration.

This function is not available when Legacy

protocol is selected.

Display settings

Allows the backlight brightness and contrast

of the MTL646 display to be adjusted.

Limit backlight

When ‘On’ is selected the maximum

backlight brightness will be automatically

set depending upon whether a ‘Single Unit’

or ‘Multiple Unit’ has been selected in the

configuration menu.

When ‘Off’ is selected the automatic

brilliance limit is overridden for special

applications, e.g. two text displays on a

three-wire system.

Quick access menu

This function enables the quick access

menu described in section 6.4. When ‘On’

is selected an operator can adjust the

screen brilliance and contrast without

having access to other conditioning

parameters.

Access code for the Quick Access Menu

Defines the four digit alphanumeric code

that must be entered to gain access to the

instrument’s quick access menu. Alpha

characters are case sensitive. Default

code 0000 allows direct access without a

code.

Access code for the Configuration Menu

Defines the four digit alphanumeric code

that must be entered to gain access to the

instrument configuration menus. Apha

characters are case sensitive. Default

code 0000 allows direct access without a

code.

Unit information

Displays the instrument model number and

the software version.

Configuration defaults

This function allows the configuration

default defined in section 6.1 to be globally

set.

6.4 Quick Access Menu

The quick access menu allows an operator to

adjust the backlight brilliance and the display

contrast without having access to the other

configuration parameters.

The quick access menu is accessed by

operating the P and Up push-buttons

simultaneously. Fig 6 shows the location of

these push-buttons. If the quick access menu

is not protected by an access code the

brilliance and contrast controls will be

displayed immediately. If an access code

other than the default code 0000 has already

been entered, the MTL646 will request that the

access code be entered. Section 6.2 explains

how an access code should be entered.

The backlight brilliance is adjusted using the

Up and Down push-buttons. Operating the P

push-button will transfer control to the display

contrast adjustment. When both are set as

required operating the E button will store both

settings and return the instrument to the

operating mode.

8

Page 13

MTL

Display mode

MTL646/7

MTL643/4

9

Page 14

7. PROGRAMMING

A detailed description of the MTL programming

protocol, together with examples of all the

instructions, are contained in the MTL646 &

MTL647 Programming Guide which may be

downloaded from the MTL web site at

www.mtl-inst.com

summary of the MTL protocol and instruction

set.

This manual only includes a

7.1 Summary of MTL protocol

• Pure ASCII protocol except for graphics

downloads, checksums and CRCs.

• Commands are two characters, case

insensitive, enclosed in angled brackets.

• Some commands require parameters.

Parameters follow the command directly.

Multiple parameters are separated by

commas. A command and its parameters

are enclosed within a single set of angled

brackets.

• All attribute commands are active until

overridden by another command.

• No spaces are allowed in

commands/parameter strings. (except in

the WT write text command)

• Any characters not enclosed in angled

brackets are written directly to the screen

at the current cursor position (operational

mode < 2). If angle brackets are required

in text, two consecutive brackets may need

to be sent depending upon operational

mode.

• Any detected parameter error causes the

command to be rejected.

• The instruments’s response to received

messages is programmable. Modes are:

No response.

Response to every correctly formatted

command.

Response to a set of correctly

formatted commands.

• Status of operator switches is encoded into

the returned message, or can be explicitly

requested.

• Communications error checking is

programmable. Modes are:

No error checking

Simple checksum

16bit Cyclic Redundancy Check.

7.2 Command format

<AB[param1],[param2]>

where:

AB is the command.

[..] indicates optional parameters

separated by commas.

examples:

<CM4,90> Cursor Move to Row 4

Column 90

<CS> Clear Screen

7.3 Response format

Ka or Ea or ?a or P0

where:

K indicates that the previous

command/command set has been

accepted.

E indicates a parameter or

communications error has been

detected in the previous command

string.

? indicates that the command is

unrecognised.

P indicates that a message has been

received but NOT actioned because the

instrument is in the conditioning mode

10

Page 15

a returns the key status

0=no key pressed

1=key1

2=key2

3=key3

4=key4

5=key5

6=key6 pressed

examples:

K0 Command accepted, no keys

pressed.

E1 Command error detected,

key 1 pressed.

?6 Command unrecognised, key

6 pressed.

P0 Command rejected,

instrument in conditioning

mode.

7.4 Operational Modes

The operational mode is defined in the

conditioning menu, see section 6.3

Mode 0:

Commands are executed immediately,

no reply message. Plain text is written

directly to the screen, no reply

message.

Mode 1:

Commands are executed immediately,

a response is returned to each

command. Plain text is written directly

to the screen, no reply message.

Mode 2:

Multiple commands can be sent, but

these are not executed until a

“Command Implement” <CI> command

is sent. One reply is returned for each

set of commands. An error in any of

the commands will result in a

Command Error response. Plain text

is ignored.

Mode 3:

As Mode 2 but the <CI> command is

replaced by a <CCn> command where

n is a single byte simple checksum of

all characters sent (including spaces)

up to, but not including the <CCn>

command. The response has a similar

single byte checksum appended to the

end of the response. The command

string is not actioned if the checksum

of the data received does not match

the parameter of the <CCn>

command. Plain text is ignored.

Mode 4:

As Mode 3 but the <CCn> is replaced

by <CRnn> where nn is a 16-bit CRC

code.

7.5 Multidrop Operation

Multidrop operation is possible. Unique unit

addresses > 0 need to be set on each

instrument.

Command <MCn> (Make Connection) is used

to define the address (n) to which subsequent

commands are directed.

Command <RC> disconnects the currently

‘connected’ unit

11

Page 16

7.6 Summary of Commands

Commands are listed in functional groups. Detailed descriptions of each command including

examples of how they should be used are included in the MTL646 & MTL647 Programming Guide

which may be downloaded from www.mtl-inst.com

7.6.1 Screen handling and text

Command Meaning Description

<CLn>

<CMy,x>

<CS> Clear Screen All pixels off, cursor homed

<CW>

<EL>

<FS> Fill Screen All pixels on, cursor homed

<FW>

<HC>

<LN>

<RS>

<SD>

<WSn>

<WTthis is a message> Write Text Sends text and ensures a response

Clear Line

Cursor Move

Clear Window

Erase Line

Fill Window

Home Cursor

Line New

Request Status

Screen Defaults

Write Soft

character

Erases all text on line n. For

parameter ranges see CM

command. Row Mode only.

Cursor moved to Row y Column x.

Row values are 0-7 (Row Mode), 063 (Pixel Mode) Column values are

0 – 119.

All pixels set to off in the defined

window area. Cursor homed in the

windowed area.

Row Mode only

Erases text from current cursor

position to end of line.

Row Mode only.

Sets all pixels in the defined

window ‘on’. Cursor Homed in the

windowed area.

Row Mode only

Returns the cursor to the top left of

the screen for the current font. This

command is window aware in Row

Mode

Sends a carriage return and line

feed to the display so that following

text is written on the next line down.

Row Mode only.

Returns switch status when

operating in Mode 0.

Works in any mode.

Returns the instrument screen to

default state. See definition at the

end of this table.

Write Soft character n. n=0-3. This

command displays the previously

downloaded soft character at the

current cursor position. It will

assume all of the currently active

attributes, just as any normal

character. Command is active in

both Row Mode <RM> and Pixel

Mode <PM>. Soft fonts are lost

when power is removed. Soft fonts

F1 to F4 can be saved to eeprom.

and restored. See <KF> and <FR>

commands.

from the instrument Operational

Mode OM>0.

12

Page 17

Note: The Screen Defaults <SD> command returns the display and its attributes to a kn own state

listed below.

Display scroll off

Key press data cleared

Window definition cleared

<VF0> Visible frame = 0

<AF0> Active frame = 0

<F1> Small font 8 x 6 Pixels

<CS> Clear Screen

<HC> Cursor homed

<WM0> Normal text

<RM> Row Mode

<IF> Inhibit Flashing

<ST> Text Steady attribute

<NA> No text Alignment

<BM0> Background Mode = 0

<NU> No Underline

7.6.2 Attributes

Command Meaning Description

<BMn>

<CA>

<DWyt,yb,xl,xr>

<EF> Enable Flashing Enables flashing for characters

<F1> Font 1 6 mm high 8 x 6 pixels.

<F2> Font 2 10 mm high 16 x 10 pixels.

<F3> Font 3 17 mm high 24 x 15 pixels.

<F4> Font 4 23 mm high 32 x 19 pixels.

<F5>

<FL> Flash Following text flashing

<IF> Inhibit Flashing Stops flashing on the whole display.

Background

Mode

Centre Align

Define Window

Font 5

If n=0, flash background is pixels off

If n=1, flash background is pixels on

If n=2, flash background is the

inverse of the character or graphic

being written.

Default state is <BM0>.

To use this command, the flashing

attribute <FL> must be set. To

enable screen flash the Enable

flash <EF> command must be sent.

Text is centred (x-direction). Use

with <WT> command.

Window aware in Row Mode only.

Creates a sub-window for text .

yt=top row, yb=bottom row, xl=left

column, xr=right column.

Row Mode only

written with the flashing attribute set

Cursor is homed.

Cursor is homed.

Cursor is homed.

Cursor is homed.

34 mm high 48 x 29 pixels.

Partial Character set only (0-9, A-Z,

space, comma, full-stop, plus,

minus). Undefined characters not

trapped. Cursor is homed.

Overrides attributes

13

Page 18

14

Page 19

Command Meaning Description

<LA>

<LF> Line Feed Line feed added after carriage

<NA>

<NL>

<NU>

<RA>

<ST> Steady Following text non-flashing

<SW>

<TW>

<UL>

<WMn> Write Mode 0=Normal, 1=OR, 2=XOR,

Left Align

No Align

No Linefeed

No Underline

Right Align

Smart Wrap

Text Wrap

UnderLine

Text is left justified. Use with <WT>

command.

Window aware in Row Mode only.

return. Row Mode only

Text is written at the current cursor

position by the <wt> command.

This is the default setting.

Carriage return and line feed are

independent actions. Row Mode

only

Cancels the <UL> command above

Text is right justified. Use with

<WT> command.

Window aware in Row Mode only.

Wraps text onto next line, does not

break words. Use with WT

command. Row Mode only.

Cancelled by any subsequent text

alignment command.

Characters are wrapped on to the

next line at the end of the line in the

current window. Row Mode only.

Cancelled by any subsequent text

alignment command.

Text in fonts F2 to F5 is underlined

in the decender area of the current

font. Underlining can be used in

both row and pixel modes.

3=Inverse

15

Page 20

7.6.3 System commands

Command Meaning Description

<AFn>

<CCn>

<CI>

<CE>

<CP> Configuration

<CRnn>

<DFn>

<FR>

<HSmnrstuv>

<KF> Keep Fonts Soft fonts F1 to F4 are saved to

Active Frame

Check Code

Command

Implement

Configuration

Enable

Prohibit

Cyclic

redundancy

check

Download Font

Font Restore

Horizontal Scroll

Subsequent writes to the

instrument are written to page

frame n. n=0 or 1. Default is 0.

Specifies a simple checksum (n) of

a previously sent command string.

Operational Mode 3.

Signal to execute previously sent

commands.

Operational Mode 2.

Entry to the menu structure by the

dual P-E keypress is enabled. This

is the default state.

Entry to the menu structure by the

dual P-E keypress is inhibited.

Specifies a 16-bit CRC (nn) of a

previously sent command string.

Operational Mode 4.

Download soft character n for the

currently active font. (n=0-3) After

this command has been issued a

binary download of a .BPM file is

expected. This file must be an

image exactly the same size (in

pixels) as the currently active font.

An image of any other size will

cause an error response. The

mechanism and .BMP file

requirements for this command is

exactly the same as that for the

Download Graphic <DG> and

Download Logo <DL> commands.

Soft fonts F1 to F4 are recovered

from eeprom. This will overwrite

any downloaded fonts that have not

been saved using the <KF>

command above.

m= 0 scroll is Right to Left,

m=1 scroll is Left to Rright.

n=Start row of block to scroll

r=Last row of block to scroll

A line of length t pixels starting at

Pixel=s above the bottom of row r

and a line of length v pixels starting

at Pixel=u above the bottom of row

r is inserted For Left to Right scroll,

the line is inserted at the left of the

screen, for Right to Left scroll at the

right of the screen.

This is a row mode command that

can be used in a window. If it is

used in a window, then the

parameters are relative to the

defined window.

Eeprom.

16

Page 21

Command Meaning Description

<MCn>

<ODn> Switch Output

<OEn> Switch Output

<PM> Pixel Mode Text is pixel aligned. Any defined

<RB> ReBoot Hardware restart activated by

<RC>

<RFm>

<RLx>

<RM> Row Mode Text is row aligned.

<SBn> Set Backlight Backlight set to intensity n=0 to

<SFnm> Save Frame Saves frame ‘m’ to memory area

<SL>

<TOn>

<VFn>

Make

Connection

De-energised

Energised

Release

Connection

Restore Frame

Restore Logo

Save Logo

Time Out

Visible Frame

Subsequent commands are

addressed to the stated node. n=1

to n=15.

Output n open circuit. n=1 or n=2.

Output n short circuit. n=1 or n=2.

windows are cleared.

deliberate watchdog timeout.

Releases the connection made with

the <MC> command above. After

this command, no instruments will

respond until a further <MCn>

command is issued.

Restores the frame saved with

<SF> to the current active frame.

Attributes are not restored

User defined logo is written to the

current visible frame. x=0 gives a

static display, x=1 enables scrolling

of the logo as at power-up. If there

is no user logo saved, the MTL logo

is displayed.

n=40.

‘n’.

The visible frame is saved to

eeprom and used as a power-up

logo to replace the MTL logo.

Command takes about 2 seconds

to complete. Saving a blank screen

re-enables the MTL logo. Intended

to be used in conjunction with the

<DL> command, but any screen

image can be saved.

Flashes a warning message on the

screen when no communication is

received for n x 10 seconds. n=0

disables the timeout function.

Default is disabled.

Page frame n is made visible. n=0

or 1. Default is 0. Cursor positions

are not saved or restored with

frames.

17

Page 22

7.6.4 Line graphics

Command Meaning Description

<BDylength,xlength,lwidth>

<HBnm>

<LHxlength, lwidth>

<LVylength, lwidth>

<VBnm>

Box Draw

Horizontal

Bargraph

Line Horizontal

Line Vertical

Vertical

Bargraph

Draws a box y length pixels high, x

length pixels wide, and with a line

width of l width pixels, from the

current cursor position (up and to

the right). Parameters can be any

value that will keep the box being

drawn on screen. Pixel Mode only.

Draw a horizontal bargraph from

the current cursor position.

n=length, m=fill both in pixels.

Row Mode only

Draws a horizontal line x length

pixels long, l width pixels wide from

the current cursor position (up and

to the right). The line length and

line width can be any value that will

keep the line being drawn on

screen. Pixel Mode only

Draws a vertical line ylength pixels

long, lwidth pixels wide from the

current cursor position (up and to

the right). The line length and line

width can be any value that will

keep the line being drawn on

screen. Pixel Mode only

Draw a vertical bargraph from the

current cursor position. n=length,

m=fill both in pixels. Row Mode only

18

Page 23

7.6.5 Pixel graphics

Command Meaning Description

<DG>

Download

Graphic

Command is followed by a .BMP file

download. See Graphics Download

section. Pixel Mode only.

<DS>

<UE> Upload Enable

<US> Upload Screen

7.7 Graphics Downloads.

The protocol is extended as follows to cover

the two simple graphics download commands

<DG> and <DS>

7.7.1 <DS> command

• Command <DL> is issued with any

additional bytes (checksum, CRC etc) as

required by the current operational mode.

• Command is acknowledged if correctly

received.

• A binary download of the .BMP file is then

expected. After the file has been

downloaded, the <CI>, <CCn> or <CRnn>

command must be sent as per the current

operational mode. “n” represents the

simple checksum of all the bytes in the

.BMP file, “nm” represents the 16-bit CRC

of all the bytes in the .BMP file

• The download is acknowledged if correctly

received (including checksum or CRC

checks).

Download

Screen

Command is followed by a .BMP file

download. See Graphics Download

section.

Enables the screen dump command

above. Needs to be sent

immediately prior to the <US>

command.

Sends a screen image back to the

user as a .bmp file. The <US>

command is acknowledged in the

normal way. After a short gap

(25ms), a 1086 byte block of data is

sent. A command acknowledge is

then sent with the check bytes as

per the current operational mode.

The check bytes include the data

block bytes and the

acknowledgement, but not the check

bytes themselves. The data block,

saved to file is a graphics image of

the screen.

• There is a 2 second timeout for the

download operation. If no bytes are

received in this time, the download is

aborted and an error response is returned.

• The downloaded logo is then displayed.

The image must be exactly 120x64 pixels

and two colour (black and white) in

standard Windows (OS2) format. An error

response is returned if these requirements

are not satisfied.

7.7.2 <DG> command

• Command <DG> follows exactly the same

mechanism as the <DS> command above,

but any size of image can be sent up to

120x64. Files in excess of this size will

cause an error response.

• The display must be in Pixel Mode <PM>

and the downloaded image is displayed at

the current cursor position.

• The image dimensions are computed from

the .BMP file sent.

19

Page 24

• The image is drawn upwards from and to

the right of the current cursor position. If

any part of the image exceeds the display

bounds the image is NOT displayed and

an error response is returned.

• The .BMP format must still be two colour,

standard Windows (OS2) format. An error

response is returned if these requirements

are not satisfied

• The downloaded image adopts the display

attributes currently in force (Normal, OR,

XOR, Inverse, Flashing, Steady)

Note:

1. The <DS> command is just a special case

of the <DG> command but because of its

fixed size is executed much more quickly.

2. Graphics can be downloaded to a hidden

frame using the <VF> and <AF>

commands and then made visible when

complete.

7.8 Cyclic Redundancy Check

The 16-bit CRC used in the protocol is the

same as used for the well-known Modbus

Protocol. Details are as follows:

The CRC is started by first preloading a 16-bit

register to all 1's. Then a process begins of

applying successive eight-bit bytes of the

message to the current contents of the

register. Only the eight bits of data in each

character are used for generating the CRC.

Start and stop bits, and the parity bit, do not

apply to the CRC.

During generation of the CRC, each eight-bit

character is exclusive ORed with the register

contents. The result is shifted in the direction

of the least significant bit (LSB), with a zero

filled into the most significant bit (MSB)

position. The LSB is extracted and examined.

If the LSB was a 1, the register is then

exclusive ORed with a preset, fixed value

(A001 hex). If the LSB was a 0, no exclusive

OR takes place.

This process is repeated until eight shifts have

been performed. After the last (eighth) shift,

the next eight-bit character is exclusive ORed

with the register's current value, and the

process repeats for eight more shifts as

described above. Finally, the content of the

register, after all the characters of the

message have been applied, represents the

CRC value.

20

Page 25

7.8.1 Procedure for generating a CRC

Step 1 Load a 16-bit register with FFFF hex

(all 1's). Call this the CRC register.

Step 2 Exclusive OR the first eight-bit byte

of the message with the low order

byte of the 16-bit CRC register,

putting the result in the CRC register.

Step 3 Shift the CRC register one bit to the

right (toward the LSB), zerofilling the

MSB. Extract and examine the LSB.

Step 4 If the LSB is 0, repeat Step 3

(another shift). If the LSB is 1,

Exclusive OR the CRC register with

the polynomial value A001 hex (1010

0000 0000 0001).

Step 5 Repeat Steps 3 and 4 until eight

shifts have been performed. When

this is done, a complete eight-bit byte

will have been processed.

Step 6 Repeat Steps 2 to 5 for the next

eight-bit byte of the message.

Continue doing this until all bytes

have been processed.

Step 7 The final contents of the CRC

register is the CRC value.

This CRC value is then appended to the

message. The LSB of the CRC is sent first

followed by the MSB.

21

Page 26

8. MAINTENANCE

8.1 Fault finding during commissioning

If a MTL646 fails to function during

commissioning the following procedure should

be followed:

Symptom Cause Check:

No Display No Power

No

Communication

Poor

Communication

Dark Display Contrast too high Contrast level in

No Backlight

or

Backlight dim

Cannot enter

configuration

menu

Communications

MTL646 displays

Push-buttons not

Incorrect wiring

parameters

incorrectly set

Incorrect

Protocol

Incorrect wiring Wiring is as per

Address

Incorrect in

Multidrop Mode

Too many

on the line.

Lines too long

Communication

speed too fast.

Backlight off or

set low

or

Multidrop mode

in use

held for long

enough (up to 2

seconds

required)

Menu inhibited

That there is 10

to 14 volts

between terminal

1 and 2 of the

seven way

connector.

Terminal 1

should be

positive.

Baud rate, data

bits, stop bits and

parity settings

match those of

the host.

Configuration

switches on the

communcations

isolator.

Protocol settings

in “Comms”

Menu

diagrams for the

chosen

configuration

Address setting

in “Comms”

menu

Configuration

settings.

Installation

guidelines

“Display

Settings” menu

Brightness level

in “Display

Settings” menu

Units setting in

“Comms” menu

Send “Program

Enable”

command (MTL

mode)

Restart unit

(Legacy mode)

8.2 Fault finding after commissioning

ENSURE PLANT SAFETY BEFORE

STARTING MAINTENANCE

Live maintenance is permitted on

intrinsically safe equipment installed

in a hazardous area, but only certified

test equipment should be used unless

a gas clearance certificate is available.

If a MTL646 fails after it has been functioning

correctly, the table shown in section 8.1 may

help to identify the cause of the failure.

If this procedure does not reveal the cause of

the fault, please contact MTL or our local

agent.

8.3 Servicing

We recommend that faulty MTL646 serial text

displays are returned to MTL or to our local

agent for repair.

8.4 Routine maintenance

The mechanical and electrical condition of the

instrument should be regularly checked.

Initially annual inspections are recommended,

but the inspection frequency should be

adjusted to suit the environmental conditions.

8.5 Guarantee

Instruments that fail within the guarantee

period should be returned to MTL or our local

agent. It is helpful if a brief description of the

fault symptoms is provided.

8.6 Customer comments

MTL is always pleased to receive comments

from customers about our products and

services. All communications are

acknowledged and whenever possible,

suggestions are implemented.

22

Page 27

9. ACCESSORIES

9.1 Tag number

The MTL646 can be supplied with a thermally

printed tag number on the rear panel. This tag

number is not visible from the front of the

instrument after installation.

9.2 MTL646 & MTL647 Programming Guide

A detailed guide to programming the MTL646

and MTL647 serial text displays may be

downloaded from the MTL website at

www.mtl-inst.com

23

Page 28

10. INDEX

Subject Section

Address 6.3

ATEX Directive 3.1; 3.7

Backlight 4, 4.2, 4.3,

6.1, 6.4

MTL protocol 2.1

Cable

Length 4.1

Parameters 3.5, 3.6, 4.1

Certificates

EC-Type Examination 3.1

Label 3.7

system 3.2

Communication speed 4.

Configuration 6.

Access 6.2

Default settings 6.1

Structure Fig 8

Quick access menu 6.4

EMC 5.3

External switches 3.5

Fault finding

During commissioning 8.1

After commissioning 8.2

Galvanic isolators 3.4

Gas groups 3.3

Guarantee 8.5

Installation 5.2

Intrinsic safety 1; 3; 4

Legacy protocol 2.2

Location 5.1

Maintenance 8.

Routine 8.4

Multidrop 2. 4.2, 4.3, 4.4,

7.5

Subject Section

Notified Body 1

MTL644 display 2.2

MTL5051 galvanic isolator 3.4, 4.2, 6.3

Power supply 3.4

Programming 7.

Commands

Attributes 7.6.2

Line graphics 7.6.4

Pixel graphics 7.6.5

Screen handling 7.6.1

System 7.6.3

Command format 7.2

Cyclic Redundancy

check. 7.8, 7.8.1

Guide 2, 9.2

Operating modes 7.4

Response format 7.3

Summary of MTL

protocol. 7.1

Servicing 8.3

Switch outputs 3.6

Systems

2-wire 4.2

3-wire 4.3

4-wire 4.4

Certificates 3.2

T rating 3.3

Terminal numbers Fig 7

Zones 3.3

24

Page 29

Modifications

8 June 2003 Issue: 1

25

Page 30

Page 31

MTL Instruments Pty Limited

1/30 Canvale Road

Canning Vale

Perth, WA 6155

Australia

Tel: +61 (0)8 9455 2994 Fax: +61 (0)8 9455 2805

E-mail: enquiries@mtlaus.com.au

MTL Canada Safety Instrumentation

#102, 4249 97 Street

Edmonton, Alberta

Canada T6E 5Y7

Tel: +1 780 485 3132 Fax: +1 780 485 3122

E-mail: cinfo@mtlnh.com

MTL Instruments Pte

Room 1002A, The Gateway

No 10 Yabao Road, Chaoyang District

Beijing 100020

China

Tel: +86 010 8562 5718/5720/5721 Fax: +86 010 8562 5725

E-mail: bjsales@mtl-inst.cn

MTL Instruments sarl

Les Carrés du Parc

10 rue des Rosiéristes

69410 Champagne au Mont d’Or

France

Tel: +33 (0)4 78 64 98 32 Fax: +33 (0)4 78 35 79 41

E-mail: info@mtl-inst.fr

MTL Instruments GmbH

An der Gümpgesbrücke 17

D-41564 Kaarst

Germany

Tel: +49 (0)2131 718930 Fax: +49 (0)2131 7189333

E-mail: info@mtl.de

MTL India Pvt. Limited

No. 36, Nehru Street

Off Old Mahabalipuram Road

Sholinganallur

Chennai - 600 119

India

Tel: + 91 (0)44 24501660/24501857 Fax: + 91 (0)44 24501463

E-mail: sales@mtlindia.com

MTL Italia srl

Via Cantù 11

I - 20092 Cinisello Balsamo MI

Italy

Tel: +39 (0)2 61802011 Fax: +39 (0)2 61294560

E-mail: info@mtl-inst.it

MTL Instruments KK

3rd Floor, Gotanda Masujima Building

1-8-13 Higashi-Gotanda, Shinagawa-Ku

Tokyo 141-0022

Japan

Tel: +81 (0)3 5420 1281 Fax: +81 (0)3 5420 2405

E-mail: sales@mtlkk.co.jp

MTL Instruments BV

PO Box 55, 6680 AB Bemmel

de Houtakker 36, 6681 CW Bemmel

The Netherlands

Tel: +31 (0)481 450250 Fax: +31 (0)481 450260

E-mail: info@mtlbenelux.com

MTL Instruments Pte Limited

31 Ubi Road 1

#04-01 Aztech Building

Singapore 408694

Tel: +65 6 487 7887 Fax: +65 6 487 7997

E-mail: sales@mtlsing.com.sg

MTL Instruments

Villa No. 4, Sector 2-17, Street 6

PO Box 53234,

Abu Dhabi, UAE

Tel: +971 2 446 6840 Fax: +971 2 446 6841

E-mail: mtlgulf@mtl-inst.com

Measurement Technology Limited

Power Court, Luton, Bedfordshire

England LU1 3JJ

Tel: +44 (0)1582 723633 Fax: +44 (0)1582 422283

E-mail: enquiry@mtl-inst.com

MTL Incorporated

4001 W. Sam Houston Parkway N. ,Suite 150

Houston TX 77043

USA

Tel: +1 281 571 8065 Fax: +1 281 571 8069

E-mail: info@mtl-inst.com

Group Internet home page http://www.mtl-inst.com/

Members of The MTL Instruments Group

Loading...

Loading...