MTI Industries Safe-T-Alert SA-10XL User Manual

PROCEDURES TO TAKE DURING AN ALARM

!

WARNING--ACTIVATION OF THIS ALARM INDICATES THE PRESENCE OF DANGEROUS

LEVELS OF GASOLINE /PROPANE VAPORS OR HEAT THAT COULD CAUSE AN EXPLOSION OR

FIRE. IT ALSO INDICATES THE PRESENCE OF RISING WATER IN YOUR BOAT.

TAKE THESE STEPS IF AN ALARM SOUNDS:

If the Fume Alarm Sounds:

Turn off all electrical equipment, generators; extinguish all open flames (oven, cook top, smoking materials, etc.).

Turn off the engine(s) if safe navigation conditions exist. Open the engine compartment, ports, hatches and doors and

ventilate the area. If you are ashore, evacuate the boat. Do not return until the area is ventilated and the detector has

returned to normal standby condition. Proceed with caution and locate and repair the cause of the leak. Seek a

qualified technician if necessary. Do not start or use the boat until all the necessary repairs are made.

If the Heat Alarm Sounds:

Check the engine(s) temperature. If there is smoke coming from the engine room/compartment and there is no automatic

fire suppression system in the engine room/compartment; put on your life jackets, radio the Coast Guard and leave the boat

if necessary. Get as far away from the boat as possible. DO NOT OPEN THE ENGINE ROOM DOOR OR HATCH.

If the Water Alarm Sounds:

Put on your life jackets. Check the bilge pump water outlet to determine that the pump is running. If it is not running,

manually start bilge pump. Open the hatch or compartment and try to determine the cause of the water leak. If more water

is entering the boat then the pump can handle, radio the Coast Guard for assistance.

SPECIFICATIONS

Power Supply - 12 VDC Operational Voltage - 7 to 15 VDC Power Draw - .200 amps @ 14 VDC

Operating Temp -220 F - 1600 F Fume Alarm Threshold - <20% LEL of Gasoline and Propane

Other gases detected but not listed; Alcohol, Acetone, Hydrogen and most other flammable gases.

Heat Sensor – Rate of Rise auto reset 1940 F

LIMITED PRODUCTS WARRANTY

MTI INDUSTRIES, INC. warrants to the original retail purchaser that its products will be free from defects of material or workmanship

for a period of Two (2) years from the date of retail purchase. If proven to have been defective in original materials or workmanship and

returned, delivery costs prepaid, MTI INDUSTRIES, INC. will replace this product free of charge.

LIMITS OF WARRANTY

Replacement is your exclusive remedy under this limited warranty or any other warranty (including any implied warranty of merchantability

for a particular purpose). Any and all implied warranties or merchantability or fitness for a particular purpose shall be limited to the

warranty period from the original date of retail purchase. MTI INDUSTRIES, INC., its dealers and distributors shall in no case be

responsible or in any way liable for any incidental or consequential damages for any reason. Some states do not allow the limitation or

exclusion of incidental or consequential damages, or allow limitations on how long an implied warranty lasts, so the above limitations may

not apply to you. This warranty gives you specific rights, and you may also have other rights, which may vary, from state to state.

PRODUCT NOT WARRANTED

NOTE- There are no user serviceable parts inside the case. Opening any SAFE-T-ALERTTM product for any reason voids the

warranty. This warranty does not cover damage or failure resulting from acts of God, abuse, misuse, neglect, or faulty installation.

WARRANTY RETURN PROCEDURES

It is MTI’s experience that an alarm is sounding for a reason. Call, ask your dealer to call, or e-mail our Customer Service Department (as

listed below) to trouble shoot the situation.

Customer Service Phone No. - 800-383-0269

Fax No. 847-546-9007

E-mail Service@mtiindustries.com

Web Site: www.mtiindustries.com If Customer Service determines that the unit is defective, a Replacement Authorization (RA) number will

be issued. No product will be accepted for service or replacement without first obtaining a RA number.

MARINE TECHNOLOGIES, INC.

SAFE-T-ALERT™ SA-10XL MARINE

GASOLINE/PROPANE, BILGE WATER AND FIRE DETECTORS

USER’S MANUAL

IMPORTANT

PLEASE READ CAREFULLY AND SAVE

ATTENTION: This user’s manual contains important detector installation, operation, trouble shooting

and warranty information. Read, follow, and keep this manual for future reference.

NOTE: If you install or purchase this detector for another person, give this manual to that person.

!

WARNING

WHY EVERY BOAT NEEDS A COMBINATION DETECTOR

Every year, boating injuries and deaths can be attributed to explosions that could have been avoided. Fumes

from even a half cup of gasoline have the explosive force of six sticks of dynamite. With a boat’s gas-powered or

propane-powered engines, vapors can easily develop in pumps, tanks, lines, or carburetors and cause explosions

or fires.

The SAFE-T-ALERT™ SA-10XL combination detector system is exclusively designed, tested for use in the

harsh marine environment. The unit is an early warning detector that monitors for the buildup of explosive gases,

high heat and heat from fire, and bilge for high water.

!

WARNING

LIMITATIONS OF COMBINATION DETECTORS

Detectors will not work without power. Some reasons your detector may not have power include an open circuit

breaker, a blown or missing fuse, a broken wire or improper wire crimp connection.

This detector may not be heard. The detector’s loudness is designed to meet or exceed regulatory standards;

however, the alarm may not be heard if units are remotely located. Individuals who are hard-of-hearing, have

consumed alcoholic beverages, have taken prescription, non-prescription or illegal drugs may not hear the alarm. If

your boat has any sleeping areas, consider installing additional detectors in that area.

This detector will only indicate the presence of gasoline fumes or heat at the sensor. The sensor cannot monitor a

compartment that is separated by a bulkhead. Gasoline fumes and heat may be present in other areas. MTI

recommends that sensors be installed in ALL compartments containing fuel tanks and/or engine(s) and compartments

where gasoline or propane fumes or heat may accumulate.

INSTALLATION INSTRUCTIONS

Assemble the following supplies: An 3/8” (9.525 mm) electric drill, ¼” (6.35 mm) and 7/64” (2.77812 mm)

drill bits, 2-1/8” (53.975mm) hole saw, electric jigsaw, screwdrivers (Phillips and slotted), stainless-steel pan

head screws, washers bolts, nuts, locking nuts, silicone sealant, 18-gauge wire, 14-gauge wire, inline fuse holder,

1A fuse, wire stripper, crimping tool, crimp connectors, adhesive-lined heat shrink tubing, split loom wire wrap,

heat gun, wire supports, and cable ties.

When you have the supplies on hand, take the following steps:

Installing the Control Panel

1. Locate the control panel at the helm where it can be easily seen and heard. Check first to be sure that there is

at least 3 inches (76.2 mm) of clearance behind the location to allow for mounting and wiring. Drill a 2 1/8

inch (53.975 mm) hole and mount the control panel. Use a marine-grade silicone sealer if the unit is exposed to

the weather. DO NOT CONNECT POWER UNTIL THE INSTALLATION IS COMPLETE.

2. Connect the cable assembly to the control panel and run it to the engine compartment. Secure the run every 18

inches (457.2 mm) with plastic wire supports.

Installing the Fume Sensor

3. Locate the fume sensor in a dry area on a forward bulkhead in the engine compartment. The sensor should be at

the same height as the starter motor. Orient the sensor so that the 4-wire cable is facing down. This will prevent

any water or condensed water vapor from entering the unit. Connect the cable assembly from the control panel to

the sensor.

CAUTION: Gasoline and Propane are heavier than air. Mount the sensor at the engine starter height. Starter

height is dependent on the engine installation

4. Connect a 1A inline fuse holder to the red (+) lead of the control panel. Run a length of red (+) 18-gauge wire to

the positive terminal on the 12V main battery. Run a length of 18-gauge yellow or black (-) wire to the negative

terminal on the 12V battery. Use ring-type insulated crimped connectors at the battery end of the run. Secure the

run every 18 inches (457.2 mm) with plastic wire supports. As added protection, use adhesive-lined shrink

tubing on all crimped connections.

Installing the Water Sensor

5. Mount the water sensor about 4” (101.6 mm) above the automatic bilge pump switch. Connect one blue lead to a

water sensor wire and the yellow lead to the other water sensor wire. Do not mount the sensor where it will get

wet or submerged in water during normal operation. Do not mount with the cable up as water can run into

the sensor assembly and damage the sensor assembly. Connect the 20 foot (6096 mm) cable.

Installing the Fire/Heat Sensor

6. Connect the white lead to one of the white heat sensor wires. Connect the Blue lead to one of the Heat Sensor

Black wires. Install the sensor above the engine(s) and as high as possible in the compartment

7. When installation is complete, run a system check of all sensors and the control panel. Be sure to turn the unit

off when leaving the boat, as constant monitoring will run down the 12V battery.

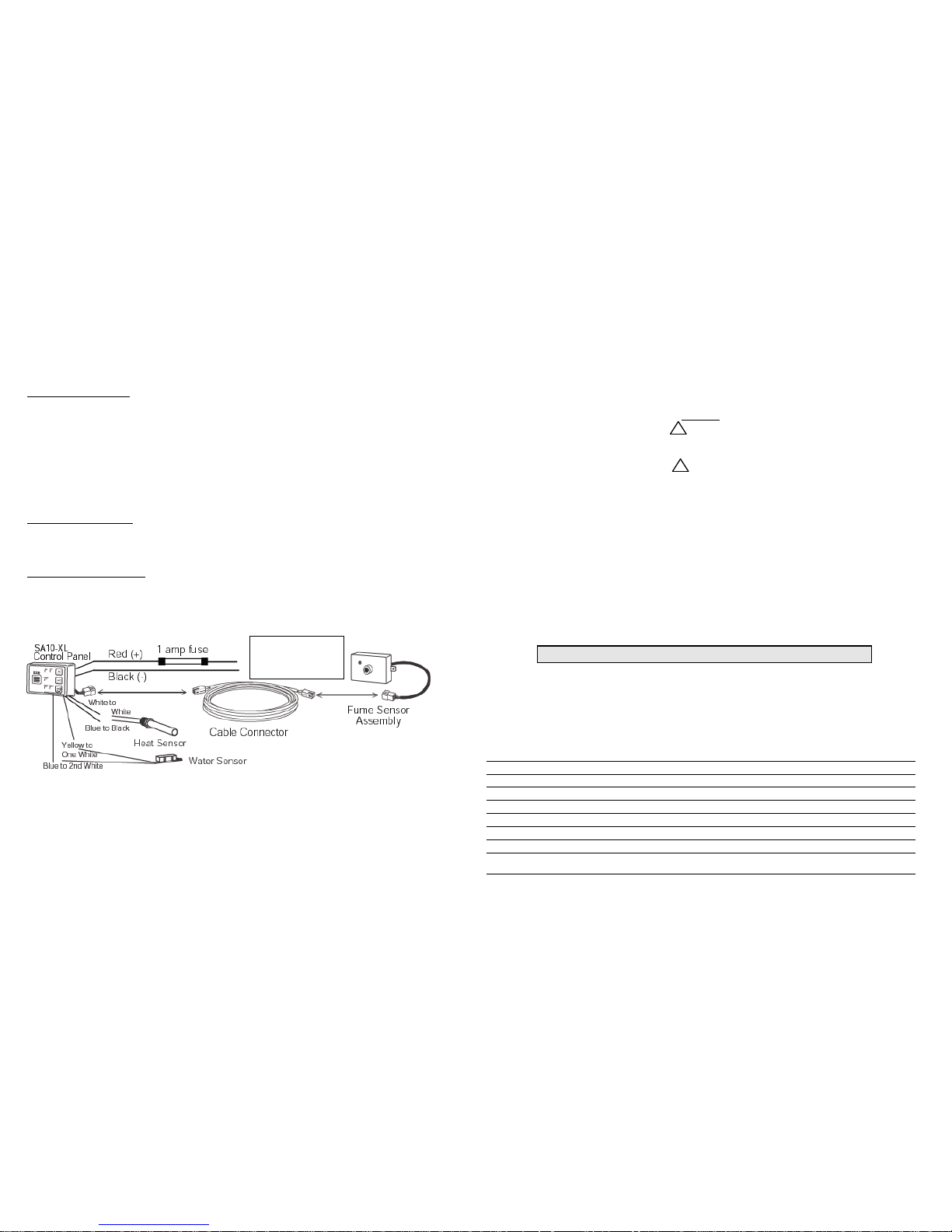

The assembled system should look similar to the following:

ADDITIONAL INSTALLATION TIPS

DO NOT mount the control panel under a cowling, or glass or plastic panel where it may not be seen or heard.

DO NOT locate the fume sensor above batteries. Hydrogen from the batteries may cause false alarms.

DO NOT locate the fume sensor behind any obstruction that will prevent air flow to the sensor.

DO NOT locate the fume sensor on the aft bulkhead. Water on the sensor will cause permanent damage to the sensor

and sensor assembly.

DO NOT locate the fume sensor within 12 inches (304.8 mm) of exhaust lines. High heat may cause false alarms.

OPERATION

The SA-10XL has supervisory circuits to warn of a missing sensor, sensor assembly malfunction, disconnected or a broken

connector sensor cable.

1. Press the control panel’s ON pad. The WAIT (YELLOW) light should light. Press the TEST pad to check the operation

of the alarm sounder and alarm light. In about two minutes the WAIT (YELLOW) light will turn off and the ON

(GREEN) light will light. The unit is now operational and is monitoring for all conditions.

2. When the sensor detects fumes, heat, or bilge water above the alarm threshold levels, the alarm will sound and the RED

alarm light will activate. The alarm will continue until the air in the monitored area returns to safe levels. See

PROCEDURES TO TAKE DURING AN ALARM.

TESTING

!

WARNING

TEST THIS DETECTOR’S OPERATION AFTER THE BOAT HAS BEEN IN STORAGE, BEFORE EACH

TRIP AND AT LEAST ONCE PER WEEK DURING USE.

!

WARNING

NEVER ENTER THE ENGINE COMPARTMENT WITH AN OPEN FLAME OR LIT SMOKING

MATERIALS. OPEN FLAMES AND SMOKING MATERIALS CAN CAUSE AN EXPLOSION AND OR

FIRE. USE ONLY A BUTANE LIGHTER TO PERFORM THIS TEST, NEVER USE GAS SOAKED

MATERIAL.

1. With the unit on, check the sensor assembly light. The RED light should be lit.

2.

When the GREEN normal operation light is lit, the sensor assembly can be tested.

3. SENSOR TEST: Direct the lighter towards the sensor and depress the lever to release gas into the sensor. The

alarm should sound and the RED alarm light on the control panel should be lit.

4. SUPERVISORY CIRCUIT TEST 1: Disconnect one end of the 20 foot (6096 mm) connector cable. The alarm

should sound and the RED alarm light on the control panel should be lit.

5. SUPERVISORY CIRCUIT TEST 2: Use a pull and rocking motion to remove the sensor (Figaro TGS 813)

from the sensor assembly. The alarm should sound and the RED alarm light on the control panel should be lit.

6. WATER SENSOR: Hold a wire with both ends stripped across both contacts on the sensor. The alarm should

sound and the RED alarm light on the control panel should be lit.

7. HEAT SENSOR: (Caution- Never use an open flame) Hold a lit 100 watt light bulb on the tip of the sensor.

The alarm and light should activate in about 30 seconds.

IF THE UNIT DID NOT TEST PROPERLY, REFER TO THE TROUBLE SHOOTING GUIDE

MAINTENANCE

1. Keep the fume sensor free of dust and debris. It is recommended that the fume sensor—Figaro TGS 813 (MTI Part No.

SA-186-S) be replaced annually due to the contamination caused in the marine environment. To remove, pull straight

out.

2. Remove the fume sensor whenever the bilge compartment or engine compartment equipment is being cleaned, painted,

power washed, etc. Direct contact with chemicals, WD-40, water, oil, etc. can cause permanent damage to the sensor.

TROUBLE SHOOTING GUIDE

Problem Cause

No Power Wire connections, missing or blown fuse, reversed wires, or defective unit.

Locked In Wait Replace the sensor assembly SA-186-SB.

Immediate Alarm When Turned On Cable disconnected or broken, Sensor assembly, check sensor assembly red light

No Audible Alarm Return unit for repair or replacement.

No Alarm During Supervision Tests Return unit for repair or replacement.

Red LED On Sensor Assembly Is Off Unit is off, Cable disconnected or broken, the SA-186-SB is defective.

No Alarm When Sensor is removed If panel tests OK; replace the sensor Figaro TGS 813.

No Alarm With Lighter Test If the panel tests OK, replace sensor Figaro TGS 813. If that does not remedy condition, replace the sensor

assembly SA-186-SB.

NOTE: To order the Figaro TGS 813 sensor, specify MTI part number SA-186-S.

Power Supply 12vDC

Recommended Wire

Gauge - 18 Ga.

Loading...

Loading...