RK

AIL ING

By MTH Electric Trains

®

RAILKING GS-4 STEAM ENGINE

OPERATING INSTRUCTIONS

Thank you for purchasing the RailKing die-cast Gs-4 steam locomotive.

The engine’s die-cast body and tender are traditionally sized for operation

on any O-27 or larger layout. The engine is compatible with any standard

AC transformer and is completely compatible with most other 3-rail

locomotives, rolling stock and accessories.

The locomotive and tender are equipped with an electronic whistle and

electronic reverse unit that are simple and fun to operate. Each feature is

described among the following pages which should be read before the

engine is operated.

2

RailKing Gs-4 Operating Manual

QUICK START - BASIC OPERATION

The RailKing Gs-4 contains state-of-the art electronics for incredibly

realistic operation. Despite these advanced features, the Gs-4 is easy to

operate with any compatible standard AC transformer. All models are

equipped with an operating smoke system that should be primed with

smoke fluid before operating. Adding 15 -20 drops of fluid through the

smoke stack should be sufficient. If you choose to not prime the units with

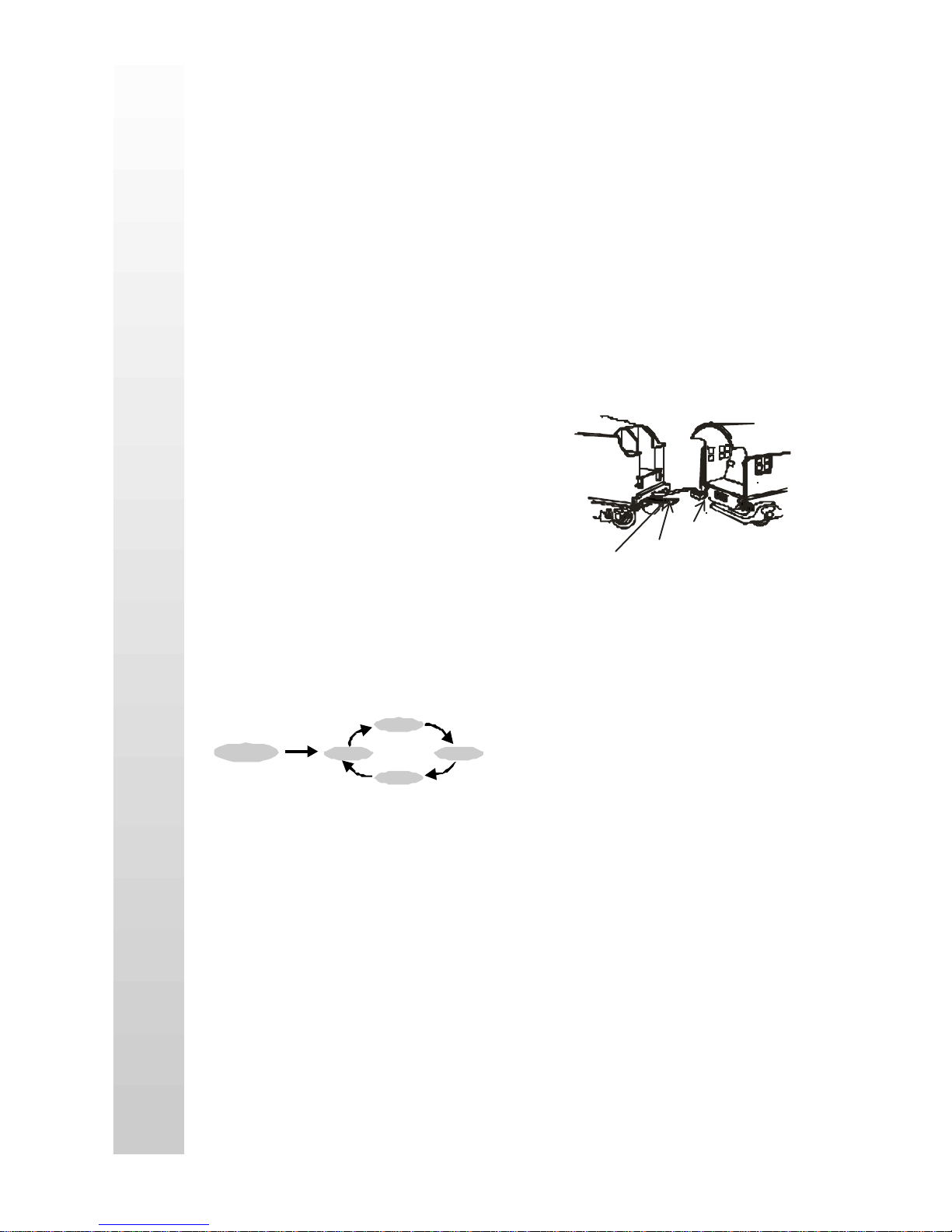

fluid, turn the smoke unit switch located under the trailing truck to the

OFF position. (See Figure 1) This will prevent any damage from

occurring to the smoke unit when running the engine without a primed

smoke unit. For more information see the section on page 4 on Smoke Unit

operation.

The Gs-4 is controlled by a

ProtoSound® DCRU® electronic reverse

unit. The reverse unit operates in the

same manner that all reverse units

function by using forward, neutral and

reverse states that are entered each time

the throttle is turned on and off or by

using the transformer direction switch (if

so equipped).

The reverse unit is designed to ignore dirty track, dead spots on switches

or minor short circuits without disrupting the engine operation, even at

slow, prototypical speeds. Before the

engine can be operated however, the

reverse unit plug that extends out of

the tender must be inserted into the

receptacle at the back of the boiler

cab as seen in Figure 1. Once the

plug is inserted, the throttle on the transformer can be advanced. You will

see that only the engine’s lights come on. The engine does not run. This is

known as the RESET state. The ProtoSound® DCRU® will not power the

motor until the throttle is turned OFF and then ON again. At this point, the

engine will now function just like any other electronic or mechanical E-unit.

Plug Tender Plug Into

Boiler Socket At Back Of Cab

Use First Hole For O-72 Operation

Use 2nd Hole For Display and 96 Inch

or larger diameter curves

Figure 1: Pluggin in the tender harness

RESET

Neutral

Reverse

Neutral

Forward

Figure 2: ProtoSound® DCRU® Cycle Phases

3

RailKing Gs-4 Operating Manual

PROTOSMOKE™ UNIT OPERATION

The Gs-4 contains a self-powered smoke unit that outputs a steady stream

of smoke through the smoke stack on the roof of the engine. The ON/OFF

switch located next to the trailing truck must be in the ON position in order

for the smoke unit to function. See Fig. 2 below.

The smoke unit is essentially a small

heating element and wick which soaks up

and then “cooks" a mineral oil-based fluid

that omits a harmless smoke. The smoke

is then forced out of the stack via a small

electric fan which runs at a constant

speed. However, the smoke intensity can

be varied by increasing the transformer

voltage setting. The higher the setting,

the more intense the smoke output.

For best results, we recommend that you add 15 - 20 drops of

ProtoSmoke™, Seuthe, LGB or LVTS fluid before you run the engine. If

you don’t choose to add the fluid, then the smoke unit switch should be

turned off. Failure to either add the fluid or turn the switch off could lead to

damage to the smoke unit heating element and or wicking. Add the fluid

through the smoke stack hole as indicated in Figure 3. After adding the

fluid, gently blow into the stack to eliminate any air bubbles. Do not

overfill the unit as overfilling can cause the fluid to leak out and coat the

interior engine components. When the smoke output begins to diminish

while running the engine, an additional 10-15 drops of smoke fluid should

be added or the smoke unit switch should be turned off.

When storing the engine for long periods of time, you may want to add at

least 15 drops of fluid to keep the wick soaked with fluid and prevent it

from drying out. After removing the engine from storage, it is advisable to

add another 25 drops of fluid, letting the wick soak up the fluid for 15

minutes prior to operation.

SMOKE UNIT MAINTENANCE

CAUTION: Operating the engine without smoke fluid and with the smoke

unit switch in the ON position can damage your smoke unit wick, causing

the wick to become hard, blackened and unabsorbant around the heating

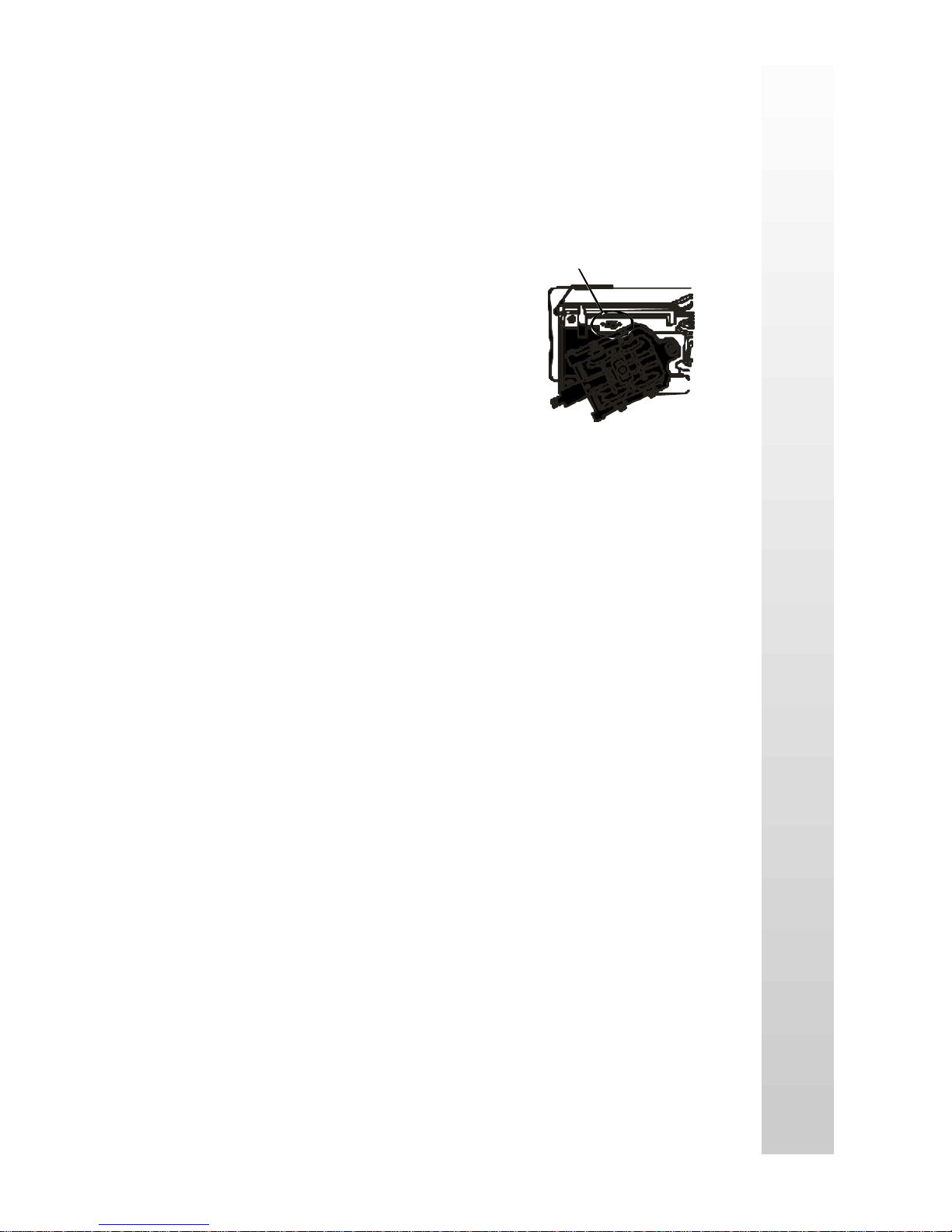

Smoke Unit

On/Off Switch Location

Figure 3: Smoke Unit Switch

4

RailKing Gs-4 Operating Manual

element. When this occurs, it may

be difficult for the wick to soak up

the smoke fluid resulting in poor or

no smoke output. If that occurs,

we recommend that you inspect

and/or replace the wick taking care

to not run the engine without fluid

in the future. You can inspect the

wick to see if it needs replacement

by removing the smoke unit

inspection cover from the body as

seen in Fig.4. After removing the

chassis and inspection cover screws lift the inspection plate away and

inspect the wick. If the wick is darkly discolored and hard, it should be

replaced.

WHISTLE OPERATION

Your Gs-4 engine is equipped with an electronic whistle which can be

activated anytime the engine is in forward, neutral or reverse by pressing

the whistle button on your transformer. The whistle will continue to blow

as long as the whistle button is depressed.

ACTIVATING LOCK-OUT CONTROL

Your Gs-4 engine features a function that allows the operator to “lock” the

engine into forward, neutral or reverse. This is especially useful on layouts

that feature “blocked” track sections. The lockout feature can be activated

by sliding the switch on the bottom of the tender from the ON position to

the OFF position once you enter the desired directional state you wish to

“lock” the engine into (ie: forward, neutral or reverse).

Note: if the engine is locked out in any of the directional states and power to

the track is turned off for an hour or more, the engine may reset to any

directional state when power is reapplied to the track. Should this occur, it

will be necessary to slide the switch back to the ON position and then

“re-lock” the engine back into the desired directional state.

Smoke Unit

Circuit Board

Mounting Screws

Smoke Unit Frame

Mounting Screws

Figure 4: Inspecting The Smoke Unit

5

RailKing Gs-4 Operating Manual

OIL & LUBRICATION INSTRUCTIONS

In order for the engine to perform correctly and quietly, it is important that

the chassis be lubricated before operation. Lubrication should include all

side rods and linkage components and pickup rollers to prevent them from

squeaking. Use light household oil and follow the lubrication points

marked “L" in Fig. 5 below.

The locomotive’s internal gearing has been greased at the factory and

shouldn’t need additional grease until after 50 hours of operation or one

year whichever comes first. Grease can be added by inserting grease into

the gear box inside the locomotive chassis. In order to access the gear box,

the boiler must be removed from the chassis by unscrewing the four chassis

screws as seen in Figure 7 on page 6. Once the boiler is removed, the gear

box can be opened up by unscrewing the two screws on the plate located in

front of the motor. Grease can then be applied into the gear box using a

grease tube dispenser.

OIL

Grease Truck

Pivot Points

OIL

OIL

G - (Grease)

Figure 5: Lubircating Teh Chassis

Tender Body

Mounting Screws

L

L

Figure 6: Lubricating The Tender

6

RailKing Gs-4 Operating Manual

In addition to the internal gearing, it is a good idea to lubricate the leading

and trailing locomotive truck “tongues” to enhance their ability to slide on

the chassis. Follow the grease points as seen in Figure 5 on page 5.

Periodically, check the locomotive wheels and pickups for dirt buildup as

this can significantly affect the engine’s ability to perform properly. Dirty

track and dirty wheels can cause both poor electrical contact as well as poor

traction, especially on elevated track sections. Finally, dirt and oil build up

can prematurely wear out the neoprene traction tires.

TRACTION TIRE REPLACEMENT

INSTRUCTIONS

Your locomotive is equipped with two neoprene rubber traction tires on

the rear set of flanged drivers. While these tires are extremely durable and

long-lasting there may arise a time where they will need to be replaced.

Should this occur, you will need to remove the side rods from the wheels in

order to slip the new tire over the grooved drive wheel.

Before the new tire can be installed, you must make sure the old tire has

been completely removed from the groove in the drive wheel. Use a razor

blade or small flatblade screwdriver pry away any remains left from the old

tire that may still be in the drive wheel groove. Once the old tire has been

completely removed, slip the new tire onto the wheel. You may find it

useful to use two small flatblade screwdrivers to assist you in stretching the

tire over the wheel. Be careful to avoid twisting the tire when stretching it

over the wheel. If a twist occurs, the tire will have to be removed and

Body Mounting

Screws

Body Mounting

Screws

Fiugre 7: Removing The Boiler From The Chassis

7

RailKing Gs-4 Operating Manual

reinstalled or a noticeable wobble in your engine will occur when operating

the locomotive. In addition, it is important to make sure that the tire is

fully seated inside the groove. Any portion of the tire extending out of the

groove can cause the engine to wobble. A razor blade can be used to trim

away any excess tire that doesn’t’t seat itself inside the groove properly.

Replacement tires are available directly from MTH Electric Trains.

HEADLIGHT REPLACEMENT

The locomotive’s headlights are controlled by track voltage and will glow

with greater intensity depending on the transformer voltage setting. The

headlight can be easily removed from its lampholders should the bulb

expire. To remove the bulb, follow the boiler removal instructions found in

the Lubrication section on the proceeding pages. Once the cab has been

separated from the chassis, gently unscrew the bulb from its socket.

Replacement bulbs are available directly from MTH Electric Trains.

O-27 OPERATION

While the Gs-4 engine is more than capable of operating on O-27 curves

and switches, you may find that certain light freight cars are prone to

derailing when being pulled or pushed by the Gs-4 through O-27 switches.

Should this occur, we suggest adding weight to the cars making them

heavier and less likely to derail.

SERVICE AND WARRANTY

INFORMATION

HOW TO GET SERVICE UNDER THE TERMS OF THE

LIMITED ONE YEAR WARRANTY

For warranty repair, do not return your product to the place of purchase. Instead, follow the

instructions below to obtain warranty service as our dealer network is not prepared to service

the product under the terms of this warranty.

1. First, write, call or FAX MTH Electric Trains, 9693-A Gerwig Lane, Columbia, MD

21046, 410-381-2580 (FAX No. 410-381-6122), stating when it was purchased and what

seems to be the problem. You will be given a return authorization number to assure that your

merchandise will be properly handled upon its receipt.

2. CAUTION: Make sure the product is packed in its original factory packaging including its

foam and plastic wrapping material so as to prevent damage to the merchandise. The shipment

must be prepaid and we recommend that it be insured. A cover letter, including your name,

address, daytime phone number, Return Authorization number and a full description of the

problem, must be included to facilitate the repairs. Please include the description regardless

of whether you discussed the problem with one of our service technicians when contacting

MTH for your Return Authorization number.

3. Please make sure you have followed the instructions carefully before returning any

merchandise for service.

LIMITED ONE YEAR WARRANTY

This item is warranted for one year from the date of purchase against defects in material or

workmanship. We will repair or replace (at our option) the defective part without charge for

parts or labor, if the item is returned to the address below within one year of the original date

of purchase. This warranty does not cover items that have been abused or damaged by careless

handling. Transportation costs incurred by the customer are not covered under this warranty.

This warranty gives you specific legal rights and you may have other rights which vary from

state to state.

ProtoSounds™ is a trademark of MTH Electric Trains. DCRU® is a registered copyright of

QS Industries, Inc.

Loading...

Loading...