MTHTrains M50, L50 Instruction Manual

Section M50 • L50

Page 501

Dated

October 2010

97-4624-01-588

VERTICAL CLOSE COUPLED

Page 502

1.

VERTICAL CLOSE COUPLED PUMPS

Storage

C.

Application Considerations

When properly installed and given

operate satisfactorily for many years.

pressures expected in a regenerative

turbine pump, close running clearances

are used to reduce internal losses.

Abrasive particles, even microscopic

ones, in high enough concentrations,

can open up the close clearances

between internal components. For

critical services it is recommended that

you keep an identical pump for stand-

by use.

1A Inspection of Equipment

shipment, inspect the equipment for

damage or missing components.

Check the shipping manifest and

Transportation Company’s local agent.

material before discarding. Parts or

accessories are sometimes wrapped

individually or fastened to the skid.

shipment in a safe place where they

will be available to those who will be

using them for installation and service.

1B Storage

it should be inspected as described

in 1A, recrated and stored in a dry

location. Standard shipping containers

are not suitable for outdoor storage.

to cover the pump’s exterior surface

with oil or other rust inhibiting coating.

All units are tested at the factory with

a water/corrosion inhibitor solution,

some of which will remain inside the

pump upon receipt. If units are fl ushed

out prior to storage, this inhibitor will

be removed and proper care must be

taken to prevent product deterioration

from improper storage.

corrosion inhibiting protective fl uid

should be added to the internal pump

cavities. Fluids used in the pump

should be selected for compatibility

with pump materials. This is very

important when optional seal and

gasket materials have been used.

should also be used. Caps alone are

not suffi cient protection

1C Placing Stored Pumps Into

Service

Special care must be taken when

placing stored pumps into service.

the inside with a process compatible

fl uid. Try to turn the pump using the

coupling or shaft. On close-coupled

units, access to the shaft is between

the pump and motor. A vise grip or

other plier type gripping device may

be used directly on the shaft. Applying

torque to the motor fan blades is not

break loose immediately, fi ll the pump

with a process compatible fl uid and try

again in a few hours.

understanding of which are the bolts

used to clamp the entire assembly

together, loosen each of them exactly

three full turns. After fi lling the pump

with water again, up to 50 foot pounds

of torque may be applied to the

coupling or shaft without fear of ruining

the impeller vanes. It should begin to

turn well before this force is reached.

Continue turning the pump while the

various fasteners are returned to their

original positions.

in Section 5 to determine the cause of

the problem.

1D Application Considerations

All electrical equipment and wiring

should conform to local and National

manufacturer’s instructions for

connecting the motor. Note the correct

assembly. Make sure the motor

While it is reasonable to assume that

good judgement has been used in

selecting all the materials in the pump

for compatibility with process fl uids,

actual conditions sometimes vary

from original specifi cations. Also,

typical material selection charts do not

consider all the temperature, pressure,

and fl uid variables. The customer’s

engineer should be consulted for fi nal

judgement on the best materials for

critical process applications.

The fi rst valve to be considered

for a regenerative turbine pumping

system might be a pressure relief

valve. Because this type of pump

has a horsepower requirement similar

to that of a positive displacement

pump (constantly rising hp along with

pressure increases) a relief valve can

be effectively used to limit horsepower.

This is helpful when a non-overloading

motor is specifi ed. It can be of

critical importance if the system

fl ow rate can vary widely. There

are almost no circumstances where

a fl ow modulating valve will work

successfully in a regenerative turbine

pumping system. The steep pumping

characteristic, typical of these pumps,

produces very large pressure changes

with small variations in fl ow rate. As

a result, the modulating fl ow from the

valve introduces sharp pressure shock

waves that shorten pump life and

may cause damage to other pieces of

equipment in the system.

A swing check valve is recommended

in the suction line even when the

pump inlet is only slightly higher than

the fl uid source. It should be the same

size as the pump inlet or sized based

on reasonable fl uid friction losses.

A foot valve is recommended when

lifting fl uid from a sump. This will

save wear and tear on any pump,

even those equipped with self priming

capability.

A Y-Strainer is recommended

immediately ahead of the pump on

any newly constructed system. This

is advisable due to the probability

that foreign material large enough to

damage pump clearances may remain

even though the piping has been

fl ushed.

entrance velocity in the pump. If a

pump requires more energy (or NPSH)

than is available at a given capacity,

the pressure at the inlet will fall below

the vapor pressure of the pumped

liquid and loss of performance will

s

= Pressure in the suction vessel in

vp

= Vapor pressure of the pumped

fl uid in PSIA.

s

= Static height of the pumped fl uid

above (+) or below (-) the centerline of

the pump in feet.

= All friction losses from the vessel

= All friction losses from the vessel

to the pump in feet.

s

s

and P

vp

are

equal. This item then becomes zero

and can be omitted from the equation.

produce a high pitched whine that

increases in intensity as the differential

pressure produced in the pump

increases. While high frequency

sound is attenuated more easily than

lower frequencies, piping structures

and the fl uids in them readily transmit

noise. Motors, bearings, and other

and sometimes create objectionable

harmonics.

Adequate support for the inlet and

discharge piping is important for noise

When ambient temperatures drop

below the freezing point of the fl uid

in a pump, consideration should be

given to heating, insulating, or draining

the pump. If you choose to drain the

pump, and it will only be for a short

period, fi rst remove the drain plugs,

Page 503

Ps - P

vp

sp. gr.

Valves in the outlet piping of a

always be open as far as possible

when the pump is started. This will

and motor. Never start the pump with

the discharge valve closed.

starting any pumping system. Without

some fl uid in the pump, it can gall

and lock up the impellers. Violent

pump failure will result from continued

operation with the inlet valve closed.

equipment is used or not, always fi ll the

pump and vent it of air before starting,

for best seal and pump life. Under

most circumstances, regenerative

turbine pumps can be made to self-

prime as long as a

small amount of

fl uid can be recirculated through the

impeller and the fl uid doesn’t heat up

noticeably.

The NPSH required varies with every

size and capacity of pump. The NPSH

from the performance curves or from

your MTH representative.

greater than that required by the pump,

it must be increased or a different

pump selected. The usual method for

increasing NPSH is to raise the static

head on the pump inlet, (H

s

).

positive suction head” above the

vapor pressure of the pumped liquid

available at the centerline of the

pump. It should always be given in

feet of pumped liquid. The NPSH is

actually a measurement of the amount

of energy available in the pumped

liquid to produce the required absolute

then drain the inlet and outlet lines.

Carefully blow out the pump with

compressed air to clear all internal

cavities of fl uid.

1E Recommended Spare Parts

installation, with two identical pumping

units in parallel, is the safest and many

times the most cost effective choice.

standby pump, ready for installation is

advised.

Special pricing and new pump

warranty is offered for factory

short as one or two days for standard

models.

- only the mechanical seals and a

complete set of “O” ring gaskets are

components show wear, they are

available from stock at the factory.

gaskets, impeller, and channel rings.

components required for servicing,

plus bearings, shaft, and drive keys

for fl exible coupled pumps, should

be obtained. A factory rebuild

should be considered whenever your

disassembly indicates rebuilding is

necessary, as this is usually more

economical.

The factory recommendation for

spare parts are all of those listed for

the exploded view drawings for each

individual type of pump.

2.

CLOSE COUPLED PUMPS

C.

Alignment

Typical Installation

equipment is installed properly and

to obtain reliable pump operation,

it is recommended that only

experienced, qualifi ed erecting

engineers undertake this task. Read

the instructions thoroughly before

beginning.

2A Location

Page 504

The fi rst consideration for locating

a pump is elevation. The lowest

possible elevation using the shortest

possible suction piping is usually

the best. Questions regarding

possible locations should be resolved

by making inlet head calculations

including all friction losses. The one

producing the highest inlet pressure

should be selected. One reason for

this precaution is that, the greater

the inlet pressure, the less likelihood

of NPSH problems. Also, a fl ooded

suction is particularly helpful on

start-up when the seals or the entire

pump can be ruined because it is not

properly primed and purged of air.

A dry, easily accessible location

is also important. Allow ample

clearance around the unit for free

air circulation. If a dry location is

not available, the pump can be

mounted on a foundation, above

the fl oor. Specify motor enclosure,

pump materials, or coatings to suit

the worst conditions expected.

easily inspected and serviced during

operation. Suffi cient head room

should be provided, particularly when

lifting devices will be used for heavier

assemblies.

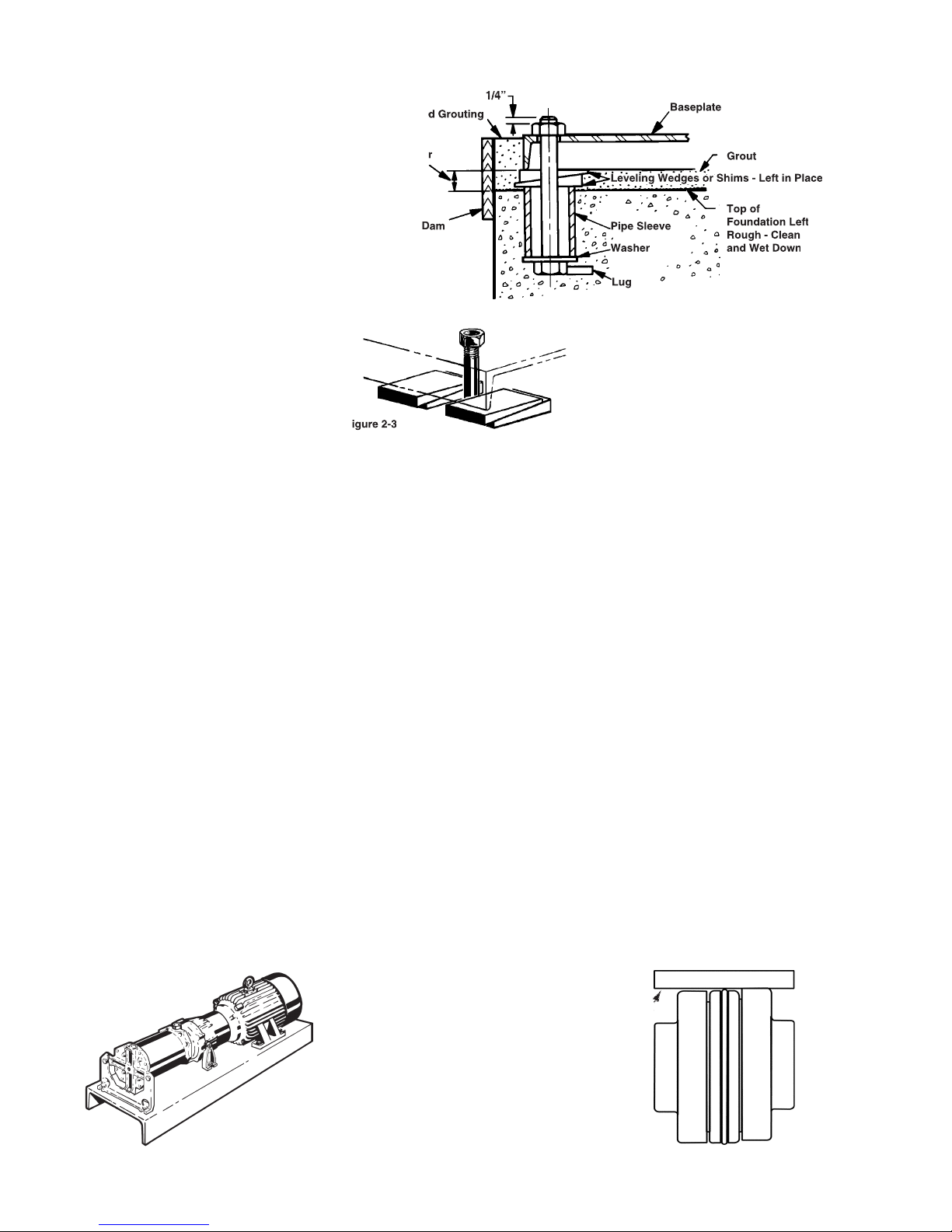

2B Foundation

enough to maintain alignment of

the unit. The pump foundation is

used as a support for the baseplate

to maintain alignment of the unit. If

the baseplate is to be grouted to the

foundation, it is only necessary to

embed the edges. It is unnecessary

to completely fi ll under the baseplate.

foundation until it has been properly

aligned.

The foundation must be a permanent

material of suffi cient mass to absorb

4. Check the baseplate for

distortion:

a. Place a straightedge along

the baseplate to determine if

it is distorted.

b. Adjust the shims until the

baseplate is not distorted.

5. Use a section of pipe to

determine if the inlet and

discharge openings are vertical

and located properly.

6. Correct the positions, if

necessary, by adjusting the

shims.

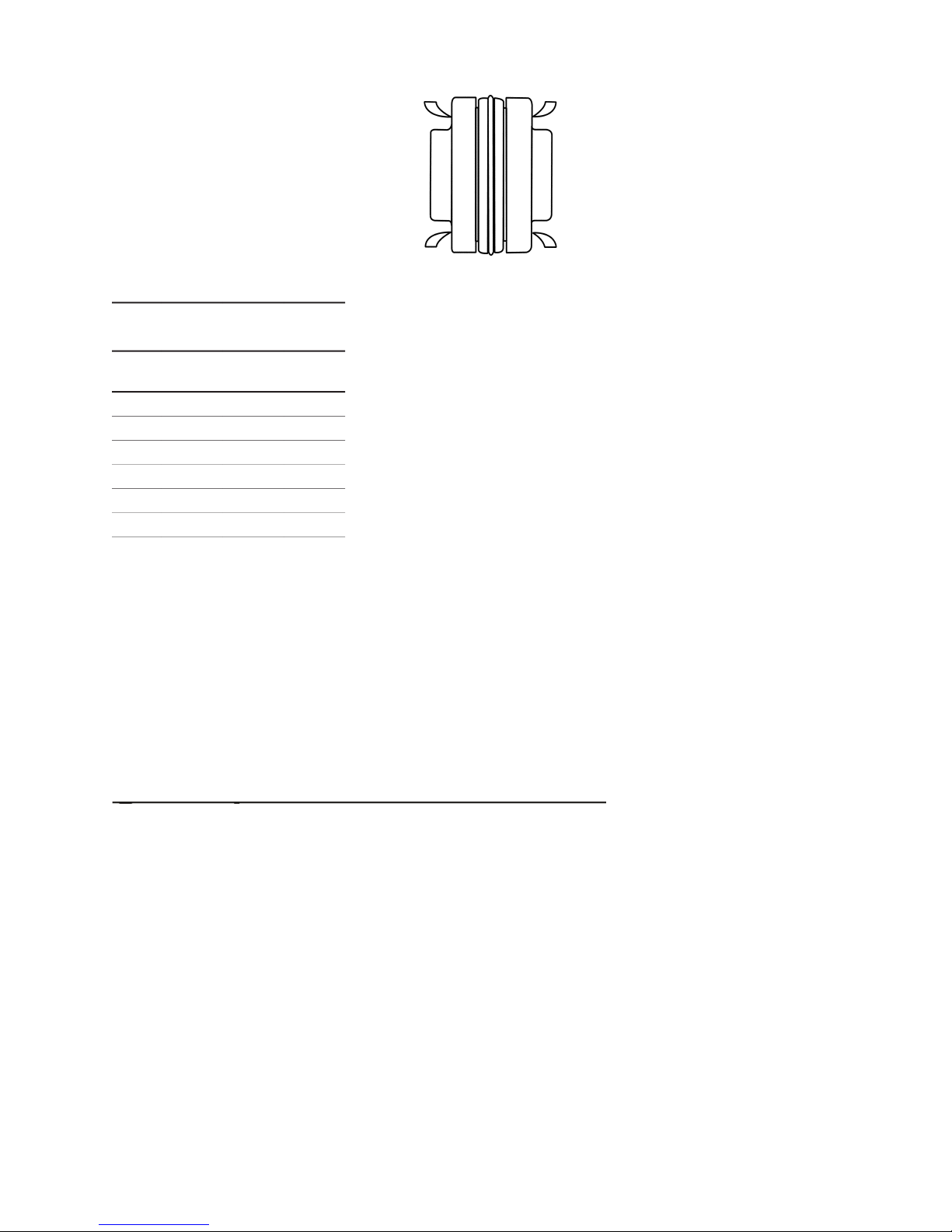

2D Alignment

Although fl exible coupled pumps

are carefully aligned prior to crating

and shipping, it is very likely that

strains imposed during transit have

altered the alignment. Complete

the following steps after the unit has

been placed on the foundation and

leveled.

To check the PARALLEL alignment:

(Refer to Figure 2-4)

two coupling fl anges.

2. Measure the maximum offset

(A), Figure 2-4, at various points

Figure 2-1

Figure 2-2

Foundation

1/4”

Finished Grouting

3/4” to 1 1/2”

Allowance for

Grout

Dam

Baseplate

Grout

Leveling Wedges or Shims - Left in Place

Pipe Sleeve

Washer

Lug

Top of

Foundation Left

Rough - Clean

and Wet Down

Figure 2-3

all normal vibrations. Locate the

foundation bolts using a layout or

template in relation to the suction

and discharge piping. If concrete is

being used, foundation bolts of the

specifi ed size can be enclosed in a

pipe sleeve two to three diameters

larger than the bolts to compensate

for minor variations in alignment.

Close coupled pumps can be

mounted on a steel base prior to

installation or mounted directly to

the foundation. Place shims under

one or more of the motor feet so

that strain and distortion will not

tightened.

2C Leveling (Flexible Coupled

and motor mounted on the baseplate:

2. Disconnect the coupling halves.

alignment procedures have been

completed.

3. Support the baseplate on metal

shims or wedges having a small

taper. (Refer to Figure 2-2)

a. Place shims close to the

foundation bolts. (Refer to

b. Also place shims close to

where the greatest weight is

located.

Figure 2-4

A

around the periphery of the

coupling. DO NOT rotate the

coupling.

3. If the maximum offset exceeds

the Parallel dimension in Chart 1

for your sleeve size, loosen the

motor or pump and place thin

metal shims under the motor

or pump feet until the offset is

corrected.

CHART 1

COUPLING TYPES JE, J, S

MAX. RPM & ALLOWABLE MISALIGNMENT

SLEEVE

SIZE

MAXIMUM

ANGULAR

B-C

3

9200

.010

.035

7600

.010

.043

5

7600

.015

.056

6

6000

.015

.070

5250

.020

.081

8

4500

.020

.094

4. Torque down the motor or pump.

5. Recheck alignment.

To check the ANGULAR alignment:

(Refer to Figure 2-5)

measure from the outside of one

fl ange to the outside of the other

at intervals around the periphery

of the coupling. DO NOT rotate

the coupling.

Figure 2-5

C

Page 505

2. Determine the maximum (B) and

minimum (C) dimensions.

3. If the difference between the

maximum and minimum exceeds

the Angular dimension

in Chart 1

for your sleeve size, loosen the

motor or pump and place thin

metal shims under the motor or

pump feet until the misalignment

is corrected.

4. Torque down the motor or pump.

5. Recheck the parallel alignment

above.

is great, this is an indication of

baseplate distortion and must be

corrected fi rst, refer to 2C Leveling.

After all leveling and alignment

operations have been completed,

piping can begin. After the piping has

been completed, refer to 2E1 Piping

Alignment. Alignment of the unit

must be rechecked to make certain

that no piping strains are causing

distortion. After approximately

two weeks of operation, check the

alignment again to make sure that

temperature changes, piping strain,

or foundation variations have not

caused misalignment. If alignment

has been maintained over this period,

the pump and motor can be doweled

to the baseplate.

2E Piping

2E1 Alignment

up and not forced into place. It is

at the pump. If the lines are ended at

the pump, particularly if the last piece

is cut a little too short or long, the

pump will be forced to meet the pipe

and strain or distortion will result.

2E2 Piping Support

piping. Other means such as

pipe hangers and pipe supports

should be used to carry piping to

avoid misalignment and distortion.

Consideration should be given to

thermally induced expansion and

contraction, particularly in long runs

of straight pipe.

2E3 Piping Size

pipe sizes should be equal to or

larger than those of the pump.

3.

CLOSE COUPLED PUMPS

Rotation

Inlet and Outlet Locations

C.

Foreign Material

Electrical

Adjustments

Cooling Water

G.

Priming

Starting

Stopping

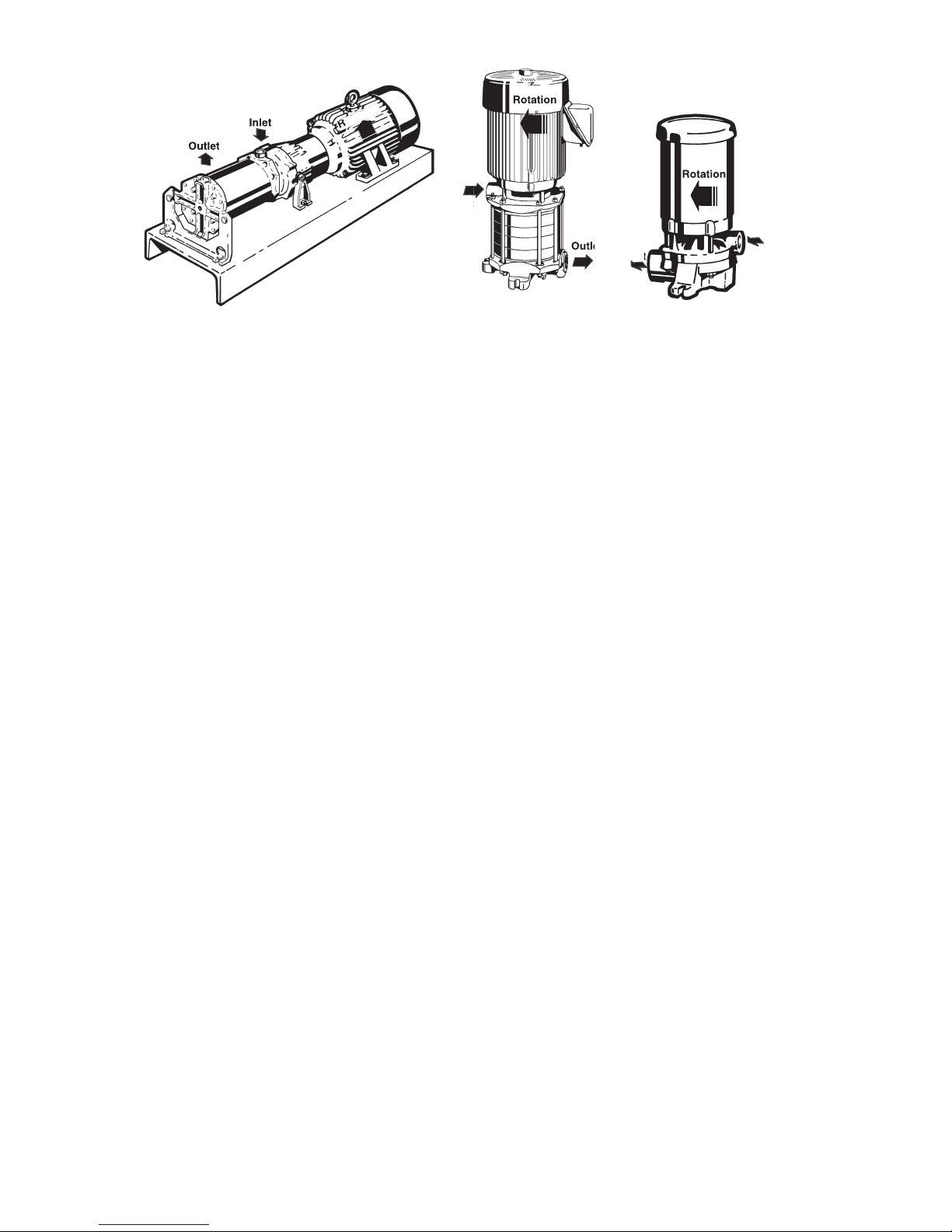

3A Rotation

The standard direction of rotation

for the pump is right-handed, or

clockwise when looking at the motor

end of the pump. A rotation arrow,

pump to indicate the correct direction

of rotation.

Operating the pump in reverse will

cause substantial performance

variations and can damage the

pump.

Always confi rm correct motor rotation

prior to connection of the coupling.

2. Observe rotation as the unit

comes to a stop.

3. Rotation should be in the

direction of the arrow.

direction:

three-phase motor.

2. On a single-phase motor,

change the leads as indicated on

the connection box cover. Some

single-phase motors may not be

3B Inlet and Outlet Locations

(Refer to Figure 3-1)

Page 506

The pump inlet is located on the end

nearest the motor, except on Model

form the motor. The discharge or

“outlet” can be on the top, side, or

bottom depending on the model and

construction of the pump. Normal

discharge position is located on

top

in horizontal confi gurations,

or in line with vertically mounted

confi gurations.

3C Foreign Material

All regenerative turbine pumps have

close running clearances in order

to maintain effi ciency. Take extra

precautions to insure that no foreign

material larger than 25 microns

or .001 inches is allowed to pass

through the pump. Even particles

of this size can damage the pump

if allowed to circulate continuously.

designed for slurries.

other material found in new piping

systems will bend the impeller

vanes and can sometimes lock up

the pump. If a new pump does not

operate properly, the fi rst thing to

check for is damage from foreign

material.

3D Electrical

follow the appropriate local and

national electrical codes. Do

not make wiring alterations that

can affect motor rotation without

When

making electrical connections to motors

provided with threaded stud electrical

terminals, the recommended torque

should be 13-16 inch-lbs. Applying

torque in excess of this range may cause

damage.

3E Adjustments

advisable on new pumps other

than those required for installation.

not uncommon for the pump to be

diffi cult to turn over by hand after the

internal parts have been allowed to

dry out. New pumps from the factory

are tested using rust inhibitors to

help preclude this possibility. On site

system fl ushing may remove these

inhibitors and subject the pump to the

out. In this case, do the following:

2 hours prior to proceeding.

2. C3 Motors/P3 Bearing Frames

a. Using a 5/32” Allen wrench

inserted into the lock

collar setscrew (#15),

using the Allen wrench as

a handle rotate shaft to

verify there is not binding.

(DO NOT LOOSEN THE

SETSCREW)

b. Remove the Allen wrench.

c. Jog the pump momentarily

and observe there is no

binding or abnormal noise.

d. This should “break” the

impeller loose without

damage, unless foreign

material has entered the

pump.

3. C30 Motors/P30 Bearing Frames

a. Rotate the shaft to verify

there is no binding.

from the outlet cover and

insert a 3/8” Allen wrench

into the socket end of the

shaft, using the wrench as a

handle. If draining fl uid from

the pump is not practical,

use the coupling on fl ex-

coupled units to turn the

shaft. Otherwise, a vise grip

or other plier-type gripping

device may be used directly

on the shaft between the

pump and the motor.

b. Remove the Allen wrench or

pliers.

c. Replace the drain plug and

was drained.

d. Jog the pump momentarily

and observe there is no

binding or abnormal noise.

e. This should “break” the

impeller(s) loose without

damage, unless foreign

material has entered the

pump.

This procedure will fl ush residue from

the close fi tting impeller surfaces. If

not immediately successful, refer to

Section 1, 1C Placing Stored Pumps

fi tting surfaces inside these pumps,

it takes only microscopic residue to

produce resistance to rotation. Once

loosened, this material is quickly

dispersed and the impellers will

fi nd their hydraulic center. If these

procedures are followed carefully,

no damage will result from “breaking

loose” the impeller.

3F Cooling Water

When the pump is used to transfer

hot fl uids, consideration should be

given to cooling the seals and/or

selecting materials that will give

satisfactory seal life. The actual

temperature at the seal faces, the

most critical area, will always exceed

the surrounding fl uid temperature.

Figure 3-1

Outlet

Rotation

Inlet

Rotation

Inlet

Outlet

Outlet

Inlet

Page 507

4.

Figure 4-1

A.

Preliminary

Disassembly Vertical Single Stage

on C3 Motors

C.

Disassembly Multistage on C3

Disassembly Multistage on C30

Inspection of Components

Reassembly Vertical Single Stage

on C3 Motors

G.

Reassembly Multistage on C3

H.

Reassembly Multistage on C30

I.

Testing and Final Adjustments

4A Preliminary

the pump or motor, disconnect the

electrical power to the motor. If the

pump and motor are to be removed as

a unit, note the wiring confi guration,

using colored or numbered tape.

piping before unbolting the pump

and motor.

2. Unbolt the motor from the base

and remove the unit. All work on

the unit should be performed on

an elevated workbench whenever

possible.

The disassembly and reassembly

procedures are broken into eight

sections covering the following units:

— Disassembly Vertical Single

Stage on C3 Motors

C

— Disassembly Multistage on C3

— Disassembly Multistage on C30

— Reassembly Vertical Single Stage

on C3 Motors

— Reassembly Multistage on C3

G

— Reassembly Multistage on C30

4-4, 4-11, and 4-12, are provided

for referencing the numbers in the

following procedures, i.e. (#1), motor

bracket.

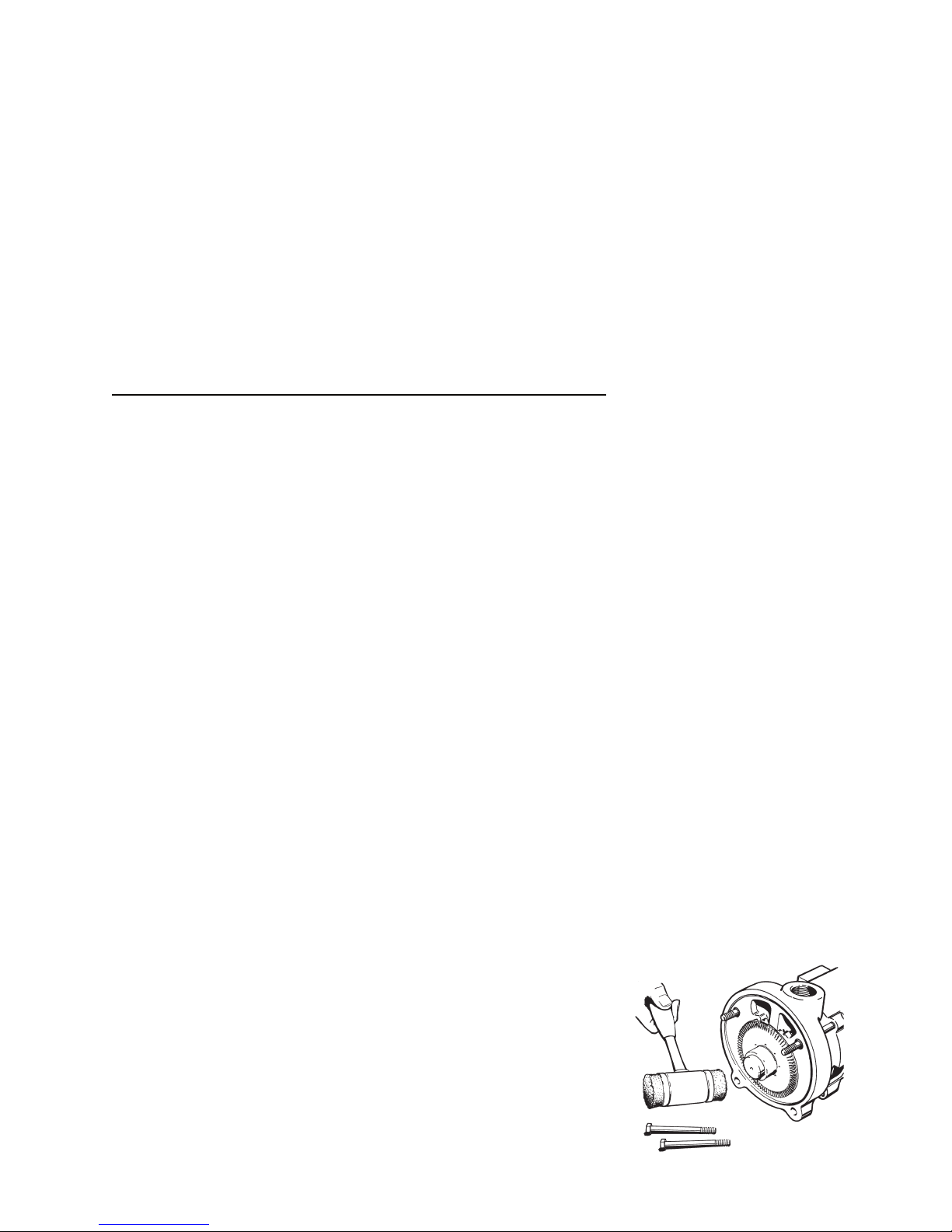

4B Disassembly Vertical Single

Stage on C3 Motors

The following tools and equipment are

needed for disassembly of C3 units.

2. 9/16” wrench or socket.

3. 5/32” hex wrench.

4. Penetrating oil.

5. 1” wood dowel (Approx. 6” long).

6. Thin blade screwdriver.

7. Two large blade screwdrivers.

To disassemble the pump:

the numbered parts in the procedures

below.

Air blown through the pump will

2. Remove the two (2) Nuts (#20)

and the two (2) 3/8” X 4” Bolts

(#19) from the Cover (#2). On

stainless steel models, remove the

four (4) Nuts (#20).

3. Remove the cover (#2). In some

cases light tapping with a plastic

or wooden mallet on the outside

diameter of the cover may be

motor bracket. Care should be

taken if a screwdriver is needed to

pry between the cover and motor

bracket. Damage to the “O” Ring

(#7) and/or impeller can result.

4. Remove the Impeller (#11). Refer

to Figure 4-1. The impeller is

a slip fi t and, under normal

conditions, can be removed by

gently tapping on the end of the

shaft sleeve with a mallet. Leave

the Impeller Key (#23) in place.

Striking the sleeve too hard could

damage the seat or rotating

element.

5. Using the 5/32” hex wrench,

loosen the Set Screws (#15) in

the Locking Collar (#14), located

on the shaft sleeve between the

motor bracket and the motor face.

3G Priming

unless they are completely fi lled

with liquid. Damage to parts of the

pump that depend on liquid for their

lubrication can occur. Impellers can

seize quickly when a pump is run dry.

Without lubrication, seal faces can be

damaged from heat buildup.

3H Starting

time, be sure that all the preceding

operations have been carried out.

turning pump are most important.

possible line restriction.

2. Open discharge valves before

pressing the starter.

3. Start the pump and let the

system clear of air.

4. Listen for foreign material being

carried through the pump.

5. Slowly close necessary valves

or otherwise place the pump into

service.

6. Listen for indications of undue

load or other sounds indicating

problems.

7. Use a clip-on ammeter to

check for a steady load after

approximately fi fteen minutes of

operation.

3I Stopping

least discharge head possible both

for minimizing strain on components,

and to be in low power mode in

anticipation of restarting.

Page 508

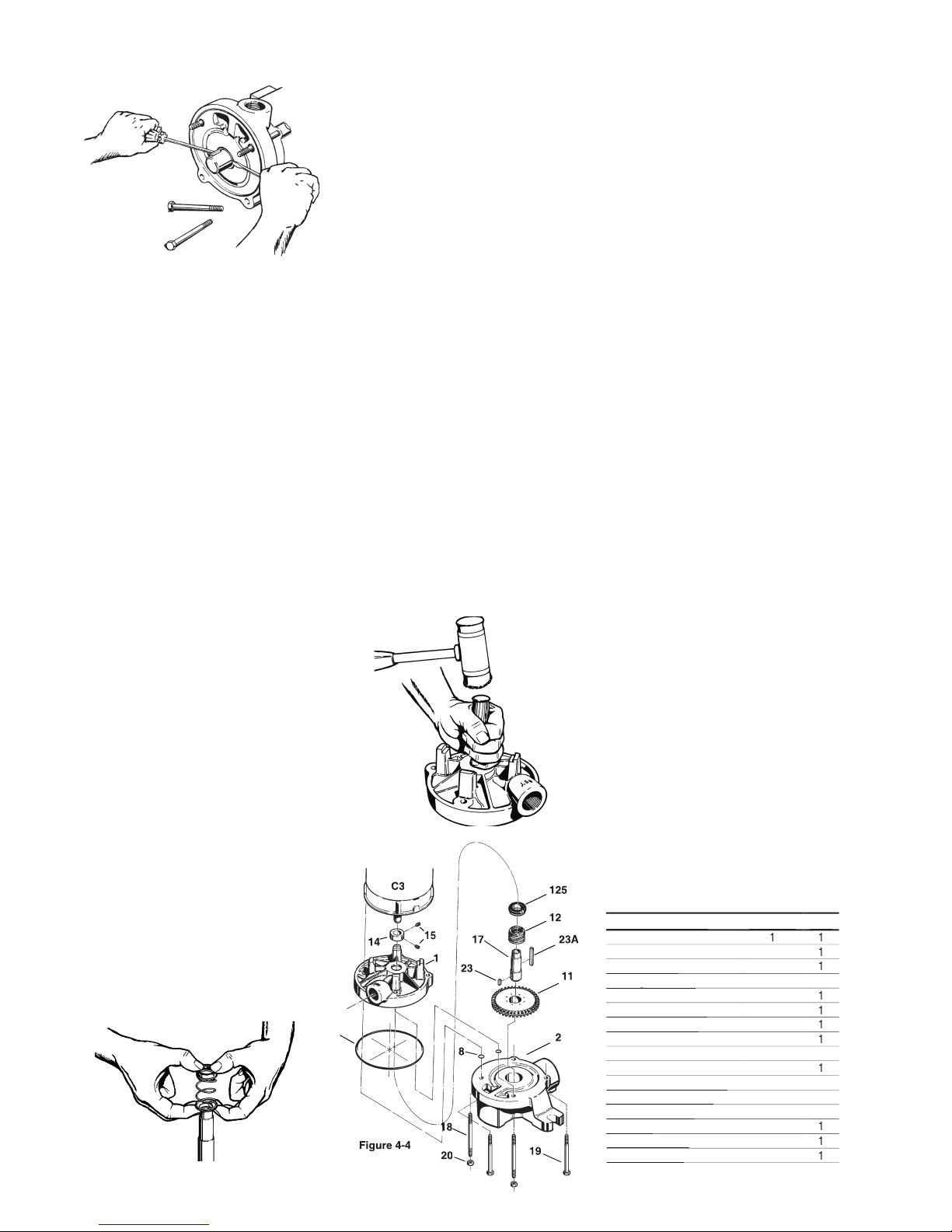

C3 VERTICAL MOUNT PUMP

The collar should now be loose

on the sleeve. Note the condition

of the setscrews in the collar and

6. Remove the Shaft Sleeve

(#17). The sleeve is a keyed fi t

and is removed using two large

screwdrivers. Refer to Figure 4-2.

a. Insert the blades of the

screwdrivers between the

spring holder on the rotating

element and the shoulder of

the shaft sleeve.

b. Holding the screwdrivers at

approximately 3 o’clock and

9 o’clock, push the handles

in toward the motor body,

using the motor bracket for

leverage.

7. In some cases a rocking motion of

the screwdrivers will be necessary

to break the sleeve loose.

will slide off with the sleeve. DO

by rotating it. (Previous models

have used a threaded shaft and

different procedures are required

in these cases.)

8. Remove the Seal Rotating

normally adheres tightly to the

sleeve and some force

may be

necessary to remove it. This is

common and if care is taken, the

element can be reassembled

and reused.

It is

recommended

that a new rotating element be

used for reassembly.

Figure 4-5

Figure 4-3

Figure 4-4

125

23

23A

18

11

15

1

C3

19

20

8

attempt to remove the seal using a

screwdriver or other sharp object.

sleeve, or element could occur.

9. Before the motor bracket (#1) can

be removed, the four (4) “O”rings

(#8), located on the upper left and

a. Gently tap on the back of the

motor bracket, alternately

between the left and the right

side, unit the motor bracket

moves approximately 1/4”.

b. Tap the motor bracket face

to move it back to its original

location.

c. Remove the “O”rings by

sliding them off the studs.

d. Slide the motor bracket

straight off. Do not attempt

to remove the motor bracket

without fi rst removing the

“O”rings (#8).

(#125). Refer to Figure 4-5.

a. Place the motor bracket face

down on a fl at surface.

b. Looking into the opening in

the center of the bracket, you

will see a portion of the seat.

c. Insert the 1” dowel and, very

gently, tap the seat until it

drops out.

d. Care must be taken with

the seats. They are a

brittle material and are

prone to breakage.

It is

recommended that a

new replacement seat

be installed during

reassembly.

3. Repeat step 2 to remove the other

bearing. Good support used

on the inner races will prevent

bearing damage.

4C Disassembly (P30)

shown in Section 4, M50 • L50 PUMP

C30 Motors / P30 Bearing Frames.

The following tools and equipment are

needed for disassembly of the P30

units:

2. Arbor press or vise

3. Thin blade screwdriver

4. Adjustable spanner wrench

5. 3/8” Hex wrench

6. 7/16” Wrench or socket

7. Gear puller

8. Penetrating oil

When installing or removing bearings

from the shaft, the use of an arbor

press is strongly recommended.

Figure 4-2

NAME/DESCRIPTION

PART NO.

QTY.

Motor Bracket

Cover/Vertical

2

“O” Ring/Casing

“O” Ring/Casing

7

“O” Ring/Guide Rod

“O” Ring/Guide Rod

8

4

Impeller

Seal Rotating Element

Seal Rotating Element

Seal Stationary Seat

Seal Stationary Seat

Lock Collar/Sleeve

Setscrew/Lock Collar

2

Shaft Sleeve

Guide Rod (Qty. 4 on S.S.)

Guide Rod (Qty. 4 on S.S.)

2

ThruBolt (Qty. 0 on S.S.

ThruBolt (Qty. 0 on S.S.

2

Nut (Qty. 4 on S.S.)

Nut (Qty. 4 on S.S.)

20

2

Plug/Drain

Plug/Drain

22

Key/Impeller Drive

Key/Impeller Drive

23

Key/Sleeve Drive

Key/Sleeve Drive

23A

Page 509

To disassemble the pedestal:

the numbered parts in the procedures

below.

Shoulder Screws (#33C) with a

3/8” hex wrench.

2. Remove the four (4) Hex

Capscrews (#33B) that hold the

the End Bell (#101), using a 7/16”

wrench or socket.

3. Position assembly horizontally

on workbench. Holding bearing

frame housing fi rmly, tap on the

coupling end of shaft with rubber

mallet until the assembly comes

apart.

4. Remove guide rod nuts and guide

5. Remove Outboard Bearing (#24A)

using a gear puller.

6. With a spanner wrench, unscrew

the Outboard Bearing Adjusting

7. Support end bell, with motor

mounting face up, and press out

shaft / bearing assembly with

arbor press. Remove Inboard

8. Disengage bearing lockwasher

tang from slot in Bearing

screwdriver. Locknut and Bearing

the area between the two bearing

surfaces only.

9. Place shaft / bearing assembly

in arbor press and remove the

4D Inspection of Components

Thoroughly clean all parts. All

components should be examined for

wear and corrosion. Replace any parts

showing visible wear.

Check to be certain that a press fi t

still exists between the shaft and the

bearings.

cleaned and regreased bearings, are

Check the shaft for galling, pitting,

and corrosion. Surface corrosion on

the pump portion of the shaft must be

during assembly. The shaft diameter

should be no smaller than .002” below

the nominal fractional seal sizes.

have occurred during disassembly.

4E Reassembly (P3)

All parts should be visually inspected

and cleaned or replaced as outlined

in 4D above. It is recommended that

the bearings be replaced any time the

bearing pedestal is disassembled for

service.

The following tools and equipment are

needed for reassembly of P3 units:

2. Rubber or plastic mallet

3. Internal snap ring pliers

4. 3/4” X 6” piece of water pipe

To reassemble the bearing frame:

the numbered parts in the reassembly

below.

the bearings on the shaft prior

to installing the shaft into the

pedestal. A steel “donut” with

the proper inside diameter and

outside diameter, refer to Chart 1,

should be used between the

Components.

4C Disassembly Multistage on C3

Motors / P3 Bearing Frames

The following tools and equipment are

needed for disassembly of C3 / P3

units.

2. Two 9/16” wrenches or sockets.

3. 5/32” hex wrench.

4. Side cutters (for removing keys).

5. 1” wood dowel (Approx. 6” long).

6. Thin blade screwdriver.

7. Two large blade screwdrivers.

8. Penetrating oil.

To disassemble the pump:

the numbered parts in the procedures

below.

Air blown through the pump will

2. Lay the pump on the workbench

horizontally.

3. Remove the four (4) Nuts (#20)

from the Guide Rods (#18).

4. Remove the eight (8) Nuts (#20)

from the Thru-Bolts (#19) located

on the inlet cover (#1 or 1IN). Pull

out the thru-bolts.

5. Using a soft mallet, loosen the

Outlet Cover (#2) by tapping lightly

around the outside edge. Slip the

cover off the Guide Rods (#18),

being careful not to bend them.

6. Do not remove the Plain Bearing

(#87) from the outlet cover unless

it is worn. This bearing is a press

fi t and cannot be removed without

being damaged.

7. Remove the four (4) Guide Rod

“O” Rings (#8).

8. Mark on the outside surface of the

Channel Rings (#9 & #10) such

that the top to bottom relationship

as well as the order is maintained.

to less permanent markings that

tend to be lost during cleaning.

9. Separate the fi rst Channel Ring

(#9) by gently tapping the ring

around the outside edge with

a soft mallet and slide it off the

guide rods, exercising care to

prevent damage. Should prying

be necessary, it should be done

evenly and with great care.

(#16) from the Channel Ring (#9)

just removed.

(#10) using the same care as with

the fi rst. The Impeller (#11) will

come off along with the channel

impeller off fi rst, as prying will

damage the impeller vanes. Hold

Loading...

Loading...