MTHTrains HO 4-8-4 GS-4, HO 4-8-4 GS-6, HO 4-8-8-4 Big Boy, Bavarian Class S 3/6 Engineer's Manual

M.T.H. HO 4-8-4 GS-4/GS-6

Steam Engine

Congratulations! You've just purchased the most

feature-rich and technically advanced HO Steam

locomotive ever produced! This highly detailed model

includes a broader range of features than you’ll find on

any other HO scale steam, including smooth

performance from a three-scale-mile-per-hour crawl to

full throttle; “cruise control” for steady speeds regardless

of curves, switches and grades; built-in decoders for

DCC and the M.T.H. Digital Command System (DCS);

and a full range of prototypical sounds. If you’re looking

for motive power that’s accurately detailed, smooth

running, and a great deal of fun to operate, it doesn’t get

any better than this!

PLEASE READ BEFORE USE AND SAVE

(PS3E+)

ENGINEER’S GUIDE

** Ps3 E+ model operates on 22” radius

curves or R3 (515mm) radius curves HO

Stud (3-Rail) Track

Passenger/Freight

Announcements

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

2

This product may be protected by one or more of the following patents: 6,019,289;

6,280,278; 6,281,606; 6,291,263; 6,457,681; 6,491,263; 6,604,641; 6,619,594; 6,624,537;

6,655,640.

©2013, M.T.H. Electric Trains®, Columbia, MD 21046

CAUTION: ELECTRICALLY OPERATED PRODUCT:

WARNING: When using electrical products, basic safety precautions should be observed, including the following:

Read this manual thoroughly before using this device.

l M.T.H. recommends that all users and persons supervising use examine the hobby transformer and other electronic equipment

periodically for conditions that may result in the risk of fire, electric shock, or injury to persons, such as damage to the primary cord,

plug blades, housing, output jacks or other parts. In the event such conditions exist, the train set should not be used until properly

repaired.

l Do not operate your layout unattended. Obstructed accessories or stalled trains may overheat, resulting in damage to your layout.

l This train set is intended for indoor use. Do not use if water is present. Serious injury or fatality may result.

l Do not operate the hobby transformer with damaged cord, plug, switches, buttons or case.

Recommended for Ages 14 and up. Not recommended for children under 14 years of age without adult supervision. As

with all electric products, precautions should be observed during handling and use to prevent electric shock.

Rev.: _ HO GS-4 PS3_6/20/2013

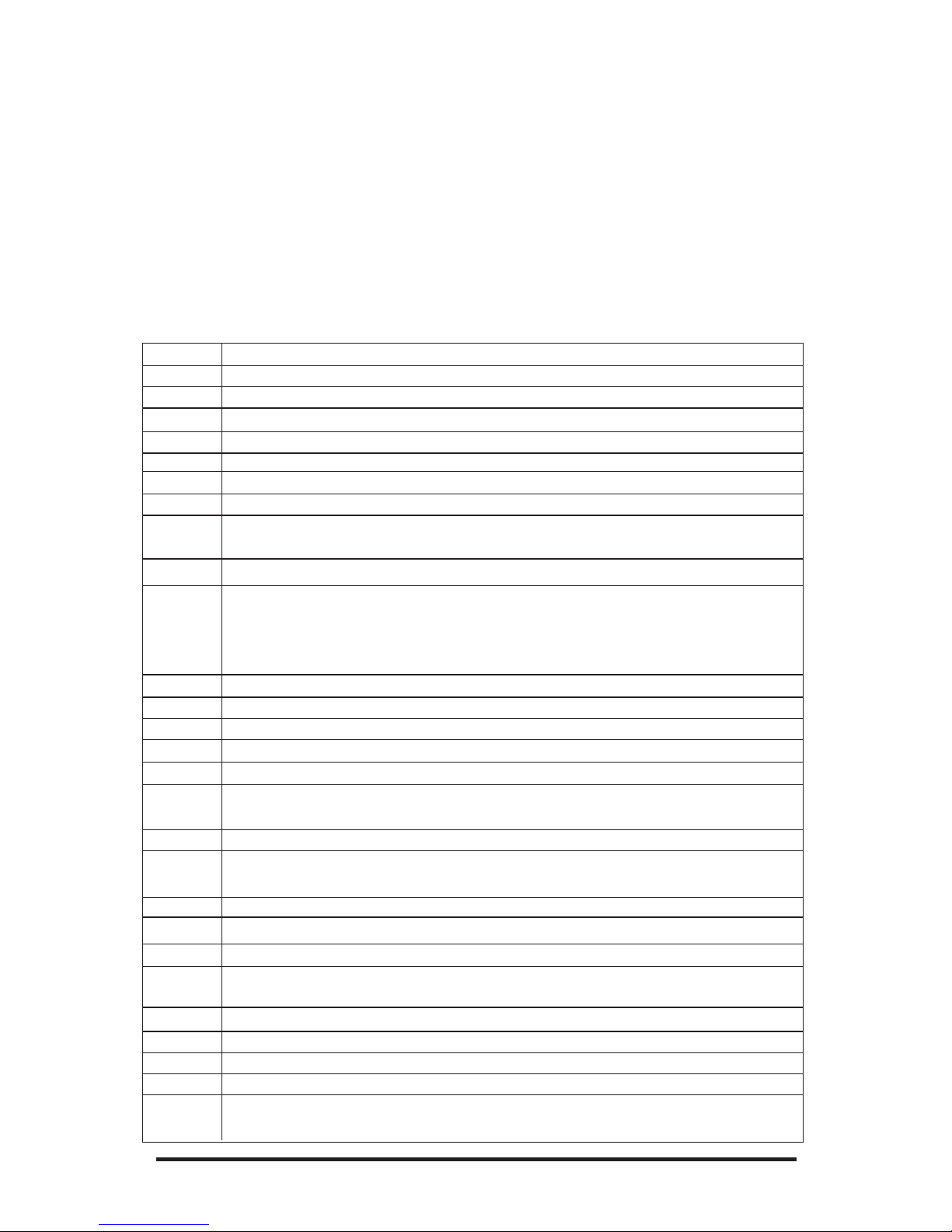

TABLE OF CONTENTS

Unpacking Your Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting to Know Your Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-up/Maintenence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Mechanical Couplers . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine and Tender Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smoke Unit Preparation and Use . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal/Installation of Drive Wheels . . . . . . . . . . . . . . . . . . . . . .

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ps3 Enhancements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCC-DCS Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventional AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCC Digital Command Control . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up/Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sounds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PFA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smoke. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forward/Reverse Signal. . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Sounds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCS Digital Command System . . . . . . . . . . . . . . . . . . . . . . . . . .

Proto-Sound® 3.0 Expanded DCC Functionality. . . . . . . . . . . . . . . . . . . .

Configuration Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cv29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature/Factory Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CV Programming (Marklin 6021 Controller) . . . . . . . . . . . . . . . . .

Advanced Consisting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited One-Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

5

5

7

8

8

9

9

9

11

12

12

12

13

13

14

16

16

16

17

18

19

20

22

23

25

25

26

27

29

34

38

39

40

41

49

49

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

3

QUICK START GUIDE

Of course, you should read your manual over before running your GS-4/6.

But if you just can’t wait, choose how you want to run below and enjoy!!

Your PS3E+ engine is designed to be run with AC power. However, you can

also use DC power if you prefer. The instructions will only reference AC

power.

I'M A DCC/MOTOROLA OPERATOR….

Step 1: Unpack your GS-4/6 (refer to unpacking instructions on pg 4)…

Step 2: Set the engine on the track …

Step 3: Power up your DCC system…

Step 4: Select engine address 3 and press “F3” to start her up…

Step 5: Turn the throttle and head on down the pike…

I RUN DCS….

Step 1: Unpack your GS-4/6 (refer to unpacking instructions on pg 4)…

Step 2: Set the engine on the track …

Step 3: Power up your DCS system…

Step 4: Add the engine to your system and start her up…

Step 5: Turn the throttle and move out….

I USE AN AC SUPPLY…

Step 1: Unpack your Engine. (refer to unpacking instruction on pg 4)…

Step 2: Set the engine on the track …

Step 3: Apply increasing AC voltage until she starts up and pulls out!

UNPACKING YOUR ENGINE

Removing and Unwrapping Your Engine

Carefully remove and unwrap the model on a soft surface. By nature, models with

high levels of detail have some small fragile parts.

Carefully remove any foam packing pieces that may be surrounding the model.

What Else is in the Box?

The following items are packed with your engine.

Quick Start Guide (1)

For those who can’t wait to get started! This will give you the basic information

to get your engine up and running!

NEM 360/362 Coupler (2)

NEM mechanical couplers along with pocket assemblies

Smoke Fluid Pipette (1)

Enough fluid to get you started, and then some.

Rear Drive Wheel Set without Traction Tires (1)

For Those who prefer not to use traction tires.

3mm Nut Driver (1)

In case you want to install the drivers with traction tires or replace the standard

drive wheels.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

4

PRODUCT OVERVIEW

Getting to Know Your M.T.H. HO Locomotive

Key Features

Your new HO is equipped with the exclusive M.T.H. Proto-Sound® 3.0

digital sound and control system. In plain English, this means your locomotive

contains state-of-the-art electronics providing realistic digital sounds, puffing

smoke perfectly synchronized with chuffing sounds and motion, precisely

controlled speed in increments of 1 scale mile per hour, and much, much, more.

Compatibility

The Proto-Sound 3.0 system is universally compatible with track power and/or

signal combinations including Conventional AC (regular AC transformer),

DCC/Motorola (NMRA Digital Command Control), or DCS (MTH Digital

Command System). Simply set your GS-4/6 on the rails, apply any one of these

power/signal sources, and move out! The Proto-Sound 3.0 system automatically

senses the track environment and adapts accordingly. For the PS 3E+ Engines you

will need to ensure that the DCS/DCC switch is in the correct position. A vast

array of realistic operation is automatic when the GS-4/6 is run on conventional

AC. You can expand access to features in a DCC environment. Experience the

most your new locomotive has to offer in the simple to use yet powerful world of

DCS. To be clear, DCS is NOT a proprietary version of DCC, as some other

manufacturers offer. DCS is a comprehensive layout control system designed with

one primary goal: make model trains do amazingly realistic things using a simple

and intuitive controller. We put the complexity on the inside, and the fun in your

hands!

Digital Sound

Your Proto-Sound 3.0 (PS3) equipped GS-4/6 contains over 100 individual

recordings. These recordings are played back dynamically at appropriate times to

create a symphony of realism for your ears. Hear the chuffs automatically

intensify or lighten when speeding up or slowing down, listen to the sounds of

brakes squeaking and squealing as you come to a stop, or enjoy the random

conversations of railmen working as your model sits at idle. It's all there and it's

incredible.

Now, your HO GS-4/6 includes the ultimate in realism Proto-Whistle. With this

incredible new feature you have variable control over the steam whistle sound in

your locomotive (when operated in DCS mode with the DCS Commander or

DCS software version 4.0 or greater).

GS-4/6

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

5

Digital Control

In standard conventional AC mode, your model still operates under digital control.

The PS 3 advance speed control system converts track voltage into digital speed

commands. Your model will run smoothly and consistently at any speed regardless

of load, hills, or curves. If you are a DCC user, you'll quickly learn to appreciate

the precision of our speed control and linear speed curve. DCS users will enjoy the

added benefits of controlling speeds in increments of 1 scale mile per hour

displayed on DCS controllers or easily changing acceleration and deceleration rates

independently without any discussion of bits or bytes. To be clear, DCS is NOT

DCC.

Lights & Smoke

As you read on, you'll notice there are no instructions for replacing light bulbs in

your GS-4/6. That's because there aren't any. We use specially designed and

controlled LEDs to create realistic lighting effects that occur automatically. Again,

NO PROGRAMMING!! Just come to a stop and watch as the headlight dims

automatically in accordance with rule 17. Of course, as you pull away, the

headlight returns to it's fully bright, yet warm, glow. Your new GS-4/6 includes

realistic Classification lighting with appropriately colored LED's in the boiler. We

even included a light in the cab so the engineer and fireman can see to do their

jobs!

MTH is renowned for our realistic smoke systems. The HO GS-4/6 is no

exception. When the smoke is on, you will experience copious puffs synchronized

precisely with chuffing sounds at 4 times per revolution of the drive wheels. Of

course, when you stop, the smoke wafts out of the stack steadily, just like the real

thing! The smoke behavior applies to all operating modes, conventional AC, DCC,

or DCS. With some DCC controllers, you can turn smoke on and off remotely.

In DCS mode, you can not only toggle smoke on and off with the press of single

button, you can actually select from 3 output levels to keep those smoke alarms

from going off!

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

6

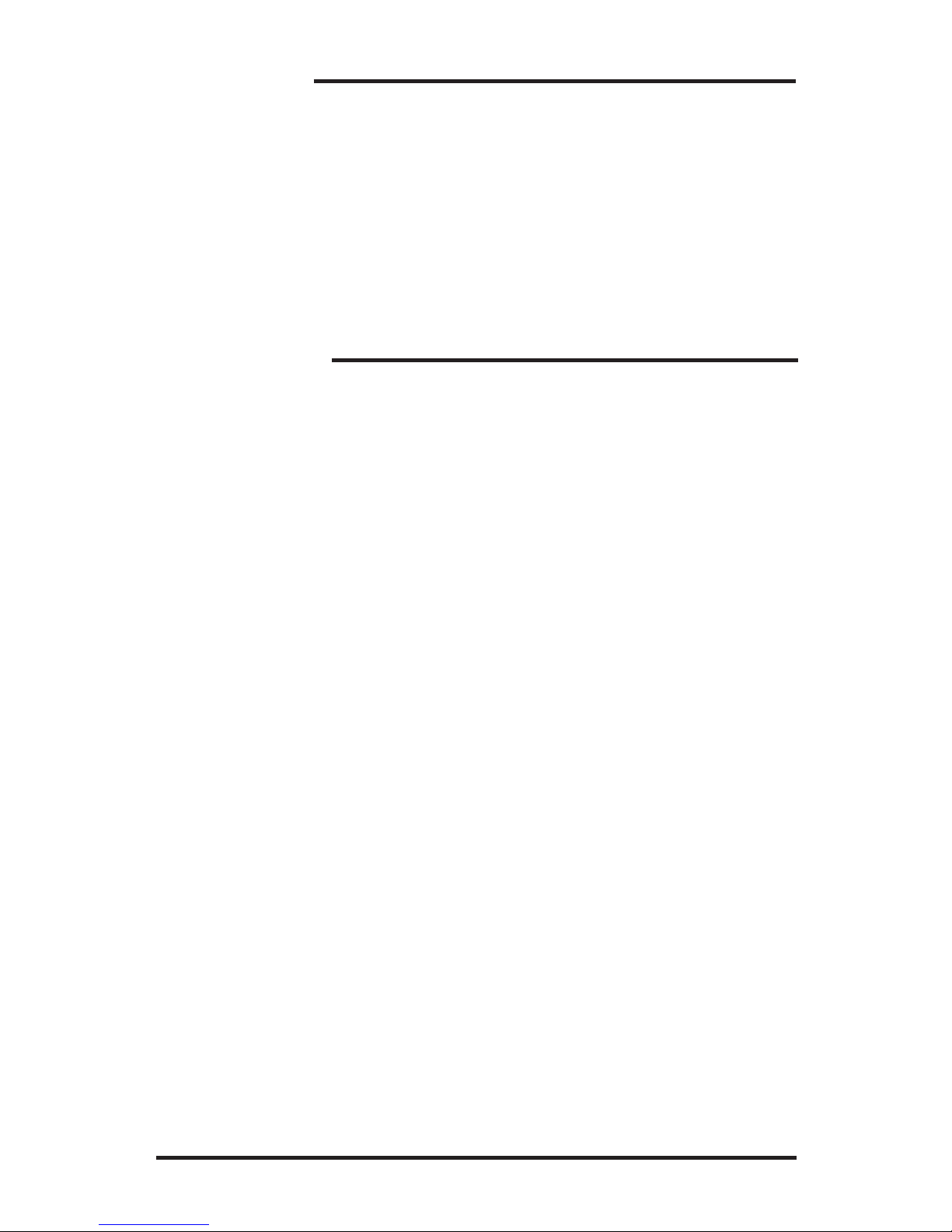

ENGINE DIAGRAM

Boiler

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

7

Tender

Drive Wheels

Cab Interior

Light

Fireman/

Engineer

Figures

Lighted

Classification

Lights

Sliding Roof Vent

Pilot Truck

Smoke Stack

Wireless Closecoupling Receiver

Drive Wheels

Control Hatch

Wireless Close

coupling drawbar

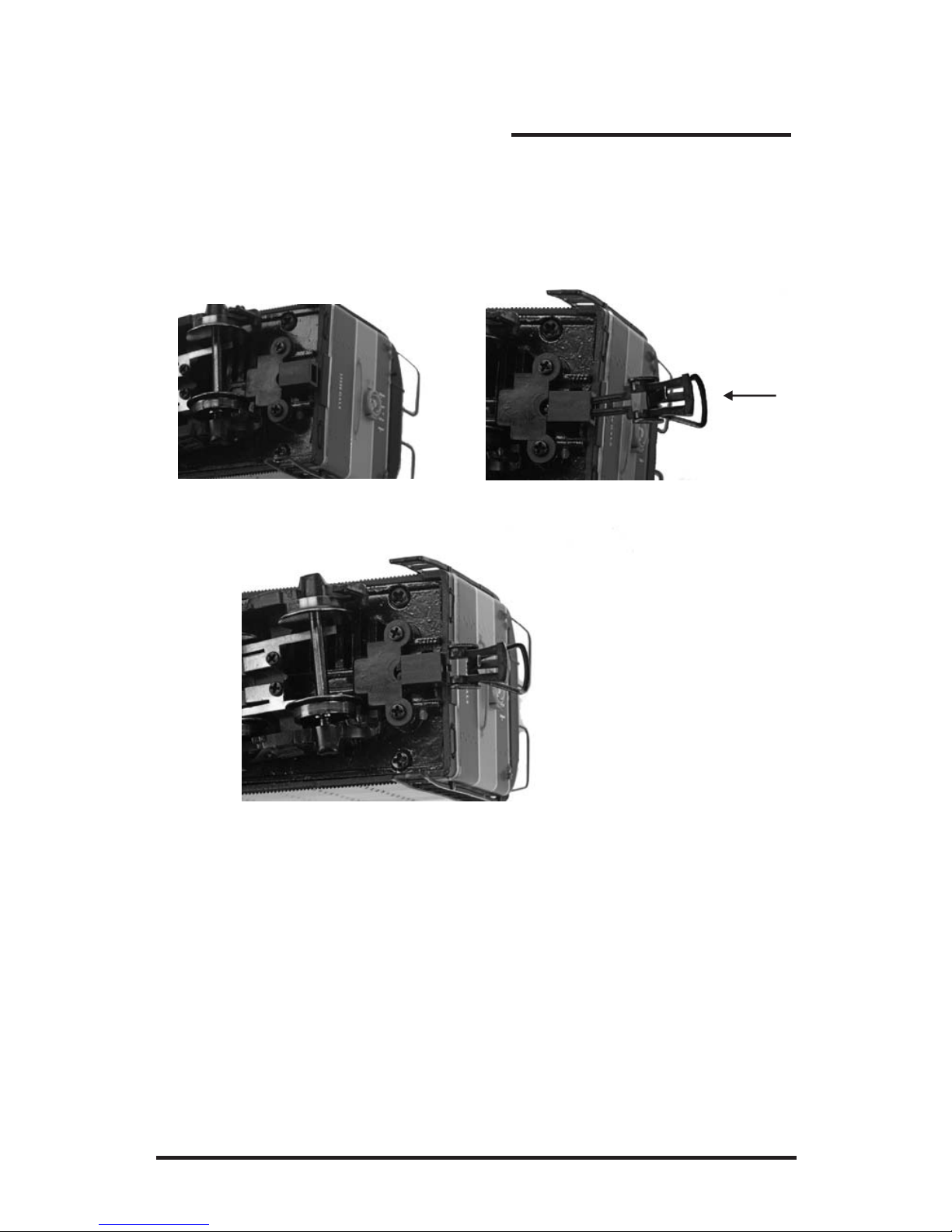

Wireless Close-Coupling Drawbar

You’re HO GS-4/6 features our all new wireless close-coupling drawbar! To attach

the engine to the tender, simply insert the prongs of the drawbar into the receiver

as depicted in the images above.

Receiver

Close-coupling

Drawbar (prongs)

Coupled

Installing The Mechanical Couplers

Your GS 4/6 comes with a mechanical NEM360/362 coupler and pocket

assembly. To install the coupler onto the rear of the tender, simply push it into

the slot as shown below.

SET-UP

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

8

SET-UP

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

9

Connection of the Engine and Tender

Your MTH HO GS-4/6 is presented and packaged as a pre-connected unit, and

features our new wireless close drawbar. Along with providing a mechanical

connection of the tender to the engine, the wireless close coupling drawbar also

provides an electrical connection between the engine and tender. No assembly is

required.

Smoke Unit Preparation and Use

Your GS-4/6 is equipped with a proven fan-driven smoke system design featured

in MTH products for over 10 years. The performance and realism of this system is

unparallel in the model train industry.

Your smoke unit comes primed from the factory however, before running the

smoke unit for more than a few minutes, you should add more fluid. Add

between 10-15 drops initially and whenever smoke output diminishes or if the

engine has been stored for a long period of time. We provided some fluid with

your model to get you started.

The smoke unit is controlled

differently depending upon how your

run your engine so, for particulars on

turning it on or off or setting the

output levels, check out the features

and operation section. You shouldn't

run your smoke unit without fluid. Doing so can cause overheating and reduce

the performance and/or life of the unit. Of course, we recommend using only

MTH ProtoSmoke fluid. Super Smoke and LVTS brands also work fine.

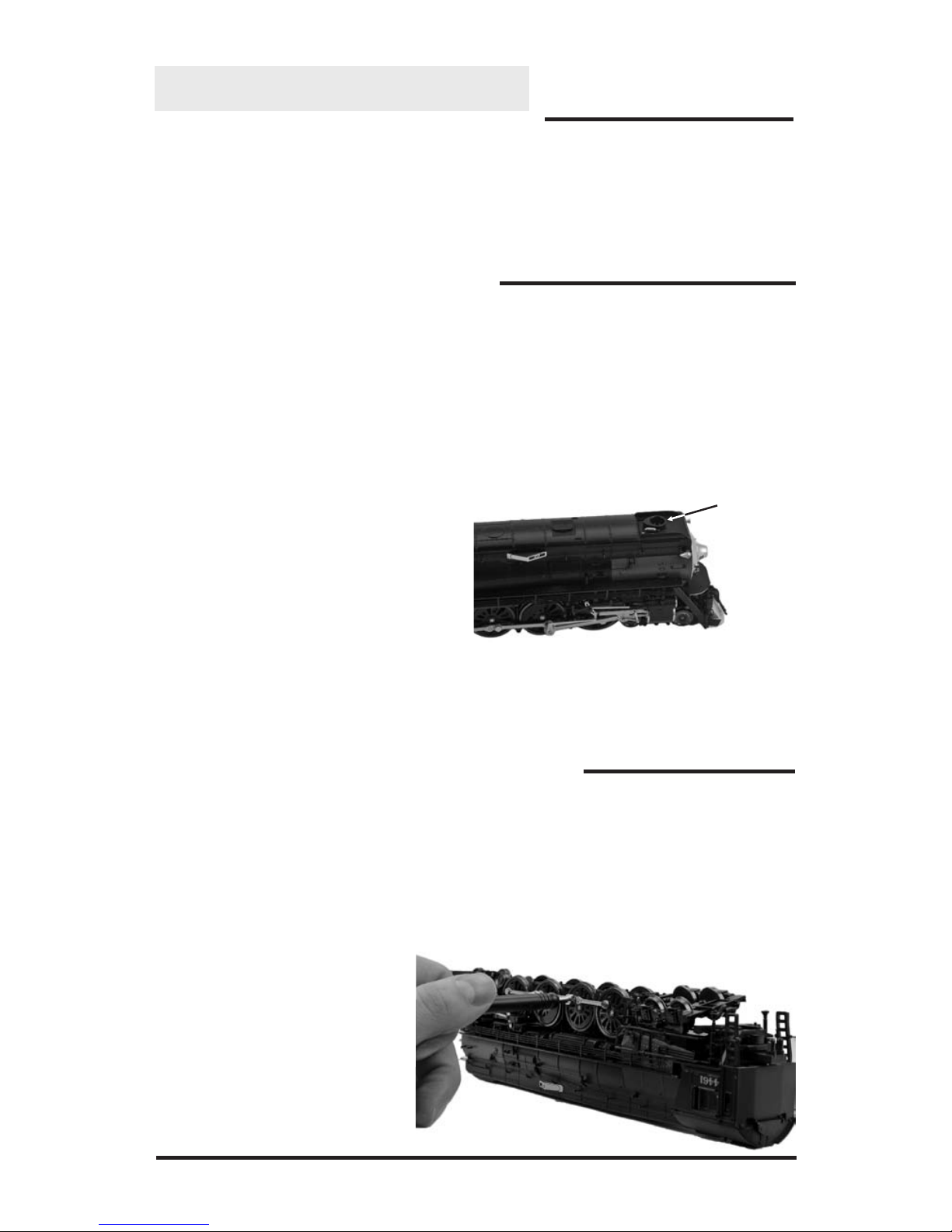

Removal/Installation of Drive Wheel Sets

Your Gs4/Gs6 comes from the factory with traction tire equipped drive wheels

installed and an alternate set without traction tires available separately in the box.

The traction tires provide exceptional pulling power on grades and through curves

but should you prefer the traditional appearance of steel drive wheels, the alternate

set can be easily installed by following the steps below.

First, position the engine upside

down in a foam cradle or other

soft surface. Using the 3mm

nut driver tool we provided in

the box, carefully remove the

drive rod screws (2) on the set

of drive wheels located 2nd

from the rear. There's one on

each side.

Smokestack

Next, remove brake shoe detail by gently prying and pulling up the part and set

aside. Remove the 5 screws holding down the rectangular chassis bottom cover.

Carefully remove the cover... then carefully remove the 2 screws holding down the

gearbox cover, set them aside and then stop. Don’t do anything further until

reading the next step completely.

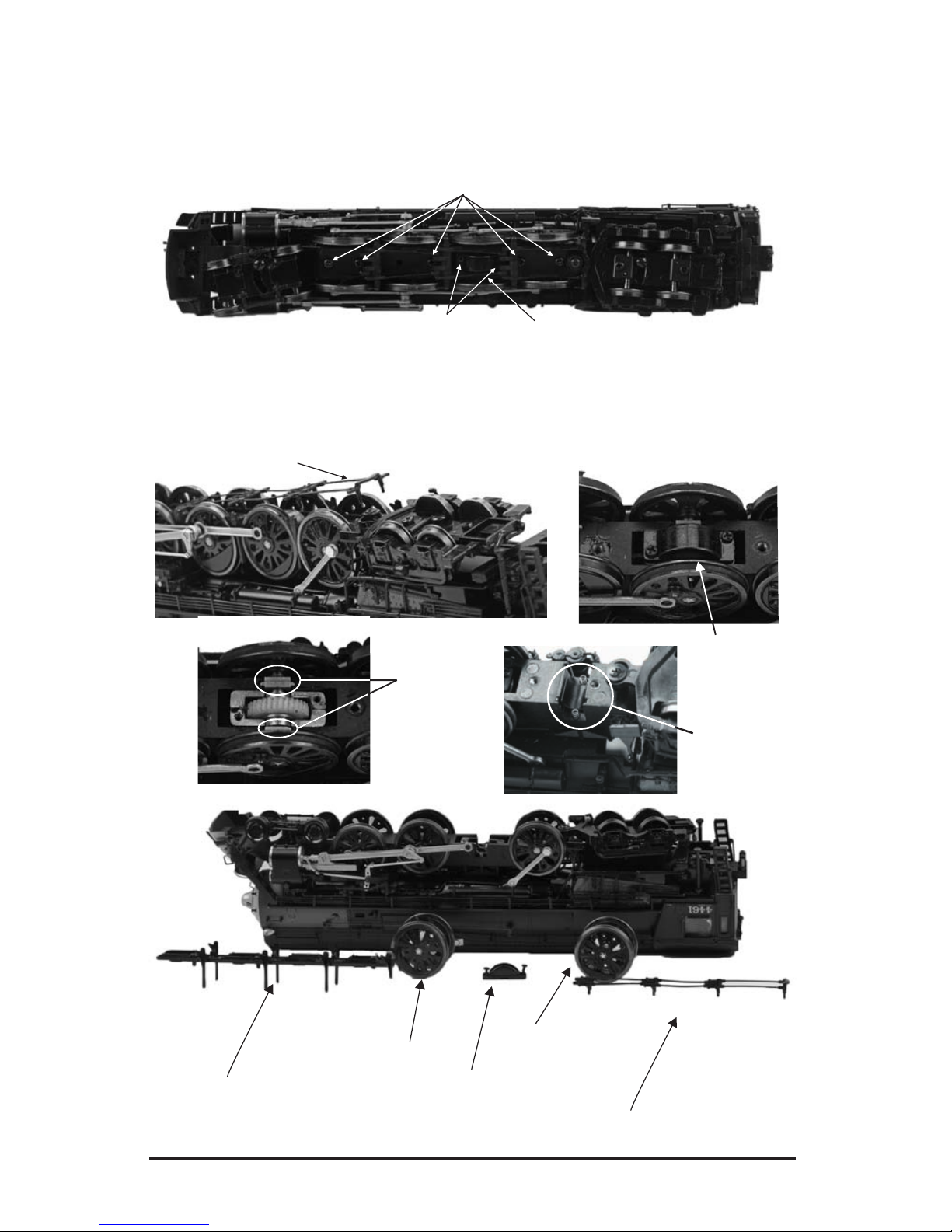

Before proceeding, there are a couple of important things to know. First, under

the square bushings on each end of the axle are tiny springs. They are critical to

the proper operation of your engine and you don't want to drop them. Next,

look closely at the wheel set and bushings and take note of their orientation.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

10

Screws

Brake Shoe Lever & Bellcrank

Traction tire

Nontraction tire

Brake Shoe Detail/bottom plate

Brake Shoe Lever & Bellcrank

Driver springs

Gearbox Cover

Gearbox CoverGearbox Screws

Gearbox cover

Gearbox cover

removed

Bushings

Now, very slowly and carefully lift the wheel set upward. Keep a close eye out for

the driver springs as they sometimes stick to the bushings and lift out. If you drop

one, you'll need some really good eyes or a magnet to find them. If they should

lift out with the wheel set, carefully set them back into cavities from which they

came.

Drop the replacement wheel set into the chassis. Make sure the bushings are in the

correct orientation. The small rectangular tabs on the front and rear must be

upward (with the engine upside down) toward the chassis bottom cover.

Reinstall the gearbox cover with 2 screws...and then reinstall the chassis bottom

cover with 5 screws, gently press the plastic molded brake shoe detail back into

place, and install the rear drive rod screws. See, you've done it.

Lubrication

Using light machine

or household oil,

apply a very small

amount to all drive

rods, linkages, axles,

and other moving

parts as shown.

Your gearbox is properly

greased at the factory and probably never needs service however, if you run

excessive hours pulling heavy loads, it's a good idea to remove the 2 screws from

the gearbox cover and re-grease using MTH gear grease or equivalent.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

11

Lubricate Axles (L)

(L)

(L)

(L)

(L)

Driver springs

Lubricate Side Rods and Linkage(Both Sides) (LL)

(L)

(L)

(LL)

PS 3 ENHANCEMENTS

DCC-DCS switch

Secondly, you will notice on the bottom of your tender, that there is a DCC-DCS

switch. To operate the engine in DCS mode, ensure the switch is set to DCS. If

you wish to run the engine in DCC mode,

ensure the switch is set to DCC.

If you inadvertently leave the switch in DCC it

won’t hurt anything, you just won’t be able to

communicate with your engine with your DCS

system. Likewise, if you leave the switch in

DCS and try to operate the engine under DCC

you may notice a humming coming from your

engine and you will likely notice that your

DCC system’s overload light will be on.

LED Lighting

Gone are the incandescent bulbs. Your new PS3.0-equipped engine has LED

lighting. MTH uses various colored LEDs to simulate the correct lighting on your

engines from the warm, yellow-orange colored light coming out of an old lantern

on your favorite steam engine to the high-intensity halogen lamp on the latest

modern diesels, LED's allow for various, correct colors. Also, they require less

power and do not emit as much heat as incandescent bulbs.

DCC/DCS switch

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

12

FEATURES AND OPERATION

Now, for the fun stuff! Your new MTH HO steam engine has more features and

operating capabilities than any HO engine ever built by any manufacturer. We're

going to walk you through everything she does in general but, you'll probably find a

few we forgot to mention on your own.

Modes of Operation

There are modes of operation with different levels of features accessible in each.

We refer to them as conventional AC, DCC/Motorola, and DCS. Here's a little

more explanation before we get into the features of each mode.

Conventional AC

When using conventional AC power, the engine will respond to changes in track

voltage. An increase in track voltage will increase the locomotive speed and a

reduction in track voltage will reduce the engine speed.

DCC/Motorola or Digital Command Control

DCC is a popular digital command control scheme wherein the track power is also

a digital control signal. That is, using a DCC controller, you can communicate with

multiple engines and have them all moving at different speeds or moving in

opposite directions on the same track at the same time. The power/command signal

remains constant and engines are “commanded” to perform as desired. MTH is

new to DCC but, we recognize it's importance to many HO operators. So, we

loaded our engine with more DCC features easily accessible to the operator than any

HO engine ever built previously. You DCC guys are in for a real treat!

DCS or Digital Control System

While the acronyms are close, this is about where the similarities between DCS and

DCC end. Yes, they are both digital control systems however, MTH DCS is NOT

DCC. There are several proprietary versions of DCC on the market but friend, this

is NOT one of them. MTH's DCS system is proven technology in the O and One

gauge markets and now, we've brought its power and simplicity it to you.

First, the power signal in DCS is NOT the command signal. Next, DCS employs a

fully functional bi-directional communication scheme opening a vast range of

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

13

advanced features and yet, is so simple and intuitive, you can enjoy them! No

programming tracks, bits and bytes, or conversion of binary to hexadecimal

numbers here! To add an engine in DCS, just press “ADD ENGINE.” After that,

If you want to start your engine, just press “START UP” or, to turn the smoke on

or off, just press “SMOKE.” No combinations of letters or numbers to remember!

We think you're really going to like this!

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

14

Conventional AC Operation

Speed Control

When using conventional AC power, the engine will respond to changes in track

voltage. An increase in track voltage will increase the locomotive speed and a

reduction in track voltage will reduce the engine speed.

(see pages 29-31 for specifics on the Marklin controller)

When power is first applied to the track, the locomotive will be silent for 1-20

seconds and the headlight will be on, indicating the super capacitors are charging

(The super capacitors provide power to the sound system during direction changes

or intermittent drops in track power due to dirty track switches, when

operating in conventional mode). When the super capacitors are charged, all the

lights will come on and the engine sounds will start up.

There should be no movement, turning the throttle knob on the transformer

counterclockwise past zero and quickly back up again will bring the engine to a

forward motion state, then increasing the throttle will begin to move the engine

forward, and speed will increase as the throttle is advanced. To change direction,

turn the throttle knob on the transformer counterclockwise past zero and quickly

back up again. Then adjust the throttle knob to control the speed of the

locomotive.

Changing Direction (AC)

or on

Smoke Unit Cover

Wick in

Poor

Condition

Wick in

Good

Condition

Sounds

In this mode, sound are pretty much automatic. If you're moving, you'll hear

chuffing sounds. If you increase or decrease the throttle quickly, you'll hear labored

or drift chuffing, respectively. Of course, if the engine has been sitting for a while, the

engineer may open the steam cocks and release the moisture, don't worry, he never

forgets to close them.

When your sitting at idle, there may be some maintenance done. You could hear

someone dopping the siderods or checking the water level in the tender and

filling it if necessary. Don't worry, all of this and more is just a normal part of

everyday operations.

When your moving at a pretty good clip and you reduce the throttle quickly, you

may hear the brakes squeak and squeal as the engineer applies them. Of course,

they'll stop when the engine does. If things get too noisy, just locate the volume

potentiometer on top the tender (underneath the hatch) and adjust the volume

from maximum down to off, whatever suits you. Turn it counterclockwise to reduce

the volume or clockwise to increase it.

When you turn the smoke on, just give it a few seconds

to warm up. It doesn't start instantly. Once you see

smoke gently streaming out (or not if you prefer) snap

the coal detail back in place and away you go.

Once on, like the sounds, the behavior is fully automatic. The model will puff out

smoke in exact synchronization with the chuffing sounds and driver rotation at 4

per revolution. Amazing!

When the output begins to diminish significantly, add 10-12 drops to recharge the

unit. Again, give it a few seconds to warm back up. The cool fluid slows the

action for a few seconds. Also, watch out for bubbles that may block the stack.

You may need to gently blow down the stack to clear it.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

15

Smoke

Smoke control in the Protosound 3 (2 rail as

well as 3 E+ models) use a potentiometer for

smoke control (exactly like volume control).To

increase or decrease smoke volume, simply use

a Phillips head screwdriver to turn the

potentiometer clockwise (increase output)

or counterclockwise (decrease output).

Running the engine without

a primed smoke unit may

cause damage

Smoke

Potentiometer

Smokestack

Volume

Potentiometer

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

16

DCC/Motorola Digital Command Control

Now, if your operating in this mode, you may very well know more about DCC

than we do so, we're going to stick to telling you about our engine in this operating

environment. First of all, in DCC mode, we brought all the features of conventional

AC along and of course, added to them. Your new engine has more user features

than any DCC engine ever built. Some of them are even ahead of the world of

DCC!!

Running the Engine

Set the engine on the rails, and apply DCC power. Refer to the Set-Up section of

this guide for instructions on how to connect the boiler and tender.

The first thing you will notice is the engine does absolutely nothing! Don't panic.

This is by design. MTH HO engines never do anything in command mode until

told to do so, regardless of what brand DCC controller you use. In this way, you

could have a fleet of MTH HO engines on the rails and they will remain shutdown

until you command them to start up.

F3 Start up/Shut Down

Select engine address 3 (factory default), press the F3 (Start Up/Shut Down) key, and

your engine will start-up. Lights, sounds, smoke, ACTION!!! Roll the throttle and

away you go. Our models are compatible with 14, 28, and 128 speed steps. We

strongly recommend 128 because in this mode, speed steps correspond directly to

scale speeds. That is, speed step 10 = 10 smph, speed step 47 = 47 smph, etc. You

get the idea. When your done, press the F3 key again, your engine will shut down.

To be clear, pressing F3 when the engine is shut down will start it up. Pressing F3

when the engine is started up will shut it down. Pretty clever, eh?

Sounds

As in conventional AC mode, the default sound arrangement is automatic. So, you

can just run your engine and its sounds will follow the action. But, you operate in

DCC for a reason. You want access to more features, right? Well, depending upon

the capabilities of your DCC controller, you now have access to a range of sound

features including bell, whistle, PFA, engine sounds on/off, master volume, Doppler,

and more.

Here's a brief description of commonly used sound features.

F1 Bell

Toggles bell sounds on/off. Listen to the last half ring of the bell when it stops!

F2 Whistle

Blows the whistle for as long as it's on. There are several different ending

signatures depending on how long you hold the button down. Check it out!

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

17

F4 PFA

PFA in MTH lingo stands for passenger and freight announcements. Since your

engine provides freight service, you'll hear freight yard sounds.. PFA is a very

popular sound feature that's a staple in almost all MTH products. We had to give

you this!

There are 4 sound sequences or segments in PFA. You advance through them at

your command. Each segment has a minimum time of ~10 seconds but more

sounds play the longer you listen.

When running the engine, simply press the F4 key to activate PFA. When you

bring the engine to a stop, the arrival sequence will play. You can remain in this

segment as long as you like.

Press F4 again, and advance to disembarking sequence. Again, you can listen to

this sequence as long as you like.

Press F4 again, and advance to the embarking sequence. Again, you can listen to

this sequence as long as you like.

Press F4 again, and advance to the departure sequence. After the engineer says

“Just keep the steam up” and the engine will automatically pull out and resume

the speed and direction of when you entered the feature. The bell ring for a short

while and then turn off automatically.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

18

Smoke

The smoke system in DCC mode operates exactly as it does in analog DC mode

with the added benefit of being able to turn it on or off remotely. Pressing F12 on

your DCC controller will toggle the smoke unit on and off again.

The manual smoke potentiometer under the control hatch (on top of the tender)

must be fully clockwise for the F12 key to function. When the smoke

potentiometer is fully counterclockwise, the smoke is always off.

Lighting

As with other feature categories, lighting in DCC mode operates just like

conventional DC with regard to rule 17, constant brightness and directional

behavior. See that section for details. DCC provides some additional control to

suit your preferences.

F0 Headlight

Toggles the headlight on/off.

F5 Lights

Toggles all lighting (except the head & tail light) on/off, including Marker LED's.

When on, all lighting behaves automatically as described elsewhere. When F5 is

off, all lighting is off.

Smoke

Potentiometer

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

19

Master Volume

F6 – Master Volume

There are 10 volume levels. Pressing F6 twice (toggling on then off) raises the Master

Volume one level. The Master Volume loops. That is, if you go past the 10th level it

will loop back around to the 1st or lowest volume level.

Forward/Reverse Signal

Just like a real engine, you can announce the direction of intended movement using

your DCC handheld and F9 and F10.

F9 – Forward Signal

Pressing F9 twice (toggling on then off) will sound the Forward Signal. This is two whistle/horn

blasts

F10 – Reverse Signal

Pressing F10 twice (toggling on then off) will sound the Reverse Signal. This is three

whistle/horn blasts

Grade Crossing Signal

Again, just like a real engine, you can trigger the Grade Crossing Signal on your engine.

This is two long, one short, one long whistle/horn blast.

F11 – Grade Crossing Signal

Pressing F11 twice (toggling on then off) will sound your Crossing Signal.

Smoke (if Equipped)

F12 – Smoke On/Off

Enabling F12 will turn the smoke unit on. Disabling F12 will turn your smoke unit off.

F13 – Smoke Volume

There are three smoke volume levels in your MTH PS 3-equipped engine –

Low/Med/High. The default for this is set to High. You can adjust the smoke output

(amount of smoke the generator puts out) by pressing the F13 button twice. This sets the

level to the next step. For example, if you are currently at the High smoke output level,

pressing F13 twice (toggling it on then off) will set the smoke volume to Low. Pressing

F13 twice again will set it to Medium and so on.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

20

Engine Sounds

F25 – Engine Sounds

You can turn the Engine Sounds On/Off by pressing the F25 button. Pressing it once

(enabling F25) will cause the Engine Sounds to shut off. TheWhistle/Horn and Bell

sounds will still be active, however. To turn the engine sounds back on press the F25

button again (disable F25).

Additional F Functions

F14-F16 – Idle Sequence

Pressing F14, F15, or F16 twice (toggling on then off) will trigger an Idle Sequence if the engine

is not moving. These vary from engine to engine and may include things like checking the coal

load, checking the water level, using the Alemite grease gun on the drivers, etc. When triggered,

these will run through the sequence that varies in duration.

F17 – Extended Start-Up

If your engine is shut down or you've just applied DCC power pressing F17 twice (toggling it

on then off) will start the Extended Start-Up sounds. This is very similar to F3 except you will

hear the crew talking back and forth about getting the engine ready to run.

F18 – Extended Shut-Down.

If your engine is already up and running you can play the Extended Shut Down

sounds by pressing F18 twice (toggling on then off). The Extended Shut Down is very

similar to F3 in that the engine will ultimately shut down, but in the case of Extended

Shut Down you will hear the crew talking back and forth about how the engine ran,

time schedules, etc.

NOTE – The engine must be sitting still in order to trigger F-Functions

F14 through F18

F19 – Labor Chuff

To force the Labor Chuff sound in a steam engine, press the F19 button once (enable

F19). As long as F19 is enabled the engine will play its Labor Chuff sounds. To set the

sound back to Normal Chuff press the F19 button again (disable F19).

F20 – Drift Chuff

To force the Drift Chuff sound in a steam engine, press the F20 button once (enable

F20). As long as F20 is enabled the engine will play its Drift Chuff sounds. To set the

sound back to Normal Chuff press the F20 button again (disable F20).

F21 – One Shot Doppler

You can set your MTH PS 3-equipped engine to simulate the actual Doppler Effect

sound a real engine makes as it passes you. To do this, press the F21 button once

(enable F21) and then listen as the engine makes that pitch shift that mimics the

Doppler Effect perfectly. Press the F21 button again (disable F21) to shut off the

Doppler Effect. With a little practice in timing and speed you can make this happen

right in front of you.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

21

F22 – Coupler Slack

When an engine couples to a train and pulls out, it has to take up the coupler slack.

You can play this sound by pressing F22 twice (toggling on then off). This feature

works two ways – While the engine is sitting still, press F22 twice to enable it. Then,

when you move the engine, it will play the Coupler Slack sound.

The second way is to simply force the sound while the engine is moving. To do this,

simply press F22 twice (toggling it on then off). The sound will play.

F23 – Coupler Close

To play the Coupler Close sound press the F23 button twice (toggling it on then off).

You can play this sound as you're coupling cars together to add realism.

F24 – Single Whistle/Horn Blast

To play a Single Horn Blast press the F24 button twice (toggling in on then off). This

plays a single, short horn blast.

F26 – Brake Sounds

Pressing the F26 button (enable F26) will disable the Brake Sounds for your engine.

The Brake Sounds occur when you reduce the speed of your engine rapidly. To enable

the Brake Sounds press the F26 button (disable F26). Brake Sounds are On by default.

F27 – Cab Chatter

Cab Chatter occurs when the engine is sitting at idle. There are various times when the

crew will talk to each other when the engine is sitting at idle. Pressing the F27 button

(enable F27) will disable the Cab Chatter. Pressing the F27 button again (disable F27)

will enable Cab Chatter. Cab Chatter is On by default.

F28 – Feature Reset

Resets Features to defaults.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

22

Function Chart

F0

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

Headlight

Bell

Horn

Start-Up/Shut Down

PFA

Lights

Master Volume

Front Coupler (Sound Only)

Rear Coupler (Sound Only)

Forward Signal

Reverse Signal

Grade Crossing

Smoke On/Off

Smoke Volume

Idle Sequence 3

Idle Sequence 2

Idle Sequence 1

Extended Start-Up

Extended Shut Down

Labor Chuff

Drift Chuff

One Shot Doppler

Coupler Slack

Coupler Close

Single Horn Blast

Engine Sounds

Brake Sounds On/Off

Cab Chatter On/Off

Feature Reset

Description

Function

DCS Digital Control System

As you may have gathered by now, DCS is an MTH exclusive Digital Control System

that provides easy access to dozens and dozens of features in our models. We

developed DCS to provide a powerful and advanced model train control system that

was simple and enjoyable to use. We've accomplished that goal. DCS further

expands the features available far beyond that of DCC. After all, in DCC, we only

had a limited number of “F” commands to fill.

As with DCC, we'll leave the detailed “how-to” system explanations to the DCS

system manuals. What you should know are all the cool features your engine has

built-in, waiting for you to experience.

Running the Engine

Set the Engine on the track and once the DCS system is connected to your track and

powered up by an AC Power Supply (depending upon which model type you have),

simply press “ADD ENG” and the system will scan the track and automatically

upload your engine into the controller. At this point, you can press “START UP”,

roll the throttle and pull out! That's it!

Speed Control

DCS engines are controlled in scale miles per hour (smph) and increments of one.

So, that means if you dial up 10, you engine will smoothly accelerate to 10 smph.

There is no need to select a speed step setting, there's only one precise linear control

at scale speeds. See, powerful yet simple.

Introducing the ultimate in prototypical operation Proto-Whistle. Your new GS-4/6

includes this amazing feature. It allows you to adjust the pitch of the steam whistle

just like you were sitting the cab pulling the whistle rope yourself. This new feature is

controllable from either your DCS Commander or with your DCS system with

software version 4.0 or greater (see your DCS or DCS Commander instruction

manual for specifics on how to operate this feature)

GS-4/6

Independent Volume Settings

Using DCS, you independently adjust the bell, whistle, engine, and accent sounds

volume. This is like a mixer so you can set up the engine fit your specific tastes and

sense of realism. Oh, they all move relatively up or down with the master volume

settings.

Sounds

Not only that but your also has a Grade Crossing Whistle Feature. So just like

the real engine, with the push of a single button, you can trigger the Grade Crossing

Whistle. To trigger the Grade Crossing Whistle press the A3 button on your DCS

Commander or the SXS softkey on your DCS Remote Handheld.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

23

Sounds

Chuff Rate

You can adjust the chuff rate from the default setting of 4 per revolution to

whatever you like between 1 and 16 per rev. Why? Some folks like to run fast and

2 or 3 chuffs per rev keeps chuffing sounds a little more distinct, even though it

isn't prototypical.

Doppler Loop

You can either press the Doppler button on the remote to activate what we refer to

as “one-shot” Doppler or, using DCS, you can program a Doppler loop that will

peak at the same point on your layout, over and over.

Custom Sounds

You can fire any of 10 individual sound bites pre-loaded into your engine. These

are typically, blow downs, steam let-offs, etc., etc. Each one at the press of a single

button. You can also make voice or other audio recordings and play them back on

command with ease.

Proto-Dispatch

Press the “MIC” (microphone) button on your DCS remote and speak. Your voice

will be digitized and played out of the model in real-time. Talk about station

announcements!

Proto-Cast

Another MTH exclusive, you can connect any audio source with a line output to

the DCS TIU and send music, train sounds, or anything you like down the rails to

be played through the engine as it moves along the track. Your holidays may never

be the same!

Smoke

In addition to a simple button labeled, go figure, “SMOKE” to toggle your smoke

on and off, you get the ability to quickly and easily adjust the output volume. In

plain English, you simply select low, med, or hi.

Lighting

As with everything in DCS, this becomes a little more than obvious. Pressing the

“HEADLIGHT” button turns of the directional head and taillight. Pressing the

Interior light will turn off the cab interior light.

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

24

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

25

Advanced DCC Operation:

This section of the manual provides more in-depth detail on how to set up and

configure your MTH PS3.0-equipped engine using the NMRA-standard CV's as

well as the manufacturer-specific CV's. It also explains some of the other F

Functions not covered in the Basic DCC Operation section. Please refer to the CV

Data Table on page 28.

Configuration Variables (CV)

Configuration Variables used on MTH PS3.0-equppied engines.

Cv1

Cv2

Cv3

Cv4

Cv5

Cv8

Cv17

Cv18

Cv19

Cv21

Cv22

Cv23

Cv24

Cv25

Cv29

Cv52

Cv53

Cv54

Cv55

Cv56

Cv63

Cv64

Cv66

Cv67Cv94

Cv95

Cv105

Cv106

Cv115CV170

Short Address: 1-127 are the valid addresses

Start Voltage (CV52, bit0 must =1. This will enable PWM Mode)

Acceleration Rate (CV52, bit0 must =1. This will enable PWM Mode)

Deceleration Rate ((CV52, bit0 must =1. This will enable PWM Mode)

Max Voltage (CV52, bit0 must =1. This will enable PWM Mode)

MFG ID. MTH =27. Also used for various resets

High Byte of Extended Address

Low Byte of Extended Address

Consist Address (bit 7=1 on an engine will tell the engine it's reversed in a

consist)

Defines active Function F1-F8 for the active consist

Defines active functions for FL and F9-F12 for the active consist (bit 0=1 will

tell an engine that you want it's FL control to operate under the consist

address – bit1-0/bit2=1 will configure the FL control for a reversed engine in

a consist)

Consist Acceleration Rate

Consist Deceleration Adjustment

Speed Table Select

Decoder Configuration

MTH PWM Mode Configuration

MTH Acceleration (1/8*sMPH/s). For example – a Value of 8 written would

give you 1sMPH/s acceleration

MTH Deceleration Rate (1/8*sMPH/s)

Factory Reset Alternate method: Send a value of 55 to CV55 on address 55

and the model will go back to Factory Default

Motorola Operating Mode (Applies to 3E+ models)

MTH Consist Acceleration Rate (1/8*sMPH/s)

MTH Consist Deceleration Rate (1/8*sMPH/s)

Forward Trim (CV52, bit0 must =1. This will enable PWM Mode)

Speed Table Selection (CV29 bit 4 must be set to 1 then CV25 must be set

to 0 or 1)

Reverse trim (CV52, bit0 must =1. This will enable PWM Mode)

User ID #1 – General Purpose use for customer

User ID #2 – General Purpose use for customer

MTH Function Assignments – See table of supported CV's and manual

section on how to re-arrange them for further information

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

26

Cv29

CV29 is the basic decoder setup CV that is used by all DCC decoder manufactures.

So, if you are familiar with CV29 from other manufacturer's decoders MTH's is no

different. The most important part of CV29 is the ability to switch between long and

short addressing. By default, CV29 on your MTH PS3.0-equipped engine is set to 2.

Long and Short Addressing

Like most DCC Decoders, your MTH PS3.0-equipped engine can be programmed

with both Long and Short Address. Short addresses are those from 1-127 and Long

addresses are those from 128-9999. You can program the engine address either with

Programming on the Main (PoM) or using a Programming Track. Since it's easiest,

in most cases, to PoM the instructions will show you how to do it this way.

By default, your MTH PS3.0-equipped engine comes programmed with both a long

and short DCC address. The default Short address is always 3. The default Long

address is 3333.

To change your engine's Short Address using PoM:

1. Call up the engine's current address on your DCC handheld

2. Enter Programming on the Main on your DCC handheld]

3. Enter the new address you want – Remember you can only use address 1-127 for

Short Addressing

4. Once you hit Enter the engine will give you a two whistle/horn blast response

5. Call up the engine on its new address and away you go

Alternatively, depending upon the type of DCC system you have, you can enter

PoM and then write the new address in the Address Menu. This only works for

2

short addressing. For example, on an MRC Prodigy Advance system, you would:

1. Call up the engine's current address on your DCC handheld

2. Hit the PROG button twice to enter PoM mode

3. Hit Enter twice so the LCD displays “Adr”

4. Type in the new Short Address (1-127) that you want and hit Enter

5. The engine will give you a two whistle/horn blast response

To change your engine's Long Address using PoM:

1. Call up the current engine's address on your DCC handheld

2. Enter Programming on the Main on your DCC handheld

3. In this step you have to tell the MTH engine that you want it to start looking at

long addresses. You do this in CV29:

a. Bring up the CV menu on your DCC handheld

b. Enter “29” to edit CV29

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

27

c. Enter “38” to change the value of CV29 and hit Enter

d. The engine will give you a two whistle/horn blast response

4. In the following steps you will now need to write values to CV17 and CV18 to

tell the engine what the long address should be5. Call up CV17 and enter the

value required for CV17. You will get a two whistle/horn blast response

6. Call up CV18 and enter the value required for CV18. You will get a two

whistle/horn blast response

In order to determine your required values for CV17 and CV18 you will need to go

to http://extranet.mth-railking.com/pdfapp/pdfs/instruction/HO%20DCC

%20addressCV17_18%20Converter.xls

Enter in the long address you want then click anywhere else in the spreadsheet and

it will return the values for CV17 and CV18 (it will also return the hex conversion

of the CV17 and CV18 values if your DCC system requires this).

Below is an example for extended address 2011:

Feature/Factory Resetting

If all else fails and you aren't sure of something, never fear. You can always get your

engine back to a known state by either performing a Feature or Factory Reset.

There are a couple of ways to reset your MTH PS 3-equipped engine:

- Factory Resets – Clears everything – takes engine to just like it

was when you got it brand new

- Send a decimal 08 to CV 8 to reset everything entirely back to factory

default

- Send a decimal 192 to reset everything except user speed tables

- Feature Resets – There are a couple of Feature Resets that you can use

- Press F20 twice (toggling on then off). This resets the smoke, volume and

lights back to their defaults

- Send a decimal 64 for a Feature Reset. This resets volumes, smoke and

light settings.

- Send a decimal 128 to reset only address values back to factory default

- This is the same as writing 55 to CV55 to engine address 55

CV 17 and CV 18 Conversion Tool

Hex Conversion C17 Value to Enter C18 Value to Enter

2011 07DB 199 219

Desired 4-Digit

Engine Address

Below is the table of Factory Default MTH supported DCC CV's. This table is

specific to the engine in the title of this manual:

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

28

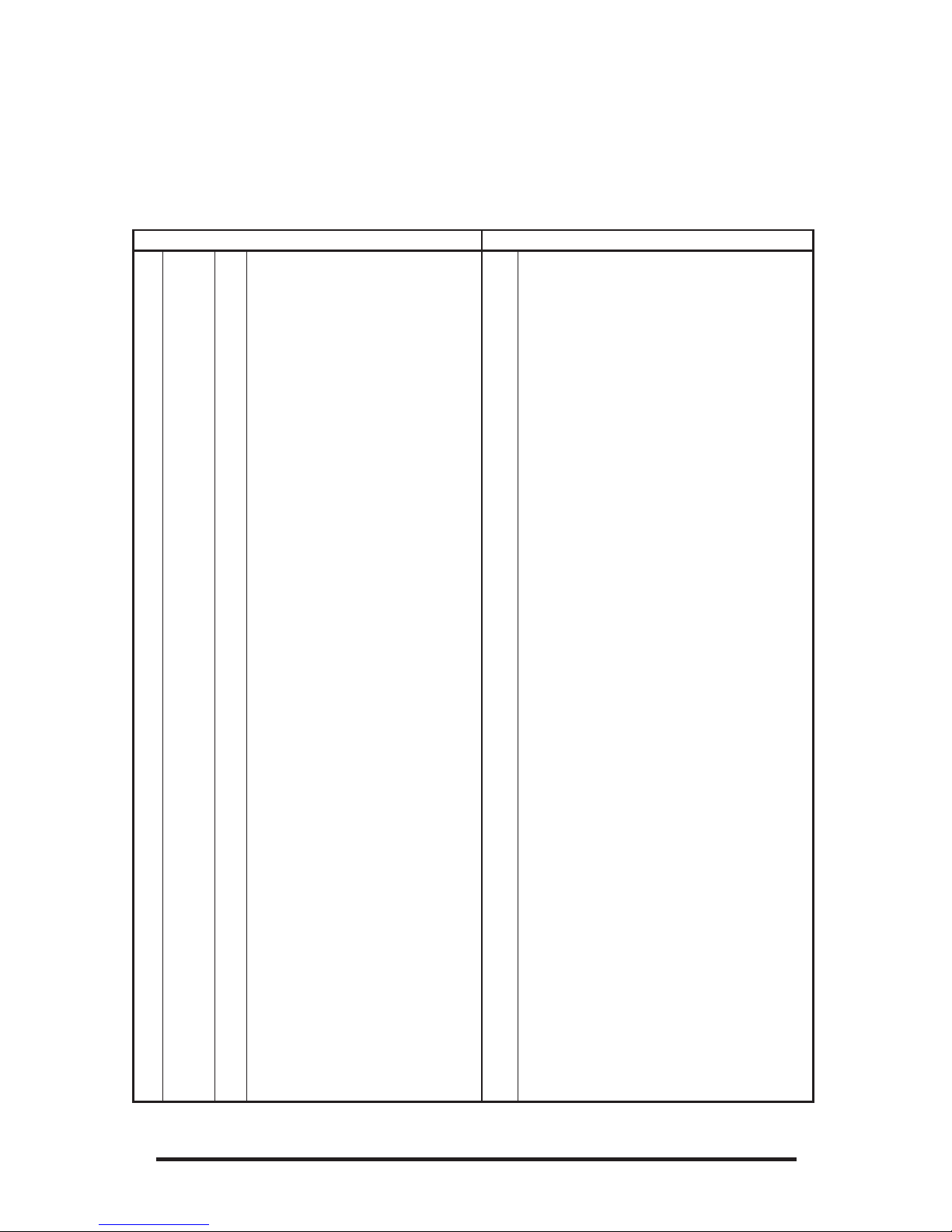

Factory Default Values for MTH PS3.0 DCC

Configuration Variables (CV’s)

Decimal

Key

1

2

3

4

5

7

8

17

18

19

21

22

23

24

25

29

52

53

54

63

64

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

105

106

115

116

3

16

0

0

0

0

0

192

0

0

0

0

0

0

0

2

0

128

64

0

0

0

0

9

19

28

38

47

57

66

76

85

94

104

113

123

132

142

151

161

170

179

189

198

208

217

227

236

246

255

0

03

10

0

0

0

0

0

C0

00

00

00

00

00

00

00

02

00

80

40

00

00

00

0

9

13

1C

26

2F

39

42

4C

55

60

68

71

7B

84

8E

97

A1

AA

B3

BD

C6

D0

D9

E3

EC

F6

FF

0

Short Address

Start Voltage (Cv52 bit 0 must =1)

Accel Adjustment

Decel Adjustment

Max Voltage (Cv52 bit 0 must =1)

NMRA Mfg Version

NMRA Mfg ID

Extended Address High Byte

Extended Address Low Byte

Consist Address

Consist Functions F1-F8

Consist Functions F9-F12

Consist Acceleration Adjustment

Consist Deceleration Adjustment

Speed Table Select

Decoder Configuration

MTH PWM Motor Configuration

MTH Acceleration Rate

MTH Deceleration Rate

MTH Consist Acceleration Rate

MTH Consist Deceleration Rate

Forward Trim

Alternate Speed Curve Step 1

Alternate Speed Curve Step 2

Alternate Speed Curve Step 3

Alternate Speed Curve Step 4

Alternate Speed Curve Step 5

Alternate Speed Curve Step 6

Alternate Speed Curve Step 7

Alternate Speed Curve Step 8

Alternate Speed Curve Step 9

Alternate Speed Curve Step 10

Alternate Speed Curve Step 11

Alternate Speed Curve Step 12

Alternate Speed Curve Step 13

Alternate Speed Curve Step 14

Alternate Speed Curve Step 15

Alternate Speed Curve Step 16

Alternate Speed Curve Step 17

Alternate Speed Curve Step 18

Alternate Speed Curve Step 19

Alternate Speed Curve Step 20

Alternate Speed Curve Step 21

Alternate Speed Curve Step 22

Alternate Speed Curve Step 23

Alternate Speed Curve Step 24

Alternate Speed Curve Step 25

Alternate Speed Curve Step 26

Alternate Speed Curve Step 27

Alternate Speed Curve Step 28

Reverse Trim

User ID #1

User ID #2

Function - Bell High Byte

Function - Bell Low Byte

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1

1

Default Value

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

CV Description

Function - Horn High Byte

Function - Horn Low Byte

Function - Start-Up/Shut Down High Byte

Function - Start-Up/Shut Down Low Byte

Function - PFA High Byte

Function - PFA Low Byte

Function - Lights High Byte

Function - Lights Low Byte

Function - Master Volume High Byte

Function - Master Volume Low Byte

Function - Front Coupler High Byte

Function - Front Coupler Low Byte

Function - Rear Coupler High Byte

Function - Rear Coupler Low Byte

Function - Forward Signal High Byte

Function - Forward Signal Low Byte

Function - Reverse Signal High Byte

Function - Reverse Signal Low Byte

Function - Grade Crossing High Byte

Function - Grade Crossing Low Byte

Function - Smoke Volume On/Off High Byte

Function - Smoke Volume On/Off Low Byte

Function - Smoke Volume High Byte

Function - Smoke Volume Low Byte

Function - Idle Sequence 3 High Byte

Function - Idle Sequence 3 Low Byte

Function - Idle Sequence 2 High Byte

Function - Idle Sequence 2 Low Byte

Function - Idle Sequence 1 High Byte

Function - Idle Sequence 1 Low Byte

Function - Extended Start-Up High Byte

Function - Extended Start-Up Low Byte

Function - Extended Shut Down High Byte

Function - Extended Shut Down Low Byte

Function - Labor Chuff High Byte

Function - Labor Chuff Low Byte

Function - Drift Chuff High Byte

Function - Drift Chuff Low Byte

Function - One Shot Doppler High Byte

Function - One Shot Doppler Low Byte

Function - Coupler Slack High Byte

Function - Coupler Slack Low Byte

Function - Coupler Close High Byte

Function - Coupler Close Low Byte

Function - Single Horn Blast High Byte

Function - Single Horn Blast Low Byte

Function - Engine Sounds High Byte

Function - Engine Sounds Low Byte

Function - Brake Sounds On/Off High Byte

Function - Brake Sounds On/Off Low Byte

Function - Cab Chatter On/Off High Byte

Function - Cab Chatter On/Off Low Byte

Function - Feature Reset High Byte

Function - Feature Reset Low Byte

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

Key

Hex

CV

Description

Function Function

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

29

CV Programming – Marklin 6021 Controller

Note: There are 4 DIP switches on the back of the Marklin 6021 Controller. For

MTH engines you will want the DIP switches set to the following:

1 - OFF

2 - ON

3 - OFF

4 - OFF

To enter programming mode using a Marklin 6021 controller, perform the

following steps:

1. Press and hold the stop and go buttons simultaneously until the

two digit LED display flashes 99.

2. Ensure that track power is off by pressing the stop button.

3. Enter the engine address or 80 on the keypad. 80 will match any

engine address.

4. Turn the speed knob counter clockwise to the direction change

position and hold it there.

5. Press the go button. The headlight should start to flash. This indicates

that the engine is waiting for the CV number to be entered.

6. Release the speed control knob.

To program a CV, perform the following steps:

1. If the desired CV number is less than 80, enter the CV number on the

keypad, confirm that the function LED is off (pressing the off key if

necessary), and go directly to the next step.

1. If the desired CV number is equal or greater than 80, enter

the hundreds and tens digits of the CV number on the keypad.

For example, to program CV 94, enter 09 on the keypad then

press the function key to tell the engine that a CV number

greater than 79 is being entered

2. Briefly turn the speed knob counter clockwise to the direction

change position. The headlight should shift to a long-short

flash pattern

3. Enter the unit's digit of the CV number preceded by a zero.

For the example of CV 94, enter 04. The state of the function

LED does not matter. Note: use 80 for 00.

2. Briefly turn the speed knob counter clockwise to the direction change

position. The headlight should shift to a single short flash pattern.

3. If the desired CV contents is less than 80, enter the CV contents on the

keypad, confirm that the function LED is off (pressing the off key if

necessary), and go directly to Step 4

1. If the desired CV content is equal or greater than 80, enter the

hundreds and tens digits of the CV contents on the keypad.

For example, to program a CV with the value 128, enter 12 on

the keypad then press the function key to tell the engine that a

number greater than 79 is being entered

M.T.H. HO 4-8-4 GS-4/ GS-6 Steam Engine

30

2. Briefly turn the speed knob counter clockwise to the direction

change position. The headlight should shift to a short-short

flash pattern.

3. Enter the units digit of the CV contents preceded by a zero.

For the example of 128, enter 08. The state of the function

LED does not matter. Note: use 80 for 00.

4. Briefly turn the speed knob counter clockwise to the direction change

position. The headlight illuminates continuously for ~1.5 seconds to

confirm successful programming. If programming was unsuccessful,

the headlight will rapidly flash for ~1.5 seconds. The headlight then

returns to the long flash pattern that indicates that the engine is

waiting for the next CV number to be entered.

5. To program more CVs, return to Step 1. To exit programming mode,

turn off track power by pressing the stop button

Note: When entering values greater than 79, the two entries are actually added

together. This applies to both the CV number and contents. Thus it is theoretically

possible to program a CV number as high as 869 (790 + 79).

Operation

Until the engine receives a packet that is addressed to it that uses the new Märklin

format, the single function key directly controls startup and shutdown. If the

function key is on, the engine will run the startup script. If the function key is off,

the engine will run the shutdown script. This allows the engine to be used with

controllers that only have a single function key, such as the Märklin 6020, or a

Märklin 6021 with DIP switch 2 in the off position.

When the engine receives a packet that is addressed to it using the new Märklin

format, the normal function mapping is used, with the function key

corresponding to function 0(head/tail light).

MTH engines support both New and Old Motorola formats. For the Old

Motorola

format the Function/Off button on the Marklin 6021 controller toggles

Start-up/Shut-Down. For the New Motorola format the Function/Off button on

the Marklin 6021 Controller toggles the Headlight/Taillight and F1-F4 are

supported. Please see page 22 for the engine's F-Function List.

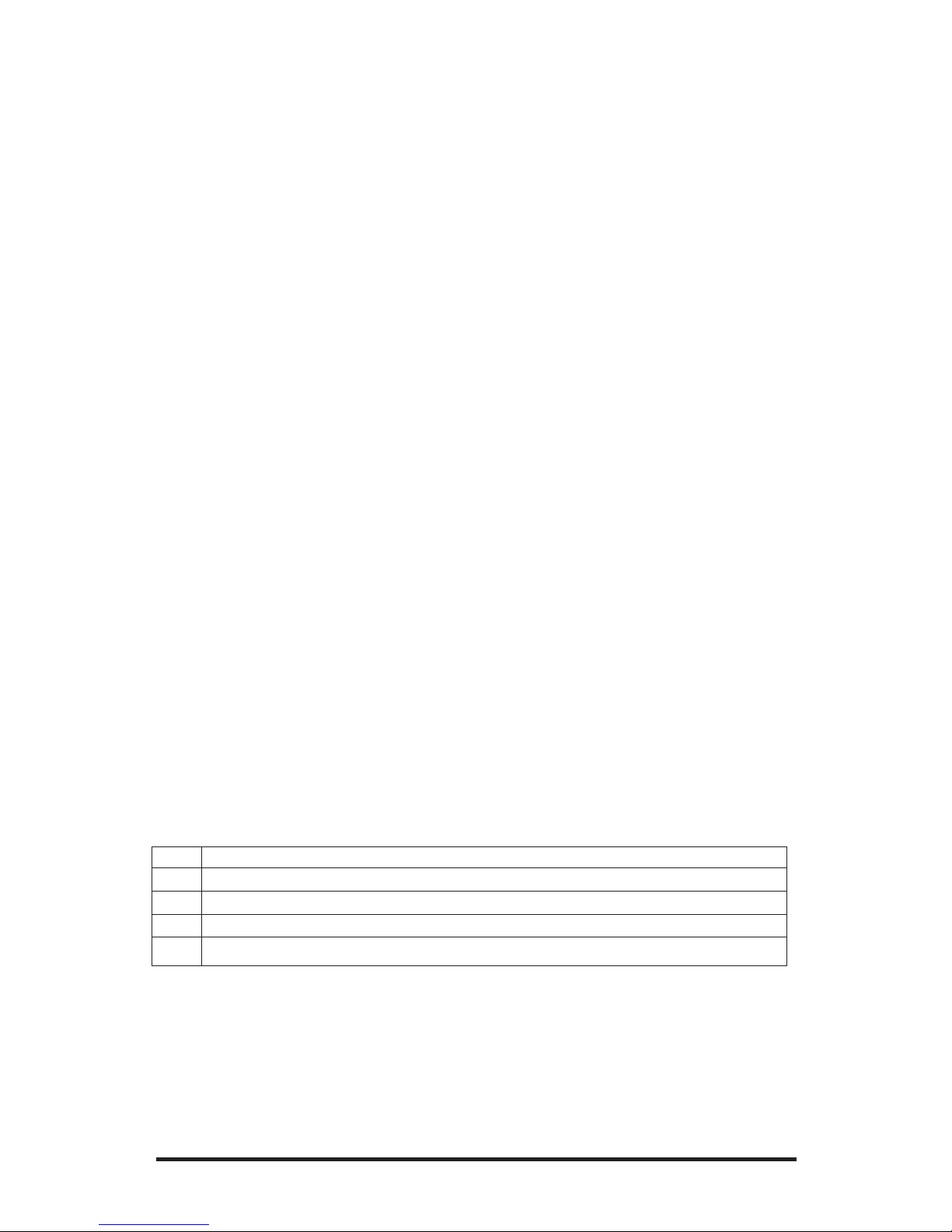

Bit Function

0 Enable 27 speed step mode

1 Enable 28 speed step mode

2 Enable extra functions at engine address + 1 and consist address + 1

3-7 Reserved

Loading...

Loading...