MTH FM TRAINMASTER

DIESEL ENGINE

OPERATING INSTRUCTIONS

Thank you for purchasing the MTH Electric Trains FM Trainmaster diesel

locomotive. This ¼” scale reproduction of the famous FM Trainmaster

locomotive measures over 18” in length and weighs almost 6 pounds.

Despite its scale size, the locomotive is capable of operating on O-31 3-rail

track with any compatible AC transformer, (see page 34 for a complete list

of compatible transformers and wiring instructions) and is completely

compatible with most other 3-rail locomotives, rolling stock and

accessories.

The locomotive is equipped with several deluxe features that are simple

and fun to operate. Each feature is described among the following pages

which should be read before the engine is operated. For those of you who

can’t wait to get started, the Quick Start Operating Instructions, found on

page 3, should be read so that you understand the basics of the operating

system.

2

MTH FM Trainmaster Diesel Operating Manual

Table Of Contents

QUICK START - BASIC OPERATION(All 3-Rail Models) 3

PROTOSMOKE™ UNIT OPERATION 4

PROTOSOUNDS® OPERATING INSTRUCTIONS 5

ProtoSound® DCRU® Reverse Unit Operation (All 3-Rail Models) 5

Horn Operation 6

Bell Operation 6

ProtoCoupler™ Operation 7

Cab Chatter Sounds 8

Squeaking Brake Sounds 8

Tips On Using The Squeaking Brake Sounds 9

Freight Yard Sounds (FYS) 10

Activating and Triggering Freight Yard Sounds 10

Tips On Using FYS Features 15

Self-Recharging Battery Backup System 16

Replacing The ProtoSound® Battery 16

ProtoSound® Volume Adjustment 17

USING “RESET" TO PROGRAM PROTOSOUNDS® 18

Entering RESET Options 18

Setting The Engine Volume 19

Programming For A Separate Bell Button Controller 20

Programming For Squeaking Brake Operation 20

Programming For Horn In Neutral Operation 21

Programming For ProtoCoupler™ Operation 22

Programming For FYS Operation 23

Activating Remote Lockout Control 23

Programming For Cab Chatter Sounds 24

ResettingAll ProtoSound® Options To Factory Default 24

REVERSE UNIT LOCK-OUT OPERATION 25

Locking The Engine Into Forward or Reverse 25

Unlocking The Engine 25

Locking The Engine Into Neutral 25

OIL & LUBRICATION INSTRUCTIONS 27

TRACTION TIRE REPLACEMENT INSTRUCTIONS 28

LIGHT BULB REMOVAL & REPLACEMENT 29

TROUBLE SHOOTING PROTOSOUND® PROBLEMS 30

ProtoSound® RESET Feature Chart 33

Transformer Wiring Chart 34

SERVICE AND WARRANTY INFORMATION 35

HOW TO GET SERVICE 35

LIMITED ONE YEAR WARRANTY 35

3

MTH FM Trainmaster Diesel Operating Manual

QUICK START - BASIC OPERATION

The MTH FM Trainmaster contains state-of-the art electronics with

several built-in automatic features for incredibly realistic operation. Despite

these advanced features, the FM Trainmaster is easy to operate with any

compatible standard AC transformer (see the compatibility chart on page

34). All models are equipped with an operating smoke system that should

be primed with smoke fluid before operating . Adding 20 - 25 drops of

fluid through the smoke stack should be sufficient. If you choose to not

prime the units with fluid , turn the smoke unit switch located under the

trailing truck to the OFF position. (See Figure 1) This will prevent any

damage from occurring to the smoke unit when running the engine without

a primed smoke unit. For more

information see the section on page 4

on Smoke Unit operation.

The FM Trainmaster model is

controlled by a ProtoSound® DCRU®

electronic reverse unit. The reverse

unit operates in the same manner that

all reverse units function by using

forward, neutral and reverse states that

are entered each time the throttle is

turned on and off or by using the

transformer direction switch (if so

equipped).

The reverse unit is designed to

ignore dirty track, dead spots on

switches or minor short circuits

without disrupting the engine

operation, even at slow, prototypical

speeds. Once the engine is placed on the track, the transformer throttle can

be advanced. You will see that only the engine’s lights come on and two

dings from the sound system will chime followed by the air compressor

pump sounds. The engine does not run. This is known as the RESET state

and is explained in more detail beginning on Page 5. The ProtoSound®

DCRU® will not power the motor until the throttle is turned OFF and then

ON again. At this point, the engine will now function just like any other

electronic or mechanical E-unit.

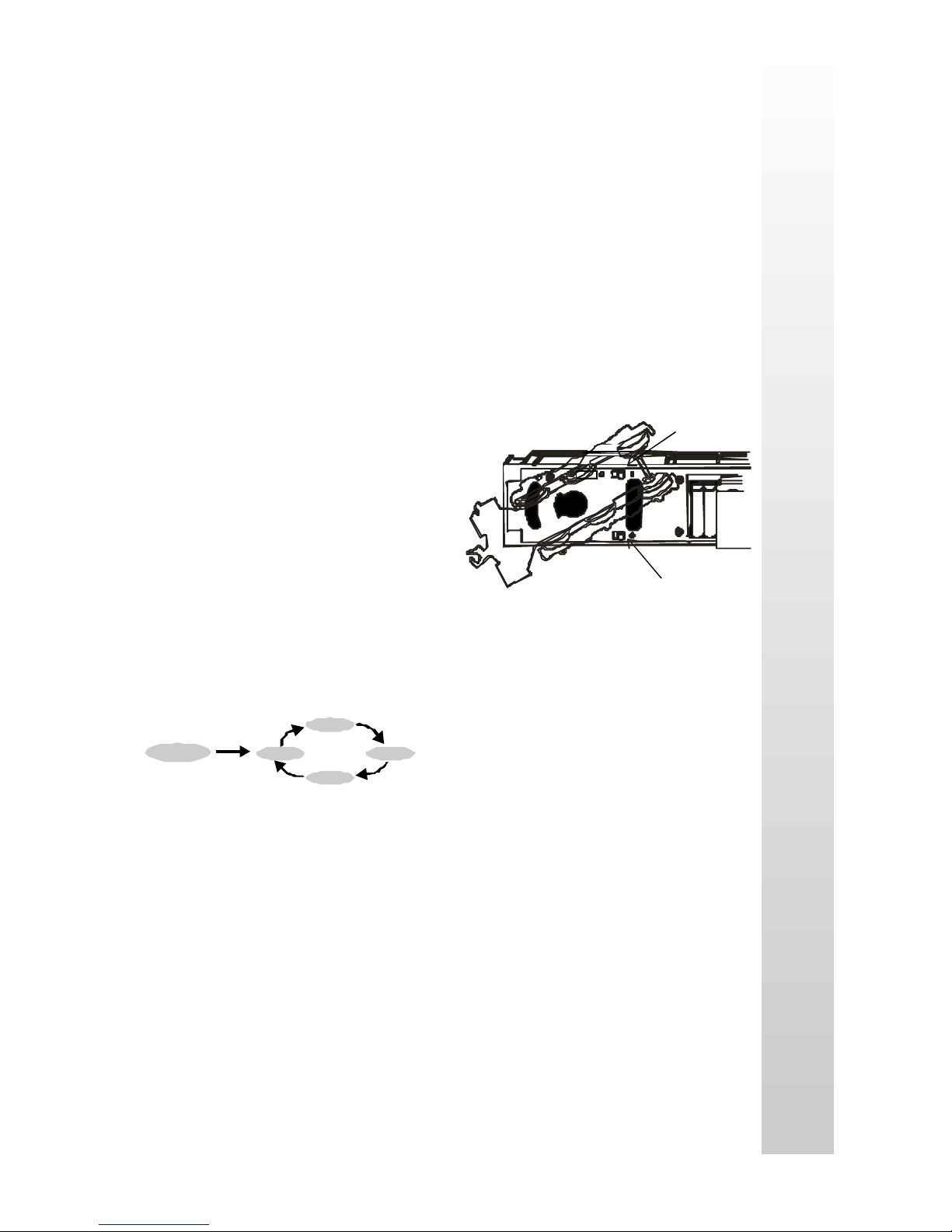

Smoke Unit Switch

ProtoCoupler

Switch

Figure 1: Locating The Smoke Unit Switch

and ProtoCoupler Switch.

RESET

Neutral

Reverse

Neutral

Forward

Figure 2: ProtoSound® DCRU® Cycle Phases

4

MTH FM Trainmaster Diesel Operating Manual

PROTOSMOKE™ UNIT OPERATION

The FM Trainmaster contains a self-powered smoke unit that outputs a steady stream of

smoke through the smoke stack on the roof of the engine. The ON/OFF switch located next to

the power truck must be in the ON position in order for the smoke unit to function. See Fig. 1

on page 3.

The smoke unit is essentially a small heating element and wick which soaks up and then

“cooks" a mineral oil-based fluid that omits a harmless smoke. The smoke is then forced out

of the stack via a small electric fan which runs at a constant speed. However, the smoke

intensity can be varied by increasing the transformer voltage setting. The higher the setting,

the more intense the smoke output.

For best results, we recommend that you add 20 - 25 drops of ProtoSmoke™, Seuthe, LGB or

LVTS fluid before you run the engine. If you don’t choose to add the fluid, then the smoke

unit switch should be turned off. Failure to either add the fluid or turn the switch off could

lead to damage to the smoke unit heating element and or wicking. Add the fluid through the

smoke stack hole. After adding the fluid, gently blow into the stack to eliminate any air

bubbles. Do not overfill the unit as overfilling can cause the fluid to leak out and coat the

interior engine components. When the smoke output begins to diminish while running the

engine, an additional 20-25 drops of smoke fluid should be added or the smoke unit switch

should be turned off. When storing the engine for long periods of time, you may want to add at

least 20 drops of fluid to keep the wick soaked with fluid and prevent it from drying out. After

removing the engine from storage, it is advisable to add another 25 drops of fluid, letting the

wick soak up the fluid for 15 minutes prior to operation.

SMOKE UNIT MAINTENANCE

CAUTION: Operating the engine without smoke fluid and with the smoke unit switch in the

ON position can damage your smoke unit wick, causing the wick to become hard, blackened

and unabsorbant around the heating element.

When this occurs, it may be difficult for the

wick to soak up the smoke fluid resulting in

poor or no smoke output. If that occurs, we

recommend that you inspect and/or replace the

wick taking care to not run the engine without

fluid in the future. You can inspect the wick to

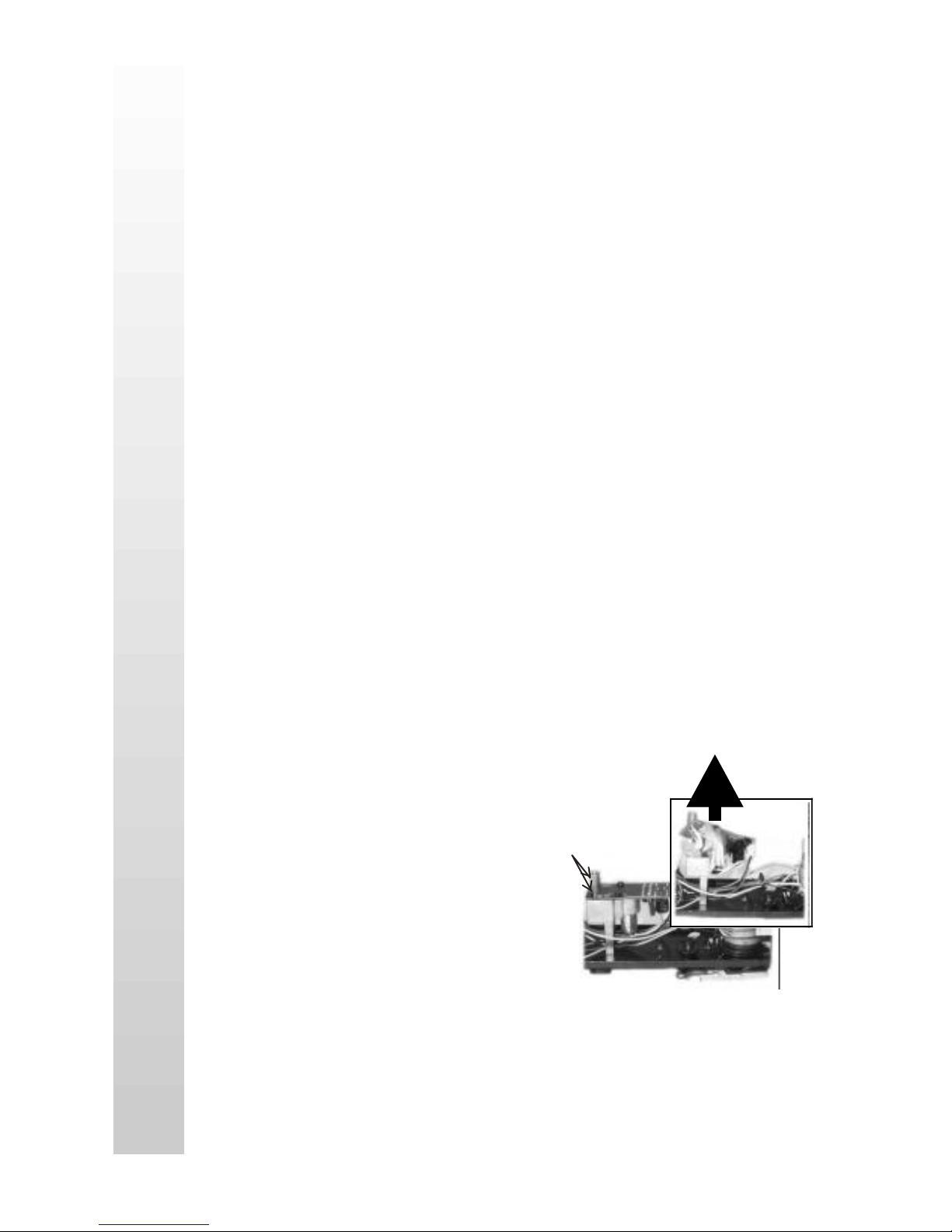

see if it needs replacement by removing the

smoke unit circuit board from the smoke unit

body as seen in Fig.2. After removing the

circuit board screws lift the circuit board away

and inspect the wick. If the wick is darkly

discolored and hard, it should be replaced.

Smoke Unit

Circuit Board

Mounting Screws

After Removing

Mounting Screws,

Lift Circuit Board

To Reveal Wicking

Figure 2: Inspecting The Smoke Unit

5

MTH FM Trainmaster Diesel Operating Manual

PROTOSOUNDS® INSTRUCTIONS

The MTH ProtoSound® digital sound and train control system provides

the operator with unprecedented realistic operation on your model railroad.

In addition to actual diesel engine, CD-equivalent 16-bit digital sounds,

you get the following features:

1.

∗

Built-In ProtoSound® DCRU® Reverse Unit * Authentic Diesel Horn Sound*

Authentic Diesel Bell Sound* Squeaking Brake Sound* Freight Yard Sounds*

Operating Remote Controlled ProtoCoupler™* Self-Recharging Battery

Back-Up System With Automatic Battery Shut-Off* Remotely Controlled

Reverse Unit Lock-Out* Remotely Adjustable Diesel Engine Volume* Authentic

Cab Chatter Neutral Sounds* Authentic Diesel Engine Startup & Shutdown

Sounds *

Each feature is described among the following pages. Though the system

is easy to use, we encourage you to read the instructions thoroughly.

PROTOSOUND® DCRU® REVERSE UNIT

As mentioned in the Basic Operating section, the engine is controlled by a

DCRU® reverse unit that contains the standard forward-neutral-reverse

states found on most reverse units. However, as described earlier, when

power is first applied to the track, the reverse unit begins in RESET or what

seems like a neutral state. Power must be interrupted again to get the

locomotive to enter the forward state. It is this first RESET state that gives

ProtoSound® its unique, remote controlled functions. The system will enter

RESET whenever power to the track is off for three or more seconds.

NEUTRAL will be referred to as the state between Forward and Reverse.

ProtoSounds® is equipped with a microprocessor, that, depending on the

amount of memory it is allotted, allows the user to utilize several remotely

activated functions. In the simplest terms, ProtoSounds® has its own

“Computer" controlling these functions. In fact, the power of this

microprocessor is the same as that of a 286 desktop computer! In order to

access many of these remotely controlled functions, the user must be in the

RESET state to do so. RESET is entered anytime power to the locomotive

has been off for more than 3 to 5 seconds. When the engine first enters

RESET, the microprocessor initiates a system check to determine if the

system, transformer and engine are operating correctly. This takes

approximately 2.2 seconds during which you will hear the engine’s startup

sounds begin. In order for ProtoSounds® to properly initiate the system

6

MTH FM Trainmaster Diesel Operating Manual

check, do not advance the transformer throttle past 10 volts when you first

enter RESET, wait for the diesel startup sounds to begin and then slowly

turn the transformer throttle to the off position and then back on again to

enter the forward phase. Interrupting the power too quickly may cause the

system to re-enter RESET (signaled by two dings of the bell). Should this

happen, wait longer before interrupting the power to enter the Forward

phase.

ProtoSounds® comes with several programmable functions, including

remote Diesel Engine Volume Adjustment, Separate Bell Button Operation

(pre-programmed at the factory), Horn In Neutral Operation,

ProtoCoupler™ On/Off Control, Squeaking Brakes and Passenger Station

or Freight Yard Proto-Effects. Each of these features are described in more

detail later. You will notice that when in RESET, your engine will not

respond to the whistle button with a horn blast or continuous bell ringing.

In fact, when in RESET and the whistle button is depressed, only one single

bell chime will be heard each time the whistle button is pressed. If you

don’t want to configure or change your locomotive using any of these

programmable features, simply leave RESET and wait 2.2 seconds before

interrupting the power to put the engine in forward. After you leave

RESET, your engine will operate normally in all the direction states of

forward, neutral and reverse. Remember though, once power is turned off

for more than 3 seconds, the next time power is applied to the track, your

engine will be back in RESET.

HORN OPERATION

Your FM Trainmaster ProtoSound®-equipped engine is equipped with a

digital recording of a diesel horn. The horn sound can be activated anytime

the engine is in forward or reverse by pressing the whistle button on your

transformer. The horn will continue to blow as long as the whistle button is

depressed. The horn will not function in RESET and must be configured

through a RESET option to allow the whistle to work when the engine is in

neutral. See page 21 for information on horn programming in the Using

RESET To Program ProtoSounds® section of this manual.

BELL OPERATION

Your FM Trainmaster ProtoSound®-equipped engine is equipped with a

digital recording of an actual diesel engine bell. The bell can be turned on

or off with any separate bell button, like the Lionel® Railsounds® No. 5906

7

MTH FM Trainmaster Diesel Operating Manual

Bell Button, by simply pushing the button. If you don’t have a separate

bell button, the bell can be controlled through your transformer’s whistle

button whenever the engine is in NEUTRAL. The bell will never ring

continuously in RESET (Remember NEUTRAL is the state between

Forward and Reverse). Once the bell is turned on, it will continue to ring

when the engine is cycled into forward or reverse until you press the bell

button or re-enter NEUTRAL and turn the bell off with the whistle button.

In fact, because of ProtoSounds® state-of-the-art design, the

microprocessor remembers its last command. Therefore, unless you turn

the bell off before you quit running your train, the next time you run the

engine, the bell will come on. No matter whether you come back an hour

later or a year later, the bell will begin chiming once the engine enters one

of the three directional states.

To turn the bell on using the transformer’s whistle button, turn on power to

the track and cycle the engine into NEUTRAL. Turn the throttle to 8 volts

or less (any higher voltage will arm the ProtoCoupler™) and press the

whistle button. The bell should begin chiming. To turn the bell off, press

the whistle button again. If you want to keep the bell on while running the

engine, simply interrupt the power with the transformer throttle or the

transformer directional switch and enter forward or reverse.

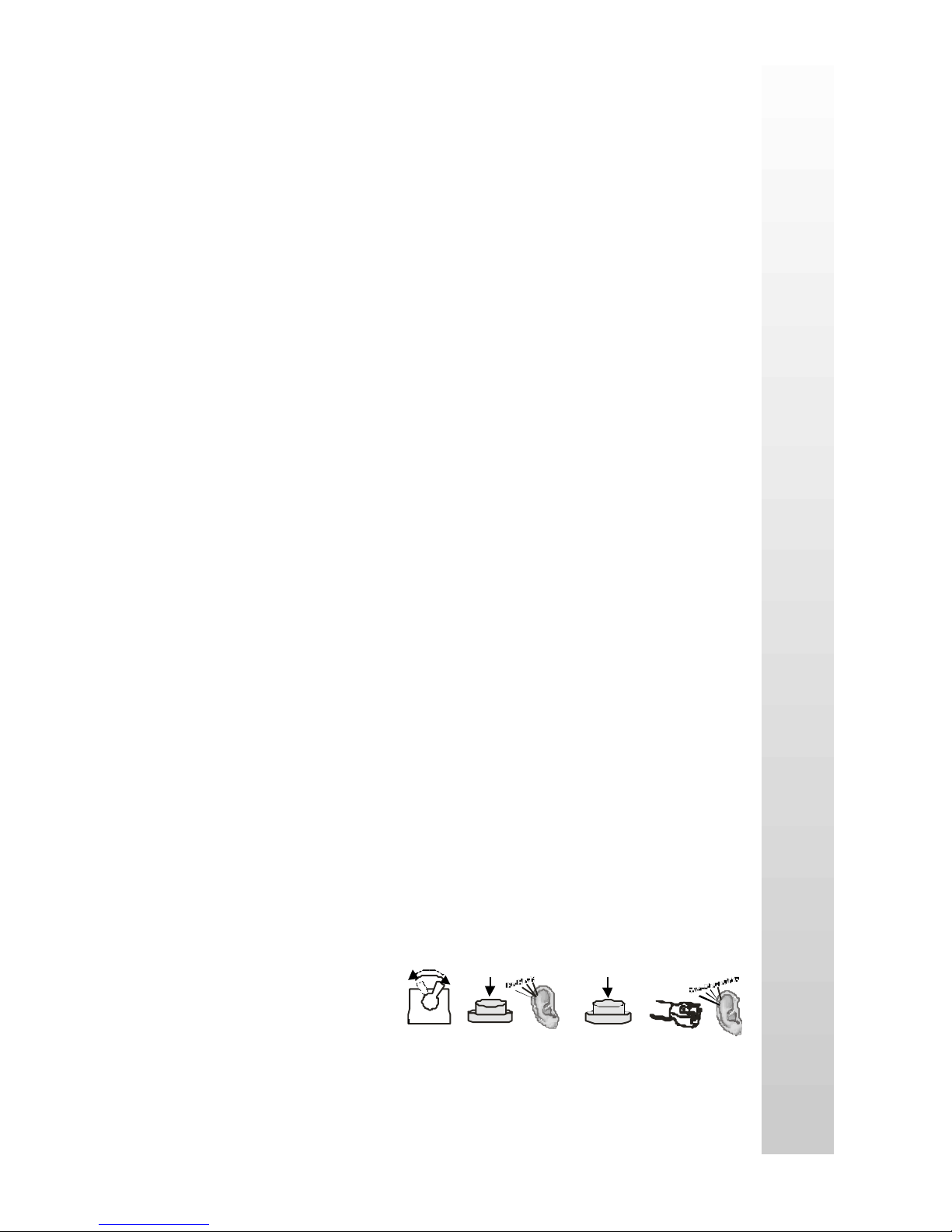

PROTO-COUPLER™ OPERATION

Your FM Trainmaster ProtoSound®-equipped locomotive is equipped

with two coil-wound ProtoCouplers™ for remote uncoupling action.

Because the ProtoCoupler™ is controlled through ProtoSounds®

microprocessor, it doesn’t require an uncoupling track section or

modification to your layout to function. The three simple steps below are

required to operate the coupler.

1. Put your engine in NEUTRAL and turn the throttle all the way up.

2. Press the transformer whistle button to “Arm" the coupler. (You

will hear a “Clank").

3. After arming the

coupler, press the whistle

button again to open the

coupler. H H

Put Engine In Neutral

At Full Power

Press & Release

The Whistle Button

Press & Release

The Whistle Button

Listen For The

Ca-Clunk Sound

See The Coupler Open

And Listen For The

Cha-Chusshh Sound

8

MTH FM Trainmaster Diesel Operating Manual

When the knuckle fires open you will hear the buzzing of the coil

energizing and the sound of the air lines coming apart. It can best be

described as a CHA-CHUSHHH sound. The coupler doesn’t have to be

fired in NEUTRAL. Once the

coupler is armed it can be fired

in Forward, Neutral or Reverse.

However, you may find that the

coupler doesn’t open when

firing the coupler at high

speeds. Reduce the voltage

setting on your transformer if

this occurs and run your engine

at a slower speed before firing

the coupler. If the coupler

continues to open erratically, try lubricating the knuckle with light oil as

indicated in Fig. 3.

For multiple heading purposes, only one of the two ProtoCouplers™ will

function at any one time. Use the coupler direction switch as shown in

Figure 1 on page 3 to select either the front or rear coupler. Simply slide

the switch toward the direction of the coupler you want to make active.

NEUTRAL-ACTIVATED CAB CHATTER SOUNDS

Your engine is equipped with four dispatacher-to-engineer “Cab Chatter”

radio transmissions that occur every 2 to 30 seconds. Each sequence will

play at random intervals to eliminate repetition. While the sounds are

selected to play randomly by the microprocessor, there is no guarantee that

you won’t hear the same message repeated twice or more times.

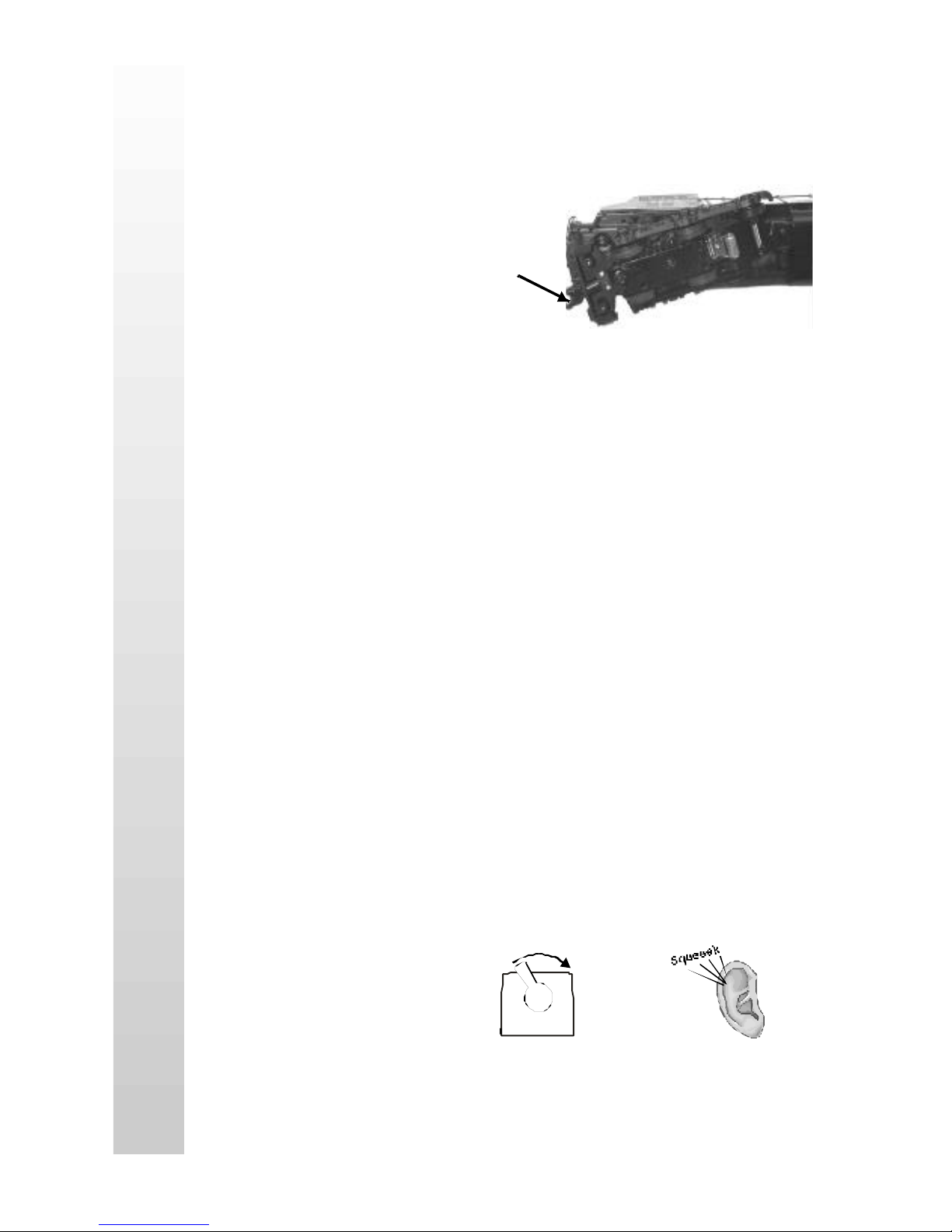

SQUEAKING BRAKE SOUNDS

ProtoSound® equipped engines feature the ability to play the sound of

squeaking brakes whenever your engine slows in speed. There are two

settings for activating the squeaking brake sounds. The default setting

allows the brake sounds to play

while the engine is in forward or

reverse and the transformer

throttle is lowered from a high

setting (greater than 14v) to a

low setting (less than 8v). The

second setting requires that a bell

Lubricate

ProtoCoupler™

Knuckle

Figure 3: Lubricating The ProtoCouplers

Throttle Down From

High Voltage To Low

Listen For The

Squeaking Brake Sounds

9

MTH FM Trainmaster Diesel Operating Manual

button be used to “arm” the brake feature and is explained in more detail in

the “Activating Freight Yard Sounds” section found later in this manual.

The sound itself is a stored recording on the ProtoSounds® software chip

and will always play the same brake sound for the same three second length

each time the voltage is reduced from high to low. Some practice may be

required to synchronize the playing of the brake sounds with the movement

of the engine. It is not uncommon for the engine to stop before the brake

sound is completed. Operators will find that by coordinating the movement

of the throttle setting from 8 volts to off will allow the engine to maintain its

movement while the brake sounds play. Note: The brake sounds will not

be heard if the transformer throttle is not set above 14 volts, then

reduced below 8 volts.

TIPS ON USING THE SQUEAKING BRAKE FEATURE

Because the squeaking brake feature always plays for approximately 3

seconds, it is possible that the brake sounds will play longer or shorter than

what visually seems prototypical. You will find that by practicing with the

brake feature, you can quickly determine how quickly to throttle down and

which speeds and voltage settings will give you the most prototypical braking

effect.

Typical users will find the feature to be a very realistic way to simulate the

sound of an engine slowing down for curves, crossings or coming to a stop at a

station, side track or switch yard. As mentioned above, you will find that

initially your engine may continue to play the brake sounds once your engine

comes to a stop or that the sounds stop prematurely before the engine comes to

a complete halt. For example, if you simply run the engine and turn the throttle

off quickly, the brake sounds will likely continue playing even though the

engine has come to a complete stop. This annoying effect can be eliminated by

simply practicing with the brake feature. In no time, you will quickly learn

how to “feather" the throttle to keep the engine moving while the brake sounds

play and then turning the throttle off just as the sounds stop. Remember that

once you stop the engine, you should turn the throttle to the off position if you

don’t want to activate the Freight Yard Sounds feature described later in this

manual.

The ProtoSound® squeaking brake feature also has the ability to simulate the

squeal of wheel flanges when your train enters a curve at high speeds. The

same brake squeaking sound plays, but you don’t need to reduce the

transformer throttle to activate the squeaking sounds. To play the squeaking

sounds as wheel flange sounds, trigger the brake feature using either method 1

or 2 above. Once triggered set the transformer throttle setting at 14 volts or

higher. As your engine enters a curve (or anywhere on the layout) quickly

“flick" your transformer whistle button about half way. This “flicking" action

causes the transformer to release a short DC signal that ProtoSounds® reads as

an indicator to activate the brake sounds. The engine won’t slow down even

though the sounds play. This simulates the wheel flange squeal of a train

traveling through a turn too quickly.

10

MTH FM Trainmaster Diesel Operating Manual

FREIGHT YARD SOUNDS (FYS)

ProtoSounds® comes equipped with operator controlled Freight Yard

Sounds, hereby referred to as FYS. This easy to use feature plays digitally

reproduced freight yard sounds whenever your engine stops on your layout

and is parked in the Neutral position. No additional wires or modifications

are needed on your layout to enjoy these amazing sound effects. The

sounds themselves are randomly generated and randomly “shuffled” on the

ProtoSounds® software chip. This gives the system the ability to produce

different sounds in a different order each time FYS is enabled. These

different sounds are heard each time you cycle the transformer throttle from

ON to OFF in the same manner that you would cycle the throttle to enter the

various states of Forward, Neutral and Reverse. The entire FYS sequence is

designed to simulate the arrival, loading or unloading and departure of a

freight train in a freight yard. Each sequence is described in more detail in

the following sections.

USING FREIGHT YARD SOUNDS

Your ProtoSound® equipped engine features an operator controlled freight

yard sound set. Once activated, this easy-to-use feature plays the sound of

freight yard activitities whenever the operator parks the engine in the

neutral position.

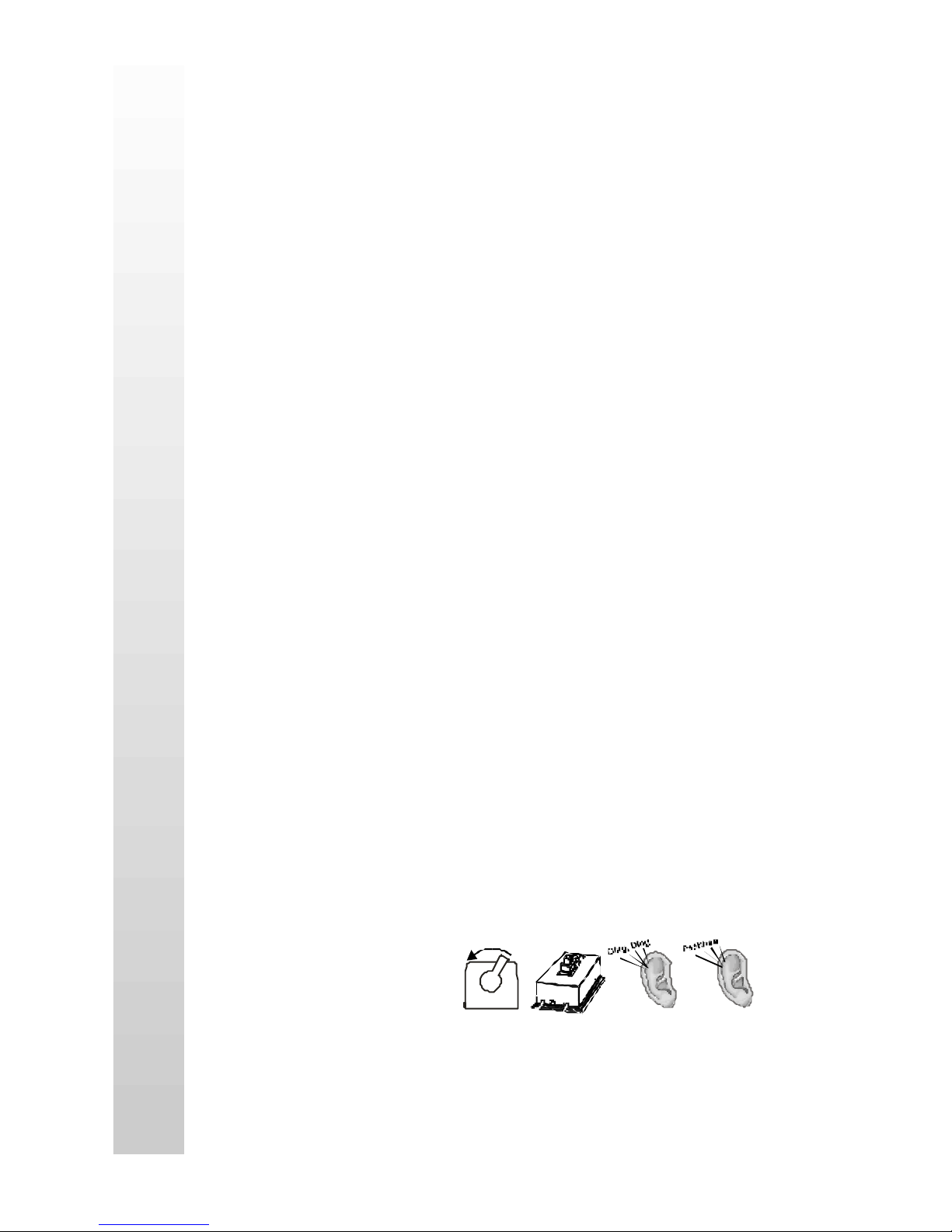

ARMING THE FREIGHT YARD FEATURE

Before FYS can be heard, ProtoSound® must be told to activate the

feature the next time the engine enters the neutral position. This can be

accomplished in one of two ways.

Option 1: If you are using a separate bell button controller to ring your

bell (like the Lionel® Railsounds® number 5906 bell activation button),

you can activate the feature by pressing and holding down the bell button

for three or more

seconds (it doesn’t

matter if you are in

Forward, Neutral or

Reverse). You will hear

the bell chiming turn on

and if you listen

Put Engine In Neutral,

Forward or Reverse

Press & Hold

The Railsounds® Bell Button

For 3 Seconds

Listen For The

Start Of The Bell Sound

Listen For The

Air Release Sound

After 3 Seconds

11

MTH FM Trainmaster Diesel Operating Manual

carefully, you should hear an air release sound after three seconds have

passed. At this time you can release the bell button. (Note: because the air

release sound may be difficult to hear, we recommend that you count out a

full three seconds before releasing the bell button.) The bell will continue

to chime, so if you want to turn off the bell ringing, simply press and release

the bell button a second time. If you were in Neutral when you triggered

the brake feature, interrupt the transformer throttle to enter either forward or

reverse and allow the engine to begin moving. (Note: the feature will only

be activated in the first direction state you enter after arming the feature

from the Neutral position. You cannot interrupt the power twice to enter

another direction state and still have the brake feature active.) Once your

engine begins moving, you can trigger the sounds to begin playing

whenever you enter Neutral.

Option 2: If you do not have a separate bell button on your layout, you

can still activate the feature with your transformer whistle button. To

activate the feature, turn on the transformer throttle and get your engine into

the Neutral position (not RESET). Once in Neutral, set the transformer

throttle at 8 volts or less and press and hold the whistle button for at least

three seconds. You will hear the bell chiming begin and if you listen

carefully, you should hear an air release sound after three seconds have

passed. At this time you can release the whistle button. (Note: because the

air release sound may be difficult to hear, we recommend that you count out

a full three seconds before releasing the whistle button.) The bell will

continue to chime, so if you want to turn off the bell ringing, simply press

and release the whistle

button a second time.

Interrupt the transformer

throttle to enter either

forward or reverse and

allow the engine to begin

moving. (Note: the feature

will only be activated in the

first direction state you enter after arming the feature from the Neutral

position. You cannot interrupt the power twice to enter another direction

state and still have the brake feature active.) Once your engine begins

moving, you can trigger the sounds to begin playing whenever you re-enter

Neutral.

Put Engine In Neutral

At Low Power

Press & Hold

The Whistle Button

For 3 Seconds

Listen For The

Start Of The Bell Sound

Listen For The

Air Release Sound

After 3 Seconds

H

12

MTH FM Trainmaster Diesel Operating Manual

ACTIVATING THE FREIGHT YARD SOUNDS

Before FYS can be heard, the feature must be armed as described on the

proceeding pages. Once armed, activating the FYS effects is accomplished

by simply interrupting the transformer throttle and parking the engine in the

Neutral position with track power remaining on. Remember, power to the

track must remain on while the engine sits in Neutral in order for the FYS

effects to operate.

At this point ProtoSounds® has taken over control of your engine and

disabled the bell and whistle buttons from responding to any futher operator

input. In addition, ProtoSounds® has reconfigured the way the reverse unit

functions by disabling the Reverse state during operation of the FYS

effects. This forces the engine to leave your freight yard in the same

direction that it arrived in. The following operator controlled “events”

control FYS’s actions and sound effects.

Event 1 (Forward) While the locomotive is running in forward (or

reverse) FYS is activated by the operator pushing and holding the bell

button down for three or more seconds. The locomotive bell begins

chiming and can be left on or turned off without disabling FYS.

Event 2 (Neural Before Reverse) The operator now interrupts the

transformer throttle to stop the engine and put it into Neutral. If the throttle

setting was at 14 volts or higher , ProtoSounds® will play the sound of

squeaking brake sounds as the engine comes to a halt.

A. Upon stopping of the engine, the operator must immediately turn

the throttle back on to keep the engine in the Neutral position. If the

bell was not turned off after activating

FYS, it now turns off automatically.

Note: Failure to turn the throttle back

on within 3 seconds of leaving the

Forward phase will disable FYS and

shutdown ProtoSounds®. The next time

you turn power back on your engine will

be in the RESET position. See page 5 for more information on

RESET.

Put Engine In Neutral

At Low Power

13

MTH FM Trainmaster Diesel Operating Manual

B. After entering Neutral, ProtoSounds® will immediately play an

air release sound followed approximately 2 seconds later by a radio

arrival message (cab chatter).

Immediately following the radio arrival

message, the sound of freight car doors

can be heard opening, followed by the

sounds of freight loading and unloading.

At this point various freight yard sounds

can be heard including the

loading/unloading operation, engine

sounds, yardman “slang”, and additional

freight car door sounds.

Event 3: (Reverse) The operator now interrupts the transformer throttle

again to enter the next reverse unit phase; reverse. In an effort to enhance

realism, FYS has disabled the reverse

phase so that it doesn’t power the motors

causing the engine to move backward.

Upon entering reverse, FYS confirms to

the operator that it has entered the reverse

phase by immediately playing a highlight

sound best described as a rumbling sound.

You may have to go through the entire

FYS sequence several times before you can

clearly identify this sound. After the rumbling highlight is played, the

freight yard sounds heard in Event 2 continue to play randomly.

Event 4: (Neutral Before Forward) The operator now interrupts the

transformer throttle again to enter the next reverse unit phase, neutral before

forward. FYS confirms to the operator that it has entered the neutral before

forward phase by emitting two quick air release sounds. This is followed

approximately two seconds later by a radio

departing message and continued freight

yard loading and unloading sounds.

Event 5: (Forward) The operator now

interrupts the transformer throttle again to

enter the next reverse unit phase; Forward.

Listen For Air Release Sound

And Cab Chatter Message

Listen For Engine

Rumbling Sound

Interrupt Throttle To

Enter The Next Phase

Listen For 2

Air Release Sounds

Interrupt Throttle To

Enter The Next Phase

14

MTH FM Trainmaster Diesel Operating Manual

FYS confirms to the operator that it has entered the Forward phase by

playing a radio message followed by the freight car door closing. Within 2

seconds of the door closing, the locomotive will give two or three whistle

blasts depending on leaving direction. Followed by the bell chiming. After

approximately 8 chimes of the bell, the

engine begins moving in the forward phase

with the bell continuing to ring another 8

chimes before automatically turning off.

Once the bell turns off, the operator regains

control of the transformer whistle and bell

buttons and can ring the bell or blow the

whistle as usual.

Note:

When entering the Forward phase of FYS, it

is important to set the transformer throttle at a high enough setting that will allow the engine

to begin moving once FYS automatically activates the motors. Otherwise the engine will just

sit still until you increase the transformer throttle setting on the transformer. However, don’t

set the throttle setting too high or the engine will go racing away faster than you might expect.

TIPS ON USING FYS FEATURES

FYS is a unique feature of ProtoSounds® that is completely controlled by the

operator. You decide how, when or if you want to utilize the feature. By

reviewing the following tips, you should find solutions or suggestions to the

various operating scenarios you might encounter when using FYS.

Tip #1: You can escape the FYS sequence by interrupting the transformer

throttle before the radio message in Event 2 (neutral before reverse).

Tip #2: You can terminate FYS at anytime by turning the transformer

throttle Off for 15 seconds.

Tip #3: You do not have to be in the Forward phase to utilize FYS. For

example, if you activate the FYS feature while in Reverse and interrupt the

throttle to enter Neutral, you will be entering Neutral Before Forward rather

than Neutral Before Reverse as defined in Event 2 above. Consequently, the

Forward phase will be rendered inactive by ProtoSounds® instead of the

Reverse phase as explained in Event 3. This will allow your train to leave the

yard in the reverse direction that it arrived.

Listen For The Sound

Of Box Door Closing

Interrupt Throttle To

Enter The Next Phase

15

MTH FM Trainmaster Diesel Operating Manual

Tip #4: You can utilize FYS even if you are double-heading with another

engine regardless of whether the second engine is equipped with an FYS

programmed ProtoSound® module. If the second engine isn’t equipped with

FYS, the only thing to remember is that you not turn up the transformer throttle

very high when entering the Reverse phase found in Event 3. If the throttle is

set too high, then the second locomotive will begin vibrating on the track as its

motors will be turning in the reverse state since they cannot be disabled

automatically like FYS equipped engines. If your second engine is equipped

with FYS, you may want to disable it when used in double-headed operations.

To disable FYS, see the section on programming for squeaking brakes and FYS

operation on page 22 and page 23 of this manual.

Tip #5: It is not necessary for the squeaking brake sounds to be heard to play

the FYS sounds. For example, the brake sounds won’t be heard if the high

voltage setting is below 13 volts when the power is interrupted to enter the

Neutral state.

Tip #6: You can leave any of the event states at any time after entering the

state by simply interrupting the transformer throttle. Any sound effects

programmed to play in that event will simply not occur. The only exception is

Event 2 and Event 5. In Event 2, interrupting the throttle has no effect on FYS

until after the radio message and the freight car doors have opened. In Event 5,

you cannot interrupt FYS until after the engine begins to move. Interrupting

the throttle before the engine begins to move has no affect on the locomotive’s

operation.

16

MTH FM Trainmaster Diesel Operating Manual

Note: Consistent activation of the wheel flange squealing is determined by the condition of

your transformer’s whistle button rectifier disc. Older rectifier discs may need to be replaced

in order to play squealing sounds.

SELF-RECHARGING BATTERY BACKUP

ProtoSounds® state-of-the-art design includes a self-recharging battery

backup system for improved performance at any speed. The battery ensures

that power to the sound system will remain on during directional changes,

setting RESET options or when travelling over dirty track and switches.

The self-recharging battery backup system is automatically turned on or off

whenever track power is turned on or off. There are no switches needed to

enjoy the benefits of the automatic battery backup system.

ProtoSounds® contains a warning alarm if the battery backup system fails

to automatically disengage when track power is turned off. Should the

backup system fail, you will hear a repeating whistle blast indicating this

has occurred. Should this happen, unplug the battery from the

ProtoSound® module (to prevent the battery from being run down) and

contact MTH for instructions on returning the locomotive for repair.

REPLACING THE PROTOSOUND® BATTERY

The ProtoSound® battery (located inside the cab body), is a special NiCad

7-cell, 8.4v battery - NOT the 6-cell, 7.2v battery found in most

convenience stores. The 6-cell NiCad is NOT recommended for use with

ProtoSound® applications. The battery is continually charged from the

track when power is applied and should last for up to five years. In

addition, the NiCad battery is a dry battery and should not leak or cause any

damage to your locomotive during its lifetime.

If you notice that the sounds seem distorted or garbled at low voltages or

become silent when power from the transformer is shut off, the battery may

be going bad. Before replacing the battery, you should put the engine in

NEUTRAL and leave the transformer throttle set at about 12 volts for 15

minutes. This should temporarily recharge the battery. If the garbled or

distorted sounds are reduced, then your battery charge has worn down. You

can give your battery a full charge by leaving the engine ON in the

NEUTRAL position for 18 hours. (Make sure the smoke unit switch is in

the OFF position to prevent harm to the smoke unit wicking).

17

MTH FM Trainmaster Diesel Operating Manual

If you need to replace the battery, replacement ProtoSound® batteries are

available from MTH ProtoSound® Electronics at 7020 Columbia Gateway

Drive, Columbia, MD 21046. A standard 9v alkaline battery can be

substituted as a temporary fix, but since alkaline batteries can’t take a

charge, it will eventually wear down. Regardless, it should give you a week

to a couple of months use while you wait for your replacement

ProtoSound® battery to arrive.

PROTOSOUND® VOLUME ADJUSTMENT

Your ProtoSound® system has two types of volume adjustment. A

manual turn knob on the bottom of the chassis (See Fig. 4 below) allows

you to control all the sounds in the system and a remote control “RESET"

option (Option # 6), allows you to control the volume level of the engine

sounds remotely from the transformer. Turning the volume adjustment

knob clockwise will increase the volume and counterclockwise will lower

the volume of all sounds; bell, horn, engine sounds, Cab Chatter, etc. For

information on operating the RESET volume adjustment option, see the

section entitled “Programming ProtoSound RESET Options” on the

following pages.

Proto-Sound® Volume Adjustment Knob

Figure 4: Adjusting The ProtoSound® Volume and selecting the ProtoCoupler

18

MTH FM Trainmaster Diesel Operating Manual

USING “RESET" TO PROGRAM

PROTOSOUNDS®

As mentioned earlier, there are several programmable options in each

ProtoSound®-equipped engine that can be remotely set from any

compatible standard AC transformer equipped with a whistle button. For a

list of compatible transformers, see the chart on page 34. This hands-off

approach gives you unprecedented control of your railroad empire’s motive

power never before seen in model railroading. Each programmable feature

can be accessed whenever your engine is in the RESET state as described

earlier on page 5. By following the instructions below you will find the

programming easy and straight forward.

ENTERING RESET OPTIONS

ProtoSound® is equipped with a few programmable features that are

accessed in the RESET state by moving the transformer throttle up and

down between full voltage and low voltage (8 volts or less) without shutting

the transformer off completely. Each time this is done you advance, one

feature at a time, through the available options. An air-release sound is

heard each time the throttle is advanced. In addition, there are special

sounds to tell you what RESET position you are in.

For example, if you want to select Feature 2, you put the engine in

RESET, and move the throttle up and down from full throttle to low two

times. After the second advance, you will hear two “clinks" indicating that

the computer is now in Feature 2. Advance the throttle again and you will

hear three “clinks" for Feature 3. Advance it two more times and you will

hear a “clank" indicating

that you are now in

Feature 5. Advance the

throttle two more times

and you will hear a

“clank" and two “clinks"

indicating Feature 7. ((5

throttle advancements = 1

clank) + (2 throttle

advancements = 2 clinks)). “Clank + “Clink" + “Clink" = Feature 7. You

can advance the throttle as quickly as you like (though you may not hear the

air-release sounds) and the computer will still remember the number of

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

2 Times

Advance The Throttle

Up & Down From

High Voltage To Low

4 More Times

Listen For The

2 Clink Sounds

Listen For 1 Clank

And 1 Clink Sounds

19

MTH FM Trainmaster Diesel Operating Manual

times the throttle is advanced by playing back the number of “Clinks" and

“Clanks" to confirm the feature you’ve selected.

SETTING THE ENGINE VOLUME

Of all the sounds that come with each ProtoSound®-equipped locomotive,

the one most often turned down is that of the engine volume because it is

the one sound normally heard whenever the engine is running and is what

usually can become tiresome to the ear over prolonged running sessions.

The volume adjustment is controlled through RESET Feature 6.

To access the feature, advance the transformer throttle to put the engine in

RESET. Move the throttle up and down, as described on page 18, 6 times.

After you hear the “clank" and “clink" indicating that you are in Feature 6,

press the whistle button to select the engine volume level you desire.

Pushing the whistle button once will give you full volume, which is the

factory setting. Pushing the whistle button a second time will give you 50%

volume, pushing it a third time will give you 25% volume and pushing it a

fourth time will give you no sound. The microprocessor will immediately

play the sound level each time the whistle button is pushed so that you can

decide if it is acceptable. You can recycle through the four choices by

simply continuing to

press the whistle button.

Once you have decided

on the appropriate

volume level, turn the

transformer throttle off

and on again or press

the transformer direction switch to lock in your selection. The volume

adjustment will remain set at the level you have chosen until you change it

again. Regardless of the engine volume setting, the horn, bell, compressor

and Cab Chatter sounds will function normally. In fact because only the

engine volume is affected by selections in Feature 6, when you select 0

volume, you can still hear the horn, bell and Cab Chatter sounds when the

engine is running or in neutral.

In RESET Mode

Move The Throttle

Up & Down From

6 Times

Listen For 1 Clank

And 1 Clink Sounds

Push The Whistle Button

Until You Reach The

Setting You Desire

Interrupt The Throttle

To “Lock-In”

The Volume Setting

H

20

MTH FM Trainmaster Diesel Operating Manual

PROGRAMMING FOR A SEPARATE BELL BUTTON

CONTROLLER

To operate ProtoSounds® with

a separate bell button controller,

like the Lionel® No. 5906 bell

button, you will need to wire up

the controller to your

transformer and track as shown

in Fig. 5. Once the button is

wired, ProtoSounds® comes

preprogrammed to allow you to

operate the bell by simply

pushing the bell button once.

To turn the bell off, push the

button again. If the bell doesn’t’t function when you press the button, you

may need to re-program ProtoSounds® to operate with a separate bell

button controller. To do this enter RESET and go to Feature 20. (See the

section Using RESET To Program ProtoSounds®on page 18.) Once in

Feature 20, press the whistle button and wait for the module to sound a bell

ding(s). Continue

pushing the whistle

button until the module

plays back two dings

(signifying that the

module has been

programmed for a bell

button). Simply turn the

throttle off and then on again to “Lock-In" the new setting. To reset the

computer to its original factory (default) setting (separate bell button

operation), repeat the above procedure but keep pushing the whistle button

until the computer only responds with one bell ding.

PROGRAMMING FOR SQUEAKING BRAKE

OPERATION

ProtoSounds® can be programmed for squeaking brake operation in three

different manners; (1)Squeaking brakes can be activated by bell button

control, (2)they can be programmed for continuous operation subject to

throttle changes or (3)they can be programmed to be turned off. The default

setting is (2) Squeaking brakes are activated for full-time operation as

described on page 8. To change the default setting, enter RESET and go to

Common

RED Wire

BLACK Wire

UAUBUCU

D

Figure 5: Wiring Up A Bell Button

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

20 Times

Listen For 5 Clank

And 0 Clink Sounds

Push The Whistle Button

Until You Hear 2 Dings

Interrupt The Throttle

To “Lock-In”

The Bell Button Setting

H

21

MTH FM Trainmaster Diesel Operating Manual

Feature 45. (See the section Using RESET To Program ProtoSounds® on

page 18 ). Once in Feature 45, press the whistle button and wait for the

module to sound a bell ding(s). Continue pressing the whistle button until

the module plays back one ding for option 1 - Squeaking brakes are

activated by the bell button. Press the whistle button again until the module

plays back two dings for option 2 - squeaking brakes are activated for

full-time operation, or

press the whistle button

again until the module

plays back three dings for

option 3 -Squeaking

brakes off. Once you

have decided on the

desired setting, simply

turn the throttle off and

then on again to “Lock-In” the new setting. To reset the computer to its

original factory default setting (option 2 - squeaking brakes are activated for

full-time operation), repeat the above procedure but keep pushing the

whistle button until the module only responds with two bell dings.

PROGRAMMING FOR HORN IN NEUTRAL

OPERATION

If you are operating your engine with a separate bell button and want to

blow your horn when your engine is in neutral, you will need to program

ProtoSounds® to do so as the factory setting only allows the horn to blow in

forward or reverse. To do this, enter RESET and go to Feature 25. (See the

section Using RESET To

Program ProtoSounds® on

page 18.) Once in Feature 25,

press the transformer whistle

button and wait for

ProtoSounds® to sound a bell

ding(s). Continue pressing

the whistle button until

ProtoSounds® sounds two

bell dings (signifying that

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

25 Times

Listen For 5 Clank

And 0 Clink Sounds

Push The Whistle Button

Until You Hear

2 Bell Dings

Interrupt The Throttle

To “Lock-In”

The Horn Setting

H

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

45 Times

Listen For 9 Clank

And 0 Clink Sounds

Push The Whistle Button

Until You Hear The

Appropriate # Of Dings

Interrupt The Throttle

To “Lock-In”

The Brake Setting

H

22

MTH FM Trainmaster Diesel Operating Manual

ProtoSounds® has been programmed to sound the horn in neutral). Turn

the throttle off and then on again to “Lock-In" your selection. Now,

whenever you are in neutral, you can blow the horn with the transformer

whistle button. To reset ProtoSounds® to its original factory setting of no

horn in neutral, repeat the above procedure but keep pressing the whistle

button in Feature 25 until ProtoSounds® only dings once instead of twice.

Note: When “Whistle In Neutral" is set, the bell will only operate with a separate bell button

and the horn will not sound in neutral if the transformer throttle setting is over 11 volts. At 11

volts or higher, ProtoSounds® may arm the coil coupler for operation whenever the whistle

button is pressed and the engine is in neutral.

PROGRAMMING FOR PROTOCOUPLER OPERATION

ProtoSounds® comes with

a RESET feature that allows

the operator to remotely turn

off the ProtoCoupler™

functions. This is especially

useful when double or

triple-heading ProtoSound®

equipped engines since every

engine equipped with a

ProtoCoupler™ will fire

when prompted to by the

operator. By turning off the ProtoCoupler™ operation on certain engines,

you can fire the couplers open on the other engines without uncoupling the

engines from each other. To turn the ProtoCoupler™ function off, enter

RESET and go to Feature 10. (See the section on Using RESET To

Program ProtoSounds® on page 18.) Once in Feature 10, press the

transformer whistle button and wait for ProtoSound® to sound a bell

ding(s). Continue pressing the whistle button until ProtoSounds® sounds

two bell dings (signifying that the ProtoCoupler™ option has been turned

off). Simply turn the transformer throttle off and then on again to lock in

the new setting.

PROGRAMMING FOR SQUEAKING BRAKES AND

FYS OPERATION

ProtoSounds® is equipped with a RESET setting to turn off the Freight

Yard Proto-Effects (FYS) features. This is especially useful if you are

double-heading engines that are both equipped with FYS. You may not

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

10 Times

Listen For 2 Clank

And 0 Clink Sounds

Push The Whistle Button

Until You Hear

2 Bell Dings

Interrupt The Throttle

To “Lock-In”

The Coupler Setting

H

23

MTH FM Trainmaster Diesel Operating Manual

want to stop at a yard and

have both engines playing

their FYS sound effects. To

turn off FYS, enter RESET

and go to Feature 28. (See

the section on Using

RESET To Program

ProtoSounds® on page 18).

Once in Feature 28, press

the transformer whistle

button and wait for

ProtoSounds® to sound a bell ding(s). Continue pressing the whistle button

until ProtoSounds® sounds two bell dings (signifying that the FYS features

have been turned off). Simply turn the transformer throttle OFF and then

ON again to lock in the new setting. To reset ProtoSounds® to its original

factory setting of FYS on, repeat the above procedure but keep pressing the

whistle button in Feature 28 until ProtoSounds® only dings once instead of

twice.

ACTIVATING REMOTE LOCK-OUT CONTROL

ProtoSound® equipped engines feature a RESET setting that allows the

operator to remotely “lock” the engine into forward, neutral or reverse.

This is especially useful on layouts that feature “blocked” track sections.

The lockout feature comes from the factory in the OFF position, meaning it

is not active when you first take the engine out of the box. This is done to

prevent novice operators from accidentally locking their engine into

forward, neutral or reverse and then mistakenly thinking that the engine’s

electronics have failed. To activate the Remote Lockout Control setting, go

to RESET Feature 40 (See the section entitled Using RESET To Program

ProtoSounds® on page 18). Once in Feature 40, press the transformer

whistle button and wait for

ProtoSounds® to sound a

bell ding. Continue

pressing the whistle button

until ProtoSounds® sounds

two bell dings signifying

that the Remote Lockout

Control has been selected.

To lock in the setting,

simply turn the throttle all

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

28 Times

Listen For 5 Clank

And 3 Clink Sounds

Push The Whistle Button

Until You Hear

2 Bell Dings

Interrupt The Throttle

To “Lock-In”

The FYS Setting

H

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

40 Times

Listen For 8 Clank

And 0 Clink Sounds

Push The Whistle Button

Until You Hear

2 Bell Dings

Interrupt The Throttle

To “Lock-In”

The Lock-Out Setting

H

24

MTH FM Trainmaster Diesel Operating Manual

the way off and then back on again. To turn the Remote Lockout Control

setting back off, go back to Feature 40 and press the whistle button until

only one bell ding sounds. To lock in the setting, simply turn the

transformer throttle off and then back on again. Alternatively, you can go

to RESET Feature 18 to reset all ProtoSound® features back to their

original factory defaults including Remote Lockout Control.

RESETTING ALL PROTOSOUND OPTIONS TO

FACTORY DEFAULTS

ProtoSounds® is equipped with

a RESET feature (Feature 18)

that resets all programmable

options back to their original

factory settings. This is a useful

feature if you find your engine

not operating the way you think it

should and don’t want to take the

time to check each RESET feature one at a time. To reset all the RESET

features back to their original factory settings, enter RESET and go to

Feature 18. (See the section entitled Using RESET To Program

ProtoSounds® on page 18). Once in Feature 18, press the transformer

whistle button and wait for ProtoSounds® to sound a garbled bell sound.

Then interrupt the throttle to enter forward.

TURNING OFF CAB CHATTER SOUNDS

“Cab Chatter" sounds occur in the neutral position every 2 to 30 seconds.

There are four “Chatter" messages which play at random times. This helps

to eliminate repetitive and boring messages. While the sounds are selected

to play randomly by the unit’s computer, there is no guarantee that you

won’t hear the same message repeated twice or more times. If you don’t

want to hear the Cab Chatter sounds, they can be turned off through Feature

23. To turn off the Cab Chatter sounds, enter RESET and go to Feature 23.

(See the section Using RESET To Program ProtoSounds® on Page 18.)

Once in Feature 23, press the transformer whistle button and wait for

ProtoSounds® to sound a bell ding(s). Continue pressing the whistle button

until ProtoSounds® sounds two bell dings (signifying that the module has

been programmed to turn the Cab Chatter off). Simply turn the transformer

throttle off and then on again to lock in your selection. To turn the Cab

Chatter sounds back on again, repeat the above process, but keep pressing

the transformer whistle button in Feature 23 until ProtoSounds® only

sounds one bell ding.

In RESET Mode

Move The Throttle

Up & Down From

High Voltage To Low

18 Times

Listen For 3 Clank

And 3 Clink Sounds

Push The Whistle Button

Until You Hear

A Warbled Bell Ding

Interrupt The Throttle

To “Lock-In”

The Default Setting

H

25

MTH FM Trainmaster Diesel Operating Manual

REVERSE UNIT LOCK-OUT OPERATION

ProtoSounds® unique design eliminates the need for a lock-out switch on

the locomotive by allowing the customer to lock the engine into any

directional state (forward, neutral or reverse) from the transformer. This

will allow users to run the engine on layouts equipped with block signals or

stop stations which would normally cycle the engine back into neutral. The

feature must be first turned on by accessing RESET Feature 40 (See page

23).

LOCKING THE ENGINE INTO FORWARD OR

REVERSE

To lock the engine into Forward or Reverse, use the transformer throttle to

enter Forward or Reverse (whichever state you want to lock the engine into)

and while the engine is moving press the whistle button. WHILE THE

HORN IS BLOWING TURN THE THROTTLE OFF AND THEN LET

GO OF THE WHISTLE BUTTON. After about one second, you will hear

a short horn blast. QUICKLY TURN THE THROTTLE BACK ON

AGAIN. Your engine is now locked into Forward or Reverse and it will

remain so until you unlock the engine, even if you wait a year to run your

engine again.

UNLOCKING THE ENGINE

Unlocking the engine is a similar procedure. WHILE THE ENGINE IS

MOVING, PRESS THE WHISTLE BUTTON. WHILE THE HORN IS

BLOWING, TURN THE THROTTLE OFF AND THEN LET GO OF

THE WHISTLE BUTTON. After three seconds without power you will

hear one chime of the RESET bell. TURN ON THE POWER AGAIN.

Your engine is now in RESET and will operate normally once you interrupt

power and enter the forward direction.

LOCKING THE ENGINE INTO NEUTRAL

To lock the engine into the NEUTRAL position, PUT THE ENGINE IN

NEUTRAL AND WITH THE THROTTLE STILL ON, PRESS THE

WHISTLE BUTTON. WHILE THE WHISTLE BUTTON IS BEING

PRESSED, TURN OFF THE THROTTLE AND LET GO OF THE

WHISTLE BUTTON. After about one second, you will hear a short blast

26

MTH FM Trainmaster Diesel Operating Manual

of the horn. QUICKLY TURN THE POWER BACK ON AGAIN. Your

engine is now locked into NEUTRAL.

NOTE: When locking the engine in the Forward or Reverse positions, the whistle button will

blow the whistle. But when locking the engine into the NEUTRAL position, the whistle button

may turn on or off sounds of the bell, coupler arming or coupler firing depending on the

transformer throttle voltage settings prior to the user’s attempt to lock out the engine.

Remember, the whistle doesn’t blow in NEUTRAL (unless you programmed it to do so using

Feature 25. See page 21 for details), only the bell rings or the coupler operates in NEUTRAL.

While it doesn’t make any difference on how the lockout function operates, you may hear one

of the three different NEUTRAL-activated sounds.

To unlock the engine from the NEUTRAL position, follow the process to

unlock the engine in the Forward or Reverse directions above.

27

MTH FM Trainmaster Diesel Operating Manual

OIL & LUBRICATION INSTRUCTIONS

In order for the engine to perform correctly and quietly, it is important that

the chassis be lubricated before operation. Lubrication should include all

gears, axles and pickup rollers to prevent them from squeaking. Use light

household oil and wheel bearing grease and follow the lubrication points

marked “L and G" in Fig. 6 above.

The locomotive’s internal gearing has been greased at the factory and

shouldn’t need additional grease until after 50 hours of operation or one

year whichever comes first. Grease can be added by inserting grease into

the gear box inside the locomotive chassis. In order to access the gear box,

the cab must be removed from the chassis by unscrewing the six chassis

screws as seen in Figure 8 on page 28. Once the cab is removed, the trucks

can be removed by unscrewing the truck block/motor mount screw located

on the underside of the drive trucks (See Figure 7). Grease can then be

applied into the gear box using a grease tube dispenser.

Grease Gears (G)

Lubricate Pickups (L)

Lubricate Blind Wheel Axle (L)

Figure 6: Lubricating The Locomotive Chassis

Truck Block/Motor Mount Attachment Screw

Figure 7: Lubricate The Tender Chassis Trucks

28

MTH FM Trainmaster Diesel Operating Manual

Periodically, check the locomotive wheels and pickups for dirt buildup as

this can significantly affect the engine’s ability to perform properly. Dirty

track and dirty wheels can cause both poor electrical contact as well as poor

traction, especially on elevated track sections. Finally, dirt and oil build up

can prematurely wear out the neoprene traction tires.

TRACTION TIRE REPLACEMENT

INSTRUCTIONS

Your locomotive is equipped with two neoprene rubber traction tires on

the middle wheel set of each drive truck. While these tires are extremely

durable and long-lasting there may arise a time where they will need to be

replaced. Should this occur, you will need to remove the trucks from the

chassis and the trucksides from the trucks in order to slip the new tire over

the grooved drive wheel. Figures 7 and 8 identify the screws necessary to

remove the body and trucks from the chassis.

Before the new tire can be installed, you must make sure the old tire has

been completely removed from the groove in the drive wheel. Use a razor

blade or small flatblade screwdriver pry away any remains left from the old

tire that may still be in the drive wheel groove. Once the old tire has been

completely removed, slip the new tire onto the wheel. You may find it

useful to use two small flatblade screwdrivers to assist you in stretching the

tire over the wheel. Be careful to avoid twisting the tire when stretching it

over the wheel. If a twist occurs, the tire will have to be removed and

reinstalled or a noticeable wobble in your engine will occur when operating

the locomotive. In addition, it is important to make sure that the tire is

Motor Mount Screw

Body Mount Screws

Body Mount Screw

(one each end)

Figure 8: Removing The Body From The Chassis

29

MTH FM Trainmaster Diesel Operating Manual

fully seated inside the groove. Any portion of the tire extending out of the

groove can cause the engine to wobble. A razor blade can be used to trim

away any excess tire that doesn’t seat itself inside the groove properly.

Replacement tires are available directly from MTH Electric Trains.

HEADLIGHT REPLACEMENT

The locomotive’s headlights are controlled by constant voltage circuits

inside the locomotive body. The headlight(s) can be easily removed from

its lampholder should the bulb expire. To remove the bulb, follow the body

removal instructions found in the Lubrication section on the proceeding

pages. Once the cab has been separated from the chassis, gently unplug the

bulb’s wire harness from the socket on the constant voltage circuit.

Replacement bulbs are available directly from MTH Electric Trains.

30

MTH FM Trainmaster Diesel Operating Manual

TROUBLE SHOOTING PROTOSOUND®

PROBLEMS

Although ProtoSound® has been designed and engineered for ease of use,

some questions may arise during initial operation. The following table

should answer most questions. If you find that your problem can’t be

resolved with this manual, contact MTH ProtoSound® Electronics (7020

Columbia Gateway Drive, Columbia, MD 21046, 410-381-2580) for

additional assistance.

HORN PROBLEMS REMEDY

The horn seems distorted at low voltages.

Your battery may be undercharged or dead. Try

recharging the battery as explained in the battery

sections.

When I press the whistle button, the bell comes on

instead.

You are trying to operate the horn in neutral. The horn

will only operate in Forward or Reverse unless you

program ProtoSounds through Feature 25. See the

instructions in the section entitled “Using RESET to

Program ProtoSounds”. Also check the transformer

wiring.

I can’t get the horn to blow when I press the whistle

button.

You may be pressing the whistle button too quickly.

Most older AC transformers contain a two--step whistle

button that releases a DC signal onto the track. It is

this DC signal that tells the horn to blow. However,

because the signal is weaker when the whistle button

is depressed fully, the ProtoSound circuit may not

recognize the signal. Try pressing the whistle button

slower, taking approximately 1 second to fully depress

the button.

BELL PROBLEMS REMEDY

When I press the whistle button to activate the bell, the

horn sounds.

You are trying to ring the bell in Forward or Reverse.

The bell only operates in Neutral unless you have

programmed ProtoSounds to recognize a separate bell

button.

When I press the whistle button to activate the bell, I

arm the coupler.

Reduce the voltage on the transformer before pressing

the whistle button to activate the bell. The bell will only

come on at 8 volts or less.

When I press the whistle button to activate the bell, the

bell only rings once.

You are trying to ring the bell in RESET instead of

neutral. Interrupt the power twice to enter Neutral, set

the voltage at 8 volts or less and press the whistle

button to activate the bell.

I can’t get the bell to ring when I press the whistle

button.

You may be pressing the whistle button too quickly.

See the 3rd remedy in the horn section above.

The bell won’t work with a separate bell button.

ProtoSounds must be programmed in order for a

separate bell button to function. Enter RESET function

number 20 (see the section entitled “Using RESET to

Program ProtoSounds”) and press the whistle button

until the bell sounds two dings. Simply turn the throttle

off and then on again to lock in the new setting. Also

check the bell button wiring.

31

MTH FM Trainmaster Diesel Operating Manual

COUPLER PROBLEMS REMEDY

The ProtoCoupler won’t let the engine uncouple on the

“Fly”.

The power required to fire the coupler open when the

engine is on the “Fly” may be greater than the

ProtoSound system is capable of providing. As a

result, you may experience times when the coupler

won’t fire open. Unfortunately, the only solution is to

stop the engine and fire the coupler in Neutral. If that

doesn’t resolve the problem, try lubricating the coupler

knuckle and rivet as explained in the ProtoCoupler

Operation section.

I can’t get the coupler to arm or fire open when I press

the whistle button.

You may be pressing the whistle button too quickly.

See the third remedy in the horn section above.

Another possibility is that ProtoSounds has been

programmed to turn the coupler function off. See the

section entitled “Using RESET to Program

ProtoSounds”

Only one coupler will function when I press the whistle

button.

Only one coupler can operate at any one time. Use

the coupler selection switch on the bottom of the

chassis to choose which coupler you want active.

DIESEL START/CAB CHATTER REMEDY

Sometimes the diesel start sounds don’t occur when I

first turn power on.

Occassionally the diesel engine start up sounds may

not occur when power is turned back on within 5

seconds of being shut off. Wait 10 -- 15 seconds

before repowering.

Sometimes the Cab Chatter sounds don’t play.

The Cab Chatter sounds only play in neutral and

ProtoSounds may be programmed to turn the sounds

off. See the section entitled “Using RESET to

Program ProtoSounds”

LOCKOUT PROBLEMS REMEDY

I can’t get the engine to run after I power up the

transformer. It sits still with the diesel compressor

sounds running.

The engine is locked out into the Neutral position.

Follow the unlocking proceedures in the Lockout

Section.

The engine won’t lock out into Forward, Neutral or

Reverse even after the short horn blast sounds.

You are waiting too long to turn the throttle back on

after the short horn blast sounds. The power must be

turned back on immediately after the short horn blast

sounds or the engine will go back into RESET. See

the lockout proceedure in the Lockout Section.

VOLUME PROBLEMS REMEDY

When I try to run the engine, the diesel volume is OFF

or very low.

The diesel volume has been programmed at a reduced

volume or to be silent. Go to RESET Feature 6 and

adjust the volume. See the section entitled “Using

RESET to Program ProtoSounds” for more

information.

When I try to set the diesel volume, it resets itself to

the original volume after I selected the new volume.

You are trying to set the volume with a poorly charged

or dead backup battery. See the section on Battery

Backup for more information.

When I try to set the Diesel Volume to O Volume, I still

hear the cab chatter sounds.

When the diesel volume is set to O, you will hear the

Cab Chatter sounds because setting the diesel volume

only controls the sound of the diesel engine itself. All

other sounds, including Cab Chatter, the horn and bell

will continue to play at the volume level set by the

manual volume control knob located on the bottom of

the chassis. See the section entitled “ProtoSound

Volume Adjustment” for more information.

The sounds seem distorted, especially when the

whistle or bell is activated.

The overall ProtoSound volume has been set to high

creating the distorted sounds. Try turning the volume

control knob located on the bottom of the chassis

counter clockwise to reduce the overall volume level.

32

MTH FM Trainmaster Diesel Operating Manual

BATTERY PROBLEMS REMEDY

I get no sounds when the engine shifts between the

direction states.

The battery may be dead or needs charging. See the

Battery Backup section for more information.

After I turn off my transformer, my engine continues to

make sounds before quitting with a ding of its bell.

ProtoSounds continues to sound for approximately 10

seconds after power to the track has been shut off.

The sounds distort at low voltages.

The battery is insufficiently charged or dead. Follow

the recharging instructions found in the section entitled

“Self Recharging Battery Backup System”.

A repeating horn blast occurs after the power has

been shut down.

The ProtoSound module has detected a problem with

the electronics. Should such a warning occur,

disconnect the battery and contact MTH for return

authorization instructions.

RESET PROBLEMS REMEDY

When I first turn the power on, the engine will not

begin to run. I have to turn the throttle off and then on

again to get the engine to operate.

This is normal behavior. When power to the track is

first turned on, ProtoSounds enters a “RESET” phase

at which time the engine undergoes a system check.

Power must be interrupted to get the engine into the

Forward Phase. See the section entitled “DCRU

Reverse Unit Operation” for more information.

Whenever I interrupt the power from RESET to enter

Forward, the engine goes back into RESET instead of

Forward. I know this occurs because the bell dings

twice.

Whenever ProtoSounds enters RESET after power

has been off for more than 15 seconds, the

microprocessor initiates a system check to determine

that everything is in working order. This system check

requires 2.2 seconds to complete during which time

the engine will play the diesel startup sounds. We

recommend that you don’t interrupt the power in

RESET until the diesel startup sounds have

completed. This will guarantee that the system check

will have been completed since the startup sounds

take longer than 2.2 seconds to play. If the problem

persists, we recommend that you operate the throttle

with a slower movement as you interrupt the power in

RESET and enter the Forwaard Phase

BRAKE SOUND PROBLEMS REMEDY

When the transformer is throttled down, the sounds

won’t play.

The brake features has not been activated. See the

section on activating the brake feature for more

information.The throttle voltage setting on the

transformer is either not starting high enough or

ending low enough to trigger the brakes sounds. Try

increasing the throttle setting to 14 volts or higher

before throttling down to 8 volts or less.

The brake sounds continue to play even after the

engine stops.

The brake feature sound record lasts for three

seconds. With practice you can control how quickly

you should stop the engine to keep it in sequence with

the sound of the brake’s squeaking.

The brake feature was activated in neutral after the

engine was running in forward, but the brake sounds

would not play when triggered after the engine went

back into forward or reverse.

The brake feature will only remain enabled if it is

triggered in the first direction state you enter after

activating the feature in neutral. You cannot interrupt

the power twice to enter another direction state and

still have the brake feature active. Therefore, in order

to make the brake sound feature operate in forward,

you must first activate the feature in the neutral

position that occurs after the engine was in the reverse

state.

After triggering the brake sound and stopping the

engine in neutral, the engine begins making freight

yard sound effects.

After you trigger the brake sounds, you cannot stop

the engine in neutral and leave the track power on

without activating the freight yard sounds. If you don’t

want to hear the freight yard sounds after entering

neutral, turn the power off for three seconds to disable

the freight yard sound effects.

33

MTH FM Trainmaster Diesel Operating Manual

FYS PROBLEMS REMEDY

The FYS feature does not begin even after stopping

the engine and hearing the brake sounds.

The power was not turned back on once the engine

enter the neutral state thus disabling FYS.The

transformer throttle was interrupted too quickly in

neutral thus disabling FYS. Leave the throttle on in

neutral until after the FYS arrival message plays.

The FYS sound effects occassionally repeat

themselves.

ProtoSounds has a built--in random number generator

that randomly selects each sound clip to play.

Because there are only a total of 8 sound clips

available in each FYS event, it is probable that a

sound can occassionally be repeated one or more

times.

Once in FYS, the engine never goes in reverse.

So that the freight yard sound effects and operation is

as realistic as possible, ProtoSounds disables the

reverse unit state whenever FYS is enabled. This way

the engine never goes into reverse as the operator

cycles through the various FYS events.

When the engine enters FYS event 5, the bell

automatically comes on.

FYS has a built--in command to turn on the bell when

the system enters Event 5. After approximately 15

rings of the bell, it automatically will turn off.

Whenever FYS is enabled, pressing the whistle and

bell buttons has no affect.

Because FYS must control various effects in each FYS

event, the bell and whistle functions are disabled until

either the FYS events have been completed, or the

engine is shut down for 3 or more seconds.

PROTOSOUND RESET FEATURE CHART

The following chart lists the available features found in your ProtoSound®

equipped engine. The default settings are listed for each feature as well as

the operation of the feature. You can reset all features to their original

factory settings by accessing Feature 18 in RESET and then pressing and

holding the transformer whistle button until you hear a soft, warbled bell

sound.

RESET # OPERATION DEFAULT CLANKS/CLINKS

6 Engine Volume Full Volume 1 Clank/1 Clinks

10 Coupler ON/OFF Coupler ON 2 Clanks/0 Clinks

18 Reset Default Settings 3 Clanks/3 Clinks

20 Remote Bell Button Bell Button Active 4 Clanks/0 Clinks

23 Cab Chatter ON/OFF Cab Chatter ON 4 Clanks/3 Clinks

25 Horn In Neutral Horn In Neutral OFF 5 Clanks/0 Clinks

27 RESERVED

28 FYS Enabled FYS ON 5 Clanks/3 Clinks

40 Lockout Enabled Lockout OFF 8 Clanks/0 Clinks

45 Squeaking Brakes Brakes Always ON 9 Clanks/0 Clinks

34

MTH FM Trainmaster Diesel Operating Manual

TRANSFORMER COMPATIBILITY AND

WIRING CHART

ProtoSounds® is designed to work with any standard AC transformer that

uses a “Pure Sine-Wave" format. The chart below lists the many Lionel®

compatible transformers, such as the Lionel KW or ZW models. In