Compatibility

This diesel engine will operate on any traditional O-31 Gauge track

system, including M.T.H.’s RealTrax® or ScaleTrax™ or traditional

tubular track. It is also compatible with most standard AC transformers.

(See page 17 for a complete list of compatible transformers and wiring instructions.)

M.T.H. ELECTRIC TRAINS

F-3 ABA Diesel Engine Set

M.T.H. ELECTRIC TRAINS

2

F-3 A B A DIESEL ENGINE SET

Set Up............................................................................................................3

Basic Operation ........................................................................................4

Throttle ..............................................................................................4

Operation Buttons ..............................................................................4

Manual Volume Control ......................................................................4

Proto-Sound 2.0 ........................................................................................5

Activating Proto-Sound 2.0 Conventional Mode Features ................5

Passenger Station Announcements ..................................................5

Tips on Using PSA ............................................................................6

Proto-CouplerfiOperation ..................................................................7

S peed Control ....................................................................................7

Lock into a Direction S tate ................................................................7

Reset to Factory Default s ..................................................................8

Automatic Sounds ..............................................................................8

Maintenance................................................................................................8

Lubrication and Greasing Instructions ................................................8

Cleaning the Wheels, T ires and T rack ............................................10

T raction T ire Replacement ..............................................................10

Proto-Smoke Unit Operation ............................................................11

Light Bulb Replacement ..................................................................12

Self-Charging Battery Back-Up ........................................................13

Troubleshooting ......................................................................................14

Compatibility............................................................................................16

Transformer Compatibility Chart ......................................................17

Additional Features with DCS Remote Control System ............18

Safety Precautions..................................................................................19

Service and Warranty Information ..................................................20

Authorized Service Centers ................................................................21

TABLE OF CONTENTS

M.T.H. ELECTRIC TRAINS

3

F-3 A B A DIESEL ENGINE SET

There are a few simple step s you must t ake before operating this Premier

Diesel.

1. Y ou should prime the operating smoke unit with smoke fluid before

operating. Add 15-20 drops of smoke fluid through the smokestack, then gen tly blow into the st ack to eliminate any air bubbles in the fluid.

(See Fig. 5 on p age 11)

2. If you choose not to prime the unit with fluid, turn the smoke unit switch

located under the engine to the OFF position. ( See Fig. 6 on p age 11)

Running the engine without a primed smoke unit may cause damage. See the

ProtoSmoke Unit Operation section of this book for more information on

smoke unit

maintenance.

3. Y ou should lubricate the wheel axles and pickup rollers to prevent them

from

squeaking. Use light household oil and follow the lubrication point s marked L

in Fig. 2 on p age 8. Do not over oil. Use only a drop or two on each pivot

point.

4. Y ou may find, if your locomotive was built several months before you set it

up, that the rechargeable battery has run down and needs to be charged

before operation. If you notice that the sounds are garbled, test and charge

the engine as described in the Self Charging Battery Back-Up section on

page 13.

At this point, you are ready to begin running your engine.

SET UP

M.T.H. ELECTRIC TRAINS

4

F-3 A B A DIESEL ENGINE SET

Throttle up the power to your track. Give enough power so that the engine s headlight

shines brightly . Then put the engine into motion by either firmly pressing the Direction

button on your transformer or remote once or dropping and advancing to throttle to put

the engine in forward.

BASIC OPERATION

Use the operation buttons on your transformer as described below.

Horn/Whistle - T o sound the horn/whistle, firmly press the Horn/Whistle button. The

horn/whistle will sound for as long as you continue to depress the button. It will stop

when you release the button. The horn/whistle has four dif ferent endings, depending

on whether you hold the button for less than three seconds, three seconds, four sec onds, five seconds or longer.

Bell - T o sound the bell, firmly press and release the Bell button. To turn the bell of f,

press

and release the Bell button again. The bell will continue to ring from the time your turn

it on until you press and release the button again to turn it of f.

Direction - Y our engine is programmed to st art in neutral. T o put the engine into for -

ward

and then to change the direction of the engine or to put it into neutral, firmly press and

release the Direction button on your transformer. Just as you must stop your car

between forward and reverse, this engine will not go directly from forward to reverse; it

OPERATION BUTTONS

MANUAL VOLUME CONTROL

To adjust the volume of all sounds

made by this engine, turn the master

volume control knob, located on the

underside of the engine, clockwise to

increase the volume and counterclockwise to decrease the volume.

(see Figure 1)

Figure 1 - Proto-Sound 2.0 Volume Adjustment Knob

THROTTLE

V olume Adjustment Knob

M.T.H. ELECTRIC TRAINS

5

F-3 A B A DIESEL ENGINE SET

This manual cont ains the operating instructions for Proto-Sound 2.0 in conventional

mode only. Instructions for accessing DCS command mode features accompany the

DCS Remote Control System equipment.

Because Proto-Sound 2.0 is an all-new system developed by M.T.H. s own research

and development team, it operates dif ferently from the original Proto-Sound. Most

Proto-Sound 2.0 features are automatically enabled, and the reset st ate has been

eliminated, so there is no need to program features as with original Proto-Sound.

Although the new system is easier to operate than original Proto-SOund, you should

read these instructions thoroughly before using Proto-Sound 2.0 features in order to

prevent harm

to yourself or your equipment.

Activating Proto-Sound 2.0 Conventional Mode Features: Proto-Sound 2.0

features are activated by sequences of Bell and Whistle button pushes described

below. Please read the full descriptions of each feature before using it. To use these

buttons to activate features rather than to blow the whistle or ring the bell, you should

press the

buttons for a shorter time (1/2 second); you may need to practice your timing to make

PROTO-SOUND 2.0

OPERATION

Passenger Station Announcements (PSA): Y our engine is equipped with a sound

package of freight yard sounds that you can play when you pull into a yard. Each

sequence described in the following will play as long as it is lef t on, randomly

generating sounds, but be sure to allow approximately 30 seconds between the

button pushes described below to allow the PSA sufficient time to run through

each sequence.

1. To cue the sound system to play the PSA, quickly, but firmly press the Bell button

Feature to be Activated Button Code

Passenger Station Announcements 1 Bell, 2 Whistles

Fire the Rear Coupler 1 Bell, 3 Whistles

Fire the Front Coupler 1 Bell, 4 Whistles

S peed Control On/Of f 1 Whistle, 2 Bells (from neutral only)

Lock into a Directional S tate/Unlock 1 Whistle, 3 Bells

Reset to Factory Default s 1 Whistle, 5 Bells ( from neutral only)

M.T.H. ELECTRIC TRAINS

6

F-3 A B A DIESEL ENGINE SET

2. Press the Direction button once to stop the engine. This will

trigger the first sequence of PSA. The reverse unit is temporarily

disabled so that the train will not move as you use the the Direction button to trigger

the sounds, and Proto-Sound 2.0 has disabled operator control over the Whistle and

Bell buttons until the full PSA sequence is complete.

3. Af ter waiting about 30 seconds for that sequence to run, press the Direction button

again to trigger the second sequence of PSA.

4. Af ter waiting about 30 seconds, press the Direction button again to trigger the third

P S A sequence.

5. Again, af ter allowing about 30 seconds for that sequence to run, press the Direction

button one more time to trigger the fourth and final PSA sequence. The PSA will con tinue, and within a few seconds, the engine will st art and move out on it s own at the

current throttle setting, in the same direction it was traveling when you began the

sequence. Once the bell turns of f, the operator regains control of the transformer s bell

and whistle buttons and can ring the bell or blow the whistle as usual.

Tips on Using PSA

You can terminate PSA at anytime by turning of f power to the track for 15 sec -

onds.

Y ou do not have to be in Forward to use PSA. At the conclusion of the full

sequence,

the train will pull away from the st ation in whatever direction you were going when

you activated the feature.

You can use PSA even if you are double-heading with another engine. If the sec -

ond

is not equipped with PSA at all, you must remember not to leave the throttle at a

high

volt age level once you have stopped the engine to run the PSA. Otherwise, the

engine without PSA will st art vibrating on the track as it s motors strain to move the

train, since they cannot be automatically disabled during the PSA cycle. If the sec ond engine is an original Proto-Sound engine equipped with PSA, you may choose

M.T.H. ELECTRIC TRAINS

7

F-3 A B A DIESEL ENGINE SET

This engine is equipped with a coil-wound Proto-Coupler for remote uncoupling action.

Because the Proto-Coupler is controlled through the Proto-Sound 2.0 microprocessor,

it does not require an uncoupling track section or modification to your layout to func tion. Use the codes listed below.

Rear Coupler: To fire the rear coupler , press the Bell button once followed immedi -

ately

by three pushes of the Horn/Whistle button. The sound of the lif t bar and air line

depletion will play , and the knuckle will be released.

PROTO-COUPLER ®OPERATION

M.T.H. engines equipped with Proto-Sound 2.0 have speed control cap abilities that

allow the engine to maint ain a const ant speed up and down grades and around

curves, much like an automobile cruise control. Y ou can add or drop cars on the run,

and the engine will maint ain the speed you set.

While the engine is programmed to st art with the speed control feature activated, you

can opt to turn it of f. This means the engine s speed will fall as it labors up a hill and

increase as it travels downward. It is also af fected by the addition or release of cars

while on the run. To maint ain a const ant speed when speed control is turned of f, you

need to adjust the track volt age yourself. When speed control is of f, the volume will

drop to allow for better low volt age operation. Full volume is restored upon reactivation

of speed control.

To turn speed control on and off: First, put the engine in neutral, then press the

transformer s Horn/Whistle button one time then immediately press the Bell button two

times. T wo whistle blast s will indicate that the engine has made the change. Repeat

the

1 Horn/Whistle, 2 bells code to return it to the other st ate. Y ou will want to do this

during the initial neutral st art-up if you ever couple this engine with another

SPEED CONTROL

Y ou can lock your engine into a directional st ate (forward, neutral, reverse) to prevent

it from changing directions. To do this, put the engine into the direction you want or in

neutral, run it at a very low speed (<10 scale mph), and quickly but firmly press your

remote s Horn/Whistle button once followed immediately by three presses of the Bell

LOCK INTO A DIRECTIONAL STATE

M.T.H. ELECTRIC TRAINS

8

F-3 A B A DIESEL ENGINE SET

To override the settings you currently have assigned to the engine and reset it to it s

factory default s, while in neutral press the Horn/Whistle button once, followed immedi ately by five quick pushes of the Bell button. T wo horn blast s will indicate that the

engine has made the change

RESET TO FACTORY DEFAULTS

Cert ain Proto-Sound 2.0 sound effects automatically play in programmed conventional

mode conditions:

Squealing Brakes: This sound plays anytime the engine s speed decreases rapidly .

Cab Chatter: This sound play when the engine idles in neutral.

Engine Start-up and Shut-down: This sound plays when the engine is initially

powered on or is powered of f for five seconds or more.

AUTOMATIC SOUNDS

MAINTENANCE

This engine should be oiled and greased in order to run properly.

Y ou should regularly lubricate the engine to prevent them from squeaking. Use light

household oil and follow the lubrication point s marked L in Figure 2. Do not over oil.

Use only a drop or two on each pivot.

LUBRICATION AND GREASING

Figure 2 - Lubrication Point s on the Engine

Pick up Rollers

(L)

Wheel Axles (L)

button. T wo Horn/Whistle blast s will indicate that the engine has

made the change. The engine will not change direction (including

going into neutral) until you repeat the 1 Horn/Whistle, 3 bells

code to return the engine to it s normal st ate, even if the engine has been kept without

power for extended periods of time.

M.T.H. ELECTRIC TRAINS

9

F-3 A B A DIESEL ENGINE SET

The locomotive s internal gearing was greased at the factory and

should not need additional grease until af ter 50 hours of operation

or one year, which ever comes first. To access the gear box, do the following:

1. Unscrew the body mount screws as shown in Figure 3 and remove the body shell

from

the chassis.

Figure 3 - Location of body mount screws

Body Mount

Screws

2. Once the body is removed, remove the trucks by unscrewing

the motor mount screw located on the underside of the drive trucks. See Figure 4.

3. Pull the motor away from the truck block and lightly

coat the motor worm gear and bronze drive gear with

grease.

4. Reassemble the truck and motor being careful not to

pinch any wires between the truck block and motor mount.

5. Repeat steps on the other motor.

6. Reassemble the engine in reverse order .

7. Grease Idler Gears. Located on the out side of the truck block.

Figure 4 - Motor Mount Screw

Motor Mount Screw

M.T.H. ELECTRIC TRAINS

10

F-3 A B A DIESEL ENGINE SET

CLEANING THE WHEELS & TRACK

Periodically check the engine wheels and pick-up rollers for dirt and buildup, which can

cause poor electrical cont act and traction and prematurely wear out the neoprene trac tion tires. Wheels and tires can be cleaned using denatured alcohol (not rubbing

alcohol), which can be found in home improvement stores, applied with a cotton swab.

Occasional cleaning of the track will also help to ensure good electrical cont act and

prolong the life of your engine s tires. To clean the track, use a clean rag and dena tured alcohol (not rubbing alcohol). Unplug the transformer and rub the rails of the

track,

turning the rag frequently to ensure that you are using clean cloth on the rails.

TRACTION TIRE REPLACEMENT

Y our locomotive is equipped with two neoprene rubber traction tires on each powered

truck block. While these tires are extremely durable, you may need to replace them at

some point.

1

. Remove the body shell by unscrewing the body mount screws.

2

. Remove the motor mount screw from the bottom of the truck block. Det aching the

truck block from the motor.

3

. Remove the truckside frames giving you access to the traction tires.

4

. Make sure the old tires have been completely removed from the groove in the drive

wheel, using a razor blade or flat head screwdriver to pry away any remains.

5

. Slip the new tire onto the wheel. Y ou may find it useful to use two small flathead

screwdrivers to stretch the tire over the wheel.

6

. If you twist the tire while stretching it over the wheel, you will need to remove

and reinst all the tire. Otherwise your engine will wobble while operating.

7

. Make sure the tires are fully seated inside the groove. Use a razor blade to trim

away

any excess tire that doesn t seat it self inside the groove properly .

One set of replacement tires is included with your model.

Additional tires are available directly from M.T.H. Part s D e p artment (Phone: 410.381.2580).

M.T.H. ELECTRIC TRAINS

11

F-3 A B A DIESEL ENGINE SET

This engine cont ains a smoke unit that output s smoke through the

smokestack on the engine. The smoke unit is essentially a small heating element and

wick that soaks up and then heat s a mineral oil-based fluid that emit s a harmless

smoke.

The smoke is then forced out of the st ack by a

small electric fan.

W ith a few easy maintenance step s, you should

enjoy trouble-free smoke unit operation for years.

When preparing to run this engine, add 15-20

drop s of smoke fluid through the smokestack.

(see figure 5) W e recommend M.T.H. ProtoSmoke,

Seuth, LGB, or LVTS fluids (a small pipette of

ProtoSmoke fluid is included). Do not over fill the

unit or the fluid may leak out and coat the interior

engine components.

If you choose not to add the fluid (or have

already added the fluid but choose to run smoke

free), turn of f the smoke unit switch located under

the engine body. (see figure 6) Failure to either

add fluid to the unit or to turn it of f may damage

the smoke unit heating element and/or wicking

material.

When the smoke output while running begins to

diminish, add another 10-15 drop s of smoke fluid

or turn the smoke unit of f.

When storing the unit for extended periods of

time, you may want to add about 15 drop s of fluid

to prevent the wick from drying out.

Af ter removing the engine from storage, add

another 25 drop s of fluid, letting the wick soak up

the fluid for 15 minutes prior to operation.

If you experience poor or no smoke output when

the smoke unit is on and has fluid, check the wick

to see if it has become hard, blackened, and

unabsorbant around the heating element. Remove

the smoke unit inspection cover from the smoke unit s body. (see figure 7) After remov ing the

inspection cover screws, lif t the inspection plate away and inspect the wick. If it is

darkly discolored and hard, it should be replaced.

PROTO-SMOKE®UNIT OPERATION

Figure 7 - Smoke Unit Inspection Cover

Add Smoke

Fluid

Figure 5 - Add Smoke Fluid

Figure 6 - Smoke Unit On/Off Switch

On/Off Smoke

Switch

Smoke Inspection Cover

M.T.H. ELECTRIC TRAINS

12

F-3 A B A DIESEL ENGINE SET

To replace the light bulb in the engine, follow these instruction and

see the diagrams below:

Remove shell by removing body mount screw shown in figure 3 on p age 9. Once the

body

shell has been removed, disconnect the bulb harness from the socket on the const ant

volt age circuit and replace the bulb.

LIGHT BULB REPLACEMENT

Figure 8 - Light Bulb

Light Bulb

To replace the light s mounted on the

inside of the shell, remove the shell,

and slide the spring cont act bracket

(see

figure 9)

off it s post. Remove the light

bulb and wires t aking care to notice

the p ath that the wires t ake on the

inside of the shell. Replace bulb S pring

Contact Bracket and reassemble

Figure 9- Spring Cont act Bracket

Spring Cont act

Bracket

M.T.H. ELECTRIC TRAINS

13

F-3 A B A DIESEL ENGINE SET

The special NiCad 7-cell 8.4v self-charging battery recharges

continuously during train operartion and should last for up to five years. The battery is

a dry battery that should not leak or cause any damage to your engine. Depending

upon when your engine was built, it may need to be charged right out of the box. If

engine sounds seem distorted or garbled at low volt ages or become silent when power

from the transformer is turned of f, test the battery to determined whether it should be

recharged.

Test: Put the engine in neutral and leave the track volt -

age

at 10-12 volt s (high enough or the light s to shine bright ly and the engine to move steadily) for 15 minutes.

Recharge: If the sounds are improved at the end of the

15-minute test charge, the battery charge has run down

and can be recharged. There are a number of ways you

can do this:

Leave the engine in neutral with track volt age at

10-12 volt s for 6-7 hours so the battery can fully recharge. If your unit has a smoke

unit,

be sure that it is turned of f.

Use M.T.H. s battery recharger (sold sep arately) that plugs into the wall outlet and

a special port under the engine

(see figure 10) to recharge the battery overnight without

leaving it on the track.

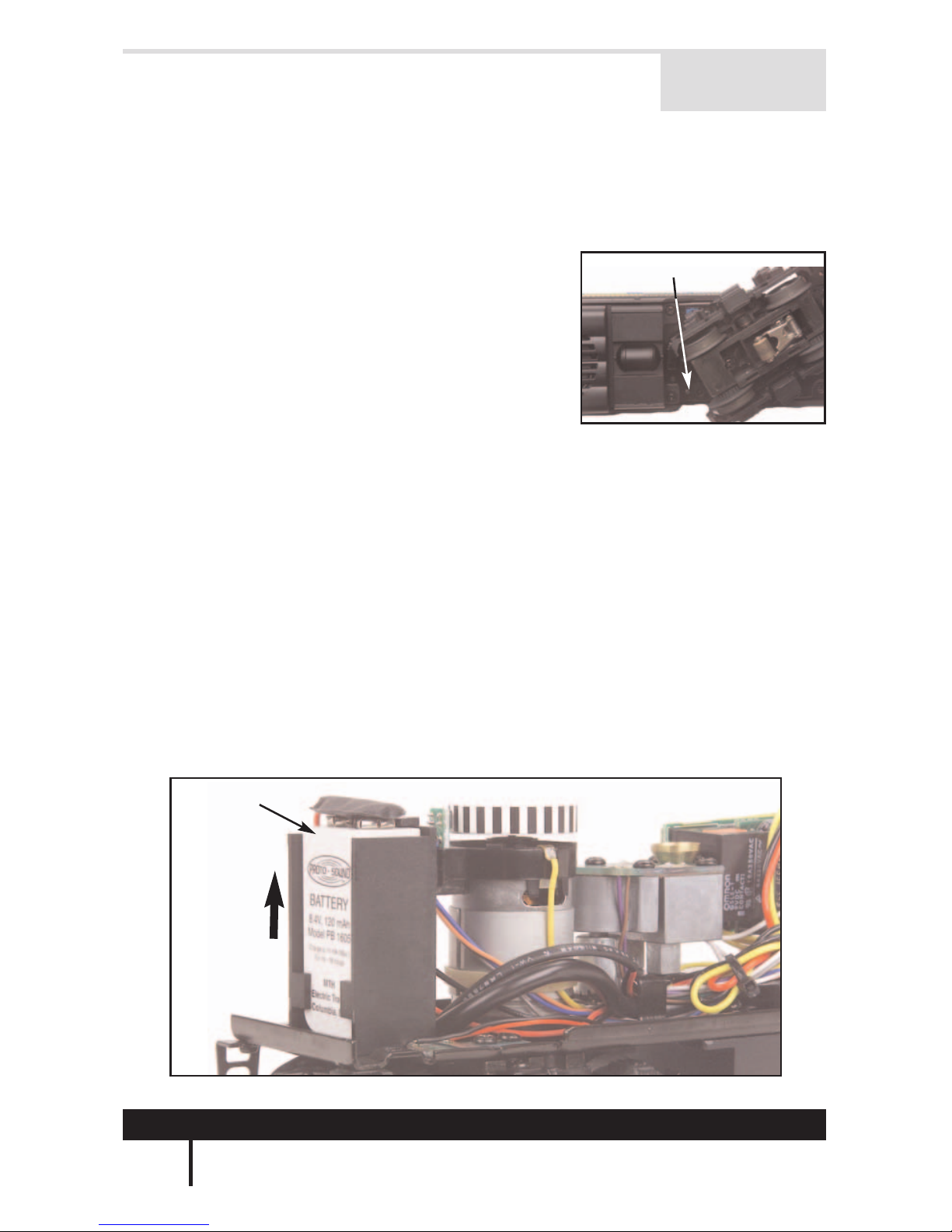

Replace: If the sounds are not improved at the end of the 15 minute test charge, the

battery must be replaced (as shown in figure 11, below). Cont act the M.T.H. Part s

D e p artment (phone: 410-381-2580; e-mail: p art s@mth-railking.com; mail: 7020

Columbia Gateway Drive, Columbia MD 21046-1532) for a replacement battery. A

SELF CHARGING BATTERY BACK-UP

Figure 11- Replacing the Battery

Replaceable

Battery

Pull

Battery

Figure 10- Battery Port

Battery

M.T.H. ELECTRIC TRAINS

14

F-3 A B A DIESEL ENGINE SET

Although Proto-Sound 2.0 has been designed and engineered for ease of use, you

may have some questions during initial operation. The following t able should answer

most questions. If your problem cannot be resolved with this t able, cont act M.T.H. for

assist ance (telephone: 410-381-2580; fax: 410-423-0009; service@mth-railking.com,

7020 Columbia Gateway Drive, Columbia MD 21046-1532).

TROUBLESHOOTING

PROTO-SOUND® 2.0

Starting Up Remedy

When I first turn the power on, the engine

will not begin to run. I have to turn the

throttle of f and on again to get the engine

to operate.

This is normal behavior. To prevent

accident al high-speed st art-up s,

ProtoSound 2.0 is programmed to st art up

in neutral

anytime track power has been turned of f

for several seconds. See the Basic

Horn/Whistle Remedy

When I press the horn/whistle button, the

bell comes on instead.

I can t get the horn to blow when I press

the whistle button.

Reverse the transformer leads.

Y ou may be pressing the button too

quickly . T ry pressing the horn/whistle but ton more slowly, t aking approximately one

full second to fully depress the button.

Bell Remedy

When I press the bell button, horn/whistle

comes on instead.

I can t get the horn to blow when I press

the whistle button.

The bell won t work on a separate bell

button.

Reverse the transformer leads.

Y ou may be pressing the button too quick ly. T ry pressing the bell button more slow ly,

taking approximately one full second to

fully depress the button.

Check the wiring of the sep arate button.

Bell Remedy

When I try to fire the coupler , PSA starts.

The Proto-Coupler won t let the engine

uncouple on the fly.

The coupler does not fire or st ay coupled.

Y ou are waiting too long between whistle

button presses.

T ry lubricating the coupler knuckle with

a dry graphite lubricant. Do NOT use oil.

The coupler needs to be cleaned. W ipe

with denatured alcohol (not rubbing

alcohol) and let dry .

M.T.H. ELECTRIC TRAINS

15

F-3 A B A DIESEL ENGINE SET

Cab Chatter Remedy

Sometimes the cab chatter sounds don t

play .

Cab chatter plays only in neutral at ran dom intervals

Lock-out Remedy

I can t get the engine to run af ter I power

up the transformer. It sit s still with the

engine sounds running.

The engine won t lock into forward, neutral

or reverse.

The engine is locked into the neutral

position. Follow the directions in to the

Lock into Direction S tate section.

Engine speed must be below 10 scale

mph. (approx. 10 volt s or less in conven tional mode)

Volume Remedy

The sounds seem distorted, especially

when the whistle or bell is activated.

Proto-Sound 2.0 volume is set too high.

T urn the volume control knob on the bot tom of the chassis counterclockwise to

reduce the volume.

Battery Remedy

The engine will not leave the initial neutral

st ate.

Iget no sounds when the engine shif ts

between direction st ates.

Af ter I turn of f m y transformer, my engine

continues to make sounds before quitting.

Check to be sure the battery is inst alled

and fully charged. See the Self Charging

Battery Back-up section.

The battery may be dead or need to be

charged. See the Self Charging Battery

Back-up section.

Proto-Sound 2.0 is designed to continue

to sound for a few seconds af ter the

power to the track has been shut of f.

PSA Remedy

The PSA sounds occasionally repeat

themselves.

Once in PSA, the engine doesn t go into

reverse.

When the PSA enters it s last sequence

the bell automatically comes on.

Proto-Sound 2.0 has a built in random

number generator that randomly select s

each sound clip to play. Because there are

a limited number of sound clip s available

in each PSA sequence, it is probable that

some of these sound clip s will be repeated

from time to time.

So that PSA effect s can be as realistic as

possible, Proto-Sound 2.0 disables the

reversing unit whenever it is enabled. This

way the engine remains still at it s stop as

the operator cycles through the PSA

sequences.

It is programmed to st art ringing the bell at

that point. Af ter approximately 12 rings of

M.T.H. ELECTRIC TRAINS

16

F-3 A B A DIESEL ENGINE SET

This engine will operate on any traditional O-31 or larger O Gauge track system,

including M.T.H. s RealT raxfi or ScaleT rax or traditional tubular track. It is also com p atible with most st andard AC transformers. (See p age 17 for a complete list of com p atible transformers and wiring instructions.)

COMPATIBILITY

PSA (continued) Remedy

When PSA is enabled, pressing the whis tle and bell automatically comes on.

I push the direction button but the next

sound clip in the sequence does not play

or the engine does not come out of PSA

af ter fourth press of direction button.

Because PSA must control various ef fects

in each sequence, Proto-Sound 2.0 t akes

control of these sound ef fect s until you

exit PSA.

Each PSA clip must play for approximately

30 seconds before PSA will advance to

the next step in the PSA cycle. Wait at

least 30 seconds in each PSA sound clip

before pressing the sound button.

M.T.H. ELECTRIC TRAINS

17

F-3 A B A DIESEL ENGINE SET

Note that many of the operational commands described in these instructions require a

bell button, so if your transformer does not have it s own bell button, you should con sider adding one to get the full benefit of the system.

TRANSFORMER

COMPATIBILITY CHART

MTH Z-500 Red Terminal Black Terminal 0-18v 50 watt Electronic

MTH Z-750 Red Terminal Black Terminal 0-21v 75 watt Electronic

MTH Z-1000 Red Terminal Black Terminal 0-21v 100 Watt Electronic

MTH Z-4000 Red Terminal Black Terminal 0-22v 390 watt Electronic

Lionel 1032 U A 5-16v 90 watt S tandard

Lionel 1032M U A 5-16v 90 watt S tandard

Lionel 1033 U A 5-16v 90 watt S tandard

Lionel 1043 U A 5-16v 90 watt S tandard

Lionel 1043M U A 5-16v 90 watt S tandard

Lionel 1044 U A 5-16v 90 watt S tandard

Lionel 1053 U A 5-16v 90 watt S tandard

Lionel 1063 U A 5-16v 90 watt S tandard

All-T rol Lef t Terminal Right Terminal 0-24v 300 watt Electronic

Powermaster A U 0-18v 135V.A. Electronic

Dallee Hostler Lef t Terminal Right Terminal Electronic

Lionel MW Outside T rack Inside T rack 5-16v 5 0 V.A. Electronic

Terminal Terminal

R.O.W. Red Terminal Black Terminal 0-24v 384 watt S tandard

Lionel RS-1 Red Terminal Black Terminal 0-18v 5 0 V.A. Electronic

Lionel R W U A 9-19v 110 watt S tandard

Lionel SW U A Unknown 130 watt S tandard

Lionel T W U A 8-18v 175 watt S tandard

Lionel ZW A,B,C or D U 8-20v 275 watt S tandard

Lionel Post War Red Terminal Black Terminal 0-18v 135 watt Electronic

Celebration

Series

Transformer Center Rail Outside Rail Min/Max Power Transformer

Rail Voltage Rating Type

M.T.H. ELECTRIC TRAINS

18

F-3 A B A DIESEL ENGINE SET

While conventional mode operation of a Proto-Sound 2.0 engine yields wonderfully

realistic sound and several train control features, command mode operation allows

the user to access a world of command functions never before accessible to O Gauge

railroaders. W ith the addition of the DCS Remote Control System (including a DCS

remote hand-held and T rack Interface Unit) users gain many advanced features,

including:

DCS Proto-Speed Control-Est ablishes desired locomotive speed in scale miles per

hour

increment s via a thumbwheel control and allows operator to set maximum speed and

acceleration/deceleration rates.

Locomotive Lighting Control-Independently controls locomotive headlight s, marker

and interior light s, and ditch light s.

Emergency Stop-Single button push stop s your trains (but does not turn of f

track power).

One Touch Global Mute/UnMute-Single button mutes or unmutes all DCS-controlled

locomotives user-defined actions, including sound, light s, and smoke.

Proto-Disp atch Operation-Public Address-like feature allows users to speak through

locomotive speaker during operation.

Proto-Cast-Allows users to play audio recordings through locomotive speaker

during operation.

Proto-Doppler Sound Effect s Set Up-Users can configure locomotive for Doppler

Operation, including setting dist ance point s for Doppler st art, repeat, and stop modes.

Independent Volume Control of Engine Sounds, Bell, Horn & Whistle for each

Locomotive.

Control up to 50 dif ferent DCS-equipped locomotives at one time with multiple TIUs.

Proto-Ef fects Set Up-User can select individual Proto-Ef fect s operations to be

active

or inactive, including cab chatter , train wreck sounds, coupler sounds, and wheel

clickety-clack sounds.

Direction Control Set Up-User can set initial individual st art-up direction (st art in for-

ward

or reverse) for double-heading operations.

ADDITIONAL

FEATURES

ACCESSIBLE WITH DCS REMOTE CONTROL SYSTEM

M.T.H. ELECTRIC TRAINS

19

F-3 A B A DIESEL ENGINE SET

User Can Query, Set and Operate T rack and Accessory

Interface

Unit s for Programming Digital Command Operations for up to 250 Accessories and

250 Individual Switches.

Not recommended for children under 10 years of age. M.T.H. recommends adult

supervision with children ages 10 - 16. As with all electric product s, precautions

should be observed during handling and use to reduce the risk of electric shock.

WARNING: When using electrical product s, basic safety precautions should be fol -

lowed

including the following:

Read this manual thoroughly before using this device.

M.T.H. recommends that all users and persons supervising use examine the hobby

transformer periodically for conditions that may result in the risk of fire, electric shock,

or injury to persons, such as damage to the primary cord, plug blades, housing, output

jacks or other p art s. In the event such conditions exist, the transformer should not be

used until properly rep aired.

As with all electrical appliances, this product should not be lef t in operation when

CAUTION:

ELECTRICALLY OPERATED PRODUCT:

M.T.H. ELECTRIC TRAINS

20

F-3 A B A DIESEL ENGINE SET

How to Get Service Under the Terms of the Limited One-Year Warranty

When you suspect an item is defective, please check the operator’s manual for st andard operation and

trouble-shooting techniques that may correct the problem. Additional information may be found on the

M.T.H. Website. Should you still require service, follow the instructions below to obt ain warranty serv ice.

First, e-mail, write, call or fax a M.T.H. Authorized Service Center (ASC) in your area to obt ain Repair

Authorization. Y ou can find the list of ASCs on the M.T.H. Website, w w w .mth-railking.com . Authorized

Service Centers are required to make warranty rep airs on items sold only from that store; all other

rep airs may-- or may not be done at the store’s own discretion. If you did not purchase the item directly

from the ASC, you will need to select a National Authorized Service Center (NASC). These centers are

compensated

by M.T.H. to perform warranty service for any customer whose rep air qualifies for warranty service. A

list of NASC ret ailers can be located on the M.T.H. Website or by calling 1-888-640-3700. Should the

warranty no longer apply, you may choose either an ASC or NASC ret ailer to service your M.T.H.

Product. A reasonable service fee will be charged.

CAUTION: Make sure the product is p acked in it s original factory p ackaging including it s foam and plas -

tic

wrapping material to prevent damage to the merchandise. There is no need to return the entire set if

only one of the component s is in need of rep air unless otherwise instructed by the Service Center . The

shipment must be prepaid and we recommend that it be insured. A cover letter including your name,

address, daytime

phone number, e-mail address (if available) , Return Authorization number (if required by the service

center) , a copy of your sales receipt and a full description of the problem must be included to facilit ate

the rep airs. Please include the description regardless of whether you discussed the problem with a

service technician when cont acting the Service Center for your Return Authorization.

Please make sure you have followed the instructions carefully before returning any merchandise for

service.

Authorized M.T.H. Service Centers are independently owned and operated and are not agent s or

represent atives of M.T.H. Electric T rains. M.T .H. assumes no responsibility, financial or otherwise, for

material lef t in their possession, or work done, by privately owned M.T.H. Authorized Service Centers.

If you need assist ance at any time email MTH Service at service@mth-railking.com,

or call 410 381-2580.

LIMITED ONE-YEAR WARRANTY

All M.T.H. product s purchased from an Authorized M.T.H. T rain Merchant are covered by this warranty.

See our website at w w w .mth-railking.com or call 1-888-640-3700 to identify an Authorized M.T.H. T rain

Merchant

near you.

M . T.H. products are warrantied for one year from the date of purchase against defect s in material or workman -

ship,

excluding wear items such as light bulbs, pick-up rollers, batteries, smoke unit wicks, and traction tires. W e will

rep air or replace (at our option) the defective p art without charge for the p art s or labor , if the item is returned to

an M.T.H. Authorized Service Center (ASC) or M.T.H. National Authorized Service Center (NASC) within one

year of the original date of purchase. This warranty does not cover damages caused by improper care, han -

SERVICE & WARRANTY INFORMATION

M.T.H. ELECTRIC TRAINS

21

F-3 A B A DIESEL ENGINE SET

PARTICIPATING N.A.S.C.

RETAILER LIST

CANAD

A

Toy T rain W orkshop

Cumberland

613-833-9331

The Train Room

Fergus

519-787-3280

CALIFORNIA

T in Plate Junction

Oakland

510-444-4780

COLORADO

Mizell T rains Inc.

W estminster

303-429-4811

CONNECTICUT

New England Hobby Supply

Manchester

860-646-0610

FLORIDA

Roundhouse South

Port Orange

386-304-7002

MARYLAND

Plaza Hobby

Cumberland

301-729-6424

Engine House Hobbies

Gaithersburg

301-590-0816

Catoctin Mount ain T rains

& Hobbies

Thurmont

301-694-8331

MICHIGAN

Michigan Model Train

Center

Pinckney

734-426-1651

Brasseur Electric T rains Inc.

Saginaw

989-793-4753

NEW HAMPSHIRE

T reasured Toys

Salem

603-898-7224

NEW YORK

Aurora Rails & Hobbies

East Aurora

716-652-5718

OHIO

Davis Electronics

Milford

513-831-6425

Rick s T oy T rains

Toledo

419-478-0171

PENNSYLVANIA

Bussinger T rains

Ambler

215-628-2366

Fairchance Pharmacy

Fairchance

724-564-7817

Toby Tyler

Pitt sburgh

412-653-5030

VIRGINIA

Locust Grove T rains

Locust Grove

540-854-8955

Davis Hobby Supplies

Port smouth

757-397-1983

TSG Hobbies

W arrenton

540-347-9212

WISCONSIN

Sommerfeld s T rains

Butler

262-783-7797

Grampa s T rain Shop

Rice Lake

715-234-2996

M.T.H. ELECTRIC TRAINS

22

F-3 A B A DIESEL ENGINE SET

PARTICIPATING A.S.C. RETAILER LIST

CANADA

Toy T rain W orkshop

Cumberland

613-833-9331

The Train Room

Fergus

519-787-3280

Credit Valley Railway

Company

S treet sville

905-826-1306

B H T rains

Terrebonne

450-492-0317

ALABAMA

Southerland Station

Huntsville

256-533-4720

Lil Bobby s Hobbies

Montgomery

334-277-1715

ARIZONA

Arizona T rain Depot

Mesa

480-833-9486

CALIFORNIA

Central Coast T rains

At ascedero

805-466-1391

T rain Shack

Burbank

818-842-3330

Roundhouse

North Hollywood

818-769-0403

Dollhouses, T rains & More

Novato

415-883-0388

T in Plate Junction

Oakland

510-444-4780

R o n s W orld

San Clemente

949-361-5596

T rucks & T rains Hobbies

Santa Rosa

707-537-6586

COLORADO

Custom Railway Supply

Colorado Springs

719-634-4616

Mizell T rains Inc.

W estminster

303-429-4811

CONNECTICUT

New England Hobby Supply

Manschester

860-646-0610

FLORIDA

Hollywood Station

Hollywood

954-921-2700

Depot Hobby Shop

Lake Worth

561-585-1982

Ready To Roll

Miami

305-688-8868

Frank s Trains & Hobbies

Inc.

Oldsmar

813-855-1041

Colonial Photo & Hobby

Orlando

407-841-1485

W arrick Custom Hobbies

Plant ation

954-370-0808

Roundhouse South

Port Orange

386-304-7002

ILLINOIS

Bike & Choo Choo

Connection

Schaumburg

847-882-7728

INDIANA

Y .O.R.K. T rains

Munster

219-838-9999

Samuelson s T rain Shop

V alp araiso

219-462-2708

IOWA

Caboose Stop Hobbies

Cedar Falls

800-642-7012

KENTUCKY

L&N Trains & Things

Louisville

502-897-9005

M.T.H. ELECTRIC TRAINS

23

F-3 A B A DIESEL ENGINE SET

MAINE

Wheels, Wing & Things

Ludlow

207-532-6277

MARYLAND

Plaza Hobby

Cumberland

301-729-6424

Hobbytown USA

Frederick

301-694-7395

Engine House Hobbies

Gaithersburg

301-590-0816

J&B Trains

Hagerstown

240-420-4930

The Train Room

Hagerstown

301-745-6681

Purkey s T oy T rains

Sykesville

410-549-6061

Catoctin Mount ain T rains

& Hobbies

Thurmont

301-694-8331

MASSACHUSETTS

Northeast T rains

Peabody

978-532-1615

East Bay Hobbies

Seekonk

508-336-5573

MICHIGAN

Michigan Model Train

Center

Pinckney

734-426-1651

Brasseur Electric T rains

Saginaw

989-793-4753

MISSOURI

Switch Stand

Saint Louis

314-781-4458

Mark Twain Hobby Center

S t. Charles

636-946-2816

NEVADA

Reno Rails

Reno

775-337-6669

NEW HAMPSHIRE

Railroad Specialties

Nashua

603-801-0801

T reasured Toys

Salem

603-898-7224

NEW JERSEY

Country and Stuff

Andover

973-786-7086

Columbus Train S tation

Columbus

609-518-1800

Atlantic Rails

Hammonton

609-567-8490

Grand Central Station

Kearny

201-955-6200

J&B Trains

Maple Shade

856-414-0092

Hobby Shop

Matawan

732-583-0505

Hobbymasters, Inc.

Red Bank

732-842-6020

Ridgefield Hobby

Ridgefield

201-943-2636

Tom s Model T rains

Scotch Plains

908-322-6122

T rains & Things

Trenton

609-883-8790

Coast T rains and

Collectibles

Wall

732-556-9005

Holly Beach T rain Depot

W ildwood

609-522-2379

NEW YORK

Aurora Rails & Hobbies

East Aurora

716-652-5718

Nassau Hobby Center, Inc.

Freeport

516-378-9594

Hobby World

Monticello

845-794-8770

City Depot, Inc.

New Hampton

845-374-3010

Americana Store

Tivoli

845-757-4246

Kross Hardware

W est Babylon

631-669-3069

NORTH CAROLINA

The Roundhouse &

Backshop

Cary

919-465-0810

T rains L T D .

Charlotte

704-566-9070

Day Bridge Station

Mount Airy

336-786-9811

The Freight Y ard

Smithfield

919-934-6229

T rain Lof t

W inston-Salem

336-760-9817

OHIO

Glen s Train Shop

Akron

330-253-6527

E&S Trains

Akron

330-745-0785

T&K Hobby Shop

Bridgeport

740-633-6607

Parma Hobby

M.T.H. ELECTRIC TRAINS

24

F-3 A B A DIESEL ENGINE SET

Sandy s Hobbies &

Collectibles

Elyria

440-365-9999

Hudson Toy, Train & Hobby

Hudson

330-653-2997

Clearview T rain & Hobby

Lorain

440-277-4488

Dixie Union Station

Mason

513-459-0460

Davis Electronics

Milford

513-831-6425

T rains-n-Things

North Canton

330-499-1666

Grand Pacific Junction

Olmstead Falls

440-235-4777

Rick s T oy T rains

Toledo

419-478-0171

Erie Railway Depot

T roy

937-440-9972

PENNSYLVANIA

American Hobby Center

Aliquipp a

724-378-3930

Allentown Toy T rain Service

Allentown

610-821-0740

On The Right T rack

Altoona

814-942-4345

Bussinger T rains

Ambler

215-628-2366

Y e Old T rain & Christmas

Shoppe

Boyertown

610-369-0755

Charleroi Sweeper Center

Charleroi

724-483-3397

Cranberry Hobby Depot

Cranberry Township

724-776-3640

Fairchance Pharmacy

Fairchance

724-564-7817

Toy T rain S tation

Feasterville Trev

215-322-5182

The Caboose

Lehighton

570-386-5352

Hobby City

McMurray

724-942-2557

The Station

New Cumberland

717-774-7096

Fryer s Store

Orwigsburg

570-366-2258

Chestnut Toybox

Philadelphia

215-545-0455

Toby Tyler

Pitt sburgh

412-653-5030

W ilcox Greenhouse &

Nursery

Titusville

814-827-3823

SOUTH CAROLINA

Emerald Train & Hobby

Greenwood

864-223-2247

TENNESSEE

Model Railroad & Hobby

Shop

Memphis

901-384-6500

TEXAS

Hobby Time

Amarillo

806-352-9660

Riverview T rains

Angleton

979-848-3895

Great T rains & Hobbies

Longview

903-757-2720

VIRGINIA

Locust Grove T rains

Locust Grove

540-854-8955

T rain Depot

Manassas

703-335-2216

Chesterfield Hobbies

Midlothian

804-379-9091

Davis Hobby Supplies

Port smouth

757-397-1983

Toy Train Center

Richmond

804-288-4475

Nutbush Express

Victoria

434-696-1902

TSG Hobbies

W arrenton

540-347-9212

Norge Station

W illiamsburg

757-564-7623

WEST VIRGINIA

Patrick s T rains

Wheeling

304-232-0714

WISCONSIN

W oodcrafters Shop

Burlington

262-763-5239

Sommerfeld s T rains

Bulter

262-783-7797

Hobby Outlet

Fond Du Lac

920-924-3770

G B TV & Tains

Greenbay

920-496-9697

Grampa s T rain Shop

Rice Lake

715-234-2996

The Train S tore

Loading...

Loading...