Page 1

M T E C o r p o r a t i o n

Sine Wave Filter

Series A

200- 600 VAC

USER MANUAL

PART NO. INSTR - 020

REL. 080310

© 2008 MTE Corporation

Page 2

Sine Wave 2-8 kHz Series A Filter

IMPORTANT USER INFORMATION

NOTICE

The MTE Corporation Sine Wave Filter is designed to convert output voltage wave

forms produced by a wide variety of PWM inverters into a low distortion sine wave for

drive and power conversion applications. The suitability of this filter for a specific

application must therefore be determined by the customer. In no event will MTE

Corporation assume responsibility or liability for any direct or consequential damages

resulting from the use or application of this filter. Nor will MTE Corporation assume

patent liability with respect to the use of information, circuits or equipment described

in this instruction manual.

Page 3

Page 4

TABLE OF CONTENTS

IMPORTANT USER INFORMATION ..................................................................................................... 0

TABLE OF CONTENTS.......................................................................................................................... 0

1. IMPORTANT SAFETY INFORMATION ............................................................................................. 1

2. INTRODUCTION................................................................................................................................. 2

REPAIR/EXCHANGE PROCEDURE............................................................................................................ 2

3. MODEL NUMBER CODES................................................................................................................. 3

4. SPECIFICATIONS .............................................................................................................................. 4

EFFICIENCY AND THERMAL RATINGS ...................................................................................................... 4

SERVICE CONDITIONS ............................................................................................................................ 5

AGENCY APPROVALS ............................................................................................................................ 5

PERFORMANCE...................................................................................................................................... 5

5 MECHANICAL DATA .......................................................................................................................... 8

200 - 230 VOLTS ................................................................................................................................... 8

380 – 480 VOLTS .................................................................................................................................. 9

550 - 600 VOLTS ................................................................................................................................. 10

6. INSTALLATION INSTRUCTIONS....................................................................................................11

OPEN PANEL CUSTOMER CONNECTIONS............................................................................................... 12

VERTICAL MOUNTING OF OPEN REACTOR & RC PANEL ............................................................... 19

350HP MCC USING OPTIONAL BAY FOR SINE WAVE INSTALLATION ....................................................... 20

ENCLOSED NEMA 1............................................................................................................................ 23

ENCLOSED NEMA 1-2 & 3R UNITS ...................................................................................................... 24

7 WIRING CONNECTIONS .................................................................................................................. 27

SINE WAVE INTERCONNECTION DIAGRAM ............................................................................................. 28

TERMINAL SPECIFICATIONS.................................................................................................................. 31

OPTION 01 .......................................................................................................................................... 33

FAN POWER ........................................................................................................................................ 34

8. FILTER DESCRIPTION .................................................................................................................... 35

BLOCK DIAGRAM............................................................................................................................ 36

9. STARTUP.......................................................................................................................................... 37

SEQUENCE OF OPERATION................................................................................................................... 37

10. TROUBLE SHOOTING................................................................................................................... 38

Page 5

Sine Wave 2-8 kHz Series A Filter

1. IMPORTANT SAFETY INFORMATION

WARNING

ONLY A QUALIFIED ELECTRICIAN CAN CARRY OUT THE ELECTRICAL

INSTALLATION OF THIS FILTER

WARNING

High voltage is used in the operation of this filter. Use Extreme caution to avoid contact

with high voltage when operating, installing or repairing this filter. INJURY OR DEATH

MAY RESULT IF SAFETY PRECAUTIONS ARE NOT OBSERVED.

After removing power, allow at least five minutes to elapse and verify that the capacitors

have discharged to a safe level before contacting internal components. Connect a DC

voltmeter across the capacitor terminals. Start with the meter on the highest scale and

progressively switch to a lower scale as the indicated voltage falls below the maximum

value of the next lower scale used.

WARNING

The opening of the branch circuit protective device may be an indication that a fault current has

been interrupted. To reduce the risk of fire or electrical shock, current-carrying parts and other

components of the filter should be examined and replaced if damaged.

WARNING

An upstream disconnect/protection device must be used as required by the National Electrical

Code (NEC).

WARNING

Even if the upstream disconnect/protection device is open, the inverter up stream of the filter may

feed high voltage to the filter. The drive safety instructions must be followed.

DEATH MAY RESULT IF THE DRIVE SAFETY PRECAUTIONS ARE NOT OBSERVED.

WARNING

The filter must be grounded with a grounding conductor connected to all grounding terminals.

WARNING

Only spare parts obtained from MTE Corporation or an authorized MTE distributor can be used.

INJURY OR

1

Part No. INSTR-020 REL. 080310

Page 6

Sine Wave 2-8 kHz Series A Filter

2. INTRODUCTION

This manual was specifically developed to

assist in the installation, interconnection and

operation of the MTE Corporation Sine Wave

filter.

This manual is intended for use by personnel

experienced in the operation and

maintenance of electronic drives. Because of

the high voltages required by the filter and

drive and the potential dangers presented by

rotating machinery, it is essential that all

personnel involved in the operation and

maintenance of this filter know and practice

the necessary safety precautions for this type

of equipment. Personnel should read and

understand the instructions contained in this

manual before installing, operating or

servicing the filter and inverter to which it is

connected.

Upon Receipt of this Filter:

The MTE Sine Wave Filter has been

subjected to demanding factory tests before

shipment. Carefully inspect the shipping

container for damage that may have occurred

in transit. Then unpack the filter and carefully

inspect for any signs of damage. Save the

shipping container for future transport of the

filter.

In the event of damage, please contact

and file a claim with the freight carrier

involved immediately.

If the equipment is not going to be put into

service upon receipt, cover and store the filter

in a clean, dry location. After storage, ensure

that the equipment is dry and that no

condensation has accumulated on the

internal components of the filter before

applying power.

Repair/Exchange Procedure

MTE Corporation requires a Returned

Material Authorization Number before it can

accept any filters that qualify for return or

repair. If problems or questions arise during

installation, setup, or operation of the filter,

please call us for assistance at

:

Director of MTE corporate quality:

Phone: 262-253-8200 ex. 148

FAX: 262-253-8210

2

Part No. INSTR-020 REL. 080310

Page 7

Sine Wave 2-8 kHz Series A Filter

3. MODEL NUMBER CODES

Model Code Part Number Configuration

SW A X Y _ _ _ _ X YY

Sine Wave filter

Series Version. A, X Options

“X” denotes Non standard Configurations 01 NC Overtemp

Mechanical Configuration P = Panel Mount

G = General Purpose

NEMA 1 or 2

W = NEMA 3R

Indicates Physical Size: A, B, C, D, etc. (A is smallest)

Current Rating (i.e. 0045 is 45 Amps)

Voltage

D 440 – 480

E 550 – 600

3

Part No. INSTR-020 REL. 080310

Page 8

Sine Wave 2-8 kHz Series A Filter

4. SPECIFICATIONS Efficiency and Thermal Ratings

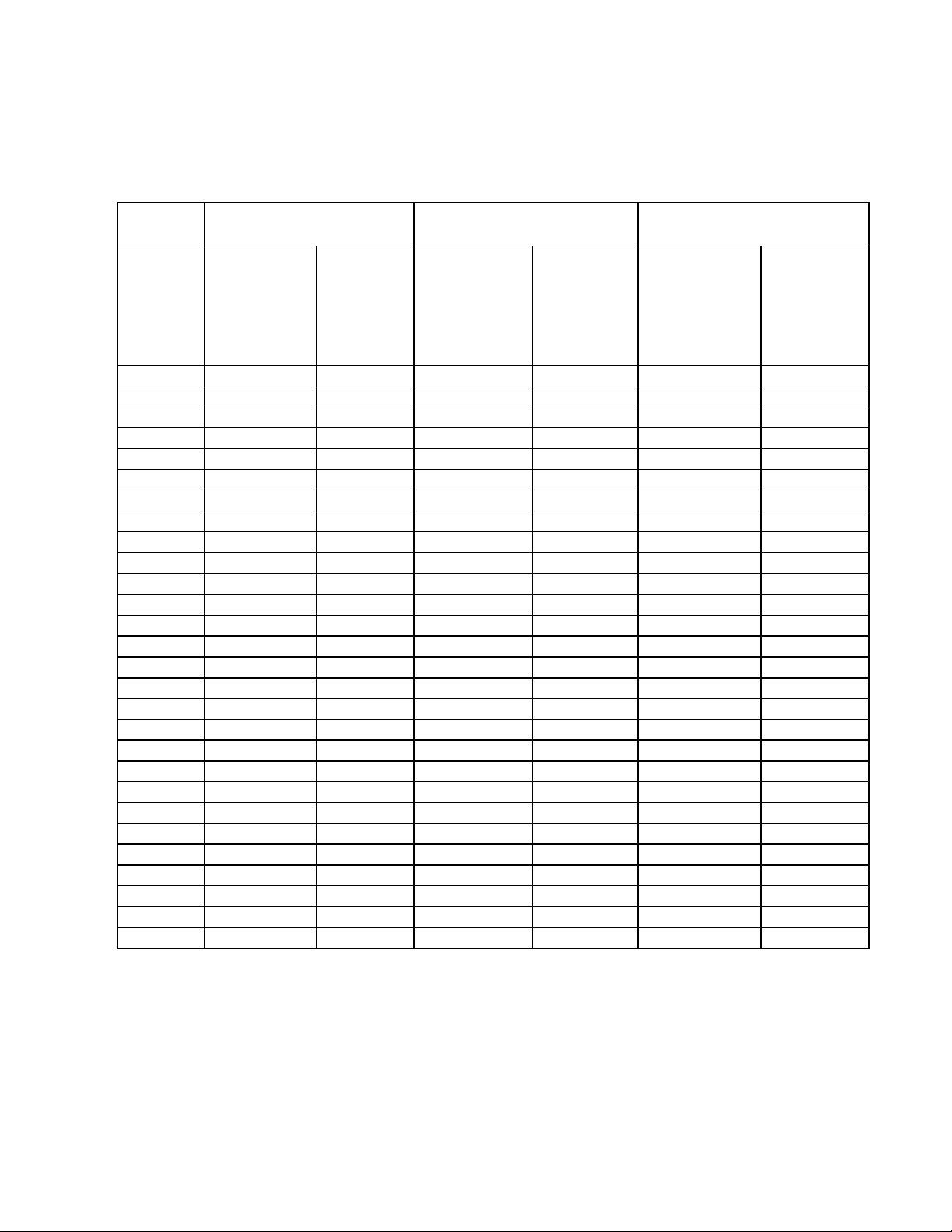

Table 1

Filter

Maximum

Output

Amps

RMS

2

3

5

7

9

12

17

22

27

30

35

45

55

65

70

80

110

130

160

200

250

305

320

365

415

515

600

720

200 - 230 VAC, 50/60 Hz

Filter Ratings

Power

Efficiency

(Typical)

(%)

Dissipation

@ Rated

Current

(Typical)

(Watts)

90.6

93.1

93.6

96.7

95.9

96.1

96.1

97.3

-

90.6

-

97.4

97.7

-

97.9

97.8

98.2

98.2

98.4

98.3

98.4

-

98.5

-

- -

- -

- -

- -

-

124

149

191

125

206

279

362

-

329

476

520

606

752

788

989

1062

1377

1617

-

1991

-

380 - 480 VAC, 50/60 Hz

Filter Ratings

Power

Efficiency

(Typical)

(%)

Dissipation

@ Rated

Current

(Typical)

(Watts)

94.04

95.08

94.88

-

98.26

98.35

98.90

98.72

99.01

-

99.08

99.01

98.97

99.13

-

99.08

99.01

99.20

99.23

99.20

99.29

99.31

-

99.37

99.40

99.29

99.24

99.33

40

53

93

128

162

151

229

216

262

360

457

454

596

878

836

996

1286

1424

1701

-

1841

2021

2944

3698

4133

550 - 600 VAC, 60 Hz Filter

Ratings

Power

Efficiency

(Typical)

(%)

Dissipation

@ Rated

Current

(Typical)

(Watts)

97.24

97.83

98.14

98.32

98.31

98.54

98.73

98.86

98.92

-

99.08

98.93

99.04

99.01

-

99.00

99.09

99.12

99.02

99.35

99.34

99.27

-

99.32

99.26

99.33

99.38

99.44

57

67

95

120

155

177

219

253

295

323

489

535

650

806

1014

1157

1589

1315

1655

2237

-

2489

3098

3229

3406

3935

4 Part No. INSTR-020 REL. 080310

Page 9

Sine Wave 2-8 kHz Series A Filter

Service Conditions

Input voltage: 200 – 600 VAC +/- 10%, 50 & 60 Hz

Input voltage wave form: PWM

Switching Frequency: 2 – 8 kHz

Operating frequency: 6 – 60 Hz without de-rating

Temperature: Open filters -40 to 50 °C

Enclosed filters -40 to 40 °C

Storage All types -40 to 90 °C

Altitude without de-rating: 1000 meters

Relative Humidity: 0 to 99% Non condensing

Agency Approvals

File E180243 (3 – 1000 HP, 120VAC through 600 VAC

50. 50/60, 60 Hz Three Phase

Note: Short Circuit rating not required under Exception No.1 of UL508A SB4.2.1 effective 4/25/06

Current Rating

Continuous current rating: 100% RMS

Intermittent current ratings: 150 % for 1 minute

Load : Conventional 3 phase motors operating in volts per Hertz mode

Standard step-up transformer with 4% minimum output impedance

“No load” continuous operation

Maximum motor lead length: 15,000 feet

Insertion loss: 10% of rated voltage maximum

Audible noise level at two meters for standard configuration: 76 DB-A

Harmonic voltage distortion feeding a transformer at full load and at 60Hz: 5% maximum

Harmonic voltage distortion feeding a motor at full load and at 60Hz: 5% typical

UL and cUL listed to UL508 Type MX and CSA-C22.2 No 14-95

Performance

5 Part No. INSTR-020 REL. 080310

Page 10

Sine Wave 2-8 kHz Series A Filter

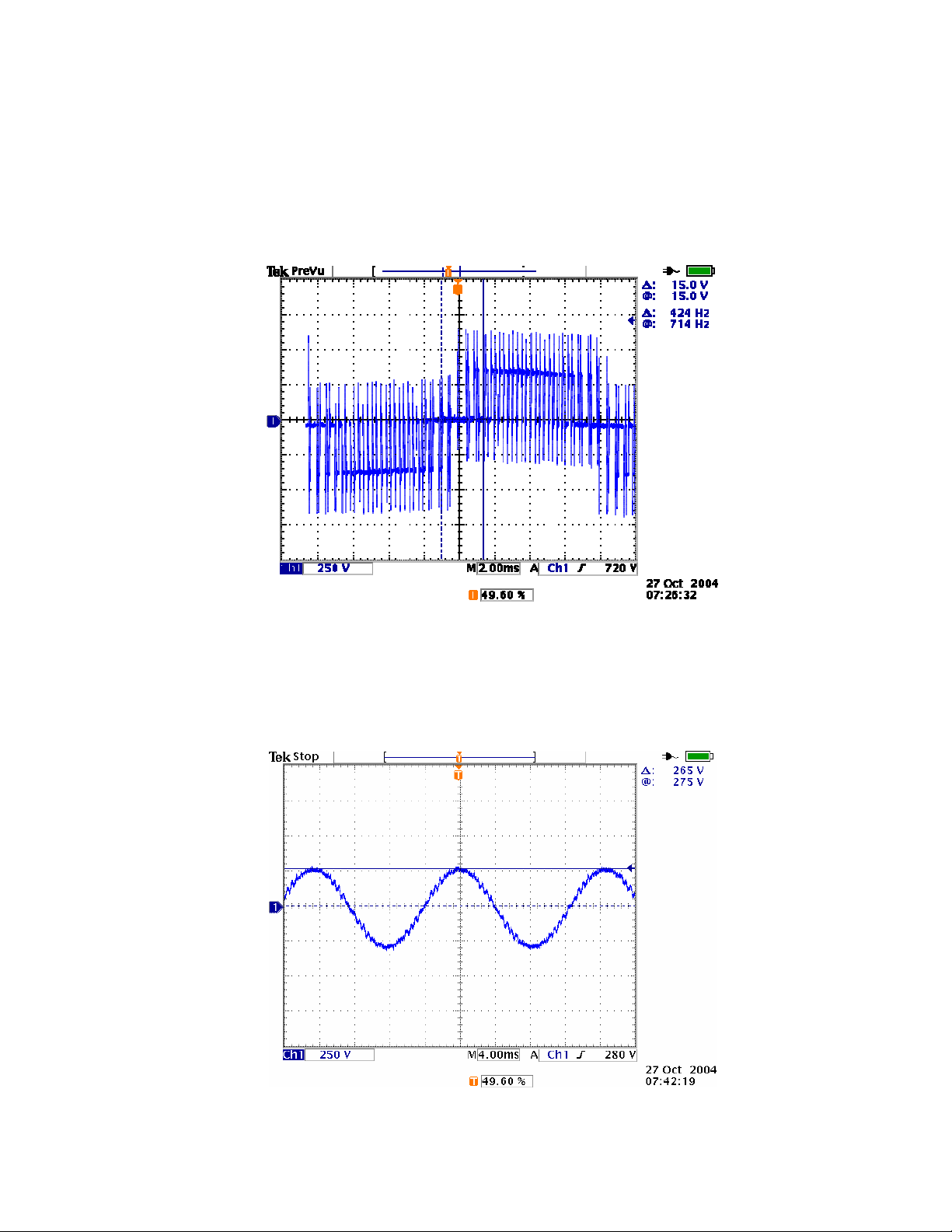

Typical Performance Data

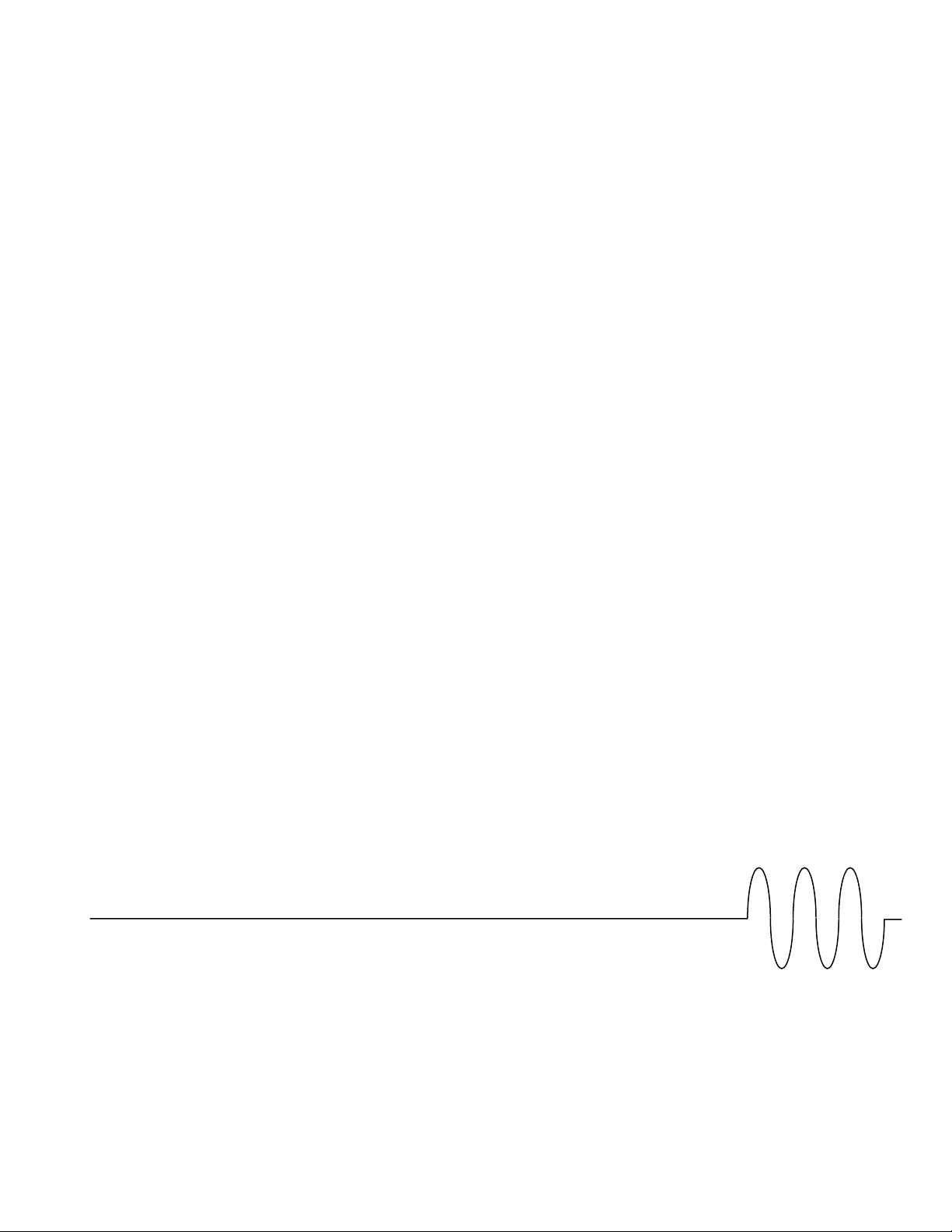

Fig.1

Raw drive output voltage

Fig. 2

Output voltage after sine wave filter

6 Part No. INSTR-020 REL. 080310

Page 11

1.05

Sine Wave 2-8 kHz Series A Filter

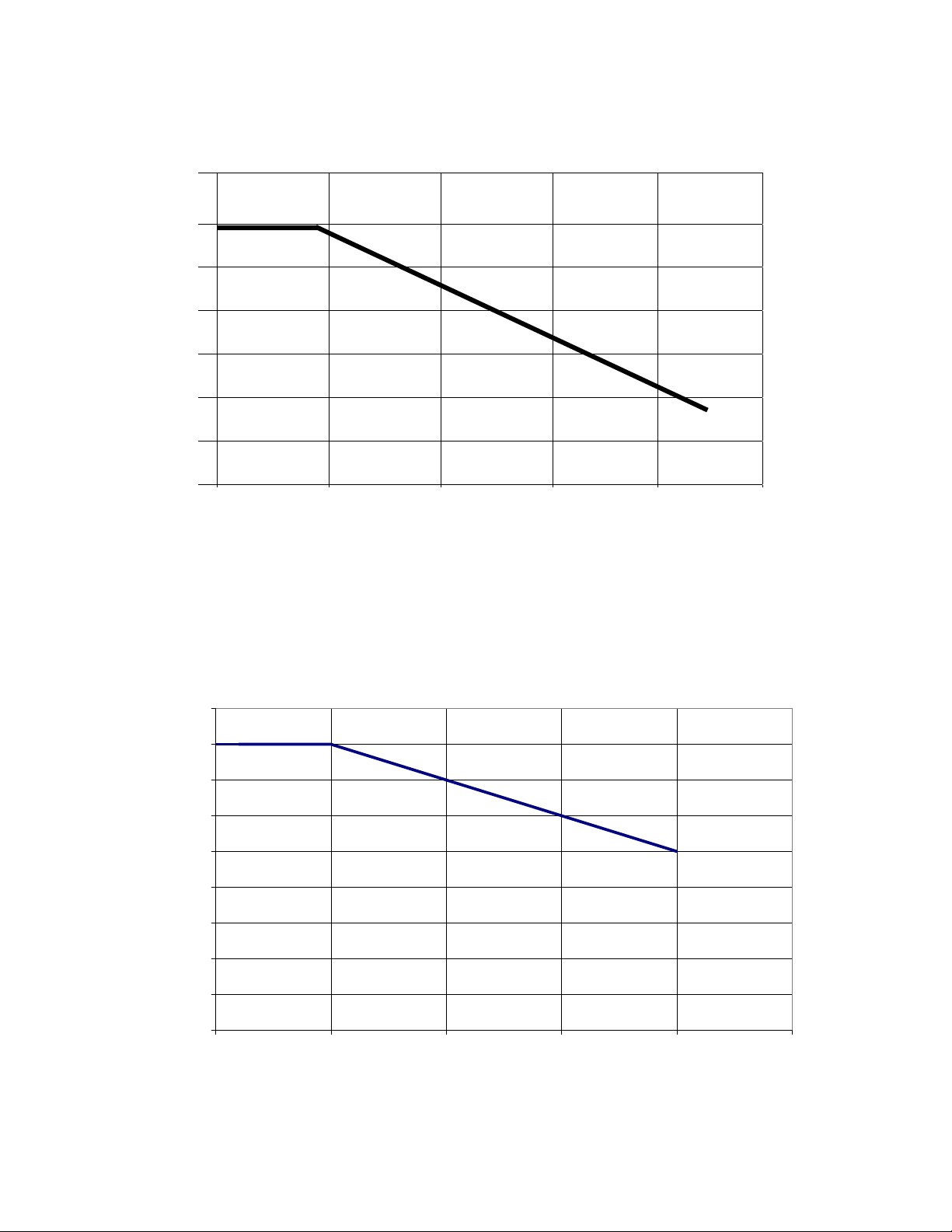

Altitude De-rating

Chart 1

Altitude Derating Curve

1.00

0.95

0.90

0.85

0.80

0.75

0.70

CURRENT DERATING FACTOR

0 3300 6600 9900 13200 16500

ALTITUDE (FEET)

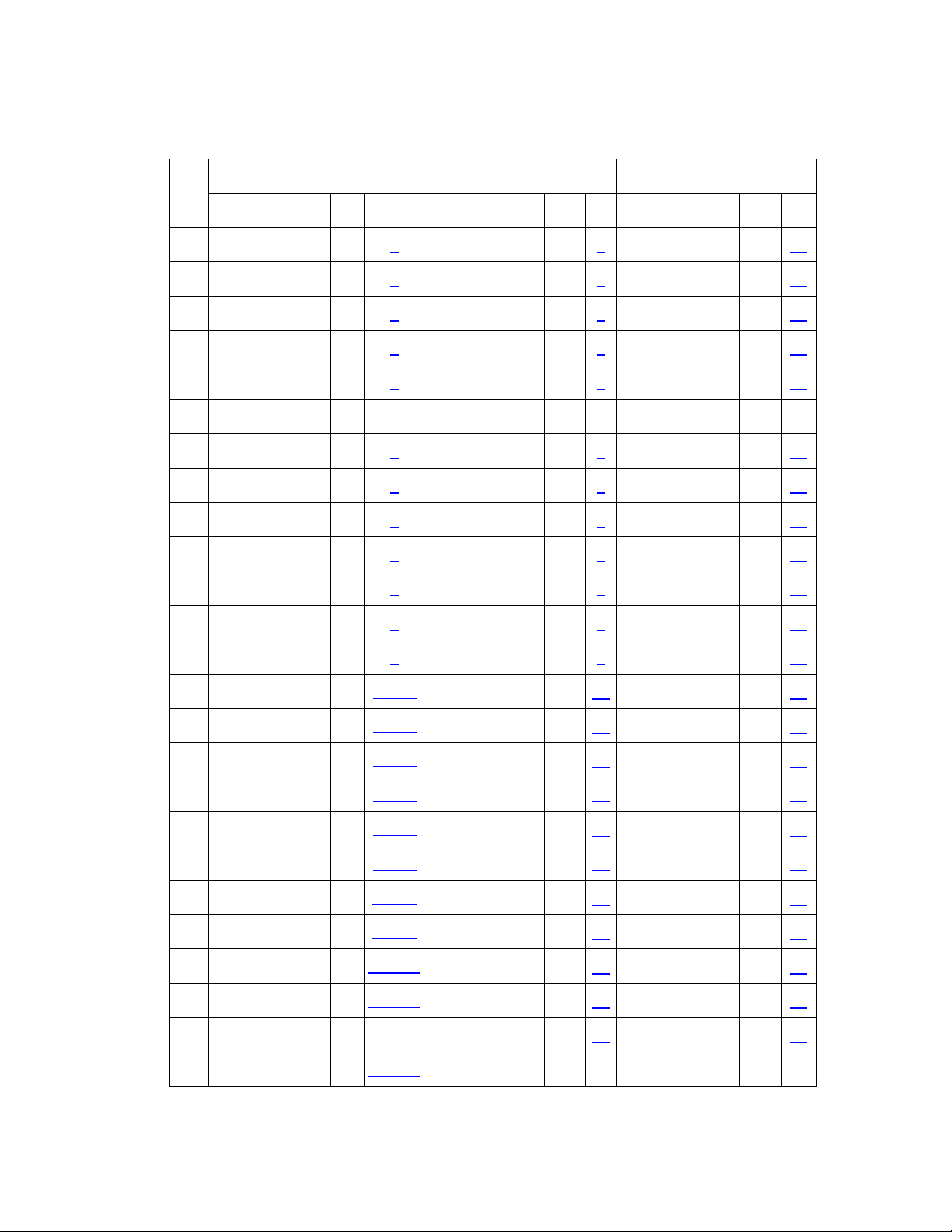

Inverter Frequency De-rating

Sine Wave Filter Current Derating for Drive output Frequency

Chart 2

1.05

1

0.95

0.9

0.85

0.8

0.75

0.7

Current Derating Factor

0.65

0.6

50 60 70 80 90 100

Output Drive Frequency Hertz

7 Part No. INSTR-020 REL. 080310

Page 12

Sine Wave 2-8 kHz Series A Filter

5 Mechanical Data

200 - 230 Volts

Table 10

Filter

Amps

3

5

7

9

12

17

22

30

45

55

70

85

Open NEMA 1* NEMA 3R

Cat PN.

SWAP0003A

SWAP0005A

SWAP0007A

SWAP0009A

SWAP0012A

SWAP0017A

SWAP0022A

SWAP0030A

SWAP0045A

SWAP0055A

SWAP0070A

SWAP0085A

WT

Lbs

16

21

24

24

27

31

32

38

47

55

60

73

Fig.

3

3

3

3

3

3

3

4

4

4

4

A17 & B

Cat PN.

SWAGA0003A

SWAGA0005A

SWAGA0007A

SWAGA0009A

SWAGA0012A

SWAGA0017A

SWAGB0022A

SWAGB0030A

SWAGB0045A

SWAGB0055A

SWAGC0070A

SWAGC0085A

WT

Lbs

32

37

40

40

43

47

57

60

69

77

215

228

Fig.

8

8

8

8

8

8

9

9

9

9

9

12

Cat PN.

SWAWA0003A

SWAWA0005A

SWAWA0007A

SWAWA0009A

SWAWA0012A

SWAWA0017A

SWAWB0022A

SWAWB0030A

SWAWB0045A

SWAWB0055A

SWAWC0070A

SWAWC0085A

WT

Lbs

89

94

97

97

100

104

133

136

145

153

249

262

Fig.

10

10

10

10

10

10

11

11

11

11

11

12

110

SWAP0110A

135

SWAP0135A

160

SWAP0160A

200

SWAP0200A

250

SWAP0250A

320

SWAP0320A

92

100

121

167

196

228

A19 & B

A19 & B

A19 & B

A2 & C

A3 & C

A4 & C

SWAGC0110A

SWAGC0135A

SWAGC0160A

SWAGC0200A

SWAGD0250A

SWAGD0320A

247

255

271

327

479

511

12

SWAWC0110A

12

SWAWC0135A

12

SWAWC0160A

13

SWAWC0200A

13

SWAWD0250A

13

SWAWD0320A

281

289

305

351

531

563

12

12

12

13

13

13

8 Part No. INSTR-020 REL. 080310

Page 13

Sine Wave 2-8 kHz Series A Filter

380 – 480 Volts

Table 2

Filter

Amps

Cat PN.

Open NEMA 1 NEMA 3R

2 SWAP0002D

3 SWAP0003D

5 SWAP0005D

9 SWAP0009D

12 SWAP0012D

17 SWAP0017D

22 SWAP0022D

27 SWAP0027D

35 SWAP0035D

45 SWAP0045D

55 SWAP0055D

65 SWAP0065D

WT

Lbs

16

18

22

27

27

30

37

38

51

57

67

77

Fig.

3

SWAGA0002D

3

SWAGA0003D

3

SWAGA0005D

3

SWAGA0009D

3

SWAGA0012D

3

SWAGA0017D

4

SWAGB0022D

4

SWAGB0027D

4

SWAGB0035D

4

SWAGB0045D

4

SWAGB0055D

5

SWAGB0065D

Cat PN.

WT

Lbs

32

34

38

94

94

94

122

123

131

137

147

157

Fig.

8

8

8

8

8

8

9

9

9

9

9

9

Cat PN.

SWAWA0002D

SWAWA0003D

SWAWA0005D

SWAWA0009D

SWAWA0012D

SWAWA0017D

SWAWB0022D

SWAWB0027D

SWAWB0035D

SWAWB0045D

SWAWB0055D

SWAWB0065D

WT

Lbs

89

91

95

100

100

100

135

136

144

150

160

170

Fig.

10

10

10

10

10

10

11

11

11

11

11

11

80 SWAP0080D

110 SWAP0110D

130 SWAP0130D

160 SWAP0160D

200 SWAP0200D

250 SWAP0250D

305 SWAP0305D

365 SWAP0365D

415 SWAP0415D

515 SWAP0515D

600 SWAP0600D

720 SWAP0720D

86

117

134

163

188

233

266

425

500

650

825

1125

5

A1& B

A2 & B

A3 & B

A4 & B

A6 & B

A7 & C

A8 & C

A10 & C

A12 & C

A13 & D

A15 & D

SWAGC0080D

SWAGC0110D

SWAGC0130D

SWAGC0160D

SWAGD0200D

SWAGD0250D

SWAGD0305D

SWAGD0365D

SWAGD0415D

SWAGD0515D

SWAGE0600D

SWAGE0720D

246

277

294

323

471

516

549

631

700

814

1012

1128

12

SWAWC0080D

12

SWAWC0110D

12

SWAWC0130D

12

SWAWC0160D

13

SWAWD0200D

13

SWAWD0250D

13

SWAWD0305D

13

SWAWD0365D

13

SWAWD0415D

13

SWAWD0515D

14

SWAWE0600D

14

SWAWE0720D

270

301

318

347

523

568

601

683

752

866

1063

1179

12

12

12

12

13

13

13

13

13

13

14

14

9 Part No. INSTR-020 REL. 080310

Page 14

Sine Wave 2-8 kHz Series A Filter

550 - 600 Volts

Table 3

Filter

Amps

Cat PN.

Open NEMA 1 NEMA 3R

2 SWAP0002E

3 SWAP0003E

5 SWAP0005E

7 SWAP0007E

9 SWAP0009E

12 SWAP0012E

17 SWAP0017E

22 SWAP0022E

27 SWAP0027E

35 SWAP0035E

45 SWAP0045E

55 SWAP0055E

WT

Lbs

18

21

24

26

27

27

37

38

45

58

63

75

Fig.

3

SWAGA0002E

3

SWAGA0003E

3

SWAGA0005E

3

SWAGA0007E

3

SWAGA0009E

3

SWAGA0012E

4

SWAGB0017E

4

SWAGB0022E

4

SWAGB0027E

4

SWAGB0035E

4

SWAGB0045E

5

SWAGB0055E

Cat PN.

WT

Lbs

34

37

40

42

94

94

101

123

130

138

143

155

Fig.

8

8

8

8

8

8

9

9

9

9

9

9

Cat PN.

SWAWA0002E

SWAWA0003E

SWAWA0005E

SWAWA0007E

SWAWA0009E

SWAWA0012E

SWAWB0017E

SWAWB0022E

SWAWB0027E

SWAWB0035E

SWAWB0045E

SWAWB0055E

WT

Lbs

91

94

97

99

100

100

107

136

143

151

156

168

Fig.

10

10

10

10

10

10

11

11

11

11

11

11

65 SWAP0065E

80 SWAP0080E

110 SWAP0110E

130 SWAP0130E

160 SWAP0160E

200 SWAP0200E

250 SWAP0250E

305 SWAP0305E

365 SWAP0365E

415 SWAP0415E

515 SWAP0515E

600 SWAP0600E

720 SWAP0720E

86

117

146

166

194

236

280

425

490

726

750

1225 A15 & D

1375

5

A1 & B

A3 & B

A4 & B

A5 & B

A6 & B

A6 & B

A8 & C

A9 & C

A11 & D

A14 & C

A16 & D

SWAGB0065E

SWAGC0080E

SWAGC0110E

SWAGC0130E

SWAGC0160E

SWAGD0200E

SWAGD0250E

SWAGD0305E

SWAGD0365E

SWAGD0415E

SWAGD0515E

SWAGE0600E

SWAGE0720E

1203

1327

166

277

306

326

354

519

547

630

696

801

916

9

SWAWB0065E

12

SWAWC0080E

12

SWAWC0110E

12

SWAWC0130E

12

SWAWC0160E

13

SWAWD0200E

13

SWAWD0250E

13

SWAWD0305E

13

SWAWD0365E

13

SWAWD0415E

13

SWAWD0515E

14

SWAWE0600E

14

SWAWE0720E

179

301

330

350

378

571

599

682

748

853

968

1254

1378

11

12

12

12

12

13

13

13

13

13

13

14

14

10 Part No. INSTR-020 REL. 080310

Page 15

Sine Wave 2-8 kHz Series A Filter

6. INSTALLATION INSTRUCTIONS

Sine Wave filters are supplied in the

following mechanical configurations:

Panel mounted assemblies

Floor mounted general purpose NEMA 1

& 3R cabinets

Panel mounted filters are designed for

mounting in the vertical plane in the

customer’s enclosure. Include the power

dissipation of the filter along with all the

other components located in the panel to

determine the internal temperature rise and

cooling requirements of the enclosure. An

option NC temperature switch may be

added to protect against filter over heating.

Allow a minimum side clearance of four (4)

inches and a vertical clearance of six (6)

inches for proper heat dissipation and

access within the enclosure. Panel mounted

Sine Wave filters generate heat and should

be positioned away from heat sensitive

components. Ensure that proper panel

orientation is maintained. Keep the

capacitors away from reactor and resistor

heat flow. Avoid locations where the filter

would be subjected to excessive vibrations.

Figures 3

drawings for the various current ratings and

show proper panel mounting orientation. For

filters above 80 amps refer to table 4 and

– 5 contain open panel outline

Figure A & B for the dimensions of the

separately mounted reactor and the RC panel.

The RC panel should be located away from

the reactor and in the lowest temperature

regions of the enclosure – generally toward

the bottom.

General purpose NEMA 1, 2 and 3R

enclosed filters are designed for floor

mounting in an environment suitable for the

enclosure type. Do not install in or near a

corrosive environment. Avoid locations

where the filter would be subjected to

excessive vibrations. Allow a minimum side

and back clearance of eight (8) inches and

front clearance of thirty-six (32 inches for

proper heat dissipation and access. Page

20 will direct you to the appropriate outline

drawings shown in fig. 8 through fig 14

Locate the filter as close to the inverter

as possible. Do not exceed a maximum

distance of 50 feet.

11 Part No. INSTR-020 REL. 080310

Page 16

Sine Wave 2-8 kHz Series A Filter

Open Panel Customer connections

Open Panel:

3 – 30 Amps 200 - 230 VAC

9 - 17 AMPS 380 - 480 VAC

9 - 12 AMPS 550 - 600 VAC

Fig. 3

17 Amp Shown

12 Part No. INSTR-020 REL. 080310

Page 17

Sine Wave 2-8 kHz Series A Filter

Open Panel:

45 – 60 AMPS 200 – 230 VAC

22 - 55 AMPS 440 - 480 VAC

17 - 45 AMPS 550 - 600 VAC

Fig. 4

45 Amp shown

13 Part No. INSTR-020 REL. 080310

Page 18

Sine Wave 2-8 kHz Series A Filter

Open Panel: 65 - 80 AMPS 440 - 480 VAC

55 - 65 AMPS 550 - 600 VAC

Fig. 5

80 Amp Shown

14 Part No. INSTR-020 REL. 080310

Page 19

Sine Wave 2-8 kHz Series A Filter

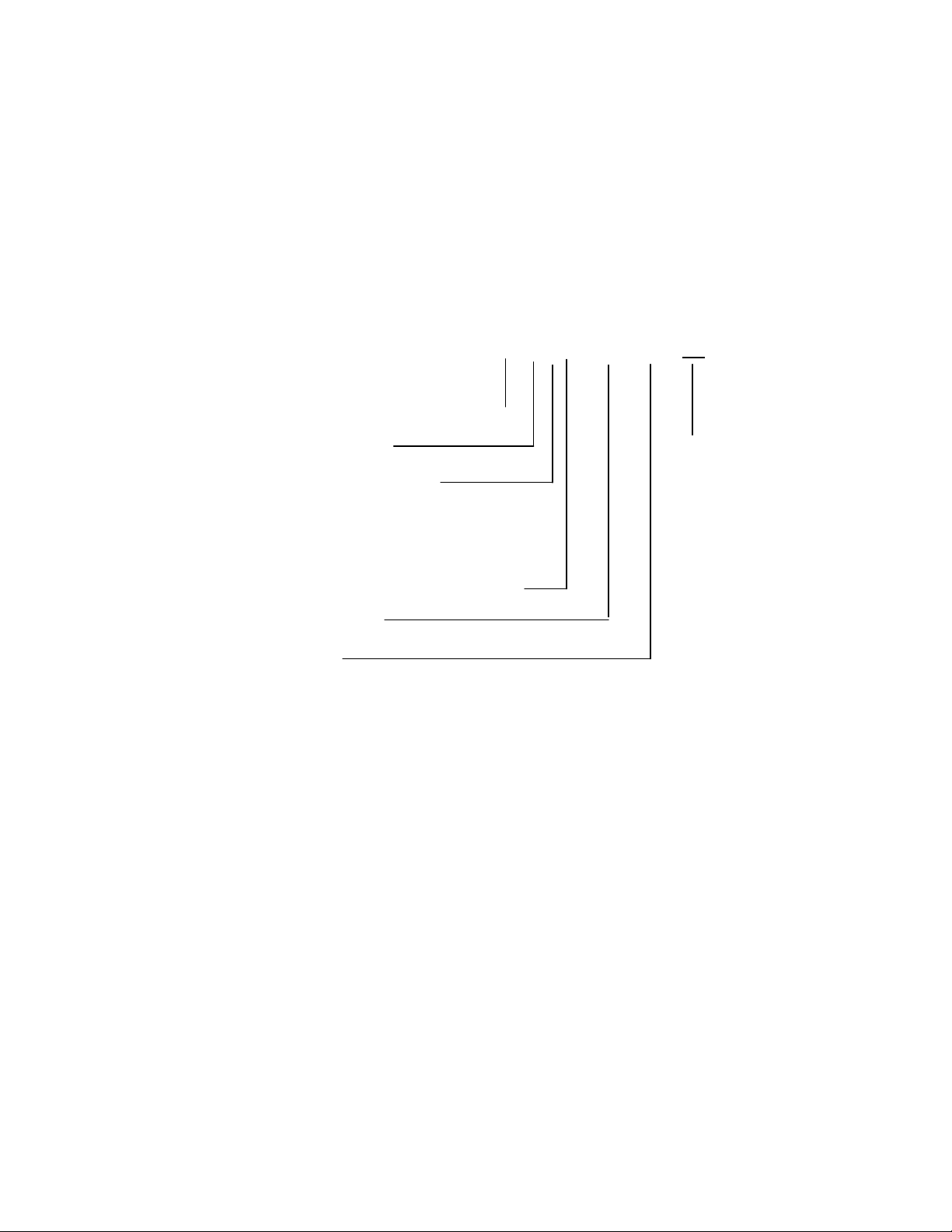

Sine Wave Filters rated 80 amps through 720 amps are made up of a reactor and a

RC panel. These components are designed to be mounted vertically within an

appropriate enclosure. The reactor generates heat and should be mounted away

from components affected by heat. Align the reactor to allow cooling air to flow

through it. A filter showing correct reactor alignment and placement is shown in

figure 6. The RC panel should be located in the lowest temperature regions of the

enclosure – generally toward the bottom. An example of an MCC application is

shown in Figure 7

Table 4

FIG. A

Figure

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

DIMENSIONS Inches

A (W) B (H) C (D) D E

14.4 13 10.5 8.75 4.6

14.4 13 10.75 8.75 4.6

14.4 13 11.25 8.75 4.6

14.4 13 11.5 9.25 4.6

14.4 13 12.25 9.75 4.6

14.4 13 13.5 10.75 4.6

14.4 13 15 11.75 4.6

22 17 12.5 6.7 7.2

22 17 13.5 7.7 7.2

22 17 15.5 8.2 7.2

22 17 17 9.7 7.2

22 17 15.5 9.7 7.2

22 17 22 12.2 7.2

22 17 17.75 11.2 7.2

33.5 28.5 19.5 12.5 11

33.5 28.5 20 12.5 11

9 6.9 8.1 4.7 4.3

14 13 11.8 6.7 7.2

11 8.8 9.8 4.8 5.6

15 Part No. INSTR-020 REL. 080310

Page 20

Sine Wave 2-8 kHz Series A Filter

RC Panel: 85 – 160 AMPS 200 - 230 VAC

110 - 160 AMPS 380 - 480 VAC

80 - 250 AMPS 550 - 600 VAC

Fig. B

16 Part No. INSTR-020 REL. 080310

Page 21

Sine Wave 2-8 kHz Series A Filter

RC Panel: 200 - 320 AMPS 200 - 230 VAC

200 - 515 AMPS 380 - 480 VAC

305, 365, 515 AMPS 550 - 600 VAC

Fig. C

17 Part No. INSTR-020 REL. 080310

Page 22

Sine Wave 2-8 kHz Series A Filter

RC Panel: 600 - 720 AMPS 440 - 480 VAC

415, 600, 720 AMPS 550 – 600 VAC

Fig. D

18 Part No. INSTR-020 REL. 080310

Page 23

Sine Wave 2-8 kHz Series A Filter

Fig. 6

Vertical MOUNTING OF OPEN REACTOR & RC Panel

600 amp open reactor & RC panel shown in customer provided enclosure and mounting

hardware.

NOTE: Maintain orientation as shown for proper component cooling. Do not place RC panel above

reactor or position capacitors above resistors. RC panel may be mounted horizontally.

19 Part No. INSTR-020 REL. 080310

Page 24

Sine Wave 2-8 kHz Series A Filter

350Hp MCC using optional bay for Sine Wave installation

Fig. 7

Note: The above Sine Wave filter example is shown with customer provided

support hardware. Other installation variations are at the customer’s discretion

as long as thermal guidelines are followed.

20 Part No. INSTR-020 REL. 080310

Page 25

Sine Wave 2-8 kHz Series A Filter

Enclosed Units

Table 5

Enclosure

Indicator

GA

GB

GC

GD

GE

WA

WB

WC

WD

WE

See Mechanical Data for enclosed weights.

Width Height Depth

13 13 13 Cab 13V NEMA 1 8

17 24 18 Cab 17V NEMA 1 9

27 47 25 Cab 26C NEMA 1 -2 12

31 72 31 Cab 30C NEMA 1 -2 13

43 72 25 Cab 42C NEMA 1 -2 14

12.5 24 18 Cab 12C NEMA 3R 10

17.5 31 21 Cab 17C NEMA 3R 11

26.5 47 30 Cab 26C NEMA 3R 12

30.5 72 40 Cab 30C NEMA 3R 13

43 72 34 Cab 42C NEMA 3R 14

Cab Part

No.

NEMA

Type

Figure

21 Part No. INSTR-020 REL. 080310

Page 26

Sine Wave 2-8 kHz Series A Filter

Enclosed Units By Current

Table 6

Filter

Current

Rating

2

3

5

7

9

12

17

22

27

30

35

45

55

65

70

80

85

110

130

135

160

200

250

305

320

365

415

515

600

720

General Purpose

Cabinets

200– 230 VAC

NEMA 1 NEMA 3R NEMA 1 NEMA 3R NEMA 1 NEMA 3R

CAB-13V CAB-12C

CAB-13V CAB-12C

CAB-13V CAB-12C

CAB-13V CAB-12C

CAB-13V CAB-12C CAB-13V CAB-12C CAB-13V CAB-12C

CAB-13V CAB-12C CAB-13V CAB-12C CAB-13V CAB-12C

CAB-13V CAB-12C CAB-13V CAB-12C CAB-17V CAB-17C

CAB-17V CAB-17C CAB-17V CAB-17C CAB-17V CAB-17C

- - CAB-17V CAB-17C CAB-17V CAB-17C

CAB-17V CAB-17C - - - CAB-17V CAB-17C CAB-17V CAB-17C CAB-17V CAB-17C

CAB-17V CAB-17C CAB-17V CAB-17C CAB-17V CAB-17C

CAB-17V CAB-17C CAB-17V CAB-17C CAB-26C CAB-26C

- - CAB-17V CAB-17C CAB-26C CAB-26C

CAB-17V CAB-17C - - - -

- - CAB-26C CAB-26C CAB-26C CAB-26C

CAB-26C CAB-26C - - - CAB-26C CAB-26C CAB-26C CAB-26C CAB-26C CAB-26C

- - CAB-26C CAB-26C CAB-30C CAB-30C

CAB-26C CAB-26C - - - CAB-26C CAB-26C CAB-26C CAB-26C CAB-30C CAB-30C

CAB-30C CAB-30C CAB-30C CAB-30C CAB-30C CAB-30C

CAB-30C CAB-30C CAB-30C CAB-30C CAB-30C CAB-30C

- - CAB-30C CAB-30C CAB-30C CAB-30C

CAB-30C CAB-30C - - - -

- -

- -

- -

- -

- -

Mounting dimensions and outline drawings for filters mounted in NEMA 1, 3R

Enclosures follow

General Purpose

Cabinets

General Purpose Cabinets

550– 600VAC

380 – 480 VAC

CAB-13V CAB-12C CAB-13V CAB-12C

CAB-13V CAB-12C CAB-13V CAB-12C

CAB-13V CAB-12C CAB-13V CAB-12C

CAB-13V CAB-12C CAB-13V CAB-12C

CAB-30C CAB-30C CAB-30C CAB-30C

CAB-30C CAB-30C CAB-42C CAB-42C

CAB-30C CAB-30C CAB-42C CAB-42C

CAB-42C CAB-42C CAB-42C CAB-42C

CAB-42C CAB-42C CAB-42C CAB-42C

22 Part No. INSTR-020 REL. 080310

Page 27

Sine Wave 2-8 kHz Series A Filter

Enclosed NEMA 1

Fig. 8 Cab - 13V

Fig. 9 Cab - 17V

23 Part No. INSTR-020 REL. 080310

Page 28

Sine Wave 2-8 kHz Series A Filter

Enclosed NEMA 1-2 & 3R units

Fig. 10 Cab - 12C

Fig. 11 Cab - 17C

24 Part No. INSTR-020 REL. 080310

Page 29

Sine Wave 2-8 kHz Series A Filter

Enclosed Outline Drawings

NEMA 1-2 and 3R Enclosures

Enclosure Dimensions

Fig. 12 Cab - 26C

Fig. 13 Cab – 30C

25 Part No. INSTR-020 REL. 080310

Page 30

Sine Wave 2-8 kHz Series A Filter

Enclosed Outline Drawings

NEMA 1-2 and 3R Enclosures Continued

Fig. 14 Cab – 42C

26 Part No. INSTR-020 REL. 080310

Page 31

Sine Wave 2-8 kHz Series A Filter

7 Wiring Connections

WARNING

Input and output wiring to the filter

should be performed by authorized

personnel in accordance with NEC and

all local electrical codes and

regulations.

Verify that the rating of the filter is compatible

with the inverter to which it is to be connected.

Follow all detailed inverter manufacturer

installation and safety instructions. Inverter and

load Cable selection / placement should be in

accordance with the requirements of the NEC

and all local electrical codes and regulations

The typical interconnection diagrams that

follow are shown for a motor load but the load

can be either a motor or a transformer. For

enclosed filters supplied in general purpose

NEMA1 and 3R cabinets and open panel filters

rated less than 80 amperes, interconnection

between the filter, motor and the inverter is

shown in Fig. 15

manual for instructions on interconnecting the

inverter and motor and the correct start-up

procedures for the inverter. The sine wave

filter is primarily designed to operate from a

drive using the volts per Hertz mode. For drive

auto-tune or feedback using the motor consult

the drive manufacture for setting the drive with

output filters.

For power supply / frequency converter

applications using a PWM inverter, the output of

the Sine wave must feed a Delta- Wye isolation

transformer to accommodate the effects of load

imbalances and to cancel tripplen harmonics. See

Fig. 17

The filter is designed for use with copper

conductors with a minimum temperature rating

of 75 degrees C. Table 7

and terminal torque requirements for the power

input and output connections.

for details.

Refer to the inverter user

lists the wire range

For panel mounted filters rated 80 amperes or

more, the filter reactor is supplied loose and

the RC network is supplied as an RC panel

assembly. Refer to fig. 16

interconnection diagram. To select appropriate

conductors for the wiring between the reactor

and the RC panel refer to table 8

contains the terminal specifications for these

connections.

Use the cable recommended by the inverter

manufacturer to connect the inverter to the

filter and the filter to the motor. Make certain,

that the selected cable size conforms to the

requirements of the National Electric Code and

all local codes.

For open filters refer to Fig. 3

location of Input, output, and ground

connections. For enclosed filters, ground

terminals will be clearly marked. Power wiring

terminations are clearly marked on the reactor.

Larger enclosed filters require power for the

fans. A terminal for 115 VAC 50/60 Hz fan

power is also provided for connecting to clean

customer power. See table 10

Grounding

The filter must always be grounded with a

grounding conductor connected to ground

terminals.

For cable shield grounding follow the inverter

manufactures recommendations. Fig 15

shows a typical shield ground connection.

Optional Over Temperature Interlock

for a typical

. Table 7

through 5 for the

for fan wiring.

& 16

The optional over temperature interlock

can be used to turn off the inverter in the

event it is setup to operate with a switching

frequency outside of the range of the filter

or an inverter / motor malfunction. The

temperature switch is normally closed and will

open when an internal reactor temperature of

180 °C is reached. See

table 9 for contact

rating information and the inverter user

manual for interconnection information.

27 Part No. INSTR-020 REL. 080310

Page 32

Sine Wave 2-8 kHz Series A Filter

Sine Wave Interconnection diagram

Open Style 2 – 80 Amps

Enclosed 2 – 720 Amps

Fig. 15

28 Part No. INSTR-020 REL. 080310

Page 33

Sine Wave 2-8 kHz Series A Filter

Interconnection diagram Open Style 80 – 720 Amp

Fig. 16

29 Part No. INSTR-020 REL. 080310

Page 34

Sine Wave 2-8 kHz Series A Filter

Isolation Transformer connections

Fig. 17

30 Part No. INSTR-020 REL. 080310

Page 35

Sine Wave 2-8 kHz Series A Filter

Terminal Specifications

Table 7

Filter

Rating

Amps

2

3

5

7

9

12

17

22

27

35

45

55

65

80

110

130

160

200

250

305

365

415

515

600

720

Input / Output Terminals

Wire Range

(AWG)

22-14 16 N/R

22-14 16 N/R

22-14 16 N/R

22-14 16 N/R

22-14 16 N/R

22-5 16 N/R

22-5 16 N/R

22-5 16 N/R

22-5 16 N/R

22-5 16 N/R

18-4 20

18-4 20

6-4 & 2-0 50

6-4 & 2-0 50

3/0 75C 250

4/0 75C 250 12

3/0 90C 250 8

4/0 90C

250MCM 75C

400MCM 90C

600MCM

4/0 2X 90C

300MCM 2X 90C

350MCM 2X 90C

600MCM 2X 90C

300MCM 3X 90C

500MCM 3X 90C

500MCM 3X 90C

Terminal

Torque

(in-lbs)

325

375 8

375

375 8

375 4

375

375 1

375 1

*Reactor to

RC Panel

Open style only

75 °C conductor

AWG

N/R

N/R

N/R

12

12

8

8

4

*See fig. 16 for customer wire connections.

*Size interconnecting wire to carry current shown on table 8.

31 Part No. INSTR-020 REL. 080310

Page 36

Sine Wave 2-8 kHz Series A Filter

Maximum RC PANEL Current for Open Wiring

Inter-connect wire sizes

Table 8

Filter

Rating

Amps Maximum Amps RMS Maximum Amps RMS Maximum Amps RMS

80 10 11 11

110 14 16 16

130 17 17 17

160 21 22 21

200 - 27 23

250 32 33 29

305 - 40 37

230 Vac Units 460 Vac Units 575 Vac units

320 41 - -

365 47 49 46

415

515

600

720

54 54

66 66

80 75

86 80

See figure 16 for interconnection details. Each of the six interconnection wires

should be rated for the current from the above RC panel wiring table. See table 7

for 75 °C wire examples.

32 Part No. INSTR-020 REL. 080310

Page 37

Sine Wave 2-8 kHz Series A Filter

Option 01

OVER TEMPERATURE INTERLOCK

Table 9

TYPE BI – METAL THERMAL SWITCH

CONTACT (NC) NORMALLY CLOSED

RATINGS

6A 120 VAC RESISTIVE

3A 240 VAC RESISTIVE

5A 120 VAC INDUCTIVE

2.5A 240 VAC INDUCTIVE

TEMPERATURE CONTACTS OPEN 180°C

33 Part No. INSTR-020 REL. 080310

Page 38

Sine Wave 2-8 kHz Series A Filter

Fan Power

All enclosed part number filters listed below have fans that require a source of

clean 115 volt 50/60 Hz power.

Table 10

Filter Voltage PN NEMA1 PN NEMA3R Cab Fans total load amps

SWAGC0200A SWAWC0200A 26C2/3 2 x 6"

200-230 VAC

380-480 VAC

550-600 VAC

Note: The clean 115 volt control power to the fans is customer supplied.

SWAGD0250A SWAWD0250A 30C2/3 2 x 10"

SWAGD0320A SWAWD0320A 30C2/3 2 x 10"

SWAGC0160D SWAWC0160D 26C2/3 2 x 6"

SWAGD0200D SWAWD0200D 30C2/3 2 x 10"

SWAGD0250D SWAWD0250D 30C2/3 2 x 10"

SWAGD0305D SWAWD0305D 30C2/3 2 x 10"

SWAGD0365D SWAWD0365D 30C2/3 2 x 10"

SWAGD0415D SWAWD0415D 30C2/3 4 x 10"

SWAGD0515D SWAWD0515D 30C2/3 4 x 10"

SWAGE0600D SWAWE0600D 42C2/3 4 x 10"

SWAGE0720D SWAWE0720D 42C2/3 4 x 10"

SWAGD0130E SWAWD0130E 30C2/3 2 x 10"

SWAGD0160E SWAWD0160E 30C2/3 2 x 10"

SWAGD0200E SWAWD0200E 30C2/3 2 x 10"

SWAGD0250E SWAWD0250E 30C2/3 2 x 10"

SWAGD0305E SWAWD0305E 30C2/3 2 x 10"

SWAGD0365E SWAWD0365E 30C2/3 2 x 10"

SWAGE0415E SWAWE0415E 42C2/3 4 x 10"

SWAGE0515E SWAWE0515E 42C2/3 4 x 10"

SWAGE0600E SWAWE0600E 42C2/3 4 x 10"

SWAGE0720E SWAWE0720E 42C2/3 4 x 10"

0.48

0.96

0.96

0.48

0.96

0.96

0.96

0.96

1.92

1.92

1.92

1.92

0.96

0.96

0.96

0.96

0.96

0.96

1.92

1.92

1.92

1.92

A terminal block labeled “Fan Power” is provided inside the enclosure for this purpose

34 Part No. INSTR-020 REL. 080310

Page 39

Sine Wave 2-8 kHz Series A Filter

8. FILTER DESCRIPTION

The MTE Series A Sine Wave Filter is a

low pass filter containing proprietary

technology, which makes it particularly

useful for filtering the output of PWM

inverters. The filter consists of a reactor

and a resistor capacitor network. Figure 18

shows a block diagram of the filter. The

PWM output from the inverter is connected

to the input terminals of the reactor. The

load, which can be either a motor or a

transformer, is connected to the output

terminals of the reactor.

MTE Series A sine-wave filters are

designed to provide a sine wave output

voltage when driven from PWM inverters

with switching frequencies from 2 kHz to 8

kHz. For drive applications, these filters

eliminate the problem of motor insulation

failures and they also reduce

electromagnetic interference by

eliminating the high dv/dt associated with

inverter output wave forms. For alternate

energy applications where an inverter is

used to return power to the utility

distribution system through a step up

transformer these filters meet the

requirements of IEEE 519.

Sine wave filters are available in open

panel, NEMA 1, 2, and 3R mechanical

configurations. For both variable torque

and constant torque applications, select

filters based on the horsepower rating of

the motor. Filter current ratings have been

designed to meet the requirements of NEC

motor current ratings. For applications that

use motors with current ratings that

exceed NEC values selected a filter with a

current rating equal to or greater than that

of the load.

For inverters feeding isolation

transformers select a filter with a current

rating equal to or greater than that of the

transformer primary current.

Typical applications for Series A sinewave filters are submersible pumps, low

voltage drives feeding medium voltage

motors, HVAC equipment, wind turbines

and applications where the distance

between the motor and inverter is up to

15,000 feet.

Note: Series A sine-wave filters can only

be used with PWM inverters with switching

frequencies set between 2 and 8 kHz.

For voltages other than 440-480, 550-600

VAC, contact the factory.

Filters for motors that will be operated

above 60 Hz should be selected based on

the frequency de-rating curve

(Chart 2

.

) shown on page 7.

35

Part No. INSTR-020 REL. 080310

Page 40

Sine Wave 2-8 kHz Series A Filter

200 V – 600 VAC

BLOCK DIAGRAM

FIGURE 18

36

Part No. INSTR-020 REL. 080310

Page 41

9. Startup

Safety Precautions

Before startup, observe the following warnings

and instructions:

Internal components of the filter are at

line potential when the filter is

connected to the drive This voltage is

extremely dangerous and may cause

death or severe injury if you come in

contact with it.

After disconnecting the utility power,

wait at least 5 minutes before doing any

work on the filter connections. After

removing power, allow at least five

minutes to elapse and verify that the

capacitors have discharged to a safe

level before contacting internal

components. Connect a DC voltmeter

across the capacitor terminals. Start

with the meter on the highest scale and

progressively switch to a lower scale

as the indicated voltage falls below the

maximum value of the scale used.

1. Read and follow safety precautions.

2. After installation, ensure that:

• All filter ground terminals are

• Power wiring to the utility, inverter,

3. Check that moisture has not

Sine Wave 2-8 kHz Series A Filter

WARNING

WARNING

Sequence of Operation

Including those of drive manufactures.

connected to ground.

filter and motor is in accordance with

the installation and connection

instructions in Chapter 5.

condensed on the filter components. If

moisture is present, do not proceed

with startup until the moisture has

been removed.

WARNING

Use extreme caution to avoid contact

with line voltage when checking for

power. INJURY OR DEATH MAY

RESULT IF SAFETY PRECAUTIONS

ARE NOT OBSERVED.

4. Refer to the inverter user manual

for the inverter startup procedure.

Observe all safety instructions in

the inverter user manual.

5. Disconnect filter output terminals

from the motor.

6. Set the inverter switching

frequency between 2 kHz and 8

kHz. Refer to the inverter user

manual.

CAUTION

Damage to the filter may occur if the

inverter frequency is not set between 2

kHz and 8 Khz.

7. Turn the inverter ON

8. Confirm that inverter voltage is

present at the input terminals (U1,

V1, W1) of the filter.

9. Confirm that inverter voltage is

present at the output terminals (U2,

V2, W2) of the filter.

10. Disconnect the inverter from the

AC Line and wait 5 minutes.

11. Connect the filter output to the

motor.

12. Refer to the inverter user manual

for the motor startup procedure.

37 Part No. INSTR-020 REL. 080310

Page 42

Sine Wave 2-8 kHz Series A Filter

10. Trouble Shooting

WARNING

INJURY OR DEATH MAY RESULT IF

THE INVERTER SAFETY

PRECAUTIONS ARE NOT OBSERVED.

CAUTION

WARNING

When properly installed, this equipment

has been designed to provide maximum

safety for operating personnel.

However, hazardous voltages and

elevated temperatures exist within the

confines of the enclosure. Servicing

should therefore be performed by

qualified personnel only and in

accordance with OSHA Regulations.

To aid in troubleshooting a block diagram is

shown in figure 17 and interconnection

diagrams are shown in figures 15 and 16 A

list of potential problems and solutions are

listed below.

After removing power, allow at least

five minutes to elapse and verify that

the capacitors have discharged to a

safe level before contacting internal

components. Connect a DC

voltmeter across the capacitor

terminals or terminals U1, V1or V1,

W1 Start with the meter on the

highest scale and progressively

switch to a lower scale as the

indicated voltage falls below the

maximum value of the scale used.

WARNING

High voltage is used in the operation of

this filter. Use Extreme caution to avoid

contact with high voltage when

operating, installing or repairing this

filter. INJURY OR DEATH MAY RESULT

IF SAFETY PRECAUTIONS ARE NOT

OBSERVED.

38

Part No. INSTR-020 REL. 080310

Page 43

Sine Wave 2-8 kHz Series A Filter

PROBLEM:

Possible cause:

Solution:

Possible cause:

Solution:

Possible cause:

Solution:

Possible cause:

Solution:

Voltage is not present at the filter Input terminals.

Power to the inverter is turned off or shut down.

Turn power on, check inverter errors.

One or more external line fuses are blown.

Verify the continuity of line fuses in all phases. Replace as

necessary.

Inverter is defective or undersized

Refer to inverter user manual. Larger filter

Inverter fault, Large filter causes over current fault by filter cap load.

Select filter to match motor FLA, increase size of drive to allow for

long lead cable application.

PROBLEM:

Possible cause:

Solution:

Possible cause:

Solution:

Possible cause:

Solution:

Sine Wave filter runs Hot

Normal operation reactor and resistors are > 120 °C

Caution parts are very hot and may cause burns. Follow installation

guidelines for clearances and check for adequate air flow.

Inverter switching frequency is not set between 2 kHz and 8 kHz

Set switching frequency above 2 kHz

Heat buildup within enclosure

Provide clearance and venting for filter components

39

Part No. INSTR-020 REL. 080310

Page 44

TROUBLESHOOTING - continued

ISO 7.2.3 Sine Wave Filter Series A 200-600 VAC User Manual INSTR-020

Revision Date Revision History

--- 10/12/05 New document written by Wayne Walcott

080310 03/09/08

By WRW Updated per ECN 5695: updated open panel Reactor size table

4; added fan power table 10 for cabinets

40 Part No. INSTR-020 REL. 080310

Loading...

Loading...