Page 1

MTE –Series RL

Line/ load Reactors

USER MANUAL

PART NO. INSTR -011

REL. 130218 REV. 004

Page 2

Important User Information

NOTICE

MTE Series RL Line/Load Reactors are components designed to improve the reliability of

adjustable frequency drives, DC drives and a wide variety of other types of power

electronic equipment. In addition they provide limited input line current harmonic

mitigation and aid in long lead protection for inverter fed motors. Note: (See MTE

harmonic filters and motor protection products for guaranteed results.) MTE reactors are

available in a large number of current ratings and a variety of inductance values. The

suitability of a line/load reactor for a specific application must therefore be ultimately

determined by the customer. In no event will MTE Corporation assume responsibility or

liability for any direct or consequential damages resulting from the use or application of

reactors. Nor will MTE Corporation assume patent liability with respect to the use of

information, circuits orequipmentdescribedinthisinstructionmanual.

This manual includes recently redesigned performance enhanced reactors. These reactors are

physically smaller and weigh less than the reactors they replace. Enhanced reactors have base

mountingbrackets with additional slotted holes to accommodate past mounting hole centers. You

may uses your existing drill pattern orchoose the newlayout.The tables contained in thismanual

reflecthistoricalmountingdimensionsforpreviousreactors.

This document supports computer searches and is best viewed with Adobe Acrobat™

PDF viewer (6 or 7). Click links are incorporated throughout the document to speedup

document navigation.

Page 3

MTE AC Line / Load Reactors

User Manual

Table of Contents

IMPORTANT USER INFORMATION..........................................................................................2

TABLE OF CONTENTS .............................................................................................................3

IMPORTANT SAFETY INFORMATION......................................................................................4

INTRODUCTION ........................................................................................................................5

MODEL NUMBER CODES.........................................................................................................6

SPARE PARTS ..........................................................................................................................7

LUG OPTION DETAILS: ............................................................................................................8

PRODUCT SPECIFICATIONS .................................................................................................10

DE-RATING CURVES..............................................................................................................13

DIMENSION REFERENCE.......................................................................................................14

MOUNTING COMPATIBILITY..................................................................................................15

MECHANICAL DETAILS OPEN REACTORS..........................................................................16

NEMA1 MECHANICAL DATA..................................................................................................18

RECOMMENDED CONDUIT ENTRY FOR FLOOR MOUNTED...............................................20

ENCLOSURE DIMINSIONS .....................................................................................................21

TECHNICAL DATA ..................................................................................................................25

INSTALLATION INSTRUCTIONS............................................................................................27

POWER WIRING CONNECTION .............................................................................................28

TYPICAL CONNECTION DIAGRAMS .....................................................................................29

SEQUENCE OF OPERATION..................................................................................................30

STARTUP.................................................................................................................................31

Page 4

MTE AC Line / Load Reactors

User Manual

IMPORTANT SAFETY INFORMATION

WARNING

ONLYAQUALIFIEDELECTRICIANCANCARRYOUTTHEELECTRICAL

INSTALLATION OF LINE/LOAD REACTORS

WARNING

Highvoltageisusedin the operationof line/load reactors. Use Extreme caution to avoid contact with high

voltagewhenoperating,installingor repairing equipment containing line/load reactors

INJURYORDEATHMAY RESULTIFSAFETYPRECAUTIONSARE NOT OBSERVED.

Line/loadreactors areused inconjunctionwithinverters,orother electricalequipment thatmayfeedback

lethal voltages. Follow the safety instructions in the equipment used with the reactor in addition to the

safetyinstruction in thismanual.

WARNING

The opening of the branch circuit protective device may be an indication that a fault current has been

interrupted. To reduce the risk of fire or electrical shock, line/load reactors should be examined and

replaced if damaged.

WARNING

Anupstream disconnect/protection device must be used as required by the National Electrical Code

(NEC).

WARNING

Even if the upstream disconnect/protection device is open, a drive or inverter down stream of the

line/load reactor may feed back high voltage to the reactor. The inverter or drive safety instructions

must befollowed.

INJURY OR DEATH MAY RESULT IF THE DRIVE SAFETY PRECAUTIONS ARE NOT

OBSERVED.

WARNING

Theframeofline/loadreactorsmustbegroundedatleast at oneof the reactor’smounting holes.

WARNING

OnlysparepartsobtainedfromMTECorporationoranauthorized MTE distributor can be used

Page 5

MTE AC Line / Load Reactors

INTRODUCTION

User Manual

This manual was specifically developed to

assist in the installation, interconnection and

operation of MTE Corporation Series RL

Line/Load Reactors

This manual is intended for use by

personnel experienced in the operation and

maintenance of electronic drives, inverters

and similar types of power electronic

equipment. Because of the high voltages

required by the equipment connected to

line/load reactors and the potential dangers

presented by rotating machinery, it is

essential that all personnel involved in the

operation and maintenance of line/load

reactors know and practice the necessary

safety precautions for this type of

equipment. Personnel should read and

understand the instructions contained in this

manual before installing, operating or

servicing line/load reactors and the drive to

which the reactor is connected.

Upon Receipt of a Reactor:

In the event of damage, please contact

and file a claim with the freight carrier

involved immediately.

If the equipment is not going to be put into

service upon receipt, cover and store the

reactor in a clean, dry location. After

storage, ensure that the equipment is dry

and that no condensation has accumulated

on the reactor before applying power.

Repair/Exchange Procedure

MTE Corporation requires a Returned

Material Authorization Number before it can

accept any reactors that qualify for return or

repair. If problems or questions arise during

installation, setup, or operation of the filter,

please call us for assistance at:

Phone: 1-262-253-8200

FAX: 1-262-253-8222

MTE Line/load Reactors have been

subjected to demanding factory tests before

shipment. Carefully inspect the shipping

container for damage that may have

occurred in transit. Then unpack the filter

and carefully inspect for any signs of

damage. Save the shipping container for

future transport of the reactor.

Page 6

MTE AC Line / Load Reactors

Option

Fundamental Current Amps

User Manual

MODEL NUMBER CODES

RL -

none blank

208 Volts

240 Volts

380 - 415 volts

480 Volts

600 Volts

Custom design

Substitute 35 amp terminal block for smaller terminal block B7

MOV

option

A

C

E

G 3

1000 100 10 1

Open Frame

NEMA 1

OVERSIZE NEMA 1

NEMA 3R

J

X

Substitute Box Lug for terminal block B

Substitute Tab terminal w/clearance hole B1

Substitute flexible leads (18 inches typical) B5

Substitute next larger Box Lug B6

Rotate terminal block 90 degrees B8

Style

↑

0

1

2

No.

Z

suffix

1

2

3

4

↑

↑

↑

↑

↑

↑

none blank

Add 3-point control circuit terminal block to 45 amps B9

Add 3-point control circuit terminal block to 750 amps B11

Sub. accessory wiring t/b B10

Substitute front facing tab (flag) terminal B14

Substitute next larger terminal block 12 to 35 amps B18

Add 3-NC over temp switches w/ 6 point terminal block T

Add 1 thermocouple per coil (customer supplied) T1

Add 3-NC over temp switches with leads T2

Add 1-NC over temp switch w/ 2 point terminal block T5

Add 3-NO over temp switches w/6 point terminal block T6

Add thermocouple to center coil only (customer supplied)… T7

Page 7

MTE AC Line / Load Reactors

User Manual

Spare Parts

For standard type “RL” AC Line / Load Reactors

Description Part No.

To adds “SLU 225” box lugs on B14 Lug Kit 001

To adds “XT 500” box lugs on B14 Lug Kit 002

Terminal Blocks

Description Part No.

For RL-00101 thru RL-00804 36-822-049

For RL-01201 thru RL-03502 36-825-004

For RL-03503 thru RL-04503 TERMBLK-013

Page 8

MTE AC Line / Load Reactors

User Manual

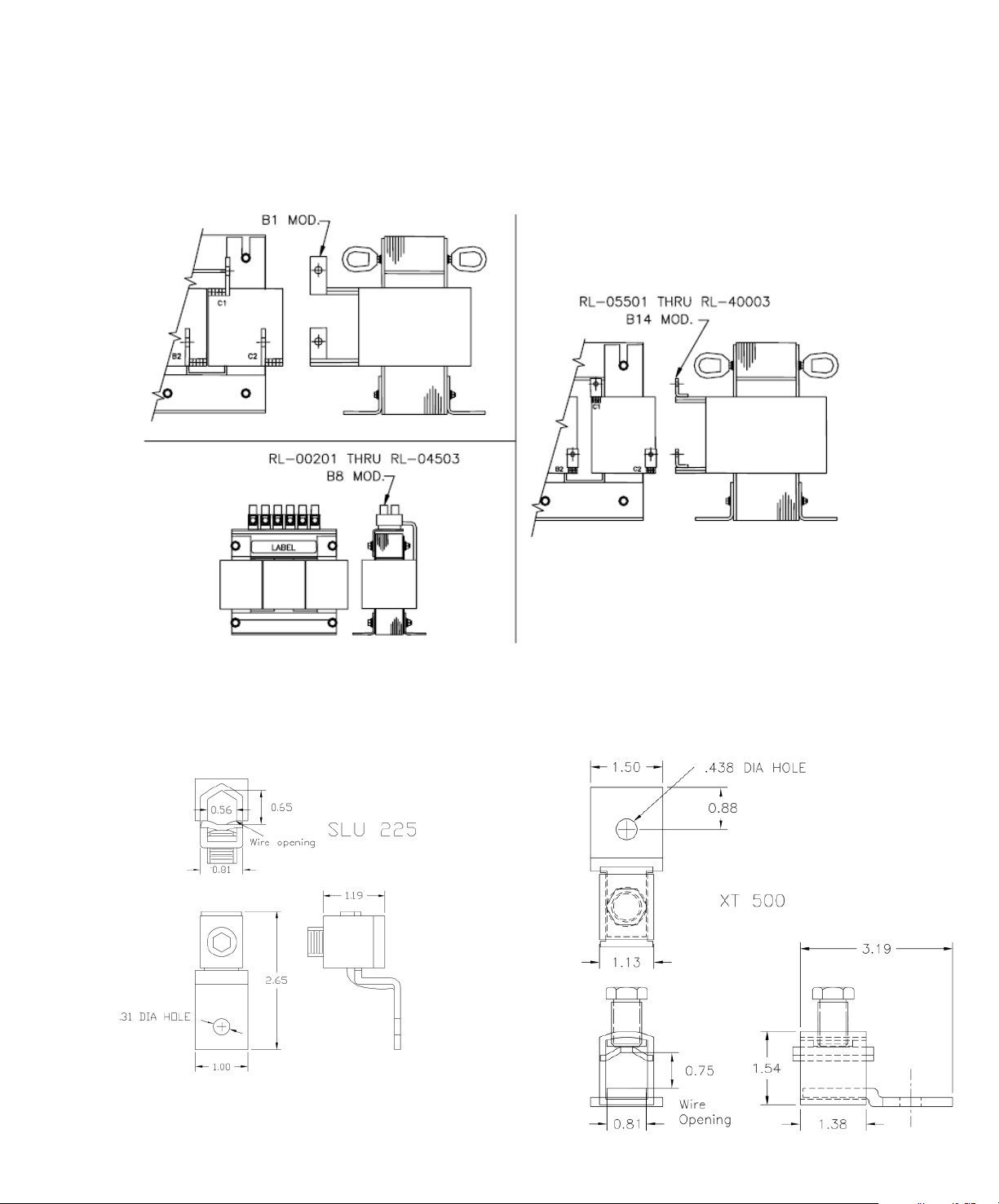

LUG OPTION DETAILS:

“B1” Terminal Modification “B14” Terminal Modification

“B8” Terminal Modification

Wire range: 2 - 0000

“SLU” Lug Option

Wire range: 00 – 500 mcm

Page 9

MTE AC Line / Load Reactors

SLU Lug Options cont.

User Manual

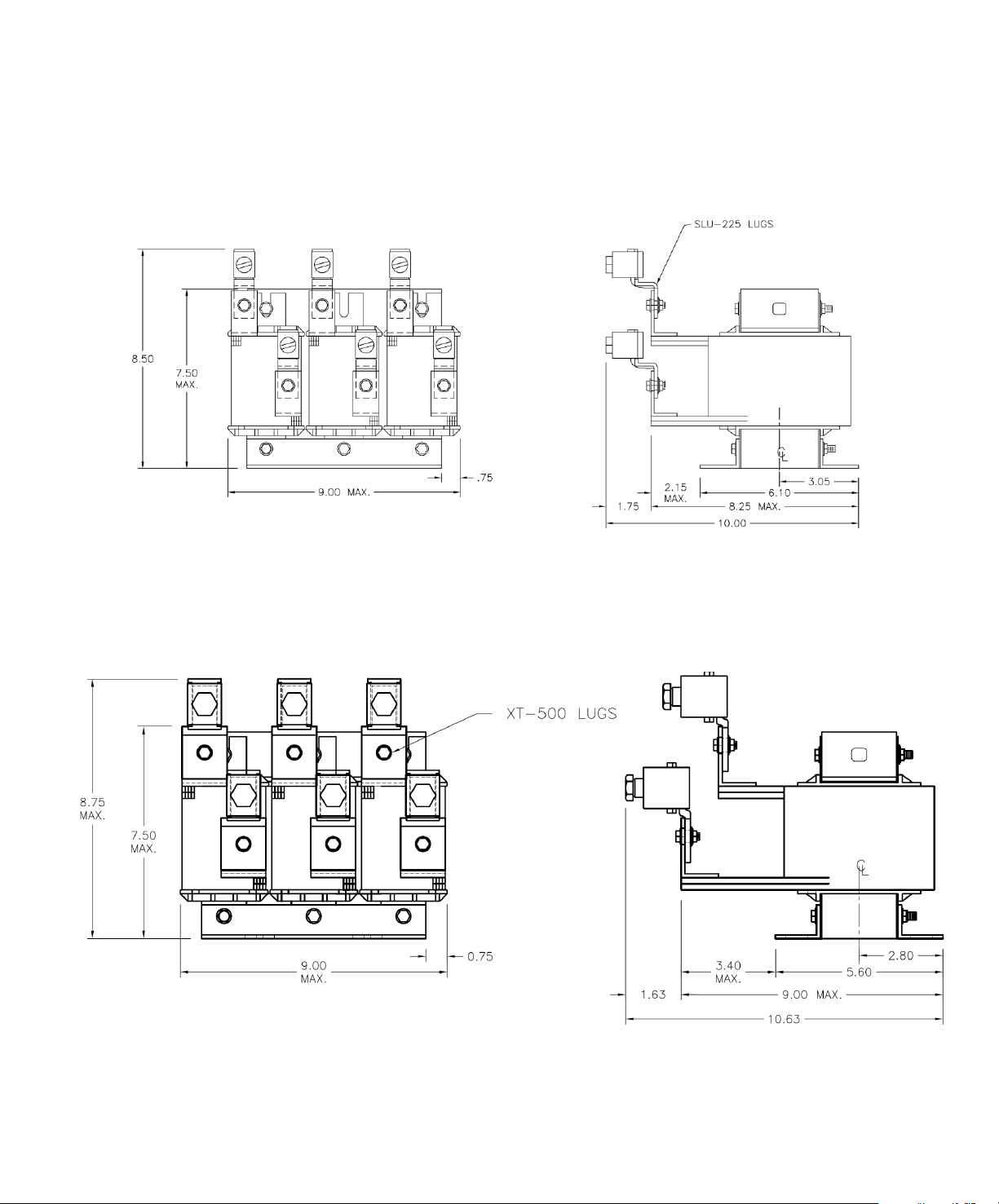

SLU 225 shown on 200 amp Reactor

XT 500 shown on 250 amp Reactor

Page 10

MTE AC Line / Load Reactors

User Manual

PRODUCT SPECIFICATIONS

Standard impedance values 1-1/2%, 2, 3%, 4%, 5% available

Impedance basis Reactor fundamental current rating

Service Factor

(Continuous)

Reactors rated 1 to 750 Amps 150% of fundamental rating

Reactors rated above 750 Amps 125% of fundamental rating minimum

Note: Select reactor based on fundamental current

rating

Overload Rating 200% of fundamental for 30 minutes

300% of fundamental for 1 minute

Maximum system voltage 600 Volts ( units with terminal blocks)

690 Volts (units with box lugs or tab terminals)

Maximum switching frequency 20 KHz

Insulation system Class N (200° C)

Temperature rise

Open or enclosed reactors 135° C (average)

Ambient temperature

Open or enclosed reactors 45° C (maximum)

Altitude (maximum) 1000 meters

Fundamental frequency

Line or Load 50/60 Hz

Approvals: CE, UL-508, CSA C22.2

Inductance curve (typical) 100% at 100% current

100% at 150% current

50% at 350% current (minimum)

Inductance tolerance +/- 10%

Impregnation: High Bond Strength “Solvent less” Epoxy, 200° C

UL94HB recognized

Dielectric Strength 3000 volts rms (4243 volts peak)

dv/dt Protection Meets NEMA MG-1, part 31 (same as inverter duty

motors)

Protection: Open reactors with terminal blocks through 45 amps

meet IP20

Page 11

MTE AC Line / Load Reactors

User Manual

PRODUCT SPECIFICATIONS (cont’d)

AGENCY APPROVALS:

UL-508, File E180243 Component Listed (1 amp – 2400 amps)

UL-508, File E180243 UL Listed NEMA 1 units (1 amp – 2400 amps)

CSA C22.2, File LR29753-13 CSA Certified (1 amp – 2400 amps)

Class N, 200° C, File E66214, Type 200-18, UL Recognized Insulation System

CE Marked

MATERIAL:

Core Steel: Electrical grade silicon steel

Windings: High dielectric withstand solid copper conductor (220° C)

Enclosures: Sheet steel in accordance with UL and CSA requirements. Painted ANSI-61

Grey

Brackets: ASTM structural steel or structural aluminum

Terminations: 1 – 45 amps - Finger safe terminal block

55 - 160 amps - Solid copper box lugs (Tab terminals are optional)

200 + amps - Copper tab terminals

Sheet Insulation: DuPont Nomex 410 (220° C)

Epoxy: Ripley Resin Type 468-2 (220° C)

CONSTRUCTION:

CORE: Electrical grade silicon steel magnetic laminations.

WINDINGS: Meet 3000 volts rms dielectric strength (coil – to coil and coil- to – core).

ASSEMBLY: Windings are assembled onto EI laminations, secured in place and epoxy

impregnated for minimum noise and maximum structural rigidity.

COLOR: Royal Blue

TESTING: Electronic Turns Count (Zero Tolerance)

Inductance

Hi-Pot 3000 Volts rms (5656 volts peak)

Mechanical Inspection

Page 12

MTE AC Line / Load Reactors

User Manual

PRODUCT SPECIFICATIONS (cont’d)

AUDIBLE NOISE: Guard-AC Line/Load Reactors offer low noise operation. Core and coil

construction, flux density control, harmonic compensation as well as our epoxy impregnation process

assure minimal audible noise radiation. Although our reactors are typically “quiet”, waveforms vary by

drive type and application and therefore reactor audible noise may vary by application. Noise levels may

be affected by type of motor and motor conductor as well as motor conductor length.

Typical audible noise levels for units selected from our catalog by HP rating are:

2 thru 12 amps 55 dBA

18 thru 100 amps 65 dBA

130 thru 400 amps 70 dBA

500 thru 1200 amps 75 dBA

Service Factor: Guard-AC reactors are compensated for the additional currents and high

frequencies caused by the presence of harmonics. The reactor fundamental current rating indicates the

typical full load motor current and is also the basis of impedance rating. Standard reactors rated 1 amps

thru 750 amps offer a full 1.5 service factor rating which allows them to carry overload current up to 150%

of their fundamental rating when applied as an input line reactor. Since the nameplate ratings of motor

drives (ASD) varies widely by manufacturer, this helps to assure that the reactor maximum current rating

is compatible with the nameplate current rating on the ASD. The service factor rating compensates for

ASD manufacturer variances in motor drive current ratings and for harmonic currents. Nominal

inductance is assured all the way up to the service factor current rating.

PWM / IGBT PROTECTION: Guard-AC reactors are protected against the high peak voltage and fast

rise time voltage pulses associated with PWM waveforms. The dielectric strength is 4000 volts rms and

Guard-AC reactors meet the ratings of an inverter duty motor (NEMA MG-1, part 31). For convenience,

they can be located either at the motor or at the drive.

HARMONIC ATTENUATION: Our unique harmonic compensation assures maximum circuit inductance

in the presence of complex waveforms and can be relied upon to minimize input total harmonic current

distortion (THID). Additionally it offers superior absorption of transient voltage spikes. Our standard

reactors will typically reduce 6-pulse rectifier input current harmonics to the following levels at full load

operating conditions:

3% reactor alone 45% or less THID

5% reactor alone 35% or less THID

3% AC reactor + 3% DC link choke 33% or less THID

5% AC reactor + 3% DC link choke 28% or less THID

(DC link choke inductance is equivalent ac impedance).

Page 13

MTE AC Line / Load Reactors

Reactor Temperature De-Rating

User Manual

DE-RATING CURVES

Altitude Derating Curve

1.05

1.00

0.95

0.90

0.85

0.80

0.75

0.70

Current De-Rating Factor

0 3300 6600 9900 13200 16500

Altitude (Feet)

1.05

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

Current De-Rating Factor

0.60

40 45 50 55 60 65 70 75 80 85 90

AmbientTemperature Deg. C

Page 14

Dimensions A, B, C show overall spacing allowances

Use dimension D and E for mounting pattern

Page 15

MTE AC Line / Load Reactors

User Manual

Mounting Compatibility

Page 16

MTE AC Line / Load Reactors

Cat. No.

Inches

mm

Inches

mm

Inches

mm

Inches

mm

Inches

mm

Lbs

Kg

User Manual

Mechanical Details Open Reactors

MTE Weight Mass

RL-00101 3.8 97 3.5 89 1.2 30 2.40 61.0 1.44 36.6 4 1.8

RL-00102 3.8 97 3.5 89 1.2 30 1.98 50.3 1.44 36.6 4 1.8

RL-00103 3.8 97 3.5 89 1.2 30 1.98 50.3 1.44 36.6 3 1.4

RL-00104 3.8 97 3.5 89 1.2 30 1.98 50.3 1.44 36.6 3 1.4

RL-00201 4.4 112 4.1 104 2.8 71 1.98 50.3 1.44 36.6 4 1.8

RL-00202 4.4 112 4.1 104 2.8 71 1.98 50.3 1.44 36.6 4 1.8

RL-00203 4.4 112 4.1 104 2.8 71 1.98 50.3 1.44 36.6 4 1.8

RL-00204 4.4 112 4.1 104 2.5 64 1.73 43.9 1.44 36.6 3 1.4

RL-00401 4.4 112 4.1 104 2.8 71 1.98 50.3 1.44 36.6 4 1.8

RL-00402 4.4 112 4.1 104 2.8 71 1.98 50.3 1.44 36.6 4 1.8

RL-00403 4.4 112 4.1 104 3.4 86 2.35 59.7 1.44 36.6 5 2.3

RL-00404 4.4 112 4.1 104 3.4 86 2.60 66.0 1.44 36.6 6 2.7

RL-00801 6.0 152 4.8 122 3.0 76 2.10 53.3 2.00 50.8 7 3.2

RL-00802 6.0 152 4.8 122 3.0 76 2.10 53.3 2.00 50.8 8 3.6

RL-00803 6.0 152 4.8 122 3.4 86 2.62 66.5 2.00 50.8 11 5.0

RL-00804 6.0 152 4.8 122 3.4 86 2.48 63.0 2.00 50.8 13 5.9

RL-01201 6.0 152 5.0 127 3.3 84 2.10 53.3 2.00 50.8 9 4.1

RL-01202 6.0 152 5.0 127 3.3 84 2.10 53.3 2.00 50.8 10 4.5

RL-01203 6.0 152 5.0 127 3.9 99 2.75 69.9 2.00 50.8 18 8.2

RL-01801 6.0 152 5.3 135 3.2 81 2.10 53.3 2.00 50.8 9 4.1

RL-01802 6.0 152 5.3 135 3.5 89 2.48 63.0 2.00 50.8 12 5.4

RL-01803 8.1 206 6.1 155 4.0 102 2.60 66.0 3.00 76.2 16 7.3

RL-02501 7.2 183 5.8 147 3.5 89 2.35 59.7 3.00 76.2 11 5.0

RL-02502 7.2 183 5.8 147 3.5 89 2.35 59.7 3.00 76.2 14 6.3

RL-02503 7.2 183 5.8 147 4.3 109 3.10 78.7 3.00 76.2 20 9.1

RL-03501 7.2 183 5.8 147 4.0 102 2.60 66.0 3.00 76.2 14 6.3

RL-03502 7.2 183 5.8 147 4.0 102 2.75 69.9 3.00 76.2 16 7.3

RL-03503 9.0 229 7.4 188 4.7 119 3.16 80.3 3.00 76.2 30 14

RL-04501 9.0 229 7.4 188 4.7 119 3.16 80.3 3.00 76.2 23 10

RL-04502 9.0 229 7.4 188 4.7 119 3.16 80.3 3.00 76.2 28 13

RL-04503 9.0 229 7.3 185 5.3 135 3.66 93.0 3.00 76.2 39 18

RL-05501 9.0 229 7.3 185 5.3 135 3.16 80.3 3.00 76.2 24 11

RL-05502 9.0 229 7.0 178 5.3 135 3.16 80.3 3.00 76.2 27 12

RL-05503 9.0 229 7.0 178 6.0 152 3.91 99.3 3.00 76.2 41 19

RL-08001 9.0 229 7.2 183 6.3 160 3.47 88.1 3.63 92.2 25 11

RL-08002 9.0 229 7.2 183 6.5 165 3.47 88.1 3.63 92.2 33 15

RL-08003 10.8 274 8.5 216 6.8 173 4.16 105.7 3.63 92.2 61 28

RL-10001 9.0 229 7.3 185 6.5 165 3.30 83.8 3.63 92.2 29 13

RL-10002 9.0 229 7.3 185 6.8 173 3.66 93.0 3.63 92.2 37 17

RL-10003 10.8 274 8.3 210 6.2 156 4.16 105.7 3.63 92.2 74 34

RL-13001 9.0 229 7.0 178 4.7 118 3.16 80.3 3.00 76.2 29 13

RL-13002 9.0 229 7.2 183 6.8 173 3.66 93.0 3.63 92.2 43 20

RL-13003 11.0 279 8.5 216 6.2 156 4.16 105.7 3.63 92.2 64 29

RL-16001 9.0 229 7.2 183 6.8 173 3.16 80.3 3.63 92.2 41 19

RL-16002 10.8 274 8.3 211 6.0 152 3.47 88.1 3.63 92.2 50 23

EA B C D

Page 17

MTE AC Line / Load Reactors

Cat. No.

Inches

mm

Inches

mm

Inches

mm

Inches

mm

Inches

mm

Lbs

Kg

User Manual

Mechanical Data Open Type Cont.

MTE Weight Mass

RL-20001B14

RL-20002B14 9.0 229 7.5 191 8.3 211 4.41 112.0 3.63 92.2 54 24

RL-20003B14 10.8 274 8.3 211 10.0 254 5.91 150.1 3.63 92.2 100 45

RL-25001B14 9.0 229 7.5 191 9.0 229 4.19 106.4 3.63 92.2 47 21

RL-25002B14 10.8 274 8.5 216 9.0 229 5.16 131.1 4.60 116.8 80 36

RL-25003B14 14.4 366 11.2 284 10.3 262 5.82 147.8 4.60 116.8 125 57

RL-32001B14 10.8 274 9.0 229 8.3 211 5.16 131.1 4.60 116.8 80 36

RL-32002B14 10.8 274 9.0 229 10.0 254 5.88 149.4 4.60 116.8 102 46

RL-32003B14 14.4 366 11.3 286 10.5 267 7.13 181.1 4.60 116.8 160 73

RL-40001B14 10.8 274 10.0 254 10.0 254 5.16 131.1 4.60 116.8 84 38

RL-40002B14 15.0 381 11.3 286 11.5 292 6.76 171.7 4.60 116.8 118 54

RL-40003B14 14.4 366 11.3 286 12.5 318 7.26 184.4 4.60 116.8 149 68

9.0 229 7.5 191 7.3 185 4.16 105.7 3.63 92.2 38 17

EA B C D

RL-50001 10.8 274 9.0 229 10.5 267 5.50 139.7 4.60 116.8 93 42

RL-50002 14.4 366 11.5 292 11.5 292 6.76 171.7 4.60 116.8 118 54

RL-50003 14.4 366 11.5 292 13.3 338 9.76 247.9 4.60 116.8 210 95

RL-60001 14.4 366 11.5 292 10.0 254 5.26 133.6 4.60 116.8 120 54

RL-60002 14.4 366 11.3 286 12.0 305 8.00 203.2 4.60 116.8 175 79

RL-60003 14.4 366 11.3 286 15.0 381 9.26 235.2 4.60 116.8 270 122

RL-75001 14.4 366 11.5 292 11.0 279 6.63 168.4 7.20 182.9 140 63

RL-75002 14.4 366 11.5 292 12.5 318 8.01 203.5 7.20 182.9 190 86

RL-75003 14.4 366 14.5 368 14.0 356 9.26 235.2 7.20 182.9 265 120

RL-85001 20.3 514 16.8 425 13.0 330 7.60 193.0 7.20 182.9 285 129

RL-85002 22.0 559 16.8 425 13.0 330 8.00 203.2 7.20 182.9 370 168

RL-85003 22.5 572 16.8 427 18.0 457 9.00 228.6 7.20 182.9 452 205

RL-100001 21.6 549 16.8 425 11.0 279 7.26 184.4 7.20 182.9 320 145

RL-100002 20.3 514 16.8 425 13.0 330 8.50 215.9 7.20 182.9 408 185

RL-100003 20.3 514 16.8 425 15.0 381 10.76 273.3 7.20 182.9 589 267

RL-120001 22.5 572 17.0 432 13.0 330 11.00 279.4 7.20 182.9 425 193

RL-120002 21.5 546 17.0 432 20.0 508 10.76 273.3 7.20 182.9 440 200

RL-120003 16.8 427 17.0 432 18.5 470 11.00 279.4 7.20 182.9 560 254

RL-140001 22.0 559 17.0 432 22.0 559 11.00 279.4 7.20 182.9 500 227

RL-140002 19.0 483 17.0 432 19.0 483 11.00 279.4 7.20 182.9 525 238

RL-140003 22.0 559 17.0 432 22.0 559 11.00 279.4 7.20 182.9 850 385

RL-150001 22.0 559 17.0 432 22.0 559 11.00 279.4 7.20 182.9 635 288

RL-150002 16.9 429 17.0 432 16.0 406 11.00 279.4 7.20 182.9 675 306

RL-150003 22.0 559 17.0 432 22.0 559 11.00 279.4 7.20 182.9 900 408

RL-180001 22.0 559 17.0 432 22.0 559 11.00 279.4 7.20 182.9 700 317

RL-180002 22.0 559 17.0 432 22.0 559 10.38 263.7 7.20 182.9 860 390

RL-180003 22.0 559 17.0 432 22.0 559 11.00 279.4 7.20 182.9 1090 494

RL-210001 24.0 610 18.0 457 24.0 610 11.00 279.4 7.20 182.9 800 363

RL-210002 24.0 610 18.0 457 24.0 610 11.00 279.4 7.20 182.9 970 440

Page 18

MTE AC Line / Load Reactors

User Manual

Recommended conduit entry for Floor Mounted

NEMA 1 enclosed reactors

Note: The entry locations shown above are for reference only. The electrician installing the reactor

guided by the local codes determines the final entry wiring. MTE does not pre- punch entry holes or

provide wiring hardware with the standard product.

Page 19

MTE AC Line / Load Reactors

User Manual

ENCLOSURE DIMINSIONS

CAB-8

CAB-12C

Page 20

MTE AC Line / Load Reactors

User Manual

ENCLOSURE DIMENSIONS

CAB-13V

CAB-17V

Page 21

MTE AC Line / Load Reactors

User Manual

ENCLOSURE DIMENSIONS

CAB-17C

CAB-26C

Page 22

MTE AC Line / Load Reactors

User Manual

ENCLOSURE DIMENSIONS

CAB-30B

CAB-42C

Page 23

MTE AC Line / Load Reactors

Catalog

Watts Loss

Wire Range

Terminal Torque

Ind.

Fund

Max

Number

(watts)

(AWG)

(in–lbs)mHAmps

Amps

User Manual

TECHNICAL DATA

RL-00101 13.5 22 – 10 4.5 100 1 1.5

RL-00102 12.8 22 – 10 4.5 50 1 1.5

RL-00103 11.9 22 – 10 4.5 36 1 1.5

RL-00104 9.6 22 – 10 4.5 18 1 1.5

RL-00201 8 22 – 10 4.5 12 2 3

RL-00202 12 22 – 10 4.5 20 2 3

RL-00203 16 22 – 10 4.5 32 2 3

RL-00204 11 22 – 10 4.5 6 2 3

RL-00401 15 22 – 10 4.5 3 4 6

RL-00402 20 22 – 10 4.5 6.5 4 6

RL-00403 20 22 – 10 4.5 9 4 6

RL-00404 21 22 – 10 4.5 12 4 6

RL-00801 20 22 – 10 4.5 1.5 8 12

RL-00802 29 22 – 10 4.5 3 8 12

RL-00803 26 22 – 10 4.5 5 8 12

RL-00804 28 22 – 10 4.5 7.5 8 12

RL-01201 26 14 - 6 16 1.25 12 18

RL-01202 31 14 - 6 16 2.5 12 18

RL-01203 41 14 - 6 16 4.2 12 18

RL-01801 36 14 - 6 16 0.8 18 27

RL-01802 43 14 - 6 16 1.5 18 27

RL-01803 43 14 - 6 16 2.5 18 27

RL-02501 48 14 - 6 16 0.5 25 37.5

RL-02502 52 14 - 6 16 1.2 25 37.5

RL-02503 61 14 - 6 16 1.8 25 37.5

RL-03501 49 14 - 6 16 0.4 35 52.5

RL-03502 54 14 - 6 16 0.8 35 52.5

RL-03503 54 18 – 4 16 1.2 35 52.5

RL-04501 54 18 – 4 16 0.3 45 67.5

RL-04502 62 18 – 4 16 0.7 45 67.5

RL-04503 65 18 – 4 16 1.2 45 67.5

RL-05501 64 6 – 0 6-4(45) & 2-0(50) 0.25 55 82.5

RL-05502 67 6 – 0 6-4(45) & 2-0(50) 0.5 55 82.5

RL-05503 71 6 – 0 6-4(45) & 2-0(50) 0.85 55 82.5

RL-08001 82 6 – 0 6-4(45) & 2-0(50) 0.2 80 120

RL-08002 86 6 – 0 6-4(45) & 2-0(50) 0.4 80 120

RL-08003 96 6 – 0 6-4(45) & 2-0(50) 0.7 80 120

RL-10001 94 6 – 0 6-4(45) & 2-0(50) 0.15 100 150

RL-10002 84 6 – 0 6-4(45) & 2-0(50) 0.3 100 150

RL-10003 108 6 – 0 6-4(45) & 2-0(50) 0.45 100 150

RL-13001 108 2 – 0000 150 0.1 130 195

RL-13002 180 2 – 0000 150 0.2 130 195

RL-13003 128 2 – 0000 150 0.3 130 195

RL-16001 116 2 – 0000 150 0.075 160 240

Page 24

MTE AC Line / Load Reactors

Catalog

Watts Loss

Wire Range

Terminal Torque

Ind

Fund

Max

Number

(watts)

(AWG)

(in–lbs)mHAmps

Amps

User Manual

TECHNICAL DATA (cont’d)

RL-16002 149 Copper Tab Not Applicable 0.15 160 240

RL-16003 138 Copper Tab Not Applicable 0.23 160 240

RL-20001B14

RL-20002B14

RL-20003B14

RL-25001B14

RL-25002B14

RL-25003B14

RL-32001B14

RL-32002B14

RL-32003B14

RL-40001B14

RL-40002B14

RL-40003B14

RL-50001 266 Copper Tab Not Applicable 0.025 500 750

RL-50002 340 Copper Tab Not Applicable 0.05 500 750

RL-50003 422 Copper Tab Not Applicable 0.085 500 750

RL-60001 307 Copper Tab Not Applicable 0.02 600 900

RL-60002 414 Copper Tab Not Applicable 0.04 600 900

RL-60003 406 Copper Tab Not Applicable 0.065 600 900

RL-75001 427 Copper Tab Not Applicable 0.015 750 1125

RL-75002 630 Copper Tab Not Applicable 0.029 750 1125

RL-75003 552 Copper Tab Not Applicable 0.048 750 1125

RL-85001 798 Copper tab Not Applicable 0.015 850 1063

RL-85002 930 Copper tab Not Applicable 0.027 850 1063

RL-85003 1133 Copper tab Not Applicable 0.042 850 1063

RL-90001 860 Copper tab Not Applicable 0.013 900 1125

RL-90002 1020 Copper tab Not Applicable 0.025 900 1125

RL-90003 1365 Copper tab Not Applicable 0.04 900 1125

RL-100001 940 Copper tab Not Applicable 0.011 1000 1250

RL-100002 1090 Copper tab Not Applicable 0.022 1000 1250

RL-100003 1500 Copper tab Not Applicable 0.038 1000 1250

RL-120001 980 Copper tab Not Applicable 0.009 1200 1500

RL-120002 1130 Copper tab Not Applicable 0.019 1200 1500

RL-120002 1550 Copper tab Not Applicable 0.03 1200 1500

RL-140001 Copper tab Not Applicable 0.008 1400 1750

RL-140002 1523 Copper tab Not Applicable 0.016 1400 1750

RL-140003 1680 Copper tab Not Applicable 0.027 1400 1750

RL-150001 1432 Copper tab Not Applicable 0.008 1500 1875

RL-150002 1671 Copper tab Not Applicable 0.015 1500 1875

RL-150003 1815 Copper tab Not Applicable 0.025 1500 1875

124 Copper Tab Not Applicable 0.055 200 300

168 Copper Tab Not Applicable 0.11 200 300

146 Copper Tab Not Applicable 0.185 200 300

154 Copper Tab Not Applicable 0.045 250 375

231 Copper Tab Not Applicable 0.09 250 375

219 Copper Tab Not Applicable 0.15 250 375

224 Copper Tab Not Applicable 0.04 320 480

264 Copper Tab Not Applicable 0.075 320 480

351 Copper Tab Not Applicable 0.125 320 480

231 Copper Tab Not Applicable 0.03 400 600

333 Copper Tab Not Applicable 0.06 400 600

293 Copper Tab Not Applicable 0.105 400 600

Contact factory for higher ratings.

Page 25

MTE AC Line / Load Reactors

User Manual

INSTALLATION INSTRUCTIONS

Open Line/Load Reactor Installation

MTEline/loadreactors are availableinopen

construction and in NEMA 1 enclosures.

Open reactorsaredesignedformounting within

anappropriateelectrical equipment

enclosure. Reactorsrated300amperesRMS

andunderaredesignedfor mountingin both a

vertical and horizontalposition. Larger

reactors must be mountedina horizontal

positiontypicallyonthefloorof theenclosure.

Includethepowerdissipation of the reactor

along with all the other componentslocated in

theenclosuretodeterminetheinternal

temperature rise and cooling requirements

of the enclosure.

Reactorsmaybelocated inanyregion ofthe

enclosurewhere the ambienttemperature

does not exceed45degreesC.Allowaminimum

sideclearancesof four (4) inches andvertical

clearancesofsix(6)inchesforproperheat

dissipationand access. Do notlocate the

reactornexttoresistorsor anyothercomponent

withoperating surfacetemperatures above 125

degree C.

Select a wellventilated,dust-freearea awayfrom

directsunlight,rainormoisture.Donotinstallin or

neara corrosiveenvironment.Avoidlocations

where the reactor will be subjected to

excessive vibrations.

NEMA 1 Line/Load Reactor Installation

Top conduit entry recommended for

NEMA 1 enclosed reactors.

MTEline/loadreactors mountedinenclosures

withpart number, CAB-8, are designed for

wall mounting.Allother enclosuresare

designedforfloormounting.

WARNING

MTE NEMA1 enclosures designed for floor

mounting must be mounted with the

enclosure base horizontal for proper

ventilation. Wall mounting a floor

mounted enclosure with the base against

thewallwillcausethe reactor to over heat

resulting in equipment damage.

Allowaminimumside,front,andback

clearancesof twelve (12) inchesand vertical

clearancesofeighteen(18) inchesforproper

heatdissipationand access. Do notlocate the

enclosurenexttoresistors oranyother

componentwithoperatingsurfacetemperatures

above 125 degreeC.

Select a wellventilated,dust-freearea away

fromdirect sunlight,rainor moisture

where the ambienttemperaturedoesnot

exceed40degreesC.

Donotinstallinornearacorrosiveenvironment.

Avoidlocationswherethereactor willbe

subjectedtoexcessivevibrations.

Wheredesirable,enclosuresmaybemounted

onvibrationisolating pads to reduceaudible

noise.Standardvibrationcontrol padsmade

fromneoprene or natural rubber and

selected for the weight ofthe enclosedreactor

are effective. Usingflexible conduit is also

helpful in abatement of audible noise.

Page 26

MTE AC Line / Load Reactors

User Manual

Power Wiring Connection

WARNING

Input and output power wiring to the

reactor should be performed by

authorized personnel in accordance

with the NEC and all local electrical

codes and

REGULATIONS

WARNING

Failure to connect reactors supplied

as a component part of a drive

system or other power electronic

system according to the system

interconnection diagram supplied by

the System Engineer will result in

equipment damage, injury, or death.

Verify that the power source to which the reactor

is to be connected is in agreement with the

nameplate data on the reactor. A fused

disconnect switch or circuit breaker should be

installed between the reactor and its source of

power in accordance with the requirements of

the NEC and all local electrical codes and

regulations. Refer to the drive, inverter, or other

electrical equipment user manual for selection of

the correct fuse rating and class.

The reactor is suitable for use on a circuit

capable of delivering not more than 65,000 rms

symmetrical amperes at 480 volts when

protected by Bussman type JJS, KTK, KTK-R,

SPP or T class fuses.

Reactor are designed for use with copper

conductors with a minimum temperature rating

of 75 degrees C. Table 2 lists the wire range and

terminal torque requirements for the power input

and output connections by reactor part number.

Refer to Figure 4 for typical electrical diagrams

describing the application of reactors in both line

and load applications. For reactors supplied as a

component part of a drive system or a

component part of power electronic apparatus

follow the interconnection diagram supplied by

the System Engineer.

WARNING

If a line reactor or a line reactor and a load

reactor are used with a drive equipped with a

bypass circuit, the reactors must be removed

from the motor circuit in the bypass mode.

Damage to the motor and other equipment will

result if this warning is not observed.

Grounding

A stud is provided on enclosed reactors for

grounding the enclosure. The enclosure must be

grounded. Open reactors must be grounded at

the designated grounding terminal or the reactor

mounting holes if no designated grounding

terminal is provided.

WARNING

The frame of line/load reactors must be

grounded at the designated grounding terminal

or one of the reactor mounting holes if no

designated grounding terminal is provided. The

enclosure of reactors supplied in enclosures

must be grounded.

INJURY OR DEATH MAY RESULT IF

SAFETY PRECAUTIONS ARE NOT

OBSERVED.

Where desirable, a flexible conduit connection to

the reactor enclosure should be made to reduce

audible noise.

Page 27

MTE AC Line / Load Reactors

User Manual

Typical Connection Diagrams

Fig 4a LINE Reactor

Connects between power source and VFD

Fig. 4b LOADReactor

Connects between ASD and load (motor)

Figure 5.Single Phase connection diagram.

Fig 4c Use individual Line Reactors for

independent start/ stop drives connected to a

common power source. If inverters are slaved

and will always run together a single reactor

sized for total motor current may be used.

Page 28

MTE AC Line / Load Reactors

User Manual

Sequence of Operation

1. Read and follow safety precautions.

2. After installation, ensure that:

All Reactorgroundterminals are connectedtoground.

Power wiring to the utility, drive and motor is in accordance with the

interconnection diagrams supplied by the System Engineer.

3. Check that moisture has not condensed on the Reactor. If moisture is

present, do not proceedwithstartupuntilthe moisture hasbeen removed.

4. Proceed with startup according to the instructions provided by the system

supplier.

WARNING

Reactors areacomponentpartofanelectrical system.Do not proceed with startup until

the system startup instructions provided by the System Engineer are understood and

followed. Injury, death and damage to equipment may result if the system startup

instructions are not followed.

WARNING

Use extreme caution toavoidcontactwith linevoltagewhen checking for

power.

INJURY OR DEATH MAY RESULT IF SAFETY PRECAUTIONS ARE

NOT OBSERVED.

Page 29

MTE AC Line / Load Reactors

User Manual

STARTUP

Safety Precautions

Before startup, observe the following warnings and instructions:

WARNING

AReactor isat linepotentialwhentheReactoris connected to the utility. This voltage

is extremelydangerousand maycausedeathorsevere injury if you come in contact

with it.

WARNING

High voltage is used in the operation of line/load reactors. Use Extreme caution to

avoid contact with high voltage when operating, installing or repairing equipment

containing line/load reactors. Line/load reactors are used in conjunction with

inverters, or other electrical equipment that may feedback lethal voltages.

Follow the safety instructions in the equipment used with the reactor in addition

to the safety instruction in this manual.

INJURY OR DEATH MAY RESULT IF SAFETYPRECAUTIONS ARE NOT

OBSERVED.

Loading...

Loading...