Page 1

M T E C o r p o r a t i o n

MATRIX FILTER

SERIES A

480 Volts 60 Hz

USER MANUAL

PART NO. INSTR - 002

REL. 060607

© 2000 MTE Corporation

PDF created with pdfFactory trial version www.pdffactory.com

Page 2

PDF created with pdfFactory trial version www.pdffactory.com

Page 3

IMPORTANT USER INFORMATION

NOTICE

The MTE Corporation Matrix Filter is designed for harmonic mitigation of six

pulse inverter drives supplying variable torque loads in a wide variety of

applications. The suitability of this filter for a specific application must

therefore be determined by the customer. In no event will MTE Corporation

assume responsibility or liability for any direct or consequential damages

resulting from the use or application of this filter. Nor will MTE Corporation

assume patent liability with respect to the use of information, circuits or

equipment described in this instruction manual.

PDF created with pdfFactory trial version www.pdffactory.com

Page 4

PDF created with pdfFactory trial version www.pdffactory.com

Page 5

TABLE OF CONTENTS

1. Safety .......................................................................................................... 1

2. Introduction ................................................................................................. 3

3. Model Number Codes.................................................................................. 4

4. Specifications .............................................................................................. 5

Ratings ....................................................................................................... 5

Service Conditions ..................................................................................... 5

Performance ............................................................................................... 6

Altitude Derating Curve ............................................................................ 10

5. Installation Instructions ............................................................................. 11

Filter Installation ....................................................................................... 11

Power Wiring Connection ......................................................................... 11

Ground and Ground Fault Protection......................................................... 12

Input and Output Terminal Specifications ................................................. 12

Outline Drawings and Mounting Dimensions ............................................ 13

Interconnection Diagrams.......................................................................... 23

6. Filter Description ....................................................................................... 26

7. Start – Up .................................................................................................. 28

8. Troubleshooting......................................................................................... 29

8. Addendum A.............................................................................................. 33

PDF created with pdfFactory trial version www.pdffactory.com

Page 6

1. IMPORTANT SAFETY INFORMATION

WARNING

ONLY A QUALIFIED ELECTRICIAN CAN CARRY OUT THE ELECTRICAL

INSTALLATION OF THIS FILTER

WARNING

High voltage is used in the operation of this filter. Use Extreme caution to avoid

contact with high voltage when operating, installing or repairing this filter. INJURY

OR DEATH MAY RESULT IF SAFETY PRECAUTIONS ARE NOT OBSERVED.

After removing power, allow at least five minutes to elapse and verify that the

capacitors have discharged to a safe level before contacting internal components.

Connect a DC voltmeter across the capacitor terminals 1, 2 and 3 on terminal block

1TB. Start with the meter on the highest scale and progressively switch to a lower

scale as the indicated voltage falls below the maximum value of the scale used.

WARNING

The opening of the branch circuit protective device may be an indication that a fault current

has been interrupted. To reduce the risk of fire or electrical shock, current-carrying parts and

other components of the filter should be examined and replaced if damaged.

WARNING

An upstream disconnect/protection device must be used as required by the National

Electrical Code (NEC).

WARNING

Even if the upstream disconnect/protection device is open, the drive down stream of the filter

may feed back high voltage to the filter. The drive safety instructions must be followed.

INJURY OR DEATH MAY RESULT IF THE DRIVE SAFETY PRECAUTIONS ARE

NOT OBSERVED.

PDF created with pdfFactory trial version www.pdffactory.com

1

Page 7

WARNING

The filter must be grounded with a grounding conductor connected to all grounding terminals.

WARNING

Only spare parts obtained from MTE Corporation or an authorized MTE distributor can be

used.

2

PDF created with pdfFactory trial version www.pdffactory.com

Page 8

2. INTRODUCTION

This manual was specifically developed to

assist in the installation, interconnection

and operation of the MTE Corporation

Matrix Filter.

This manual is intended for use by

personnel experienced in the operation and

maintenance of electronic drives. Because

of the high voltages required by the filter

and drive and the potential dangers

presented by rotating machinery, it is

essential that all personnel involved in the

operation and maintenance of this filter

know and practice the necessary safety

precautions for this type of equipment.

Personnel should read and understand the

instructions contained in this manual before

installing, operating or servicing the filter

and the drive to which the filter is

connected.

Upon Receipt of this Filter:

The MTE Matrix Filter has been subjected

to demanding factory tests before shipment.

Carefully inspect the shipping container for

damage that may have

occurred in transit. Then unpack the filter

and carefully inspect for any signs of

damage. Save the shipping container for

future transport of the filter.

In the event of damage, please contact

and file a claim with the freight carrier

involved immediately.

If the equipment is not going to be put into

service upon receipt, cover and store the

filter in a clean, dry location. After storage,

ensure that the equipment is dry and that

no condensation has accumulated on the

internal components of the filter before

applying power.

Repair/Exchange Procedure

MTE Corporation requires a Returned

Material Authorization Number before it can

accept any filters that qualify for return or

repair. If problems or questions arise during

installation, setup, or operation of the filter,

please call us for assistance at:

Phone: 262-253-8200

FAX: 262-253-8222

PDF created with pdfFactory trial version www.pdffactory.com

3

Page 9

3. MODEL NUMBER CODES

Standard series A model number codes are of the form MA-BCDEFG-XY with the

number coded as outlined below.

Character

M Always M for Matrix Filter

A Designates number of input phases 1 Single phase

3 Three phase

B Characters B through E designate the Example: 0075 is a 75 Hp filter

C Horsepower rating of the filter using

D four digits with leading zeros

E

F Indicates mechanical configuration N Nema1

R Reactive components only

M Magnetic components only

P Panel mounted

W Weather proof

D Dust tight

H Hose down

G Designates input voltage and frequency A 208-240 v / 60Hz

B 240 v / 50 Hz

C 380-415 v / 50 Hz

D 480 v / 60 Hz

E 600 v / 60 Hz

F 690 v / 50 Hz

G 690 v / 60 Hz

H 120 v / 60 Hz

J

K

L 277 v / 60Hz

XY Designates filter guaranteed harmonic 12 is 12% THID

current performance 8 is 8% THID

Description Code

4

PDF created with pdfFactory trial version www.pdffactory.com

Page 10

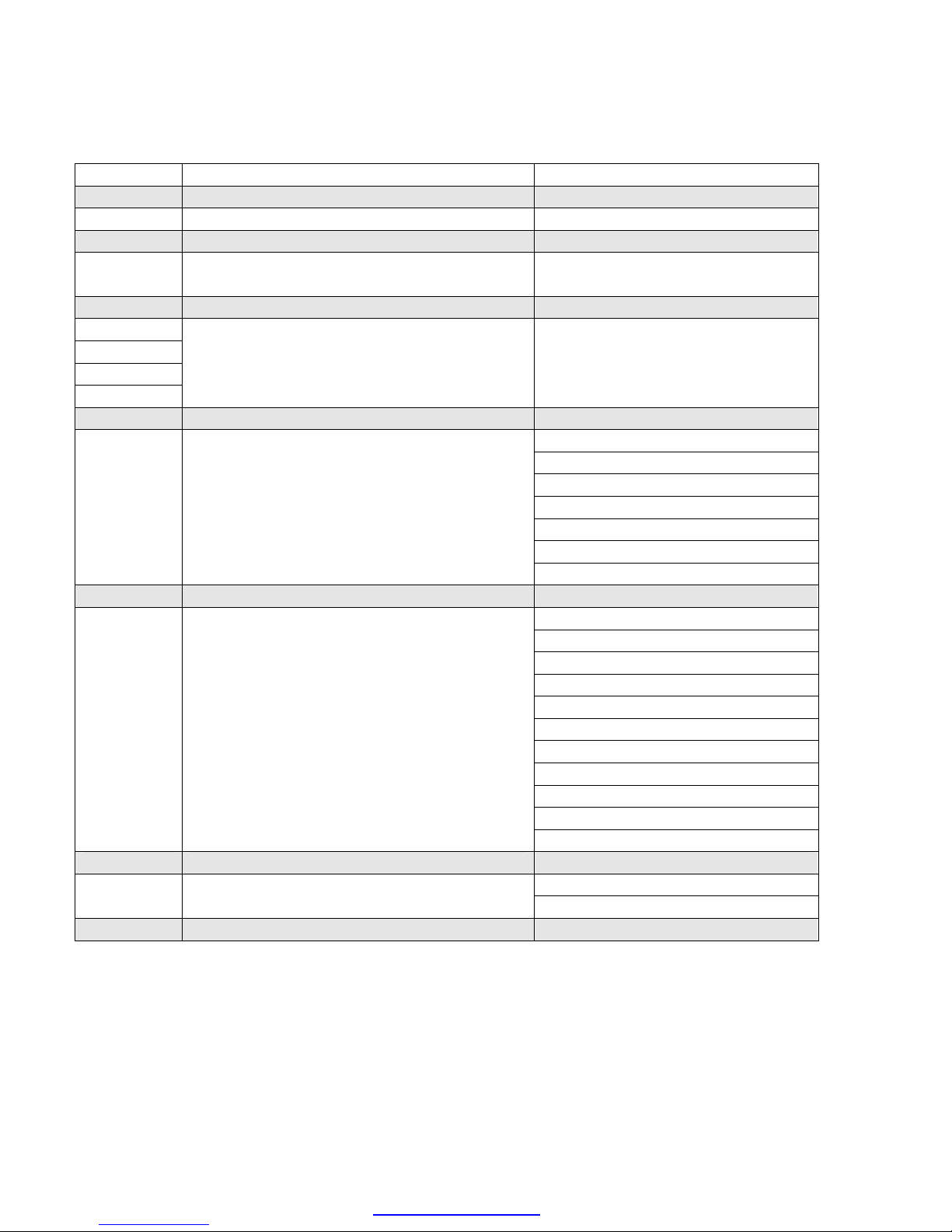

4. SPECIFICATIONS

Maximum

Dissipation

Dissipation

Ratings

THID Rating 12% 8%

480 VAC Three Phase Input Filter Ratings

(Panel Mounted)*

Power

Maximum

HP

3 6 6 97 47 27 98 40 37

5 9 10 98 66 35 98 63 42

7.5 13 14 98 98 35 98 98 42

10 16 18 98 114 45 98 108 60

15 24 27 98 166 50 98 170 75

20 31 34 98 204 85 98 212 100

25 39 43 98 275 85 98 257 100

30 46 51 98 295 105 98 323 130

40 60 66 98 390 125 98 374 155

50 75 82 98 475 150 98 506 190

60 89 97 98 586 150 98 584 190

75 110 121 98 659 200 98 655 250

100 143 157 98 837 215 98 838 280

125 179 197 98 971 250 98 1051 305

150 207 228 99 1018 275 99 1057 340

200 276 304 98 1521 380 98 1775 600

250 347 382 99 1767 450 98 1889 675

300 415 457 99 1994 575 99 2099 750

Input

Amps

RMS

Output

Amps

RMS

Efficiency

(Typical)

(%)

@ Rated

HP

(Typical)

(Watts)

Weight

(lbs)

Efficiency

(Typical)

(%)

Power

@ Rated HP

(Typical)

(Watts)

Weight

(lbs)

*Refer to Addendum A for Enclosed Current Ratings

Service Conditions

Load: 6 pulse variable torque rectifier only

Input voltage: 480 VAC +/- 10%, 60 + 0.75 Hz, 3 phase

Input voltage line unbalance: 1% maximum

Maximum source impedance: 6.00%

Minimum source impedance: 1.5%

Service Factor: 1.00

PDF created with pdfFactory trial version www.pdffactory.com

5

Page 11

SPECIFICATIONS – continued

Ambient Temperature

Operating: -40 to +50 degrees C (panel mounted construction)

Storage: -40 to +90 degrees C

Altitude: 0 to 3300 Feet above sea level. Refer to Figure 1 for altitude derating.

Relative Humidity: 0 to 95% non-condensing

Agency Approvals

UL-508 File E180243 Component Recognized

(3-1000 HP, 120 VAC through 600 VAC

50, 50/60, 60 HZ Three Phases

CAN/CSA C22, 2 No. 14-95

Performance

Total Harmonic Current Distortion:

Standard: 12% maximum no load to full load

Optional: 8% maximum no load to full load

Standby Current:

Without Optional Capacitor Contactor: Refer to Table 1

With Optional Capacitor Contactor: Refer to Drive Users Manual

12% Filter Voltage Regulation with nominal 480 volts RMS source

Maximum output voltage at no load: 502 volts RMS, 710 volts peak

Maximum PCC* voltage with 6.00% source impedance at no load: 490 volts RMS, 693 volts peak

Minimum output voltage at full load: 460 volts RMS, 600 volts peak

8% Filter Voltage Regulation with nominal 480 volts RMS source

Maximum output voltage at no load: 502 volts RMS, 710 volts peak

Maximum PCC voltage with 6.00% source impedance at no load: 490 volts RMS, 693 volts peak

Minimum output voltage at full load: 460 volts RMS, 600 volts peak

*Note: PCC is the point of common coupling with the power distribution system

6

PDF created with pdfFactory trial version www.pdffactory.com

Page 12

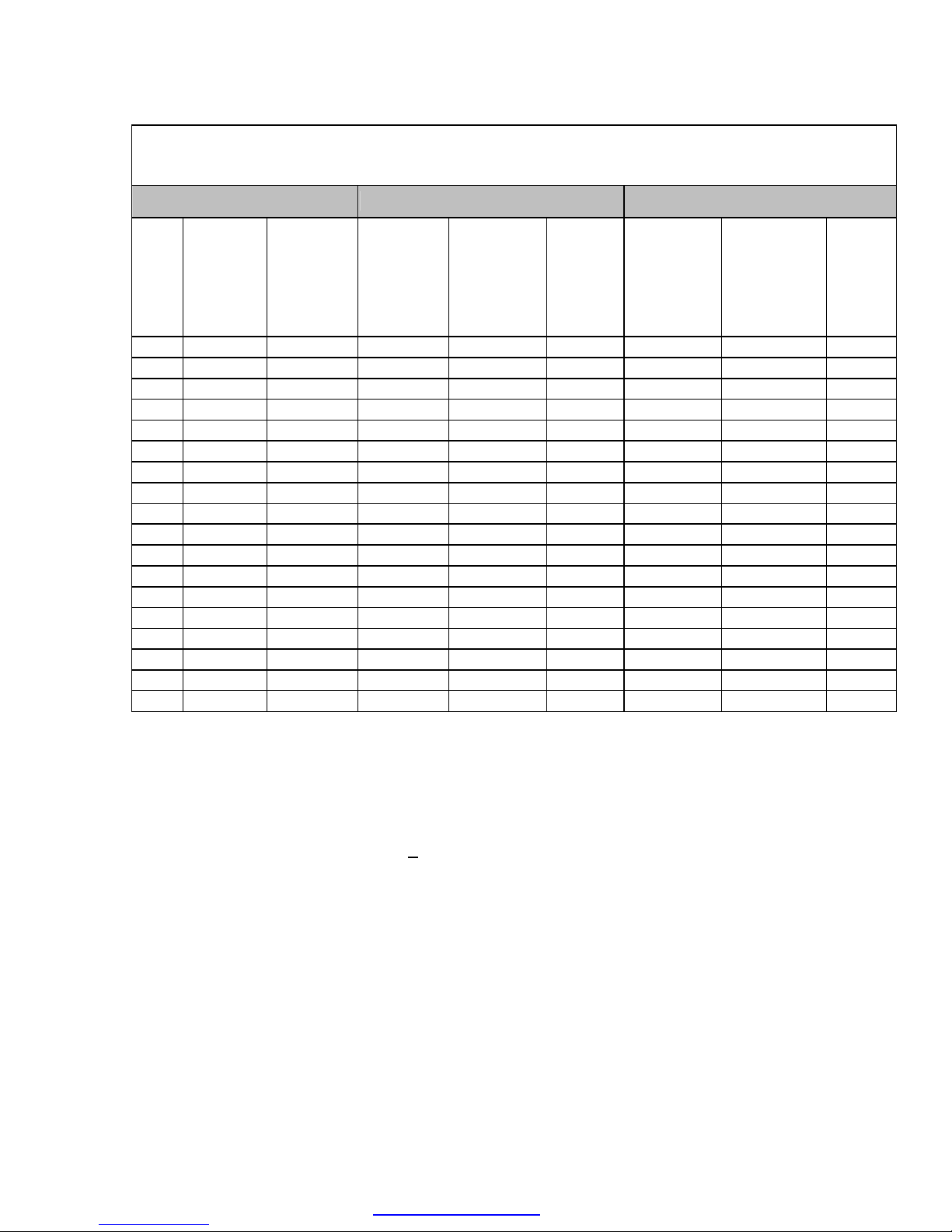

SPECIFICATIONS - continued

Table 1. 480 VAC Three Phase Input Filters

Standby Current Ratings Without Optional Capacitor Contactor

Standby

Current

HP

(Typical)

Amps

RMS

3 1.7 25 11.0 100 41.0

5 2.3 30 16.0 125 64.0

7-1/2 4.0 40 16.0 150 81.0

10 4.5 50 23.0 200 101.0

15 7.9 60 23.0 250 121.0

20 11.0 75 27.0 300 148.0

HP Standby

Current

(Typical)

HP

Amps

RMS

12% Filter THD vs Load

12

10

8

6

4

Percent THD

2

0

0 20 40 60 80 100

Percent Load

Standby

Current

(Typical)

Amps

RMS

Typical Worst Case

8% Filter THD vs Load

9

8

7

6

5

4

3

Percent THD

2

1

0

0 20 40 60 80 100

Percent Load

Typical Worst Case

7

PDF created with pdfFactory trial version www.pdffactory.com

Page 13

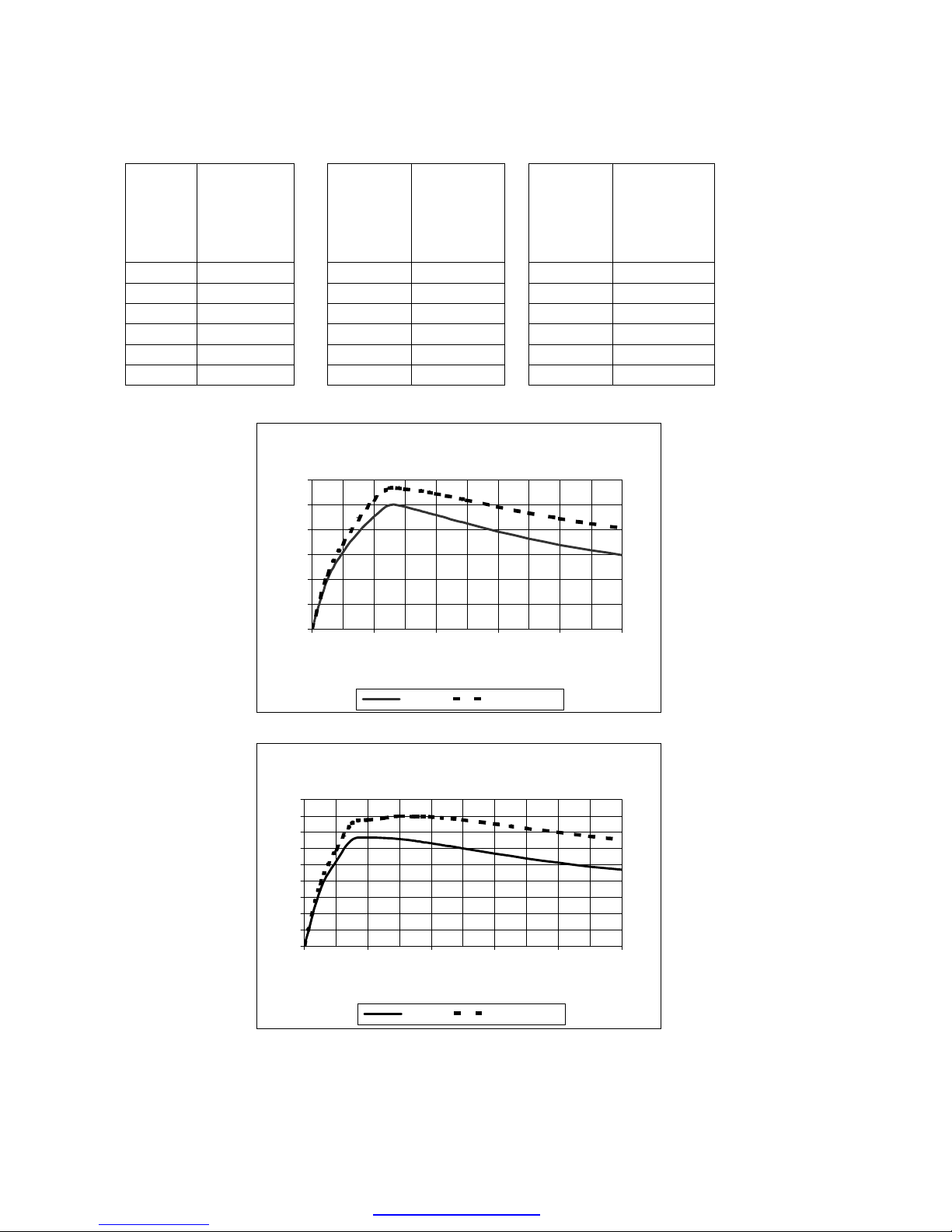

SPECIFICATIONS – continued

12% Filter Harmonic Spectrum

100% Load

7%

6%

5%

4%

3%

2%

1%

Harmonic Curent

0%

180

300

420

540

Frequency - Hz

Typical Worst Case

660

780

900

1020

1140

8% Filter Harmonic Spectrum

100% Load

6%

5%

4%

3%

2%

1%

Harmonic Current

0%

180

300

420

540

Frequency - Hz

660

780

900

1020

1140

Typical Worst Case

8

PDF created with pdfFactory trial version www.pdffactory.com

Page 14

SPECIFICATIONS - continued

12% and 8% Filter Power Factor vs Load

Leading PF For All Loads

1.2

1

0.8

0.6

PF

0.4

0.2

0

0 20 40 60 80 100

Percent Filter Load

Typical Worse Case

Performance With Unbalanced Line Voltage (Typical)

All Components at Nominal Values

and Worse Case Service Conditions

Nominal THID

1% Unbalance

2% Unbalance

3% Unbalance

12% Filter 30% Load 8% Filter 30% Load

Nominal THID

1% Unbalance

2% Unbalance

3% Unbalance

12% Filter 100% Load 8% Filter 100% Load

5.85% 4.71%

6.09% 4.92%

6.64% 5.46%

7.45% 6.29%

9.38% 6.42%

9.79% 6.90%

10.97% 8.13%

12.66% 9.80%

PDF created with pdfFactory trial version www.pdffactory.com

9

Page 15

1.05

Figure 1. Altitude Derating Curve

1.00

0.95

0.90

0.85

0.80

0.75

0.70

CURRENT DERATING FACTOR

0 3300 6600 9900 13200 16500

ALTITUDE (FEET)

10

PDF created with pdfFactory trial version www.pdffactory.com

Page 16

5. INSTALLATION

INSTRUCTIONS

Filter Installation

Panel mounted filters are designed for

mounting in the vertical plane in the

customer’s enclosure. Include the power

dissipation of the filter along with all the

other components located in the panel to

determine the internal temperature rise and

cooling requirements of the enclosure.

Select a well ventilated, dust-free area away

from direct sunlight, rain or moisture.

Do not install in or near a corrosive

environment.

Avoid locations where the filter would be

subjected to excessive vibrations.

The Matrix Filters are supplied as sub-panel

and panel mountable components that are

designed to be mounted in a vertical

position on a main panel located within an

appropriate electrical enclosure. Allow

minimum side clearances of four (4) inches

and vertical clearances of six (6) inches for

proper heat dissipation and access. Figures

2 though 11 contain outline drawings for the

various ratings and show proper mounting

orientation.

Power Wiring Connection

WARNING

Input and output power wiring to the

filter should be performed by

authorized personnel in accordance

with the NEC and all local electrical

codes and regulations.

Verify that the power source to which the

filter is to be connected is in agreement with

the nameplate data on the filter. A fused

disconnect switch or circuit breaker should

be installed between the filter and its source

of power in accordance with the

requirements of the NEC and all local

electrical codes and regulations. Refer to

the drive user manual for selection of the

correct fuse rating and class.

The filter is suitable for use on a circuit

capable of delivering not more than 100,000

rms symmetrical amperes at 480 volts when

protected by Bussman type JJS, KTK, KTKR, SPP or T class fuses.

For 480VAC applications rated 15 Hp and

below, interconnection between the filter, its

power source, and the drive is shown in

Figure 12. Refer to the drive user manual

for instructions on interconnecting the drive

and motor and the correct start-up

procedures for the drive.

The filter is designed for use with copper

conductors with a minimum temperature

rating of 75 degrees C. Table 2 lists the wire

range and terminal torque requirements for

the power input and output connections by

horsepower rating.

For 480 VAC filters rated 20 Hp or more, the

filter reactors are supplied on a sub-panel

and the filter capacitors are supplied on one

or more assembles. Refer to Figure 13 for

the interconnection diagram. The capacitor

assembly should be located in the lowest

temperature regions of the enclosure –

generally toward the bottom – and the

reactor assembly may be located in any

region where the ambient temperature

does not exceed 50 degrees C. Size the

conductors interconnecting the reactor and

capacitor assemblies to carry the current

shown in Table 3. For terminal

specifications on the capacitor assembly,

refer to Table 4.

PDF created with pdfFactory trial version www.pdffactory.com

11

Page 17

INSTALLATION

INSTRUCTIONS – continued

Grounding and Ground Fault

Protection

Table 2. Input and Output Terminal Specifications

Filter

Rating(HP)

3 22 -14 4.5 22 – 14 4.5

5 22 - 14 4.5 22 – 14 4.5

7.5 22 - 14 4.5 22 – 5 16

10 22 - 5 16 22 – 5 16

15 22 - 5 16 22 – 5 16

20 22 - 5 16 18 – 4 20

25 22 - 5 16 18 – 4 20

30 18 – 4 20 18 – 4 20

40 18 – 4 20

Wire Range

(AWG)

Input Terminals Output Terminals

The filter must always be grounded with a

grounding conductor connected to all ground

terminals.

Due to high leakage currents associated with

variable frequency drives, ground fault

protective devices do not necessarily operate

correctly when placed ahead of a matrix filter

feeding a drive. When using this type of

device, its function should be tested in the

actual installation.

Terminal Torque

(in-lbs)

Wire Range

(AWG)

6-4

2-0

Terminal Torque

(in-lbs)

45

50

50

60

75

100

125 2 – 0000 150 2 – 0000 150

150 2 – 0000 150 2 – 0000 150

200 2-0000 150

250

300

6-4

2-0

6-4

2-0

6-4

2-0

6-4

2-0

00

000-0000

250-350 MCM

500 MCM

00

000-0000

250-350 MCM

500 MCM

45

50

45

50

45

50

45

50

180

250

325

375

180

250

325

375

6-4

2-0

6-4

2-0

6-4

2-0

2-0000 150

00

000-0000

250-350 MCM

500 MCM

00

000-0000

250-350 MCM

500 MCM

00

000-0000

250-350 MCM

500 MCM

45

50

45

50

45

50

180

250

325

375

180

250

325

375

180

250

325

375

12

PDF created with pdfFactory trial version www.pdffactory.com

Page 18

INSTALLATION INSTRUCTIONS – continued

Figure 2. 3 – 10 HP, 480 VAC Outline Drawing

All dimensions are in inches

33

PDF created with pdfFactory trial version www.pdffactory.com

Page 19

INSTALLATION INSTRUCTIONS – continued

Figure 3. 15 HP, 480 VAC Outline Drawing

All dimensions are in inches

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 20

INSTALLATION INSTRUCTIONS – continued

Figure 4. 20 - 40 HP, 480 VAC Outline Drawing

All dimensions are in inches

REACTOR ASSEMBLY

CAPACITOR ASSEMBLY

NOTE: CAPACITOR ASSEMBLY MAY BE MOUNTED IN EITHER PLANE

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 21

INSTALLATION INSTRUCTIONS – continued

Figure 5. 50 - 60 HP, 480 VAC Outline Drawing

All dimensions are in inches

REACTOR ASSEMBLY

CAPACITOR ASSEMBLY

NOTE: CAPACITOR ASSEMBLY MAY BE MOUNTED IN EITHER PLANE

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 22

INSTALLATION INSTRUCTIONS – continued

Figure 6. 75 HP, 480 VAC Outline Drawing

All dimensions are in inches

REACTOR ASSEMBLY

CAPACITOR ASSEMBLY

NOTE: CAPACITOR ASSEMBLY MAY BE MOUNTED IN EITHER PLANE

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 23

INSTALLATION INSTRUCTIONS – continued

Figure 7. 100 HP, 480 VAC Reactor Assembly Outline Drawing

All dimensions are in inches

REACTOR ASSEMBLY

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 24

INSTALLATION INSTRUCTIONS – continued

Figure 8. 100 HP, 480 VAC Capacitor Assembly Outline Drawing

All dimensions are in inches

NOTE: TWO CAPACITOR ASSEMBLIES REQUIRED

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 25

INSTALLATION INSTRUCTIONS – continued

CAPACITOR

Figure 9. 125 - 150 HP, 480 VAC Outline Drawing

All dimensions are in inches

REACTOR ASSEMBLY

NOTE: SEE TABLE FOR NUMBER OF CAPACITOR ASSEMBLIES

NO. OF

HP

125 2

150 3

PANELS

NOTE: CAPACITOR ASSEMBLY MAY BE MOUNTED IN EITHER PLANE

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 26

INSTALLATION INSTRUCTIONS – continued

Figure 10. 200 - 300 HP, 480 VAC Vertical Mounting Outline Drawing

All dimensions are in inches

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 27

INSTALLATION INSTRUCTIONS – continued

Figure 11. 200 - 300 HP, 480 VAC Horizontal Mounting Outline Drawing

All dimensions are in inches

480 VAC Matrix Filters rated 200 HP through 300 HP, are constructed from a reactor assembly

and a capacitor assembly. These assemblies are designed to be mounted vertically. The reactor

assembly may be mounted above the capacitor assembly as shown in Figure 10 or the

assemblies may be mounted separately as shown in Figure 11. The capacitor assembly should

be located in the lowest temperature regions of the enclosure – generally toward the bottom.

The reactor and capacitor assemblies are shipped vertically oriented bolted and banded front-toback to a common pallet.

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 28

INSTALLATION INSTRUCTIONS – continued

Figure 12. 3 – 15 HP Interconnection Diagram

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 29

INSTALLATION INSTRUCTIONS – continued

Figure 13. 20 – 300 HP Interconnection Diagram

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 30

INSTALLATION INSTRUCTIONS – continued

Table 3. Capacitor Assembly Current Ratings

HP

20 13 100 50

25 13 125 79

30 20 150 100

40 20 200 124

50 28 250 149

60 28 300 182

75 34

Current Rating

(Amps RMS)

Table 4. Capacitor Assembly Terminal Specifications

Filter Rating (HP)

HP

Capacitor Terminals

NOTE: Two terminals per phase

Current Rating

(Amps RMS)

20 – 150 HP

200 – 300 HP

Wire Range (AWG) Terminal Torque (in lbs)

14 – 10

8

4 – 6

1/0 – 3

6-00

35

40

45

50

120

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 31

6. FILTER DESCRIPTION

The MTE Matrix Filter is a low pass filter

containing proprietary technology which makes

it particularly useful for harmonic mitigation of

adjustable speed drives. Figure 14 shows a

block diagram of the filter. Three phase AC

power is connected to the input section which

contains a three phase AC reactor and circuitry

which inhibits oscillation of the filter with the AC

power system. The center leg consists of a

series reactor and capacitor bank. Because of

the capacitor bank the filter operates with

leading power factor at all loads, but unlike trap

filters the MTE Matrix Filter does not produce

significant voltage rise at the point of common

coupling with the power system. The standard

12% filter output section consists of an AC

output reactor.

The 8% filter is comprised of a standard 12%

filter plus an additional output reactor.

Matrix filters are horsepower and current

rated. Current ratings have been

established on the basis of 115% of the

NEC 480 VAC motor ratings. Because the

filter operates at near unity power factor, a

motor drive system fed by a Matrix Filter

and operating at rated horsepower will draw

significantly less current than the filters

rated input current. For a drive system with

a typical efficiency of .85 and a Matrix Filter

with an efficiency of .98, the power into the

filter is (1/.98)(1/.85)(746)(HP) where HP is

the motor horsepower rating. The filter input

power is also equal to (√3)(Line

Current)(Line to Line Voltage). Equating

these two quantities and then calculating

the line current as a percent of rated filter

current for 10 HP, 100HP, and 300HP for

480 VAC results in the following data.

HP Rated Filter Current

%

10 67

100 75

300 78

Filter enclosures have been designed to

accommodate filter power dissipation at

rated horsepower. Filters mounted on open

panels are designed to carry rated current.

Select a matrix filter to match the horsepower

rating of the drive. For multiple drive

applications, the horsepower rating of the filter

should be equal to the total horsepower ratings

of the drives. For example, select a 100 Hp filter

to feed three 30Hp and one 10 Hp drives.

Multiple drives fed from a single filter may be

operated independently.

Because the filter supplies harmonic currents

required by the drive, linear loads (such as

space heaters, incandescent lighting and AC

motors operated across the line) should not be

connected to the output of the filter.

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 32

Figure 14. Block Diagram

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 33

7. STARTUP

Safety Precautions

Before startup, observe the following

warnings and instructions:

WARNING

Internal components of the filter are at

line potential when the filter is

connected to the utility. This voltage is

extremely dangerous and may cause

death or severe injury if you come in

contact with it.

WARNING

After disconnecting the utility power,

wait at least 5 minutes before doing any

work on the filter connections. After

removing power, allow at least five

minutes to elapse and verify that the

capacitors have discharged to a safe

level before contacting internal

components. Connect a DC voltmeter

across the capacitor terminals 1, 2 and

3 on terminal block 1TB. Start with the

meter on the highest scale and

progressively switch to a lower scale

as the indicated voltage falls below the

maximum value of the scale used.

Sequence of Operation

1. Read and follow safety precautions.

2. After installation, ensure that:

• All filter ground terminals are

connected to ground.

• Power wiring to the utility, drive

and motor is in accordance with

the installation and connection

instructions in Chapter 5.

3. Check that moisture has not

condensed on the filter components. If

moisture is present, do not proceed

with startup until the moisture has

been removed.

4. Disconnect the filter output from the

drive.

5. Connect the filter to the utility.

WARNING

Use extreme caution to avoid contact

with line voltage when checking for

power. INJURY OR DEATH MAY

RESULT IF SAFETY PRECAUTIONS

ARE NOT OBSERVED.

6. Confirm that line voltage is present at

the input terminals (A1, B1, C1) of the

filter.

7. Confirm that line voltage is present at

the output terminals (A2, B2, C2) of the

filter.

8. Disconnect the filter from the utility.

9. Connect the filter output to the drive.

10. Refer to the drive user manual for the

drive startup procedure. Observe all

safety instructions in the drive user

manual.

WARNING

INJURY OR DEATH MAY RESULT IF

THE DRIVE SAFETY PRECAUTIONS

ARE NOT OBSERVED.

CAUTION

Damage to equipment may occur if the

drive startup procedures are not observed.

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 34

8. TROUBLESHOOTING

WARNING

When properly installed, this equipment

has been designed to provide maximum

safety for operating personnel. However,

hazardous voltages exist within the

confines of the enclosure. Servicing

should therefore be performed by

qualified personnel only and in

accordance with OSHA Regulations.

To aid in troubleshooting, a block diagram is

shown in Figure 14, and a list of potential

problems and solutions are listed below.

WARNING

High voltage is used in the operation of

this filter. Use Extreme caution to avoid

contact with high voltage when

operating, installing or repairing this

filter. INJURY OR DEATH MAY RESULT

IF SAFETY PRECAUTIONS ARE NOT

OBSERVED.

After removing power, allow at least five

minutes to elapse and verify that the

capacitors have discharged to a safe

level before contacting internal

components. Connect a DC voltmeter

across the capacitor terminals 1, 2 and 3

on terminal block 1TB. Start with the

meter on the highest scale and

progressively switch to a lower scale as

the indicated voltage falls below the

maximum value of the scale used.

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 35

TROUBLESHOOTING - continued

PROBLEM:

Possible cause:

Solution:

Possible cause:

Solution:

PROBLEM:

Possible cause:

Solution:

Line voltage is not present at the filter output terminals.

Power to the filter is turned off.

Turn power on.

One or more external line fuses are blown.

Verify the continuity of line fuses in all phases. Replace as

necessary.

Harmonic current distortion exceeds 12% on one or more

input phases.

One or more capacitor fuses have blown.

Verify the continuity of capacitor fuses in all three phases. Replace

as necessary.

Possible cause:

Solution:

Possible cause:

Solution:

Possible cause:

Solution

Possible cause:

Solution

Possible cause:

Solution:

On filters rated 20HP and above, the capacitor assembly has not

been connected.

Check interconnection of capacitor assembly with reactor panel

(Figure 13).

A capacitor has failed.

Inspect the tops of all capacitors for bowing. Replace failed

capacitors. Also replace the fuse in series with the failed capacitor.

Source impedance is less than 1.5%.

Add a minimum 1.5% impedance line reactor to the filter input

Input source voltage harmonic distortion.

Identify equipment causing harmonic voltage distortion and add

filters as required or accept elevated THVD

Line voltage unbalance exceeds 1%.

Balance input line voltage to 1% or less.

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 36

TROUBLESHOOTING - continued

PROBLEM:

Possible cause:

Solution:

Possible cause:

Solution:

Possible cause:

Solution:

Possible cause:

Solution:

Harmonic current distortion exceeds 8% on one or more

phases.

The output reactor required for an 8% filter was not installed. (See

Figure 14.)

Install the required output reactor.

One or more capacitor fuses have blown.

Verify the continuity of capacitor fuses in all three phases. Replace

as necessary.

On filters rated 20HP and above, the capacitor assembly has not

been connected.

Check interconnection of capacitor assembly with reactor panel

(Figure 13).

A capacitor has failed.

Inspect the tops of all capacitors for bowing. Replace failed

capacitors. Also replace the fuse in series with the failed capacitor.

Possible cause:

Solution

Possible cause:

Solution

Possible cause:

Solution:

Source impedance is less than 1.5%.

Add a minimum 1.5% impedance line reactor to the filter input

Input source voltage harmonic distortion.

Identify equipment causing harmonic voltage distortion and add

filters as required or accept elevated THVD

Line voltage unbalance exceeds 1%.

Balance input line voltage to 1% or less.

33

PDF created with pdfFactory trial version www.pdffactory.com

Page 37

TROUBLESHOOTING – continued

PROBLEM:

Possible cause:

Solution:

Possible cause:

Solution:

Filter output voltage is not within specification

Filter input voltage is not within specification.

Check the AC input line voltage and verify that it is within tolerance.

Refer to the filter service conditions and performance specifications

in Chapter 3 for tolerances.

Source impedance is out of tolerance.

Verify that the source impedance is within tolerance. Refer to the

filter service conditions and performance specifications in Chapter 3

for tolerances.

PDF created with pdfFactory trial version www.pdffactory.com

33

Page 38

PDF created with pdfFactory trial version www.pdffactory.com

33

Loading...

Loading...