Page 1

HYDROCAL 1005 Manual for Installation and Operation Edition 01.2011

HYDROCAL1005

Gas-in-Oil Analysis System with

Transformer Monitoring Functions

Manual for installation and operation

Page 2

HYDROCAL 1005 Manual for Installation and Operation Page 2/111

Copyright MTE Meter Test Equipment AG

All rights reserved.

The contents of this manual are

subject to change without notice.

All efforts have been made to ensure

the accuracy of this publication but

MTE Meter Test Equipment AG can

assume no responsibility for any errors Customs tariff number:

or their consequences 9027.1010

Page 3

HYDROCAL 1005 Manual for Installation and Operation Page 1/111

Summary

1. General ....................................................................................................................................... 4

2. Mounting of HYDROCAL1005 unit ............................................................................................ 5

2.1 Locations for installation of HYDROCAL1005 ....................................................................... 5

2.2 Security precautions for installation ...................................................................................... 6

2.3 Preparation for installation .................................................................................................... 8

2.3.1 Power supply for the unit ............................................................................................... 8

2.3.2 Requested tools: ........................................................................................................... 8

2.4 Installation of the HYDROCAL1005 unit ............................................................................... 8

2.5 Electrical Installation of HYDROCAL1005 unit .................................................................... 11

2.6 Completion of Installation ................................................................................................... 12

3. Hardware components of HYDROCAL 1005 .......................................................................... 14

3.1 Front view of HYDROCAL1005 .......................................................................................... 14

3.2 Rear side of HYDROCAL1005 unit ..................................................................................... 15

3.3 Connections on the measuring and controller card ............................................................. 17

3.4 Measurement and extraction Components ......................................................................... 22

4. Software on HYDROCAL unit ................................................................................................. 24

4.1 General information ............................................................................................................ 24

4.2 Description of Gas measurement Process ......................................................................... 24

4.3. Operation Cycles ................................................................................................................ 25

4.3.1. Zero measurement ...................................................................................................... 25

4.3.1.1 Safety function and error observation for Zero measurement cycle ...................... 25

4.3.2 Depression .................................................................................................................. 26

4.3.2.1. Safety function and error observation for depression cycle .................................. 26

4.3.3. Leak detection ............................................................................................................. 27

4.3.3.1. Safety function and error observation for leak detection cycle .............................. 27

4.3.4. Filling to level 1 ............................................................................................................ 28

4.3.4.1. Safety function and error observation for filling to level 1 cycle............................. 28

4.3.5. Degassing ................................................................................................................... 29

4.3.5.1. Safety function and error observation for degassing cycle .................................... 29

4.3.6. Filling to level 2 ............................................................................................................ 30

4.3.6.1. Safety function and error observation for filling to level 2 cycle............................. 30

4.3.7. Measurement .............................................................................................................. 31

4.3.7.1. Safety function and error observation for measurement cycle .............................. 31

4.3.8. Flushing ....................................................................................................................... 32

4.3.8.1. Safety function and error observation for flushing cycle ....................................... 32

4.3.9. Draining ....................................................................................................................... 33

4.3.9.1. Safety function and error observation for draining cycle ....................................... 33

4.3.10. Wait ......................................................................................................................... 34

4.3.10.1. Safety function and error observation for wait cycle ............................................. 34

4.4 Operation of HYDROCAL1005 by its keyboard .................................................................. 35

4.4.1 Contrast Set-up ........................................................................................................... 35

4.5 Main menu .......................................................................................................................... 36

4.6 Extraction Menu .................................................................................................................. 37

4.7 Display of stored „Gas-in-oil“measuring values................................................................... 37

4.7.1 Graphic display................................................................................................. 37

4.7.2 Table presentation............................................................................................ 38

Page 4

HYDROCAL 1005 Manual for Installation and Operation Page 2/111

4.8 Status of alarms ...................................................................................................... 39

4.8.1 Acknowledgment of alarms ......................................................................................... 39

4.9 Device set – up ........................................................................................................ 40

4.9.1 Menu Transformer data setup .......................................................................... 41

4.9.1.1. DGA Adjustment: Input of correction factor .............................................................. 41

4.9.1.1 Hot Spot calculation .................................................................................. 42

4.9.1.2 Ageing Rate / Loss of Life ......................................................................... 44

4.9.2 Configuration of analogue outputs.................................................................... 45

4.9.3 Configuration of analogue inputs (external sensors) ........................................ 45

4.9.4 Configuration of alarms and digital outputs ...................................................... 48

4.9.5 Unit Setup ........................................................................................................ 51

4.9.5.1 Digital Output Test..................................................................................... 52

4.9.5.2 Device options .......................................................................................... 52

4.9.5.2.1.

Configuration of user settings ......................................................................... 53

4.9.5.3 Date. Time & Clock Settings ..................................................................... 53

4.9.5.4 Configuration of the communication .......................................................... 55

4.9.5.5 Ethernet setup ........................................................................................... 56

4.9.5.6 Alert SMS setup ........................................................................................ 57

4.9.5.7 Internal modem setup ............................................................................... 58

4.9.5.8 RS 232 / RS 485 setup ......................................................................................... 59

4.9.5.9 MODBUS .............................................................................................................. 66

5. Windows Software HydroSoft ................................................................................................ 76

5.1 Purpose of the program ...................................................................................................... 76

5.2 Remarks for use of this operation handbook ...................................................................... 76

5.3 Requirements to the PC ..................................................................................................... 76

5.4 Installation .......................................................................................................................... 77

5.4.1 Microsoft .NET .NET Framework 1.1 Redistributable .................................................. 77

5.4.2 Microsoft Data Access Components ............................................................................ 77

5.4.3 Adaptation of installation ............................................................................................. 78

5.5 Functions of HydroSoft program ......................................................................................... 78

5.6 Start of program ................................................................................................................. 78

5.7 Preparation / rename of a new customer list....................................................................... 79

5.8 Opening a new transformer station ..................................................................................... 80

5.9 Opening a file for a new transformer .................................................................................. 80

5.9.1 Modem settings ........................................................................................................... 82

5.9.2 RS232 interface settings ............................................................................................. 82

5.10 Settings of HYDROCAL1005 unit ....................................................................................... 82

5.10.1 Alert Setup................................................................................................................... 83

5.10.2 External sensors (see also chapter 4.7.3) ................................................................... 86

Page 5

HYDROCAL 1005 Manual for Installation and Operation Page 3/111

5.10.3 Alert SMS Setup .......................................................................................................... 87

5.10.4 Input of DGA Level Adjustment ................................................................................... 89

5.10.5 Analog Output Setup ................................................................................................... 90

5.10.6 Digital Output Setup .................................................................................................... 91

5.10.7 Device Setup (Clock settings) ...................................................................................... 91

5.10.5.1. Ethernet ................................................................................................................ 92

5.10.5.2. Modbus-TCP ........................................................................................................ 93

5.10.5.3. MODBUS .............................................................................................................. 93

5.11 Data transmission from / to the HYDROCAL1005 unit ........................................................ 93

5.12 View of results .................................................................................................................... 96

5.12.1 Sensor selection .......................................................................................................... 96

5.12.2 Time range selection ................................................................................................... 96

5.12.3 Result window ............................................................................................................. 97

5.12.4 Print and export of results ............................................................................................ 97

5.13 View of alarm status ........................................................................................................... 98

5.13.1 Alarm selection ............................................................................................................ 98

5.13.2 Time range selection ................................................................................................... 98

5.13.3 Alarm window ................................................................ .............................................. 99

5.13.4 Status of alarms .......................................................................................................... 99

5.13.5 Print and export of results ............................................................................................ 99

5.14 Online Sensors ................................................................................................................. 100

6. RS 485 Wiring ........................................................................................................................ 101

7. HYDROSOFT Scheduler ........................................................................................................ 102

7.1 General ............................................................................................................................ 102

7.2 Scheduler ......................................................................................................................... 102

7.2.1 Configuring a Transformer for automatic History Data Update .................................. 102

7.2.1.1 Connection Scheduler Dialog ............................................................................. 103

7.2.2 Scheduler Status Visualization .................................................................................. 103

7.2.2.1 Status Icons ....................................................................................................... 103

7.2.2.2 Transformer ........................................................................................................ 104

7.2.2.3 Station ................................................................................................................ 104

7.2.2.4 Customer ............................................................................................................ 104

7.2.2.5 Example ............................................................................................................. 104

7.2.3 HydroSoft and the Windows Task Scheduler ............................................................ 105

7.2.3.1 Command Line Options for Windows Task Scheduler ........................................ 106

7.2.3.2 IdleClose ............................................................................................................ 106

7.2.3.3 Minimized ........................................................................................................... 106

7.2.4 Internal Operation ...................................................................................................... 106

7.2.5 Data Directory Lock ................................................................................................... 107

8. Technical data HYDROCAL1005 ........................................................................................... 108

9. Dimensional drawings HYDROCAL1005 .............................................................................. 110

Page 6

HYDROCAL 1005 Manual for Installation and Operation Page 4/111

1. General

The HYDROCAL 1005 is a permanently-installed multi-gas-in-oil analysis system with transformer

monitoring functions. It allows for the individual measurement of moisture and the key gases hydrogen (H2), carbon monoxide (CO), acetylene (C2H2) and ethylene (C2H4) dissolved in transformer oil.

As hydrogen (H2) is involved in nearly every fault of the isolation system of power transformers and

carbon monoxide (CO) is a sign of an involvement of the cellulosic / paper isolation the presence and

increase of acetylene (C2H2) and ethylene (C2H4) further classifies the nature of a fault as overheating, partial discharge or high energy arcing. The device can serve as a compact transformer monitoring system by the integration / connection of other sensors present on a transformer via its analog

inputs:

5 analog outputs 0/4-20mADC

4 analog inputs 0/4-20 mADC (Option)

6 analog inputs 0/4-20 mADC +20% / 0-80 VAC +20% (option)

configurable by jumpers

It is further equipped with digital outputs for the transmission of alarms or the execution of control

functions (e. g. control of a cooling system of a transformer):

5 digital relay outputs

5 digital opto-coupler outputs (Option)

Key Advantages

Hydrogen (H2), Carbon monoxide (CO), acetylene (C2H2) and ethylene (C2H4) measurement

Moisture-in-oil measurement

Communication interfaces ETHERNET 10/100 Mbit/s (copper-wired or fibre-optical) and RS 485

to support proprietary communication protocols and to be open / prepared for substation commu-

nication protocols IEC 61850, MODBUS, DNP 3 etc.

Optional on-board GSM and analog modems for remote communication

6 analog AC current inputs for the connection of capacitive HV bushing sensors for HV bushing

monitoring applications

The present operating instructions are divided in the following sections:

Instructions for mounting the HYDROCAL 1005 unit (chapter 2)

Hardware components of HYDROCAL 1005 (chapter 3)

Description of software of the HYDROCAL 1005 unit (chapter 4)

Description of Windows software HydroSoft (chapter 5)

RS 485 Wiring (chapter 6)

New HydroSoft Scheduler functions (chapter 7)

Technical Data of HYDROCAL 1005 (chapter 8)

HYDROCAL 1005 dimensional drawings (chapter 9)

Page 7

HYDROCAL 1005 Manual for Installation and Operation Page 5/111

2. Mounting of HYDROCAL1005 unit

2.1 Locations for installation of HYDROCAL1005

To ensure the correct function of the HYDROCAL1005 the location of mounting is very important.

For a typical transformer, four places are possible:

Pos. 1

On return side of cooling circuit:

Please install the unit on a straight piece of tube on the cooler output between the cooler

and the main oil tank. In order to avoid negative pressure, the unit must absolutely be

mounted on the downstream side (after the bend) of the oil circulation pump.

Remark: Choose this place only in case of continuous oil flux through the cooler.

Pos. 2

Flange below on the transformer tank:

The flange must be at minimum height of 40 cm in order to allow installation and mounting

of HYDROCAL1005 unit.

Pos. 3

Upper filling valve:

It is possible to mount the Hydrocal 1005 unit on this position, if the filling level of

the oil is min. 100 cm higher than the mounting position. This position is not recommended, because the filling process is influenced by the hydrostatic pressure of

the oil and it may be difficult to operate and read the data of the unit.

Pos. 4

Never install the HYDROCAL1005 unit on top of the cooler or on the suction face of

the pump. In this case, filling oil step cannot be carried out in the right way.

Page 8

HYDROCAL 1005 Manual for Installation and Operation Page 6/111

2.2 Security precautions for installation

The following security precautions must be strictly observed during the installation. Otherwise no

warranty claims will be accepted.

Never remove the protection cap from the sensor before you are ready to

mount the unit on the valve of the transformer.

The protection cap protects the sensor against dust and other foreign bodies.

Additionally it protects the thread of the measuring head and/or adapters.

Note: Use the protection cap also after dismounting of the unit.

Never close the aeration holes for oxygenation. They are situated in bottom side of the protection cover and at the back plate of the device

Never use or stock chemicals with hydrocarbon contents near the measuring sensor.

Never clean the measuring head with solvents, because its gases will strongly

impair the measuring accuracy and the sensitivity of the sensors.

Never apply a negative pressure to the measuring head.

Negative pressure can cause problem during filling process.

Remove the HYDROCAL1005 unit from the valve every time you degas or

refill the transformer. You can also close the valve of the transformer

Never install the HYDROCAL unit on a valve that is closed for a long period of time. Remove the unit if this cannot be avoided. Please refer to

De-installation instructions

Never install the HYDROCAL1005 on the suction side of the cooling

pump!

The HYDROCAL 1005 should be installed on positions located 100 cm below of the oil level inside the transformer

Never install the HYDROCAL1005 unit on an elbow or curve of a tube.

The unit cannot operate by negative pressure produced by turbulences in

curves.

Page 9

HYDROCAL 1005 Manual for Installation and Operation Page 7/111

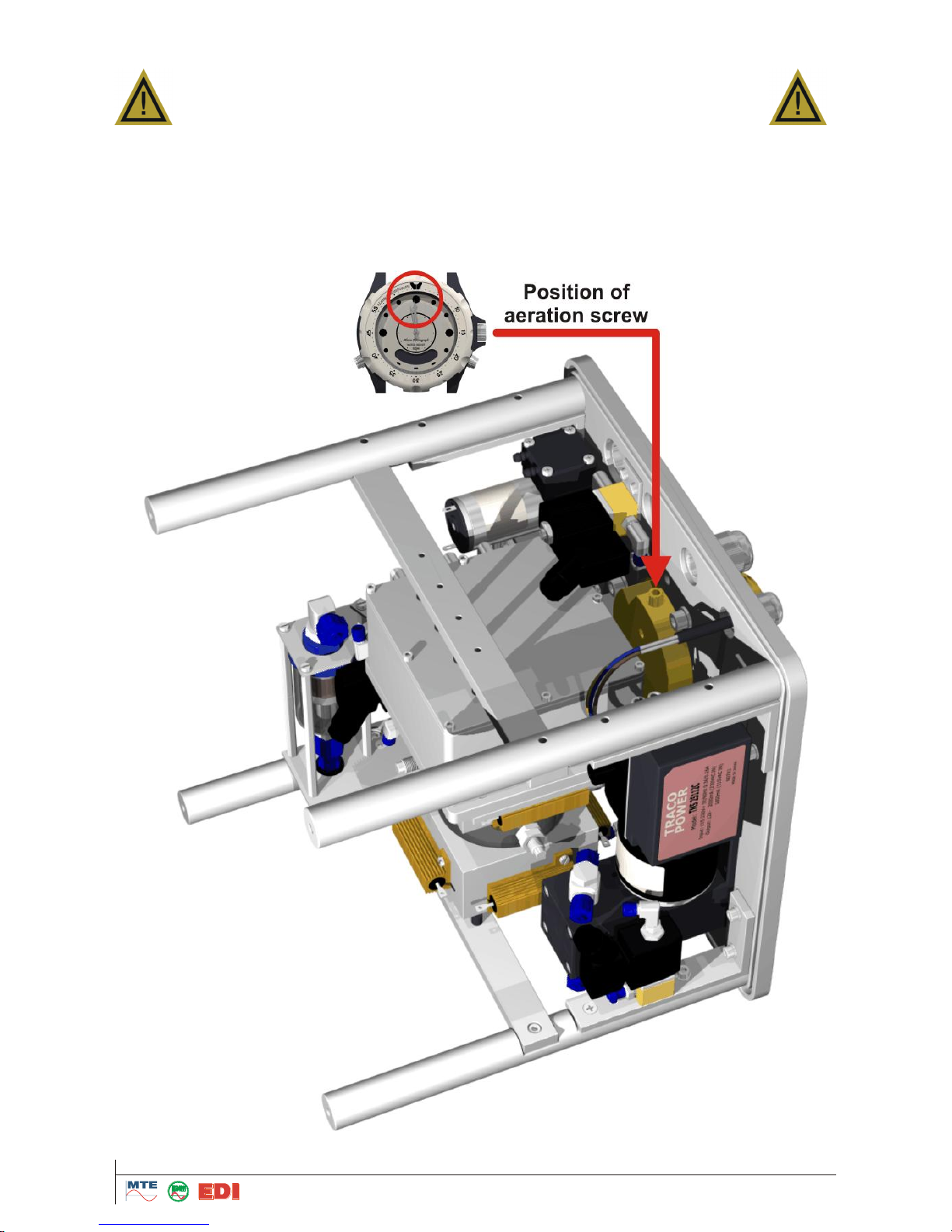

Never install or remove the HYDROCAL1005 without opening first the

aeration screw.

Never use galvanized fittings or valves to mount the HYDROCAL1005

unit.

Galvanized fittings or valves can react with oil; this will produce incorrect

measuring values.

Never clean the HYDROCAL1005 unit with high pressure cleaning

equipment.

High pressure cleaning equipment used to clean transformers can seriously

damage the HYDROCAL1005 unit.

Never use a chaining key tool for mounting.

Use of such tools can damage the surface of the measuring head and the

threads. Please use an adjustable thin spanner for 1 ½“.

Attention!!!

Faulty or inappropriate handling of the sensor head like malfunction by

negative pressure, paint or solvent liquids make the warranty invalid.

Page 10

HYDROCAL 1005 Manual for Installation and Operation Page 8/111

2.3 Preparation for installation

Before installation, a visual inspection of the unit must be carried out. Remove the protection cover

and check visually the components. All cables and tubes must be connected.

2.3.1 Power supply for the unit

The HYDROCAL1005 unit requires an auxiliary power supply of 110 / 230V close to the unit. The

power needed is max. 350 VA.

2.3.2 Requested tools:

Long Allen key, size 4 for aeration screw

Bucket, oil absorber, cleaning rag

Teflon-band

Drill / screw driver

Digital multimeter

Tin spanner M55 or adjustable tin spanner of 1 ½“ for valve and fittings

To seal the thread of the measuring head, either Teflon band (minimum 4 to 5 layers must be applied) or an O-Ring must be used.

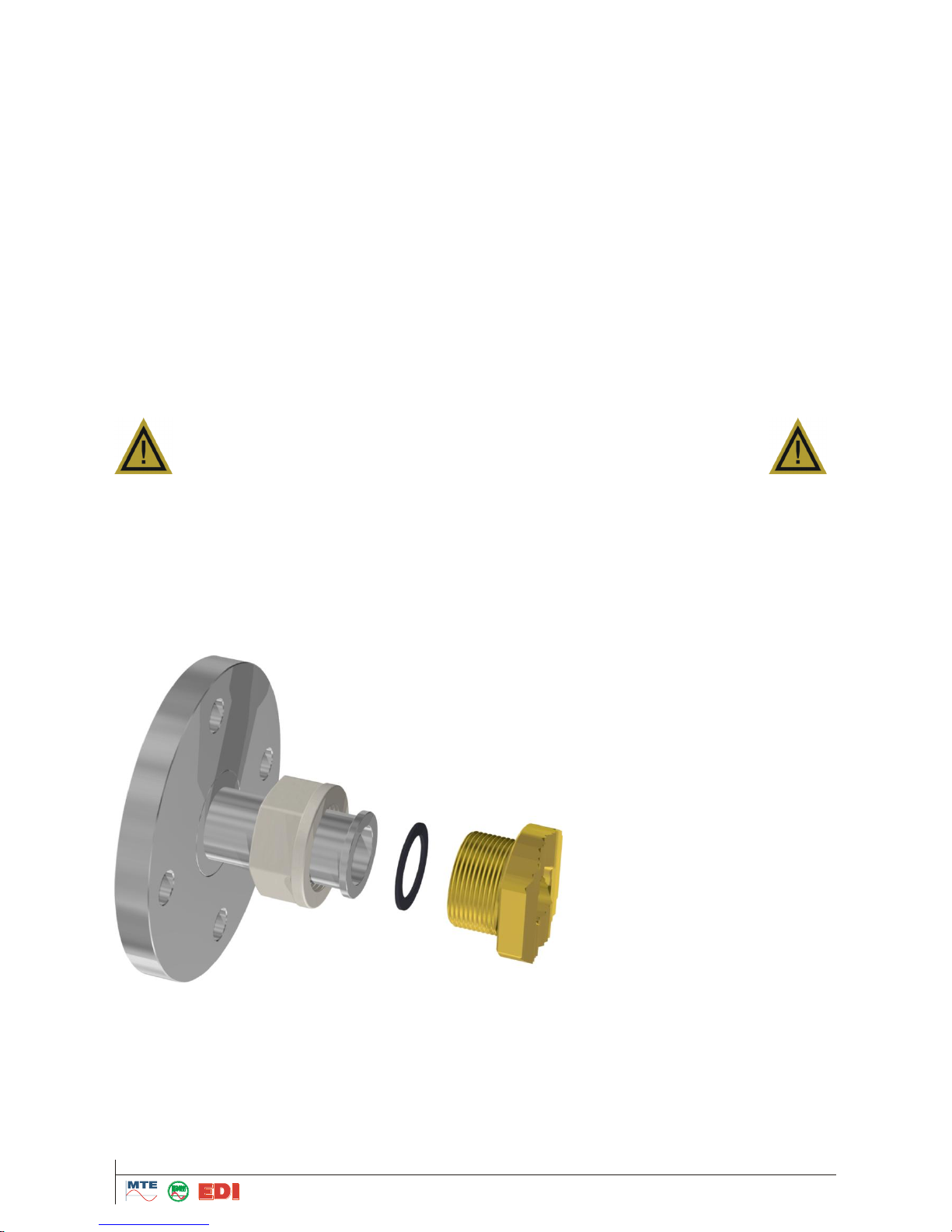

2.4 Installation of the HYDROCAL1005 unit

Attention!!!

Mount the unit horizontally on the valve. The aeration screw must be in

the 12 o’clock position.

Please mount the HYDROCAL1005 unit on a valve with full opening (full bore valve) or a ball valve

with an internal thread of 1½” (DIN ISO 228: G 1½) . The HYDROCAL unit has a 1½’’ thread (Dimensional drawings, see. chapter 8). As an option a valve with NPT 1½ standard can also be used.

A good oil flux should exist on the mounting location. If necessary, use a reduction piece (adapter).

It is recommended to mount the HYDROCAL 1005 unit to valve with a union- or sleeve nut. In this

case the device has not to be turned to fix during the installation. An O-ring should be used as sealing.

In case there exist strong vibrations on the mounting valve, the valve should be relieved by a support.

Then mount the unit according to the following steps:

Page 11

HYDROCAL 1005 Manual for Installation and Operation Page 9/111

Only remove the protection cap (slowly while turning)

when you are ready to mount the measuring head!

Clean the internal side of the installation valve.

In case you don’t use a union or sleeve nut as connection point with o-ring, wind 4 to 5 layers of

Teflon band on the Hydrocal 1005 connection thread and mount it either directly into the valve or

into an additional adapter. If you use an adapter it should be mounted to the valve, before the Hy-

drocal 1005 will be mounted to the adapter. Wind 4 to 5 layers of Teflon band on the thread of the

adapter and mount it into the valve. Make sure that everything is fixed mechanically.

Turn the unit in order to get 12 o clock position.

Page 12

HYDROCAL 1005 Manual for Installation and Operation Page 10/111

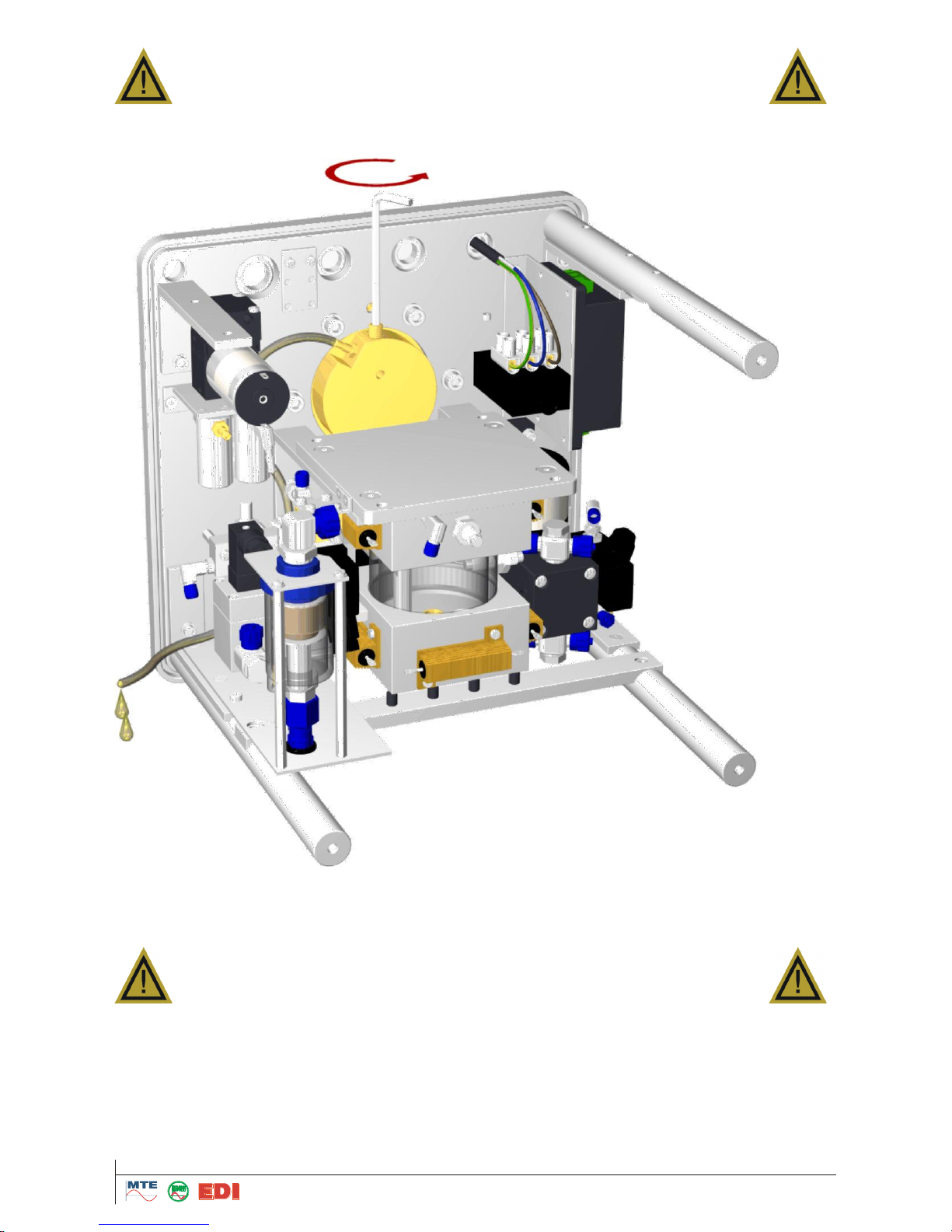

Attention!!!

The following steps must be done according to the company procedures.

Work carefully in order to prevent air entering into the transformer. Use a

bucket to catch oil coming out as described on following drawing.

Unscrew the aeration screw 3 – 4 turns with Allen key No. 4. (Aeration is active).

Open the valve slowly until oil comes of the sample tube.

As soon as no air bubbles sort on the sample tube, close the aeration screw. Then fully open the

valve. Remove the oil from the measuring head externally.

Do not use any solvents for cleaning!

Page 13

HYDROCAL 1005 Manual for Installation and Operation Page 11/111

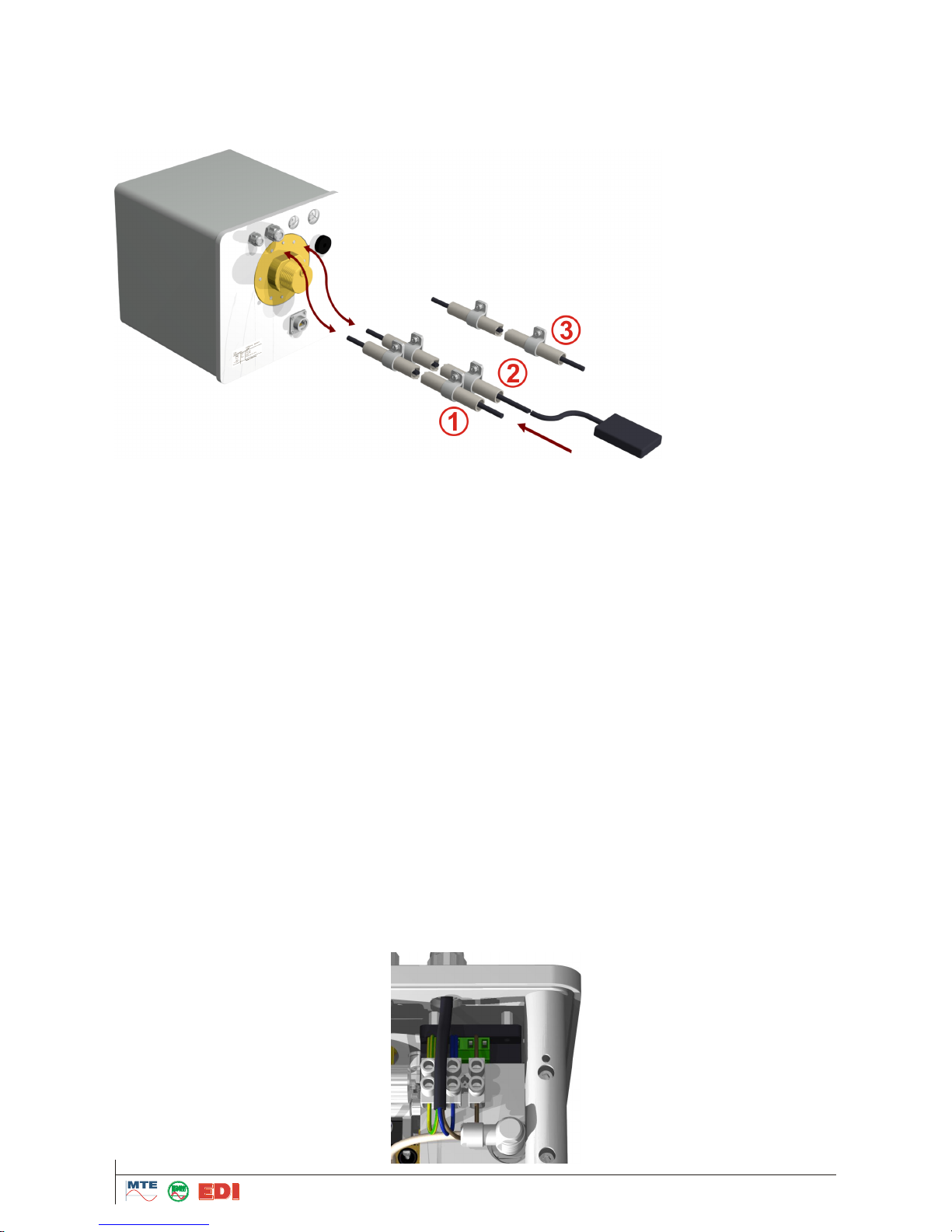

2.5 Electrical Installation of HYDROCAL1005 unit

Use steel protected cables for power supply, alarm-cables and communication cables and con-

nect them to the appropriate connectors.

Recommendations for main supply cable:

Mains supply cable (3-wire)

(1) Phase 230VAC 20%

(2) Neutral

(3) Protection Earth

Wire : 1,5mm2

If optional GSM Modem is used, GSM antenna must be connected to Hydrocal as above draw-

ing:

Recommendations for alarm and external sensor cables:

Cable Specification (or equivalent)

Type: e.g. Ölflex FD855CP

Cable : 13,3mm (of external cable)

Wire : 0,5mm2 (of 16 intern. wires)

Connect the power supply to the HYDROCAL1005 unit. The display shows the specified condi-

tions confirming that the HYDROCAL1005 is functioning correctly.

o Brown (L)

o Blue (N)

o Green - yellow (PE)

Page 14

HYDROCAL 1005 Manual for Installation and Operation Page 12/111

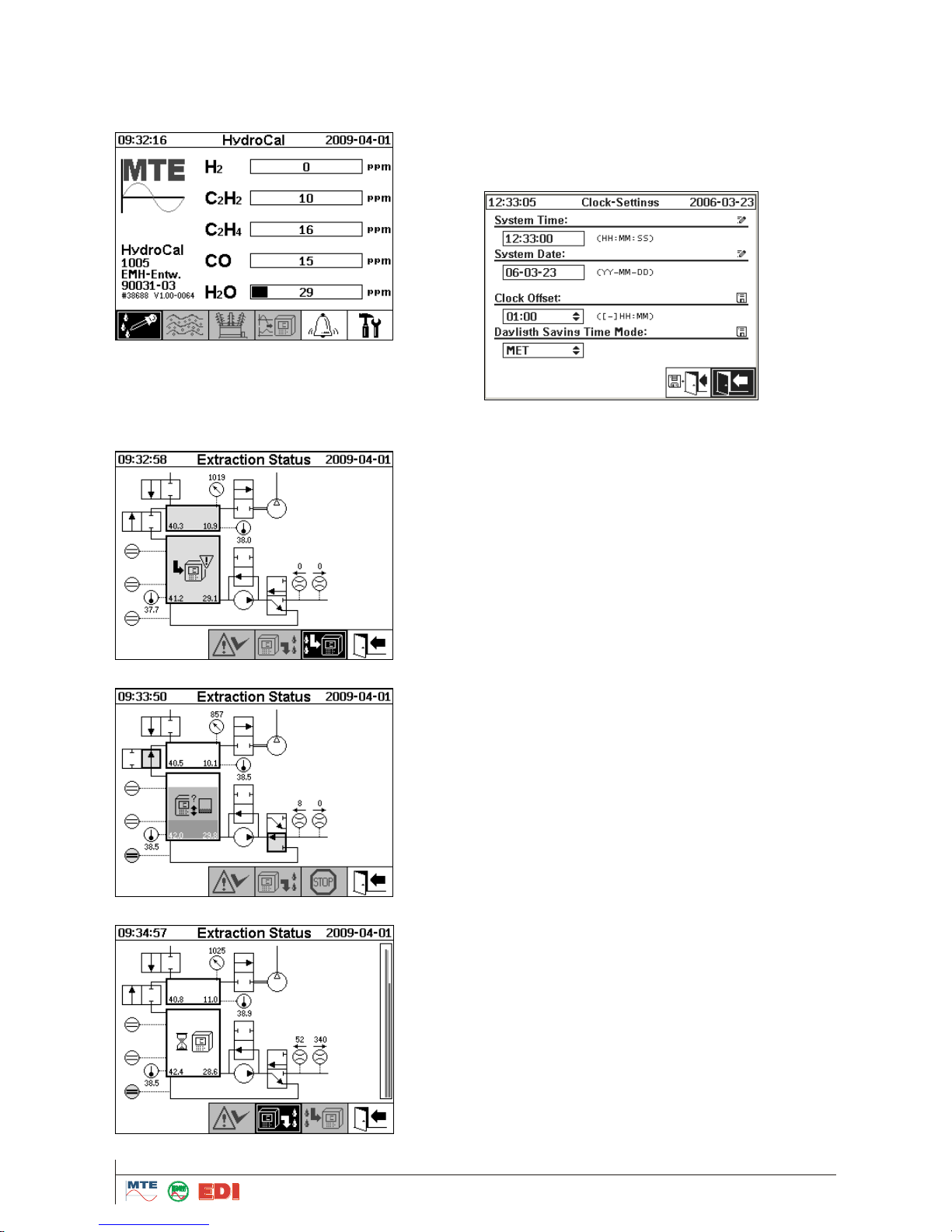

2.6 Completion of Installation

START-SCREEN

At first, date and time must be setup, refer to chapter

4.9.5.3.

The HYDROCAL1005 has a sub menu allowing con-

figuration of time, date as well as clock

MOUNT-BUTTON

The Hydrocal is currently not installed.

After the mount button is activated,

the Detect-Cycle will start.

DETECT-SCREEN

The Hydrocal filled up to level 1.

A circulation is made to remove air from the system.

Finally system is drained to level 0.

UNMOUNT-BUTTON

The Hydrocal is installed in normal operation.

(Currently Sync. Wait)

The selected Button is the unmount button.

(Controlled draining and stopping)

Page 15

HYDROCAL 1005 Manual for Installation and Operation Page 13/111

Then, if everything is working correctly put the housing in correct position and secure it with the

knurled thumbscrews.

The measuring cycle of the HYDROCAL1005 unit is synchronized on the hour mark; this means

the first measuring value is available approx. 2, 22 or 42 min. after the hour mark and can be read

on the display.

After first start-up, in all cases date and time have to be checked on the HYDROCAL1005 display

and eventually have to be adjusted manually in clock settings (chapter 3.7.5.2) or with HydroSoft

(chapter 4.10.7).

Page 16

HYDROCAL 1005 Manual for Installation and Operation Page 14/111

3. Hardware components of HYDROCAL 1005

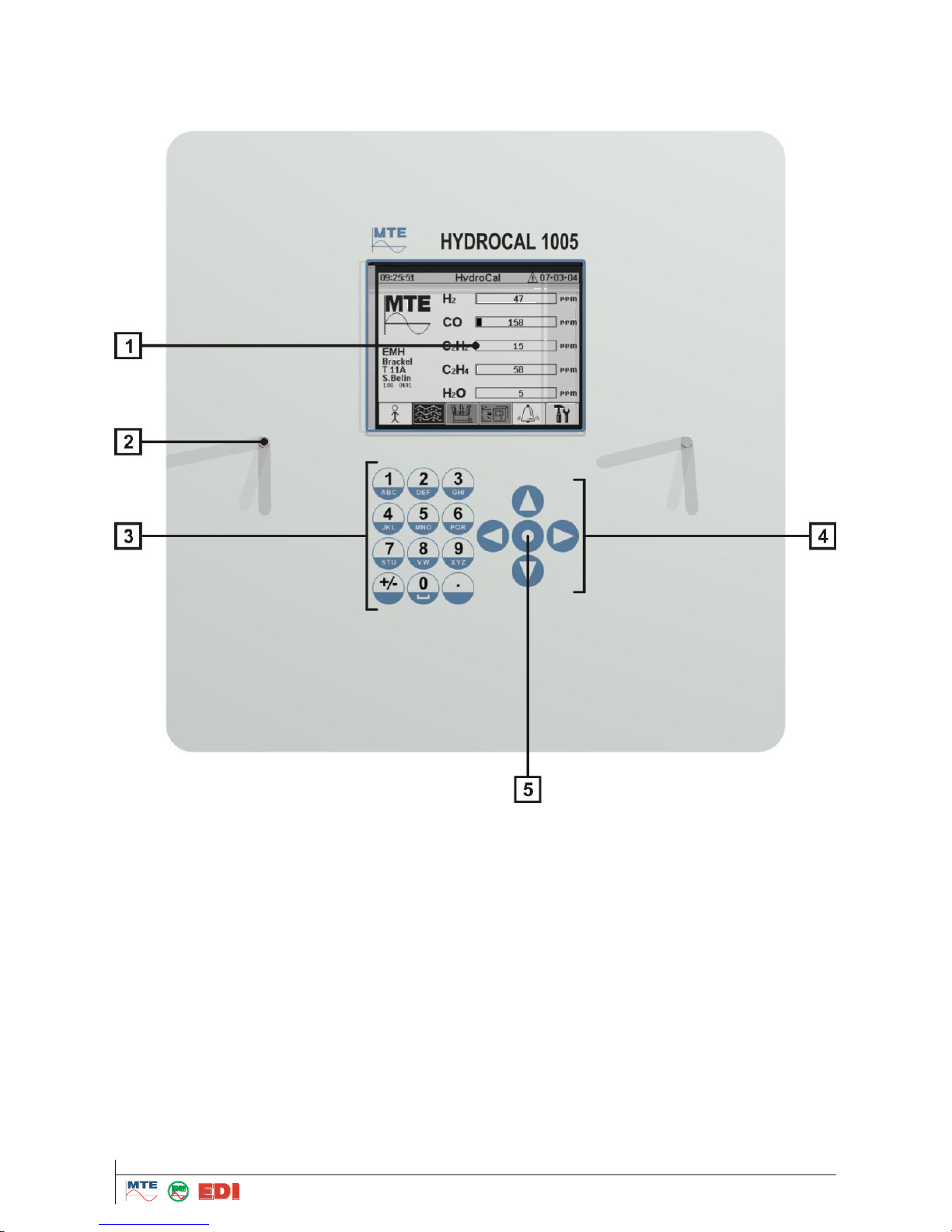

3.1 Front view of HYDROCAL1005

On the front side of the HYDROCAL1005 unit the following operating elements are available.

[1]

LCD-display with 240 x 320 pixels

[2]

Screw mounting to mount the cover

[3]

Alphanumeric keyboard to enter numbers and text

[4]

Arrow-buttons to move in the menus, for data input and contrast set-up from the main

display (Up an Down)

[5]

Enter button to confirm and stop functions and data

Page 17

HYDROCAL 1005 Manual for Installation and Operation Page 15/111

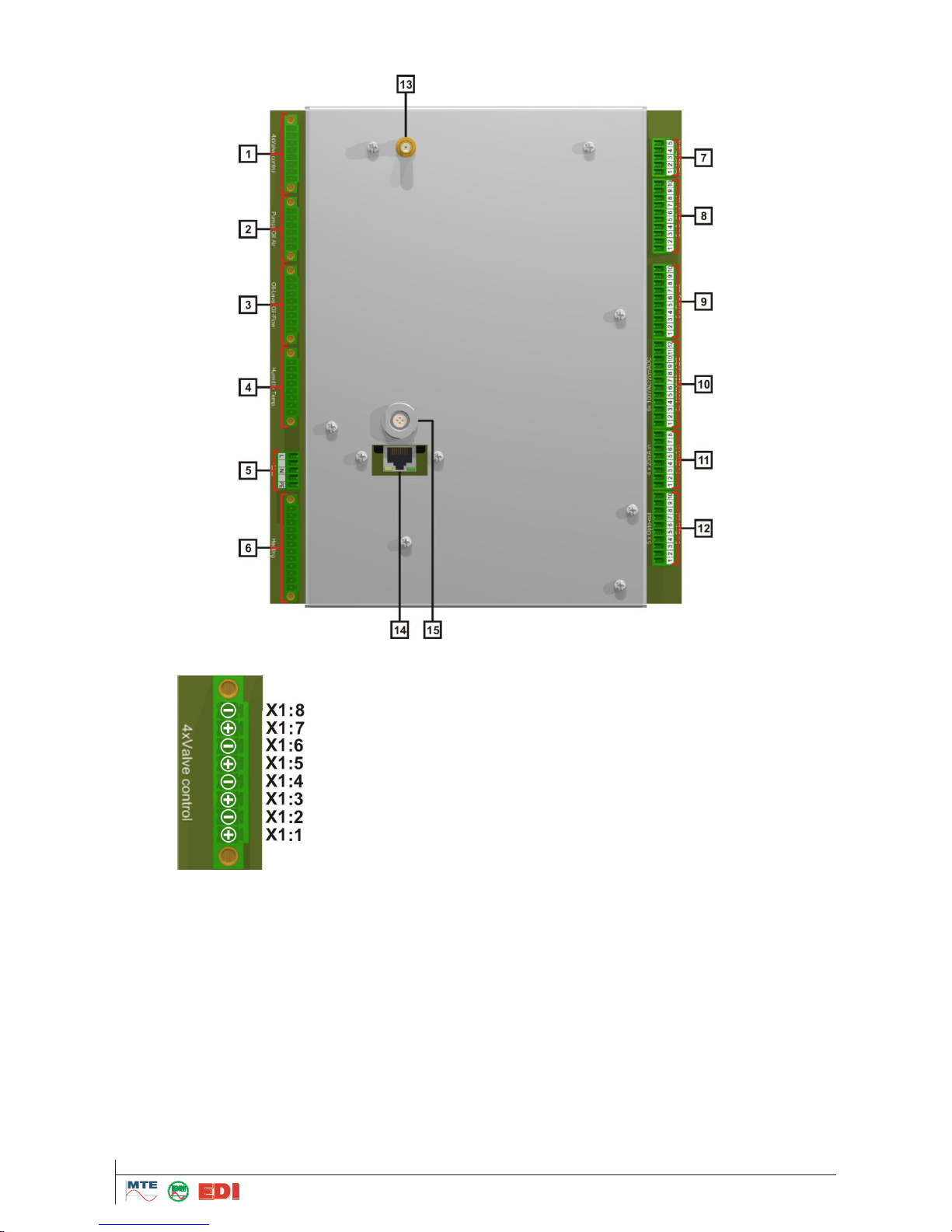

3.2 Rear side of HYDROCAL1005 unit

[1]

Measuring sensor with an internal thread of 1½ (DIN ISO 228: G 1½) or optionally (NPT

1½)

Page 18

HYDROCAL 1005 Manual for Installation and Operation Page 16/111

[2]

Entrance for power supply 88 VAC

min

… 276 VAC

max

Optional: 88 VDC

min

… 390 VDC

max

max. 350 VA, 50/60 Hz

Then, power supply must be connected as follow :

o Brown (L)

o Blue (N)

o Green - yellow (PE)

[3]

System outlet for digital and analogue inputs and outputs

Communication outlet for communication via analogue or GSM/GPRS-modem

[4]

ETHERNET connector

[5]

Gas Air Outlet

Page 19

HYDROCAL 1005 Manual for Installation and Operation Page 17/111

3.3 Connections on the measuring and controller card

[1]

Connector ST13: 4 x Valve Control

Connection for valve control

Page 20

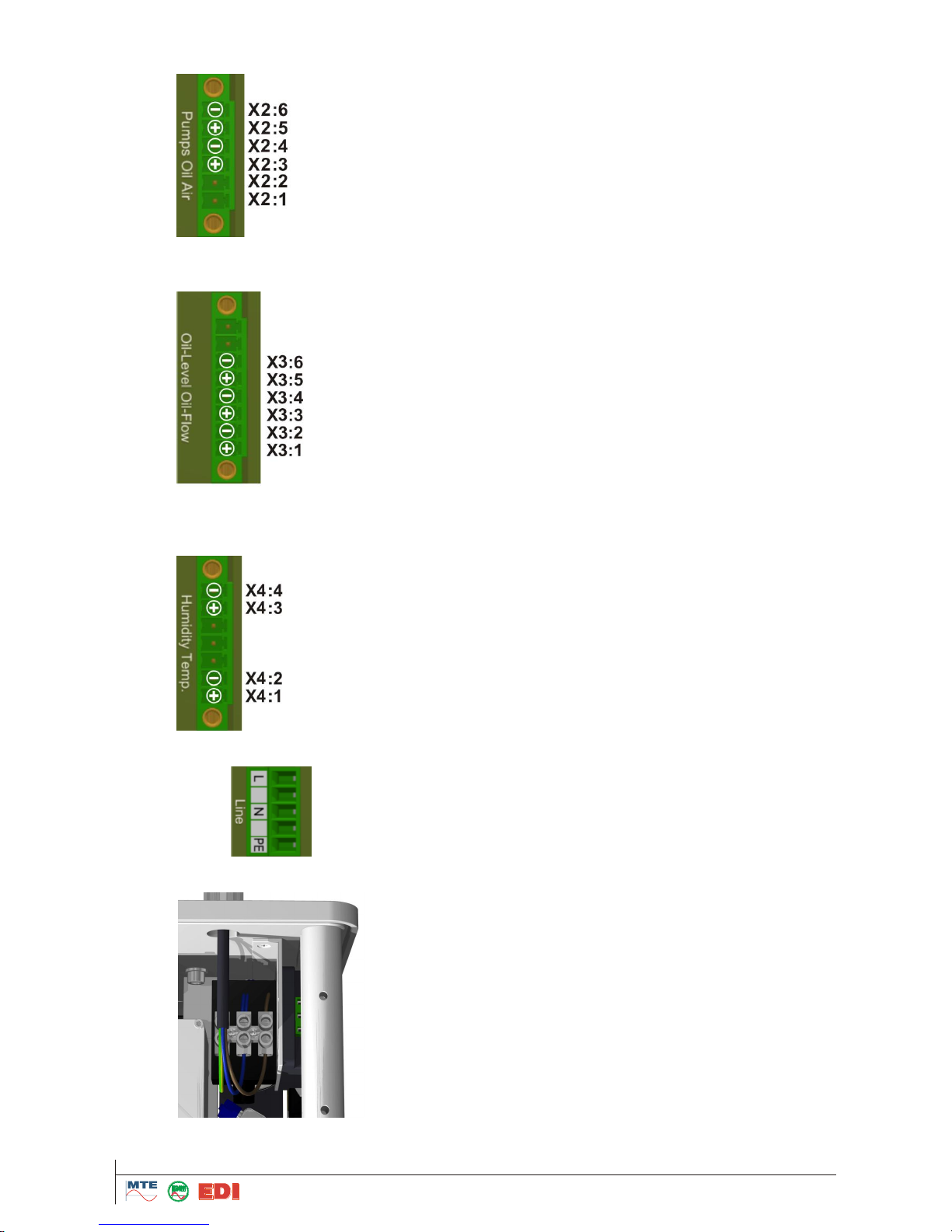

HYDROCAL 1005 Manual for Installation and Operation Page 18/111

[2]

Connector ST14: Pumps Oil Air

Connection for pumps oil air control

[3]

Connector ST11: Oil Level / Oil-Flow

Connection for oil level / oil flow control

[4]

Connector ST3: Humidity Temperature

Connection for humidity temperature control

[5]

Connector KL1: Power supply

Note: The connection [5] is connected to a filter module from

where the connection to the power supply 88 VAC

min

…

276 VAC

max

and PE is made

As showed on picture on the left side, usually you just need to

connect cables to the main power supply connector

Brown L

Blue N

Green/yellow PE

Page 21

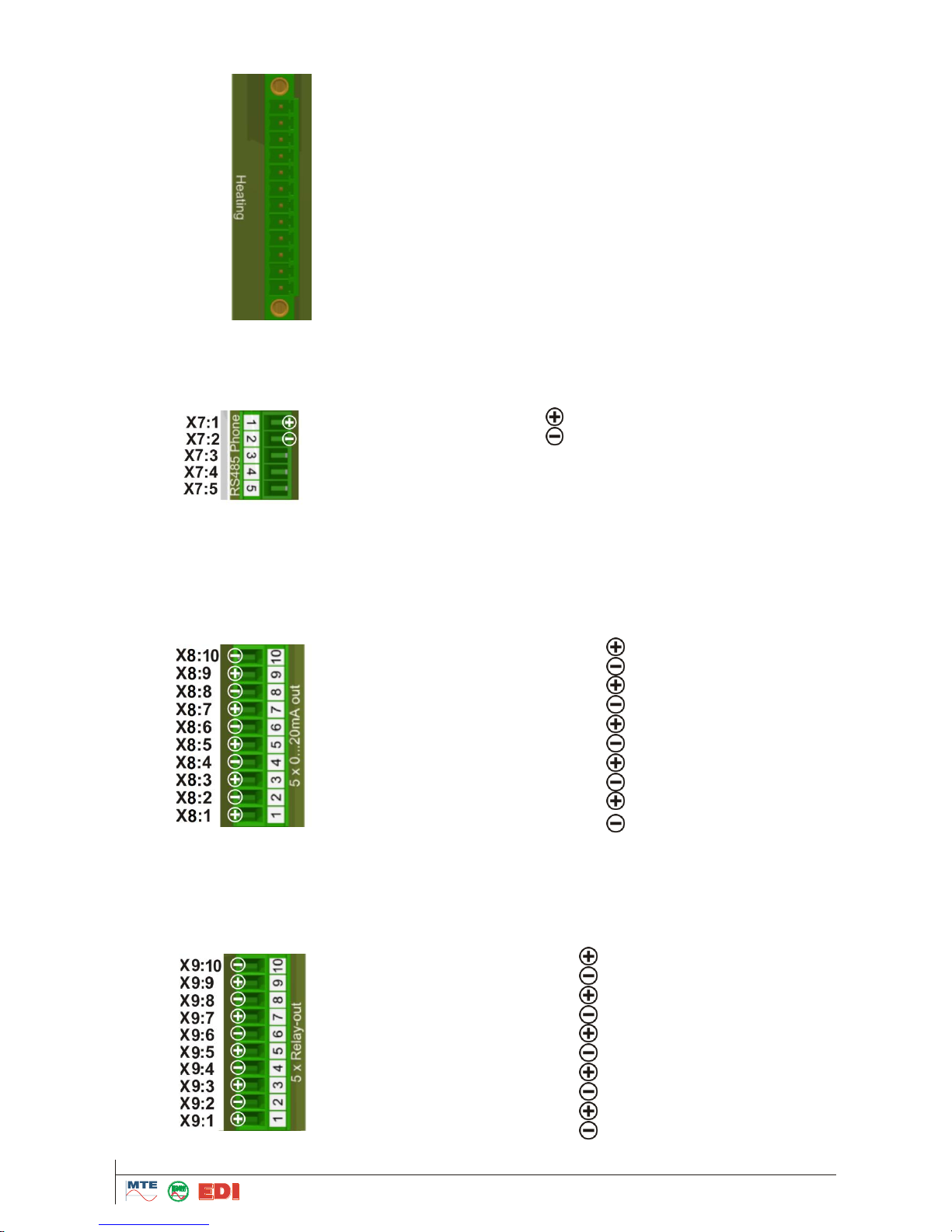

HYDROCAL 1005 Manual for Installation and Operation Page 19/111

[6]

Connector ST12: Heating

Connection of the heating resistors, depending from the supply

voltage

[7]

Connector KL302: Interface RS485 and Modem

X7:1 (OUT B ) RS485

X7:2 (OUT A ) RS485

X7:3 GNDIO Signal ground not shield

X7:4 Phone B

X7:5 Phone A

[8]

Connector KL301: Analogue Outputs

4…. 20 mADC

X8:1 (Analogue output 1 )

X8:2 (Analogue output 1 )

X8:3 (Analogue output 2 )

X8:4 (Analogue output 2 )

X8:5 (Analogue output 3 )

X8:6 (Analogue output 3 )

X8:7 (Analogue output 4 )

X8:8 (Analogue output 4 )

X8:9 (Analogue output 5 )

X8:10 (Analogue output 5 )

[9]

Connector KL402: Relay Outputs

12 VDC / 220 VDC/VAC / 2 A / 60 W

X9:1 (Relay output 1 )

X9:2 (Relay output 1 )

X9:3 (Relay output 2 )

X9:4 (Relay output 2 )

X9:5 (Relay output 3 )

X9:6 (Relay output 3 )

X9:7 (Relay output 4 )

X9:8 (Relay output 4 )

X9:9 (Relay output 5 )

X9:10 (Relay output 5 )

Page 22

HYDROCAL 1005 Manual for Installation and Operation Page 20/111

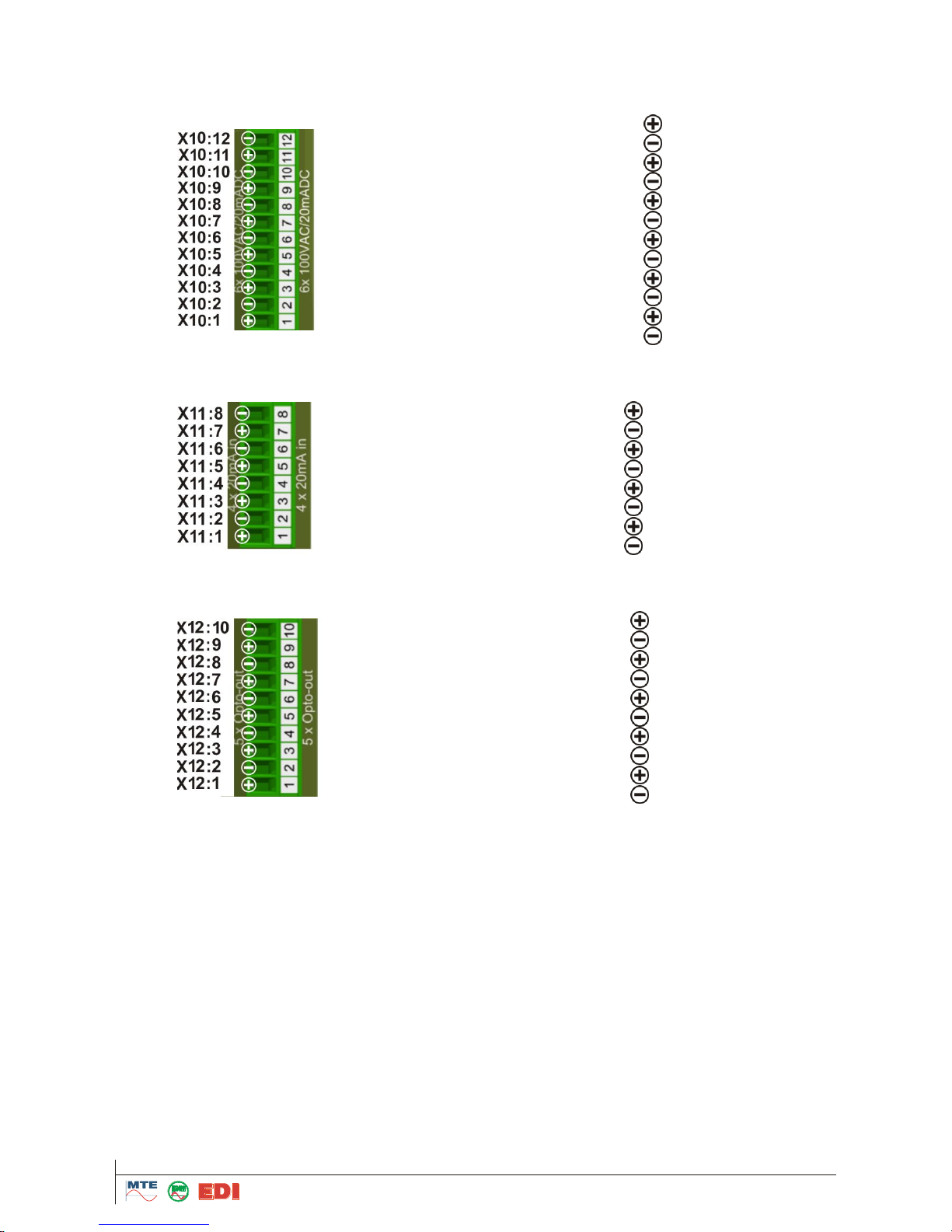

[10]

Connector KL102: Analogue AC Inputs (in Option)

6 x 0 ... 80V +20%

6 x 0/4 … 20mA +20%

X10:1 (Analogue AC input 1 )

X10:2 (Analogue AC input 1 )

X10:3 (Analogue AC input 2 )

X10:4 (Analogue AC input 2 )

X10:5 (Analogue AC input 3 )

X10:6 (Analogue AC input 3 )

X10:7 (Analogue AC input 4 )

X10:8 (Analogue AC input 4 )

X10:9 (Analogue AC input 5 )

X10:10 (Analogue AC input 5 )

X10:11 (Analogue AC input 5 )

X10:12 (Analogue AC input 5 )

[11]

Connector KL101: Analogue DC Inputs (in Option)

0/4 … 20 mA

X11:1 (Analogue DC input 1 )

X11:2 (Analogue DC input 1 )

X11:3 (Analogue DC input 2 )

X11:4 (Analogue DC input 2 )

X11:5 (Analogue DC input 3 )

X11:6 (Analogue DC input 3 )

X11:7 (Analogue DC input 4 )

X11:8 (Analogue DC input 4 )

[12]

Connector KL301: Opto coupler output (in Option)

5 VDC / UCE: 4 V / UEC: 7 V / UCE: 40 mA

X12:1 (Opto coupler output 1 )

X12:2 (Opto coupler output 1 )

X12:3 (Opto coupler output 2 )

X12:4 (Opto coupler output 2 )

X12:5 (Opto coupler output 3 )

X12:6 (Opto coupler output 3 )

X12:7 (Opto coupler output 4 )

X12:8 (Opto coupler output 4 )

X12:9 (Opto coupler output 5 )

X12:10 (Opto coupler output 5 )

[13]

GSM/GPRS-module / GSM antenna

Connector Mini-BNC

Page 23

HYDROCAL 1005 Manual for Installation and Operation Page 21/111

[14]

ETHERNET connector

Copper-wired or Fibre-optical

These sockets are connected with the back plane. It means that normally only con-

nection on back plane is needed

[15]

Measuring cell connector

Page 24

HYDROCAL 1005 Manual for Installation and Operation Page 22/111

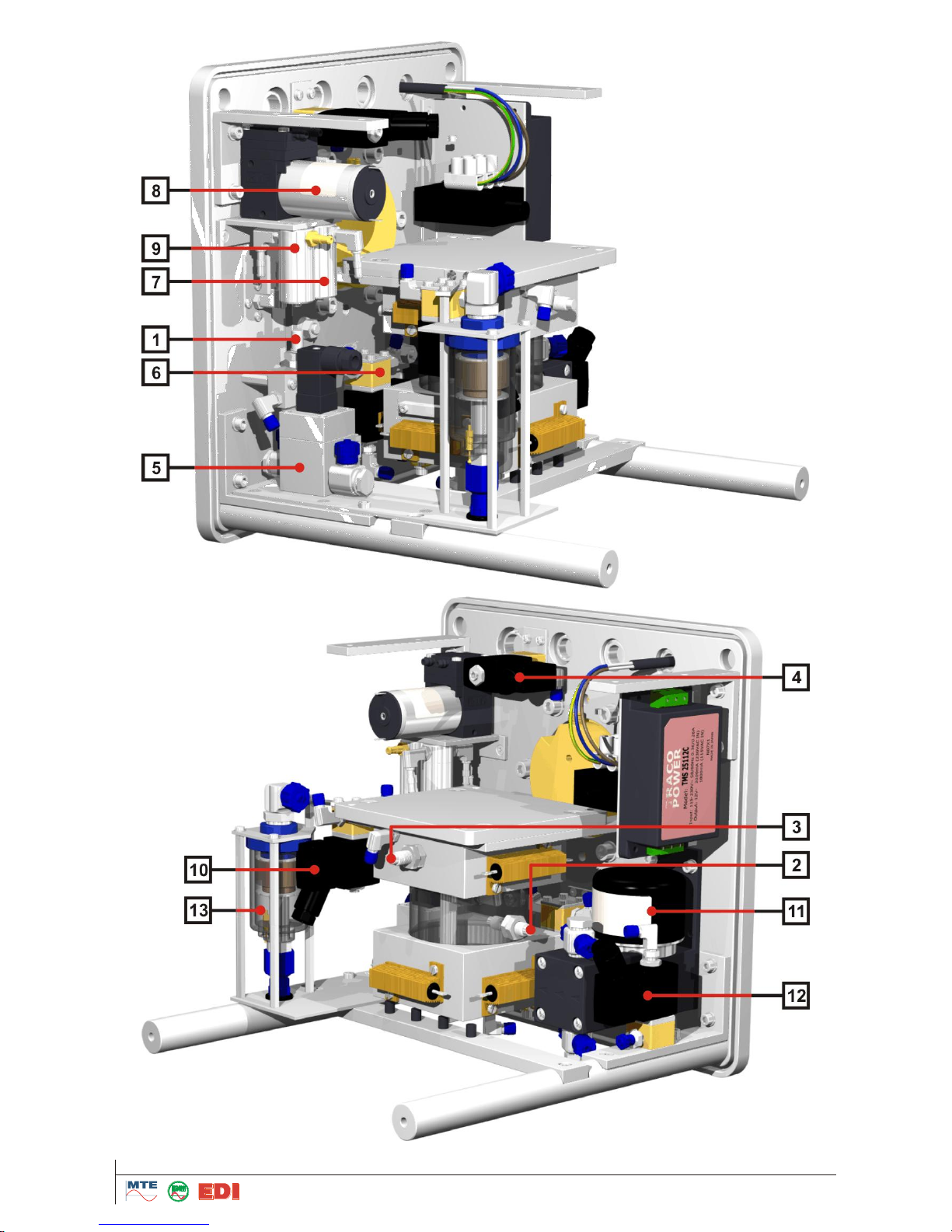

3.4 Measurement and extraction Components

[1]

Capacitive Sensor F0 (ZERO)

[2]

Capacitive Sensor FI (Level 1)

[3]

Capacitive Sensor FII (Level 2)

[4]

Valve V6 (Safety)

[5]

Flow meter (Flow IN / OUT)

[6]

Valve V1 (Filling / Circulation / Draining)

[7]

Valve V3 (Vacuum Generation / Ventilation)

[8]

Compressor K1

[9]

Valve V4 (Pressure / Ventilation)

[10]

Valve V2 (Oil chamber Connection <-> Gas Chamber / Measuring Cell)

[11]

Pump P1

[12]

Bypass Valve Pump V5

[13]

Oil separator

Page 25

HYDROCAL 1005 Manual for Installation and Operation Page 23/111

Page 26

HYDROCAL 1005 Manual for Installation and Operation Page 24/111

4. Software on HYDROCAL unit

4.1 General information

The gas-in-oil analyzer HYDROCAL1005 is based on a microprocessor controlled measuring system. A 32 Bit „Coldfire“ processor with a clock frequency of 240 MHz (bus clock 80 MHz) is used.

The software has been developed with the language „C“. The system has a flash memory of 16 / 32 /

64 Mbyte for measuring data. This offers approximately 2 / 4 / 8 years time storage capacity for the

measuring data.

After this period, the oldest data will be overwritten by the latest values. When using additional external sensors, the storage capacity depends on the number of sensors and the time interval selected

for storage. The following formula can be used to determine the storage capacity (in the example 64

Mbyte is used):

12

1

20

1/288/23000

264

n

n

StdagesSensorstordayBytedayByte

Byte

dayshMemorydept

With one additional sensor with a time interval of 5 minutes the following calculation results:

days

dayByte

Byte

dayBytedayByte

Byte

dayshMemorydept 2500

/26456

264

/3456/23000

264

2020

Also an additional reduction of the storage time takes place by the definition of alarms. Each change

of alarm status requires 12 Bytes.

Attention: To avoid any loss of data, it is proposed to read out regularly

the measuring data by the Windows based software “HydroSoft”.

4.2 Description of Gas measurement Process

Page 27

HYDROCAL 1005 Manual for Installation and Operation Page 25/111

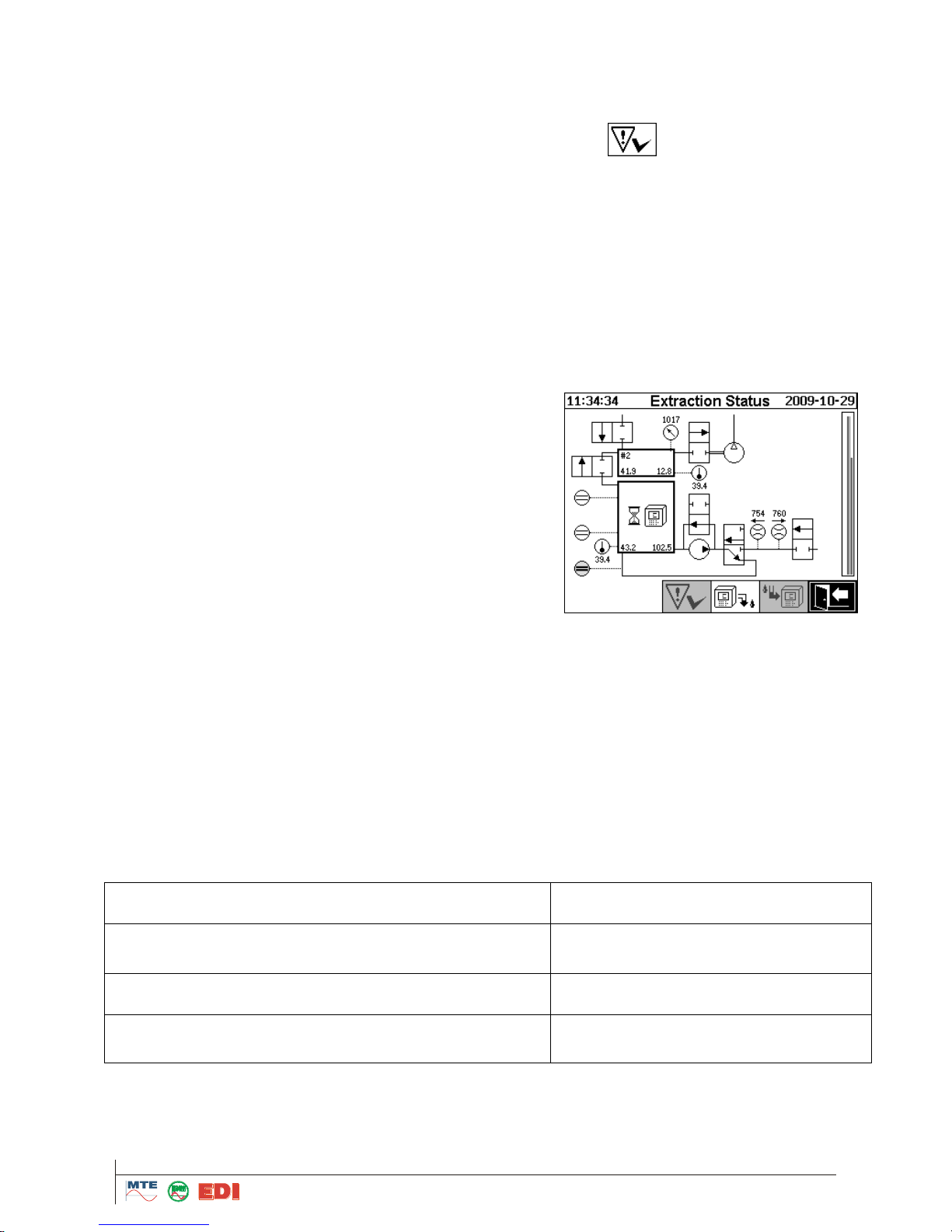

4.3. Operation Cycles

This chapter describes each process steps and provides information in regards to the safety functions as

well as how to reset errors. The consequence of all errors is that the cycle will be interrupted immediately and

all valves will be closed.

For all observed errors, you can acknowledged them by pressing button ..

If nothing changes, check status of all components according to actual cycle.

Check that all tubes go straight into the FESTO quick screws and any oil/air leakages have appeared

Check that cables and all pins of the plug go straight into their socket; pushing the plug in carefully.

4.3.1. Zero measurement

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “not active”

[2]

Capacitive Sensor FI “not active”

[3]

Capacitive Sensor FII “not active”

[4]

Valve V6 “closed”

[5]

Flow meter “not active”

[6]

Valve V1 “circulating”

[7]

Valve V3 “closed”

[8]

Compressor K1 “not active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “closed”

[11]

Pump P1 “active”

[12]

Valve V5 “open”

4.3.1.1 Safety function and error observation for Zero measurement cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Measurement chamber

Measurement chamber offline

Pressure Sensor

Pressure stability

Page 28

HYDROCAL 1005 Manual for Installation and Operation Page 26/111

4.3.2 Depression

For pressure compensation of the measurement chamber

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “not active”

[2]

Capacitive Sensor FI “not active”

[3]

Capacitive Sensor FII “not active”

[4]

Valve V6 “closed”

[5]

Flow meter “not active”

[6]

Valve V1 “circulating”

[7]

Valve V3 “open”

[8]

Compressor K1 “active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “closed”

[11]

Pump P1 “not active”

[12]

Valve V5 “open”

4.3.2.1. Safety function and error observation for depression cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Measurement chamber

Measurement chamber offline

Pressure Sensor

Pressure does not decrease

Page 29

HYDROCAL 1005 Manual for Installation and Operation Page 27/111

4.3.3. Leak detection

During the leak detection cycle the pressure stability of the complete system is checked

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “not active”

[2]

Capacitive Sensor FI “not active”

[3]

Capacitive Sensor FII “not active”

[4]

Valve V6 “closed”

[5]

Flow meter “not active”

[6]

Valve V1 “draining / filling”

[7]

Valve V3 “closed”

[8]

Compressor K1 “not active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “open”

[11]

Pump P1 “not active”

[12]

Valve V5 “open”

4.3.3.1. Safety function and error observation for leak detection cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Measurement chamber

Measurement chamber offline

Pressure Sensor

Leakage

Flow meter

V6 closed

Page 30

HYDROCAL 1005 Manual for Installation and Operation Page 28/111

4.3.4. Filling to level 1

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “active”

[2]

Capacitive Sensor FI “active”

[3]

Capacitive Sensor FII “not active”

[4]

Valve V6 “open”

[5]

Flow meter “active”

[6]

Valve V1 “draining / filling”

[7]

Valve V3 “closed”

[8]

Compressor K1 “not active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “open”

[11]

Pump P1 “not active”

[12]

Valve V5 “open”

4.3.4.1. Safety function and error observation for filling to level 1 cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Filling Sensor 0, 1

Flow meter

Timer

- Filling level 1 lost

- Filling stopped?

- Filling timeout

Measurement chamber

Measurement chamber offline

Pressure Sensor

- leakage

- flow stuck

Filling Sensor 0, 1, 2

Measurement chamber offline

Page 31

HYDROCAL 1005 Manual for Installation and Operation Page 29/111

4.3.5. Degassing

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “active”

[2]

Capacitive Sensor FI “active”

[3]

Capacitive Sensor FII “not active”

[4]

Valve V6 “closed”

[5]

Flow meter “not active”

[6]

Valve V1 “draining / filling”

[7]

Valve V3 “closed”

[8]

Compressor K1 “not active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “closed”

[11]

Pump P1 “active”

[12]

Valve V5 “closed”

4.3.5.1. Safety function and error observation for degassing cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Filling Sensor 0, 1

Flow meter

- Filling level 1 lost

- Filling stopped

Measurement chamber

Measurement chamber offline

Pressure Sensor

- depression lost, leakage

- V4 closed

Flow meter

V6 closed

Page 32

HYDROCAL 1005 Manual for Installation and Operation Page 30/111

4.3.6. Filling to level 2

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “active”

[2]

Capacitive Sensor FI “active”

[3]

Capacitive Sensor FII “active”

[4]

Valve V6 “open”

[5]

Flow meter “active”

[6]

Valve V1 “draining / filling”

[7]

Valve V3 “closed”

[8]

Compressor K1 “not active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “open”

[11]

Pump P1 “not active”

[12]

Valve V5 “open”

4.3.6.1. Safety function and error observation for filling to level 2 cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Filling Sensor 0, 1, 2

Flow meter

Timer

- Flow Stuck

- Flow leak

- Level Timeout

- Avoid flooding meas. chamber

Measurement chamber

Measurement chamber offline

Pressure Sensor

- No pressure rise

Page 33

HYDROCAL 1005 Manual for Installation and Operation Page 31/111

4.3.7. Measurement

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “active”

[2]

Capacitive Sensor FI “active”

[3]

Capacitive Sensor FII “active”

[4]

Valve V6 “closed”

[5]

Flow meter “not active”

[6]

Valve V1 “circulating”

[7]

Valve V3 “closed”

[8]

Compressor K1 “not active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “closed”

[11]

Pump P1 “not active”

[12]

Valve V5 “open”

4.3.7.1. Safety function and error observation for measurement cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Measurement chamber

Measurement chamber offline

Page 34

HYDROCAL 1005 Manual for Installation and Operation Page 32/111

4.3.8. Flushing

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “active”

[2]

Capacitive Sensor FI “active”

[3]

Capacitive Sensor FII “active”

[4]

Valve V6 “closed”

[5]

Flow meter “not active”

[6]

Valve V1 “circulating”

[7]

Valve V3 “open”

[8]

Compressor K1 “active”

[9]

Valve V4 ” open”

[10]

Valve V2 “closed”

[11]

Pump P1 “not active”

[12]

Valve V5 “open”

4.3.8.1. Safety function and error observation for flushing cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Measurement Chamber

Measurement Chamber offline

Pressure Sensor

No depression

Page 35

HYDROCAL 1005 Manual for Installation and Operation Page 33/111

4.3.9. Draining

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “active”

[2]

Capacitive Sensor FI “active”

[3]

Capacitive Sensor FII “active”

[4]

Valve V6 “open”

[5]

Flow meter “active”

[6]

Valve V1 “draining / filling”

[7]

Valve V3 “open”

[8]

Compressor K1 “active”

[9]

Valve V4 ” open”

[10]

Valve V2 “open”

[11]

Pump P1 “active”

[12]

Valve V5 “closed”

4.3.9.1. Safety function and error observation for draining cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating with normal parameters

Filling Sensor 0, 1, 2

Flowmeter

Timer

- Flow Stuck

- Flow leak

- Level Timeout

- Avoid transformer aeration

Measurement chamber

Measurement chamber offline

Pressure Sensor

No depression

Page 36

HYDROCAL 1005 Manual for Installation and Operation Page 34/111

4.3.10. Wait

Step

No.

Status of the components

[1]

Capacitive Sensor F0 “not active”

[2]

Capacitive Sensor FI “not active”

[3]

Capacitive Sensor FII “not active”

[4]

Valve V6 “closed”

[5]

Flow meter “not active”

[6]

Valve V1 “circulating”

[7]

Valve V3 “closed”

[8]

Compressor K1 “not active”

[9]

Valve V4 ”closed”

[10]

Valve V2 “closed”

[11]

Pump P1 “active”

[12]

Valve V5 “open”

4.3.10.1. Safety function and error observation for wait cycle

Observed Components

Detectable Errors

Filling Sensor 0, 1, 2

Operating in normal parameters

Measurement chamber

Measurement chamber offline

Page 37

HYDROCAL 1005 Manual for Installation and Operation Page 35/111

4.4 Operation of HYDROCAL1005 by its keyboard

The HYDROCAL1005 unit when in use can be operated by its built-in keyboard. For this its external

housing must be removed. Loosen the knurled thumb screws on the front side and remove carefully

the housing. The unit can then be operated by the keyboard as shown below:

Following the description of functions of the keyboard:

Moves the cursor horizontally

Enter button: Selection of active menus or submenus

Moves the cursor in the tables and contrast set-up from the main display

Alphanumerical input of customer specific data

4.4.1 Contrast Set-up

Contrast of HYDROCAL1005 display can be setup while pushing on up and down arrow keys from

the main display.

Page 38

HYDROCAL 1005 Manual for Installation and Operation Page 36/111

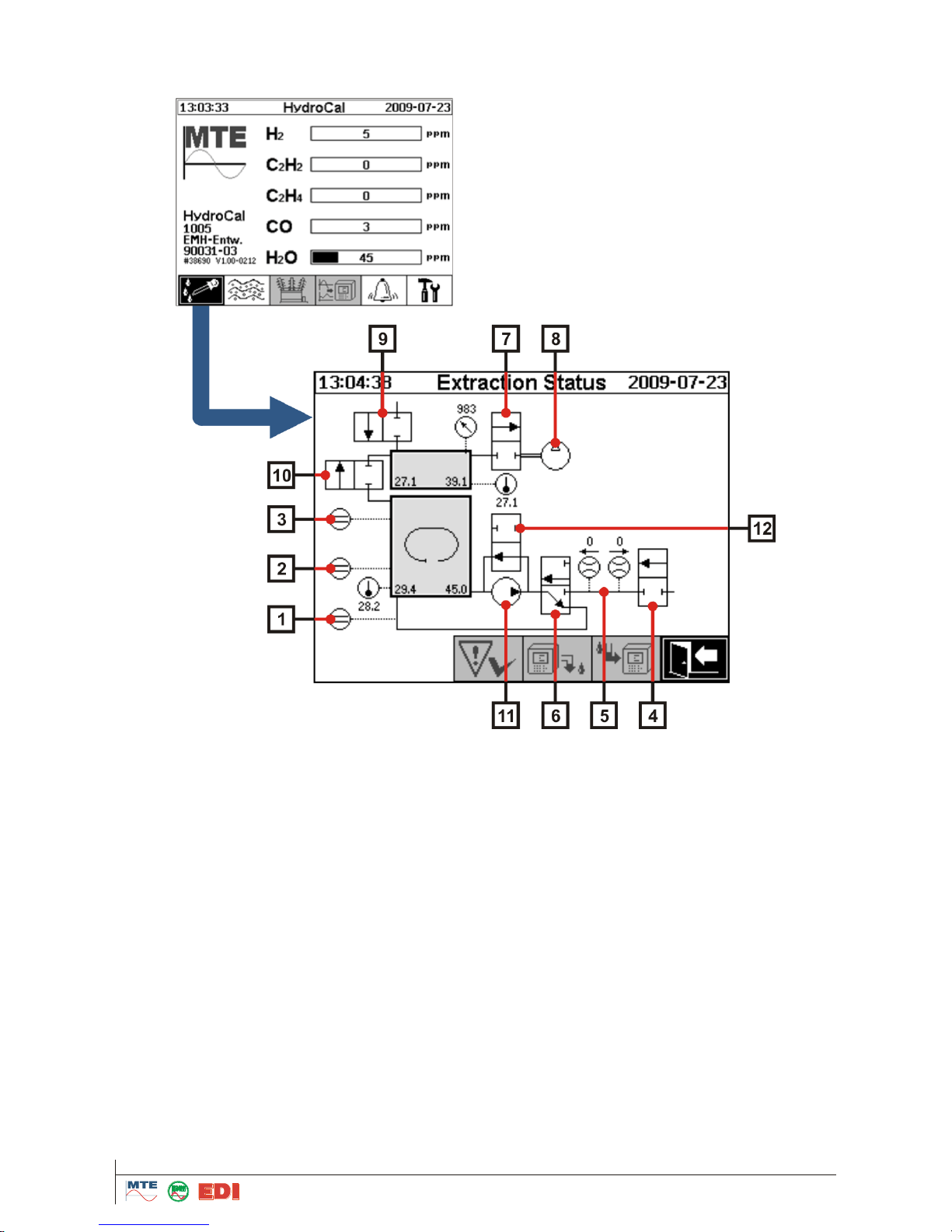

4.5 Main menu

After connection of the HYDROCAL1005 unit to the power supply, the main menu appears on the

display. The actual measuring values of concentration for hydrogen, carbon monoxide, acetylene,

ethylene and moisture in the oil are displayed. If other sensors are connected or an unacknowledged alarm exists, then the display will change every 5 seconds (can be also changed in

setup menu) to these measuring values.

In the main menu, the following sub menus can be activated.

Extraction status menu

„Gas-in-oil“-menu

Alarm menu / history of alarms

Configuration menu

Transformer menu: not yet available

External sensor menu

Remark:

From the main display under Customer, Station, Transformer and Comment data, you find Serial

Number of the unit (For example: #11111) and Firmware version implemented on the unit (For

example: V 1.00-0212).

To display immediately external sensor screen, you can push on 2.

To display immediately alert status screen, you can push on 3

Page 39

HYDROCAL 1005 Manual for Installation and Operation Page 37/111

4.6 Extraction Menu

Please refer chapter 2.6.”Installation completion”

4.7 Display of stored „Gas-in-oil“measuring values

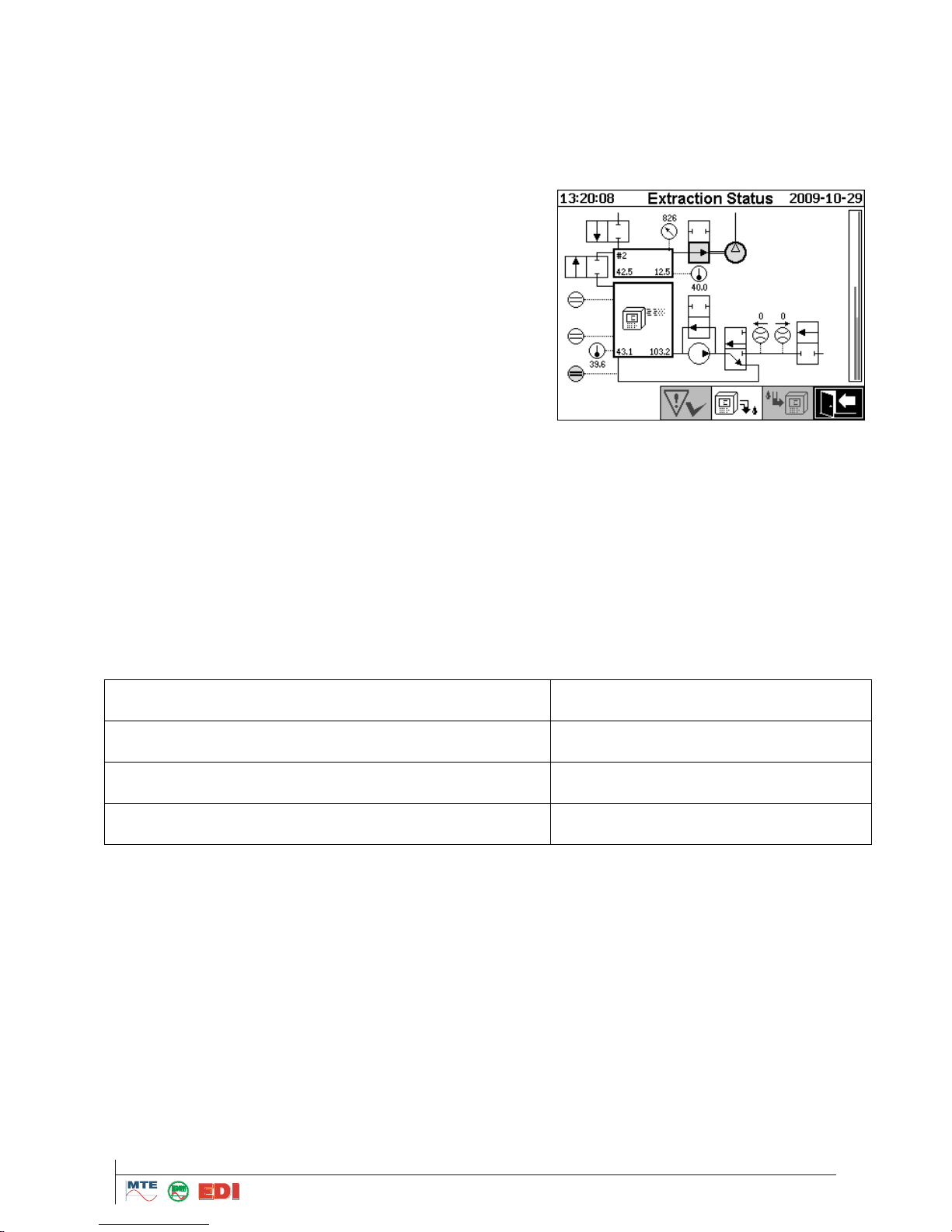

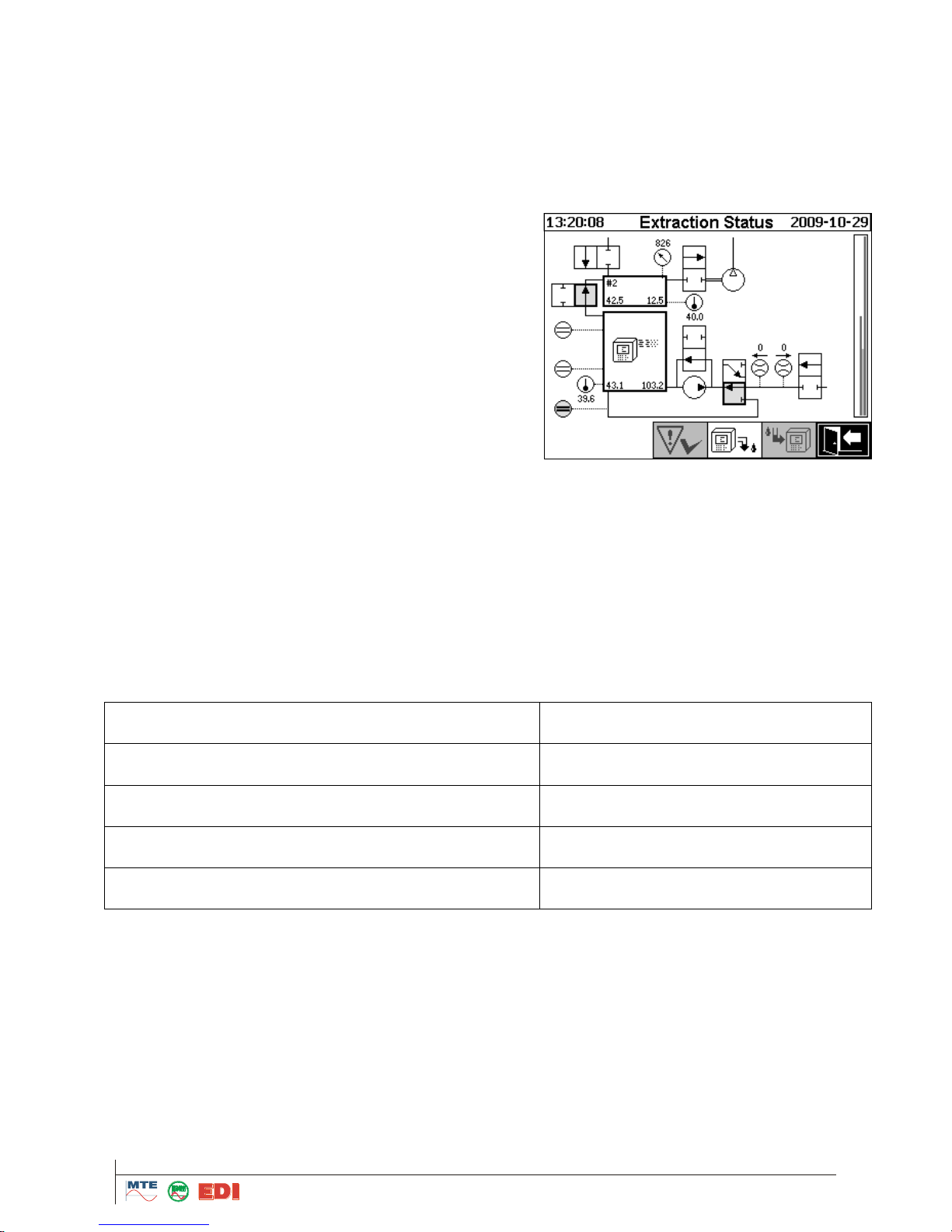

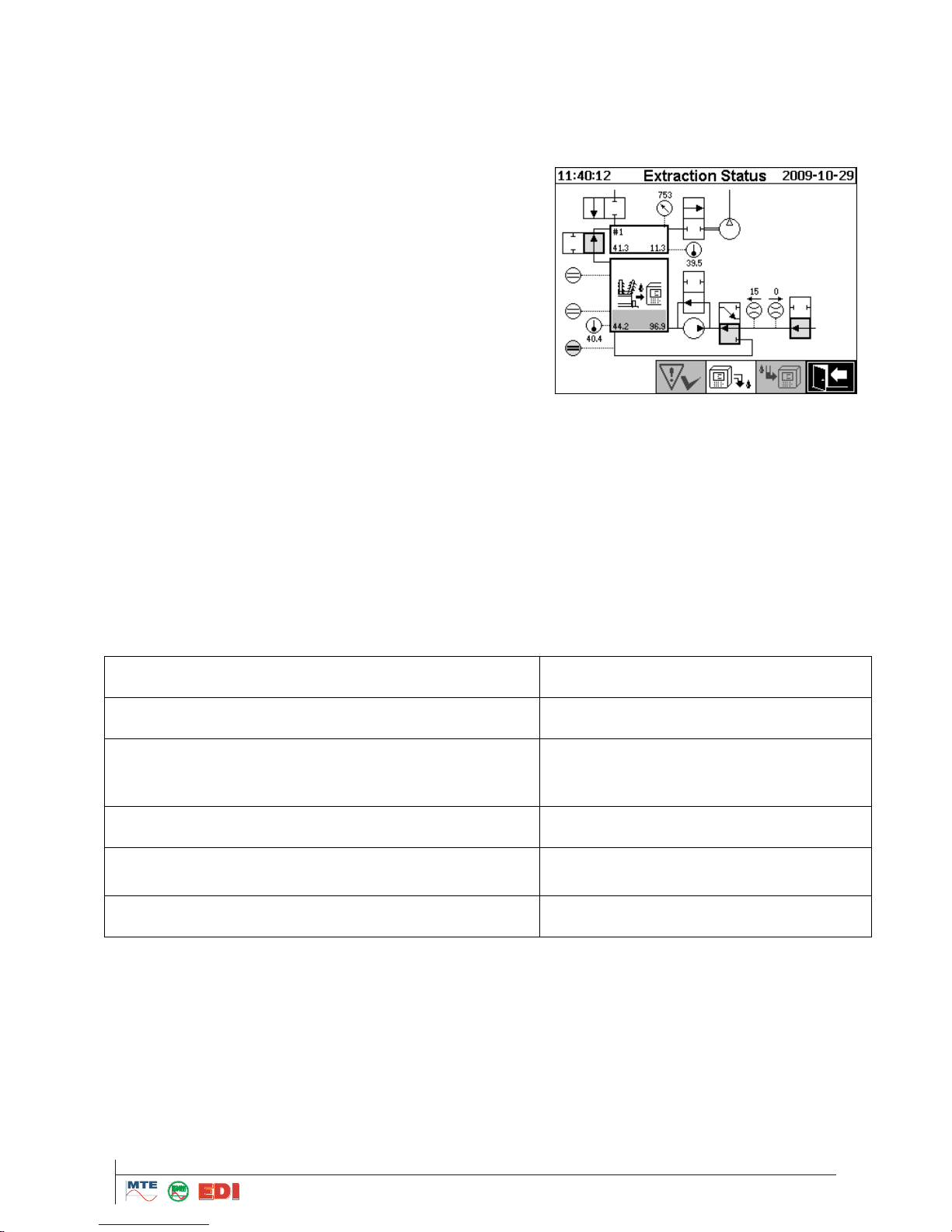

In the menu „Gas-in-oil“ an overview in the form of a bar chart with the composition of measured

gases in the oil are shown. The values for H2, C2H2, C2H4, CO and H2O indicate their actual measurement values of the total gas content. I.e. as shown below: 30ppm is H2, 131ppm is C2H2, 46ppm

is C2H4, 308ppm is CO and 0.0ppm is H2O.

The following values are available:

Hydrogen

acetylene

ethylene

Carbon monoxide

Moisture

Temperatures: - 1 Temperature in sensor area (measure cell)

- 2 Temperature of oil

4.7.1

Graphic display

After selection of the measuring quantity, a graph displaying the trend over the time is shown

Page 40

HYDROCAL 1005 Manual for Installation and Operation Page 38/111

Following functions are available:

Scroll graph to the right

Scroll graph to the left

Zoom-out with minimum resolution of 3 days / page

Zoom-in with maximum resolution of 8 hours / page

Go to table presentation

Exit

4.7.2

Table presentation

After selection of presentation in form of a table, the measured values are shown with time and current record number. The most recent measured value is on top of the table.

The following functions for tables are available

Scroll up one line

Scroll up one page

Scroll down one page

Scroll down one line

Scroll one page up / down

Go to graphic display

Exit

Page 41

HYDROCAL 1005 Manual for Installation and Operation Page 39/111

4.8 Status of alarms

In the menu status of all programmed alarms are presented in a table.

All alarms defined are shown together with their status. In the column „Date / Time” the last change

of status is shown. The followings alarm statuses are available:

OK, Symbol : No active alarm for this measuring value exists.

o If a date exists: For this measuring value an acknowledged alarm existed in the past.

o If no date exists: For this measuring value no alarm existed in the past.

High - Alarm active:

o Symbol : The defined “Level 1“ for a High - Alarm has been exceeded at the date/time indi-

cated.

o Symbol : The defined “Level 2“ for a High - High - Alarm has been exceeded in past. The

value has fallen below the limit at the time indicated, however it is still over the limit of “Level

1“.

High - Alarm inactive, Symbol : The defined level for a High - Alarm has been exceeded in

the past. The value has fallen below the limit at the time indicated.

High - High - Alarm active, Symbol : The defined level for a High - High - Alarm has been

exceeded at the time indicated.

High - High - Alarm inactive, Symbol : The defined “Level 2“ for a High - High - Alarm has

been exceeded in the past. The value has fallen below “Level 1“ at the time indicated.

In history of alarms, the following functions are available:

Acknowledge alarm selected

Scroll up one line

Scroll down one line

Show details of alarm selected.

Exit

4.8.1 Acknowledgment of alarms

For confirmation of an alarm, a password is required (Default password is 999).

Page 42

HYDROCAL 1005 Manual for Installation and Operation Page 40/111

4.9 Device set – up

First of all, you can define the application language while selecting it by the keyboard. You can

choice between: English, German, French, Russian, Polish and Turkish.

Before any amendment of settings can be made, the system asks for the password (Default password is 999).

After input of password by the alphanumeric keyboard and confirmation with enter

button, the

device setup menu is opened:

The following configurations can be modified:

Transformer data, e.g.: allocation of sensors to algorithms for calculation of life expectancy and input of correction factors

Configuration of Analogue outputs

Configuration of Analogue inputs (extern sensors)

Configuration of alarms

Configuration of the unit

Page 43

HYDROCAL 1005 Manual for Installation and Operation Page 41/111

4.9.1

Menu Transformer data setup

This data is not necessarily required for operation of the unit. In the menu „Transformer Setup”, input

of correction factor, Hot-Spot Calculation as well as Ageing Rate / Loss-of-Life Calculation are possible. Parameters can be set only on the device not in HydroSoft.

4.9.1.1. DGA Adjustment: Input of correction factor

Results of laboratory analysis can be introduced in this menu. These can be used for calculation of

correction factors for definition of the gas content.

By operation of the arrow keys (

) the different fields can be chosen. For the input

of results of laboratory analysis, first the date of analysis should be entered in the field „Sample

Date“. Then the average value of gas concentration is calculated and presented. After the results of

laboratory analysis have been introduced in the fields „Laboratory Value“ for H

2

, C2H2, C2H4, and

CO, the button is activated and new correction factors are calculated.

Page 44

HYDROCAL 1005 Manual for Installation and Operation Page 42/111

These values can be used. The new values are stored and activated by the button „Store and

exit“. For the following measured values the new correction factor will then be used.

4.9.1.1 Hot Spot calculation

HYDROCAL1005 can calculate the Hot-Spot temperature. For this calculation, it is important to know

that system needs external sensor references. These references are: minimum one of Load Current,

Top oil Temperature as well as Cooling Stage (this last reference is not necessary required but can

improve the calculation). The references have to be set up as external sensors.

Page 45

HYDROCAL 1005 Manual for Installation and Operation Page 43/111

4.9.1.1.1 External Sensors

After selection of the external sensor submenu, following screen will be displayed:

By operation of the arrow keys (

) the different fields can be chosen. First of

all, you must define each field with required information.

For Load Current, you can select between “Load Current” and “None”.

Remark: A Load Current external sensor must exist.

See chapter 4.9.3

For Top Oil Temperature, you can select between “Top oil Temperature”, “Ambient temperature”,

“Hot-Spot temperature”, “1” (Temperature of oil on the sensor), “2” (Temperature in sensor

area (ambient temp)) and “None”.

Remark: A Top Oil Temperature external sensor must exist.

An Ambient Temperature external sensor must exist

A Virtual Hot-Spot Temperature sensor must exist

See chapter 4.9.3

For Cooling Stage, you can select between “Cooling Stage”, “Ageing rate”, “Loss of Life” and

“None”

Remark: A Cooling Stage external sensor must exist.

A Virtual Ageing rate sensor must exist

A Virtual Loss of Life sensor must exist

See chapter 4.9.3

If necessary, you have to define previously external sensor references as analogue input while pushing button (See chapter 4.9.3 for setup).

Then, you must define calculation interval. Calculation interval in the field "Calculation interval" is edited by arrow keys and confirmed by the alphanumeric keyboard. The sample interval is made in

seconds or by a button in days – hours – min - seconds. For a double point the button is used.

After confirmation by the

button, the value will be converted and displayed in days –hours – min

- seconds.

At the end, the new references and calculation interval are stored and activated by the button

„Store and exit“.

Page 46

HYDROCAL 1005 Manual for Installation and Operation Page 44/111

4.9.1.1.2 Cooling stage #1

By operation of the arrow keys (

) the different fields can be chosen. First of

all, you must define each field with required information. Followings information must be entered:

Cooling stage #1 condition

o Sensor reading less / equal: in mA

Hot-Spot Calculation parameters

o Rated Current: Ir in Amp

o Winding Exponent: y

o Gradient at rated Current: gr

o Hot-Spot-Factor: H

o Winding Time Constant: Tw in second

Usually, all data can be known through transformer manufacture technical specifications.

At the end, conditions and parameters are stored and activated by the button „Store and exit“.

For Cooling Stage #2 and Cooling Stage #3, please apply exactly the same procedure

in order to setup required information.

4.9.1.2 Ageing Rate / Loss of Life

After selection of the Ageing Rate / Loss of Life submenu, following screen will be displayed:

By operation of the arrow keys (

) the different fields can be chosen. First of

all, you must define each field with required information. Followings information must be entered:

Kind of Insulation (Paper): you can select between “Normal” and “Thermally Updated”

Hot-Spot Temperature Sensor: you can select between “None”, “1” (Temperature of oil on the

sensor), “2” (Temperature in sensor area (ambient temp)), “Top Oil temperature”, “Ambient temperature” and “Hot-Spot temperature”

Transformer Loss-of-Live: in hour

Transformer Time into Service: in hour

… into Service since: YYYY-MM-DD

If necessary, you have to define previously Hot-Spot Temperature Sensor as analogue input while

pushing button (See chapter 3.6.3 for setup).

Page 47

HYDROCAL 1005 Manual for Installation and Operation Page 45/111

At the end, setup is stored and activated by the button „Store and exit“.

4.9.2 Configuration of analogue outputs

The HYDROCAL1005 has 5 analog outputs for measured gas-in-oil concentration as well as for external sensors values. The output signal is 0-20 mA or 4-20 mA.

The screen also allows to apply test currents to the outputs to verify the functionality. The test current overlays the real signal. Leaving the screen will apply the real signals to all outputs again.

First a quantity / variable must be selected. The following functions are available:

Scroll up / down marking

Enter button: selection of active menus or submenus

Store configuration of outputs and exit

Exit

The following measuring quantities are available in "Sensor" field:

H2 - C2H2 - C2H4 - CO - H2O concentration

H2 - C2H2 - C2H4 - CO - H2O Daily trend

H2 - C2H2 - C2H4 - CO - H2O Weekly trend

Temperature 1

Temperature 2

All quantities / variables defined under external sensors

The following analog outputs signals are available in the field "Mode":

OFF

0…20 mA

4…20 mA

TEST: Allow simulating an output signal between 0 and 20 mA. The following values can be de-

fined in the field "Sensor”: 0, 1, 3, 4, 5, 10, 15, 19 and 20 mA

4.9.3 Configuration of analogue inputs (external sensors)

The HYDROCAL1005 has a total of 14 analogue inputs. The first six inputs are for bushing sensors

and allow an AC signal of either 0 .. 20 mA or 0 .. 80 V (configurable by jumper). The next four inputs

are for external sensors and a DC signal of 0/4 .. 20 mA can be applied.

In addition to the analogue inputs there are so called virtual sensors. These virtual sensors are configured in the same way as the analogue inputs and are explained in this chapter as well.

Page 48

HYDROCAL 1005 Manual for Installation and Operation Page 46/111

External sensors with standard output signals (0(4)...20mA) can be connected to the HYDROCAL1005 analogue inputs.

Note: No power supply is available for external sensors.

First an input number must be selected. The first 10 input numbers are assigned to the analogue inputs (1 .. 6 bushing, 7 .. 10 external sensors and 11 … 14 virtual sensors).

The following functions are available:

Scroll up marking

Scroll down marking

Scroll up / down marking

Enter button : selection of active menus or submenus

Exit

As soon as an input is selected and made available for configuration , the following functions

are available:

Scroll up / down

Enter button: selection of active menus or submenus

Cancel input

Scroll up

Scroll down

Page 49

HYDROCAL 1005 Manual for Installation and Operation Page 47/111

Selection of different input possibilities for the input mode [Mode], and the unit [Unit] See below.

Store alarm configuration and exit

Exit without storage

The following inputs signal can be selected by pressing the button:

The first 6 can be set-up in 0..80VAC, 0..20mA AC, 0..20 mA or 4..20 mA

The last 4 can be set-up in 0..20 mA or 4..20 mA

The following unit s can be selected by pressing button:

… (No unit)

ppm

ppm/Day

ppm/Week

ºC

%

mA

A

KA

V

KV

The external sensors names in the field "External sensor #" are edited by arrow keys and confirmed

by

and the alphanumeric keyboard.

The sample interval in the field "Sample interval" is edited by arrow keys and confirmed by

and the alphanumeric keyboard. The sample interval is made in seconds or by a button in days –

hours – min - seconds. For minus the button and for a double point the button are used.

After confirmation by the

button, the value will be converted and displayed in days –hours – min

- seconds.

For conversion of input units, the inputs „Minimum Value“ are made under the input signals 0V, 0 mA

or 4 mA and „Maximum Value“ are made under the input signals 10V or 20mA. In addition, the dis-

play range can be limited by inputting introduction of „Minimum Display“ and „Maximum Display“.

Remark: on following display, you could see 4 additional inputs named:

#11: H.-Spot for Hot-Spot Temperature

#12: Ag.Rate for Ageing Rate

#13: L.o.life for loss of Life

#14:

All of them are virtual sensors and any cases have to be considered as real analog inputs. However

these values are displayed on the main display as external sensors (See Chapter 3.3: Main Menu

“External sensor setup”).

Page 50

HYDROCAL 1005 Manual for Installation and Operation Page 48/111

4.9.4

Configuration of alarms and digital outputs

The HYDROCAL1005 unit has 10 digital outputs for alarms. The first 5 (Out1 ...5) are relay outputs.

The „on“ status is closed and the „off“ status is open (output #1 can be configured for reverse operation by a jumper on the circuit board). The next 5 outputs (Out 6..10) are optional opto-couplers, with

status „contact closed“ for “on“ and „contact open“ for “off“. You can have up to 16 possibilities to

setup Alarms. Alarms can be triggered either by internal gas or temperature sensors or by external

sensors. Configuration of alarms is shown on the following pictures:

First a quantity / variable must be selected. For this choice, the following functions are available:

Configuration of SMS transmitting functionality

Scroll up marking

Scroll down marking

Scroll up / down marking

Select setting for alarm

Select setting for configuration of alarm

Exit

The following measuring quantities are available:

H2 - C2H2 - C2H4 - CO - H2O concentration

H2 - C2H2 - C2H4 - CO - H2O Daily trend

H2 - C2H2 - C2H4 - CO - H2O Weekly trend

Temperature 1

Temperature 2

All quantities / variables defined under external sensors

Page 51

HYDROCAL 1005 Manual for Installation and Operation Page 49/111

After a measuring variable has been selected and opened with for configuration, the following

functions are available:

Selection of different input possibilities for the alarm mode (mode), Action (action1..2)

and choice of the output (clamp1..2)

Activation of input over alphanumeric keyboard for the values: Alarm limit (Level1..2),

Delay (Delay1..2)

Scroll up

Scroll down

Scroll up / down

Cancel alarm

Store configuration of alarm and exit

Exit without storage

Following alarm settings can be chosen by pressing the button :

High: An alarm is triggered when Level 1 is exceeded.

High-High: An alarm in 2 steps is triggered. The first alarm is triggered when Level 1 is ex-

ceeded; the second alarm is triggered after exceeding Level 2.

Low: An alarm is triggered when a value falls below the limit defined in Level 1.

Low-Low: An alarm in 2 steps is triggered. Step 1 is alarm is triggered when the measured value

falls below the limit defined in Level 1, the second alarm is triggered below Level 2 when the

measured value falls below the limit defined in Level 2.

Low-high: An alarm in 2 steps is triggered. Step 1 is triggered when the measured value falls be-

low the limit defined in Level 1, the second alarm is triggered after exceeding Level 2.

Range: An alarm is triggered when the measured value is between the limits defined in Levels 1

and 2.

The alarm limits are edited by arrow keys and confirmed by the button and the alphanumeric

keyboard. The quantity is defined by the unit. This is “ppm” for gas concentration and „°C” for tem-

peratures and for external sensors the unit defined for the respective sensor (e.g. Volt, Ampere ...).

The alarm limits must be within the corresponding measuring ranges. This is 0...2000 ppm for gases,

0...+100°C for temperatures and for external sensors the limit is defined for the respective sensor.

Delays (Delay1...2) can be programmed to suppress alarms if the limits are exceeded only for a

short time. Input of delay time is made in seconds or by a button in days – hours – min - seconds.

For minus the button and for a double point the button are used. After confirmation by the

button, the value will be converted and displayed in days –hours – min - seconds.

Page 52

HYDROCAL 1005 Manual for Installation and Operation Page 50/111

For example: if CO Alarm is setup as follow (delay 1: 10min and delay 2: 20min)

In the event of alarms, CO alarms will be activated as follow:

Note: CO measurement interval is 20 min.

The following actions can be selected by pressing the

button:

Log entry: An entry in the history of alarms is made; this has to be confirmed (see history of

alarms).

Output: An entry in the history of alarms is made; this has to be confirmed (see history of alarms)

and an output is switched on (If the measured value exceeded the limits in the field "Level 1 & 2").

The status „on“ described above is activated. If the measured value falls under the limit, the output is switched off again.

Out, hold: An entry in the history of alarms is made; this has to be confirmed (see history of

alarms) and an output is switched on (If the measured value exceeded the limits in the field "Level

1 & 2"). The status „on“ described above is activated. If the measured value for this output falls

under the limit, the output remains switched on. Only a manual deleting of alarm allows that the

output is switched off again (see chapter 5.11 or 4.6).

Log & SMS: An entry in the history of alarms is made; this has to be confirmed (see history of

alarms) and an entry in the history of alarms is made, this has to be confirmed (see history of

alarms) and an SMS is sent to the number indicated.

Output & SMS: An entry in the history of alarms is made; this has to be confirmed (see history of

alarms) and an output is switched on (If the measured value exceeded the configured limits in the

field "Level 1 & 2"). The status „on“ described above is activated. If the measured value falls under the limit, the output is switched off again. In addition, an SMS is sent to the number indicated.

Page 53

HYDROCAL 1005 Manual for Installation and Operation Page 51/111

Out, hold & SMS: An entry in the history of alarms is made; this has to be confirmed (see history

of alarms) and an output is switched on (If the measured value exceeded the configured limits in

the field "Level 1 & 2"). The status „on“ described above is activated. If the measured value for

this output falls under the limit, the output remains switched on. Only a manual deleting of alarm

allows that the output is switched off again (see chapter 4.11 or 3.6). In addition, an SMS is sent

to the number indicated.

If it is possible to use the same output for different alarms and therefore, collection alarms can be

defined.

4.9.5 Unit Setup

The following setup can be modified:

Digital Output Test

Device Options setup (Backlight display)

Date. Time & Clock Settings

Communication settings

Exit

Page 54

HYDROCAL 1005 Manual for Installation and Operation Page 52/111

4.9.5.1 Digital Output Test

This is for Test of the 10 Digital Outputs.

For testing the 5 alarms relay outputs, please check Fields KL 402 #.

For testing the 5 alarms opto-coupler outputs, please check Fields KL 103 #.

4.9.5.2 Device options

The configuration of the Backlight display as well as User Name and Password (String and Numeric

Password) are made in the following menu:

The following functions are available for Display Backlight Timeout:

Scroll up / down marking

Enter button: selection of active menus or submenus

Store the configuration and exit

Exit

Input of delay time is made in seconds or by a button in days – hours – min - seconds. For minus the

button and for a double point the buttons are used. After confirmation by the

button,

the value will be converted and displayed in days –hours – min - seconds.

Note: 0 means that the screen will be always enlightened.

Page 55

HYDROCAL 1005 Manual for Installation and Operation Page 53/111

Input of new User Name and Password are made by operation of the arrow keys (

) the different fields are selected. Selection is confirmed by the enter

button. The customer

data can be modified by the alphanumeric keyboard and the arrow keys.

Remark:

User Name is used for Modem login. The default “User Name” is “EMH”

String Password is used also for Modem Login. The default “String Password” is “KWA”

Numeric Password is used for Device Setup menu, Customer Data Setup as well as for commu-

nication from HydroSoft Software to the unit (The default password is 999).

Toggling of the main Display is made by operation of the arrow keys (

) the differ-

ent fields are selected. Selection is confirmed by the enter

button. You have followings possibili-

ties:

“Standard” means that your Main Display will switched every 5 seconds

“Slow” means that your Main Display will switch every 15 seconds

“Very Slow” means that your Main display will switch every 25 seconds

These amendments are stored by selection of button or are rejected by selection of the

.

4.9.5.2.1.

Configuration of user settings

By operation of the arrow keys (

) the different fields are selected. Selection is

confirmed by the enter

button. The customer data can be modified by the alphanumeric keyboard and the arrow keys. These amendments are stored by selection of button or are rejected by selection of the . In the main menu (standard display) up to 26 characters can be en-

tered. Only the first 10 characters will be displayed.

Reset

The activation of the reset button will perform a software reset of the device.

4.9.5.3 Date. Time & Clock Settings

The HYDROCAL1005 has a sub menu allowing configuration of time, date as well as clock

Page 56

HYDROCAL 1005 Manual for Installation and Operation Page 54/111

The following functions are available:

Scroll up / down marking

Enter button: selection of active menus or submenus

Store the configuration and exit

Exit

Input of time in the field ""System Time" is made in - hours - minutes - seconds. For a double point,

used the button.

Input of date in the field ""System Date" is made in - year - month - days - . For minus the button

is used.

Page 57

HYDROCAL 1005 Manual for Installation and Operation Page 55/111

The HYDROCAL1005 has a universal GMT clock in order to modify the time zone.

The time zone setup in the field "Clock offset" is made by button. The time zone values are between -6 and +6 hours. Variable „Custom" allows manual setup in the field on the right side. Input of

time is made in - hours - minutes -. For a double point, used the button.

Note: "None“ means that GMT clock is not activated. The setting “None” is recommended

Input of time mode in the field "Daylight Saving Time Mode" is made by button:

MET (Middle European Time) adjusts the official local time forward, one hour from its official

standard time for the duration of the spring and summer months.

NONE means that the function is not activated

These amendments are stored by selection of button or are rejected by selection of the

.

4.9.5.4

Configuration of the communication

The configuration of the communication is made in the following menu:

The following functions are available:

Ethernet / Network setup

Alert SMS setup

Internal modem setup

RS 232 / 485 setup, MODBUS setup

Page 58

HYDROCAL 1005 Manual for Installation and Operation Page 56/111

Status information activation

Scroll up / down marking

Enter button: selection of active menus or submenus

Exit

Note: on the main display, you have the currently communication status.

4.9.5.5 Ethernet setup

The device is equipped with an Ethernet interface to allow the integration into a TCP/IP local area

network. How the device has to be incorporated into the network (on site) has to be defined by the

network administrator. Hydrocal supports static and dynamic integration.

Dynamic integration via DHCP

The network administrator will have given the information that the devices in the network will be

automatically configured (by DHCP).

Static setup

The network administrator has to deliver the following information that will be entered into the corresponding fields in the Hydrocal network screen:

IP address

Network mask

Default gateway

TCP Port Number

The TCP Port Number may also be defined by the network administrator. Depending on the requirements of other software or devices installed, the port number must be assigned obeying specific

rules. If non of these limitations apply, the port number should be assigned in a range 49152 ..

65535 (possible range is 1 .. 65535, but some numbers are reserved e.g. by HTTP or FTP).

Page 59

HYDROCAL 1005 Manual for Installation and Operation Page 57/111

Remark: For test purposes a DHCP server can be activated on the device. This feature is only implemented to allow the connection of a laptop / portable computer with Windows standard network

configuration. Only for the time of the test the DHCP server would be activated, allowing service staff

to communicate with the device via Ethernet. The device is not designed to serve as a real DHCP

server in a real network environment.

4.9.5.6 Alert SMS setup

The configuration of the alert SMS transmission is made in the following menu if HYDROCAL1005 is