Page 1

WARNING

High Voltage! Only a qualified electrician can carry out the electrical

installation of this filter.

Quick Reference

❶

Selection Guide

Pages 7 – 16

❷

Installation Guide

Pages 17 – 22

❸

Startup/Troubleshooting

Pages 23 – 25

❹

Reference Drawings

Pages 28 – 100

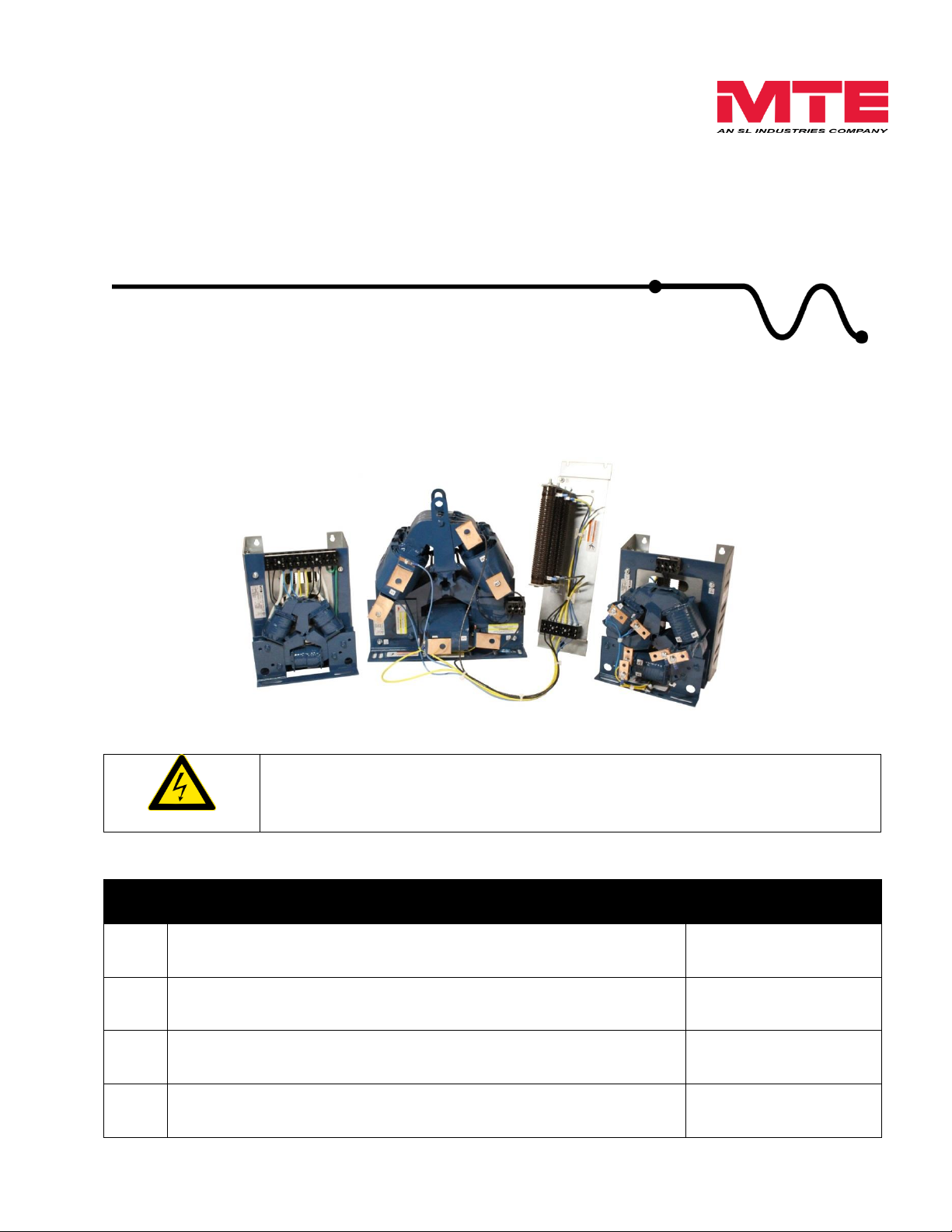

dV Sentry™

380V – 600V

TECHNICAL REFERENCE MANUAL

FORM: DVS-TRM-E

REL. September 2014

REV. 001

© 2014 MTE Corporation

Page 2

dV Sentry Technical Reference Manual 380V – 600V

TABLE OF CONTENTS

1. WARNINGS ................................................................................................................................. 3

WARNINGS AND CAUTIONS ............................................................................................................. 3

PRODUCT SAFETY LABELING .......................................................................................................... 4

GENERAL SAFETY INSTRUCTIONS ................................................................................................... 4

2. INTRODUCTION .......................................................................................................................... 6

RECEIPT & REPAIR STATEMENT ...................................................................................................... 6

3. HOW TO SELECT ....................................................................................................................... 7

SELECTION GUIDE ......................................................................................................................... 7

MODEL NUMBER CODE SYSTEM: .................................................................................................... 8

PART NUMBER SELECTION TABLES ................................................................................................. 9

4. PRODUCT SPECIFICATIONS ................................................................................................... 12

PERFORMANCE SPECIFICATIONS .................................................................................................. 12

ENCLOSURES .............................................................................................................................. 13

AGENCY APPROVALS ................................................................................................................... 13

WARRANTY ................................................................................................................................. 13

5. DV/DT FILTER PERFORMANCE .............................................................................................. 14

FILTER EFFICIENCY + WATT LOSS ................................................................................................. 15

ALTITUDE DERATING .................................................................................................................... 16

MOTOR FREQUENCY DERATING .................................................................................................... 16

6. HOW TO INSTALL .................................................................................................................... 17

INSTALLATION CHECKLIST ............................................................................................................ 17

G

ROUNDING

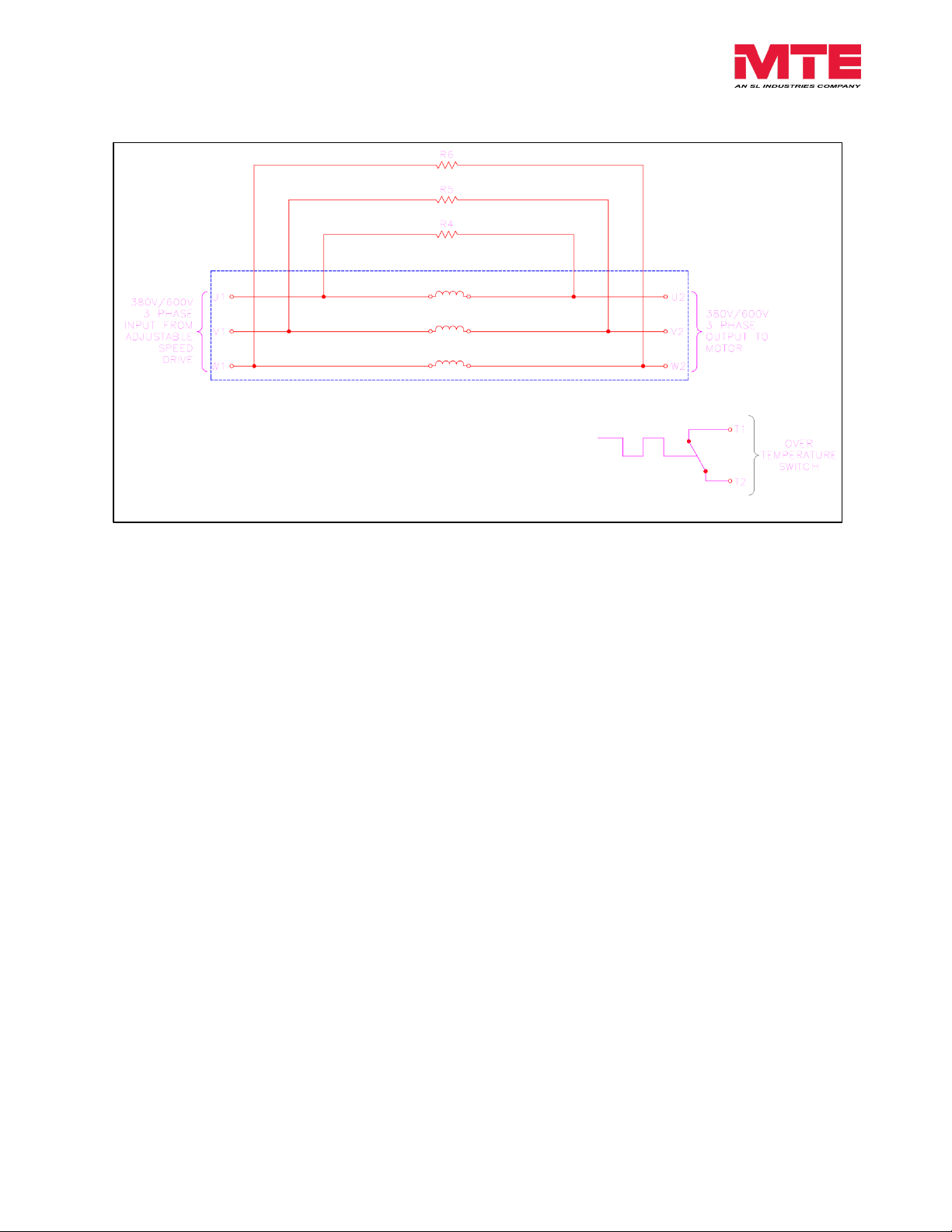

BASIC SCHEMATIC DIAGRAM ......................................................................................................... 19

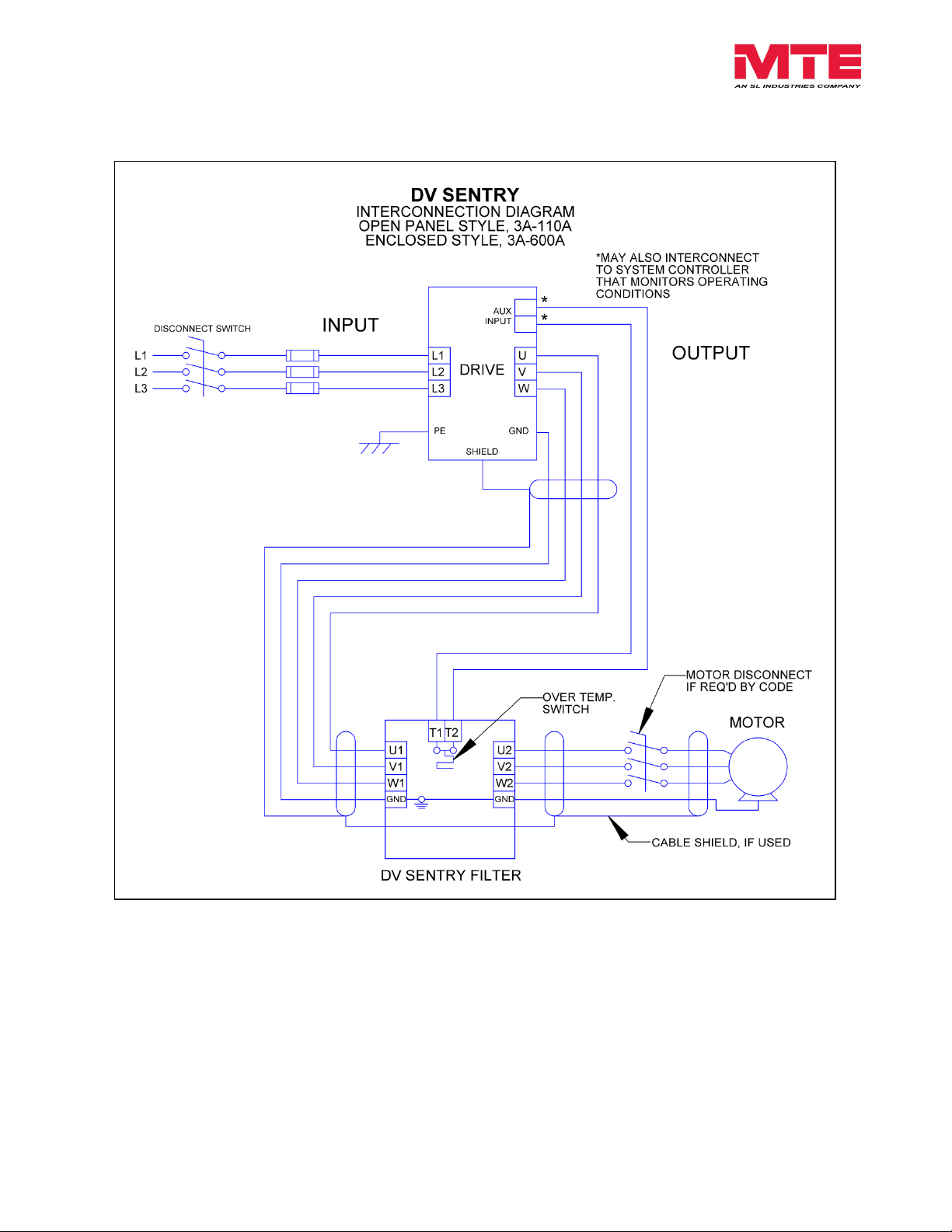

INTERCONNECTION DIAGRAM – PANEL (3A-110A) AND ENCLOSED (3A-600A) ................................ 20

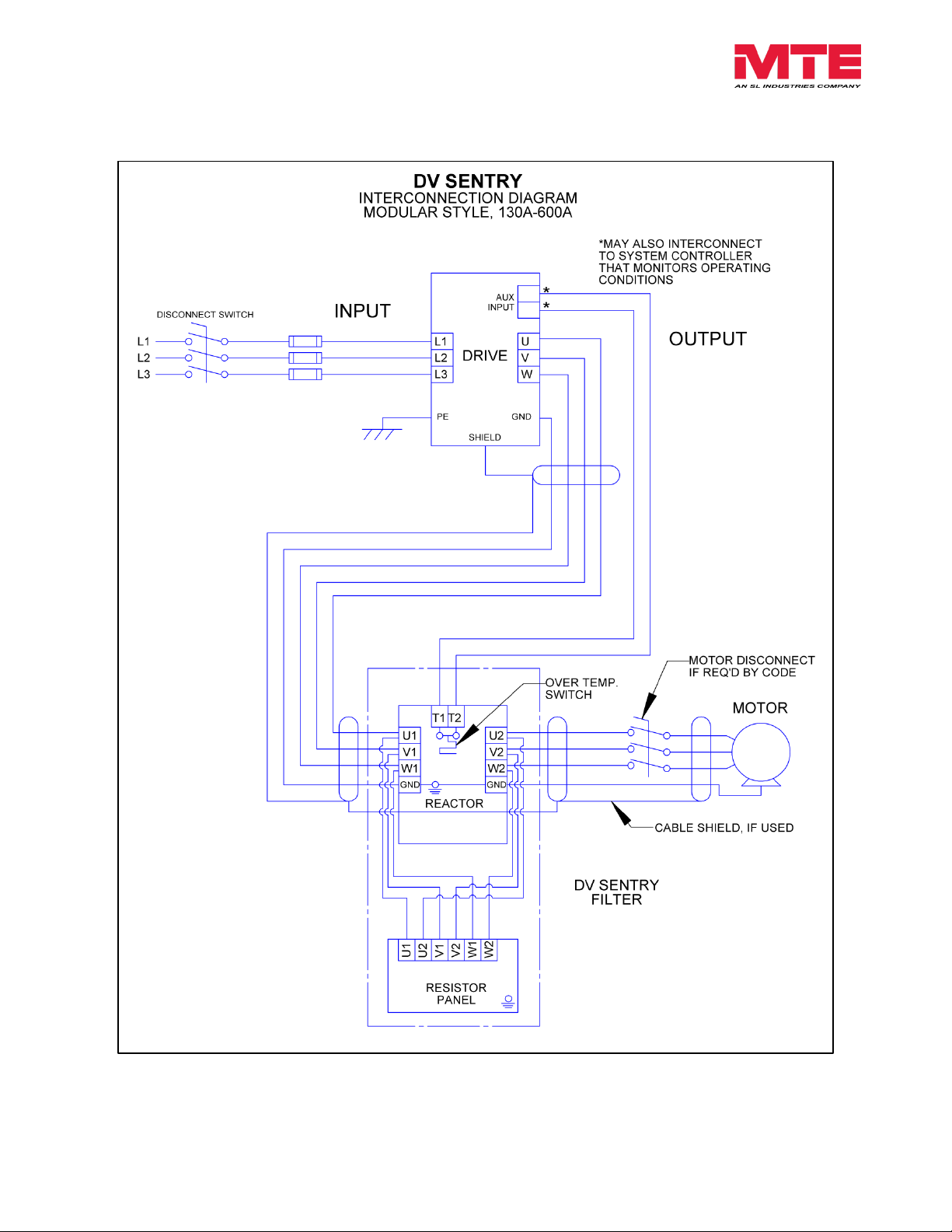

INTERCONNECTION DIAGRAM – MODULAR (130A-600A) ................................................................ 21

TORQUE RATINGS ........................................................................................................................ 22

7. START UP ................................................................................................................................. 23

STARTUP CHECKLIST ................................................................................................................... 23

8. TROUBLESHOOTING ............................................................................................................... 25

APPENDIX .................................................................................................................................... 27

............................................................................................................................... 18

Form: DVS-TRM-E September 2014 REV. 001 1

Page 3

dV Sentry Technical Reference Manual 380V – 600V

List of Figures

Figure 6-1: Basic Schematic Diagram ..................................................................................... 19

Figure 6-2: Open Panel and Enclosed Diagram ...................................................................... 20

Figure 6-3: Modular Diagram .................................................................................................. 21

List of Tables

Table 3-1: Panel Selection Table .............................................................................................. 9

Table 3-2: Enclosed NEMA 1/2 Selection Table ...................................................................... 10

Table 3-3: Enclosed NEMA 3R Selection Table ...................................................................... 11

Table 4-1: Performance Specifications .................................................................................... 12

Table 5-1: Performance Chart ................................................................................................. 14

Table 5-2: Filter Efficiency & Watt Loss ................................................................................... 15

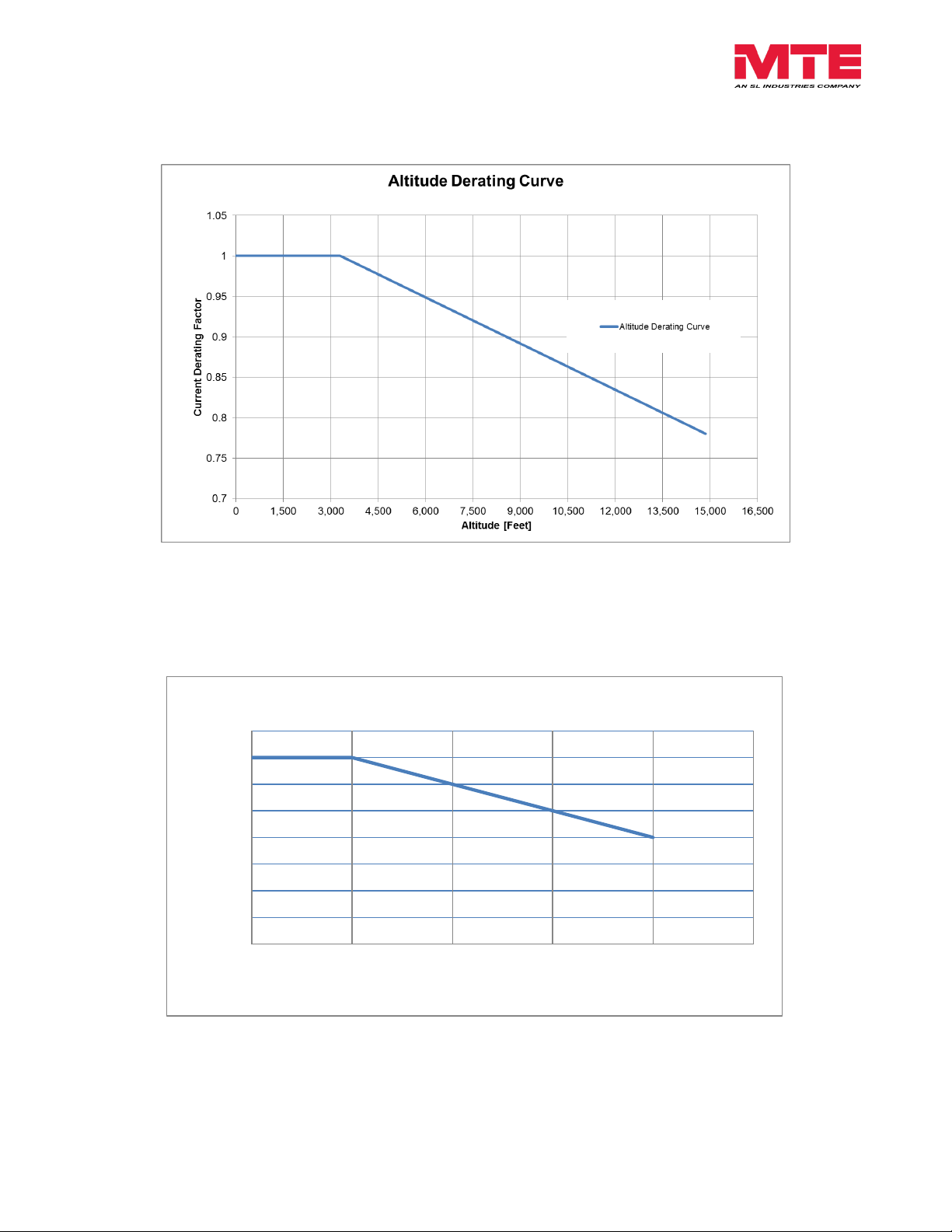

Table 5-3: Altitude Derating Curve ......................................................................................... 16

Table 5-4: Current Derating for Drive Output Frequency ........................................................ 16

Table 6-1: Torque Ratings ....................................................................................................... 22

Table 8-1: Troubleshooting Guide ........................................................................................... 25

Form: DVS-TRM-E September 2014 REV. 001 2

Page 4

dV Sentry Technical Reference Manual 380V – 600V

WARNING

WARNING describes situations that can lead to serious faults,

physical injuries, or even death.

Caution

Caution describes situations that can lead to malfunction or

possible equipment damage.

WARNING

High Voltage Warning: warns of situations that dangerously

high voltage is involved. Failure to use proper precautions may

lead to serious injury or even death.

WARNING

General Warning: warns of situations that can result in serious

injury or death if proper precautions are not used.

Caution

General Caution: identifies situations that could lead to

malfunction or possible equipment damage.

1. WARNINGS

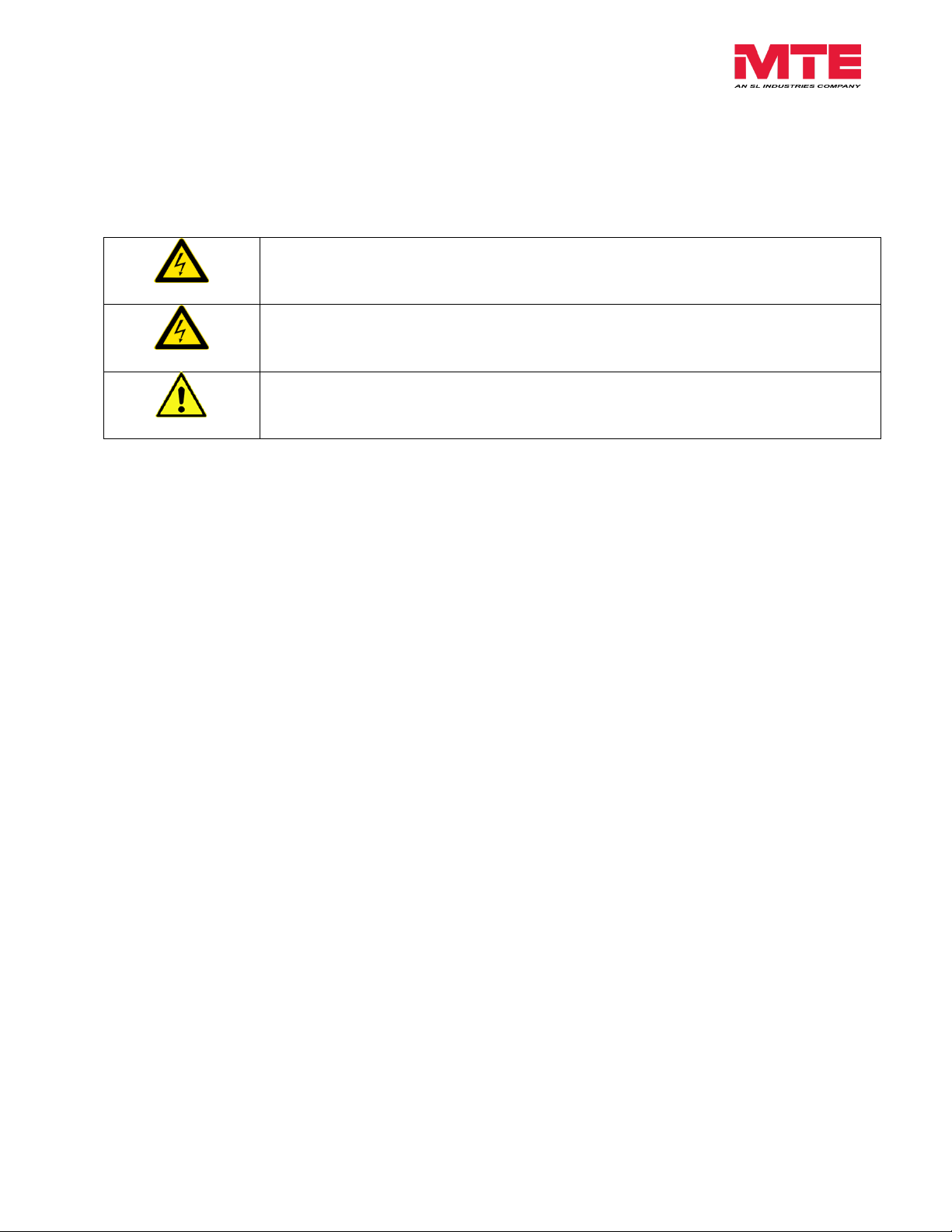

Warnings and Cautions

There are two types of warnings in this manual:

The following symbols are used in this manual.

Form: DVS-TRM-E September 2014 REV. 001 3

Page 5

dV Sentry Technical Reference Manual 380V – 600V

WARNING

High Voltage! Only a qualified electrician can carry out the electrical

installation of this filter.

WARNING

High voltage is used in the operation of this filter. Use Extreme caution to

avoid contact with high voltage when operating, installing or repairing this

filter.

Injury or death may result if safety precautions are not

observed.

WARNING

The opening of the branch circuit protective device may be an indication that a

fault current has been interrupted. To reduce the risk of fire or electrical shock,

current-carrying parts and other components of the filter should be examined and

replaced if damaged.

WARNING

An upstream disconnect/protection device must be used as required by the

National Electrical Code (NEC) or governing authority.

WARNING

Even if the upstream disconnect/protection device is open, the drive down stream

of the filter may feedback high voltage to the filter. The drive safety instructions

must be followed. Injury or death may result if safety precautions are not

observed.

WARNING

The filter must be grounded with a grounding conductor connected to all grounding

terminals. Modular filters must have reactor grounded through a 2”x2” area

cleaned of paint and varnish on lower mounting bracket.

Label notes to installer to refer to instruction manual first before

installing.

High Voltage: surfaces on product can have high voltage which can

cause injury.

Connect Thermal Switch: connecting the thermal switch can reduce

risk of damage.

Hot Surfaces: surfaces of product can be hot at times and cause

burns.

Product Safety Labeling

The following labels are placed on the DVS product:

General Safety Instructions

Form: DVS-TRM-E September 2014 REV. 001 4

Page 6

dV Sentry Technical Reference Manual 380V – 600V

WARNING

Only spare parts obtained from MTE Corporation or an authorized MTE distributor

can be used.

Caution

Loose or improperly secured connections may damage or degrade filter

performance. Visually inspect and secure all electrical connections before

power is applied to the filter.

Caution

Wiring should not be routed underneath panel in resistor housing. Doing so could

result in fire or damage to the product.

Caution

Product should not be mounted on wood or any other combustible surface. Doing

so could lead to fire or damage to the product.

Form: DVS-TRM-E September 2014 REV. 001 5

Page 7

dV Sentry Technical Reference Manual 380V – 600V

2. INTRODUCTION

The purpose of the manual is to properly specify, size, install, interconnect and operate the

dV/dt filter.

For most current information, please refer to website

http://www.mtecorp.com/products/dvsentry/

This manual is intended for use by personnel experienced in the operation and maintenance of

inverters. Because of the high voltages required by the filter, inverter and the potential dangers

presented by rotating machinery, it is essential that all personnel involved in the operation and

maintenance of this filter know and practice the necessary safety precautions for this type of

equipment. Personnel should read and understand the instructions contained in this manual

before installing, operating or servicing the filter and inverter to which it is connected.

Receipt & Repair Statement

Upon Receipt of this Filter:

The dV/dt filter has been subjected to demanding factory tests before shipment. Carefully

inspect the shipping container for damage that may have occurred in transit. Then unpack the

filter and carefully inspect for any signs of damage. Save the shipping container for future

transport of the filter.

In the event of damage, please contact and file a claim with the freight carrier involved

immediately.

If the equipment is not going to be put into service upon receipt, cover and store the filter in a

clean, dry location. After storage, ensure that the equipment is dry and that no condensation or

dirt has accumulated on the internal components of the filter before applying power.

Repair/Exchange Procedure:

MTE Corporation requires a Return Material Authorization Number and form before we can

accept any filters that qualify for return or repair. If problems or questions arise during

installation, setup, or operation of the filter, please contact MTE for assistance at:

Toll Free: 1-800-455-4MTE (1-800-455-4683)

International Tel: 262-253-8200

Fax: 262-253-8222

Form: DVS-TRM-E September 2014 REV. 001 6

Page 8

dV Sentry Technical Reference Manual 380V – 600V

3. HOW TO SELECT

Selection Guide

The dV Sentry Motor Protection Filter is intended for use on inverter duty motors. It will

typically be used with lead lengths up to 1,000 feet. The dV Sentry Motor Protection Filter will

provide both common mode and differential mode reduction to prevent overvoltage that can

occur due to reflected wave phenomena. The differential mode filtering reduces EMI,

increases motor life, and reduce cables voltage stress. The added common mode protection

will reduce bearing failures, degradation of cable insulation to ground, and further reduce EMI.

The suitability of this filter for a specific application must therefore be determined by the

customer. In no event will MTE Corporation assume responsibility or liability for any direct or

consequential damages resulting from the use or application of this filter. Nor will MTE

Corporation assume patent liability with respect to the use of information, circuits or equipment

described in this instruction manual.

*For non-inverter duty motors, please refer to the SineWave Guardian filter.

dV Sentry Motor Protection Filters are available in Panel, NEMA 1/2, and 3R mechanical

configurations.

Please verify information below for proper selection:

Lead Length: This product is suitable for applications with motor leads up to 1,000 ft.

Contact MTE Application Engineering for possible longer applications.

Voltage: Input voltage from 380V – 600V. See Table 4-1 (p13) for specification.

Current Rating: Support for 3 Amps – 600 Amps.

Switching Frequency: Support for carrier frequency of 2kHz – 10kHz see Table 4-1

(p13).

Drive Output Frequency: Support for 0Hz to 90Hz without derating, >90Hz to 120Hz

with derating. See (p17) for derating curve.

Temperature: Maximum ambient temperature, 60C (open), 50C (enclosed). See

Table 4-1 (p13) for specification.

Altitude: 3,300 feet above sea level without derating. See

(p17) for derating curve.

Enclosure Type: Panel, NEMA 1/2 & NEMA 3R, see (p14) for enclosure descriptions.

Motor Insulation Class: Verify motor meets inverter duty standards per NEMA MG1

Section 31.

*Filters cannot be paralleled for higher current ratings.

Form: DVS-TRM-E September 2014 REV. 001 7

Page 9

dV Sentry Technical Reference Manual 380V – 600V

Model Number Code System:

DVS X _ _ _ _ E

dV Sentry Filter

Type

P = Panel

G = General Purpose (NEMA 1/2)

W = Weather (NEMA 3R)

Current Rating

(i.e. 0045 is 45 Amps)

Voltage Rating

(380V – 600V)

Form: DVS-TRM-E September 2014 REV. 001 8

Page 10

dV Sentry Technical Reference Manual 380V – 600V

380V

Motor

KW

480V

Motor

HP

550V-

600V

Motor

HP

Filter

Amp

Rating

Part

Number

App.

Wt.

(lbs.)

Open Magnetics

(in.)

(H x W x D)

Ref.

Fig.

Watts*

Loss

Resistor Panel

(in.)

(H x W x D)

Ref.

Fig.

0.5- 1.1

0.5-1.5

0.5 - 2

3

DVSP0003E

7

9.1 x 6.7 x 7.7

A-1

227

-

-

1.5 2 3

4

DVSP0004E

7

9.1 x 6.7 x 7.7

A-2

227

-

-

2.2 - 3 3 5

5

DVSP0007E

7

9.1 x 6.7 x 7.7

A-3

227

-

- 4 5

7.5

9

DVSP0009E

7

9.1 x 6.7 x 7.7

A-4

227

-

-

5.5

7.5

10

12

DVSP0012E

7

9.1 x 6.7 x 7.7

A-5

227

-

-

7.5

10

15

17

DVSP0017E

8

9.1 x 6.7 x 7.5

A-6

334

-

-

11

15

20

22

DVSP0022E

11

9.1 x 6.7 x 8.2

A-7

278

-

- - 20

25

27

DVSP0027E

11

9.1 x 6.7 x 8.2

A-8

267

-

-

15

25

30

35

DVSP0035E

15

12.0 x 9.0 x 7.9

A-9

260

-

-

18.5-22

30

40

45

DVSP0045E

15

12.0 x 9.0 x 7.9

A-10

219

-

- - 40

50

45

DVSP0055E

22

12.0 x 9.0 x 8.2

A-11

297

-

-

30

50

60

65

DVSP0065E

31

12.0 x 9.0 x 11.0

A-12

376

-

-

37

60

75

80

DVSP0080E

30

12.0 x 9.0 x 11.0

A-13

336

-

-

45 - 55

75

100

110

DVSP0110E

32

12.0 x 9.0 x 11.0

A-14

363

-

-

-

100

125

130

DVSP0130E

51

13.5 x 13.6 x 7.9

A-15

393

18.4 x 5.0 x 7.0

A-70

75 - 90

125

150

160

DVSP0160E

69

13.5 x 13.6 x 9.0

A-16

412

18.4 x 5.0 x 7.0

A-70

110

150

200

200

DVSP0200E

69

13.5 x 13.6 x 9.0

A-17

449

18.4 x 5.0 x 7.0

A-70

132

200

250

250

DVSP0250E

89

15.0 x 15.1 x 10.3

A-18

550

18.4 x 5.0 x 7.0

A-71

160

250

300

305

DVSP0305E

94

15.2 x 15.1 x 10.4

A-19

616

18.4 x 5.0 x 7.0

A-71

185-200

300

350

365

DVSP0365E

124

15.1 x 15.1 x 11.8

A-20

703

18.4 x 5.0 x 7.0

A-71 - 350

450

415

DVSP0415E

124

15.1 x 15.1 x 11.8

A-21

703

18.4 x 5.0 x 7.0

A-71

250

400–450

500 - 550

515

DVSP0515E

157

14.9 x 15.1 x 13.3

A-22

1027

18.4 x 5.0 x 7.0

A-72

315

500

600

600

DVSP0600E

164

15.1 x 15.1 x 13.4

A-23

1062

18.4 x 5.0 x 7.0

A-72

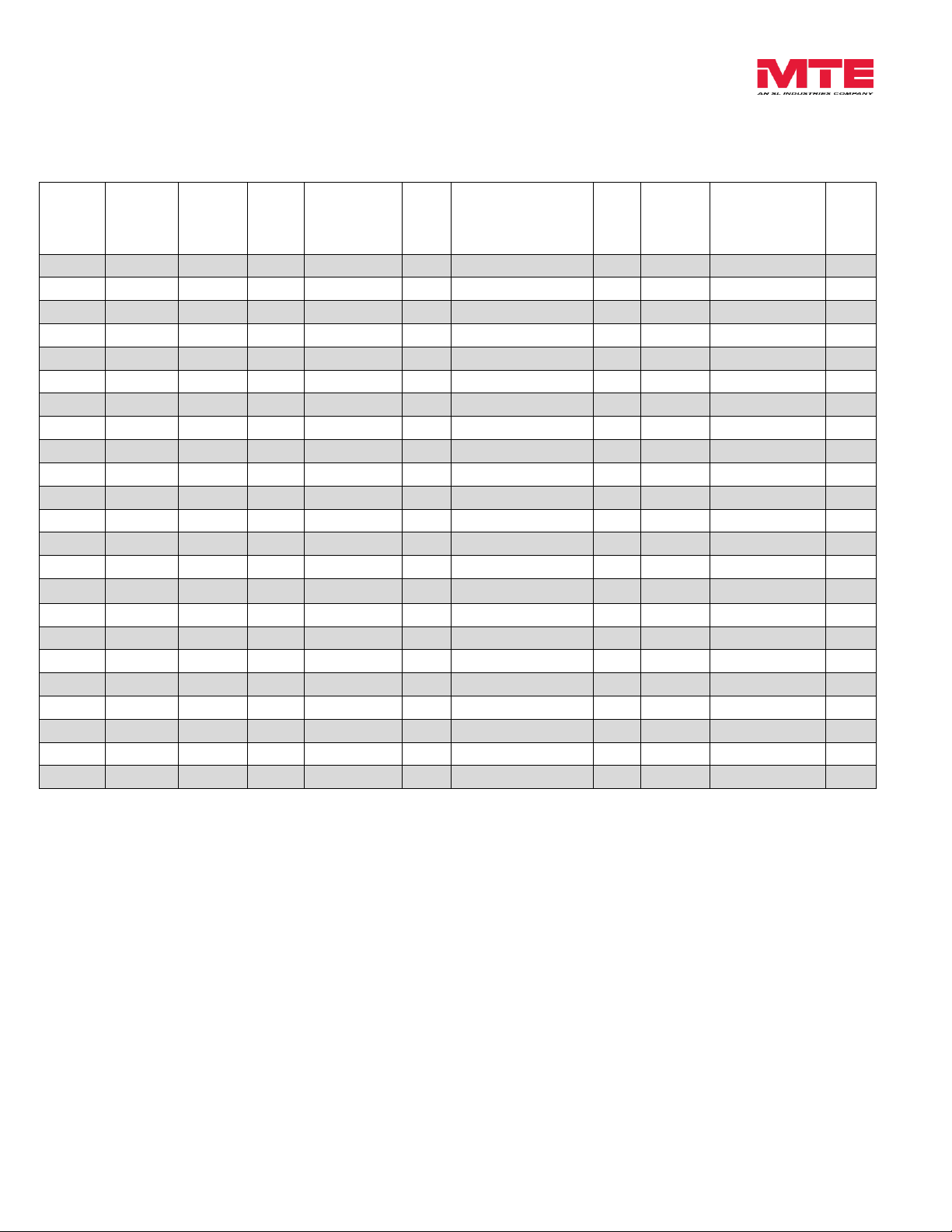

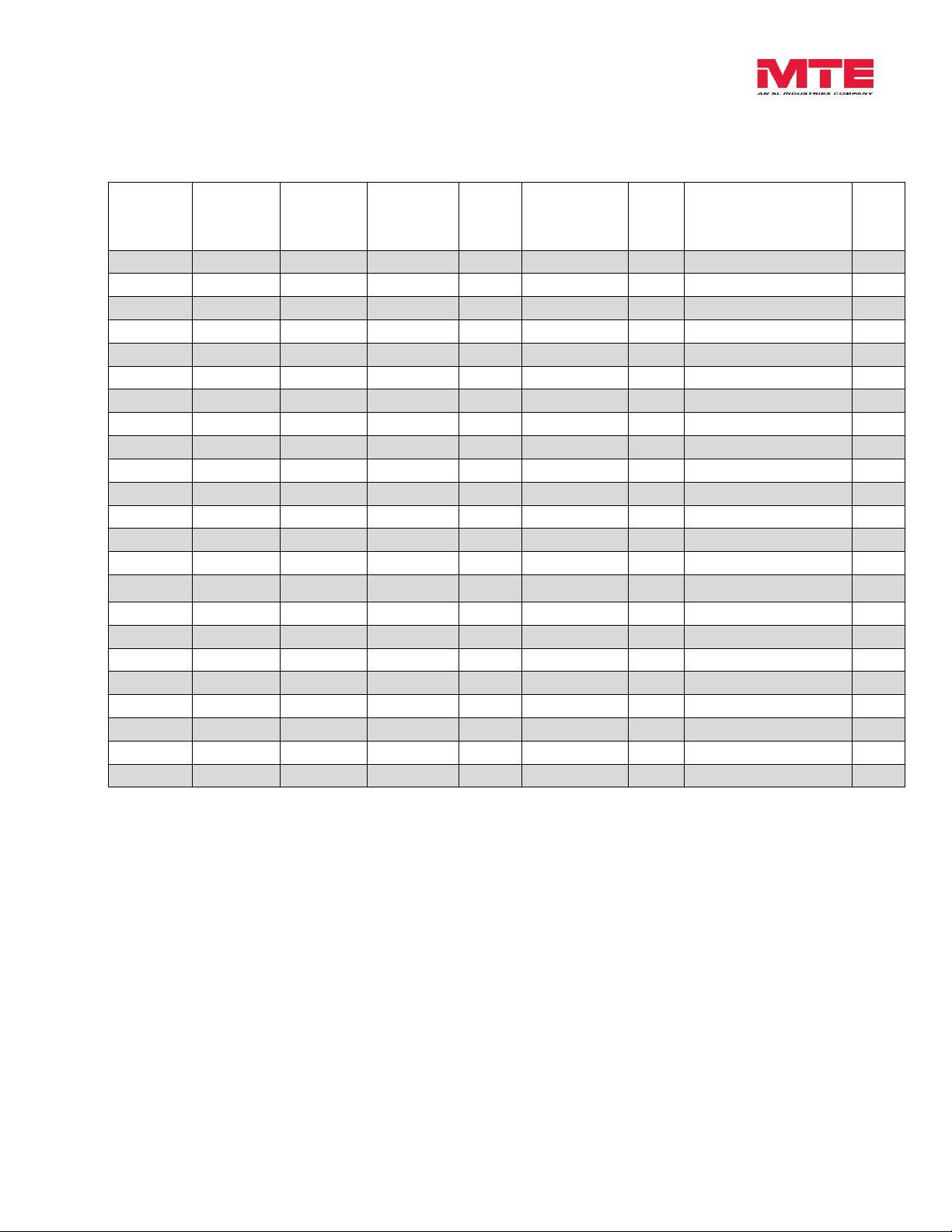

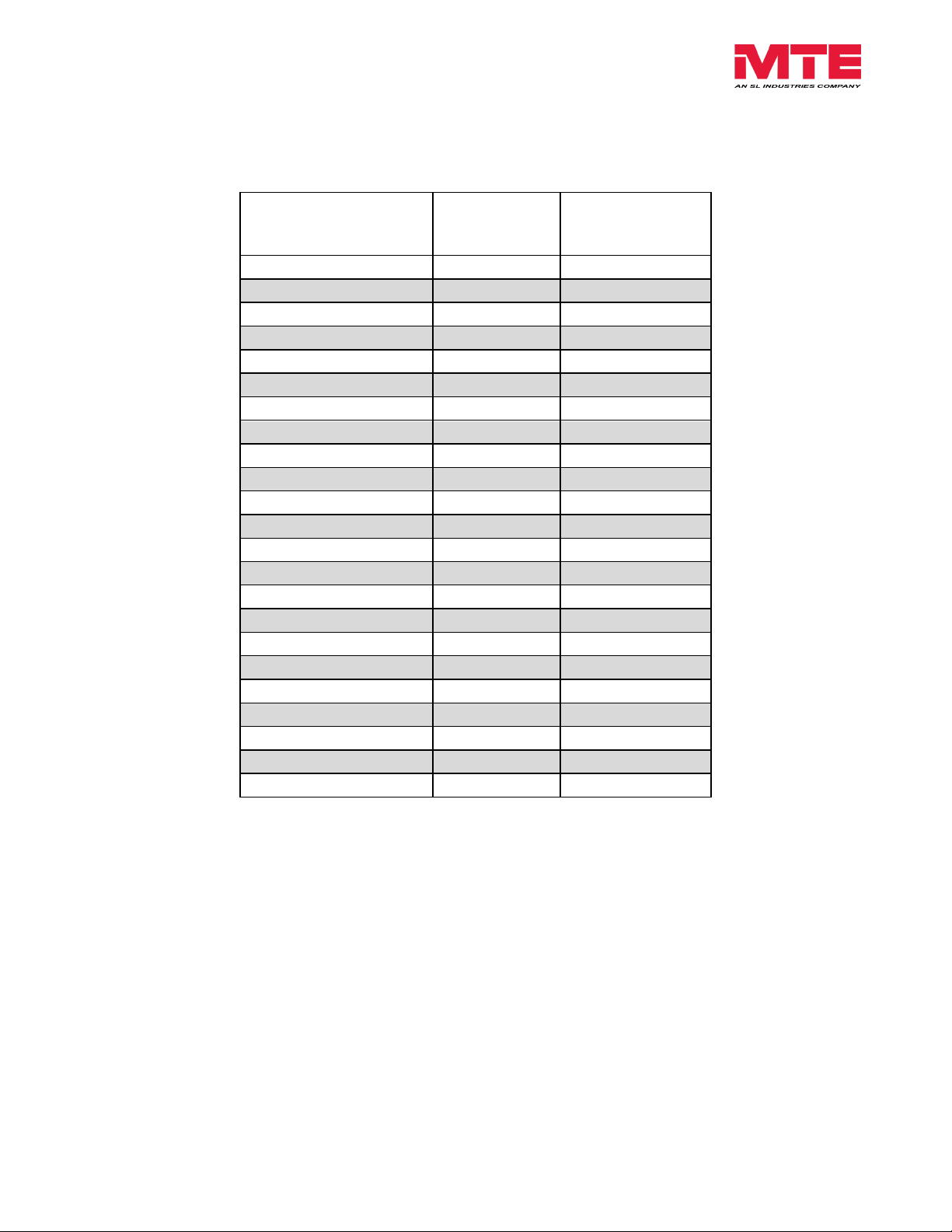

Part Number Selection Tables

Table 3-1: Panel Selection Table

*Based on a typical 480V, 60Hz output frequency, 1,000 feet of drive cable, 2kHz carrier

frequency at full load application.

Form: DVS-TRM-E September 2014 REV. 001 9

Page 11

dV Sentry Technical Reference Manual 380V – 600V

380V

Motor

KW

380V

Motor

HP

480V

Motor

HP

550V- 600V

Motor

HP

Filter

Amp

Rating

Part

Number

App.

Wt.

(lbs.)

NEMA 1/2 Enclosure

(in.)

(H x W x D)

Ref.

Fig.

0.5 – 1.1

0.5 – 1.5

0.5 – 1.5

0.5 - 2

3

DVSG0003E

18

13.2 x 13.0 x 13.0

A-24

1.5 2 2 3 4

DVSG0004E

18

13.2 x 13.0 x 13.0

A-25

2.2 - 3 3 3 5 5

DVSG0007E

18

13.2 x 13.0 x 13.0

A-26

4

5.5 5 7.5

9

DVSG0009E

18

13.2 x 13.0 x 13.0

A-27

5.5

7.5

7.5

10

12

DVSG0012E

18

13.2 x 13.0 x 13.0

A-28

7.5

10

10

15

17

DVSG0017E

19

13.2 x 13.0 x 13.0

A-29

11

15

15

20

22

DVSG0022E

22

13.2 x 13.0 x 13.0

A-30

- - 20

25

27

DVSG0027E

22

13.2 x 13.0 x 13.0

A-31

15

20

25

30

35

DVSG0035E

24

13.2 x 13.0 x 13.0

A-32

18.5 - 22

25 – 30

30

40

45

DVSG0045E

24

13.2 x 13.0 x 13.0

A-33

- - 40

50

45

DVSG0055E

32

13.2 x 13.0 x 13.0

A-34

30

40

50

60

65

DVSG0065E

40

13.2 x 13.0 x 13.0

A-35

37

50

60

75

80

DVSG0080E

40

13.2 x 13.0 x 13.0

A-36

45 - 55

60 – 75

75

100

110

DVSG0110E

43

13.2 x 13.0 x 13.0

A-37

- - 100

125

130

DVSG0130E

93

24.0 x 17.1 x 17.1

A-38

75 - 90

100 – 120

125

150

160

DVSG0160E

111

24.0 x 17.1 x 17.1

A-39

110

150

150

200

200

DVSG0200E

111

24.0 x 17.1 x 17.1

A-40

132

175

200

250

250

DVSG0250E

127

33.9 x 18.3 x 20.9

A-41

160

220

250

300

305

DVSG0305E

165

33.9 x 18.3 x 20.9

A-42

185 - 200

250 – 270

300

350

365

DVSG0365E

195

33.9 x 18.3 x 20.9

A-43

- - 350

450

415

DVSG0415E

195

33.9 x 18.3 x 20.9

A-44

250

340

400 – 450

500 - 550

515

DVSG0515E

317

51.3 x 27.7 x 24.9

A-45

315

430

500

600

600

DVSG0600E

325

51.3 x 27.7 x 24.9

A-46

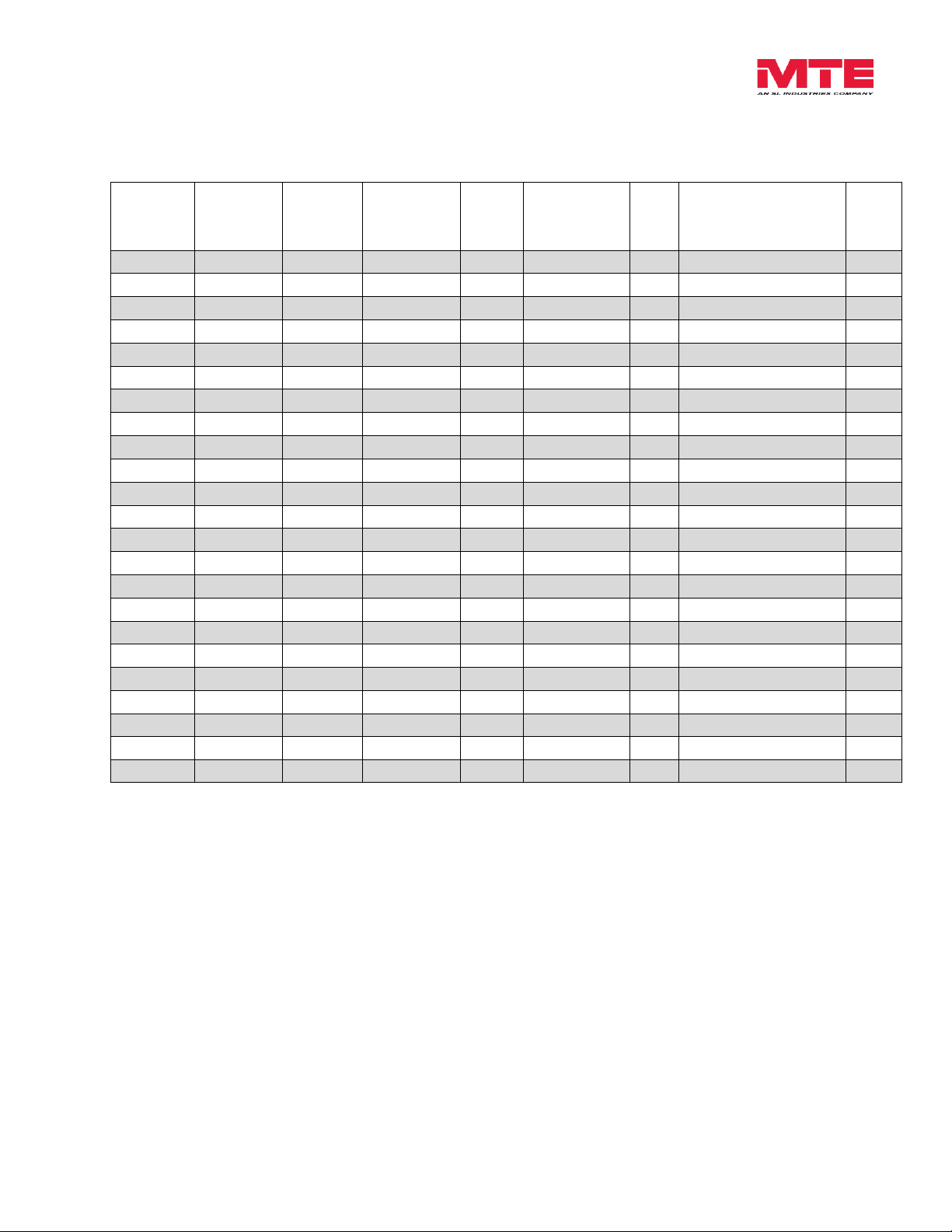

Part Number Selection Tables

Table 3-2: Enclosed NEMA 1/2 Selection Table

Form: DVS-TRM-E September 2014 REV. 001 10

Page 12

dV Sentry Technical Reference Manual 380V – 600V

380V

Motor

KW

380V

Motor

HP

480V

Motor

HP

550V- 600V

Motor

HP

Filter

Amp

Rating

Part

Number

App.

Wt.

(lbs.)

NEMA 3R Enclosure

(in.)

(H x W x D)

Ref.

Fig.

0.5 – 1.1

0.5 – 1.5

0.5 – 1.5

0.5 - 2

3

DVSW0003E

24

15.5 x 10.9 x 12.0

A-47

1.5 2 2 3 4

DVSW0004E

24

15.5 x 10.9 x 12.0

A-48

2.2 - 3 3 3 5 5

DVSW0007E

24

15.5 x 10.9 x 12.0

A-49 4 5.5 5 7.5

9

DVSW0009E

24

15.5 x 10.9 x 12.0

A-50

5.5

7.5

7.5

10

12

DVSW0012E

24

15.5 x 10.9 x 12.0

A-51

7.5

10

10

15

17

DVSW0017E

25

15.5 x 10.9 x 12.0

A-52

11

15

15

20

22

DVSW0022E

28

15.5 x 10.9 x 12.0

A-53

- - 20

25

27

DVSW0027E

28

15.5 x 10.9 x 12.0

A-54

15

20

25

30

35

DVSW0035E

30

15.5 x 10.9 x 12.0

A-55

18.5 - 22

25 – 30

30

40

45

DVSW0045E

30

15.5 x 10.9 x 12.0

A-56

- - 40

50

45

DVSW0055E

75

24.0 x 12.5 x 22.9

A-57

30

40

50

60

65

DVSW0065E

84

24.0 x 12.5 x 22.9

A-58

37

50

60

75

80

DVSW0080E

84

24.0 x 12.5 x 22.9

A-59

45 - 55

60 – 75

75

100

110

DVSW0110E

85

24.0 x 12.5 x 22.9

A-60 - -

100

125

130

DVSW0130E

133

33.9 x 18.3 x 26.0

A-61

75 - 90

100 – 120

125

150

160

DVSW0160E

151

33.9 x 18.3 x 26.0

A-62

110

150

150

200

200

DVSW0200E

151

33.9 x 18.3 x 26.0

A-63

132

175

200

250

250

DVSW0250E

167

33.9 x 18.3 x 26.0

A-64

160

220

250

300

305

DVSW0305E

172

33.9 x 18.3 x 26.0

A-65

185 - 200

250 – 270

300

350

365

DVSW0365E

202

33.9 x 18.3 x 26.0

A-66

- - 350

450

415

DVSW0415E

202

33.9 x 18.3 x 26.0

A-67

250

340

400 – 450

500 - 550

515

DVSW0515E

330

51.3 x 27.7 x 30.0

A-68

315

430

500

600

600

DVSW0600E

338

51.3 x 27.7 x 30.0

A-69

Part Number Selection Tables

Table 3-3: Enclosed NEMA 3R Selection Table

Form: DVS-TRM-E September 2014 REV. 001 11

Page 13

dV Sentry Technical Reference Manual 380V – 600V

Service Load Condition

Invertor Duty Three Phase Motors

Voltage

380 – 600 VAC +/- 10%, 60Hz

Input Voltage Wave Form

PWM

Inverter Switching Frequency

2kHz – 10kHz (3-110A models)

2kHz – 5kHz (130A-600A models)

Inverter Operating Frequency

0 – 90 Hz without derating

Maximum Ambient

Temperature

60C Open filters

50C Enclosed Filter

Insertion Loss (Voltage)

1.7% at 60 Hz, 2.6% at 90 Hz

Efficiency

>98%

Current range

3A – 600A

Available form factors

Panel

NEMA 1/2

NEMA 3R

Altitude without derating

1,000 feet above sea level

Maximum Motor Lead Length

1,000 feet

Relative Humidity

0% to 99% non-condensing

Current Rating

100% RMS Continuous

150% for 1 minute

200% for 10 sec

*Operating in overload will result in increased proportional voltage drop

Audible Noise

<65db at 1 meter

Rise Time

Less than 0.1 uS

Peak Voltage

150% of DC bus voltage up to 1,000 feet

Common Mode Reduction

50%+ Peak Current Reduction Typical

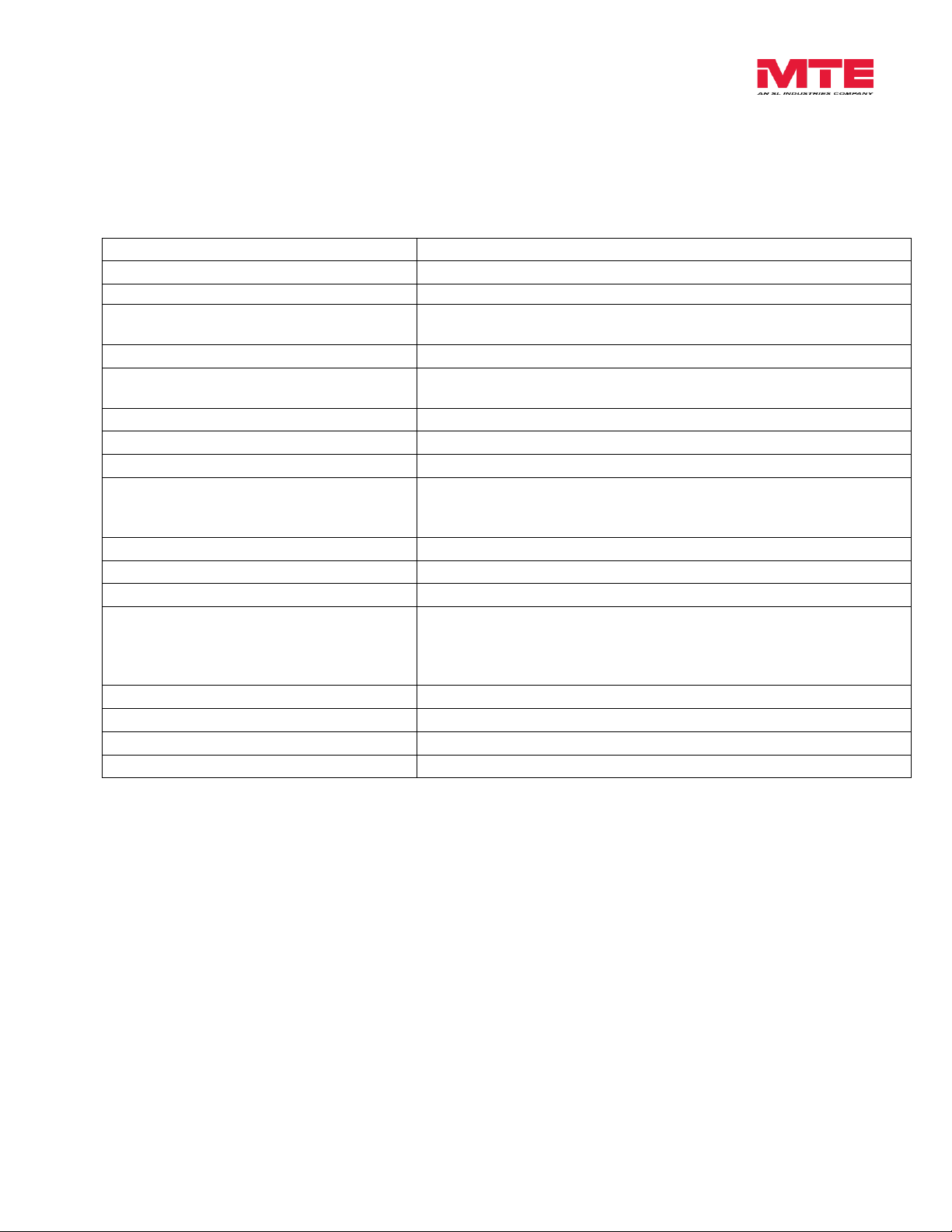

4. PRODUCT SPECIFICATIONS

Performance Specifications

Table 4-1: Performance Specifications

Form: DVS-TRM-E September 2014 REV. 001 12

Page 14

dV Sentry Technical Reference Manual 380V – 600V

Enclosures

MTE enclosures are designed to provide a degree of protection for electrical components and

prevent incidental personnel contact with the enclosed equipment. Depending on the enclosure

selected, these enclosures meet the requirements of NEMA 1/2 or 3R.

An approximate cross reference guide between NEMA, UL, CSA and IEC enclosure follows.

Type 1 NEMA / IEC IP20 Enclosure:

Are designed for indoor use and will provide protection against contact with the

enclosed equipment.

Type 2 NEMA / IEC IP20 Enclosure:

Are designed for indoor use and will provide protection against contact with the

enclosed equipment and provide a degree of protection against limited amounts of

falling water and dirt.

Type 3R NEMA / IEC IP23 Enclosure:

Are designed for outdoor use primarily to provide protection against contact with the

enclosed equipment and provide a degree of protection against falling rain sleet and

external ice formation.

Agency Approvals

UL and cUL listed to UL508 Type MX and CSA-C22.2 No 14-95

File E180243

CE Marked

Warranty

Three years from the date of shipment. See www.mtecorp.com for details.

Over Temperature Interlock

The standard over temperature interlock should be used to turn off the inverter in the event it is

setup to operate with a switching frequency outside of the range of the filter or an inverter

malfunction. The interlock is a normally closed contact.

Form: DVS-TRM-E September 2014 REV. 001 13

Page 15

dV Sentry Technical Reference Manual 380V – 600V

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 200 400 600 800 1000 1200

Peak Voltage at Motor (Kvolts)

Cable Length (ft.)

65 Amp DV Sentry Overall Performance - 50hp 480 Vac Motor

Unfiltered

With DVSentry

1.5 x Bus

Drive Bus

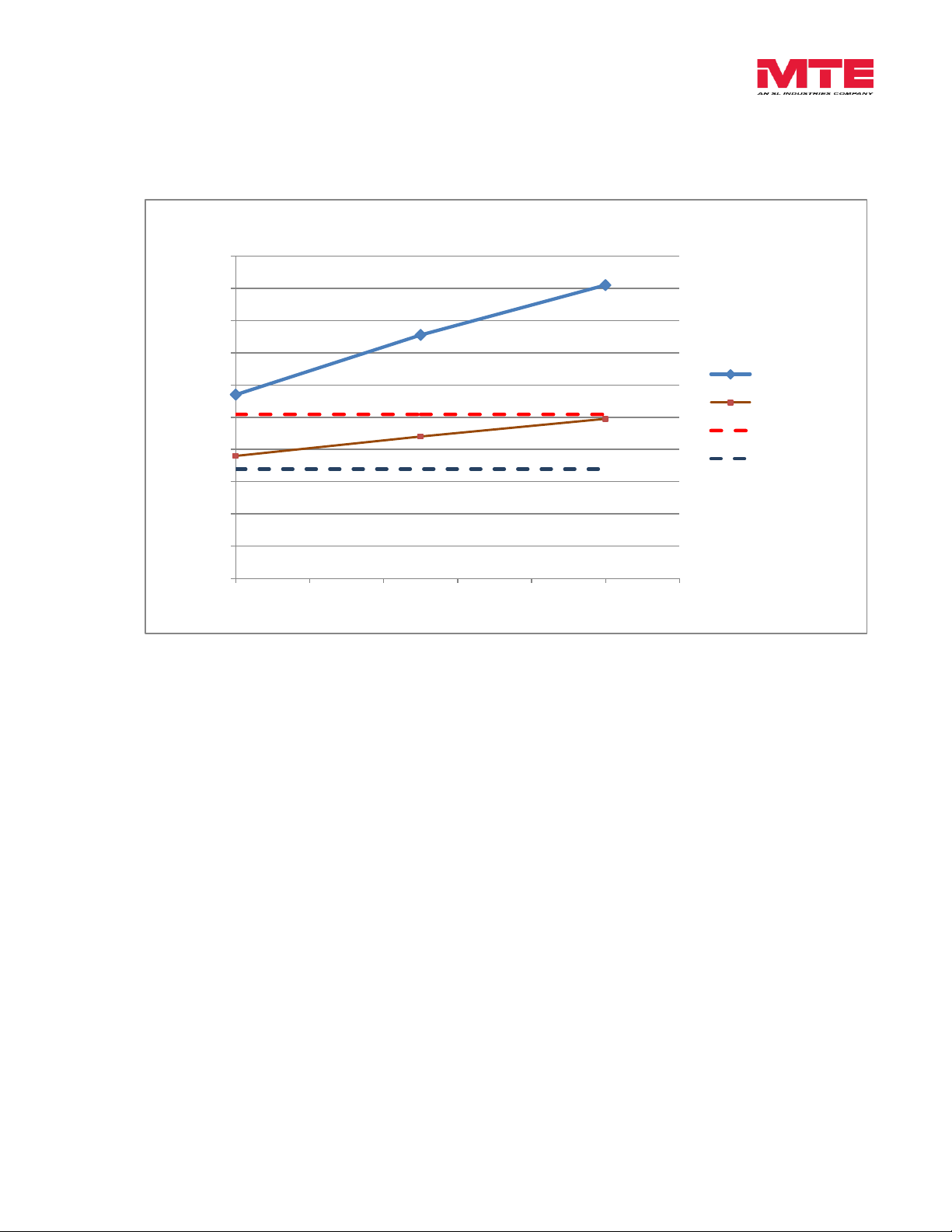

5. dV/dt Filter Performance

Table 5-1: Performance Chart

Form: DVS-TRM-E September 2014 REV. 001 14

Page 16

dV Sentry Technical Reference Manual 380V - 600V

Maximum Output Amps

RMS/Filter Current

Rating Amps RMS

Efficiency

%

Typical Power

Dissipation

Watts*

3

97.5%

227

5

97.5%

227

7

97.5%

227

9

97.5%

227

12

97.5%

227

17

98.0%

334

22

98.4%

278

27

98.5%

267

35

98.8%

260

45

99.1%

219

55

99.3%

297

65

99.4%

376

80

99.5%

336

110

99.6%

363

130

99.6%

393

160

99.7%

412

200

99.7%

449

250

99.8%

550

305

99.8%

616

365

99.8%

703

415

99.8%

703

515

99.8%

1027

600

99.8%

1062

Filter Efficiency + Watt loss

Table 5-2: Filter Efficiency & Watt Loss

*Based on a typical 480V, 60Hz output frequency, 1,000 feet of drive cable, 2kHz carrier

frequency at full load application.

Form: DVS-TRM-E September 2014 REV. 001 15

Page 17

dV Sentry Technical Reference Manual 380V - 600V

0.65

0.7

0.75

0.8

0.85

0.9

0.95

1

1.05

80 90 100 110 120 130

Current Derating Factor

Output Drive Frequency Hertz

DV Sentry Filter Current Derating For Drive Output Frequency

Altitude Derating

Table 5-3: Altitude Derating Curve

Motor Frequency Derating

Form: DVS-TRM-E September 2014 REV. 001 16

Table 5-4: Current Derating for Drive Output Frequency

Page 18

dV Sentry Technical Reference Manual 380V - 600V

WARNING

Prior to installation, please refer to all general warnings on page 4.

Failure to practice this can result in body injury!

WARNING

Input and output wiring to the filter should be performed by authorized

personnel in accordance with NEC and all local electrical codes and

regulations.

WARNING

The filter is designed for use with copper conductors with a minimum

temperature rating of 75 degrees C.

6. HOW TO INSTALL

Installation Checklist

dV/dt filters are supplied in the following mechanical configurations:

Panel mounted assemblies

Floor mounted general purpose NEMA 1/2 & 3R cabinets

Panel filters are designed for mounting in the customer’s enclosure. Include the power

dissipation of the filter along with all the other components located in the panel to determine the

internal temperature rise and cooling requirements of the enclosure. A general guideline is to

allow a side clearance of four (4) inches and a vertical clearance of six (6) inches for proper

heat dissipation and access within the enclosure. Clearances may be less if proper ventilation

exists. Filter components must operate within temperatures specified in this manual or filter

operating life will be compromised. Also be aware of minimum electrical clearances as defined

by the appropriate system safety standard(s). Open panel dV Sentry Filters generate heat and

should be positioned away from heat sensitive components. Ensure that proper panel

orientation is maintained. Keep the capacitors away from reactor heat flow. Avoid locations

where the filter would be subjected to excessive vibrations. Locate the filter as close to the

inverter as possible.

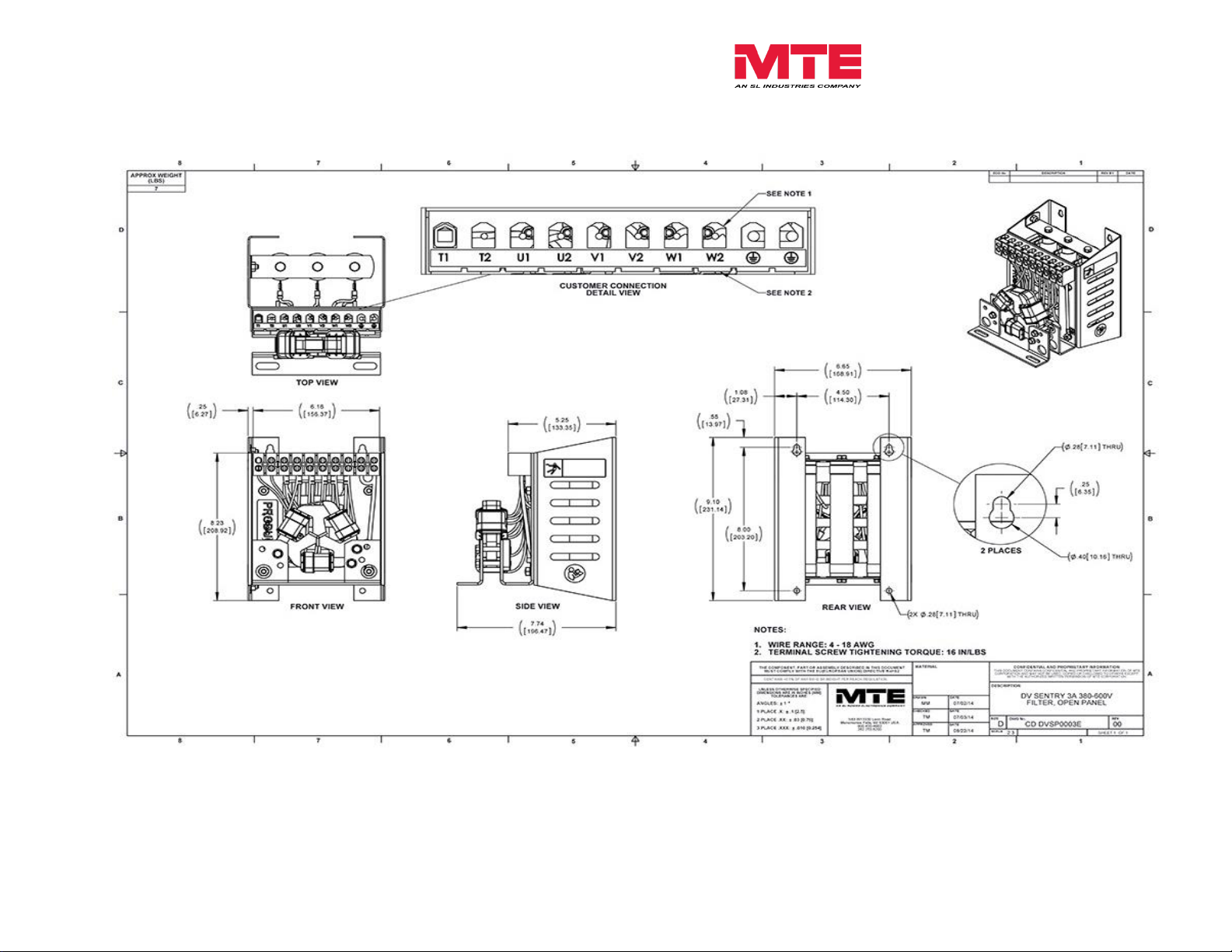

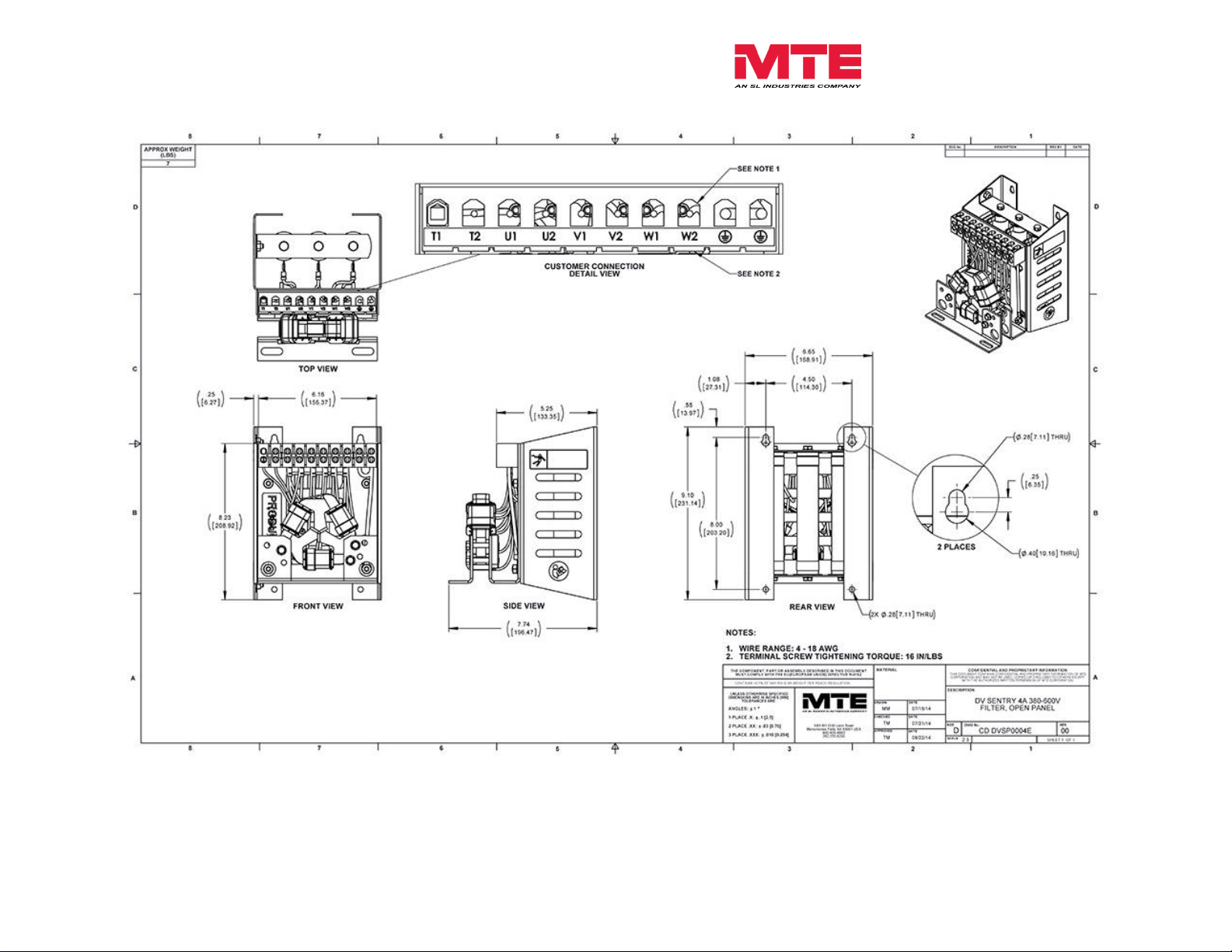

Figure 6-2 contain panel outline drawings for the various current ratings and show proper panel

alignment. For filters above 130 amps refer to Figure 6-3 for the dimensions of the separately

mounted filter. Connect the motor and inverter leads to the reactor terminals to complete the

filter wiring.

General purpose NEMA 1/2 and 3R enclosed filters are designed for floor mounting in an

environment suitable for the enclosure type. Do not install in or near a corrosive environment.

Avoid locations where the filter would be subjected to excessive vibrations. Allow a minimum

side and back clearance of eight (8) inches and front clearance of thirty-six (32 inches for proper

heat dissipation and access.

Form: DVS-TRM-E September 2014 REV. 001 17

Page 19

dV Sentry Technical Reference Manual 380V - 600V

WARNING

The filter must always be grounded with a grounding conductor

connected to ground terminals.

WARNING

For modular units, ensure a 2” X 2” area is cleaned of paint

and varnish on lower mounting bracket for ground connection.

Grounding

*The filter must always be grounded with a grounding conductor connected to ground terminals.

Form: DVS-TRM-E September 2014 REV. 001 18

Page 20

dV Sentry Technical Reference Manual 380V - 600V

Basic Schematic Diagram

Figure 6-1: Basic Schematic Diagram

Form: DVS-TRM-E September 2014 REV. 001 19

Page 21

dV Sentry Technical Reference Manual 380V - 600V

Interconnection Diagram – Panel (3A-110A) and Enclosed (3A-600A)

Figure 6-2: Open Panel and Enclosed Diagram

Form: DVS-TRM-E September 2014 REV. 001 20

Page 22

dV Sentry Technical Reference Manual 380V - 600V

Interconnection Diagram – Modular (130A-600A)

Figure 6-3: Modular Diagram

Form: DVS-TRM-E September 2014 REV. 001 21

Page 23

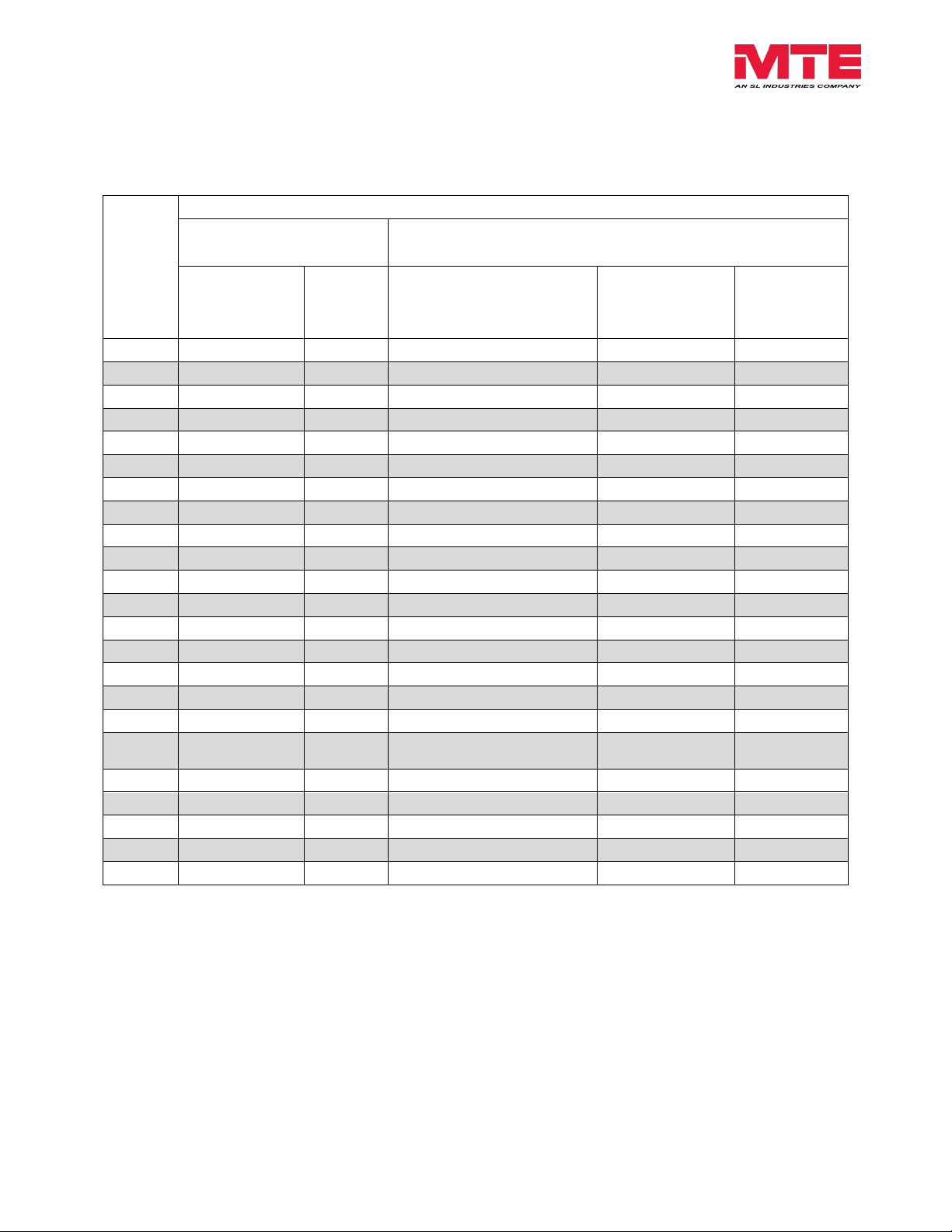

dV Sentry Technical Reference Manual 380V - 600V

Filter

Rating

(Amps)

DV SENTRY Terminals

Input /Output Power

U1-V1-W1 / U2-V2-W2

Resistor Panel Terminals

U1-V1-W1 / U2-V2-W2

Recommended

Minimum

Wire Size

(AWG)

Terminal

Torque

(in-lbs.)

Resistor Panel Part

Number

Recommended

Wire Size (awg)

Terminal

Torque

(in-lbs.)

3

14

16

N/A

N/A

N/A

5

14

16

N/A

N/A

N/A

7

14

16

N/A

N/A

N/A

9

14

16

N/A

N/A

N/A

12

14

16

N/A

N/A

N/A

17

12

16

N/A

N/A

N/A

22

10

16

N/A

N/A

N/A

27

10

16

N/A

N/A

N/A

35

8

16

N/A

N/A

N/A

45

8

16

N/A

N/A

N/A

55

6

16

N/A

N/A

N/A

65

6

N/A

N/A

N/A

N/A

80

4

N/A

N/A

N/A

N/A

110

2

N/A

N/A

N/A

N/A

130

1

N/A

RESPANEL-012

14

16

160

4(2x) or 2/0

N/A

RESPANEL-012

14

16

200

3(2x) or 3/0

N/A

RESPANEL-012

14

16

250

1 (2x) or

250kcmil

N/A

RESPANEL-013

14

16

305

2/0 (2x)

N/A

RESPANEL-013

14

16

365

3/0 (2x)

N/A

RESPANEL-013

14

16

415

4/0 (2x)

N/A

RESPANEL-013

14

16

515

300kcmil (2x)

N/A

RESPANEL-014

14

16

600

350kcmil(2x)

N/A

RESPANEL-014

14

16

Torque Ratings

Table 6-1: Torque Ratings

Note: To prevent flexing or bending of the coil windings attached to dV Sentry filter, use

appropriate strain relief to prevent stress on terminals. For flat copper terminal tabs, use two

wrenches to tighten customer provided cable mounting hardware.

Note: Refer to reference drawings for termination wire ranges.

Form: DVS-TRM-E September 2014 REV. 001 22

Page 24

dV Sentry Technical Reference Manual 380V - 600V

WARNING

Internal components of the filter are at line potential when the filter is connected

to the drive. This voltage is extremely dangerous and may cause death or severe

injury if you come in contact with it.

WARNING

Use extreme caution to avoid contact with line voltage when checking for power.

INJURY OR DEATH MAY RESULT IF SAFETY PRECAUTIONS ARE NOT

OBSERVED.

WARNING

Damage to equipment or serious injury may occur if the inverter startup

procedures are not observed.

Caution

Damage to the filter may occur if the appropriate output carrier frequency is not

observed.

7. START UP

Startup Checklist

Safety Precautions

Before startup, observe the following warnings and instructions:

Form: DVS-TRM-E September 2014 REV. 001 23

Page 25

dV Sentry Technical Reference Manual 380V - 600V

Sequence of Operation

1. Read and follow safety precautions, including those of drive manufactures.

2. After installation, ensure that:

All filter ground terminals are connected to ground.

Power wiring to the utility, inverter, filter and motor is in accordance with the

installation and connection instructions in Chapter 6.

3. Check that moisture has not condensed on the filter components. If moisture is present,

do not proceed with startup until the moisture has been removed.

4. Refer to the inverter user manual for the inverter startup procedure. Observe all safety

instructions in the inverter user manual.

5. Connect filter temperature safety overload switch into the control circuit so that the drive

will shut down in an overload situation.

6. Set the inverter switching frequency to the appropriate setting.

Form: DVS-TRM-E September 2014 REV. 001 24

Page 26

dV Sentry Technical Reference Manual 380V - 600V

WARNING

INJURY OR DEATH MAY RESULT IF THE DRIVE SAFETY PRECAUTIONS ARE

NOT OBSERVED.

WARNING

When properly installed, this equipment has been designed to provide maximum

safety for operating personnel.

However, hazardous voltages and elevated temperatures exist within the confines

of the enclosure. Servicing should therefore be performed by qualified

personnel only and in accordance with OSHA Regulations.

WARNING

High voltage is used in the operation of this filter. Use Extreme caution to avoid

contact with high voltage when operating, installing or repairing this filter.

INJURY OR DEATH MAY RESULT IF SAFETY PRECAUTIONS ARE NOT

OBSERVED.

PROBLEM:

Voltage is not present at the filter Input terminals.

Possible cause:

Solution:

Power to the inverter is turned off or shut down

Turn power on, check inverter errors

Possible cause:

Solution:

One or more external line fuses are blown.

Verify the continuity of line fuses in all phases, replace as necessary

Possible cause:

Solution:

Damage to inverter – dV/dt interconnect cables

Replace damaged cable

Possible cause:

Solution:

Inverter setup parameters are incorrect

Verify motor current, voltage and shutdown parameters are valid

8. TROUBLESHOOTING

To aid in troubleshooting, two interconnection diagrams, Modular Unit Interconnection Diagram

(p20) and Enclosed Unit Interconnection Diagram (p21) are included, and this table below list

potential problems and solutions.

Table 8-1: Troubleshooting Guide

Form: DVS-TRM-E September 2014 REV. 001 25

Page 27

dV Sentry Technical Reference Manual 380V - 600V

PROBLEM:

dV/dt filter runs Hot

Possible cause:

Solution:

Normal operation, reactor and resistors are > 100 °C

Caution parts are very hot and may cause burns. Follow

installation guidelines for clearances and check for adequate air

flow.

Possible cause:

Solution:

Motor coil damage windings shorted

Replace motor inspect wiring

Possible cause:

Solution:

Heat buildup within enclosure

Provide clearance and venting for filter components.

Check carrier frequency and overload settings.

Possible cause:

Solution:

Multi motor applications create complex loading and resonances

with dV/dt filter.

Use only one dV/dt filter per drive for a single motor only

For multiple line applications, use a sine wave filter.

Form: DVS-TRM-E September 2014 REV. 001 26

Page 28

dV Sentry Technical Reference Manual 380V - 600V

APPENDIX

Reference Drawings

Form: DVS-TRM-E September 2014 REV. 001 27

Page 29

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 1: DVSP0003E

Form: DVS-TRM-E September 2014 REV. 001 28

Page 30

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 2: DVSP0004E

Form: DVS-TRM-E September 2014 REV. 001 29

Page 31

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 3: DVSP0007E

Form: DVS-TRM-E September 2014 REV. 001 30

Page 32

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 4: DVSP0009E

Form: DVS-TRM-E September 2014 REV. 001 31

Page 33

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 5: DVSP0012E

Form: DVS-TRM-E September 2014 REV. 001 32

Page 34

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 6: DVSP0017E

Form: DVS-TRM-E September 2014 REV. 001 33

Page 35

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 7: DVSP0022E

Form: DVS-TRM-E September 2014 REV. 001 34

Page 36

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 8: DVSP0027E

Form: DVS-TRM-E September 2014 REV. 001 35

Page 37

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 9: DVSP0035E

Form: DVS-TRM-E September 2014 REV. 001 36

Page 38

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 10: DVSP0045E

Form: DVS-TRM-E September 2014 REV. 001 37

Page 39

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 11: DVSP0055E

Form: DVS-TRM-E September 2014 REV. 001 38

Page 40

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 12: DVSP0065E

Form: DVS-TRM-E September 2014 REV. 001 39

Page 41

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 13: DVSP0080E

Form: DVS-TRM-E September 2014 REV. 001 40

Page 42

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 14: DVSP0110E

Form: DVS-TRM-E September 2014 REV. 001 41

Page 43

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 15: DVSP0130E

Form: DVS-TRM-E September 2014 REV. 001 42

Page 44

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 16: DVSP0160E

Form: DVS-TRM-E September 2014 REV. 001 43

Page 45

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 17: DVSP0200E

Form: DVS-TRM-E September 2014 REV. 001 44

Page 46

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 18: DVSP0250E

Form: DVS-TRM-E September 2014 REV. 001 45

Page 47

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 19: DVSP0305E

Form: DVS-TRM-E September 2014 REV. 001 46

Page 48

dV Sentry Technical Reference Manual 380V - 600V

Figure A-20 DVSP0365E

Form: DVS-TRM-E September 2014 REV. 001 47

Page 49

dV Sentry Technical Reference Manual 380V - 600V

Figure A- 21: DVSP0415E

Form: DVS-TRM-E September 2014 REV. 001 48

Page 50

dV Sentry Technical Reference Manual 380V - 600V

Figure A-22: DSVP0515E

Form: DVS-TRM-E September 2014 REV. 001 49

Page 51

dV Sentry Technical Reference Manual 380V - 600V

Figure A-23: DVSP0600E

Form: DVS-TRM-E September 2014 REV. 001 50

Page 52

dV Sentry Technical Reference Manual 380V - 600V

Form: DVS-TRM-E September 2014 REV. 001 51

Page 53

dV Sentry Technical Reference Manual 380V - 600V

Figure A-24: DVSG0003E

Form: DVS-TRM-E September 2014 REV. 001 52

Page 54

dV Sentry Technical Reference Manual 380V - 600V

Figure A-25: DVSG0004E

Form: DVS-TRM-E September 2014 REV. 001 53

Page 55

dV Sentry Technical Reference Manual 380V - 600V

Figure A-26: DVSG0007E

Form: DVS-TRM-E September 2014 REV. 001 54

Page 56

dV Sentry Technical Reference Manual 380V - 600V

Figure A-27: DVSG0009E

Form: DVS-TRM-E September 2014 REV. 001 55

Page 57

dV Sentry Technical Reference Manual 380V - 600V

Figure A-28: DVSP0012E

Form: DVS-TRM-E September 2014 REV. 001 56

Page 58

dV Sentry Technical Reference Manual 380V - 600V

Figure A-29: DVSG0017E

Form: DVS-TRM-E September 2014 REV. 001 57

Page 59

dV Sentry Technical Reference Manual 380V - 600V

Figure A-30: DVSG0022E

Form: DVS-TRM-E September 2014 REV. 001 58

Page 60

dV Sentry Technical Reference Manual 380V - 600V

Figure A-31: DVSG0027E

Form: DVS-TRM-E September 2014 REV. 001 59

Page 61

dV Sentry Technical Reference Manual 380V - 600V

Figure A-32: DVSG0035E

Form: DVS-TRM-E September 2014 REV. 001 60

Page 62

dV Sentry Technical Reference Manual 380V - 600V

Figure A-33: DVSG0045E

Form: DVS-TRM-E September 2014 REV. 001 61

Page 63

dV Sentry Technical Reference Manual 380V - 600V

Figure A-34: DVSG0055E

Form: DVS-TRM-E September 2014 REV. 001 62

Page 64

dV Sentry Technical Reference Manual 380V - 600V

Figure A-35: DVSG0065E

Form: DVS-TRM-E September 2014 REV. 001 63

Page 65

dV Sentry Technical Reference Manual 380V - 600V

Figure A-36: DVSG0080E

Form: DVS-TRM-E September 2014 REV. 001 64

Page 66

dV Sentry Technical Reference Manual 380V - 600V

Figure A-37: DVSG0110E

Form: DVS-TRM-E September 2014 REV. 001 65

Page 67

dV Sentry Technical Reference Manual 380V - 600V

Figure A-38: DVSG0130E

Form: DVS-TRM-E September 2014 REV. 001 66

Page 68

dV Sentry Technical Reference Manual 380V - 600V

Figure A-39: DVSG0160E

Form: DVS-TRM-E September 2014 REV. 001 67

Page 69

dV Sentry Technical Reference Manual 380V - 600V

Figure A-40: DVSG0200E

Form: DVS-TRM-E September 2014 REV. 001 68

Page 70

dV Sentry Technical Reference Manual 380V - 600V

Figure A-41: DVSG0250E

Form: DVS-TRM-E September 2014 REV. 001 69

Page 71

dV Sentry Technical Reference Manual 380V - 600V

Figure A-42: DVSG0305E

Form: DVS-TRM-E September 2014 REV. 001 70

Page 72

dV Sentry Technical Reference Manual 380V - 600V

Figure A-43: DVSG0365E

Form: DVS-TRM-E September 2014 REV. 001 71

Page 73

dV Sentry Technical Reference Manual 380V - 600V

Figure A-44: DVSG0415E

Form: DVS-TRM-E September 2014 REV. 001 72

Page 74

dV Sentry Technical Reference Manual 380V - 600V

Figure A-45: DVSG0515E

Form: DVS-TRM-E September 2014 REV. 001 73

Page 75

dV Sentry Technical Reference Manual 380V - 600V

Figure A-46: DVSG0600E

Form: DVS-TRM-E September 2014 REV. 001 74

Page 76

dV Sentry Technical Reference Manual 380V - 600V

Figure A-47: DVSW0003E

Form: DVS-TRM-E September 2014 REV. 001 75

Page 77

dV Sentry Technical Reference Manual 380V - 600V

Figure A-48: DVSW0004E

Form: DVS-TRM-E September 2014 REV. 001 76

Page 78

dV Sentry Technical Reference Manual 380V - 600V

Figure A-49: DVSW0007E

Form: DVS-TRM-E September 2014 REV. 001 77

Page 79

dV Sentry Technical Reference Manual 380V - 600V

Figure A-50: DVSW0009E

Form: DVS-TRM-E September 2014 REV. 001 78

Page 80

dV Sentry Technical Reference Manual 380V - 600V

Figure A-51: DVSW0012E

Form: DVS-TRM-E September 2014 REV. 001 79

Page 81

dV Sentry Technical Reference Manual 380V - 600V

Figure A-52: DVSW0017E

Form: DVS-TRM-E September 2014 REV. 001 80

Page 82

dV Sentry Technical Reference Manual 380V - 600V

Figure A-53: DVSW0022E

Form: DVS-TRM-E September 2014 REV. 001 81

Page 83

dV Sentry Technical Reference Manual 380V - 600V

Figure A-54: DVSW0027E

Form: DVS-TRM-E September 2014 REV. 001 82

Page 84

dV Sentry Technical Reference Manual 380V - 600V

Figure A-55: DVSW0035E

Form: DVS-TRM-E September 2014 REV. 001 83

Page 85

dV Sentry Technical Reference Manual 380V - 600V

Figure A-56: DVSW0045E

Form: DVS-TRM-E September 2014 REV. 001 84

Page 86

dV Sentry Technical Reference Manual 380V - 600V

Figure A-57: DVSW0055E

Form: DVS-TRM-E September 2014 REV. 001 85

Page 87

dV Sentry Technical Reference Manual 380V - 600V

Figure A-58: DVSW0065E

Form: DVS-TRM-E September 2014 REV. 001 86

Page 88

dV Sentry Technical Reference Manual 380V - 600V

Figure A-59: DVSW0080E

Form: DVS-TRM-E September 2014 REV. 001 87

Page 89

dV Sentry Technical Reference Manual 380V - 600V

Figure A-60: DVSW0110E

Form: DVS-TRM-E September 2014 REV. 001 88

Page 90

dV Sentry Technical Reference Manual 380V - 600V

Figure A-61: DVSW0130E

Form: DVS-TRM-E September 2014 REV. 001 89

Page 91

dV Sentry Technical Reference Manual 380V - 600V

Figure A-62: DVSW0160E

Form: DVS-TRM-E September 2014 REV. 001 90

Page 92

dV Sentry Technical Reference Manual 380V - 600V

Figure A-63: DVSW0200E

Form: DVS-TRM-E September 2014 REV. 001 91

Page 93

dV Sentry Technical Reference Manual 380V - 600V

Figure A-64: DVSW0250E

Form: DVS-TRM-E September 2014 REV. 001 92

Page 94

dV Sentry Technical Reference Manual 380V - 600V

Figure A-65: DVSW0305E

Form: DVS-TRM-E September 2014 REV. 001 93

Page 95

dV Sentry Technical Reference Manual 380V - 600V

Figure A-66: DVSW0365E

Form: DVS-TRM-E September 2014 REV. 001 94

Page 96

dV Sentry Technical Reference Manual 380V - 600V

Figure A-67: DVSW0415E

Form: DVS-TRM-E September 2014 REV. 001 95

Page 97

dV Sentry Technical Reference Manual 380V - 600V

Figure A-68: DVSW0515E

Form: DVS-TRM-E September 2014 REV. 001 96

Page 98

dV Sentry Technical Reference Manual 380V - 600V

Figure A-69: DVSW0600E

Form: DVS-TRM-E September 2014 REV. 001 97

Page 99

dV Sentry Technical Reference Manual 380V - 600V

Figure A-70: RESPANEL-012

Form: DVS-TRM-E September 2014 REV. 001 98

Page 100

dV Sentry Technical Reference Manual 380V - 600V

Figure A-71: RESPANEL-013

Form: DVS-TRM-E September 2014 REV. 001 99

Loading...

Loading...