Page 1

.50

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

IMPORTANT;

Read Safety Rules

and Instructions

PRINTED IN U.S.A.

MODEL NUMBERS

190-469A

TMO-33849A

36”

SNOW THROWER

ATTACHMENT

FORM No. 770-0106

(Rev. 8/79)

Page 2

LIMITED WARRANTY

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm,

any part or parts found to be defective in material or workmanship. Transportation charges

under this warranty must be paid by the purchaser unless return is requested by

MTD PRODUCTS INC.

This warranty will not apply to any part which has become inoperative due to misuse,

excessive use, accident, neglect, improper maintenance, alterations, or unless the unit

has been operated and maintained in accordance with the instructions furnished. This

warranty does not apply to the engine, motor, battery, battery charger or component parts

thereof. Please refer to the applicable manufacturer’s warranty on these items.

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distributor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will not be accepted by the factory unless prior written

permission has been extended by MTD.

This warranty gives you specific legal rights. You may also have other rights which vary

from state to state.

Page 3

IMPORTANT

Safe Operation Practices for Snow Throwers

TRAINING

1. Read the owner's guide instruction manual careful

ly. Be thoroughly familiar with the controls and

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate equipment. Never

allow adults to operate equipment without proper

instruction.

3. Keep the area of operation clear of all persons, es

pecially small children and pets.

4. Exercise caution to avoid slipping or falling, es

pecially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment

is to be used and remove all door mats, sleds,

boards, wires and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting engine or motor.

3. Do not operate equipment without wearing ade

quate winter outer garments. Wear footwear which

will improve footing on slippery surfaces.

4. Handle fuel with care, it is highly flamamble.

(A) Use approved fuel container.

(B) Never add fuel to a running engine or hot en

gine.

(C) Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

(D) Replace gasoline cap securely and wipe up

spilled fuel.

(E) Open doors if engine is run in the garage—ex

haust fumes are dangerous.

5. Adjust coilector housing height to clear gravel or

crushed rock surface.

6. Never attempt to make any adjustments while en

gine or motor is running (except where specifically

recommended by manufacturer).

7. Never operate the snow thrower without good vis

ibility or light.

8. Let engine and machine adjust to outdoor tempera

tures before starting to clear snow.

OPERATION

1. Do not put hands or feet near rotating parts. Keep

clear of discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing a gravel drive, walks, or roads. Stay alert

for hidden hazards and traffic. Do not carry pas

sengers.

3. After striking a foreign object, stop the engine

(motor), remove wire from spark plug, thorough

ly inspect the snow thrower for any damage, and

repair the damage before restarting and operat

ing the snow thrower.

4. If the unit should start to vibrate abnormally, stop

the engine (motor) and check immediately for the

cause. Vibration is generally a warning of trouble.

5. Stop engine (motor) whenever you leave the oper

ating position, before unclogging the collector/

impeller housing or discharge guide, and making

any repairs, adjustments, or inspections.

6. Take ail possible precaution when leaving the ve

hicle unattended, disengage the power take-off,

lower the attachment, shift into neutral, set the

parking brake, stop the engine, remove the key.

/. When cleaning, repairing, or inspecting make cer

tain collector/impeller, and all moving parts have

stopped. Disconnect spark plug wire and keep

wire away from plug to prevent accidental start

ing. Disconnect cord on electric motors.

8. Do not run engine indoors, exhaust fumes are

dangerous.

9. Do not clear snow across the face of slopes. Ex

ercise extreme caution when changing direction

on slopes. Do not attempt to clear steep slopes.

10. Never operate snow thrower without guards,

plates, or other safety protective devices in place.

n. Never operate snow thrower near glass enclosure,

automobiles, window wells, drop-offs, etc., with

out proper adjustment of snow discharge angle.

Keep children and pets away.

12. Do not overload machine capacity by attempting

to clear snow at too fast a rate.

13. Never operate machine at high transport speeds

on slippery surfaces. Use care when backing.

14. Never direct discharge at bystanders or allow any

one in front of unit.

15. Disengage power to collector/impeller when

transporting or not in use.

16. Only use attachments and accessories approved by

manufacturer of snow thrower (such as wheel

weights, counter weights, cabs, etc.).

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts, etc. at

frequent intervals for proper tightness to be sure

equipment is in safe working condition.

2. Never store machine with fuel in the fuel tank in

side a building where open flame or spark are pres

ent. Allow engine to cool before storing in any

enclosure.

3. Always refer to owner's guide instructions for im

portant details if snow thrower is to be stored for

an extended period.

4. Ron machine a few minutes after throwing snow

to prevent freeze up of collector/impeller.

Page 4

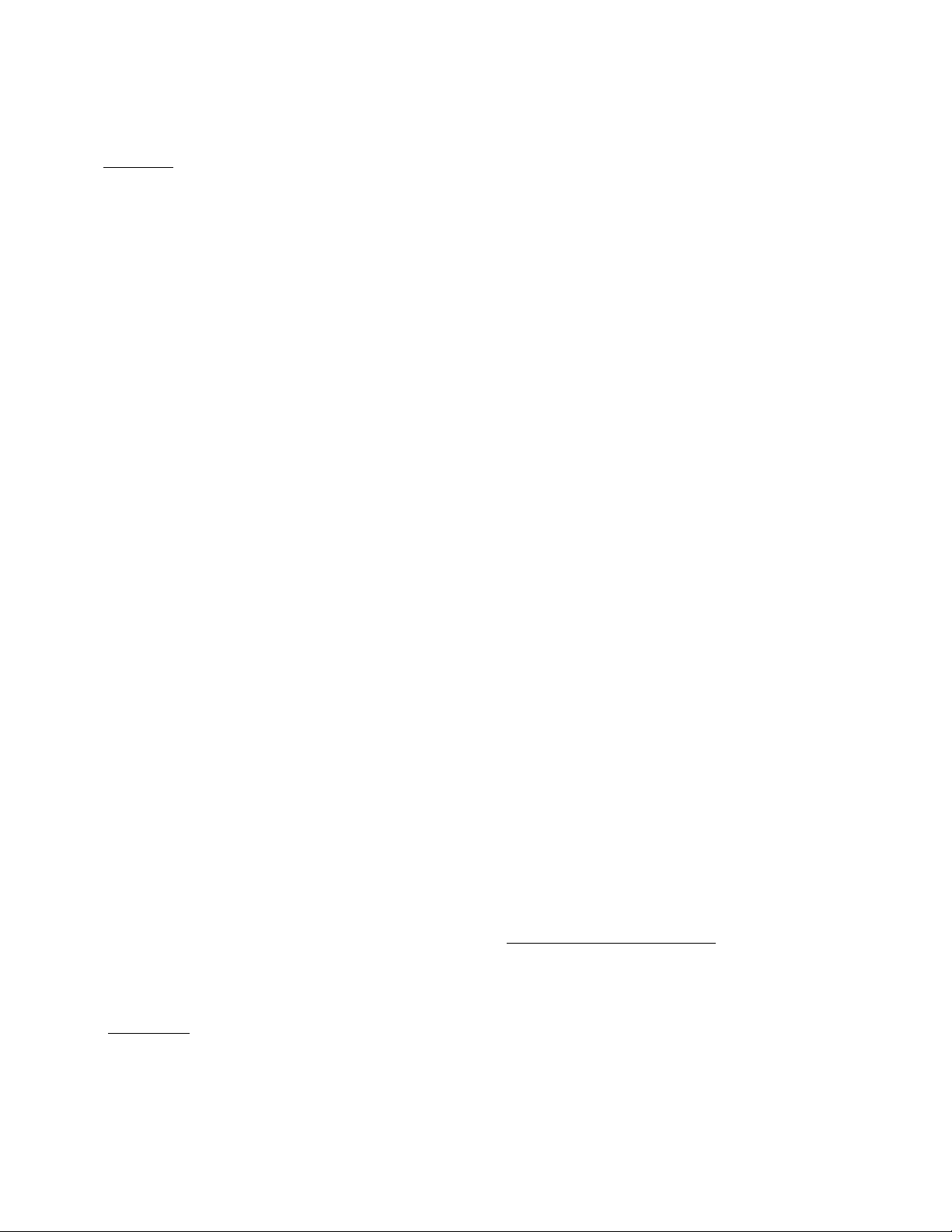

LIST OF CONTENTS IN HARDWARE PACK

SEE FIGURE 1

+

G

FIGURE 1

A (1)

B (2)

C (2)

D (2)

E

— F

0

1

J

\

/

N

I

/

R*"

t

p

wm

S—

T

Q-'

G

H (4)

I

J

K (2)

L (2)

M (2)

N (2)

0 (2)

P (2)

Q (8)

R-(2)

S (4)

T (4)

U (4)

V (2)

W (2)

X (6)

Y (3)

Z (2)

AA (1)

"V"-Belt 1/2" X 85" long

Clevis Pins

Flat Washers

Hair Pin Cotters

Hair Pin Cotters

(7)

Hex Top Lock Nut 5/16-18 Thread

(2)

Flat Washers

(2)

Carriage Bolts 5/16-18 x 5/8" long

Lock Washers 5/16" I.D.

(8)

Hex Nuts 5/16-18 Thread

(4)

Flat Washers

Hex Bolts 5/16-18 x 1.00" long

Hex Bolts 5/16-18 x .75" long

Hex Bolts 5/16-18 x 1.25" long

Hex Bolts 3/8-16 X 1.00" long

Lock Washers 3/8" I.D.

Hex Nuts 5/16-18 Thread

External Lock Washers 5/16" I.D.

Lock Washers 1/2" I.D.

Hex Nuts 1/2-13 Thread

Hex Bolts 1/2-13 X 1.25" long

Hex Bolts 5/16-18 x 2.00" long

Flat Washers

Hex Center Lock Nuts 1/4-20 Thread

Chute Flange Keeper Ass'yHelper Springs

Lift Handle Shaft

FIGURE 2

FIGURE 3

LIST OF LOOSE PARTS IN CARTON

SEE FIGURES 2 and 3.

AB (1)

AC (1)

AD (1)

AE

AF

AG (2)

AH (2)

Preassembled Chute Crank & Support

Channel Supporting Bracket - L.H.

Channel Supporting Bracket - R.H.

Linkage Arm Assembly - L.H.

(1)

Linkage Arm Assembly - R.H.

(1)

Linkage Brackets

Drift Cutters

_AI (1} Preassembled Chute Assembly

AJ (1) Preassembled Idler Assembly

TOOLS REQUIRED

1. Adjustable Wrench

2. A strong piece of wire

3. A screwdriver

4. A pair of pliers

5. A 7/16" Open End Wrench

6. A 1/2" Open End Wrench

7. A 9/16" Open End Wrench

8. A 3/4" Open End Wrench

Page 5

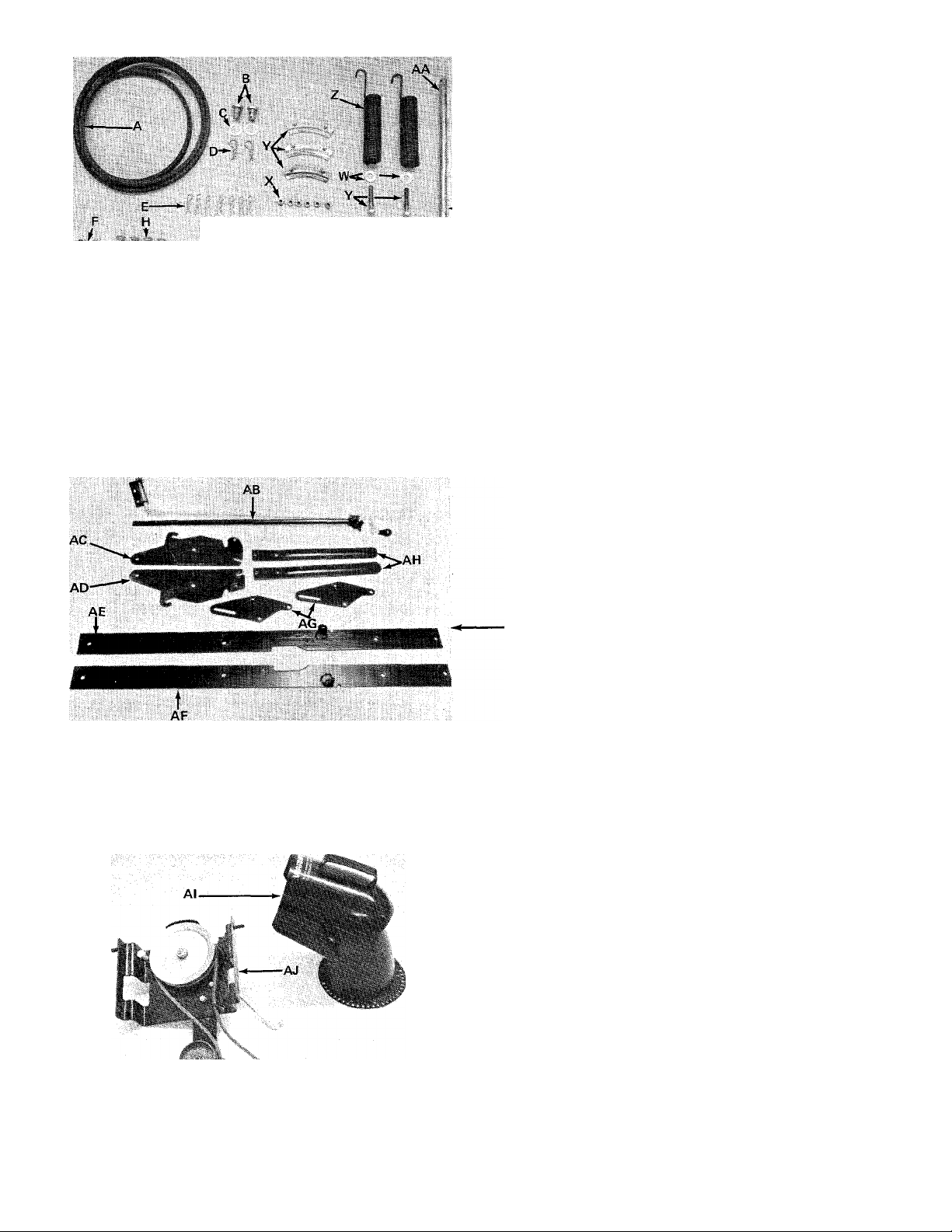

FIGURE 4

HEX BOLT (U)

LOCKWASHER (S)

ASSEMBLY INSTRUCTIONS

1. Remove the snow thrower, all loose parts and

hardware package from the carton.

2. Tip the snow thrower forward, so that the augers

are face down.

■ 3. Assemble the linkage arms (Ref. AE & AF) to the

housing assembly as shown in figure 4. Be sure

the linkage arms have the large notch up. Secure

with four hex bolts (U) 1/2-13 x 1.25" Lg., four

hex nuts (T) and lockwashers (S) provided.

HELPER bPRING (Z)

FIGURES

4. Place helper spring (Z) in position on linkage arm

assemblies. Secure with flat washers (W) and hex

bolts (V) provided in hardware pack. See figure

5. Thread bolt approximately one inch into the

spring insert. Adjustment is made in step number

26.

Tip the snow thrower back in normal position so

that is rests on linkage arms.

Assemble the drift cutters (AH) to the snow

thrower housing with four carriage bolts (H),

lockwashers (I) and hex nuts (J). See figure 6.

Heads of carriage bolts assemble from the inside

of housing.

DRIFT

CUTTER

CARRIAGE BOLT

(H)

LOCK WASHER (I)

HEX NUT (J)

FIGURES

Page 6

FIGURE 7

CHUTE ASSEMBLY (Al)

NOTE

Before setting the chute assembly on

the spiral housing assembly, grease the

housing for ease of operation. See

figure 7.

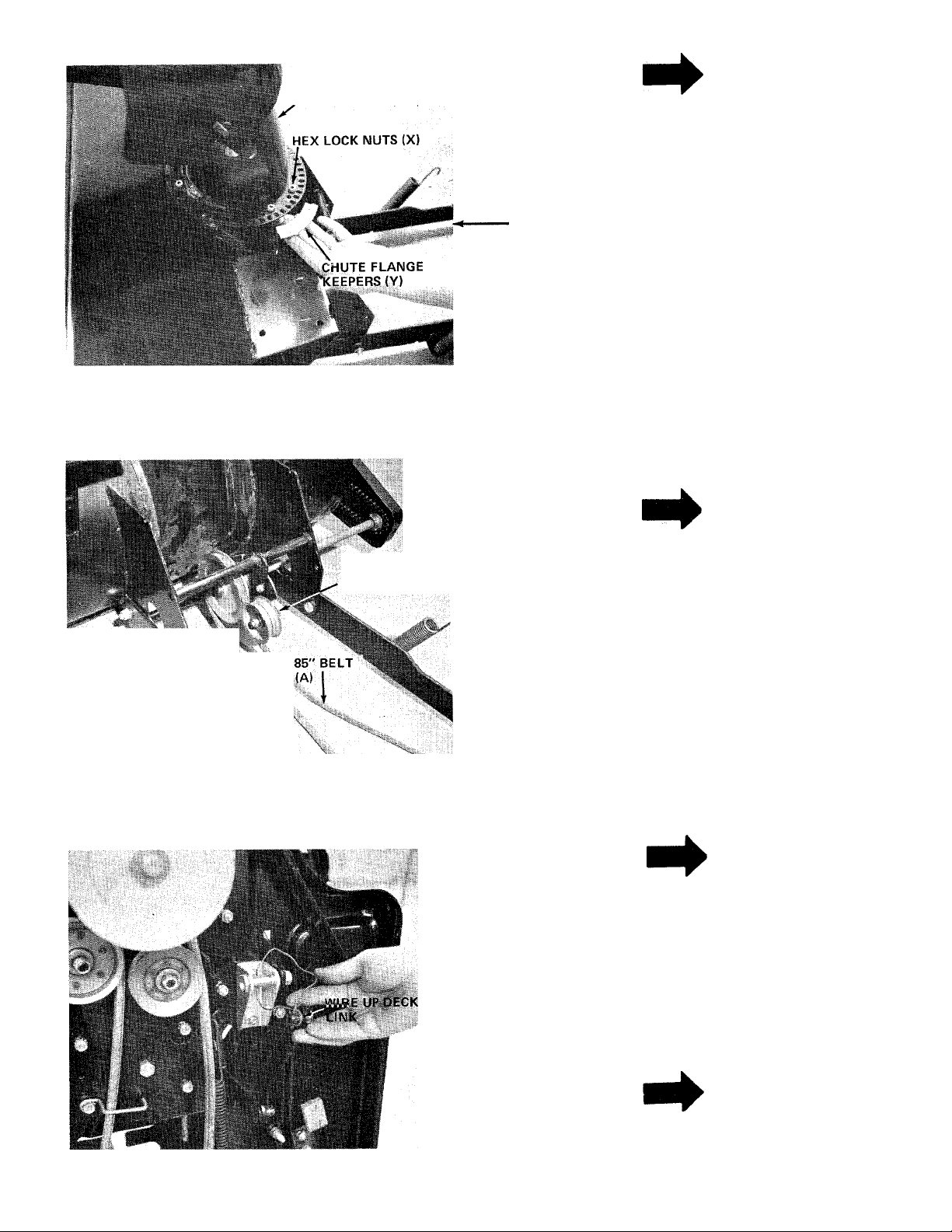

7. Assemble the chute assembly (Al) to the housing

using three chute flange keepers (Y) and six hex

lock nuts (X). See figure 7.

■8. Place the 85" belt (A) in position on the idler of

the snow thrower as shown in figure 8.

NOTE

FIGURES

IDLER PULLEY

The idler bracket has three holes for

belt tension adjustment. Normally, the

idler pulley is assembled in the center

hole. If the belt is too tight to

assemble, the idler pulley may be

moved to the top hole.

PREPARING THE LAWN

TRACTOR FOR ASSEMBLY

OF SNOW THROWER

1. Remove the gas cap and place a piece of plastic

film on the gas cap to prevent gas from leaking out

of the tank.

NOTE

If unit is electric start remove the

battery.

2. Remove the spark plug wire from spark plug and

grounrd.

3. Remove the mowing deck.

4. With a piece of wire hold the front left hand deck

hanger out of the way. See figure 9.

FIGURE 9

NOTE

This hanger bracket is straight.

Page 7

FIGURE 10

NOTE

After removing the deck, check the

deck links. The weld pins should be

outboard. If not, change them. It is

easier to change deck links by re

moving the transmission cover and

knob. After changing deck jinks,

reassemble the transmission cover and

knob.

Remove the second bolt on the running boards as

shown in figure 10. (Right and left hand sides).

Replace the bolts with hex bolts (N) 5/16-18 x

1.25" Lg. provided with snow thrower. Fasten

with 5/16-18" nut (Q) and lock washer (I).

Tighten with wrench.

FIGURE 11

7. Tip the lawn tractor up on its rear wheels so that

the unit rests on the back on the seat.

Remove the belt keeper and shoulder bolt at

engine pulley (if these were replaced when deck

was removed).

9. Assemble the channel supporting brackets right

and left hand to lawn tractor. See figures 12 and

13.

10. Hook thp'^!^ of channel supporting bracket right ^

hand''fAD) of oki^ pedal mounting

bracket. See figure 12.

11. Place flanged edge of channel support bracket

over hex bolt (N) (which you assembled in step 6).

Secure with lock washer (I) and hex nut (Q). See

figure 13.

FIGURE 12

Page 8

HEX BOLT

(N)

FIGURE 13

1 V

u>vin DIM COTTFR^i^

.12. Pre-assemble the linkage bracket (AG) to the

idler assembly (AJ), as shown in figure 14.

Secure with hair pin cotter (E). NOTE: Slot in

linkage bracket goes to the rear.

LINKAlU EiBACKl I -tO'

FIGURE 14

FLARVASHFI.:-;

CONTROL ROD

(K<^

HAIR PIN COTTERS (E)

IHp

■ 13. Assemble the other linkage bracket (AG) to the

other side of idler assembly (AJ). Secure with

hair pin cotter (E). Place flat washer (K) over

control rod. Next, place control rod up through

linkage bracket. Secure with another flat washer

(K) and hair pin cotter (E). See figure 15.

FIGURE 15

Page 9

FIGURE 16

BELT GUARD

IDLER PULLEY

14. Be sure belt on idler assembly is in position on

i

idler pulley between belt guard and weld pin as

shown in figure 16.

15. Place the idler assembly in position between

channel supporting brackets and start hex lock

nuts (F) and flat washers (G) over weld studs as

shown in figure 17.

FIGURE 17

16. Place lift handle links down through idler

assembly and secure to linkage brackets with

hair pin cotters (E). See figure 17.

17. Start hex bolts (O) and lock washers (P) through

center of channel support and idler assembly. See

figure 18.

18. Tighten nuts and bolts in steps 15 and 16

securely with wrenches.

FIGURE 18

Page 10

19. Slip the idler assembly belt over the engine pulley

as shown in figure 19.

NOTE

Be sure the belt runs between idler

pulley and guard as shown in figure 19.

20. Replace the engine pulley belt keeper and large

shoulder bolt. See figure 20.

FIGURE 20

21. Set the lawn tractor back down on all four wheels.

22. Roll the lawn tractor over the snow thrower and

attach the free end of the 85" belt to the pulley

on the idler assembly. Be sure to twist the belt so

that the top of belt coming off the idler goes

toward the left side of unit. See figure 8.

NOTE

If belt is installed incorrectly spirals

will run in reverse. Twist belt in other

direction to correct. Refer to step 22.

FIGURE 21

LINKAGE AFIM

23. Place the holes in the end of the linkage arms

in line with slot in the linkage brackets and

secure with lift handle shaft (AA) and hair pin

cotters (E). See figure 21. Lower the lift handle

on the lawn tractor to its lowest position.

NOTE

Linkage arms must be mounted on_the

outside of linkage brackets. Refer to

10

figure 21.

Page 11

FIGURE 22

24. With a piece of strong wire hook the end of

helper springs (Z) up into grille mount on lawn

tractor. See figure 22.

25. After springs are installed raise and lower the lift

handle on lawn tractor to be sure snow thrower

is properly hooked up.

26. Using a 1/2" wrench, tighten securely hex bolts

(V) which are threaded into the spring inserts.

Refer to step number 4.

27. Attach the pre-assembled chute crank and support

(AB) to the snow thrower housing. Secure the

support with two hex bolts (L), lock washers

(I) and hex nuts (Q). Secure the chute crank with

two hex bolts (M), lock washers (I) and hex nuts

(Q). See figure 23. Be sure teeth on chute crank

link up with holes in chute flange before

tightening bolts.

Remove the piece of plastic film from the gas cap.

Reinstall the battery and replace the spark plug

wire.

29. Check tire pressure. It may be necessary to put

more air into the front tires due to the weight of

the snow thrower.

FIGURE 23

11

Page 12

OPERATING INSTRUCTIONS

This snow thrower is capable of handling heavy

snow conditions. If given the opportunity to function

within reasonable requirements it should give many

years of service. Become fully familiar with all aspects

of both the lawn tractor and snow thrower prior to

its usage.

BEFORE PLACING SNOW THROWER INTO OPERATION

1. Check all nuts and bolts for correct tightness

and be sure that ail parts are properly assembled.

2. Test all controls for smooth operation.

A. Lift lever

B. Discharge chute control crank

C. Discharge chute and deflector

3. Starting and stopping snow thrower.

The snow thrower is driven by a V-belt driven from

the lawn tractor engine. It is operated through the

lift disengagement handle. Start lawn tractor engine

and run at full throttle. Slowly engage (push forward)

the lift handle.

To stop snow thrower operation, pull the lift handle

towards you and lock handle.

DISCHARGE CHUTE CONTROL CRANK

The discharge chute control crank is located on left

hand side of lawn tractor. Turn crank to the right to

direct snow to the right hand side. Turn it to the left

to direct snow to left hand side.

TO RAISE AND LOWER SNOW THROWER

Lift lever to raise and lower snow thrower is located

on the right hand side of lawn tractor. To raise snow

thrower pull back on lift lever until it reaches over

center stop. To lower snow thrower, push lift lever

forward slowly until snow thrower reaches gcound

level.

When snow thrower and lawn tractor

are not in use, lower snow thrower to

ground lever. This will prevent excess

weight on the front tires.

OPERATING ADJUSTMENTS

A

When making skid shoe or chute

- deflector adjustment, turn rider enengine off.

Upper Chute Deflector: The upper chute deflector

mounted on the top of the chute determines the

distance snow is thrown. Moving top of deflector

down decreases distance of throw and raising deflector

increases distance of throw. Operator must get off

lawn tractor to make this adjustment. Disengage

spirals (by raising snow thrower) before making this

adjustment.

SKID SHOE ADJUSTMENT (See Figure 24)

The skid shoes are mounted on each side of spiral

housing. These regulate the distance the shave plate

is raised above the plowing surface. When removing

snow from a gravel driveway or an uneven surface, it

is advisable to keep shave plate as high above the

surface as possible to prevent possible damage to

spiral.

CAUTION

PREPARATION

1. Check the lawn tractor and thrower to make

certain both are in good operating condition.

2. Fill gas tank out of doors and avoid spilling

gasoline over engine. Do not fill tank while

engine is running. Wipe up any spilled gas.

3. Do not remove any guards or covers while

operating lawn tractor and thrower.

Snow thrower chute has a discharge radius of 180

degrees. Adjust discharge by turning the chute crank.

SKID SHOE

12 FIGURE 24

Page 13

On blacktop or concrete surface, keep shave plate

as close to the surface as possible. Skid shoes can be

adjusted so that shave plate will rest directly on the

surface. Turning skid shoes around will allow even

wear on skid shoes.

Raise snow thrower off the ground and place a block

at each end of shave plate. Loosen 4 nuts securing

skid shoes to spiral housing (2 nuts on each side).

Move skid shoes up or down to desired position and

tighten nuts securely. Adjust both skid shoes to the

same height to keep spiral level. See figure 24.

OPERATION

The thrower controls are conveniently located at the

operator's position on the lawn tractor. By engaging

the lift handle to the spiral, snow is thrown through

chute by the motion of the spiral. Turning chute

crank directs snow discharge and deflector controls

distance snow is thrown.

A

If snow thrower becomes plugged with

snow, or jammed due to hitting a

foreign object, disengage snow thrower

immediately and stop lawn tractor

engine. Clear snow from chute if

plugged, before resuming operation.

CAUTION

OPERATING SPEED

The spiral speed is directly related to engine speed.

For maximum snow removal and discharge, maintain

high engine R.P.M. (full throttle). The lawn tractor's

forward speed is controlled by selecting one of the

forward speeds. It is advisable to operate the lawn

tractor at a slow ground speed (1st gear) for safe

and efficient snow removal.

DEEP OR DRIFTED SNOW

In deep, drifted, or banked snow, it will be nec

essary to use full throttle and first speed. Drive the

spiral into the snow, disengage clutch and allow spiral

to clear the snow. Repeat this method until a path is

cleared. On the second pass, overlap the first enough

to allow the spiral to handle the snow without repeated

clutching and declutching of the lawn tractor.

In extremely deep snow, raise thrower from the

ground, drive lawn tractor ahead in the deep snow to

remove top layers first. Do not drive lawn tractor into

snow bank where snow has not been removed to

ground level. Disengage lawn tractor clutch and allow

thrower to clear the snow. Reverse lawn tractor and

lower thrower to the ground. Drive lawn tractor

ahead and repeat process to remove balance of snow.

Working with repeated passes into and out of drifts

will eventually move even the deepest of snow piles.

NOTE

If spiral is jammed or bent from hit

ting a foreign object, stop lawn tractor

engine. Remove spark plug wire from

spark plug and then remove foreign

object from spiral. If spiral damage

is noted, repair prior to continuing

operation. Then replace spark plug

wire and resume operation.

SNOW CONDITIONS

Snow removal conditions vary greatly from light

fluffy snowfall to the wet heavy snow. Therefore,

operating instructions must be flexible to fit conditions

encountered. The operator must adapt the lawn

tractor and snow thrower to depth of snow, wind

direction, temperature, and surface conditions.

OPERATING TIPS

1. Whenever possible discharge snow down wind.

2. Do not attempt to remove ice or hard packed

frozen snow.

3. Always overlap each pass slightly to assure

conhplete snow removal.

4. A frozen or stuck spiral or chute must be broken

loose or thawed with care. When attempting to

loosen frozen or jammed spiral, shut off rider

engine and remove spark plug wire. Never attempt

to clear snow thrower at any time with lawn

tractor engine running.

USE OF TIRE CHAINS

Tire chains should always be used when extra

traction is needed. They add maneuverability in

13 handling snow removal jobs.

Page 14

LUBRICATION

1.

Spiral drive chain: Lubricate chain every 40

operating hours with No. 30 oil. It is important

that oil reaches inside each roller. Wipe off excess

oil from chain.

2.

Pivot and friction points: To maintain smooth

and free operation, apply a few drops of No. 30

oil as required to all pivot and friction points.

The spiral and idler pulley bearings are self-lubricating.

However, periodic lubrication with No. 30 oil will

lengthen service life.

SPIRAL DRIVE CHAIN ADJUSTMENT

Periodically check spiral drive belt to insure that it is

properly adjusted. It is important to maintain proper

belt adjustment to obtain maximum belt life.

If belt is stretched beyond idler take up, replace with

a new belt of the type specified in parts list.

Excessive slack in spiral drive chain due to normal

chain stretch can be removed by adjusting spiral

housing nuts.

TO ADJUST SPIRAL CHAIN:

1. Disengage snow thrower and loosen the mounting

nuts 2 or 3 complete turns.

2. Tighten the adjustment mounting nuts to tighten

chajn.

BELT TENSION ADJUSTMENT

The idler bracket has three holes for belt tension

adjustment. As the belt stretches from normal wear,

more belt tension may be required. Check the idler

spring for wear against the drive shaft at least once a

season. If the idler spring is rubbing against the drive

shaft, the belt has stretched and must be adjusted.

Remove the idler pulley from the bracket, and

reassemble in next lower hole on the bracket.

STORAGE

At the end of the snow season the following steps

are recommended:

1. Remove snow thrower assembly from lawn tractor

tractor.

2. Wash off any salt deposit which may have dried

on the thrower and housing. Paint or cover

exposed metal with a light coat of oil.

3. Lubricate thrower following lubricating in

structions for recommended lubricant. Thrower

drive chain must be oiled thoroughly to prevent

rust from forming. The preferred method is to

remove the chain and soak in oil for several hours

before reinstalling.

4. Store thrower in a dry place.

CAUTION

Do not over tighten chain. A correctly

adjusted chain will have a slight

amount of slack. An over tightened

chain will result in early failure of

chain.

3. Tighten mounting nuts to securechain adjustment.

Check chain clearance. It must clear chain guard

assembly. Test chain and repeat adjustment if

necessary until all excess slack is removed.

SHAVE PLATE AND SKID SHOES

Both the shave plate and skid shoes are subject to

wear and are designed to be easily replaced. Replace

before wear is excessive. Failure to do so will result

in damage to the spiral housing.

14

Page 15

NOTES

Page 16

190-469A

TM0-33849A

EXPLODED VIEW

16

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

Page 17

PARTS LIST FOR 190-469A and TMO-33849A 36" SNOW THROWER ATTACHMENT

REF.

NO.

PART

NO.

1 05023

715-0118

2

05375

3

4 712-0158

736-0105

5

736-0179

6

05225

7

710-0260

8

05140

9

712-0107

10

11 726-0111

05404

12

712-0267

14

736-0119

15

710-0260

16

736-0163

17

713-0177

18

713-0189

19

05379

20

715-0118

21

736-0119

22

712-0267

23

736-0105

24

712-0130

25

05244

26

712-0267

27

736-0119

28

741-0162

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

_

715-0118

713-0188

756-0192

750-0252

736-0235

736-0300

710-0427

738-0244

05401

720-0170

05403

05120

736-0117

720-0171

726-0100

46 05837

754-0236

47

713-0154

48

738-0140

49

05724

50

732-0383

51

COLOR

CODE

DESCRIPTION

Spiral Plate

Spring PinSpir. 5/16x1.75”

Lg.

Spiral Ass’y-

Hex Cent. L-Nut 5/16-18

Thd.*

Bell. Wash.

FI-Wash.

Top Chute Ass’yCar. Bolt5/16-18x.62” Lg.*

Chute Wing Ass’y.

Hex Cent. L-Nut V4-20 Thd.

Push Cap .188” Dia. Rod

Chute Ass’y.

NEW

PART

REF.

NO.

52 756-0217 FI. Idler with Flange

53

54

55 741-0174

56

57 736-0231 FI-Wash.

58 756-0215 5.50 O.D. X 5/8 Pulley

59 710-0198 Hex Sems Scr. 5/16-18 x .75”

60

61

62

63 736-0921 L-Wash. 1/2” Scr.*

64

65

PART

712^0130

NO.

COLOR

CODE

DESCRIPTION

Hex Ins. Jam Nut 3/8-16 Thd.

736-0119 L-Wash. 5/16” Scr.*

Self Aligning Brg.

710-0538 Hex Scr. 5/16-18 X.62” Lg.

716-0119 Snap Ring for .75 Dia. Shaft

710-0474

05432

Hex Scr. 1/2-13x1.25” Lg.*

Spiral Housing Ass’y.

712-0206 Hex Nut 1/2-13Thd.*

710-0260 Car. Bolt5/16-18X.62”Lg.*

66 712-0267 Hex Nut5/16-18Thd.*

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16” Scr.*

Car. Bolt 5/16-18 X.62” Lg.*

FI-Wash.

Sprocket Hub Ass’y.—40

Teeth

#420 Chain X 1/2” Pitch—77

Links 74

Chain Guard Ass’y.

67

736-0119 L-Wash. 5/16” Scr.*

05378

68

Shave Plate

69 710-0389 Car. Bolt 3/8-16 X.75” Lg.*

05002

70

71 712-0798

Slide Shoe

Hex Nut 3/8-16

72 736-0105 Bell. Wash.

73

710-0538 Hex Scr. 5/16-18 X.62” Lg.

736-0227

FI-Wash.

75 741-0170 Flange Brg. with Flats

Spring Pin SfUr.—5/16 76 05360 Brg. Housing Ass’y.

L-Wash. 5/16” Scr.*

Hex Nut 5/16-18” Thd.*

77

710-0260 Car. Bolt5/16-18X.62”Lg.*

78 05139 Guide Blade

Bell. Wash. 79 736-0119 L-Wash. 5/16” Scr.*

Hex Ins. L-Nut 3/8-16” Thd. 80 712-0267

Bearing Housing

81 736-0119

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16”.Scr.*

Hex Nut 5/16-18” Thd.* 82 712-0267 Hex Nut 5/16-18 Thd.*

L-Wash. 5/16” Scr.*

Self Aligning Brg. w/Set Scr. 84

Comes with Ref. No. 29

Spring Pin Spir.—5/16 X1.75

14 Teeth Sprocket Ass’y.

1.875” Dia. Flat Idler

Idler Spacer 89

FI-Wash. 90

FI-Wash.

Hex Scr. 3/8-16x2.00” Lg.* 92 715-0139

Drive Shaft

Crank Support Tubing Ass’y.

Hand Knob 5/16-18 Thd.

Chute Crank Brkt.

Chute Crank

FI-Wash.

Knob—Black 3/8” Dia. Hole

716-0121

83

85

736-0242

712-0267

Snap Ring fori .50” Dia. Shaft

Bell. Wash.

Hex Nut 5/16-18 Thd.*

86 714-0111 Cotter Pin 3/32x1.00” Lg.*

712-0267 Hex Nut 5/16-18 Thd.*

87

88 736-0119

710-0376

711-0584

05066 Joint Brkt. Ass’y.

91

L-Wash. 5/16” Scr.*

Hex Scr. 5/16-18 X1.00” Lg. *

Joint Block

Spring Pin Roll 3/16" X.81"

Lg.*

93 715-0103

Spring Pin Roll 1 /8 X .75”

Lg.*

94

710-0118

05402 Chute Brkt.

95

05118 Sprocket Shaft Ass’y.

96

97 05031

Hex Scr. 5/16-18 X.75” Lg.*

Chute Flange Keeper Ass’y.

Push Nut 3/8” Rod

N

Linkage Arm Ass’y.

98 738-0229

“V”-Belt 1/2” X 85” Lg.(Kevlar 99

Master Link for #420 Chain

Shoulder Scr.

Idler Brkt. Ass’y.

Extension Spring

100 05136

101

N X.565

102

I 103

736-0250

748-0193

05838

710-0347

Spiral Axle

FI-Wash.

Plastic Bushing

Spacer .3801.D. x .630 O.D.

Linkage Arm Ass’y.—R.H.

Hex Bolt 3/8-16 X 1.75" Lg.*

NEW

PART

N

‘For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order by part

number and size as shown on parts list.

17

Page 18

190-469A

TMO-33849A

exploded view

18

Page 19

PARTS LIST FOR 190-469A and TMO-33849A 36" SNOW THROWER ATTACHMENT

REF.

NO.

. 3

PART

NO.

1 710-0528

2 736-0119

712-0267

4

712-0116

5 756-0218

6 754-0185

COLOR

CODE

DESCRIPTION

Hex Scr. 5/'16-18 x 1.25” Lg.*

L-Wash. 5/16” Scr.*

Hex Nut 5/16-18 Thd.*

Hex Ins. Jam Nut 3/8-24 Thd.

Flat Idler 3.25” O.D.

“V”-Belt 1/2 X 49” Lg.

NEW

PART

7 712-0242 He'x Jam Nut 5/8-11 Thd.

8 736-0158

9 756-0216

10

738-0129 Shoulder Screw

05644

11

L-Wash.

6.50” O.D. X 5/8 Pulley

Channel Supporting

Brkt.-R.H.

12 05835

05838

13

14 714-0101

736-0192

15

710-0528

16

736-0169

17

712-0798

18

08253

19

736-0119

20

712-0267

21

22 05406

714-0388

23

Linkage Brkt.

Linkage Arm Ass’y.—R.H.

Inten. Cotter Pin .500” Dia.*

FI-Wash.

Hex Scr. 5/16-18 X1.25” Lg. *

L-Wash. 3/8” Scr.*

Hex Nut 3/8-16Thd.*

Bearing Housing

L-Wash. 5/16” Scr.*

Hex Nut 5/16-18” Thd.*

Belt Guard

#61 Hi-Pro-Key 3/16 X

N

N

5/8” Dia.

738-0246

24

756-0213

25

754-0202

26

732-0146

27

738-0140

28

714-0111

29

736-0300

30

747-0131

31

736-0192

32

33 714-0101

34 710-0198

Pulley Spindle

4.00 O.D. X 5/8 Pulley

“V”-Belt V2 X 85” Lg.

Extension Spring

Shoulder Screw

Cotter Pin 3/32” Dia. x 1.00”*

FI-Wash.

Control Rod

FI-Wash.

Intern. Cotter Pin .500” Dia.*

HexSemsScr. 5/16-18 x

.75”*

35 05409

741-0919

36

05411

37

738-0242

38

712-0130

39

736-0300

40

41 711-0310

736-0192

42

714-0101

43

Clutch Idler Brkt. Ass’y-

Ball Bearing

Channel Ass’y.

Lift Handle Shaft

Hex Ins. L-Nut3/8-16” Thd.

FI-Wash.

Lift Brkt. Pin 1/2 x 1-3/16" Lg.

FI-Wash.

Intern. Cotter Pin .500” Dia.*

05645 Channel Supporting

44

710-0253 Hex Scr. 3/8-16x1.00” Lg.*

45

736-0169 L-Wash. 3/8” Scr.*

46

47

736-0119 L-Wash. 5/16” Scr.

712-0267 Hex Nut 5/16-18” Thd.*

48

732-0323

49

50 05837

710-0646 Hex Scr. 5/16-18 x2.0” Lg.

51

736-0159

52

711-0509

i

Brkt.-R.H.

Helper Spring

Linkage Arm Ass’y.—-L.H.

Special

FI-Wash. 5/16” Scr.*

Spring Insert

19

N

Page 20

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Ports and service for oil MTD manufactured power equipment are

available through the authorized service firms listed below. All orders

should specify the model number of your unit, parts number

description of parts and the quantity of each part required.

ALABAMA BIRMINGHAM

Auto Electric & Carburetor Co

ARKANSAS FORT SMITH

Mity Mite Motors, Inc

Sutton’s Lawn Mower Shop

CALIFORNIA PORTERVILLE

Biliious

.................................................

Lawn Mower Supply Co

J.W. Jewett Co

COLORADO DENVER

South Denver Lawn Equip

FLORIDA JACKSONVILLE

Radco Distributors

Small Eng. Dist

GEORGIA EAST POINT

East Point Cycle & Key

ILLINOIS LYONS

Keen Edge Co

INDIANA ELKHART

Parts & Sales Inc.................................2101 Industrial Pkwy.. 46514

IOWA DUBUQUE

Power Lawn & Garden Equip

LOUISIANA NEW ORLEANS

Suhren Engine Co...............................8330 Earhart Blvd

MARYLAND TAKOMAPARK

Center Supply Co.........................6867 New Hampshire Ave.. 20012

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co

MICHIGAN LANSING

Lorenz Service Co

Power Equipment Dist.........................36463 South Gratiot.. 48043

MINNESOTA HOPKINS

Hance Distributing Inc.........................420 Excelsior Ave. W.. 55343

Power Tools Inc

MISSISSIPPI BILOXI

Biloxi Sales & Service, Inc

MISSOURI KANSAS CITY

Automotive Equip. Service

Ross-Frazier Supply Co

Henzier, Inc

NEWJEfiSEY BELLMAWR

Lawnmower Parts Inc

Feld Distributor

NEW YORK CARTHAGE

Gamble Dist., Inc

........................................

..........................

...............................

.............................

....................................

.....................................

...........................

..............................

.......................

..........................

....................................

...........................................................

...........

2625 4th Ave. S

4515South 16th Street 72901

NORTH LITTLE ROCK

...............

.....................

............. 527 West Evans

......................

..................

...........................

......................

Rt. 4 Box 368

75 North D Street.... 93257

SAN BERNARDINO

25608 E. Baseline .... 92410

SAN FRANCISCO

981 Folsom St

2403 Market St

OPA LOCKA

2351 N.W. 147th St.... 33054

2834 Church St

8615 Ogden Ave

............

2551 J.F. Kennedy

300 Birnie Ave

2500 S. Pennsylvania. 48910

MOUNT CLEMENS

ST. PAUL

3771 Sibley Memorial Hwy. .55122

506 Caillavet St

ST. JOSEPH

8th and Monteray

ST. LOUIS

2015 Lemay Ferry Rd.. 63125

717 Creek Rd

RUTHERFORD

28 Glen Rd

...................

3117 Holmes St 64109

..................

...........

35233

...............

..............

72117

94107

.........

80223

...........

32206

..........

30344

..........

60534

___

52001

.......

70118

............

01107

..........

39533

____

64503

08030

07070

West Ehd Ave.13619

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS AND

SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service should be

handled by your nearfest authorized engine service firm. Check the

yellow pages of your telephone directory under the listin'-

Engines—Gasoline, Briggs S Stratton or Tecumseh Lauson.

GTP Leisure Products Inc

NORTH CAROLINA GOLDSBORO

Smith Hardware Co

Dixie Sales Company..........................327 Battleground Ave. 27402

OHIO CARROLL

Stebe's Mid-State Mower Supply ...Box 366-71 High St. ..43112

Bleckrie, Inc

National Central

Burton Supply Co

OKLAHOMA ADA

Ada Auto Supply

Victory Motors, Inc

Forest Sales Inc...................................1039 NW63rd St

OREGON PORTLAND

Kenton Supply Co

PENNSYLVANIA CHESTER

Stull Equipment Corp..........................742 W. Front St

EECOInc

Thompson Rubber Co

Bluemont Co

TENNESSEE KNOXVILLE

Master Repair Service

Memphis Cycle & Supply Co

American Sales & Service, Inc...........1922 Lynnbrook

TEXAS DALLAS

Marr Brothers, Inc

Woodson Sales Corp

Bullard Supply Co

Catto & Putty, Inc

UTAH SALT LAKE CITY

A-1 Engine & Mower Co

VERMONT BURLINGTON

Vermont Hdwe. Co. Inc

VIRGINIA RICHMOND

RBI Corp...............................................963 Myers St

WASHINGTON SEATTLE

Bailey’s Inc

WEST VIRGINIA CHARLESTON

Young’s, Inc

WISCONSIN APPLETON

Automotive Supply Co

.............

...................................

.................................

...............................................

........................................

................................

......................................... 1414 14th Ave

.........................................

..................

.......................... .515 N. George St. ... 27530

...........................

......................

......................

..............................

........................

.........................

...............................

..........................

...............................

.....................

.......................

........................

SYRACUSE

420 Marcellus St

GREENSBORO

CLEVELAND

7900 Lorain Ave

WADSWORTH

687 Seville Rd

YOUNGSTOWN

1301 Logan Ave. Box 929 . .44501

301 E. 12th St

MUSKOGEE

.......

605 S. Cherokee

OKLAHOMA CITY

8216 N. Denver Ave... 97217

HARRISBURG

4021 N.6thSt

PHILADELPHIA

5222-24 N. Fifth St.... 19120

PITTSBURGH

11125 Frankstown Rd. 15235

2000 Western Ave. ...37921

MEMPHIS

.............

421 Monroe Ave

423 E. Jefferson

FORT WORTH

1702 N. Sylvania

HOUSTON

2409 Commerce St.... 77003

SAN ANTONIO

414 Live Oak

437 E. 9th St................84111

180 Flynn Ave

233 Virginia St., E

123 S. Linwood Ave... 54911

..........

..........

.............

..............

.........

..........

...........

................

.........

..........

..........

.........

...............

.............

...............

.............

.......

132v

44102

44281

74820

74401

73116

19013

17110

3810».

38116

75203

76111

78298

05401

23260

98102

25301

WARRANTY PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer from defects in workmanship and materials, defects which are NOT detected at the time of

manufacture. It does not provide tor the unlimited and unrestricted replacement of parts. Use and maintenance are the responsibility of the

customer. The manufacturer cannot assume responsibility for conditions which it has no control. Simply put, if it’s the manufacturer's fault, it's

the manufacturer's responsibility: if it's the customer's fault, it's the custamer's responsiblity.

CLAIMS AGAINST THE MANUFACTURER S

WARRANTY INCLUDES

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warranty period.

3. Repair of Defects within the warranty period.

All claims MUST be substantiated with the following information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

MTD PRODUCTS INC • 5965 GRAFTON ROAD • P.O. BOX 36900 • CLEVELAND OHIO 44136

Loading...

Loading...