Page 1

TEN CENTS

’X

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Important:

Read Safety Rules and

Instructions Carefully

Model Nos.

19468-6

19468-7

TMO-285A

197-468A

and

63584

PRINTED IN U.S.A.

FORM NO. 770-6647

REV. 7-76

Page 2

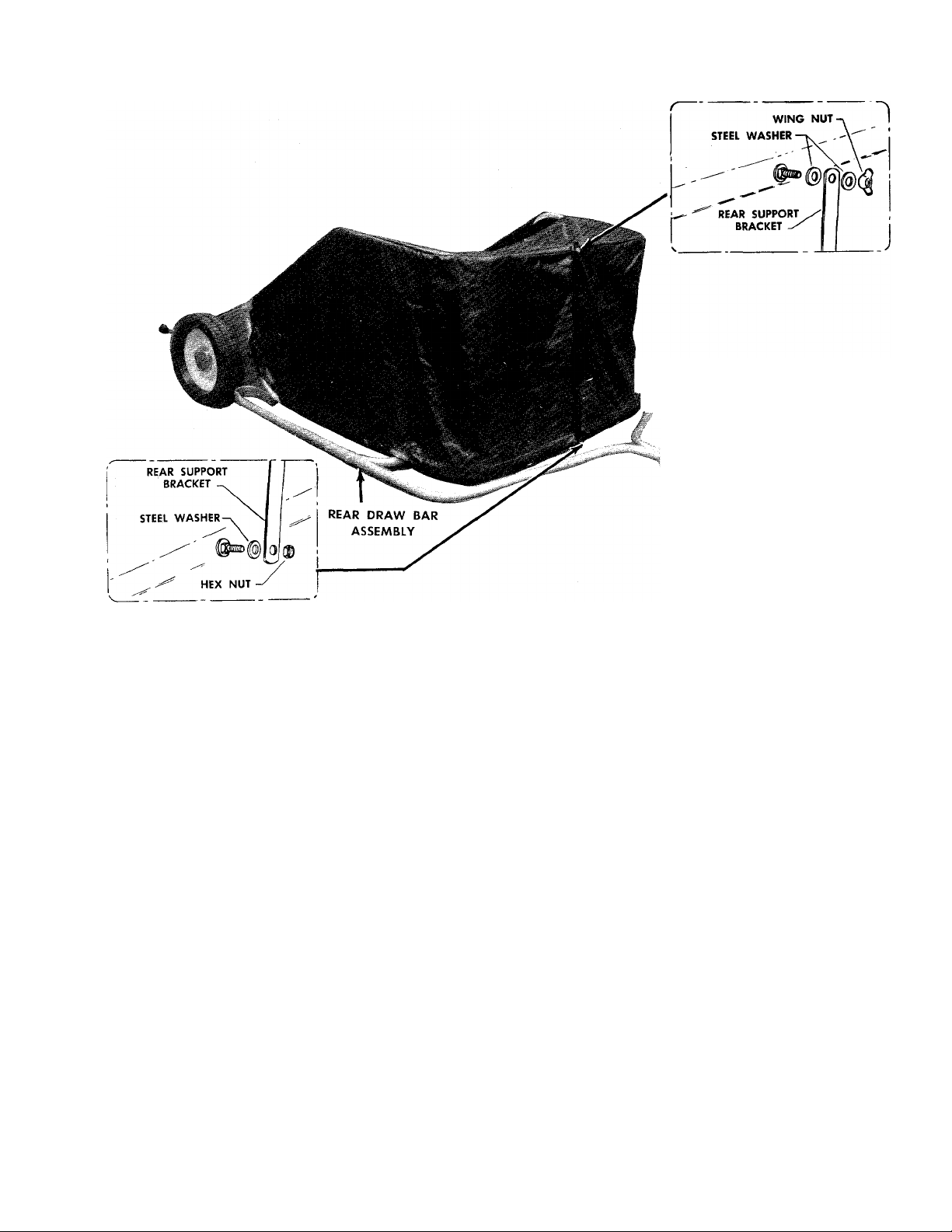

I FRONT DRAW BAR

ASSEMBLY

ASSEMBLY

Your Two-Stage Sweeper has been assembled at

the factory except for the Front Draw Bar

Assembly and the Hopper which has been

shipped in the storage position.

To assemble, slide the Front Draw Bar onto the

Rear Draw Bar as shown and fasten securely with

nuts and bolts provided. To prepare the Hopper

for operation, remove the Rear Support Bracket

from the underside of the Hopper, and assemble

to the Lower Mounting Bolt of the Hopper as

shown above. Lift the Upper Frame and assemble

the other end of the support to the Top Mounting

Bolt as shown;

For Storage—The Hopper can be collapsed by

removing the support from the Top Mounting

Bolt only, allowing the Hopper and support to fold

down to the storage position.

OPERATION

Your Sweeper is a precision piece of equipment.

Engineering skill and experience have been

combined to provide the ultimate in safety and

efficiency. However, as with any type of precision

equipment, carelessness or error on the part of

the operator can result in damage to your

equipment. Therefore, exercise caution at all

times and do not subject your sweeper to misuse.

SWEEPING SPEED

Your sweeper has been designed to operate at

approximately AVz mph which is a fast walk and in

the middle of the range of most riding mower

speeds. Varying conditions may dictate another

speed and therefore, it is recommended you try

sweeping at different speeds to find the one most

suited to your conditions.

BRUSH HEIGHT ADJUSTMENT

To adjust your unit to the best operating height

adjustment, press the adjust lever in an outward

direction until the trunnion on the adjust lever

clears the end plate.

Move the lever UP for greater clearance between

lawn and brush or down for less clearance. After

the desired clearance is obtained allow the adjust

lever to spring back locking the trunnion in the

proper positioning hole.

Follow the same procedure for the opposite

wheel. See figure 1.

Page 3

Figure 1

DUMPING OF SWEEPER

Your sweeper can be dumped very easily without

removing or disconnecting a part. Simply lift the

hopper as shown and swing it over the sweeper

and dump. See figure 2.

LUBRICATION

The bearings in your Sweeper have been

prelubricated at the factory, however, it is

recommended that a few drops of light oil should

be added to the impeller and brush shaft bearings

twice a year. Also, the wheels and pinions should

be removed, the axles cleaned and an even coat of

light oil applied. See figure 3.

A

If you are planning on dumping your

Sweeper near a fire use care not to

get too close, the brushes can be

destroyed by excessive heat or

flame.

CAUTION

Figure 3

Figure 2

Page 4

19468-6

19468-7

TMO-285A

197-468A

and

63584

39 41

All Unnumbered Parts Interchangeable With

Opposite Side.

Page 5

PARTS LIST FOR MODELS 19468-6,19468-7, TMO-285A, 197-468A AND 63584

REF.

PART

NO.

NO.

1 4111-92

2 1652-13

3 1629-56

4 1530-6

4111-91

5

6 2120-69

7 2626-74

1548-12

8

9 2651-49

10 1632-229

11 1650-21

12 1540-17

DESCRIPTION

Assembly—End Plate R.H.

Bearing

Retai ner— Bear! ng

Rivet (3/16 Dia. X5/16)

Assembly—End Plate L.H.

Assembly—Pulley

Pulley

Rollpin (.156 Dia. x1 V4)

Belt (3/8 Round Sect.)

Shaft—Brush Drive (Short)

Ring—Retainer

Washer—Flat (5/8x15/16

xl/16)

13 2632-231

14 4703-24

1507-12 Screw (10-32 X1 -1 /8 Sems)

*15

16

3703-25

*17

1507-8

3118-44 Assembly—Dust Cover R.H.

18

Ю 2155-18

Shaft—Brush Drive (Long)

Baffle—Top

Baffle—Front

Screw (10-32 X 3/8 Sems)

Assembly—Wheel Adj.

Lever

20

21

22

2643-18

3118-45

1631-39

Knob—Wheel Adjust

Assembly—Dust Cover L.H.

Axle—Wheel

23 1552-13 Washer—Bowed

24

1657-45

*25

1038

26 4622-98

27 2679-2

Bushing—Spacer

Nut—Hex

Cover—Sweeper

Ass’y- Brush and Channel

28 2182-7 Assembly—Brush Retainer

*29 1509-31 Bolt(1 /4-20 X1-1 /8 Hex Hd.)

*30

1538-8

Nut (t^-20 Hex Lock)

31 1025 Washer—Lock (5/16 Split)

32 1671-1 Pawl

33 2692-6

34 2692-7

35

3108-148

36

4636-18

37

1652-52

38

3619-58 Tire

Pinion R.H.

Pinion L.H. Hd.)

Assembly—Wheel

Wheel—Gear & Rim

Bushing

*39 141 Washer (3/8x7/8x3/16)

142 Cotter Pin (1 /8x5/8)

*40

41

2674-32 Cap—Hub

42

4697-13

*43 1509-44

Draw—Bar—Rear

Bolt(5/16-18 x3/4 Sem Hex)

REF.

*44

*48 769

NO.

PART

NO.

DESCRIPTION

1538-6 Nut (5/16-18 Hex Lock)

45 4697-14

1552-14

46

47

1132-128

Draw—Bar—Front (R.H.)

Washer—Bowed

Ass’y.—Bracket & Pin

Bolt (5/16-18x2-5/8

Hex Hd.)

49

4647-29 Frame Catcher—Lower

50

4647-30

51 0773-13

52

1513-87 Bolt—Shouider (Pivot)

*53

1538-13 Nut(3/8-16 Hex Lock)

54

2603-77 Brace—Frame

Frame Catcher—Upper

Basket—Fabric

55 4709-24 Panel—Catcher Bottom

*56

1095

57

1694-26

*58

1507-6 Bolt (10-32 X 3/8 Truss Hd.)

*59

1534-8 Nut (10-32 Hex Lock)

*60 1507-11

63 1513-93

64

1694-34

65 2723-4

66

1629-63 Retainer—Skirt

67

1693-3 Skirt

1117

*68

Screw (10-32x1/2 Philips)

Clamp

Screw (10-32 X 3/8 Sems)

Bolt (5/16x1-3/8 Special)

Coupling—Half (Clamp)

Scraper—Impeller Pulley

Screw (10-32 X 3/8 Phillips

Hd.)

•69 1540-125

Washer (.59 x 1 -1 /8 x .015)

*70 70 Nut (5/16-18 Hex)

71

1540-32

72 1522-1

Washer (.78 X1-1/4 X.015)

Screw (10-12x5/8 Sheet

Metal)

73

1509-90

74

1018

75

1632-228 Shaft—Impeller (Short)

76 2632-230

77

1530-1 Rivet—(3/16.Dia. x 1 /4 Truss

78

1540-81

79

4697-15 Draw & Bar—Front (L.H.)

80

1509-38

81

1543-69 Washer (21 /64 x 3/4 x 3/32

Bolt (V4-20 X11/4 Hex Hd.)

Lockwasher(1^ Std. Split)

Shaft—Impeller (Long)

Washer(17/64x 3/4 xl/16)

Bolt (10-32x3/8 Hex Hd.)

Nylon)

82

2653-28 Support

83

1509-69 Bolt (1/4-20x1 3/4 Hex Hd.)

84

1539-79

Nut (V4-2O Wing-Lock)

‘Standard Harbware Item—May Be Purchased Locally

Page 6

Loading...

Loading...