Page 1

12 Volt Battery

Trimmer

Model TB55B

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

P/N 769-00532 (12/02)

PRINTED IN USA

Operator’s Manual

Page 2

2

TABLE OF CONTENTS

Content Page

Calling Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning and Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Accessories and Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Inside Back Cover

This operator’s manual is an important part of your new trimmer. It will help you assemble, prepare and maintain the unit

for best performance. Please read and understand what it says.

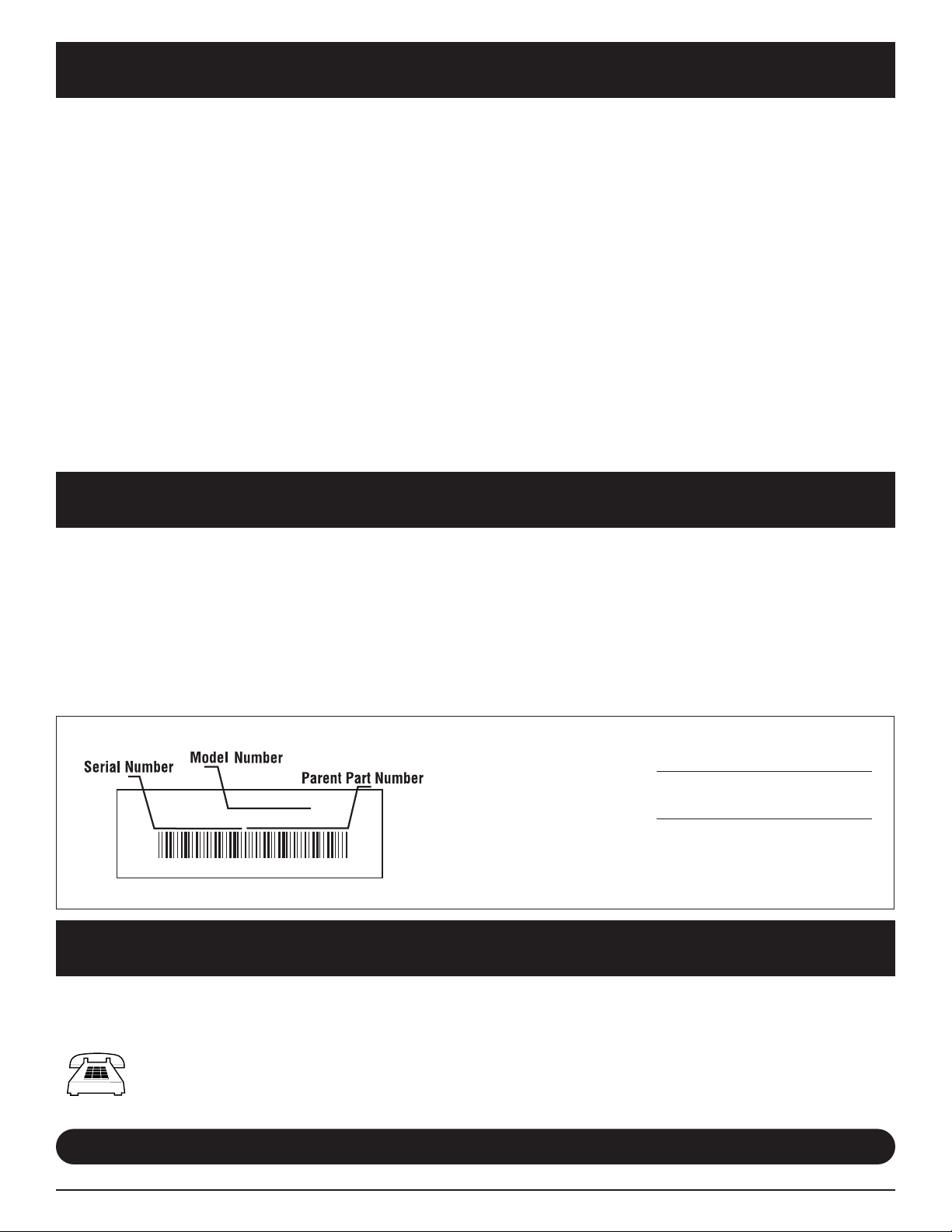

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the

information from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

• You can locate the model number on the unit. A sample model plate is explained below. For future reference,

please copy the model number and the serial number of the equipment in the space below.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, please call the Customer Support Department.

Call 1-800-520-5520 to reach a Customer Support representative. Please have your unit’s model number

and serial number ready when you call. See previous section to locate this information. You will be asked to

enter the serial number in order to process your call.

FINDING MODEL NUMBER

CALLING CUSTOMER SUPPORT

For more details about your unit, visit our website at www.troybilt.com

Copy the model and parent

part number here:

Copy the serial number here:

S/N :

MODEL :

ITEM :

Page 3

3

READ ALL INSTRUCTIONS

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

• Do not operate this unit when tired, ill or under the

influence of alcohol, drugs or medication.

• Children and teens under the age of 15 must not use

the unit, except for teens guided by an adult.

• Inspect the unit before use. Replace damaged parts.

Check for battery leaks. Make sure all fasteners are in

place and secure. Replace cutting attachment parts

that are cracked, chipped or damaged in any way.

Make sure the cutting attachment is properly installed

and securely fastened. Be sure the cutting attachment

shield is properly attached, and positioned as

recommended. Failure to do so can result in personal

injury to the operator and bystanders, as well as

damage to the unit.

• Avoid dangerous environments. Never operate your

unit in damp or wet conditions. Moisture is a shock

hazard.

• Do not use the unit in the rain.

• Do not handle the unit with wet hands.

• Use only 0.080 inch (

2.03 mm) diameter Genuine

Factory Parts™ replacement line. Never use metalreinforced line, wire or rope. These can break off and

become dangerous projectiles.

• Be aware of the risk of injury to the head, hands and feet.

• Clear the area to be cut before each use. Remove all

objects such as rocks, broken glass, nails, wire or

string. They can be thrown or become entangled in the

cutting attachment. Clear the area of children,

bystanders, and pets. At a minimum, keep all children,

bystanders and pets outside a 50-foot (15 m.) radius;

there still may be a risk to bystanders from thrown

objects. Bystanders should be encouraged to wear

eye protection. If you are approached, stop the motor

and cutting attachment immediately.

• This unit was not designed to be used as a

brushcutter. Do not attach or operate this unit with any

type of brushcutting blade or brushcutting attachment.

SAFETY WARNINGS FOR BATTERY TRIMMERS

• Battery tools do not have to be plugged into an

electrical outlet; therefore, they are always in operating

condition. Be aware of possible hazards even when

the tool is idle. Take care when performing

maintenance or service.

• Remove or disconnect the battery before servicing,

cleaning or removing material from the unit.

• Only use the charging station provided with your unit.

Do not substitute any other charging equipment. Use

of any other means of charging could cause the

batteries to explode, resulting in possible serious

personal injury.

DANGER: Failure to obey a safety warning

will result in serious injury to yourself or to

others. Always follow the safety precautions

to reduce the risk of fire, electric shock and

personal injury.

WARNING: Failure to obey a safety warning

can result in injury to yourself and others.

Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

CAUTION: Failure to obey a safety warning

may result in property damage or personal

injury to yourself or to others. Always follow

the safety precautions to reduce the risk of

fire, electric shock and personal injury.

SAFETY ALERT SYMBOL: Indicates danger,

warning or caution. Attention is required in

order to avoid serious personal injury. May be

used in conjunction with other symbols or

pictographs.

SYMBOL MEANING

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

NOTE: Advises you of information or instructions vital

to the operation or maintenance of the

equipment.

SYMBOL MEANING

DANGER: When using battery trimmers,

basic safety precautions should always be

followed to reduce the risk of fire, electric

shock and personal injury. Carefully read and

understand the entire operator's manual

before using your trimmer. Pay close

attention to the operating instructions and

safety warnings.

RULES FOR SAFE OPERATION

Page 4

4

RULES FOR SAFE OPERATION

• Do not charge the unit in the rain or in wet locations.

SAFETY WARNINGS FOR CHARGING STANDS

AND LEAD-ACID BATTERIES

• Before using the charging stand, read all instructions

and cautions in this manual, as well as on the charging

stand, and on the unit.

• Do not expose charger to rain or snow.

• To reduce risk of injury, charge only sealed lead-acid

rechargeable batteries. Other types of batteries may

burst, causing personal injury and damage.

• To reduce risk of damage to charger body and cord,

pull it by the charger body (not the cord) when

disconnecting the charger.

•Make sure the charger cord is located in an area where

it will not be stepped on, tripped over or otherwise

subjected to damage or stress.

•Do not operate the charger with a damaged cord or

plug. If damaged, replaced the charger immediately.

• Do not operate charger if it has received a sharp blow,

been dropped or has been damaged in any way. If the

charger case is damaged, replace the charger.

• Do not disassemble the charger. The charger is not

serviceable; disassembly may result in a electric shock

or fire.

• To reduce the risk of electric shock, unplug the charger

from the outlet before you clean or service the unit.

• Do not use the charger outdoors.

• Use only the following type and size battery: 12 volt

DC, sealed lead-acid battery (182391).

• Do not dispose of batteries in fire. The cell may

explode. Batteries should be recycled. Consult your

local waste authority for information regarding available

recycling and/or disposal options.

• Exercise care when handling the batteries. Be careful

and avoid shorting the battery with conducting

materials like rings, bracelets and keys. The battery or

conductor may overheat and cause burns.

• Charge the battery in a location where the temperature

is between 50˚F (10˚C) and 100˚F (38˚C).

• Do not open or mutilate the battery. Released

electrolyte is corrosive and may cause damage to the

eyes or skin. It may be toxic if swallowed.

WHILE OPERATING

• Wear safety glasses or goggles that are marked as

meeting ANSI Z87.1-1989 standards. Also wear

ear/hearing protection when operating this unit. Wear a

face or dust mask if the operation is dusty. Long sleeve

shirts are recommended.

• Wear heavy, long pants, boots and gloves. Do not

wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• The cutting attachment shield must always be in place

while operating the unit. Do not operate unit without

the trimming lines extended, and the proper line

installed. Do not extend the trimming line beyond the

length of the shield.

• Adjust the D-handle to your size to provide the best grip.

• Be sure the cutting attachment is not in contact with

anything before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Do not carry around a unit

with your finger on the trigger switch.

• Use the right tool. Only use this tool for the purpose

intended.

• Do not overreach. Always keep proper footing and

balance.

Always hold the unit with both hands when operating.

Keep a firm grip on both the battery housing grip and

the D-handle.

• Keep hands, face and feet at a distance from all

moving parts. Do not touch or try to stop the cutting

attachment when it is rotating.

• Do not operate the motor faster than the speed needed

to cut, trim or edge. Do not run the motor at high

speed when you are not cutting.

• Always stop the motor when cutting is delayed or

when walking from one cutting location to another.

• If you strike or become entangled with a foreign object,

stop the motor immediately and check for damage. Do

not operate before repairing damage. Do not operate

the unit with loose or damaged parts.

• Release the trigger, ensure the lock-off button resets

and allow the motor to stop for maintenance or repair.

• Use only Genuine Factory Parts™ replacement parts

when servicing this unit. These parts are available from

your authorized service dealer. Do not use

unauthorized parts, accessories or attachments. Using

unauthorized parts may lead to serious injury, damage

to the unit and a voided warranty.

• Keep the unit clean of vegetation and other materials.

They may become lodged between the cutting

attachment and shield.

OTHER SAFETY WARNINGS

• Disconnect the unit from the power supply when it is idle,

when you are storing or transporting it, when you are

servicing it, and when you are changing attachments.

• Store the unit in a dry area, locked up to prevent

unauthorized use or damage, and stored in a high

place out of the reach of children.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use. See the Cleaning and Storage

instructions.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

SAVE THESE INSTRUCTIONS

Page 5

5

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution.

May be used in conjunction with other

symbols or pictographs.

•WARNING - READ

OPERATOR'S MANUAL

Read the operator’s manual(s) and follow

all warnings and safety instructions.

Failure to do so can result in serious injury

to the operator and/or bystanders.

• WEAR EYE AND HEARING

PROTECTION

WARNING: Thrown objects and loud

noise can cause severe eye injury and

hearing loss. Wear eye protection

meeting ANSI Z87.1 standards and ear

protection when operating this unit.

Use a full face shield when needed.

SYMBOL MEANING

• THROWN OBJECTS AND

ROTATING CUTTER CAN

CAUSE SEVERE INJURY

WARNING: Do not operate without

the cutting attachment shield in place.

Keep away from the rotating cutting

attachment.

• SHARP BLADE

WARNING: Sharp blade on cutting

attachment shield. To prevent serious

injury, do not touch line cutting blade.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders,

especially children and pets, at least

50 feet (15 m) from the operating area.

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

RULES FOR SAFE OPERATION

Page 6

6

APPLICATIONS

As a trimmer:

• Cutting grass and light weeds

• Decorative trimming around trees, fences, etc.

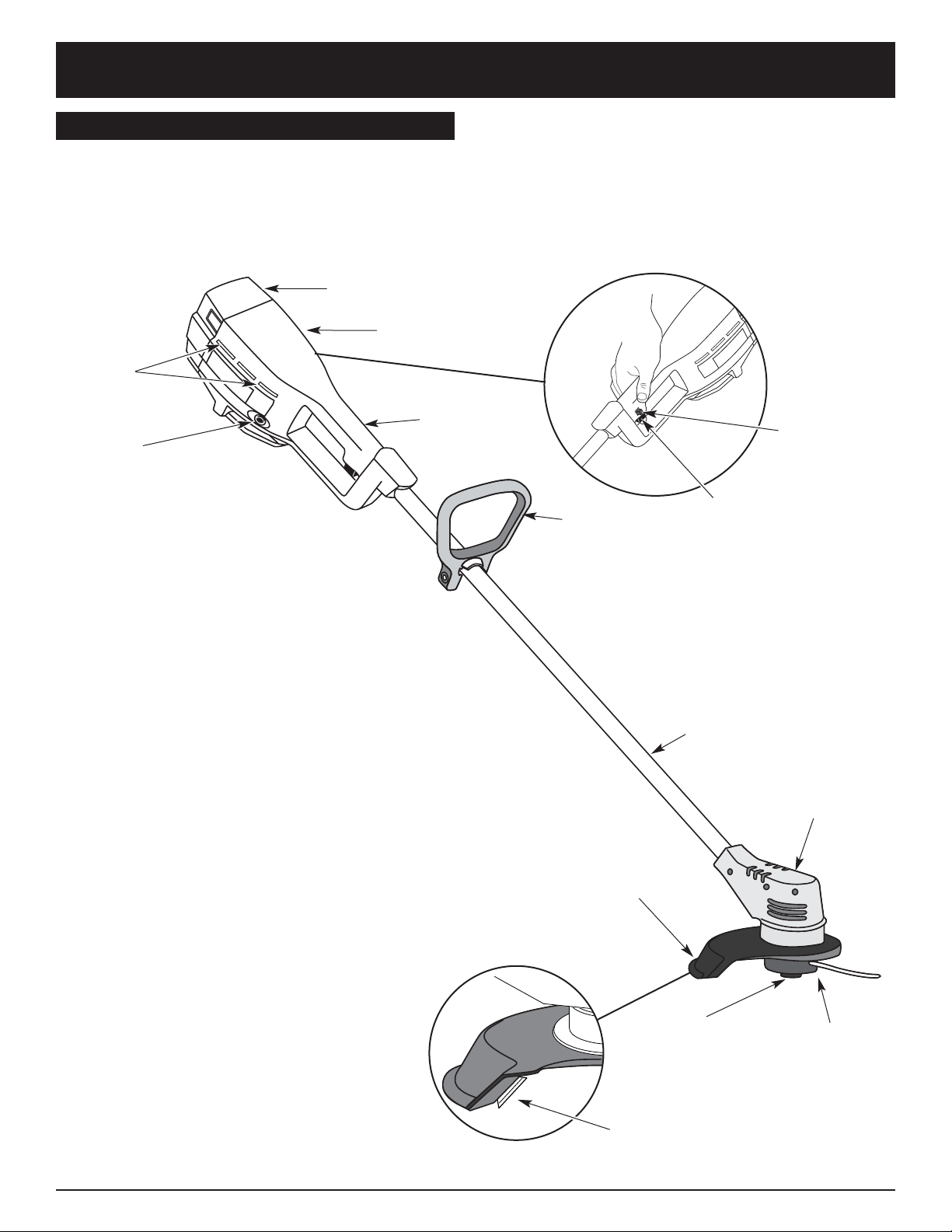

KNOW YOUR UNIT

RULES FOR SAFE OPERATION

Motor Housing

D-handle

Line Cutting Blade

Bump Knob

Trigger

Lock-Off Button

Bump Head

Cutting Attachment

Motor Wire Housing Tube

Hand Grip

Overload Protection

Switch

Battery Housing

Cutting

Attachment

Shield

Battery Door

Air Vents

Page 7

7

ASSEMBLY INSTRUCTIONS

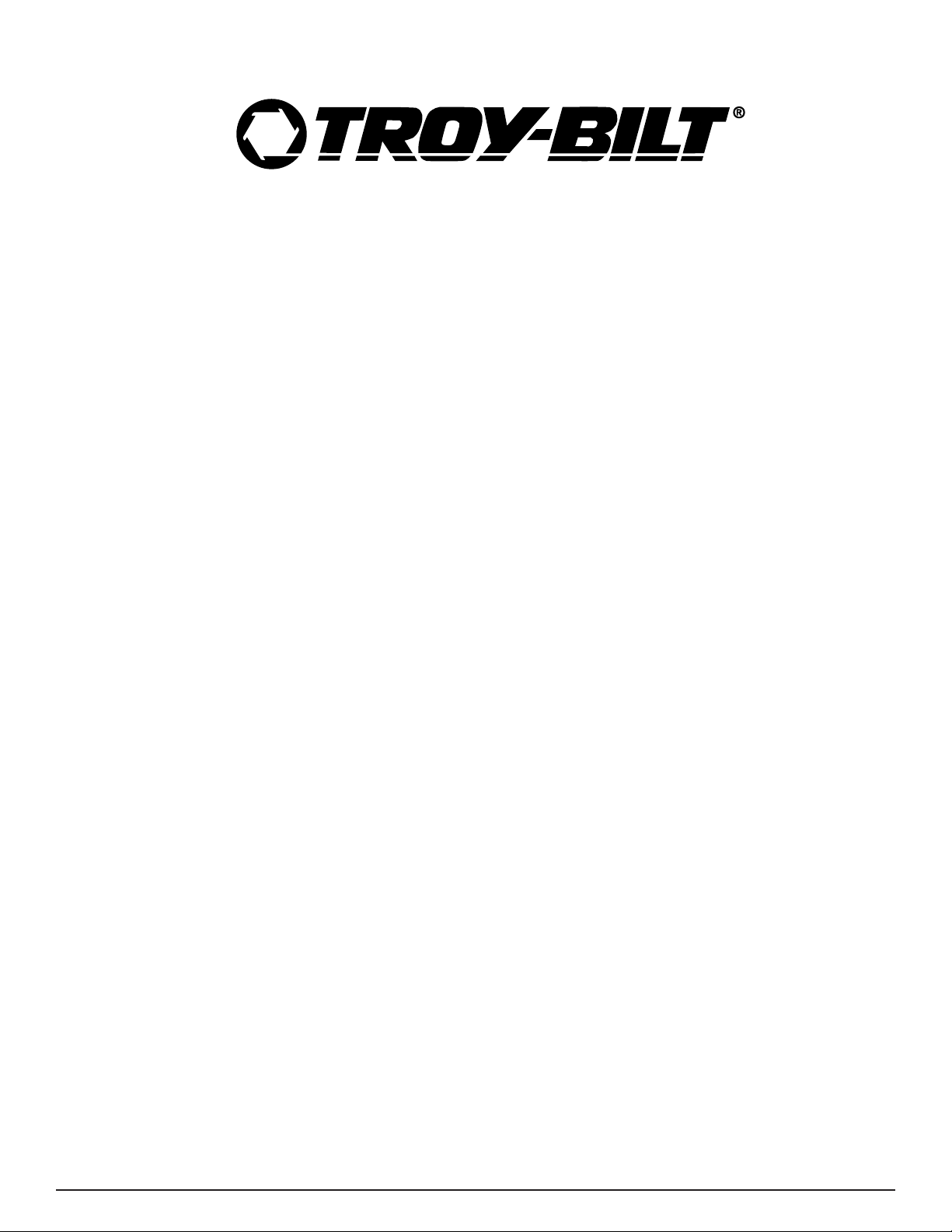

3. Plug the charger into the wall outlet and wind any

excess wire onto the cord wrap on the charging

station (Fig. 3).

Wall Outlet

Charging Station

Screws

Wall

Stud

Cord Wrap

Charger

Fig. 3

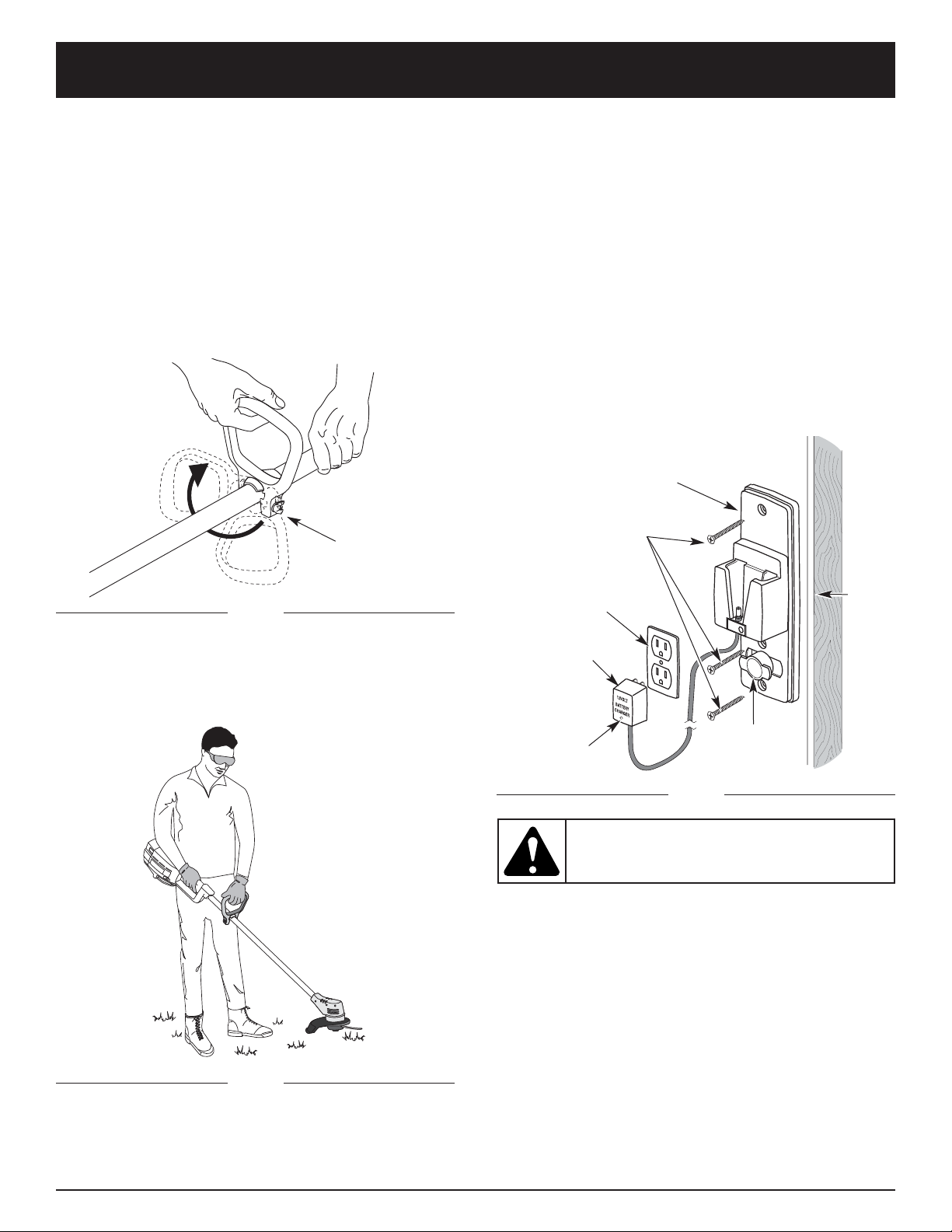

ADJUSTING THE D-HANDLE

NOTE: The D-handle comes mounted on the backside

of the shaft.

Fig. 1

Fig. 2

MOUNTING THE CHARGING STATION

NOTE: Mount the charging unit and allow the unit to

charge for at least 36 hours prior to first use.

This unit may stay on the charging station continuously

without overcharging. Place the charging station where

the unit is intended to be stored. This should be a cool,

dry and well ventilated place, where the unit can be

locked-up and out of the reach of children.

The unit should be stored and charged in a location

where the temperature is between 50˚F (10˚C) and 100˚F

(38˚C).

1. Locate a place for the charging station near a wall

outlet and high enough to keep the unit off the floor.

2. Locate the wall stud and mount the charging station

to the wall using the three (3) screws provided

(Fig 3). Make sure that the screws enter the wall stud

to provide a secure mount.

Charging

Indicator Light

CAUTION: To prevent injury or damage to

the unit, the charging station must be

mounted securely to the wall.

1. Locate the wing nut on the D-Handle. Untighten the

wing nut enough to loosen the D-Handle (Fig. 1).

NOTE: Do not remove wing nut, washer, or bolt.

2. Rotate the D-Handle to the upright position on the

front side of the shaft housing (Fig. 1).

NOTE: The D-handle should slant towards the

powerhead of the unit.

3. Hold the unit in the operating position. If necessary,

reposition the D-handle to the location that provides

the best grip (Fig. 2).

Wing Nut

4. Tighten the wing nut until the D-Handle is secure.

Page 8

8

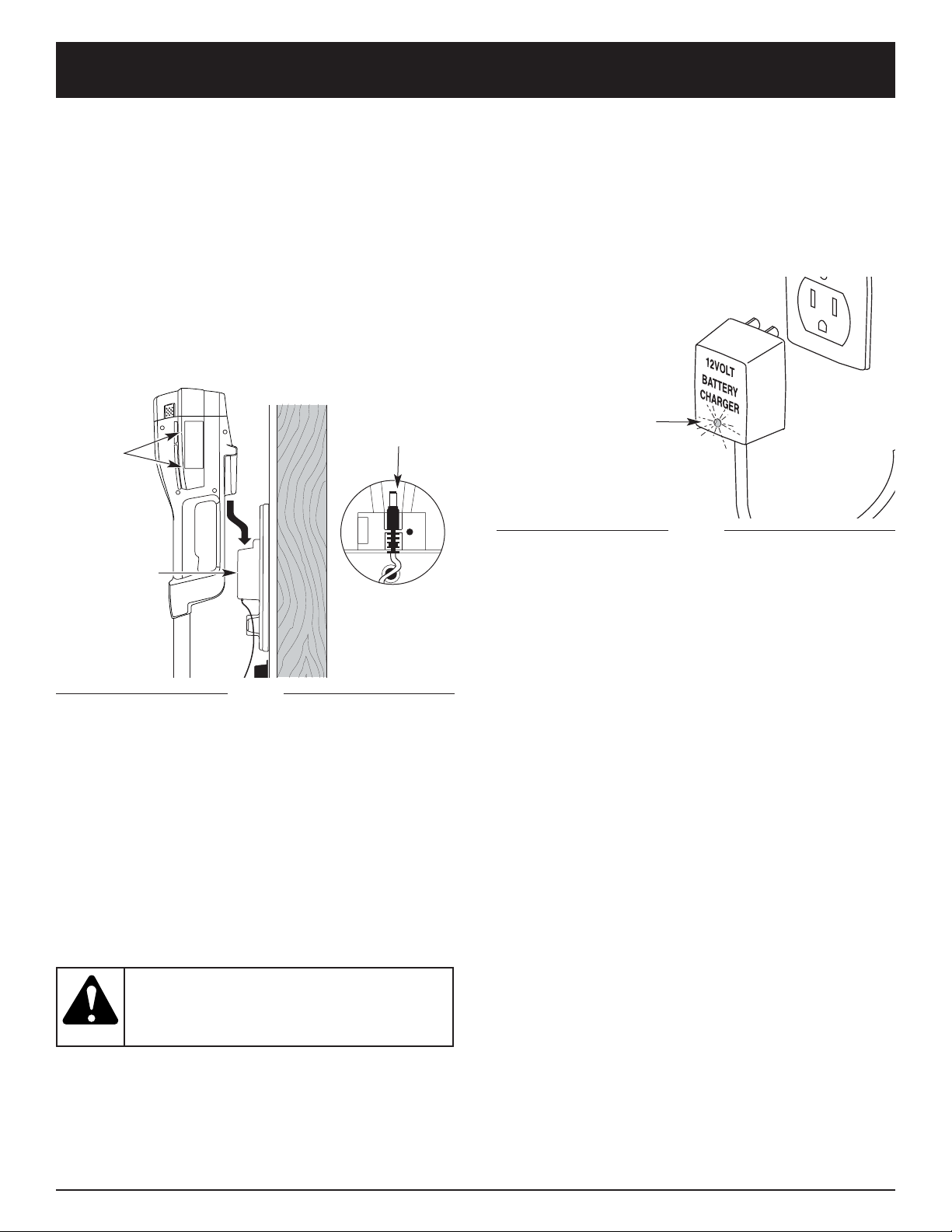

OPERATING INSTRUCTIONS

2. When the red indicator light on the charger is on, the

battery is being charged (Fig. 5). If the light fails to

come on, check that:

a. The charger is plugged into a working wall outlet.

b. The unit is firmly seated into the charging station and

the barrel connector is fully inserted into the unit.

c. The barrel connector is properly installed in the

charging station. If it isn’t, refer to Replacing the

Charger.

d. Power is on at the wall outlet.

NOTE: If the wall outlet is operated by a switch, be sure

the switch is ON.

Air Vents

CHARGING THE UNIT

Make sure the charging station is securely fastened to a

wall and the charger is plugged into a working wall

outlet.

NOTE: Allow the unit to charge for at least 36 hours

prior to first use.

1. Slide the unit down into the charging station until it is

firmly seated (Fig. 4). The barrel connector in the

charging station will insert into the unit. If it doesn’t,

refer to Replacing the Charger.

NOTE: The battery will heat up while the unit charges.

Be sure the air vents on the battery housing are

kept clear for proper ventilation (Fig. 4).

Charging Tips for Maximum Performance

• Store and charge the unit where temperatures are

between 50˚ F (10˚ C) and 100˚ F (38˚ C). Storing the

unit or batteries above 100˚ F (38˚ C) will reduce

battery life.

• Storage below 50˚ F (10˚ C) will not reduce battery

life, but may require a longer charging time.

• Store the unit on the charging station when not in

use. The unit is designed so that the battery cannot

be overcharged.

NOTE: The charging indicator light will remain lit when

the unit is properly installed in the charging

station.

Temperature Effects on Charging Time

• 50˚ F (10˚ C) to 100˚ F (38˚ C) – Battery will charge

within 24 hours.

• 40˚ F (4 ˚C) to 50˚ F (10˚ C) – Battery will require up to

48 hours for a full charge.

• Below 40˚ F (4 ˚C) – Battery will not reach full charge.

NOTE: The unit run time will be reduced when the

battery is not fully charged.

Fig. 4

Charging

Station

Barrel

Connector

Fig. 5

Charging

Indicator Light

3. Charge the battery until the Charging Indicator Light

on the charger turns from red to green (Fig. 5).

NOTE: The unit’s operating time and the life of the

battery will be shorten if the unit is not fully

charged between uses.

4. Place the unit back on the charging station after

each use. The unit is designed so that the battery

cannot be overcharged.

WARNING: If the wall outlet is not working

properly, have the wall outlet checked by a

qualified electrician. This will help prevent

serious personal injury.

Page 9

9

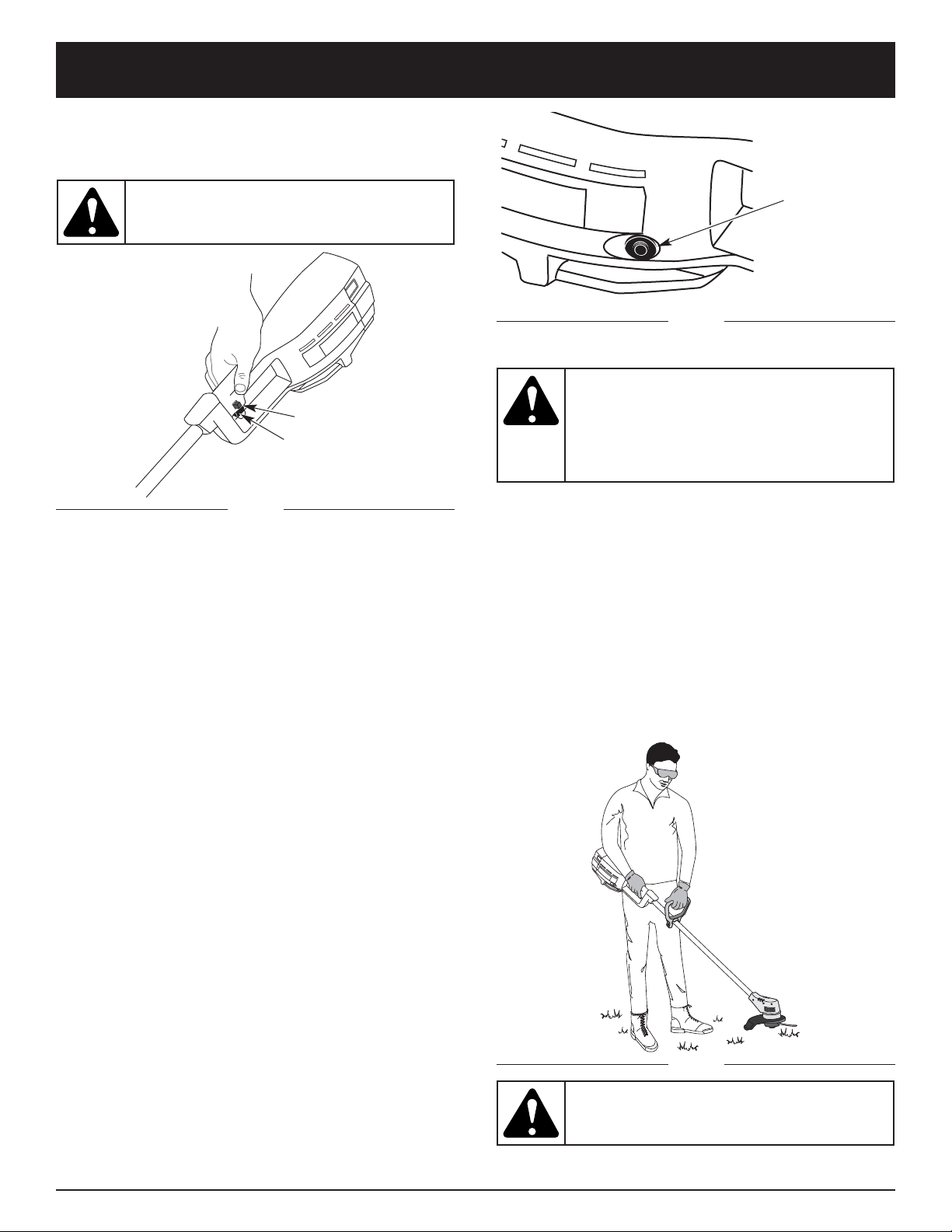

OPERATING INSTRUCTIONS

WARNING: To prevent serious injury, do not

carry the unit with your finger on the trigger.

HOLDING THE UNIT

Before operating the unit, stand in the operating position

and check that:

• The operator is wearing eye protection and proper

clothing.

• The operator’s right arm is slightly bent, the right hand

holding the housing grip.

•With a straight left arm, the left hand holding the

D-handle.

• The unit is at waist level.

• The trimmer bump head is parallel to the ground and

easily contacts the material to be cut without the

operator having to bend over (Fig. 8).

Fig. 8

2. Depress and hold the trigger.

3. Release the lock-off button.

STOPPING THE UNIT

Release the trigger to stop the trimmer.

STARTING THE UNIT

1. Press and hold the lock-off button in (Fig. 6). This

allows the trigger to operate.

Fig. 6

Lock-Off Button

Fig. 7

Overload

Protection

Switch

Trigger

OVERLOAD PROTECTION SWITCH

This unit is equipped with an overload protection switch

to prevent overheating damage to the motor.

If the switch pops out:

1. Release the trigger and allow the unit to cool for a

minute.

2. Press the overload switch to reset. Resume

operation (Fig. 7).

If the switch pops again shortly after the first time:

1. Allow the unit to cool for 15 to 30 minutes.

2. After the unit has cooled, press the overload switch

to reset. Resume operation

If the switch does not stay in or continues to pop out

during operation, take the unit to an authorized service

dealer for repair.

WARNING: Dress properly to reduce the risk

of injury when operating this unit. Do not wear

loose clothing or jewelry. Wear eye and

ear/hearing protection. Wear heavy, long

pants, boots and gloves. Do not wear short

pants, sandals or go barefoot.

WARNING: To prevent serious personal

injury, ensure the lock-off button resets each

time the trigger is released.

Page 10

10

OPERATING INSTRUCTIONS

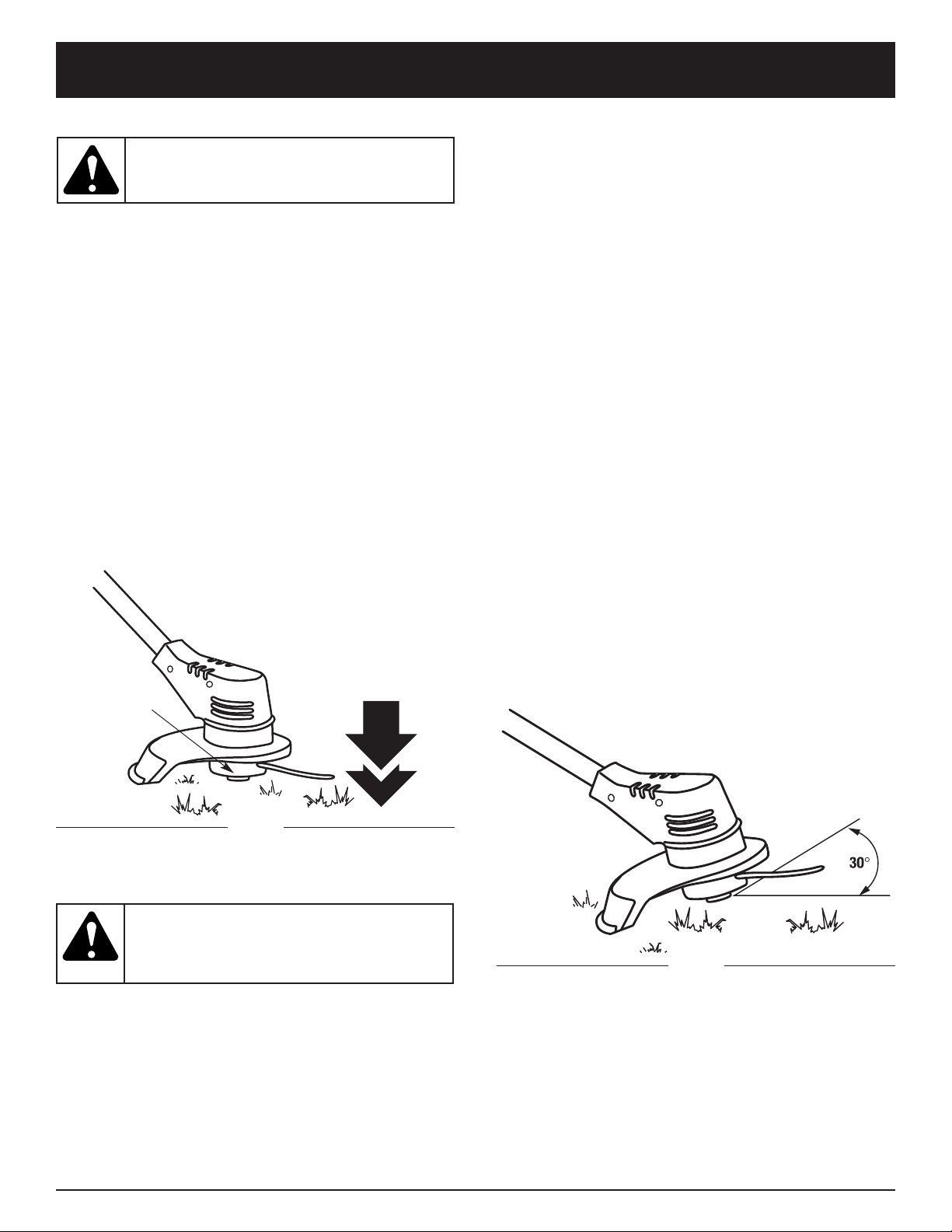

TIPS FOR BEST TRIMMING RESULTS

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip of the

line to do the cutting, especially along walls. Cutting with

more than the tip will reduce cutting efficiency and may

overload the motor.

• Cut grass over 8 inches (200 mm) by working from top

to bottom in small increments to avoid premature line

wear or motor drag.

• Cut from right to left whenever possible. Cutting to the left

improves the unit's cutting efficiency. Clippings are

thrown away from the operator.

• Slowly move the trimmer into and out of the cutting

area at the desired height. Move either in a forwardbackward or side-to-side motion. Cutting shorter

lengths produces the best results.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

• Following the trimming techniques previously explained

• What vegetation is cut

• Where vegetation is cut

For example, the line will wear faster when trimming against

a foundation wall as opposed to trimming around a tree.

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences and more.

Rotate the whole unit so that the cutting attachment is at

a 30° angle to the ground (Fig. 10).

NOTE: Always keep the trimming line fully extended.

Line release becomes more difficult as cutting

line becomes shorter.

Each time the head is bumped, approximately 1 inch

(25.4 mm) of trimming line is released. A blade in the

string guard will cut the line if excess line is released.

For best results, tap the head on bare ground or hard

soil. If line release is attempted in tall grass, the motor

may overheat. Always keep the trimming line fully

extended. Line release becomes more difficult as the

cutting line becomes shorter.

Fig. 9

Bump Head

OPERATING THE TRIMMER

Clear the area to be cut before each use. Remove all

objects such as rocks, broken glass, nails, wire, or string

which can be thrown or become entangled in the cutting

attachment. Clear the area of children, bystanders, and

pets. At a minimum, keep all children, bystanders and

pets outside a 50 feet (15m) radius; there still may be a

risk to bystanders from thrown objects. Bystanders

should be encouraged to wear eye protection. If you are

approached, stop the motor and cutting attachment

immediately.

NOTE: Remove protective tape from the line cut-off

blade before operating trimmer.

ADJUSTING TRIMMING LINE LENGTH

The bump head allows the operator to release more

trimming line without stopping the motor. As line

becomes frayed or worn, additional line can be released

by lightly tapping the trimming head on the ground while

operating the trimmer (Fig. 9).

CAUTION:

Do not remove or alter the line

cutting blade assembly. Excessive line length will

make the unit overheat. This may lead to serious

personal injury or damage to the unit.

WARNING: Always wear eye, hearing, foot

and body protection to reduce the risk of

injury when operating this unit.

Fig. 10

Page 11

11

MAINTENANCE AND REPAIR INSTRUCTIONS

SERVICING DOUBLE INSULATED UNITS

This unit is double-insulated. In a double-insulated unit,

two systems of insulation are provided instead of

grounding. There is no grounding provided and no

means of grounding should be added to this unit.

Extreme care and knowledge of the system is required

when servicing a double-insulated unit. Service should

be performed by qualified service personnel only.

Replacement parts for a double-insulated unit must be

identical to the parts they replace. Refer any repair to an

authorized service dealer. A double-insulated unit is

marked with the words “double insulation” or “double

insulated.”

LINE INSTALLATION

Always use genuine Genuine Factory Parts™ 0.080 in.

(2.03 mm.) replacement line. Using line other than

specified may cause the unit to overheat or fail.

There are two methods to replace the trimmer line:

•Wind the inner reel with new line

• Install a prewound inner reel

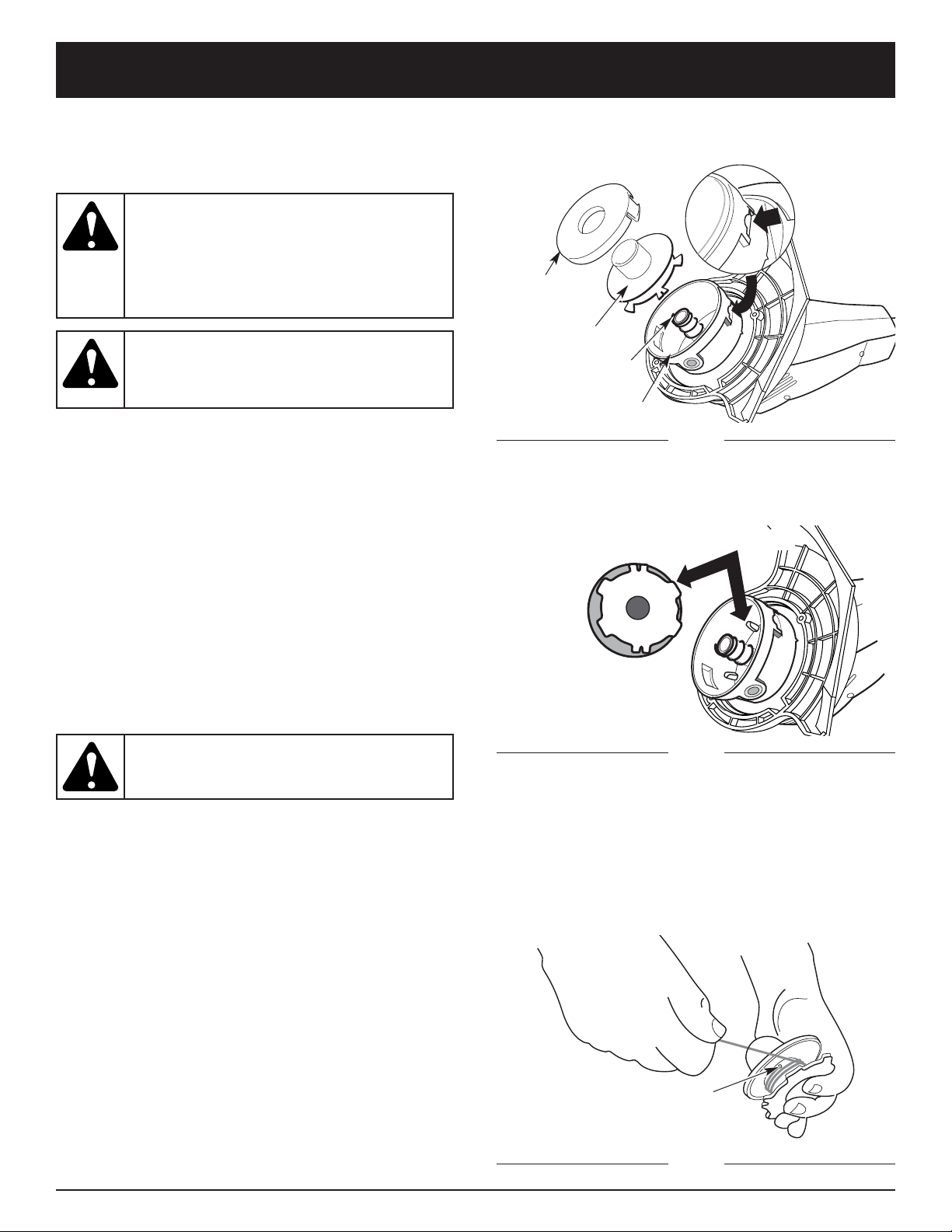

Winding the Existing Reel

1. Remove the bump head cover by pressing in both

bump head cover tabs visible on either side of the

bump head outer spool (Fig. 11).

NOTE: The spring will push the cover up when the tabs

release.

2. Remove the inner reel and spring (Fig. 11).

3. Use a clean cloth to wipe the inner surface of the

outer spool (Fig. 11).

WARNING: Never use metal-reinforced line,

wire, chain or rope. These can break off and

become dangerous projectiles.

WARNING: To prevent serious personal

injury, remove or disconnect the battery

before servicing, cleaning or removing

material from the unit.

WARNING: Battery tools do not have to be

plugged into an electrical outlet; therefore, they

are always in operating condition. To prevent

serious personal injury, take extra precautions

and care when cleaning, performing

maintenance and service, or when changing

the cutting attachment or other attachments.

The warranty on this unit does not cover items that have

been subjected to operator abuse or negligence. To

receive full value from the warranty, the operator must

maintain the unit as instructed in this operator’s manual.

Outer Spool

Spring

Inner Reel

Press Tabs

Bump Head

Cover

Fig. 11

Indexing Teeth

Inner Reel Hole

4. Check the indexing teeth on the inner reel and outer

spool for wear (Fig. 12). If necessary, remove burrs

or replace the reel and spool.

NOTE: Always clean the inner reel, outer spool and shaft

before reassembling the bump head.

5. Take approximately 12 feet (3.6 m) of new trimming

line and insert one end of the line into the hole in the

inner reel (Fig. 13).

6. Wind the line, in even and tight layers, onto the reel

(Fig. 13). Wind the line in the direction indicated on

the inner reel.

NOTE: Failure to wind the line in the direction indicated

will cause the bump head to operate incorrectly.

Fig. 12

Fig. 13

Page 12

12

MAINTENANCE AND REPAIR INSTRUCTIONS

11. Install the bump head cover over the inner reel. Align

the tabs on the cover with the slots in the outer

spool and press the cover evenly down until it snaps

into place.

NOTE: Make sure the bump head cover tabs snap into

place or the inner reel will come out during

operation.

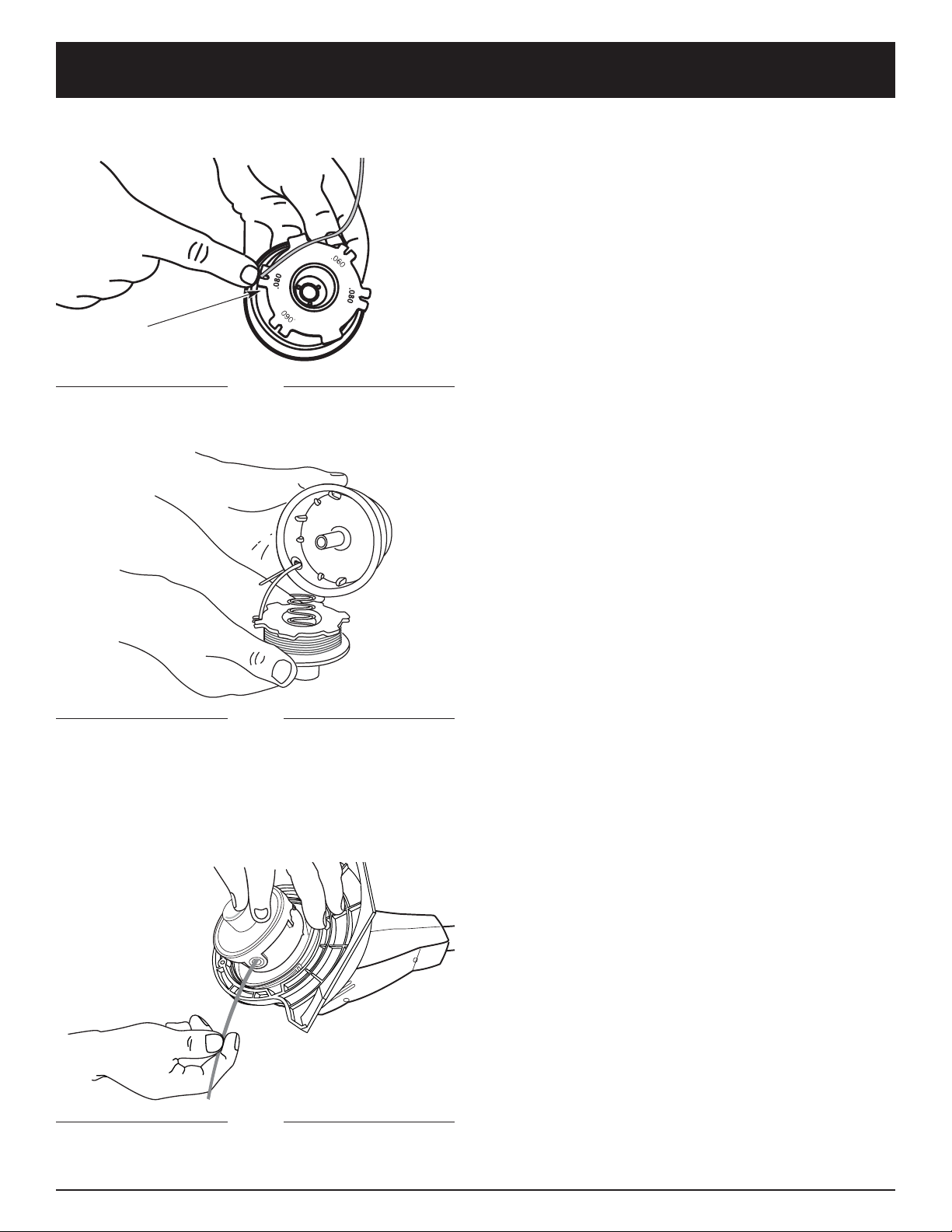

8. Insert the end of the line through the eyelet in the

outer spool (Fig. 15).

INSTALLING A PREWOUND REEL

Always use genuine replacement line. Using larger line

then the specified may make the motor overheat or fail.

1. Remove the bump head cover by pressing in both

bump head cover tabs visible on either side of the

bump head outer spool (Fig. 11).

NOTE: The spring will push the cover up when the tabs

release.

2. Remove the old inner reel and spring from the outer

spool (Fig. 11).

3. Remove the spring from the old inner reel

(Fig. 11).

4. Use a clean cloth to wipe the inner surface of the

outer spool (Fig. 12).

5. Insert the end of the line, on the prewound reel,

through the eyelet in the outer spool (Fig. 15).

6. Place inner reel and spring inside the outer spool.

NOTE: The spring must be assembled on the inner reel

before reassembling the bump head.

7. Hold the inner reel in place, grasp the line end and

pull firmly to release the line from the holding slot in

the inner reel (Fig. 16).

8. Install the bump head cover over the inner reel. Align

the tabs on the cover with the slots in the outer

spool and press the cover evenly down until it snaps

into place.

NOTE: Make sure the bump head cover tabs snap into

place or the inner reel will come out during

operation.

9. Place inner reel and spring inside the outer spool.

NOTE: The spring must be assembled on the inner reel

before reassembling the bump head.

10. Hold the inner reel in place, grasp the line end and

pull firmly to release the line from the holding slot in

the inner reel (Fig. 16).

Fig. 15

Fig. 16

7. Insert the end of the line into one of the two holding

slots (Fig. 14).

Fig. 14

Holding

Slot

Page 13

13

WARNING: If the battery pack has signs of

leakage, do not touch. Do not open or

mutilate the battery. Released electrolyte is

corrosive and may cause damage to the eyes

or skin. To avoid serious injury, take the unit

to an authorized service dealer for repair.

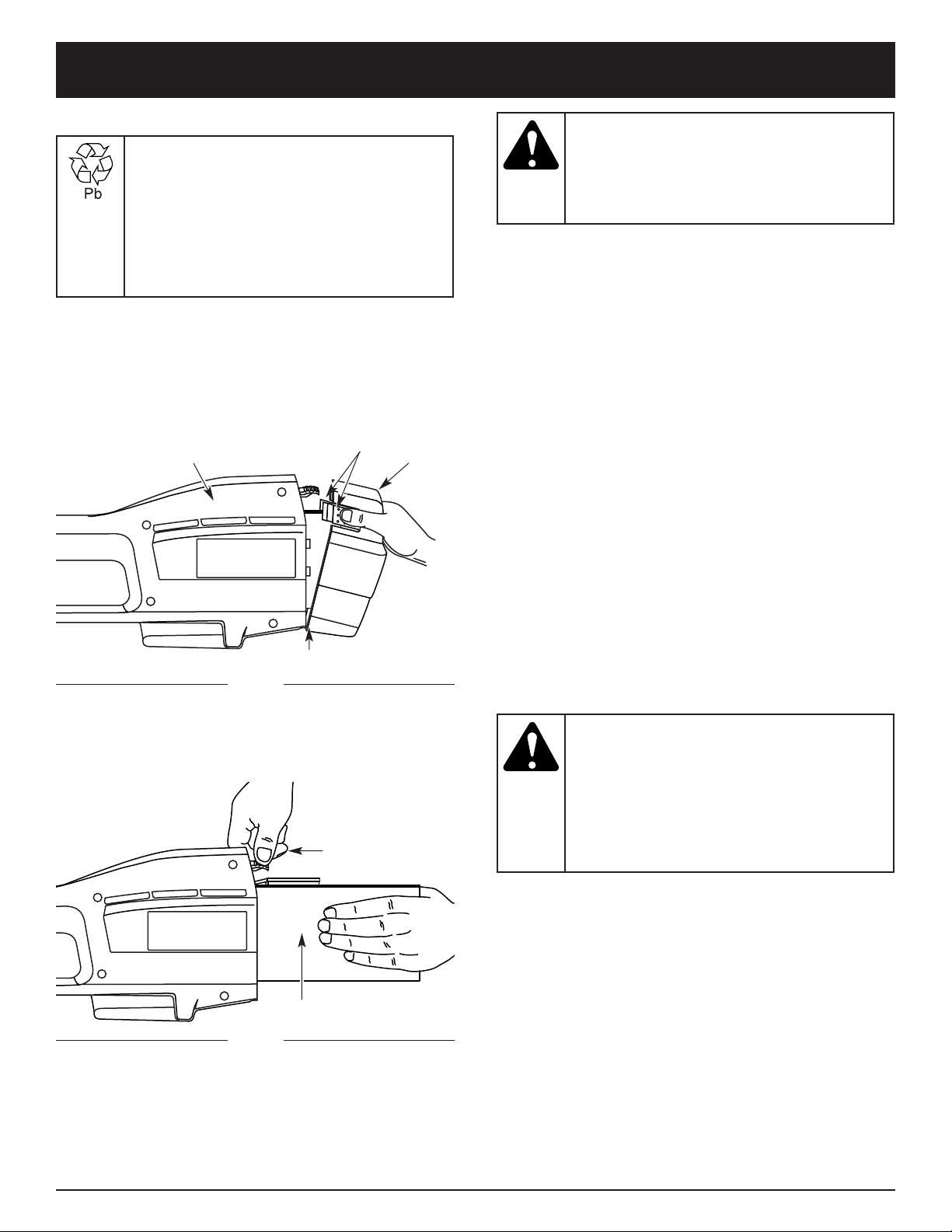

BATTERY PACK REPLACEMENT

Removing the Battery

1. Push the two latches on the side of the battery housing

door in and swing the door down. Unhook the door

from the slot on the bottom of the battery housing by

lifting up and away. Set the door aside (Fig. 17).

Fig. 17

Fig. 18

Installing the Battery

1. Slide the battery into the battery housing until the

battery retaining latch locks the battery into place

(Fig 18).

2. Reinstall the door by hooking over the slot on the

bottom of the battery housing. Swing the battery

housing door closed until the two latches snap into

place.

For best performance when reinstalling the battery:

• Check the battery terminals for corrosion and clean

them if necessary. Clean the terminals using a dry

scrubbing pad and wipe clean with a dry cloth. Never

use liquids to clean terminals.

• Check the battery casing for signs of damage and

replace it if needed.

NOTE: If you clean or replace the battery, apply a small

amount of electrically conductive grease to the

terminals only. This grease is available at any

local electronics store. Do not use automotive or

bearing grease.

Storing the Battery Pack

If you are removing the battery for replacement or for

storage, cover the battery pack’s terminals with heavy

duty electrical tape.

Latches

Hook

Battery

Retaining Latch

Door

Battery

Battery Housing

2. Push down on the battery retaining latch while

pulling battery out (Fig. 18).

NOTE: You might notice grease on the terminal contacts

when the battery is removed. This is normal.

MAINTENANCE AND REPAIR INSTRUCTIONS

To preserve natural resources, please recycle

or dispose of properly. THIS PRODUCT

CONTAINS A SEALED LEAD-ACID BATTERY

AND MUST BE DISPOSED OF PROPERLY.

Local, state, or federal laws may prohibit

disposal of sealed lead-acid batteries in

ordinary trash. Consult your local waste

authority for information regarding available

recycling and/or disposal options.

WARNING: Do not attempt to destroy or

disassemble battery or remove any of its

components. Sealed lead-acid batteries must

be recycled or disposed of properly. Never

touch both terminals with metal objects

and/or body parts, a short circuit may result.

Keep away from children. Failure to comply

with these warnings could result in fire and/or

serious personal injury.

Page 14

14

CLEANING

Switch off the unit and disconnect it from the power

source. Use a small brush to clean off the outside of the

unit. Do not use strong detergents. Household cleaners

that contain aromatic oils such as pine and lemon, and

solvents such as kerosene, can damage plastic housing

or handle. Wipe off any moisture with a soft cloth. Also

keep the air vents free of obstructions.

STORAGE

• Allow the unit to cool before storing.

• Lock the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

MAINTENANCE AND REPAIR INSTRUCTIONS

WARNING: To avoid serious personal injury,

always turn your trimmer off and remove the

battery before you clean or service it.

REPLACING THE CHARGER

Replace the charger if it is damaged, if the barrel

connector or cord become damaged, or if the barrel

connector is not contacting the unit properly.

Your trimmer requires a 12V charger (182534) and

charging station (180295). The charging instructions

refer only to these parts.

1. Unplug the charger from the wall outlet and remove

the unit from the charging station.

2. Remove the screw from the clamp holding the barrel

connector in place using a standard or T-20 Torx bit

screwdriver (Fig. 19).

3. Remove the barrel connector from the slot and

replace the charger, if needed.

4. Insert the narrow side of the barrel connector wire

into the groove in the slot of the charging station.

Ensure that the barrel connector is inserted correctly

and secure (Fig. 19).

5. Reinstall the clamp and screw.

6. Plug the charger into the wall outlet. Refer to

Charging the Unit for charging instructions.

Barrel Connector

Clamp

Charging Station

Fig. 19

Edge of Barrel

Connector Wire

Groove

Charger

CAUTION: Only use the type of charger

specified for this unit. Any other type may

cause damage to the unit, damage to the

batteries or possible injury.

WARNING: Battery tools do not have to be

plugged into an electrical outlet; therefore,

they are always in operating condition. To

prevent serious personal injury, take extra

precautions and care when cleaning the unit.

ACCESSORIES AND REPLACEMENT PARTS

Cutting Attachment Shield . . . . . . . . . . . . . . . . . 180293

Replacement Line . . . . . . . . . . . . . . . . . . . . . . . 610375

Replacement Line Cartridge . . . . . . . . . . . . . . . . 180292

Inner Reel Spring . . . . . . . . . . . . . . . . . . . . . . . . 180374

Bump Head Cover . . . . . . . . . . . . . . . . . . . . . . . 180376

Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182534

Charging Station . . . . . . . . . . . . . . . . . . . . . . . . . 180295

12 Volt Battery Pack . . . . . . . . . . . . . . . . . . . . . . 182391

Page 15

15

TROUBLESHOOTING

CAUSE ACTION

Cutting attachment bound with grass Stop the unit and clean cutting attachment

Cutting attachment out of line Refill with new line

Inner reel bound up Replace the inner reel

Cutting attachment dirty Clean inner reel and outer spool

Line welded Disassemble, remove the welded section

and rewind the line

Line twisted when refilled Disassemble and rewind the line

Not enough line is exposed Push the Bump Knob and pull out line until

4 inches (102 mm.) of line is outside of the

cutting attachment

CAUSE ACTION

Battery is not charged Charge the battery

Overload protection switch has popped Reset overload protection switch

MOTOR OPERATES SLOWLY OR WILL NOT OPERATE

BATTERY WILL NOT CHARGE

CAUSE ACTION

No power to charger or battery Check charger and charging station

Battery has failed Replace the battery

CUTTING ATTACHMENT WILL NOT ADVANCE LINE

SPECIFICATIONS

Motor.................................................................................................................................................. 12 Volt DC, 15 Amps

Battery......................................................................................................................................... Sealed Lead-Acid, 12 Volt

Motor Wire Housing Tube............................................................................................................................ Aluminum Tube

Unit Weight (With battery, cutting attachment shield and D-handle)...................................................... 10.2 lbs. (4.63 kg.)

Cutting Mechanism.............................................................................................................................................Bump Head

Line Spool Diameter...................................................................................................................................... 3 in (76.2 mm)

Trimming Line Diameter......................................................................................................................... 0.080 in (2.03 mm.)

Cutting Path Diameter................................................................................................................................. 10 in. (254 mm)

BATTERY AND MOTOR

Page 16

16

MANUFACTURER’S LIMITED WARRANTY FOR:

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind Troy-Bilt LLC During the period of

the Warranty, the exclusive remedy is repair or

replacement of the product as set forth above. (Some

states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to

you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. TroyBilt LLC shall not be liable for incidental or

consequential loss or damages including, without

limitation, expenses incurred for substitute or

replacement lawn care services, for transportation or

for related expenses, or for rental expenses to

temporarily replace a warranted product. (Some states

do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold.

Alteration of the safety features of the product shall void

this Warranty. You assume the risk and liability for loss,

damage, or injury to you and your property and/or to

others and their property arising out of the use or misuse

or inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for

whom it was purchased as a gift.

How State Law Relates to this Warranty: This warranty

gives you specific legal rights, and you may also have

other rights which vary from state to state.

To locate your nearest service dealer dial

1-800-520-5520.

Troy-Bilt LLC

P.O. Box 361131

Cleveland, OH 44136-0019

The limited warranty set forth below is given by Troy-Bilt

LLC with respect to new merchandise purchased and used

in the United States, its possessions and territories.

Troy-Bilt LLC warrants this product against defects in

material and workmanship for a period of two (2) years

commencing on the date of original purchase and will, at its

option, repair or replace, free of charge, any part found to

be defective in material or workmanship. This limited

warranty shall only apply if this product has been operated

and maintained in accordance with the Operator’s Manual

furnished with the product, and has not been subject to

misuse, abuse, commercial use, neglect, accident,

improper maintenance, alteration, vandalism, theft, fire,

water or damage because of other peril or natural disaster.

Damage resulting from the installation or use of any

accessory or attachment not approved by Troy-Bilt LLC for

use with the product(s) covered by this manual will void

your warranty as to any resulting damage. This warranty is

limited to ninety (90) days from the date of original retail

purchase for any Troy-Bilt product that is used for rental or

commercial purposes, or any other income-producing

purpose.

HOW TO OBTAIN SERVICE: Warranty service is

available, WITH PROOF OF PURCHASE THROUGH

YOUR LOCAL AUTHORIZED SERVICE DEALER. To locate

the dealer in your area, visit our website at www.troybilt.com,

check for a listing in the Yellow Pages, call 1-800-520-

5520 or write to

P.O. Box 361131, Cleveland, OH 44136-

0019

.

This limited warranty does not provide coverage in

the following cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments,

Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting

Line, Inner Reels, Starter Pulley, Starter Ropes, Drive

Belts

C. Troy-Bilt LLC does not extend any warranty for

products sold or exported outside of the United

States of America, its possessions and territories,

except those sold through Troy-Bilt’s authorized

channels of export distribution.

Troy-Bilt LLC reserves the right to change or improve the

design of any Troy-Bilt Product without assuming any

obligation to modify any product previously manufactured.

Page 17

Désherbeuse à

batterie de 12 volts

Model TB55B

P/N 769-00532 (12/02)

IMPRIME AUX ÉTATS-UNIS

Manuel de L’utilisateur

IMPORTANT : LISEZ LES RÈGLES ET CONSIGNES DE SÉCURITÉ SOIGNEUSEMENT

Page 18

F2

TABLE DES MATIÈRES

Contenu Page

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F2

Consignes de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F3

Familiarisez-vous avec votre appareil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F6

Instructions de montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F7

Mode d'emploi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F8

Entretien et réparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F11

Nettoyage et entreposage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F14

Accessoires/pièces de rechange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F14

Tableau de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F15

Caractéristiques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F15

Garantie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F16

Liste des Pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Intérieure de la Couverture Arrière

Ce manuel de l'utilisateur est un élément important de votre nouvelle désherbeuse/débroussailleuse. Il a été conçu pour

vous aider à assembler, préparer et faire l'entretien de l'appareil afin d'assurer des performances optimales. Prenez soin

de lire et comprendre son contenu.

Avant d'assembler votre nouvel équipement, repérez la plaque signalétique de l'appareil et copiez ses informations dans

l'espace ci-dessous. Ces informations sont essentielles si vous désirez obtenir de l'aide auprès de notre service

technique ou d'un distributeur agréé.

• Le numéro de modèle se trouve sur le côté du carter du moteur. Un exemple de plaque signalétique est présenté

ci-dessous. Veuillez copier le numéro de modèle et le numéro de série de l'équipement dans l'espace ci-dessous

afin de pouvoir vous y référer ultérieurement.

Si vous éprouvez des difficultés à assembler ce produit ou si vous avez des questions concernant les commandes, le

fonctionnement ou l'entretien de cet appareil, veuillez communiquer avec notre service technique.

Appelez le 1-800-520-5520 pour joindre un de nos représentants. Veuillez avoir les numéros de modèle et

de série de l'appareil à portée de main lorsque vous appelez. Reportez-vous à la section précédente pour

savoir où trouver ces informations. On vous demandera le numéro de série au moment de traiter votre

demande.

TROUVER LE NUMÉRO DE MODÈLE

SERVICE TECHNIQUE

Pour de plus amples informations à propos de votre appareil, visitez www.troybilt.com

Numéro de modèle

Numéro de série

Numéro de pièce mère

Copiez le numéro de

modèle / pièce mère ici :

Copiez le numéro de série ici :

MODEL :

S/N :

ITEM :

Page 19

F3

CONSIGNES DE SÉCURITÉ

DANGER:

le non-respect d’un avertissement

peut causer dommages matériels ou

blessures graves pour tous. Respectez les

consignes de sécurité afin de réduire les

risques d'incendie, d'électrocution et de

blessures.

AVERTISSEMENT: le non-respect d’un

avertissement peut causer dommages

matériels ou blessures graves pour tous.

Respectez les consignes de sécurité afin de

réduire les risques d'incendie, d'électrocution

et de blessures.

MISE EN GARDE: le non-respect d’un

avertissement peut causer dommages

matériels ou blessures graves pour tous.

Respectez toujours les consignes de sécurité

afin de réduire les risques d'incendie,

d'électrocution et de blessures.

SYMBOLE ALERTE DE SÉCURITÉ : indique

un danger, un avertissement ou une mise en

garde. Soyez vigilant afin d'éviter toute

blessure grave. Ce symbole peut être

combiné à d'autres symboles ou

pictogrammes.

SYMBOLE SIGNIFICATION

Les symboles de sécurité attirent votre attention sur

des dangers potentiels. Ces symboles et leurs détails

explicatifs méritent que vous les lisiez et compreniez

bien. Les avertissements de sécurité ne peuvent éviter

les dangers de par eux-mêmes. Les consignes ou

mises en garde qu'ils donnent ne remplacent pas des

mesures préventives appropriées contre les accidents.

REMARQUE: donne des informations ou des

instructions vitales pour le fonctionnement ou

l'entretien de l'équipement.

SYMBOLE SIGNIFICATION

AVANT UTILISATION

• Veuillez lire les instructions avec soin. Familiarisez-vous avec

les commandes et l'utilisation correcte de cet appareil.

• N'utilisez pas l'appareil si vous êtes fatigué, malade ou sous

l'effet de l'alcool, de drogues ou de médicaments.

•

Les enfants et adolescents de moins de 15 ans ne doivent pas

utiliser l'appareil exceptés les adolescents assistés d'un adulte.

• Inspectez l'appareil avant utilisation. Remplacez les pièces

endommagées.

Recherchez s'il y a des fuites de batterie.

Assurez-vous que les fixations sont solidement en place.

Remplacez les pièces de l'accessoire de coupe qui sont

fendillées, ébréchées ou endommagées. Assurez-vous que

l'accessoire de coupe est correctement installé et solidement

fixé. Assurez-vous que le protecteur d'accessoire de coupe est

correctement fixé et positionné comme recommandé. Vous

risquez sinon de causer des blessures à l'opérateur et aux

spectateurs, et d'endommager l'appareil.

• N'utilisez que du fil de remplacement Genuine Factory Parts

MC

d'origine de 2,03 mm (0,080 po) de diamètre. N'utilisez

jamais de fil, de chaîne ou de cordon à renfort métallique car

ils peuvent se briser et se transformer en projectile

dangereux.

• Soyez conscient des risques de blessure à la tête, aux mains

et aux pieds.

• Dégagez la zone de coupe avant chaque usage. Enlevez tous

les objets pouvant être projetés ou happés par l'accessoire de

coupe : cailloux, verre brisé, clous, fil ou ficelle. Éloignez

enfants, spectateurs et animaux de la zone de coupe. Tenez-les

à au moins 15 m (50 pi) de là mais sachez que les spectateurs

risquent quand même d'être atteints par des objets projetés.

Les spectateurs doivent porter des protections oculaires.

Arrêtez immédiatement le moteur et l'accessoire de coupe si

quelqu'un s'approche de vous.

• Cet appareil n'est pas conçu pour servir de débroussailleuse.

N'utilisez cet appareil avec aucun type de lame ou

d'accessoire de débroussaillage.

AVERTISSEMENTS DE SÉCURITÉ POUR LES

DÉSHERBEUSES À BATTERIE

• Il n’est pas nécessaire de brancher dans une prise les outils à

batterie, ils peuvent donc fonctionner à tout moment. Pensez

aux dangers potentiels même si l’outil ne fonctionne pas.

Faites attention lorsque vous effectuez l'entretien ou la

maintenance.

• Enlevez ou déconnectez la batterie avant tout entretien,

nettoyage ou retrait de pièces de l’appareil.

• Utilisez uniquement la station de charge fournie avec

l'appareil. Si vous y substituez un autre, vous risquez de faire

exploser les batteries et causer des blessures graves.

• Ne chargez pas l’appareil sous la pluie ou dans un lieu humide.

AVERTISSEMENTS DE SÉCURITÉ

CONCERNANT LES SUPPORTS DE CHARGE ET

LES BATTERIES RECHARGEABLES AU PLOMB

• Lisez toutes les instructions et précautions du manuel

concernant l’appareil et son support de charge avant

d’utiliser ce dernier.

• N’exposez pas le chargeur à la pluie ou à la neige.

AVERTISSEMENT: Respectez toujours les

consignes de sécurité durant l’utilisation des

désherbeuses à batterie afin de réduire les

risques d’incendie, d’électrocution et de

blessures. Prenez soin de bien lire et

comprendre tout le manuel de l’utilisateur

avant d’utiliser la désherbeuse. Faites

particulièrement attention au mode d'emploi

et aux avertissements de sécurité.

LIRE TOUTES LES INSTRUCTIONS

Page 20

F4

• Afin de réduire les risques de blessures, ne chargez que les

batteries hermétiques rechargeables au plomb. Les autres

types de batteries peuvent exploser et causer des blessures

et des dommages.

• Pour réduire le risque de choc électrique, cet appareil est

pourvu d’une fiche polarisée (une lame est plus large que

l’autre). Cet appareil ne être inséré dans une prise polarisée que

d’une seule manière. S’il n’est pas possible d’insérer

entièrement la fiche dans la prise, essayez de brancher la fiche

dans l’autre sens. Si malgré tout, il n’est pas possible d’insérer

la fiche, remplacez le cordon par un cordon qui comporte les

bonnes fiches. Ne modifiez cet appareil en aucun cas.

• Pour éviter d’endommager le corps du chargeur et son cordon,

tirez sur le premier au moment de débrancher le chargeur.

• Placez le cordon du chargeur de façon qu’il ne soit pas

piétiné, accroché ou endommagé d’une manière quelconque.

• N'utilisez pas le chargeur si le cordon ou la prise est

endommagée, sinon remplacez-les immédiatement.

• N’utilisez pas le chargeur s’il a reçu un coup dur, est tombé

ou a été endommagé. Si le boîtier du chargeur est

endommagé, remplacez le chargeur.

• Ne démontez par le chargeur car il n'est pas conçu pour cela

et vous risquez de provoquer l'électrocution ou un incendie.

• Pour diminuer les risques d’électrocution, débranchez le

chargeur de la prise avant tout entretien ou nettoyage.

• N'utilisez pas le chargeur en plein air.

• Utilisez uniquement une batterie de type et de format suivants

: batterie hermétique rechargeable de 12 volts c.c.

• Ne jetez pas la batterie dans le feu car ses éléments

pourraient exploser. Recyclez la batterie. Consultez à ce

sujet vos responsables locaux en matière de recyclage et de

mise au rebut.

• Ne chargez pas la batterie sous la pluie ou dans un lieu

humide.

• Manipulez la batterie avec soin afin de ne pas provoquer de

court-circuit avec des objets conducteurs tel que des anneaux,

des bracelets ou des clés. La batterie ou l’objet conducteur

pourrait en effet surchauffer et causer des brûlures.

• Chargez la batterie dans un endroit où la température se

situe entre 10ºC (50ºF) et 38ºC (100ºF).

• Évitez d’ouvrir ou d’endommager la batterie. Une fois

relâché, l’électrolyte, qui est corrosif, peut endommager les

yeux ou la peau. Il peut aussi être toxique s’il est avalé.

PENDANT L'UTILISATION

• Pour éviter tout démarrage accidentel, ne transportez jamais

l’appareil le doigt sur la détente.

• Portez des lunettes de sécurité conformes aux normes ANSI

Z87.1-1989 ainsi que des protège-oreilles durant l'utilisation. En

cas de poussière, portez un masque facial ou antipoussières.

Les chemises à manches longues sont conseillées.

• Restez en alerte. Faites attention à ce que vous faites. Faites

preuve de bon sens.

• Portez des pantalons épais et longs, des bottes et des gants.

Ne marchez pas pieds nus et évitez les pantalons courts et

les sandales.

• Habillez-vous correctement. Ne portez pas de vêtements

lâches ni de bijoux pour éviter qu’ils ne soient happés par

des pièces mobiles. Relevez les cheveux au-dessus des

épaules.

• Ajustez la poignée en D selon votre taille pour mieux

l'agripper.

• N'utilisez l'appareil qu'en plein jour ou avec un bon éclairage

artificiel.

• Utilisez les outils appropriés. N'employez cet outil que pour

son usage prévu.

• Ne vous étirez pas. Tenez-vous toujours en équilibre.

• Ne forcez pas l’appareil. Il fonctionnera mieux et posera

moins de risques de blessures à la vitesse pour laquelle il a

été conçu.

• Tenez toujours l'appareil des deux mains lorsqu’il est en

marche. Agrippez fermement la poignée du boîtier de batterie

et la poignée en D.

• N'utilisez que des pièces de équipement original rechange et

accessoires Genuine Factory Parts

MC

d'origine pour cet appareil.

Elles sont disponibles auprès de votre concessionnaire agréé.

L'utilisation de pièces ou accessoires autres que ceux de

éqiupement original peut causer des blessures graves,

endommager l’appareil et annuler sa garantie.

• La désherbeuse est conçue pour couper l'herbe et les

mauvaises herbes légères, et pour la taille décorative. Ne

l’utilisez pas comme coupe-bordure.

• Avant de démarrer l'appareil, assurez-vous que l'accessoire

de coupe ne touche aucun objet.

• Si vous heurtez ou happez un corps étranger, arrêtez

l’appareil immédiatement et vérifiez qu’il n’est pas

endommagé. Réparez les dommages avant de continuer.

N’utilisez pas l'appareil avec des pièces desserrées ou

endommagées.

• Relâchez la manette, mettez le bouton de verrouillage et

laissez le moteur s'arrêter en cas d’entretien ou de

réparation.

• Gardez les mains, le visage et les pieds éloignés des pièces

mobiles. Ne touchez pas ni essayez d'arrêter l'accessoire de

coupe en rotation.

• Arrêtez toujours le moteur lors d’une interruption ou si vous

vous déplacez d'un lieu de coupe à l’autre.

• Le protecteur d'accessoire de coupe doit toujours être mis

lors de l'utilisation de l'appareil. N’utilisez pas l'appareil sans

que le fil, de type approprié, soit bien déployé. Assurez-vous

que le fil ne dépasse pas le protecteur de sécurité.

• Gardez l'appareil exempt d'accumulation de végétation ou

autres matières. Celles-ci peuvent rester logées entre

l'accessoire de coupe et le protecteur.

AUTRES AVERTISSEMENTS DE SÉCURITÉ

• Laissez le moteur se refroidir avant de l'entreposer ou de le

transporter. Attachez bien l'appareil pendant le transport.

• Rangez l'appareil dans un endroit verrouillé et sec, ou élevé

et sec, hors de portée des enfants, pour éviter une utilisation

indésirable ou un accident.

• Ne trempez et n'arrosez jamais l'appareil avec de l'eau ou

tout autre liquide. Gardez les poignées sèches, propres et

exemptes de débris. Nettoyez après chaque usage. Voir les

sections Nettoyage et Entreposage.

• Conservez ces instructions. Consultez-les souvent et

servez-vous en pour instruire d'autres usagers. Si vous

prêtez l'appareil à quelqu'un, prêtez-lui également ces

instructions.

CONSERVEZ CES INSTRUCTIONS

CONSIGNES DE SÉCURITÉ

Page 21

F5

SYMBOLE SIGNIFICATION

• SYMBOLE ALERTE DE

SÉCURITÉ

Indique un danger, un avertissement

ou une mise en garde. Ce symbole

peut être combiné à d'autres

symboles ou pictogrammes.

•AVERTISSEMENT - LISEZ LE

MANUEL DE L'UTILISATEUR

Lisez le manuel de l'utilisateur et

suivez tous les avertissements et

consignes de sécurité. Vous pourriez

à défaut entraîner des blessures

graves pour vous ou d'autres

personnes.

• PORTEZ DES PROTECTIONS

(YEUX ET OREILLES)

AVERTISSEMENT: les objets

projetés et les bruits forts peuvent

endommager la vue et l’ouïe. Portez

une visière de norme ANSI Z87.11989 et des protège-oreilles pendant

l'utilisation.

SYMBOLE SIGNIFICATION

• LES OBJETS PROJETÉS ET LA

TÊTE ROTATIVE PEUVENT

CAUSER DES BLESSURES

GRAVES

AVERTISSEMENT: ne faites pas

fonctionner sans protecteur de

sécurité en plastique. Tenez-vous à

l'écart de l'accessoire de coupe

rotatif.

• LAME AIGUISÉE

AVERTISSEMENT: le protecteur

d'accessoire de coupe comporte

une lame aiguisée. Ne touchez pas

la lame pour éviter des blessures

graves.

• ÉLOIGNEZ LES SPECTATEURS

AVERTISSEMENT: éloignez tout

spectateur, les enfants et les

animaux domestiques en particulier,

d'au moins 15 m (50 pi) de la zone

de coupe.

SYMBOLES DE SÉCURITÉ ET INTERNATIONAUX

Ce manuel de l'utilisateur décrit les symboles et pictogrammes de sécurité et internationaux pouvant apparaître sur ce

produit. Consultez le manuel de l'utilisateur pour les informations concernant la sécurité, le montage, le fonctionnement,

l'entretien et les réparations.

CONSIGNES DE SÉCURITÉ

Page 22

F6

APPLICATIONS

Comme désherbeuse :

• Coupe d'herbe et de mauvaises herbes légères

• Taille autour des arbres, des clôtures, etc.

CONSIGNES DE SÉCURITÉ

FAMILIARISEZ-VOUS AVEC VOTRE APPAREIL

Carter

Bouton de butée

Poignée en D

Lame coupante

Détente

Bouton de

verrouillage

Accessoire de coupe

Boîtier des fils du moteur

Poignée

Commutateur de

protection contre les

surcharges

Boîtier de batterie

Protecteur

d'accessoire

de coupe

Porte de batterie

Évents

Page 23

F7

MISE EN GARDE : Fixez bien la station au

mur pour éviter tout risque de blessures ou

de dommages à l’appareil.

INSTRUCTIONS DE MONTAGE

3. Branchez le chargeur dans la prise murale et

enroulez tout excédent de fil autour de l’enrouleur de

la station de charge (Fig. 3).

Prise murale

Station de charge

Vis

Poteau

mural

Enrouleur

Chargeur

Fig. 3

MONTAGE DE LA STATION DE CHARGE

NOTA :Montez la station de charge et chargez l’appareil

pendant 36 heures au moins avant sa première

utilisation.

Comme l'appareil peut rester sur sa station de charge

sans danger, vous pouvez placer la station là où

l'appareil sera rangé. L’endroit doit être frais, sec et bien

aéré, et l’appareil doit y être verrouillé hors de portée

des enfants.

Rangez et chargez l’appareil dans un endroit où la

température se situe entre 10ºC (50ºF) et 38ºC (100ºF).

1. Placez la station de charge près d’une prise murale,

assez haut pour qu’elle ne soit pas sur le sol.

2. Repérez le poteau du mur et montez la station au mur

à l'aide des trois vis fournies (Fig. 3). Assurez-vous

que les vis pénètrent dans le poteau pour bien tenir.

Indicateur de

charge

Fig. 1

Fig. 2

RÉGLAGE DE LA POIGNÉE EN D

REMARQUE : La poignée en D est déjà en position à

l'arrière de l'arbre et n'a normalement pas besoin

d'être déplacée.

1. Repérez l'écrou papillon sur la poignée en D.

Dévissez l'écrou papillon suffisamment pour

desserrer la poignée en D (Fig. 1).

REMARQUE : il n'est pas nécessaire d'enlever l'écrou

papillon, la rondelle ou le boulon.

2. Tournez la poignée en D à la verticale, sur le devant

du corps de l'arbre (Fig. 1).

REMARQUE : la poignée en D doit être inclinée vers la

tête d'entraînement de l'appareil.

3. Tenez l'appareil en position de fonctionnement.

Repositionnez au besoin la poignée en D de manière

à assurer la meilleure prise possible (Fig.2).

Écrou

papillon

4. Serrez l'écrou papillon jusqu'à bien fixer la poignée

en D.

Page 24

F8

MODE D'EMPLOI

2. Lorsque l’indicateur rouge du chargeur s’allume, la

batterie est en train de se charger (Fig. 5). S’il ne

s’allume pas, vérifiez les points suivants :

a. Chargeur branché dans une bonne prise murale.

b. Appareil bien assis dans la station de charge et

connecteur rond bien inséré dans l’appareil.

c. Connecteur rond bien installé dans la station de

charge. Voir Remplacement du chargeur.

d. Prise murale sous tension.

NOTA :Si la prise murale fonctionne par interrupteur,

mettez-le sous tension.

Évents

CHARGE DE L’APPAREIL

Veillez à ce que la station de charge soit bien fixée au mur

et que le chargeur soit branché dans une bonne prise.

NOTA :Chargez l’appareil pendant 36 heures au moins

avant sa première utilisation.

1. Glissez l’appareil dans la station de charge jusqu’à

ce qu’il soit bien assis (Fig. 4). Le connecteur rond

de la station de charge s’insère alors dans l’appareil.

Voir Remplacement du chargeur.

NOTA :La batterie chauffe pendant la charge. Assurez-

vous que les évents du boîtier de la batterie sont

toujours dégagés (Fig. 4).

Charge : conseils pour des performances maximales

• Rangez et chargez l'appareil dans un endroit où les

températures se situent entre 10ºC (50ºF) et 38ºC

(100ºF). Un stockage de l’appareil ou de la batterie à

des températures supérieures à 38ºC (100ºF) réduira la

vie de la batterie.

• Un stockage à moins de 10ºC (50ºF) ne la réduira pas

mais rallongera le temps de charge.

• Rangez l’appareil sur la station après utilisation. Il est

conçu de façon à ce que la batterie ne puisse être

surchargée.

NOTA :L’indicateur de charge reste allumé lorsque

l’appareil est bien installé sur la station.

Effets de la température sur les temps de charge

• De 10ºC (50ºF) à 38ºC (100ºF) – Batterie chargée en

moins de 24 heures.

•De 4ºC (40ºF) à 10ºC (50ºF) – La charge peut

nécessiter jusqu’à 48 heures.

•Moins de 4ºC (40ºF) – La batterie ne sera pas chargée

complètement.

NOTA :Le temps de fonctionnement sera réduit si la

batterie n’est pas complètement chargée.

Fig. 4

Station de

charge

Connecteur

rond

Fig. 5

Indicateur de

charge

3. Chargez la batterie jusqu’à ce que l’indicateur rouge

du chargeur se mette au vert (Fig. 5).

NOTA :La durée de fonctionnement de l’appareil et la

durée de vie de la batterie seront raccourcies si

l’appareil n’est pas complètement chargé entre

les utilisations.

4. Replacez l’appareil sur la station après chaque

utilisation. L’appareil est conçu de manière à ce que

la batterie ne puisse être surchargée.

AVERTISSEMENT : Pour éviter des blessures

graves, faites vérifier la prise par un électricien

qualifié si elle ne fonctionne pas correctement.

Page 25

F9

MODE D'EMPLOI

TENUE DE L’APPAREIL

Avant de faire marcher l'appareil, tenez-vous en position

de fonctionnement et vérifiez les points suivants :

• L'opérateur porte une visière et des vêtements

appropriés.

• Le bras droit est légèrement plié et la main tient l'arbre

par la poignée du boîtier.

• Le bras gauche est droit et la main tient la poignée en D.

• L'appareil est à hauteur de ceinture.

• La tête Bump Head de la désherbeuse est parallèle au

sol et touche facilement la végétation sans que

l'opérateur ne doive se pencher (Fig. 8).

2. Appuyez sur la détente et gardez-la enfoncée.

3. Relâchez le bouton de verrouillage.

POUR ARRÊTER L’APPAREIL

Pour arrêter la désherbeuse, relâchez la détente.

POUR DÉMARRER L’APPAREIL

1. Appuyez sur le bouton de verrouillage et maintenezle enfoncé (Fig. 6). Cela permet d’utiliser la détente.

Fig. 6

Bouton de verrouillage

Fig. 7

Commutateur de

protection contre

les surcharges

Détente

COMMUTATEUR DE PROTECTION CONTRE

LES SURCHARGES

Cet appareil est équipé d’un commutateur de protection

contre les surcharges pour éviter d’endommager le

moteur en cas de surchauffe.

Si le commutateur se déclenche

1. Relâchez la détente et laissez l’appareil refroidir

pendant une minute.

2. Appuyez sur le commutateur de surcharge pour le

réarmer et reprenez le travail (Fig. 7).

Si le commutateur se déclenche de nouveau juste

après la première fois

1. Laissez l’appareil refroidir pendant 15 à 30 minutes.

2. Après cela, appuyez sur le commutateur de

surcharge pour le réarmer et reprenez le travail.

Si le commutateur ne reste pas en place et continue de

sauter, faites réparer l’appareil par un concessionnaire

agréé.

AVERTISSEMENT : Pour éviter des

blessures graves, vérifiez que le bouton de

verrouillage s’enclenche chaque fois que la

détente est relâchée.

AVERTISSEMENT : Portez des vêtements

appropriés pour diminuer les risques de

blessures durant l'utilisation de l'appareil. Ne

portez pas de vêtements amples ni de bijoux.

Portez des lunettes de sécurité et des protègeoreilles. Portez des pantalons épais et longs, des

bottes et des gants. Ne marchez pas pieds nus

et évitez les pantalons courts et les sandales.

AVERTISSEMENT : Pour éviter des

blessures graves, ne transportez pas

l’appareil le doigt sur la détente.

Fig. 8

Page 26

F10

MODE D'EMPLOI

NOTE :Gardez toujours le fil bien déroulé. Il devient plus

difficile de donner du fil à mesure que le fil de

coupe devient plus court.

Chaque fois que vous donnez un coup sur la tête, vous

déroulez environ 25,4 mm (1 po) de fil. La lame du

protecteur de sécurité raccourcit le fil si vous le

déroulez trop.

Pour de meilleurs résultats, tapez la tête sur un sol

dégagé ou sur un sol dur. Si vous donnez du fil dans un

lieu d'herbe haute, vous risquez de surchauffer le

moteur. Gardez toujours le fil bien déroulé. Il devient

plus difficile de donner du fil à mesure que le fil de

coupe se raccourci

Fig. 9

Fig. 10

CONSEILS POUR BIEN DÉSHERBER

• Le bon angle pour l'accessoire de coupe est parallèle

au sol.

NOTE :Ne posez pas la Bump Head sur le sol.

• NE FORCEZ PAS L’APPAREIL. Coupez avec la pointe

du fil (surtout le long des murs). Si vous utilisez plus

que la pointe, vous réduisez l’efficacité de la coupe et

risquez de surcharger le moteur.

•Coupez l'herbe mesurant plus de 200 mm (8 po) en

procédant de haut en bas par petits incréments pour

éviter d'user le fil prématurément ou de freiner le

moteur.

• Coupez de droite à gauche si possible. Cela améliore

l'efficacité de coupe de l'appareil. De plus, les

morceaux sont projetés loin de l’opérateur.

• Déplacez lentement la désherbeuse dans et hors de la

zone de coupe à la hauteur voulue. Procédez d'avant

en arrière ou d'un bord vers l'autre. Les coupes de

longueur plus courte donnent les meilleurs résultats.

• Ne désherbez que lorsque l'herbe et les mauvaises

herbes sont sèches.

• La vie utile de votre fil dépend de l’utilisation des

techniques précédentes, des matières coupées et du

lieu de coupe. Par exemple, le fil s'use plus vite si

vous coupez le long d'un mur de fondation que si vous

coupez autour d'un arbre. Le fil peut se briser dans les

cas suivants :

•Happement de corps étrangers.

•Usure normale du fil.

• Coupe de mauvaises herbes épaisses à longues tiges.

• Forcer le fil dans des objets comme des murs ou des

poteaux de clôture.

Bump Head

UTILISATION DE LA DÉSHERBEUSE

Dégagez la zone de coupe avant chaque usage. Enlevez

tous les objets pouvant être projetés ou happés par

l'accessoire de coupe : cailloux, verre brisé, clous, fil ou

ficelle. Éloignez enfants, spectateurs et animaux de la

zone. Tenez-les à au moins 15 mètres (50 pieds) de là

mais sachez que les spectateurs risquent quand même

d'être atteints par des objets projetés. Conseillez-leur de

porter des protecteurs oculaires. Arrêtez immédiatement

le moteur et l'accessoire de coupe si quelqu'un

s'approche de vous.

NOTE :Retirez le ruban protecteur de la lame de

raccourcissement du fil avant d’utiliser la

désherbeuse.

RÉGLAGE DE LA LONGUEUR DU FIL

La tête de butée Bump Head vous permet de donner du

fil sans arrêter le moteur. Lorsque le fil devient effiloché

ou usé, vous pouvez le faire avancer en cognant

légèrement la tête au sol (Fig. 9) pendant que la

désherbeuse est en marche.

COUPE DÉCORATIVE

La coupe décorative consiste à déblayer, à un angle de

30 degrés, la végétation autour des arbres, des bornes,

des clôtures, etc. (Fig. 10).

MISE EN GARDE: n'enlevez pas ni n'altérez

l'ensemble de la lame coupante. Un excès de fil

surchauffera l'désherbeuse. Ceci pourrait causer

des blessures graves ou endommager l'appareil.

AVERTISSEMENT : Afin d'éviter des

blessures graves, portez des lunettes de

sécurité en tout temps pendant l’utilisation de

l’appareil. Portez un masque facial ou

antipoussières dans les lieux poussiéreux.

Page 27

F11

ENTRETIEN D’APP AREILS À DOUBLE ISOLEMENT

Cet appareil possède un double isolement. Au lieu d’une

mise à la terre, les appareils à double isolement

comportent deux systèmes d’isolement. Comme il se

doit, aucun moyen de mise à la terre n’est fourni sur ce

type d’appareil.

L’entretien de ces appareils exige soins minutieux et

compétence technique, et doit être effectué par un

personnel qualifié uniquement. Les pièces de rechange

doivent être identiques aux pièces remplacées. Confiez

toute réparation à un concessionnaire agréé. Un appareil

à double isolement porte l’indication « double insulation »

ou « double insulated ».

ENTRETIEN ET RÉPARATIONS

INSTALLATION DU FIL

Utilisez toujours un fil de remplacement Genuine Factory

PartsMCd'origine de 2,03 mm (0,080 po). Un autre fil

pourrait surchauffer ou endommager le moteur.

AVERTISSEMENT : N'utilisez jamais de fil ou

de cordon à renfort métallique car ils peuvent se briser

et se transformer en projectile dangereux.

Vous pouvez remplacer le fil de deux façons

• Rembobiner du fil neuf dans le moulinet intérieur.

• Installer un moulinet intérieur prérembobiné.

Rembobiner le moulinet existant

1. Retirez le couvercle de la Bump Head en appuyant

sur ses deux languettes visibles sur les deux côtés

de la bobine extérieure (Fig. 11).

NOTE :Le ressort pousse le couvercle vers le haut

lorsque les languettes sont désengagées.

2. Enlevez le moulinet intérieur et son ressort (Fig. 11).

3. Nettoyez la surface interne de la bobine extérieure à

l'aide d'un tissu propre (Fig. 11).

AVERTISSEMENT : Pour éviter des blessures

graves, enlevez ou déconnectez la batterie

avant tout entretien, nettoyage, changement

d'accessoires ou retrait de pièces de l'appareil.

AVERTISSEMENT : Il n’est pas nécessaire

de brancher dans une prise les outils à

batterie, ils peuvent donc fonctionner à tout

moment. Pour éviter des blessures graves,

faites très attention lorsque vous effectuez un

entretien ou que vous changez l’accessoire

de coupe ou autres.

La garantie de cet appareil ne couvre pas les pièces

ayant souffert d’abus ou de négligence de la part de

l’opérateur. Pour bénéficier pleinement de la garantie,

l’opérateur doit faire l’entretien de l’appareil

conformément au manuel de l’utilisateur.

Bobine extérieure

Ressort

Moulinet intérieur

APPUYEZ

SUR LES

LANGUETTES

Couvercle

de la Bump

Head

Fig. 11

Dents de positionnement

Trou du moulinet intérieur

4. Vérifiez l'état d'usure des dents de positionnement du

moulinet et de la bobine (Fig. 12). Enlevez les ébarbures

ou remplacez le moulinet et la bobine au besoin.

NOTE : Nettoyez toujours le moulinet intérieur, la bobine

extérieure et l'axe avant de remonter la Bump Head.

5. Prenez environ 3,6 m (12 pi) de fil neuf et insérez-en une

extrémité dans le trou du moulinet intérieur (Fig. 13).

6. Enroulez le fil en couches uniformes serrées sur le

moulinet (Fig. 13). Enroulez le fil dans le sens indiqué

sur le moulinet intérieur.

NOTE :Le fait de ne pas enrouler le fil dans le sens

indiqué entraînera un mauvais fonctionnement

de la Bump Head.

Fig. 12

Fig. 13

Page 28

F12

ENTRETIEN ET RÉPARATIONS

11. Installez le couvercle de la Bump Head sur le