Page 1

P/N 769-03340A (09/07)

For service call 1-800-345-8746, or 1-800-668-1238 in Canada to

obtain a list of authorized service dealers near you.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS.

OTHER PATENTS PENDING.

Service on this unit both within and after the warranty period should be

performed only by an authorized and approved service dealer.

Copy the serial number here:

Copy the model and parent part number here:

All information, illustrations, and specifications in this manual are based on

the latest product information available at the time of printing. We reserve

the right to make changes at any time without notice.

Copyright© 2007 MTD SOUTHWEST INC, All Rights Reserved.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . . . .9

Replacing Saw Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Oiling the Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E15

SAVE THESE INSTRUCTIONS

Before beginning, locate the unit’s model plate. It lists the model and

serial numbers of your unit. Refer to the sample plate below and

copy the information for future reference.

Pole Saw

OPERATOR'S MANUAL

PS720r

MODEL :

S/N :

ITEM :

Page 2

this unit. Wear a face or dust mask if the operation is dusty.

• Wear heavy, long pants, boots, gloves and a long sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• Use the unit only in daylight or good artificial light.

• Use the right tool. Only use this tool for the purpose intended.

• Always stop the engine/motor when operation is delayed or when

walking from one location to another.

• Use only genuine factory replacement parts and accessories for

this unit. These are available from your authorized service dealer.

Use of any unauthorized parts or accessories could lead to serious

injury to the user or damage to the unit, and void your warranty.

KICKBACK SAFETY PRECAUTIONS

• With a basic understanding of kickback, you can reduce or eliminate

the element of surprise. Sudden surprise contributes to accidents.

• Grip saw firmly. Hold the pole saw firmly with both hands when the

motor is running. Keep a good firm grip on the saw with both hands,

the right hand on the rear handle, and the left hand on the front handle.

• Do not let the nose of the guide bar contact a log, branch, ground

or other obstruction.

• Always cut with the engine running at full speed. Fully squeeze

the throttle trigger and maintain a steady cutting speed.

• Do not over reach.

• Follow the manufacturer’s sharpening and maintenance instructions

for the saw chain.

• Use only replacement bars and chains specified by the manufacturer

or the equivalent.

OTHER SAFETY PRECAUTIONS

• DO NOT operate a pole saw with one hand! Serious injury to the

operator, helpers, or bystanders may result from one-handed

operation. A pole saw is intended for two-handed use.

• Do not operate a pole saw if you are fatigued.

READ ALL INSTRUCTIONS

BEFORE OPERATING

• Carefully read and understand the operator's manual of the unit

that powers this attachment.

• Read this operating instruction manual carefully. Be thoroughly

familiar with the controls and the proper use of the equipment.

Know how to stop the unit and disengage the controls quickly.

• Do not operate this unit when tired, ill, or under the influence of

alcohol, drugs, or medication.

• Never allow children to operate the equipment. Never allow

adults unfamiliar with the instructions to use the unit. Never allow

adults to operate the equipment without proper instruction.

• All guards and safety attachments must be installed properly

before operating the unit.

SPECIAL SAFETY WARNINGS FOR GAS POWERHEADS

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the fuel tank.

Never remove the cap of the fuel tank, or add fuel, when the engine

is hot. Never operate the unit without the fuel cap securely in place.

Loosen the fuel tank cap slowly to relieve any pressure in the tank.

• Mix and add fuel in a clean, well-ventilated area outdoors where

there are no sparks or flames. Slowly remove the fuel cap only

after stopping engine. Do not smoke while fueling or mixing fuel.

Wipe up any spilled fuel from the unit immediately.

• Avoid creating a source of ignition for spilled fuel. Do not start

the engine until fuel vapors dissipate.

• Move the unit at least 30 feet (9.1 m) from the fueling source and site

before starting the engine. Do not smoke. Keep sparks and open

flames away from the area while adding fuel or operating the unit.

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated area outdoors.

POLE SAW OPERATING PROCEDURES

• Keep bystanders, especially children and pets, at least 50 ft (15

m) away.

• Wear safety glasses or goggles that are marked as meeting ANSI

Z87.1-1989 standards, and ear/hearing protection when operating

• IMPORTANT SAFETY INSTRUCTIONS •

Read the Operator’s Manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

FOR QUESTIONS, CALL 1-800-345-8746 IN U.S. OR

1-800-668-1238 in CANADA

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve your

careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give

are not substitutes for proper accident prevention measures.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SYMBOL MEANING

SAFETY ALERT:

Indicates danger, warning or

caution. Attention is required in order to avoid serious

personal injury. May be used in conjunction with other

symbols or pictographs.

DANGER:

Failure to obey a safety warning will result

in serious injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire, electric

shock and personal injury.

WARNING:

Failure to obey a safety warning can

result in injury to yourself and others. Always follow the

safety precautions to reduce the risk of fire, electric

shock and personal injury.

CAUTION:

Failure to obey a safety warning may

result in property damage or personal injury to yourself

or to others. Always follow the safety precautions to

reduce the risk of fire, electric shock and personal injury.

RULES FOR SAFE OPERATION

SYMBOL MEANING

WARNING:

When using the unit, you must follow the

safety rules. Please read these instructions before operating

the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

WARNING:

Gasoline is highly flammable, and its

vapors can explode if ignited. Take the following

precautions:

WARNING:

Kickback may occur when the nose or

tip of the guide bar touches an object, or when the

wood closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast

reverse action, kicking the guide bar rapidly back

towards the operator. Pinching the saw chain along the

top of the guide bar may push the guide bar rapidly

back towards the operator. Either of these reactions

may cause you to lose control of the saw, which could

result in serious injury to the user.

Do not rely exclusively upon the safety devices built

into your saw. As a pole saw user, you should take

several steps to keep your cutting jobs free from

accident or injury.

Page 3

RULES FOR SAFE OPERATION

• Do not wear loose clothing or jewelry, as they can get caught in

moving parts. Non-skid footwear is recommended when working

outdoors. Wear protective hair covering to contain long hair.

• Use safety glasses, safety footwear, snug fitting clothing,

protective gloves, and protective hearing and head gear.

• Use caution when handling fuel. Move the pole saw at lest 30

feet (9.1 m) from the fueling point before starting the engine.

• Keep the work area clean. Cluttered areas invite injuries. Do not

start cutting until you have a clear work area, secure footing, and

a planned retreat path from the falling branches.

• Stay Alert. Watch what you are doing. Use common sense. Do

not operate the pole saw when you are tired. Keep all parts of

your body away from the saw chain when the motor is operating.

Before you start the saw, make sure the saw chain is not

contacting anything.

• Disconnect the pole saw when not in use, before servicing, and

when changing accessories and attachments such as saw chain

and guard.

• Check damaged parts. Before further use of the pole saw, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center, unless otherwise indicated in this instruction manual.

• Use extreme caution when cutting small sized brush and sapling,

as slender material may catch the saw chain and be whipped

toward you or pull you off balance.

• Do not operate a pole saw in a tree unless you are specifically

trained to do so. When cutting a limb that is under tension, be

alert for spring back so that you will not be struck when the

tension in the wood fibers is released.

• Do not expose the pole saw to rain. Do not use the pole saw in

damp or wet locations.

• Do not use the pole saw in the presence of flammable liquids or

gases.

• All pole saw service, other than the items listed in the user

manual safety and maintenance instructions, should be

performed by competent pole saw personnel. Do not attempt to

repair it yourself; there are no user serviceable parts inside.

• The pole saw will do a better and safer job when used at the rate

for which it was intended.

• Use the right tool. Cut wood only. Do not use the pole saw for

purposes for which it was not intended. For example, do not use

the pole saw for cutting plastic, masonry, or non-building materials.

• Use devices, such as low-kickback chain, guide bar nose

guards, chain brakes and special guide bars, which reduce the

risks associated with kickback.

• There are no other replacement components for achieving

kickback protection in accordance with CSA Z62.3.

• Do not operate a pole saw that is damaged, improperly adjusted,

or not completely and securely assembled. Be sure that the saw

chain stops moving when the trigger is released.

• Do not attempt operations beyond your capacity or experience.

• Never remove, modify or make inoperative any safety device

furnished with your unit.

• This saw is classified by CSA as a Class 2C saw. It is intended for

infrequent use by homeowner’s, cottagers and campers, and for

such general applications such as clearing, pruning, cutting

firewood, etc. It is not intended for prolonged use. If the intended

use involves prolonged periods of operation, this may cause

circulatory problems in the user’s hands due to vibration. It may

be appropriate to use a saw having an anti-vibration feature.

• Safety clothing required by your safety organizations, government

regulations, or your employer should be used; otherwise, snug

fitting clothing, safety footwear, and hand and ear protection

should be worn.

• Low-kickback saw chain is chain that has met the kickback

performance requirements of ANSI B175.1-1991 and is in

accordance with CSA Z62.3. Do not use other replacement chain

unless it has met these requirements for your specific model.

• Do not use any other cutting attachment or accessories. Use only

original equipment manufacturer replacement parts and accessories,

which are designed specifically to enhance the performance and

maximize the safe operation of our products. Failure to do so may

cause poor performance and possible injury. Use only the chain and

bar supplied with this product. Do not use any other cutting

attachment. Use of such attachments will void your factory warranty

and could result in serious bodily injury.

• Never touch the chain or attempt to service the saw while the

engine is running. Make sure all moving parts have stopped.

Allow the chain to cool, as the chain can be hot.

• Check the bar and chain at frequent intervals for proper

adjustment. Make sure the bar and chain are properly tightened

and sharpened. Visually inspect for damage. Repair any damage

before restarting or operating the pole saw.

• Do not cut near electrical cables or power lines.

• Do not use the pole saw to fell a tree. Use a standard chain saw

for this application.

MAINTENANCE AND STORAGE

• Allow the unit to cool before storing or transporting. Be sure to

secure the unit while transporting.

• Always use the transport guard on the bar and chain during

transportation and storage.

• Store the unit in a locked up and dry or high and dry place to

prevent unauthorized use or damage, out of the reach of

children.

• Never douse or squirt the unit with water or any other liquid. Keep

handles dry, clean and free from debris. Clean after each use.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan someone this unit, also loan

them these instructions.

• Only qualified personnel should perform any repairs or

maintenance procedures that are not described in this manual.

SAVE THESE INSTRUCTIONS

Page 4

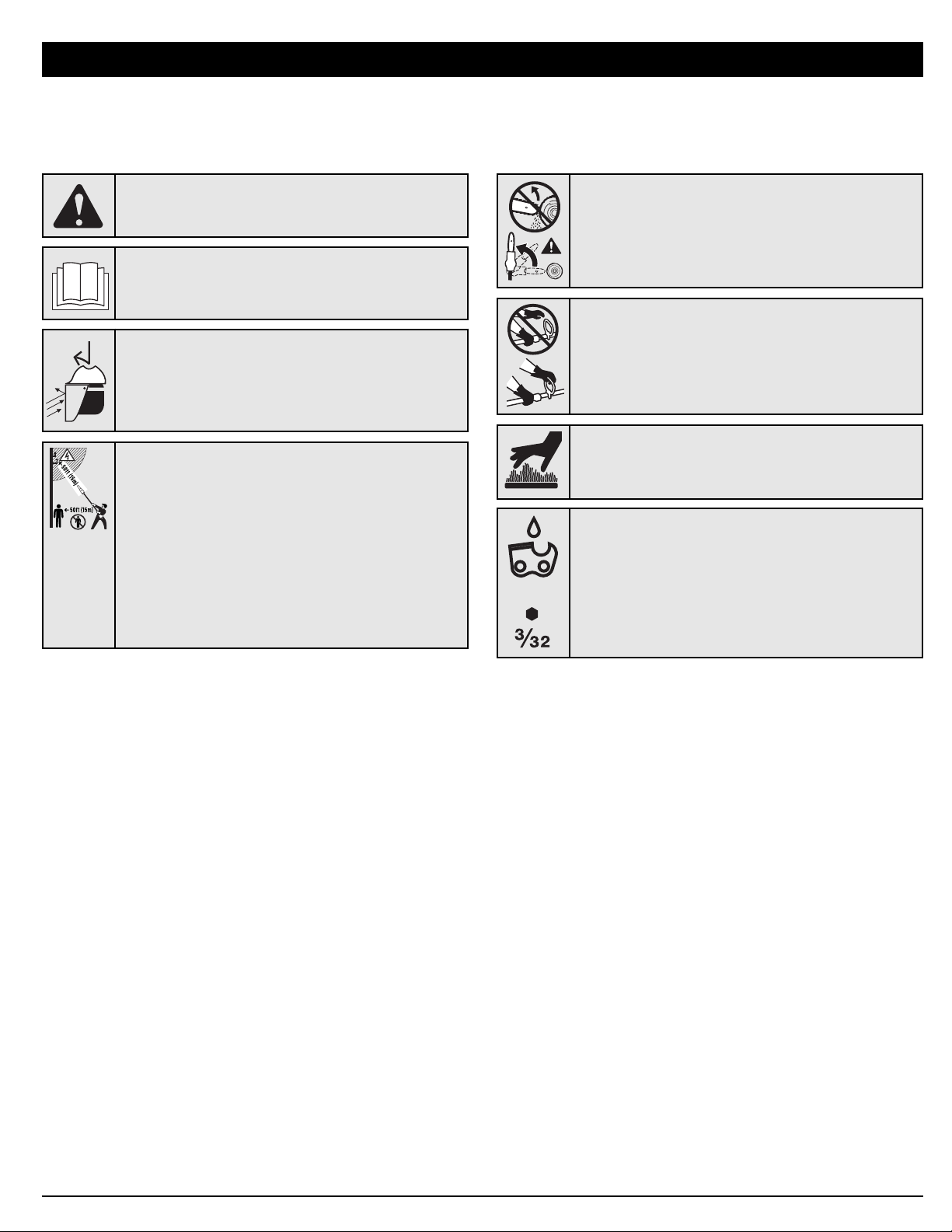

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating, maintenance, and repair information.

RULES FOR SAFE OPERATION

•

WARNING: READ OPERATOR'S MANUAL

R

ead the operator’s manual(s) and follow all warnings

and safety instructions. Failure to do so can result in

serious injury to the operator and/or bystanders.

• GUIDE BAR WARNING

Contact of the guide bar tip with any object should be

avoided. Tip contact may cause the guide bar to move

suddenly upward and backward, which may cause

serious injury.

SYMBOL MEANING

•

WEAR EYE AND HEARING PROTECTION

WARNING:

Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear eye

protection meeting ANSI Z87.1 standards and ear

protection when operating this unit. Use a full face

shield when needed.

•

HOT SURFACE WARNING

Do not touch a hot surface. You may get burned.

These parts get extremely hot from operation. They

remain hot for a short time after the unit is turned off.

• KEEP BYSTANDERS AWAY

WARNING:

Keep all bystanders, especially

children and pets, at least 50 feet (15 m) from the

operating area.

•

POWER LINES CAN CAUSE SEVERE

INJURY

WARNING:

Do not operate unit near power lines.

Contact with a power line may cause serious injury

or damage to the unit. Maintain a clearance of at

least 50 ft (15 m) between the pole saw (including

any branches it is contacting) and any electrical line.

• USE BOTH HANDS

Always use both hands while operating the chain

saw. Never use only one hand to operate the saw.

•

SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

SYMBOL MEANING

•

CHAIN OIL ADJUSTMENT INDICATOR

The chain must be continously coated with oil to

function properly. Make sure to set the Oil

Adjustment Screw to allow a sufficient amount of oil

to flow continuously onto the chain.

Use a 3/32-inch Allen wrench to adjust the Oil

Adjustment Screw.

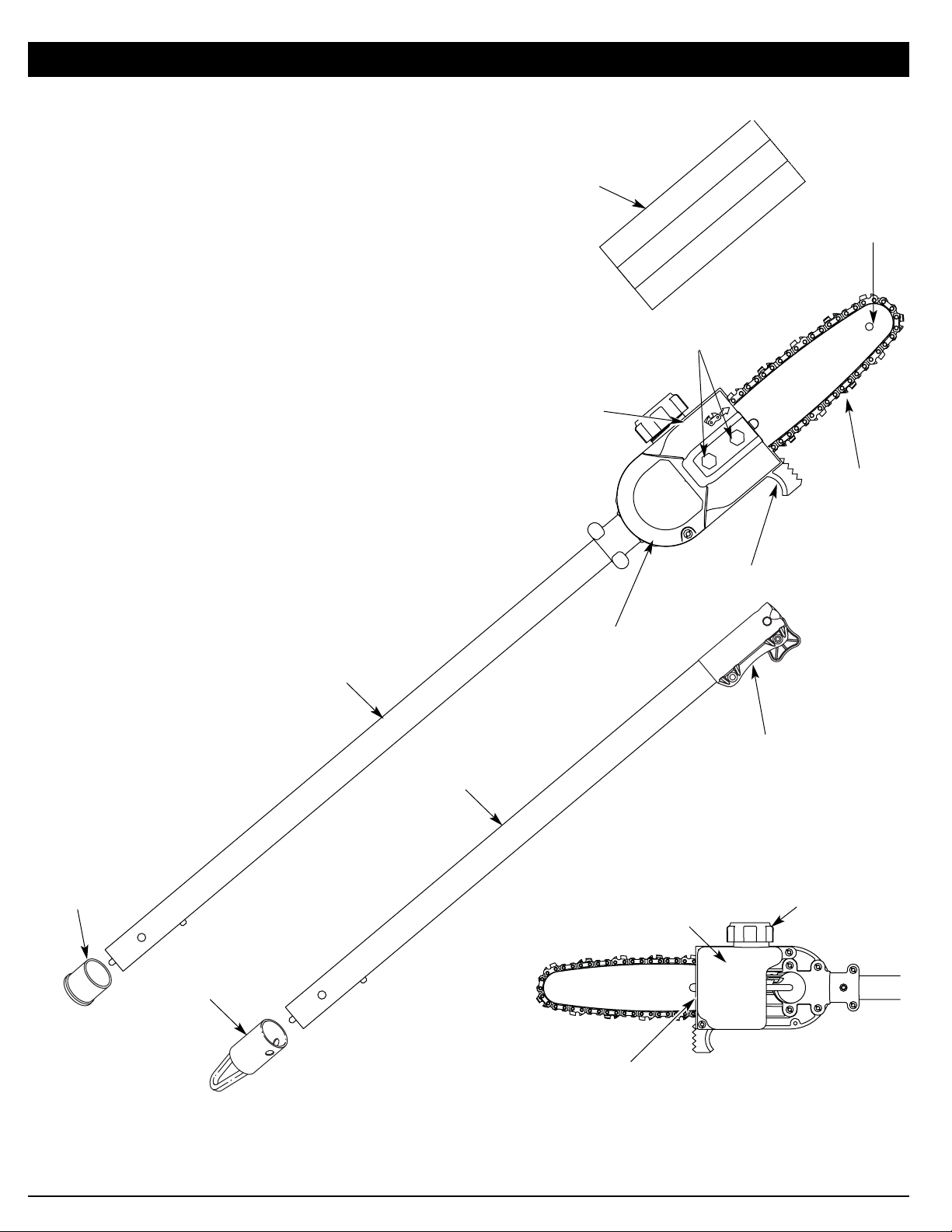

Page 5

Guide Bar

Saw Chain

Drive Shaft

Guide Bar

Nose

Chain

Guard

Hook

Bar Retaining Nuts

KNOW YOUR UNIT

Extension

Boom

Tension

Adjustment Screw

Oil Adjustment Screw

Oil Reservoir

Chain Transport

Guard

Hanger

Coupler

Oil Tank Cap

Shipping

Cap

Page 6

The add-on should be installed with the release button in the

primary hole.

Check Flex Shaft Engagement Prior to Using

1. Start the unit.

2. Briefly engage and release the trigger.

3. Check that add-on is operating.

4. If the add-on is not operating, remove add-on and repeat steps

for installing the add-on.

5. Recheck operation of add-on attachment.

4. Turn the knob clockwise to tighten (Fig. 3).

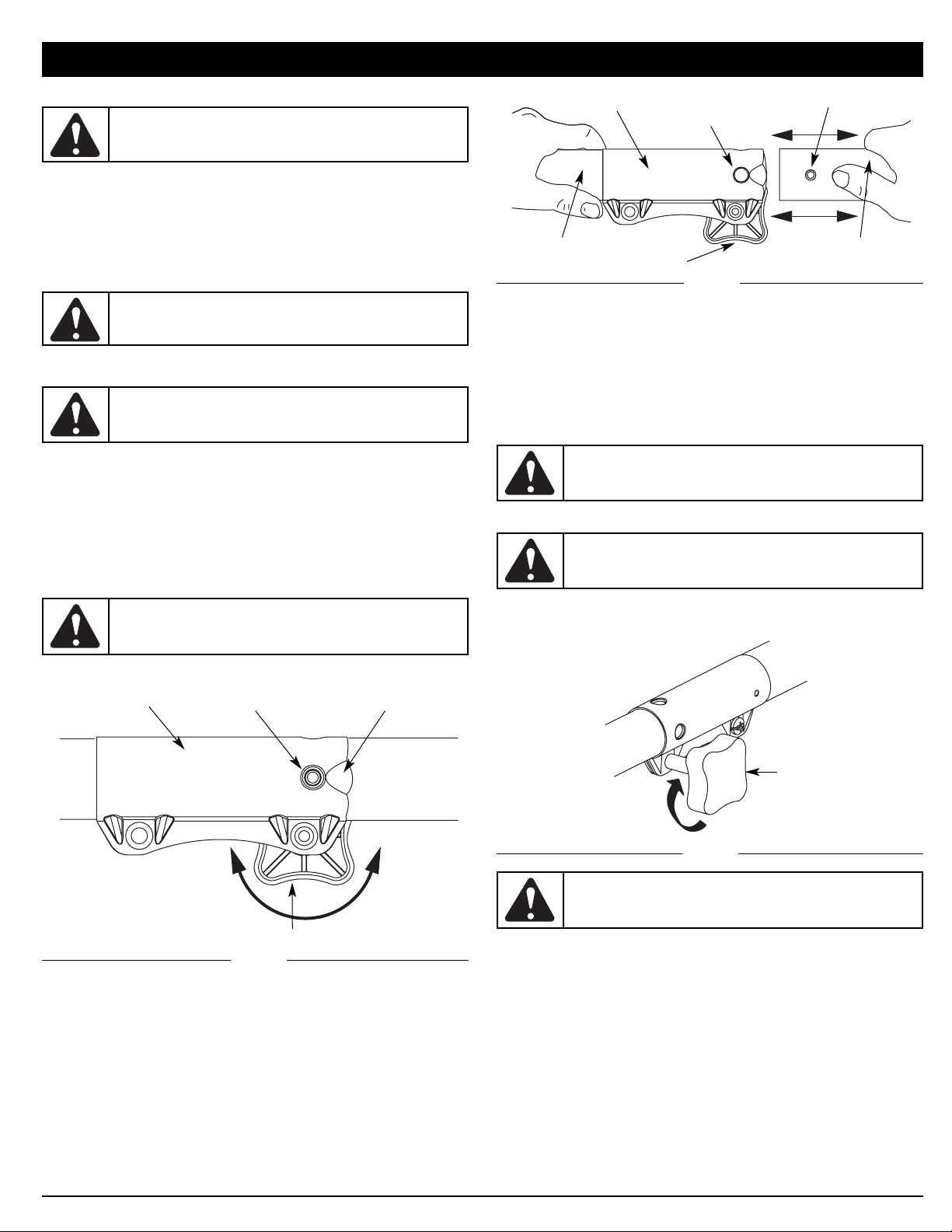

ASSEMBLING THE COUPLER

The Trimmer Plus add-on may be mounted to different power tools.

The instruction manuals for the basic power tool and the

attachment contain the information necessary for operation of the

power tool combination. Therefore, aways read BOTH instruction

manuals before using the power tool for the first time. Keep the

manuals in a safe place for future reference.

NOTE: To make installing or removing the add-on easier, place the

unit on the ground or on a work bench.

Removing the Add-On or Extension Boom

1. Turn the knob counterclockwise to loosen (Fig. 1).

Fig. 1

Coupler

Release Button

Guide Recess

Knob

Primary Hole

Upper Shaft

Housing

Coupler

2. Press and hold the release button (Fig. 1).

3. While firmly holding the upper shaft housing, pull the add-on or

extension boom out of the coupler (Fig. 2).

Fig. 2

Fig. 3

Knob

Lower Shaft

Housing

Release Button

Knob

Clockwise

Counterclockwise

ASSEMBLY INSTRUCTIONS

WARNING:

Prior to operation, read and understand

the operator’s manual for unit to be used with this addon.

WARNING:

To avoid serious personal injury and

damage to the unit, shut the unit off before removing or

installing add-ons.

CAUTION:

The add-ons with the coupler system is

to be used in the primary hole only. Using the wrong

hole could lead to personal injury or damage to the unit.

CAUTION:

Lock the release button in the primary

hole (Fig. 2) and securely tighten the knob before

operating this unit.

WARNING:

To avoid serious personal injury and

damage to the unit, NEVER install more than one

extension boom to a power tool.

Installing the Add-On or Extension Boom

1. Remove the hanger or shipping cap from the top of the shaft

housing.

2. Turn knob counterclockwise to loosen (Fig. 1).

3. While firmly holding the add-on or extension boom, push it

straight into the coupler (Fig. 2).

NOTE: Aligning the release button with the guide recess will help

installation (Fig. 1).

FILLING THE OIL RESERVOIR

Follow the following steps to fill the oil reservoir:

1. Place the unit on a flat surface.

2. Remove the Oil Tank Cap.

3. Open the oil bottle provided with your unit.

4. Pour oil into the reservoir until filled (7 oz.).

NOTE: The oil reservoir may be filled to the lip of the fill opening without

damaging the unit.

DANGER:

Failure to fill the oil reservoir will cause

irreparable damage to the unit. Make sure the oil

reservoir is always filled.

WARNING:

Oil constantly flows from the oil

reservoir to oil the chain. Check the oil level constantly

so that the oil level does not drop below half full.

5. Repeat steps 1–4 for the add-on or extension boom.

Page 7

Fig. 4

Fig. 5

Fig. 6

OPERATING PRECAUTIONS

1. Keep bystanders 50 feet (15 meters) away when operating the

saw.

2. Do not use the pole saw to cut down trees. Use a chain saw

without a pole attachment.

3. Make sure the oil tank is full and oil is lubricating the chain

prior to starting.

4. Grip pole saw securely—one hand on the grip, the other on

the handle.

5. Keep finger off the trigger until ready to make cut.

6. Before starting the pole saw, make sure the chain is not

touching anything.

7. Keep all parts of your body away from the chain when the saw

is running.

8. Do not force the chain saw while cutting. Apply light pressure.

It will do the job better and safer at the rate for which it was

intended.

9. When cutting limbs or branches that are under tension, use

extreme caution. Be alert for wood springing back. When

wood tension is released, the limb could spring back and

strike operator causing severe injury or death.

10. When carrying pole saw from one place to another:

• hold pole at balance point

• keep guide bar and chain to the rear

11. Do not cut small brush and saplings with the pole saw.

Slender matter may catch in the chain and be whipped toward

you. This could also pull you off balance.

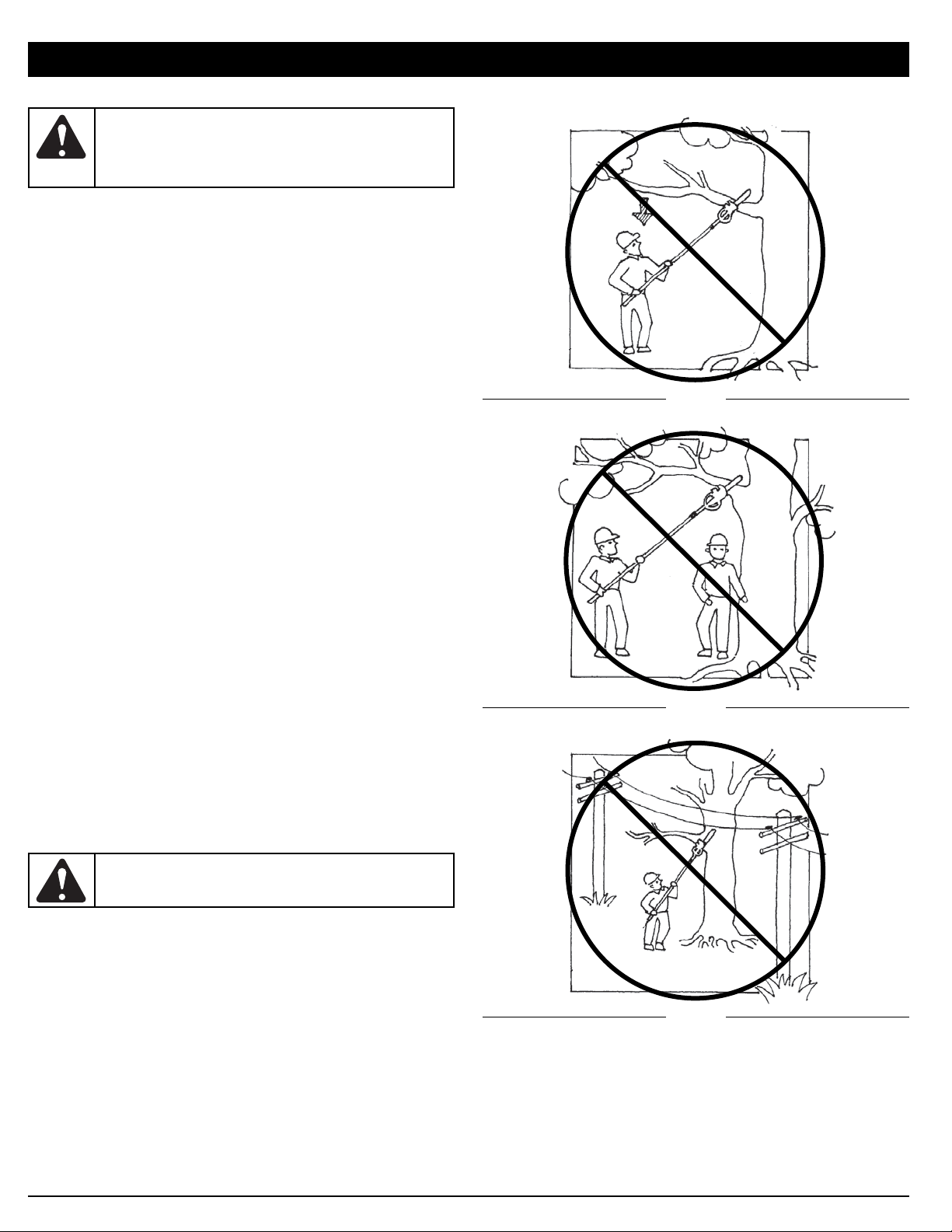

12. Never stand directly under the limb you are trimming. Always

position yourself out of the path of falling debris (Fig. 4).

13. Never stand on a ladder or other type of unstable support

while using the pole saw.

14. Always use both hands to operate pole saw. Keep a firm,

steady pressure on the pole saw while cutting, but do not try

to force the saw through the wood.

15. Do not use the pole saw to cut limbs larger than 4” (10 cm)

in diameter.

16. Keep other persons away from cutting end of pole saw and at

a safe distance from work area. (Fig. 5).

17. Do not use the pole saw near cable, electric power or

telephone lines. Maintain a minimum clearance of 50 feet (15

m) from all power lines (Fig. 6).

STARTING INSTRUCTIONS

Start and operate your pole saw without assistance. For specific

starting instructions, see the appropriate section of your powerhead

manual. Proper starting methods reduce the risk of injury.

1. Place the pole saw on firm ground or other solid surface in an

open area.

2. Maintain good balance and secure footing.

OPERATING INSTRUCTIONS

WARNING:

Dress properly to reduce the risk of

injury when operating this unit. Do not wear loose

clothing or jewelry. Wear eye and ear/hearing protection.

Wear heavy long pants, boots and gloves. Wear a hard

hat. Use a full face shield when needed.

WARNING:

To reduce the risk of fire and burn

injuries, start the engine at least 30 ft. (9.1 m) from the

fueling spot, outdoors only.

Page 8

OPERATING TIPS

• Avoid kickback. Kickback can result in severe injury or death.

• Do not operate the pole saw while in a tree, on a ladder or any

other unstable work surface, or in any awkward position. You

may lose control of the pole saw causing severe injury.

• Do not extend your arms above shoulders when using the pole

saw.

• Seek professional help if you are facing conditions beyond your

ability.

• Trimming a tree is the process of cutting limbs from a living tree.

Make sure your footing is firm. Keep your feet apart. Divide your

weight evenly on both feet.

• Before starting unit, always check the chain lubrication and oil

tank level.

NOTE: The chain must be continously coated with oil to function

properly. Make sure that the oil adjustment screw is set

appropriately.

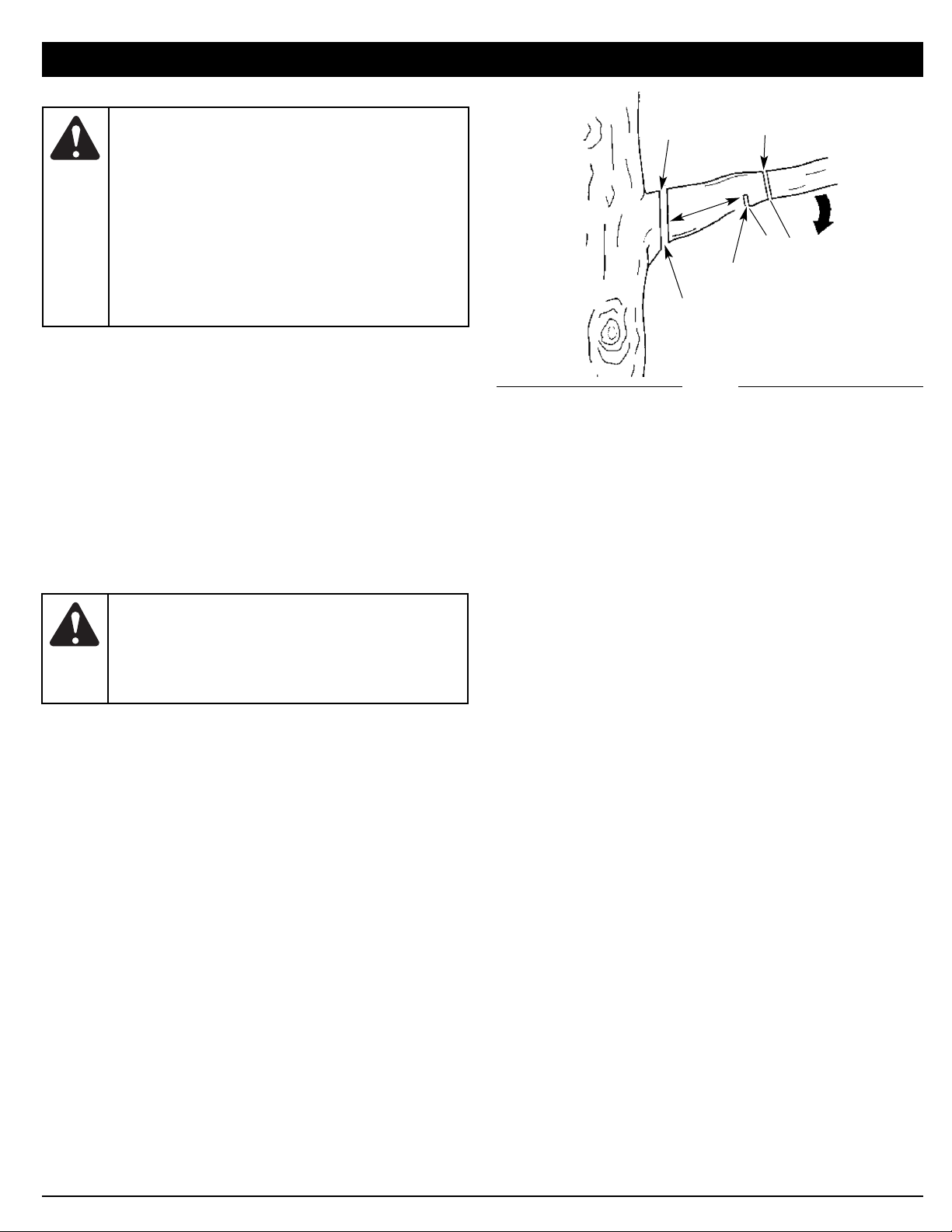

Fig. 7

Cut 2

Cut 4

Cut 3

Cut 1

6”

2 - 4”

To trim a limb (pruning):

1. Make the first cut six inches from tree trunk on the underside

of the limb. Use the top of the guide bar to make this cut. Cut

a third of the way through the diameter of the limb (Fig. 7).

2. Move two to four inches farther out on the limb. Make the

second cut from above the limb. Continue the cut until you cut

the limb off.

3. Make the third cut as close to the tree trunk as possible on

underside of limb stub. Use the top of the guide bar to make

this cut. Cut a third through the diameter of stub.

4. Make the fourth cut directly above the third cut. Cut down to

meet the third cut. This will remove the limb stub.

OPERATING INSTRUCTIONS

WARNING:

Kickback may occur when the nose or

tip of the guide bar touches an object, or when the

wood closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast

reverse action, kicking the guide bar rapidly back

towards the operator. Pinching the saw chain along the

top of the guide bar may push the guide bar rapidly

back towards the operator. Either of these reactions

may cause you to lose control of the saw, which could

result in serious injury to the user.

Do not rely exclusively upon the safety devices built

into your saw. As a chain saw user, you should take

several steps to keep your cutting jobs free from

accident or injury.

WARNING:

If the oil tank runs out, the oil ajustment

screw hole becomes clogged, or the chain fails to get

proper lubrication in any fashion, the chain will overheat

and cause irreversible damage to the unit and may

result in severe injury. Excessive heat from friction can

lead the chain to catastrophically fail and come off the

bar while operating.

Page 9

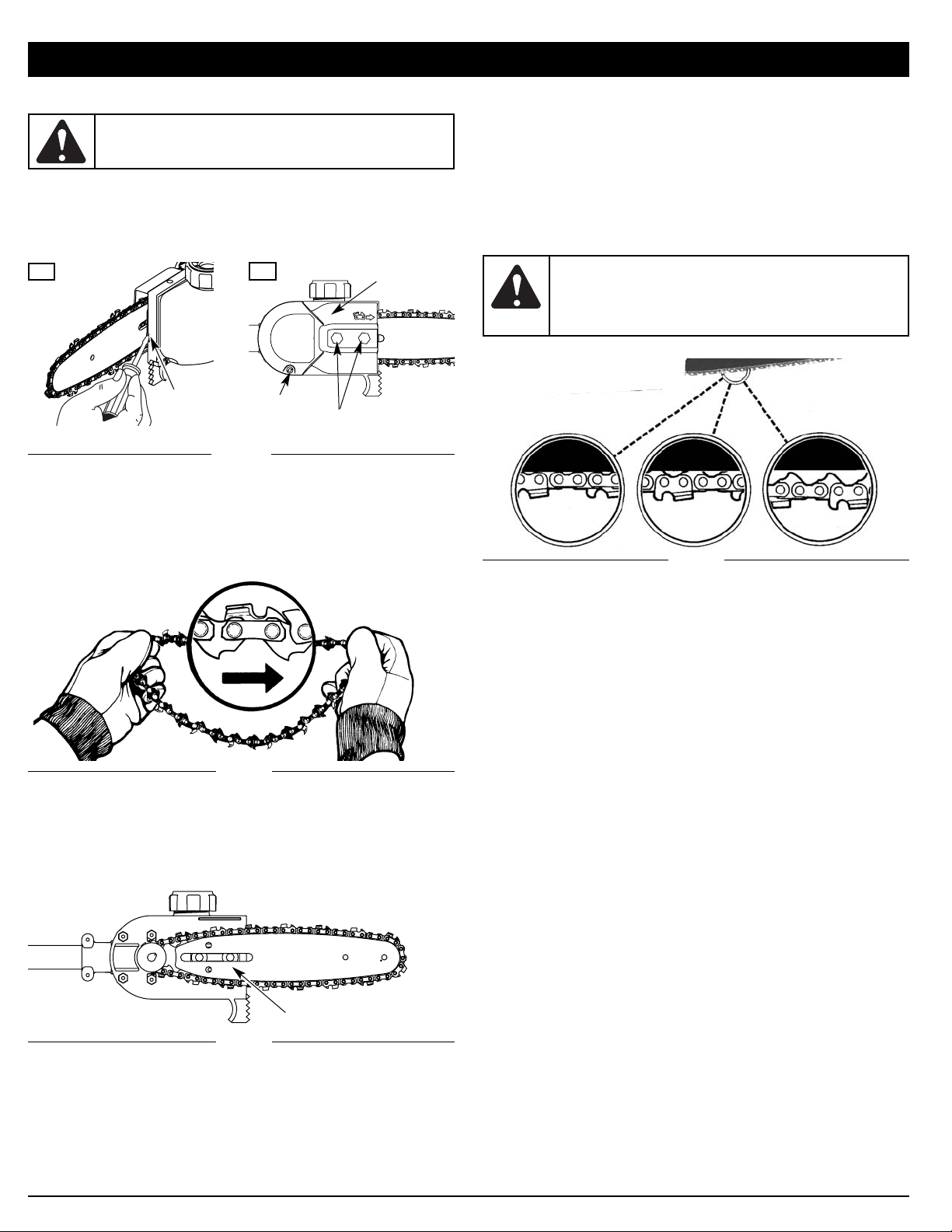

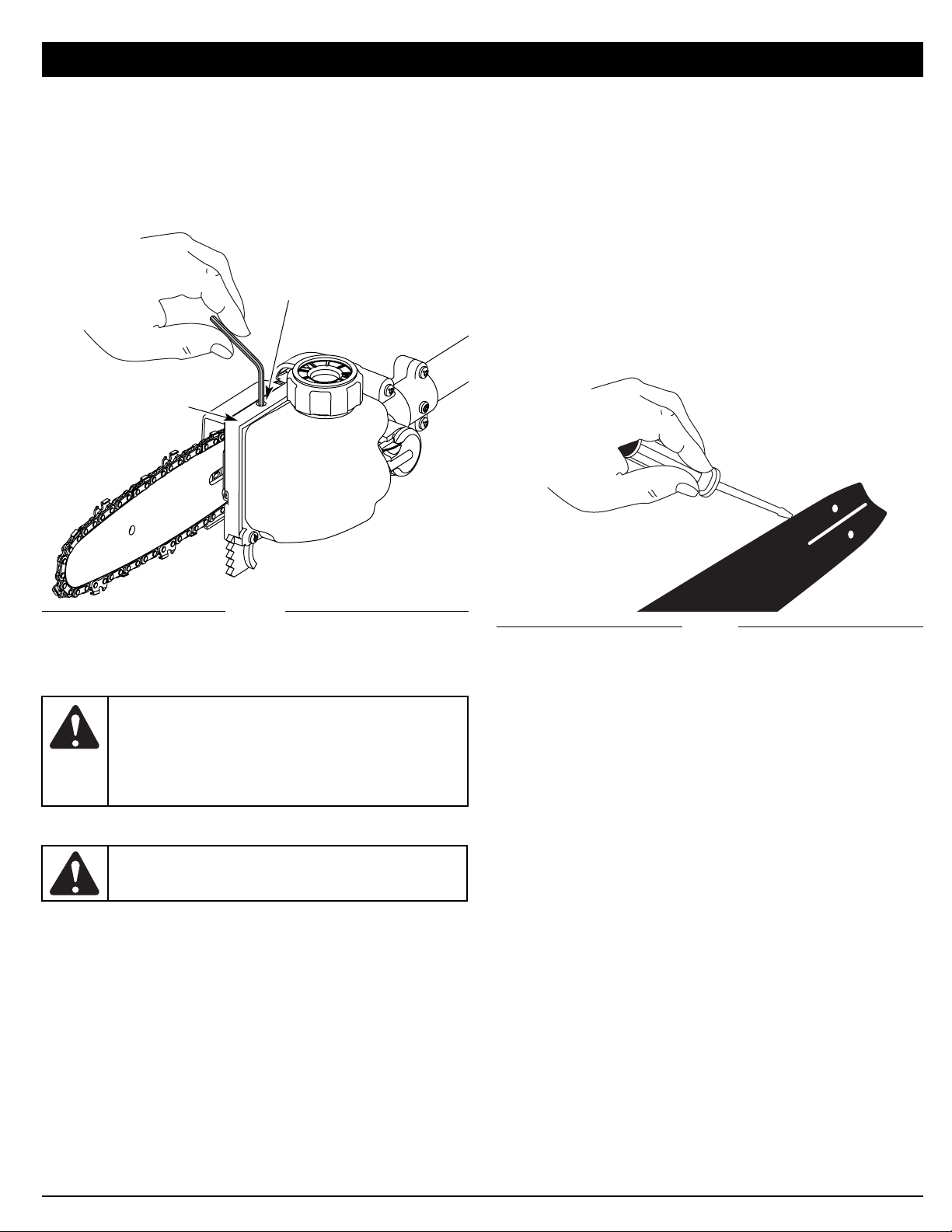

SAW CHAIN REPLACEMENT/INSTALLATION

1. Using a straight screwdriver turn tension adjustment screw

counterclockwise (Fig. 8, A) 4 turns.

2. Remove the bar retaining nuts and screw. Then take off the

chain guard (Fig. 8, B).

Fig. 8

B

A

Bar Retaining Nuts

Chain

Guard

Screw

Tension

Adjustment

Screw

Fig. 9

3. Take off the chain and bar.

4. Prepare new chain and/or bar, and fit the chain into the groove

in the bar.

5. Loop the saw chain over the drive sprocket with the cutting

edges of the chain pointing in the direction of rotation (Fig. 9).

Fig. 10

Fig. 11

SAW CHAIN TENSION ADJUSTMENT

Proper tension of the saw chain is extremely important and must

be checked before starting, as well as during, any cutting

operation. Taking the time to make needed adjustments to the saw

chain will result in improved cutting performance and prolonged

chain life.

NOTE: A new chain and bar will need readjustment after as few

as 5 cuts. This is normal during the break-in period, and

the interval between future adjustments will lengthen

quickly (Fig. 11).

A

C

B

To adjust the saw chain tension:

1. Loosen the bar retaining nuts so they are hand tight (Fig. 8, B).

2. Holding the nose of the bar up, use the screwdriver to turn the

guide bar adjustment screw clockwise to tighten the chain

(Fig. 8, A). Turning the screw counterclockwise loosens the

chain on the guide bar.

3. While wearing heavy duty work gloves (after you’ve made the

adjustment), move the saw chain back and forth on the guide

bar to be sure the chain moves freely and is in proper mesh

with the sprocket. Never move the chain with your bare hands.

NOTE: If the chain is difficult to rotate or if it binds on the guide

bar, there is too much tension applied and it must be

adjusted. To decrease tension, turn the adjustment screw

counterclockwise, slowly. Move the chain back and forth

until it moves freely.

4. Holding the nose in upper position, securely tighten the bar

retaining nuts.

MAINTENANCE AND REPAIR INSTRUCTIONS

WARNING:

Whenever handling the saw chain,

always wear work gloves for protection against sharp

cutting edges.

CAUTION:

If a chain is too loose or too tight, the

bar chain and saw bearings will wear more rapidly.

Refer to Figure 11 for information concerning correct

cold tension (A), correct warm tension (B), and a chain

in need of adjustment (C).

6. Adjust the tension adjustment screw (Fig. 8, A) to allow

insertion of the bar (Fig. 10). Make sure the chain follows the

slot in the guide bar and adjust the tension adjustment screw

to make the chain fit snugly on the underside of the bar.

7. Install the chain guard and tighten bar retaining nuts and

screw (Fig. 8, B).

Page 10

OILING THE CHAIN

The pole saw chain is self-lubricating. Oil is dispersed onto the

chain as the unit is used. Keep an adequate amount of oil in the

oil tank. Use the bar-chain oil provided in the hardware pack.

Always use bar-chain and sprocket oil or similar chain saw oil.

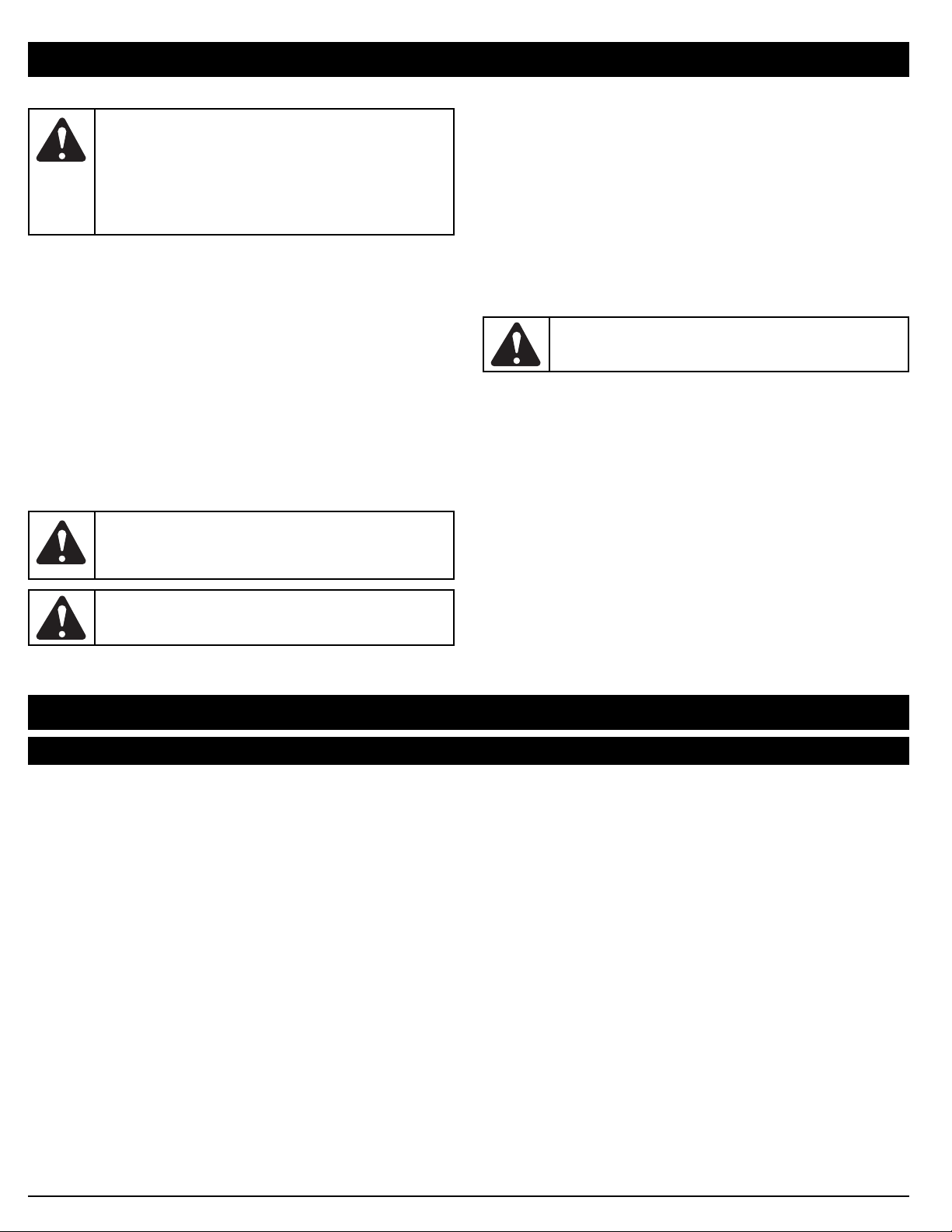

Setting the Oil Adjustment Screw

The Oil Adjustment Screw is located on top of the gearbox

assembly (Fig. 12).

1. Insert a 3/32-inch Allen wrench into the oil adjustment screw.

2. Turn the screw counterclockwise to increase oil flow to the chain, or

3. Turn the screw clockwise to restrict the oil flow to the chain.

GUIDE BAR MAINTENANCE

NOTE: Proper maintenance of the guide bar is essential to the

performance of your pole saw. Proper guide bar

maintenance will keep your saw in good working order.

Most guide bar problems can be prevented merely by keeping the

chain saw well maintained.

Incorrect filing and non-uniform cutter and depth gauge settings

cause most guide bar problems, primarily resulting in uneven bar

wear. As the bar wears unevenly, the rails widen, which may cause

chain clatter and difficulty in making straight cuts.

Insufficient guide bar lubrication and operating the saw with a

chain that is too tight will contribute to rapid bar wear. Refer to

Saw Chain Tension Adjustment and Oiling the Chain.

To help minimize bar wear, the following guide bar maintenance is

recommended:

Bar Wear

Turn guide bar frequently at regular intervals (for example, after 5

hours of use), to ensure even wear on top and bottom of bar.

Bar Grooves

Bar grooves (or rails which support and carry the chain) should be

cleaned if the saw has been heavily used or if the saw chain

appears dirty. Rails should always be cleaned every time the saw

chain is removed.

To clean guide bar rails:

1. Remove chain guard, bar, and chain. Refer to Saw Chain

Replacement / Installation.

2. Using a screwdriver, putty knife, wire brush or other similar

instrument, clear residue from the rails on the guide bar (Fig. 13).

This will keep the oil passages open to provide proper

lubrication to the bar and chain.

3. Ensure the sprocket in the bar turns freely during cleaning.

4. Reinstall the bar, chain, chainguard, screw, and bar retaining

nuts. Refer to Saw Chain Replacement / Installation.

Oil Passages

Oil passages at the bar pad should be cleaned to ensure proper

lubrication of the bar and chain during operation. This can be done

using a soft wire small enough to insert into the oil discharge hole.

MAINTENANCE AND REPAIR INSTRUCTIONS

WARNING:

Ensure that the unit is off and the spark

plug is disconnected (gas powerheads) before

performing any maintenance on your saw.

Fig. 12

Oil

Adjustment

Screw

Gearbox Assembly

Fig. 13

WARNING:

If the oil tank runs out, the oil ajustment

screw hole becomes clogged, or the chain fails to get

proper lubrication in any fashion, the chain will overheat

and cause irreversible damage to the unit and may

result in severe injury. Excessive heat from friction can

lead the chain to catastrophically fail and come off the

bar while operating.

Page 11

CHAIN MAINTENANCE

A low-kickback saw chain should always be used in conjunction

with other kickback protection devices such as the hand guard,

which is furnished with your unit.

Always use a replacement saw chain designed as “low-kickback”

or a saw chain which meets the low-kickback performance.

A standard saw chain (a chain which does not have the kickback

reducing guard links) should only be used by an experienced

professional chain saw operator.

Low-Kickback Saw Chain

A low-kickback saw chain is a chain which has met the kickback

performance requirements of ANSI B175.1. Do not use other

replacement chain unless it has met these requirements for your

specific model.

By keeping the saw chain in good working condition and correctly

serviced as recommended in this manual, you will be able to

maintain the safety system of your polesaw over the life of the

product.

Chain Tension

Check the chain tension frequently and adjust as often as

necessary to keep the chain snug on the bar, but loose enough to

be pulled around by hand. Refer to Saw Chain Tension Adjustment.

Breaking in a New Saw Chain

A new chain and bar will need readjustment after as few as 5 cuts.

This is normal during the break-in period, and the interval between

future adjustments will begin to lengthen quickly.

Over a period of time, however, the moving parts of the saw chain

will become worn, resulting in what is called chain stretch. This is

normal. When it is no longer possible to obtain correct chain

tension adjustment, a link will have to be removed to shorten the

chain. See your MTD Authorized Service Center to have this repair

performed.

CLEANING AND STORAGE

• Slacken the chain if you have retensioned it at operating

temperature during cutting work.

• The chain contracts as it cools down. If it is not slackened, it

may damage the gearbox and bearings.

Storing the Machine for a Short Period

Wait for the engine to cool down. Drain the fuel tank and store the

machine in a dry place well away from sources of ignition until you

need it again.

• Attach the transport guard to the bar/chain before storing the

unit.

• Store the unit in a dry, high and/or locked location, out of the

reach of children and other unauthorized persons.

Long-Term Storage

• Remove the saw chain and guide bar, clean them, and spray

them with corrosion inhibiting oil.

• Attach the transport guard to the bar/chain before storing.

POLE SAW ADD-ON

Approximate Operating Weight of Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3 lbs. (1.5 kg)

Drive Shaft Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 inches (66 cm)

Cutting Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 inches (254 mm)

MAINTENANCE AND REPAIR INSTRUCTIONS

SPECIFICATIONS

WARNING:

Unless you have experience and

specialized training for dealing with kickback (see

Important Safety Instructions), always use a lowkickback saw chain, which significantly reduces the

danger of kickback. Low-kickback saw chain does not

completely eliminate kickback. A low-kickback or

“safety chain,” should never be regarded as total

protection against injury.

WARNING:

Never remove, modify or make

inoperative any safety device furnished with your unit.

The hand guard and low-kickback saw chain are major

safety features provided for your protection.

WARNING:

Never use a loop of chain that has more

than 3 links removed from it. This could damage the

sprocket.

WARNING:

Ensure that the unit is off and the spark

plug is disconnected (for gas powerheads) when

working on the saw chain. Wear heavy duty gloves too.

Page 12

MANUFACTURER’S LIMITED WARRANTY FOR:

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose, applies after

the applicable period of express written warranty above as to

the parts as identified. No other express warranty or guaranty,

whether written or oral, except as mentioned above, given by

any person or entity, including a dealer or retailer, with respect

to any product shall bind MTD. During the period of the

Warranty, the exclusive remedy is repair or replacement of the

product as set forth above. (Some states do not allow limitations

on how long an implied warranty lasts, so the above limitation may

not apply to you.)

The provisions as set forth in this Warranty provide the sole and

exclusive remedy arising from the sales. MTD shall not be liable

for incidental or consequential loss or damages including,

without limitation, expenses incurred for substitute or

replacement lawn care services, for transportation or for

related expenses, or for rental expenses to temporarily replace

a warranted product. (Some states do not allow limitations on how

long an implied warranty lasts, so the above limitation may not

apply to you.)

In no event shall recovery of any kind be greater than the amount of

the purchase price of the product sold. Alteration of the safety

features of the product shall void this Warranty. You assume the risk

and liability for loss, damage, or injury to you and your property

and/or to others and their property arising out of the use or misuse or

inability to use the product.

This limited warranty shall not extend to anyone other than the

original purchaser, original lessee or the person for whom it was

purchased as a gift.

How State Law Relates to this Warranty: This warranty gives you

specific legal rights, and you may also have other rights which vary

from state to state.

To locate your nearest service dealer dial 1-800-345-8746 in the

United States or 1-800-668-1238 in Canada.

MTD LLC

P. O. Box 361131

Cleveland, OH 44136-0019

The limited warranty set forth below is given by MTD

LLC (“MTD”) with respect with new merchandise purchased and used

in the United States, its possessions and territories.

MTD warrants this product against defects in material and

workmanship for a period of two (2) years commencing on the date of

original purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in material or workmanship.

This limited warranty shall only apply if this product has been operated

and maintained in accordance with the Operator’s Manual furnished

with the product, and has not been subject to misuse, abuse,

commercial use, neglect, accident, improper maintenance, alteration,

vandalism, theft, fire, water, or damage because of other peril or

natural disaster. Damage resulting from the installation or use of any

accessory or attachment not approved by MTD for use with the

product(s) covered by this manual will void your warranty as to any

resulting damage.

This warranty is limited to ninety (90) days from the date of original

retail purchase for any MTD product that is used for rental or

commercial purposes, or any other income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE THROUGH YOUR LOCAL AUTHORIZED

SERVICE DEALER. To locate the dealer in your area, please check for

a listing in the Yellow Pages or contact the Customer Service

Department of MTD by calling 1-800-345-8746 or writing to P. O. Box

361131, Cleveland, OH 44136-0019 or if in Canada call 1-800-668-

1238. No product returned directly to the factory will be accepted

unless prior written permission has been extended by the Customer

Service Department of MTD.

This limited warranty does not provide coverage in the

following cases:

A. Wear items - Bump Knobs, Outer Spools, Cutting Line, Inner

Reels, Starter Pulley, Starter Ropes, Drive Belts

B. MTD does not extend any warranty for products sold or

exported outside of the United States of America, its

possessions and territories, except those sold through MTD’s

authorized channels of export distribution

MTD reserves the right to change or improve the design of any

TrimmerPlus® Product without assuming any obligation to modify

any product previously manufactured.

Page 13

P/N 769-03340A (09/07)

Copiez le numéro de série ici :

Copiez le numéro de modèle / pièce mère ici :

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F1

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F2

Familiarisez-vous avec votre appareil . . . . . . . . . . . . . . . . . . . . .F5

Instructions de montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F6

Mode d’emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F7

Entretien et réparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F9

Chainion replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F9

Huiler la chaine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F10

Nettoyage et entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F11

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F11

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F12

Liste des pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E15

Toutes les informations, illustrations et spécifications contenues dans

ce manuel tiennent compte des dernières informations techniques

disponibles au moment de mettre sous presse. Nous nous réservons

le droit d'y apporter des modifications à tout moment, sans préavis.

Copyright© 2007 MTD SOUTHWEST INC., Tous droits réservés.

Obtenez la liste des concessionnaires agréés appelez le 1-800-345-

8746 aux États-Unis ou le 1-800-668-1238 au Canada.

NE RETOURNEZ PAS L'APPAREIL AU DÉTAILLANT CHEZ QUI

VOUS L'AVEZ ACHETÉ. TOUT SERVICE SOUS GARANTIE

NÉCESSITE UNE PREUVE D'ACHAT.

CE PRODUIT EST COUVERT PAR UN OU PLUSIEURS BREVETS

AMÉRICAINS, ET D’AUTRES SONT EN INSTANCE.

Tout entretien effectué sur cet appareil pendant et après la période

de garantie doit être fait par un concess- ionnaire agréé uniquement.

Avant d'assembler votre nouvel équipement, repérez la plaque

signalétique de l'appareil et copiez ses informations dans l'espace cidessous. Ces informations sont essentielles si vous désirez obtenir de

l'aide auprès de notre service technique ou d'un distributeur agréé. Un

exemple de plaque signalétique est présenté ci-dessous.

CONSERVER CES INSTRUCTIONS

MANUEL DE L'UTILISATEUR

PS720r

Sie de Pole

MODEL :

S/N :

ITEM :

Page 14

• IMPORTANTES CONSIGNES DE SÉCURITÉ •

PROCÉDURES D’OPÉRATION DE LA TRONÇONNEUSE

• Tenez les visiteurs, surtout les enfants et les animaux ft familiers

à une distance d'au moins 15 m (50 pi).

• Portez des lunettes de sécurité conformes aux normes ANSI

Z87.1 ainsi que des protège-oreilles durant l'utilisation de

l'appareil. Portez un masque facial ou antipoussières si vous

travaillez dans un lieu poussiéreux.

• Portez des pantalons épais et longs, des bottes, des gants et

une chemise à manches longues. Ne marchez pas pieds nus et

évitez les vêtements lâches, bijoux, pantalons courts et

sandales. Relevez les cheveux au-dessus des épaules.

• N'utilisez l'appareil qu'en plein jour ou avec un bon éclairage artificiel.

• Utilisez les outils appropriés. N'employez l’outil que pour son

usage prévu.

• Arrêtez toujours l’appareil si vous suspendez la coupe ou si vous

vous déplacez d'un lieu de travail vers un autre.

• N’utilisez que des pièces de rechange et accessoires d’usine pour cet

appareil. Ils sont disponibles auprès de votre concessionnaire agréé.

L’utilisation de toutes pièces ou de tous accessoires non-autorisés

peut entraîner des blessures graves ou des dommages à l’appareil et

l’annulation de votre garantie.

ATTENTION AUX REBONDS

• Comprendre ce qui cause les rebonds peut réduire ou éliminer

l’élément de surprise. L’effet de surprise contribue aux accidents.

• Agarre la sierra firmemente: Sostenga la sierra firmemente con

ambas manos cuando el motor esté en marcha. Mantengo un

buen agarre en la sierra con ambas manos, la mano derecha en

la manija posterior, y la mano izquierda en la manija frontal,

cuando el motor este en marcha. Utilice un agarre firme con los

dedos y el pulgar al rededor de las manijas de la sierra.

• No permita que la nariz de la barra guía tenga contacto con un

tronco, rama, el suelo u otra obstrucción.

LISEZ TOUTES LES INSTRUCTIONS AVANT L'UTILISATION

• Prenez soin de bien lire et comprendre le manuel de l'appareil qui

alimente cet accessoire.

• Veuillez lire le manuel de l'utilisateur attentivement. Familiarisez-vous avec

les commandes et l'utilisation correcte de l’appareil. Sachez comment

arrêter l’appareil et désactiver les commandes rapidement.

• N'utilisez pas l'appareil si vous êtes fatigué, malade ou sous

l'effet de l'alcool, de drogues ou de médicaments.

• Ne laissez pas les enfants faire fonctionner l’appareil. Ne laissez jamais

des adultes qui ne se sont pas familiarisés avec les instructions utiliser

l’appareil. Ne laissez jamais des adultes n'ayant jamais reçu les

instructions nécessaires faire fonctionner l’appareil.

• Tous les accessoires de sécurité et protections doivent être

correctement installés avant d'utiliser cet appareil.

AVERTISSEMENTS DE SÉCURITÉ SPÉCIAUX POUR TÊTES

D’ENTRAÎNEMENT À ESSENCE

• Ne stockez le carburant que dans des contenants conçus et

homologués pour stocker ces matières.

• Arrêtez toujours le moteur et laissez-le refroidir avant de remplir le

réservoir. N'enlevez jamais le bouchon du réservoir et n'ajoutez jamais

de carburant alors que le moteur est chaud. Ne faites jamais marcher

l'appareil sans que le bouchon soit bien mis. Desserrez celui-ci

lentement afin de réduire la pression du réservoir.

• Mélangez et ajoutez le carburant dans un endroit aéré et propre, en

plein air, à l'abri des étincelles ou des flammes. N'enlevez lentement le

bouchon du réservoir d'essence qu'après avoir arrêté le moteur. Ne

fumez pas pendant le remplissage ou le mélange de carburant.

Essuyez immédiatement tout déversement.

• Évitez de mettre le feu au carburant déversé. Ne démarrez pas le

moteur avant que les vapeurs de carburant ne se soient dissipées.

• Éloignez l'appareil d'au moins 9,1 m (30 pi) de la source et du site de

ravitaillement en carburant avant de démarrer le moteur. Ne fumez

pas et éloignez toute source d'étincelles ou de flammes vives du lieu

de ravitaillement ou de fonctionnement de l'appareil.

• Évitez de démarrer ou de faire marcher l'appareil à l'intérieur

d'une pièce ou d'un bâtiment fermé. La respiration de fumées

d'échappement peut tuer. Ne faites marcher l’appareil qu'à

l'extérieur, dans un lieu aéré.

Lisez le(s) manuel(s) de l'utilisateur et suivez tous les

avertissements et consignes de sécurité. Vous pourriez à défaut

entraîner des blessures graves pour vous ou d'autres personnes.

SI VOUS AVEZ DES QUESTIONS, APPELEZ LE

1-800-345-8746

AUX ÉTATS-UNIS, OU LE 1-800-668-1238 AU CANADA

Les symboles de sécurité attirent votre attention sur des dangers potentiels. Ces symboles et leurs détails explicatifs méritent que vous

les lisiez et compreniez bien. Les avertissements de sécurité ne peuvent éviter les dangers de par eux-mêmes. Les consignes ou mises

en garde qu'ils donnent ne remplacent pas des mesures préventives appropriées contre les accidents.

REMARQUE: donne des informations ou des instructions

vitales pour le fonctionnement ou l'entretien de l'équipement.

SYMBOLE SIGNIFICATION

ALERTE DE SÉCURITÉ :

Indique un danger, un

avertissement ou une mise en garde. Soyez vigilant afin

d'éviter toute blessure grave. Ce symbole peut être

combiné à d'autres symboles ou pictogrammes.

DANGER :

l e non-respect d’un avertissement peut

causer dommages matériels ou blessures graves pour

tous. Respectez les consignes de sécurité afin de réduire

les risques d'incendie, d'électrocution et de blessures.

AVERTISSEMENT :

le non-respect d’un avertissement

peut causer dommages matériels ou blessures graves pour

tous. Respectez les consignes de sécurité afin de réduire les

risques d'incendie, d'électrocution et de blessures.

MISE EN GARDE :

le non-respect d’un avertissement

peut causer dommages matériels ou blessures graves pour

tous. Respectez toujours les consignes de sécurité afin de

réduire les risques d'incendie, d'électrocution et de

blessures.

CONSIGNES DE SÉCURITÉ

SYMBOLE SIGNIFICATION

AVERTISSEMENT :

suivez soig-neusement les

consignes de sécurité lorsque vous utilisez cet appareil.

Dans l'intérêt de votre sécurité et de celle des personnes

à proximité, prenez soin de lire ces instructions avant de

faire fonctionner la machine. Veuillez garder les

instructions en lieu sûr pour usage ultérieur.

AVERTISSEMENT :

l'essence est extrêmement

inflammable et ses vapeurs peuvent exploser si on y

met le feu. Veuillez prendre les précautions suivantes.

AVERTISSEMENT :

Les rebonds peuvent se

produire si la tête du guide-chaîne touche un objet, ou si le

bois se resserre sur la chaîne de la tronçonneuse dans la

coupe. Si un contact a lieu avec la tête du guide-chaîne, la

tronçonneuse peut, en l’espace d’une seconde, être projetée

de manière incontrôlée dans un mouvement en arc, en

direction de l’opérateur. Coincer la chaîne le long de la partie

supérieure du guide-chaîne peut pousser le guide-chaîne

peut pousser le guide-chaîne vers l’arrière, vers l’opérateur.

Chacune de ces réactions peut vous faire perdre contrôle de

la tronçonneuse et peut entraîner de sérieuses blessures.

Ne comptez pas exclusivement sur les dispositifs de sécurité

qui équipent votre tronçonneuse. Vous devriez prendre

plusieurs mesures pour éviter tout accident ou toute blessure

lorsque vous vous servez de votre tronçonneuse.

Page 15

CONSIGNES DE SÉCURITÉ

• Scier, le moteur à vitesse maxima.

• No sobrepase su alcance.

• Follow the manufacturer’s sharpening and maintenance

instructions for the saw chain.

• Utiliser uniquement les guides-chaînes et chaînes spécifiés par

le fabricant ou leur équivalent.

AUTRES PRÉCAUTIONS DE SÉCURITÉ

• Ne pas utiliser la tronçonneuse d’une seule main! De graves blessures à

l’opérateur, toute personne l’aidant ou spectateurs pourraient en résulter. Un

tronçonneuse est conçue pour être utilisée des deux mains.

• Ne vous servez pas d’une tronçonneuse si vous êtes fatigué.

• S’habiller de maniere appropriee: Ne pas porter de vêtements trop

amples ou de bijoux cars ils risquent de vous gêner et de se faire

prendre dans une partie mobile de l’appareil. L’utilisation des

élastiques et des semelles antidérapantes est recommandée pour

tout travail à l’extérieur. Les cheveux longs doivent être protégés par

un casque ou autre protection.

• Vetements et equipement recommandes: Porter des chaussures,

gants et lunettes de protection, des habits moulants, des

protecteurs d’oreilles et un casque.

• Faites attention lorsque vous manipulez le carburant. Déplacez

la tronçonneuse à au moins 9.1 m (30 pieds) de l’endroit où vous

l’avez ravitaillée avant de lancer le moteur.

• Garder le secteur de travail net: Un lieu de travail encombré est propice

aux blessures. Ne pas commencer de coupe avant d’avoir un lieu de

travail dégagé, une position stable et une voie de retraite plannifiée.

• Rester vigilant: Attention à ce que vous faites. Utiliser votre sens

commun. Ne pas manier la tronçonneuse par moments de fatigue.

Rester à l’écart de la chaîne quand le moteur est en marche. Avant de

mettre le moteur en marche, s’assurer que la chaîne ne touche rien.

• Débrancher la tronçonneuse quand non utilisée, avant tout

service, et pour tout changement de pièces et accessoires tels le

guide-chaîne et la chaîne.

• Examiner les pieces: Avant toute autre utilisation de la tronçonneuse, un

guide-chaîne ou toute autre pièce endommagée devrait être examinée

soigneusement afin de pouvoir déterminer si son fonctionnement sera

adéquat à sa fonction prévue. Vérifier le montage, l’alignement et la fixation

de toute pièce mobile; vérifier qu’il n’y a pas de piéces cassées ou tout

autre problème qui affecteraient son fonctionnement. Un guide-chaîne ou

toute pièce endommagée devrait être réparée correctement ou remplacée

par un centre de réparations agréé, sauf indication contraire dans ce

manuel d’instructions.

• Observer les alentours de votre secteur de travail: Etre vigilant lors de la

coupe de petits buissons et arbustres car les matériaux plus fins peuvent

«s’attraper» dans la chaîne et être projetés dans votre direction ou vous

faire perdre l’équilibre.

• Ne jamais se servir de la tronçonneuse en se tentant dans un arbre à

moins d’avoir reçu une formation spéciale. Faire attention à ne pas étre

heurté par les branches sous tension qui se relâchent lors de leur coupe.

• N’utilisez pas l'appareil sous la pluie. Ne l’utilisez pas à proximité

de l’eau.

• Ne pas utiliser la tronçonneuse en présence de produits (liquides ou gaz)

combustibles.

• Tous les services d’entretien de la tronçonneuse, à l’exception de ceux

mentionnés dans le manuel d’utilisation et d’entretien, doivent être

effectués par un personnel compétent. Ne pas essayer de faire les

réparations soi-même ; il n’y a pas de pièces internes réparables.

• Ne pas forcer la tronconconneuse: La tronçonneuse aura une

meilleure performance, et une plus sûre, si elle est utilisée au

rythme pour lequel elle a été conçue.

• Utiliser le bon outil: Ne couper que du bois. Ne pas utiliser la

tronçonneuse à des fins pour lesquelles ellen n’apas été conçue. Ne

jamais utilser la tronçonneuse pour couper plastique, maçonnerie, ou

tout autre matériel n’étant pas pour la construction.

• Utilice mecanismos tales como cadenas de contragolpe bajo,

protectores para la nariz de la barra guía, chain brakes y barras

guías especiales, los cuales reducen los peligros relacionados

con el contragolpe.

• Il n’y aucune autre pièce de rechange qui permet d’obtenir une

protection contre les rebonds selon la norme de I’ACNOR Z62-3.

• Ne jamais utiliser une tronçonneuse endommagée, mal ajustée,

non complètement ou incorrectement montée. S’assurer qu’il y a

arrêt de la chaîne quand la gâchette est relâchée.

• Ne pas utiliser la tronçonneuse au delà de vos capacités ou expérience.

• Ne jamais en lever, modifier ou paralyser un dispositif de sécurité

fourni avec l’appareil.

• Cette tronçonneuse est classifiée tronçonneuse catégorie 2C par

ACNOR. Elle est conçue pour des usages infréquents de travaux tels

que dégager, tailler ou couper du bois… par des propriétaires de

maison ou résidences secondaires ou par des campeurs. Elle n’est

pas conçue pour une utilisation prolongée. Si le travail prévu demande

de longues périodes d’utilisation, la vibration risque de causer des

problèmes de circulation aux mains de l’opérateur. Il serait approprié

d’utiliser une tronçonneuse pourvue d’un dispositif anti-vibration.

• Les vêtements de protection éxigés par vos organisations /

syndicats de travail, par les règlementations gouvernementales ou

par votre employeur doivent être utilisés ; sinon, des habits

moulants, des chaussures de sécurité et un protection pour les

oreilles et les mains doivent être portés.

• Une chaîne à «rebonds réduits» répond aux normes de performance

pour «rebonds réduits» exigées par ANSI B175.1-1991 et correspond

aux critères de la norme ACNOR Z62.3. Ne pas utiliser d'autre chaîne

de rechange à moins qu'elle ne réponde aux exigences de votre

modèle en particulier.

• N'utiliser aucun autre accessoire ou accessoire de coupe. Utilisez

exclusivement les accessoires et pièces de rechange d’origine du fabrican,

qui ont été spécifiquement concus pour des performances et pour une

sécurité optimales lors de l'utilisation de nos produits. Faute de quoi, vous

risquez d'obtenir des performances réduites, voire de vous mettre en

danger. Utilisez exclusivement la chaine et la barre fournies avec ce

produit. Ne pas utiliser d'autre accessoire de coupe. L'utilisation de ce type

d'accessoires provoquera l'annulation de votre garantie fabricant et risque

de vous exposer à des accidents graves.

• Ne touchez jamais la chaîne et n’essayez jamais de travailler à la

tronçonneuse lorsque le moteur tourne. Assurez-vous que toutes

les pièces mobiles soient bien arrêtées. Laissez la tronçonneuse

refroidir car la chaîne peut être chaude.

• Vérifiez le guide-chaîne et la chaîne régulièrement et ajustez si

nécessaire. Assurez-vous que le guide-chaîne et la chaîne soient

bien serrés et que la chaîne soit bien aiguisée. Inspectez

visuellement pour tout dommage. Réparez tout dommage avant

d’utiliser ou de remettre la tronçonneuse en marche.

• Ne pas vous en servir près de câbles électriques ou de lignes à

haute tension.

• Ne pas utiliser la perche élagueuse pour abattre un arbre.

Utilisez une tronçonneuse normale pour ce faire.

ENTRETIEN ET ENTREPOSAGE

• Laissez le moteur refroidir avant de l'entreposer ou de le

transporter. Attachez bien l'appareil pendant le transport.

• Toujours utiliser la sécurité de la barre et de la chaîne lors des

transports et du rangement de l’appareil.

• Rangez l'appareil dans un endroit verrouillé et sec, ou élevé et

sec, hors de portée des enfants, pour éviter une utilisation

indésirable ou un accident.

• Ne trempez et n'arrosez jamais l'appareil avec de l'eau ou tout

autre liquide. Gardez les poignées sèches, propres et exemptes

de débris. Nettoyez après chaque usage.

• Conservez ces instructions. Consultez-les souvent et servezvous en pour instruire d'autres usagers. Si vous prêtez l'appareil

à quelqu'un, prêtez-lui également ces instructions.

• Les réparations ou les procédures d'entretien qui ne sont pas

décrites dans le manuel doivent être strictement confiées à des

techniciens qualifiés.

CONSERVEZ CES INSTRUCTIONS

Page 16

• SYMBOLES DE SÉCURITÉ ET INTERNATIONAUX •

Ce manuel de l'utilisateur décrit les symboles et pictogrammes de sécurité et internationaux pouvant apparaître sur ce produit. Consultez le

manuel de l'utilisateur pour les informations concernant la sécurité, le montage, le fonctionnement, l'entretien et les réparations.

CONSIGNES DE SÉCURITÉ

•

AVERTISSEMENT : LISEZ LE MANUEL

DE L'UTILISATEUR

Lisez le manuel de l'utilisateur et suivez tous les

avertissements et consignes de sécurité. Vous

pourriez à défaut entraîner des blessures graves pour

vous ou d'autres personnes.

•

AVERTISSEMENT SUR LE GUIDECHAÎNE

Évitez tout contact de l’extrémité du guide-chaîne

avec tout objet. Le contact de l’extrémité peut

entraîner un mouvement brusque du guide-chaîne

vers le haut et en arrière, ce qui entraîner de

sérieuses blessures.

SYMBOL MEANING

•

PORTEZ DES PROTECTIONS (TÊTE,

YEUX ET OREILLES)

AVERTISSEMENT :

les objets projetés et les

bruits forts peuvent endommager la vue et l’ouïe.

Portez une visière de norme ANSI Z87.1-1989 et des

protège-oreilles pendant l'utilisation. la chute d’objets

peut causer des blessures graves à la tête. Protégezvous la tête pendant l'utilisation de l'appareil.

•

AVERTISSEMENT SURFACE CHAUDE

Ne pas toucher aux surfaces chaudes. Vous pourriez

vous brûler. Ces pièces deviennent très chaudes à

l'utilisation. Elles restes chaudes brièvement après

l'arrêt.

•

ÉLOIGNEZ LES SPECTATEURS

AVERTISSEMENT :

éloignez les spectateurs, les

enfants et les animaux domestiques en particulier,

d'au moins 15 m (50 pi) de la zone de coupe.

•

LES LIGNES ELECTRIQUES PEUVENT

ENTRAINER DE GRAVES BLESSURES

AVERTISSEMENT :

Ne pas utiliser l’appareil à

proximité des lignes électriques. Tout contact avec

une ligne électrique peut entraîner de graves

blessures ou endommager l’appareil. Maintenir une

distance d’au moins 50 pieds (15 m) entre la scie à

long manche (incluant les branches avec lesquelles

elle entre en contact) et toute ligne électrique.

•

TENEZ À DEUX MAINS

Tenez toujours la tronçonneuse à deux mains lors de

son utilisation. Ne la tenez jamais à une main.

•

SYMBOLE ALERTE DE SÉCURITÉ

Indique un danger, un avertissement ou une mise en

garde. Ce symbole peut être combiné à d'autres

symboles ou pictogrammes.

SYMBOL MEANING

•

INDICATEUR D’AJUSTEMENT DE

L’HUILE POUR LA CHAÎNE

La chaîne doit constamment être enduit d’une

couche d’huile pour fonctionner correctement.

Assurez-vous de régler la vis d’ajustement de l’huile

pour permettre à une quantité suffisante d’huile

d’imbiber la chaîne continuellement.

Utiliser une clef Allen de 3/32 pouces pour régler la

vis d’ajustement de l’huile.

Page 17

FAMILIARISEZ-VOUS AVEC VOTRE APPAREIL

Guidechaîne

Chaîne

Bouchon du

réservoir a huile

Arbre de

Transmission

Tête du

guide-chaîne

Couvercle

du pignon

Capteur de

chaîne

Ecrous du guide-chaîne

Bras

d’extension

Vis de réglage

de tension

Vis d’ajustement de l’huile

Reservoir d’huile

Garde à chaînes de

transport

Crochet de

rangement

Coupleur

Couvercle

pour

transport

Page 18

L’accessoire doit être installé avec le bouton de déclenchement dans

le trou principal.

Vérifiez que le bras flexible est bien engagé avant l’utilisation

1. Démarrez l’appareil.

2. Appuyez brièvement sur la détente, puis relâchez-la.

3. Vérifiez le fonctionnement de l’accessoire.

4. S’il ne fonctionne pas, retirez-le et répétez la

procédure d’installation.

5. Vérifiez de nouveau le fonctionnement de l’accessoire.

2. Appuyez sur le bouton de déclenchement et maintenez-le

enfoncé (Fig. 1).

3. En tenant fermement le logement de l’arbre supérieur, retirez

l’accessoire du couplage (Fig. 2).

Coupleur

Bouton de

déclenchement

Renfoncement-

guide

Bouton

À droiteÀ gauche

Trou principal

Corps de l'arbre

supérieur

Coupleur

Corps de l'arbre

inférieur

Bouton de déclenchement

Bouton

MONTAGE DU COUPLEUR

L’ajout Trimmer Plus peut être monté de différentes manières sur les

outils électriques. Les manuels d’utilisation de l’outil électrique de

base et de l’attache comprennent des informations nécessaires pour

l’utilisation de l’outil électrique combiné. Ainsi, il est nécessaire de lire

toujours les DEUX manuels d’utilisation avant d’utiliser l’outil

électrique pour la première fois. Conserver les manuels en lieu sûr

pour référence future.

REMARQUE : pour faciliter l'installation ou le retrait d'accessoires,

placez l'appareil au sol ou sur un établi.

Retrait de l'accessoire

1. Dévissez le bouton vers la gauche (Fig. 1).

Fig. 1

Fig. 2

Fig. 3

Bouton

INSTRUCTIONS DE MONTAGE

AVERTISSEMENT :

veuillez bien assimiler le

manuel des accessoires avant utilisation.

MISE EN GARDE :

l'accessoire de coupe et autres

ajouts du système EZ-LinkMD doivent utiliser le trou

principal sauf indication contraire de leurs manuels.

L'utilisation du mauvais trou pourrait causer des

blessures graves ou endommager l'appareil.

AVERTISSEMENT :

pour éviter des blessures

graves, éteignez l'appareil avant d'enlever ou d'installer

des accessoires.

REMPLIR LE RESERVOIR D’HUILE

Suivez les étapes suivantes pour remplir le réservoir d’huile :

1. Installer l’appareil sur une surface plane.

2. Retirer le bouchon du réservoir d’huile.

3. Ouvrir le bidon d’huile fourni avec l’appareil.

4. Verser l’huile dans le réservoir jusqu’à ce qu’il soit plein.

REMARQUE : Le réservoir d’huile peut être rempli jusqu’au bord de

l’ouverture du réservoir sans pour autant endommager l’appareil.

DANGER :

Le fait de ne pas remplir le réservoir

d’huile endommagera l’appareil de manière irréversible.

Assurez-vous que le réservoir d’huile est toujours plein.

AVERTISSEMENT :

L’huile coule en continu du

réservoir d’huile sur la chaîne. Vérifiez constamment

que le niveau d’huile ne descend pas en dessous de la

moitié du réservoir.

5. Répétez les étapes 1-4 pour suivants ou le bras d’extension.

Installation de l'accessoire

1. Enlevez le crochet ou le couvercle pour transport de la partie

supérieure du corps de l'arbre.

2. Dévissez le bouton vers la gauche (Fig. 1).

3. Tenez fermement l'accessoire et enfoncez-le tout droit dans le

coupleur (Fig. 2).

REMARQUE : alignez le bouton de déclenchement avec le

renfoncement-guide pour faciliter l'installation (Fig. 1).

4. Serrez le bouton en le tournant à droite (Fig. 3).

MISE EN GARDE :

verrouillez le bouton de

déclenchement dans le trou principal et vissez bien le

bouton avant de faire marcher l'appareil.

AVERTISSEMENT:

Pour éviter des blessures

graves et des dégâts à l’unité, ne raccordez JAMAIS

plus d’une rallonge à un outil électrique.

Page 19

Fig. 4

Fig. 5

Fig. 6

PRECAUTIONS D’UTILISATION

1. Éloigner les spectateurs à une distance de 15 mètres (50

pieds) quand la scie est em marche.

2. Ne pas utiliser la perche élagueuse pour abattre un arbre; A

cet effet, utiliser la tronçonneuse sans la perche

3. S’assurer que le réservoir d’huile est plein et que l’huile lubrifie

la chaîne avant utilisation.

4. Tenir la perche élagueuse fermement, une main sur la canne,

l’autre sur la poignée.

5. Ne mettre le doigt sur l’interrupteur qu’au moment de couper.

6. S’assurer que la chaîne ne touche rien, avant de mettre

l’appareil en marche.

7. Rester à l’écart de la chaîne lorsque le moteur est en marche.

8. Ne pas forcer l’appareil pendant la coupe. Une légère pression

est suffisante et vous obtiendrez une meilleure performance et

une plus s˚re en l’utilisant à la puissance pour laquelle il a été

conçu.

9. Rester vigilant en coupant petites ou grosses branches sous

tension, car au moment où la tension se relâche, le bois peut

avoir un mouvement ressort et heurter l’utilisateur pouvant

ainsi causer de sérieuses blessures parfois mortelles.

10. Avant de déplacer la perche élagueuse:

• tenir l’appareil à son point d’équilibre (vers le bout de la

tronçonneuse)

• garder chaîne et guide chaîne vers l’arrière.

11. Ne pas couper de petits buissons ou jeunes arbres avec la

perche élagueuse. Les fines branches peuvent se coincer

dans la chaîne et être projetées vers vous, ce qui peut vous

faire perdre votre équilibre.

12. Ne jamais se tenir sous la branche que vous coupez. Rester

toujours à l’écart des chutes de débris (Fig. 4).

13. Ne jamais se mettre sur une échelle ou autre support instable

pendant l’utilisation de la perche élagueuse.

14. Toujours utiliser les deux mains pour utiliser l’appareil. Garder

une pression constante et ferme pendant la coupe sans forcer

dans le bois

15. Ne pas utiliser la scie à poteau pour couper des branches

d'un diamètre supérieur à 10 cm (4 po).

16. Garder tout le monde à l’écart de la partie coupante de la

perche élagueuse et à une bonne distance de la zone de

travail (Fig. 5).

17. Ne pas utiliser la perche élagueuse près de câbles, fils

téléphoniques ou électriques. Garder une distance d’au moins

10 pieds (Fig. 6).

CONSIGNES DE DEMARRAGE

Démarrer et utiliser votre scie à long manche sans aucune

assistance. Pour des consignes de démarrage spécifiques,

consulter la section appropriée du manuel. Les méthodes de

démarrage appropriées réduisent les risques de blessures.

1. Disposer la scie à long manche sur un sol ferme ou une autre

surface dure, sans une zone à ciel ouvert.

2. Maintenir un bon équilibre et une bonne assise.

MODE D’EMPLOI

AVERTISSEMENT :

Portez des vêtements

appropriés pour diminuer les risques de blessures durant

l'utilisation de l'appareil. Ne portez pas de vêtements

amples ni de bijoux. Portez des lunettes de sécurité et

des protège-oreilles. Portez des pantalons épais et longs,

des bottes et des gants. Ne marchez pas pieds nus et

évitez les pantalons courts et les sandales.

AVERTISSEMENT :

Afin de réduire les risques

d’incendie et de brûlures, démarrer le moteur à au

moins 30 pieds (9,1 m) du point d’essence, à l’extérieur

uniquement.

Page 20

TAILLER UN ARBRE (ELAGUAR)

• Eviter les rebonds. Ils peuvent causer de graves blessures

parfois mortelles.

• Ne pas utiliser la perche élagueuse en étant sur un arbre, une

échelle ou autre endroit en position instable. Vous risquez de

perdre le contrôle de la perche élagueuse, ce qui pourrait causer

de sérieuses blessures.

• Ne pas allonger les bras au-dessus des épaules pendant

l’utilisation de la perche élagueuse.

• Veuillez consulter un professionnel si les conditions de travail

sont au-delà de vos capacités

• Tailler un arbre signifie couper des branches d’un arbre vivant.

S’assurer de votre bon équilibre. Garder les pieds écartés.

Répartir votre poids.

• Avant de démarrer l’appareil, toujours vérifier la lubrification de

la chaîne et le niveau d’huile du réservoir.

REMARQUE : La chaîne doit être constamment imbibée d’huile

pour fonctionner correctement. S’assurer que la vis

d’ajustement de l’huile est réglée de manière appropriée.

Fig. 7

2

4

3

1

6 po

2-4 po

Pour tailler une branche (élagage) :

1. Faire la première coupe à 6 pouces du tronc du dessous de la

branche. Utiliser le haut du guide-chaîne pour cette coupe.

Couper 1/3 du diamètre de la branche (Fig. 7).

2. Faire la seconde coupe mais du dessus à deux ou quatre

pouces plus loin sur la branche. Continuer à couper jusqu’à ce

que la branche tombe.

3. Faire la troisième coupe le plus près possible du tronc par le

dessous de la souche de la branche. Utiliser la partie

supérieure du guide-chaîne pour faire cette coupe. Couper 1/3

du diamètre de la souche.

4. La quatrième coupe se fait directement au-dessus de la

troisième. Couper pour atteindre l’autre côté et faire tomber la

souche de la branche.

MODE D’EMPLOI

AVERTISSEMENT :

Les rebonds peuvent se

produire si la tête du guide-chaîne touche un objet, ou

si le bois se resserre sur la chaîne de la tronçonneuse

dans la coupe. Si un contact a lieu avec la tête du

guide-chaîne, la tronçonneuse peut, en l’espace d’une

seconde, être projetée de manière incontrôlée dans un

mouvement en arc, en direction de l’opérateur. Coincer

la chaîne le long de la partie supérieure du guidechaîne peut pousser le guide-chaîne peut pousser le

guide-chaîne vers l’arrière, vers l’opérateur. Chacune de

ces réactions peut vous faire perdre contrôle de la

tronçonneuse et peut entraîner de sérieuses blessures.

Ne comptez pas exclusivement sur les dispositifs de

sécurité qui équipent votre tronçonneuse. Vous devriez

prendre plusieurs mesures pour éviter tout accident ou

toute blessure lorsque vous vous servez de votre

tronçonneuse.

AVERTISSEMENT :

Si le réservoir d’huile est vide,

le trou de la vis d’ajustement de l’huile se colmate, ou

la chaîne n’est plus lubrifiée ; par conséquent la chaîne

sera en surchauffe est endommagera l’appareil de

manière irréversible jusqu’à pouvoir entraîner de graves

blessures. La chaleur excessive due à la friction peut

entraîner la sortie catastrophique de la chaîne sur l’axe

de la barre en pleine utilisation.

Page 21

CHAINION REMPLACEMENT

1. En vous servant d’un tournevis plat, tournez la vis de réglage

de la tension dans le sens contraire des aiguilles d’une montre

(Fig. 8, A) 4 temps.

2. Retirez la vis et les écrous maintenant le guide-chaîne en

place. Enlevez ensuite la protection du pignon (Fig. 8, B).

Fig. 9

3. Retirer la chaîne et le guide.

4. Préparer la nouvelle chaîne et/ou le guide et ajuster la chaîne

dans la rainure du guide.

5. Passez la chaîne par dessus le pignon avec les lames de la

chaîne tournées dans la direction de la rotation (Fig. 9).

REGLAGE DE LA TENSION DE LA CHAINE

La tension de la chaîne est d’une importance capitale et doit être

contrôlée avant de commencer et pendant tout travail de coupe.

Prendre le temps de faire les réglages nécessaires à la chaîne de

votre tronçonneuse est synonyme de bonne performance et de

longévité de votre outil.

REMARQUE : La tension d’une chaîne neuve doit être contrôlée

fréquemment pendant son rodage, après aussi peu que

cinq coupes. Les intervalles entre réglages s’espaceront

rapidement (Fig. 11).