Page 1

Operator’s Manual

4-Cycle Gasoline Trimmer

Model H70SS

SAVE THESE INSTRUCTIONS

For a list of service providers, please refer to the phone numbers

found on page 6 or at the end of the Trouble Shooting section of

this manual.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF

PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS.

OTHER PATENTS PENDING.

Service on this unit both within and after the warranty period should

be performed only by an authorized and approved service dealer.

All information, illustrations, and specifications in this manual

are based on the latest product information available at the

time of printing. We reserve the right to make changes at any

time without notice.

Copyright© 2007 MTD SOUTHWEST INC, All Rights Reserved.

P/N 769-02747C (2/07)

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Starting & Stopping Instructions . . . . . . . . . . . . . . . . . . . . . .4

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E11

WARNING: When using the unit, you must follow

the safety rules. Please read these instructions

before operating the unit in order to ensure the

safety of the operator and any bystanders. Please

keep these instructions for later use.

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls

and proper use of the unit.

• This unit was not designed to be used as a brushcutter. Do

not attach or operate this unit with any type of brushcutting

blade or brushcutting attachment.

• Do not operate this unit when tired, ill, or under the influence

of alcohol, drugs, or medication.

• Children and teens under the age of 15 must not use the

unit, except for teens guided by an adult.

• All guards and safety attachments must be installed properly

before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check

for fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

• Carefully inspect the area before starting the unit. Remove all

debris and hard or sharp objects such as glass, wire, etc.

• Be aware of the risk of injury to the head, hands and feet.

• Clear the area of children, bystanders, and pets. At a minimum,

keep all children, bystanders, and pets outside a 50 feet (15 m)

radius; there still may be a risk to bystanders from thrown

objects. Bystanders should be encouraged to wear eye

protection. If you are approached, stop the unit immediately.

• Use only 0.105 inches (2.67 mm) diameter original equipment

manufacturer replacement line. Never use metal-reinforced

line, wire, or rope. These can break off and become dangerous

projectiles.

• Squeeze the throttle control and check that it returns automatically to the idle position. Make all adjustments or repairs

before using unit.

RULES FOR SAFE OPERATION

• IMPORTANT SAFETY INSTRUCTIONS •

Page 2

2

SAFETY WARNINGS FOR GAS UNITS

• Store fuel only in containers specifically designed and

approved for the storage of such materials.

• Avoid creating a source of ignition for spilled fuel. Do not

start the engine until fuel vapors dissipate.

• Always stop the engine and allow it to cool before filling the

fuel tank. Never remove the cap of the fuel tank, or add fuel,

when the engine is hot. Never operate the unit without the

fuel cap securely in place. Loosen the fuel tank cap slowly to

relieve any pressure in the tank.

• Add fuel in a clean, well-ventilated outdoor area where there

are no sparks or flames. Slowly remove the fuel cap only

after stopping engine. Do not smoke while fueling or mixing

fuel. Wipe up any spilled fuel from the unit immediately.

Always wipe unit dry before using.

• Move the unit at least 30 feet (9.1 m) from the fueling source

and site before starting the engine. Do not smoke or allow

sparks and open flames near the area while adding fuel or

operating the unit.

WHILE OPERATING

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can be fatal. Operate this unit only

in a well-ventilated outdoor area.

• Wear safety glasses or goggles that meet ANSI Z87.1

standards and are marked as such. Wear ear/hearing

protection when operating this unit. Wear a face or dust

mask if the operation is dusty.

• Wear heavy long pants, boots, gloves and a long sleeve shirt.

Do not wear loose clothing, jewelry, short pants, sandals or

go barefoot. Secure hair above shoulder level.

• The cutting attachment shield must always be in place while

operating the unit as a trimmer. Do not operate unit without

both trimming lines extended, and the proper line installed.

Do not extend the trimming line beyond the length of the

shield.

• This unit has a clutch. The cutting attachment remains

stationary when the engine is idling. If it does not, have the

unit adjusted by an authorized service technician.

• Adjust the D-handle to your size in order to provide the best

grip.

• Be sure the cutting attachment is not in contact with anything

before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position

whenever pulling the starter rope. The operator and unit must

be in a stable position while starting. Refer to

Starting/Stopping Instructions.

RULES FOR SAFE OPERATION

• Use the right tool. Only use this tool for its intended purpose.

• Do not overreach. Always keep proper footing and balance.

• Always hold the unit with both hands when operating. Keep a

firm grip on both handles or grips.

• Keep hands, face, and feet at a distance from all moving

parts. Do not touch or try to stop the cutting attachment

when it rotates.

• Do not touch the engine, gear housing or muffler. These parts

get extremely hot from operation, even after the unit is turned off.

• Do not operate the engine faster than the speed needed to

cut, trim or edge. Do not run the engine at high speed when

not cutting.

• Always stop the engine when cutting is delayed or when

walking from one cutting location to another.

• If you strike or become entangled with a foreign object, stop

the engine immediately and check for damage. Do not

operate before repairing damage. Do not operate the unit

with loose or damaged parts.

• Stop the unit, switch the engine to off, and disconnect the

spark plug for maintenance or repair.

• Use only original equipment manufacturer replacement parts

and accessories for this unit. These are available from your

authorized service dealer. Use of any unauthorized parts or

accessories could lead to serious injury to the user, or

damage to the unit, and void your warranty.

• Keep unit clean of vegetation and other materials. They may

become lodged between the cutting attachment and shield.

• To reduce fire hazard, keep the engine and muffler free from

grass, leaves, and excessive grease.

AFTER USE

• Clean cutting blades with a household cleaner to remove any

gum buildup. Oil the blade with machine oil to prevent rust.

• Lock up and store the cutting blade in an appropriate area to

protect the blade from unauthorized use or damage.

OTHER SAFETY WARNINGS

• Never store a fueled unit inside a building where fumes may

reach an open flame or spark.

• Allow the engine to cool before storing or transporting. Be

sure to secure the unit while transporting.

• Store the unit in a dry area, locked up or up high to prevent

unauthorized use or damage, out of the reach of children.

• Never douse or squirt the unit with water or any other liquid.

Keep handles dry, clean and free from debris. Clean after

each use, see Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan someone this unit, also loan

them these instructions.

SAVE THESE INSTRUCTIONS

WARNING: Gasoline is highly flammable, and its

vapors can explode if ignited. Take the following

precautions:

Page 3

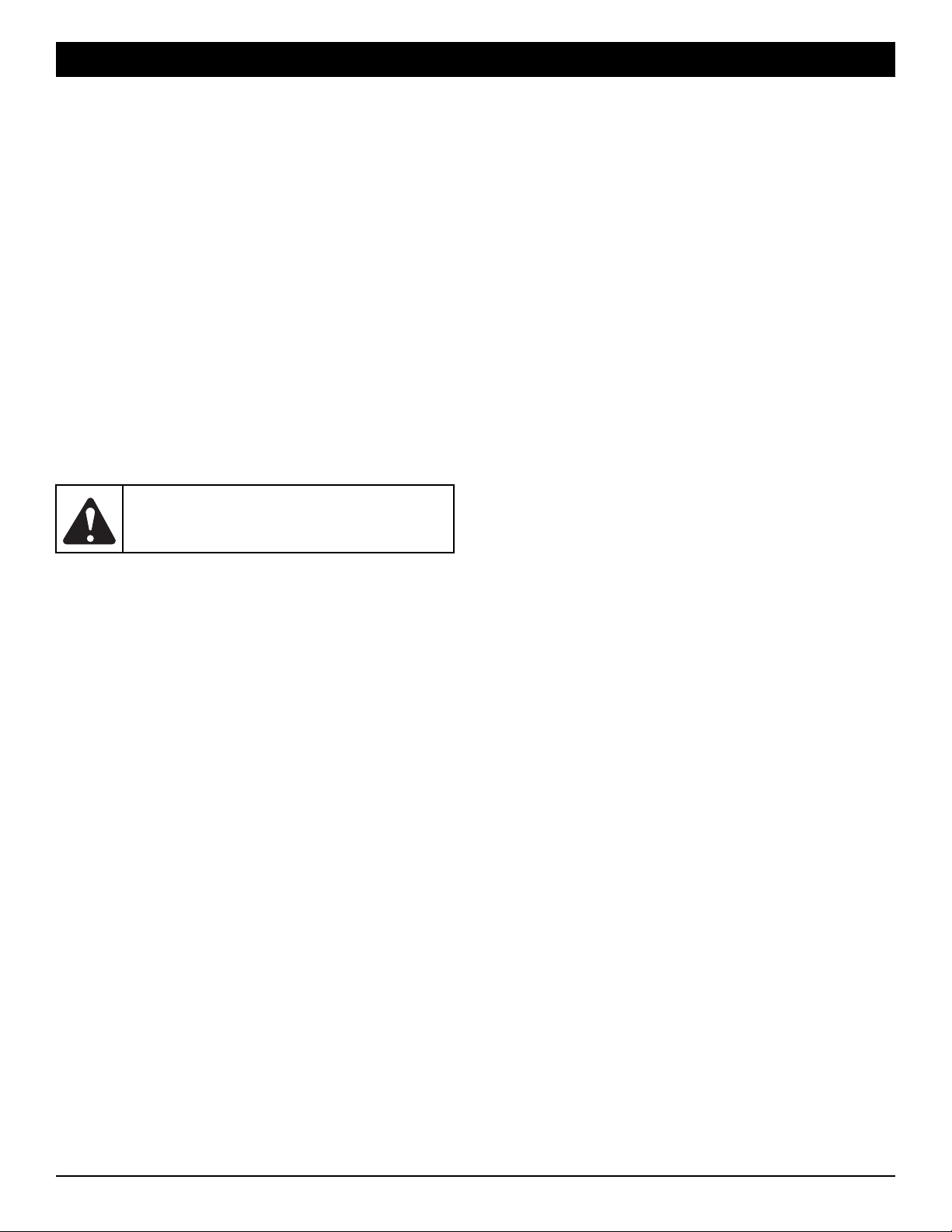

This operator's manual describes safety and international

symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly,

operating and maintenance and repair information.

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be

used in conjunction with other symbols or

pictographs.

• WARNING - READ OPERATOR'S MANUAL

Read the operator’s manual(s) and follow all

warnings and safety instructions. Failure to do so

can result in serious injury to the operator and/or

bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear

eye protection meeting ANSI Z87.1 standards

and ear protection when operating this unit. Use

a full face shield when needed.

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially

children and pets, at least 50 feet (15 m) from the

operating area.

• THROWN OBJECTS AND ROTATING CUTTER

CAN CAUSE SEVERE INJURY

WARNING: Do not operate without the cutting

attachment shield in place. Keep away from the

rotating cutting attachment.

• SHARP BLADE

WARNING: Sharp blade on cutting attachment

shield. To prevent serious injury, do not touch the

line cutting blade.

APPLICATIONS

• Cutting grass and light weeds

• Edging

• Decorative trimming around trees, fences, etc.

NOTE: The below illustration may differ slightly from your unit.

Cutting Attachment

Shield

Throttle

Control

D-Handle

Cutting

Attachment

Shaft Grip

Shaft

Housing

Line

Cutting

Blade

On/Off Stop Control

KNOW YOUR UNIT

3

Page 4

4

ASSEMBLY INSTRUCTIONS

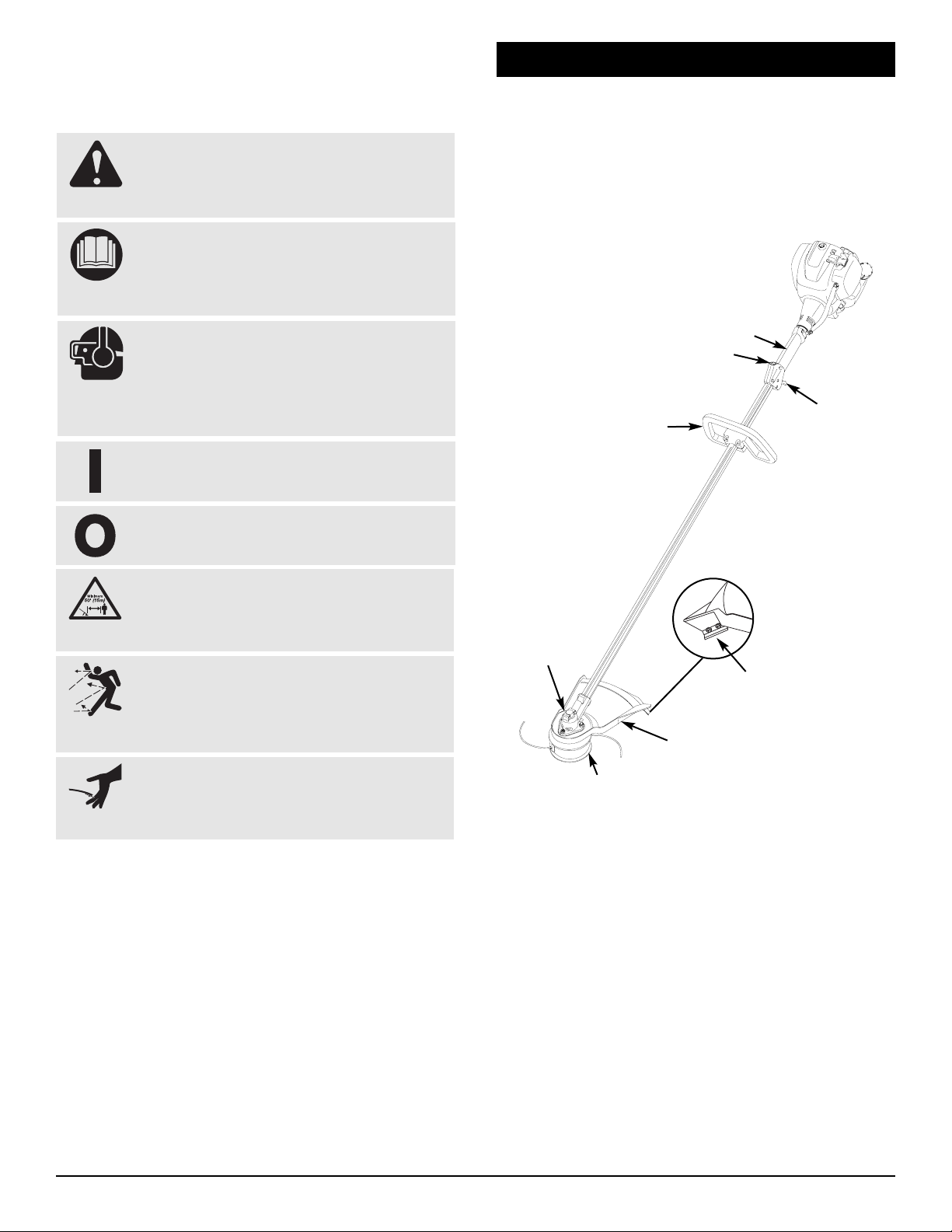

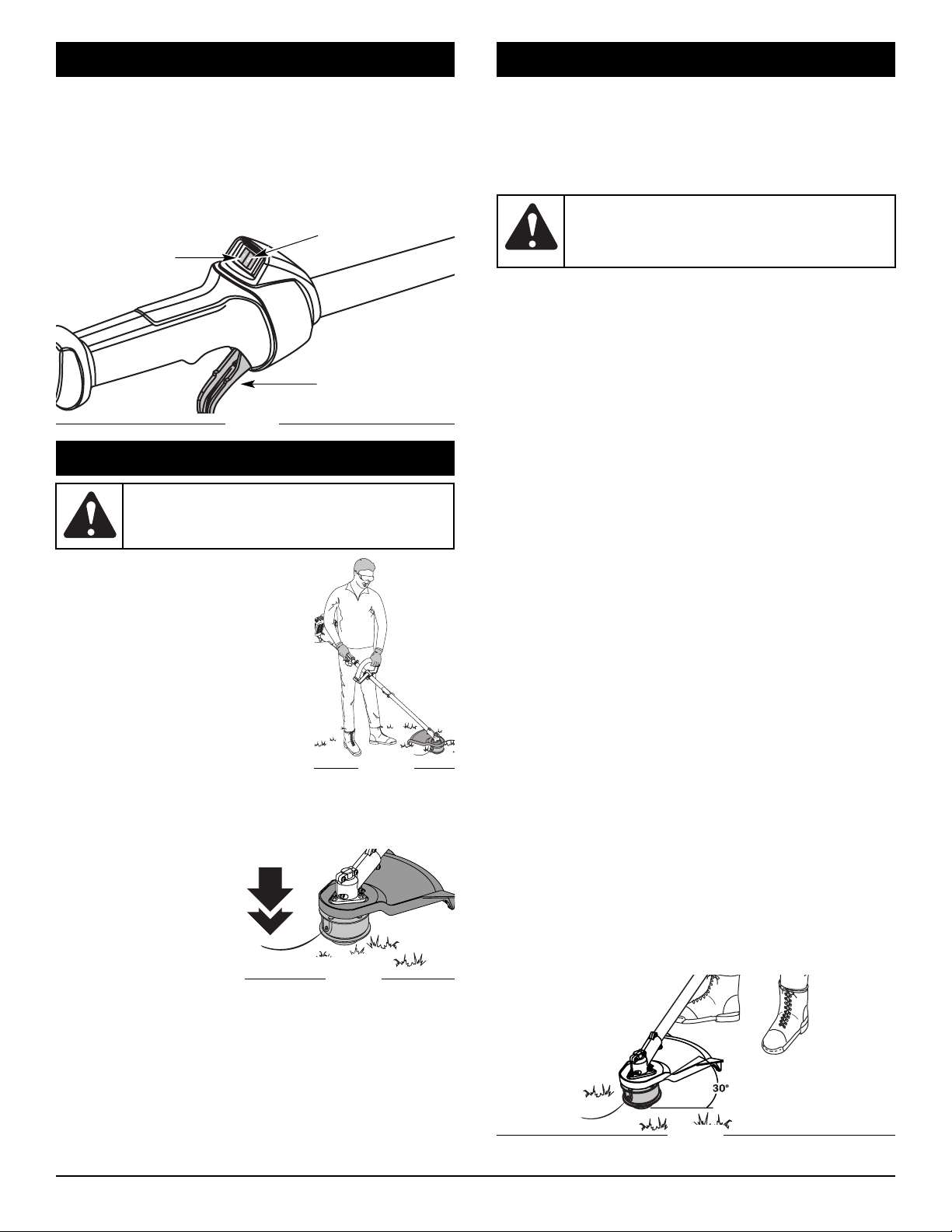

INSTALLING AND ADJUSTING THE D-HANDLE

If your unit has the D-Handle pre-installed, please follow the

“To Adjust” instructions only.

To Install

1. Remove the screws and

bottom clamp piece that

were installed on the Dhandle for shipping.

2. Place the D-handle over

the shaft housing and onto

the bottom clamp (Fig. 1).

Place it a minimum of 6 in

(15.24 cm) from the end of

the shaft grip.

3. Start screws with a large Flat-head or T-25 Torx

screwdriver. Do not tighten until you make the handle

adjustment.

To Adjust

4. If the D-handle was pre-installed, loosen the screws on the

handle just enough to move it.

5. While holding the unit in the operating position, manuever

the D-handle to the location that provides you the best grip

(Fig. 2).

6. Tighten the clamp screws evenly, until the D-handle is

secure.

INSTALL THE HARNESS

1. Push the strap through the center of the buckle.

2. Pull the strap over the cross bar and down through the slot

in the buckle (Fig. 3).

3. Put the harness on over head and onto shoulder. Snap it

on to the support fitting (Fig. 4).

4. Adjust length to fit the operator’s size. Pull tab to lengthen,

pull strap to shorten (Fig 6).

(4) Screws

D-Handle

Bottom

Clamp

Fig. 1

Minimum

6 inches

(15.24 cm)

STARTING/STOPPING INSTRUCTIONS

1. Check the oil level in the crankcase. Refer to Checking the

Oil Level in the Honda Engine Manual that came with the

unit.

2. Fill the fuel tank with fresh, clean unleaded gasoline. Refer

to Fueling the Unit in the Honda Engine Manual that came

with the unit.

NOTE: There is no need to turn the unit on. The On/Off Stop

Control is in the ON (I) position at all times (Fig. 8).

3. When starting a cold engine or after refueling, fully press

and release the primer bulb 10 times, slowly. Some amount

of fuel should be visible in the primer bulb and fuel lines

(Fig. 6). If you can’t see fuel in the bulb, press and release

the bulb as many times as it takes before you can see fuel

in it.

4. Move the choke lever into the choke or closed position

(Fig. 6).

5. Crouch in the starting position and do not squeeze the

throttle control (Fig. 7). Pull the starter rope 2 times with a

controlled and steady motion.

NOTE: The unit may or may not start for a brief period of time.

Continue to step 6.

6. M

ove the choke lever into the run or open position (Fig. 6).

7. Crouch in the starting position and do not squeeze the

throttle control (Fig. 7). Pull the starter rope 1-5 times with

a controlled and steady motion or until the unit starts.

8. Let the unit warm in an idle state for 10 seconds. After 10

sec idle warm up period, gradually squeeze the throttle

lever to allow the unit to accelerate slowly to maximum

speed.

IF

... The engine does not start, go back to step 3.

IF

... The engine stops while you are squeezing the throttle, go

back to step 7 and run unit at half throttle for a few minutes

to allow the unit to warm up.

NOTE: To restart a warm engine, leave the choke lever in the

run or open position. It is not necessary to press the

primer bulb.

Choke Lever

Primer Bulb

Fig. 6

Fig. 7

Fig. 2

Fig. 3

Support Fitting

Fig. 4

Fig. 5

WARNING: Always use the shoulder harness

when using the cutting blade to avoid serious

personal injury.

Page 5

Each time the head is bumped, about 1 inch (25.4 mm) of

trimming line releases. A blade in the cutting attachment shield

will cut the line to the proper length if any excess line is released.

For best results, tap the bump knob on bare ground or hard

soil. If you attempt a line release in tall grass, the engine may

stall. Always keep the trimming line fully extended. Line release

becomes more difficult when the cutting line gets shorter.

NOTE: Do not rest the Bump Head on the ground while the

unit is running.

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects such as walls or fence posts

TIPS FOR BEST TRIMMING RESULTS

• For best trimming results, operate unit at full throttle.

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip of the line to

do the cutting, especially along walls. Cutting with more than the

tip will reduce cutting efficiency and may overload the engine.

• Cut grass over 8 inches (200 mm) by working from top to

bottom in small increments to avoid premature line wear or

engine drag.

• Cut from left to right.

• Slowly move the trimmer into and out of the cutting area at

the desired height. Move either in a forward-backward or

side-to-side motion. Cutting shorter lengths produces the

best results.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

- Proper adherence of explained trimming techniques

- What vegetation is cut

- Where vegetation is cut

For example, the line will wear faster when trimming against a

foundation wall as opposed to trimming around a tree. It is

normal for some line breakage to occur from regular use.

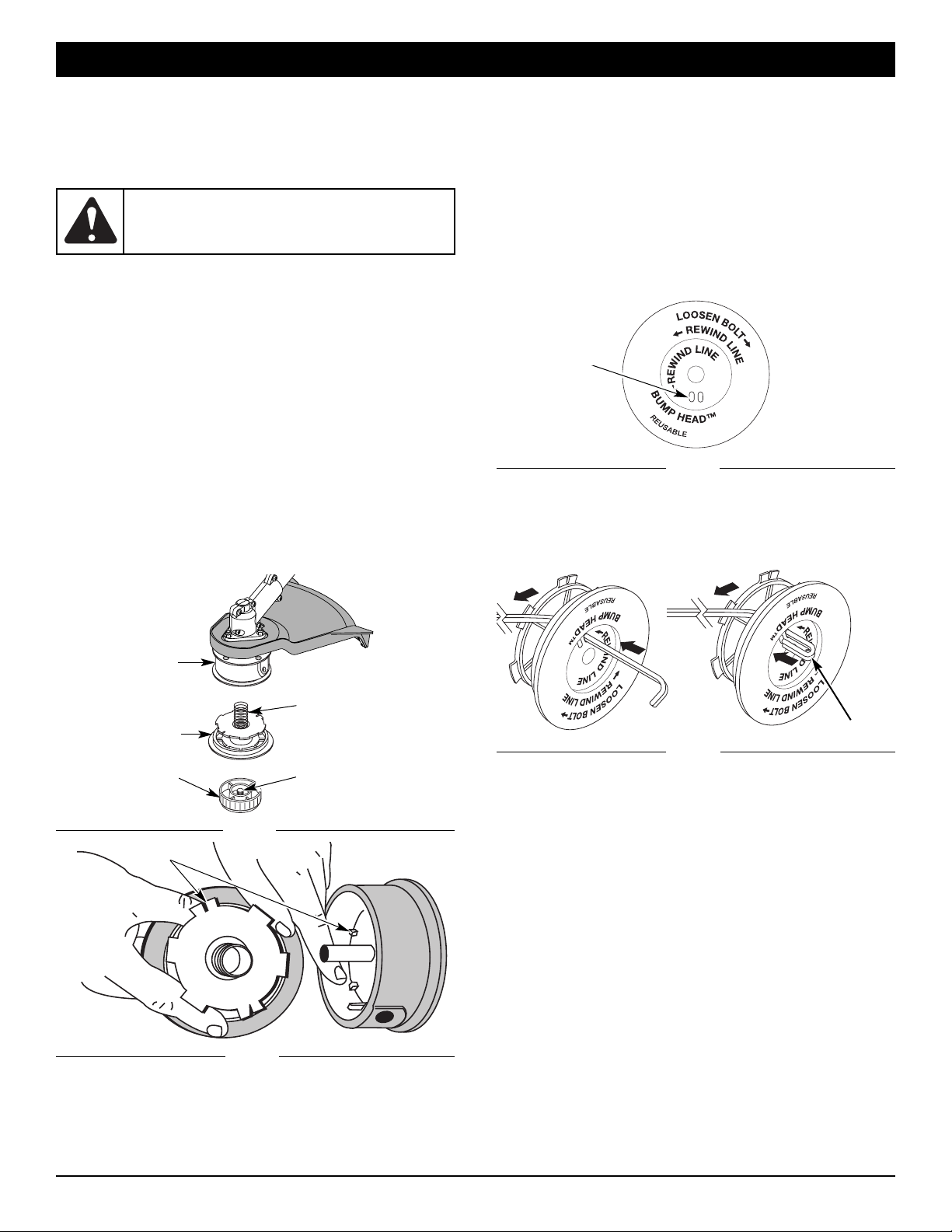

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences and more.

Rotate the whole unit so that the cutting attachment is at a 30°

angle to the ground (Fig. 11).

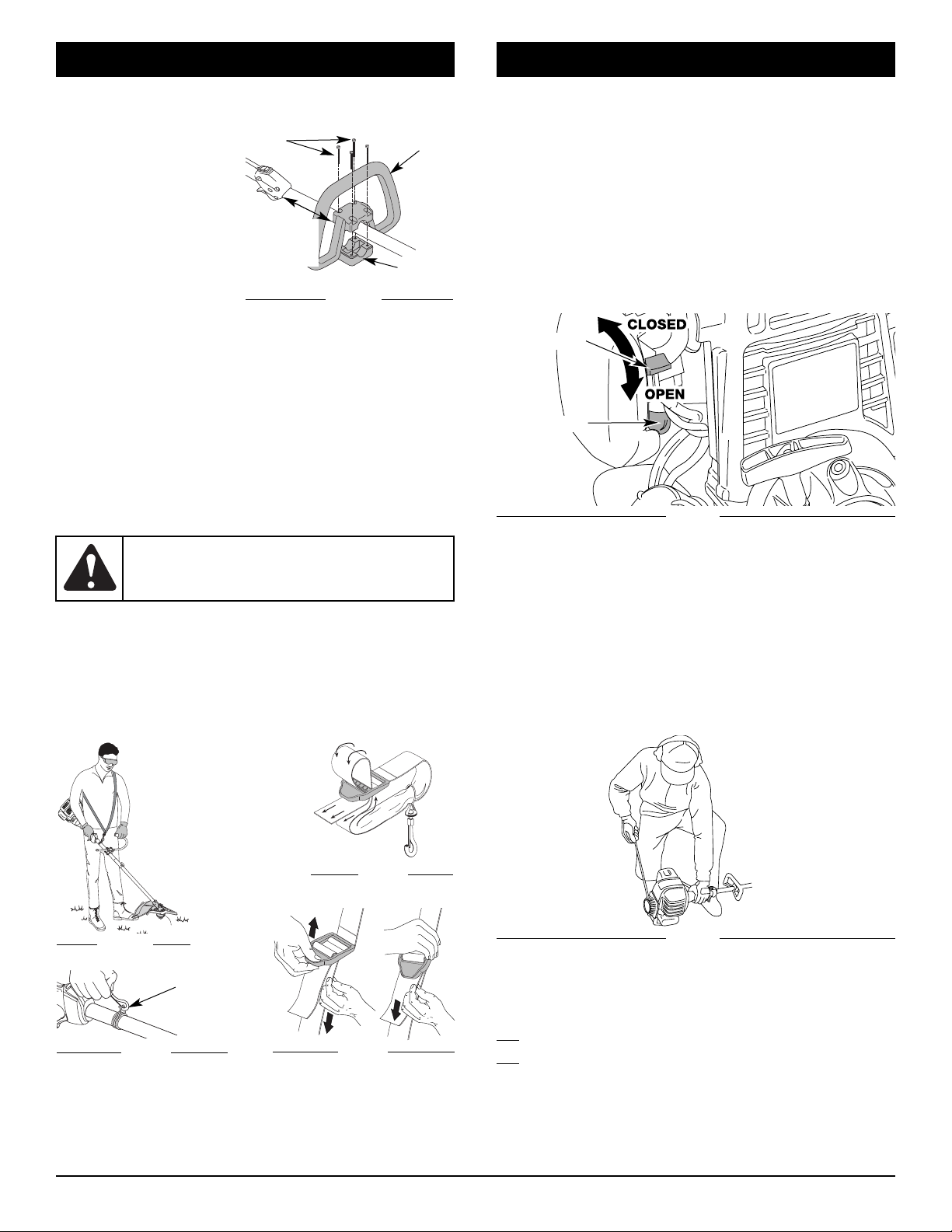

HOLDING THE TRIMMER

Before operating the unit, stand in the

operating position (Fig. 9). Check for the

following:

• The operator is wearing eye protection

and proper clothing

• With a slightly-bent right arm, the

operator’s right hand is holding the

shaft grip

• The operator’s left arm is straight, the

left hand holding the handle

• The unit is at waist level

• The cutting attachment is parallel to the ground and easily

contacts the grass without the need to bend over.

Adjusting Trimming Line Length

The Bump Head cutting

attachment allows you to

release trimming line without

stopping the engine. To

release more line, lightly tap

the cutting attachment on the

ground (Fig. 10) while

operating the trimmer at high

speed.

NOTE: Always keep the trimming line fully extended. Line

release becomes more difficult as cutting line becomes

shorter.

Fig. 9

Fig. 11

WARNING: Always wear eye, hearing, foot and

body protection to reduce the risk of injury when

operating this unit.

WARNING: Do not remove or alter the line cutting

blade assembly. Excessive line length will make

the clutch overheat. This may lead to serious

personal injury or damage to the unit.

Fig. 10

5

STOPPING INSTRUCTIONS

Note: This unit has a Momentary Switch. The On/Off Contol

Switch will be in the On position at all times.

1. Release your hand from the throttle control. Allow the

engine to cool down by idling.

2. Press the On/Off Stop Control in the OFF (O) position and

hold until the unit completely stops running. (Fig. 8)

Start/On ( I )

Stop/Off (O)

Throttle

Control

Fig. 8

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

STARTING/STOPPING INSTRUCTIONS

Page 6

6

Loop

Fig. 15

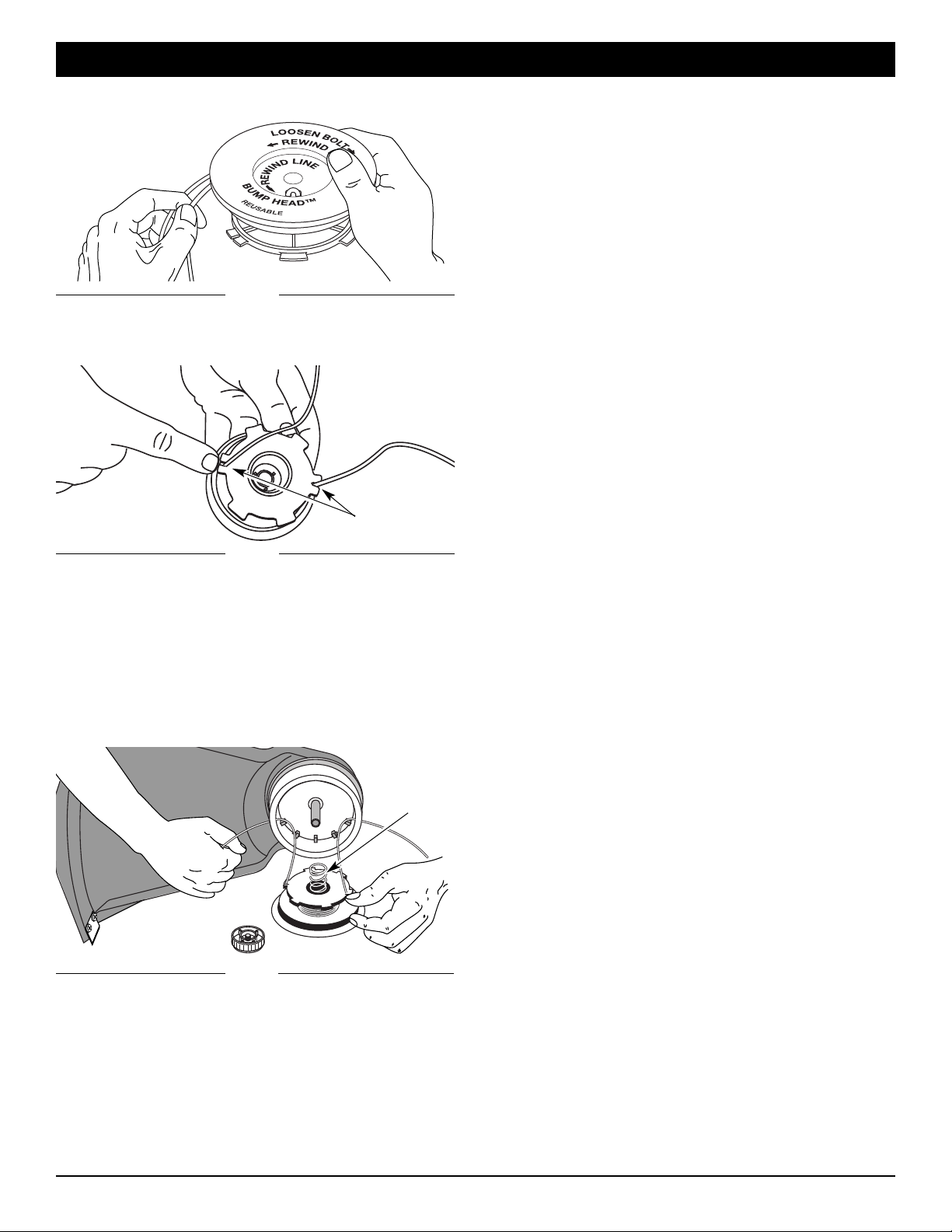

Line Installation

This section covers both SplitLine™ and standard single line

installation.

Always use original equipment manufacturer 0.105 in. (2.67

mm) replacement line. Using line other than the specified may

make the engine overheat or fail.

There are two methods to replace the trimming line:

• Wind the inner reel with new line

• Install a prewound inner reel

Winding the Existing Inner Reel

1. Hold the outer spool with one hand and unscrew the Bump

Knob clockwise (Fig. 12). Inspect the bolt inside the Bump

Knob to make sure it moves freely. Replace the Bump

Knob if damaged.

2. Remove the inner reel from the outer spool

(Fig. 12).

3. Remove spring from the inner reel (Fig. 12).

4. Use a clean cloth to clean the the inner reel, spring, shaft,

and inner surface of the outer spool.

5. Check the indexing teeth on the inner reel and outer spool

for wear (Fig. 13). If necessary, remove burrs or replace the

reel and spool.

WARNING: Never use metal-reinforced line, wire,

chain or rope. These can break off and become

dangerous projectiles.

NOTE: SplitLine™ can only be used with the inner reel with

the slotted holes. Single line can be used on either type

of inner reel. Use figure 15 to identify the inner reel you

have.

NOTE: Always use the correct line length when installing

trimming line on the unit. The line may not release

properly if the line is too long.

SplitLine™ Installation

6. Take approximately 10 feet (3 m) of new trimming line.

Insert one end of the line through one of the two holes in

the inner reel (Fig. 15). Pull the line through the inner reel

until only about 4 inches is left out.

7. Insert the end of the line into the open hole in the inner reel

and pull the line tight to make the loop as small as possible

(Fig. 16).

8. Before winding, split the line back about 6 inches.

Bump Knob

Bolt

Inner Reel

Spring

Outer Spool

Fig. 12

Indexing Teeth

Fig. 13

Fig. 14

Slotted Holes

MAINTENANCE AND REPAIR INSTRUCTIONS

Page 7

7

9. Wind the line in tight even layers in the direction indicated

on the inner reel. (Fig. 16)

NOTE: Failure to wind the line in the direction indicated will

cause the cutting attachment to operate incorrectly.

10. Insert the ends of the line into the two holding slots (Fig. 17).

11. Insert the ends of the line through the eyelets in the outer

spool and place inner reel with spring inside the outer spool

(Fig. 18). Push the inner reel and outer spool together.

While holding the inner reel and outer spool, grasp the ends

and pull firmly to release the line from the holding slots in

the reel.

NOTE: The spring must be assembled on the inner reel before

reassembling the cutting attachment.

12. Hold the inner reel in place and install the Bump Knob by

turning counterclockwise. Tighten securely.

MAINTENANCE AND REPAIR INSTRUCTIONS

Installing a Pre Wound Reel

1. Hold the outer spool with one hand and unscrew the Bump

Knob clockwise (Fig. 12). Inspect the bolt inside the Bump

Knob to make sure it moves freely. Replace the Bump

Knob if damaged.

2. Remove the old inner reel from the outer spool

(Fig. 12).

3. Remove the spring from the old inner reel

(Fig. 12).

4. Place the spring in the new inner reel.

NOTE: The spring must be assembled on the inner reel before

reassembling the cutting attachment.

5. Insert the ends of the line through the eyelets in the outer

spool (Fig. 18).

6. Place the new inner reel inside the outer spool. Push the

inner reel and outer spool together. While holding the inner

reel and outer spool, grasp the ends and pull firmly to

release the line from the holding slots in the spool.

7. Hold the inner reel in place and install the Bump Knob by

turning counterclockwise. Tighten securely.

Replacement Parts

For replacement parts, refer to the Accessories / Replacement

Parts section.

Storage

• Store the unit locked up to prevent unauthorized use or

damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

Long Term Storage

If the unit will be stored for an extended time, use the following

storage procedure:

1. Thoroughly clean the unit and inspect it for any loose or

damaged parts. Repair or replace damaged parts and

tighten loose screws, nuts or bolts. The unit is ready for

storage.

Transporting

• Secure the unit while transporting.

Accessories / Replacement Parts

Replacement Line Cartridge 753-1160

Inner Reel Spring 610636

Bump Head Knob Assembly 180814

Fig. 16

Holding Slots

Fig. 17

Spring

Fig. 18

Page 8

TROUBLESHOOTING

CAUSE ACTION

Cutting attachment bound with grass Stop the engine and clean cutting attachment

Cutting attachment out of line Refill with new line

Inner reel bound up Replace the inner reel

Cutting head dirty Clean inner reel and outer spool

Line welded Disassemble, remove the welded section and rewind

Line twisted when refilled Disassemble and rewind the line

Not enough line is exposed Push the bump knob and pull out line until 4 inches

(102 mm) of line is outside of the cutting attachment

CUTTING ATTACHMENT WILL NOT ADVANCE LINE

CAUSE ACTION

Oil, cleaner or lubricant in cutting head Clean and thoroughly dry the cutting head

CUTTING LINE ADVANCES UNCONTROLLABLY

Drive Shaft Housing ........................................................................................................................................................... Aluminum Tube

Throttle Control............................................................................................................................. Finger-Tip Trigger w/Momentary Switch

Approximate Unit Weight (No fuel, with cutting attachment, shield and D-handle) ............................................................ 13 lbs. (5.9 kg)

Cutting Mechanism.............................................................................................................................................. Dual String Cutting Head

Line Spool.................................................................................................................................................................... Bump Line Releaser

Line Spool Diameter ................................................................................................................................................... 4 inches (101.6 mm)

Trimming Line Diameter......................................................................................................................................... 0.105 inches (2.67 mm)

Cutting Path Diameter ............................................................................................................................................... 17 inches (43.18 cm)

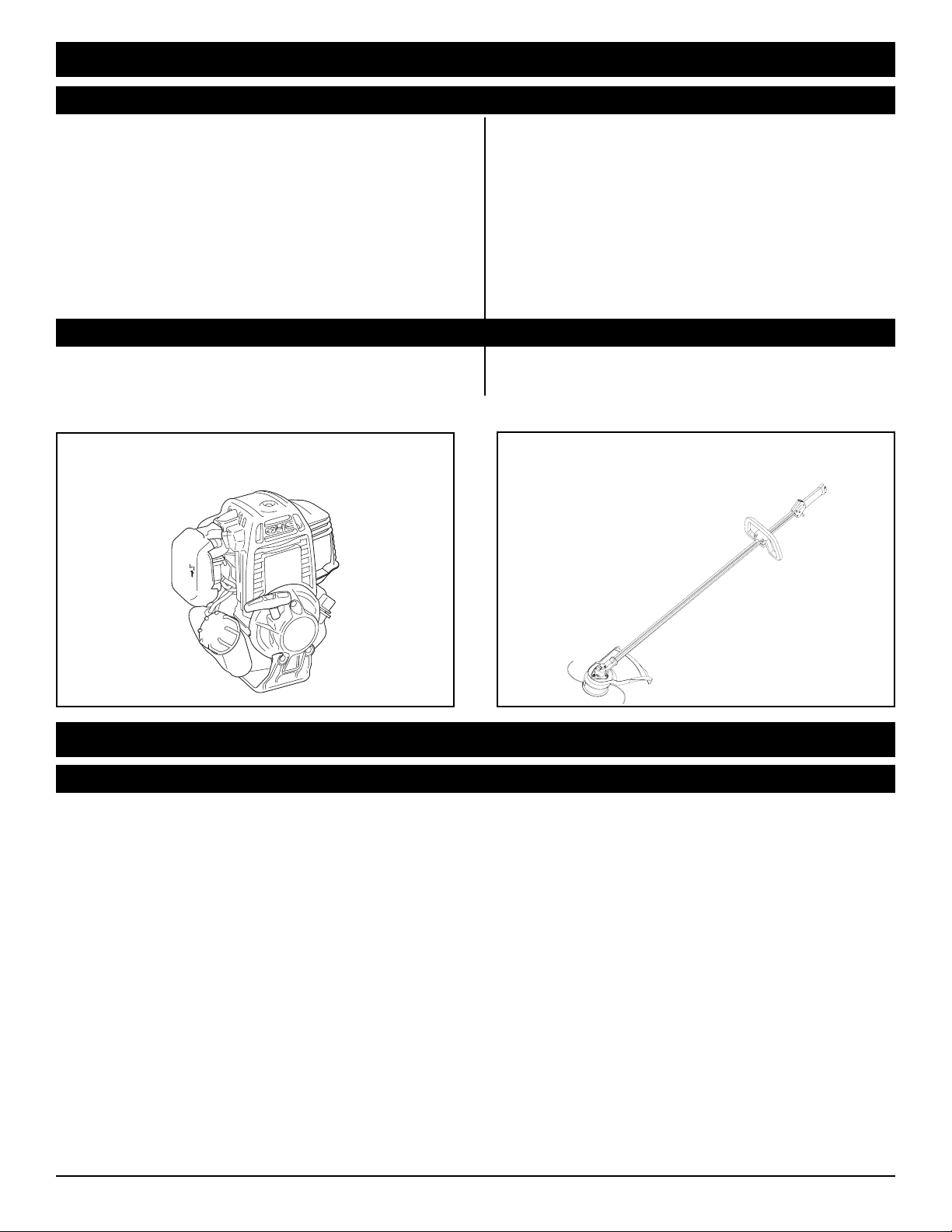

SPECIFICATIONS

DRIVE SHAFT AND CUTTING ATTACHMENT*

For engine service and warranty please call 1-800-426-7701

to locate the closest service dealer in your area.

For boom service and warranty please call 1-800-800-7310

8

Page 9

NOTE

9

Page 10

MANUFACTURER’S LIMITED WARRANTY FOR:

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose, applies

after the applicable period of express written warranty above

as to the parts as identified. No other express warranty or

guaranty, whether written or oral, except as mentioned

above, given by any person or entity, including a dealer or

retailer, with respect to any product shall bind MTD Pro LLC

During the period of the Warranty, the exclusive remedy is

repair or replacement of the product as set forth above.

(Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the sole

and exclusive remedy arising from the sales. MTD Pro LLC

shall not be liable for incidental or consequential loss or

damages including, without limitation, expenses incurred for

substitute or replacement lawn care services, for

transportation or for related expenses, or for rental

expenses to temporarily replace a warranted product. (Some

states do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the amount

of the purchase price of the product sold. Alteration of the safety

features of the product shall void this Warranty. You assume the

risk and liability for loss, damage, or injury to you and your

property and/or to others and their property arising out of the

use or misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the

original purchaser, original lessee or the person for whom it was

purchased as a gift.

How State Law Relates to this Warranty: This warranty gives

you specific legal rights, and you may also have other rights

which vary from state to state.

To locate your nearest service dealer dial 1-800-800-7310.

MTD PRO LLC

P.O. Box 361131

Cleveland, OH 44136-0019

The limited warranty set forth below is given by MTD Pro LLC

with respect to new merchandise purchased and used in the

United States, its possessions and territories.

MTD Pro LLC warrants this product against defects in material

and workmanship for a period of two (2) years commencing on

the date of original purchase and will, at its option, repair or

replace, free of charge, any part found to be defective in material

or workmanship. This limited warranty shall only apply if this

product has been operated and maintained in accordance with

the Operator’s Manual furnished with the product, and has not

been subject to misuse, abuse, commercial use, neglect,

accident, improper maintenance, alteration, vandalism, theft, fire,

water or damage because of other peril or natural disaster.

Damage resulting from the installation or use of any accessory or

attachment not approved by MTD Pro LLC for use with the

product(s) covered by this manual will void your warranty as to

any resulting damage. This warranty is limited to ninety (90) days

from the date of original retail purchase for any MTD Pro product

that is used for rental or commercial purposes, or any other

income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE THROUGH YOUR LOCAL

AUTHORIZED SERVICE DEALER. To locate the dealer in your

area check for a listing in the Yellow Pages, call 1-800-800-7310

or write to

P.O. Box 361131, Cleveland, OH 44136-0019

.

This limited warranty does not provide coverage in the

following cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting Line,

Inner Reels, Starter Pulley, Starter Ropes, Drive Belts

C. MTD Pro LLC does not extend any warranty for products

sold or exported outside of the United States of America,

its possessions and territories, except those sold through

MTD Pro’s authorized channels of export distribution.

MTD Pro LLC reserves the right to change or improve the design of any

MTD Pro Product without assuming any obligation to modify any product

previously manufactured.

Page 11

Manuel de L’utilisateur

Désherbeuse à gaz à 4-temps

Model H70SS

CONSERVEZ CES INSTRUCTIONS

Pour une liste des fournisseurs agréés, veuillez consulter les numéros

de téléphone en page 6 ou à la fin de la section Résolution des

Pannes de ce manuel.

NO REGRESE SU UNIDAD AL VENDEDOR. PARA SOLICITAR

SERVICIO POR LA GARANTIA, DEBERA PRESENTAR PRUEBA DE

SU COMPRA.

ESTE PRODUCTO ESTA CUBIERTO POR UNA O MAS PATENTES

DE EE.UU., OTRAS PATENTES EN TRAMITE.

El servicio de esta unidad, ya sea durante o después del período

cubierto por la garantía, debe ser realizado solamente por un

proveedor de servicios autorizado y aprobado.

Toutes les informations, illustrations et spécifications contenues dans

ce manuel tiennent compte des dernières informations techniques

disponibles au moment de mettre sous presse. Nous nous réservons

le droit d'y apporter des modifications à tout moment, sans préavis.

Copyright© 2007 MTD SOUTHWEST INC., Tous droits réservés.

P/N 769-02747C (2/07)

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F1

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F1

Familiarisez-vous avec votre appareil . . . . . . . . . . . . . . . . .F3

Instructions de montage . . . . . . . . . . . . . . . . . . . . . . . . . . .F4

Instructions de demerrage et arrêt . . . . . . . . . . . . . . . . . . .F4

Mode d'emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F5

Entretien et réparations . . . . . . . . . . . . . . . . . . . . . . . . . . . .F6

Nettoyage et entreposage . . . . . . . . . . . . . . . . . . . . . . . . . .F7

Tableau de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . .F8

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F8

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F10

Liste des pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E11

AVERTISSEMENT : Lorsque vous utilisez la

machine, vous devez suivre les consignes de

sécurité. Veuillez lire ces instructions avant d’opérer

la machine pour vous assurer de la sécurité de

l’opérateur et de tout spectateur. Veuillez conserver

ces instructions pour un usage ultérieur.

LISEZ TOUTES LES INSTRUCTIONS AVANT UTILISATION

• Lisez soigneusement cette notice. Familiarisez-vous avec les

commandes et la marche à suivre pour une bonne utilisation

de l'appareil.

• Cet appareil n'est pas conçu pour servir de débroussailleuse.

N'utilisez cet appareil avec aucun type de lame ou

d'accessoire de débroussaillage.

• N’utilisez pas cet appareil lorsque vous êtes fatigué, malade, ou

sous l’influence de l’alcool, de drogues, ou de médicaments.

• Tout enfant ou adolescent de moins de 15 ans ne doit pas

utiliser cet appareil, à moins que l'adolescent soit sous la

supervision d’un adulte.

• Toutes les protections et tous les dispositifs de sécurité

doivent être installés correctement avant utilisation de

l’appareil.

• Inspectez l’appareil avant utilisation. Remplacez les pièces

endommagées. Détectez les fuites de carburant éventuelles.

Assurez-vous que tous les accessoires sont bien en place.

Remplacez les pièces susceptibles d’être fissurées,

ébréchées, ou endommagées. N’utilisez pas cet appareil si

des pièces ont du jeu ou sont endommagées.

• Inspectez la zone avec attention avant de démarrer cet

appareil. Retirez tous les débris et objets durs ou tranchants

tels que du verre, les câbles, etc…

• Soyez conscient des risques de blessures à la tête, aux

mains et aux pieds.

• Eloignez les enfants, les personnes à proximité et les

animaux familiers de la zone d’utilisation. Au minimum, faites

reculer les enfants, les personnes à proximité et les animaux

familiers de 50 pieds (15 m) ; il existe néanmoins un risque

de projectiles pour les personnes à proximité. Encouragezles à porter des lunettes de sécurité. Si quelqu’un

CONSIGNES DE SÉCURITÉ

• IMPORTANTE INFORMACION DE SEGURIDAD •

Page 12

F2

s’approche de vous, arrêtez l’appareil immédiatement.

• Utilisez uniquement un fil de 0,105 pouces (2,67mm) de

diamètre provenant du fabricant. N’utilisez jamais de câbles,

cordons ou pièces renforcées en métal, qui peuvent céder et

devenir des projectiles dangereux.

• Appuyez sur la manette des gaz et vérifiez que le régime du

moteur revienne automatiquement au ralenti. Effectuez tous

les réglages et réparations avant d’utiliser l’appareil.

ALERTES DE SECURITE POUR LES APPAREILS A ESSENCE

• Stockez uniquement le carburant dans des conteneurs

prévus spécifiquement à cet effet et approuvés pour le

stockage de telles substances.

• Evitez tout ce qui pourrait enflammer le carburant renversé.

Ne démarrez pas le moteur avant que les vapeurs de

carburant ne se soient dissipées.

• Coupez toujours le moteur et laissez-le refroidir avant de

remplir le réservoir d’essence. Ne retirez jamais le bouchon

du réservoir d’essence et ne remplissez jamais ce dernier

lorsque le moteur est chaud. Ne démarrez jamais l’appareil

sans avoir bien revissé le bouchon du réservoir d’essence.

Dévissez lentement le bouchon du réservoir d’essence afin

de réduire la pression.

•A

joutez le carburant en extérieur, dans une zone propre, bien

aérée, et dépourvue de toute source d’étincelles ou de flammes.

Dévissez lentement le bouchon du réservoir d’essence

uniquement après avoir arrêté le moteur. Ne fumez pas en

remplissant le réservoir ou en mélangeant le carburant. L’essence

s’étant échappée de l’appareil doit être essuyée immédiatement.

Essuyez l’appareil systématiquement avant utilisation.

• Eloignez l’appareil d’au moins 30 pieds (9,1 m) du site et de

la source du carburant avant de démarrer le moteur. Ne

fumez pas ou assurez-vous qu’il n’y a pas de source

d’étincelles et de flammes, à proximité, lorsque vous ajoutez

du carburant ou faites tourner l’appareil.

LORS DU FONCTIONNEMENT DE L'APPAREIL

• L'appareil ne doit pas être démarré ou opéré à l'intérieur d'un

espace ou d’un bâtiment clos. L’inhalation des fumées

d’échappement peut être fatale. Cet appareil doit fonctionner

uniquement en extérieur, dans une zone bien aérée.

• Portez des lunettes de sécurité conformes aux normes ANSI

Z87.1, lesquelles doivent être indiquées sur les lunettes

mêmes. Portez des bouchons d’oreille et des casques

antibruit lors de l’utilisation de cet appareil. Portez un

masque si l'appareil émet de la poussière.

• Portez un pantalon long et épais, des bottes, des gants et

une chemise à manches longues. Ne portez pas de

vêtements amples, de bijoux, de pantalons courts, de

sandales et ne soyez pas pieds nus. Veillez à ce que vos

cheveux restent au-dessus du niveau des épaules.

• L’écran de l’accessoire de coupe doit toujours être utilisé

lorsque vous vous servez de cet appareil comme

débroussailleuse. N'utilisez jamais cet appareil sans une

longueur suffisante des deux fils de coupe, ces derniers devant

être ceux recommandés par le fabricant. La longueur des fils

de coupe ne doit jamais aller au-delà de celle de l’écran.

• Cet appareil dispose d’un embrayage. L'accessoire de coupe

reste immobile lorsque le moteur tourne au ralenti. Dans le cas

contraire, faites ajuster cet appareil par un technicien agréé.

•A

justez la poignée D à votre taille afin d’assurer une prise optimale.

CONSIGNES DE SÉCURITÉ

• Assurez-vous que l’accessoire de coupe n’est pas en

contact avec tout autre élément avant de démarrer l’appareil.

• Utilisez cet appareil uniquement en plein jour ou si vous

disposez d’un éclairage artificiel suffisant.

• Evitez les démarrages accidentels. Soyez en position de

démarrage lorsque vous tirez sur le cordon du démarreur.

L’utilisateur et l’appareil doivent être sur un sol ferme lors du

démarrage. Référez-vous aux consignes relatives au

démarrage/à l’arrêt de l’appareil.

• Utilisez le bon outil. N’utilisez pas un outil pour des fonctions

pour lesquelles il n’a pas été prévu.

• N’étendez pas trop le bras. Restez toujours à distance et en

équilibre.

• Tenez toujours l’appareil à deux mains lorsqu'il est en marche.

Assurez une prise ferme sur les deux poignées ou grips.

• Gardez vos mains, votre visage et vos pieds à distance des

parties en mouvement. Ne touchez pas et ne tentez pas

d'arrêter l'accessoire de coupe lorsqu'il est en rotation.

• Ne touchez pas au moteur, à la transmission ou au pot

d'échappement. Ces parties deviennent extrêmement chaudes

lors du fonctionnement, même après l'arrêt de l'appareil.

• L'appareil ne doit pas fonctionner à un régime supérieur à

celui adapté pour la coupe ou la tonte. Ne faites pas tourner

le moteur à haut régime lorsque vous ne coupez rien.

• Arrêtez toujours le moteur lorsque la coupe est interrompue

ou lorsque vous vous rendez à une autre aire de coupe.

• Si vous butez ou bloquez sur un objet, arrêtez le moteur

immédiatement et vérifiez que l'appareil n'a pas été

endommagé. Ne redémarrez pas l'appareil avant de l'avoir

réparé. Ne faites pas fonctionner l’appareil si certaines

pièces ont du jeu ou sont endommagées.

• Arrêtez l’appareil, coupez le moteur, et déconnectez la

bougie avant de l’entretenir ou de le réparer.

• Pour cet appareil, utilisez uniquement les pièces et accessoires

de rechange du fabricant. Ils sont disponibles auprès d’un

fournisseur officiel. L’utilisation de pièces ou accessoires non

agréés pourrait entraîner de graves blessures pour l'utilisateur,

ou endommager l'appareil, et annuler votre garantie.

• Dégagez l’herbe et les autres substances nichées dans

l’appareil. Elles peuvent se coincer entre l’accessoire de

coupe et l’écran.

• Réduire le risque d'incendie, garder le moteur et le silencieux

libère de l'herbe, des feuilles, et de la graisse excessive.

APRES UTILISATION

• Nettoyez les lames de coupe à l’aide d’un produit d’entretien

d’intérieur afin de retirer les dépôts. Graissez la lame à l'huile

pour l’empêcher de rouiller.

• Verrouillez et entreposez la lame de coupe dans une zone

appropriée afin qu'elle ne soit pas utilisée sans autorisation

ou endommagée.

AUTRES MISES EN GARDE DE SECURITE

• N’entreposez jamais un appareil à essence à l’intérieur d’un

bâtiment où les vapeurs peuvent entrer en contact avec toute

source de flammes ou d’étincelles.

• Laissez refroidir le moteur avant de le ranger ou de le

déplacer. Lorsque vous déplacez l’appareil, assurez-vous

qu’il ne pose aucun danger.

• Entreposez l’appareil dans une zone sèche, verrouillée ou

hors de la portée des enfants.

• Ne mouillez ou ne pulvérisez jamais d’eau ou tout autre liquide,

AVERTISSEMENT: l'essence est extrêmement

inflammable et ses vapeurs peuvent exploser si on y

met le feu. Veuillez prendre les précautions suivantes.

Page 13

Ce manuel de l'utilisateur décrit les symboles et pictogrammes

de sécurité et internationaux pouvant apparaître sur ce produit.

Consultez le manuel de l'utilisateur pour les informations

concernant la sécurité, le montage, le fonctionnement, l'entretien

et les réparations.

SYMBOLE SIGNIFICATION

• SYMBOLE ALERTE DE SÉCURITÉ

Indique un danger, un avertissement ou une mise

en garde. Ce symbole peut être combiné à

d'autres symboles ou pictogrammes.

• LISEZ LE MANUEL DE L'UTILISATEUR

AVERTISSEMENT - Lisez le manuel de

l'utilisateur et suivez tous les avertissements et

consignes de sécurité. Vous pourriez à défaut

entraîner des blessures graves pour vous ou

d'autres personnes.

• PORTEZ DES PROTECTIONS (YEUX ET

OREILLES)

AVERTISSEMENT: les objets projetés et les

bruits forts peuvent endommager la vue et l’ouïe.

Portez une visière de norme ANSI Z87.1-1989 et

des protège-oreilles pendant l'utilisation.

• COMMANDE MARCHE/ARRÊT

ALLUMAGE / DÉMARRAGE / MARCHE

• COMMANDE MARCHE/ARRÊT

ARRÊT ou STOP

• ÉLOIGNEZ LES SPECTATEURS

AVERTISSEMENT: éloignez tout spectateur, les

enfants et les animaux domestiques en

particulier, d'au moins 15 m (50 pi) de la zone de

coupe.

• LES OBJETS PROJETÉS ET LA TÊTE

ROTATIVE PEUVENT CAUSER DES

BLESSURES GRAVES

AVERTISSEMENT: ne faites pas fonctionner

sans protecteur de sécurité en plastique. Tenezvous à l'écart de l'accessoire de coupe rotatif.

• LAME AIGUISÉE

AVERTISSEMENT: le protecteur d'accessoire de

coupe comporte une lame aiguisée. Ne touchez

pas la lame pour éviter des blessures graves.

APPLICATIONS

• Coupe le gazon et des mauvaises herbes

• Coupe-bordures

• Finition autour des arbres, clôtures, etc.

REMARQUE : l’illustration ci-dessous peut être légèrement

différente de votre appareil.

Protecteur

d'accessoire de coupe

Manette

des gaz

Poignée

en D

Accessoire

de coupe

Prise de l'arbre

Corps de

l'arbre

Lame

coupante

Commande

Marche/Arrêt

FAMILIARISEZ-VOUS AVEC L’APPAREIL

F3

CONSIGNES DE SÉCURITÉ

sur l’appareil. Veillez à ce que les poignées restent sèches,

propres et dépourvues de tout dépôt. Nettoyez l’appareil après

chaque utilisation, voir les consignes portant sur le nettoyage

et le stockage.

• Conservez ces consignes. Consultez-les souvent et utilisez-les

pour mettre en garde les autres utilisateurs. Si vous prêtez cet

appareil à quelqu'un, donnez-lui ces consignes.

CONSERVEZ CES CONSIGNES

Page 14

F4

INSTRUCTIONS DE MONTAGE

INSTALLATION ET RÉGLAGE DE LA POIGNÉE EN D

Si la poignée en D est pré-installée sur votre machine, veuillez

seulement suivre les

instructions « Ajuster ».

Installation

1. Retirez les vis, écrous et

la bride inférieure posés

sur la poignée en D avant

livraison.

2. Placez la poignée sur le

corps de l'arbre et audessus de la bride

inférieure (Fig. 1). Placezla à au moins 15,24 cm

(6 po) de l’extrémité de la prise de l'arbre.

3. Maintenez d’un doigt chaque écrou hex dans le renfoncement

de la bride inférieure. Commencez à visser à l’aide d’un grand

tournevis à lame plate ou T-25 Torx. Ne serrez pas avant de

régler le guidon.

Réglage

4. S

i elle a déjà été préinstallée, desserrez les quatre vis de

fixation de la poignée en D juste assez pour pouvoir la déplacer.

5. Tenez l'appareil en position d’utilisation (Fig. 2), puis

positionnez la poignée de manière à assurer une prise idéale.

6. Serrez les vis de bride uniformément jusqu'à bien fixer la

poignée.

INSTALLER LE HARNAIS

1. Faites passer la bandoulière au centre de la boucle.

2. Tirez la bandoulière par-dessus la traverse et à travers la

fente de la boucle (Fig. 2).

3. Passez le harnais par-dessus la tête puis sur l'épaule.

Accrochez-le au raccord de soutien (Fig. 4).

4. Réglez la longueur en fonction de la taille de l'opérateur.

Tirez la languette pour rallonger ou tirez la bande pour

raccourcir (Fig. 5).

(4) vis

Poignée

en D

Bride

inférieure

Fig. 1

15,24 cm

(6 po)

minimum

1. Vérifier le niveau d’huile dans le carter-moteur. Consulter la

section « Vérification du niveau d’huile » dans le manuel du

moteur Honda qui est fourni avec l’appareil.

2. Remplir le réservoir d’essence de carburant propre et sans

plomb. Consulter la section « Remplissage du réservoir de

l’appareil » dans le manuel du moteur Honda qui est fourni

avec l’appareil.

REMARQUE : il est inutile de mettre l’appareil en marche. La

commande On/Off est sur la position ON ( I ) en

permanence (Fig. 8).

3. Pour faire démarrer un moteur froid ou après avoir fait le

plein, appuyer lentement sur l’amorce dix fois de suite. Une

certaine quantité de carburant devrait être visible dans

l’amorce et les tuyaux (Fig. 6). Si le carburant n’est pas

visible dans l’amorce, appuyer dessus autant de fois que

nécessaire jusqu’à ce qu’il arrive.

4. Placer le levier de l’étrangleur en position d’étranglement

ou fermée.

5. S’accroupir et ne pas appuyer sur la manette des gaz

(Fig. 7). Tirer sur le cordon du démarreur à 2 reprises d’un

mouvement contrôlé et ferme.

Remarque : il se peut que l’appareil prenne un temps avant de

démarrer. Passer à l’étape 6.

6. Placer le levier de l’étrangleur en position marche ou

ouverte.

7. S’accroupir et ne pas appuyer sur la manette des gaz

(Fig. 7). Tirer sur le cordon du démarreur à cinq reprises si

nécessaire d’un mouvement contrôlé et ferme ou jusqu’à

ce que l’appareil démarre.

8. Laisser l’appareil chauffer au ralenti pendant 10 secondes.

Après 10 secondes au ralenti, appuyer progressivement sur

la manette des gaz pour permettre à l’appareil d’accélérer

lentement jusqu’à sa vitesse maximum.

SI...

le moteur ne démarre pas, retourner à l’étape 3.

SI...

l

e moteur s’arrête lorsque vous appuyez sur la manette des

gaz, retourner à l’étape 7 et faites tourner l’appareil à mi-régime

pendant quelques minutes pour lui permettre de chauffer.

Etouffer le

Levier

Ampoule

d'apprêt

Fig. 6

Fig. 7

INSTRUCTIONS DE DÉMARRAGE ET ARRÊT

Raccord

Fig. 3

Fig. 4

Fig. 5

Fig. 2

AVERTISSEMENT: portez toujours le harnais

d'épaule lorsque vous utilisez la lame de coupe

afin d'éviter de vous blesser.

Ouvrir

Fermé

Page 15

Chaque fois que vous donnez un coup sur la tête, vous déroulez

environ 25,4 mm (1 po) de fil. La lame du protecteur d'accessoire

de coupe est conçue pour couper le fil à la bonne longueur si vous

déroulez trop de fil.

Pour de meilleurs résultats, tapez la tête Bump HeadMC sur un sol

dégagé ou dur. Si vous donnez du fil dans un lieu d'herbe haute,

vous risquez de caler le moteur. Gardez toujours le fil bien déroulé.

Il devient plus difficile de donner du fil à mesure que le fil de coupe

se raccourci.

REMARQUE : ne posez pas la tête Bump HeadMC sur le sol

lorsque l’appareil est en marche.

Le fil peut se briser dans les cas suivants :

• Happement de corps étrangers

• Usure normale du fil

• Coupe de mauvaises herbes épaisses à longues tiges

• Forcer le fil dans des objets comme des murs ou des

poteaux de clôture

CONSEILS POUR BIEN DÉSHERBER

• Pour meilleurs les résultats qui taillent, opérer l'unité à plein

étrangle.

• Le bon angle pour l'accessoire de coupe est parallèle au sol.

• Ne forcez pas l'accessoire. Coupez avec la pointe du fil

(surtout le long des murs). Utiliser plus que la pointe diminue

l'efficacité de la coupe et peut surcharger le moteur.

• Coupez l'herbe de plus de 200 mm (8 po) en procédant de

haut en bas par petits incréments pour éviter d'user le fil

prématurément ou de freiner le moteur.

• Le fait de couper de gauche à droite améliore l’efficacité de

coupe de la machine. Les copeaux sont expulsés dans la

direction opposée à l’opérateur.

• Déplacez lentement la désherbeuse dans et hors de la zone de

coupe à la hauteur voulue. Procédez d'avant en arrière ou d'un

côté à l'autre. Les coupes de longueur plus courte donnent les

meilleurs résultats.

• Ne désherbez que lorsque l'herbe et les mauvaises herbes

sont sèches.

• La durée de vie de votre fil de coupe dépend de l’application

des techniques de coupe précédentes, du type de végétation

à couper et du lieu de coupe

Par exemple, le fil s'use plus vite si vous coupez le long d'un

mur de fondation que si vous coupez autour d'un arbre.

COUPE DÉCORATIVE

La coupe décorative consiste à déblayer la végétation autour des

arbres, des bornes, des clôtures, etc. Tournez entièrement

l'appareil de manière à ce que l'accessoire de coupe soit à un

angle de 30° par rapport au sol (Fig. 11).

TENUE DE LA DÉSHERBEUSE

Avant de faire marcher l'appareil, tenezvous en position de fonctionnement (Fig.

9). Vérifiez les points suivants:

• L'opérateur porte une visière et des

vêtements appropriés.

• Le bras droit est légèrement plié et la

main tient l'arbre par sa prise.

• Le bras gauche est droit et la main

tient la poignée.

• L'appareil est au-dessous de la ceinture.

• L'accessoire de coupe est parallèle au

sol et touche facilement la végétation sans que l'opérateur ne

doive se pencher.

RÉGLAGE DE LA LONGUEUR DU FIL

L'accessoire de coupe Bump HeadMC vous permet de donner du

fil sans arrêter le moteur. Pour avoir plus de fil, tapez doucement

l'accessoire de coupe sur le sol (Fig. 10) tout en faisant marcher la

désherbeuse à haut régime.

REMARQUE : gardez toujours le fil bien déroulé. Il devient plus

difficile de donner du fil à mesure que le fil de coupe

devient plus court.

Fig. 9

Fig. 11

AVERTISSEMENT: portez toujours des protections

(yeux, oreilles, pieds et corps) pour diminuer les

risques de blessures durant l'utilisation de l'appareil.

Fig. 10

F5

MODE D’EMPLOI

Démarrage/

Allumage (I)

Arrêt (O)

Manette

des gaz

Fig. 8

INSTRUCTIONS DE DÉMARRAGE ET ARRÊT

Remarque : pour redémarrer un moteur chaud, laisser le levier

d’étranglement en position marche ou ouverte. Il n’est

pas nécessaire d’appuyer sur l’amorce.

CONSIGNES POUR ARRETER L’APPAREIL

1. Relâcher la manette des gaz. Laisser le moteur refroidir en

le faisant tourner au ralenti.

2. Appuyer sur la commande On/Off pour la mettre en

position OFF et la garder enfoncée jusqu’à ce que le

moteur soit complètement arrêté. (Fig. 8)

MODE D’EMPLOI

AVERTISSEMENT: n'enlevez pas ni n'altérez

l'ensemble de la lame coupante. Un excès de fil

surchauffera l'embrayage. Ceci pourrait causer

des blessures graves ou endommager l'appareil.

Page 16

F6

Boucle

Fig. 15

ENTRETIEN ET RÉPARATIONS

INSTALLATION DU FIL

Cette section couvre l’installation de fil SplitLineMC et

l’installation de fil simple standard.

Utilisez toujours un fil de remplacement d’origine du fabricant

de 2,67mm (0,105 po). Un autre fil pourrait surchauffer ou

endommager le moteur.

Vous pouvez remplacer le fil de deux façons:

• Rembobinez du fil neuf dans le moulinet intérieur

• Installer un moulinet intérieur prérembobiné

Rembobiner le moulinet intérieur existant

1. Tenez la bobine extérieure d'une main et dévissez le

bouton de butée vers à droite (Fig. 12). Inspectez le boulon

à l'intérieur du bouton de butée pour vous assurer qu'il se

déplace librement. Remplacez le bouton de butée s'il est

endommagé.

2. Retirez le moulinet intérieur de la bobine extérieure (Fig. 12).

3. Retirez le ressort du moulinet (Fig. 12).

4. N

ettoyez le moulinet intérieur, le ressort, et l'arbre et la surface

interne de la bobine extérieure à l'aide d'un tissu propre (Fig. 13).

5. Vérifiez l'état d'usure des dents de positionnement sur le

moulinet intérieur et la bobine extérieure (Fig. 14). Enlevez les

ébarbures ou remplacez le moulinet et la bobine au besoin.

AVERTISSEMENT: n'utilisez jamais de fil, de chaîne

ou de cordon à renfort métallique car ils peuvent se

briser et se transformer en projectile dangereux.

REMARQUE : le SplitLineMC peut être utilisé seulement avec

le moulinet intérieur à trous allongés. Le fil simple peut

être utilisé avec les deux sortes de moulinet intérieur.

Identifiez votre type de moulinet en vous référant à la

Figure 10.

REMARQUE : utilisez toujours la bonne longueur de fil lorsque

vous posez le fil sur l'appareil. Le fil risque de ne pas

se dérouler correctement s'il est trop long.

Installation du SplitLine

MC

6. Découpez environ 3 m (10 pi) de fil neuf. Insérez une extrémité

de fil dans l'un des deux trous du moulinet intérieur (Fig. 14).

Tirez le fil jusqu’à ne laisser que 10 cm (4 po) environ.

7. Insérez l’extrémité du fil dans le trou ouvert du moulinet et tirez

sur le fil pour que la boucle soit le plus petit possible (Fig. 15).

8. Avant de rembobiner le fil, séparez-le en deux sur une

longueur d’environ 15 cm (6 po).

Bouton de

butée

Boulon

Moulinet

intérieur

Ressort

Bobine

extérieure

Fig. 12

Dents de positionnement

Fig. 13

Fig. 14

Trou s

allongés

Page 17

9. Enroulez le fil en couches uniformes serrées dans le sens

indiqué sur le moulinet intérieur (Fig. 16).

REMARQUE : n

e pas enrouler le fil dans le sens indiqué entraînera

un mauvais fonctionnement de l'accessoire de coupe.

10. Insérez les extrémités du fil dans les deux fentes de

retenue (Fig. 17).

11. I

nsérez les extrémités du fil dans les œillets de la bobine

extérieure et placez le moulinet et le ressort dans la bobine (Fig.

18). Enfoncez le moulinet et la bobine ensemble. Tout en tenant le

moulinet et la bobine, saisissez les extrémités et tirez fermement

pour dégager le fil des fentes de retenue de la bobine.

REMARQUE : le ressort doit être installé dans le moulinet

intérieur avant de remonter l'accessoire de coupe.

12. Maintenez le moulinet intérieur en place et installez le

bouton de butée en le tournant à gauche. Vissez bien.

ENTRETIEN ET RÉPARATIONS

F7

Installation d'un moulinet prérembobiné

1. Tenez la bobine extérieure d'une main et dévissez le

bouton de butée vers à droite (Fig. 12). Inspectez le boulon

à l'intérieur du bouton de butée pour vous assurer qu'il se

déplace librement. Remplacez le bouton de butée s'il est

endommagé.

2. Retirez l'ancien moulinet intérieur de la bobine extérieure

(Fig. 12).

3. Retirez le ressort de l'ancien moulinet intérieur (Fig. 12).

4. Placez le ressort dans le moulinet intérieur neuf.

REMARQUE : le ressort doit être installé dans le moulinet

intérieur avant de remonter l'accessoire de coupe.

5. Insérez les extrémités du fil dans les œillets de la bobine

extérieure (Fig. 18).

6. Placez le moulinet intérieur neuf dans la bobine. Poussez le

moulinet et la bobine ensemble. Tout en tenant le moulinet

et la bobine, saisissez les extrémités et tirez fermement

pour dégager le fil des fentes de retenue de la bobine.

7. Maintenez le moulinet intérieur en place et installez le

bouton de butée en le tournant à gauche. Vissez bien.

Pièces de rechange

Pour les pièces de rechange, veuillez consulter la section

Accessoires/Pièces de rechange.

ENTREPOSAGE

• Rangez l'appareil dans un lieu verrouillé pour éviter toute

utilisation ou accident indésirable.

• Rangez l'appareil dans un lieu sec et bien aéré.

• Rangez l'appareil hors de la portée des enfants.

ENTREPOSAGE DE LONGUE DURÉE

Si l’appareil doit être rangé pour une longue période, suivez la

procédure suivante :

1. Nettoyez soigneusement l'appareil et vérifiez qu'il ne

comporte pas de pièces desserrées ou endommagées.

Réparez ou remplacez les pièces endommagées, puis

serrez les vis, écrous et boulons desserrés. L'appareil est

alors prêt pour l'entreposage.

TRANSPORT

• Attachez bien l'appareil lors du transport.

Accessoires/Pièces de rechange

Cartouche de fil 733-1160

Ressort du dévidoir intérieur 610636

Ensemble tête d’avance du fil par frappe au sol 180814

Fig. 16

Fentes de

retenue

Fig. 17

Ressort

Fig. 18

Page 18

DÉPANNAGE

CAUSE SOLUTION

Accessoire de coupe engorgé d'herbes Arrêtez le moteur et nettoyez l'accessoire

Accessoire de coupe mal aligné Chargez du fil neuf

Moulinet intérieur bloqué Remplacez le moulinet

Tête de coupe sale Nettoyez le moulinet intérieur et la bobine extérieure

Fil soudé Démontez et déposez la partie soudée, et rembobinez le fil

Fil tordu durant la recharge Démontez puis rembobinez le fil

Quantité insuffisante de fil exposée Enfoncez le bouton de butée et tirez le fil jusqu’à en extraire

102 mm (4 po) à l’extérieur de l’accessoire de coupe

LA TÊTE DE COUPE NE FAIT PAS AVANCER LE FIL

CAUSE SOLUTION

Présence d'huile dans la tête de coupe Nettoyez l'accessoire de coupe

LE FIL DE COUPE AVANCE DE MANIÈRE INCONTRÔLÉE

Logement de l’arbre d’entraînement ..............................................................................................................................Tube en aluminium

Manette des gaz ............................................................................Gâchette actionnée du bout des doigts avec interrupteur momentané

Poids approximatif de l'appareil (sans carburant, avec accessoire de coupe, écran et poignée en anneau)....................13 livres (5,9 kg)

Mécanisme de coupe..........................................................................................................................................Tête de coupe à fil double

Dévidoir de fil ...............................................................................................................................................Avance du fil par frappe au sol

Diamètre du dévidoir de fil ..........................................................................................................................................4 pouces (101,6 mm)

Diamètre du fil de coupe..........................................................................................................................................0,105 pouce (2,67 mm)

Diamètre de coupe.....................................................................................................................................................17 pouces (43,18 cm)

CARACTÉRISTIQUES

ARBRE D'ENTRAÎNEMENT et ACCESSOIRE DE COUPE*

Pour l’entretien du moteur et des informations sur la garantie

de ce dernier, veuillez appeler le 1-800-800-7310 pour trouver

le concessionnaire le plus proche.

Pour l’entretien du tube et des informations sur la garantie de

ce dernier, veuillez appeler le 1-800-800-7310.

F8

Page 19

DÉPANNAGE

F9

Page 20

GARANTIE LIMITÉE DU FABRICANT POUR:

Aucune garantie implicite, y compris toute garantie de valeur

marchande ou d'adaptation à une fin particulière, ne

s'applique après la période applicable de garantie expresse

écrite ci-dessus concernant les pièces qui sont identifiées.

Aucune autre garantie ou caution expresse, écrite ou orale,

à l'exception de celle mentionnée ci-dessus, accordée par

toute personne ou entité, y compris tout distributeur ou

détaillant, concernant tout produit n'engagera la

responsabilité de MTD PRO LLC. Pendant la période de

garantie, le recours exclusif est la réparation ou le

remplacement du produit dans les conditions énoncées cidessus. (Certains états ne permettent pas la limitation de la

garantie implicite, il est donc possible que la limitation ci-dessus

ne s'applique pas à vous.)

Les clauses énoncées dans la présente Garantie constituent

le recours unique et exclusif inhérent aux ventes. MTD PRO

LLC ne sera en aucun cas tenue pour responsable de tout

dommage indirect ou consécutif ou de dommages

comprenant, entre autres, les dépenses encourues du fait

du recours à des services de remplacement ou de

substitution pour l'entretien des pelouses, le transport ou

des frais connexes, ou les frais entraînés par une location

destinée à remplacer provisoirement un produit sous

garantie. (Certains états ne permettent pas la limitation de la

garantie implicite, il est donc possible que la limitation ci-dessus

ne s'applique pas à vous.)

Aucun recouvrement, quel qu'il soit, ne sera d'un montant

supérieur au prix du produit vendu. Toute modification des

dispositifs de sécurité du produit annulera la présente Garantie.

Vous assumez tout risque et toute responsabilité résultant de la

perte, de l'endommagement ou du préjudice que vous et votre

propriété et/ou d'autres et leur propriété pourront encourir d'un

fait de l'utilisation normale, de la mauvaise utilisation ou de

l'incapacité d'utiliser le produit.

La présente garantie limitée n'est accordée qu'à l'acheteur initial,

au preneur initial ou à la personne à laquelle le produit a été

offert.

Le Droit des États vis à vis de la présente garantie : la

présente garantie vous confère certains droits juridiques et vous

pouvez bénéficier d'autres droits lesquels varient d'un état à

l'autre.

Pour obtenir l'adresse du distributeur réparateur le plus proche,

composez le : 1-800-800-7310.

MTD PRO LLC

P.O. Box 361131

Cleveland, OH 44136-0019

La garantie limitée énoncée ci-après est accordée par MTD PRO

LLC et concerne les marchandises neuves achetées et utilisées

aux États-Unis, ses possessions et territoires.

MTD PRO LLC garantit ce produit contre tout vice de matière ou

de façon pendant une période de deux (2) ans à compter de la

date d'achat initiale et elle se réserve le choix de réparer ou de

remplacer, à titre gratuit, toute pièce présentant un vice de

matière ou de façon. Cette garantie limitée ne s'appliquera que

dans la mesure où le produit aura été utilisé et entretenu

conformément au Manuel de l'utilisateur fourni avec le produit

et n'aura pas fait l'objet d'un usage inadéquat, abusif,

commercial ou négligent, d'un accident, d'un entretien

inadéquat, d'une modification, de vandalisme, d'un vol, d'un

incendie, de dégâts d'eau ou d'un endommagement résultant

d'un autre péril ou d'un désastre naturel. Les dommages

résultats de l'installation ou de l'utilisation de tout accessoire ou

équipement non approuvé par MTD PRO pour une utilisation

avec le(s) produit(s) couvert(s) par le présent manuel annuleront

la garantie en ce qui concerne les dommages qui en résulteraient

éventuellement. La présente garantie est limitée à quatre-vingtdix (90) jours à compter de la date d'achat au détail initiale pour

tout produit MTD PRO utilisé à des fins locatives ou

commerciales, ou toute utilisation produisant des revenus.

POUR L'OBTENTION DU SERVICE DE GARANTIE : le service

au titre de la garantie est disponible, SUR PRÉSENTATION

D'UNE PREUVE D'ACHAT, AUPRÈS DU DISTRIBUTEUR AGRÉÉ

LOCAL. Pour trouver un distributeur dans votre région, consultez

les Pages Jaunes, appelez le 1-800-800-7310 ou écrivez à

l'adresse MTD PRO LLC, PO Box 361131, Cleveland, OH 44136-

0019.

La garantie limitée n'offre aucune couverture dans les cas

suivants :

A. Mises au point : bougies, réglages de carburateur, filtres

B. Éléments pouvant s'user : boutons de butée, bobines

extérieures, fil de coupe, moulinets intérieurs, poulie du

démarreur, cordons de démarrage, courroies

d'entraînement

C. MTD PRO LLC n'accorde aucune garantie pour les

produits vendus ou exportés des États-Unis d'Amérique,

de leurs possessions et territoires, exception faite en ce

qui concerne les produits vendus par l'intermédiaire de

ses canaux agréés de distribution à l'exportation.

MTD PRO LLC se réserve le droit de modifier ou d'améliorer la

conception de ses produits sans pour autant assumer

l'obligation de modifier tout produit d'une fabrication plus

ancienne.

Page 21

Manual del Dueño

Recortador 4 Ciclos a

Gasolina Model H70SS

CONSERVE ESTAS INSTRUCCIONES

Para obtener una lista de los proveedores de servicio, consulte

los números de teléfonos que aparecen en la página 6, al final de

la sección Localización y Solución de Problemas de este manual.

NO REGRESE SU UNIDAD AL VENDEDOR. PARA SOLICITAR

SERVICIO POR LA GARANTIA, DEBERA PRESENTAR PRUEBA

DE SU COMPRA.

ESTE PRODUCTO ESTA CUBIERTO POR UNA O MAS

PATENTES DE EE.UU., OTRAS PATENTES EN TRAMITE.

El servicio de esta unidad, ya sea durante o después del período

cubierto por la garantía, debe ser realizado solamente por un

proveedor de servicios autorizado y aprobado.

Toda la información, las ilustraciones y las especificaciones

contenidas en este manual se basan en la información más reciente

disponible en el momento de impresión del manual. Nos reservamos

el derecho de hacer cambios en cualquier momento sin aviso previo.

Copyright© 2007 MTD SOUTHWEST INC. Todos los derechos

reservados.

P/N 769-02747C (2/07)

INDICE DE CONTENIDOS

Llamadas a apoyo al cliente . . . . . . . . . . . . . . . . . . . . . . . .E1

Normas para una operación segura . . . . . . . . . . . . . . . . . .E1

Conozca su unidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E3

Instrucciones de ensamble . . . . . . . . . . . . . . . . . . . . . . . . .E4

Instrucciones de arranque y apagado . . . . . . . . . . . . . . . . .E4

Instrucciones de operación . . . . . . . . . . . . . . . . . . . . . . . . .E5

Instrucciones de mantenimiento y reparación . . . . . . . . . .E6

Limpieza y almacenamiento . . . . . . . . . . . . . . . . . . . . . . . .E7

Cuadro de solución de problemas . . . . . . . . . . . . . . . . . . .E8

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E8

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E12

Lista de Piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E11

ADVERTENCIA: Al utilizar la unidad, debe

observar las reglas de seguridad. Lea estas

instrucciones antes de operar la unidad a fin de

garantizar la seguridad del operador y cualquier

transeúnte. Guarde estas instrucciones para uso

posterior.

LEA TODAS LAS INSTRUCCIONES ANTES DE OPERAR LA

UNIDAD

• Lea las instrucciones cuidadosamente. Familiarícese con los

controles y el uso adecuado de la unidad.

• No opere esta unidad cuando esté cansado, enfermo o bajo

la influencia de alcohol, drogas o medicamentos.

• Los niños y los adolescentes menores de 15 años de edad

no deben usar la unidad. Los adolescentes pueden hacerlo

bajo la supervisión de un adulto.

• Todos los dispositivos de protección y los accesorios de

seguridad deben estar instalados adecuadamente antes de

operar la unidad.

• Inspeccione la unidad antes de usarla. Reemplace las piezas

dañadas. Verifique si hay fugas de combustible. Asegúrese

de que todos los fijadores estén en su lugar y asegurados.

Reemplace las piezas que estén agrietadas, astilladas o

dañadas en cualquier forma. No opere la unidad con piezas

sueltas o dañadas.

• Inspeccione cuidadosamente el área antes de operar la unidad.

Elimine todos los escombros y los objetos duros o filosos tales

como cristal, alambre, etc.

• Esté consciente del riesgo de lesión en la cabeza, las manos

y los pies.

• No permita niños, espectadores ni mascotas en el área. Los

niños, los espectadores y las mascotas deben estar fuera de

un radio de 50 pies (15 m.) como mínimo; de todas formas los

espectadores correrán el riesgo de ser golpeados por objetos

lanzados por la unidad. Se debe exhortar a los espectadores

a que usen protección para los ojos. Si se le acerca alguien

apague la unidad de inmediato.

NORMAS PARA UNA OPERACIÓN SEGURA

• IMPORTANTE INFORMACION DE SEGURIDAD •

Page 22

E2

• Use sólo línea de reemplazo del fabricante original del equipo

con un diámetro de 0.105 de pulgada (2.67 mm). Nunca use

línea reforzada con metal, alambre o soga. Se pueden romper

y convertirse en proyectiles peligrosos.

• Oprima el control del estrangulador y compruebe que regresa

automáticamente a la posición de marcha en vacío. Haga

todos los ajustes o reparaciones antes de usar la unidad.

AVISOS DE SEGURIDAD PARA LAS UNIDADES QUE

FUNCIONAN CON GASOLINA

• Almacene el combustible solamente en recipientes diseñados

y aprobados específicamente para el almacenamiento de

dichos materiales.

•E

vite crear una fuente de ignición para el combustible derramado.

No arranque el motor hasta que se disipen los vapores del

combustible.

• Pare siempre el motor y deje que se enfríe antes de llenar el

tanque de combustible. Nunca quite la tapa del tanque de

combustible, ni agregue combustible, cuando el motor esté

caliente. Nunca opere la unidad sin la tapa de combustible bien

colocada en su lugar. Afloje la tapa del tanque de combustible

lentamente para aliviar cualquier presión que haya en el tanque.

• Mezcle y agregue el combustible en un área exterior bien

ventilada, donde no haya chispas ni llamas. Quite lentamente la

tapa de combustible sólo después de haber parado el motor.

No fume mientras esté llenando de combustible o mezclándolo.

Limpie de la unidad inmediatamente cualquier combustible

derramado. Seque siempre la unidad antes de usarla.

• Mueva siempre la unida a 30 pies (9.1 m) como mínimo de la

fuente y sitio de combustible antes de arrancar el motor. No

fume ni permita chispas ni llamas expuestas cerca del área

mientras esté agregando combustible u operando la unidad.

CUANDO ESTÉ OPERANDO

• Nunca arranque ni opere la unidad dentro de un cuarto o edificio

cerrado. Respirar los vapores del escape puede ser fatal. Opere

esta unidad solamente en un área exterior bien ventilada.

• Use gafas protectoras que cumplan con la norma Z87.1 de

ANSI y tengan la marca que lo indica. Use protección para la

oreja/audición cuando opere esta unidad. Use máscara facial

o para polvo si la operación produce mucho polvo.

• Use pantalones largos fuertes, botas, guantes y camisa de

mangas largas. No use ropa holgada, joyas, pantalones

cortos, sandalias, ni esté descalzo. Asegúrese el cabello por

encima del nivel de los hombros.

• El protector del accesorio de corte debe estar siempre

colocado cuando se utilice la unidad como recortador. No

opere la unidad sin ambas líneas de corte extendidas y con

la línea adecuada instalada. No extienda la línea de corte

más allá de la longitud del protector.

•E

sta unidad tiene un embrague. El accesorio de corte permanece

estacionario cuando la unidad está en marcha en vacío. Si no

sucede así, haga que un técnico de servicio autorizado ajuste la

unidad.

• Ajuste la manija en D a su tamaño para proporcionar un

mejor agarre.

• Antes de arrancar la unidad asegúrese de que el accesorio

de corte no esté en contacto con nada.

• Use la unidad solamente de día o con buena luz artificial.

NORMAS PARA UNA OPERACIÓN SEGURA

•E

vite arranques accidentales. Esté en la posición de arranque

cada vez que hale la cuerda de arranque. El operador y la unidad

deben estar en una posición estable al arrancar. Consulte las

Instrucciones de Arranque/Parada.

• Use la herramienta correcta. Use esta herramienta solamente

para el propósito para el cual fue diseñada.

• No se estire demasiado. Mantenga siempre la base de apoyo

y equilibrio adecuados.

• Sostenga siempre la unidad con ambas manos cuando la

opere. Mantenga un agarre firme sobre ambas manijas.

• Mantenga las manos, la cara y los pies alejados de todas las

partes en movimiento. No toque ni trate de parar el accesorio

de corte cuando esté girando.

• No toque el motor, la caja de engranajes ni el silenciador.

Estas piezas están muy calientes durante la operación, incluso

después de que se apaga la unidad.

• No opere el motor a más velocidad de la necesaria para

cortar, recortar o recortar bordes. No haga funcionar el

motor a alta velocidad cuando no esté cortando.

• Pare siempre el motor cuando deje de cortar o cuando esté

caminando de un lugar de corte hacia otro.

• Si golpea o se enreda con un objeto extraño, pare el motor

inmediatamente y verifique si ha habido algún daño. No lo

opere antes de reparar el daño. No opere la unidad con

piezas sueltas o dañadas.

• Pare la unidad, apague el motor y desconecte la bujía para

mantenimiento o reparación.

• Use solamente piezas y accesorios de reemplazo del fabricante

del equipo original para esta unidad. Éstos están disponibles en

su proveedor de servicio autorizado. El uso de cualquier pieza o

accesorio no autorizado podría causar lesiones graves al

usuario, o daños a la unidad, y anular su garantía.

• Mantenga la unidad limpia de vegetación y otros materiales.