Page 1

jqa=mкзЗмЕнл=^внбЙеЦЙлЙддлЕЬ~Сн=√=p~~êÄêΩÅâÉå=√=dÉêã~åó

H12

FORM NO. 769-08347

Page 2

2

English

Français

Deutsch

Italiano

Português

Español

15

26

39

52

64

77

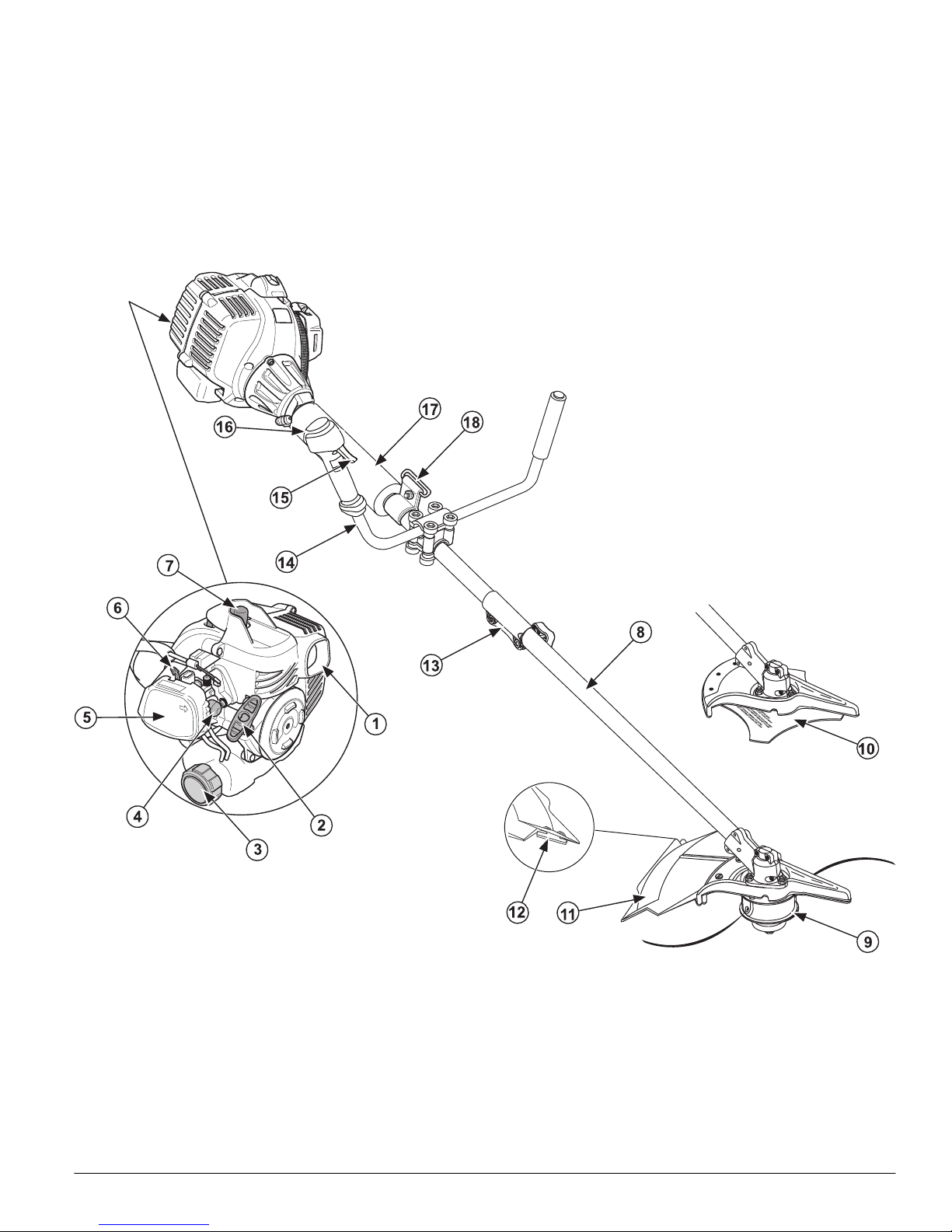

Page 3

3

en GET TO KNOW YOUR APPLIANCE

fr PRÉSENTATION DE VOTRE APPAREIL

de LERNEN SIE IHR GERÄT KENNEN

it CONOSCERE L’APPARECCHIO

pt CONHEÇA O SEU APARELHO

es CONOZCA SU EQUIPO

Typ 1

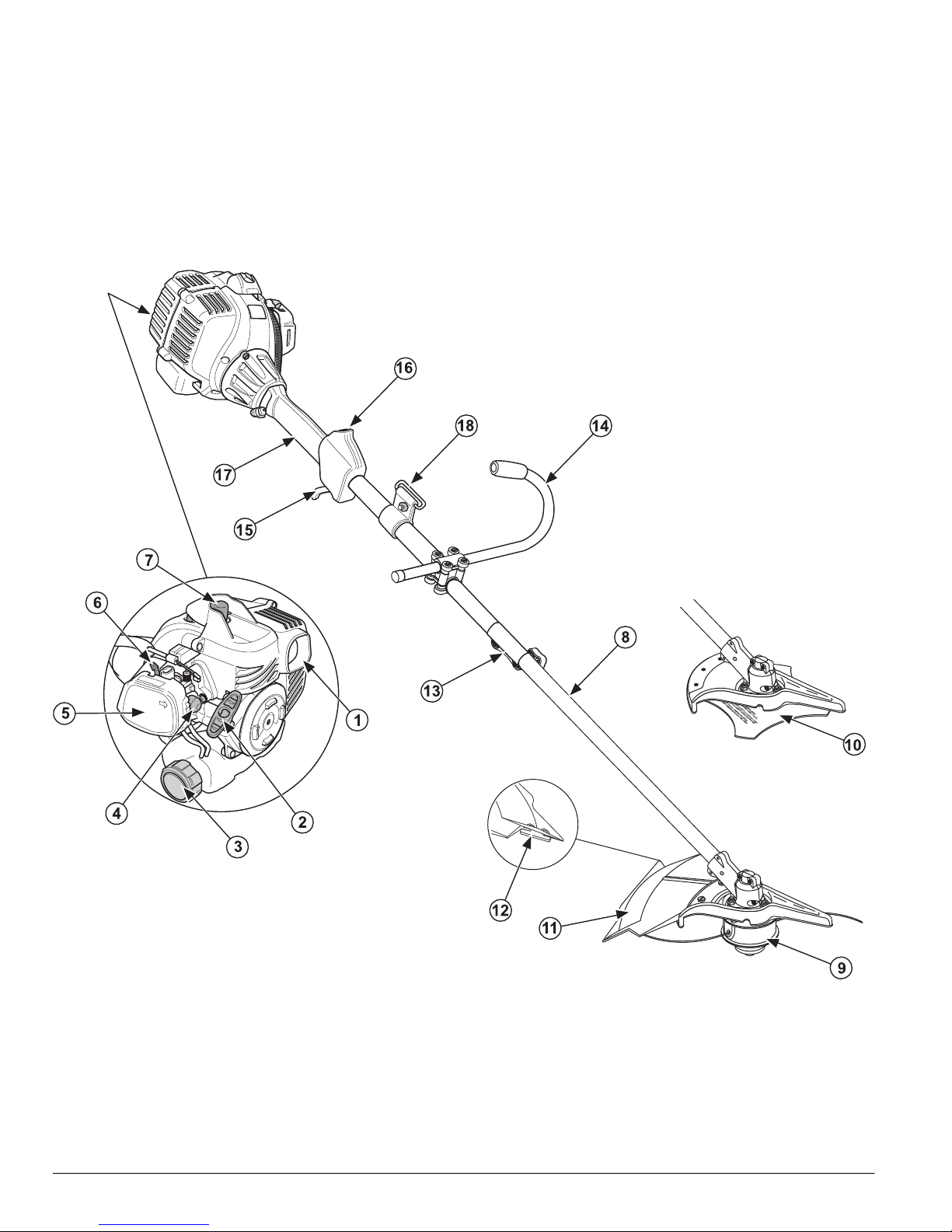

Page 4

4

en GET TO KNOW YOUR APPLIANCE

fr PRÉSENTATION DE VOTRE APPAREIL

de LERNEN SIE IHR GERÄT KENNEN

it CONOSCERE L’APPARECCHIO

pt CONHEÇA O SEU APARELHO

es CONOZCA SU EQUIPO

Typ 2

Page 5

5

Description of the parts

* Depending on the model

Description des pièces

* Selon le modèle

Beschreibung der Teile

* Je nach Ausführung

Descrizione delle parti

* A seconda della versione

Descrição das peças

* De acordo com o modelo

Descripción de las partes

* Según la versión

1. Exhaust 10. Cutting blade with cover *

2. Starter handle 11. Cutting attachment cover

3. Tank cap 12. Line cutting blade

4. Intake pump/primer 13. EZ link *

5. Air filter cover 14. Handle bar

6. Choke lever * 15. Throttle

7. Spark plug 16. Ignition switch

8. Shaft 17. Shaft handle

9. Line coil 18. Shoulder belt holder

1. Pot d’échappement 10. Lame de coupe

2. Poignée de démarrage avec couvercle *

3. Bouchon du réservoir 11. Couvercle de l’accessoire

4. Pompe d’amorçage / de coupe

Bouton d’amorçage 12. Lame coupe-fil

5. Couvercle du filtre à air 13. Embrayage EZ *

6. Manette de starter * 14. Guidon

7. Bougie 15. Manette des gaz

8. Arbre 16. Interrupteur d'allumage

9. Bobine de fil 17. Poignée sur arbre

18. Fixation de la bandoulière

1. Auspuff 11. Schneidaufsatz-

2. Startergriff abdeckung

3. Tankdeckel 12. Fadenschneidklinge

4. Ansaugpumpe/Primer 13. EZ-Link *

5. Luftfilterabdeckung 14. Griffstange

6. Chokehebel * 15. Gashebel

7. Zündkerze 16. Zündschalter

8. Schaft 17. Schaftgriff

9. Fadenspule 18. Schulterriemenhalterung

10. Schneidklinge mit Abdeckung *

1. Marmitta 10. Copertura attrezzo *

2. Maniglia di avviamento a fili di nylon

3. Tappo del serbatoio 11. Lama di taglio

4. Pompa di aspirazione/ con coperchio

iniettore 12. Lama per taglio fili

5. Coperchio del filtro aria 13. Giunto EZ-Link *

6. Leva dello starter * 14. Manubrio

7. Candela di accensione 15. Leva dell’acceleratore

8. Asta 16. Interruttore di accensione

9. Bobina a fili di nylon 17. Maniglia sull’asta

18. Fissaggio della tracolla

1. Escape 11. Cobertura do adaptador

2. Punho de ignição de corte

3. Tampa do depósito 12. Lâmina de corte

4. Bomba de aspiração/ 13. EZ-Link *

Primer 14. Barra do punho

5. Cobertura do filtro de ar 15. Alavanca de aceleração

6. Alavanca do acelerador * 16. Interruptor de ignição

7. Vela de ignição 17. Punho da lança

8. Lança 18. Dispositivo de fixação

9. Bobina do fio da correia de ombro

10. Lâmina de corte do fio

com cobertura *

1. Escape 11 Cobertura del accesorio

2. Manija del arrancador de corte

3. Tapa del tanque 12. Cuchilla de corte

4. Bomba de aspiración/ para el hilo

primer 13. EZ-Link *

5. Cobertura del filtro 14. Barra con empuñadura

de aire 15. Palanca del acelerador

6. Palanca del cebador * 16. Conmutador de

7. Bujía encendido

8. Mango 17. Empuñadura del mango

9. Bobina para el hilo 18. Soporte para la correa

10 Cuchilla de corte para colgar del hombro

con cobertura *

Page 6

6

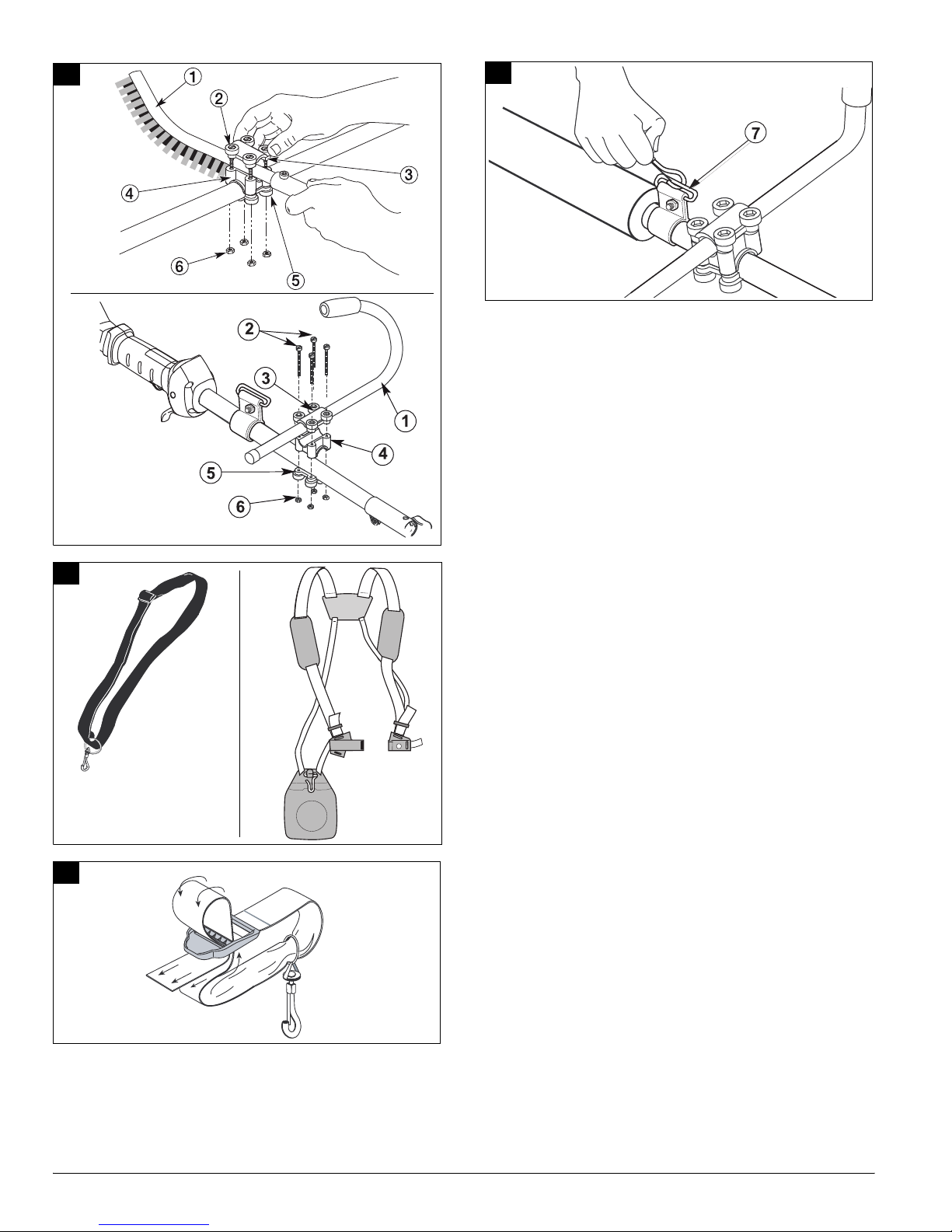

Description of the parts – Figs. 1–4

Description des pièces – Fig. 1–4

Beschreibung der Teile – Abb. 1–4

Descrizione delle parti – Fig. 1–4

Descrição das peças – Fig. 1–4

Descripción de las partes – Figuras 1 a 4

1

a)

b)

2

a)

b)

3

1. Handle bar 5. Lower clamp

2. Screw 6. Nut

3. Upper clamp 7. Quick-release lock

4. Middle clamp

1. Guidon 5. Bride inférieur

2. Vis 6. Écrou

3. Bride supérieure 7. Fermeture rapide

4. Bride médiane

1. Griffstange 5. Untere Klemme

2. Schraube 6. Mutter

3. Obere Klemme 7. Schnellverschluss

4. Mittlere Klemme

1. Manubrio 5. Morsetto inferiore

2. Vite 6. Dado

3. Morsetto superiore 7. Arresto rapido

4. Morsetto intermedio

1. Barra de retenção 5. Braçadeira inferior

2. Parafuso 6. Porca

3. Braçadeira superior 7. Fecho rápido

4. Braçadeira média

1. Barra manija 5. Grapa inferior

2. Tornillo 6. Tuerca

3. Grapa superior 7. Cierre rápido

4. Grapa central

4

Page 7

7

5

a) b)

6

a)

b)

Page 8

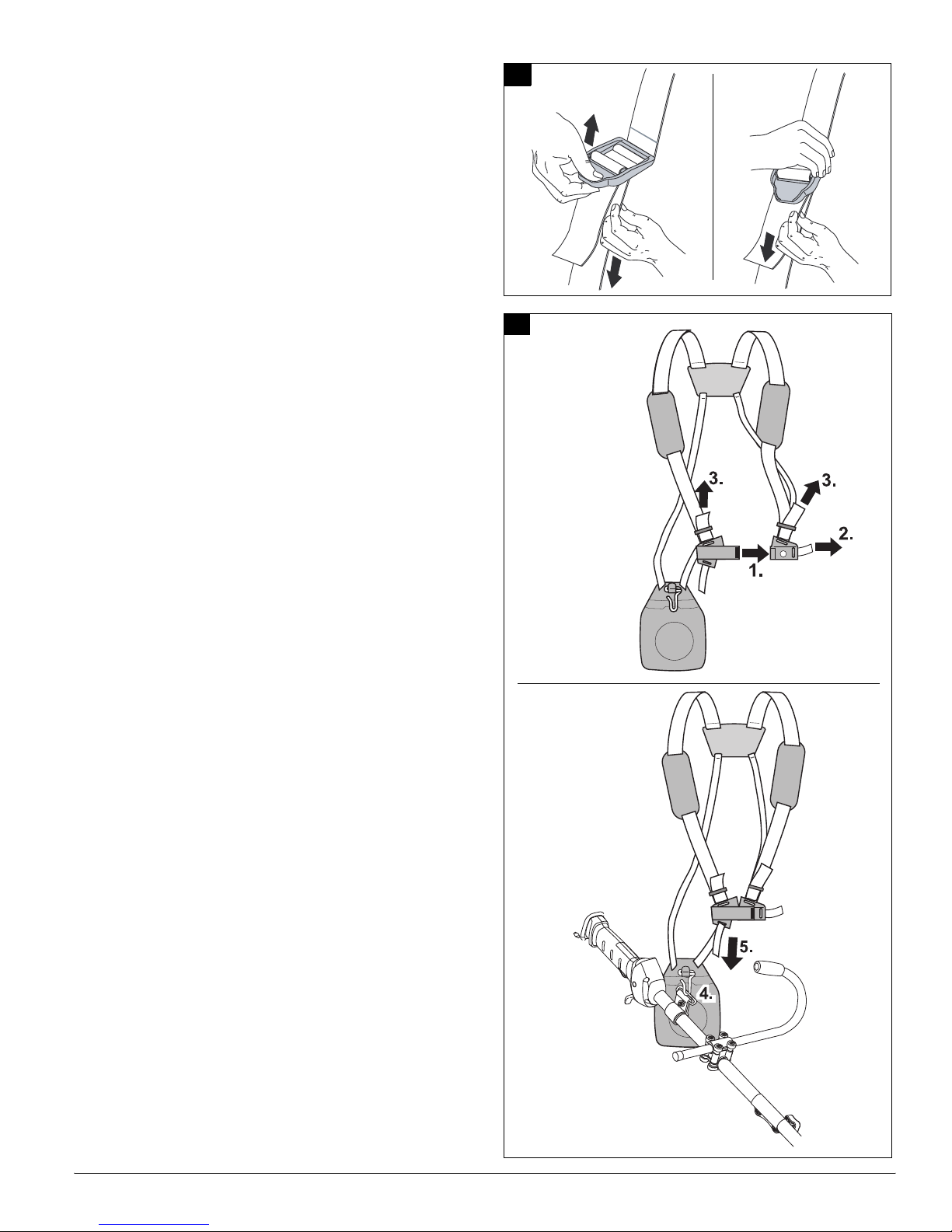

8

Depending on the model –

Description of the parts – Figs. 7–9

Selon le modèle –

Description des pièces – Fig. 7–9

Je nach Ausführung –

Beschreibung der Teile – Abb. 7–9

A seconda della versione –

Descrizione delle parti – Fig. 7–9

De acordo com o modelo –

Descrição das peças – Fig. 7–9

Según la versión –

Descripción de las partes – Figuras 7 a 9

3

4

1

2

7

7

2

6

1

5

8

3

9

1. EZ-Link™ 5. Main hole

2. Release button 6. Upper shaft tube

3. Button 7. Lower shaft tube

4. Guide groove

1. Lien EZ™ 4. Rainure de guidage

2. Bouton 5. Trou principal

de déclenchement 6. Tube d’arbre supérieur

3. Bouton 7. Tube d’arbre inférieur

1. EZ-Link™ 5. Hauptloch

2. Auslöseknopf 6. oberes Wellenrohr

3. Knopf 7. unteres Wellenrohr

4. Führungsrille

1. Giunto EZ-Link™ 6. Tubo dell’albero

2. Pulsante di sgancio superiore

3. Manopola 7. Tubo dell’albero

4. Gola di guida inferiore

5. Foro principale

1. EZ-link™ 5. Furo principal

2. Botão de 6. Tubo ondulado

accionamento superior

3. Botão 7. Tubo ondulado inferior

4. Fenda de guia

1. Link EZ™ 5. Orificio principal

2. Botón de traba 6. Tubo superior del eje

3. Botón 7. Tubo inferior de eje

4. Ranura guía

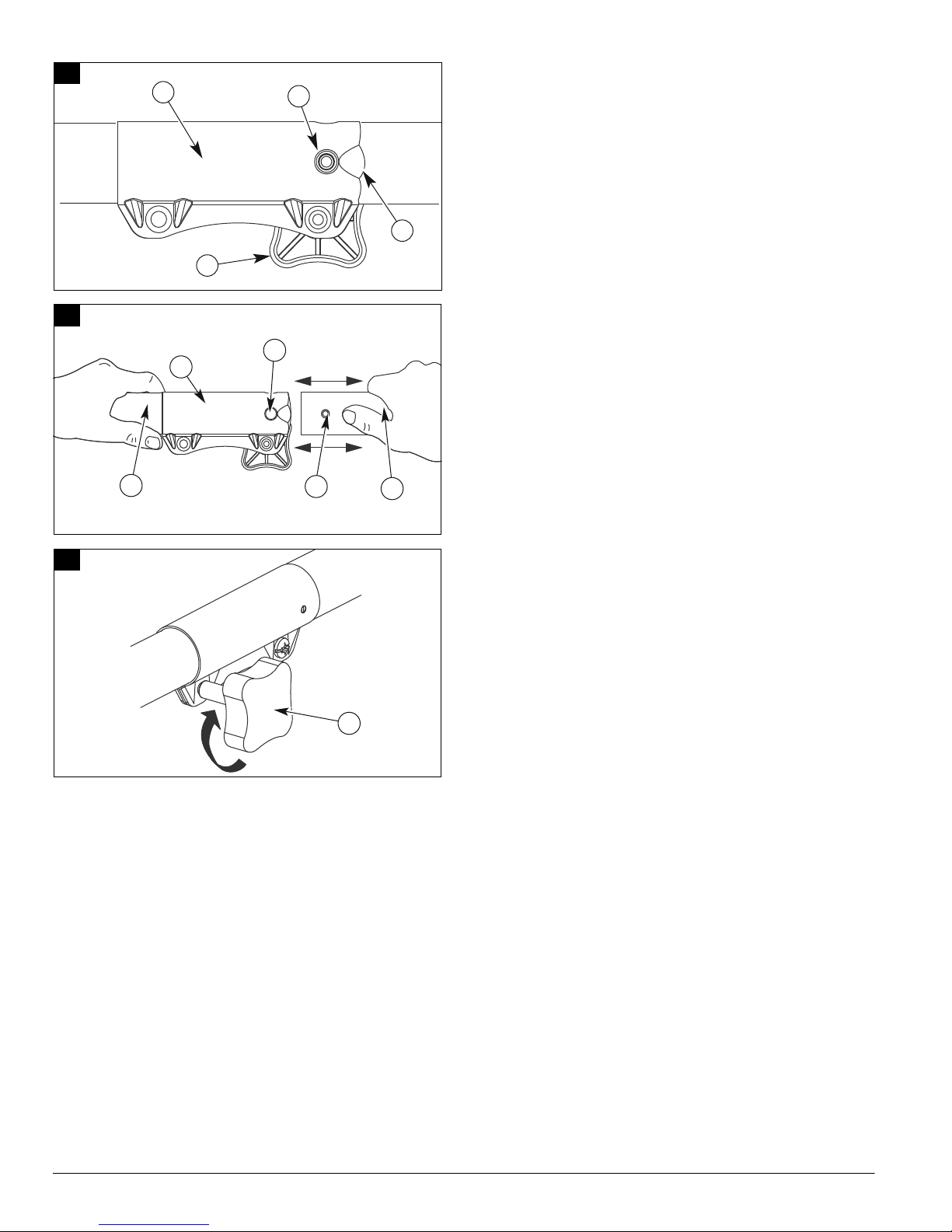

Page 9

9

Description of the parts – Figs. 10–13

Description des pièces – Fig. 10–13

Beschreibung der Teile – Abb. 10–13

Descrizione delle parti – Fig. 10–13

Descrição das peças – Fig. 10–13

Descripción de las partes – Figuras 10 a 13

1. Cutting attachment 6. Drive shaft housing

plate 7. Safety bar slot

2. Screws 8. Shaft bush hole

3. Guard attachment 9. Cutting attachment

4. Safety bar 10. Cutting holder

5. Drive shaft

1. Tôle de protection 6. Carter de l’arbre

de l’accessoire d’entraînement

de coupe 7. Fente pour tringle

2. Vis de sécurisation

3. Fixation de la tôle 8. Trou pour douille

de protection d’arbre

4. Tringle de sécurisation 9. Accessoire de coupe

5. Arbre d’entraînement 10. Fixation de coupe

1. Schneidaufsatz- 6. Antriebswellengehäuse

schutzblech 7. Sicherungsstangen-

2. Schrauben schlitz

3. Schutzblechbefestigung 8. Wellenbuchsenloch

4. Sicherungsstange 9. Schneidaufsatz

5. Antriebswelle 10. Schneidhalterung

3

1

2

10

4

7

8

6

5

11

1. Lamiera di protezione 6. Alloggiamento

dell’attrezzo a fili dell’albero motore

di nylon 7. Fessura dell’asta

2. Viti di sicurezza

3. Fissaggio della lamiera 8. Foro nella bussola

di protezione dell’albero

4. Asta di sicurezza 9. Attrezzo di taglio

5. Albero motore a fili di nylon

10. Fissaggio lama di taglio

1. Chapa de protecção 6. Caixa do veio

do adaptador de corte de accionamento

2. Parafusos 7. Ranhura da barra

3. Fixação da chapa de segurança

de protecção 8. Furo da bucha do veio

4. Barra de segurança 9. Adaptador de corte

5. Veio de accionamento 10. Dispositivo de fixação

do corte

1. Chapa de cobertura 6. Carcasa del eje motriz

del cabezal de corte 7. Ranura para la barra

2. Tornillos de seguridad

3. Sujeción de la chapa 8. Orificio buje para el eje

de protección 9. Cabezal de corte

4. Barra de seguridad 10. Soporte de corte

5. Eje motriz

12

4

10

9

13

Page 10

10

Description of the parts – Figs. 14–16

Description des pièces – Fig. 14–16

Beschreibung der Teile – Abb. 14–16

Descrizione delle parti – Fig. 14–16

Descrição das peças – Fig. 14–16

Descripción de las partes – Figuras 14 a 16

3

4

5

2

1

14

15

16

1. Nut 4. Safety bar

2. Blade holder 5. Drive shaft housing

3. Blade

1. Écrou 4. Tringle de sécurisation

2. Fixation de lame 5. Carter d’arbre

3. Lame de coupe d’entraînement

1. Mutter 4. Sicherungsstange

2. Klingenhalterung 5. Antriebswellengehäuse

3. Schneidklinge

1. Dado 4. Asta di sicurezza

2. Disco di arresto 5. Alloggiamento

della lama dell’albero

3. Lama di taglio motore

1. Porca 4. Barra de segurança

2. Retentor da lâmina 5. Caixa do veio

3. Lâmina de corte de accionamento

1. Tuerca 3. Hoja de la cuchilla

2. Soporte para la hoja 4. Barra de seguridad

de la cuchilla 5. Carcasa para el

eje motriz

Page 11

11

Description of the parts – Figs. 17–19

* Depending on the model

Description des pièces – Fig. 17–19

* Selon le modèle

Beschreibung der Teile – Abb. 17–19

* Je nach Ausführung

Descrizione delle parti – Fig. 17–19

* A seconda della versione

Descrição das peças – Fig. 17–19

* De acordo com o modelo

Descripción de las partes – Figuras 17 a 19

*Según la versión

1. Throttle 6. Operating position (3) *

2. Throttle lock * 7. Choke lever *

3. Ignition switch 8. Intake pump/primer

4. Full choke position (1) * 9. Starter rope

5. Half choke intermediate

position (2) *

1. Manette des gaz 6. Position de service (3) *

2.

Cran d’arrêt de la manette *

7. Manette de starter *

des gaz 8. Pompe d’aspiration /

3. Interrupteur d’allumage Bouton d’amorçage

4. Starter en position (1) * 9. Cordon du lanceur

5. Starter en position

médiane (2) *

A

1

2

3

B

17

5

4

6

7 8

18

19

1. Gashebel 6. Betriebsposition (3) *

2. Gashebelsperre * 7. Chokehebel *

3. Zündschalter 8. Ansaugpumpe/Primer

4. volle Chokeposition (1) * 9. Starterseil

5. halbe Choke

Zwischenposition (2) *

1. Leva acceleratore 6. Posizione di

2. Blocco leva acceleratore * funzionamento (3) *

3. Interruttore di accensione 7. Levetta della farfalla aria *

4.

Farfalla aria tutta aperta (1) *

8. Pompa di aspirazione/

5. Farfalla aria aperta a metà iniettore

posizione intemedia (2) * 9. Fune di avviamento

1. Alavanca de aceleração 6. Posição de

2. Bloqueio da alavanca * funcionamento (3) *

de aceleração 7.

Alavanca do estrangulador *

3. Interruptor de ignição 8. Bomba de aspiração/

4. Posição do estrangulador

Primer

fechado (1) * 9. Cabo de arranque

5. Posição intermédia

do estrangulador (2) *

1. Palanca del acelerador 6. Posición de

2. Bloqueo de acelerador * funcionamiento (3) *

3. Llave de encendido 7. Palanca del cebador *

4. Posición máxima 8. Bomba de aspiración/

para el cebador (1) * primer

5. Posición central para 9. Cuerda de arranque

el cebador (2) *

20

Page 12

12

Description of the parts – Figs. 24–26

Description des pièces – Fig. 24–26

Beschreibung der Teile – Abb. 24–26

Descrizione delle parti – Fig. 24–26

Descrição das peças – Fig. 24–26

Descripción de las partes – Figuras 24 a 26

1. Coil housing 4. Bump knob

2. Spring 5. Meshing teeth

3. Coil

1. Carter de bobine 4. Bouton actionné

2. Ressort par le sol

3. Bobine 5. Dents d’encochage

21

22

23

24

1. Spulengehäuse 4. Auftippknopf

2. Feder 5. Einrastzähne

3. Spule

1. Capsula portabobina 4. Pulsante a percussione

2. Molla 5. Denti di arresto

3. Bobina

1. Caixa da bobina 4. Tampa de bloqueio

2. Mola do fio da bobina

3. Bobina 5. Dentes de engate

1. Carcasa para la bobina 4. Botón de cierre

2. Muelle 5. Dientes de traba

3. Bobina

25

26

Page 13

13

Description of the parts – Fig. 33

Description des pièces – Fig. 33

Beschreibung der Teile – Abb. 33

Descrizione delle parti – Fig. 33

Descrição das peças – Fig. 33

Descripción de las parte – Figura 33

27

28

29

30

31

1. Air filter cover 3. Retaining plate

2. Air filter

1. Capot du filtre à air 3. Patte de retenue

2. Filtre à air

1. Luftfilterabdeckung 3. Haltelasche

2. Luftfilter

1. Coperchio del filtro aria 3. Linguetta di arresto

2. Filtro dell'aria

1.

Cobertura do filtro de ar

3. Pala de retenção

2. Filtro de ar

1. Cobertura del filtro de aire 3. Eclisa de sujeción

2. Filtro de aire

32

2

1

3

33

Page 14

14

Description of the parts – Figs. 37–38

Description des pièces – Fig. 37–38

Beschreibung der Teile – Abb. 37–38

Descrizione delle parti – Fig. 37–38

Descrição das peças – Fig. 37–38

Descripción de las partes – Figuras 37 a 38

1. Air filter cover 3. Spark plug

2. Idle speed controller

1. Capot du filtre à air 3. Bougie

2. Vis régulatrice du ralenti

1. Luftfilterabdeckung 3. Zündkerze

2. Leerlaufdrehzahlregler

35

34

36

1. Coperchio del filtro aria 3. Candela di accensione

2. Regolatore del numero

di giri al minimo

1. Cobertura do filtro de ar 3. Vela de ignição

2. Regulador de rotações

de ponto morto

1. Cobertura del filtro de aire 3. Bujía

2. Regulador de marcha

en vacío

2

1

37

0,63 mm

3

38

Page 15

15

Enter all information on the rating plate of your unit

in the following field.

You can find the rating plate near the engine.

These specifications are very important for subsequent

identification when ordering spare parts and for customer

service.

Safe operating practices

Using the unit correctly

This unit is designed

– to be used in accordance with the descriptions and safety

instructions indicated in this operating manual

–for private use

– for trimming lawn edges and small inaccessible areas

of grass (e.g. under bushes),

– for cutting wild growth, shrubs and undergrowth.

It is not permitted to use this unit for any other purposes.

The user is liable for all injuries to third parties and damage

to their property.

Operate the unit only in the technical condition as stipulated

and delivered by the manufacturer.

Arbitrary changes to the unit will exclude the manufacturer

from any liability for resulting injury and/or damage.

Safety instructions

Read all instructions before operating

Please read these instructions carefully.

Familiarize yourself with the operation and handling

of the unit.

Do not use this unit if you are tired or ill or under

the influence of alcohol, drugs or medication.

Children and young people under 16 years of age must

not operate the unit.

Check the unit before using it. Replace damaged parts.

Check whether fuel is leaking out.

Ensure that all connections are attached and tight.

Replace cutting attachment parts which are cracked,

flawed or damaged in any other way.

Ensure that the cutting attachment has been installed

correctly and attached securely. Ensure that the guard

for the cutting attachment has been attached correctly

and is in the recommended position. If these instructions

are not followed, the user and bystanders may be injured

or the unit damaged.

Use only original replacement lines which have a dia-

meter of 2.41 mm. Never use a metal-reinforced string,

wire, chain, rope, etc. These may break off and become

dangerous projectiles.

Always be aware of the risk of injury to head, hands

and feet.

Depress the throttle. It must automatically return

to the home position. Perform all settings and/or

repairs before operating the unit.

Before using the unit, always clear the area which you

want to trim. Remove all objects such as stones, broken

glass, nails, wire or string which could be ejected

or become entangled in the cutting attachment.

Remove children, bystanders and animals from the area.

Keep children, bystanders and animals at a minimum

distance of 15 m; there is always a risk of bystanders

being hit by ejected objects. Bystanders should wear eye

protection. If somebody approaches, immediately

switch off the engine and cutting attachment.

Safety instructions for petrol-driven lawn trimmers

Caution: Petrol is highly flammable and the vapours may

explode if ignited. Take the following precautions:

Store petrol in designated and permitted containers only.

Keep ignition sources away from spilled petrol.

Do not start the engine until the petrol vapours have

evaporated.

Before filling the tank, always switch off the engine

and leave it to cool down. Never remove the tank

cap and never fill the tank while the engine is hot.

Before using the unit, ensure that the tank cap

is screwed on tightly. Slowly unscrew the tank cap

to reduce the pressure in the tank gradually.

Mix petrol and fill the tank in a clean, well ventilated

outdoor area only where there are no sparks or flames.

After switching off the engine, slowly unscrew the tank

cap. Do not smoke while mixing petrol or filling the tank.

Immediately wipe any spilled petrol off the unit.

Before switching on the engine, carry the unit at least

10 m away from the filling station. While filling the tank

or using the unit, do not smoke and keep sparks and

naked flames out of the area.

Page 16

16

Safety instructions

Operating the unit

Never start the unit and never leave it running in a closed

room or building. The inhalation of exhaust gases may

be fatal. Use the unit outdoors only.

Wear eye and ear protection when using the unit.

If working in a dusty environment, wear a face

or dust mask. A long-sleeved shirt is recommended.

Wear thick, long trousers, boots and gloves. Do not wear

loose clothing, jewellery, short trousers, sandals and do

not walk barefoot. Pin your hair above your shoulders.

The cutting attachment guard must always be attached

when the unit is being used as a lawn trimmer.

Both trim lines must be pulled out and the correct line

must be installed. The trim line must not be pulled out

over the end of the guard.

The unit has a clutch. The cutting attachment stops

when the unit is running at no load. If it does not stop,

have the unit adjusted by a mechanic at your authorised

dealer.

Before switching on the unit, ensure that the line

spool/cutting blade cannot strike an object.

Adjust the handle bar to your height so that the you have

the unit under control.

Do not touch the cutting attachment on the unit.

Operate the unit in daylight or adequate artificial lighting

only.

Avoid starting the unit unintentionally.

Be ready to operate the unit when you pull the starter

rope. User and unit must be in a stable position when

the unit is started. Follow the Start/Stop instructions.

Use this unit for its designated purpose only.

Do not stretch too far over the unit. Always have a secure

footing and keep your balance.

When operating the unit, always hold the unit firmly with

both hands. Always hold both sides of the handle bar

firmly.

When operating the unit, always wear the shoulder belt.

Keep your hands, face and feet away from all moving

parts. Do not touch the cutting attachment while

it is rotating and do not attempt to stop it.

Do not touch the engine or muffler. These parts become

very hot while the unit is being used. They remain hot

for a short time even when the unit is switched off.

Do not let the engine run quicker than required for cutting

or trimming of lawn edges. Do not run the engine at high

speed when it is not cutting.

Always switch off the engine if you cannot start cutting

immediately or if you are moving from one place

to another.

If you strike or ensnare a foreign object, immediately

switch off the engine and check whether the unit

has been damaged. Never use the unit with loose

or damaged parts.

Stop and switch off the engine for maintenance, repairs

or when changing the cutting attachment or other

attachments. Also pull out the spark-plug terminal.

Use only original spare parts for repairs.

These parts can be purchased from your authorised

dealer.

Never use parts, accessories or attachments which

are not authorised for this unit. Otherwise, the user may

be seriously injured and the unit damaged.

In addition, your warranty may be deemed null and void.

Keep the unit clean and ensure that there are no plants

or other objects caught between the cutting attachment

and guard.

To reduce the risk of fire, please replace damaged

mufflers and spark extinguishers and remove grass,

leaves, excess lubricants and layers of soot from

the engine and muffler.

Have all repairs carried out by a repair shop only.

Operating times

Observe the national/municipal regulations concerning times

of use (if required, ask your local authority).

Working with the cutting blade

(depending on model)

Before operating the unit, please read all safety

instructions carefully.

Always keep the handle bar between the user and

cutting attachment.

NEVER cut material if the cutting blade is 75 cm

or higher above ground level.

The unit may recoil if the rotating blade strikes an object

which cannot be cut immediately. Recoils may be strong

enough to throw the unit and/or user in any direction and

may cause the user to lose control of the unit. Recoils

may occur without warning if the blade gets caught, jams

or locks. This can easily happen in areas in which the

material to be cut is difficult to see.

Never use the undergrowth blade to cut undergrowth

thicker than 12.7 mm. Otherwise, violent recoils may

occur.

Do not attempt to touch or stop the blade while it is

rotating.

A rotating blade may cause injuries, even when the

engine has been switched off or the throttle has been

released. Hold the unit firmly until the blade has come to

a standstill.

Do not run the engine at high speed when it is not

cutting.

If you strike or ensnare a foreign object, immediately

switch off the engine and check whether the unit has

been damaged. Have the repair damaged before

continuing to use the unit.

Do not use the unit with a bent, cracked or blunt blade.

Throw away bent, twisted, cracked or broken blades.

Do not sharpen the cutting blade.

The sharpened tip of the blade may break off during

operation. This may result in serious injuries.

Replace the blade.

Page 17

17

Safety instructions

If extremely violent vibrations occur, switch off the engine

IMMEDIATELY. Vibrations are a sign of problems.

Check thoroughly for loose bolts, nuts or other damage

before you continue cutting. If required, repair or replace

the affected parts.

After operating the unit

Clean the cutting blades with a household detergent

to remove any remnants. Lubricate the blade with

machine oil to prevent rust.

Store and lock away the blade securely to protect

it from damage and unauthorised use.

Other safety instructions

As long as the tank still has petrol in it, never store

the unit in a building where vapours could come into

contact with sparks or naked flames.

Leave the engine to cool down before transporting

or conveying the unit. Attach the unit securely for

transportation.

Store the unit in a dry condition, locked away or high

up to prevent unauthorised use and damage.

Keep the unit away from children.

Never douse or splash the unit with water or other

liquids. Keep the handle bar dry, clean and dust-free.

Clean the unit after each use and follow the instructions

for cleaning and storage.

Dispose of waste petrol/oil or any packaging remnants

in accordance with local regulations.

Keep this manual. Read it frequently and use it to instruct

other users. If you lend this unit to somebody else, also

include this manual.

Keep this manual

Safety and international symbols

This operating manual describes safety and international symbols and pictograms which may be displayed on this unit.

Read this user handbook in order to familiarise yourself with all safety, installation, operating and repair instructions.

Symbol Meaning

Safety and warning symbol

Indicates danger, warning or a reason to be cautious. Can be used together with other symbols or pictograms.

Read operating manual

Non-compliance with the operating instructions and precautions may result in serious injuries.

Read the operating manual before starting or operating the unit.

Wear eye and ear protection

Caution: Ejected objects may cause serious eye injuries and excess noise may cause loss of hearing.

When operating the unit, wear eye and ear protection.

Wear head protection

Caution: Falling objects may cause serious head injuries. Wear head protection when operating the appliance.

Keep bystanders away

Caution: All bystanders, especially children and pets, must be kept at least 15 m from the working area.

Petrol

Always use clean and fresh lead-free petrol for mixing petrol.

Oil

Use only authorised oil according to the operating manual for mixing petrol.

Page 18

18

Safety instructions

Symbol Meaning

Ejected objects and rotating parts may cause serious injuries!

Caution: Do not use the unit if the protective housing has not been correctly positioned for cutting.

Keep away from the rotating line coil and cutting blade.

Ignition switch

ON / START / RUN

Ignition switch

OFF or STOP

Beware of hot surfaces

Do not touch hot muffler cover, gearbox or cylinder. You could burn yourself. These parts become extremely

hot while the unit is being used. They remain hot for a short time even when the unit is switched off.

Sharp blade

Caution: Sharp blade on the guard as well as sharp cutting blade. To prevent grievous injury do not touch

the blade.

Choke settings

1 • FULL CHOKE start position.

2 • HALF CHOKE intermediate position.

3 • Operating position.

Maximum rpm

Do not let the unit run more quickly than the maximum rpm.

Wear foot and hand protection

While operating this unit, wear heavy duty boots and protective gloves.

Do not fill up with fuel of specification E85.

If fuel of specification E85 (ethanol content >15 %) is used, the engine may be damaged.

The use of an unauthorised fuel will void the warranty.

Page 19

19

Installation manual

Installing and setting the handle bar

1. Position the handle bar between the upper and middle

clamp (Fig. 1).

2. Hold the three parts together and screw the four (4) bolts

through the upper clamp into the middle clamp.

Note: The holes in the upper and middle clamps are in align-

ment only if the unit has been assembled correctly.

3. Hold the clamps and the handle bar over the shaft

housing and on the lower clamp.

4. Hold each of the hex nuts in the lower clamp recess with

one finger. Loosely screw in the bolts with a large crosshead screwdriver. Do not tighten the screws until the

handle bar has been set correctly.

5. Hold the unit in the operating position (Fig. 20) and

position the handle bar until you have a secure footing.

6. Evenly tighten the bolts in the holder until the handle bar

is secure.

Attaching and adjusting the shoulder strap/harness

(depending on model)

Single shoulder strap

1. Pull the belt through the buckle (Fig. 3).

2. Pull the shoulder belt over your head and place

the pad on your shoulder.

3. Latch the hook of the shoulder belt into the metal holder

(Fig. 4). Adjust the belt to a comfortable length (Fig. 5).

Harness (double shoulder strap)

1. Place harness over your shoulders.

2. Close the catch on the abdominal belt.

If required, readjust (Fig. 6a).

3. Adjust shoulder belt and abdominal belt to the correct

length/width (Fig. 6a).

4. Latch the hook of the harness into the metal holder on

the unit and adjust the attachment pad to a comfortable

length (Fig. 6b).

Using the EZ-LinkTM system (depending on model)

Note: To facilitate installation and removal of attachments,

place the unit on the ground or a workbench.

Removing the cutting attachment or other

attachments

1. To loosen the attachment, rotate the screw handle

to the left (Fig. 7).

2. Press and hold down the release button (Fig. 7).

3. Hold the upper shaft housing securely and pull

the cutting attachment or other attachment directly

out of the EZ-LinkTM coupling (Fig. 8).

Installing the cutting attachment or other

attachments (depending on model)

1. To loosen the attachment, rotate the screw handle

to the left (Fig. 7).

2. Hold the attachment securely and push directly into the

EZ-Link

TM

coupling (Fig. 8).

Note: Alignment of the release button with the guide groove

facilitates installation (Fig. 7).

3. Secure the attachment by rotating the button to the right

(Fig. 9). Before operating the unit, ensure that the rotary

handle is secure.

Removing and installing the cutting attachment

guard (depending on model)

If the unit is used for cutting undergrowth (with cutting blade),

remove the cutting attachment guard.

Remove the cutting attachment guard from the guard holder

by unscrewing the three (3) screws with a flat screwdriver

(Fig. 10). Keep parts for subsequent use.

If the unit is used as a lawn trimmer, install the guard

for the cutting attachment.

Install the cutting attachment guard in the guard holder

by screwing in the three (3) screws with a flat screwdriver.

Tighten the screws (Fig. 10).

Removing the cutting attachment and attaching

the cutting blade (depending on model)

Note: To facilitate removal or installation of the cutting blade

or the cutting attachment, place the unit on the ground

or a workbench.

Removing the cutting attachment

Note: First attach the guard to the cutting blade.

1. Align the shaft bush hole with the slot for the safety bar

and guide the safety bar into the shaft bush hole (Fig. 11).

2. Hold the safety bar in place by gripping it together

with the shaft of the unit (Fig. 12).

3. While holding the safety bar, remove the cutting

attachment by screwing it clockwise off the drive shaft

(Fig. 13). Keep the cutting attachment for subsequent

use.

Page 20

20

Installation manual

Installing the cutting blade

4. Remove the cutting attachment guard.

See Removing and installing the cutting attachment

guard.

5. Place the cutting blade on the drive shaft (Fig. 14).

6. Centre the cutting blade on the drive shaft housing

(Fig. 14).

7. Ensure that the cutting blade is centred and is situated

flat against the drive shaft housing.

8. Align the shaft bush hole with the slot for the safety bar

and guide the safety bar into the shaft bush hole (Fig. 11).

9. Attach the cutting holder and nut to the drive shaft

(Fig. 14). Check that the blade has been installed

properly.

10. While holding the safety bar, tighten the nut anticlockwise (Fig. 15). – Tightening torque 37 Nm –

If you do not have a torque wrench, turn the nut against

the blade holder until it is situated firmly on the shaft

bush. Check that the blade has been installed

properly and then turn the nut anti-clockwise a further

¼ to ½ turn (Fig. 15).

11. Remove the safety bar from the safety bar slot.

12. Remove the guard from the cutting blade.

Removing the cutting blade and installing the

cutting attachment (depending on model)

Removing the cutting blade

1. Attach the guard to the cutting blade.

2. Align the shaft bush hole with the slot for the safety bar

and guide the safety bar into the shaft bush hole (Fig. 11).

3. Hold the safety bar in place by gripping it together

with the shaft of the unit (Fig. 12).

4. While holding the safety bar, loosen the nut on the blade

by turning it clockwise with a screw key or socket

wrench (Fig. 16).

5. Remove the nut, blade holder and blade.

Keep the nut and blade together in a secure location for

subsequent use. Keep them out of the reach of children.

Installing the cutting attachment

6. Align the shaft bush hole with the slot for the safety bar

and guide the safety bar into the shaft bush hole (Fig. 11).

Place the blade holder on the drive shaft with the flat

surface against the drive shaft housing (Fig. 13).

Rotate the cutting attachment anti-clockwise onto

the drive shaft. Tighten firmly.

Note: The blade holder must be installed on the drive

shaft in the illustrated position, otherwise the cutting

attachment will not function properly.

7. Remove the safety bar.

8. Install the cutting attachment guard. See Removing and

installing the cutting attachment guard.

Information on oil and fuel

Recommended oil grade

Use quality oil only, API classification TC (TSC-3)

which is offered for air-cooled two-stroke engines.

Mix the oil for two-stroke engines according

to the instructions on the container, 1:40 (2.5 %).

Recommended petrol grade

Danger: Under certain conditions petrol is extremely

flammable and explosive.

– Refuel only in a well ventilated area and with the engine

switched off. Do not smoke and switch off all ignition

sources in the vicinity of the tank or at the fuel storage

depot.

– Do not overfill the petrol tank (there must be no fuel

in the inlet nozzle). After filling up the petrol tank,

ensure that the tank cap is closed and secured.

– When filling up the petrol tank, do not spill any fuel.

Spilled fuel or petrol vapours may ignite. If fuel has been

spilled, ensure that the area is dried before the engine

is restarted.

– Prevent repeated or prolonged skin contact or inhalation

of the vapours.

Always use clean, fresh lead-free petrol (maximum

60 days old).

Minimum octane number: 91 ROZ

Fill the tank with petrol

Remove the tank cap.

Fill fuel tank. Never overfill!

Firmly close the petrol tank again.

Move the unit approx. 10 m from the filling station/fuel

container before starting the engine.

See instructions on mixing oil and petrol

Age and/or incorrectly mixed fuel are the main reasons

for the unit not running properly. Use fresh, clean, lead-free

petrol only. Follow exactly the instructions for the correct

petrol/oil mixture.

Correctly mix two-stroke engine oil and lead-free petrol,

1:40 (2.5 %). Do not mix directly in the tank.

Page 21

21

Operating manual

Starting the engine

Note: The engine uses Advanced Starting Technology™

(spring-supported starting process) which significantly

reduces the energy expenditure required to start

the engine. You must pull out the starter rope until

the engine starts by itself (spring-supported).

It is not necessary to pull violently on the rope –

the pulled rope does not resist greatly.

Please note that this method of starting the engine

is quite different (and much easier) from what you

are used to.

1. Mix petrol (gasoline) with oil. Fill the tank with the mixture.

See instructions on mixing oil and petrol.

2. Put the ignition switch in the START (I) position (Fig. 17).

Note: On some models the switch is permanently

in the ON [I] position.

Tip: If starting a unit which has not been used for a long

time (or brand new or difficult to start), press the intake

pump 20 times.

3. Slowly and fully press the intake pump 10 times.

The fuel must be visible in the pump (Fig. 18).

If this is not the case, press a further three times

or until the fuel can be seen.

On appliances with a choke lever

4. Move the choke lever to position 1 (Fig. 18).

Tip: Ensure that the choke is engaged in position (1).

5. With the unit on the ground, press the throttle lock and

actuate the throttle. Hold down the throttle. Pull the

starter rope 3 x in a controlled and continuous

movement (Fig. 19).

6. Move the choke lever to position 2 (Fig. 18).

7. To start the engine, pull the starter rope in a controlled

and continuous movement 1–5 times (Fig. 19).

8. Press on the throttle to warm up the engine

for 15–30 seconds.

Note: At lower temperatures the engine may require longer

to warm up and reach maximum speed.

Note: The unit has warmed up adequately when the engine

accelerates without faltering.

9. When the engine has warmed up, move the choke lever

to position 3 (Fig. 18). The unit is now ready to use.

If... the engine falters, move the choke lever to position 2

(Fig. 18) and leave the engine to warm up longer.

If…The engine does not start, repeat steps 3–7.

If... It is not necessary to use the choke to start a hot engine.

Move the switch to the ON [I] position and the choke

lever to position 2.

If... Move the choke lever to position 3 if the engine floods

when attempting to start it. Press the throttle.

Pull forcefully on the starter rope.

The engine must start after 3 (three) to 8 (eight) attempts.

On appliances without a choke lever

1. Pull the starter rope in controlled and continuous

movement, unil the engine starts (Fig. 19).

Note: During the starting process do not actuate the throttle.

2. After starting the engine, wait 10–15 seconds before

you actuate the throttle.

If… The engine fails to start repeat the procedure.

Stopp the engine

1. Take your hand off the throttle (Fig. 17). Leave the idling

engine to cool down.

2. Move the switch (depending on model) to the OFF [0]

position and hold (depending on model) until the engine

is off (Fig. 17).

Holding the lawn trimmer

Before using the unit, place yourself in the operating position

(Fig. 20). Check the following:

The user is wearing eye protection and the correct

clothing.

The shoulder belt has been set to the correct height.

The handle bar has been set in such a way that you can

grip it with both hands without having to stretch out your

arms.

The unit is below waist height.

Hold the cutting attachment parallel to the ground

so that the vegetation to be cut can easily be reached

without the user having to bend forward.

Setting the length of the trimmer line

(depending on model)

You can release the trim line with the bump knob cutting

attachment without stopping the engine. To release more

line, tap the cutting attachment on the ground (Fig. 21)

while running the lawn trimmer at a higher speed.

Note: The trim line should always have the max. length.

The shorter the trim line becomes, the more difficult

it is to release.

Each time the head is bumped, approx. 25 mm of cutting line

are released. A blade in the cutting attachment guard cuts

the line back to the correct length if too much line is released.

It is best to bounce the bump head on bare ground or hard

earth. If you attempt to release the trim line in tall grass,

the engine may stall. Always keep the trim line fully extended.

The shorter the trim line is, the more difficult it is to release.

Note: Do not run the bump head along the ground.

The line may break by:

becoming entangled with foreign objects

normal material fatigue

attempting to cut thick-stalked weeds

striking walls, garden fences, etc.

Page 22

22

Operating manual

Tips for best trim results

Keep the cutting attachment parallel to the ground.

Use only the tip of the line for cutting, especially along

walls. If more than the tip is used for cutting, the cutting

capacity is reduced and the engine may overload.

Cut grass which is taller than 20 cm from the top down

in small stages to prevent premature wear of the line and

engine resistance.

If possible, cut from left to right. Cutting to the right

improves the cutting capacity of the unit.

Grass clippings are then ejected by the user.

Slowly move the lawn trimmer at the required height

in and out of the cutting area. Walk either forwards

and backwards or from side to side.

Better results are achieved by cutting shorter pieces.

Cut dry grass and weeds only.

The service life of the cutting line depends on the following:

Follow the previous cutting tips;

for the vegetation which is to be cut;

where it is cut.

For example, a line wears out more quickly if it is cutting

against a house wall than around a tree.

Decorative cutting

You will receive a decorative cut if you cut all vegetation

around trees, posts, fences, etc.

Rotate the whole unit until you are holding the cutting

attachment at an angle of 30° to the ground. (Fig. 22).

Working with the cutting blade

(depending on model)

Before operating the unit, please place it in the operating

position (Fig. 20). See “Holding the lawn trimmer”.

Tips for working with the cutting blade:

Cut rhythmically.

Stand firmly but comfortably on the ground.

Before you start cutting, set the unit to full speed.

At full speed the blade has maximum cutting force and

will therefore not jam so easily, stick or cause blade

impacts which may result in serious injury to the user

or other persons.

When cutting, move the upper part of your body from

right to left.

Always release the throttle and reduce the engine

to no load when you are not cutting.

Rotate the unit in the same direction in which the blade

is cutting. This promotes cutting.

Move one or two steps to the next trimming area after

swinging back the unit and stand firmly again.

The blade features a second cutting side which can

be used by removing the blade, turning it round and

reinstalling it.

Follow these instructions to prevent vegetation from

wrapping itself around the blade:

Cut at full speed.

Swing from right to left into the vegetation which

is to be cut (Fig. 23).

When swinging back, avoid vegetation which has just

been cut.

Maintenance and repair

Caution: Before performing any work on the unit:

– Switch off the engine.

– Wait until all moving parts have come to standstill;

the engine must have cooled down.

– Remove spark-plug terminal from the engine to prevent

the engine from starting unintentionally.

Have all repairs carried out by a repair shop only.

At the end of the season have the unit inspected and

serviced by a specialist company.

Installing the cutting line (depending on model)

This section deals with both the installation

of the Split-Line™ and the simple standard line.

Always use a replacement cutting line with a diameter

of 2,41 mm. If using a cutting line which has a length other

than the one indicated, the engine may overheat or misfire.

There are two methods of replacing the cutting line:

Wind the new line onto the inner coil.

Install an inner coil with a prewound line.

Wind the line onto the existing inner coil

1. Hold the outer spool with one hand and unscrew

the bump head clockwise with the other hand (Fig. 24).

Check that the bolt inside the bump knob can move

freely. Replace a damaged bump knob.

2. Remove the inner coil from the outer coil. (Fig. 24).

3. Take the spring out of the inner coil (Fig. 24).

4. Clean the inner coil, the spring, the shaft and the inner

surface of the outer coil with a clean cloth (Fig. 25).

5. Check the teeth on the inner and outer coils for wear

(Fig. 26). If required, remove burrs or replace the coils.

Note: The Split-Line™ (double lines) can be used on a coil

with slot-type holes only. Single line can be used on both

coil types. Use Figure 27 to identify your coil type.

Note: Always install the correct trim line length in the unit.

The line may not be released correctly if it is too long.

Page 23

23

Maintenance and repair

Installing the single line

To install the Split-Line™, please read Point 8

6. Take approx. 7.3 metres of new trim line and fold in half.

Feed each end of the line through each of the two holes

in the coil (Fig. 28). Pull the line through the coil until

the loop is as small as possible.

7. Wind the lines onto the coil in tight, even layers (Fig. 29).

Wind the line in the direction indicated on the coil.

Place your index finger between the two lines to prevent

them from overlapping. Do not overlap the ends

of the line. In addition to step 11.

Split-Line™

8. Take approx. 3.65 metres of new trim line.

Feed one end of the line through one of the two holes

in the coil (Fig. 30). Pull the line through the coil until there

is only approx. 10 cm left.

9. Feed the end of the line into the open hole in the coil

and pull the line tight until the loop is as small as possible

(Fig. 30).

10. Before winding the line, divide a length of approx. 15 cm.

11. Wind the line in tight, even layers in the direction

indicated on the coil.

Note: If the line is not wound in the direction indicated

on the coil, the cutting attachment will not run correctly.

12. Feed the ends of the line into the two retaining slots

(Fig. 31).

13. Feed the ends of the line through the eyes in the coil

housing and place the coil with spring in the coil housing

(Fig. 24) Press the coil and coil housing together.

Hold coil and coil housing and simultaneously grip

the ends of the line and pull firmly to detach the line

from the retaining slots in the coil.

Note: The spring must be installed on the coil before

the cutting attachment is reinstalled.

14. Hold the spool in place and install the bump head

by rotating it anti-clockwise. Tighten firmly.

Installing a coil with prewound line

1. Hold the outer spool with one hand and unscrew

the bump head clockwise with the other hand (Fig. 24).

Check that the bolt inside the bump knob can move

freely. Replace a damaged bump knob.

2. Remove the old inner coil from the outer coil (Fig. 24).

3. Take the spring out of the inner coil (Fig. 24).

4. Clean the inner coil, the spring, the shaft and the inner

surface of the outer coil with a clean cloth.

5. Insert the spring into the new inner coil.

Note: The spring must be installed on the inner coil before

the line coil is reinstalled.

6. Feed the ends of the line into the eyes in the outer

coil (Fig. 32).

7. Insert the new inner coil into the outer coil (Fig. 32).

Then press to connect both coils. Hold the inner and

outer coils, grip the ends of the line and pull firmly

to release the line from both retaining slots in the coil.

8. Hold the inner spool in place and firmly tighten the bump

head again by rotating it anti-clockwise.

Cleaning the air filter

After ten operating hours clean and lubricate the air filter.

It is important to service these components properly.

If the air filter is not cleaned and serviced, any warranty

will be deemed null and void.

1. Open air filter cover: Press retention plate (3) and open

cover (1) (Fig. 33).

2. Remove the air filter (2) (Fig. 33).

3. Wash the filter with detergent and water (Fig. 34).

Flush out the filter thoroughly, leave to drip and

dry completely.

4. Use adequately clean oil (SAE 30) to lubricate the filter

easily (Fig. 35).

5. Press on the filter to distribute the oil and remove excess

oil (Fig. 36).

6. Install filter.

7. Close air filter cover, ensuring that it locks in place.

Note: If the unit is used without the air filter, the warranty

will be voided.

Adjust carburettor

The idle speed can be set with the screw (Fig. 37).

Have this setting carried out by a specialist company only.

Check/replace spark plug

Use a Champion RDJ7J spark plug (or an equivalent

spark plug). The correct electrode gap is 0,63 mm.

Every 50 operating hours take out the spark plug and check

its condition.

1. Stop the engine and leave it to cool down.

2. Remove spark-plug terminal.

3. Remove dirt from around the spark plug.

4. Unscrew spark plug to the left with a spark plug wrench.

5. Check/set the electrode gap 0,63 mm (Fig. 38).

Note: Replace a damaged, sooted or dirty spark plug.

6. Screw in spark plug and tighten to a torque

of 12.3–13.5 Nm. Do not tighten too tightly.

Cleaning

Use a small brush for cleaning the outside of the unit.

Do not use abrasive detergents. Household cleaners which

contain aromatic oils such as pine oil or lemon as well as

solvents such as kerosene may damage the plastic housing

and handle. Wipe damp areas with a soft cloth.

Storage

Never store the unit with fuel in the tank or where fumes

are within reach of a spark or naked flame.

Before storing the unit, leave the engine to cool down.

Store the unit locked away or high up to prevent

unauthorised use and damage. Keep the unit away from

children.

Page 24

24

Maintenance and repair

Long-term storage

If the unit is to be stored for a prolonged period, proceed

as follows:

1. Drain all the fuel out of the tank and pour into a container

with the same two-stroke mixture. Do not use fuel which

has been stored for longer than 60 days.

2. Start the engine and leave running until it stops.

This ensures that there is no fuel left in the carburettor.

3. Leave the engine to cool down. Take out the spark plug

and pour a high-quality engine oil or two-stroke oil into

the cylinder. Slowly pull the starter rope to distribute

the oil. Reinstall the spark plug.

Note: Before starting the lawn trimmer after storage, take out

the spark plug and pour all the oil out of the cylinder.

4. Thoroughly clean the unit and check for loose and

damaged parts. Repair or replace damaged parts and

tighten loose screws, nuts and bolts. The unit can now

be stored.

5. Store the unit locked away or high up to prevent

unauthorised use and damage. Keep the unit away

from children.

Transportation

Before transporting the unit, leave it to cool down.

Empty the fuel tank before transporting the unit.

Filler cap must be closed tightly.

Secure the unit to prevent it from shifting during

transportation.

Warranty

The warranty regulations issued by our company or the

importer are valid in all countries. We shall repair any faults

on your unit free of charge in accordance with the warranty,

provided the fault was due to defective materials or manufacturing. If claiming under the warranty, please contact your

seller or your nearest branch.

Troubleshooting

Engine does not start

Cause Procedure

Ignition switch set to OFF Set switch to ON.

Fuel tank empty Fill fuel tank.

Intake pump not depressed adequately

Slowly and fully depress the intake pump 10 times

Engine flooded On appliances with a choke lever:

Implement the starting process with the choke lever

in the operating position.

On appliances without a choke lever:

Press the throttle and pull the starter cable.

Old or incorrectly mixed fuel Empty the tank/fill with fresh fuel mixture.

Dirty spark plug Replace or clean spark plug.

Engine does not run constanly at no load

Cause Procedure

Air filter blocked Clean or replace air filter.

Old or incorrectly mixed fuel Empty the tank/fill with fresh fuel mixture.

Carburettor incorrectly adjusted Have carburettor adjusted by customer service personnel.

Engine does not accelerate

Cause Procedure

Old or incorrectly mixed fuel Empty the tank/fill with fresh fuel mixture.

Carburettor incorrectly adjusted Have carburettor adjusted by customer service personnel.

Page 25

25

Troubleshooting

If you have any further questions, please contact your authorised dealer on site.

All information, diagrams and specifications in these operating instructions are based on the latest product information

at the time of going to press. We reserve the right to make changes without prior notice.

Engine has no power or stops during cutting

Cause Procedure

Cutting head entangled with grass Stop the engine and clean the cutting attachment.

Dirty air filter Clean or replace air filter.

Old or incorrectly mixed fuel Empty the tank/fill with fresh fuel mixture.

Carburettor incorrectly adjusted Have carburettor adjusted by customer service personnel.

Cutting head does release line

Cause Procedure

Cutting head entangled with grass Stop the engine and clean the cutting attachment.

No line in the cutting head Wind up new line.

Coil jammed Replace coil.

Cutting head dirty Clean coil and coil housing.

Line fused together Pull apart, take out the fused part and wind up the line

again.

Line twisted when wound up Pull apart and wind up the line again.

Not enough line released Tap the bump head and pull out the line until 10 cm of line

is outside the cutting attachment.

Loading...

Loading...