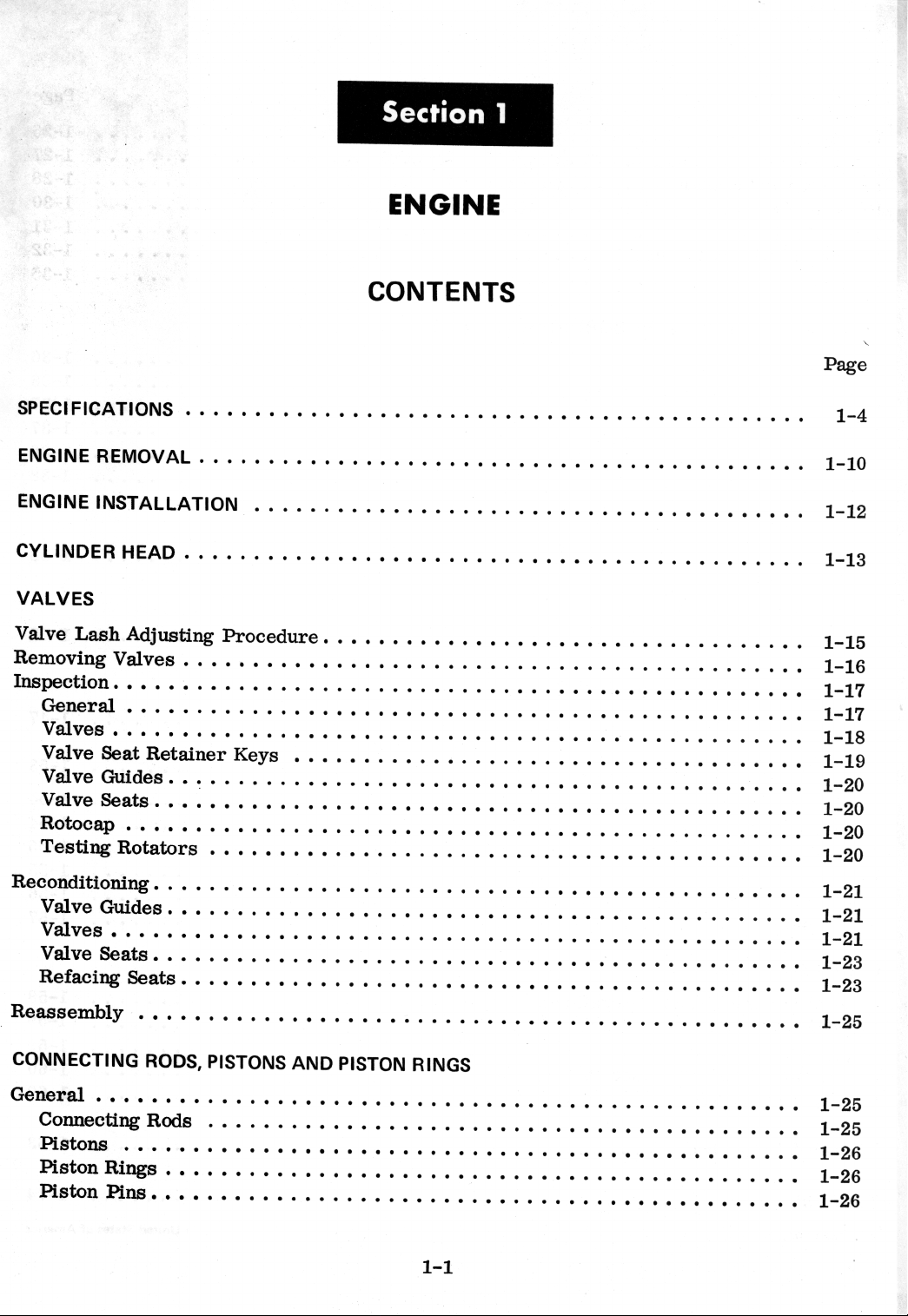

Page 1

Page 2

Page 3

Page 4

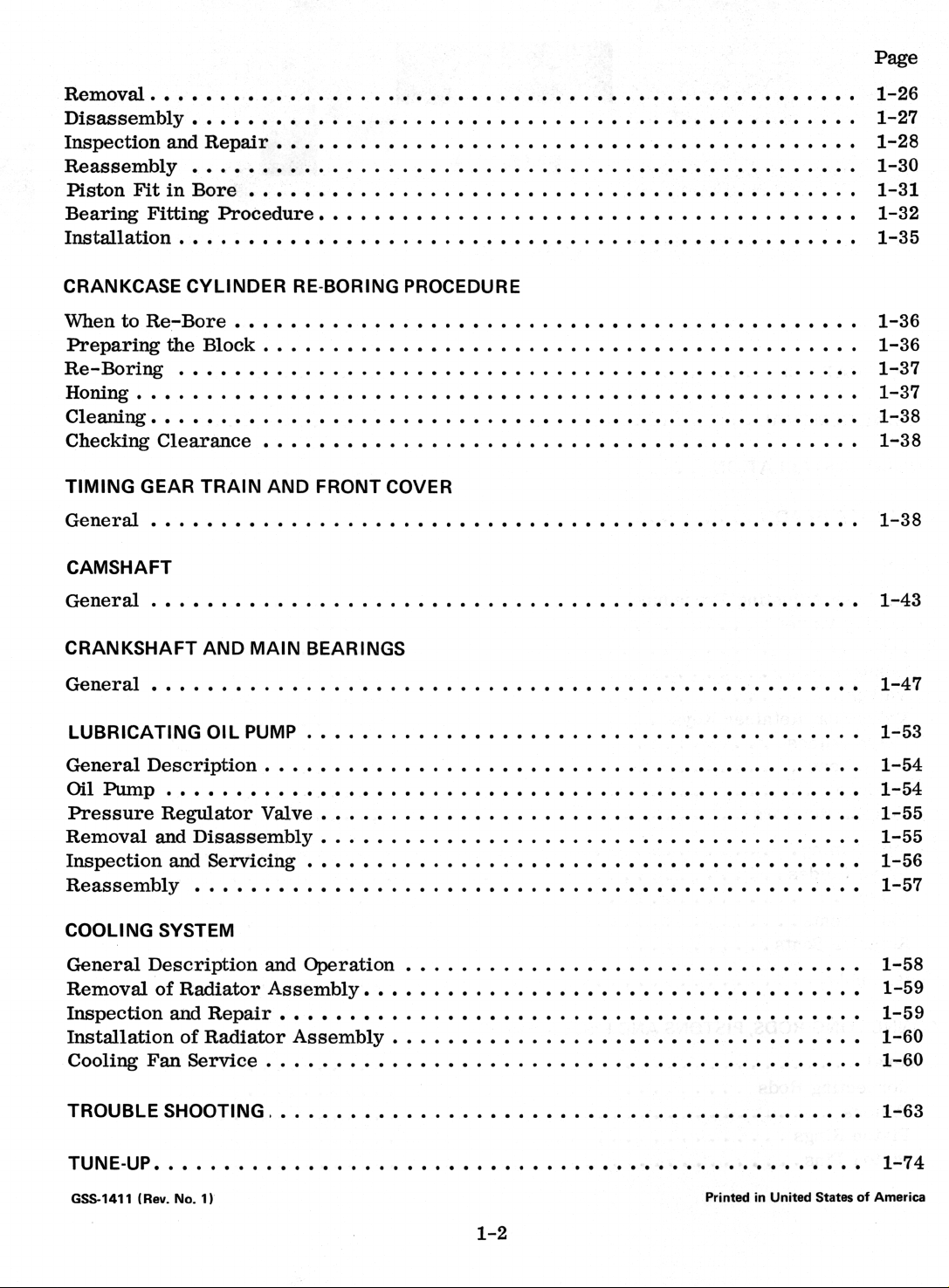

FICA TIONS

General

Model C-60

Numberofcylinders 4

Bore and stroke -inches. 2-5/8 x 2-3/4Displacement-cubic

inches 59.5

Engine rpm (governed) Eng. Sere No. U312389 Eng. Sere No. U312390

and below and above

Low idle.:t. 25 475 475

Highidle.:t.25 2000 2080

Ratedload.:t.l0 1800 1900

Compression ratio. 6.5-1

Compression pressure at cranking speed -psi. 120

Firing order. 1-3-4-2

Ignition timing

High idle 16oBTDC

.375rpmorbelow mc

Distributor point gap -inch. 020

Sparkpluggap-inch 023

Cylinder bore -inches. 2.625 -2.627

Camshaft bearing bore diameters

Front -inches. Center-inches Rear-inch

1.8740 -1.8755

1.7490 -1.7505

.8740 -.8755

Crankshaft and Main Bearings

Crankshaft

Type Counterbalanced

Number of main journals. 3

Main journal diameter -inches. 1.623 -1.624

Crankpin diameter -inches. 1.498 -1.499

Main Bearings

Type Tri-metal,precision

Running clearance -inch. 002 -.003

Thrust bearing location. Center

Thrust bearing side clearance -inch. 004 -.008

GSS-1411 (Rev. No.1)

SPECI

Crankcase

Printed in United States of America

1-4

Page 5

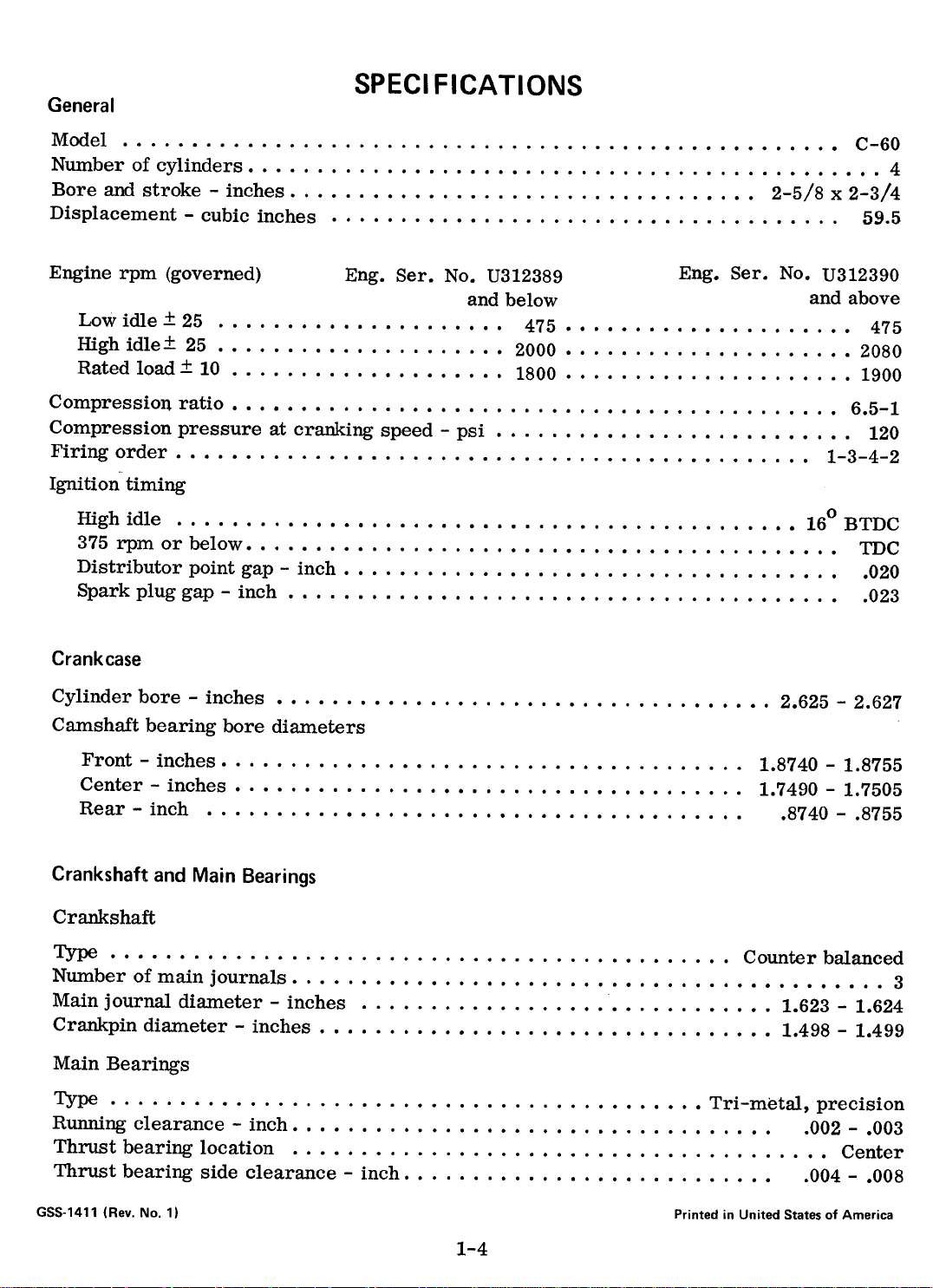

Bearing aD and spread

Front and rear -inches. 1.777 + .020

Center -inches. 1.777 + .002 to .015

Camshaft

Drive. Helical gear

CaIn lobe lift (total) -inch. 232 :t. .002

Diameter at bearing areas

Front-inches Center-inches Rear-inch

1.871- 1.8721.746

-1.747

.872 -.873

Thrust taken by Thrust plate

Number of bearings. 3 (bored in crankcase)

Bearing running clearance

Front and center -inch. Rear-inch

End clearance -inch.

.002 -.0045

.001 -.0035

.003 -.012

Connecting Rods

Type I-Beam

Side clearance -inch. 005 -.012

Bearing running clearance -inch. 002 -.003

Bearing type

Upper end. Bronze bushing

Lower end. Tri-metal, precision

Bearing OD and spread -inches. 1.625 + .025

Piston pin bushing (installed and bored) ill -inch. 6879 -.6882

Pistons

Type Full skirt

Material Grey iron

Overall length -inches. 2.875

Diameter -inches. 2.6230 -2.6234

* Skirt clearance, bottom -inch. 0016 -.0024

(measured at 900 from pin hole)

Number of rings per piston. 3

Piston pin hole bore -inch. 6877 -.6880

*See "Piston Fit in Bore", page 1-31.

1-5

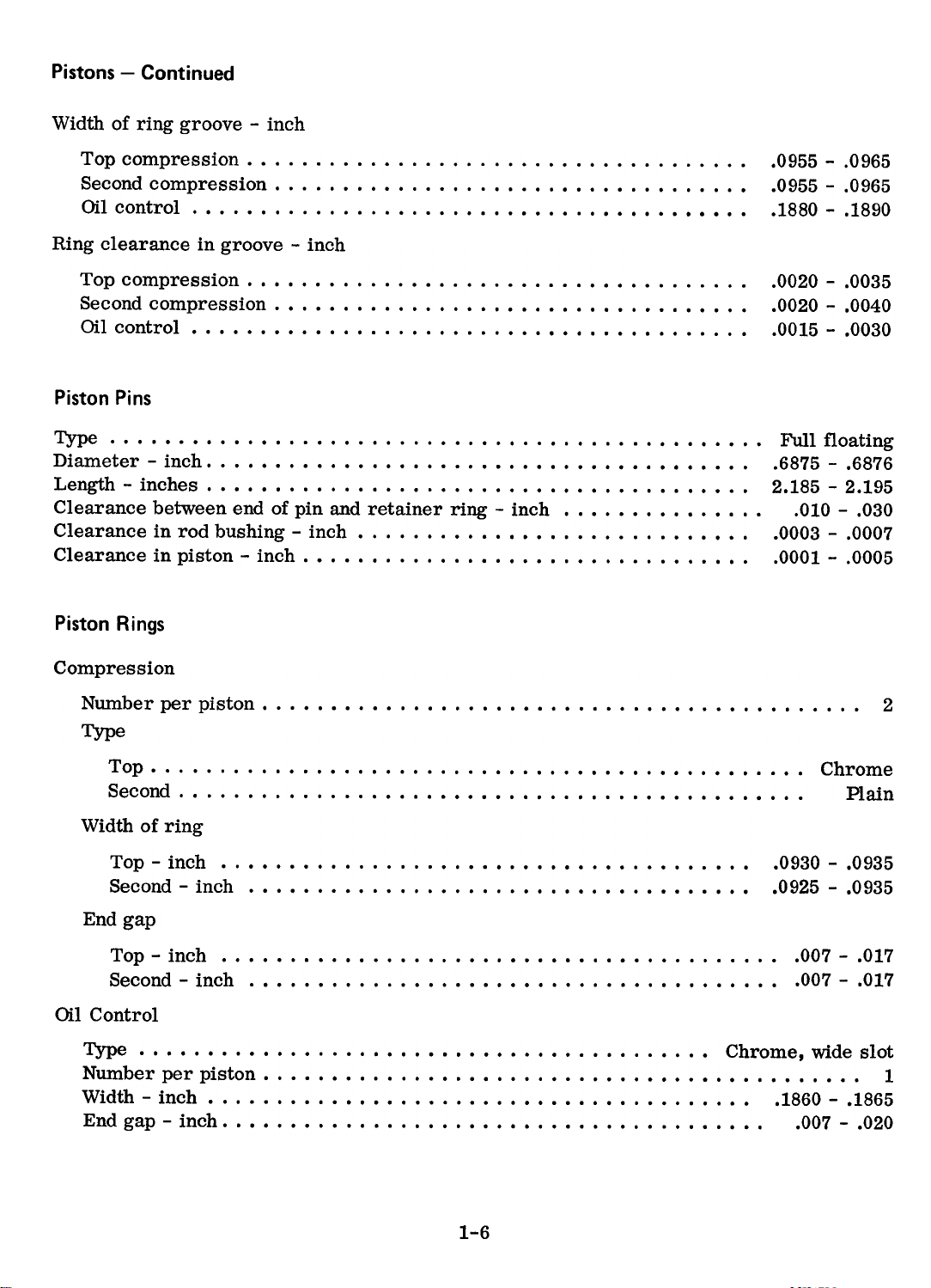

Page 6

Pistons -Continued

Width of ring groove -inch

Topcompression Second compression. Oilcontrol

Ring clearance in groove -inch

Topcompression .

Second compression. Oilcontrol

Piston Pins

Type Diameter -inch. Length -inches. Clearance between end of pin and retainer ring -inch. Clearance in rod bushing -inch. Clearance in piston -inch.

Piston Rings

.0955 -.0965

.0955 -.0965.1880

-.1890

.0020 -.0035

.0020 -.0040

.0015 -.0030

Full floating

.6875 -.6876

2.185 -2.195

.010 -.030

.0003 -.0007

.0001- .0005

Compression

Number per piston. Type

Second..

Chrome

2

Plain

Width of ring

Top -inch. Second -inch.

.0930 -.0935

.0925 -.0935

gap

Top -inch. Second -inch.

.007 -.017

.007 -.017

Oil Control

Type Chrome, wide slotNumber

per piston. 1

Width -inch. 1860 -.1865

End gap -inch. 007 -.020

Top.

End

1-6

Page 7

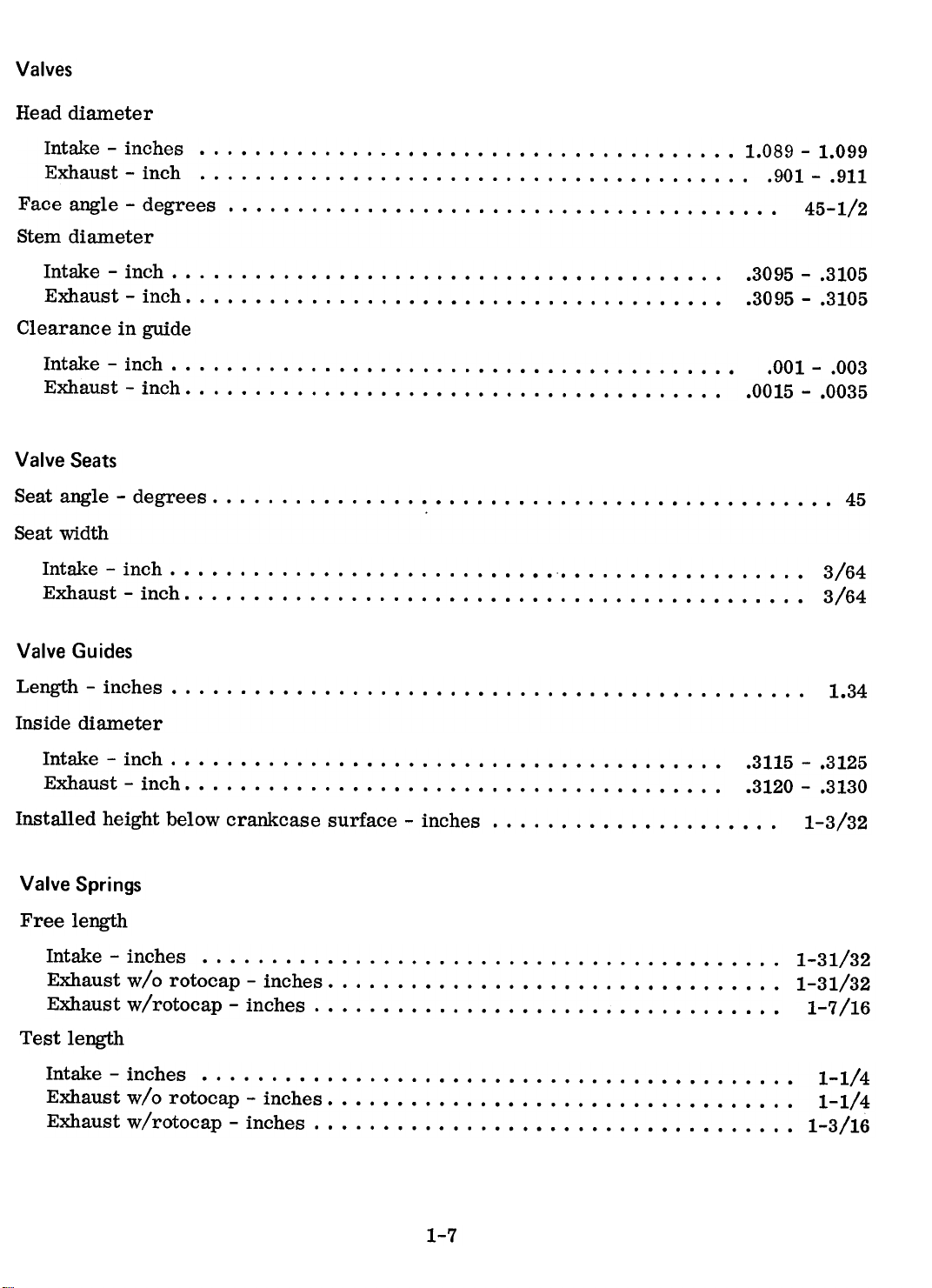

Valves

Head diameter

Intake-inches 1.089-1.099

Exhaust-inch 901-.911

Face angle-degrees 45-1/2

Stem diameter

Intake-inch Exhaust-inch

-.3105.3095

-.3105

in guide

Intake-inch Exhaust-inch

Valve Seats

Seat angle -degrees. 45

Seat width

Intake-inch Exhaust-inch

Valve Guides

Length -inches. Inside diameter

Intake-inch Exhaust -inch.

.001 -.003

.0015 -.0035

3/64

3/64

1.34

.3115 -.3125.3120

-.3130

height below crankcase surface -inches.

Valve Springs

length

Intake-inches Exhaust w /0 rotocap -inches. Exhaust w/rotocap -inches.

Test length

Intake -inches. 1-1/4

Exhaust w /0 rotocap -inches. 1-1/4

Exhaust w/rotocap -inches. 1-3/16

.3095

Clearance

Installed

1-3/32

Free

1-31/321-31/32

1-7

1-7/16

Page 8

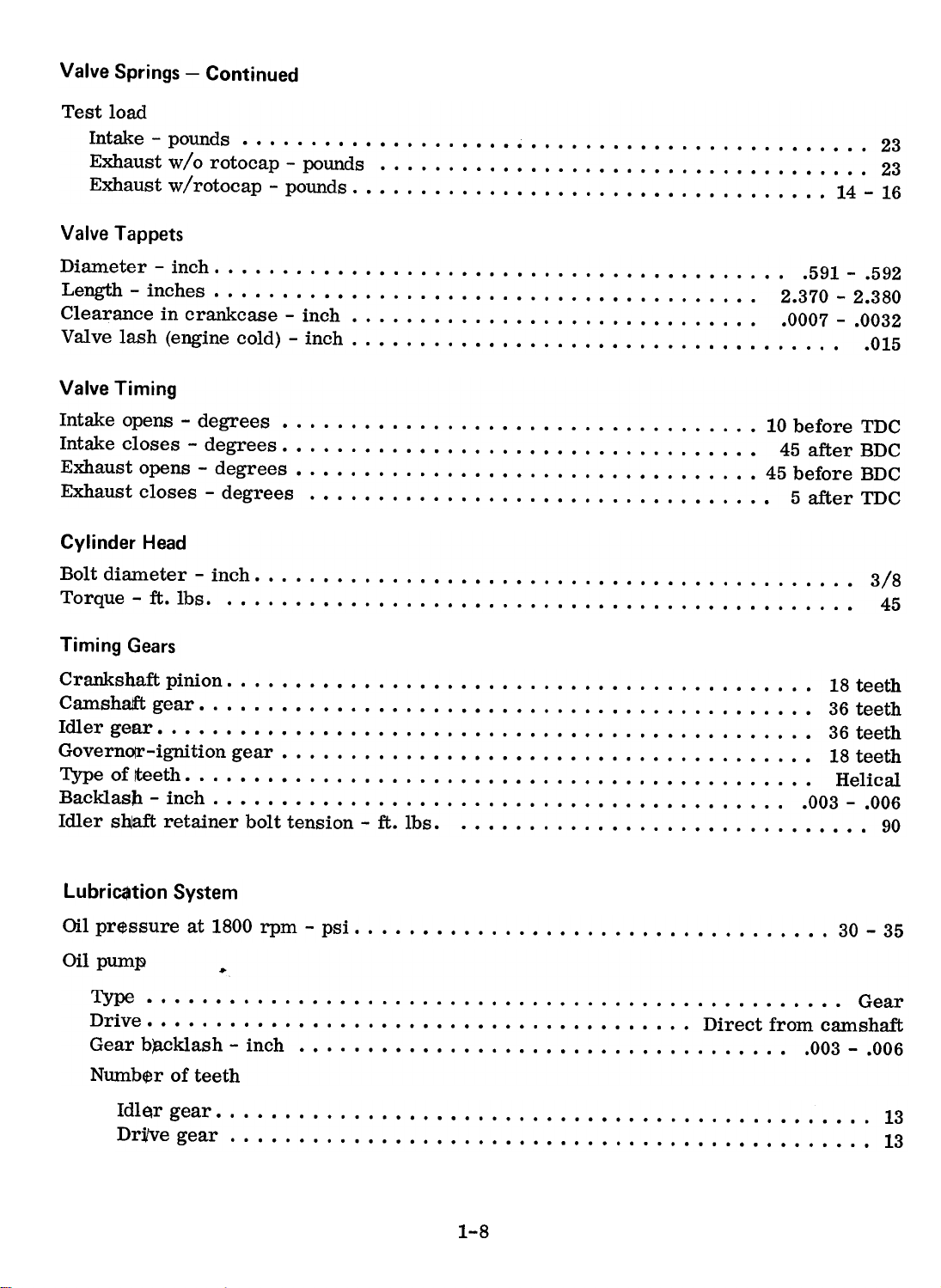

Valve Springs -Continued

Test load

Intake -pounds. 23

Exhaust w /0 rotocap -pounds. 23

Exhaust w/rotocap -pounds. 14 -16

Valve Tappets

Diameter -inch. 591- .592

Length -inches. 2.370 -2.380

Clearance in crankcase -inch. 0007 -.0032

Valve lash (engine cold) -inch. 015

Valve Timing

Intake opens -degrees. 10 before TDC

Intake closes -degrees. 45 after BDC

Exhaust opens -degrees. 45 before BDC

Exhaust closes -degrees. 5 after TDC

Cylinder Head

Boltdiameter-inch 3/8

Torque-ft.lbs. 45

Gears

Crankshaft pinion. 18 teeth

Camshalft gear. 36 teeth

Idler gear. 36 teeth

GovernQr-ignition gear. 18 teeth

Type of teeth. Helical

Backlasb -inch. 003 -.006

Idler shiaft retainer bolt tension -ft. lbs. 90

LubriC$tion System

Oil pressure at 1800 rpm -psi. 30 -35

Oil pump .

Type Gear

Drive. Direct from camshaft

Gear b;acklash -inch. 003 -.006

Timing

1-8

Numb~r of teeth

Idler gear. 13

Drilvegear 13

Page 9

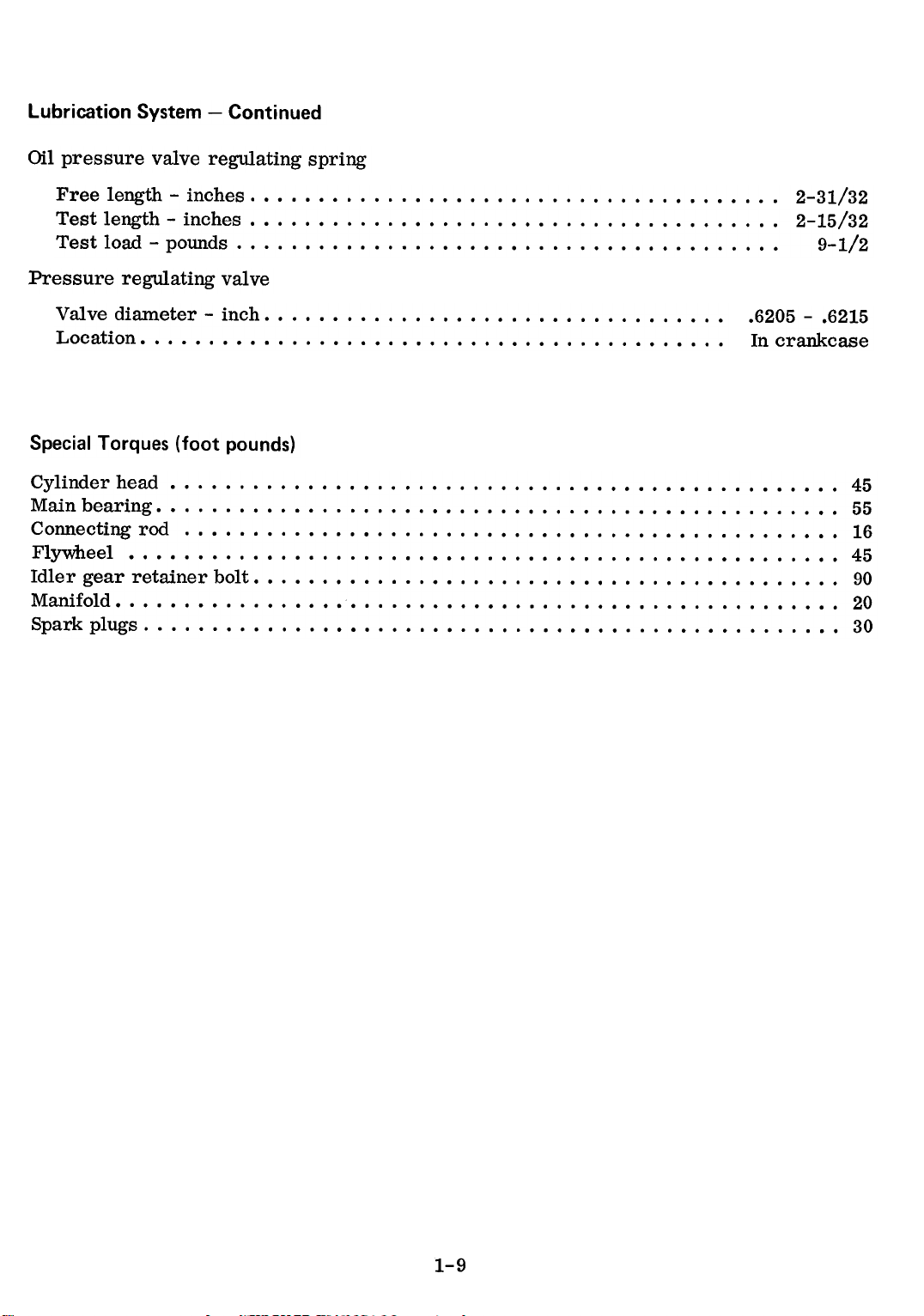

lubrication System -Continued

Oil pressure valve regulating spring

Free length -inches. 2-31/32

Test length -inches. 2-15/32

Testload-pounds 9-1/2

regulating valve

Valve diameter -inch. Location

.6205 -.6215

In crankcase

Special Torques (foot pounds)

Cylinder head 45

Main bearing. 55

Connecting rod 16

Flywheel. 45

Idler gear retainer bolt. 90

Manifold 20

Spark plugs 30

Pressure

1-9

Page 10

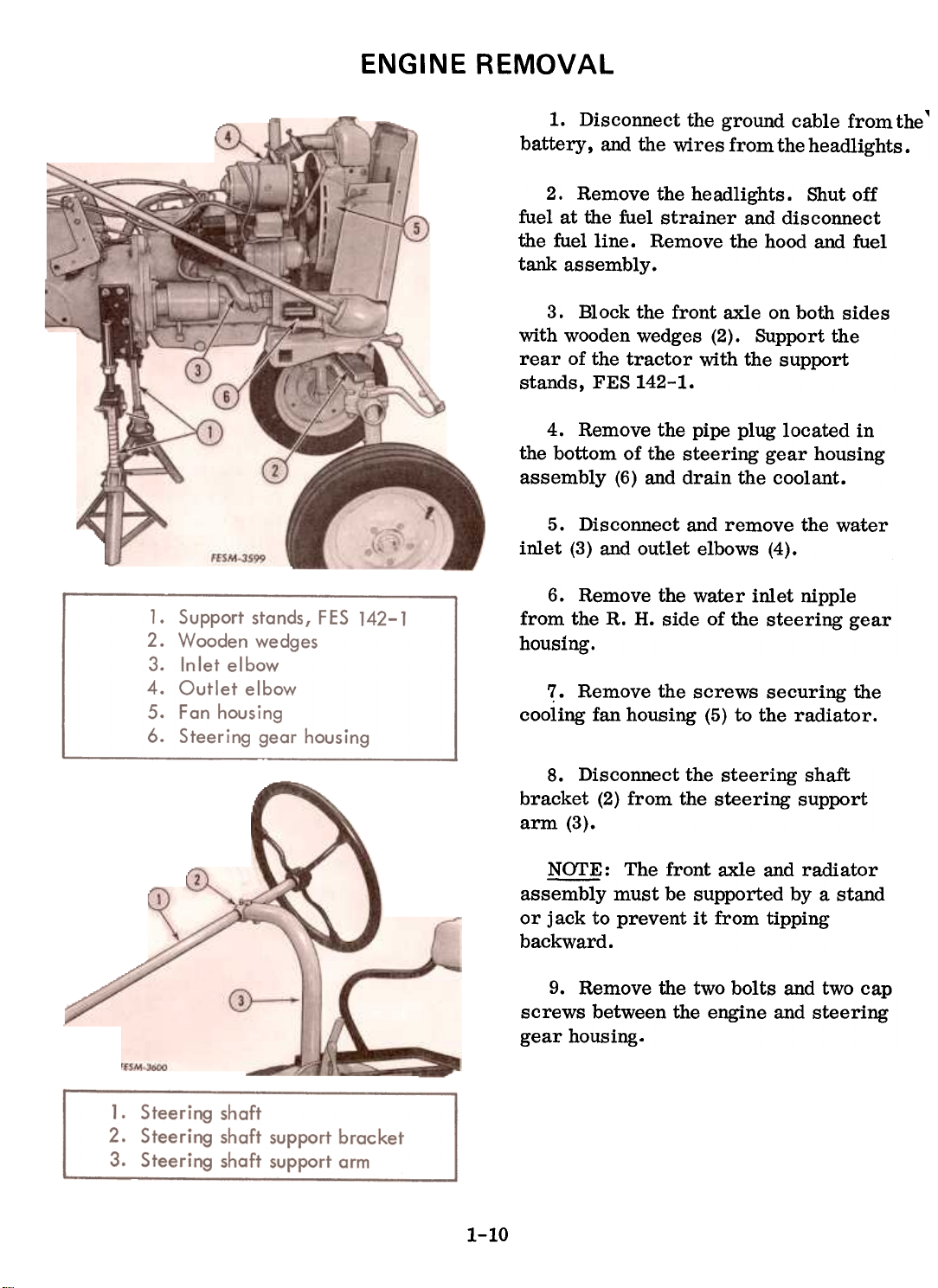

REMOVAL

1. Disconnect the ground cable from the ~

battery, and the wires from the headlights.

2. Remove the headlights. Shut off

fuel at the fuel strainer and disconnect

the fuel line. Remove the hood and fuel

tank assembly.

3. Block the front axle on both sides

with wooden wedges (2). Support the

rear of the tractor with the support

standst FES 142-1.

4. Remove the pipe plug located in

the bottom of the steering gear housing

assembly (6) and drain the coolant.

5. Disconnect and reDlove the vvater

inlet (3) and outlet elbovvs (4).

6. Remove the water inlet nipple

from the R. H. side of the steering gear

housing.

'? Remove the screws securing the

cooling fan housing (5) to the radiator.

8. Disconnect the steering shaft

bracket (2) from the steering support

arm (3).

~: The front axle and radiator

assembly must be supported by a stand

or jack to prevent it from tippingbackward.

9. Remove the two bolts and two cap

screws between the engine and steering

gear housing.

ENGINE

1-10

Page 11

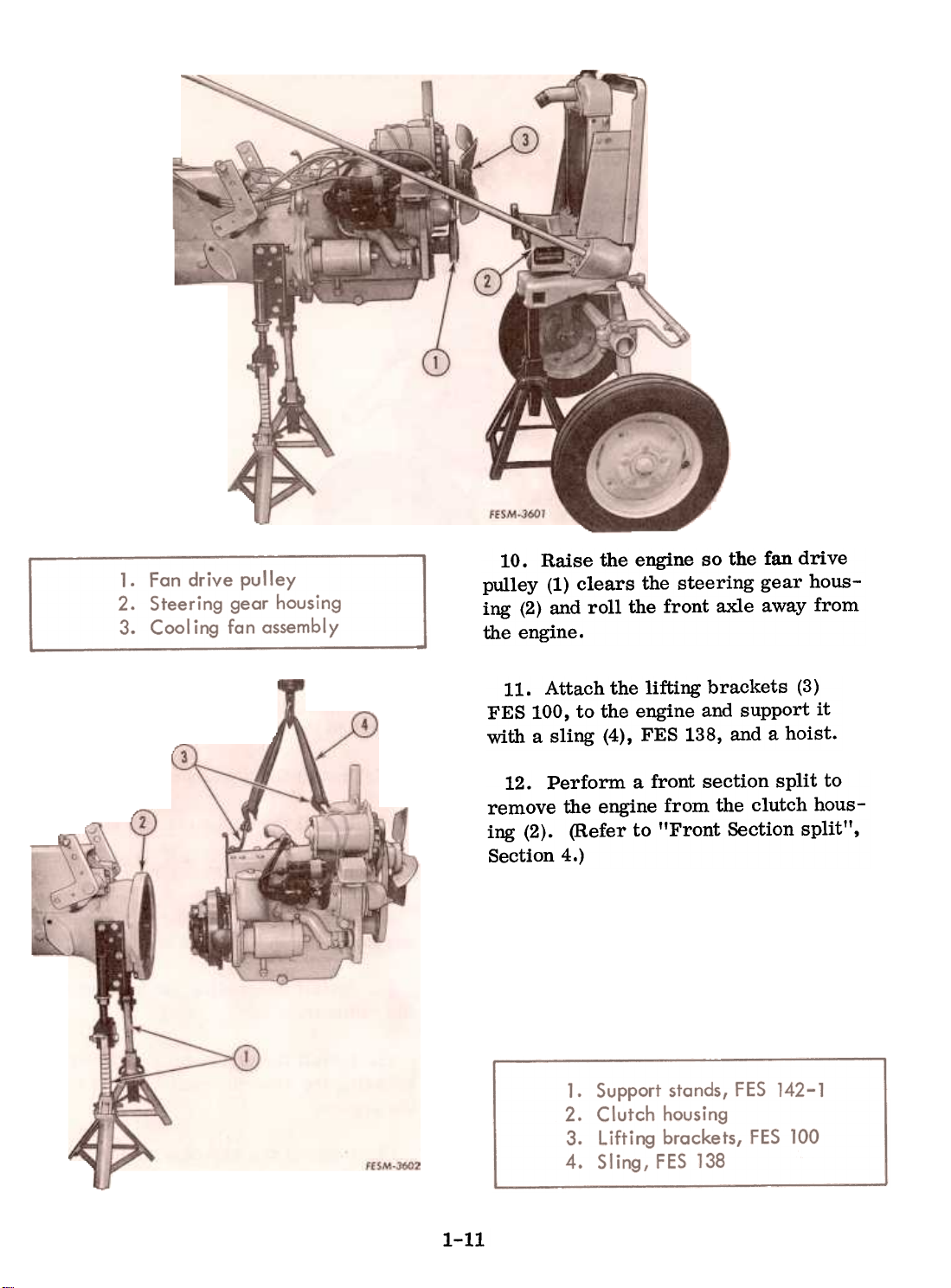

10. Raise the engine so the fan drive

pulley (1) clears the steering gear housing (2) and roll the front axle away from

the engine.

11. Attach the lifting brackets (3)

FES 100, to the engine and support it

with a sling (4), FES 138, and a hoist.

12. Perform a front section split to

remove the engine from the clutch hous-

ing (2). (Refer to "Front Section split",

Section 4.)

1-11

Page 12

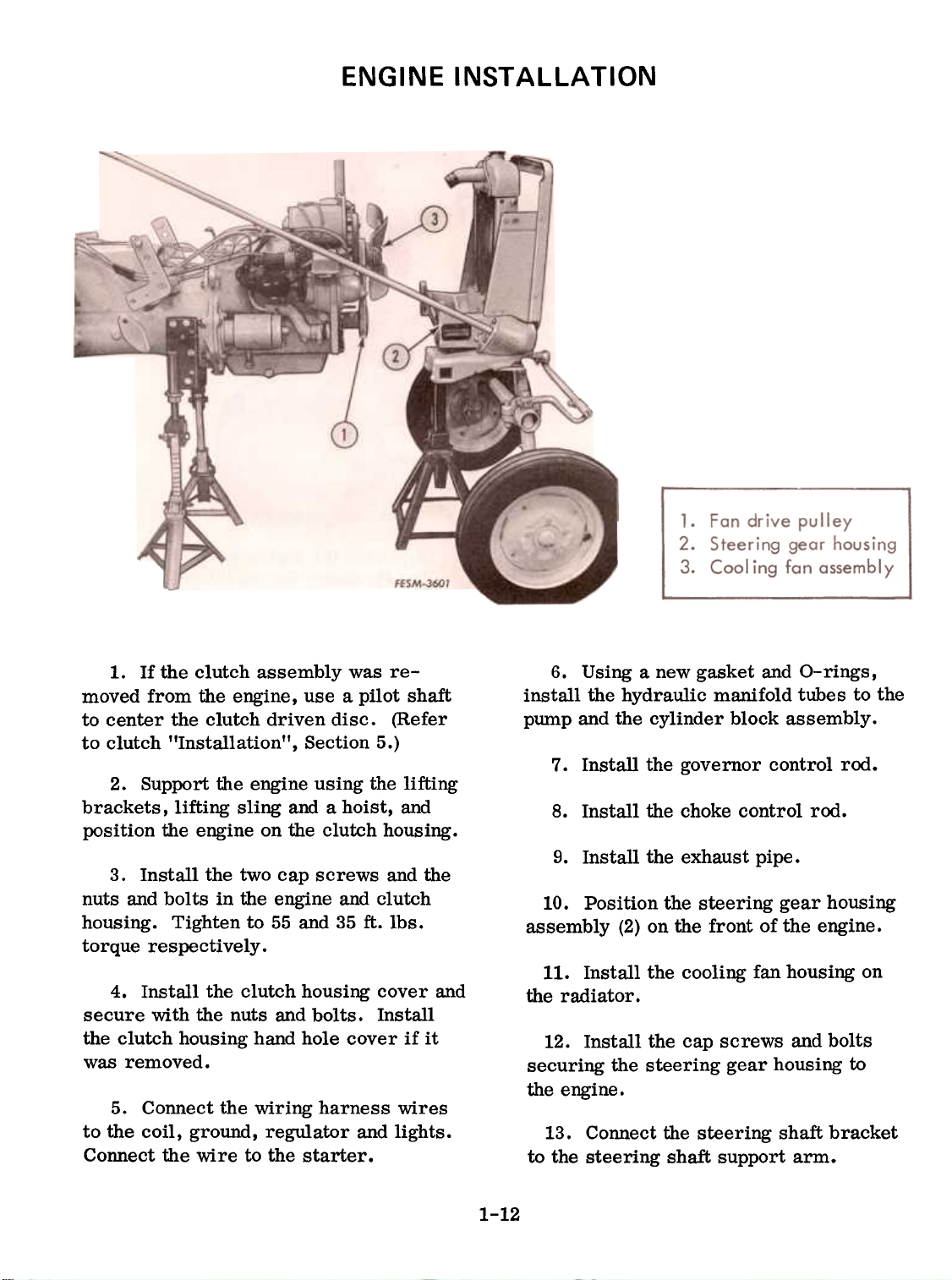

ENGINE INSTALLATION

1. If the clutch assembly was removed from the engine, use a pilot shaft

to center the clutch driven disc. (Refer

to clutch "Installation", Section 5.)

2. Support the engine using the lifting

brackets, lifting sling and a hoist, and

position the engine on the clutch housing.

3. Install the two cap screws and the

nuts and bolts in the engine and clutch

housing. Tighten to 55 and 35 ft. lbs.

torque respectively.

4. Install the clutch housing cover and

secure with the nuts and bolts. Install

the clutch housing hand hole cover if it

was removed.

5. Connect the wiring harness wires

to the coil, ground, regulator and lights.

Connect the wire to the starter.

6. Using a new gasket and O-rings,

install the hydraulic manifold tubes to the

pUInp and the cylinder block assembly.

7. Install the governor control rod.

8. Install the choke control rod.

9. Install the exhaust pipe.

10. Position the steering gear housing

assembly (2) on the front of the engine.

11. Install the cooling fan housing on

the radiator.

12. Install the cap screws and bolts

securing the steering gear housing to

the engine.

13. Connect the steering shaft bracket

to the steering shaft support arm.

1-12

Page 13

14. Install the water inlet nipple in the

steering gear housing.

recommended coolant. (Refer to

Operator's Manual.)

15. Install and connect the water inlet

and outlet elbows and hoses.

16. Install the pipe plug in the steering

gear housing and fill the radiator with the

Removal

1. Remove the pipe plug in the bottom

of the steering gear housing and drain

the coolant.

2. Disconnect and remove the head-

lights.

17. Install the hood and fuel tank as-

sembly. Connect the fuel line to the fuelstrainer.

18. Connect the wires to the lights and

the ground wire to the battery.

HEAD

4. Remove the water outlet elbow

and hose.

Remove the spark plugs.

3. Disconnect the fuel line from the

fuel strainer. Remove the hood and fuel

tank from the tractor.

6. Remove the cylinder head capscrews,

and remove the cylinder head

and gasket from the engine.

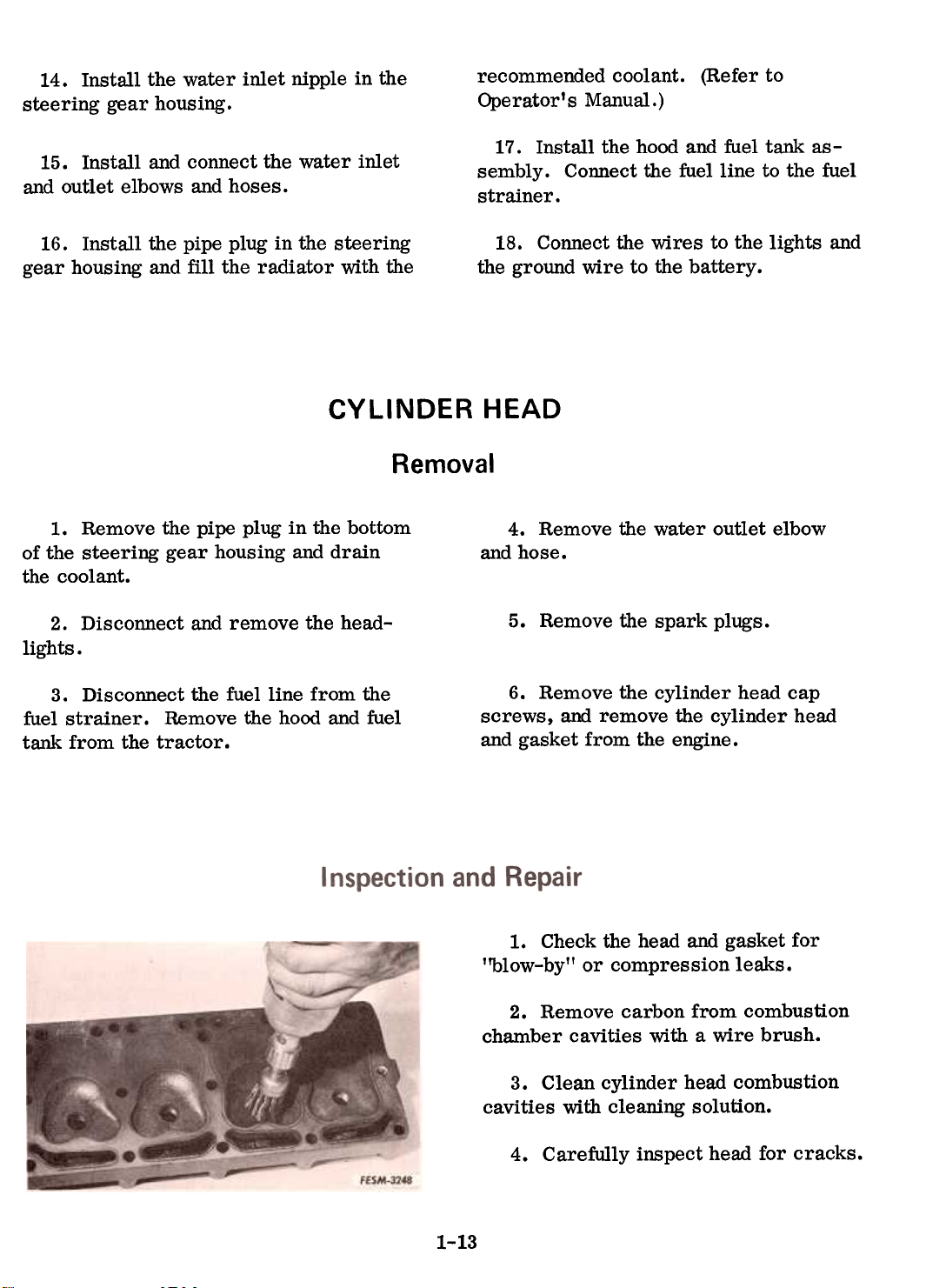

1. Check the head and gasket for

"blow-by" or compression leaks.

2. Remove carbon from combustion

chamber cavities with a wire brush.

3. Clean cylinder head combustion

cavities with cleaning solution.

Carefully inspect head for cracks.

CYLINDER

5.

4.

1-13

Page 14

Installation

5. Use a straight edge and inspect for

warped head, particularly in any area

which shows "blow-by. II

6. Inspect water jacket in head for an

acc~ation of rust or lime depositwhich

would affect circulation of cooling

water and cause hot spots. Clean ifnecessary.

7. Thoroughly clean the gasket surfaceto

insure proper sealing of the new gasket.

Be sure to use a ~ gasket.

1. Using a new gasket, install the cyl-

inder head on the engine.

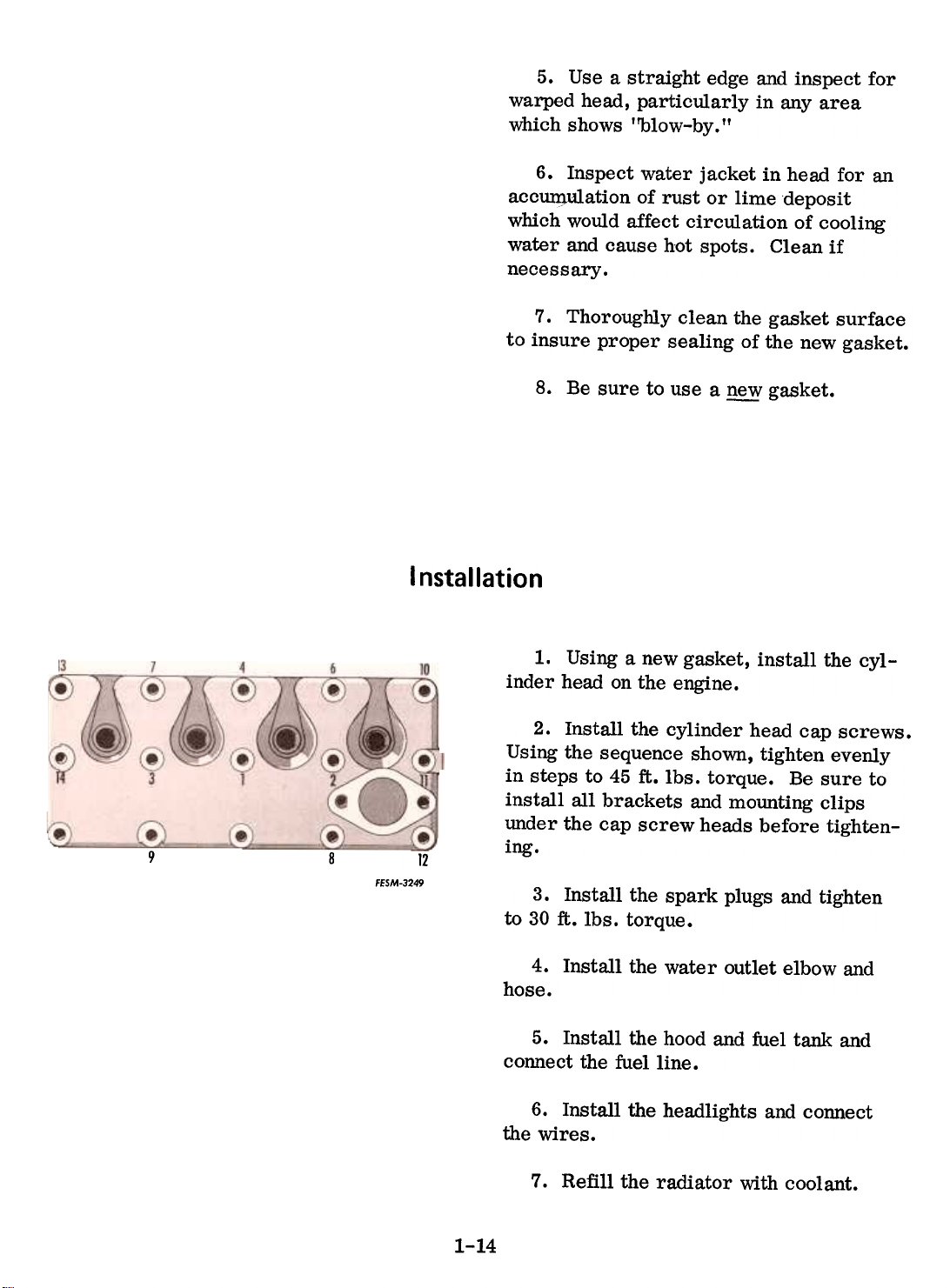

2. Install the cylinder head cap screws.

Using the sequence shown, tighten evenly

in steps to 45 ft. lbs. torque. Be sure to

install all brackets and mounting clips

under the cap screw heads before tighten-

9

8

12

FESM-3249

ing.

3. Install the spark plugs and tighten

to 30 ft. lbs. torque.

4. Install the water outlet elbow andhose.

5. Install the hood and fuel tank and

connect the fuel line.

6. Install the headlights and connectthe

wires.

8.

7.

1-14

Refill the radiator with coolant.

Page 15

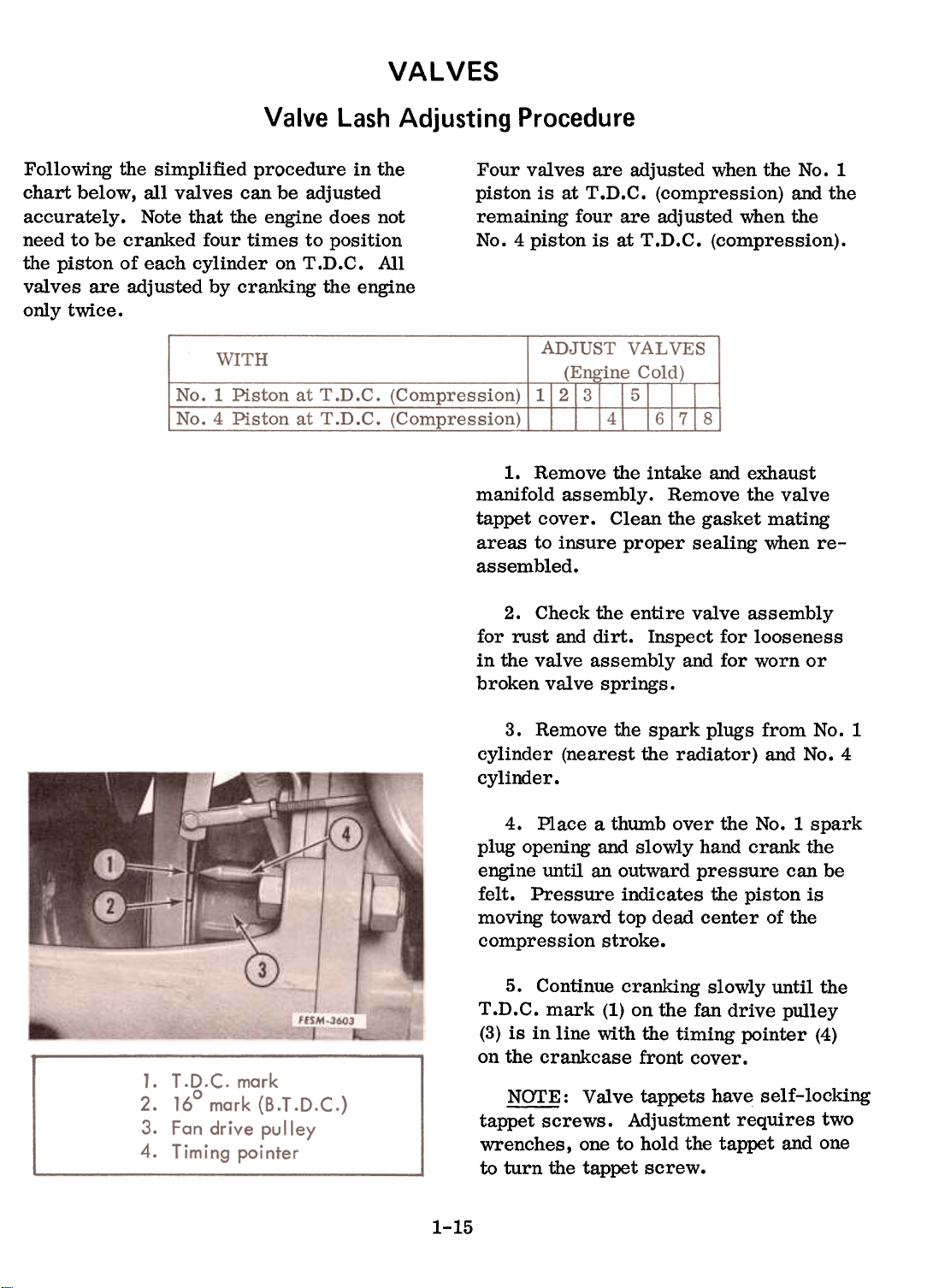

Valve lash Adjusting Procedure

Following the simplified procedure in the

chart below, all valves can be adjusted

accurately. Note that the engine does notneed

to be cranked four times to positionthe

piston of each cylinder on T .D.C. All

valves are adjusted by cranking the engine

only twice.

Four valves are adjusted when the No.1

piston is at T .D.C. (compression) and the

remaining four are adjusted when the

No.4 piston is at T .D.C. (compression).

1. Remove the intake and exhaust

manifold assembly. Remove the valve

tappet cover. Clean the gasket mating

areas to insure proper sealing when re-assembled.

2. Check the entire valve assembly

for rust and dirt. Inspect for looseness

in the valve assembly and for worn or

broken valve springs.

3. Remove the spark plugs from No.1

cylinder (nearest the radiator) and No.4

cylinder.

4. Place a thumb over the No.1 spark

plug opening and slowly hand crank the

engine until an outward pressure can be

felt. Pressure indicates the piston is

moving toward top dead center of the

compression stroke.

5. Continue cranking slowly until the

T .D.C. mark (1) on the fan drive pulley

(3) is in line with the timing pointer (4)

on the crankcase front cover.

~ : Valve tappets have self-locking

tappet screws. Adjustment requires two

wrenches, one to hold the tappet and one

to turn the tappet screw.

VALVES

1-15

Page 16

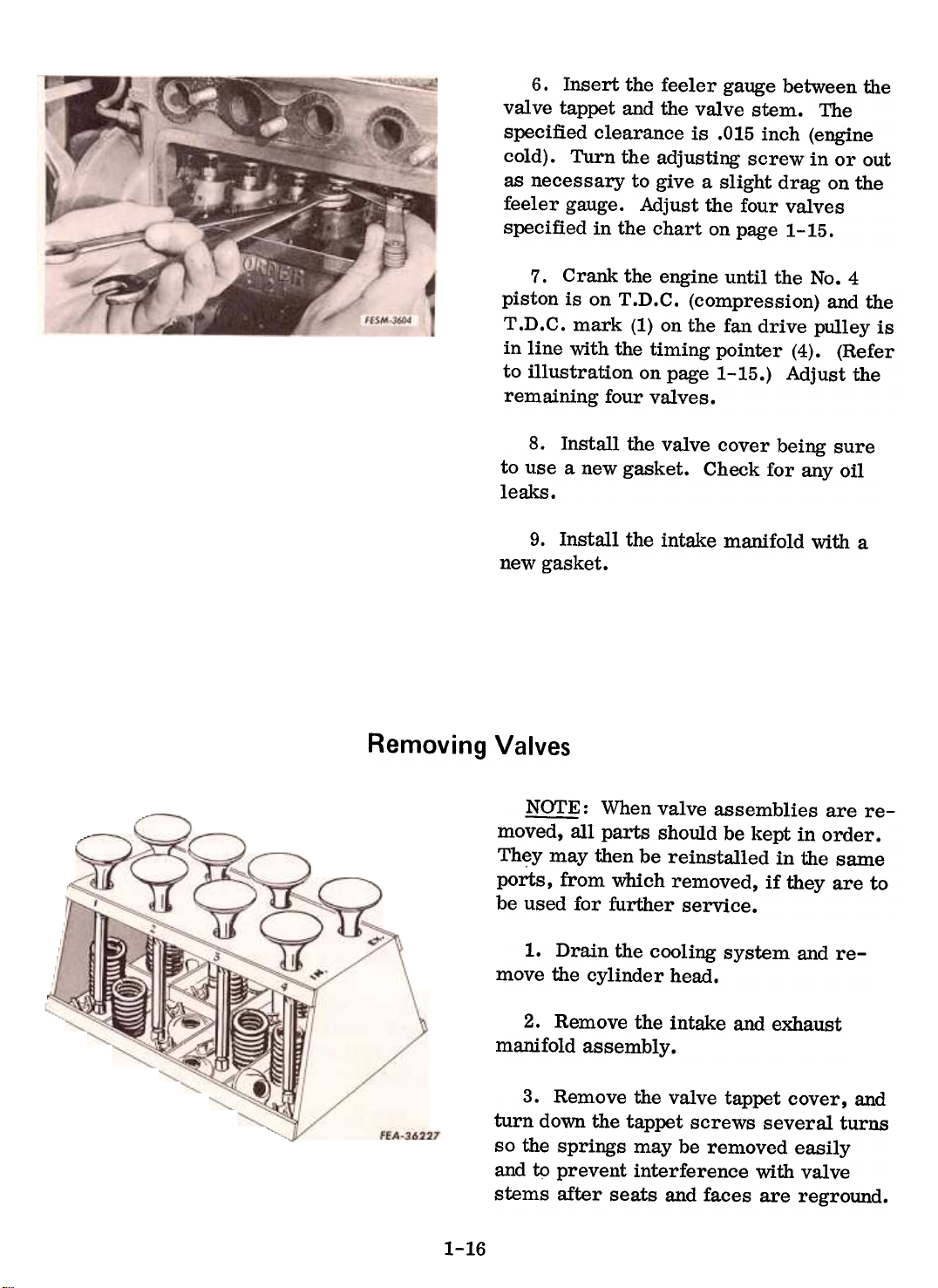

6. Insert the feeler gauge between the

valve tappet and the valve stem. The

specified clearance is .015 inch (engine

cold). Turn the adjusting screw in or out

as necessary to give a slight drag on the

feeler gauge. Adjust the four valves

specified in the chart on page 1-15.

7. Crank the engine until the No.4

piston is on T .D.C. (compression) and the

T .D.C. mark (1) on the fan drive pulley is

in line with the timing pointer (4). (Refer

to illustration on page 1-15.) Adjust the

remaining four valves.

8. Install the valve cover being sure

to use a new gasket. Check for any oilleaks.

9. Install the intake manifold with a

new gasket.

Removing Valves

~: When valve assemblies are re-

moved, all parts should be kept in order.

They may then be reinstalled in the same

ports, from which removed, if they are to

be used for further service.

1. Drain the cooling system and re-

move the cylinder head.

2. Remove the intake and exhaust

manifold assembly.

3. Remove the valve tappet cover, and

turn down the tappet screws several turns

so the springs may be removed easily

and t9 prevent interference with valve

stems after seats and faces are reground.

1-16

Page 17

with a valve spring compressor (2) and

remove the valve spring seat keys (1).

Be careful not to compress the springs

more than necessary as they can be

distorted.

seats and valve springs. Be sure to keep

valves in order so they may be installed

in the same port.

camshaft must be removed.

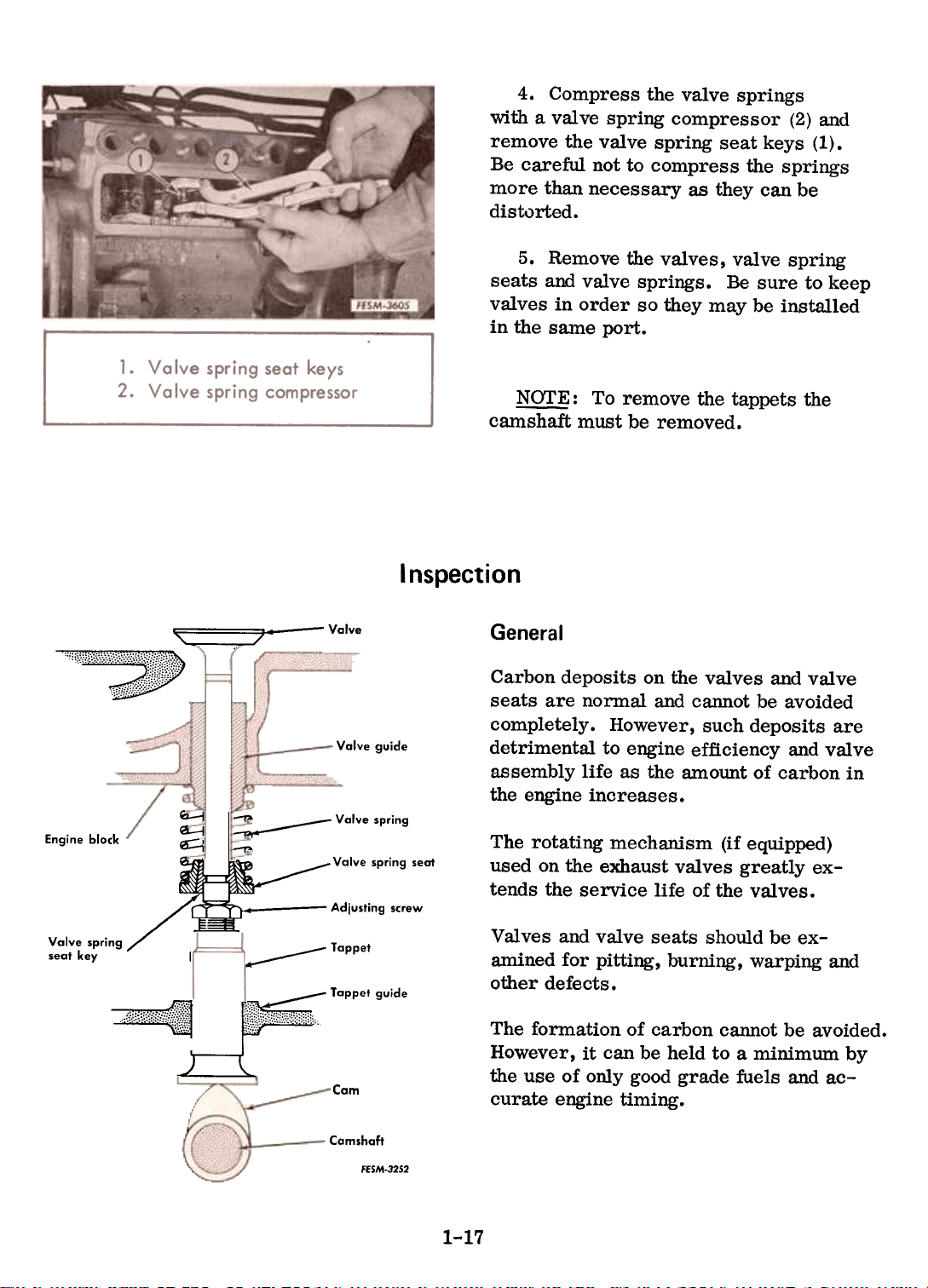

Inspection

4. Compress the valve springs

5. Remove the valves, valve spring

~ : To remove the tappets the

-,~, ~ 7--Valve

':!;i~1ii,\:;~~:::::,',"""."",',':"".

Ql-J ~ Valve spring

Engine block ~ ~

Valve spring

seat key I

..(1.:);;:,;;:[,:'(!,

Valve guide

spring seat

Adjusting screw

Tappet

Tappet guide

Cam

General

Carbon deposits on the valves and valve

seats are normal and cannot be avoided

completely. However, such deposits are

detrimental to engine efficiency and valve

assembly life as the amount of carbon in

the engine increases.

The rotating mechanism (if equipped)

used on the exhaust valves greatly extends the service life of the valves.

Valves and valve seats should be examined for pitting, burning, warping and

other defects.

The formation of carbon cannot be avoided.

However, it can be held to a minimum by

the use of only good grade fuels and ac-

curate engine timing.

.--Valve

1-17

Camshaft

FfSM-32S2

Page 18

Warpage, burning and pitting of valves is

mainly directed against the exhaust valves

which are exposed to the high temperature

flow of exhaust gases. Such defects are

generally caused by valves failing to seat

tightly and evenly, permitting exhaust blowby. This, in turn, can generally be traced

to hard particles of carbon being present

on the slopes of the valve seats. It may,

however, be due to weak springs, insuf-

ficient valve clearance, or warpage and

misali.e;nment of the valve stem or guide.

Warpa~e, chiefly occurs on the valve stem

due to its exposure to heat. Out-of-round

wear occurs when the seat has been pounded

by a valve head which is not in line with its

stem or guide.

Misalignment is a result of wear, warpage,

and distortion. Wear, when accentuated by

insufficient lubrication, will eventually

create sloppy clearances with resultant

misalignment.

cylinder head bolts to the specified footpounds torque and in the sequence recommended. Valve clearances are also affected

in this manner. Thus any abnormal wear,warpage

or distortion affecting a valve

guide will destroy its function as an accurate bearing to maintain the valve head

concentric with its seat, and will prevent

leak-proof seating.

Oil and air sucked past worn intake valve

stems and guides into the combustion

chamber, cause excessive oil consumption,

form excessive carbon, and dilute fuel.

Examine the engine for signs which may

indicate the reason for the need of valve

reconditioning. Dry and rusted valve

springs are an indication that the oil passages to the valve levers may be blocked,

causing wear on the valves and guides, and

resulting in improper valve action. A de-

fective gasket under the valve cover will

permit the entrance of dirt which will

cause undue wear on the valve stems andguides

and damage to the valve springs.

Warpage of the valves, and in known ex-

treme instances, that of the crankcase, can

result from the engine overheating due to a

blocked, dirty or insufficiently filled cool-

ing system.

Most frequE;'!ntly, however, warpage of a

valve stem or a guide is due to uneven temperatures being applied along its length.

The lower part of the guide and stem is

near the combustion heat, and the upper

portions are closer to cylinder head waterpassages.

Valve materials are carefully

chosen to withstand such varying temperatures. However, an engine that is allowed

to operate continually in an overheated con-

dition is definitely open to valve stem and

guide distortion and warpage. Distortion

can also be caused by failure to tighten

Valves

1. Remove all carbon from the valve

head and stem. Valve stems should be

lightly polished with an extremely fine

abrasive cloth sufficiently to remove the

carbon deposits only. Because of the

nature of the valve deposits, solvent cleaning ordinarily will not remove all the deposits from the valves. Wire brushes will

do this job satisfactorily, but only brasswire

brushes should be used since steel

brushes may scratch the surface. Such

scratches are likely to cause localized

stresses in an operating valve and may

eventually result in fatigue fractures of

the valve. For similar reasons the use of

coarse emery paper should be avoided.

1-18

Page 19

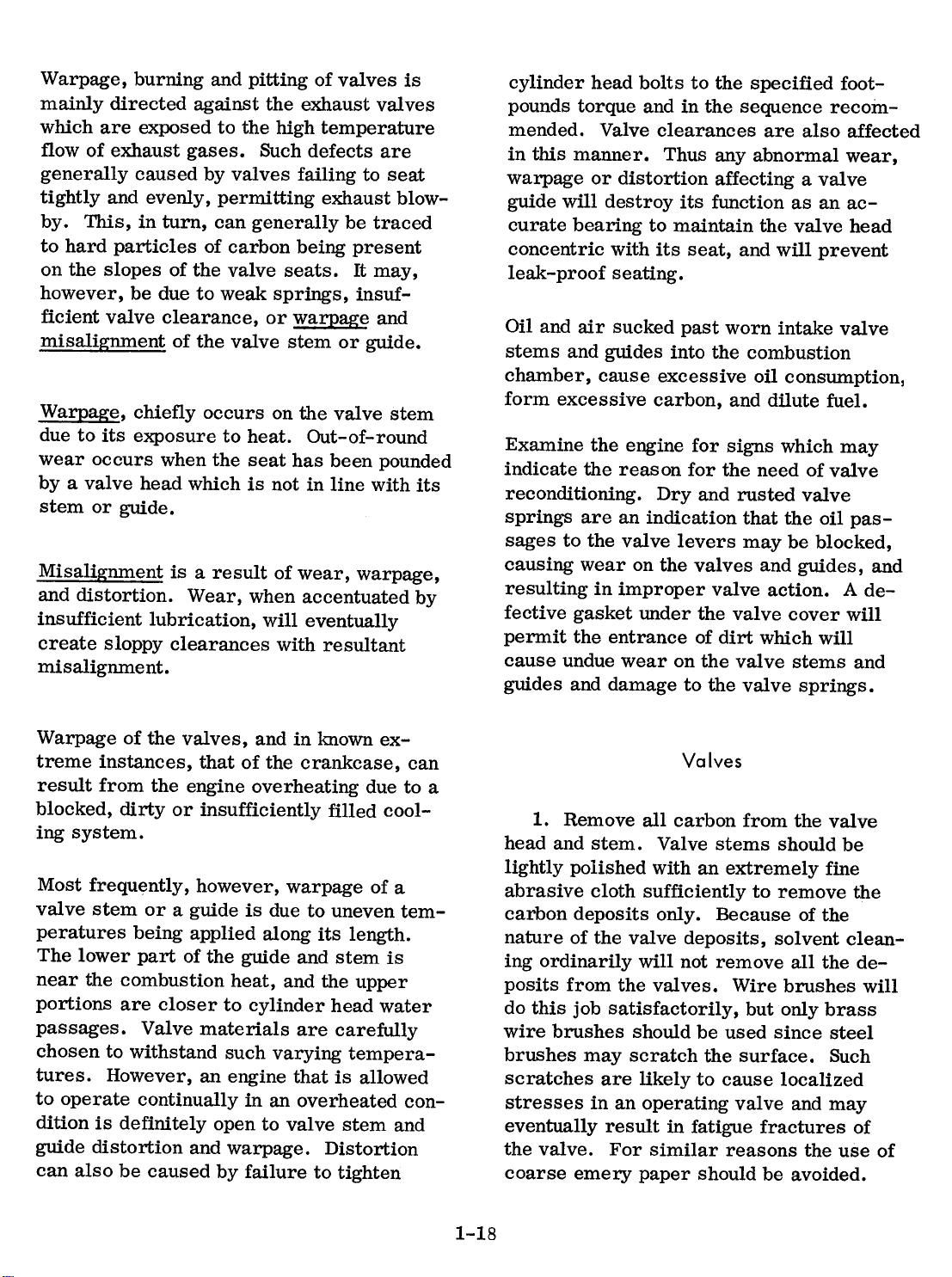

2. Inspect each valve. See that the

stem is not worn excessively and that the

head is not burned or warped. Check the

WRONG

CORRECT

WRONG

FEA-64460

grooves in the stem to see that they have

not lost the shoulders through wear, which

prevents the valve seat retainer keys from

fitting snugly.

3. All valves having bent, worn, warped

or seriously pitted stems should be re-

placed. Replace any valve that cannot be

satisfactorily refaced with a definite mar-

gin maintained. The amount of grinding

necessary to true the valve face is a def-

inite indication of the valve head warpage

from the axis or centerline of its stem.

With excessive warpage, a knife edge will be

ground on part or all of the valve head due

to the considerable amount of metal that

must be removed to completely reface.

Maximum heaviness in a valve head is required for strength and to provide as large

an area as possible for heat dissipation.

Knife edge valves lead to breakage and

warpage.

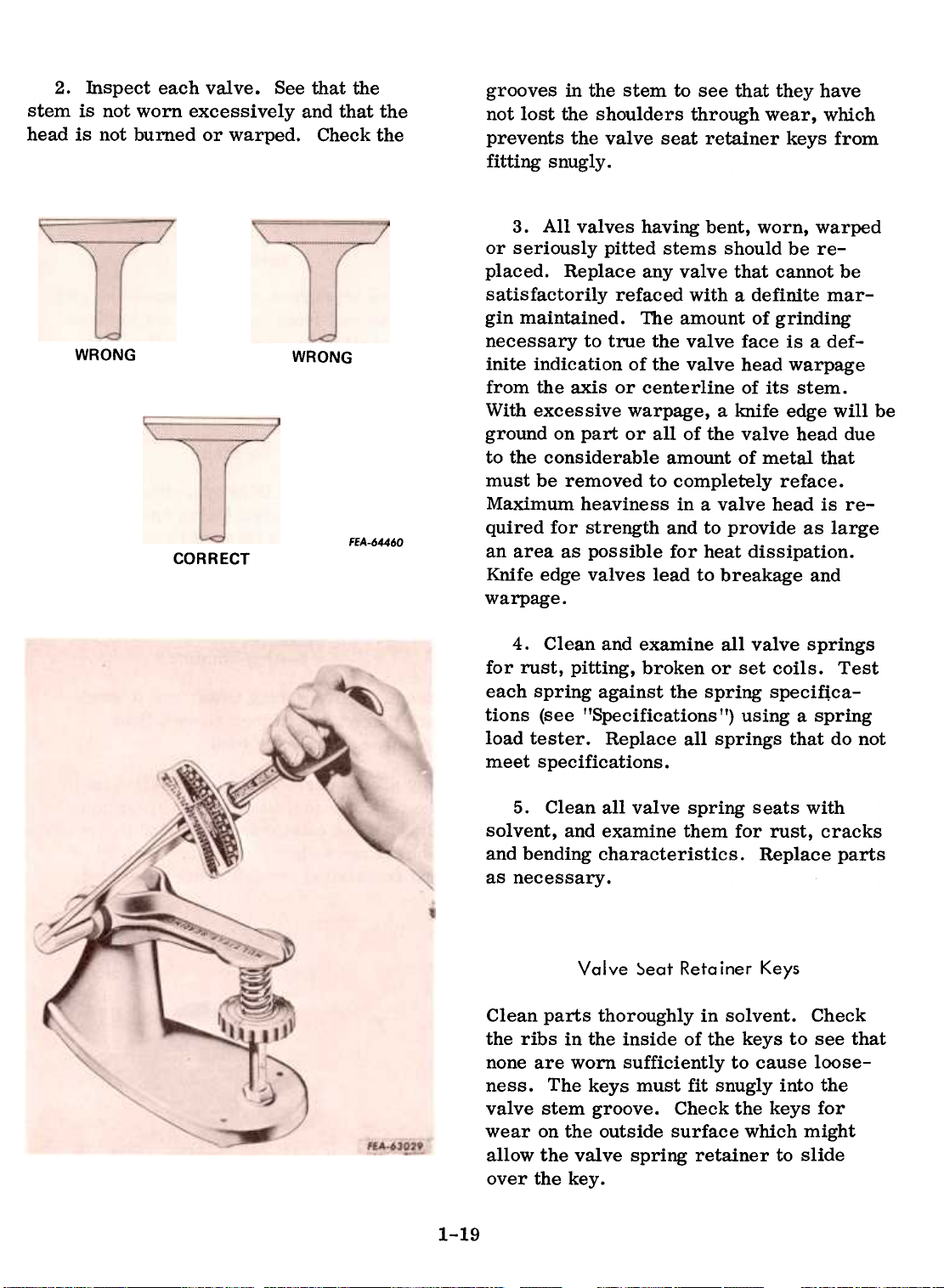

4. Clean and examine all valve springs

for rust, pitting, broken or set coils. Test

each spring against the spring specif\ca-

tions (see "Specifications II) using a spring

load tester. Replace all springs that do not

meet specifications.

5. Clean all valve spring seats with

solvent, and examine them for rust, cracks

and bending characteristics. Replace parts

as necessary.

Valve ::>eat Retainer Keys

Clean parts thoroughly in solvent. Check

the ribs in the inside of the keys to see that

none are worn sufficiently to cause loose-

ness. The keys must fit snugly into the

valve stem groove. Check the keys for

wear on the outside surface which might

allow the valve spring retainer to slide

over the key.

1-19

Page 20

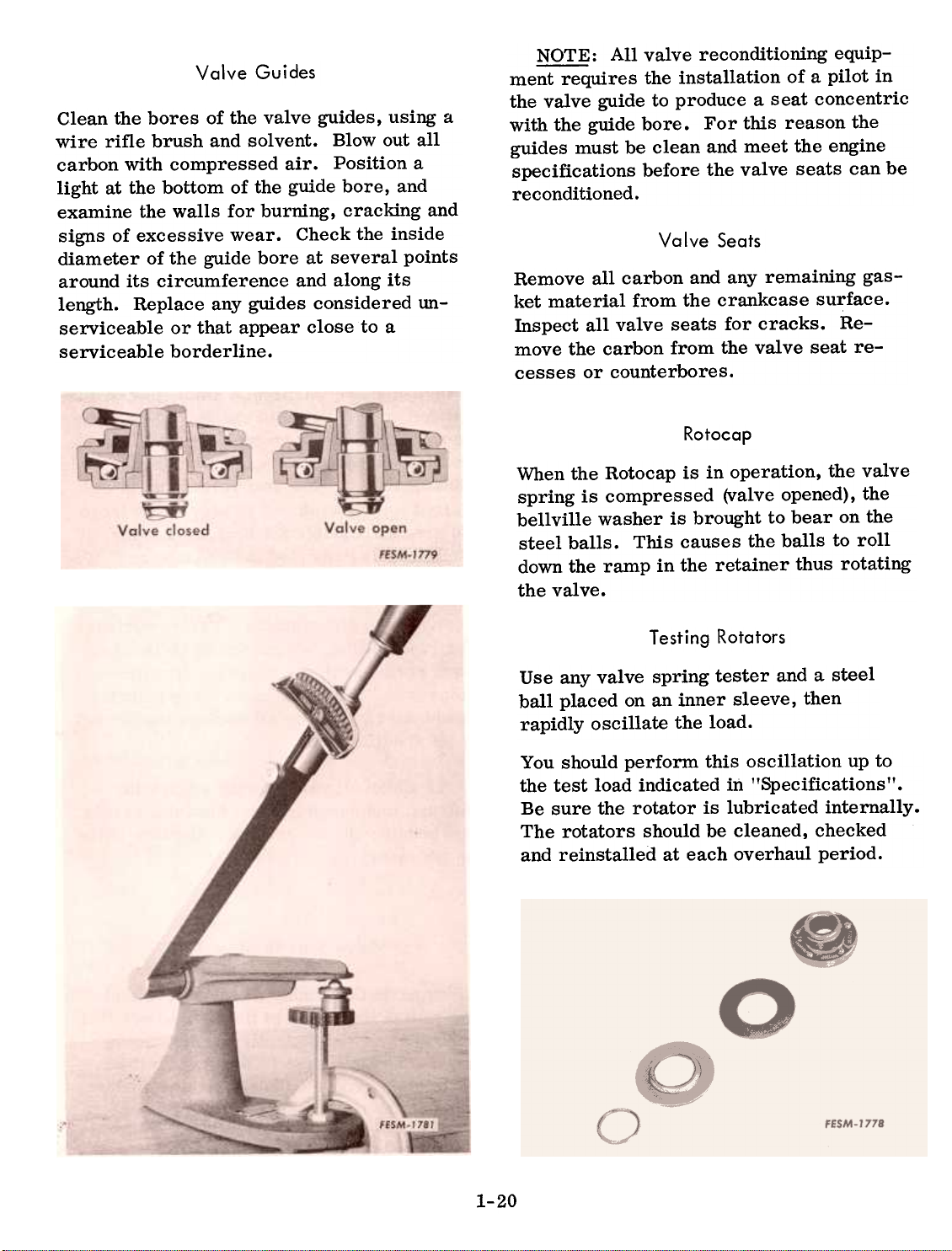

Valve Guides

Clean the bores of the valve guides, using awire

rifle brush and solvent. Blowout all

carbon with compressed air. Position a

light at the bottom of the guide bore, and

examine the walls for burning, cracking and

signs of excessive wear. Check the inside

diameter of the guide bore at several points

around its circumference and along its

length. Replace any guides considered un-

serviceable or that appear close to a

serviceable borderline.

~: All valve reconditioning equip-

ment requires the installation of a pilot in

the valve guide to produce a seat concentric

with the guide bore. For this reason the

guides must be clean and meet the engine

specifications before the valve seats can be

reconditioned.

Valve Seats

Remove all carbon and any remaining gas-

ket material from the crankcase surface.

Inspect all valve seats for cracks. Re-

move the carbon from the valve seat recesses or counterbores.

Rotocap

When the Rotocap is in operation, the valve

spring is compressed (valve opened), the

bellville washer is brought to bear on the

steel balls. This causes the balls to roll

down the ramp in the retainer thus rotating

the valve.

Testing Rotators

Use any valve spring tester and a steel

ball placed on an inner sleeve, then

rapidly oscillate the load.

You should perform this oscillation up tothe

test load indicated in "Specifications".

Be sure the rotator is lubricated internally.

The rotators should be cleaned, checked

and reinstalled at each overhaul period.

1-20

Page 21

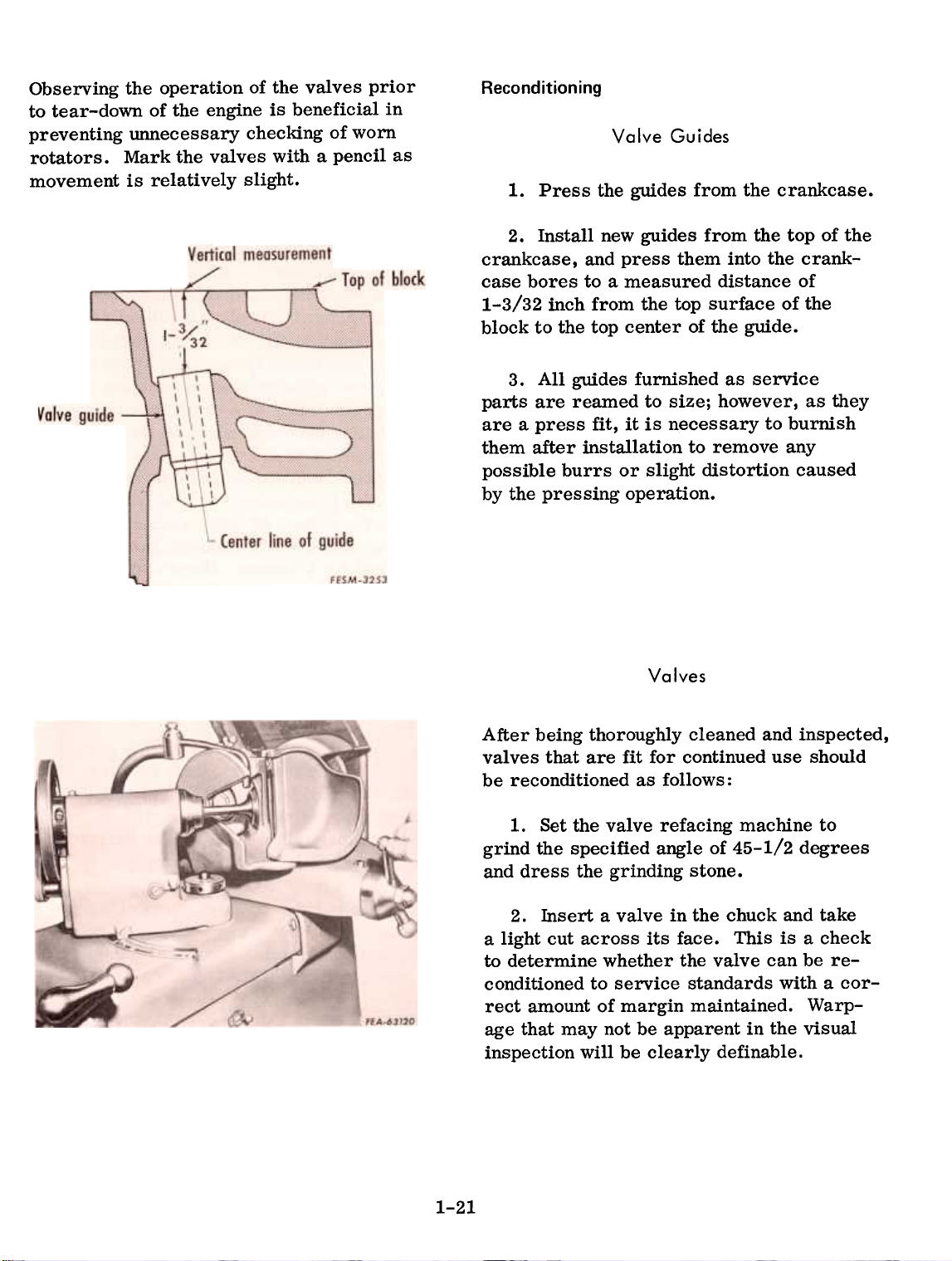

Observing the operation of the valves prior

to tear-down of the engine is beneficial in

preventing unnecessary checking of worn

rotators. Mark the valves with a pencil as

movement is relatively slight.

Reconditioning

Valve Guides

1. Press the g11ides from the crankcase.

2. Install new guides from the top of the

crankcase, and press them into the crankcase bores to a measured distance of

1-3/32 inch from the top surface of the

block to the top center of the guide.

3. All guides furnished as service

parts are reamed to size; however, as they

are a press fit, it is necessary to burnish

them after installation to remove any

possible burrs or slight distortion caused

by the pressing operation.

Valves

After being thoroughly cleaned and inspected,

valves that are fit for continued use should

be reconditioned as follows:

1. Set the valve refacing machine to

grind the specified angle of 45-1/2 degrees

and dress the grinding stone.

2. Insert a valve in the chuck and take

a light cut across its face. This is a check

to determine whether the valve can be reconditioned to service standards with a cor-

rect amount of margin maintained. Warp-

age that may not be apparent in the visual

inspection will be clearly definable.

1-21

Page 22

Avoid taldng heavy grinding cuts as this

heats the valve head excessively, producing

an unsatisfactory valve face, and necessi-

tates dressing the grinding wheel frequent-

ly. Repeated light grinding cuts are preferred until a true face of even width is obtained around the valve. Avoid passing the

stone beyond the face of the valve as this

will cause ridging and grooving of the

stone surface and make dressing of the

stone necessary. Reject all valves with

distorted heads which produce an uneven

face and valves which grind down to a thin

edge.

One of the principal difficulties in recondi-

tioning valves is to obtain nearly identical

angles on the valve seat and valve face.

The importance of these angles in the

grinding operation cannot be overempha-

sized, because it is impossible to produce

a flat or square seat by lapping.

The grinding stones on both the valve re-

facing machine and valve seat grinder

should be dressed before starting a re-

conditioning job.

You will be unable to determine how closely

the angle of the seat will match the valve

face until the valve and seat have been

ground and a check made with a very light

tint of Prussian blue. If a full seat-width

contact around the entire circle of seated

valve is not shown, the angles do not match.

It will then be necessary to redress the

valve seat grinding stones, changing the

angle sufficiently to correct the error. The

correction should be made on the valve

seat, and not on the valve. No more

material should be removed from the valve

face than.is necessary to true it up and remove the burned or pitted portion. New

valves should not be refaced, but should be

checked for trueness. When a satisfactory

match of valve seat and valve face angles

has been obtained, the adjustment of both

the valve refacer and the seat grinder should

be locked in position, in order to eliminate

this trial-by-error method on additional

valves having the same angle.

At times unusually large amounts of heat

scale may be found on exhaust valves,

which is hard on the grinding stone. Fre-

quent redressing of the stone will be neces-

sary to maintain a smooth even surface and

a uniform set of valve face angles.

After refacing each valve, inspect the end

of the stem. If wear is noticeable, reface

the end of the stem. Grind sufficiently to

true-up the end of the stem.

Perhaps it has been noticed that on many

International Harvester Farm Eq11ipment

engines, the valve face and seat are ground

to an "interference angle". This means

that the sum of the seat angle and the face

angle do not equal 90 degrees.

1-22

~;~'i":,

Page 23

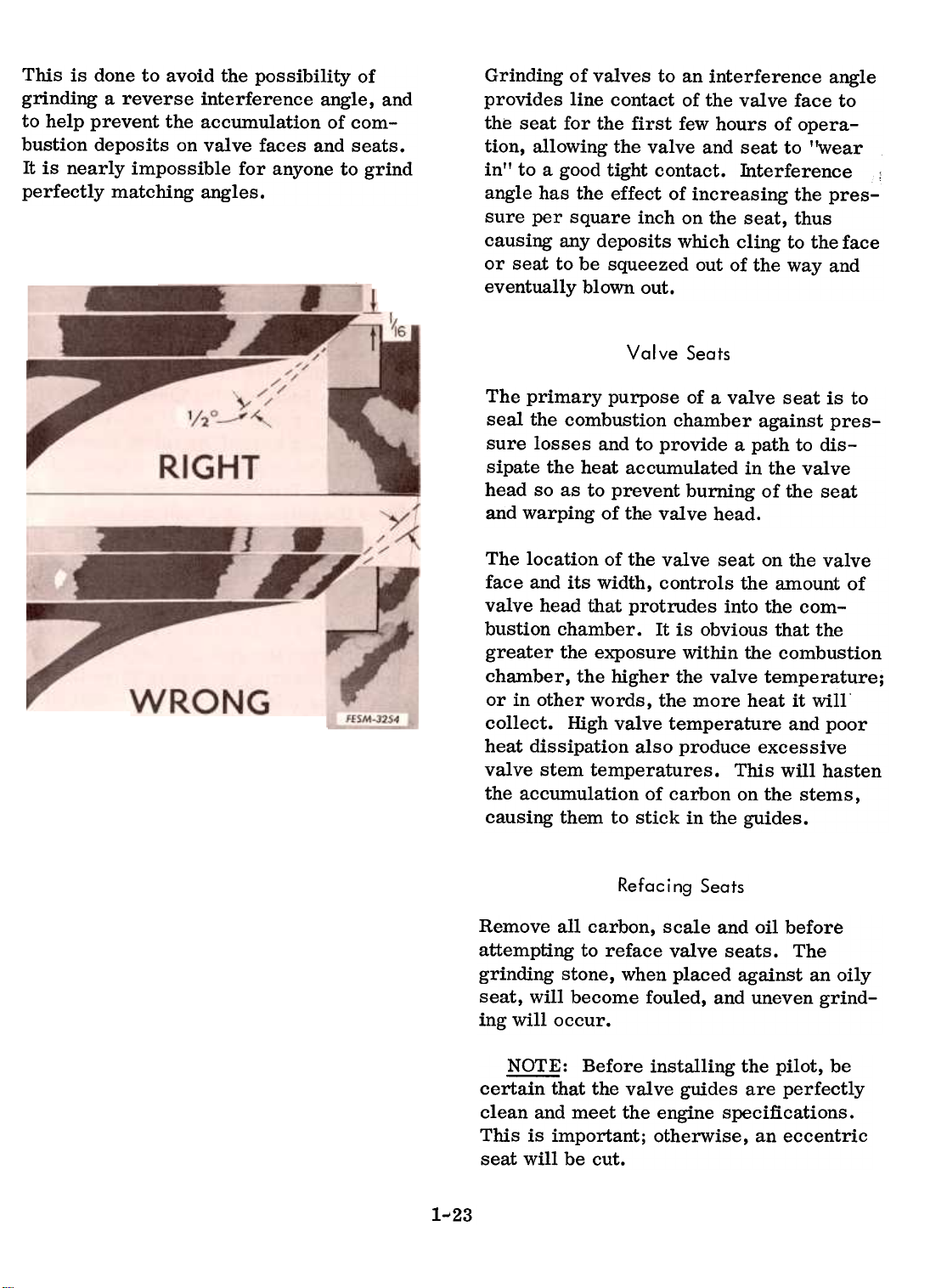

This is done to avoid the possibility of

grinding a reverse interference angle, and

to help prevent the accumulation of combustion deposits on valve faces and seats.

It is nearly impossible for anyone to grind

perfectly matching angles.

Grinding of valves to an interference angle

provides line contact of the valve face to

the seat for the first few hours of operation, allowing the valve and seat to "wear

in" to a good tight contact. Interference

angle has the effect of increasing the pres-

sure per square inch on the seat, thus

causing any deposits which cling to the face

or seat to be squeezed out of the way and

eventually blown out.

Seats

The primary purpose of a valve seat is to

seal the combustion chamber against pres-

sure losses and to provide a path to dis-

sipate the heat accumulated in the valve

head so as to prevent burning of the seat

and warping of the valve head.

The location of the valve seat on the valve

face and its width, controls the amount ofvalve

head that protrudes into the combustion chamber. It is obvious that the

greater the exposure within the combustion

chamber, the higher the valve temperature;

or in other words, the more heat it will'

collect. High valve temperature and poor

heat dissipation also produce excessivevalve

stem temperatures. This will hastenthe

accumulation of carbon on the stems,

causing them to stick in the guides.

Valve

1-'23

Refacing Seats

Remove all carbon, scale and oil before

attempting to reface valve seats. The

grinding stone, when placed against an oily

seat, will become fouled, and uneven grind-

ing will occur.

~: Before installing the pilot, be

certain that the valve guides are perfectly

clean and meet the engine specifications.

This is important; otherwise, an eccentric

seat will be cut.

Page 24

the stone to the correct angle.

Lightly lubricate and install the pilot of the

correct size into the valve guide bore.

to clear away grinding dust. Grind the

seat sufficiently to provide an even,

smooth surface.

Lower the grinder head over the pilot

shank until the stone just clears the valveseat.

Turn on the power and very gently

allow the stone to contact the valve seat.

Very little pressure other than the normal

weight of the stone should be used. Sudden

hard pressure can cause cocking of the

pilot in the guide and result in eccentric

grinding. Raise the stone frequently from

the valve seat to prevent overheating and

Correct Seat

Seat too wide

Check the seat concentricity, roundness

and valve face contact using Prussianblue.

Spread an extremely thin film of

this blue on the valve face and insert the

valve into its guide. With pressure on the

exact center of the valve head, make a

quarter turn rotation in the seat. Remove

the valve and inspect the impression made

upon the seat by the transfer of blueing,

and upon the valve face by the removal of

blueing. Check several times to guarantee

that no error was made. If a full seat-

width contact around the entire circle of

seated valve is not shown, the angles do

not match. It will then be necessary to re-

dress the valve seat grinding stones,

changing the angle sufficiently to correct

the error. The correction should be made

on the valve seat, and not on the valve.

The location of the area of contact between

the valve and the seat is a very important

factor in securing maximum valve life.

Seating the valve with the sharp edge of the

seat not contacting the valve face is un-

desirable. This sharp edge tends to break

off face deposits which may lead to valve

failure.

Dress

Seat too narrow

FEA-63042

FESM-32SS

Similarly, the location of the upper line of

contact well below the top of the valve face,

is also undesirable because a large overhang prevents rapid cooling of the outer

edge of the valve.

After grinding the seats it may be found

that the seats are considerably wider than

the specified width of 3/64 inch. Valve

seats that are too wide may be narrowed

by grinding down the top edge of the seat

with a stone mounted on the grinder head.

The stone must be a smaller angle than

the valve seat (1~ preferably).

1-24

Page 25

Reassembly

1. Coat the valve stems with engine

oil and insert the intake and exhaust

valves into their original positions.

2. Install the valve springs and valve

spring seats. Compress the valve springs

and install the valve seat retainer keys.

Release the springs and remove the valvecompressor.

4. Install the valve tappet cover using

a new gasket.

5. Install the intake and exhaust mani-

fold assembly using a new gasket. Tighten

the nuts evenly in steps to 20 ft. lbs.torque.

6. Install the cylinder head. Refer to

3. Adjust the valve tappets. Refer to

page 1-15.

page 1-14.

7. Refill the radiator with coolant.

CONNECTING RODS, PISTONS AND PISTON RINGS

General

Connecting Rods

The connecting rods serve as the links be-

tween the pistons and the crankshaft. The

surfaces of the rods must be kept free of

scoring and dents because of the high

stresses under which they function. The

rod has a bushing at each end, the one at

the upper end is a bushing for the piston

pin which anchors it to the piston. The

bearing at the crankshaft or lower end is

inserted in two halves which fit around

the crankshaft and are secured by a bear-

ing cap. The bearing cap is furnished

only with its connecting rod.

1-25

The lower bearings used in these engines

are the replaceable insert type and insure correct running clearances when

they are properly installed. This is possible without boring. reaming, scraping

or using shims. The three important

fundamentals on bearings and bearing

fitting are "bearing crush," "bearing

spread," and "bearing clearance." An explanation of these will be covered later.

Page 26

Pistons

The piston is one of the most important

units in the engine, and its condition has

much to do with the performance of the

engine. Its function is to receive the

force of the combustion pressure and

transmit it to the connecting rod and

crankshaft. The escape of combustion

pressure past the piston is prevented by

the piston rings. The fit of the piston and

rings in the sleeve must be close enough

to prevent the escape of combustion gases

but must be free enough to keep friction

to its working minimum.

Piston Rings

The pistons are fitted with three piston

rings. One oil regulating ring is fitted to

each piston. The oil regulating ring pro-

vides an even circulation of lubricating

oil and, therefore, an allover lubricating

and cooling action for the piston and

crankcase cylinder. Excess oil is wiped

by the rings, back down to the crankcase.

The remaining rings are compression

rings. Rings should be installed on a

piston so that the gaps are 90 degrees

from the thrust side of the piston and 180

degrees from one gap to another.

Piston Pins

The piston pin is made of steel and is

cylindrical in shape. Its purpose is to

anchor the piston to the connecting rod.

The pin is retained in the piston by re-

tainer rings that lock into grooves of the

piston pin bore. The pin is allowed to

float in its bushing in the upper end of the

rod. It is usually necessary to heat the

piston in order to remove the pin.

Cylinder

ridge

Worn rings

fit ridge

New ring

interference

Removal

1. Remove the cylinder head. (Refer

to page 1-13.)

2. Remove the drain plug and drain

the engine lubricating oil from the crankcase oil pan. Replace the drain plug.

3. Remove the cap screws securing

the oil pan, and remove the oil pan and

gasket.

IMPORTANT: Before proceeding with

piston and connecting rod removal, the

ridge, existing on the cylinder wall at the

upper end of the ring travel, must be removed by using a ridge reamer. This

prevents damage to the piston ring lands

during removal of pistons, and prevents

damage to new top piston rings after the

installation of new rings.

FESM-3257

1-26

>!~t;Z;-..,

",..~"..

\!:':!:!:

Page 27

4. Remove the oil pump screen and

tube assembly.

5. Remove the connecting rod bearing

cap nuts. Remove the bearing cap. Be

sure that each bearing and cap can be

identified with the connecting rod from

which it was removed. Each connecting

rod should be found numbered on the carn-

shaft side of the rod, indicating its position in the engine.

IMPORTANT: Pistons must be handled

carefully to avoid damage and knocking

out-of-round or alignment. When removing a piston from the crankcase, do

not allow the skirt of the piston to strike

the crankcase or connecting rod. Mark

the pistons so they can be installed in the

same position and cylinder from which

they were removed. The dome of the

piston is stamped with an arrow, indi-

cating its position when properly installed.

6. Push the connecting rod and piston

assembly to the top and lift out from the

crankcase. Replace the cap on the connecting rod to avoid damage.

Disassembly

7. Crank the engine by hand to make

each rod and cap accessible and remove

all pistons and connecting rods in the

same manner.

1. Remove the piston rings with a

piston ring expander. Remove the top

ring first and the remaining rings inorder.

2. Remove the piston pin retainer

rings.

3. Remove the piston pins from the

pistons. As an aid in removing the pin,

heat the piston in hot-to-boiling water

and then remove the pin, being careful

not to damage the piston.

1-27

Page 28

nspection and Repair

1. Wash all parts in a cleaning solvent.

Clean the carbon from the piston ring

grooves with a broken ring or ring groovecleaner.

2. Inspect the connecting rods, caps,

bearing shells and pin bushings as

follows:

(a) All connecting rod bearings and

piston pin bushings should be replaced in

a major overhaul.

(b) Test rods for alignment. Rods

only slightly misaligned can be straightened

using the proper equipment. Badly twisted

or bent rods must be replaced.

3. Inspect the pistons for cracks,

breaks or scores.

4. Measure the piston skirt at right

angles to the pin to determine if it is

worn excessively; replace if necessary.

The specified piston diameter is 2.6230

to 2.6234 inches.

~: On a used piston, it will probably be found that the piston ring side

clearances tend to increase toward the

top of the piston due to the higher operating temperature prevalent at this point.

\Vhen this side clearance becomes excessive, the piston will have to be replaced.

5. Measure the crankcase cylinder

bores for excessive wear. The specified

bore ill is 2.625 to 2.627 inches. Replace-

ment pistons are available in .020 and

.040 inch oversizes.

6. Inspect the piston pins for wear; if

wear is perceptible, replace pins. Replace piston pins showing signs of cor-

rosion or etching. Specified piston pin

diameter is .6875 to .6876 inch.

7. Inspect the connecting rod bushings

for scratches and burrs. Replace ifnecessary.

8. Connecting rod bolts must be

cleaned of all foreign matter including

the anti -rust materials that may be caked

in the threads. This is also true of the

connecting rod bolt nuts.

A good method of checking to determine

thread condition is to turn the connecting

rod bolt (threads lubricated mth a light

engine oil) all the way into a standard nut

mth the fingers. If the bolt runs in relatively free mthout sticking or mthout the

need for applying more than a very light

(2-4 foot-pounds) wrench effort, the bolt

is satisfactory for use.

9. Rings should be checked also for

the specified side clearance by measuring

the clearance between the piston ring and

the piston ring land as shown.

1-28

I

Page 29

10. Inspect the piston rings for damage.

Faulty rings cannot always be detected by

the eye. Engine performance and irregu-

larities such as excessive oil consumption

must be taken into consideration. Where-

ever there is doubt as to the serviceability

of the piston rings, it is advisable to replace such parts.

11. Insert each ring into the cylinder

bore for that piston. Force them squarely

down inside the sleeve or cylinder bore.

Position a feeler gauge between the ends of

the ring, and compare the existing gap

against the specified gap. If it is neces-

sary to remove material from the ring

ends because the end gap is too close,

clamp a mill file in a vise, hold the ring in

proper alignment and dress off the ends

squarely to obtain the desired gap.

12. Inspect the "windows" of the oil

regulating ring and piston for blocked oil-

ways. Failure to keep the oilways clear

will result in uneven lubrication and "hot-

spots" of the piston and cylinder sleeve.

All rings should fit loosely in the piston

grooves without binding.

13. Place connecting rods in an arbor

press and press old piston pin bushings

from the connecting rods.

14. Align the new piston pin bushing on

the connecting rod so that the oil hole in

the bushing will match with the oil hole in

the connecting rod. Press the bushing into

the rod.

15. Press the bushing into place in the

connecting rod and then ream to provide

the specified piston pin clearance of .0003

to .0007 inch.

1-29

Page 30

Reassembly

1. Before assembling the piston and

connecting rod, check the fit of the piston

pin in the piston for proper end clearance

as follows:

(d) Using a feeler gauge, in the gap

between the piston pin and the retainer

ring, check for end clearance. Specified

end clearance is .010 to .030 inch.

(e) Remove the retainer rings and

proceed with the assembly as follows:

(a) Prepare the piston and the pin

for assembly as outlined in Step 2.

(b) Push the pin into the piston and

install a retainer ring at each side of the

piston.

(c) Push one end of the piston pin

until it stops against the retainer ring on

the opposite side of the piston.

Top ring

Inner groove up

Lower ring

Outer groove down

Oil control

ring

~: When assembling the pistons tothe

rods, the front of the piston will be

indicated by an arrow.

2. With the piston pin at room temperature (700) and generously coated with clean

engine lubricating oil, and the piston heated

in hot water to approximately 1500F the piston pin can be entered into one boss of the

piston by pushing with the hand. While the

piston is hot, quickly and correctly position

the connecting rod inside the piston, align

the bushing in the rod bore with the piston

pin holes in the piston and push the piston

pin completely into position. Thoroughly

dry the piston with compressed air.

3. Install a retainer ring in the groove

at each side of the piston to secure the

piston pin.

FESM-326 I

4. Using a piston ring expandert install

the ringst oil control ring firstt into the

grooves of the pistons.

Position the ring gaps 90 degrees from the

thrust side of the piston (in line with the

piston pin bore) and 180 degrees from one

gap to another.

Be sure the compression rings are installed with their grooves positioned as

shown.

1-30

Page 31

Piston Fit in Bore

Specified piston-to-bore clearance is .0016

to .0024 inch and can be determined using

a 1/2 inch wide feeler gauge and a spring-type

tension scale (FES 108).

The thickness of the feeler gauge that canbe

removed with a 2 to 8 pound pull repre-

sents the piston-to-bore clearance as out-lined

in the "Piston Clearance Chart."Clearances

should conform to specifications.

The chart shows the relationship between

the feeler gauge thickness and pounds pull

in measuring piston-to-bore clearance.

Note that with a given feeler gauge thick-

ness the actual clearance is less than the

feeler gauge used when the pound pull is

towards the high side of the pound pull

range. This is especially true with the

thinner feeler gauges.

determine piston-to-bore clearanceproceed

as follows:

1. Select a feeler gauge (free of dents

or burrs) of one of the thicknesses listed

in the chart. Position the feeler gauge inthe

cylinder bore so that it extends theentire

length of the piston 900 from the

piston pin location.

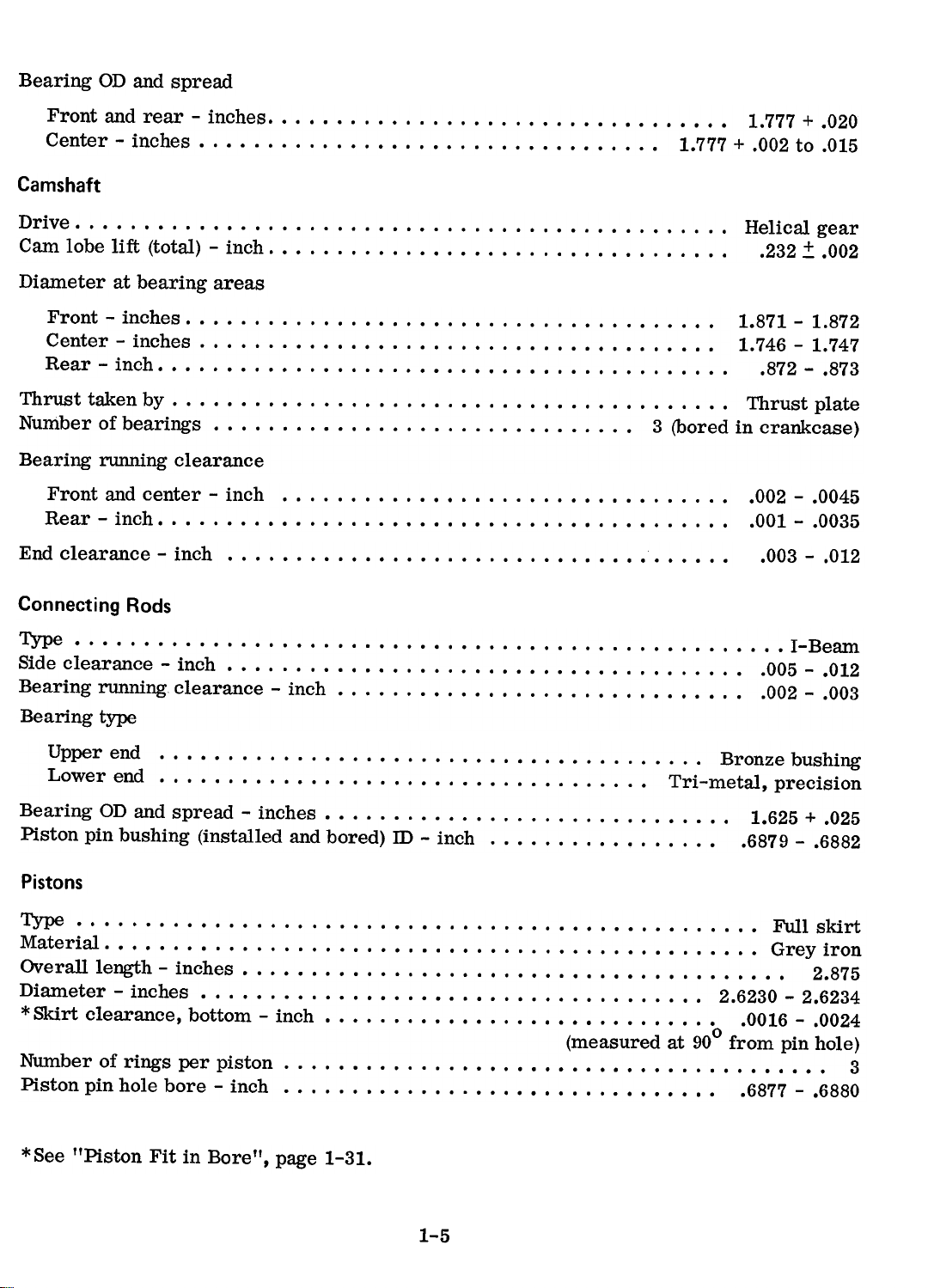

Pull

inLbs.

2

4

6

8

PISTON CLEARANCE CHART

Feeler Gauge Thickness

.00151.002

.003

.00351.004

.0045

Clearance in Inches

.00161.00221.00331.00391.00441.005

.00131.00181.00291.00351.004

.001

.0046

2. Invert the piston and install it in the

bore so that the end of the piston is about

1-1/2 inches below the top of the cylinder

block and the piston pin is parallel to the

crankshaft axis.

3. Hold the piston and slowly pull the

scale in a strai~ht line with the feeler

gauge, noting the pull required to remove

the feeler gauge. Check three times and

record the average of the three readings

obtained. Do not bend or kink the feeler

gauge.

4. Refer to the chart to determine the

actual clearance. The clearance is shownwhere

the horizontal column indicatingpounds

pull and the vertical column indi-cating

the thickness of the feeler gaugeused

intersect.

EXAMPL~: If a .003 inch feeler gaugeis

used and it takes 8 pounds pull to removethe

feeler gauge, the clearance is .0023 inch.

To

.00151.00261.00311.00361.0042

.0008/.00131.0023/.00281.00331.00381-31

Page 32

5. Repeat step 3 with the piston at right

angles to the crankshaft axis. Determine

the clearance as instructed in step 4.

6. Measuring piston-to-bore clearance

with the piston pin parallel and at right

angles to the crankshaft axis will reflect

any "out of round" in the bore.

Bearing Fitting Procedure

C_AUTION: Bearings or bearing caps

must not be filed, lapped or modified in any

manner to reduce journal-to-bearing clearance. Premature bearing failure will re-

sult from attempts to reduce journal-to-

bearing running clearances. While such

methods will make a tighter fit at the top

and bottom of the bearing, it will result in

an out-of-round bore and distortion of the

bearing shell. New bearing shells will

have to be installed eventually and addi-

tional problems will be encountered. Such

modification alters the engineered fit of

the bearing shells in their bores and de-

stroys the desired "crush".

1. When installing precision type bear-

ings, it is important that the bearing shells

fit tightly in the rod or crankcase bore. To

accomplish this, the diameter of the bearing at right angles to the parting line is

slightly larger than the actual diameter of

the bore onto which the bearing will be

assembled. When the bearing cap is drawn

up tight the bearing is compressed, assur-

ing a positive contact between the bearing

back and bore. The increased bearing

diameter is called "bearing crush".

1. Bearing locking tangs

Be certain the bearings are fully seated

and the locking tangs (1) on the bearings

fit into the recesses.

2. To assemble the bearings with the

correct "bearing crush," tighten the clamping bolts alternately and evenly to the

specified torque with a torque wrench.

1-32

Page 33

SOFT MALLET (STRIKE LIGHTLY

AND SQUARELY)

BEARING

FEA.63050

~:;;:;;~~~

WOOD BLOCK

3. Main and connecting rod bearings

are designed with the "spread" (width

across the open ends) slightly greater than

the diameter of the crankcase bore or

connecting rod bore into which they are to

be assembled. For example, the width

across the open ends of the connecting rod

bearing not in place is approximately .025

inch more than when the bearing is in position in the rod. This condition causes the

bearing to fit snugly in the rod bore and the

bearing must be "snapped" or lightly

forced into its seat.

Rough handling in shipment, storage, or

normal use in an engine, may cause the

bearing spread to be increased or decreased from the specified width. Bearing

spread should therefore be carefully meas-

ured and corrected as necessary before

installation in an engine. Bearing spread

can be safely adjusted as follows if care

and judgment are exercised.

(a) EXCESSIVE SPREAD: If meas-

urement of bearing indicates that dimension

"A " is excessive, place bearing on a wood

block and strike the side lightly and square-

ly with a soft mallet. Recheck measurement

and, if necessary, continue until correct

width is obtained.

~

DECREASING SPREAD

(b) INSUFFICIENT SPREAD: If

measurement of bearing indicates insufficient spread, place bearing on a wood

block and strike the back of the bearing

lightly and squarely with a soft mallet.

Recheck measurement and if necessary

continue until correct width is obtained.

1- 33

Page 34

4. BEARING CLEARANCE: When in-

stalling bearings in an engine, the proper

clearance between bearing surface should

be checked closely. Specified bearing

clearance is .002 to .003 inch. To get an

accurate measurement of this clearance,

the IIPlastigage II method, or virgin lead,

(a) Remove bearing cap and wipe

bearing surface and exposed half of crank-

shaft journal free of oil.

(b) Place a piece of "Plastigage" the

full width of bearing insert.

can be used. The following instructions

can be used when measuring with

"Plastigage":

(c) Reinstall the bearing cap and

tighten the self-locking cap screws to 16

foot-pounds torque.

(d) Remove the bearing cap. The

flattened plastic material will be found adhering to either the bearing shell or the

crankshaft.

(e) To determine the bearing clearance, compare the width of the flattened

plastic material at its widest point with

the graduations on the envelope. The number within the graduation on the envelope

indicates the clearance in thousandths of an

inch.

(f) If using virgin lead, carefully remove the flattened lead and measure its

thickness with a micrometer.

~: Do not turn crankshaft duringthe

above procedure.

Should the readings not fall within the specified limits, and the torque wrench is known

to be accurate in its measurement, remove

the bearing from the connecting rod and

replace it with a new one. However, with

the precision bearings used, no difficulty

should be encountered providing the crank-

shaft and/or connecting rod are in proper

condition.

1-34

Page 35

Installation

I. Cyl indor numbor toward camshaft I

NOTE: When reinstalling a piston and

connecting rod assembly, install the assembly in the same cylinder bore and in

the same position from which it was removed. Connecting rods are stamped with

the cylinder number on one side of the rod

and on the same side of the bearing cap,

No.1 starting at the front end of the en-

gine. Be sure to install the numbered

side of both the rod and bearing cap so

both are on the camshaft side of the

engine.

1. Generously coat the piston ring

compressor and bore with lubricating oil.

Install the ring compressor on the piston

and insert the piston and connecting rod

assembly through the top of the crankcase.'

2. Push down on the piston carefully

until it is in the crankcase bore.

3. Wipe clean and oil the crankshaft

journals and fit the connecting rod bearings as outlined in "Bearing Fitting

Procedure."

4. Install all the pistons, connecting

rods and bearings in the same manner.

5. Check the connecting rod side

clearance by inserting a feeler gauge between the bearing cap and lobe of the

crankshaft. The specified side clearance

is .005 to .012 inch.

6. Install the oil pump screen and

tube assembly.

7. Install the crankcase oil pan and

new gasket. Fill the crankcase to the

level on the gauge with the grade of

engine oil specified in Operator's manual.

8. Install the cylinder head and

gasket. (Refer to page 1-14.)

1-35

I

Page 36

Crankcase Cylinder Re-Boring Procedure

This section covers re-boring of the cyl-

inder bore with the engine disassembled.

However, if re-boring is the only service

to be performed on the engine, the crankshaft need not be removed.

When to Re-Bore

Replacement piston ring kits may be used

to extend the life of the piston if cylinder

wear has not been excessive. Inspect cylinder bores for scoring and roughness

which indicate excessive wear. Check cyl-

inder bores for taper and out-of-round by

the use of a cylinder gauge placed at the

top, middle, and bottom of bores, both

parallel and at right angle to the centerline

of crankshaft. To be within safe limits, the

taper from top to bottom of the ring travel

area must not exceed 0.005 in. and the out-

of-round (egg-shape) condition must not

exceed .005 in. in the cylinder bores. If

the bore is worn beyond these limits, a

re-b~ring job is required. It is advisable

to re-bore for the smallest possible oversize pistons and rings. If only one or two

bores require correction, it is not neces-

sary to re-bore all cylinders to the same

oversize.

Preparing the Block

Clean the water jacket with materials that

will remove rust and scale and then flush

thoroughly. Degrease the crankcase so

that the abrasive material from the boring

operation may be completely removed

before reassembly.

Before setting up a boring machine on the

block, the top of block must be carefully

cleaned to remove all foreign materials,

such as carbon, rust, or gasket cement.

Use a 14 in. fine-cut, mill file to draw-file

the block for removal of all burrs and high

spots around the top edge and bolt holes.

This will provide a smooth, true working

surface for the boring operation. This is

very important because the alignment of

the cylinder bores depends entirely on the

tightness of this working surface.

1...36

Page 37

Re-Boring

When re-boring cylinders, all crankshaft

bearing caps must be in place and torqued

to specifications to avoid possible distortion of bores in final assembly. If all bores

require the same correction, to save time

bore the cylinder having the greatest

amount of wear and taper first. If this

cylinder cleans up to the smallest desired

oversize, you can be sure that the remaining, smaller cylinder bores will clean up

to the same size. Oversize pistons furnished for service are .020 in. and .040 in.

oversize. No attempt should be made to

cut down oversize pistons to fit cylinderbores.

Use a good single point boring bar with a

sharp tool and bore all cylinders the same

size, to within .002 to .001 in. of the desired finished oversize to permit finishing

honing operations.

Honing

For best results, hone the cylinders to the

finished size. This operation must remove all boring tool marks. Final finish

should be in the range of 20 to 35 microinches. If you have no means for measuring the finish, the use of about 120 ~rit

stones will produce approximately the

correct finish.

To center the boring machine on each

cylinder, follow closely the instructions of

the boring machine manufacturer.

~: If the crankshaft has not been

removed, be sure the crankshaft is out of

the way of the boring cutter when boring

each cylinder.

Cylinders that are too smooth will retard

run-in and may result in ring scuffing.

When cylinders are too rough, rapid ring

wear will result. A rigid type wet hone is

preferred for the final sizing operation, but

a spring hone of the glaze-breaking type

may be used if the other is not available.

Spring hones should be equipped with 220

grit stones and stock removal should not

exceed 0.003 in. This type of hone should

be dipped into SAE 10 or 20 lubricating oil

before beginning the operation. Dull or

dirty stones cut unevenly and generate excessive heat. Keep honing equipment sharp

and clean. When finished honing, pass the

hone through the entire cylinder bore at a

rate of 60 cycles per minute or as neces-

sary to provide a 30 degree (relative to the

top of the sleeve) cross-hatch pattern on

cylinder walls. This will insure maximum

ring life and minimum oil consumption.

1-37

Page 38

The success of any re-boring job depends

on the accuracy and smoothness of the

finished bores, the amount of piston clear-

ance, and the thoroughness with which you

clean the block and crankcase of all cuttings and abrasive materials resulting

from boring and honing. The best reboring job will be a total loss unless the

crankcase is thoroughly cleaned. Foreign

material which remains causes rapid

wear of pistons, rings, and cylinder walls,

and will seriously damage engine bearings.

Checking Clearance

Refer to "Piston Fit in Bore", page 1-31

For thorough cleaning of the crankcase,

washing in a tank of hot, agitated clean-

ing solution is the recommended proce-

dure. If this cannot be done, use a good

cleaning solution and air pressure blast

followed by careful wiping with clean

cloths and light lubricating oil. Surfaces

should be wiped until a clean cloth shows

no discoloration. Wash and blowout oilpassages.

TIMING GEAR TRAIN AND FRONT COVER

The crankcase front cover encloses the

timing gear train. It is of one piece construction. It also provides mounting for

the governor and ignition drive. The

Removal

1. Support the engine and remove the

radiator, steering gear housing assembly

and front axle from the tractor.

Remove the cooling fan assembly

General

gear train is comprised of the crankshaft

gear, camshaft gear, idler gear and the

ignition l.U1it and governor drive gear.

3. Remove the distributor and dis-

tributor drive.

2.

(3).1-38

Page 39

4. Remove the engine governorassembly.

5. Remove the fan drive pulley

from the crankshaft using removing tools

FES 33-1 and a two jaw puller as shown.

NOTE: If the fan drive pulley has a

wear sleeve installed, inspect the sleeve

for excessive wear or damage. To re-

move the wear sleeve,indent the sleeve

surface li.e;htly with a blunt chisel. This

will expand the sleeve for easy removal.

GSS-1411 (Rev. No.1)

1-39

Printed in United States of America

Page 40

6. Remove the cap screws from the

front cover, and remove the cover and

gasket. Clean the gasket mating areas

to insure proper sealing when re-

assembled.

7. Remove the idler gear shaft bolt

and remove the idler gear.

8. Remove the crankshaft gear with a

puller.

~: Before removing any gears it

is advisable to check the backlash of the

gears to determine which, if any, require

service. Check the backlash with a dial

indicator or feeler gauges. The speci-

fled backlash is .003 to .006 inch.

1. Clean all parts thoroughly in a

cleaning solvent and dry with com-

pressed air.

2. Remove all gasket material from

the crankcase and front cover with a

putty knife so that a clean surface can be

had when the new gaskets are installed.

Reassembly and Installation

9. Using a puller, remove the cam-

shaft gear.

10. Remove the ignition drive seal.

3. Inspect all gears for excessive

wear, chipping or cracks.

4. Inspect all keys and keyways for

wear or damage and replace as

necessary .

5. Be sure to install a new front

cover oil seal and gasket.

1. Install a new ignition drive oil seal

in the crankcase. The seal must be

square in its bore and positioned 23/32

inch from the ignition mounting flange

face.

2. Install the key in the camshaft if

it was removed. Heat the camshaft gear

in boiling water. Install the camshaft

gear on the shaft with the timing marks

facing out.

GSS-1411 (Rev. No.1) Printed in United States of America

1-40

Page 41

l8-tooth

CronKshoft

3. Install the key in the crankshaft if it

was removed. Heat the crankshaft gear

and install the gear, being sure the single

timing mark of the camshaft gear and the

single mark on the crankshaft gear are

aligned.

4. Install the idler gear and shaft.

Tighten the bolt to 90 ft. lbs. torque. The

idler gear is correctly timed by lining up

the double punch mark on the idler gear

with the double punch mark on the crank-

shaft gear.

FESM-3267

~ : Before installing the crank-

case front cover, mark the top surfaces

of the two teeth on each side of the §l!;!g!f:

punch mark on the idler gear with chalk.

5. Install the crankcase front cover

with a new oil seal and gasket. po 1!.QL

tighten the cap screws at this time.

NOTE: If necessary, install a new

wear sleeve onto the fan drive pulleyusing

the FES 33-4 fan drive pulley wear

sleeve installer as shown. Be sure to

apply a sealer onto the pulley O. D. or the

I. D. of the wear sleeve before installing

the wear sleeve onto the pulley.

6. Install the fan drive pulley (1) using

installing tool, FES 33-1 as shown. It

may be necessary to block the flywheelto

prevent the crankshaft from rotating.

7. Tighten the front cover cap screws

to 20 ft. lbs. torque. This permits the

seal and the cover to be centered by the

fan drive pulley hub and insures an even

contact of the seal around the pulley hub.

GSS-1411 (Rev. No.1)

1-41

Printed in United States of America

Page 42

~: Before installing the governor

assembly, mark the front surface of the

ignition drive gear having a single punch

mark with chalk.

8. Install the governor assembly with

a new housing gasket. Time the ignition

drive gear as follows:

With the engine on top dead center of

number 1 firing stroke, mesh the marked

tooth of the ignition drive gear with the

two chalk marked teeth on the idler gear.

9. Position the ignition unit distributor arm and drive shaft lug (A) for firing

number one cylinder. Install the ignition

unit on the engine, meshing distributor

lug (A) and governor drive slots (B).

~: Remove the secondary cables

from No.2, 3 and 4 spark plugs to prevent any chance of accidentally starting

the engine.

1-42

Page 43

10. Place the number one spark plug

cable in a position so that the spark to

ground will be audible when hand crank-

ing the engine. Then advance or retard

the ignition distributor until spark occurs

as the T .D.C. mark (1) on the fan drive

pulley (3) aligns with pointer while ~

cranking engine. Never time the spark

before top dead center.

~ : Final ignition timing must be

made with a timing light. The specified

ignition timing is 16 degrees (2) before

T .D.C. at 2000 engine rpm.

11. Install the cooling fan assembly.

(Refer to page 1-62.)

12. Install the radiator assembly,

steering gear housing assembly and

front axle on the tractor.

CAMSHAFT

The camshaft is a single piece, drop

forged shaft, with three bearing journals.

The journals are supported by the

machined bores in the crankcase. A

helical gear, keyed to the shaft at the

forward end of the camshaft is driven by

the crankshaft.

The camshaft operates at one-half the

engine speed.

General

The camshaft extends through the rear

bearing bore into the oil pump body. This

extended portion of the shaft is smaller in

diameter than the rear bearing journal

and carries a Woodruff key to drive the

oil pump drive gear.

The camshaft has the main function of

operating the intake and exhaust valve

mechanism, by action of the lobes upon

the valve tappets during rotation.

1-43

Page 44

Removal

of the camshaft only, requires

the removal of the engine from the

tractor and removal of head, valves, oilpan,

oil pump, flywheel and crankcase

front cover from the engine.

2. Remove the flywheel, and remove

the oil pump body and gears. Refer to

page 1-55. Remove the key in the rear of

the camshaft.

3. Remove the crankcase front cover.

Refer to page 1-38.

4. Remove the two cap screws in the

camshaft retainer plate through openings

in the cam drive gear.

5. Turn the crankcase upside down so

the tappets (1) will fall away from the

camshaft to provide clearance for re-

moval.

6. Withdraw the camshaft (2) from the

front carefully so the crankcase bores

are not damaged by nicks from the edges

of the cam lobes.

7. If necessary to remove the cam-

shaft gear (3), press the gear off.

8. Remove the thrust plate and key if

the camshaft gear was removed.

1. Remove the valve tappet cover, and

remove the valve assemblies. Refer topage

1-16. Be sure to identify each as-

sembly for proper reassembly.

I nspection and Repair

1. Clean all parts in a cleaning

solvent and dry with compressed air. As

inspection is completed, coat each part

with clean engine oil and store safely

until reassembly.

2. Inspect the camshaft journals for

excessive wear. The specified journal

diameters are 1.871 to 1.872 inches for

9. Lift the valve tappets out of thecrankcase.

Be sure to identify the

tappets so they can be installed in their

original bores.

the front, 1.746 to 1.747 inches for the

center and .872 and .873 inch for the rear

journal. If excessively worn or out-of-

round, the camshaft must be replaced.

Check any run-out on the camshaft using

a dial indicator at the center bearing

journal. Place the shaft in a lathe or be-

tween centering blocks. The total run-

out must not exceed .002 inch.

1-44

Removal

Page 45

3. Check the crankcase bearing bore

inside diameters. The specified ill is

1.8740 to 1.8755 inches for the front, 1.7490to

1.7505 inches for the center and .8740 to

.8755 inch for the rear.

4. fuspect the camshaft lobes for ex-

cessive wear, chipping, scoring and replace if necessary. If the lifting areas of

the cam lobes, when compared with new

camshaft, show amount of wear exceeding

.020 inch, the camshaft must be replaced.

If a new camshaft is not available for comparison, the cam lobe wear can be measured with a micrometer in the following

manner. Take a reading across A-C and

deduct the reading B-D; this will give the

lobe lift. When the cam lobe wear limit

has been reached, this lift will be .020 in.

less than the specified lift of .232 inch.

The camshaft must then be replaced with

a new one.

5. Replace the camshaft gear if the

teeth are excessively worn, chipped or

scored. Small nicks or burrs can be removed with a hone or fine mill file.

6. Check the condition of the thrustflange

and replace if excessively worn.

7. Inspect the tappets. Replace any

that are scratched or worn.

8. Be sure to use new gaskets in re-

assembly.

Installation

1. Install the valve tappets in their

original bores.

2. Place the camshaft thrust plate on the

shaft and install the key in the keyway. Heat

the camshaft gear in boiling water and install

the gear (with the timing mark facing out).

3. Check the end clearance with a

feeler gauge between the camshaft frontjournal

and the thrust plate. Be sure thedrive

gear is in place against the shoulder

on camshaft. The specified end clearanceis

.003 to .012 inch. If the end play is ex-cessive,

replace the thrust plate with a

new one.

1-45

Page 46

4. Coat the camshaft with engine oil

and install the camshaft in the crankcase.

Be sure the camshaft gear (3) is cor-

rectly indexed with the timing mark on

the crankshaft gear (2).

5. Secure the thrust plate to the crankcase and tighten the cap screws to 20 ft.

lbs. torque. Access to each of the two

screws is through the holes in the carn-

shaft gear.

6. Install the front cover and fan drive

pulley. Refer to page 1-40.

7. Install the key in the rear of the

camshaft, and install the oil pump gears

and body. Install the flywheel.

8. Install the valve assemblies andhead.

Refer to page 1-25.

9. Install the oil pan.

10. Install the engine in the tractor.

Refer to page 1-12.

11. Install the steering gear housing

assembly, front axle and the radiator

assembly on the front of the engine.

12. Start the engine and bring up to

operating temperature.

(a) Inspect for oil leaks and check

for correct engine oil pressure.

(b) Check and adjust the ignition

timing .

(c) Check and adjust the valve

clearance if necessary. Refer to

page 1-15.

1-46

Page 47

CRANKSHAFT AND MAIN BEARINGS

The crankshaft is supported in the crankcase by replaceable insert bearings. The

precision-type bearings are not adjust-able.

When running clearances becomeexcessive,

replacement is necessary.

The connecting rods and all crankshaft

journals are rifle-drilled to provide

positive lubrication. Each main bearing

cap, which contains the lower half of the

insert bearings, is numbered consecutively

to correspond with a number stamped on

the camshaft side of the crankcase. The

bearing caps are not interchangeable.

No.1 bearing cap is at the front of the

engine.

CAUTION: Extreme care must be

taken to guarantee cleanliness of the

crankcase, crankshaft and bearings after

service has been completed. Whene.ver

possible, the crankshaft should be removed when new bearings are being installed in order to clean the crankcase

thoroughly. AIl bearing surfaces must

be free of grit and burrs. Small particles

of dust and dirt left between the crank-

shaft and bearings will cause rapid wear

and scoring of the crankshaft journal and

insert. Any foreign material left between

the bearings and the crankcase and bear-

ing caps will cause distortion of the bear-

ing and a reduction in operating bearing

clearance at localized point. The fric-

tional heat thus produced will in turn

cause the bearing material to melt away

from the steel back of the bearing at that

point. Such melted material wiIl create

further hot spots until complete bearing

failure takes place. Anything that inter-

feres with the operating clearance of any

bearing or the proper heat dissipation has

its effect upon bearing life. Cleanliness

cannot be overstressed.

The crankshaft front and rear oil seals

will also be worn and should be replaced.

This cleaning of the crankcase and replacing of oil seals is the best insurance

against early bearing failures through

dirt or foreign material left in the crankcase oil distribution bores or from dirt

entering worn oil seals.

Main bearings are available in standard

production size for new shafts or for used

shafts having little or no wear and .002

inch undersize for shafts slightly worn.

Also available are .010, .020 and .030 inch

undersize for use with regound crank-

shafts. When servicing main bearings,

one defective bearing will require the replacement of all three bearings; otherwise

crankshaft "lay" or alignment cannot be

maintained.

The replacement of crankshaft main bearings without removing the crankshaft

should be done 2!Y.Y. in an emergency.

When these bearings are worn sufficiently

to require replacement or have failed

through lack of lubrication, the entire

crankcase and its oil distribution bores

should be thoroughly cleaned. This can-

not be accomplished without the removal

of the crankshaft.

General

1-47

Page 48

Removal

To completely service the crankshaft and

bearings, the crankcase oil, cooling and

hydraulic systems must be drained and

the engine removed from the tractor.

Refer to page 1-10.

1. Remove the fan drive pulley. (Refer

to page 1-39.)

2. Remove the front cover. (Refer topage

1-38.)

3. Remove the flywheel and the rear

oil seal retainer.

4. Remove the crankcase oil pan, and

remove the oil pump screen and tube.

5. Remove the crankshaft bearing cap

bolts. Tap the caps lightly with a lead

hammer, if necessary, to dislodge them

and remove squarely from position.

6. Remove the lower bearing from

each cap. If they are to be reassembled,

be certain that they are identified as to

their original positions. Wrap them in

clean cloths and store until reassembly.

NaTE: If the crankshaft is to be re-moved

disregard step 7.

7. Remove the upper bearing halves

from between the crankshaft and the

crankcase with a thin piece of flexible

soft sheet metal. Push against the end

of the bearing without the positioning nut,

while turning the crankshaft in the direc-

tion of rotation. The bearing will slide

from position easily.

8. Remove the connecting rod bearing

cap nuts and bolts and remove the caps.

Push the piston and rod assemblies to the

top of their travel.

9. Lift the crankshaft out of the crank-case.

1-48

Page 49

nspection and Repair

1. Clean all parts with cleaning solvent

and dry with compressed air.

2. Inspect the bearings for wear and

evidence of uneven bearing support. Examine the bearing caps and supporting

surfaces of the crankcase for high spots

and burrs.

3. Inspect the crankshaft journals for

scoring and measure the diameter of each

journal with a micrometer. Specified

journal diameter is 1.623 to 1.624 inches.

Measure each journal at two points, one

at right angles to the other, in order to

detect any out-of-roundness.

Move the micrometer over the entire

width of the journal.

4. Check the connecting rod journals

for out-of-round condition. Use a micrometer and take measurements at least

three places around the journals. The

specified rod journal diameter is 1.498

to 1.499 inches.

5. Inspect the crankshaft gear teeth

for excessive wear and chipping. If

necessary to replace it, pull the gear

with a puller.

6. Inspect the crankcase for sludge

and deposits and thoroughly clean it.

7. Replace all seals and gaskets with

new ones.

1-49

I

Page 50

Installation

1. Wipe all surfaces of the crankshaft

bearing bores of crankcase and bearing

caps free of oil, and place bearing halves