Page 1

Operator’s Manual

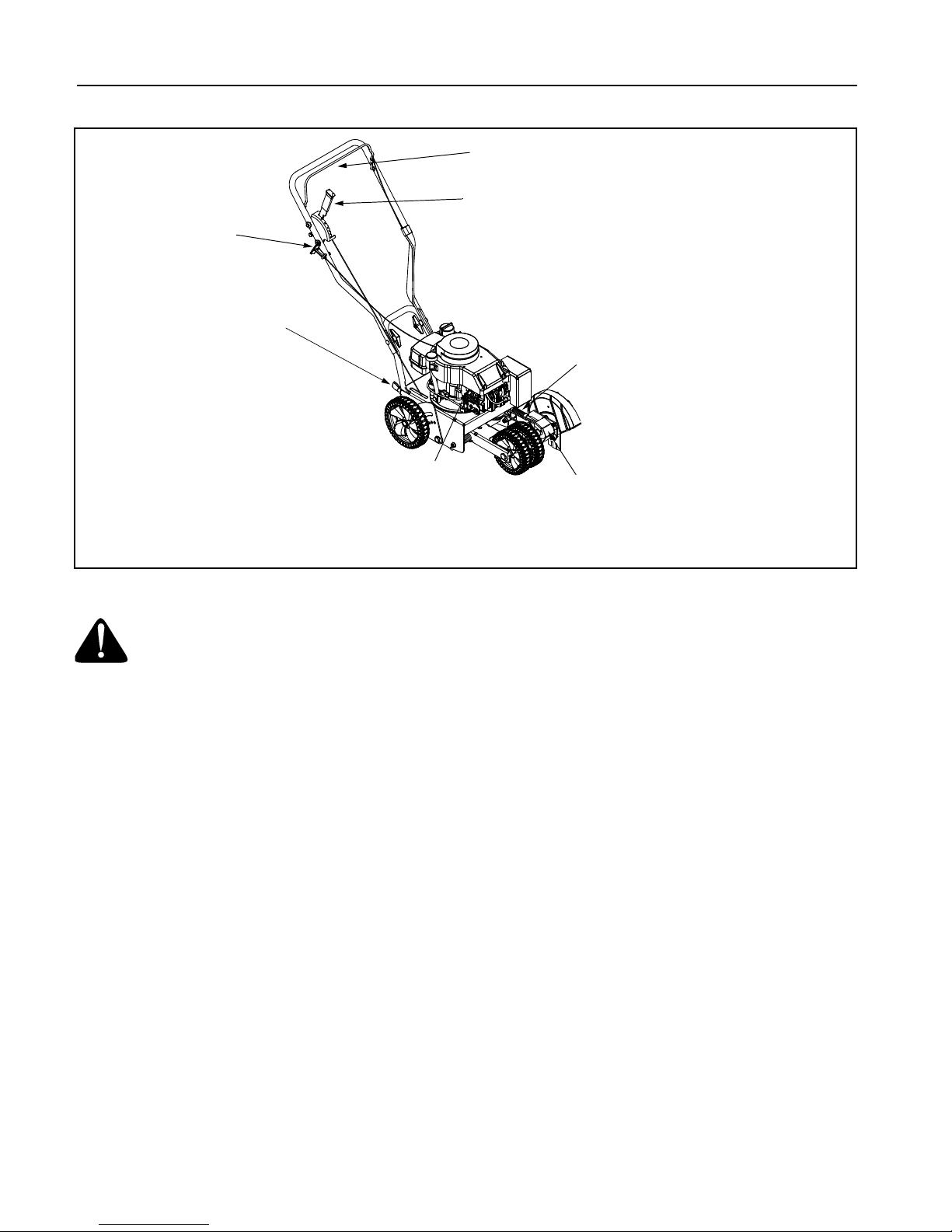

Edger

Models 520

550

551

Model 550 and 551 Shown

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO.

769-00527C.fm

(10/03)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices 3

Assembling Your Edger 5

Know Your Edger 6

Operating Your Edger 7

Making Adjustments 8

Content Page

Maintaining And Servicing Your Edger 10

Off Season Storage 12

Trouble Shooting 12

Illustrated Parts List 13

Warranty 20

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new lawn mower. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, p lease locate the model plate on th e

equipment and copy the information from it in the space pr ovided below. A sample model plate is

also given below. You can locate the model plate by standing at the operating position an d

looking down at the rear of the deck. This information will be necessary to use the

manufacturer’s web site and/or help from the Customer Suppor t Department or an authorized

service dealer.

Copy the model number here:

www.mtdproducts.com

MTD LLC

P. O. BOX

CLEVELAND,OH

330-220-4683

800-800-7310

361131

44136

Copy the serial number here:

CUSTOMER SUPPORT

Please do NOT return the unit to the retailer from where it was purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, opera tion or

maintenance of this unit, you can seek help from the experts. Choose from the options below:

Visit mtdproducts.com for many useful suggestions. Click on Customer Support button and

you will get the four options reproduced here. Click on the appr opriate button and help is

immediately available.

The answer you are

looking for could be just

a mouse click away!

If you prefer to reach a Customer Support Representat ive, please call 1-800-800-7310.

The answer you are

looking for could be just

a mouse click away!

Engine

Manual

The engine manufactur er is responsible for all engine-related issu es with regards to

performance, power-rating, specifica tions, warranty and service. Please re fer to the engine

manufacturer’s Owner’s/Operator’s Manual, packed separately with your unit, for more

information.

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT

FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF

AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE THIS MACHINE. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL — HEED ITS WARNING.

WARNING: The Engine Exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with

any type of power equipment, carelessness or err or on the part of the o perator can result in serious in jury.

If you violate any of these rules, you may cause serious injury to yourself or others.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regu lar reference a nd for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this m achine without

proper instruction.

5. To help avoid blade contact or a thrown object

injury, keep bystanders, helpers, children and pets

at least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

PREPARATION

1. Thoroughly inspect the area where the equipment

is to be used. Remove all stones, sticks, wire,

bones, toys and other foreign objects which could

be tripped over or picked up and thrown by the

blade. Thrown objects can cause serious personal

injury.

2. Always wear safety glasses or safety goggles

during operation and while performing an

adjustment or repair to protect your eyes. Thrown

objects which ricochet can cause serious injury to

the eyes.

3. Wear sturdy, rough-soled work shoes a nd closefitting slacks and shirts. Shirts and pants that cover

the arms and legs and steel-toed shoes are

recommended. Never operate this ma chine in bare

feet, sandals, slippery or light weight (e.g. canvas)

shoes.

4. Never attempt to make any adjustments while the

engine is running, except where specifically

recommended in the operator’s manual.

5. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Washer your skin and change clothes immediately.

a. Use only an approved gasoline containe r.

b. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than ½ inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move unit to another area.

Wait five minutes before starting the engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark or

pilot light as on a water heater, space heater,

furnace,clothes dryer or other gas

appliances.

j. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Do not put hands or feet near rotating parts.

Contact with the rotating blade can amputate hands

and feet.

2. The blade control handle is a safety device. Never

bypass its operation. Doing so, makes the machine

unsafe and may cause personal injury.

3. Never operate without blade guard, debris shield

and blade control handle in place and working.

3

Page 4

4. Never operate with damaged safety devices.

Failure to do so, can result in personal injury.

5. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

6. Do not operate machine while under the influence

of alcohol or drugs.

7. Muffler and engine become hot and can cause a

burn. Do not touch.

8. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles. Walk, never r un.

9. Do not operate this machine if it has been dropped

or damaged. Return machine to your nearest

authorized servicing dealer for examination and

repair.

10. Do not operate this machine with a damaged or

excessively worn cutting blade.

11. Never attempt to clear material from the blade

guard while the engine is running. Sh ut the engine

off, disconnect the spark plug wire and ground

against the engine to prevent unintended starting.

12. Do not overload machine capacity by attempting to

edge at too fast of a rate.

13. Stay alert for uneven sidewalks, terrain etc. Always

push slowly over rough surfaces. Do not use this

machine on gravel surfaces.

14. Do not operate machine in rain or wet soil

conditions.

15. Always operate machine from behind the handle s

and position yourself where the direct line of sight

to cutting blade is blocked by guards.

16. Always stop engine when edging or trimming is

delayed or when transporting machine from one

location to another.

17. Never leave a running machine unattende d. Stop

the engine, disconnect spark plug wire and gr ound

against the engine to prevent unintended starting.

18. Only use parts and accessories made for this

machine by the manufacturer. Failure to do so, can

result in personal injury.

19. If situations occur which are not covered in this

manual, use care and good judgment. Contact an

authorized MTD service dealer or telephone 1-800-

800-7310.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Before cleaning, repairing, or inspecting,

disconnect the spark plug wire and ground against

the engine to prevent unintended start ing.

3. Check bolts, and screws for proper t ightness at

frequent intervals to keep the mach ine in safe

working condition. Also, visually inspect machine

for any damage.

4. Do not change the engine governor setting or overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. The blade, blade guard and de bris shield are

subject to wear and damage. For you r safety

protection, frequently check all components and

replace with original equipment manufacturer’s

(O.E.M.) parts only. “Use of parts which do not

meet the original equipment specifications may

lead to improper performance and compromise

safety!”

6. Maintain or replace safety and instruction labels, as

necessary.

7. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

8. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace,clothes dryer etc.

9.

Always refer to the operator’s manual for proper

instructions on off-season storage.

WARNING: YOUR RESPONSIBILITY

Restrict the use of this power machine to persons who read, understand and follow the warnings

and instructions in this manual and on the machine.

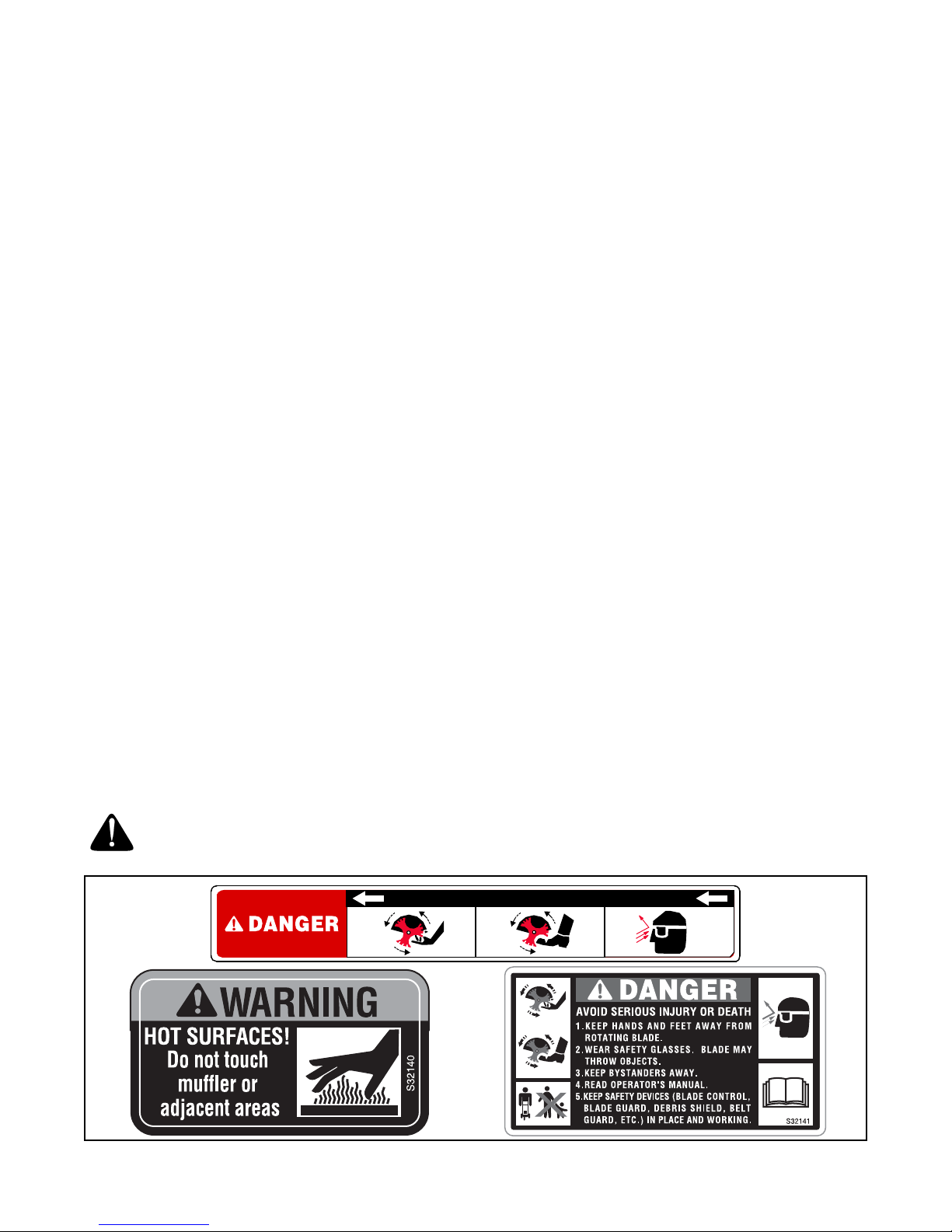

KEEP AWAY — ROTATING BLADE

Figure 1

4

Page 5

SECTION 2: ASSEMBLING YOUR EDGER

IMPORTANT:

GASOLINE or OIL. After setting up the unit, service

engine with gasoline and oil as instructed in the

separate engine manual packed with your unit.

NOTE: Reference to right or left hand side of the edger

is observed from the operating position.

This unit is shipped WITHOUT

Grounding the Engine’s Spark Plug

• Disconnect the spark plug wire from the spark plug.

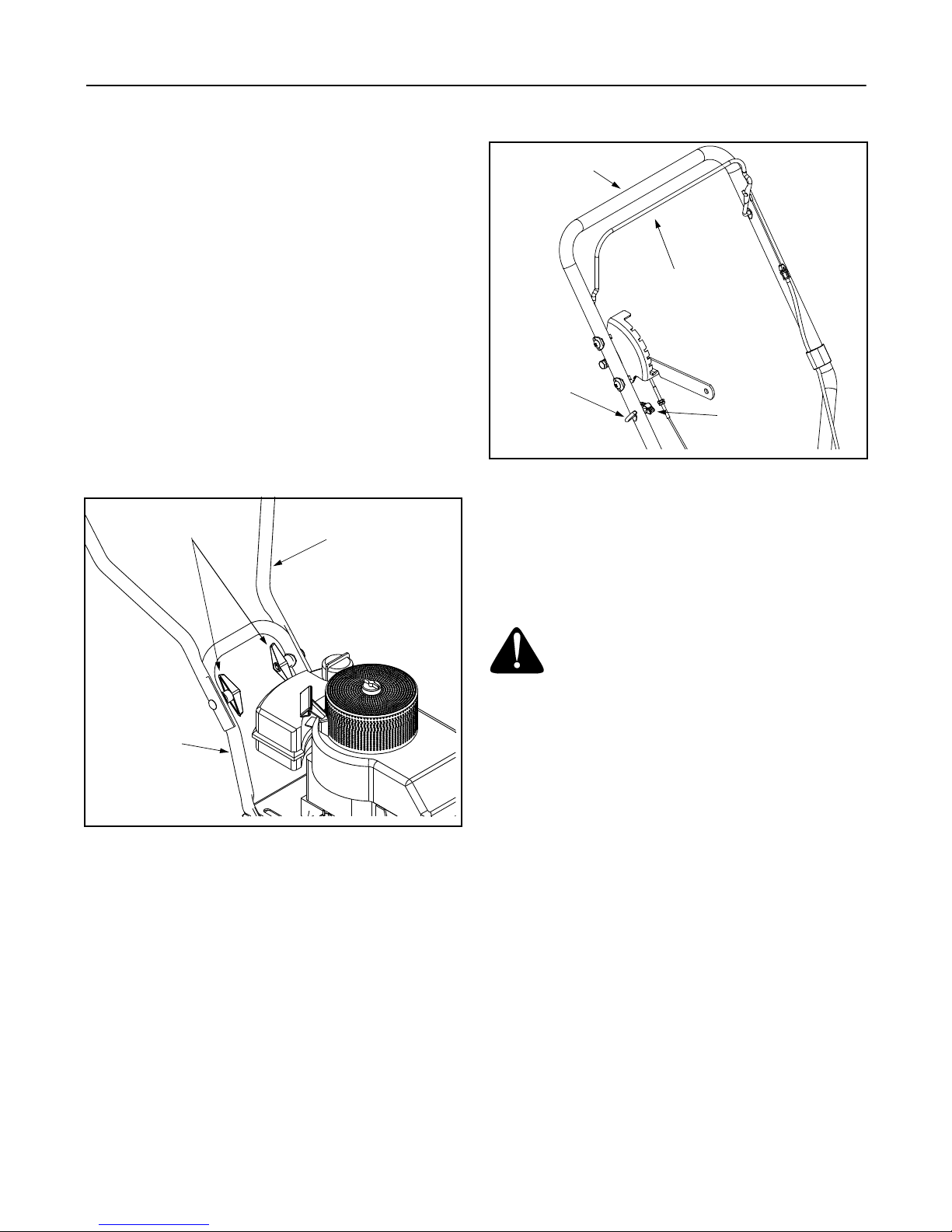

Positioning the Edger Handles

• Remove and discard any packaging cardboard that

may be present between the upper handle and the

lower handle.

• Depress the blade control bail at the top of the

upper handle and pivot the upper handle upwar d

until it snaps into place.

• Tighten the wing knobs which are located on both

the left and right sides of the handle. See Figur e 2 .

Wing Knobs

Upper Handle

Upper Handle

Blade Control Bail

Rope Guide

Wing Knob

Figure 3

IMPORTANT:

wire is properly grounded as instructed earlier in this

section before proceeding on to the next step.

• Stand behind the unit and hold the blade control

bail against the upper handle and gently pull the

starter rope out of the engine.

Make certain that the engine’s spark plug

Lower Handle

Figure 2

Attaching the Starter Rope

• Locate the eyebolt found on the right side of the

upper handle.

• Loosen, but do NOT remove, the wing knob which

secures the rope guide to the upper handle. See

Figure 3.

WARNING: The edger blade WILL rotate

when the starter rope is pulled.

NOTE: The starter rope will not pull out of the engine

unless the blade control bail (refer to Figure 3) is

depressed against the upper handle.

• Slip the starter rope through the top of the rope

guide.

• Retighten the wing knob which secures the rope

guide to the upper handle.

5

Page 6

SECTION 3: KNOW YOUR EDGER

Pull Rope / Recoil Starter

Curb Height

Adjustment Lever

(If Equipped)

Primer

NOTE:

Wheel and blade styles vary by model. Yours may differ slightly.

Model 550 and 551 Shown.

Blade Control Bail

Blade Depth

Control Lever

(Transport Position Shown)

Bevel Adjustment

Lever

(If Equipped)

Spindle Sheaves Belt Guard

Figure 4

WARNING: Be familiar with all controls

and their proper operation. Know how to

stop the machine and disengage them

quickly.

NOTE: Refer to the Engine Manual packed with your

edger for a detailed description of all engine-related

controls and components.

Pull Rope / Recoil Starter

The pull rope/recoil starter is used to start the engine.

Primer

The primer is used to pump gas into the carburetor and

aid in starting the engine. Use it to start a cold engine,

but do not use it to restart a warm engine after a short

shutdown.

NOTE: Refer to the Engine Manual packed with your

edger for a detailed description of all engine-related

controls and components.

Blade Control Bail

Located on the upper handle, the blade control bail

must be depressed against the upper handle in order to

operate the unit. Releasing the blade control stops the

engine and the edger blade. See Figure 4.

Blade Depth Control Lever

The blade depth control lever is located on the right

side of the upper handle. It is used to control the depth

of the cut. The further forward the blade depth control

lever is moved, the deeper into the soil the edger blade

will cut. See Figure 4.

Bevel Adjustment Lever (if so equipped)

The bevel adjustment lever, if so equipped, is locate d

on the front, left portion of the edger, behind the edger

blade. It is used to vary the angle of the edger blad e

between one of three positions for edging/trenching or

beveled edging. See Figure 4.

Curb Height Adjustment Lever

(if so equipped)

The curb height adjustment lever, if so equipped, is

found on the rear portion of the edger.When placed in

an applicable notch, it aids in stabilizing the edger while

edging grass along a curb. See Figure 4.

IMPORTANT:

before operating the edger.

Become familiar with all the controls

6

Page 7

SECTION 4: OPERATING YOUR EDGER

WEAR YOUR

SAFETY GLASSES

FORESIGHT IS BETTER

THAN NO SIGHT

Adding Gasoline And Oil

Service the engine with gasoline and oil as instr ucted in

the Engine Manual packed with your edg er. Read

instructions carefully.

Starting The Engine

NOTE: Refer to the Engine Manual packed with your

edger for a detailed description of all engine-related

controls and components.

To start the edger’s engine, proceed as follows:

• Attach the spark plug wire to the spark plug. Make

certain the metal cap on the end of the spark plug

wire is fastened securely over the metal tip on the

spark plug.

• Move the blade depth control le ver back to the

START position in the adjacent (top) notch.

• Depress the primer bulb three times, pausing two to

three seconds between each push. In cold weather

(below 50°F /19°C), it may be necessary to depress

the primer bulb four or five times.

The operation of any edger can result

in foreign objects being thrown into

the eyes, which can result in severe

eye damage. Always wear safety

glasses or eye shields. We

recommend wide vision safety mask

for over spectacles or standard

safety glasses

WARNING: Do not lower blade if blade is

over concrete, asphalt, rocks or the like. The

blade can strike the supporting surface,

resulting in personal injury or property

damage.

WARNING: Never fill fuel tank indoors, with

engine running or until the engine has been

allowed to cool for at least two minutes after

running.

IMPORTANT:

Using the primer to restart a warm engine

after a short shutdown is usually not necessary. Doing

so may result in a flooded engine .

• Standing behind the unit, depress the blade con trol

bail and hold it against the upper handle with your

left hand.

WARNING: This control mechanism is a

safety device. Never atte mpt to bypa ss its

operation.

• With your right hand, grasp the recoil starter handle

and slowly pull the rope outward until engine

reaches the start of its compression cycle (the rope

will pull slightly harder at this point).

• After slowly allowing the rope to recoil, pull the rope

with a rapid, continuous, full arm stroke. Keep a firm

grip on starter handle throughout the en tire stroke.

• Allow the starter handle to slowly return to the

eyebolt.

NOTE: If the engine fails to start after three pulls,

depress the primer an additional two times before

pulling the starter rope again.

To begin edging, proceed as follows:

• Move the blade depth control lever to the left and

place it into any of the five lower notches. The

further forward the blade depth control lever is

moved, the deeper or lower the blade will cut into

the ground.

IMPORTANT:

For best results, proceed slowly along the

path being edged, slowly moving the edger back and

forth through the cutting area.

Stopping The Engine

To stop the edger’s engine, proceed as follows:

• Release the blade control handle.

NOTE: See your engine manual packed with your unit

for more detailed instructions.

IMPORTANT:

wire is properly grounded as instructed in SECTION 2:

Assembling The Edger before storing the edger for its

next use.

Make certain that the engine’s spark plug

7

Page 8

SECTION 5: MAKING ADJUSTMENTS

Bevel Adjustment (models so equipped)

NOTE: Edger features vary by mod el. All edger models

do NOT come equipped for blade tilt adjus tment nor is

there a blade tilt kit available to modify your edger if it

was not purchased equipped to do so.

The angle of the edger blade can be adjusted by

placing the bevel adjustment lever in one of three

positions for edging/trenching or beveled edging. See

Figure 5.

Bevel

Adjustment

Lever

Beveling

Edging/Trenching

Position Shown

Figure 5

WARNING: Rotating cutting blade may

throw objects causing personal injury.

Keep area clear of bystanders and do not

operate without guards in place.

Edging

Set the bevel adjustment lever (refer to Figure 5) in the

center notch to place the edger blade in a 90° position

for edging. See Figure 7.

Edging/Trenching Position

Figure 7

Trenching (models so equipped)

NOTE: Edger features vary by model. All ed ger models

do NOT come equipped for trenching. If your edger was

not purchased equipped to do so, you may purchase

part no. 736-04088 (flat washer) an d p art no. 7 81-07 48

(triplex edger blade) to utilize this feature.

WARNING: Disconnect the spark plug wire

and ground against the engine before

performing the following steps.

WARNING: The edger blade is sharp. Wear

leather work gloves to protect your hands

when working around the edger blade.

Beveling

Set the bevel adjustment lever (refer to Figure 5) in the

first (left hand) or third (right hand) notch to place the

edger blade in position for beveling. See Figure 6.

Beveling Positions

Figure 6

• Working in front of the edger, loosen the f lange lock

nut on top of frame, allowing the idler pulley

assembly to pivot slightly out from the frame. See

Figure 8.

• With your other hand, carefully rea ch under the rear

of the unit and remove the belt from around the

engine flywheel pulley. See Figure 8.

Flange Lock Nut

Engine

Flywheel Pulley

Figure 8

8

Spindle

Sheaves Belt Guard

Page 9

• Remove the spindle sheaves belt guard by

removing the two self-tapping screws which secure

it to the blade plate assembly. See Figure 9.

Blade Plate

Assembly

• Secure with the bell washer and the hex lock nut

removed earlier. See Figure 11.

Hex

Screws

Spindle Sheaves

Belt Guard

Spindle Sheaves

Note: Wheel and blade styles vary by model.

Figure 9

• Use two wrenches (one wrench to prevent the hex

bolt head from spinning and the other to unthre ad

the hex lock nut) to remove th e hex lock nut and

bell washer that secure the edger blade, leaving the

edger blade in place. See Figure 10.

Edger Blade

Flat Washer

Triplex Blade

Bell Washer

Hex Lock Nut

Figure 11

IMPORTANT:

Use a torque wrench to tighten the hex

lock nut to between 37 foot-lbs. and 50 foot-lbs.

• Reinstall the spindle belt guard with th e self tapping

screws removed earlier.

• Carefully place the drive belt back onto the engine

flywheel pulley, and retighten the f lange lock nut on

the top of the frame.

IMPORTANT:

Make certain that the drive belt is seated

correctly on the blade spindle and that it is riding

smoothly on the spindle sheaves and is not pinched

between them. Repeat the first three steps if the belt is

pinched.

• Set the bevel adjustment lever (refer to Figure 5) in

the center notch to place the edger blade in a 90°

position (see Figure 7) and place the blade depth

control lever in the lowest position.

Bell Washer

Hex Bolt Head

Note: Wheel styles vary by model.

Hex Lock Nut

Figure 10

• Install the flat washer (part no. 736-04088) and the

triplex edger blade (part no. 781-0748) that ar e

packed separately in the box.

IMPORTANT:

For best results, proceed slowly along the

path being trenched, slowly moving the edger back and

forth through the cutting area.

NOTE: Utilizing this feature will enable you to create a

wider cutting path for such things as laying wire for

landscape lighting or invisible fences.

Edging Along A Curb (models so

equipped)

NOTE: Edger feat ures vary by model. All edger models

do NOT come equipped to edge along a curb nor is

there a curb wheel kit available to modify your edger if it

was not purchased equipped to do so.

On models so equipped, the right, rear wheel of the

edger can be lowered into one of five positions to ease

the task of edging along a curb.

To adjust the height of the curb wheel, proceed as

follows:

9

Page 10

• Lower the right, rear wheel by moving the curb

height adjustment lever slightly to the left. See

Figure 12.

Curb Height

Adjustment

Lever

(Normal Operating

Position)

Figure 12

• Pivot the right, rear wheel into an applicable

position in relation to the height of the curb to be

edged along.

• Release the curb height adjustment lever to lock

the wheel in position. See Figure 13.

Curb Height Adjustment Lever

Figure 13

SECTION 6: MAINTAINING & SERVICING YOUR EDGER

(Lowered Position)

WARNING: Disconnect the spark plug wire

and ground against the engine before

performing any adjustment, repairs or

maintenance.

Lubrication

Engine

Refer to the Engine Manual packed with your edger for

a detailed description of all engine-related service

specifications.

Wheels

Lubricate the wheels and bearings at least once a

season with a light oil. Also if the wheels are removed

for any reason, lubricate the surface of the axle bolt and

the inner surface of the wheel with light oil.

Pivot Points

Lubricate the pivot points on the blade control bail,

blade depth control lever, and if applicable, the blade

adjustment lever, and curb height adjustment lever with

light oil at least once a season.

Bearing Block

On the Model 550 and551, the bearing block is

equipped with a grease fitting. Lubricate with a gre ase

gun after every 25 hours or at least once a season. On

the Model 521, simply apply oil through the tiny hole in

the cover plate. See Figure 14.

Model 550 and 551

Shown

Lube

Fitting

Figure 14

Replacing the Edger Blade

WARNING: The edger blade is sharp. Wear

leather work gloves to protect your hands

when working around the edger blade.

WARNING: Disconnect the spark plug wire

and ground against engine before

performing the following steps.

• Working in front of the edger, loosen the f lange lock

nut on top of frame, allowing the idler pulley

assembly to pivot slightly out from the frame. See

Figure 15.

10

Page 11

• With your other hand, carefully reach under the rear

of the unit and remove the belt from around the

engine flywheel pulley.

• Remove the spindle sheaves belt guard by

removing the two self-tapping screws which secure

it to the blade plate assembly. See Figure 9.

• Use two wrenches (one wrench to prevent the hex

bolt head from spinning and the other to remove the

hex lock nut and bell washer) to remove the edger

blade. Refer to Figure 10.

• Remove and discard the edger blade but retain the

bell washer and hex lock nut.

• Install the replacement edger blade, the bell

washer (cupped side facing inward) and the hex

lock nut removed earlier.

IMPORTANT:

Use a torque wrench to tighten the hex

lock nut to between 37 foot-lbs. and 50 foot-lbs.

• Reinstall the spindle belt guard with th e self tapping

screws removed earlier.

• Carefully place the drive belt back onto the engine

flywheel pulley, and retighten the f lange lock nut on

the top of the frame.

IMPORTANT:

Make certain that the drive belt is seated

correctly on the blade spindle and that it is riding

smoothly on the spindle sheaves and is not pinched

between them. Repeat the first three steps if the belt is

pinched.

Replacing the Drive Belt

IMPORTANT:

of the drive belt on the two idler pulleys and the engine

flywheel pulley prior to performing the f ollowing steps.

Refer to Figure 15.

To aid in reassembly, note the orientation

Flange Lock Nut

• With your other hand, carefully rea ch under the rear

of the unit and remove the belt from around the

engine flywheel pulley.

• Remove the spindle sheaves belt guard by

removing the two self-tapping screws which secure

it to the blade plate assembly. See Figure 9.

• Carefully remove the belt from off of the pulleys,

again making sure to note the orientation of the

belt. Discard the belt.

Install the replacement belt (Part No. 754-04 032) in the

same configuration that the original belt was routed as

follows:

• Working from the front of the edger, pl ace the belt

onto the spindle sheaves, route it back onto the two

idler pulleys, and then place it onto th e engine

flywheel pulley.

IMPORTANT:

Make certain that the “V” side of the belt is

seated into the top pulley and the flat side of the belt is

seated into the bottom pulley. See Figure 15.

• Reinstall the spindle sheaves belt guard with the

self tapping screws removed earlier.

• Make certain that the drive belt is on the engine

flywheel pulley and idler pulleys, and retighten the

flange lock nut on the top of the frame.

IMPORTANT:

Make certain that the drive belt is seated

correctly and that it is riding smoothly on the spindle

sheaves and is not pinched between them. Repeat the

first three steps if the belt is pinched.

WARNING: Never operate the edger without

the spindle sheaves belt guard in place.

Engine

Flywheel

Pulley

Flat Side

of Belt

Idler Pulley

Assembly

“V” Side

of Belt

Figure 15

The edger drive belt is subject to wear and should be

replaced if any signs of cracking, shredding or rotting

are present. To replace the belt, proceed as follows:

• Working in front of the edger, loosen the f lange lock

nut on top of frame, allowing the idler pulley

assembly to pivot slightly out from the frame. See

Figure 15.

Spindle Sheaves

Belt Guard

11

Page 12

SECTION 7: OFF-SEASON STORAGE

Observe the following when preparing the edger for

long-term storage:

• Clean and lubricate unit thoroughly as instructed on

page 10 of this manual.

• Refer to the Engine Manual packed separat ely with

the edger for engine manufacturers’s storage

instructions.

• Coat the edger blade with chassis grease to

prevent rusting and corrosion.

• Store the edger in a dry, clean area. Do not sto re

next to any corrosive materials, such as lawn

fertilizer.

• Coat the edger, especially any springs and

bearings with a light oil or silicone spray.

IMPORTANT:

equipment in an poorly ventilated or metal storage

shed, care should be taken to rustproof the equipment.

When storing any type of power

SECTION 8: TROUBLESHOOTING

Trouble Possible Cause(s) Corrective Action

Engine fails to start Dirty air cleaner

Engine needs to be primed

Fuel tank empty

Stale fuel in gasoline tank

Spark plug wire disconnected.

Spark plug fouled

Engine flooded

Engine runs erratic Spark plug wire loose

Stale fuel in gasoline tank

Vent in gas cap plugged

Water or dirt in fuel system

Dirty air cleaner

Carburetor out of adjustment

Engine overheats Engine oil level low

Air flow restricted

Dirty air filter

Carburetor not adjusted properly

Excessive vibration Edger blade bent or dam aged

Blade spindle bent or damaged

Drive belt slips Belt worn or stretched Replace drive belt.

Refer to the Engine Manual packed with your unit.

Push primer bulb two or three times.

Fill tank with clean, fresh gasoline.

Drain gasoline and refill tank with clean, fresh gasoline.

Connect the spark plug wire to the spark plug.

Clean, adjust gap or replace spark plug.

Refer to the Engine Manual packed with your unit.

Connect and tighten spark plug wire .

Drain gasoline and refill tank with clean, fresh gasoline.

Clear vent of any debris.

Drain fuel tank. Refill with fresh fuel.

Refer to the Engine Manual packed with your unit.

Refer to the Engine Manual packed with your unit.

Fill crankcase with proper oil.

Clean the area around the engine’s cooling fins.

Replace the engine’s air filter.

Refer to the Engine Manual packed with your unit.

Replace edger blade.

Contact an authorized MTD service dealer.

12

Page 13

SECTION 9: PARTS LIST FOR MODEL 520/550/551 HANDLE

1

12

19†

8

20

11

5

17

7

10

3

2

15

14

18

6

13

16

9

11

REF.

NO.

1 710-3103 Screw, 5/16-18

2 710-0449 Screw, 5/16-18

3 710-1205 Eye Bolt

4 710-3008 Screw, 5/16-18

5 710-0606 Screw

6 712-3004A Hex Lock Nut, 5/16-18

7 720-0279 Wing Nut

8 720-0142 Grip

9 720-0241 Wing Knob

10 732-0369 Compression Spring

11 736-0451 Saddle Washer,.320 ID x.93 OD

PART

NO. DESCRIPTION

6

4

REF.

NO.

12 746-04036 Wheel Adjustment Cable

13 746-04035 Control Cable (Briggs & Stratton)

14 747-0976A Bail Handle

15 749-1225 Upper Handle

16 749-4044 Lower Handle

17 781-0741 Depth Index Bracket

18 781-0742 Depth Index Lever

19 720-0297† Foam Grip

20 712-3027 Hex Flange Nut, 1/4-20

†If so equipped

PART

NO. DESCRIPTION

746-04052 Control Cable (Tecumseh)

13

Page 14

Model 520/550/551 Frame

15

2

5

9

3

11

10

6

14

7

8

1

REF.

NO.

1 710-0191 Screw, 3/8-24

2 710-0599 Screw, 1/4-20

3 710-0654A Screw, 3/8-16

4 710-0944 Screw, 3/8-16

5 712-0431 Flange Lock Nut, 3/8-16

6 731-04168 Debris Guard

7 736-0320 Flat Washer, 3/8 ID x 1.37 OD

8 736-0452 Bell Washer,.396 x 1.140

9 736-3052 Flat Washer,.406 x 1.00

10 736-3090 Flat Washer,.260 x.720

11 750-04142 Pulley Mount Spacer

12 756-0313 Flat Idler Pulley, 1.88 OD

13 756-1035A Idler Pulley

14 756-1150A Combination Flywheel Pulley

15 787-01072 Frame

PART

NO. DESCRIPTION

13

12

4

14

Page 15

Model 520 Spindle Assembly

28†

29†

20

22

11

18

10

19

21

1

7

24

23

26

3

4

7

15

17

17

9

17

13

5

8

16

25

27

2

12

14

6

V-BELTS are specially designed to engage and

disengage safely. A substitute (non-OEM) V-Belt

can be dangerous by not disengaging completely.

REF.

NO.

1 687-02019 Blade Plate Assembly

2 710-0395 Hex Screw, 5/16-18

3 710-0599 Self-tapping Screw, 1/4-20

4 710-1143A Hex Screw, 5/8-18

5 711-1017 Clevis Pin

6 712-3004A Hex Lock Nut, 5/16-18

7 712-3027 Hex Flange Nut, 1/4-20

8 712-3056 Jam Nut, 5/8-18

9 714-0104 Cotter Pin

10 718-04012 Bearing Cup

11 731-04158 Blade Guard

12 731-04207 Bearing Block

13 732-04169 Compression Spring

14 736-0119 Lock Washer

15 736-0187 Flat Washer

PART

NO. DESCRIPTION

REF.

NO.

16 736-0317 Bell Washer,.63 ID x 1.2 OD

17 736-3090 Flat Washer,.260 x.72

18 738-04025 Pin, 1/4-20

19 741-0524 Bearing,.625 ID x 1.57 OD

20 736-04088 Flat Washer

21 750-04105 Spacer,.63 x 1.12 x 1.06

22 750-0547 Spacer,.632 ID x.875 OD

23 754-04032 Belt

24 756-0449 Sheave

25 781-0080 Blade

26 781-0427 Belt Guard

27 787-01075 Cover Plate

28 736-04088† Flat Washer

29 781-0748† Tri Star Blade

PART

NO. DESCRIPTION

†If so equipped

15

Page 16

Model 550 And 551 Spindle Assembly

30†

31†

22

24

10

19

9

20

23

1

6

26

25

28

3

4

6

7

16

27

18

29

8

2

21

13

11

14

5

17

17

15

12

V-BELTS are specially designed to engage and

disengage safely. A substitute (non-OEM) V-Belt

can be dangerous by not disengaging completely.

REF.

NO.

1 687-02019 Blade Plate Assembly

2 710-0395 Hex Screw, 5/16-18

3 710-0599 Self-tapping Screw, 1/4-20

4 710-1143A Hex Screw, 5/8-18

5 712-3004A Hex Lock Nut, 5/16-18

6 712-3027 Hex Flange Nut, 1/4-20

7 712-3056 Jam Nut, 5/8-18

8 714-3010 Cotter Pin

9 718-04012 Bearing Cup

10 731-04158 Blade Guard

11 731-04207 Bearing Block

12 732-04169 Compression Spring

13 732-0188A Double Torsion Spring

14 736-0119 Lock Washer

15 736-0187 Flat Washer

16 736-0317 Bell Washer,.63 ID x 1.2 OD

PART

NO. DESCRIPTION

REF.

NO.

17 736-3090 Flat Washer,.260 x.72

18 737-3000 Lube Fitting, 3/16

19 738-04025 Pin, 1/4-20

20 741-0524 Bearing,.625 ID x 1.57 OD

21 747-04110 Blade Adjustment Rod

22 736-04088 Spacer.635 ID x.88 OD

23 750-04105 Spacer,.63 x 1.12 x 1.06

24 750-0547 Spacer,.632 ID x.875 OD

25 754-04032 Belt

26 756-0449 Sheave

27 781-0080 Blade

28 781-0427 Spindle Belt Guard

29 787-01081 Index Bracket

30 736-04088† Flat Washer

31 781-0748† Tri Star Blade

PART

NO. DESCRIPTION

†If so equipped

16

Page 17

Model 520 Wheel Assembly

(Frame shown for reference only)

6

3

1

8

8

3

1

1

5

REF.

NO.

1 712-0431 Flange Lock Nut, 3/8-16

2 732-04045 Torsion Spring

3 734-1987 Wheel 8x1.8

4 734-1988 Wheel 7x1.8

5 738-04037 Shoulder Screw,.50 x 9.36, 3/8-16

6 738-04038 Shoulder Screw,.50 x 12.90, 3/8-16

7 738-04039 Shoulder Screw,.50 x 3.19, 3/8-16

8 750-0289 Spacer,.510 ID x.875 OD

9 750-04129 Spacer,.525 x.775

10 787-01074 Wheel Bracket

PART

NO. DESCRIPTION

9

2

7

10

1

8

4

17

Page 18

Model 550 And 551 Wheel Assembly

(Frame shown for reference only)

2

4

7

18

2

8

17

4

2

10

8

2

1

9

13

PART

NO. DESCRIPTION

1 687-02022 Curb Height Adjustment Lever

2 712-0431 Flange Lock Nut, 3/8-16

3 732-04045 Torsion Spring

4 734-1987 Wheel 8x1.8

5 734-1988 Wheel 7x1.8

6 736-0182 Spring Washer,.500 x 1.00

7 736-0208 Flat Washer,.51 ID x 1.5 OD

8 736-0232 Wave Washer,.531 ID x.781 OD

9 736-0234 Washer,.385 x 1.5

10 738-0213 Shoulder Screw,.498 x 1.445

11 738-0380 Shoulder Screw,.50 x.27

12 738-04036 Shoulder Screw,.50 x 4.62

13 738-04037 Shoulder Screw,.50 x 9.36, 3/8-16

14 738-04041 Shoulder Screw,.50 x 11.61

15 750-04129 Spacer,.525 x.775

16 750-04165 Spacer,.525 x.775

17 750-0664 Spacer,.505 ID x.88 OD

18 781-0100 Curb Height Adjuster Plate

19 787-01074 Wheel Bracket

14

11

6

REF.

NO.

15

19

3

12

16

5

8

18

Page 19

NOTES

19

Page 20

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by MTD LLC with

respect to new merchandise purchased and used in the

United States, its possessions and territories.

“MTD”warrants this product against defects in material and

workmanship for a period of two (2) years commencing on the

date of original purchase and will, at its option, repair or

replace, free of charge, any part found to be defective in

materials or workmanship. This limited warranty shall only

apply if this product has been operated and maintained in

accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse,

commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water, or damage because of

other peril or natural disaster. Damage resulting from the

installation or use of any part, accessory or attachment not

approved by MTD for use with the product(s) covered by this

manual will void your warranty as to any resulting damage.

Normal wear parts are warranted to be free from defects in

material and workmanship for a period of thirty (30) days from

the date of purchase. Normal wear parts include, but not

limited to items such as: batteries, belts, blades, blade

adapters, grass bags, rider deck wheels, seats, snow thrower

skid shoes, shave plates, auger spiral rubber and tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized

service dealer. To locate the dealer in your area, check your

Yellow Pages, or contact MTD LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-800-800-7310 or 1330-220-4683 or log on to our Web site at

www.mtdproducts.com.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

may carry a separate manufacturer’s warranty. Refer

to applicable manufacturer’s warranty for terms and

conditions.

b. Log splitter pumps, valves, and cylinders have a

separate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening, tune-ups, brake adjustments, clutch

adjustments, deck adjustments, and normal

deterioration of the exterior finish due to use or

exposure.

d. Service completed by someone other th an an

authorized service dealer.

e. MTD does not extend any warranty for products sold or

exported outside of the United States, its possessions

and territories, except those sold through MTD’s

authorized channels of export distribution.

f. Replacement parts that are not genuine MTD parts.

g. Transportation charges and service calls.

No implied warranty, including any implied w arranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, except as

mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product,

shall bind MTD. During the period of the warranty, the

exclusive remedy is repair or replacement of the product

as set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. MTD

shall not be liable for incidental or consequential loss or

damage including, without limitation, expenses incurred

for substitute or replacement lawn care services or for

rental expenses to temporarily replace a warranted

product.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, or limitations on how

long an implied warranty lasts, so the above exclusions or

limitations may not apply to you.

In no event shall recovery of any kind be gre ater than the

amount of the purchase price of the product sold. Alteration

of safety features of the product shall void this warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the

original purchaser or to the person for whom it was purchased

as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

IMPORTANT:

Owner must present Original Proof of

Purchase to obtain warranty coverage.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-800-800-7310, 1-330-220-4683

Loading...

Loading...