Page 1

Gasoline Chain Saws

SAFETY

OPERATION

MAINTENANCE

USER MANUAL

Models : MS354, EB356, EB358

This product has been tested at a computed kickback angle (CKA) and conforms to ANSI B175.1-2000, Annex C.

CAN/CSA-Z62.1-03

WARNING • PLEASE READ

Beware of kickback. Hold chain saw firmly with both hands when using. For your own safety, please read and follow the

ety precautions in this manual before attempting to operate your chain saw. Improper use can cause serious injury.

saf

an

aiw

PN 9096-311009

inted in

Pr

T

Page 2

INTRODUCTION 1 - GENERAL INFORMATION

PLEASE READ

Dear Customer,

Thank you for purchasing a McCulloch product. With prop-

er operation and maintenance, it will provide you with years

of service.

In order to make the best use of your investment, be CER-

TAIN to familiarize yourself with the contents of the

ENTIRE user manual before attempting to operate and

maintain your unit.

Be sure to carefully follow the step-by-step instructions in

this manual to start, operate and maintain your new product.

In the manual there will be the following call-outs: NOTE:,

WARNING / CAUTION and WARRANTY.

A NOTE: is used to convey additional information, to high-

light a particular explanation, or to expand a step description.

A WARNING or CAUTION identifies a procedure which, if

not undertaken or if improperly done, can result in serious

personal injury and/or damage to the unit.

The (WARRANTY SYMBOL) serves notice that unless

instructions or procedures are followed, any damage

caused will void the warranty and repairs will be at owner’s

expense.

Pay particular attention to the safety precautions. They are

written for your protection and contain important information you must know to safely operate your chain saw.

FOR WARRANTY OR SERVICE CONTACT THE NEAREST

AUTHORIZED SERVICE CENTER - LOCATE YOUR NEAR-

EST SERVICE CENTER BY CALLING THE TOLL FREE

NUMBER IN THIS MANUAL.

TABLE OF CONTENTS

1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . .3

1-1. General Identification

1-2. Safety Features

2 SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2-1. Kickback Safety Precautions

2-2.

Other Safety Precautions

2-3. General Safety Precautions for chain saw users

2-4. More About Kickback

2-5. Kickback safety Labels

2-6. International Symbols

3 ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . .7

3-1.

Tools for Assembly

3-2. Assembly Requirements

3-3. Guide Bar / Saw Chain / Clutch Cover Installation

3-4. Saw Chain Tension Adjustment

3-5. CHAIN BRAKE

4 FUEL AND LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . .10

4-1. Fuel

4-2. Mixing Fuel

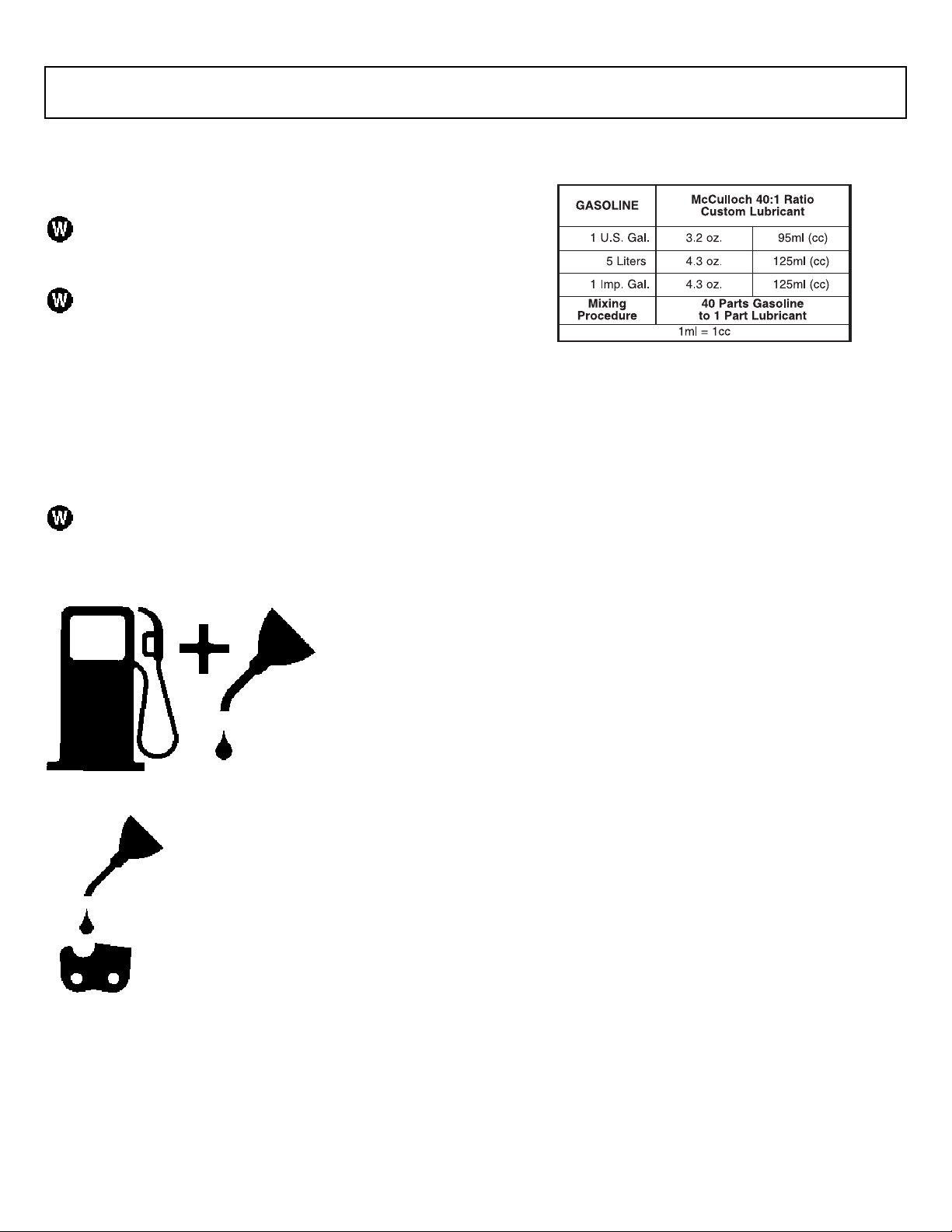

4-3. Fuel and Lubrication Symbols

Fuel Mixing Table

4-4. Recommended Fuels

4-5. Chain and Bar Lubrication

5 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . .11

5-1. Engine Pre-Start Checks

5-2. To Start Engine

5-3. Re-Starting a Warm Engine

5-4. To Stop Engine

5-5. CHAIN BRAKE

5-6. Saw Chain / Bar Lubrication

5-7. Automatic Oiler

6 GENERAL CUTTING INSTRUCTIONS . . . . . . . . . . . . . . . .13

6-1. Felling

6-2. Limbing

6-3.

Bucking

6-4. Bucking Using a Sawhorse

7 MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . .15

7-1.

Pre

ventive Maintenance

7-2. Air Filter

Fuel Filter

7-3.

7-4. Spark Arrester Screen

k Plug

Spar

7-5.

uretor Adjustment

Carb

7-6.

ing a Chain Sa

Stor

7-7.

Removing a Unit From Storage

7-8.

AR / CHAIN MAINTENANCE

B

8

Guide Bar Maintenance

8-1.

Chain Maintenance

8-2.

Chain Replacement Inf

8-3.

OUBLESHOO

TR

9

PART LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

10

®

Mechanical Test

®

Operational Test

w

or

THE ENGINE

TING

. . . . . . . . . . . . . . . . . . . . . .

mation

. . . . . . . . . . . . . . . . . .

18

20

2 3

Page 3

25

24

4

5

6

7

3

2

8

1

16

17

18

19

20

21

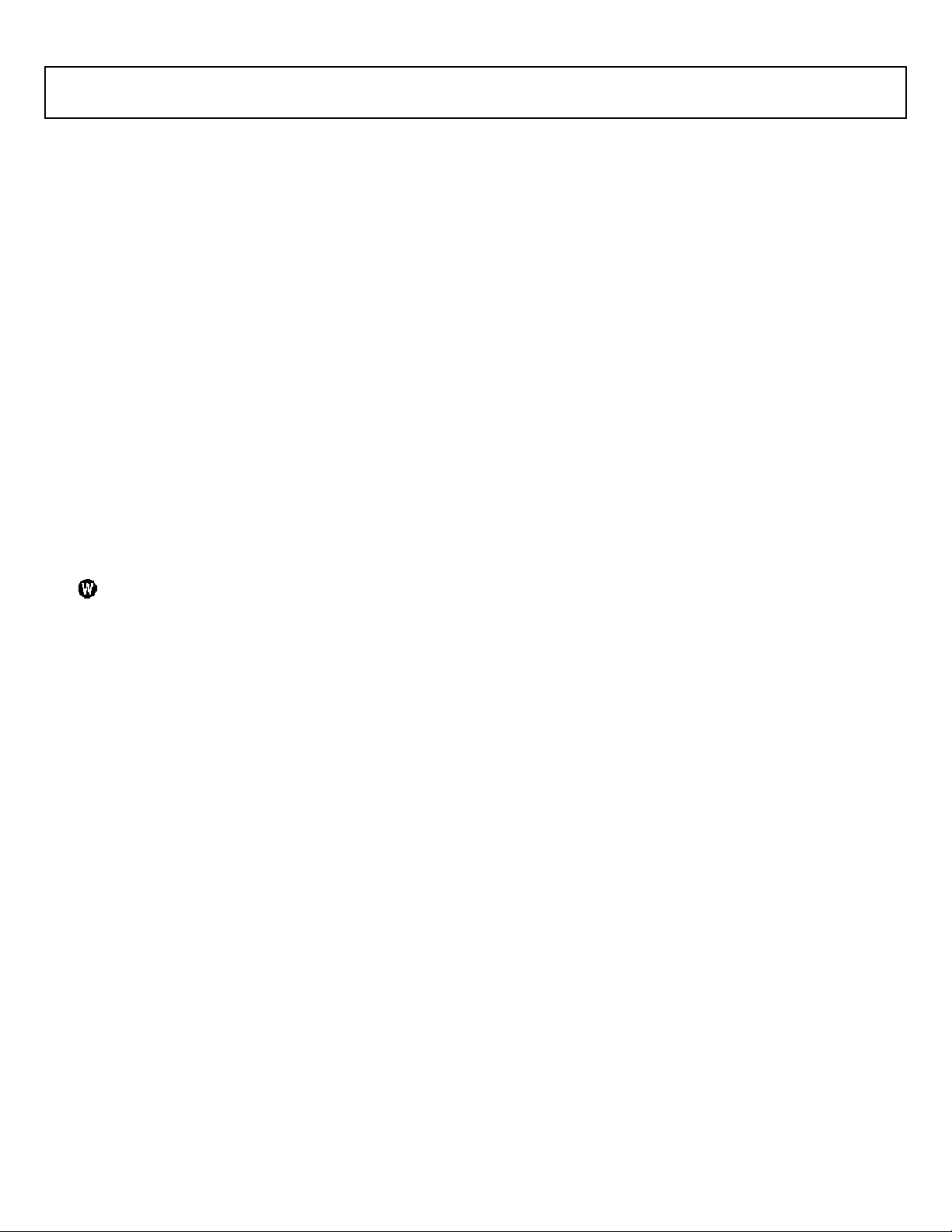

1-1.GENERAL IDENTIFICATION

1. SAW CHAIN

2. GUIDE BAR

3. SPARK ARRESTER SCREEN

4. CHAIN BRAKE

5. FRONT HANDLE

6. ST

ARTER HANDLE

7. STOP SWITCH

8. SAFETY TRIGGER

9. REAR HANDLE / BOOT LOOP

TANK CAP

OIL

10.

11. FUEL TANK CAP

12. STARTER COVER

UCKING SPIKE

B

13.

14. BAR RETAINING NUTS

15. MUFFLER SHIELD

ARK PLUG

SP

16.

17. AIR CLEANER COVER

18. CHOKE LEVER

THROTTLE LATCH

19.

20. PRIMER BULB

21. THROTTLE / TRIGGER

SAW CHAIN ADJUSTMENT SCREW

22.

CHAIN CA

23.

24. SCREWDRIVER/WRENCH

CARRY CASE (Available on some models)

25.

®

LEVER /HAND GUARD

TCHER

22

15

23

14

13

12

11

10

9

1-2. SAFETY FEATURES

Numbers preceding the descriptions correspond with the

numbers on preceding page to help you locate the safety

feature.

1 LOW KICKBACK SAW CHAIN helps significantly

reduce kickback, or the intensity of kickback, due to

specially designed depth gauges and guard links.

3 SPARK ARRESTER SCREEN retains carbon and

other flammable particles over 0.023 inches (0.6mm)

in size from engine exhaust flow. Compliance with

local, state and federal laws and/or regulations governing the use of a spark arrester screen is the user’s

responsibility

See Saf

.

ety Precautions f

information.

4 CHAIN BRAKE®LEVER / HAND GUARD protects

ent it slips off the front

s left hand in the e

the oper

ator’

handle while sa

w is r

unning.

v

4 CHAIN BRAKE®is a safety feature designed to

reduce the possibility of injury due to kickback by

stopping a moving saw chain in milliseconds. It is activated by the CHAIN BRAKE®lever.

7

immediately stops the engine when

OP SWITCH

ST

tripped. Stop switch must be pushed to ON position to

start or restart engine.

SAFETY

8

of the engine

TRIGGER

. Throttle trigger (20) cannot be

ents accidental acceler

v

pre

squeezed unless the safety latch is depressed.

23 CHAIN CATCHER reduces the danger of injury in the

ent sa

v

e

w chain breaks or der

ails during operation.

The chain catcher is designed to intercept a whipping

chain.

or additional

ation

Page 4

2 - SAFETY PRECAUTIONS

SAFETY PRECAUTIONS FOR CHAIN SAW USERS

(ANSI B175.1-2000, Annex C. CAN/CSA-Z62.1-03)

2-1. KICKBACK SAFETY PRECAUTIONS

WARNING

Kickback may occur when the nose or tip of the guide bar

touches an object, or when the wood closes in and pinches the saw chain in the cut. If bar tip makes contact with

something it may cause a lightning-fast reverse reaction,

kicking the guide bar up and back towards the operator.

Pinching the saw chain along the top of the guide bar may

push the guide bar rapidly back towards the operator.Either

of these reactions may cause you to lose control of the saw,

which could result in serious personal injury. Do not rely

exclusively upon the safety devices built into your saw. As

a chain saw user, you should take several steps to keep

your cutting jobs free from accident or injury.

1. With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents.

2. Keep a good firm grip on the saw with both hands, the

right hand on the rear handle, and the left hand on the

front handle, when the engine is running. Use a firm

grip with thumbs and fingers encircling the chain saw

handles. A firm grip will help you reduce kickback and

maintain control of the saw. Don’t let go.

3. Make sure that the area in which you are cutting is

free from obstructions. Do not let the nose of the guide

bar contact a log, branch, or any other obstruction

which could be hit while you are operating the saw.

4. Cut at high engine speeds.

5. Do not overreach or cut above shoulder height.

6. Follow manufacturer’s sharpening and maintenance

instructions for the saw chain.

7. Only use replacement bars and chains specified by

the manufacturer or the equivalent.

w chain is chain that has met the

k sa

TE:Low-kic

NO

kickback performance requirements of ANSI B175.1-2000

ican National Standard for Power Tools Gasoline-

(Amer

ered Chain Sa

w

o

P

on the representative sample of chain saws below 3.8 c.i.d.

specified in ANSI B175.1-2000.

2-2. OTHER SAFETY PRECAUTIONS

1. DO NOT operate a chain saw with one hand! Serious

injury to the operator, helpers, bystanders, or any

combination of these persons may result from onehanded operation. A chain saw is intended for twohanded use.

DO NO

2.

3. Use safety footwear, snug-fitting clothing, protective

gloves, and eye, hearing and head protection devices.

kbac

T oper

ws Saf

ate a chain sa

ety Requirements) when tested

w when y

ou are f

atigued.

4. Use caution when handling fuel. Move the chain saw

at least 9.1m (30 feet) from the fueling point before

starting the engine.

5. DO NOT allow other persons to be near when starting

or cutting with the chain saw. Keep bystanders and

animals out of the work area.

6. DO NOT start cutting until you have a clear work area,

secure footing, and a planned retreat path from the

falling tree.

7. Keep all parts of your body away from the saw chain

when the engine is running.

8. Before you start the engine, make sure that the saw

chain is not contacting anything.

9. Carry the chain saw with the engine stopped, the

guide bar and saw chain to the rear, and the muffler

away from your body.

10. DO NOT operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Be sure that the saw chain stops moving

when the throttle control trigger is released.

11. Shut off the engine before setting the chain saw down.

12. Use extreme caution when cutting small size brush

and saplings because slender material may catch the

saw chain and be whipped toward you or pull you off

balance.

13. When cutting a limb that is under tension, be alert for

springback so that you will not be struck when the tension in the wood fibers is released.

14. Keep the handles dry, clean, and free of oil or fuel mix-

.

ture

15. Operate the chain saw only in well-ventilated areas.

16. DO NOT operate a chain saw in a tree unless you

ve been specifically trained to do so.

ha

17. All chain saw service, other than the items listed in the

user manual safety and maintenance instructions,

should be performed by competent chain saw service

personnel.

18. When transporting your chain saw, use the appropriate guide bar scabbard.

19. DO NOT operate your chain saw near or around flam-

le liquids or gases whether in or out of doors. An

mab

explosion and/or fire may result.

USE THE RIGHT TOOL: Cut wood only. Do not use

20.

the chain sa

or e

F

ed.

plastic

21. Do not attempt to add fuel or lubricating oil to saw

while engine is r

w f

xample

, masonry, or non-building materials.

, do not use the chain sa

unning.

poses f

or pur

or which it w

as not intend-

or cutting

w f

4 5

Page 5

2 - SAFETY PRECAUTIONS

NOTE: These safety precautions are intended primarily for

the consumer or occasional user. When using a chain saw

for logging purposes, refer to the Code of Federal

Regulations, Section 1910.226(5); 2.5.1., of American

National Standard Safety Requirements for Pulpwood

Logging, ANSI 03.1-1978; and relevant state safety codes.

These models are classified according to CAN/ CSAZ62.1-03 as a Class 1C saw. They are intended for infrequent use by homeowners, cottagers, and campers, and for

such general applications as clearing, pruning, cutting firewood, etc. They are not intended for prolonged use. If the

intended use involves prolonged periods of operation, this

may cause circulatory problems in the user’s hands due to

vibration. All models covered in this manual employ an antivibration feature for increased comfort and safety.

2-3. GENERAL SAFETY PRECAUTIONS

FOR CHAIN SAW USERS

1. Fatigue causes carelessness. Be more cautious

before rest periods and towards the end of your shift.

2. Personal protective clothing required by your safety

organizations, government regulations, or your

employer should be used. At all times when using a

chain saw, snug-fitting clothing, protective eye wear,

safety footwear, and hand, leg, and hearing protection

should be worn.

3. Before refueling, servicing, or transporting your chain

saw, switch off the engine.To help prevent fire, restart

your chain saw at least 9.1m (30ft) from the fuelling

area.

4. When a chain saw is being used, a fire extinguisher

should be available.

5. When felling, keep at least 2 tree lengths away from

your fellow workers.

6. Plan your work, ensuring an obstacle-free work area

and, in the case of felling, at least one escape path

from the falling tree.

w the instructions in your operator’s manual for

ollo

F

7.

starting the chain saw and control the chain saw with

rip on both handles when it is in operation.

m g

a fir

Keep handles dry, clean, and free of oil.

8. When transporting your chain saw, use the appropri-

, which should be available

ers

anspor

ate tr

for the guide bar and saw chain.

9. Never operate a chain saw that is damaged or improperly adjusted or that is not completely and securely

assemb

when the power control system trigger is released.

ver adjust the guide bar or saw chain when the

Ne

engine is operating.

10.

Beware of carbon monoxide poisoning. Operate the

chain sa

11. Do not attempt a pruning or limbing operation in a

standing tree unless specifically trained to do so.

12. Guard against kickback. Kickback is the upward

motion of the guide bar that occurs when the sa

chain, at the nose of the guide bar, contacts an object.

tation co

Be sure that the saw chain stops moving

led.

w in w

v

entilated areas only

ell-v

.

Kickback can lead to dangerous loss of control of the

chain saw.

13. A chain saw is intended for two-handed use. Serious

injury to the operator, helpers, and/or bystanders can

result from one-handed oper

14. See section 2-5, 2-6 for symbol definitions, page 5.

15. When carrying a chain saw with the engine running,

engage the chain brake.

16. Allow your chain saw to cool before refueling, and do

not smoke.

17. Keep other persons or animals a safe distance away

from a running chain saw or the area where a tree is

being felled.

18. Use extreme caution when cutting small brush and

saplings because slender material can catch the saw

chain and be whipped toward you.

19. When cutting a limb that is under tension or compression, be alert for springback.

20. This gas-powered saw is classified according to CAN/

CSA-Z62.1-03 as a Class 1C saw. It is intended for

infrequent use by homeowners, cottagers, and

campers, and for such general applications as clearing, pruning, cutting firewood, etc. It is not intended for

prolonged use.

Prolonged periods of operation can cause circulatory

problems in the user’s hands due to vibration. For

such use, it may be appropriate to use a saw having

an anti-vibration feature.

ation.

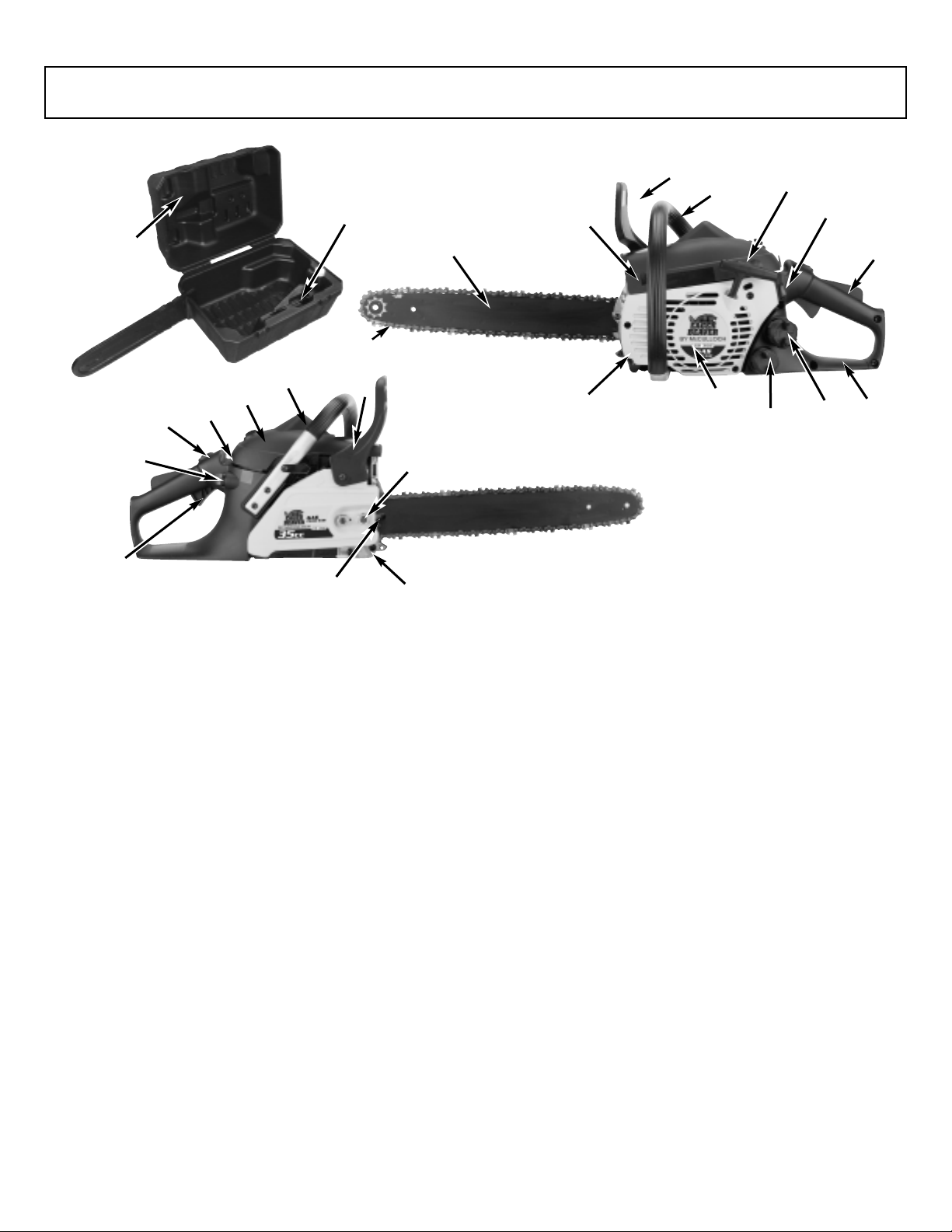

2-4. MORE ABOUT KICKBACK

WARNING

DANGER! BEWARE OF KICKBACK!

Kickback can lead to dangerous loss of control of the chain

saw and result in serious or fatal injury to the saw operator

or to anyone standing close by. Always be alert. Rotational

kickback and pinch-kickback are major chain saw operational dangers and the leading cause of most accidents.

BEWARE OF:

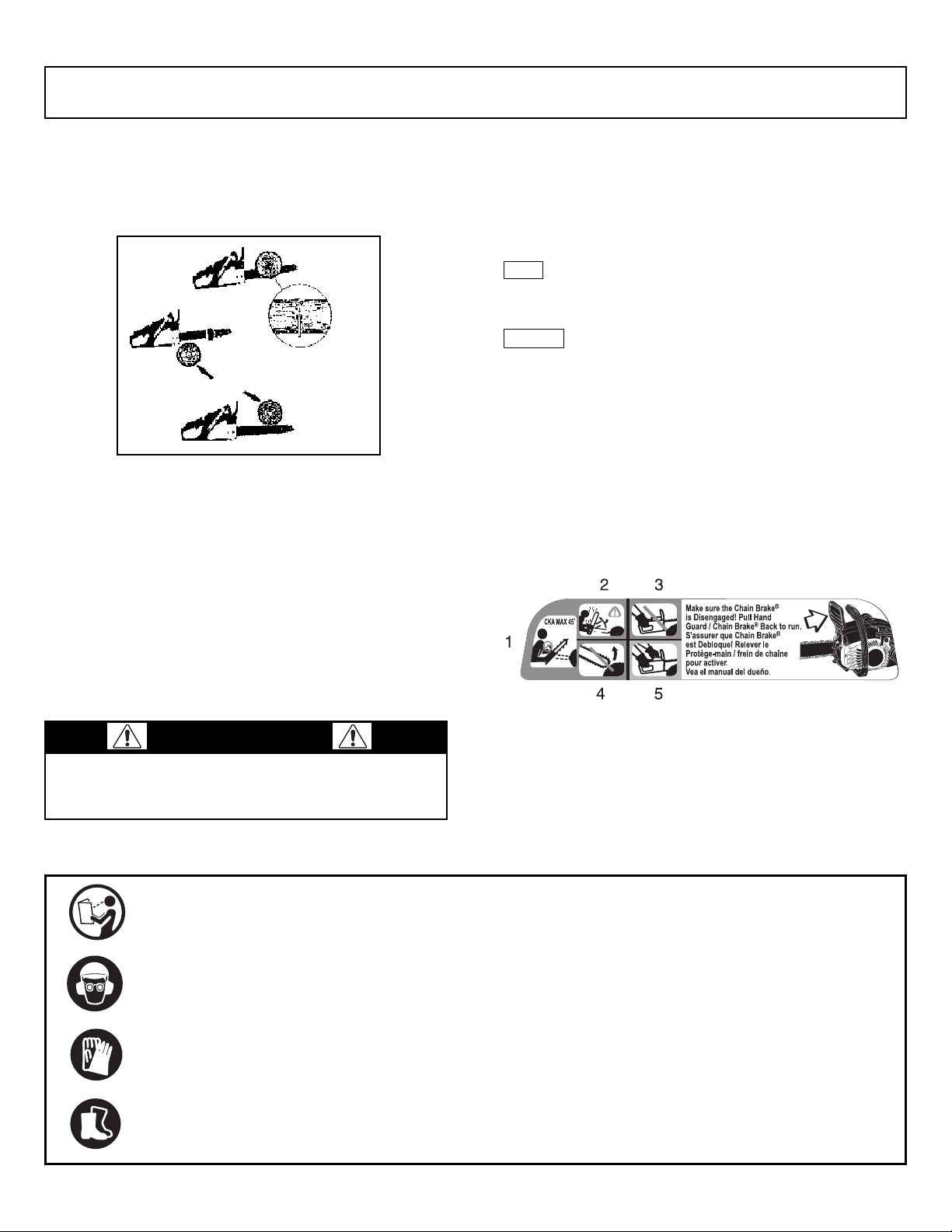

ROTATIONAL KICKBACK (Figure 2-4A)

A = Kickback path

B = Kic

w

kback reaction zone

A

A

2-4A

B

A

Page 6

2 - SAFETY PRECAUTIONS

THE PUSH (PINCH-KICKBACK) AND PULL

REACTIONS (Figure 2-4B)

A = Pull

B = Solid objects

C = Push

A

B

B

C

2-4B

KICKBACK may occur when the NOSE or TIP of the guide

bar touches an object, or when wood closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast

reverse reaction, kicking the guide bar up and back toward

the operator.

PINCHING the saw chain along the BOTTOM of the guide

bar may PULL the saw forward away from the operator.

PINCHING the saw chain along the TOP of the guide bar

may PUSH the guide bar rapidly back toward the operator.

Any of these reactions may cause you to lose control of the

saw, which could result in serious personal injury.

2-5. KICKBACK SAFETY LABELS

Your McCulloch Chain Saw is provided with a safety label

located on the chain brake lever. This label, along with the

safety instructions on these pages, should be carefully read

before attempting to operate this unit.

HOW TO READ SYMBOLS AND COLORS:

RED

WARNING

Used to warn that an unsafe procedure should not be performed.

GREEN

Recommended cutting procedures.

RECOMMENDED

WARNING (Figure 2-5A)

1. Worst-case computed kickback angle.

2. Beware of kickback.

3. Do not attempt to hold saw with one hand.

4. Avoid bar nose contact.

RECOMMENDED

5. Hold saw properly with both hands.

WARNING

The engine exhaust from this product contains chemi-

cals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

2-6. INTERNATIONAL SYMBOLS

Read User Manual.

Wear head, eye and hearing protection.

Wear gloves to protect your hands.

Wear safety boots to protect against electric shock.

2-5A

Use of these personal safety items is

highly recommended to reduce the risk

of accidental injur

6 7

y.

Page 7

3 - ASSEMBLY INSTRUCTIONS

3-1. TOOLS FOR ASSEMBLY (YOUR SAW

WAS ASSEMBLED AT THE FACTORY)

ou will need these tools to assemble your chain saw:

Y

1. Combination wrench-screwdriver (contained in your

s kit or in lid of carry case).

user’

2. Heavy duty work gloves (user supplied).

3-2. ASSEMBLY REQUIREMENTS

Your new chain saw will require adjustment of chain, filling

the fuel tank with correct fuel mixture and filling the oil tank

with lubricating oil before the unit is ready for operation.

WARNING

DO NOT start saw engine until unit is properly prepared.

Read the entire user manual before attempting to operate

your unit. Pay particular attention to all safety precautions.

Your user manual is both a reference guide and handbook

provided to furnish you with general information to assemble, operate and maintain your saw.

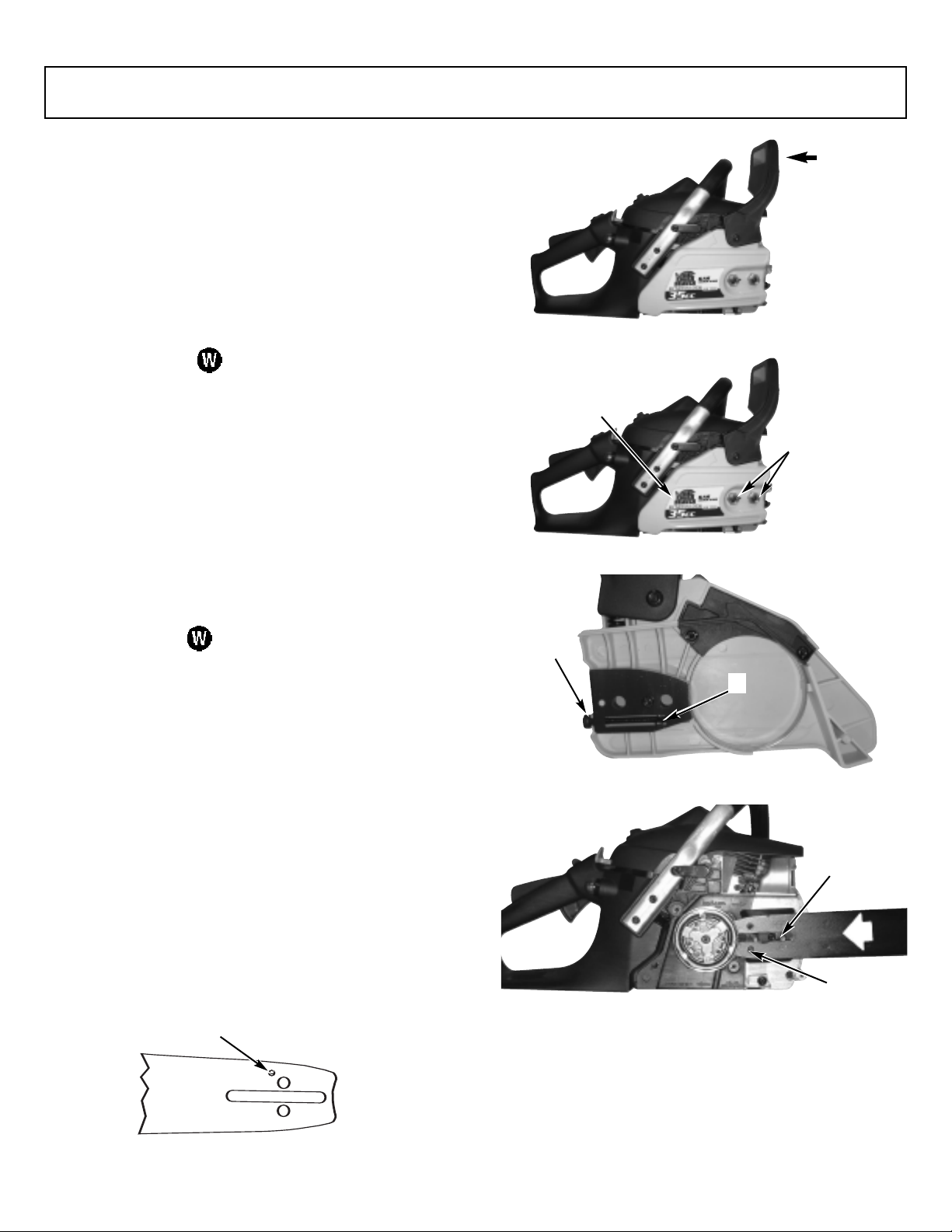

3-3. GUIDE BAR / SAW CHAIN / CLUTCH

COVER INSTALLATION

WARNING

Always wear protective gloves when handling chain.

3-3B

C

B

3-3C

TO INSTALL GUIDE BAR:

CAUTION

To ensure the bar and chain receive oil, ONLY USE THE

ORIGINAL STYLE BAR with the oil passage hole (A) as

illustrated above (Figure 3-3A).

1. Make sure the CHAIN BRAKE

into the DISENGAGED position (Figure 3-3B)

Remove the bar retaining nuts (B). Remove clutch

2.

cover (C) by pulling straight out, some force may be

required. (Figure 3-3C)

:

TE

NO

for shipping the chain saw.

3. Using a screwdriver or the wrench supplied in the

4.

Discard the tw

user’s kit or in the upper half of the carrying case.Turn

the adjustment scre

until the TANG (E) (projecting prong) is to the end of

its travel (Figure 3-3D).

Place the slotted end of the guide bar o

Slide guide bar behind clutch dr

(F).

guide bar stops (Figure 3-3E).

o plastic w

w (D) COUNTERCLOCKWISE

A

®

lever is pulled back

They are only used

.

ashers

um (G) until the

er the bar bolt

v

D

E

3-3D

F

G

3-3E

3-3A

Page 8

3 - ASSEMBLY INSTRUCTIONS

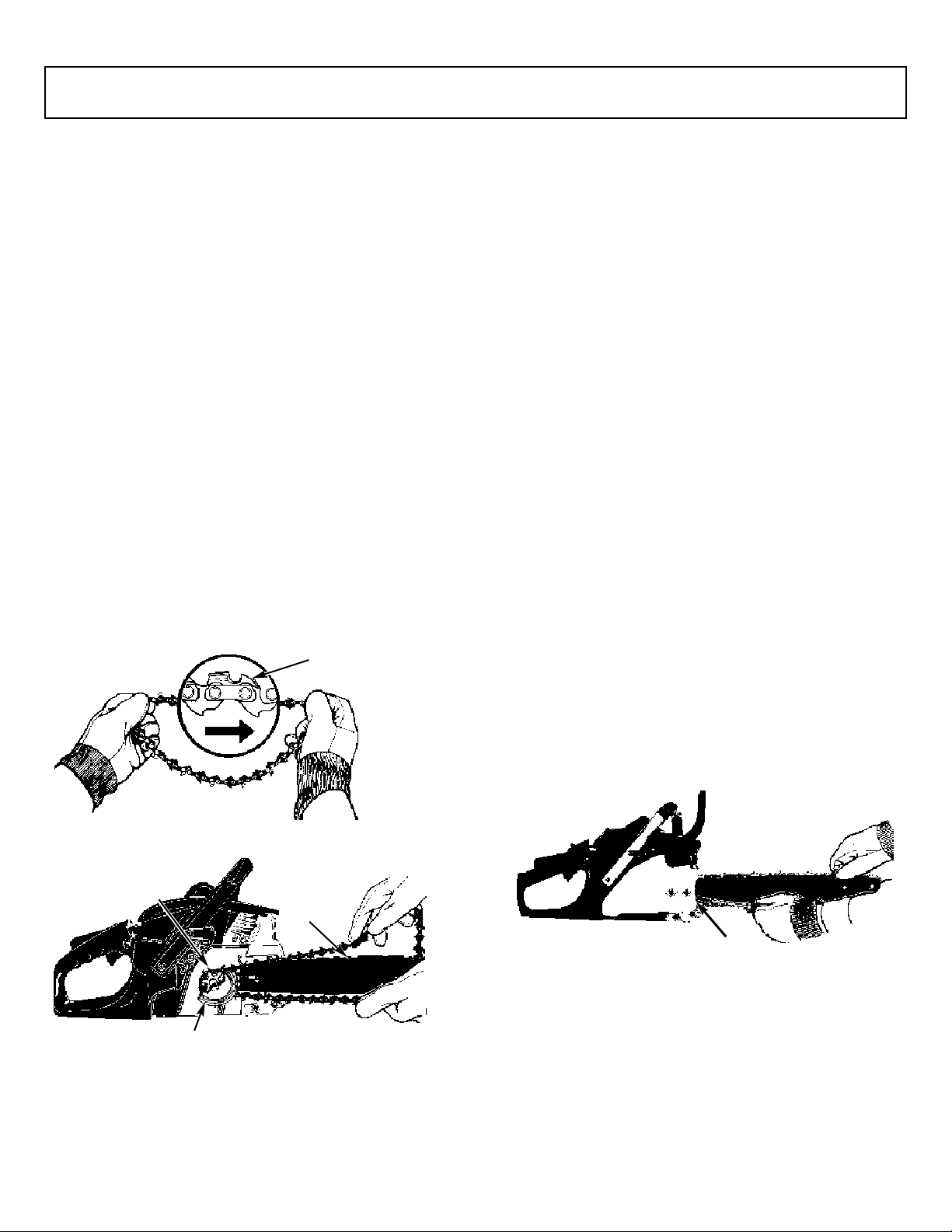

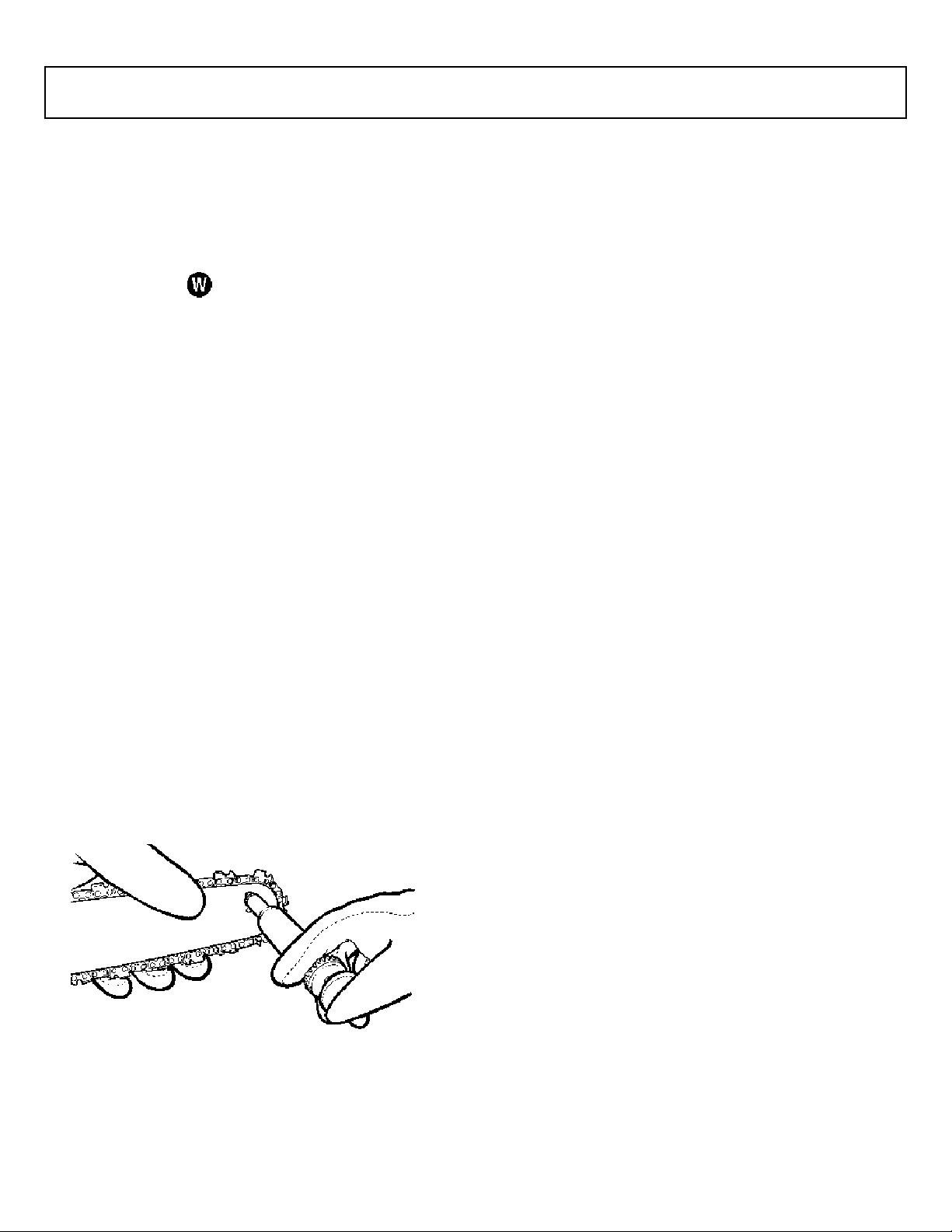

TO INSTALL SAW CHAIN:

WARNING

Always wear heavy duty gloves when handling saw chain

or making sa

1. Spread chain out in a loop with cutting edges (A)

pointing CLOCKWISE around loop (Figure 3-3F).

2. Slip the chain around the sprocket (B) behind the

clutch (C). Make sure the links fit between the sprocket teeth (Figure 3-3G).

3. Guide the drive links into the groove (D) and around

the end of the bar (Figure 3-3G).

NOTE: The saw chain may droop slightly on the lower part

of bar. This is normal.

4. Pull guide bar forward until chain is snug. Ensure all

drive links are in the bar groove.

5. Install the clutch cover making sure the tang is posi-

tioned in the lower hole in the guide bar. Make sure

the chain does not slip off of the bar. Install the bar

retaining nuts hand tight and follow tension adjustment instructions in Section 3-4.

NOTE: The guide bar retaining nuts are installed only hand

tight at this point because saw chain adjustment is

required. Follow instructions in Section 3-4, Saw Chain

Tension Adjustment.

w chain adjustments.

A

3-4. SAW CHAIN TENSION ADJUSTMENT

Proper tension of saw chain is extremely important and

must be checked before starting, as well as during any cutting operation.

Taking the time to make needed adjustments to the saw

chain will result in improved cutting performance and prolonged chain life.

WARNING

Always wear heavy duty gloves when handling saw chain

or making saw chain adjustments.

TO ADJUST SAW CHAIN:

1. Hold nose of guide bar up and turn adjustment screw

(D) CLOCKWISE to increase chain tension. Turning

screw COUNTERCLOCKWISE will decrease amount

of tension on chain. Ensure the chain fits snugly all the

way around the guide bar (Figure 3-4A).

2. After making adjustment, and while still holding nose

of bar in the uppermost position, tighten the bar

retaining nuts securely. Chain has proper tension

when it has a snug fit all around and can be pulled

around by gloved hand.

NOTE: If chain is difficult to rotate on guide bar or if it binds,

too much tension has been applied. This requires minor

adjustment as follows:

A. Loosen the bar retaining nuts so it is finger tight.

Decrease tension by turning the bar adjustment screw

COUNTERCLOCKWISE slowly. Move chain back and

forth on bar. Continue to adjust until chain rotates

freely, but fits snugly. Increase tension by turning bar

adjustment screw CLOCKWISE.

B. When saw chain has proper tension, hold nose of bar

in uppermost position and tighten the bar retaining nut

securely.

3-3F

B

D

D

3-4A

C

3-3G

8 9

Page 9

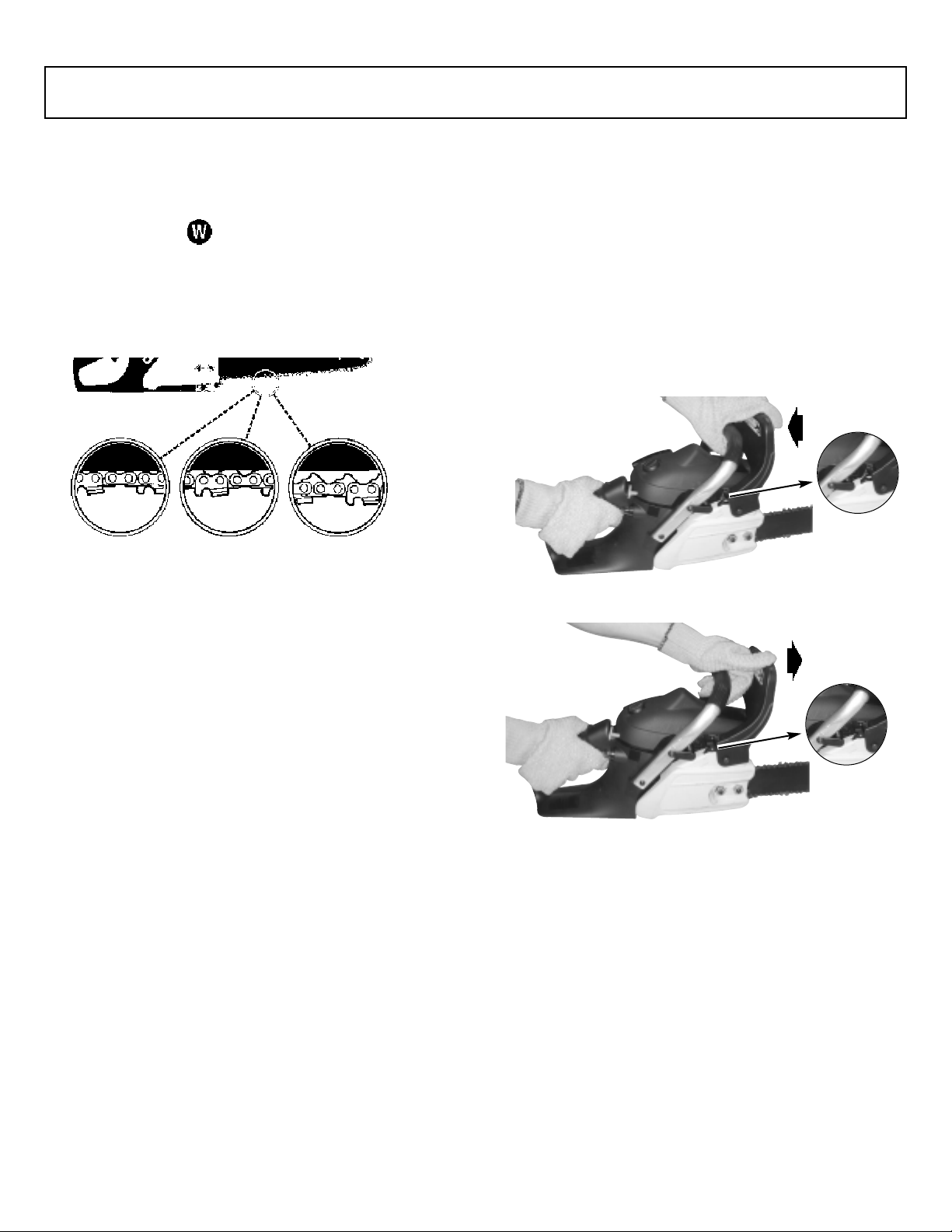

3 - ASSEMBLY INSTRUCTIONS

CAUTION

w saw chain stretches, requiring adjustment after as

A ne

few as 5 cuts. This is normal with a new chain, and the

interval between future adjustments will lengthen quickly.

CAUTION

If saw chain is TOO LOOSE or TOO TIGHT, the sprocket,

bar, chain, and crankshaft bearings will wear more rapidly.

Study Figure 3-4B for information concerning correct cold

tension (A), correct warm tension (B), and as a guide for

when saw chain needs adjustment (C).

A

3-5. CHAIN BRAKE®MECHANICAL TEST

Your chain saw is equipped with a CHAIN BRAKE®that

reduces possibility of injury due to kickback. The brake is

activated if pressure is applied against brake lever when,

as in the event of kickback, operator’s hand strikes the

lever. When the brake is actuated, chain movement stops

abruptly.

B

3-4B

C

To Test CHAIN BRAKE®:

The CHAIN BRAKE

1.

move) when BRAKE LEVER IS PULLED BACK AND

LOCKED. Be sure the chain bareak latch is in the on

position. (Figure 3-5A).

2. The CHAIN BRAKE®is ENGAGED (chain is stopped)

when brake lever is in forward position and the chain

break latch is in the off position. You should not be

able to move chain (Figure 3-5B).

NOTE: The brake lever should snap into both positions. If

strong resistance is felt, or lever does not move into either

position, do not use your saw. Take it immediately to an

Authorized Service Center for repair.

®

is DISENGA

3-5A

GED (chain can

ON

WARNING

The purpose of the CHAIN BRAKE®is to reduce the possibility of injury due to kickback; however, it cannot provide

the intended measure of protection if the sa

carelessly.

ys test the CHAIN BRAKE

a

Alw

iodically while on the job

per

®

ore using y

bef

.

w is oper

our sa

ated

w and

OFF

3-5B

Page 10

4 - FUEL AND LUBRICATION

4-1. FUEL

Use regular g

Factory Parts 40:1 custom 2-cycle engine oil for best

results. Use mixing ratios in Section 4-3.

Never use straight gasoline in your unit.This will cause

permanent engine damage and void the manufacturer’s warranty for that product. Never use a fuel mixture that

has been stored for over 90 days.

If 2-cycle lubricant other than Genuine Factory Parts

Custom Lubricant is to be used, it must be a premium

grade oil for 2-cycle air cooled engines mixed at a 40:1

ratio.Do not use any 2-cycle oil product with a recommended mixing ratio of 100:1. If insufficient lubrication is the

cause of engine damage, it voids the manufacturer’s

engine warranty for that occurrence.

rade unleaded gasoline mixed with Genuine

4-2. MIXING FUEL

Mix fuel with Genuine Factory Parts brand 2 cycle oil in an

approved container. Use mixing table for correct ratio of fuel

to oil. Shake container to ensure thorough mix.

Lack of lubrication voids engine warranty.

4-3.FUEL AND LUBRICATION SYMBOLS

FUEL MIXING TABLE

4-4.RECOMMENDED FUELS

Some conventional gasolines are being blended with oxygenates such as alcohol or an ether compound to meet

clean air standards. Your McCulloch engine is designed to

operate on any gasoline intended for automotive use

including oxygenated gasolines.

4-5.CHAIN AND BAR LUBRICATION

Always refill the chain oil tank each time the fuel tank is

refilled. We recommend using Genuine Factory Parts

Chain, Bar and Sprocket Oil, which contains additives to

reduce friction and wear and to assist in the prevention of

pitch formation on the bar and chain.

Oil Only

Gasoline and Oil

Mix 40:1

10 11

Page 11

5 - OPERATING INSTRUCTIONS

5-1. ENGINE PRE-START CHECKS

WARNING

Never start or operate the saw unless the bar and chain are

properly installed.

1. Fill the fuel tank (A) with correct fuel mixture (Figure

5-1A).

2. Fill the oil tank (B) with correct chain and bar oil

(Figure 5-1A).

3. Be certain the CHAIN BRAKE®is disengaged (C)

before starting unit (Figure 5-1A).

NOTE: See page 9 Fig. 3-5A & 3-5B.

C

5-1A

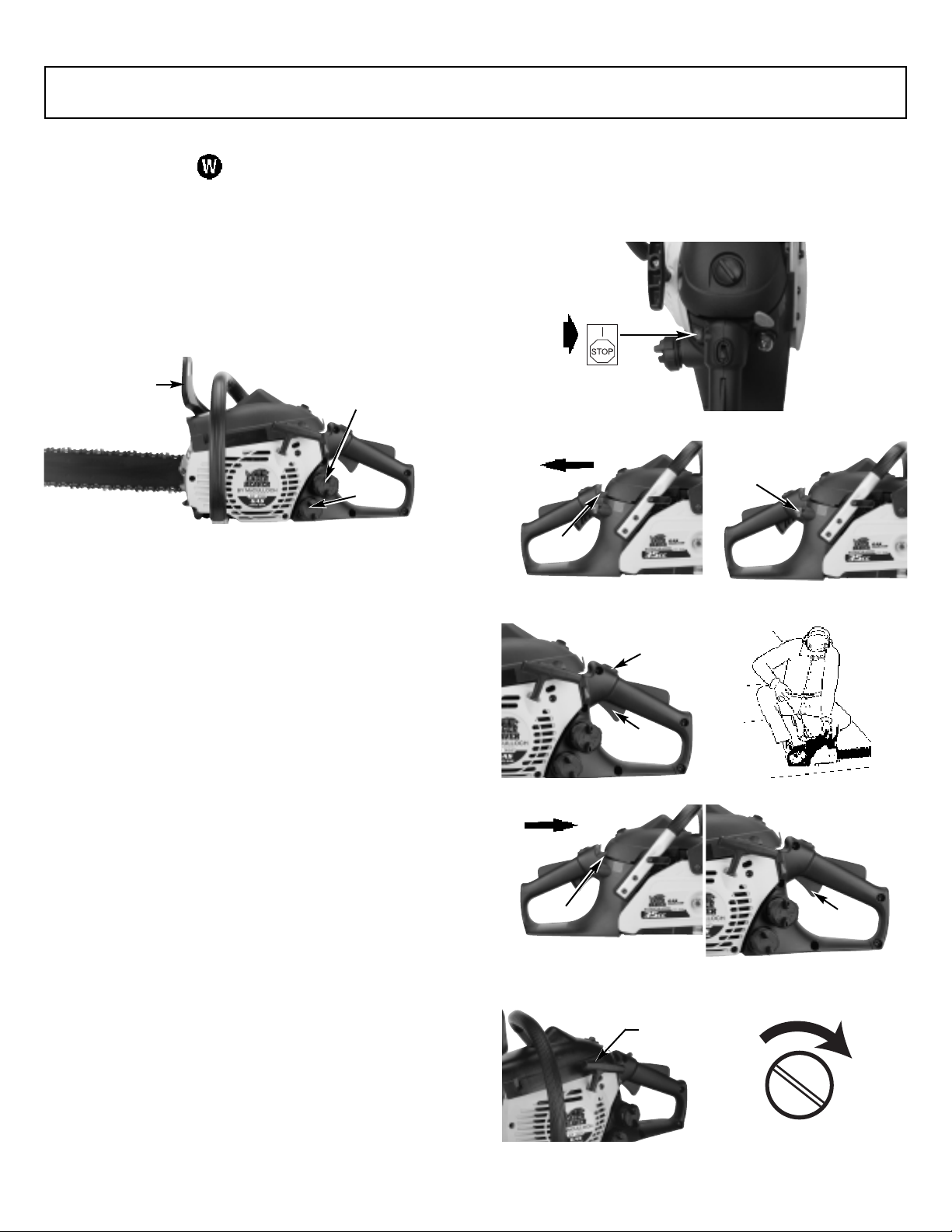

5-2. TO START ENGINE

1. Press red STOP switch to the “I” ON position (Fig. 5-

2A).

2. Pull out the choke (A) to the point where it latches in

place. (Fig. 5-2B)

3. Push the primer bulb (B) 10 times. (Fig. 5-2C)

4. Latch throttle advance: depress latch and hold (C)

squeeze throttle trigger (D) release trigger and then

the latch. (Fig. 5-2D)

5. Place the saw on a firm and level surface. Hold the

oot as illustr

w securely with y

sa

on the starter 4 times. Watch the chain in case it runs.

(Fig. 5-2E)

NOTE: If the engine sounds as if it wants to start before the

4th pull, end the tugging of the starter and proceed as

described in the next step.

6. Push in the choke (E) as far it will go. (Fig. 5-2F)

Hold the sa

7.

4 times. The engine should start.

Let the engine r

8.

the tr

9. If the engine does not start up, repeat the above

steps

w securely and tug shar

igger (F) and put it into idle

.

our f

or 10 seconds to w

un f

.

A

B

ated. Pull sharply

ply on the star

arm up. Press

5-2G)

(Fig.

ter

2. Using a Phillips or slotted screwdriver - turn screw 1/4

to 1/2 turn clockwise (to the right). Unit should then

idle properly. (Figure 5-2H)

NOTE: If chain turns while idling - turn screw back to the

left until chain stops and unit continues to idle.

5-2A

B

A

5-2B

C

D

5-2D

E

5-2F 5-2G

5-2C

5-2E

F

IMPORTANT IDLING INFORMATION

In some cases due to operating conditions (altitude, temperature etc.) your chain saw may need a slight adjustment

to the idle speed.

m up - See the User's Manual section 5-2, step 7

After w

- If unit does not Idle after restar

steps to adjust idle.

1. Idle adjustment access (G). (Figure 5-2H)

ar

ting 2 times

, f

ollo

w these

G

5-2H 5-2H

Page 12

5 - OPERATING INSTRUCTIONS

5-3. RE-STARTING A WARM ENGINE

1. Make sure the on/off switch is in the “I” position.

2. Pull out the choke to the point where it latches in

place.

3. Depress the primer bulb 10 times.

4. Set the throttle latch.

5. Pull the starter rope rapidly 4 times. The engine

should start.

6. Push in the choke as far it will go.

7. Release the thtrottle latch.

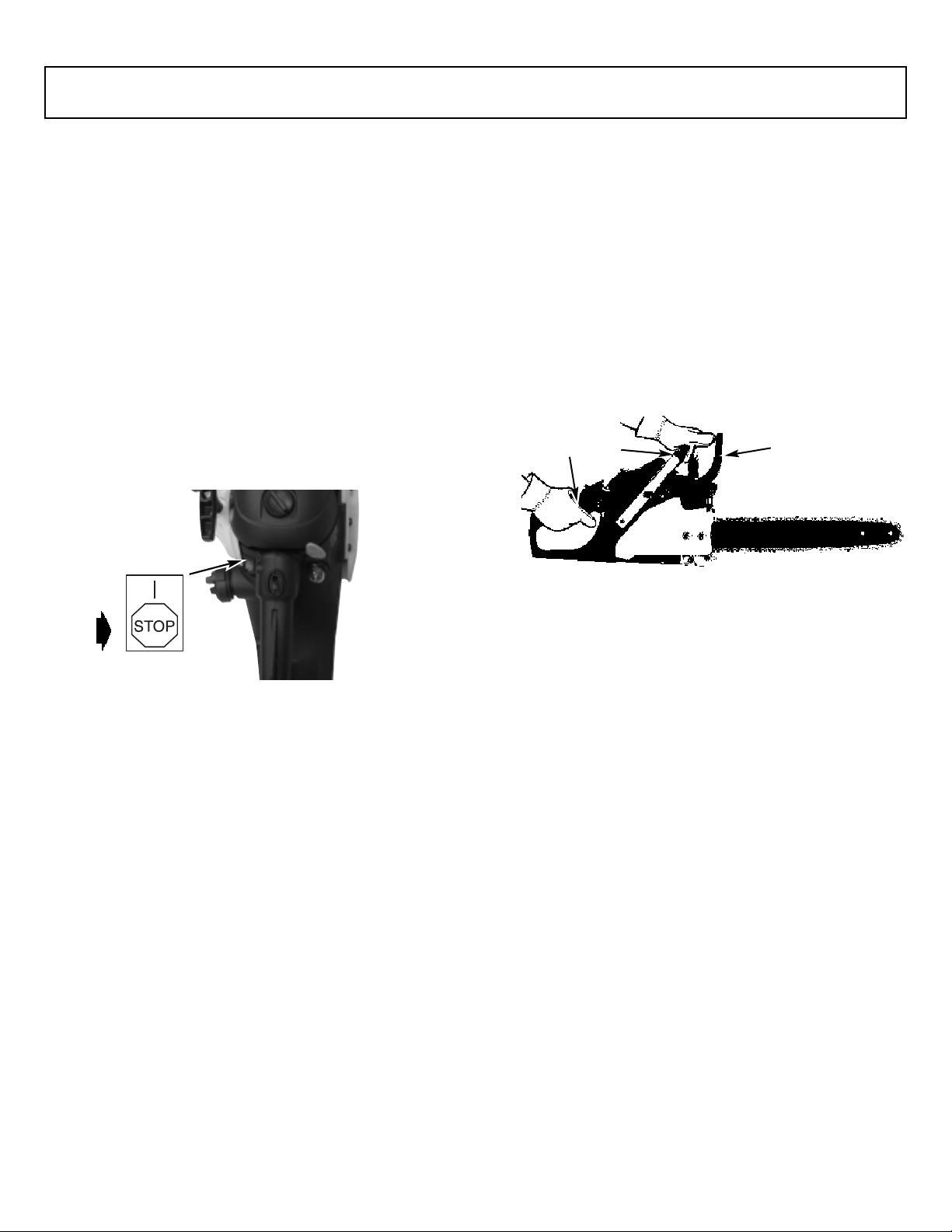

5-4. TO STOP ENGINE

1. Release trigger and allow engine to return to idle

speed.

2. Press STOP switch down to stop engine Figure 5-4A.

NOTE: For emergency stopping, simply activate CHAIN

BRAKE

®

and move STOP switch down.

WARNING

Activate the CHAIN BRAKE®slowly and deliberately. Keep

the chain from touching anything; don’t let the saw tip for-

ard.

w

6. Chain should stop abruptly. When it does, immediately

release the throttle trigger.

WARNING

If chain does not stop, turn engine off and take your unit to

the nearest Authorized Service Center for service.

7. If CHAIN BRAKE

off and return the CHAIN BRAKE

GED position.

GA

A

®

functions properly, turn the engine

B

5-5A

®

to the DISEN-

C

5-4A

INERTIA CHAIN BRAKE®ACTION :

NOTE: THIS SAW IS EQUIPPED WITH AN INERTIA

CHAIN BRAKE.IF THE SAW KICKS BACK WHILE IN USE,

THE INERTIA OF THE MOVING SAW WILL ACTIVATE

THE BRAKE. A BRAKE BAND AROUND THE CLUTCH

DRUM ACTIVATES AND STOPS THE MOVING CHAIN.

5-5.CHAIN BRAKE®OPERATIONAL TEST

est the CHAIN BRAKE

T

function.

Perform a CHAIN BRAKE®test prior to initial cutting, follow-

xtensive cutting, and definitely following any CHAIN

ing e

.

BRAKE®ser

vice

TEST CHAIN BRAKE®AS FOLLO

Place sa

1.

2. Start engine.

3. Grasp the rear handle (A) with your right hand (Figure

5-5A).

4. With your left hand, hold the front handle (B) [not

CHAIN BRAKE

Squeeze the throttle trigger to 1/3 throttle, then imme-

5.

diately activ

5A).

w on a clear

®

ate the CHAIN BRAKE

®

iodically to ensure proper

per

WS:

, firm, flat surface.

lever (C)] firmly (Figure 5-5A).

®

er (C) (Figure 5-

v

le

5-6.SAW CHAIN / BAR LUBRICATION

Adequate lubrication of the saw chain is essential at all

times to minimize friction with the guide bar.

Never starve the bar and chain of oil. Running the saw with

too little oil will decrease cutting efficiency, shorten saw

chain life, cause rapid dulling of chain, and cause excessive wear of bar from overheating. Too little oil is evidenced

by smoke, bar discoloration or pitch build-up.

NOTE: Saw chain stretches during use, particularly when it

is new, and it will occasionally be necessary to adjust and

tighten it. New chain will require adjustment after about 5

utes of operation.

min

5-7.AUTOMATIC OILER

en

our chain sa

Y

oiler system.

amount of oil to the bar and chain. As the engine speed

increases

w adjustment.

flo

mately the same time as the fuel supply runs out.

12 13

w is equipped with an automatic clutch dr

The oiler automatically deliv

, so does the oil flo

The oil reser

w to the bar pad.

oir will r

v

ers the proper

un out at appro

There is no

iv

-

xi

Page 13

6 - GENERAL CUTTING INSTRUCTIONS

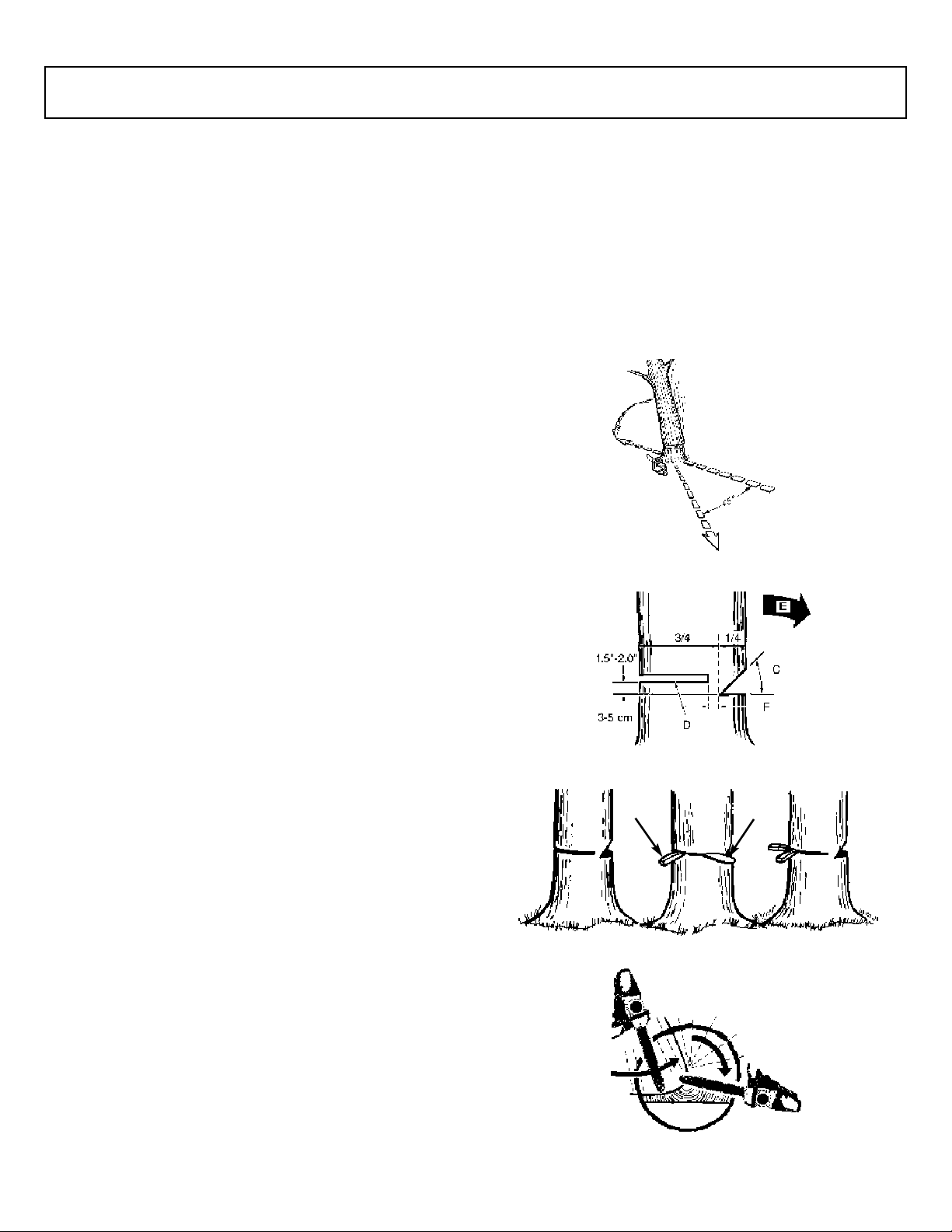

6-1.FELLING

elling is the term for cutting down a tree. Small trees up to

F

6-7 inches (15-18cm) in diameter are usually cut in a single

cut. Larger trees require notch cuts. Notch cuts determine

the direction the tree will fall.

FELLING A TREE:

WARNING

A retreat path (A) should be planned and cleared as necessary before cuts are started. The retreat path should

extend back and diagonally to the rear of the expected line

of fall, as illustrated in Figure 6-1A.

CAUTION

If felling a tree on sloping ground, the chain saw operator

should keep on the uphill side of the terrain, as the tree is

likely to roll or slide downhill after it is felled.

NOTE: Direction of fall (B) is controlled by the notching cut.

Before any cuts are made, consider the location of larger

branches and natural lean of the tree to determine the way

the tree will fall.

WARNING

Do not cut down a tree during high or changing winds or if

there is a danger to property. Consult a tree professional.

Do not cut down a tree if there is a danger of striking utility

wires; notify the utility company before making any cuts.

GENERAL GUIDELINES FOR FELLING

TREES:

Normally felling consists of 2 main cutting operations,

notching (C) and making the felling cut (D).

Start making the upper notch cut (C) on the side of the tree

facing the felling direction (E). Be sure you don t make the

lower cut too deep into the trunk.

The notch (C) should be deep enough to create a hinge (F)

of sufficient width and strength.

enough to direct the fall of the tree for as long as possible.

The notch should be wide

FELLING CUT:

Use wooden or plastic wedges (G) to prevent binding

1.

the bar or chain (H) in the cut. Wedges also control

felling (Figure 6-1C).

2. When diameter of wood being cut is greater than the

bar length, make 2 cuts as shown (Figure 6-1D).

WARNING

As the felling cut gets close to the hinge, the tree should

begin to fall.When tree begins to fall, remove saw from cut,

stop engine, put chain saw down, and leave area along

retreat path (Figure 6-1A).

B

A

6-1A

6-1B

G

H

WARNING

Never walk in front of a tree that has been notched.

Make the felling cut (D) from the other side of the tree and

1.5 - 2.0 inches (3-5 cm) above the edge of the notch (C)

(Figure 6-1B).

Never saw completely through the trunk. Always leave a

hinge

. The hinge guides the tree. If the trunk is completely

cut through, control over the felling direction is lost.

Insert a wedge or felling lever in the cut well before the tree

becomes unstable and starts to move. This will prevent the

ve mis-

guidebar from binding in the f

judged the f

entered the range of the falling tree before you push it over.

alling direction.

elling cut if y

e sure no b

Mak

ou ha

ystanders ha

v

WARNING

Before making the final cut, always recheck the area for

bystanders, animals or obstacles.

6-1C

e

6-1D

Page 14

6 - GENERAL CUTTING INSTRUCTIONS

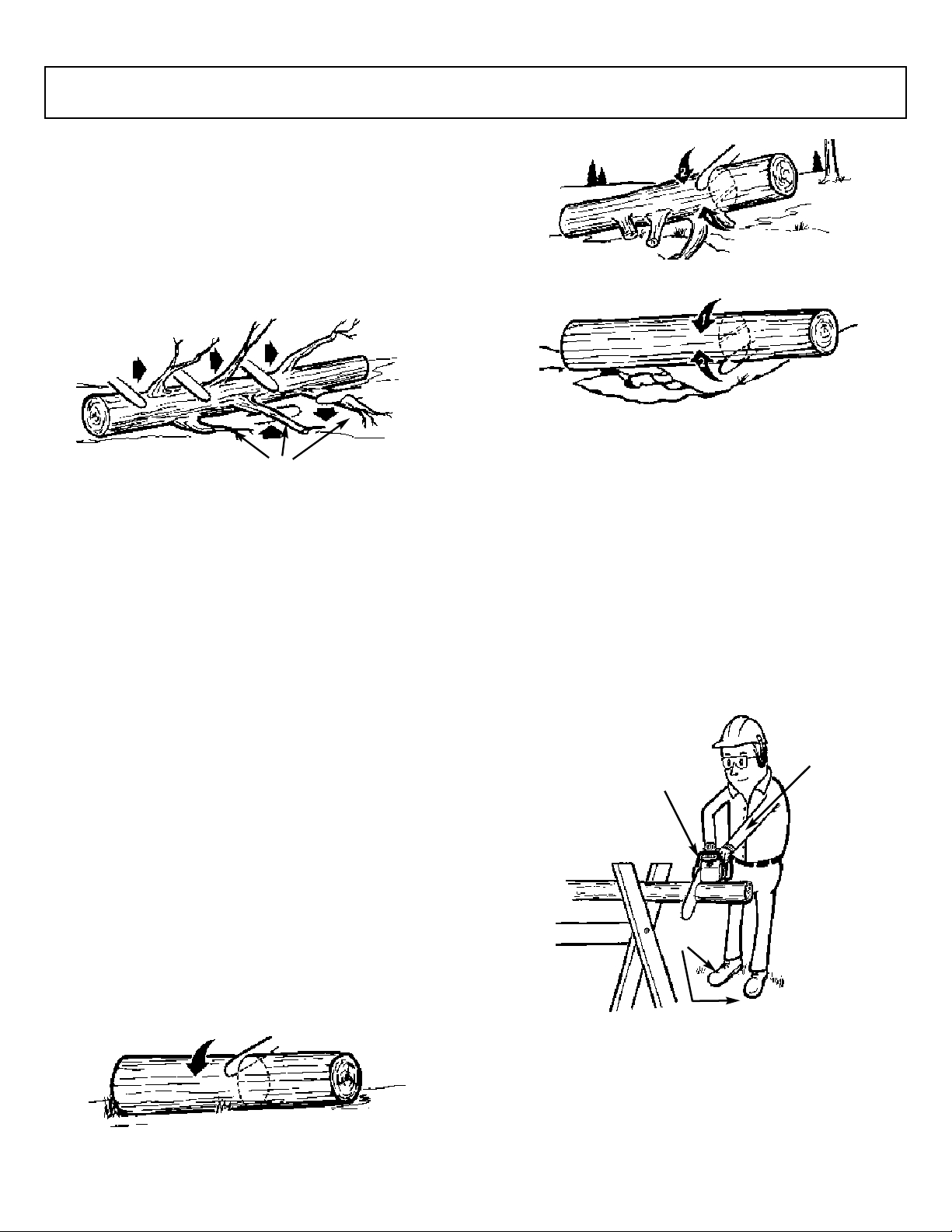

6-2. LIMBING

Limbing a tree is the process of remo

from a fallen tree. Do not remove supporting limbs (A) until

after the log is bucked (cut) into lengths (Figure 6-2A).

Branches under tension should be cut from the bottom up

to avoid binding the chain saw.

ving the branches

WARNING

Never cut tree limbs while standing on tree trunk.

A

6-2A

6-3. BUCKING

Bucking is cutting a fallen log into lengths. Make sure you

have a good footing and stand uphill of the log when cutting

on sloping ground. If possible, the log should be supported

so that the end to be cut off is not resting on the ground. If

the log is supported at both ends and you must cut in the

middle, make a downward cut halfway through the log and

then make the undercut. This will prevent the log from

pinching the bar and chain. Be careful that the chain does

not cut into the ground when bucking as this causes rapid

dulling of the chain.

When bucking on a slope, always stand on the uphill side.

1. Log supported along entire length: Cut from top (over-

k), being careful to a

uc

b

(Figure 6-3A).

2. Log supported on 1 end: First, cut from bottom (under-

buck) 1/3 diameter of log to avoid splintering. Second,

cut from above (overbuck) to meet first cut and avoid

pinching (Figure 6-3B).

3. Log supported on both ends: First, overbuck 1/3 diam-

eter of log to avoid splintering. Second, underbuck to

meet first cut and avoid pinching (Figure 6-3C).

NOTE: The best way to hold a log while bucking is to use a

sawhorse. When this is not possible, the log should be

raised and supported by the limb stumps or by using supporting logs. Be sure the log being cut is securely supported.

void cutting into the ground

6-3B

6-3C

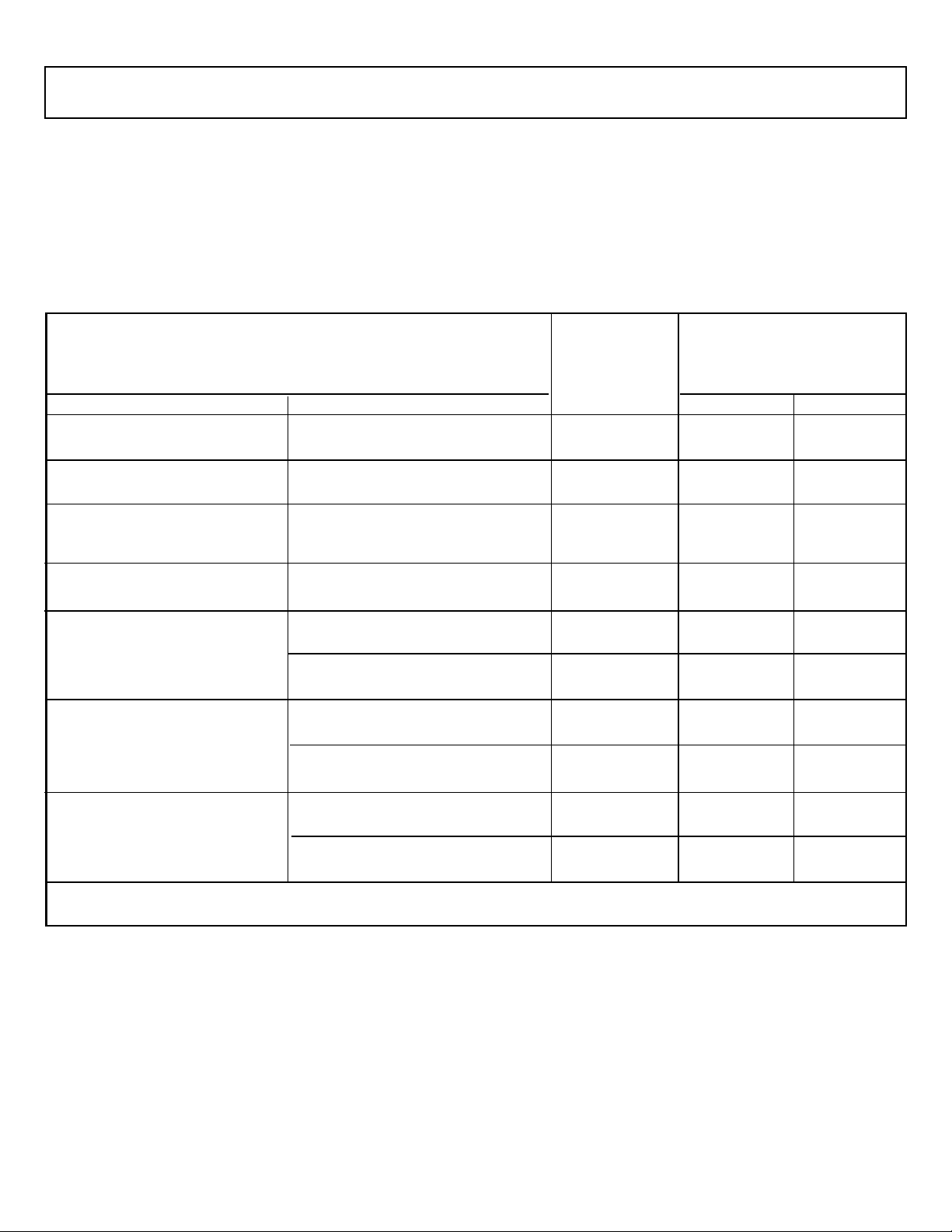

6-4.BUCKING USING A SAWHORSE

For personal safety and ease of cutting, the correct position

for vertical bucking is essential (Figure 6-4A).

VERTICAL CUTTING:

A. Hold the saw firmly with both hands and keep the saw

to the right of your body while cutting.

B. Keep the left arm as straight as possible.

C. Keep weight on both feet.

CAUTION

While the saw is cutting, be sure the chain and bar are

being properly lubricated.

B

A

C

6-3A

6-4A

14 15

Page 15

7 - MAINTENANCE INSTRUCTIONS

All chain saw service, other than items listed here in your user manual maintenance

instructions, should be performed by your nearest Authorized Service Center.

7-1.PREVENTIVE MAINTENANCE

A good preventive maintenance program of regular inspection and care will increase life and improve performance of your

McCulloch chain saw. This maintenance checklist is a guide for such a program.

Cleaning, adjustment, and parts replacement may be required, under certain conditions, at more frequent intervals than those

indicated.

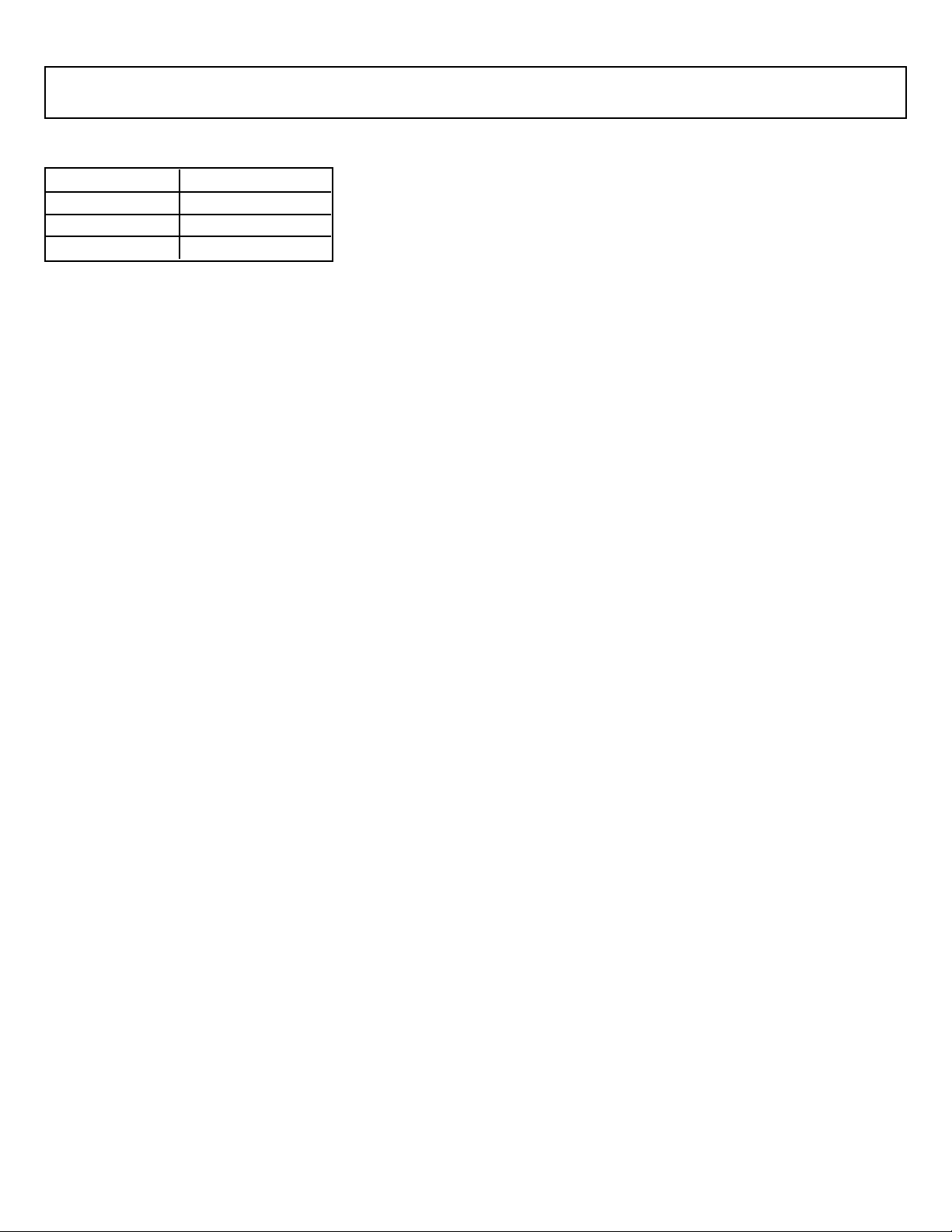

MAINTENANCE CHECKLIST

ITEM

SCREWS / NUTS / BOLTS

AIR FILTER

FUEL FILTER / OIL FILTER

SPARK PLUG

SPARK ARRESTER SCREEN

FUEL HOSES

ACTION

INSPECT / TIGHTEN

CLEAN OR REPLACE

REPLACE

CLEAN / ADJUST / REPLACE

INSPECT

REPLACE AS REQUIRED

INSPECT

*REPLA

CE AS REQ

UIRED

EACH USE

✔

✔

✔

HOURS OF

OPERATION

10

✔

✔

✔

20

✔

CHAIN BRAKE®COMPONENTS

*Recommended f

or Maintenance b

INSPECT

*REPLA

uthor

y a A

CE AS REQ

ed Ser

iz

UIRED

vice Center

echnician.

T

✔

Page 16

7 - MAINTENANCE INSTRUCTIONS

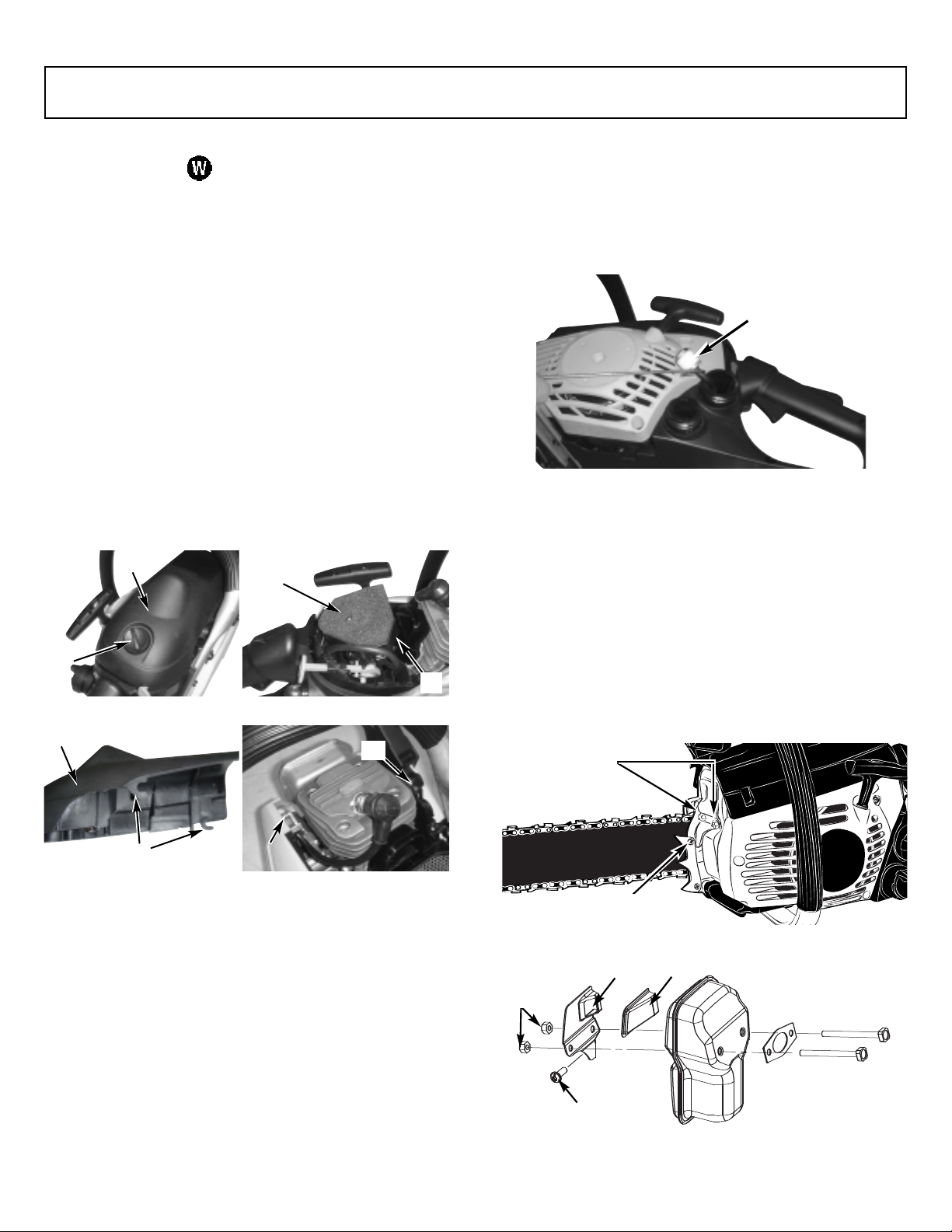

7-2. AIR FILTER

CAUTION

ver operate saw without the air filter. Dust and dirt will be

Ne

drawn into engine and damage it. Keep the air filter clean!

TO CLEAN AIR FILTER:

1. Remove knob (A) holding air filter cover in place,

remove the top cover (B) by loosening the cover

retaining screws. Cover will lift off.(Figure 7-2A)

2. Completely remove the air filter box (B) from the unit.

(Figure 7-2B)

3. Clean air filter box by using air cleaner or brush.

NOTE: Never clean air filter with liquid material or it may

cause air filter damaged.

4. Install air filter. Install engine / air filter cover. Make

sure latche (E) latch (F) and cover fit properly. Tighten

the cover retaining knob securely. (Figure 7-2C &

Figure 7-2D)

WARNING

Never perform maintenance when the engine is hot, to

avoid any chance of burning hands or fingers.

B

A

7-2A

B

C

D

7-2B

F

5. Pull filter off with a twisting motion. Discard filter.

6. Install new filter. Insert end of filter into tank opening.

Make sure filter sits in bottom corner of tank. Use a

long handle screwdriver to aid in filter placement if

necessary.

7. Fill tank with fresh fuel / oil mixture. See Section 4,

Fuel and Lubrication. Install fuel cap.

B

7-3A

7-4. SPARK ARRESTER SCREEN (Figure 7-

4A)

NOTE: A clogged spark arrester screen will dramatically

reduce engine performance.

1. Remove the 2 nuts (A) and pull muffler out. (Figure74A).

2. Remove the 1 screw (B) that holds the spark arrester

cover (C) . (Figure 7-4B)

3. Discard the used spark arrester screen (D) and

replace it with a new one.

4. Reasemble the muffler components and install the

muffler to the cylinder.Tighten securely.

A

E

7-2C 7-2D

F

7-3.FUEL FILTER

CAUTION

The fuel filter

er oper

v

Ne

should be replaced after each 20 hours of use. Drain fuel

tank completely bef

1. Completely remove the fuel cap from the gas tank.

2.

3. Reach into fuel tank opening and hook fuel line.

NOTE: Do not pull hose completely out of tank.

4. Lift filter (A) out of tank (Figure 7-3A).

ate y

ore changing filter

m a hook at the end.

Bend a piece of soft wire to f

Carefully pull the fuel line toward the opening until you

can reach it with y

our fingers.

or

w without a fuel filter

our sa

.

.

B

7-3A

C

A

B

16 17

D

7-4B

Page 17

7 - MAINTENANCE INSTRUCTIONS

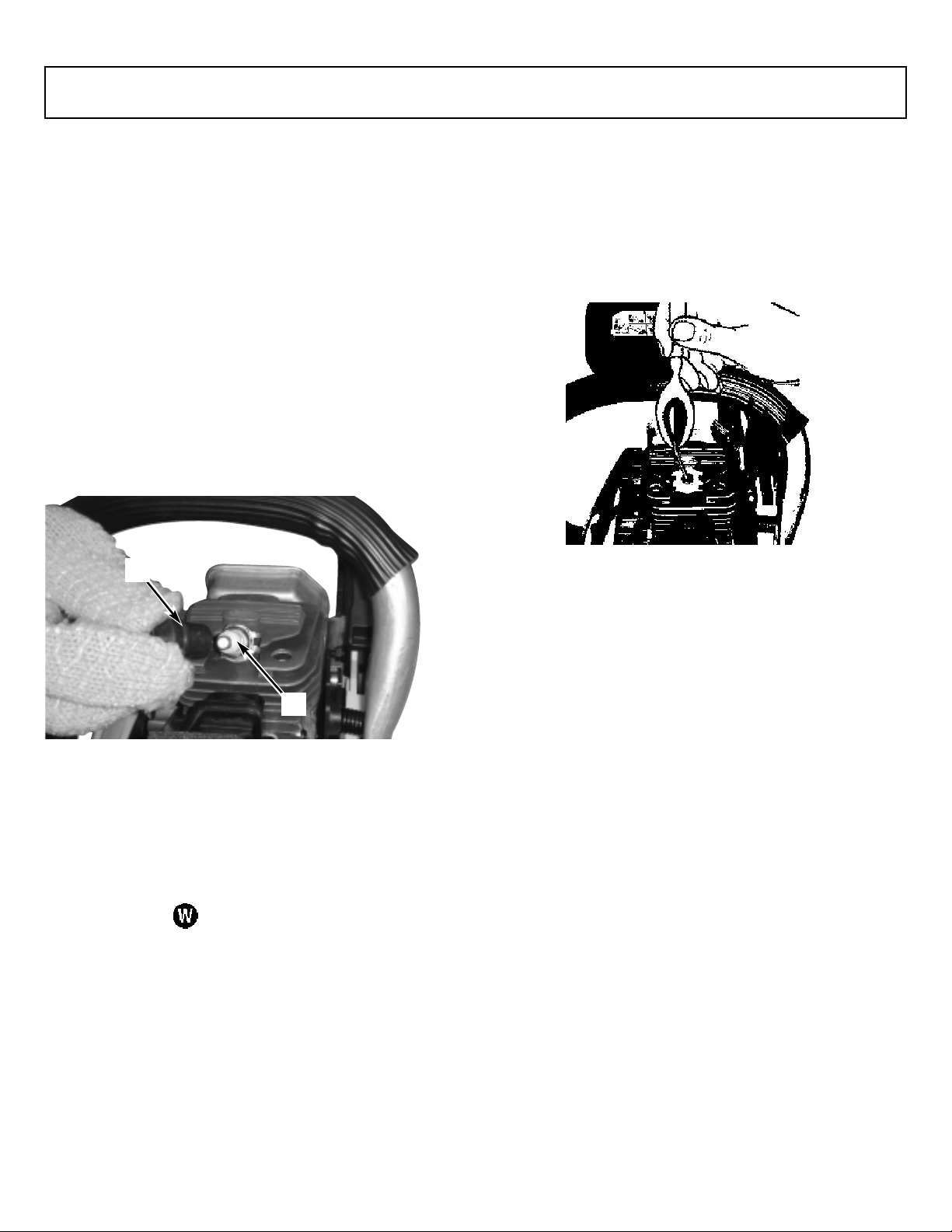

7-5. SPARK PLUG

NOTE: For efficient operation of saw engine, spark plug

must be kept clean and properly gapped.

1. Push STOP switch down.

2. Remove air cleaner cover.

3. Disconnect the wire connector (G) from the spark plug

(H) by pulling and twisting at the same time (Figure 75A).

4. Remove spark plug with spark plug socket wrench.

DO NOT USE ANY OTHER TOOL.

5. Check electtrode gaps with wire feeler gauge and set

gaps to .025” (.635mm) if necessary.

6. Reinstall a new spark plug.

NOTE: A resistor spark plug must be used for replacement

(Part no. 9295-310801).

NOTE: This spark ignition system meets all requirements

of the Canadian Interference-Causing Equipment

Regulations.

G

4. Using a spark plug wrench, remove the spark plug.

5. Pour 1 teaspoon of clean 2-cycle oil into the combustion chamber. Pull starter rope slowly several times to

coat internal components. Replace spark plug (Figure

7-7A).

NOTE: Store the unit in a dry place and away from possible sources of ignition such as a furnace, gas hot water

heater, gas dryer, etc.

7-7A

H

7-5A

7-6.CARBURETOR ADJUSTMENT

The carburetor was pre-set at the factory for optimum per-

ormance. If further adjustments are necessary, please take

f

your unit to the nearest Authorized Service Center listed in

the Yellow Pages.

7-7.STORING A CHAIN SAW

CAUTION

Never store a chain saw for longer than 30 days without

performing the following procedures.

Storing a chain saw for longer than 30 days requires storage maintenance. Unless the storage instructions are followed, fuel remaining in the carburetor will evaporate, leaving gum-like deposits. This could lead to difficult starting

and result in costly repairs.

e the fuel tank cap slo

v

Remo

1.

sure in tank. Carefully drain the fuel tank.

2. Start the engine and let it run until the unit stops to

ve fuel from carburetor.

remo

3. Allow the engine to cool (approx. 5 minutes).

wly to release an

y pres

7-8.REMOVING A UNIT FROM STORAGE

1. Remove spark plug.

2. Pull starter rope briskly to clear excess oil from combustion chamber.

3. Clean and gap spark plug or install a new spark plug

with proper gap.

4. Prepare unit for operation.

5. Fill fuel tank with proper fuel / oil mixture. See Fuel

and Lubrication Section.

-

Page 18

8 - BAR / CHAIN MAINTENANCE

8-1. GUIDE BAR MAINTENANCE

Frequent lubrication of the guide bar (railed bar which supports and carries the saw chain) sprocket tip is required.

Proper maintenance of the guide bar, as explained in this

section, is essential to keep your saw in good working condition.

SPROCKET TIP LUBRICATION:

CAUTION

The sprocket tip on your new saw has been pre-lubricated

at the factory. Failure to lubricate the guide bar sprocket tip

as explained below will result in poor performance and

seizure, voiding the manufacturer’s warranty.

Lubrication of the sprocket tip is recommended after 10

hours of use or once a week, which ever occurs first.

Always thoroughly clean guide bar sprocket tip before lubrication.

TOOLS FOR LUBRICATION:

The Lube Gun (optional) is recommended for applying

grease to the guide bar sprocket tip. The Lube Gun is

equipped with a needle nose tip which is necessary for the

efficient application of grease to the sprocket tip.

TO LUBRICATE SPROCKET TIP:

WARNING

Wear heavy duty work gloves when handling the bar and

chain.

1. Move the STOP switch down.

NOTE: It is not necessary to remove the saw chain to lubri-

cate the guide bar sprocket tip. Lubrication can be done on

the job.

2. Clean the guide bar sprocket tip.

3. Using the Lube Gun (optional), insert tip of lube gun

into the lubr

appears at outside edge of sprocket tip (Figure 8-1A).

4. Rotate saw chain by hand. Repeat lubrication procedure until the entire sprocket tip has been greased.

ication hole and inject g

8-1A

GUIDE BAR MAINTENANCE:

Most guide bar problems can be prevented merely by keeping the chain saw well maintained.

Insufficient guide bar lubrication and operating the saw with

chain that is TOO TIGHT will contribute to rapid bar wear.

rease until it

To help minimize bar wear, the following guide bar maintenance procedures are recommended.

BAR WEAR - Turn guide bar frequently at regular intervals

or example, after 5 hours of use), to ensure even wear on

(f

top and bottom of bar.

BAR GROOVES - Bar grooves (or rails which support and

carry the chain) should be cleaned if saw has been used

heavily or if saw chain appears dirty. Rails should always be

cleaned every time saw chain is removed.

OIL PASSAGES - Oil passages on the bar should be

cleaned to ensure proper lubrication of the bar and chain

during operation.

NOTE: The condition of the oil passages can be easily

checked. If the passages are clear, the chain will automatically give off a spray of oil within seconds of starting the

w.Your saw is equipped with an automatic oiler system.

sa

8-2. CHAIN MAINTENANCE

CHAIN TENSION:

Check the chain tension frequently and adjust as often as

necessary to keep the chain snug on the bar, but loose

enough to be pulled around by hand.

BREAKING IN A NEW SAW CHAIN:

A new chain and bar will need chain readjustment after as

few as 5 cuts.This is normal during the break-in period, and

the interval between future adjustments will begin to lengthen quickly.

WARNING

Never have more than 3 links removed from a loop of chain.

This could cause damage to the sprocket.

CHAIN LUBRICATION:

Always make sure the automatic oiler system is working

properly. Keep the oil tank filled with Genuine Factory Parts

Chain, Bar and Sprocket Oil.

Adequate lubrication of the bar and chain during cutting

operations is essential to minimize friction with the guide

bar.

Never starve the bar and chain of lubricating oil. Running

the saw dry or with too little oil will decrease cutting efficiency, shorten saw chain life, cause rapid dulling of chain, and

lead to excessive wear of bar from overheating.Too little oil

is evidenced by smoke or bar discoloration.

CHAIN SHARPENING:

Chain sharpening requires special tools to ensure that cutters are sharpened at the correct angle and depth. For the

inexperienced chain saw user, we recommend that the saw

chain be professionally sharpened by the nearest

Authorized Service Center.If you feel comfortable sharpening your own saw chain, special tools are available from the

nearest Authorized Service Center.

18 19

Page 19

8 - BAR / CHAIN MAINTENANCE

8-3.CHAIN REPLACEMENT INFORMATION

Bar Length Drive Links

14” Bar 52 DL

16” Bar 56 DL

18” Bar 62 DL

There may be other quality equivalent replacement components for achieving kickback protection.

Page 20

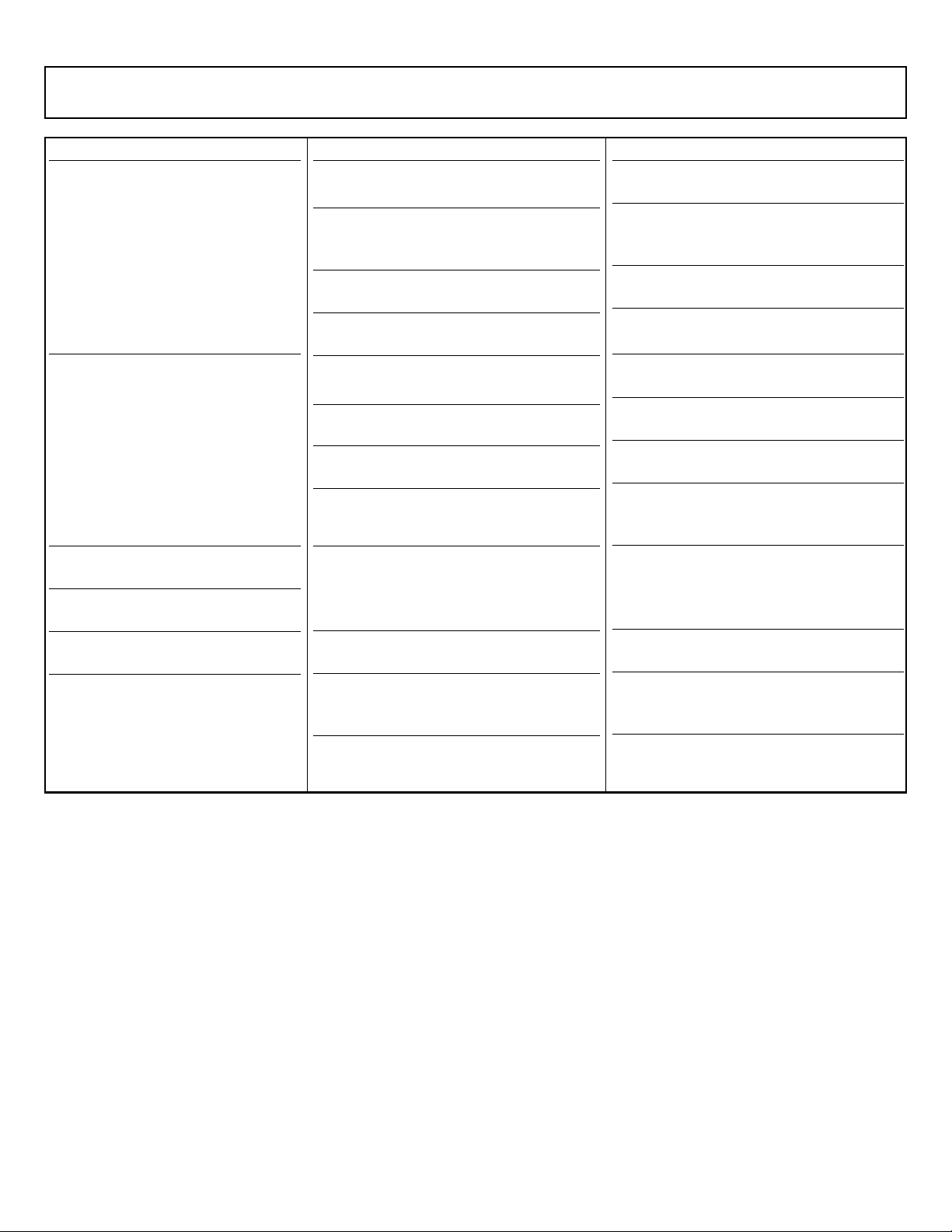

9 - TROUBLESHOOTING THE ENGINE

PROBLEM

Unit won’t start or starts but will

not run.

Unit starts, but engine has low

power.

Engine hesitates.

No power under load.

PROBABLE CAUSE

Incorrect starting procedures.

Incorrect carburetor mixture

adjustment setting.

Fouled spark plug

Fuel filter plugged.

Incorrect lever position on choke.

Dirty spark arrester screen.

Dirty air filter.

Incorrect carburetor mixture

adjustment setting.

Incorrect carburetor mixture

adjustment setting.

CORRECTIVE ACTION

Follow instructions in the User Manual.

Have carburetor adjusted by an

Authorized Service Center.

Clean / gap or replace plug.

Replace fuel filter.

Move to RUN position.

Replace spar

ve, clean and reinstall filter.

Remo

Have carburetor adjusted by an

Authorized Service Center.

Have carburetor adjusted by an

Authorized Service Center.

k arrester screen.

Runs erratically.

Smokes excessively.

Incorrectly gapped spark plug.

Incorrect carburetor mixture

adjustment setting.

Incorrect fuel mixture.

Clean / gap or replace plug.

Have carburetor adjusted by an

Authorized Service Center.

Use properly mixed fuel (40:1 mixture).

20

Page 21

MANUEL DE UTILISATION

Tronçonneuses à essence

SECURITE

FONCTIONNEMENT

ENTRETIEN

Modèles : MS354, EB356, EB358

Ce produit a été testé à un certain angle de rebond calculé (CKA : Computed Kickback Angle) et il est conforme à la norme

ANSI B175.1-2000, Annexe C. CAN/CSA-Z62.1-03

AVERTISSEMENT • LIRE ATTENTIVEMENT

enez toujours la tronçonneuse f

T

Attention aux rebonds

lire attentivement ce manuel et suivre toutes les measures de précautions indiquées avant de vous servir de la tronçon-

Utilisé incorrectement, cet outil peut causer des dommages matér

.

neuse

PN 9096-311009

.

ermement et des deux mains. Pour votre propre sécurité, veuillez

ves.

a

ials et/ou cor

porels g

r

an

aiw

inted in

Pr

T

Page 22

INTRODUCTIOIN

A LIRE ATTENTIVEMENT

Cher Client,

Nous vous remercions de l’achat d’un produit McCulloch.

Correctement utilisé et entretenu, il vous procurera des

années de satisfaction.

Il est IMPERATIF que vous preniez connaissance de LA

TOTALITE de ce manuel avant d’utiliser l’outil ou de

procéder à des opérations d’entretien.

Veillez à bien suivre les instructions pas à pas données

dans le présent manuel pour démarrer, mettre en oeuvre et

maintenir votre nouveau produit en condition.

Ce manuel contient également des mises en garde et renseignements intitulés:

ATTENTION et GARANTIE.

Une REMARQUE: fournit des renseignements complé-

mentaires, éclaircit un point ou explique une étape à suivre en plus de détails.

La notice

AVERTISSEMENT ou ATTENTION est utilisée

pour identifier une procédure qui, si négligée ou incorrectement exécutée, peut entraîner des dommages matériels

et/ou corporels graves.

Le SYMBOLE DE GARANTIE indique que si les procédures ou instructions ne sont pas respectées, les dommages ne seront pas couverts par la garantie et les réparations seront à la charge du propriétaire.

Les précautions de sécurité sont pour votre protection;

Veuillez les lire attentivement; vous devez connaitre ces

importants renseignements afin d’utiliser correctement

votre tronçonneuse.

POUR LA GARANTIE OU LES RÉPARATIONS,

VEUILLEZ PRENDRE CONTACT AVEC LE CEN-

TRE DE MAINTENANCE AGRÉÉ LE PLUS

PROCHE DE CHEZ VOUS - POUR SAVOIR QUEL

EST LE CENTRE DE RÉP

PROCHE,APPELEZ LE NUMÉRO GRATUIT

DONNÉ DANS PRÉSENT MANUEL.

REMARQUES, AVERTISSEMENT /

ARATION LE PLUS

.

TABLE DES MATIERES

1 RENSEIGNEMENTS GENERAUX . . . . . . . . . . . . . . . . . . . .23

1-1. Identification des Principaux Composants

1-2. Dispositifs de Sécurité

2 MEASURES DE SECURITE . . . . . . . . . . . . . . . . . . . . . . . . .24

2-1. Précautions pour Eviter les Rebonds

2-2.

Mesures de Sécurité Supplémentaires

2-3. Précautions Générales de Sécurité

2-4. Rebonds: Conseils Supplémentaires

2-5. Etiquetas de Seguridad por Contragolpe

2-6. Symboles Internationaux

3 INSTRUCTIONS POUR MONTAGE . . . . . . . . . . . . . . . . . . .28

3-1.

Outils pour Montage

3-2. Montage d Eléments

3-3. Guide-Chaîne / Chaîne / Installation du Carter

d’Embrayage

3-4. Réglage de la Tension de la Chaîne

3-5. Test Mécanique du CHAIN BRAKE

4 CARBURANT ET LUBRIFICATION . . . . . . . . . . . . . . . . . . .31

4-1. Carburant

4-2. Mélange du Carburant

4-3. Symboles de Carburant et Lubrification

Tableau des Proportions

4-4. Carburants Recommandes

4-5. Lubrification de la Chaîne et du Guide-Chaîne

5 FONCTIONNEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5-1. Vérification du Moteur

5-2. Mise en Marche du Moteur

5-3. Redémarrage d’un Moteur Chaud

5-4. Arrêt du Moteur

5-5. Test Opérationnel du CHAIN BRAKE

5-6. Lubrification de la Chaîne et du Guide-Chaîne

5-7. Graissage Automatique

6 INSTRUCTIONS POUR LA COUPE . . . . . . . . . . . . . . . . . . 34

6-1. Abattage

6-2.

Ebranchage

6-3. Tronçonnage

6-4. Tronçonnage sur Chevalet

7

ENTRETIEN

7-1. Entretien Préventif

Filtre à Air

7-2.

7-3. Filtre à Essence

Gr

7-4.

Bougie

7-5.

Réglage du Carb

7-6.

Entreposage d’une Tronçonneuse

7-7.

Prepar

7-8.

8 ENTRETIEN DE DU GUIDE-CHAINE / CHAINE

Entretien du Guide-Chaîne

8-1.

Entretien de la Chaîne

8-2.

Inf

8-3.

9 DEP

10

ANNAGE DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . .

NOMENCLA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

ille Pare-Etincelles

ateur

ur

ation Apres Emmagasinage

mations Concer

or

TURE

nant le Remplacement de la Chaîne

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

®

®

. . . . . . . . .

39

41

63

Page 23

1 - RENSEIGNMENTS GENERAUX

21

25

20

19

18

17

16

22

24

15

4

5

6

7

3

2

8

1

13

12

11

10

9

14

23

1-1. IDENTIFICATION DES PRINCIPAUX

1. CHAINE

2. GUIDE-CHAINE

3. PARE-ETINCELLES

4. LEVIER DU CHAIN BRAKE

ARCEAU PROTECTEUR

5. POIGNEE AVANT

6. POIGNEE DU LANCEUR

7. INTERRUPTEUR D’ARRET

OU DE SECURITE

VERR

8.

9. POIGNEE ARRIERE / ETRIER

10. BOUCHON DU RESERVOIR D’HUILE DE CHAINE

BOUCHON DU RESER

11.

12. CAPOT DU LANCEUR

REMUAGE

POINTE

13.

14. ECROU DU GUIDE-CHAINE

15. PROTECTEUR DE SILENCIEUX / CARTER D’EMBRAYAGE

BOUGIE

16.

17. COUVERCLE DU FILTRE A AIR

18. LEVIER DU STARTER

GACHETTE PRE-ACCELERATEUR

19.

20. POMPE D’AMORÇAGE

CCÉLÉRATEUR / GCHETTE

A

21.

22. VIS DE REGLAGE DE CHAINE

23. CAPTEUR DE CHAINE

24. TOURNEVIS / CLÉ PLATE

FOURRE-T

25.

modèles)

DE

OUR R

OB

®

(FREIN DE CHAINE) /

VOIR A CARBURANT

(Disponible sur certains

USTE

1-2. IDISPOSITIFS DE SECURITE

Afin de vous aider à localiser les dispositifs de sécurité, les

numéros précédant les descriptions correspondent à ceux de

la page précédente.

1 Grâce aux limiteurs de profondeur spécialement conçus

et aux maillons

REDUITS»

3 LE PARE-ETINCELLES empêche la projection de car-

bone et autres particules inflammables de plus de

0,6mm (0,023 pouces) de l’échappement.

lois et/ou réglementations locales, d’états ou gouvernementales est à la responsabilité de l’utilisateur. Voir les

Sections Mesures de Sécurité pour plus de détails.

4 LE LEVIER DU CHAIN BRAKE®(FREIN DE CHAINE)

/ARCEAU PROTECTEUR

l’utilisateur si elle glisse de la poignée avant, pendant

que la tronçonneuse est en opération.

4 CHAIN BRAKE®est un dispositif de sécurité conçu

pour minimiser la possibilité de blessures causées par

un rebond; le levier du CHAIN BRAKE®arrête la

tronçonneuse instantanément.

7 Déclanché, L’INTERRUPTEUR D ARRET stoppe immé-

diatement le moteur. Pour faire redémarrer le moteur, il

est nécessaire de mettre l’interrupteur sur la position

«mise en marche» ON.

8 LA MANETTE DE SECURITE empêche l’accélération

involontaire du moteur. Il n’est pas possible d’appuyer

sur la gâchette d’accélération (20) à moins que la

gâchette de sécurité ne soit enclenchée.

23

LE CAPTEUR DE CHAINE

blessures en cas de rupture ou de sortie de la chaîne. Le

capteur de chaîne est conçu de manière à intercepter la

chaîne.

2322

UNE TRONCONNEUSE A «REBONDS

aide à réduire les rebonds et leur intensité.

Le respect des

protège la main gauche de

réduit le danger de

Page 24

2 - MEASURES DE SECURITE

MESURES DE SECURITE POUR L UTILISATEUR

(ANSI B175.1-2000, Annexe C, CAN/CSA-Z62.1-03)

2-1. PRECAUTIONS POUR EVITER LES

REBONDS

AVERTISSEMENT

Un rebond risque de se produire lorsque le nez ou la pointe

du guide-chaîne touche un objet ou lorsque le bois se

referme et pince la chaîne coupante en cours de coupe. Si

la pointe du guide entre en contact avec quelque chose,

cela risque de provoquer une réaction qui fait rebondir le

guide-chaîne en direction de l'opérateur. Lorsque la chaîne

coupante est pincée au sommet du guide-chaîne, cela

risque de pousser rapidement le guide-chaîne en direction

de l'opérateur. L'une ou l'autre de ces réactions risque de

vous faire perdre le contrôle de la scie, ce qui risque de

provoquer un accident corporel grave. Ne vous fiez pas

uniquement aux dispositifs de sécurité qu'intègre votre

scie. En tant qu'utilisateur de cette scie à chaîne, vous

devez prendre plusieurs précautions pour éviter tout accident ou toute blessure pendant vos opérations de coupe.

1. Comprendre ce qui cause les rebonds et comment ils

ont lieu, peut réduire ou même éliminer l’élément de

surprise. L’effet de surprise contribue aux accidents.

2. Quand le moteur est en marche, tenir toujours la

tronçonneuse fermement et correctement: des deux

mains, pouces et doigts bien refermées sur les

poignées, la main droite sur la poignée arrière, et la

main gauche sur la poignée avant.Vous pourrez ainsi

maîtriser votre tronçonneuse et en réduire les risques

de rebonds en la tenant fermement. Ne lâchez pas

prise.

3. Votre secteur de travail doit être libre d’obstacle.

S’assurer que la pointe du guide-chaîne n entre pas

en contact de br

pendant son fonctionnement.

4. Scier toujours le moteur à plein régime.

5. Ne pas scier au delà de la hauteur des épaules; ne

pas se pencher trop en avant.

6. Suivre les instructions du fabricant pour l’affûtage et

l’entretien de la tronçonneuse.

7. N’utiliser que des chaînes et guide-chaînes recommandés par le fabricant ou leur équivalent.

REMARQUE : Une chaîne à «rebonds réduits» répond aux

normes de performances pour «rebonds réduits» exigées

par ANSI B175.1-2000.

Power Tools Gasoline Powered Chain Saws Safety

Requirements) (Normes Nationales Américaines pour

Outils à Moteur et Nor

Tronçonneuses à Essence) quand la chaîne est testée sur

tronçonneuse avec un déplacement de pouce cubique de

moins de 3,8 (3.8 c.i.d.) comme spécifié par ANSI B175.1-

2000.

anches, troncs ou autres surfaces

ican National Standard for

(Amer

mes de Sécurité pour

2-2. MESURES DE SECURITE SUPPLEMENTAIRES

1. NE JAMAIS utiliser la tronçonneuse d’une seule main!

L’utilisateur, et toutes autres personnes autour risqueraient de graves blessures. Une tronçonneuse est

conçue pour être utilisée à deux mains.

2. NE JAMAIS utiliser la tronçonneuse par moments de

fatigue.

3. Porter des chaussures de sécurité, des vêtements de

sécurité bien ajustés, des gants de protection ainsi

que des dispositifs protecteurs appropriés pour yeux,

oreilles et tête.

4. Etre prudent pendant toute manipulation de carburant. S’éloigner d’au moins 9.1m (30 pieds) de l’endroit où le plein d’essence a été fait avant de mettre le

moteur en marche.

5. Ne laissez personne se trouver à proximité quand

vous faites démarrar ou utilisez votre tronçonneuse.

6. Avant d’entreprendre l’abattage, veuiller à vous tenir

sur une surface stable afin de ne pas perdre l’équilibre, vérifier que votre zone de travail et voie de retraite

sont sans obstacle.

7. Rester à l’écart de la chaîne lorsque le moteur est en

marche.

8. Avant de faire démarrer le moteur, s’assurer que la

chaîne de la tronçonneuse ne puisse pas entrer en

contact avec quoi que ce soit.

9. Après avoir arrêté le moteur, transporter la tronçonneuse par sa poignée avant, le guide-chaîne et

chaîne dirigés vers l’arrière et le silencieux à l’opposé

de votre corps.

10. NE JAMAIS se servir d’une tronçonneuse endommagée, mal ajustée ou incorrectement assemblée.

S’assurer que la chaîne s’immobilise lorsque vous

relâchez la gâchette d’accélération.

Arrêter le moteur avant de déposer la tronçonneuse.

11.

xtrêmement pr

Etre e

12.

buissons et arbustes car les matériaux plus fins peu-

ent «s’attraper» dans la chaîne et être projetés dans

v

otre direction ou v

v

13. Faire attention aux branches courbées par la tension

qui peuv

Garder les poignées sèches

14.

d’huile ou de mélange de carburants.

15. Se servir de la tronçonneuse que dans des endroits

bien aérés

16. NE JAMAIS utiliser votre tronçonneuse lorsque vous

êtes dans un arbre à moins que vous ayez eu une formation spéciale

17. Tous autres services d’entretien de la tronçonneuse, à

l’exception de ceux indiqués dans le manuel d’utilisation et d’entretien, doiv

sonnel de réparation de tronçonneuse compétent.

ent vous heurter en se dépliant.

.

udent lors de la coupe de petits

aire perdre l’équilibre

ous f

, propres et sans tr

.

ent être accomplis par un per

.

ace

-

Page 25

2 - MEASURES DE SECURITE

18. Quand vous transportez votre tronçonneuse, veuillez

utiliser le protège-lame approprié.

19. A l’extérieur ou à l’intérieur, NE PAS UTILISER votre

tronçonneuse près de tout produit inflammab

uides, gas…). Une explosion et/ou un feu pourrait en

résulter.

20. UTILISER LE BON OUTIL : Ne couper que du bois.

Ne pas utiliser la tronçonneuse à des fins pour

lesquelles ellen n’apas été conçue. Ne jamais utilser

la tronçonneuse pour couper plastique, maçonnerie,

ou tout autre matériel n’étant pas pour la construction.

21. Ne tentez pas d'ajouter du carburant ou de l'huile de

graissage à la scie pendant que le moteur est en train

de tourner.

REMARQUE : Ces précautions de sécurité s'adressent

incipalement aux utilisateurs amateurs ou occasionnels.

pr

Lorsque v

forestière, veuillez vous reporter au Code de la réglementation fédérale, section 1910.226(5) ; 2.5.1., à la norme

américaine nationale Exigences en matières d'exploitation

du bois à pâte, ANSI 03.1-1978, et aux autres codes de

sécurité pertinents. Ces modèles sont classés par le CSA

comme étant des scies de Classe 1C. Elles sont destinées

à une utilisation occasionnelle par les propriétaires de

maisons individuelles, les propriétaires de maisons de

vacances et les campeurs, pour un usage général tel que

nettoyage, élagage, coupe de bois à brûler, etc. Ils ne sont

pas destinés à une utilisation prolongée. Si l'utilisation

prévue implique une mise en oeuvre de longue durée, les

vibrations risquent de causer des problèmes circulatoires

au niveau des mains de l'utilisateur. Tous les modèles couverts par le présent manuel utilisent une fonction anti-vibrations pour plus de confort et de sécurité.

ous utilisez la scie à chaîne pour l'exploitation

le (liq-

2-3. PRÉCAUTIONS GÉNÉRALES DE

SÉCURITÉ

1. La fatigue est cause d'imprudences. Accordez une

ant les périodes de repos et

attention par

en fin de journée de travail.

2. Vous devez utiliser les vêtements de protection individuelle e

réglementations officielles et votre employeur.

Lorsque vous utilisez une scie à chaîne, vous devez

ter un habillement ajusté, des protections ocu

por

laires, des chaussures de sécurité, et des protections

pour les mains, les jambes et l'audition.

vant tout opération d'ajout de carburant, de mainte-

A

3.

nance ou de transport de votre scie à chaîne, arrêtez

le moteur. Afin d'éviter tout risque d'incendie, redémarrez v

de la zone d'ajout de carburant.

4. Lorsque vous utilisez une scie à chaîne, vous devez

voir un extincteur à disposition.

a

5. Lors de l'abattage, restez à au moins deux arbres de

distance de vos collègues.

ticulière a

xigés par les organismes de sécur

otre scie à chaîne à au moins 9.1m (30pieds)

v

ité, les

6. Planifiez votre travail, choisissez une zone de travail

sans obstacle et, en cas d'abattage, possédant au

moins une issue vous permettant de fuir l'arbre qui

.

tombe

7. Suivez les instructions données dans votre manuel de

l'opérateur pour démarrer la scie à chaîne et contrôlez

la scie à chaîne en le tenant fermement par ses deux

poignées lorsqu'elle est en cours d'utilisation. Gardez

les mains propres, sèches et non grasses.

8. Lorsque vous transportez votre scie à chaîne, utilisez

les capots de transport appropriés pour le guidechaîne et la chaîne coupante.

9. Ne jamais utiliser une scie à chaîne qui est endommagée ou mal réglée, ou qui n'est pas complètement

et correctement assemblée. Assurez-vous que la

chaîne coupante s'arrête bien de tour

relâchez l'interr

imentation.

Ne jamais ajuster le guide-chaîne ou la chaîne

coupante lorsque le moteur est en train de tourner.

10. Faites attention à l'empoisonnement par monoxyde

de carbone. N'utilisez la scie à chaîne que dans des

zones bien ventilées.

11. Ne tentez pas de réaliser des opérations d'élagage ou

d'ébranchage sur un arbre sur pied si vous n'avez pas

reçu de formation spécifique pour cela.

12. Faites attention aux rebonds. Le rebond est le mouvement vers le haut du guide-chaîne qui se produit

lorsque la chaîne coupante, au niveau du nez du

guide-chaîne, entre en contact avec un objet. Le

rebond peut provoquer une perte de contrôle dangereuse de la scie à chaîne.

13. Une scie à chaîne est prévue pour être utilisée à deux

. Si vous l'utilisez avec seulement une main,

mains

isquez de v

ous r

v

et/ou les personnes à proximité à un accident grave.

14. Voir la section 2-5, 2-6, pages 13-14, pour les définitions des symboles

15. Lorsque vous transportez une scie à chaîne dont le

moteur tourne, enclenchez le frein de chaîne.

Laissez votre scie à chaîne refroidir avant de remettre

16.

du carburant, et ne fumez pas.

-

17. Veillez à ce que les autres personnes ou les animaux

restent à une distance de sécurité de la scie à chaîne

en train de fonctionner ou de la zone dans laquelle

l'arbre coupé doit tomber.

18. Faites très attention lorsque vous coupez de petits

buissons ou des arbustes car des éléments de petite

taille peuvent se prendre dans la chaîne coupante et

vous fouetter.

19. Lorsque vous coupez une branche qui est sous tension ou comprimée, faites attention à la détente possible.

2524

upteur du système de contrôle de l'al-

xposer et d'e

ous e

.

ner lorsque vous

xposer vos aides

Page 26

2 - MEASURES DE SECURITE

20. Cette chaîne à essence a été classée par le CSA

dans la catégorie des chaînes de Classe 1C. Elle a

été conçue pour une utilisation occasionnelle par les

iétaires de maisons individuelles, les proprié-

propr

taires de maisons de vacances et les campeurs, et

pour des applications générales telles que nettoyage,

élagage, coupe de bois à brûler, etc. Elle n'a pas été

prévue pour une utilisation prolongée. En cas d'utilisation prolongée, les vibrations risquent de causer des

problèmes circulatoires aux mains de l'utilisateur.

Pour ce type d'utilisation, mieux vaut peut-être utiliser

une scie possédant une fonction antivibration.

A

B

B

C

2-4. REBONDS: CONSEILS SUPPLEMEN-

TAIRES

AVERTISSEMENT

DANGER! ATTENTION AUX REBONDS!

Les rebonds peuvent vous faire perdre contrôle de votre

outil et entrainer des blessures graves et même mortelles

soit à l’utilisateur soit à une personne se trouvant à proximité. Soyez toujours vigilant. Les dangers les plus importants

pendant l’utilisation d’une tronçonneuse proviennent des

rebonds causés par une rotation ou un coinçage, la cause

principale de la plupart des accidents.

ATTENTION AUX:

REBONDS ROTATIFS (Figure 2-4A)

A = Trajectoire rebonds

B = Zone de réaction rebonds

A

A

B

A

2-4B

EL CONTRAGOLPE puede ocurrir cuando la NARIZ o la

PUNTA de la barra guía toca un objeto, o cuando la

a se cierra y pellizca la cadena al momento del

mader

corte.

El contacto de la punta algunas veces puede causar una

reacción reversiva relámpago, pateando la barra guía

hacia arriba y atrás hacia el operador.

EL PELLIZCADO de la cadena de la sierra a lo largo de la

BASE de la barra guía puede JALAR la sierra hacia adelante lejos del operador. PELLIZCANDO la cadena de la

sierra a lo largo de la PUNTA de la barra guía puede

EMPUJAR la barra guía rápidamente para atrás hacia el

operador.

Cualquiera de estas reacciones puede causar que usted

pierda el control de la sierra, lo cual puede resultar en

serias lesiones personales.

AVERTISSEMENT

La fumée ressor

duits chimiques reconnus par l'Etat de Californie

comme étant cancérigènes, provoquant des anomalies

foetales et d'autres dommages corporels.

tant de ce produit contient des pro-

LES REA

COINCA

A = Propulsion vers l’avant

B = Objets solides

C = P

CTIONS DE POUSSEE (REBOND

GE) ET DE PR

oussée v

ers l’utilisateur

OPULSION

2-4A

(Figure 2-4B)

Page 27

2 - MEASURES DE SECURITE

2-5. ETIQUETTE SECURITE POUR REBONDS

Votre scie à chaîne McCulloch possède une étiquette de

sécurité située sur le capot du filtre à air. Cette étiquette,

ainsi que les instructions de sécurité contenues dans ces

pages , doivent être soigneusement lues avant toute utilisation de cette unité.

INTERPRETATIONS DES SYMBOLES ET

COULEURS :

VERT

Utilisé pour vous prévenir qu’une procédure dangereuse

est à éviter.

ROUGE

Procédé de coupe recommandé.

AVERTISSEMENT

RECOMMANDE

AVERTISSEMENT(Figure 2-5A)

1. Angle de rebond calculé dans les pires situations.

2. Attention aux rebonds.

3. Ne pas se servir de la tronçonneuse d’une seule main.

4. Eviter tout contact avec la pointe du guide-chaîne.

RECOMMANDE

5. Tenir la tronçonneuse fermement, des deux mains..

2-5A

2-6. INTERNATIONAL SYMBOLS

Lire le manuel d’utilisation.

Protez des protections (tête, yeux et oreilles)

Portez des gants pour protéger vos mains

Portez des bottes de protection contre le choc électrique

L’utilisation des ces dispostifs de sécurité est foretement recommandé afim

de réduire tout risque de blessures

accidentelles.

2726

Page 28

3 - INSTRUCTIONS POUR MONTAGE

3-1. OUTILS POUR MONTAGE(LA PLUPART

DES UNITÉS SONT ASSEMBLÉES À

L’USINE)

Ces outils vous seront nécessaires pour monter votre

tronçonneuse:

1. Ensemble clé à molette-tournevis (qui se trouve dans le

kit de l'utilisateur ou dans le couvercle de la boîte de

transport).

2. Des gants de protection robustes, non inclus.

3-2. MONTAGE D’ELEMENTS