Page 1

A

MTD Products Aktiengesellschaft • Saarbrücken • Germany

890

Part No: 769-01306A 12/04

Save Instructions

Do Not Throw Away

Read Manual Thoroughly

Page 2

2

17

31

47

63

79

95

English

Français

Deutsch

Italiano

Português

Español

Page 3

3

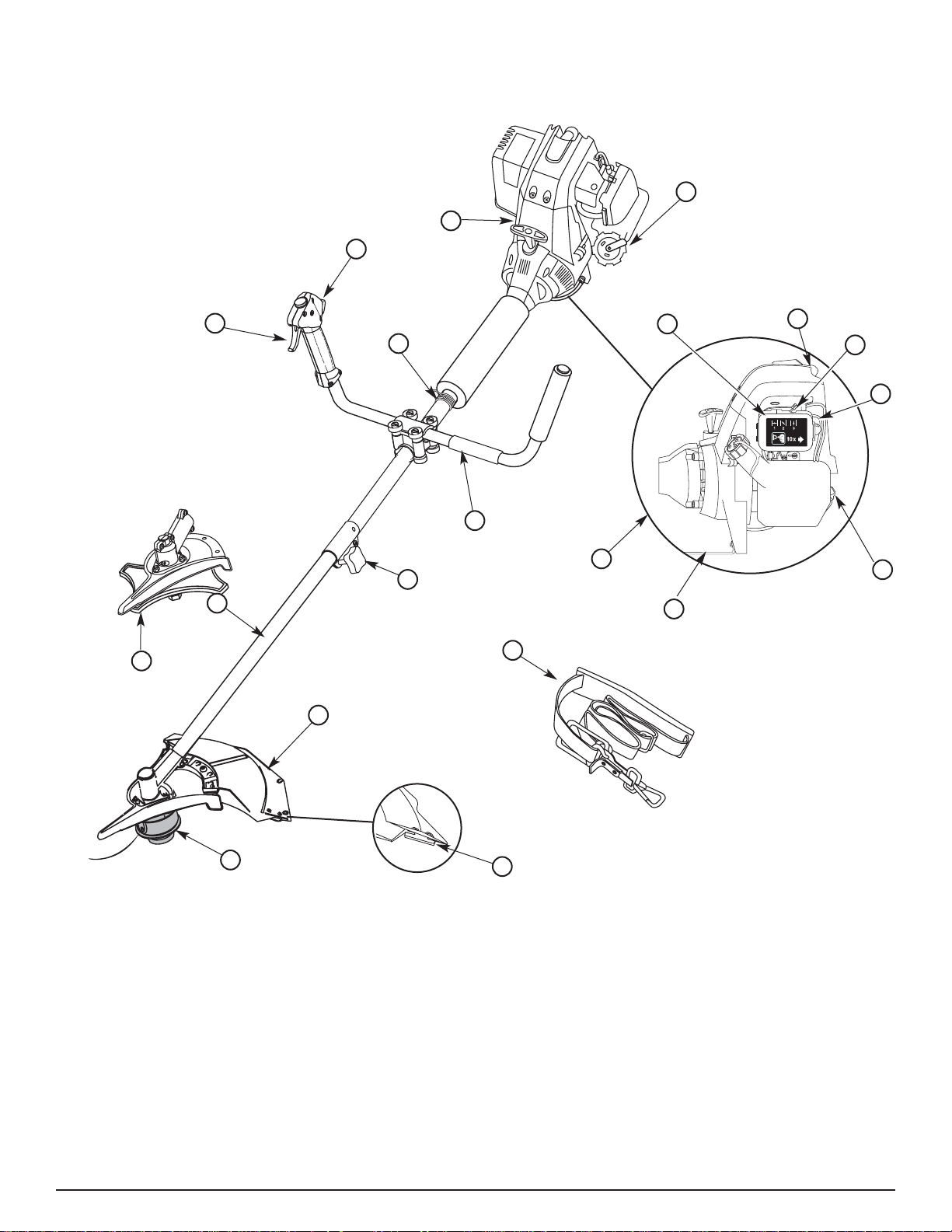

Description of Parts

1. Power Head

2. Fuel Cap

3. Starter Rope Grip

4. Spark Plug

5. Choke Lever

6. Primer

7. Air Filter/Muffler Cover

8. Harness Support

9. Ignition Switch

10. Throttle Trigger

11. Handlebar

12. EZ-Link (according to

model)

13. Shaft Tube

14. Cutting Attachment

Guard

15. Line Cutting Blade

16. Cutting Attachment

17. Cutting Blade with Cover

18. Harness

19. Foot Stand

20. Oil Fill Plug/ Dipstick

Description des pièces

1. Tête d'entraînement

2. Bouchon du carburant

3. Poignée de la corde de

démarrage

4. Bougie

5. Levier d'étrangleur

6. Amorceur

7. Couvercle du filtre à

air/silencieux

8. Soutien du harnais

9. Contact d'allumage

10. Manette des gaz

11. Poignée

12. EZ-Link (selon la

version)

13. Tube de l'arbre

14. Protecteur d'accessoire

15. Lame coupante

16. Accessoire de coupe

17. Lame de coupe avec

couvercle

18. Harnais

19. Support

20. Bouchon de remplissage

/ jauge d'huile

2

3

4

19

5

6

1

10

11

14

13

15

12

16

17

18

9

8

7

20

KNOW YOUR UNIT

FAMILIARISEZ-VOUS AVEC L’APPAREIL

LERNEN SIE IHR GERÄT KENNEN

PANORAMICA SULL’UNITÀ

FAMILIARIZE-SE COM A SUA MÁQUINA

CONOZCA SU UNIDAD

Page 4

4

Descripción de las piezas

1. Cabeza motriz

2. Tapa del combustible

3. Mango de la cuerda de arranque

4. Bujía de encendido

5. Palanca del obturador

6. Cebador

7. Cubierta del filtro de aire / silenciador

8. Soporte del arnés

9. Interruptor de encendido

10. Gatillo del regulador

11. Barra de la manija

12. EZ-Link (según la versión)

13. Tubo del eje

14. Protección del accesorio de corte

15.Cuchilla limitadora de línea

16. Accesorio de corte

17. Cuchilla de corte con cubierta

18. Arnés

19. Estribo

20. Tapa del llenado de Aceite / Medidor

Beschreibung der Teile

1. Motorkopf

2. Tankverschluß

3. Starterleinengriff

4. Zündkerze

5. Chokehebel

6. Einspritzvorrichtung

7. Luftfilter/Schalldämpfer-Abdeckung

8. Schulterriemenhalterung

9. Zündschalter

10. Gashebel

11. Griffstange

12. EZ-Link (je nach Ausführung)

13. Achsenrohr

14. Schneidaufsatzabdeckung

15. Schnurschneidklinge

16. Schneidaufsatz

17. Schneidklinge mit Abdeckung

18. Schulterriemen

19. Fußstütze

20. Ölstöpsel/Ölmessstab

Descrição das peças

1. Cabeça do motor

2. Tampão do depósito de combustível

3. Pega da corda de arranque

4. Vela

5. Alavanca do estrangulador

6. Iniciador

7. Tampa do filtro de ar/silencioso

8. Apoio dos arreios

9. Interruptor da ignição

10. Gatilho do acelerador

11. Guiador

12. EZ-Link (conforme o tipo)

13. Tubo do veio

14. Resguardo do dispositivo de corte

15. Lâmina de corte do fio

16. Dispositivo de corte

17. Lâmina de corte com cobertura

18. Arreios

19. Apoio para o pé

20. Tappo del serbatoio dell’olio / Asta di livello

Descrizione dei componenti

1. Testa motore

2. Tappo serbatoio

3. Avvio a strappo

4. Candela

5. Leva starter

6. Innesco

7. Coperchio blocco filtro aria/marmitta

8. Aggancio tracolla

9. Interruttore di accensione

10. Leva acceleratore

11. Impugnatura

12. EZ-Link (secondo la versione)

13. Tubo dell’albero

14. Protezione pezzo di taglio

15. Lama falciante a filo

16. Pezzo di taglio

17. Lama falciante con copertura

18. Tracolla

19. Poggiapiede

20. Plugue de abastecimento de óleo/vareta

Page 5

5

Fig. 8

Fig. 7

Fig. 1

Fig. 3

Fig. 4

1

1

1

5

7

6

6

2

2

2

4

4

3

3

Fig. 2

Fig. 5

Fig. 6

5

7

Page 6

6

According to model –

Description of Parts – Figs. 7–9

3

Fig. 9

1. EZ-Link

®

2. Release Button

3. Knob

4. Guide Recess

5. Primary Hole

6. Upper Shaft Tube

7. Lower Shaft Tube

Description of Parts – Figs. 1–3

1. Handlebar

2. Screw

3. Top Clamp

4. Middle Clamp

5. Bottom Clamp

6. Nut

7. Release Tab

Según la versión –

Descripción de las piezas – Fig. 7-9

1. EZ-Link

®

2. Botón de desconexión

3. Perilla

4. Hueco de guía

5. Orificio primario

6. Tubo superior del eje

7. Tubo inferior del eje

Descripción de las piezas – Fig. 1–3

1. Barra de la manija

2. Tornillo

3. Abrazadera superior

4. Abrazadera media

5. Abrazadera inferior

6. Tuerca

7. Desconexión

Je nach Ausführung –

Beschreibung der Teile – Abb. 7–9

1. EZ-Link

®

2. Auslöseknopf

3. Knopf

4. Führungsrille

5. Hauptloch

6. oberes Wellenrohr

7. unteres Wellenrohr

Beschreibung der Teile – Abb. 1–3

1. Griffstange

2. Schraube

3. Obere Klemme

4. Mittlere Klemme

5. Untere Klemme

6. Mutter

7. Schnellverschluss

Conforme o tipo –

Descrição das peças – Figuras 7–9

1. EZ-Link

®

2. Botão de

destravamento

3. Maçaneta

4. Recorte de guia

5. Orifício principal

6. Tubo do veio

superior

7. Tubo do veio inferior

Descrição das peças – Figuras 1–3

1. Guiador

2. Parafuso

3. Chapa de aperto superior

4. Chapa de aperto média

5. Chapa de aperto

inferior

6. Porca

7. Desengate

Selon la version –

Description des pièces – Figs. 7–9

1. EZ-Link

MD

2. Bouton de

déclenchem.

3. Bouton

4. Renfoncement-guide

5. Trou principal

6. Tube de l'arbre

supér.

7. Tube de l'arbre infér.

Description des pièces – Fig. 1–3

1. Poignée

2. Vis

3. Bride supérieure

4. Bride médiane

5. Bride inférieure

6. Écrou

7. Détachement

Secondo la versione –

Descrizione dei componenti – figg. 7–9

1. EZ-Link

®

2. Pulsante sgancio

3. Manopola

4. Guida

5. Foro primario

6. Tubo albero sup.

7. Tubo albero inf.

Descrizione dei componenti – figg. 1–3

1. Impugnatura

2. Vite

3. Morsetto superiore

4. Morsetto mediano

5. Morsetto inferiore

6. Dado

7. Sgancio

Page 7

7

Fig. 10

1

2

3

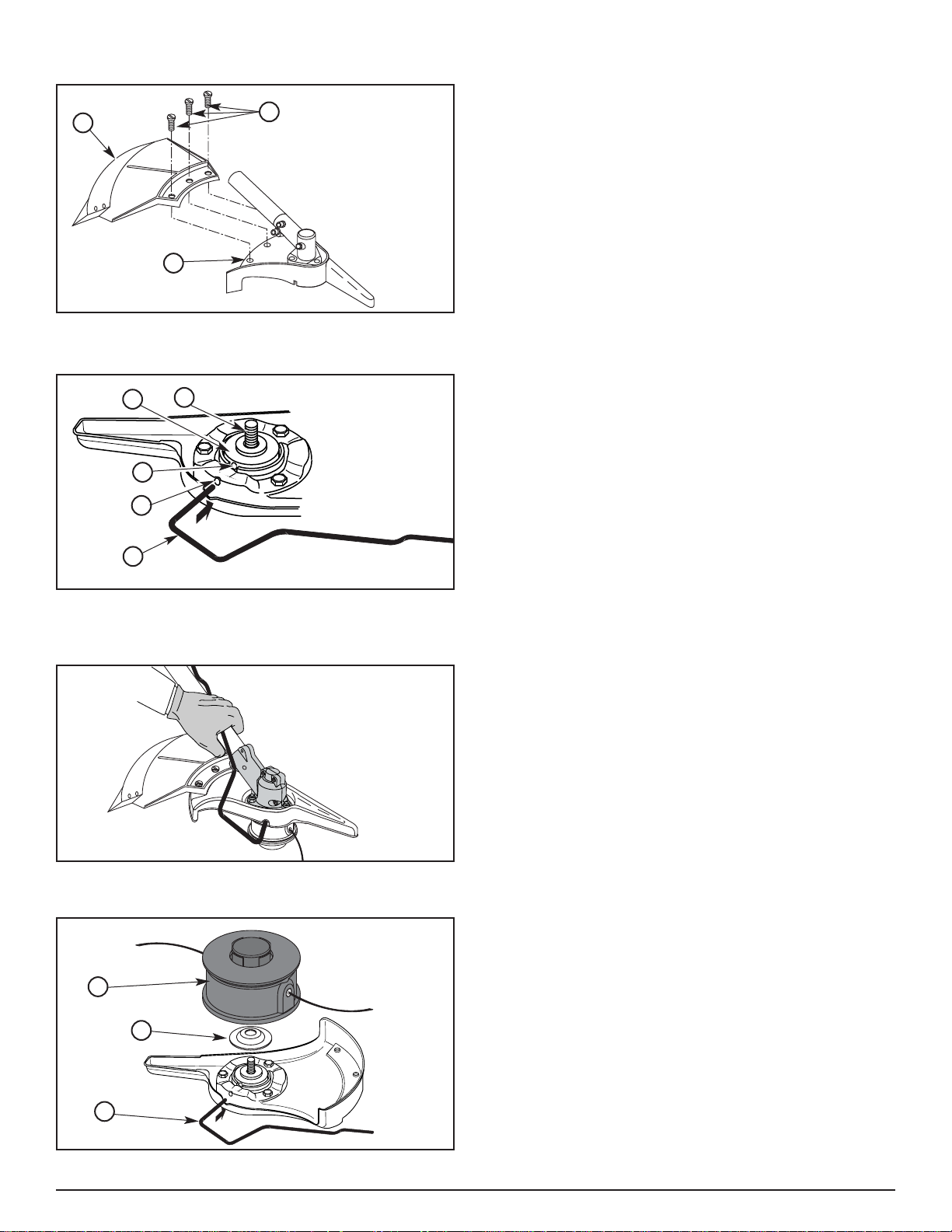

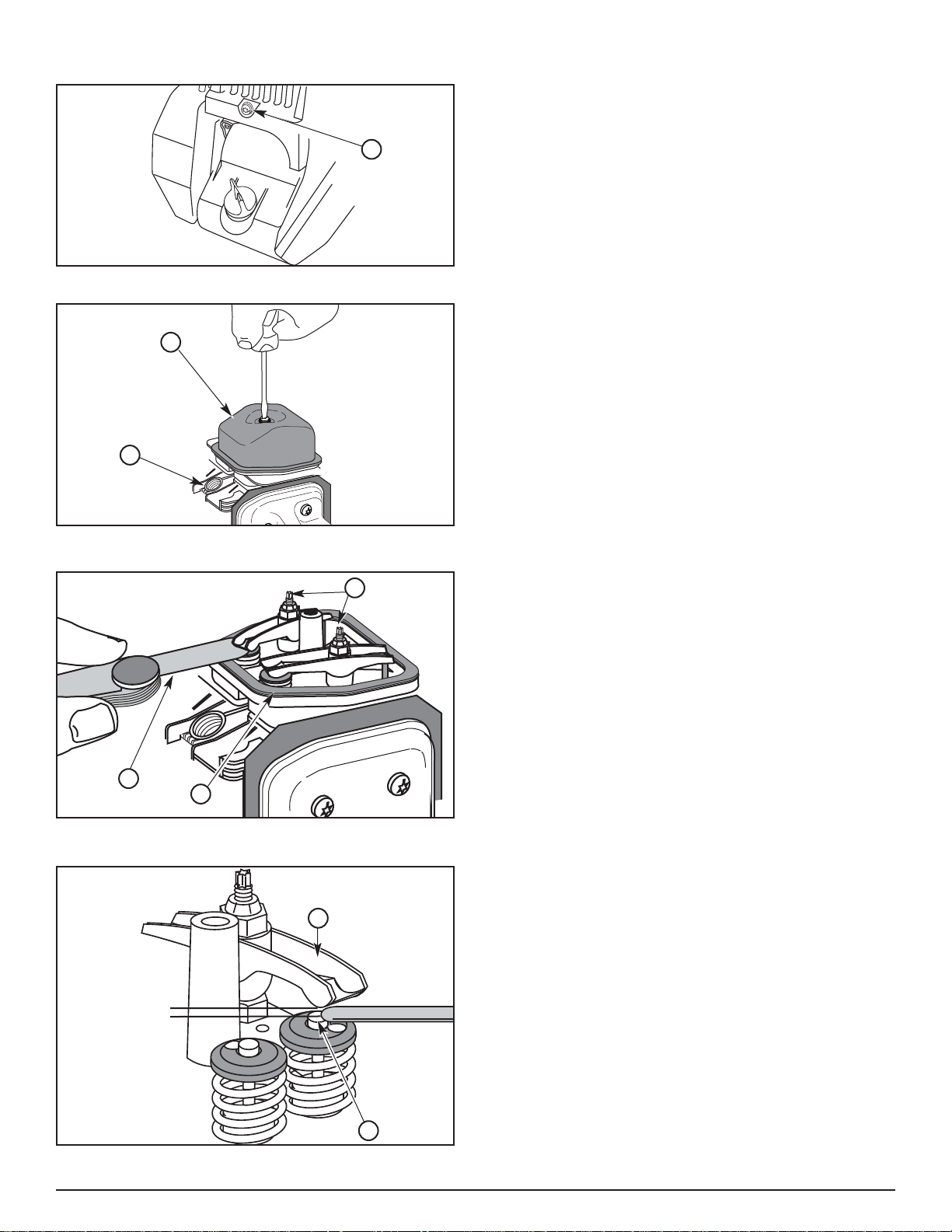

Description of Parts – Figs. 10–13

1. Cutting Attachment

Guard

2. Screws

3. Guard Mount

4. Locking Rod

5. Output Shaft

6. Output Shaft Bushing

7. Locking Rod Slot

8. Shaft Bushing Hole

9. Cutting Attachment

10. Blade Retainer

Descripción de las piezas – Fig. 10–13

1. Protección del

accesorio de corte

2. Tornillos

3. Montaje de

protección

4. Varilla de cierre

5. Eje de salida

6. Casquillo del eje de salida

7. Ranura de la varilla de

cierre

8. Orificio del casquillo del

eje

9. Accesorio de corte

10. Retén de la cuchilla

Beschreibung der Teile – Abb. 10–13

1. Schneidaufsatzschutzblech

2. Schrauben

3. Schutzblechbefestigung

4. Sicherungsstange

5. Antriebswelle

6. Antriebswellen-buchse

7. Sicherungsstangenschlitz

8. Wellenbuchsenloch

9. Schneidaufsatz

10. Klingenhalterung

Descrição das peças – Figuras 10–13

1. Resguardo do

dispositivo de corte

2. Parafusos

3. Base de fixação do

resguardo

4. Vareta de

travamento

5. Eixo de saída

6. Bucha do eixo de saída

7. Ranhura da vareta de

travamento

8. Orifício da bucha do eixo

9. Dispositivo de corte

10. Retentor da lâmina

Description des pièces – Figs. 10–13

1. Protecteur d'accessoire de coupe

2. Vis

3. Support du

protecteur

4. Tige de blocage

5. Arbre de sortie

6. Bague de l'arbre de sortie

7. Fente de la tige de blocage

8. Trou de la bague de l'arbre

9. Accessoire de coupe

10. Retenue de la lame

Descrizione dei componenti – figg. 10–13

1. Protezione pezzo di

taglio

2. Viti

3. Supporto

protezione

4. Perno bloccante

5. Albero in uscita

6. Bronzina albero in uscita

7. Foro perno blocc.

8. Foro bronzina alb.

9. Pezzo di taglio

10. Staffa lama

Fig. 11

Fig. 12

Fig. 13

5

7

6

4

4

8

9

10

Page 8

8

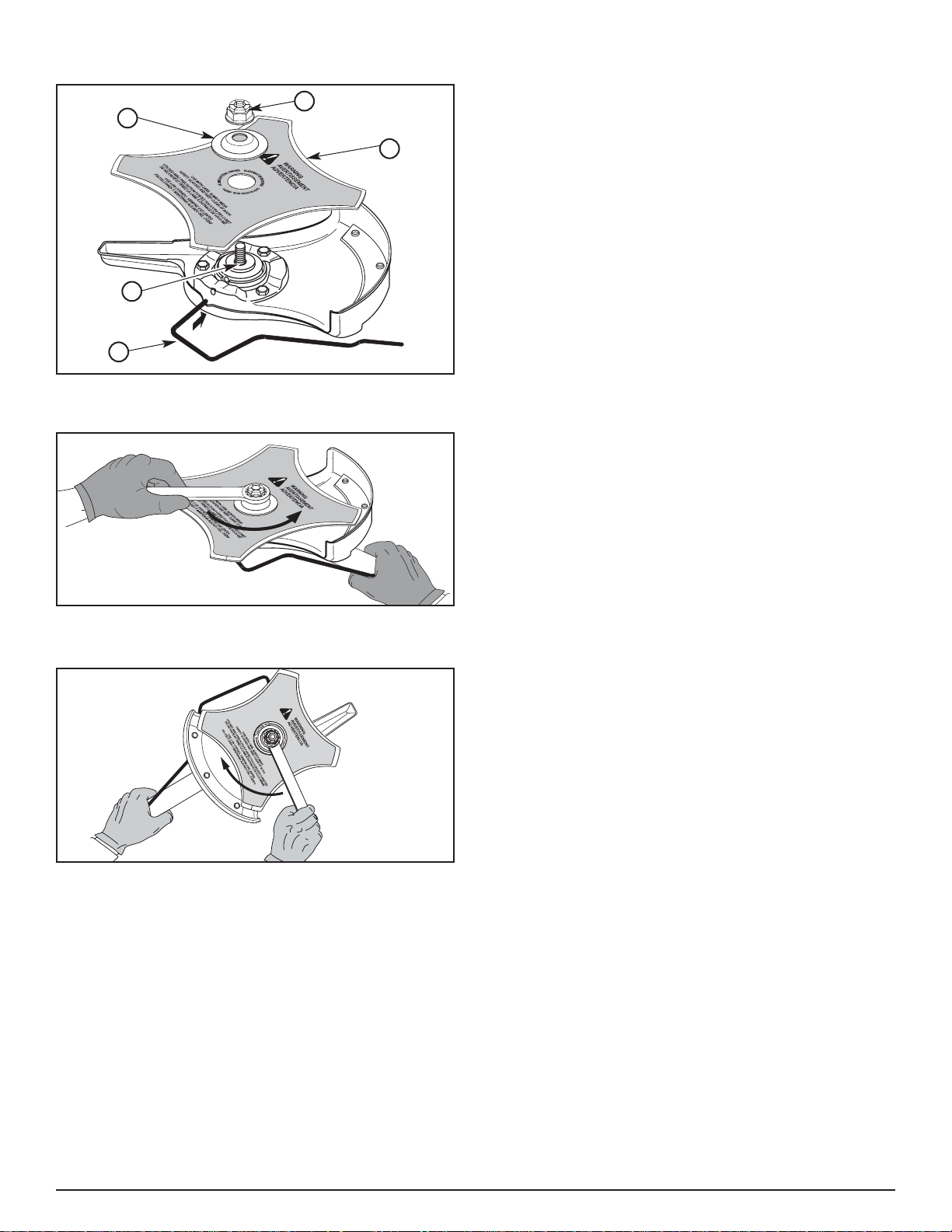

Description of Parts – Figs. 14–16

1. Locking Nut

2. Blade Retainer

3. Cutting Blade

4. Locking Rod

5. Output Shaft

Descripción de piezas – Fig. 14–16

1. Contratuerca

2. Retén de la cuchilla

3. Cuchilla de corte

4. Varilla de cierre

5. Eje de salida

Beschreibung der Teile – Abb. 14–16

1. Gegenmutter

2. Klingenhalterung

3. Schneidklinge

4. Sicherungsstange

5. Antriebswelle

Descrição das peças – Figuras 14–16

1. Contraporca

2. Retentor da lâmina

3. Lâmina de corte

4. Vareta de travamento

5. Eixo de saída

Description des pièces – Figs. 14–16

1. Écrou de blocage

2. Retenue de la lame

3. Lame de coupe

4. Tige de blocage

5. Arbre de sortie

Descrizione dei componenti – figg. 14–16

1. Dado autobloccante

2. Staffa lama

3. Lama falciante

4. Perno bloccante

5. Albero in uscita

1

3

2

4

5

Fig. 14

Fig. 15

Fig. 16

Page 9

9

Fig. 18

Fig. 17

1

3

2

Fig. 19

4

5

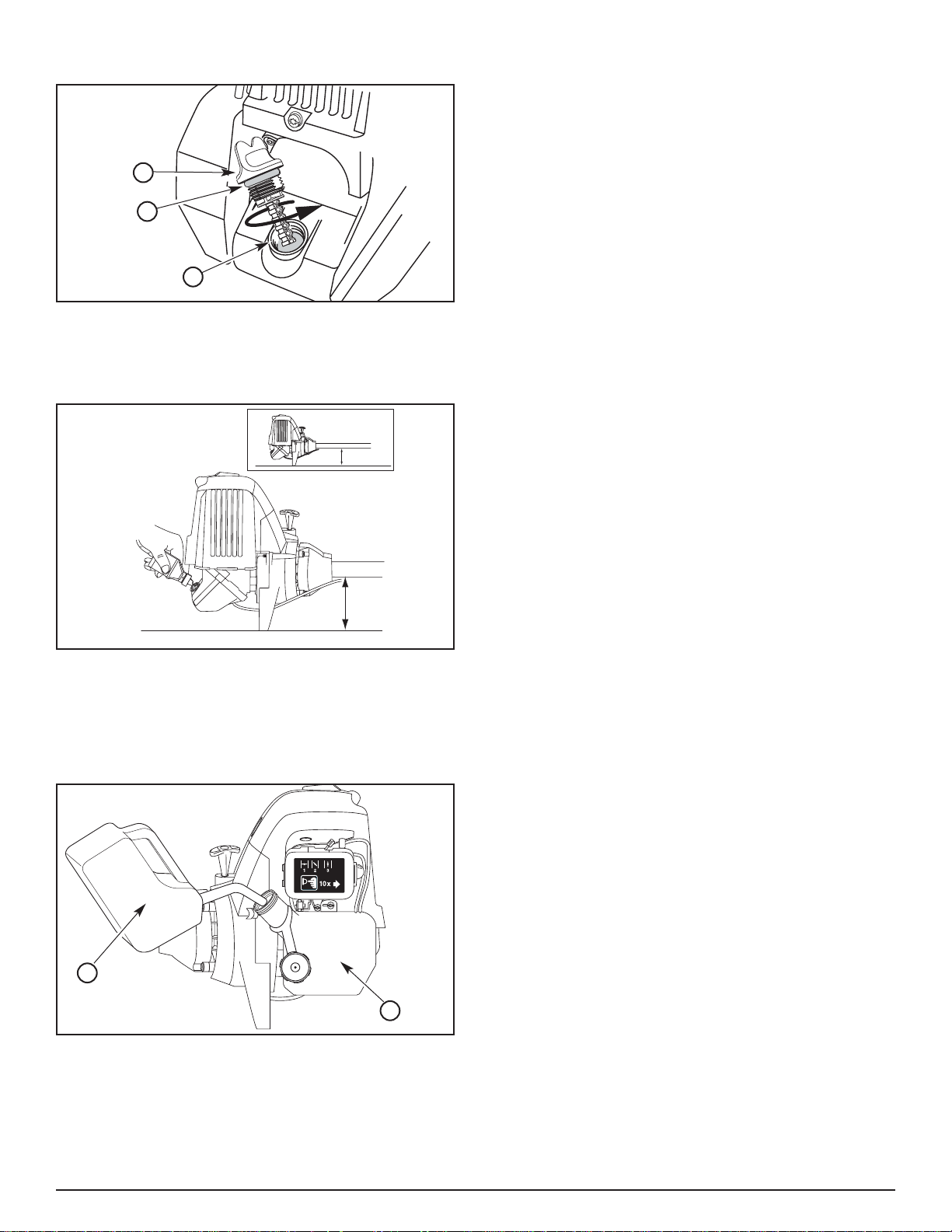

Description of Parts – Figs. 17–19

1. Oil Fil Plug/Dipstick

2. O-Ring

3. Oil Fill Hole

4. Unleaded Petrol

5. Petrol Tank

1. Bouchon de remplissage

/ jauge d'huile

2. Joint torique

3. Orifice de remplissage

d’huile

4. Essence sans plomb

5. Orifice de

remplissage d’huile

1. Ölstöpsel/-Ölmessstab

2. O-Ring

3. Öleinlassloch

4. Bleifreies Benzin

5. Treibstofftank

1. Tappo del serbatoio

dell’olio / Asta di livello

2. Anello di tenuta toroidale

3. Foro di riempimento

dell’olio

4. Benzina senza

piombo

5. Serbatoio della

benzina

1. Plugue de abastecimento

de óleo/vareta

2. Anel de vedação

3. Orifício de abastecimento

de óleo

4. Tanque de

combustível

5. Gasolina sem

chumbo

1. Tapón de relleno de aceite/

varilla de medición

2. Anillo en “O”

3. Orificio de llenado de aceite

4. Gasolina sin

plomo

5. Tanque de

Combustible

Descripción de piezas – Fig. 17–19

Beschreibung der Teile – Abb. 17–19

Descrição das peças – Figuras 17-19

Description des pièces – Figs. 17–19

Descrizione dei componenti - figg. 17-19

Page 10

10

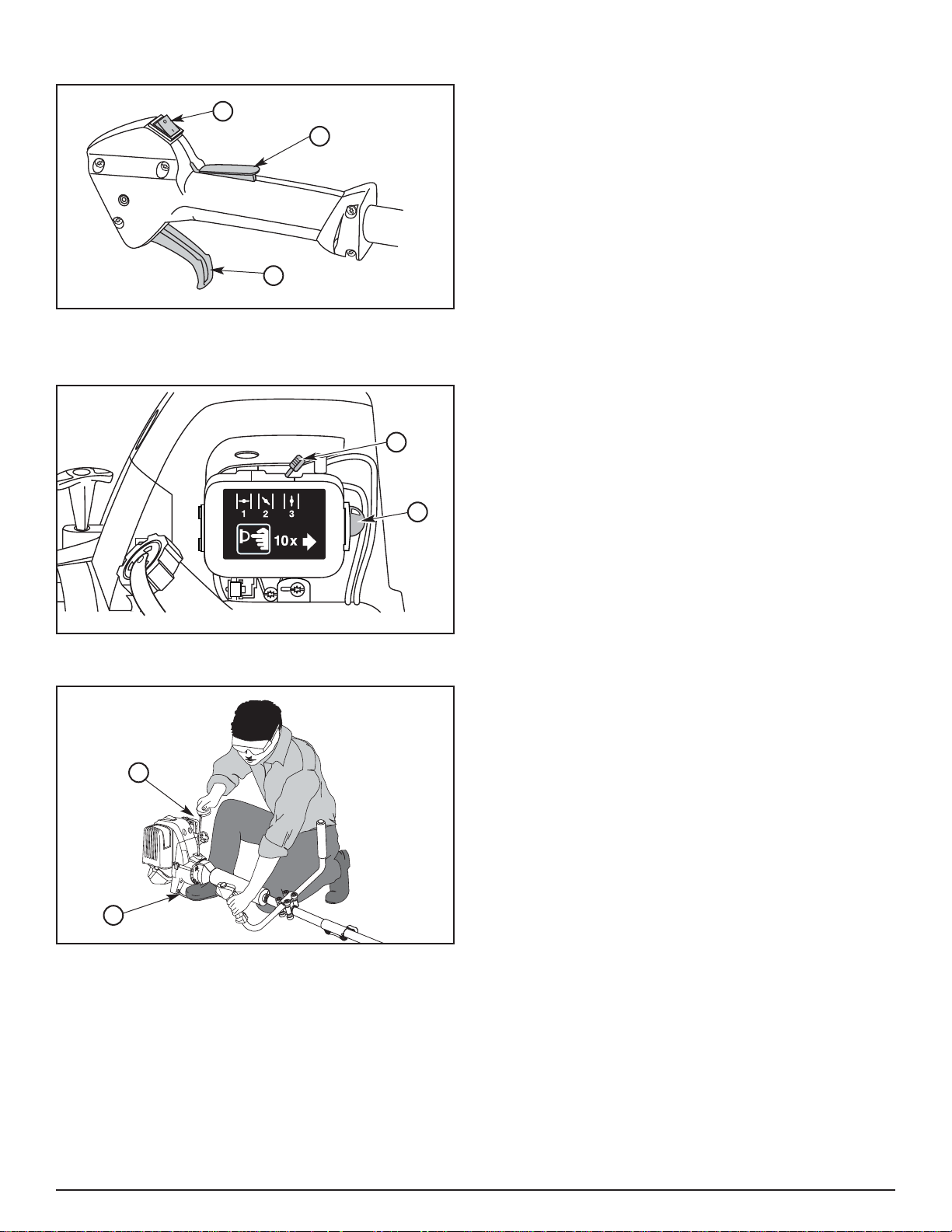

Description of Parts – Figs. 20–22

1. Throttle Trigger

2. Throttle Lock-Out

3. Ignition Switch

4. Choke Lever

5. Primer

6. Starter Rope

7. Foot Stand

Descripción de piezas – Fig. 20–22

1. Gatillo del regulador

2. Apagado del

regulador

3. Interruptor de

encendido

4. Palanca del obturador

5. Cebador

6. Cuerda de arranque

7. Estribo

Beschreibung der Teile – Abb. 20–22

1. Gashebel

2. Drosselsperre

3. Zündschalter

4. Chokehebel

5. Einspritzvorrichtung

6. Starterleine

7. Fußstütze

Descrição das peças – Figuras 20–22

1. Gatilho do acelerador

2. Trava de desengate do

acelerador

3. Interruptor da ignição

4. Posição de operação

5. Iniciador

6. Corda de arranque

7. Apoio para o pé

Description des pièces – Figs. 20–22

1. Manette des gaz

2. Déverrouilleur de

manette des gaz

3. Contact d'allumage

4. Levier d'étrangleur

5. Amorceur

6. Corde de démarrage

7. Support

Descrizione dei componenti - figg. 20–22

1. Leva acceleratore

2. Sblocco accelerat.

3. Accensione

4. Leva starter

5. Innesco

6. Avvio a strappo

7. Poggiapiede

1

3

2

6

7

Fig. 20

Fig. 21

Fig. 22

4

5

Page 11

11

Fig. 23

Fig. 24

Fig. 25

Fig. 26

Description of Parts – Figs. 27–29

1. Outer Spool

2. Spring

3. Inner Reel

4. Bump Knob

5. Indexing Teeth

5

Fig. 27

Fig. 28

Fig. 29

Description des pièces – Figs. 27–29

1. Bobine extérieure

2. Ressort

3. Moulinet intérieur

4. Bouton de butée

5. Dents de positionnement

1

2

3

4

Page 12

12

Fig. 30

Fig. 31

Descripción de piezas – Fig.

27–29

1. Bobina exterior

2. Resorte

3. Carrete interior

4. Perilla percusiva

5. Dientes de posición

Beschreibung der Teile – Abb. 27–29

1. Spulengehäuse

2. Feder

3. Spule

4. Auftippknopf

5. Schaltzähne

Descrição das peças – Figuras 27–29

1. Bobina exterior

2. Mola

3. Carreto interior

4. Batente

5. Dentes de encaixe

Descrizione dei componenti – figg. 27–29

1. Bobina esterna

2. Molla

3. Rocchetto

4. Bump Knob

5. Dente

Fig. 32

Fig. 33

Fig. 34

Fig. 35

1

2

a

b

Page 13

13

Fig. 36

Fig. 37

Fig. 40

2

3

1

4

Fig. 39

Fig. 38

Description of Parts – Fig. 34

1. Full

2. Add 41-44 ml (1.4 - 1.5 oz)

5

7

6

Descripción de piezas – Fig. 34

Beschreibung der Teile – Abb. 34

Descrição das peças – Figuras 34

Description des pièces – Fig. 34

Descrizione dei componenti - figg. 34

1. Plein

2. Ajoutez 41-44 ml (1,4-1,5 oz)

1. Voll

2. 40-45 ml Öl einfüllen

1. Pieno

2. Aggiungete 41-44 ml

1. Cheio

2. Adicionar de 41 a 44 ml

(1,4 a 1,5 onça)

1. Lleno

2. Agregue 1.4-1.5 Onzas

(41-44 ml)

Page 14

14

Fig. 41

1

2

3

4

Fig. 43

Fig. 42

Descripción de piezas – Fig. 36-40

1. Palanca del

obturador

2. Cubierta del

filtro de aire

3. Filtro de aire

4. Orejeta

5. Placa posterior

6. Ranura de la placa posterior

7. Ranuras

Beschreibung der Teile – Abb. 36-40

1. Chokehebel

2. Luftfilter-abdeckung

3. Luftfilter

4. Riegel

5. Montageplatte

6. Schlitz auf der Montageplatte

7. Schlitze

Descrição das peças – Figuras 36-40

1. Alavanca do

estrangulador

2. Cobertura do filtro

de ar

3. Filtro de ar

4. Guia

5. Placa posterior

6. Fenda da placa posterior

7. Fendas

Description des pièces – Figs. 36-40

1. Levier d'étrangleur

2.

Couvercle du filtre à air

3. Filtre à air

4. Languette

5. Plaque arrière

6. Fente de la plaque arrière

7. Fentes

Descrizione dei componenti – figg. 36-40

1. Leva starter

2. Coperchio del filtro

dell’aria

3. Filtro dell’aria

4. Linguetta

5. Piastra posteriore

6. Scanalatura della piastra

posteriore

7. Scanalature

Description of Parts – Figs. 41-43

1. Idle Speed Adjuster

2. Engine Cover

3. Muffler Cover

4. Screws

Descripción de piezas – Fig. 41-43

1. Ajuste de marcha

lenta

2. Cubierta del motor

3. Cubierta del silenciador

4. Saque los tornillos

Beschreibung der Teile – Abb. 41-43

1. Lehrlaufdrehzahlregler

2. Motorabdeckung

3. Auspuffabdeckung

4. Schrauben entfernen

Descrição das peças – Figuras 41-43

1. Regulador da

velocidade lenta

2. Cobertura do motor

3. Cobertura do silencioso

4. Remova os parafusos

Description des pièces – Figs. 41-43

1. Vis de réglage du ralenti

2. Couvercle du moteur

3. Couvercle du

silencieux

4. Retirez les vis

Descrizione dei componenti – figg. 41-43

1. Vite regime minimo

2. Coperchio del motore

3. Coperchio della

marmitta

4. Rimuovete le viti

Description of Parts – Figs. 36-40

1. Choke Lever

2. Air Filter Cover

3. Air Filter

4. Tab

5. Back Plate

6. Back Plate Slot

7. Slots

Page 15

15

.003–.006 in.

(.076–0.152 mm)

4

3

2

1

6

5

7

8

Fig. 47

Fig. 46

Fig. 45

Fig. 44

Description of Parts – Figs. 44-47

1. Screw

2. Rocker Arm Cover

3. Spark Plug Hole

4. Adjusting Nuts

5. Feeler Gauge

6. Gasket

7. Rocker Arm

8. Valve Stem

Descripción de piezas – Fig.

44-47

Beschreibung der Teile – Abb. 44-47

Descrição das peças – Figuras 44-47

Description des pièces – Fig. 44-47

Descrizione dei componenti - figg. 44-47

1. Vis

2. Cache-culbuteur

3. Trou de bougie

4. Écrous de réglage

5. Jauge d'épaisseur

6. Joint

7. Culbuteur

8. Tige de soupape

1. Schraube

2.

Kipphebelabdeckung

3. Zündkerzenloch

4. Einstellmuttern

5. Fühlerlehre

6. Dichtung

7. Kipphebel

8. Ventilspindel

1. Vite

2. Coperchio del

bilanciere

3. Foro della candela

d’accensione

4. Dadi di regolazione

5. Calibro a spessori

6. Guarnizione

7. Bilanciere

8. Gambo della valvola

1. Parafuso

2. Cobertura do braço

de balancim

3. Orifício da vela de

ignição

4. Porcas de ajuste

5. Calibrador de folga

6. Gaxeta

7. Braço de balancim

8. Haste da válvula

1. Tornillo

2. Cubierta del

balancín

3. Orificio de la bujía

de encendido

4. Tuercas de ajuste

5. Calibrador

6. Junta

7. Balancín

8. Vástago de la válvula

Page 16

16

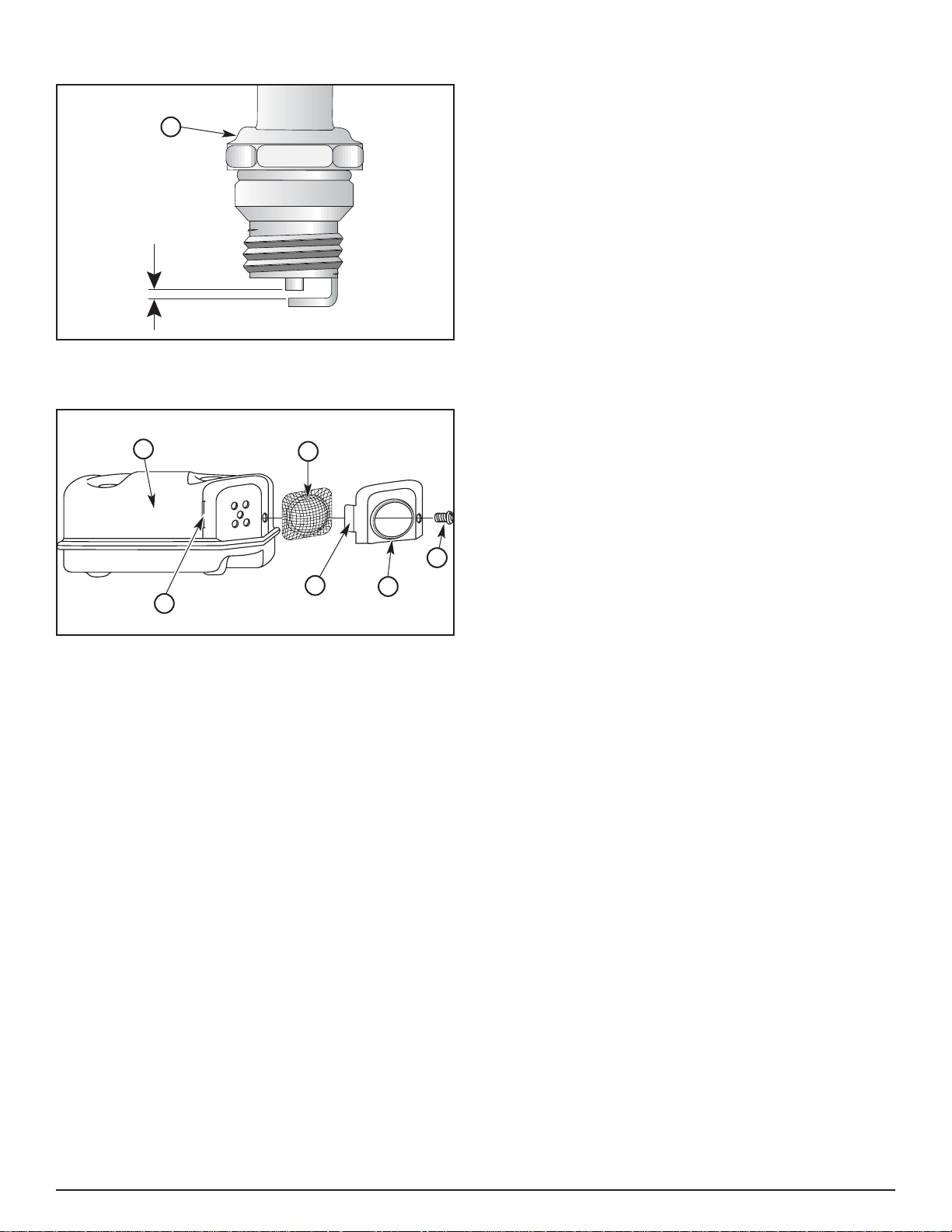

Fig. 48

0.655 mm.

(0.025 in.)

1

Fig. 49

7

6

5

4

3

2

Description of Parts – Figs. 48-49

1. Spark Plug

2. Muffler

3. Spark Arrestor

4. Screw

5. Spark Arrestor Cover

6. Tab

7. Slot

Descripción de piezas – Fig. 48-49

Beschreibung der Teile – Abb. 48-49

Descrição das peças – Figuras 48-49

Description des pièces – Fig. 48-49

Descrizione dei componenti - figg. 48-49

1. Bougie

2. Silencieux

3. Écran pareétincelles

4. Vis

5. Couvercle du pareétincelles

6. Languette

7. Fente

1. Zündkerze

2. Auspuff

3. Funkengitter

4. Schraube

5. Funkengitterabdeckung

6. Riegel

7. Schlitz

1. Candela

2. Marmitta

3. Schermo del

parascintille

4. Vite

5. Coperchio del parascintille

6. Linguetta

7. Scanalatura

1. Vela

2. Silencioso

3. Tela do extintor de

centelhas

4. Parafuso

5. Cobertura do extintor de

centelhas

6. Guia

7. Fenda

1. Bujía de encendido

2. Silenciador

3. Pantalla del

parachispas

4. Tornillo

5. Cubierta del

parachispas

6. Orejeta

7. Ranura

Page 17

17

Enter all the information shown on the identification plate

of your lawn product into the box below.

The identification plate is located on the engine.

This information is very important for identifying any

spare parts that are to be ordered at a later date, and for

customer service.

READ ALL INSTRUCTIONS

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

• Do not operate this unit when tired, ill, or under the

influence of alcohol, drugs, or medication.

• Children and teens under the age of 15 must not use

the unit, except for teens guided by an adult.

• Inspect the unit before use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are in

place and secure. Replace cutting attachment parts

that are cracked, chipped, or damaged in any way.

Make sure the cutting attachment is properly installed

and securely fastened. Be sure the cutting attachment

shield is properly attached, and positioned as

recommended. Failure to so can result in personal

injury to the operator and bystanders, as well as

damage to the unit

• Use only 2.41 mm (0.095 in.) diameter genuine

replacement line. Never use metal-reinforced line,

wire, chain or rope, etc. These can break off and

become a dangerous projectile.

• Be aware of the risk of injury to the head, hands and feet.

• Clear the area to be cut before each use. Remove all

objects such as rocks, broken glass, nails, wire, or

string which can be thrown or become entangled in

the cutting attachment. Clear the area of children,

bystanders, and pets. At a minimum, keep all children,

bystanders and pets outside a 15 m (50 ft.) radius;

there still may be a risk to bystanders from thrown

objects. Bystanders should wear eye protection. If you

are approached, stop the engine and cutting

attachment immediately.

• Squeeze the throttle trigger and check that it returns

automatically to the neutral position. Make all

adjustments or repairs before using unit.

SAFETY WARNINGS FOR GAS TRIMMERS

WARNING: Petrol (gasoline) is highly flammable, and

its vapors can explode if ignited. Take the following

precautions:

• Store fuel only in containers specifically designed and

approved for the storage of such materials.

• Avoid creating a source of ignition for spilled fuel. Do

not start the engine until fuel vapors dissipate.

• Always stop the engine and allow it to cool before

filling the fuel tank. Never remove the cap of the fuel

tank, or add fuel, when the engine is hot. Never

operate the unit without the fuel cap securely in place.

Loosen the fuel tank cap slowly to relieve any pressure

in the tank.

• Add fuel in a clean, well-ventilated area outdoors

where there are no sparks or flames. Slowly remove

the fuel cap only after stopping engine. Do not smoke

while fueling or mixing fuel. Wipe up any spilled fuel

from the unit immediately.

• Move the unit at least 9.1 m (30 ft.) from the fueling

source and site before starting the engine. Do not

smoke, keep sparks and open flames from the area

while adding fuel or operating the unit.

WHILE OPERATING

• Never start or run the unit inside a closed room or

building. Breathing exhaust fumes can kill. Operate

this unit only in a well ventilated area outdoors.

• Wear safety glasses or goggles and ear/hearing

protection when operating this unit. Wear a face or

dust mask if the operation is dusty. Long sleeve shirts

are recommended.

• Wear heavy, long pants, boots and gloves. Do not

wear loose clothing, jewelry, short pants, sandals or

go barefoot. Secure hair above shoulder level.

• This unit has a clutch. The cutting attachment remains

stationary when the engine is idling. If it does not, have

the unit adjusted by an authorized service technician.

SAFETY WARNINGS

SAFE OPERATING PRACTICES

USE THE UNIT CORRECTLY

This unit is intended exclusively:

– For use in accordance with the descriptions and safety

instructions specified in this operating manual

– For use in the garden

– For trimming lawn edges and small or inaccessible

grassy areas (e.g. under bushes)

– As well as for cutting rank weeds, shrubs and

undergrowth

This unit is not permitted for any other use. The user is

liable for any injury to third parties

or damage to their property.

Operate the unit only in the delivered technical condition

as stipulated by the manufacturer.

Any unauthorised changes to the unit will exempt the

manufacturer from liability for any resulting damage.

Page 18

18

• The cutting attachment guard must always be in place

while operating the unit as a trimmer. Do not operate

unit without both trimming lines extended, and the

proper line installed. Do not extend the trimming line

beyond the length of the shield.

• Adjust the handlebar to your size to provide the best

grip.

• Be sure the cutting attachment is not in contact with

anything before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position

whenever pulling the starter rope. The operator and

unit must be in a stable position while starting. Refer

to the Starting/Stopping Instructions.

• Use the right tool. Only use this tool for the purpose

intended.

• Do not overreach. Always keep proper footing and

balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on both handlebar grips.

• Always use the shoulder harness when using this unit.

• Keep hands, face, and feet at a distance from all

moving parts. Do not touch or try to stop the cutting

attachment when it is rotating.

• Do not touch the engine or muffler. These parts get

extremely hot from operation. When turned off they

remain hot for a short time.

• Do not operate the engine faster than the speed

needed to cut, trim or edge. Do not run the engine at

high speed when not cutting.

• Always stop the engine when cutting is delayed or

when walking from one cutting location to another.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do

not operate the unit with loose or damaged parts.

• Stop and switch the engine to off for maintenance,

repair, or for changing the cutting attachment or other

attachments.

• Use only genuine replacement parts when servicing

this unit. These parts are available from your

authorized service dealer.

• Do not use parts, accessories or attachments not

authorized for this unit. Doing so could lead to serious

injury to the user, or damage to the unit, and void your

warranty.

• Keep unit clean of vegetation and other materials.

They may become lodged between the cutting

attachment and guard.

•To reduce fire hazard, replace faulty muffler and spark

arrestor, keep the engine and muffler free from grass,

leaves, excessive grease or carbon build up.

• Have all repairs carried out by a specialist only.

WHILE OPERATING WITH CUTTING BLADE

• Read and understand all safety warnings before

operating this unit.

• Keep the handlebar between the operator and cutting

attachment or blade at all times.

• NEVER cut with the cutting blade located over 76 cm

(30 in.) or more above the ground level.

• Kick back may occur when the spinning blade

contacts an object that it does not immediately cut.

Kick back can be violent enough to cause the unit

and/or operator to be propelled in any direction, and

possibly lose control of the unit. Kick back can occur

without warning if the blade snags, stalls or binds. This

is more likely to occur in areas where it is difficult to

see the material being cut.

• For operation with the brush blade, do not cut

anything thicker than 12.7 mm (1/2 in.) or a violent

kickback could occur.

• Do not attempt to touch or stop the blade when it is

rotating.

•A coasting blade can cause injury while it continues to

spin after the engine is stopped or the throttle trigger

is released. Maintain proper control until the blade has

completely stopped rotating.

• Do not run the unit at high speed when not cutting.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Have any damage repaired before attempting

further operations. Do not operate unit with a bent,

cracked or dull blade. Discard blades that are bent,

warped, cracked or broken.

• Do not sharpen the cutting blade. Sharpening the blade

can cause the blade tip to break off while in use. This

can result in severe personal injury. Replace the blade.

•Stop the engine IMMEDIATELY if you feel excessive

vibration. Vibration is a sign of trouble. Inspect thoroughly

for loose nuts, bolts or damage before continuing. Repair

or replace affected parts as necessary.

AFTER USE

• Clean cutting blades with a household cleaner to

remove any gum buildup. Oil the blade with machine

oil to prevent rust.

• Lock up and store the cutting blade in an appropriate

area to protect the blade from unauthorized use or

damage.

OTHER SAFETY WARNINGS

• Never store the unit, with fuel in the tank, inside a

building where fumes may reach an open flame or spark.

• Allow the engine to cool before storing or transporting.

Be sure to secure the unit while transporting.

• Store the unit in a dry place, locked up or up-high to

prevent unauthorized use or damage. Keep out of the

reach of children.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use, see Cleaning and Storage

instructions.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

SAVE THESE INSTRUCTIONS

SAFETY WARNINGS

Page 19

19

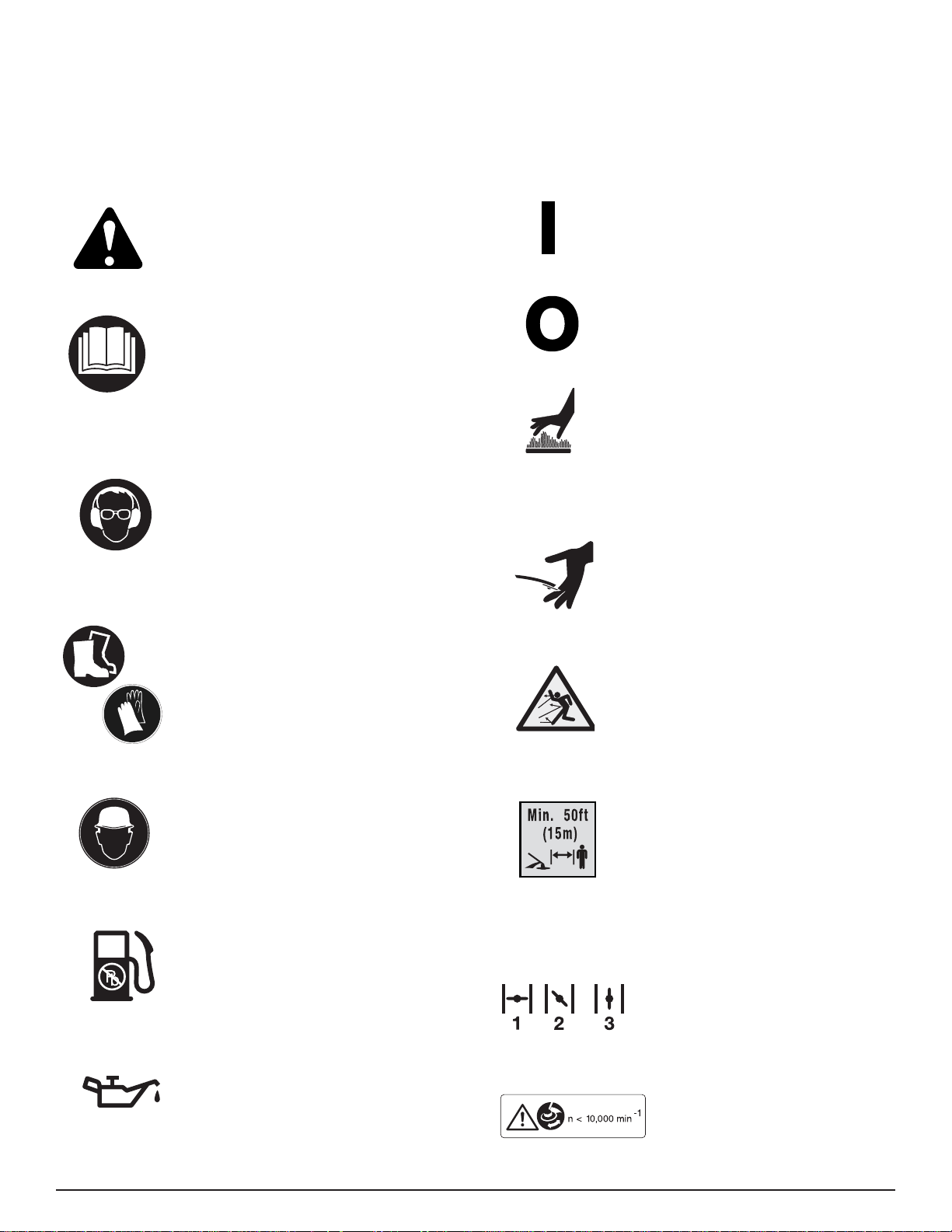

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning, or

caution. May be used in conjunction

with other symbols or pictographs.

•WARNING - READ

OPERATOR'S MANUAL

Read the Operator’s Manual(s) and

follow all warnings and safety

instructions. Failure to do so can

result in serious injury to the

operator and/or bystanders.

• WEAR EYE AND HEARING

PROTECTION

WARNING:

Thrown objects and loud

noise can cause severe eye injury and

hearing loss. Wear eye protection

meeting ANSI Z87.1-1989 standards and

ear protection when operating this unit.

Use a full face shield when needed.

• WEAR PROTECTIVE

FOOTWEAR AND GLOVES

Wear hard-wearing boots and

gloves when operating this unit.

• WEAR HEAD PROTECTION

WARNING: Falling objects can

cause severe head injury. Wear head

protection when operatin this unit.

• UNLEADED PETROL

Always use clean, fresh unleaded

petrol.

• OIL

Refer to operator's manual for the

proper type of oil.

SYMBOL MEANING

• IGNITION SWITCH

ON / START / RUN

• IGNITION SWITCH

OFF or STOP

• HOT SURFACE WARNING

Do not touch a hot muffler or

cylinder. You may get burned.

These parts get extremely hot from

operation. When turned off they

remain hot for a short time.

• SHARP BLADE

WARNING: Sharp blade on cutting

attachment shield. To prevent

serious injury, do not

touch line cutting blade.

• KEEP BYSTANDERS AWAY

WARNING:

Objects can be

thrown from unit. Do not operate

unit without proper attachments

and guards in place.

• THROWN OBJECTS CAN

CAUSE SEVERE INJURY

WARNING:

Keep all bystanders,

especially children and pets, at

least 15 meters (50 ft.)

from the operating area.

• CHOKE CONTROL

1 • FULL choke position.

2 • PARTIAL choke position.

3 • RUN position.

• MAXIMUM RPM

Do not operate the unit faster

than the maximum RPM.

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

Page 20

20

ASSEMBLY INSTRUCTIONS

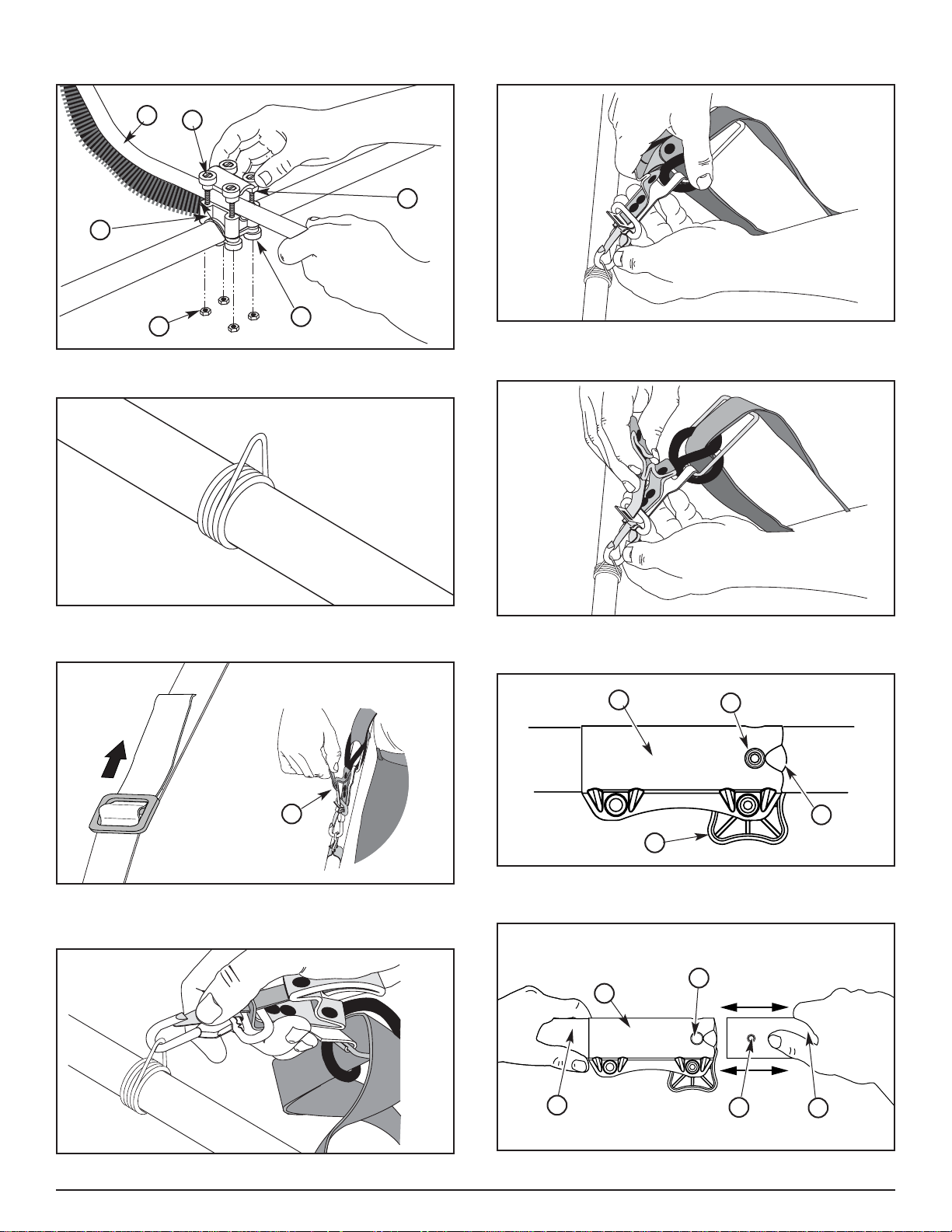

INSTALLING AND ADJUSTING THE HANDLEBAR

1. Place the handlebar between the top and middle

clamp pieces (Fig. 1).

2. While holding the three pieces together, install the

four (4) screws through the top clamp and into

middle clamp.

NOTE: The holes in the top and middle clamp will line up

only when assembled correctly.

3. Place the clamps and the handlebar over the shaft

housing and onto the bottom clamp.

4. Hold each hex nut in the bottom clamp recess with a

finger. Start screws with a large Phillips screwdriver.

Do not tighten until you make the handlebar

adjustment.

5. While holding the unit in the operating position

(Fig. 23), position the handlebar to the location that

provides you the best grip.

6. Tighten the clamp screws evenly, until the handlebar

is secure.

INSTALLING AND ADJUSTING THE SHOULDER

HARNESS

Shoulder Harness

1. Loop the strap through the buckle (Fig. 3).

2. Place the harness over the head and the cushioned

pad onto the shoulder.

3. Snap the shoulder harness hook onto the metal

support (Fig. 4). Adjust the length of the harness to a

comfortable position.

Emergency Quick Release

1. For fast release from the unit, pull up on the quick

release tab (Fig. 3)

2. To reasemble the clamp:

a. Place the hook over the release plate (Fig. 5).

b.Insert the pin into the plate (Fig. 6).

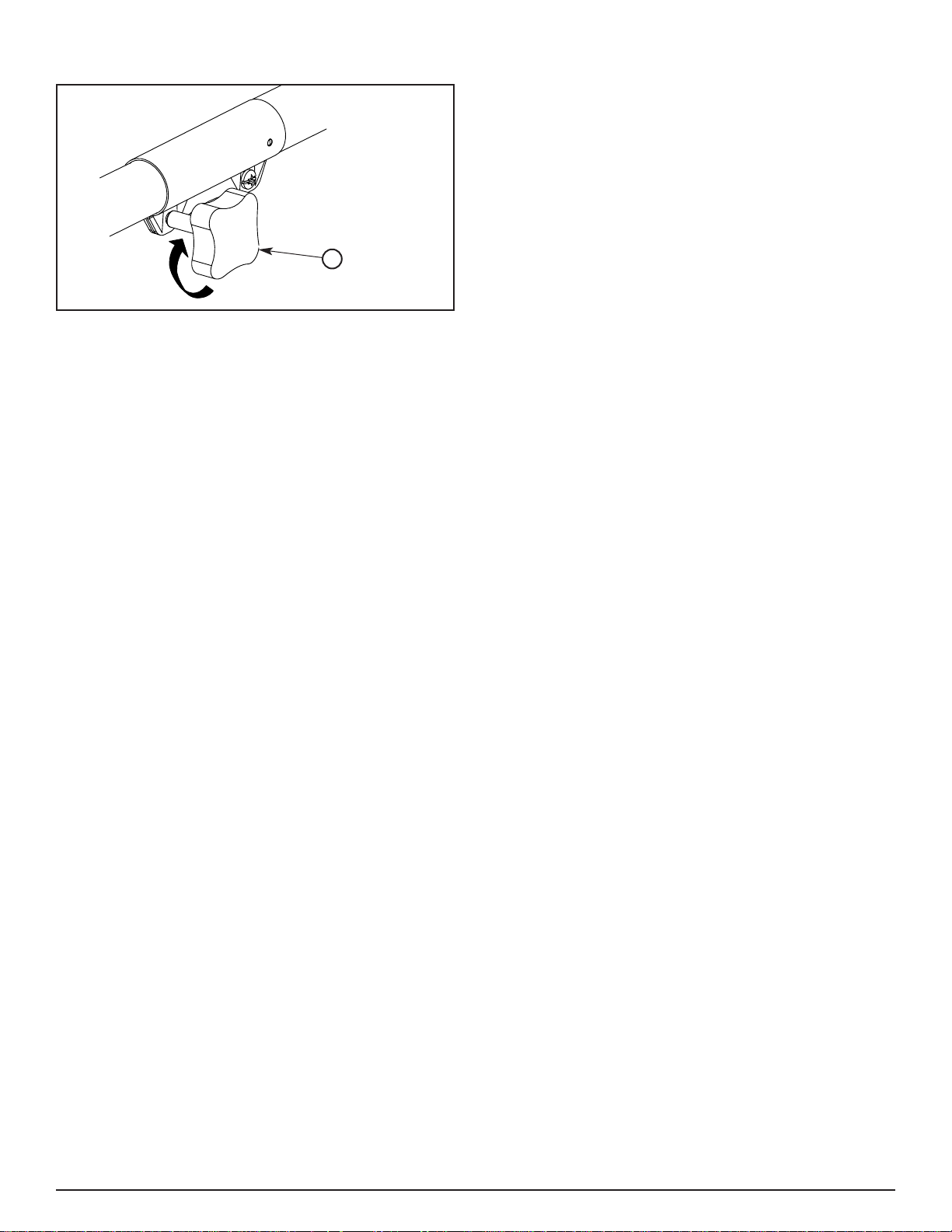

OPERATING THE EZ-LINK® SYSTEM

NOTE: To make installing or removing the add-on easier,

place the unit on the ground or on a work bench.

Removing the Cutting Attachment or Add-Ons

1. Turn the knob counterclockwise to loosen (Fig. 7).

2. Press and hold the release button (Fig. 7).

3. While firmly holding the upper shaft tube, pull the

cutting attachment or add-on straight out of the EZLink® coupler (Fig. 8).

Installing the Cutting Attachment or Add-Ons

1. Turn knob counterclockwise to loosen (Fig.7).

2. While firmly holding the add-on, push it straight into

the EZ-Link® coupler (Fig. 8).

NOTE: Aligning the release button with the guide recess

will help installation (Fig. 7).

3. Turn the knob clockwise to tighten (Fig. 9). Ensure it

is tight before operating the unit.

REMOVING AND INSTALLING CUTTING

ATTACHMENT GUARD

Remove the cutting attachment guard when using the

unit as a brushcutter.

Remove the cutting attachment guard from the guard

mount by removing the three (3) screws with a flat blade

screwdriver (Fig. 10). Store parts for future use.

Install the cutting attachment guard when using the unit

as a grass trimmer.

Install the cutting attachment guard on the guard mount

by inserting the three (3) screws into the guard mount.

Tighten securely with a flat blade screwdriver (Fig. 10).

REMOVING THE CUTTING ATTACHMENT AND

INSTALLING THE CUTTING BLADE

NOTE: To make removing or installing the cutting blade

or cutting attachment easier, place the unit on

the ground or on a work bench.

Remove the Cutting Attachment

1. Align the shaft bushing hole with the locking rod slot

and insert the locking rod into the shaft bushing hole

(Fig. 11).

2. Hold the locking rod in place by grasping it next to

the shaft tube of the unit (Fig. 12).

3. While holding the locking rod, remove the cutting

attachment by turning it clockwise off of the output

shaft (Fig. 13). Store the cutting attachment for future

use.

Install the Cutting Blade

4. Remove the cutting attachment guard. See

Removing and Installing Cutting Attachment Guard.

5. Place the cutting blade on the output shaft (Fig. 14).

6. Center the cutting blade on the output shaft bushing

(Fig. 14).

7. Ensure that the cutting blade is centered and sitting

flat against the output shaft bushing.

8. Align the shaft bushing hole with the locking rod slot and

insert the locking rod into the bushing hole (Fig. 11).

9. Put the blade retainer and nut on the output shaft

(Fig. 14). Make sure that the blade is installed

correctly.

10. Tighten counterclockwise against the blade while

holding the locking rod (Fig. 15).

Page 21

21

• If using a torque wrench and an 5/8 inch socket

tighten to:

37 - 38 Nm

325 - 335 in•lb

27 - 28 ft.•lb

•Without a torque wrench, use a 5/8 inch closed-end or

socket wrench, turning the nut until the blade retainer

is snug against the shaft bushing. Make sure that the

blade is installed correctly, then rotate the nut an

additional 1/4 to 1/2 turn counterclockwise (Fig. 15).

11. Remove the locking rod from the locking rod slot.

12. Remove the blade cover.

REMOVE THE CUTTING BLADE AND

INSTALL THE CUTTING ATTACHMENT

Remove the Cutting Blade

1. Put the blade cover on the cutting blade.

2. Align the shaft bushing hole with the locking rod slot and

insert the locking rod into the bushing hole (Fig. 11).

3. Hold the locking rod in place by grasping it next to

the shaft tube of the unit (Fig. 12).

4. While holding the locking rod, loosen the nut on the

blade by turning it clockwise with a 5/8 inch closedend or socket wrench (Fig. 16).

5. Remove the nut, blade retainer, and blade. Store the

nut and blade together for future use in a secure

place. Store out of reach of children.

Install the Cutting Attachment

6. Align the shaft bushing hole with the locking rod slot

and insert the locking rod into the shaft bushing hole.

(Fig. 11). Place the blade retainer on the output shaft

with the flat surface against the output shaft bushing

(Fig. 13). Screw the cutting attachment counterclockwise onto the output shaft. Tighten securely.

NOTE: The blade retainer must be installed on the

output shaft in the position shown for the cutting

attachment to work correctly.

7. Remove the locking rod.

8. Install the cutting attachment guard. See Removing

and Installing Cutting Attachment Guard.

ASSEMBLY INSTRUCTIONS

OIL AND FUEL RECOMMENDATIONS

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase

is extremely important. Check the oil before each use

and change the oil regularly. Failure to use the correct

oil, or using dirty oil, can cause premature engine wear

and failure.

Use a high-quality SAE 30 weight oil of API (American

Petroleum Institute) service class SF, SG, SH.

ADDING OIL TO CRANKCASE – INITIAL USE

NOTE: This unit is shipped without being filled with oil.

In order to avoid damage to the unit, put oil in

the crankcase before attempting to start unit.

1. Place the unit on a flat level surface.

2. Remove the oil plug / dipstick from the crankcase

(Fig. 17).

3. Pour the 100ml of oil into the oil fill hole (Fig. 18).

NOTE: Never add oil to the fuel or fuel tank.

4. Wipe up any oil that may have spilled and reinstall

the oil fill plug / dipstick.

RECOMMENDED FUEL TYPE

Old fuel is the primary reason for the unit not running

properly. Be sure to use fresh, clean, unleaded petrol.

NOTE: This is a four cycle engine. In order to avoid

damage to the unit, do not mix oil with petrol.

Definition of Blended Fuels

Today's fuels are often a blend of petrol and

oxygenates such as ethanol, methanol or MTBE (ether).

Alcohol-blended fuel absorbs water. As little as 1%

water in the fuel can make fuel and oil separate or form

acids when stored. Use fresh fuel (less than 60 days old),

when using alcohol-blended fuel.

Using Blended Fuels

If you choose to use a blended fuel, or its use is

unavoidable, follow recommended precautions.

• Always use fresh unleaded petrol

• Use the fuel additive STA-BIL®or an equivalent.

• Drain tank and run the engine dry before storing unit.

Using Fuel Additives

The use of fuel additives, such as STA-BIL®Petrol

Stabilizer or an equivalent, will inhibit corrosion and

minimize the formation of gum deposits. Using a fuel

additive can keep fuel from forming harmful deposits in

the carburetor for up to six (6) months. Add 23 ml (0.8 oz.)

of fuel additive per gallon of fuel according to the

instructions on the container. NEVER add fuel additives

directly to the unit's petrol tank.

Page 22

22

STARTING INSTRUCTIONS

Cold Start - First Start of the Day or Engine Ran

Out of Fuel

WARNING: Operate this unit only in a well ventilated

area outdoors. Carbon monoxide exhaust fumes can

be lethal in a confined area.

1. Check oil level in crankcase. Refer to the Checking

the Oil Level section.

2. Fill the fuel tank with fresh, clean, unleaded petrol.

Refer to the Fueling the Unit section.

3. Put the Start/Stop Engine Control in the START [I]

position (Fig. 20).

4. Place the choke lever in Position 1 (Fig. 21).

NOTE: Slide the choke lever directly above the

appropriate symbol on air filter cover decal

(Fig. 21).

5. Fully press and release the primer bulb slowly 10

times. Petrol should be felt and visible in the bulb

(Fig. 21). If petrol has not entered the bulb, press

three more times, or until it does.

6. While pressing the throttle lock-out, squeeze the

throttle control to the wide open (full throttle)

position (Fig. 20).

7. With the unit in the starting position and your foot on

the foot stand wire form (Fig. 22), pull the starter rope

briskly 5 times in Position 1. If the engine attempts to

run before the fifth pull, proceed to step 8.

8. Move the choke lever to Position 2 (Fig. 21).

NOTE: The engine will not run in Position 1.

9. Pull the starter rope 1 to 3 pulls until the engine

starts. Run for 15-30 seconds. If the unit fails to start

return to step 7.

10. Move the choke lever to Position 3 and run at full

throttle for 30 seconds.

WARNING: Avoid accidental starting. Crouch in the

starting position whenever pulling the starting rope. To

avoid serious personal injury, the operator and unit

must be in a stable position while starting.

11. Release the throttle control to the idle position and

begin operation.

NOTE: If the engine does not start using these

procedures, repeat steps 5 through 11 using

TWO (2) pulls in Position 1.

Engine Re-Start - Warm Engine With Fuel

1. Put the Start/Stop Engine Control in the START [I]

position (Fig. 20).

2. Move the choke lever to Position 1 (Fig. 21).

3. Fully press and release the primer bulb slowly 10

times. Petrol should be felt and visible in the bulb

(Fig. 21). If petrol has not entered the bulb, press

three more times, or until it does.

4. While pressing the throttle lock-out, squeeze the

throttle control to the wide open (full throttle)

position (Fig. 20).

OPERATING INSTRUCTIONS

OIL AND FUEL RECOMMENDATIONS

FUELING UNIT

WARNING: Petrol is extremely flammable and its

vapors can explode if ignited. To avoid serious

personal injury, always stop the engine and allow it to

cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames away

from the area.

1. Remove fuel cap (Fig. 19).

WARNING: Remove fuel cap slowly to avoid injury

from

petrol spray.

2. Place spout of petrol container into the fill hole on

the fuel tank (Fig. 19) and fill tank.

WARNING: Add petrol in a clean, well-ventilated area

outdoors. Avoid creating a source of ignition for spilt

fuel.

NOTE: Do not overfill tank.

3. Wipe up any petrol that may have spilled

4. Reinstall the fuel cap.

WARNING: Never operate the unit without the fuel

cap securely in place.

5. Move the unit at least 9.1 m (30 ft.) from the fueling

source and site before starting the engine.

NOTE: Dispose of the old petrol in accordance to Local

regulations.

Page 23

23

5. With the unit in the starting position and foot on the

wire form (Fig. 22), pull the starter rope briskly until

the engine starts.

6. When the engine starts, move the choke lever to

Position 3, and run at full throttle for 30 seconds.

NOTE: If the engine does not start using the Engine

Re-start procedures, revert to the Cold Start

procedures.

NOTE: 4-stroke engines, like cars, are able to start in

the idle position. As an alternate method, you

may want to start your unit in the idle position

when the unit is warm. With the Start/Stop

control in the START position, pull the starter

rope briskly. When the engine starts, run at full

throttle for 30 seconds. If the unit fails to start or

dies, revert to the Engine Re-Start procedure.

STOPPING INSTRUCTIONS

1. Release your hand from the throttle control (Fig. 20).

Allow the engine to idle.

2. To stop the engine, put the Start/Stop Engine

Control in the STOP [O] position (Fig. 20).

COLD WEATHER OPERATION

Your new 4-Cycle trimmer is shipped for operation in

conditions above 4ºC (40°F). For operation in conditions

that are below this, use the following instructions along

with your Operator's Manual. This will prepare the unit

for cold weather operation and provide improved

starting results.

WARNING: Refer to section Recommended Oil Type

and follow all warnings and safety instructions in the

operator’s manual. Failure to do so can result in

serious injury to the operator and/or bystanders.

ADDING OIL TO CRANKCASE – INITIAL USE

NOTE: This unit is shipped without oil in the crankcase.

In order to avoid damage to the unit, put oil in the

crankcase before attempting to start unit.

Your unit is supplied with one 100 ml (3.4 fl oz.) bottle of

SAE 30 SF, SG, SH oil.

For cold weather operation, temperatures below 4º C

(40°F) use a high-quality SAE 10W30 weight oil of API

(American Petroleum Institute) service class SF, SG, SH.

Follow the instructions in your Operator's Manual for

adding the correct amount of oil to this unit.

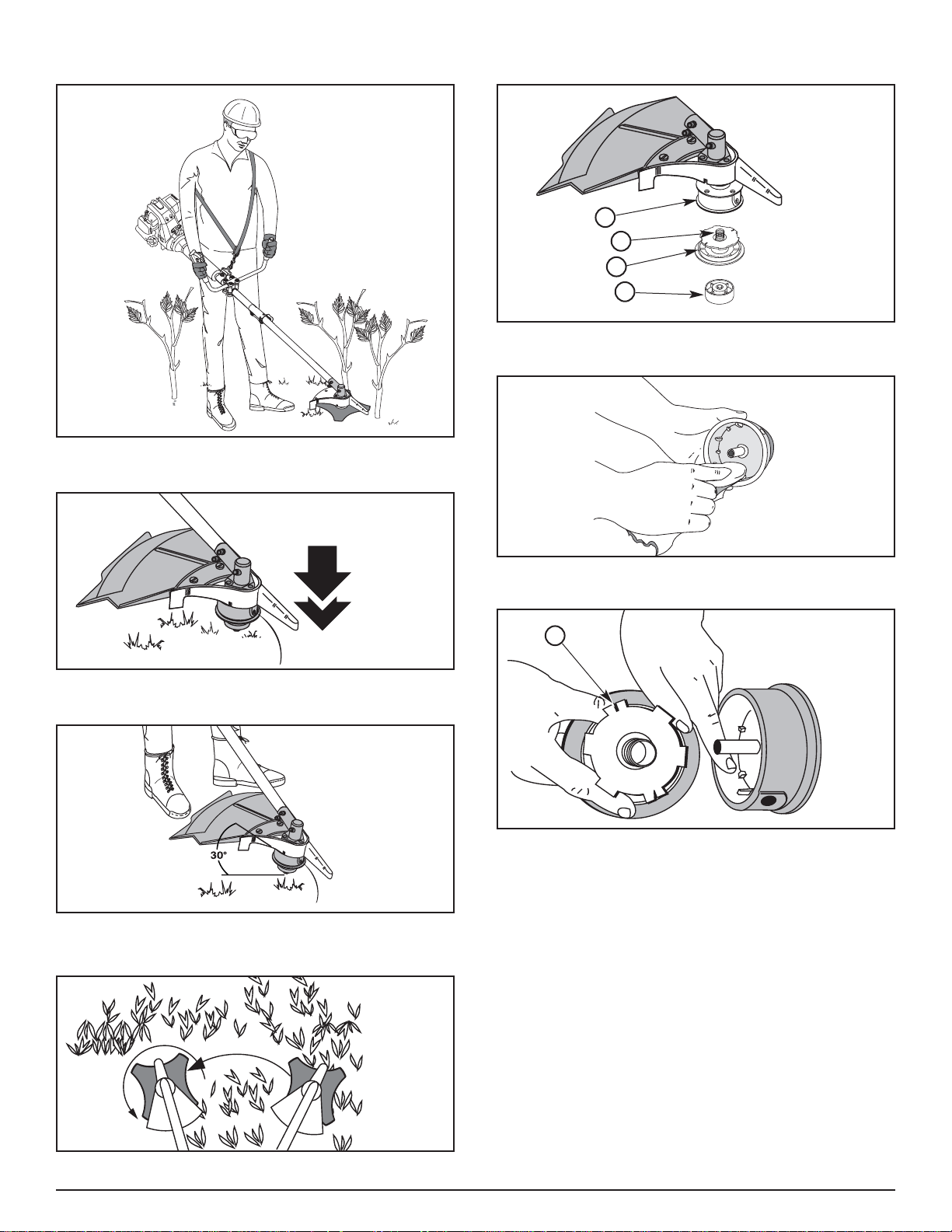

HOLDING THE TRIMMER

Before operating the unit, stand in the operating position

(Fig. 23). Check for the following:

• The operator is wearing eye protection and proper

clothing.

• Harness is adjusted to proper position.

• The handlebar is adjusted so the hands grip it without

over-extending arms.

• The unit is below waist level.

• The cutting attachment is parallel to the ground and

easily contacts the vegetation to be cut without the

operator having to bend over.

ADJUSTING TRIMMING LINE LENGTH

The Bump Head cutting attachment allows you to release

trimming line without stopping the engine. To release

more line, lightly tap the cutting attachment on the ground

(Fig. 24) while operating the trimmer at high speed.

NOTE: Always keep the trimming line fully extended.

Line release becomes more difficult as cutting

line becomes shorter.

Each time the head is bumped, about 25.4 mm (1 in.) of

trimming line is released. A blade in the cutting

attachment guard will cut the line to the proper length if

excess line is released. For best results, tap the Bump

Head on bare ground or hard soil. If line release is

attempted in tall grass, the engine may stall. Always keep

the trimming line fully extended. Line release becomes

more difficult as the cutting line becomes shorter.

NOTE: Do not rest the Bump Head on the ground.

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects like walls or fence posts

TIPS FOR BEST TRIMMING RESULTS

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip of

the line to do the cutting, especially along walls.

Cutting with more than the tip will reduce cutting

efficiency and may overload the engine.

• Cut grass over 200 mm (8 in.) by working from top to

bottom in small increments to avoid premature line

wear or engine drag.

• Cut from left to right whenever possible. Cutting to the

right improves the unit's cutting efficiency. Clippings

are thrown away from the operator.

• Slowly move the trimmer into and out of the cutting

area at the desired height. Move either in a forwardbackward or side-to-side motion. Cutting shorter

lengths produces the best results.

OPERATING INSTRUCTIONS

Page 24

24

LINE INSTALLATION

This section covers both SplitLine™ and standard single

line installation.

Always use geniune 2.41mm. (0.095 in) replacement line.

Line other than specified may make the engine overheat

or fail.

WARNING: Never use metal-reinforced line, wire,

chain, or rope, etc. These can break off and become

dangerous projectiles.

There are two methods to replace the trimming line.

• Wind the inner reel with new line

• Install a prewound inner reel

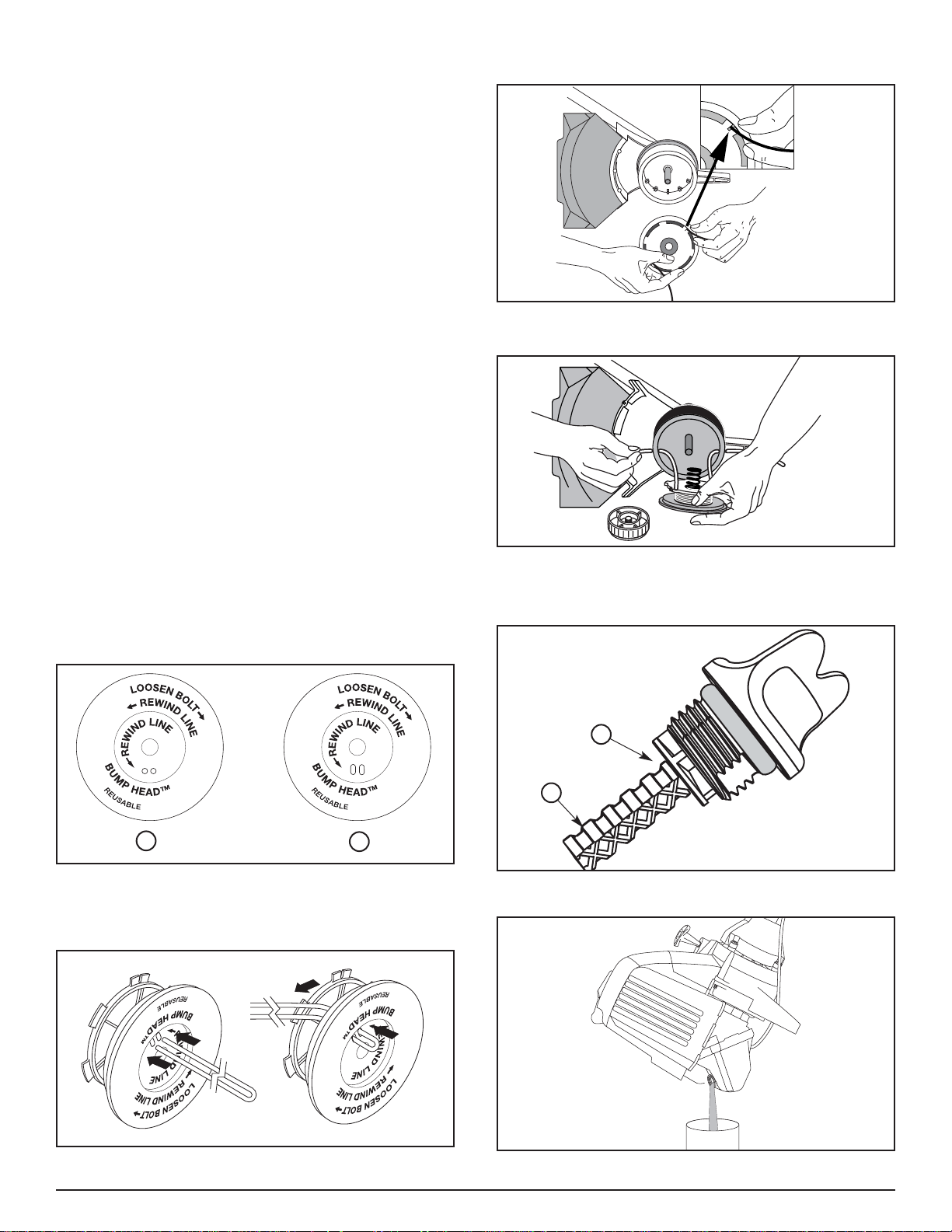

WINDING THE EXISTING INNER REEL

1. Hold the outer spool with one hand and unscrew the

Bump Knob clockwise (Fig. 27). Inspect the bolt

inside the bump knob to make sure it moves freely.

Replace the bump knob if damaged.

2. Remove the inner reel from the outer spool (Fig. 27).

3. Remove spring from the inner reel (Fig. 27).

4. Use a clean cloth to clean the the inner reel, spring,

shaft, and inner surface of the outer spool (Fig. 28).

5. Check the indexing teeth on the inner reel and outer

spool for wear (Fig. 29). If necessary, remove burrs

or replace the reel and spool.

NOTE: SplitLine™ can only be used with the inner reel

with the slotted holes. Single line can be used

on either type of inner reel. Use Figure 30 to

identify the inner reel you have.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

• Following the previous trimming techniques

• What vegetation is being cut

•Where it’s being cut

For example, the line will wear faster when trimming

against a foundation wall as opposed to trimming

around a tree.

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences, etc.

Rotate the whole unit so that the cutting attachment is at

a 30° angle to the ground (Fig. 25).

USING THE CUTTING BLADE

Before operating the unit with the cutting blade stand in

the operating position (Fig. 23). Refer to Holding the

Trimmer.

Cutting Blade Operating Tips

To establish a rhythmic cutting procedure:

• Plant feet firmly, comfortably apart.

• Bring the engine to full throttle before entering the

material to be cut. The blade has maximum cutting

power at full throttle and is less likely to bind, stall, or

cause blade thrust, which can result in serious

personal injury to the operator or others.

• Cut while swinging the upper part of your body from

right to left.

• Always release the throttle trigger and allow the engine

to return to idle speed when not cutting.

• Swing the unit in the same direction as the blade

spins, which increases the cutting action.

•Move forward to the next area to be cut after the

return swing and plant feet again.

• The cutting blade is designed with a second cutting

edge, which can be used by removing the blade,

turning it upside down, and reinstalling it.

To reduce the chance of material wrapping

around the blade, follow these steps

• Cut at full throttle.

• Swing the unit into material to be cut from your right to

your left (Fig. 26).

• Avoid the material just cut as you make the return

swing.

OPERATING INSTRUCTIONS

MAINTENANCE AND REPAIR INSTRUCTIONS

Page 25

25

MAINTENANCE AND REPAIR INSTRUCTIONS

NOTE: Always use the correct line length when

installing trimming line on the unit. The line may

not release properly if the line is too long.

Single Line Installation (Fig. 30, a & b)

Go To Step 8 for SplitLine™ Installation.

6. Take approximately 6 m (20 feet) of new trimming

line, loop it into two equal lengths. Insert each end of

the line through one of the two holes in the inner reel

(Fig. 31). Pull the line through the inner reel so that

the loop is as small as possible (Fig. 31).

7. Wind the lines in tight even layers, onto the reel .

Wind the line in the direction indicated on the inner

reel. Place your index finger between the two lines to

stop the lines from overlapping. Do not overlap the

ends of the line. Proceed to step 11.

SplitLine™ Installation (Fig. 30, b)

8. Take approximately 3 m (10 feet) of new trimming

line. Insert one end of the line through one of the two

holes in the inner reel. Pull the line through the inner

reel until only about 4 inches is left out.

9. Insert the end of the line into the open hole in the

inner reel and pull the line tight to make the loop as

small as possible.

10. Before winding, split the line back about 15 cm.

11. Wind the line in tight even layers in the direction

indicated on the inner reel.

NOTE: Failure to wind the line in the direction indicated

will cause the cutting attachment to operate

incorrectly.

12. Insert the ends of the line into the two holding slots

(Fig. 32).

13. Insert the ends of the line through the eyelets in the

outer spool and place inner reel with spring inside

the outer spool (Fig. 33). Push the inner reel and

outer spool together. While holding the inner reel and

outer spool, grasp the ends and pull firmly to release

the line from the holding slots in the reel.

NOTE: The spring must be assembled on the inner reel

before reassembling the cutting attachment.

14. Hold the inner reel in place and install the bump

knob by turning counterclockwise. Tighten securely.

INSTALLING A PREWOUND REEL

1. Hold the outer spool with one hand and unscrew the

bump knob clockwise (Fig. 27). Inspect the bolt

inside the bump knob to make sure it moves freely.

Replace the bump knob if damaged.

2. Remove the old inner reel from the outer spool

(Fig. 27).

3. Remove the spring from the old inner reel

(Fig. 27).

4. Place the spring in the new inner reel.

NOTE: The spring must be assembled on the inner reel

before reassembling the cutting attachment.

5. Insert the ends of the line through the eyelets in the

outer spool (Fig. 33).

6. Place the new inner reel inside the outer spool. Push

the inner reel and outer spool together. While holding

the inner reel and outer spool, grasp the ends and

pull firmly to release the line from the holding slots in

the spool.

7. Hold the inner reel in place and install the bump

knob by turning counterclockwise. Tighten securely.

CHECKING THE OIL LEVEL

CAUTION: To prevent extensive engine wear and

damage to the unit, always maintain the proper oil

level in the crankcase. Never operate the unit with the

oil level below the bottom of the dipstick.

The importance of checking and maintaining the proper

oil level in the crankcase cannot be overemphasized.

Check oil before each use:

1. Stop engine and allow oil to drain into the crankcase.

2. Place the unit on a flat, level surface to get a proper

oil level reading.

3. Keep dirt, grass clippings, etc., out of the engine.

Clean the area around the oil fill plug/dipstick before

removing it.

4. Remove the oil fill plug/dipstick and wipe off oil.

Reinsert it all the way back in.

5. Remove the oil fill plug/dipstick and check oil level.

Oil should be up to the top of the dipstick (Fig. 34).

6. If the level is low, add a small amount of oil to the oil

fill hole and recheck. Repeat until the oil level

reaches the top of the dipstick.

NOTE: Do not overfill the unit.

DANGER: OVERFILLING OIL CRANKCASE MAY

CAUSE SERIOUS PERSONAL INJURY! The

importance of checking and maintaining the proper oil

level in the crank case cannot be overemphasized.

Check oil before each use and change as needed.

Refer to Changing the Oil.

CHANGING THE OIL

For a new engine, change the oil after the first 10 hours

of operation. Change the oil while the engine is still

warm. The oil will flow freely and carry away more

impurities.

CAUTION: Wear gloves to prevent injury when

handling the unit.

1. Unplug spark plug boot to eliminate starting.

2. Remove the oil fill plug/dipstick.

3. Pour the oil out of the oil fill hole and into a container

by tipping the unit to a vertical position (Fig. 35).

Allow ample time for complete drainage.

4. Wipe up any oil residue on the unit and clean up any

oil that may have spilled. Dispose of the oil

according to Federal, State and local regulations.

Page 26

26

MAINTENANCE AND REPAIR INSTRUCTIONS

5. Refill the crankcase with 100 ml (3.4 floz) of SAE 30

SF, SG, SH oil.

6. Replace the oil fill plug/dipstick.

7. Reconnect spark plug boot.

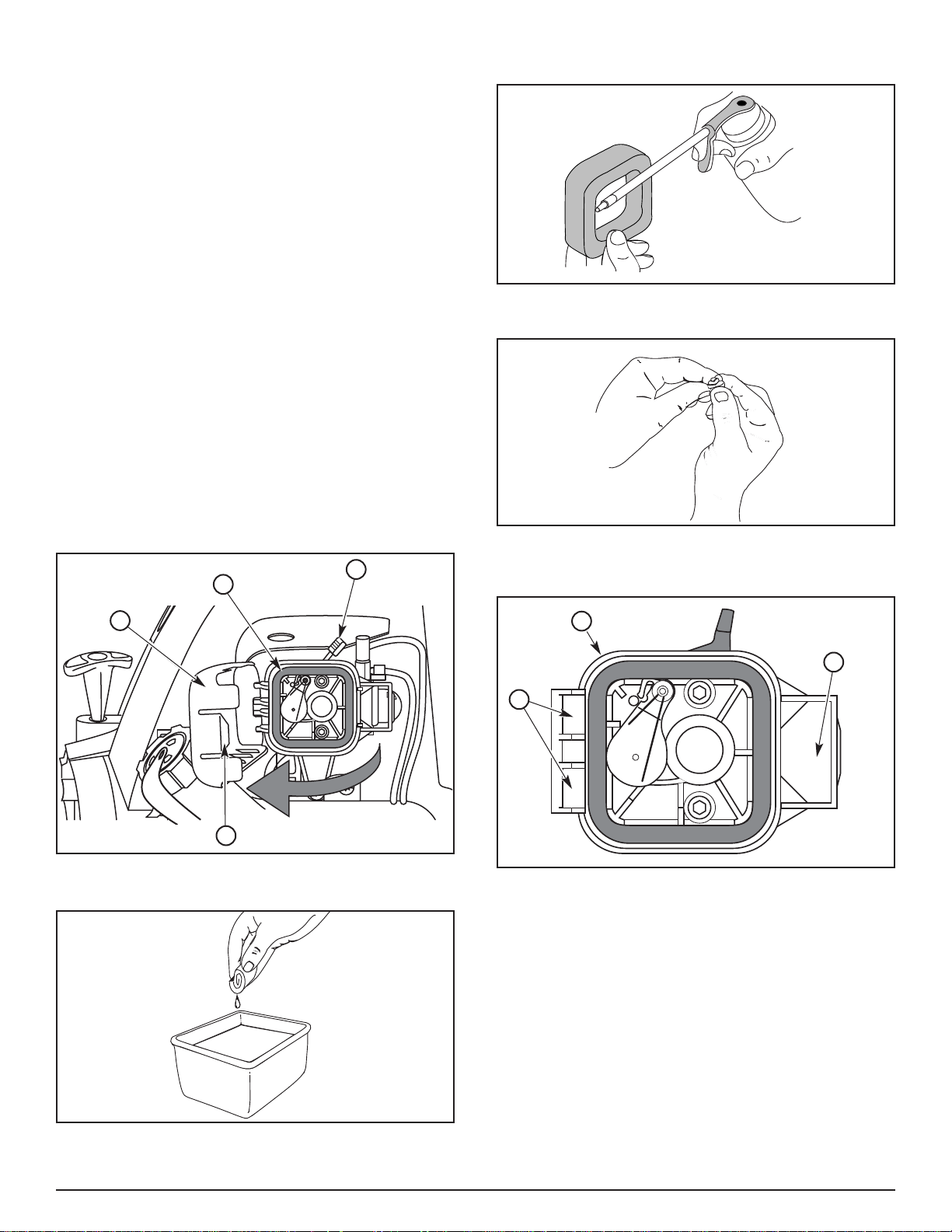

AIR FILTER MAINTENANCE

Cleaning the Air Filter

WARNING: To avoid serious personal injury, always

turn your trimmer off and allow it to cool before you

clean or do any maintenance on it.

Clean and re-oil the air filter every 10 hours of operation.

It is an important item to maintain. Not maintaining the

air filter will VOID the warranty.

1. Open the air filter cover. Push the tab on the right

side of the cover in, pull the air filter cover out and to

the left (Fig. 36).

NOTE: It may be necessary to remove the fuel cap to

completely remove the air filter cover

2. Remove the air filter (Fig. 36).

3. Wash the filter in detergent and water (Fig. 37). Rinse

the filter thoroughly and allow it to dry.

4. Apply enough clean SAE 30 motor oil to lightly coat

the filter (Fig. 38).

5. Squeeze the filter to spread and remove excess oil

(Fig. 39).

6. Replace the filter.

NOTE: If the unit is operated without the air filter, you

will VOID the warranty.

7. Reinstall the air filter cover. Position the hooks on the

left side of the air filter cover into the slots at the left

side of the back plate (Fig. 40).

NOTE: It may be necessary to remove the fuel cap to

reinstall the air filter cover

8. Swing the cover to the right until the tab on the air

filter cover snaps into place in the slot on the back

plate (Fig. 40).

9. Replace the fuel cap, if removed.

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable. An idle

adjustment screw is reached though a hole in the top of

the engine cover (Fig 41).

NOTE: Careless adjustments can seriously damage your

unit. An authorized service dealer should make

carburetor adjustments.

Check Fuel

Old fuel is usually the main reason for the unit not

running properly. Drain and refill the tank with clean,

fresh unleaded fuel prior to doing any adjustments. Refer

to Oil and Fuel Information.

Clean Air Filter

The condition of the air filter is important to the operation

of the unit. A dirty air filter will restrict air flow and

change the air/fuel mixture. This is often mistaken for an

out of adjustment carburetor. Check the condition of the

air filter before adjusting the idle speed screw. Refer to

Air Filter Maintenance.

Adjust Idle Speed Screw

WARNING: The cutting attachment may be spinning

during idle speed adjustment. Wear protective

clothing and observe all safety instructions to prevent

serious personal injury.

If after checking the fuel and cleaning the air

filter the engine still will not idle, adjust the idle speed

screw as follows.

1. Start the engine and let it run at a high idle for a

minute to warm up.

2. Release the throttle trigger and let the engine idle. If

the engine stops, insert a small phillips or flat blade

screwdriver into the hole in the engine cover

(Fig. 41). Turn the idle speed screw in, clockwise,

1/8 of a turn at a time (as needed) until the engine

idles smoothly.

NOTE: The cutting attachment should not rotate when

the engine idles.

3. If the cutting attachment rotates when the engine

idles, turn the idle speed screw counterclockwise 1/8

of a turn at a time (as needed), to reduce idle speed.

Checking the fuel mixture, cleaning the air filter, and

adjusting the idle speed screw should solve most engine

problems.

If not and:

• The engine will not idle

• The engine hesitates or stalls on acceleration

• There is a loss of engine power

Have the carburetor adjusted by an authorized service

dealer.

WARNING: When the unit is turned off make sure the

cutting attachment has stopped before the unit is set

down to prevent serious personal injury.

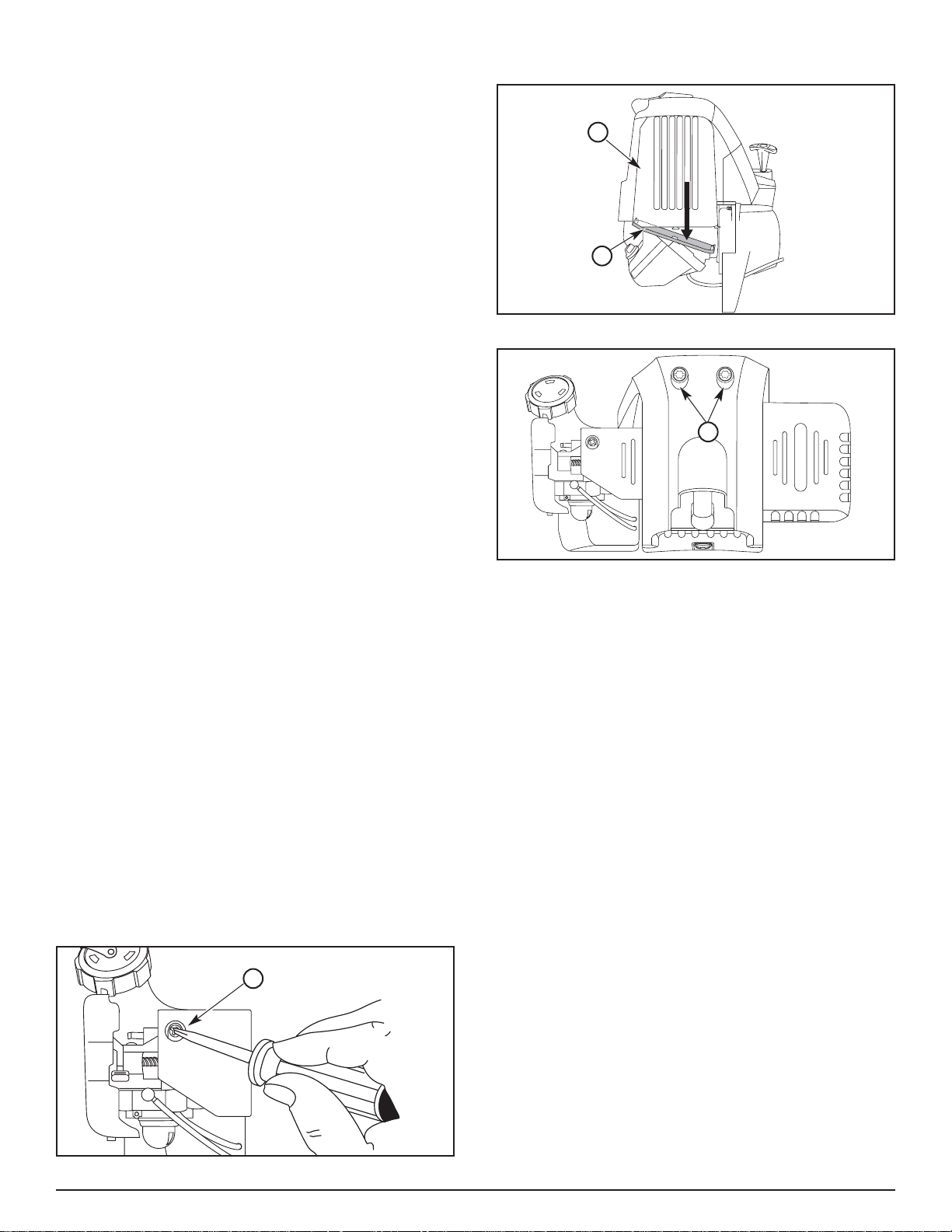

ROCKER ARM CLEARANCE

This requires disassembly of the engine. If you feel

unsure or unqualified to perform this, take the unit to an

authorized service center.

NOTE: Inspect the valve to rocker arm clearance with a

feeler gauge after the first 10 hours of operation

and then every 25 hours of operation thereafter.

• The engine must be cold when checking or adjusting

the valve clearance.

Page 27

27

NOTE: A rocker arm cover gasket can be purchased

from your local authorized dealer.

12. Reinstall the engine cover. Check alignment of the

cover before tightening the screws. Tighten screws.

13. Reinstall the muffler cover. Slip the rear tab on the

muffler cover into the engine cover rear slot. Then

slide the remaining slots into the tabs until they snap

into place (Fig. 42).

14. Check the spark plug and reinstall. See Replacing

the Spark Plug.

15. Replace the spark plug wire.

REPLACING THE SPARK PLUG

Use only genuine replacement spark plugs. The correct

air gap is 0.655mm (0.025 in). Remove the plug after

every 25 hours of operation and check its condition.

1. Stop the engine and allow it to cool. Grasp the plug

wire firmly and pull the cap from the spark plug.

2. Clean dirt from around the spark plug. Remove the

spark plug from the cylinder head by turning a 5/8 in.

socket counterclockwise.

3. Replace cracked, fouled or dirty spark plug. Set the

air gap at 0.655 mm (0.025 in) using a feeler gauge

(Fig. 48).

4. Install a correctly gapped spark plug in the cylinder

head. Tighten by turning the 5/8 in. socket clockwise

until snug.

If using a torque wrench torque to;

12.3–13.5 Nm (110–120 in.•lb.).

Do not over tighten.

SPARK ARRESTOR MAINTENANCE

1. Remove the muffler cover. See Rocker Arm

Clearance.

2. With a flat blade screwdriver or Torx T20 bit, remove

the screw attaching the spark arrestor cover to the

muffler (Fig. 49).

3. Pull the tab on the spark arrestor cover out of the

muffler. Remove the spark arrestor cover.

4. Remove the spark arrestor screen from the spark

arrestor cover.

5. Clean the spark arrestor screen with a wire brush, or

replace.

6. Reinstall the spark arrestor screen, spark arrestor

cover, and screw.

• This task should be performed inside, in a clean, dust

free area.

1. Remove the muffler cover by pressing down on the

corner with a flat blade screwdriver (Fig. 42). Slide

the notches on the sides of the muffler cover over

the tabs on the engine cover and remove.

2. Remove the two (2) screws on top of the engine

cover with a Flat-head or T20 screwdriver (Fig. 43).

3. Remove the screw on back of the engine cover

(Fig. 44).

4. Disconnect the spark plug wire.

5. Clean dirt from around the spark plug. Remove the

spark plug from the cylinder head by turning a 5/8 in.

socket counterclockwise.

6. Remove the engine cover.

7. Clean dirt from around the rocker arm cover.

Remove the screw holding the rocker arm cover with

a large flat blade screwdriver or Torx T25 bit

(Fig. 45). Remove the rocker arm cover and gasket.

8. Pull the starter rope slowly to bring the piston to the

top of its travel, (known as top dead center). Check

that:

• The piston is at the top of its travel while looking in

the spark plug hole (Fig. 45).

• Both rocker arms move freely, and both valves are

closed.

If not, repeat step 8.

9. Slide the feeler gauge between the rocker arm and

the valve return spring. Measure the clearance

between the valve stem and rocker arm (Fig 46).

Do both intake and exhaust valves.

The recommended clearance for both intake and

exhaust is .076 - 0.152 mm (0.003 – .006 in). Use a

standard automotive 0.127 mm (0.005 in) feeler gauge.

The feeler gauge should slide between the rocker arm

and valve stem with a slight amount of resistance,

without binding (Fig. 47).

10. If the clearance is not within specification:

a. Turn the adjusting nut using a 5/16 inch wrench or

nut driver (Fig. 46).

• To increase clearance, turn the adjusting nut

counterclockwise.

• To decrease clearance, turn the adjusting nut clockwise.

b.Recheck both clearances, and adjust as necessary.

11. Reinstall the rocker arm cover using a new gasket.

Torque the screw to 2.2–3.4 N

•m ( 20–30 in•lb).

MAINTENANCE AND REPAIR INSTRUCTIONS

Page 28

28

MAINTENANCE AND REPAIR INSTRUCTIONS

CLEANING

Use a small brush to clean off the outside of the unit. Do

not use strong detergents. Household cleaners that

contain aromatic oils such as pine and lemon, and

solvents such as kerosene, can damage plastic housing

or handle. Wipe off any moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes

may reach an open flame or spark.

• Allow the engine to cool before storing.

• Store the unit in a dry place, locked up or up-high to

prevent unauthorized use or damage. Keep out of the

reach of children.

LONG TERM STORAGE

If the unit will be stored for an extended time, use the

following storage procedure.

1. Drain all petrol from the petrol tank and drain into a

container. Do not use petrol that has been stored for

more than 60 days.

2. Start the engine and allow it to run until it stalls. This

ensures that all fuel has been drained from the

carburetor.

3. Allow the engine to cool. Remove the spark plug and

put 30 ml (1 oz.) of any high quality motor oil into the

cylinder. Pull the starter rope slowly to distribute the

oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil

from the cylinder before attempting to start the

trimmer after storage.

4. Change the oil. See Changing the Oil. Dispose of the

old oil in accordance with Local regulations.

5. Thoroughly clean the unit and inspect for any loose

or damaged parts. Repair or replace damaged parts

and tighten loose screws, nuts or bolts. The unit is

ready for storage.

6 Store the unit in a dry place, locked up or up-high to

prevent unauthorized use or damage. Keep out of the

reach of children.

Page 29

29

TROUBLESHOOTING

CAUSE ACTION

Cutting attachment bound with grass Stop the engine and clean cutting attachment

Cutting attachment out of line Refill with new line

Inner reel bound up Rewind /replace the inner reel

Cutting head dirty Clean inner reel and outer spool

Line welded Disassemble, remove the welded section and rewind

Line twisted when refilled Disassemble and rewind the line

Not enough line is exposed Push the bump knob and pull out line until 4 inches

(102 mm) of line is outside of the cutting attachment

CAUSE ACTION

Old fuel Drain fuel tank and add fresh fuel

Improper carburetor adjustment Take to an authorized service dealer for an adjustment

Fouled spark plug Replace or clean the spark plug

CAUSE ACTION

Empty fuel tank Fill fuel tank with fresh fuel

Primer bulb wasn't pressed enough Press primer bulb fully and slowly 10 times

Engine is flooded Squeeze the trigger and pull the starter rope

Old fuel Drain fuel tank and add fresh fuel

Fouled spark plug Replace or clean the spark plug

ENGINE WILL NOT START

ENGINE WILL NOT IDLE / LOW IDLE SPEED

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STALLS WHEN CUTTING

CAUSE ACTION

Air filter is plugged Replace or clean the air filter

Old fuel Drain fuel tank and add fresh fuel

Improper carburetor adjustment Adjust according to the Carburetor Adjustments section

CAUSE ACTION

Old fuel Drain fuel tank and add fresh fuel

Improper carburetor adjustment Take to an authorized service dealer for an adjustment

Cutting attachment bound with grass Stop the engine and clean the cutting attachment

Dirty air filter Clean or replace the air filter

CUTTING ATTACHMENT WILL NOT ADVANCE LINE

If further assistance is required, contact your local authorized service dealer.

All information, illustrations, and specifications in this manual are based on the latest product information available at the

time of printing. We reserve the right to make any changes at any time without notice.

Page 30

30

SPECIFICATIONS

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 4-Cycle

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.2 cc ( 1.6 cu. in.)

Clutch Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Centrifugal

Operating RPM (Trimmer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,200-8,300 rpm

Operating RPM (Brushcutter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8,000-9,800 rpm

Idle Speed RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,000-3,600 rpm

Ignition Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rocker Switch

Valve clearance (intake and exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .076-.0152mm (.003–.006 in.)

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.655 mm ( 0.025 inch )

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SAE 30 Oil

Crankcase Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 ml ( 3.4 oz )

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unleaded

Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diaphragm, All-Position

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Auto Rewind

Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Baffled with Guard

Throttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Manual Spring Return

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .591 ml (20 oz )

ENGINE

DRIVE SHAFT & CUTTING ATTACHMENT

Drive Shaft Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum Tube (EZ-LinkTM)

Throttle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Finger-Tip Trigger

Unit Weight (No Fuel, with Bull Horn Handle, 4 Tooth Cutting Blade) . . . . . . . . . . . . . . . . . . . . . . . . 6.13 kg (14.5 lbs)

Cutting Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-Tooth Cutting Blade, Dual String Cutting Head

Line Spool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bump Line Releaser

Line Spool Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101.6 mm (4 inches)

Trimming Line Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.41 mm (0.095 inch)

Cutting Path Diameter, Cutting Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.7 cm (18 inches)

Cutting Path Diameter, Cutting Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204 mm (8 Inches)

Shoulder Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Quick Release

Sound Pressure Level (Idle) Measured . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76 LpA