Page 1

Date:

9/23/2005

Service Kit

753-05193

PURPOSE:

This service kit provides a shim (spacer) to reduce the gap between the end of the cylinder ram and the back of the

wedge. Perform the Pre-service Inspection to determine if this kit is required or not.

NOTE: These materials are prepared for use by trained technicians who are experienced in the service and repair

of equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced

individuals. Such individuals should seek the assistance of an authorized service technician or dealer.

Read through and understand these instructions completely before proceeding with repair.

NOTE: Save this Instruction Sheet. Refer to it when ordering replacement parts.

Subject:

Models

Affected:

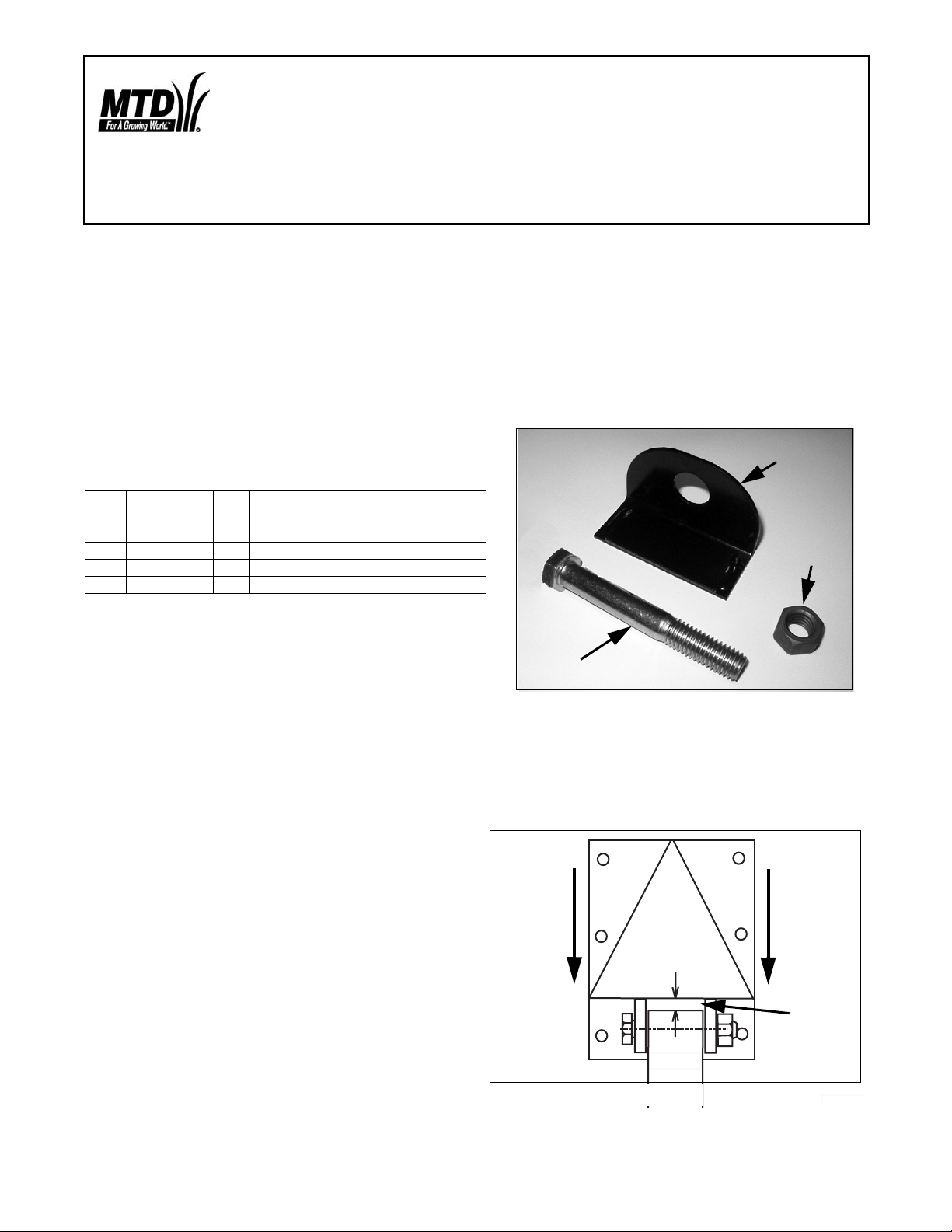

Service Kit Contents

Log Splitter Wedge Shim

2004 and 2005 Model Year Log

Splitters built between May 1,

2004 and September 15, 2005.

1

(See Figure 1)

ITEM

NO.

1 681-04052 1 SHIM ASSEMBLY

2 710-1806 1 SCREW: HHCS: 1/2”-13 x 3.25: GR5

3 712-3022 1 NUT: LOCK: 1/2”-13

4 769-02077 1 THIS INSTRUCTION SHEET

PART

NUMBER

QTY DESCRIPTION

3

Pre-service Inspection:

These instructions are written with the assumption that

the unit has been in service already or is being prepared

for delivery.

1. To determine if this service kit is required the following check must be made.

2. Place beam in the horizontal position and lock in

place.

3. Check engine oil level and hydraulic fluid level.

4. Start engine and extend ram so the splitting wedge is

about 4”- 8” from beam’s foot. Turn off engine.

.

5. Release pressure in the system by shuttling the direction control lever from the forward to the retract positions

several times.

6.Using two 3/4” wrenches loosen the cylinder to wedge

mounting bolt to relax the wedge.

7. With wood blocking braced against the beam’s foot,

push the wedge back toward the cylinder’s ram end and

secure in this position.

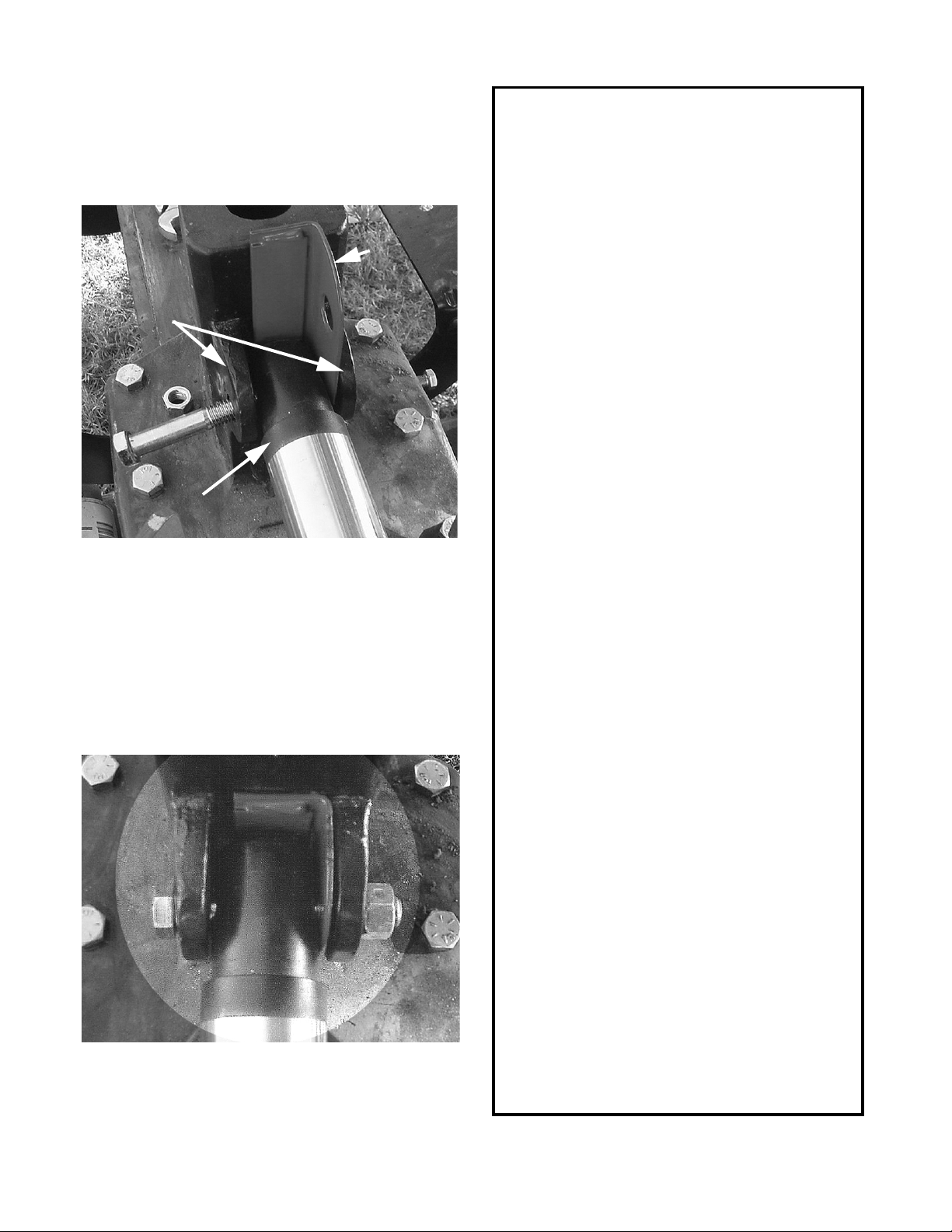

8. Using a.035” feeler gage, try to insert the gage

between the end of the ram and the back side of the

wedge pocket. See Figure 2.

2

FIGURE 1

If the gage

rect and this kit is not required. Stop here.

If the gage goes into the gap, the shim provided

should be installed. Proceed to Step 9.

does not go

in the gap, the gap is cor-

PUSH

Wedge

Back

.035"

max.

GAP

FIGURE 2

Service Kit 753-05193 Pg 1 of 2 Form No. 769-02077

Page 2

9. Using two 3/4” wrenches, remove and discard the

bolt and nut securing the cylinder ram to the wedge.

10. Slide the wedge away from the cylinder ram enough

to slip the Shim Assembly, Item 1, between the wedge

and cylinder ram. See Figure 3.

SHIM

ASSEMBLY

(ITEM 1)

WEDGE EARS

CYLINDER RAM

FIGURE 3

NOTES

11. Re-align the hole in the cylinder ram end and the

holes in the wedge ears.

12. Slip the new 1/2”-13 x 3.25 Screw, Item 2, through

the wedge, cylinder ram and shim assembly holes.

13. Secure with the new 1/2”-13 Lock Nut, Item 3.

DO NOT tighten the lock nut down. There should be

only 2 to 3 threads that show past the nut.

See Figure 4.

14. This completes the installation of this service kit.

Service Kit 753-05193 Pg 2 of 2 Form No. 769-02077

Loading...

Loading...