Page 1

A

MTD Products Aktiengesellschaft • Saarbrücken • Germany

700 / 710

Part No: 769-01319 12/04

Page 2

2

11

21

31

41

51

61

English

Français

Deutsch

Italiano

Português

Español

Page 3

3

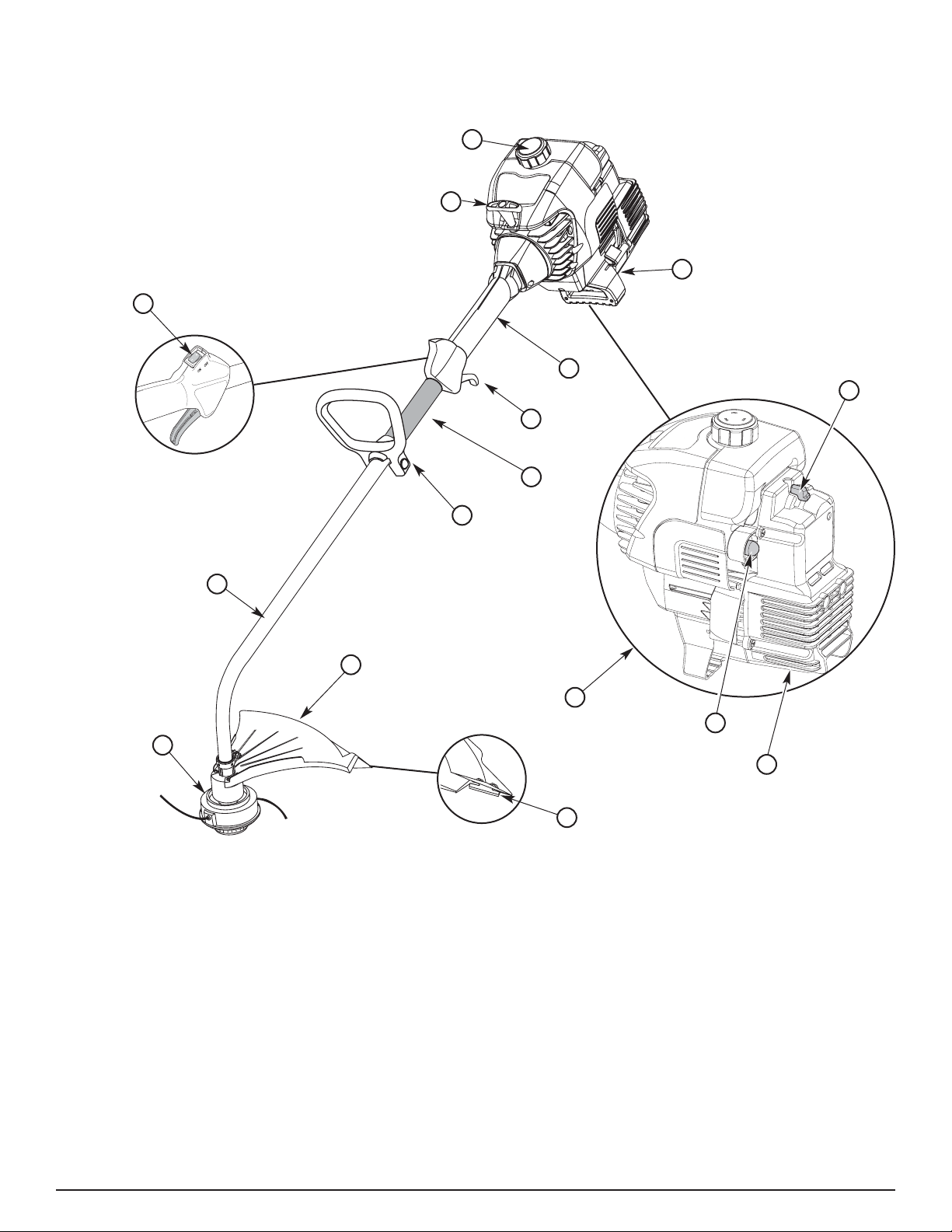

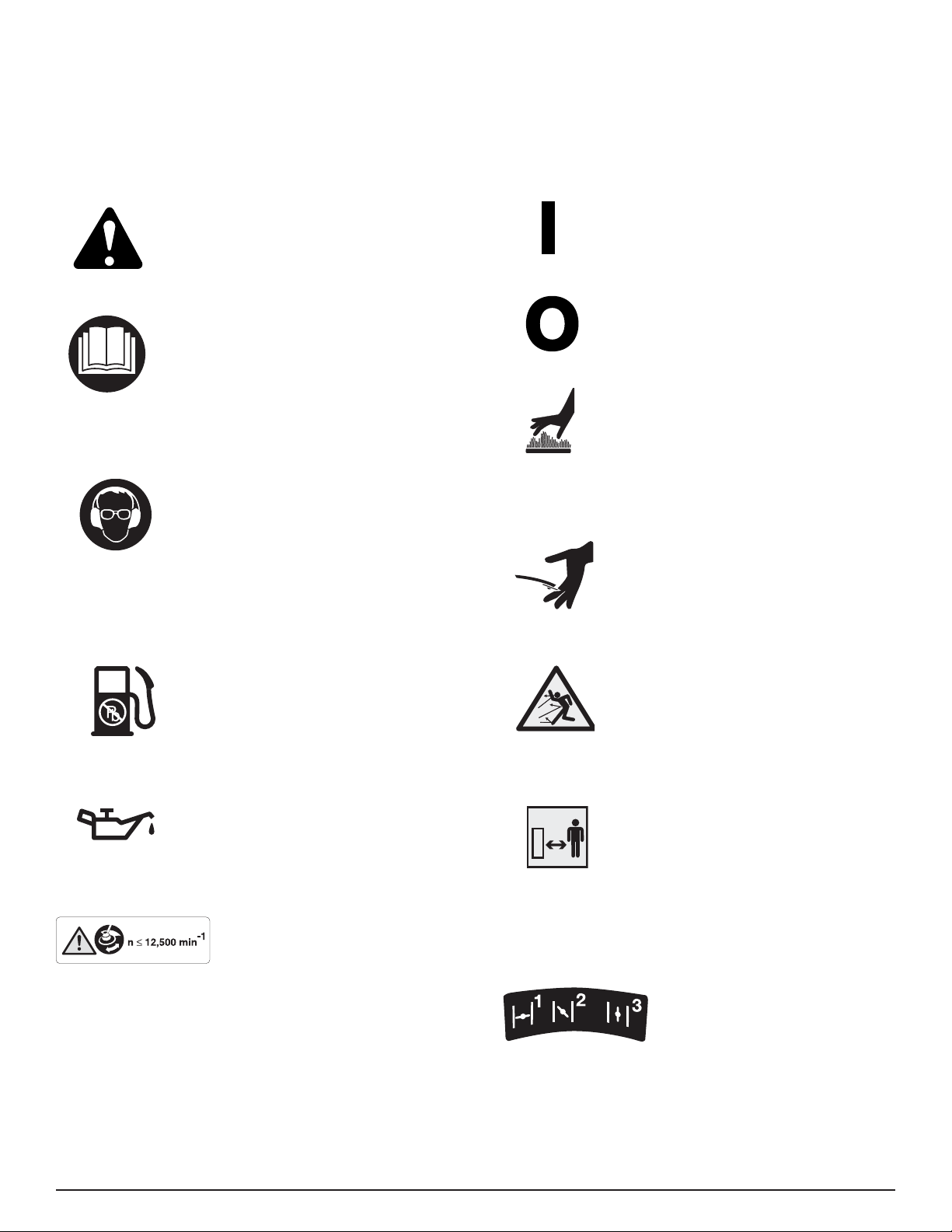

KNOW YOUR UNIT

FAMILIARISEZ-VOUS AVEC L’APPAREIL

LERNEN SIE IHR GERÄT KENNEN

PANORAMICA SULL’UNITÀ

FAMILIARIZE-SE COM A SUA MÁQUINA

CONOZCA SU UNIDAD

2

3

4

5

6

1

10

11

14

13

15

12

16

8

7

Description of Parts

1. Power Head

2. Fuel Cap

3. Starter Rope Grip

4. Spark Plug

5. Choke Lever

6. Primer

7. Air Filter/Muffler Cover

8. Shaft Tube Grip

9. Ignition Switch

10. Throttle Trigger

11. D-Handle

12. Limiter Sleeve

13. Shaft Tube

14. Cutting Attachment Guard

15. Line Cutting Blade

16. Cutting Attachment

Description des pièces

1. Tête d'entraînement

2. Bouchon du carburant

3. Poignée de la corde

de démarrage

4. Bougie

5. Levier d'étrangleur

6. Amorceur

7. Couvercle du filtre à

air/silencieux

8. Poignée

9. Interrupteur

10. Gâchette d’accélération

11. Poignée en D

12. Manchon du limiteur

13. Tube

14. Carter de protection de

coupe

15. Coupe-fil

16. Bobine de fil

9

Page 4

4

Componentes

1. Motor

2. Tapón del depósito de

combustible

3. Asa del arrancador de cuerda

4. Bujía

5. Palanca del starter

6. Bomba de cebado

7. Cárter del filtro de aire/tubo de escape

8. Asa

9. Interruptor

10. Gatillo de aceleración

11. Asa en forma de D

12. Manguito limitador

13. Tubo

14. Cárter de protección de corte

15. Cortahilo

16. Bobina de hilo

Beschreibung der Teile

1. Motor

2. Tankdeckel

3. Griff des Anlassers

4. Zündkerze

5. Starterhebel

6. Ansaugpumpe

7. Gehäuse des Luftfilters/Abgasrohrs

8. Griff

9. Schalter

10. Beschleunigungsdrücker

11. D-förmiger Griff

12. Begrenzermanschette

13. Rohr

14. Schutzgehäuse für den Schnitt

15. Fadenabschneider

16. Fadenspule

Descrição das peças

1. Motore

2. Tappo del serbatoio

3. Impugnatura del cavo per l'avvio

4. Candela

5. Leva dello starter

6. Cicchetto

7. Carter del filtro dell'aria /tubo di scappamento

8. Impugnatura

9. Interruttore

10. Acceleratore

11. Impugnatura a D

12. Manicotto di limitazione

13. Tubo

14. Carter di protezione del taglio

15. Filo di taglio

16. Bobina del filo

Descrizione dei componenti

1. Motor

2. Tampa do depósito

3. Pega do lançador

4. Vela

5. Alavanca do starter

6. Bomba de escorvamento

7. Cárter do filtro de ar/escape

8. Punho

9. Interruptor

10. Gatilho de aceleração

11. Pega em D

12. Saia limitadora

13. Tubo

14. Resguardo de protecção de corte

15. Corta-fio

16. Bobina de fio

Page 5

5

Fig. 3

Fig. 2

Fig. 1

1

2

3

4

5

6

7

8

9

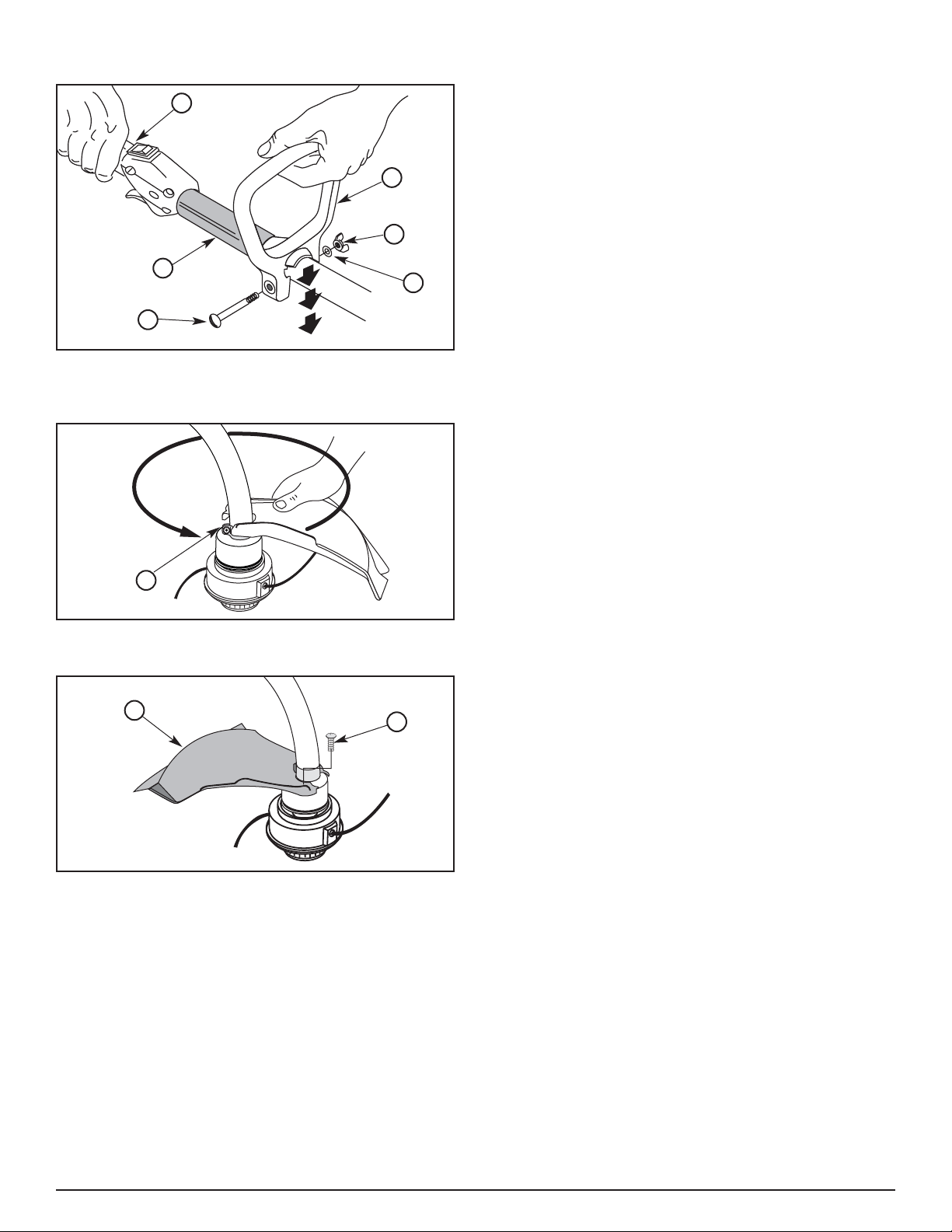

Description of Parts – Figs. 1–3

1. Shaft Tube Grip

2. Handle

3. Wing Nut

4. Washer

5. Bolt

6. Limiter Sleeve

7. Clamp Assembly

8. Cutting Attachment

Guard

9. Screws (4)

Description des pièces – Figs. 1–3

1. Poignée

2. Poignée en D

3. Vis papillon

4. Rondelle

5. Boulon

6. Manchon du limiteur

7. Dispositif de fixation

8. Carter de protection

de coupe

9. 4 vis

Beschreibung der Teile – Abb. 1–3

1. Griff

2. D-förmiger Griff

3. Flügelschraube

4. Unterlegscheibe

5. Bolzen

6. Begrenzermanschette

7. Befestigungsvorrichtung

8. Schutzgehäuse für

den Schnitt

9. 4 Schrauben

Descrizione dei componenti – figg. 1–3

1. Impugnatura

2. Impugnatura a D

3. Vite a farfalla

4. Rondella

5. Bullone

6. Manicotto di

limitazione

7. Dispositivo di

fissaggio

8. Carter di protezione

9. 4 viti

Descripción de las piezas – Fig. 1–3

1. Asa

2. Asa en forma de D

3. Tornillo de mariposa

4. Arandela

5. Perno

6. Manguito limitador

7. Dispositivo de

fijación

8. Cárter de

protección de corte

9. 4 tornillos

Descrição das peças – Figuras 1–3

1. Punho

2. Pega em D

3. Porca borboleta

4. Anilha

5. Parafuso

6. Saia limitadora

7. Dispositivo de

fixação

8. Resguardo de

protecção de corte

9. 4 parafusos

Page 6

6

1

3

5

4

6

7

8

9

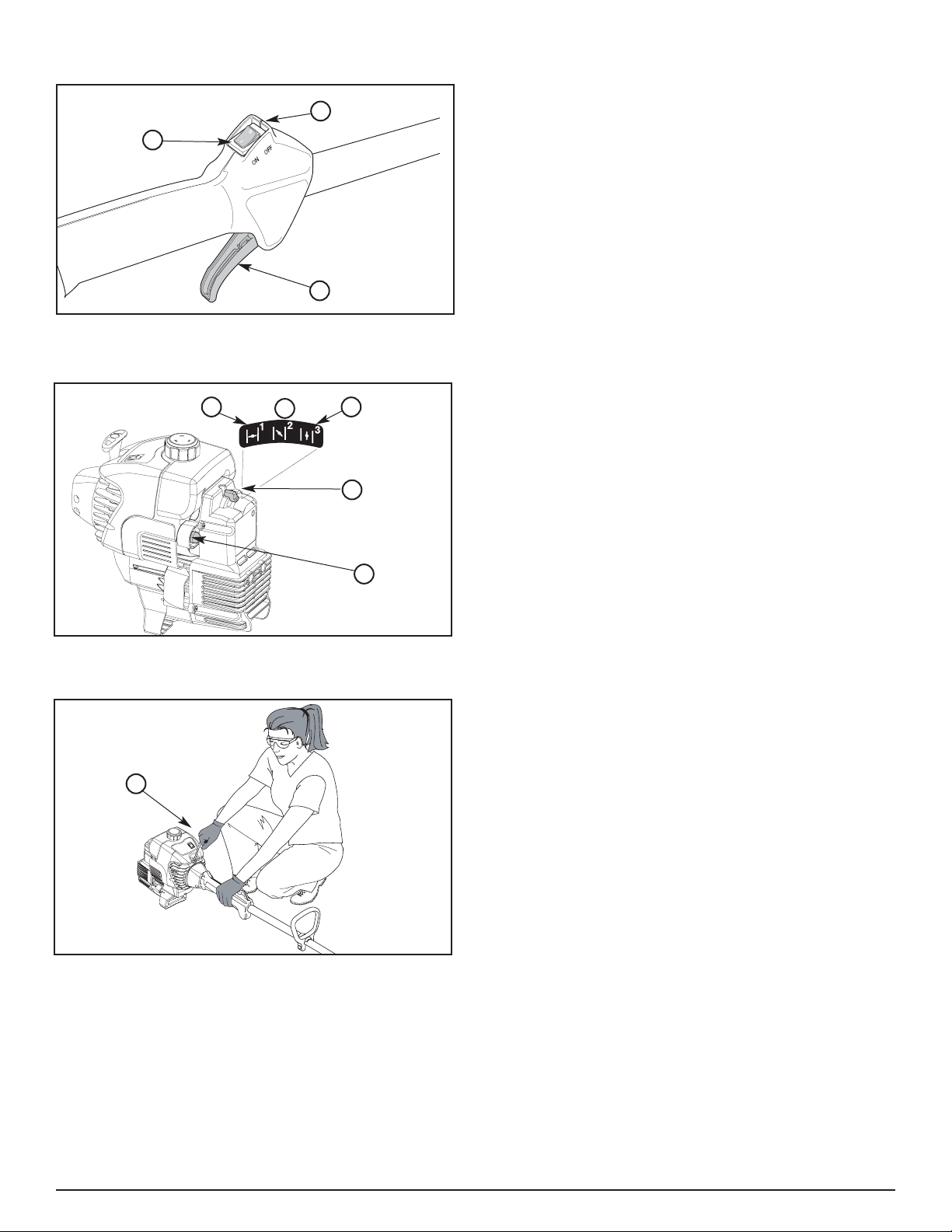

Description of Parts – Figs. 4-7

1. Throttle Trigger

2. OFF (O)

3. ON (I)

4. Full Choke Position (1)

5. Partial Choke Position (2)

6. Run Position (3)

7. Choke Lever

8. Primer

9. Starter Rope

Descripción de piezas –

Fig. 4-7

1. Gatillo del regulador

2. Apagado (O)

3. Encendido (I)

4. Posición de obturación

completa (1)

5. Posición de obturación

parcial (2)

6. Posición de marcha

(3)

7. Palanca del obturador

8. Cebador

9. Cuerda de arranque

10. Estribo

Beschreibung der Teile – Abb. 4-7

1. Gashebel

2. Aus (O)

3. Ein (I)

4. volle Chokeposition (1)

5. halbe Choke

Zwischenposition (2)

6. Betriebsposition (3)

7. Chokehebel

8. Einspritzvorrichtung

9. Starterleine

Descrição das peças – Figuras 4-7

1. Gatilho do acelerador

2. Parado (O)

3. Funcionamento (I)

4. Posição de

estrangulamento total (1)

5. Posição de estrangulamento parcial (2)

6. Posição de operação (3)

7. Posição de

operação

8. Iniciador

9. Corda de arranque

10. Apoio para o pé

Description des pièces – Figs. 4-7

1. Manette des gaz

2. Arrét (O)

3. Marche (I)

4. Étranglement

maximum Position (1)

5. Position

d'étranglement

partielle (2)

6. Position Marche (3)

7. Levier d'étrangleur

8. Amorceur

9. Corde de démarrage

Descrizione dei componenti - figg. 4-7

1. Leva acceleratore

2. Arresto (O)

3. Avivio (I)

4. Posizione 1

(massimo)

5. Posizione 2 (parziale)

6. Posiz. 3 (normale)

7. Leva starter

8. Innesco

9. Avvio a strappo

Fig. 4

Fig. 5

Fig. 6

2

Page 7

7

Fig. 8

Fig. 9

Fig. 10

1

2

3

4

5

Descripción de piezas – Fig. 10-11

1. Perno

2. Perilla percusiva

3. Bobina exterior

4. Resorte

5. Carrete interior

Beschreibung der Teile – Abb. 10-11

1. Bolzen

2. Auftippknopf

3. Spulengehäuse

4. Feder

5. Spule

Descrição das peças – Figuras 10-11

1. Perno

2. Batente

3. Bobina exterior

4. Mola

5. Carreto interior

Descrizione dei componenti – figg. 10-11

1. Bullone

2. Bump Knob

3. Bobina esterna

4. Molla

5. Rocchetto

Description of Parts – Figs. 10-11

1. Bolt

2. Bump Knob

3. Outer Spool

4. Spring

5. Inner Reel

Description des pièces – Figs. 10-11

1. Bouton

2. Bouton de butée

3. Bobine extérieure

4. Ressort

5. Moulinet intérieur

Fig. 7

Fig. 11

Page 8

8

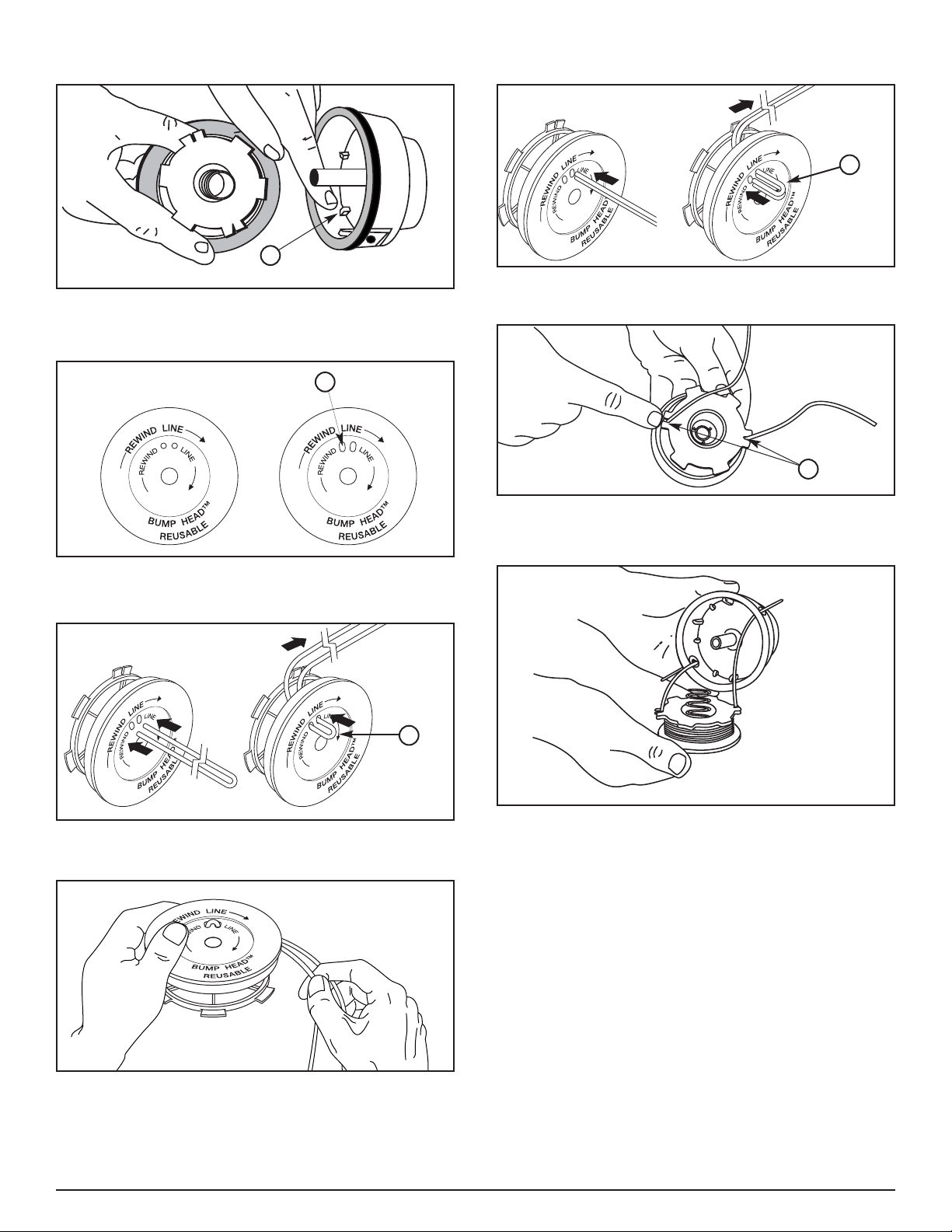

Description of Parts – Figs. 12-18

1. Indexing Teeth

2. Slotted Holes

3. Loop

4. Holding Slots

Description des pièces – Figs. 12-18

Fig. 15

Fig. 16

Fig. 14

Fig. 13

Fig. 12

Fig. 17

Fig. 18

1

4

3

2

3

1. Dents de

positionnement

2. Trous allongés

3. Boucle

4. Fentes de retenue

Page 9

9

Descripción de piezas – Fig. 12-18

1. Dientes de posición

2. Orificios ranurados

3. Bucle

4. Ranuras de retención

Beschreibung der Teile – Abb. 12-18

1. Schaltzähne

2. Schlitzförmige

Löcher

3. Schlaufe

4. Halteschlitze

Descrição das peças – Figuras 12-18

1. Dentes de encaixe

2. Fendas

3. Laço

4. Fendas de retenção

Descrizione dei componenti – figg. 12-18

1. Dente

2. Asole

3. Occhiello

4. Fessure di

bloccaggio

Fig. 19

Fig. 20

2

2

3

1

Fig. 21

Fig. 22

Fig. 23

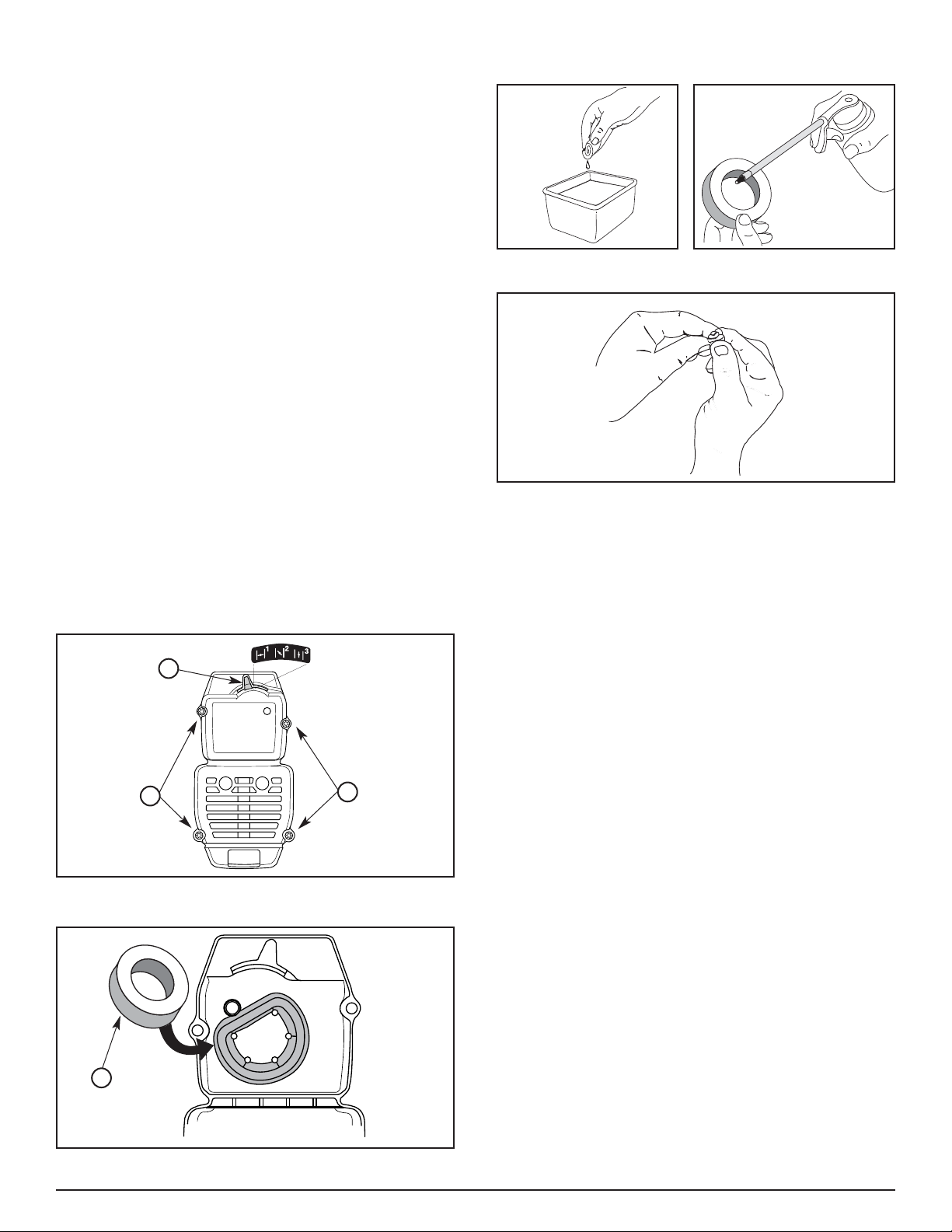

Description of Parts – Figs. 19-23

1. Choke Lever

2. Screw

3. Air Filter

Descripción de piezas – Fig. 19-23

1. Palanca del

obturador

2. Tornillo

3. Filtro de aire

Beschreibung der Teile – Abb. 19-23

1. Chokehebel

2. Schraube

3. Luftfilter

Descrição das peças – Figuras 19-23

1. Alavanca do

estrangulador

2. Parafuso

3. Filtro de ar

Description des pièces – Figs. 19-23

1. Levier d'étrangleur

2. Vis

3. Filtre à air

Descrizione dei componenti – figg. 19-23

1. Leva starter

2. Vite

3. Filtro dell’aria

Page 10

10

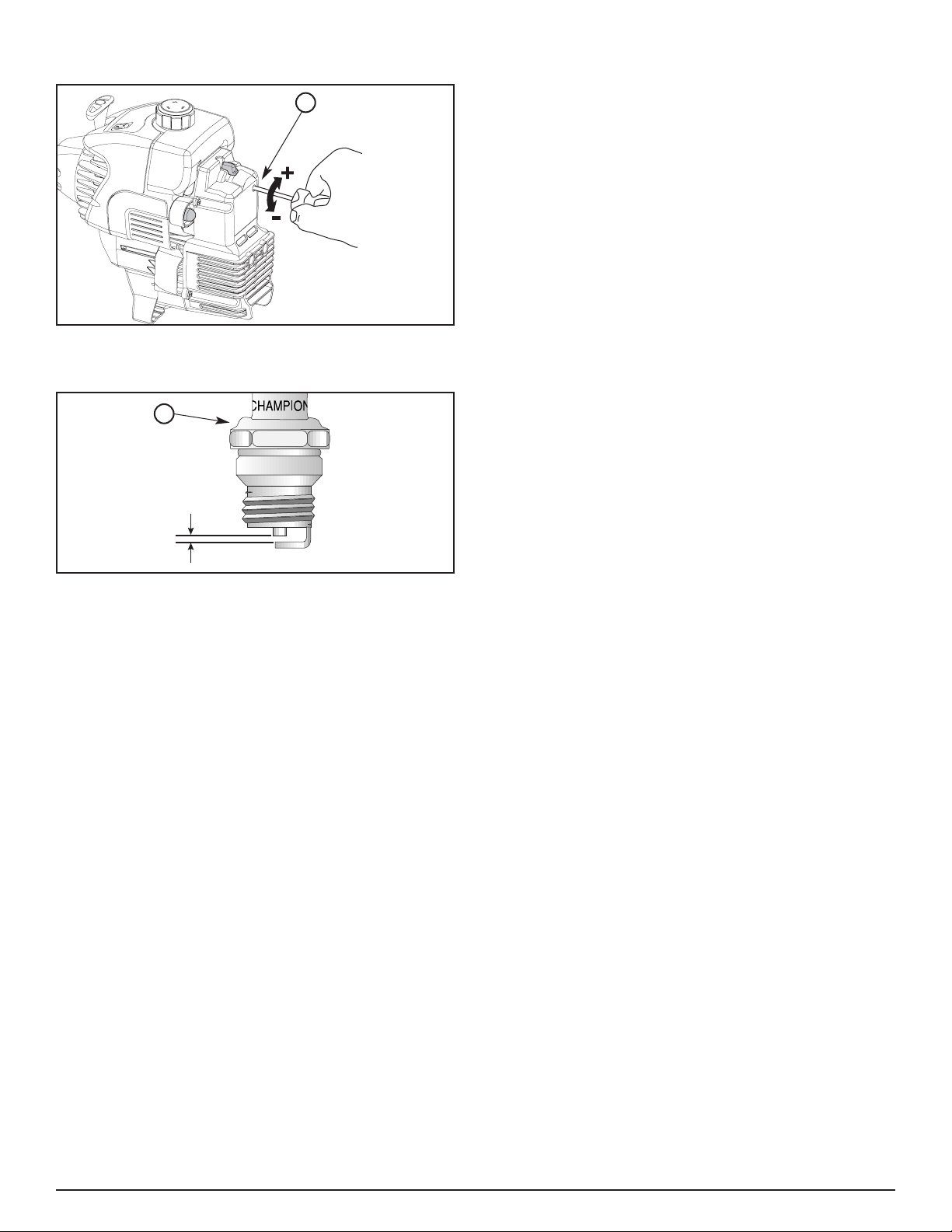

Description of Parts – Figs. 24-25

1. Idle Speed Adjuster

2. Spark Plug

Descripción de piezas – Fig. 24-25

1. Ajuste de marcha

lenta

2. Bujía de encendido

Beschreibung der Teile – Abb. 24-25

1. Lehrlaufdrehzahlregler

2. Zündkerze

Descrição das peças – Figuras 24-25

1. Regulador da

velocidade lenta

2. Vela

Description des pièces – Figs. 24-25

1. Vis de réglage du

ralenti

2. Bougie

Descrizione dei componenti – figg. 24-25

1. Vite regime minimo 2. Candela

0.020 in.

(0.5 mm.)

Fig. 25

2

Fig. 24

1

Page 11

11

Enter all the information shown on the identification plate

of your lawn scarifier into the box below.

The identification plate is located on the engine.

This information is very important for identifying any

spare parts that are to be ordered at a later date, and for

customer service.

READ ALL INSTRUCTIONS BEFORE

OPERATING

• Read the operator’s manual carefully. Be thoroughly

familiar with the controls and proper use of the unit.

Know how to stop the unit.

• Never allow children to operate the unit. Never allow

adults to operate the unit without proper instruction.

• Inspect the unit before use. Check for fuel leaks.

Replace damaged parts. Make sure the cutting

attachment is properly installed and securely fastened.

Be sure the cutting attachment shield is properly

attached, and positioned as recommended. Failure to

do so can result in personal injury to the operator and

bystanders, as well as damage to the unit.

• Use only 2.00 mm (0.080 inch) diameter genuine

replacement line. Never use metal-reinforced line,

wire, chain, or rope, etc. These can break off and

become a dangerous projectile.

• Do not operate this unit when tired, ill, or under the

influence of alcohol, drugs, or medication.

• Be aware of the risk of injury to the head, hands and

feet.

• Clear the area to be cut before each use. Remove all

objects such as rocks, broken glass, nails, wire, or

string which can be thrown or become entangled in

the cutting attachment.

• Clear the area of children, bystanders, and pets. At a

minimum, keep all children, bystanders and pets

outside a 15 m (50 ft.) radius; there still may be a risk

to bystanders from thrown objects. Bystanders should

wear eye protection. If you are approached, stop the

engine and cutting attachment immediately.

SAFETY WARNINGS FOR PETROL TRIMMERS

WARNING: Petrol (Gasoline) is highly flammable, and

its vapors can explode if ignited. Take the following

precautions:

• Store fuel only in containers specifically designed and

approved for the storage of such materials.

• Always stop the engine and allow it to cool before filling

the fuel tank. Never remove the cap of the fuel tank, or

add fuel, when the engine is hot.

•Mix and add fuel in a clean, well-ventilated area

outdoors where there are no sparks or flames. Never

fill fuel tank indoors. Slowly remove the fuel cap only

after stopping engine. Do not smoke whilst fueling or

mixing fuel. Wipe up any spilled fuel from the unit

immediately.

SAFETY WARNINGS

SAFE OPERATING PRACTICES

USE THE UNIT CORRECTLY

This unit is intended exclusively:

– for use in accordance with the descriptions and safety

instructions specified in this operating manual,

– for use in the garden,

– for trimming lawn edges and small or inaccessible

grassy areas, e.g. under bushes),

– as well as for cutting rank weeds, shrubs and

undergrowth.

This unit is not permitted for any other use. The user is

liable for any injury to third parties

or damage to their property.

Operate the unit only in the delivered technical condition

as stipulated by the manufacturer.

Any unauthorized changes to the unit will exempt the

manufacturer from liability for any resulting damage or

injuries.

Page 12

12

WHILE OPERATING

• Never start or run the unit inside a closed room or

building. Breathing exhaust fumes can kill. Operate

this unit only in a well ventilated area outdoors.

• Wear safety glasses or goggles and ear/hearing

protection when operating this unit. Wear safety

glasses for all operations, i.e. preparation, operation

and maintenance.

• Wear heavy, long pants, boots, gloves and long sleeve

shirt. Do not wear, short pants, sandals or go barefoot.

• The cutting attachment guard must always be in place

while operating. Do not operate unit without both

trimming lines extended, and the proper line installed.

Do not extend the trimming line beyond the length of

the guard.

• The unit does not have a clutch and the cutting

attachment continues rotating when the engine is

idling.

• Adjust the D-handle to your size to provide the best

grip.

• Be sure the cutting attachment is not in contact with

anything before starting the unit.

• The operator and unit must be in a stable position

while starting. See Fig. 6 and Starting/Stopping

Instructions.

• Use the right tool. Only use this tool for the purpose

intended.

• Do not touch the engine or muffler. These parts get

extremely hot from operation. When turned off they

remain hot for a short time.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do

not operate the unit with loose or damaged parts.

• If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration

is generally a warning of trouble.

• Stop and switch the engine to off for maintenance,

repair, or for changing the cutting attachment or other

attachments.

• Use only accessories and replacement parts approved

by the manufacturer when servicing this unit. These

parts are available from your authorized service dealer.

• Do not use parts, accessories or attachments not

authorized for this unit. Doing so could lead to serious

injury to the user, or damage to the unit, and void your

warranty.

OTHER SAFETY WARNINGS

• Never store the unit, with fuel in the tank, inside a

building where fumes may reach an open flame or

spark.

• Allow the engine to cool before storing or transporting.

Be sure to secure the unit while transporting.

• Clean after each use, see Cleaning and Storage

instructions.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

• Have all repairs carried out by a specialist workshop

only.

SAVE THESE INSTRUCTIONS

SAFETY WARNINGS

Page 13

13

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning, or

caution. May be used in conjunction

with other symbols or pictographs.

•WARNING - READ

OPERATOR'S MANUAL

Read the Operator’s Manual(s) and

follow all warnings and safety

instructions. Failure to do so can

result in serious injury to the

operator and/or bystanders.

• WEAR EYE AND HEARING

PROTECTION

WARNING:

Thrown objects and loud

noise can cause severe eye injury and

hearing loss. Wear eye protection

meeting ANSI Z87.1-1989 standards and

ear protection when operating this unit.

Use a full face shield when needed.

• UNLEADED PETROL

Always use clean, fresh unleaded

petrol.

• OIL

Refer to operator's manual for the

proper type of oil.

• MAXIMUM RPM

Do not operate the unit faster

than the maximum RPM.

SYMBOL MEANING

• IGNITION SWITCH

ON / START / RUN

• IGNITION SWITCH

OFF or STOP

• HOT SURFACE WARNING

Do not touch a hot muffler or

cylinder. You may get burned.

These parts get extremely hot from

operation. When turned off they

remain hot for a short time.

• SHARP BLADE

WARNING: Sharp blade on cutting

attachment shield. To prevent

serious injury, do not

touch line cutting blade.

• KEEP BYSTANDERS AWAY

WARNING:

Keep all bystanders,

especially children and pets, at

least 15 meters (50 ft.)

from the operating area.

• THROWN OBJECTS CAN

CAUSE SEVERE INJURY

WARNING:

Keep clear of blower

outlet. Never point the blower at

yourself or others. Objects can be

thrown from blower. Do not

operate unit without proper

attachments and guards in place.

• CHOKE CONTROL

1 • FULL choke position.

2 • PARTIAL choke position.

3 • RUN position.

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

Page 14

14

ASSEMBLY INSTRUCTIONS

INSTALLING THE D-HANDLE

1. For your safety, the D-Handle must be assembled in

front of the limiter sleeve. Push the D-Handle down

over the shaft tube so that the handle slants back

towards the engine (Fig. 1).

CAUTION: Do not force the D-handle over the limiter

sleeve. Damage to the D-handle or unit may occur.

3. Install the bolt, washer, wing nut and tighten.

ADJUSTING THE D-HANDLE

1. Loosen the wing nut. It is not necessary to remove

the wing nut, washer and bolt.

2. Rotate the D-handle to place the grip above the top

of the shaft housing.

3. While holding the unit in the operating position

(Fig. 7), position the D-handle to the location that

provides you the best grip, and tighten the wing nut

(Fig. 1).

INSTALLING THE CUTTING ATTACHMENT

GUARD

1. Place the cutting attachment guard onto the shaft

tube above the clamp assembly (Fig. 2).

2. Push the cutting attachment guard down to the top

of the string head assembly and then rotate the

cutting attachment guard until the screw holes align

and the guard fits into the recessed pocket (Fig. 3).

OIL AND FUEL RECOMMENDATIONS

RECOMMENDED OIL TYPE

Use high quality oil formulated for use in 2-cycle, aircooled engines. Mix the oil according to the instructions

on the 2-cycle engine oil container, 40:1 (2.5 %).

RECOMMENDED FUEL TYPE

Always use clean, fresh, unleaded petrol (gasoline).

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons

for the unit not running properly. Be sure to use fresh,

clean unleaded fuel. Follow the instructions carefully for

the proper fuel/oil mixture.

Thoroughly mix the proper ratio of 2-cycle engine oil

with unleaded petrol, 40:1 (2.5 %). Do not mix them

directly in the tank.

OPERATING INSTRUCTIONS

STARTING INSTRUCTIONS

NOTE: Squeeze the throttle control until the engine has

started and warmed up.

1. Mix petrol (gasoline) with oil. Fill fuel tank with fuel/oil

mixture. See Oil and Fuel Mixing Instructions.

2. Put the ignition switch in the ON (I) position (Fig. 4).

3. TIP: When you are trying to start a unit that has

been dormant for a while (or if it is brand new or

difficult to start), be sure to press and release the

primer bulb 20 times.

Fully press and release primer bulb slowly 10 times.

You should feel and see fuel in the bulb (Fig. 5). If

fuel hasn't entered the bulb, press three more times,

or keep pressing until it does.

4. Place the choke lever in Position 1 (Fig. 5).

TIP: Make sure choke lever locks into (1) position.

5. With the unit on the ground, squeeze the throttle

control and hold.

700: Pull starter rope briskly 3 times (Fig. 6).

710: Pull the starter rope out with a controlled and

steady motion 3 times.

6. Place the choke lever in Position 2 (Fig. 5).

7. 700: Pull starter rope briskly 1 to 3 times to start the

engine (Fig. 6).

710: Pull the starter rope out with a controlled and

steady motion 1 to 5 times to start the engine (Fig. 6).

Page 15

15

NOTE: The unit uses Advanced Starting Technology™,

which significantly reduces the effort required to

start the engine. You must pull the starter rope out

far enough to hear the engine attempt to start.

There is no need to pull the rope briskly-- there is

no harsh resistance when pulling. Be aware that

this starting method is vastly different from (and

much easier than) what you may be used to.

8. If the engine does not start, repeat steps 3 through 7.

9. Keep throttle trigger depressed to warm up engine.

After the engine warms up for 10 to 15 seconds,

place the choke lever in Position 3 (Fig. 18).

NOTE: If the engine floods while attempting to start,

place the choke lever in the Position 3, squeeze

the throttle trigger, and pull the starter rope

briskly. The engine should start within three (3) to

eight (8) pulls.

NOTE: Choking is not required when starting a warm

engine. Start a warm engine with the ignition

switch in the ON position and the choke lever in

Position 2.

STOPPING INSTRUCTIONS

1. Release your finger from the throttle trigger (Fig. 4).

Allow the engine to cool down by idling.

2. Put the ignition switch in the OFF (O) position (Fig. 4).

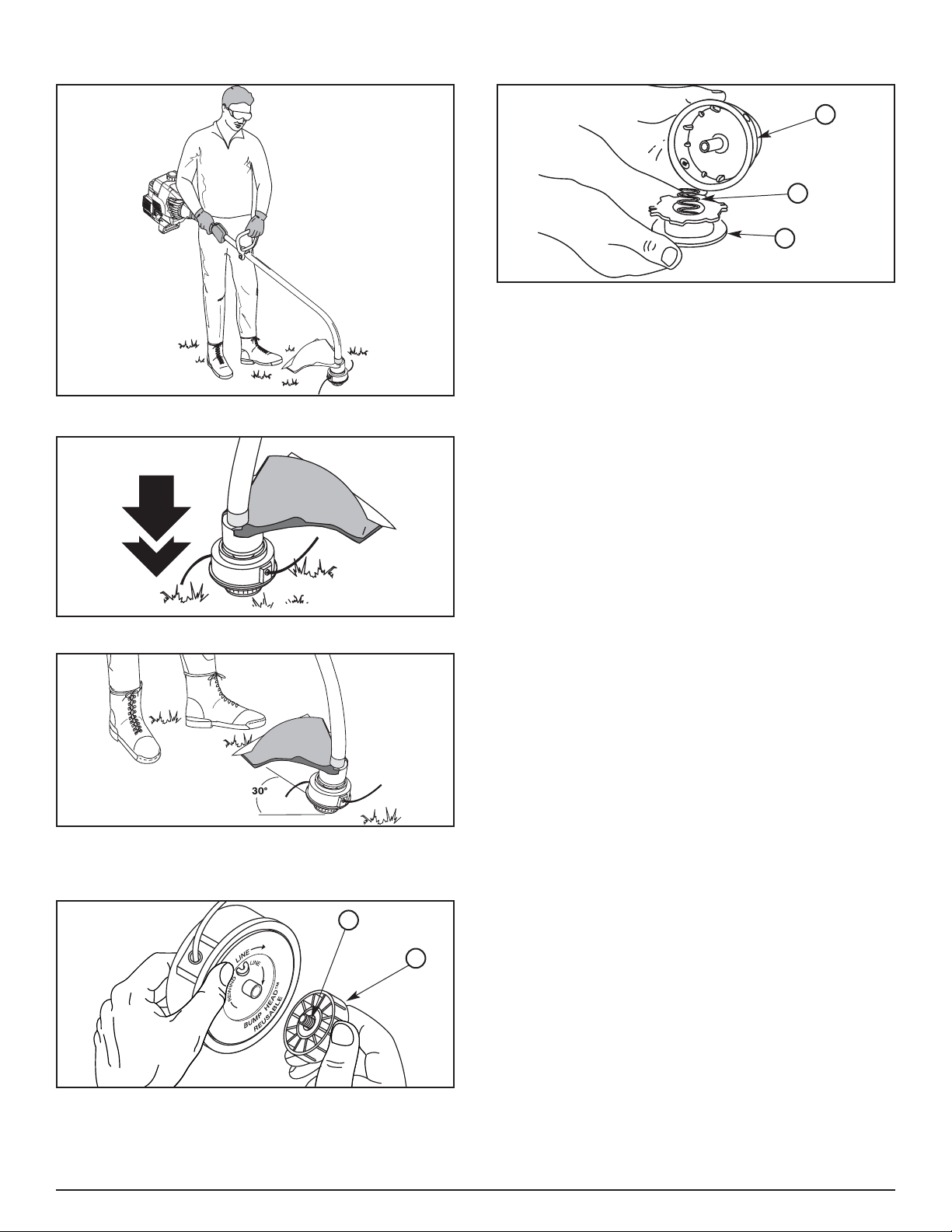

ADJUSTING TRIMMING LINE LENGTH

The Bump Head cutting attachment allows you to release

trimming line without stopping the engine. To release

more line, lightly tap the cutting attachment on the

ground (Fig. 8) while operating the trimmer at high speed.

NOTE: Always keep the trimming line fully extended.

Line release becomes more difficult as cutting

line becomes shorter.

A blade in the cutting attachment guard will cut the line to

the proper length if excess line is released. For best

results, tap the Bump Head on bare ground or hard soil. If

line release is attempted in tall grass, the engine may stall.

Some line breakage will occur from:

• Normal line fatigue

• Forcing the line into objects such as walls or fence

posts

TIPS FOR BEST TRIMMING RESULTS

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip of

the line to do the cutting, especially along walls.

Cutting with more than the tip will reduce cutting

efficiency and may overload the engine.

• Cut grass over 200 mm (8 in.) by working from top to

bottom in small increments to avoid premature line

wear or engine drag.

• Cut from left to right whenever possible. Cutting to the

right improves the unit's cutting efficiency. Clippings

are thrown away from the operator.

• Slowly move the trimmer into and out of the cutting

area at the desired height. Move either in a forwardbackward or side-to-side motion. Cutting shorter

lengths produces the best results.

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences, etc.

Rotate the whole unit so that the cutting attachment is at

a 30° angle to the ground (Fig. 9).

OPERATING INSTRUCTIONS

MAINTENANCE AND REPAIR INSTRUCTIONS

LINE INSTALLATION

This section covers both Split-Line™ and standard

single line installation.

Always use 2.0 mm. (0.080 in.) replacement line. The

engine may overheat or fail if you use a line size other than

specified.

There are two methods to replace the trimming line.

•Wind the inner reel with new line

• Install a prewound inner reel

Winding the Existing Inner Reel

1. Hold the outer spool with one hand and unscrew the

Bump Knob counterclockwise (Fig. 10). Inspect the

bolt inside the Bump Knob to make sure it moves

freely. Replace the Bump Knob if damaged.

2. Remove the inner reel from the outer spool (Fig. 11).

3. Remove spring from the inner reel (Fig. 11).

4. Use a clean cloth to clean the the inner reel, spring,

shaft, and inner surface of the outer spool

5. Check the indexing teeth on the inner reel and outer

spool for wear (Fig. 12). If necessary, remove burrs

or replace the reel and spool.

NOTE: Split-Line™ can only be used with the inner reel

with the slotted holes. Single line can be used on

either type of inner reel. Use figure 13 to identify

the inner reel you have.

NOTE: Always use the correct line length when installing

trimming line on the unit. The line may not release

properly if the line is too long.

Page 16

16

Single Line Installation

Go To Step 8 for Split-Line™ Installation

6. Take approximately 7.6 meters (25 ft.) of new

trimming line, loop it into two equal lengths. Insert

each end of the line through one of the two holes in

the inner reel (Fig. 14). Pull the line through the inner

reel so that the loop is as small as possible.

7. Wind the lines in tight even layers, onto the reel (Fig.

15). Wind the line in the direction indicated on the

inner reel. Place your index finger between the two

lines to stop the lines from overlapping. Do not

overlap the ends of the line. Proceed to step 11.

Split-Line™ Installation

8. Take approximately 3.65 meters (12 ft.) of new

trimming line. Insert one end of the line through one

of the two holes in the inner reel (Fig. 16). Pull the

line through the inner reel until only about 4 inches is

left out.

9. Insert the end of the line into the open hole in the

inner reel and pull the line tight to make the loop as

small as possible (Fig. 16).

10. Before winding, split the line back about 6 inches.

11. Wind the line in tight even layers in the direction

indicated on the inner reel.

NOTE: Failure to wind the line in the direction indicated

will cause the cutting attachment to operate

incorrectly.

12. Insert the ends of the line into the two holding slots

(Fig. 17).

13. Insert the ends of the line through the eyelets in the

outer spool and place inner reel with spring inside the

outer spool (Fig. 18). Push the inner reel and outer spool

together. While holding the inner reel and outer spool,

grasp the ends and pull firmly to release the line from

the holding slots in the reel.

NOTE: The spring must be assembled on the inner reel

before reassembling the cutting attachment.

14. Hold the inner reel in place and install the Bump Knob

by turning clockwise. Tighten securely.

Installing a Prewound Reel

1. Hold the outer spool with one hand and unscrew the

Bump Knob counterclockwise (Fig. 10). Inspect the

bolt inside the Bump Knob to make sure it moves

freely. Replace the Bump Knob if damaged.

2. Remove the old inner reel from the outer spool (Fig. 11).

3. Remove the spring from the old inner reel (Fig. 11).

4. Use a clean cloth to clean the the inner reel, spring,

shaft, and inner surface of the outer spool.

5. Place the spring in the new inner reel.

NOTE: The spring must be assembled on the inner reel

before reassembling the cutting attachment.

6. Insert the ends of the line through the eyelets in the

outer spool (Fig. 18).

7. Place the new inner reel inside the outer spool. Push

the inner reel and outer spool together. While holding

the inner reel and outer spool, grasp the ends and pull

firmly to release the line from the holding slots in the

spool.

8. Hold the inner reel in place and install the Bump

Knob by turning clockwise. Tighten securely.

AIR FILTER MAINTENANCE

Removing the Air Filter/Muffler Cover

1. Place the choke lever in the position 2.

NOTE: The choke lever must be in position 2 (Fig. 19) to

remove the air filter/muffler cover.

2. Remove the four (4) screws securing the air

filter/muffler cover (Fig. 19). Use a flat blade or T-20

Torx bit screwdriver.

3. Pull the cover from the engine. Do not force.

Cleaning the Air Filter

Clean and re-oil the air filter every 10 hours of operation.

It is an important item to maintain. Failure to maintain

your air filter properly can result in poor performance or

can cause permanent damage to your engine.

1. Remove the air filter/muffler cover. See Removing

the Air filter/Muffler Cover.

2. Remove the air filter from inside the air filter/muffler

cover (Fig. 20).

3. Wash the filter in detergent and water (Fig. 21). Rinse

the filter thoroughly. Squeeze out excess water.

Allow it to dry completely.

4. Apply enough clean oil to lightly coat the filter (Fig. 22).

5. Squeeze the filter to spread and remove excess oil.

6. Replace the air filter inside the air filter/muffler cover

(Fig. 20).

NOTE: Operating the unit without the air filter and air

filter/muffler cover assembly, will VOID the

warranty.

Reinstalling the Air Filter/Muffler Cover

1. Place the air filter/muffler cover over the back of the

carburetor and muffler.

NOTE: The choke lever must be in position 2 (Fig. 19) to

install the air filter/muffler cover.

2. Insert the four (4) screws into the holes in the air

filter/muffler cover (Fig. 19) and tighten. Use a T-20

Torx bit screwdriver. Do not over tighten. Do not

force.

Check Fuel Mixture

Old and/or improperly mixed fuel is usually the reason

for the unit not running properly. Drain and refill the tank

with fresh, properly mixed fuel prior to making any

adjustments.

MAINTENANCE AND REPAIR INSTRUCTIONS

Page 17

17

MAINTENANCE AND REPAIR INSTRUCTIONS

Clean Air Filter

The condition of the air filter is important to the operation

of the unit. A dirty air filter will restrict air flow and

change the air/fuel mixture. This is often mistaken for an

out of adjustment carburetor. Check the condition of the

air filter before adjusting the idle speed screw. Refer to

Air Filter Maintenance.

Adjust Idle Speed Adjuster

If after checking the fuel mixture and cleaning the air

filter the engine

still will not idle, adjust the idle speed adjuster as

follows.

1. Start the engine and let it run about 2–3 minutes at a

high speed (full throttle) to warm up.

2. Release the throttle trigger and let the engine idle. If

the engine stops, insert a small phillips screwdriver

into the hole in the air filter/muffler cover (Fig. 23).

Turn the idle speed adjuster in, clockwise, 1/8 of a

turn at a time (as needed) until the engine idles

smoothly. See Specifications for idle RPM.

NOTE: The unit does not have a clutch and the cutting

attachment continues rotating when the engine is

idling.

3. To reduce the idle speed, turn the idle speed

adjuster counterclockwise 1/8 of a turn at a time (as

needed).

Checking the fuel mixture, cleaning the air filter, and

adjusting the idle

speed screw should solve most engine problems.

If not and:

• The engine will not idle,

• The engine hesitates or stalls on acceleration,

• There is a loss of engine power,

Have the carburetor adjusted by an authorized service

dealer.

REPLACING THE SPARK PLUG

Use a Champion RDJ7Y spark plug (or equivalent). The

correct air gap is 0.5 mm (0.020 in.). Remove the plug

after every 50 hours of operation and check its

condition.

1. Stop the engine and allow it to cool. Grasp the plug

wire firmly and pull the cap from the spark plug.

2. Clean dirt from around the spark plug.

3. Replace cracked, fouled or dirty spark plug. Set the

air gap at 0.5 mm (0.020 in.) using a feeler gauge

(Fig. 24).

4. Install a correctly gapped spark plug in the cylinder

head. Tighten by turning the 5/8 in. socket clockwise

until snug.

Do not over tighten.

CLEANING

Use a small brush to clean off the outside of the unit. Do

not use strong detergents. Household cleaners that

contain aromatic oils

such as pine and lemon, and solvents such as kerosene,

can damage plastic housing or handle. Wipe off any

moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes

may reach an open flame or spark.

• Allow the engine to cool before storing.

• Store the unit in a dry place, locked up or up-high to

prevent

unauthorized use or damage. Keep out of the reach of

children.

LONG TERM STORAGE

If the unit will be stored for an extended time, use the

following storage procedure.

1. Drain all fuel from the fuel tank and drain into a

container with the same 2-cycle fuel mixture. Do not

use fuel that has been stored for more than 60 days.

2. Start the engine and allow it to run until it stalls. This

ensures that all fuel has been drained from the

carburetor.

3. Allow the engine to cool. Remove the spark plug and

put 30 ml (1 oz.) of any high quality motor oil or 2cycle oil into the cylinder. Pull the starter rope slowly

to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil

from the cylinder before attempting to start the

trimmer after storage.

4. Thoroughly clean the unit and inspect for any loose

or damaged parts. Repair or replace damaged parts

and tighten loose screws, nuts or bolts. The unit is

ready for storage.

5 Store the unit in a dry place, locked up or up-high to

prevent unauthorized use or damage. Keep out of

the reach of children.

Page 18

18

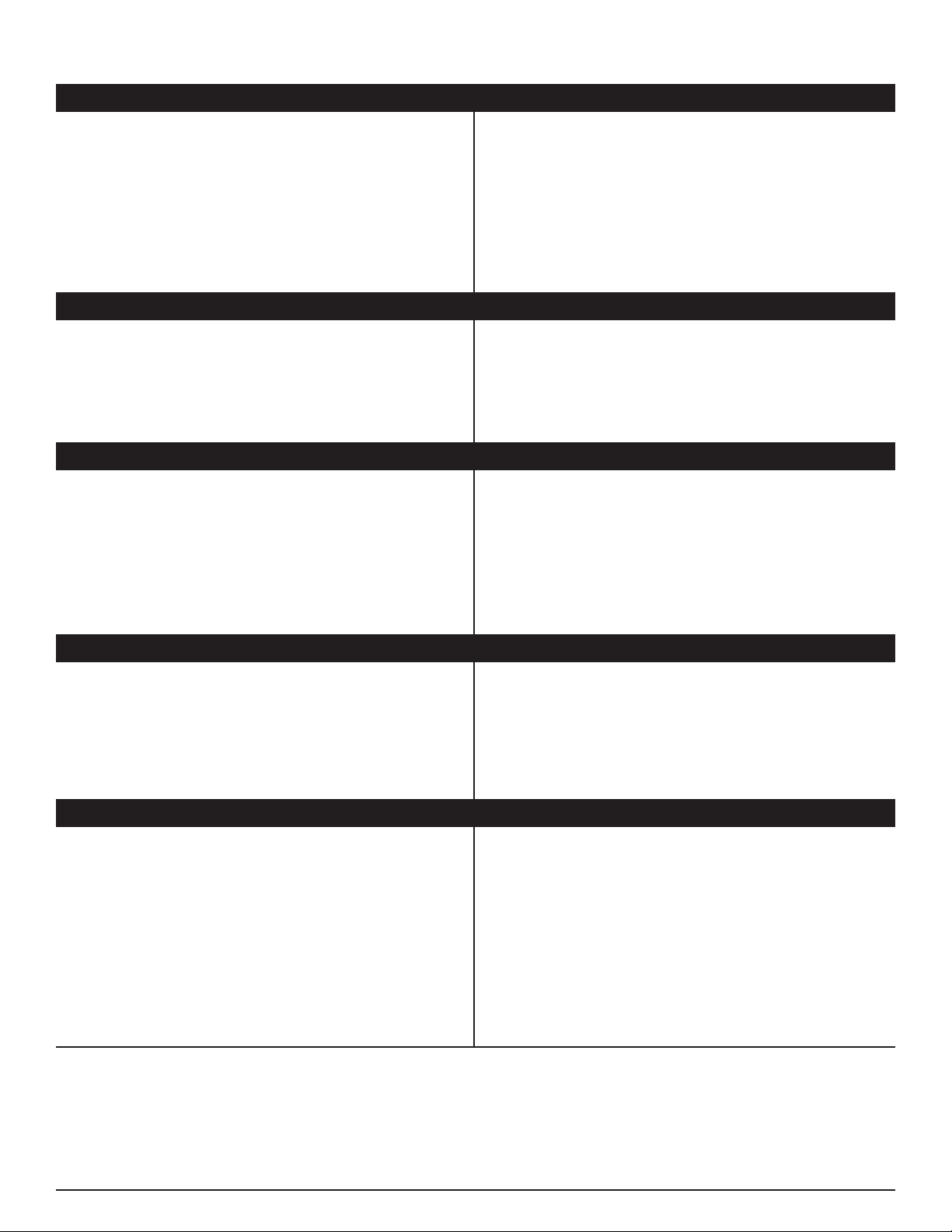

TROUBLESHOOTING

CAUSE ACTION

Cutting attachment bound with grass Stop the engine and clean cutting attachment

Cutting attachment out of line Refill with new line

Inner reel bound up Rewind /replace the inner reel

Cutting head dirty Clean inner reel and outer spool

Line welded Disassemble, remove the welded section and rewind

Line twisted when refilled Disassemble and rewind the line

Not enough line is exposed Push the bump knob and pull out line until 4 inches

(102 mm) of line is outside of the cutting attachment

CAUSE ACTION

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Improper carburetor adjustment Take to an authorized service dealer for an adjustment

Fouled spark plug Replace or clean the spark plug

CAUSE ACTION

Empty fuel tank Fill fuel tank with properly mixed fuel

Primer bulb wasn't pressed enough Press primer bulb fully and slowly 10 times

Engine is flooded Squeeze the trigger and pull the starter rope

(with choke in Position 3)

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Fouled spark plug Replace or clean the spark plug

ENGINE WILL NOT START

ENGINE WILL NOT IDLE / LOW IDLE SPEED

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STALLS WHEN CUTTING

CAUSE ACTION

Air filter is plugged Replace or clean the air filter

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Improper carburetor adjustment Adjust according to the Carburetor Adjustments section

CAUSE ACTION

Old or improperly mixed fuel Drain fuel tank and add fresh fuel mixture

Improper carburetor adjustment Take to an authorized service dealer for an adjustment

Cutting attachment bound with grass Stop the engine and clean the cutting attachment

Dirty air filter Clean or replace the air filter

CUTTING ATTACHMENT WILL NOT ADVANCE LINE

If further assistance is required, contact your local authorized service dealer.

All information, illustrations, and specifications in this manual are based on the latest product information available at the

time of printing. We reserve the right to make any changes at any time without notice.

Page 19

19

SPECIFICATIONS

ENGINE

Engine Type........................................................................................................................................... Air-Cooled, 2-Cycle

Ignition Type.......................................................................................................................................................... Electronic

Displacement........................................................................................................................................... 31 cm3(1.9 cu. in.)

Maximum Engine Performance in accordance with ISO 8893.......................................................................... 75 kw (1 hp)

Idle RPM...................................................................................................................................................... 3200 min-1(rpm)

Operating RPM............................................................................................................................................ 7700 min-1(rpm)

Fuel.......................................................................................................................................... Fuel/Oil Mixture (40:1) 2,5 %

Ignition Switch ............................................................................................................................................... Rocker On/Off

Starter............................................................................................................................................................... Auto Rewind

Fuel Tank Capacity........................................................................................................................................ 355 ml (15 oz.)

DRIVE SHAFT & CUTTING HEAD

Drive Shaft Housing............................................................................................................................................. Steel Tube

Throttle Control ........................................................................................................................................ Finger-Tip Trigger

Cutting Head.......................................................................................................................................... Bump Line Release

Trimming Line Diameter............................................................................................................... 2 mm (0.080 in.), dual line

Cutting Path Diameter.................................................................................................................................. 381 mm (15 in.)

Mass (without fuel).......................................................................................................................................... 4.5 kg (10 lbs)

ACCESSORIES on request

GUARANTEE

The guarantee conditions that apply in each country are

published by either our company or the importer of our

products. Faults will be repaired free of charge within the

framework of the guarantee, provided that they have been

caused by a material defect or manufacturing error. In the

case of a guarantee repair, please contact your dealer or

our nearest branch office.

Page 20

20

Page 21

21

Reportez dans l'encadré ci-dessous toutes les

indications figurant sur la plaquette signalétique qui se

trouve à proximité du moteur de l'appareil.

Les indications qu'elle contient sont d'une importance

capitale car elles permettront plus tard de déterminer les

pièces de rechange et d'accomplir les prestations de

service après-vente.

POUR VOTRE SECURITE

UTILISATION CONFORME DE L’APPAREIL

Cet appareil est exclusivement destiné à servir

– conformément aux descriptions et consignes de

sécurité fournies dans la présente notice d'instructions

– dans le jardin domestique et le jardin d'agrément,

– pour tondre les bordures gazonnées et les surfaces

herbeuses restreintes ou difficiles d'accès (par ex.

sous les buissons)

– ainsi que pour couper les pousses sauvages, les

buissons et les broussailles.

Toute utilisation sortant de ce cadre sera réputée non

conforme. Tout dommage envers un tiers et ses biens

est à la charge de l'utilisateur.

N'utilisez l'appareil que dans l'état technique où vous

l'avez acheté et tel que prescrit par le fabricant.

Toute modification volontaire de l'appareil exclut toute

responsabilité du fabricant envers les dommages qui

pourraient en résulter.

LISEZ TOUTES LES INSTRUCTIONS AVANT

L’UTILISATION

• Veuillez lire le manuel de l'utilisateur soigneusement.

Familiarisez-vous très bien avec les commandes et

l'utilisation correcte de l’appareil. Sachez comment

arrêter l’appareil.

• Ne laissez pas les enfants faire fonctionner l’ appareil.

Ne laissez jamais des adultes actionner l’appareil sans

formation préalable.

• Inspectez l'appareil avant utilisation. Remplacez les

pièces endommagées. Regardez s'il y a des fuites de

carburant. Assurez-vous que les fixations sont

solidement en place. Remplacez les pièces de

l'accessoire de coupe qui sont fendillées, ébréchées

ou endommagées. Assurez-vous que l'accessoire de

coupe est correctement installé et solidement fixé.

Assurez-vous que le protecteur d'accessoire de coupe

est correctement fixé et positionné comme

recommandé. Vous risquez sinon de causer des

blessures à l'opérateur et aux spectateurs, et

d'endommager l'appareil.

• N'utilisez que du fil de remplacement d'origine de 2,03

mm (0,080 po) de diamètre. N'utilisez jamais de fil ou

de cordon à renfort métallique, etc. Car il peut se

briser et se transformer en projectile dangereux.

• N'utilisez pas l'appareil si vous êtes fatigué, malade ou

sous l'effet de l'alcool, de drogues ou de

médicaments.

• Attention aux risques de blessure à la tête, aux mains et

aux pieds.

• Dégagez la zone de coupe avant chaque usage.

Enlevez tous les objets pouvant être projetés ou

happés par l'accessoire : cailloux, verre brisé, clous, fil

ou ficelle.

• Éloignez enfants, spectateurs et animaux de la zone.

Tenez-les à au moins 15 m (50 pi) de là mais sachez

que les spectateurs risquent quand même d'être

atteints par des objets projetés. Les spectateurs

doivent porter des protections oculaires. Arrêtez

immédiatement le moteur et l'accessoire si quelqu'un

s'approche de vous.

CONSIGNES DE SECURITE

ATTENTION : L’essence est hautement inflammable et

les vapeurs d’essence peuvent exploser en cas de

contact avec une flamme. Prenez les précautions

suivantes :

• Stockez toujours le carburant dans des conteneurs

spécialement conçus et agréés pour le stockage de ce

type de produit.

• Arrêtez toujours le moteur et laissez-le refroidir avant

de remplir le réservoir. Vous ne devez jamais enlever le

bouchon du réservoir ou ajouter du carburant tant que

le moteur est chaud.

AVERTISSEMENTS DE SÉCURITÉ

Page 22

22

• Mélangez et ajoutez le carburant dans un lieu

extérieur, aéré et propre, à l'abri d’étincelles ou de

flammes. Ne remplissez jamais le réservoir de

carburant à l'intérieur. Retirez lentement le bouchon

du réservoir, seulement après avoir arrêté le moteur.

Ne fumez pas pendant le remplissage ou le mélange

de carburant. Essuyez immédiatement tout

déversement de carburant.

PENDANT L’UTILISATION

• Ne démarrez et n’utilisez jamais l’appareil dans une

pièce ou un bâtiment fermé. L’inhalation des fumées

d’échappement peut être mortelle. N’utilisez cet

appareil qu’en extérieur, dans une zone bien ventilée.

• Portez des lunettes de sécurité et des protège-oreilles

lorsque vous faites marcher l'appareil. Portez des

lunettes de sécurité pour toutes les activités, ex.

préparation, fonctionnement, entretien.

• Portez des pantalons épais et longs, des bottes, des

gants et une chemise à manches longues. Ne marchez

pas pieds nus et évitez les pantalons courts et les

sandales.

• Le carter de protection de coupe doit toujours être en

place lorsque l’appareil est utilisé. La longueur du fil

de coupe ne doit pas dépasser celle du carter de

protection.

• L'appareil n'est pas muni d'un accouplement et,

lorsque le moteur tourne à vide, la bobine de fil

continue de tourner.

•Réglez la poignée en D à votre taille afin d’assurer la

meilleure prise en main possible.

• Assurez-vous que la bobine de fil n’est en contact

avec aucun objet avant de mettre l’appareil en

marche.

• L’utilisateur et l’appareil doivent être en position stable

lors du démarrage. Reportez-vous à la Figure 6 et aux

Instructions pour le démarrage/l’arrêt.

• Utilisez l’outil approprié. N’utilisez cet outil que pour

l’usage auquel il est destiné.

• Ne touchez pas le moteur et le pot d’échappement. Ces

éléments chauffent énormément lorsque l’appareil est en

fonctionnement. Une fois qu’il est arrêté, ils restent

chauds pendant un court moment.

• Ne faites pas tourner le moteur à vitesse élevée

lorsque vous n’effectuez pas de coupe.

AVERTISSEMENTS DE SÉCURITÉ

• En cas de contact avec un corps étranger, arrêtez le

moteur immédiatement et vérifiez que l’appareil n’est

pas endommagé. N’utilisez pas l’appareil avant de

l’avoir remis en état. N’utilisez pas l’appareil si

certaines pièces sont mal serrées ou endommagées.

•Si l’appareil se met à vibrer de manière anormale,

arrêtez le moteur et procédez immédiatement à une

vérification. Les vibrations indiquent généralement la

présence d’un problème.

• Coupez le moteur et mettez-le en position Arrêt pour

toute opération d’entretien ou de maintenance et lors

du changement de la bobine de fil ou d’un autre

accessoire.

• Utilisez uniquement des accessoires et des pièces de

rechange homologués par le fabricant pour l'entretien.

Elles sont disponibles auprès de votre

concessionnaire agréé.

• N'utilisez pas de pièces ou accessoires non autorisés

pour cet appareil. Cela pourrait causer des blessures

graves ou endommager l'appareil et annuler la

garantie.

AUTRES CONSIGNES DE SECURITE

• S’il y a du carburant dans le réservoir, n’entreposez

jamais l’appareil dans un bâtiment où les vapeurs

pourraient entrer en contact avec une flamme nue ou

une étincelle.

• Laissez le moteur refroidir avant de ranger ou de

transporter l’appareil. Veillez à protéger l’appareil pour

le transport.

• Nettoyez l’appareil après chaque utilisation ; reportezvous aux instructions de la section «Nettoyage et

entreposage».

• Conservez ce manuel. Reportez-vous souvent aux

instructions qu’il comporte et transmettez ces

instructions aux autres utilisateurs. Si vous prêtez cet

appareil, prêtez également ces instructions.

•

Confiez toutes les réparations exclusivement à un atelier

spécialisé.

CONSERVEZ CES INSTRUCTIONS

Page 23

23

SYMBOLES DE SECURITE ET SYMBOLES INTERNATIONAUX

Le présent manuel d’utilisation décrit les symboles et pictogrammes de sécurité et internationaux susceptibles d’apparaître sur cet

outil. Lisez le manuel d’utilisation pour obtenir des informations complètes sur la sécurité, le montage, le fonctionnement, l’entretien

et la maintenance de votre matériel.

SYMBOLE SIGNIFICATION

• SYMBOLE D’ALERTE DE SECURITE

Ce symbole indique un danger, donne un avertissement ou invite à prendre des précautions. Il

peut être combiné à d’autres symboles ou pictogrammes.

•ATTENTION – LIRE LE MANUEL D’UTILISATION

Lisez le manuel d’utilisation et suivez tous les avertissements et consignes de sécurité.

Le non-respect de ces instructions peut entraîner de graves blessures pour l’utilisateur et/ou

les personnes se trouvant à proximité.

• PORTER DES PROTECTIONS OCULAIRES ET AUDITIVES

ATTENTION : Les projections d’objets et le niveau sonore peuvent provoquer des lésions aux

yeux et une perte auditive. Portez des lunettes protectrices et une protection antibruit lors de

l’utilisation de l’appareil.

Servez-vous d'un masque protecteur si nécessaire.

• TENIR TOUTE PERSONNE A DISTANCE

ATTENTION : Toutes les personnes se trouvant à proximité, notamment les enfants, ainsi que

les animaux, doivent se trouver à une distance d’au moins 15 mètres de la zone où est utilisé

l’appareil.

• ESSENCE SANS PLOMB

Utilisez toujours une essence sans plomb, propre et neuve.

• HUILE

Reportez-vous au manuel d’utilisation pour connaître le type d’huile à utiliser.

• LES PROJECTIONS D’OBJETS PEUVENT PROVOQUER DE GRAVES BLESSURES

ATTENTION : Tenez-vous à l’écart de la sortie du souffleur. Ne dirigez jamais le souffleur vers

vous ou vers des tiers. Le souffleur peut provoquer des projections. N’utilisez l’appareil que si

les équipements et carters appropriés sont en place.

AVERTISSEMENTS DE SÉCURITÉ

Page 24

24

SYMBOLE SIGNIFICATION

•INTERRUPTEUR

MARCHE

•INTERRUPTEUR

ARRET

•ATTENTION SURFACE CHAUDE

Ne touchez pas un pot d’échappement ou un cylindre chaud. Vous risqueriez de vous brûler.

Ces éléments chauffent énormément lorsque l’appareil est en fonctionnement. Une fois qu’il

est arrêté, ils restent chauds pendant un court moment.

• LAME AIGUISÉE

ATTENTION : Lame tranchante sur le protecteur d'accessoire de coupe. Ne touchez pas la

lame coupante pour éviter des blessures graves.

• LEVIER DE STARTER

1 • Position starter.

2 • Position intermédiaire.

3 • Position pleine puissance.

• RÉGIME MAXIMUM

Ne faites pas tourner l'appareil à un régime supérieur au régime maximum.

AVERTISSEMENTS DE SÉCURITÉ

Page 25

25

INSTRUCTIONS DE MONTAGE

INSTALLATION DE LA POIGNEE EN D

1. Pour votre sécurité, la poignée en D doit être

assemblée à l’avant du manchon du limiteur.

Enfoncez la poignée en D sur le tube de l'arbre afin

de l’incliner vers le moteur (Fig. 1).

MISE EN GARDE : ne forcez pas la poignée en D sur le

manchon du limiteur. Cela pourrait endommager la

poignée en D ou l’ appareil.

3. Posez le boulon, la rondelle et l'écrou, et serrez.

REGLAGE DE LA POIGNEE EN D

1. Desserrez la vis papillon. Il n’est pas nécessaire

d’enlever la vis, la rondelle et la vis.

2. Faites pivoter la poignée en D de manière à placer la

poignée au-dessus du tube.

3. Tout en maintenant l’appareil en position de

fonctionnement (Fig. 13), placez la poignée en D à

l’endroit qui vous assure la meilleure prise en main et

serrez la vis papillon (Fig. 1).

INSTALLATION DU CARTER DE

PROTECTION DE COUPE

1. Placez le carter de protection de coupe sur le tube,

au-dessus du dispositif de fixation (Fig. 2).

2. Abaissez le carter de protection de coupe sur la

partie supérieure du dispositif de coupe, puis faitesle pivoter de manière à l’ajuster par rapport aux trous

destinés à recevoir les vis et à l’insérer

convenablement à son emplacement (Fig. 3).

RECOMMANDATIONS D'HUILE ET DE CARBURANT

TYPE D'HUILE RECOMMANDÉ

Utilisez une huile de haute qualité conçue pour les

moteurs à 2-temps refroidis par air. Mélangez l’huile

selon les instructions du récipient d'huile 2-temps, 40:1

(2,5 %).

TYPE DE CARBURANT RECOMMANDÉ

Utilisez toujours de l’essence sans plomb fraîche et

propre.

INSTRUCTIONS DE MÉLANGE D'HUILE ET

DE CARBURANT

En général, si l'appareil ne fonctionne pas correctement,

c'est que le carburant est vieux ou mal mélangé. Prenez

soin d'utiliser de l’essence sans plomb fraîche et propre.

Suivez à la lettre les instructions de mélange de

carburant et d'huile.

Mélangez soigneusement l'huile moteur

2-temps avec de l'essence sans plomb selon un ratio de

40:1 (2,5 %). Ne les mélangez pas directement dans le

réservoir.

Page 26

26

MODE D'EMPLOI

INSTRUCTIONS DE MISE EN MARCHE

1. Mélangez l'essence (carburant pour moteur

thermique) et l'huile. Remplissez le réservoir avec ce

mélange deux temps. Voir les instructions relatives

au mélange de l'huile et de l'essence.

2. Amenez l'interrupteur sur la position MARCHE [I]

(Fig. 4).

3. UN CONSEIL : lors du démarrage de l'appareil

resté longtemps sans servir (ou s'il s'agit du tout

premier démarrage ou encore s'il ne démarre pas

facilement), appuyez 20 fois sur la pompe

d'amorçage.

Commencez par appuyer 10 fois lentement et

complètement sur la pompe d'amorçage. Le

carburant doit être visible dans la pompe (Fig. 5). Si

ce n'est pas le cas, appuyez trois fois de plus ou

autant de fois que nécessaire pour que le carburant

devienne visible.

4. Amenez le levier du starter sur la position Starter (1)

(Fig. 5).

UN CONSEIL : remarque : veillez à ce que le

starter ait encoché en position (1).

5. Appareil sur le sol, actionnez la gâchette

d'accélération et maintenez le levier appuyé.

700: Tirez énergiquement le câble du lanceur (vous

devrez généralement répéter le lancement 3 fois)

(Fig. 6).

710: Tirez sur le lanceur avec un mouvement

contrôlé et constant de 3 fois.

6. Ramenez le levier du starter sur la position 2 (Fig. 5).

7. 700: Pour faire démarrer le moteur, tirez 1 à 3 fois,

énergiquement, le cordon du lanceur (Fig. 6).

710: Tirez sur le lanceur avec un mouvement

contrôlé et constant de 1 à 5 fois pour démarrer le

moteur.

REMARQUE : L’appareil utilise Advanced Starting

Technology™ qui réduit de manière significative

l’effort requis pour démarrer le moteur. Vous

devez tirez le lanceur suffisamment loin pour

entendre le moteur essayer de démarrer. Il n’est

pas nécessaire de tirer le lanceur de façon

brusque – il n’y a pas de forte résistance

lorsqu’on le tire. Soyez conscient que cette

méthode de démarrage est fortement différente

(et beaucoup plus facile que) de celle à laquelle

vous êtes accoutumé.

8. Répétez les opérations 3 à 7 si le moteur refuse de

démarrer.

9. Appuyez sur la gâchette d'accélération afin que le

moteur chauffe pendant 10 à 15 secondes. Amenez le

levier de starter sur la position 3 (Fig. 5).

REMARQUE : si le moteur est déjà chaud lorsque vous

voulez le faire démarrer, inutile d'employer le starter.

Amenez l'interrupteur sur la position MARCHE [I]

puis faites démarrer le moteur en position 2.

REMARQUE : si le moteur se noie pendant l'essai de

démarrage, amenez le levier du starter sur la position

3. Appuyez sur la gâchette d'accélération. Tirez

énergiquement le cordon du lanceur. Le moteur doit

démarrer au bout de 3 (trois) à 8 (huit) essais.

INSTRUCTIONS DE MISE À L'ARRÊT

1. Relâchez la gâchette d'accélération (Fig. 4). Laissez

tourner le moteur à vide pour qu'il refroidisse.

2. Amenez l'interrupteur sur la position ARRÊT [O] (Fig. 4).

PRISE EN MAIN DU COUPE-BORDURE

Avant d’utiliser l’appareil, tenez-vous dans la position

adéquate (Fig. 7).

REGLAGE DE LA LONGUEUR DU FIL DE

COUPE

La bobine de fil permet de libérer du fil de coupe sans

arrêter le moteur. Pour ce faire, donnez un petit coup

sec sur le sol avec la bobine (Fig. 8) tout en faisant

fonctionner le coupe-bordure à vitesse élevée.

REMARQUE : Le fil de coupe doit toujours être bien

tendu. Il est plus difficile de libérer du fil lorsque le fil

de coupe se raccourcit.

Si une longueur de fil excessive est libérée, une lame,

située dans le carter de protection de coupe, coupe le fil

à la longueur convenable. Pour de meilleurs résultats,

donnez des coups secs de bobine sur un sol nu ou dur.

Si vous tentez de libérer du fil en tapant dans l’herbe

haute, le moteur risque de caler.

Le fil de coupe peut se rompre dans les cas suivants :

• Usure normale du fil

• Fil approché d’un corps comme un mur ou un pieu de

clôture

ASTUCES POUR DE MEILLEURS

RESULTATS DE COUPE

• Maintenez la bobine de fil parallèle au sol.

• Ne forcez pas sur la bobine. Réalisez le travail avec la

pointe du fil, en particulier le long des murs. Si vous

utilisez plus que la pointe du fil pour effectuer la

coupe, l’efficacité de la coupe s’en trouve réduite et le

moteur risque d’être surchargé.

• Coupez l’herbe sur 20 cm en travaillant de haut en bas

par petites progressions pour éviter une usure

prématurée du fil ou une résistance du moteur.

• Effectuez la coupe de gauche à droite lorsque c’est

possible. L’appareil offre une meilleure efficacité de

coupe lorsque le mouvement est effectué vers la

droite. Les débris sont rejetés à distance de

l’utilisateur.

• Déplacez le coupe-bordure lentement à l’intérieur et à

l’extérieur de la zone à couper à la hauteur souhaitée.

Effectuez un mouvement d’avant en arrière ou d’un

côté à l’autre. La coupe de petites longueurs donne

les meilleurs résultats.

COUPE D’ORNEMENT

La coupe d’ornement est réalisée en enlevant toute la

végétation autour des arbres, des poteaux, des clôtures,

etc.

Faites pivoter l’appareil tout entier de telle sorte que la

bobine de fil se trouve à un angle de 30° par rapport au

sol (Fig. 9).

Page 27

27

ENTRETIEN ET RÉPARATIONS

INSTALLATION DU FIL DE COUPE

Cette section couvre l’installation de fil Split-LineMCet

l’installation de fil simple standard.

Utilisez toujours un fil de rechange de 2 mm. Le moteur

peut chauffer ou tomber en panne en cas d’utilisation

d’un fil de taille différente à la taille indiquée.

Deux méthodes permettent de remplacer le fil de coupe:

• Enroulement du nouveau fil sur la bobine interne

• Installation d’une bobine interne de fil pré-enroulé

Enroulement du fil sur la bobine interne existante

1. Maintenez la bobine externe d’une main et dévissez

le bouton de butée de l’autre en le tournant dans le

sens inverse des aiguilles d’une montre (Fig. 10).

Vérifiez que la vis située à l’intérieur du bouton de

butée bouge librement. Remplacez le bouton de

butée s’il est endommagé.

2. Retirez la bobine interne de la bobine externe (Fig. 11).

3. Enlevez le ressort de la bobine interne (Fig. 11).

4. Utilisez un chiffon propre pour nettoyer la bobine

interne, le ressort, l’arbre et la surface intérieure de la

bobine externe (Fig. 12).

5. Vérifiez l’usure des dents d’arrêt sur les bobines

interne et externe (Fig. 13). Si nécessaire, enlevez les

débris ou remplacez les bobines.

REMARQUE : Le Split-LineMCpeut être utilisé seulement

avec le moulinet intérieur à trous allongés. Le fil

simple peut être utilisé avec les deux sortes de

moulinet intérieur. Identifiez votre type de moulinet

en vous référant à la figure 13.

REMARQUE : Utilisez toujours la bonne longueur de fil

lorsque vous posez le fil sur l'appareil. Le fil risque

de ne pas se dérouler correctement s'il est trop long.

Installation du fil simple

Pour l’installation du Split-LineMC, passez à l’étape 8.

6. Découpez environ 7,6 m (25 pi) de fil neuf et faitesen deux boucles de longueurs égales. Insérez

chaque extrémité de fil dans l'un des deux trous du

moulinet (Fig. 14). Tirez le fil à travers le moulinet

pour que la boucle soit le plus petit possible.

7. Enroulez les fils en couches uniformes serrées sur le

moulinet (Fig. 15). Enroulez le fil dans le sens indiqué sur

le moulinet intérieur. Placez votre index entre les deux

fils pour les empêcher de se superposer. Ne superposez

pas les extrémités du fil. Passez à l’étape 11.

Installation du Split-Line

MC

8. Découpez environ 3,65 m (12 pi) de fil neuf. Insérez

une extrémité de fil dans l'un des deux trous du

moulinet intérieur (Fig. 16). Tirez le fil jusqu’à ne

laisser que 10 cm (4 po) environ.

9. Insérez l’extrémité du fil dans le trou ouvert du

moulinet et tirez sur le fil pour que la boucle soit le

plus petit possible (Fig. 16).

10. Avant de rembobiner le fil, séparez-le en deux sur

une longueur d’environ 15 cm (6 po).

11. Enroulez le fil en couches uniformes serrées dans le

sens indiqué sur le moulinet intérieur.

REMARQUE : ne pas enrouler le fil dans le sens indiqué

entraînera un mauvais fonctionnement de

l'accessoire de coupe.

12. Insérez les extrémités du fil dans les deux fentes de

retenue (Fig. 17).

13. Insérez les extrémités du fil dans les œillets de la

bobine extérieure et placez le moulinet et le ressort

dans la bobine (Fig. 18). Enfoncez le moulinet et la

bobine ensemble. Tout en tenant le moulinet et la

bobine, saisissez les extrémités et tirez fermement

pour dégager le fil des fentes de retenue du moulinet.

REMARQUE : le ressort doit être installé dans le moulinet

intérieur avant de remonter l'accessoire de coupe.

14. Maintenez le moulinet en place et installez le bouton de

butée en le tournant à droite. Vissez bien.

Installation d’une bobine de fil préenroulé

1. Maintenez la bobine externe d’une main et dévissez

le bouton de butée de l’autre en le tournant dans le

sens inverse des aiguilles d’une montre (Fig.10).

Vérifiez que la vis située à l’intérieur du bouton de

butée bouge librement. Remplacez le bouton de

butée s’il est endommagé.

2. Retirez l’ancienne bobine interne de la bobine

externe (Fig. 11).

3. Enlevez le ressort de l’ancienne bobine interne (Fig. 11).

4. Utilisez un chiffon propre pour nettoyer la bobine

interne, le ressort, l’arbre et la surface intérieure de la

bobine externe.

5. Placez le ressort dans la nouvelle bobine interne.

REMARQUE : Le ressort doit être installé sur la bobine

interne avant le remontage de la bobine de fil.

6. Insérez les extrémités du fil dans les œillets de la

bobine externe (Fig. 18).

7. Placez la nouvelle bobine interne dans la bobine

externe (Fig. 18). Appuyez afin d’assembler les deux

bobines. Tout en maintenant la bobine interne et la

bobine externe, saisissez les extrémités du fil et tirez

fermement afin de libérer le fil des deux fentes de

retenue de la bobine.

8. Maintenez la bobine interne en place et remettez le

bouton de butée en le tournant dans le sens des

aiguilles d’une montre. Serrez bien.

ENTRETIEN DU FILTRE À AIR

Démontage du carter du filtre à air/pot d’échappement

1. Placez le levier du starter en position intermédiaire (2).

REMARQUE : Le levier du starter doit être en position

intermédiaire (2) (Fig. 19) pour que le carter du filtre à

air/pot d’échappement puisse être enlevé.

2. Enlevez les quatre (4) vis retenant le carter du filtre à

air/pot d’échappement (Fig. 19). Utilisez un tournevis

à lame plate ou à embout Torx n°T20.

3. Enlevez le carter du moteur. Ne forcez pas.

Nettoyage du filtre à air

Nettoyez et lubrifiez le filtre à air après dix heures de

fonctionnement. Il est important de bien entretenir ce

composant. Si vous n’assurez pas l’entretien du filtre à

air, la garantie sera ANNULEE.

1. Enlevez le carter du filtre à air/pot d’échappement.

Reportez-vous à la section «Démontage du carter du

filtre à air/pot d’échappement».

2. Retirez le filtre à air de l’intérieur du couvercle du filtre

à air/silencieux (Fig. 20).

3. Lavez le filtre avec un détergent et de l’eau (Fig. 21).

Rincez-le consciencieusement. Egouttez-le. Laissez-le

sécher complètement.

Page 28

28

4. Appliquez suffisamment d’huile propre pour enduire

légèrement le filtre (Fig. 22).

5. Pressez le filtre afin d’étaler l’huile et d’éliminer

l’excès d’huile.

6. Replacez le filtre à air à l'intérieur du couvercle du

filtre à air/silencieux (Fig. 20).

REMARQUE : L’utilisation de l’appareil sans filtre à air et

carter de filtre à air/pot d’échappement entraînera

l’ANNULATION de la garantie.

Remise en place du carter du filtre à air/pot

d’échappement

1. Placez le carter du filtre à air/pot d’échappement sur

l’arrière du carburateur et du pot d’échappement.

REMARQUE : Le levier du starter doit être en position

intermédiaire (2) (Fig. 19) pour que le carter du filtre à

air/pot d’échappement puisse être remis en place.

2. Insérez les quatre (4) vis dans les orifices du carter du

filtre à air/pot d’échappement (Fig. 19) et serrez-les.

Utilisez un tournevis à lame plate ou à embout Torx

n°T20. Ne serrez pas trop. Ne forcez pas.

Vérification du mélange de carburant

L’utilisation d’un carburant vieux ou incorrectement

mélangé est la principale cause d’un mauvais

fonctionnement de l’appareil. Vidangez le réservoir et

remplissez-le de carburant neuf convenablement mélangé

avant de procéder à un quelconque réglage.

Nettoyage du filtre à air

L’état du filtre à air joue un rôle essentiel sur le

fonctionnement de l’appareil. Un filtre à air encrassé

entrave la circulation de l’air et modifie le mélange

air/carburant. Les effets produits sont souvent attribués

par erreur à un mauvais réglage du carburateur. Vérifiez

l’état du filtre à air avant de régler le ralenti. Reportezvous à la section «Entretien du filtre à air».

Réglage du ralenti

Si, après vérification du mélange de carburant et

nettoyage du filtre à air, le ralenti n’est toujours pas

convenable, réglez-le de la manière suivante :

1. Démarrez le moteur et laissez-le tourner à haut régime

(à pleins gaz) pendant 2 à 3 minutes pour se réchauffer.

2. Relâchez la gâchette d’accélération et laissez le

moteur au ralenti. S’il s’arrête, insérez un petit

tournevis cruciforme ou à lame plate dans l’orifice du

carter du filtre à air/pot d’échappement (Fig. 23).

Tournez la vis de réglage du ralenti d’un huitième de

tour à la fois (selon les besoins), dans le sens des

aiguilles d’une montre, jusqu’à ce que le moteur

tienne le ralenti. Reportez-vous aux indications

concernant le nombre de tours/minutes au ralenti.

REMARQUE : L'appareil n'est pas muni d'un

accouplement et, lorsque le moteur tourne à vide, la

bobine de fil continue de tourner.

3. Pour réduire la vitesse de ralenti, tournez la vis de

réglage du ralenti d’un huitième de tour à la fois

(selon les besoins), dans le sens inverse des aiguilles

d’une montre.

La vérification du mélange de carburant, le nettoyage du

filtre à air et le réglage du ralenti devraient résoudre la

plupart des problèmes liés au moteur.

Si ce n’est pas le cas et que :

• le ralenti ne fonctionne pas,

• le moteur hésite ou cale à l’accélération,

• le moteur perd de sa puissance,

faites régler le carburateur par un distributeur agréé.

REMPLACEMENT DE LA BOUGIE

Utilisez une bougie Champion RDJ7Y (ou une bougie

équivalente). L’écartement correct est de 0,5 mm.

Vérifiez la bougie après 50 heures de fonctionnement.

1. Arrêtez le moteur et laissez-le refroidir. Retirez le

capuchon de la bougie.

2. Désencrassez la bougie.

3. Remplacez la bougie si elle est fissurée ou

encrassée. Etablissez l’écartement à 0,5 mm.

4. Installez la bougie dans le cylindre. Serrez en

tournant la douille dans le sens des aiguilles d’une

montre. Ne serrez pas trop.

NETTOYAGE

Utilisez une petite brosse pour essuyer l’extérieur de

l’appareil. N’utilisez pas de détergents forts. Les

produits ménagers contenant des huiles aromatiques

comme le pin ou le citron et les solvants comme le

kérosène pourraient endommager la poignée ou le carter

en plastique. Essuyez toute trace d’humidité à l’aide

d’un chiffon sec.

ENTREPOSAGE

• Ne rangez jamais l’appareil avec de l’essence dans le

réservoir dans un endroit où les vapeurs pourraient

entrer en contact avec une étincelle ou une flamme nue.

• Laissez le moteur refroidir avant de ranger l’appareil.

• Rangez l’appareil dans un endroit sec, fermé à clé ou

en hauteur afin d’empêcher une utilisation non

autorisée ou un endommagement. Tenez-le hors de

portée des enfants.

ENTREPOSAGE LONGUE DUREE

Si l’appareil est entreposé pendant une longue période,

procédez de la manière suivante :

1. Vidangez tout le carburant du réservoir dans un

conteneur comportant un mélange identique de

carburant pour moteur à deux temps. N’utilisez pas

un carburant qui a été entreposé pendant plus de 60

jours.

2. Démarrez le moteur et laissez-le fonctionner jusqu’à

ce qu’il cale. Cela permet de s’assurer que tout le

carburant a été vidé du carburateur.

3. Laissez le moteur refroidir. Enlevez la bougie et

mettez 30 ml d’huile à moteur haute qualité ou

d’huile pour moteur à deux temps dans le cylindre.

Tirez lentement sur le câble du lanceur afin de

répartir l’huile. Réinstallez la bougie.

REMARQUE : Enlevez la bougie et vidangez toute l’huile

du cylindre avant de redémarrer le coupe-bordure

après la période d’entreposage.

4. Nettoyez bien l’appareil et vérifiez qu’il n’y a pas

d’élément mal serré ou endommagé. Remettez en

état ou remplacez les pièces endommagées et

resserrez les vis, écrous ou boulons si nécessaire.

L’appareil est prêt à être entreposé.

5. Rangez l’appareil dans un endroit sec, fermé à clé ou

en hauteur afin d’empêcher une utilisation non

autorisée ou un endommagement. Tenez-le hors de

portée des enfants.

ENTRETIEN ET RÉPARATIONS

Page 29

29

CAUSE

Contact sur ARRÊT

Réservoir de carburant vide

La poire d'amorçage n'a pas été pressée assez fort

Moteur noyé

Carburant vieux ou mal mélangé

Bougie encrassée

LE MOTEUR REFUSE DE DÉMARRER

LE MOTEUR NE SE MET PAS AU RALENTI

RÉGIME RALENTI FAIBLE

LE MOTEUR MANQUE DE PUISSANCE OU SE CALE DURANT LA COUPE

LA TÊTE DE COUPE NE FAIT PAS AVANCER LE FIL

DÉPANNAGE

SOLUTION

Mettez le contact sur CONTACT

Remplissez le réservoir

Pressez-la complètement et lentement de 10 fois

Suivez la procédure de démarrage, levier d'étrangleur

sur MARCHE

Drainez le réservoir / Ajoutez un mélange de carburant frais

Remplacez ou nettoyez-la

CAUSE

Filtre à air bouché

Carburant vieux ou mal mélangé

Mauvais réglage du carburateur

SOLUTION

Remplacez ou nettoyez-le

Drainez le réservoir / Ajoutez un mélange de carburant frais

Ajustez

CAUSE

Carburant vieux ou mal mélangé

Mauvais réglage du carburateur

SOLUTION

Drainez le réservoir / Ajoutez un mélange de carburant frais

Faites-le régler par un concessionnaire agréé

CAUSE

Tête de coupe engorgée d'herbes

Filtre à air sale

Carburant vieux ou mal mélangé

Mauvais réglage du carburateur

SOLUTION

Arrêtez le moteur et nettoyez l'accessoire de coupe

Remplacez ou nettoyez-le

Drainez le réservoir / Ajoutez un mélange de carburant frais

Faites-le régler par un concessionnaire agréé

CAUSE

Tête de coupe engorgée d'herbes

Filtre à air sale

Carburant vieux ou mal mélangé

Mauvais réglage du carburateur

SOLUTION

Arrêtez le moteur et nettoyez l'accessoire de coupe

Remplacez ou nettoyez-le

Drainez le réservoir / Ajoutez un mélange de carburant frais

Faites-le régler par un concessionnaire agréé

Si vous avez besoin d'aide, contactez votre concessionnaire agréé.

Toutes les informations, illustrations et spécifications contenues dans ce manuel tiennent compte des dernières

informations techniques disponibles au moment de mettre sous presse.Nous nous réservons le droit de les modifier à

tout moment, sans préavis.

Page 30

30

CARACTÉRISTIQUES

MOTEUR

Type de moteur......................................................................................................................... Deux temps Refroidi par air

Type d’allumage................................................................................................................................................ Electronique

Cylindrée....................................................................................................................................................... 31 cc (1,9 po3)

Puissance maximale du moteur conforme à la norme ISO 8893.................................................................. 0,75 kW (1 HP)

Régime ralenti .......................................................................................................................................... 3200 min-1(tr/min)

Régime de fonctionnement...................................................................................................................... 7700 min-1(tr/min)

Carburant..................................................................................................................... Mélange essence/huile (40:1) 2,5 %

Interrupteur..................................................................................................................................... Commutateur à bascule

Starter ................................................................................................................................................... Retour automatique

Capacité du réservoir de carburant ........................................................................................................................... 355 ml

ARBRE D’ENTRAINEMENT ET TETE DE COUPE

Carter de l’arbre d’entraînement..................................................................................................................... Tube en acier