Page 1

OWNEirS OtIIDE

• ASSEMBLY • OPERATION • MAINTENANCE •

LEAF

BLOWERS

Model Series

692 thru 699

Important:

Read Safety Rules

and Instructions Carefully

WARNING: This unit is equipped with an internal combustion engine and should not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order by

the operator.

In the State of California the above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest engine authorized sen/ice

AMERICA

dealer or contact the service department, P.O. Box 368022, Cleveland, Ohio 44136-9722.

IMPORTANT!

Record the exact Model No. and Serial No.

which appear on the frame of your unit in the

space below. You must have these numbers,

along with the .date of purchase, in order to

receive warranty or service.

MODEL NO.

24D-690

SERIAL NO.

FORM NO. 770-8585L

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSON

AL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

▲

▲

BEFORE AHEMPTING TO OPERATE YOUR LIfAF BLOWER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL: ^ HEED ITS WARNING.

Your leaf blower was built to be operated according to the rules for safe operation in this manual. As with

DANGER:

any type of power equipm ent, careiessness or error on the part of the operator can result in serious injury.

This unit is capable of an putating fingers and hands and throwing objects.

SAFE OPERATION PRACTICES

I. GENERAL OPERATION

k 1. Read this owner’s guide carefully in its entinity before

attempting to assemble this machine. Read, undei stand, and

follow all instructions on the machine and in the manual(s)

before operation. Be completely familiar with the controls and

the proper use of the machine before operating it. Keep this

manual in a safe place for future and regular reference and for

ordering replacement parts.

2. Your leaf blower is a powerful tool, not a plaything. Therefore,

exercise extreme caution at all times. Your unit has been

designed to perform one job; to blow leaves. Do nc t use it for

any other purpose.

3. Never allow children under 14 to operate the unit. Children 14

years and older should only operate under close parental

supervision. Only responsible individuals who are ft miliar with

these rules of safe operation should be allowed tn use your

unit.

4. Keep the area of operation clear of all persons, [ articularly

small children and pets. Stop the engine when the; are in the

vicinity of the unit.

5. Always wear safety glasses or safety goggles durinii operation

and while performing an adjustment or repair, to p otect eyes

from debris or foreign objects that may be thiown from

machine.

6. Wear close fitting slacks and shirt. Shirt and slacks that cover

the arms and legs are recommended. Do not wear loose fitting

clothes or jewelry and secure hair so it is abovn shoulder

length. They can be caught in moving parts.

7. Do not operate the unit while under the influence of alcohol or

drugs.

8. Never place your hands or any part of your body Dr clothing

near rotating parts. Keep clear of the discharge op ming at all

times. Never insert your hands, fingers, feet, or an^ other part

of your body or clothing into the discharge or air-irtake open

ings as the rotating impeller inside the housing can Dause seri

ous injury.

9. Never operate unit without directional discharge chute and

plastic impeller guard properly affixed to unit. These devices

shield the operator from accidental contact with tlie rotating

impeller.

10. Keep all guards and safety devices in place and operating prop

erly.

II. Exercise caution when operating blower. Do not allow the dis

charge to point in the direction of by-standers or pets.

12. If your machine should start making an unusual noise or vibra

tion, immediately stop the engine, disconnect the spark plug

wire and move the wire away from the spark plug. Allow the

machine to stop and take the following steps:

• Inspect for damage.

• Repair or replace any damaged parts.

• Check for any loose parts and tighten to assure continued

safe operation.

13. Muffler and engine become hot and can cause a bu n. Do not

touch.

14. Do not allow leaves or other debris to build-up on engine’s

muffler. The debris could ignite and cause afire.

15. Do not operate engine if air cleaner or cover over carburetor

air-intake is removed, except tor adjustment. Removal of such

parts could create a fire hazard.

16. Only use accessories approved for this machine by the manu

facturer. Read, understand, and follow all instructions provid

ed with the approved accessory.

17. Only operate unit in good daylight. Do not operate unit at night

or in dark areas where your vision may be impaired.

18. If situations occur which are not covered by this manual, use

care and good judgment. Contact your dealer for assistance.

II. CHILDREN

‘Tragic accidents can occur if the operator is not alert to the pres

ence of small children. Children are often attracted to the blowing

activity. Never assume that children will remain where you last saw

them.

1. Keep children out of the work area and under the watchful eye

of a responsible adult other than the operator.

2. Be alert and turn the unit off if a child enters the area.

3. Never allow children under the age of 14 to operate the leaf

blower.

III. SERVICE

‘ 1. Use extreme care in handling gasoline and other fuels. They

are extremely flammable and the vapors are explosive.

a. Store fuel and oil in approved containers, away from heat

and open flame, and out of the reach of children.

b. Check and add fuel before starting the engine. Never

remove gas cap or add fuel while the engine is running.

Allow engine to cool at least two minutes before refueling.

c. Replace gasoline cap securely and wipe off any spilled

gasoline before starting the engine as it may cause a fire or

explosion.

d. Extinguish all cigarettes, cigars, pipes and other sources of

ignition.

e. Never refuel unit indoors because flammable vapors will

accumulate in the area.

f. Never store the machine or fuel container inside where

there is an open flame or spark such as a gas hot water

heater, clothes dryer or furnace.

2. Never run your machine in an enclosed area as the exhaust

from the engine contains carbon monoxide, which is an odor

less, tasteless and deadly poisonous gas.

3. To reduce fire hazard, keep engine and muffler free of leaves,

grass, and other debris build-up. Clean up fuel and oil spillage.

Allow unit to cool at least 5 minutes before storing.

4. Before cleaning, repairing, or inspecting, make certain the

impeller and all moving parts have stopped. Disconnect the

spark plug wire and keep wire away from spark plug to prevent

accidental starting. Do not use flammable solutions to clean

air filter.

5. Keep all nuts, bolts, and screws tight to be sure the equipment

is in safe working condition.

Page 3

6. Never tamper with safety devices. Check their proper opera

tion reguiarly.

7. Do not aiter or tamper with the engine’s governor setting. The

governor controls the maximum safe operating speed of the

engine. Over-speeding the engine is dangerous and will cause

damage to the engine and to other moving parts of the machine.

OWNER’S

MANUAL

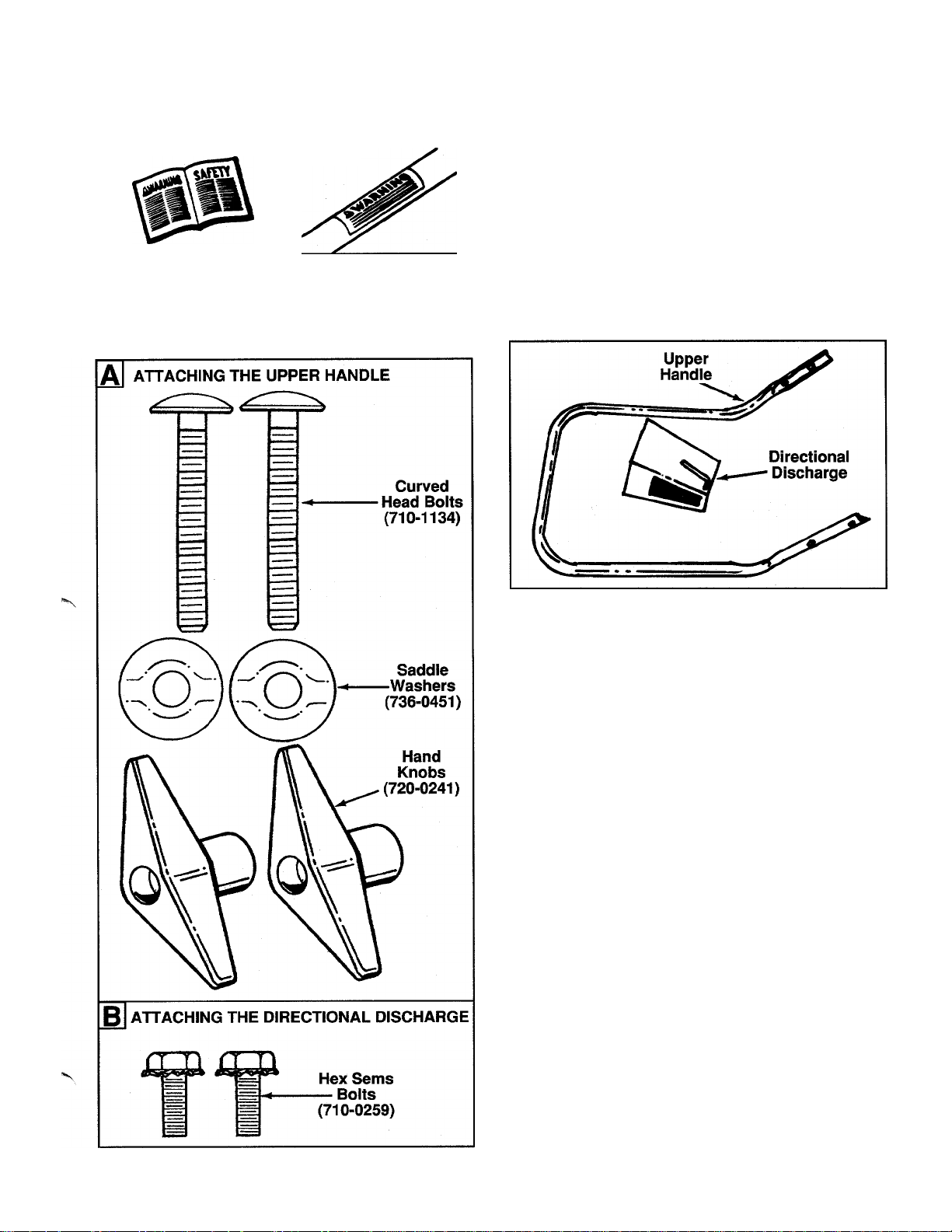

HARDWARE PACK

SAFETY LABEL

CONTENTS OF

▲

Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this

manual and on the machine.

WARNING — YOUR RESPONSIBILITY

LOOSE PARTS IN CARTON

UNPACKING

TO REMOVE UNIT FROM CARTON

1. Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to

open carton.

2. Remove loose parts if included with unit (i.e.,

owner’s manual, etc.)

3. Cut along dotted lines and lay carton down flat.

4. Remove packing material.

5. Roll or slide unit out of carton. Check carton

thoroughly for loose parts.

6. Lay out the contents of hardware pack according

to the illustration at left.

TOOLS REQUIRED FOR ASSEMBLY

(1) 1/2" Open End or Box Wrench

Page 4

FIGURE 1.

ASSEMI3LY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, service engine

with gasoline and oil as instructed in the separate

engine manuai packed with your unit.

NOTE: Reference to right or left hand side of the

leaf blower is observed from behind the unit in the

operating position.

ATTACHING THE UPPER HANDLE (Hardware A)

Place the upper handle over the lower handle, lining

up the holes in the upper handle with the middle

holes in lower handle. Secure with curved head bolts

-and hand knobs. See figure 1.

Directional

Discharge

FIGURE 2.

OPERATION

GAS AND OIL FILL-UP

Service the engine with gas and oil as insti ucted in

the separate engine manual packed with your leaf

blower. Read instructions carefully.

WARNING: Never fill fuel tank i idoors,

with engine running or until the engine

A

TO START ENGINE

A

1. Attach spark plug wire securely to spark plug.

has been aliowed to cooi for at least two

minutes after running.

WARNING: Revolving blades -- keep

hands away from all openings.

AHACHING THE DIRECTIONAL DISCHARGE (Hardware B)

Slip end of directional discharge over chute opening.

-Secure in position with hex sems bolts. See figure 2.

2. Move choke lever on engine to CHOKE position.

(A warm engine may not require choking.)

3. Move throttle control lever on engine to FAST

position.

4. Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

will pull slightly harder at this point). Let the rope

rewind slowiy.

Pull rope with a rapid, continuous, full arm stroke.

5.

Keep a firm grip on starter handle. Let rope

rewind siowiy. Do not let starter handle snap back

against starter.

Repeat instructions 4 and 5 until engine fires.

6.

When engine starts, move choke control gradual

ly to RUN position.

Page 5

TO STOP ENGINE

1. To stop engine, move throttle control lever to OFF

position.

2. Disconnect spark plug wire and ground to prevent

accidental starting while equipment is un

attended.

ADJUSTMENTS

WARNING: Do not at any time make any

adjustment to the unit without first stop

A

TWO-WAY DISCHARGE

The leaf blower can be adjusted to discharge toward

the front of the unit or to the side. Simply push down

on the handle and swing door toward the front to dis

charge out the side, or to the side to discharge out the

front. See figure 3.

ping engine and disconnecting spark

piug wire.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

to the engine while the engine is running

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load.

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

Do not make unnecessary adjustments. Factory set

tings are satisfactory for most applications and condi

tions. If adjustment is needed, refer to the separate

engine manual packed with your leaf blower.

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

MAINTENANCE

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

A

lubricating or performing any repairs or

maintenance.

Directional

Discharge

FIGURE 3.

HEIGHT ADJUSTMENT

The height adjustment crank is located on the right

hand side of the leaf blower. See figure 4. Turn the

crank clockwise to raise the discharge chute. Turn the

crank counterclockwise to lower.

FIGURE 4.

LUBRICATION

Wheels-Rear wheels are provided with light oil bear

ings. Place a few drops of SAE 30 oil on each bearing

once a season.

Directional Discharge-Lubricate the spring and the

pivot point on the door mechanism at least once a

season with light oil.

ENGINE

Refer to the separate engine manual for engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specifications.

Clean the engine regularly with a cloth or brush.

Keep the cooling system (blower housing area) clean

to permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

Page 6

OFF-SEASON STORAGE

The following steps should be taken to prep;

leaf blower for storage.

1. Clean and lubricate the vacuum thoroi

described in the lubrication instructions.

2. Refer to engine manual for correct engine

instructions.

3. If storing in an unventilated or metal

shed, coat metal parts with a light oil or si

prevent rust.

4. Store in a dry, clean area. Do not store

corrosive materials, such as fertilizer.

îre your

ghiy as

storage

storage

icone to

next to

OPTIONAL EQUIPMEIsIT

Hose Attachment Kit Model 290-204-000 is available

as optional equipment. See figure 5.

TROUBLE SHOOTING

PROBLEM

Engine fails to start

POSSIBLE CAUSE(S)

1. Fuel tank empty, or stale fuel.

2. Spark plug wire disconnected.

3. Faulty sparkplug.

CORRECTIVE ACTION

1. Fill tank with clean, fresh fuel.

2. Connect wire to spark plug.

3. Clean, adjust gap or replace.

Loss of power;

operation erratic

Engine overheats

Too much vibration

Unit does not

discharge

tRefer to the engine manual packed with your unit.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service

dealer.

1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel lin 3 (if so

equipped) or stile fuel.

4. Water or dirt in fuel system

5. Carburetor out 3f adjustment.

6. Dirty air cleane ■.

1. Carburetor not adjusted

properly,

2. Engine oil level low.

Loose parts or damaged

crankshaft.

1. Directional discharge clogged.

2. Foreign object edged in air

vane plate asstsmbly.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean fresh

gasoline.

4. Disconnect fuel line at carburetor to drain

fuel tank. Refill with fresh fuei.

5. Adjust carburetor.t

1. Adjust carburetor.t

2. Fill crankcase with proper oii.

Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration

continues, have unit serviced by an

authorized service dealer.

1. Stop engine immediately and disconnect

spark plug wire. Clean directional discharge.

2. Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

Page 7

Page 8

Model No. 692 699

Air Filter Element 491588 33268

Foam Pre-Cleaner

Spark Plug

Engine Oil (SAE 30) 737-0208 (21 oz. req’d.) 737-0208 (26 oz. req’d.)

Hose Kit (Optional) 290-204-000 290-204-000

491435

J19LM

—

J-8C

The only way to ensure the performance of your

product is to use original equipment parts and

accessories, which are designed and engineered to

exacting specifications. When you substitute, you take

a chance on quaiit/, reliability, safety and performance.

Use original equipment parts—See your iocai service

dealer.

For Rep lacement Parts, Contact:

SERVICE DEPARTMENT • P.O BOX 368022 • CLEVELAND, OHIO 44136-9722

Loading...

Loading...