Page 1

OWNHrSGUW

$1.00

• ASSEMBLY

OPERATION • MAINTENANCE •

Made ^

in

AMERICA

WARNING: This unit is equipped with an internai combustion engine and should not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine's exhaust system is equipped with a spark arrester meeting applicable local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order by

the operator.

In the State of California the above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest engine authorized service

dealer or contact the service department, P.O. Box 368022, Cleveland, Ohio 44136-9722.

FORM NO. 770-8584J

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SATETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER

THE PERSONAL SAFETY AND/OR PROPERTY DF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS

A

IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR POWER VACUUM. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— ^ HEED ITS WARNING.

Your power vacuum was built to be operated according to the rules for safe operation in this manuai.

DANGER: As with any type of powi.>r equipment, careiessness or error on the part of the operator can resuit in

A

serious injury. If you viol: ite any of these rules, you may cause serious injury to yourseif or others.

RULES FOR SAFE OPERATION

Read this operating and service instruction manuei carefully.

Be thoroughly familiar with the controls and proper use of the

power vacuum.

Never allow children to operate this power vacuum.

Keep the area of operation clear of all persons, [ articulariy

small children and pets.

Check fuel before starting engine. Do not fill fuel tank indoors,

when engine is running, or while engine is hot. W pe off any

spilled fuel before starting engine.

Do not change engine governor settings.

Do not put hands near rotating parts for any reason.

If the power vacuum should start to vibrate abnormally, stop

the engine and check immediately for the cause. Vibration is

generally a warning of trouble.

Before cleaning, repairing or inspecting, make certa n all mov

ing parts have come to a complete stop. Disconnect spark plug

wire and keep wire away from plug to prevent accid mtal start

ing. Also keep throttle control lever in the stop positi )n.

If the power vacuum should become blocked with dr bris at any

point, shut engine off and wait until the impeller comes to a

complete stop before attempting to remove the obstruction.

Disconnect spark plug wire to prevent accidental stai ting.

10. Check all bolts for tightness at frequent periods.

11. Never store this power vacuum with fuel in the tank. Allow

engine to cool before storing in any enclosure.

12.

Keep bag and equipment free of debris when not in use.

13.

Never operate this power vacuum unless air duct and vacuum

bag are properly affixed in their place. Large zippered end of

bag must be closed when operating to prevent objects from

being blown out.

14.

Never empty vacuum bag when engine is running.

15.

Never change inlet nozzle or auxiliary hose attachment when

engine is running.

16. The manufacturer recommends that the operator wear safety

glasses or some other suitable eye protection when operating

this machine.

17.

Check the vacuum bag frequently for wear and replace when

necessary.

18.

Never operate as a leaf blower unless impeller guard and guard

assembly are properly affixed in their place.

Exercise caution whenever operating as a leaf blower. Do not

19.

allow discharge to be pointed in the direction of persons.

20.

No one should operate this unit while intoxicated or while tak

ing medication that impairs the senses or reactions.

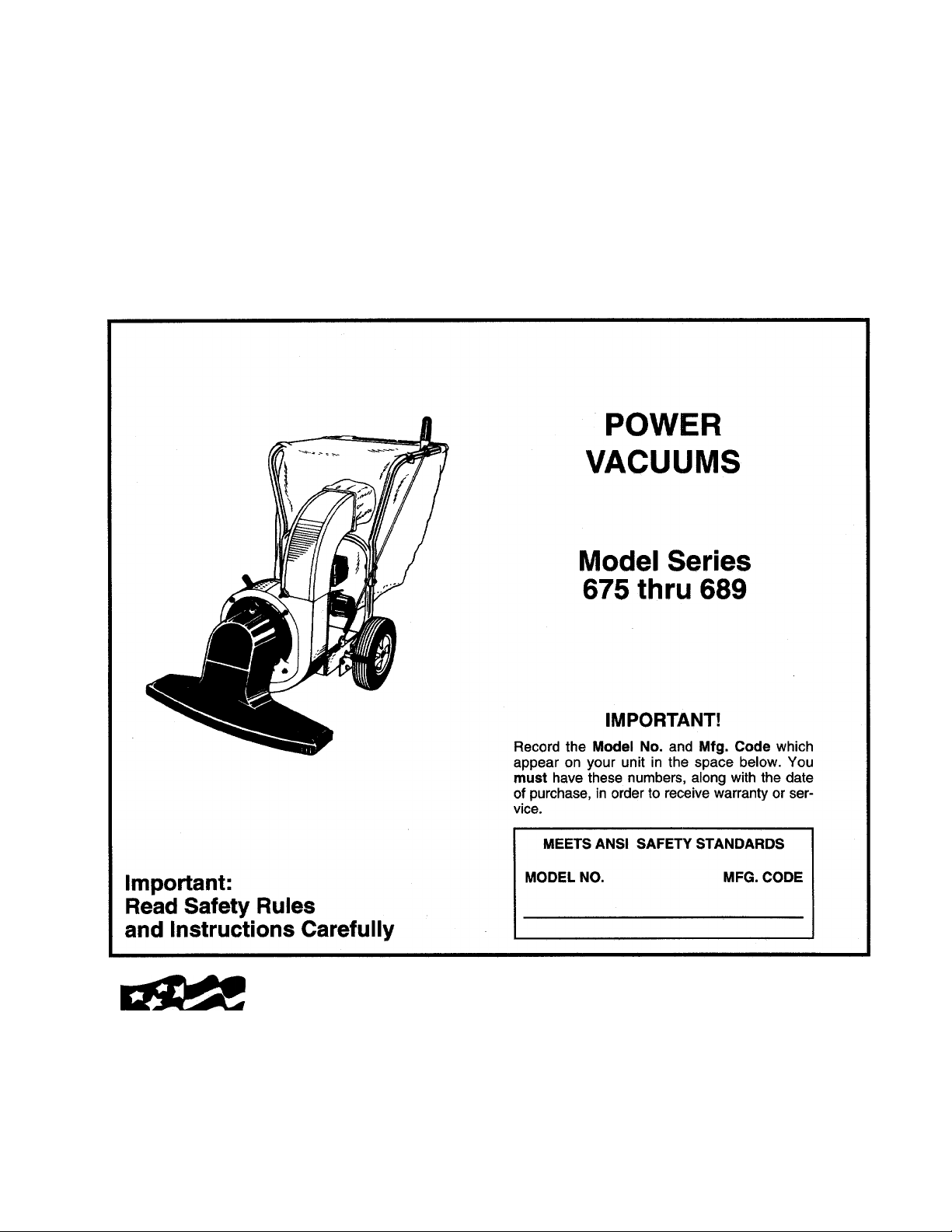

CONTENTS OF HARDWARE PACK

(Hardware pack may contain extra items which are not used on your unit. Quantities of parts and part

numbers are shown in parentheses.)

ATTACHING THE NOZZLE AND

AIR DUCT ASSEMBLY

Hand Knobs

(Qty. 2)

(720-0170)

Cupped

Washers (Qty. 3)

■ (736-0242)

ATTACHING THE

B

UPPER HANDLE

Hex Bolts 1/4-20 X

1-3/4" Long (Qty. 4)

(710-0136)

He c Lock Nuts

1A -20 Thread

(Qty. 4)

(712-0107)

INSTALLING THE BAG

m

t

ATTACHING THE CLUTCH ROD

(Self-Propelled Units Only)

Clutch Grip and Extension^____.

Spring are Not Shown ( )

Clevis Pin

(Qty. 1)

(711-0679)-

Hairpin Clip

(Qty. 1)

(714-0145)

Flat

Washer (Qty. 1)'

(736-0231)

I

I I I I I I I I I I I I I I I

0

INCHES

I

I I I

(E

Stu d Pins (Qty. 2)

(711-0737)

Push-On

S peed Nuts

(Qty. 2)

(1539-019)

Hex Lock

Nut 1/4-20 Thread

(Qty. 1)

(712-0107)

Hex Jam Nut

1/4-20 Thread

(Qty. 1)

(712-0298)

(Thinner Nut)

FIGURE 1.

Page 3

ASSEMBLY INSTRUCTIONS

V IMPORTANT: This unit Is shipped WITHOUT

GASOLINE or OIL. After assembly, service engine

with gasoiine and oii as instructed in the separate

engine manuai packed with your unit.

Upper

Nozzie

Handie^

Air

Duct

Assembiy

Directionai

Discharge

Assembiy

impeiier

Guard

Clutch

_____ Rod

(Self-Propelled

FiGURE 2.-Loose Parts in Carton

Models Only)

H

c—

FIGURE 3.—Optional Tow Bar Kit

Cupped

Washer^

NOTE: Reference to right or left hand side of the

vacuum is observed from behind the unit in the

operating position.

UNPACKING

Remove the vacuum, loose parts, hardware pack and

literature from the carton. Make certain all parts and

literature have been removed before the carton is dis

carded.

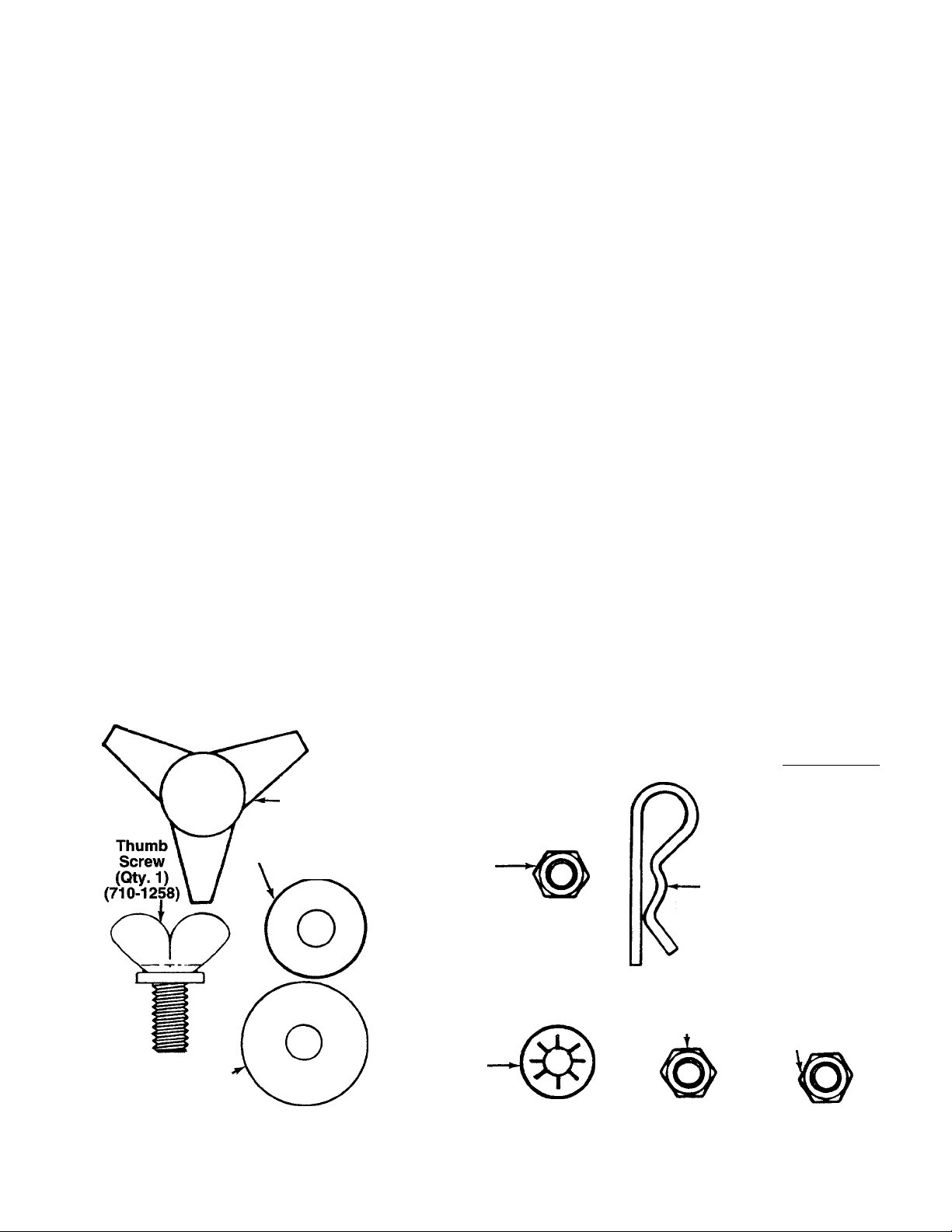

LOOSE PARTS IN CARTON

-{See Figure 2)

(1) Nozzle

(1) Upper Handle

(1) Air Duct Assembly

(1) Clutch Rod (Self-Propelled Models Only)

(1) Directional Discharge Assembly

(1) Impeller Guard

(1) Bag

TOW BAR KIT

Standard for push models, optional for self-pro

pelled models.

-(See Figure 3)

(2) Hex Bolts 5/16-18 x 1" Long

A

(2)

(4) Shoulder Spacers

B

(4)

C

D

E

F

G

H

1

Hex Nut 5/16-18 Thread

(2)

(1) Truss Machine Screw 1/4-20 x 3/4" Long

(1)

Lock Washer 1/4" I.D.

(1)

Hex Nut 1/4-20 Thread

(1)

(1) Shoulder Bolt

(1)

(2) Cupped Washers 3/8" I.D.

(2)

Hex Jam Lock Nut 3/8-16 Thread

(1)

(2) Tow Bar Halves (Not Shown)

(2)

FIGURE 4.

Handle

FiGURE 5.

Nozzle

Upper

Hand

Knob

ATTACHING THE NOZZLE (Hardware A)

Place nozzle in position on front of housing so that it

rests in flanges. Secure with one hand knob and

cupped washer (cupped side of washer against the

-nozzle). See figure 4.

AHACHING THE UPPER HANDLE (Hardware B)

Place the upper handle in position over lower handle.

Fasten with four hex bolts and lock nuts provided.

-See figure 5. Two 7/16" wrenches are required.

Page 4

11

Hand

Knob

FIGURE 6.

Cupped

.Washer

Cup|)ed

Was tier

Thumb

Screw

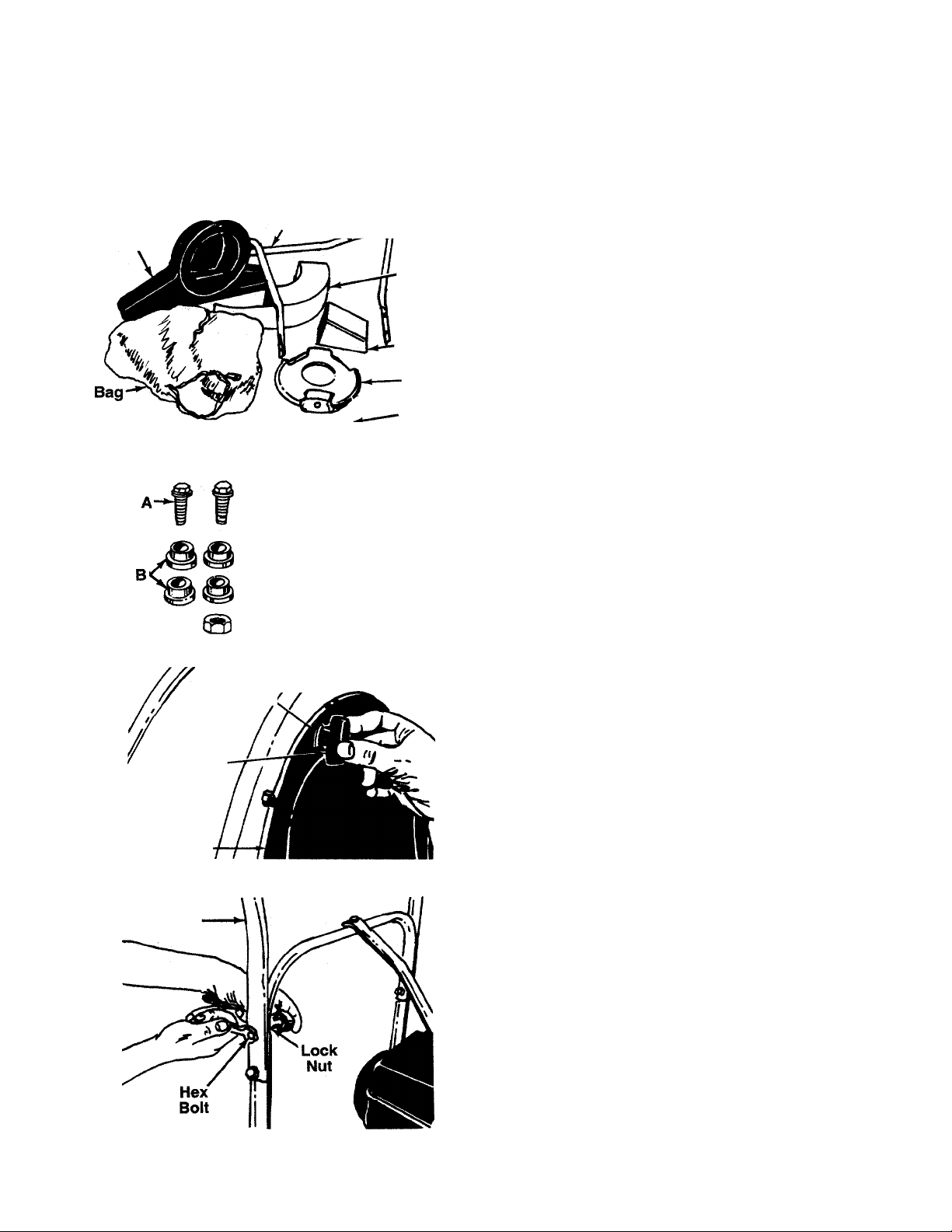

ATTACHING THE AIR DUCT ASSEMBLY (Hardware A)

Place air duct assembly over opening on top ot hous

ing. Secure front of air duct assembly with one flat

washer, cupped washer (cupped side of washer

against flat washer) and a hand knob. Secure back

(close to engine) with one cupped washer (cupped

side against air duct assembly) and thumb screw. See

-figure 6.

FIGURE 7.

Pin

Handle

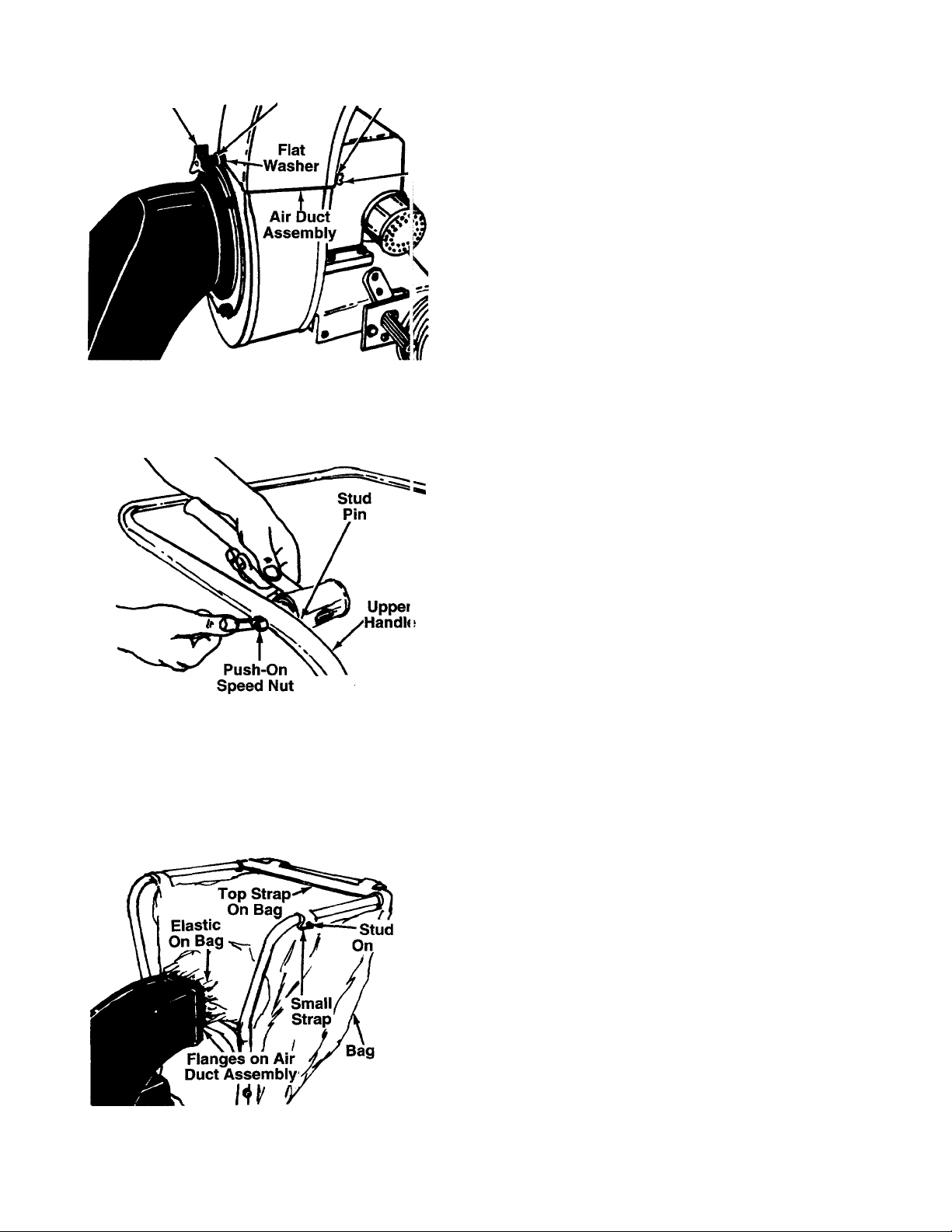

INSTALLING THE BAG (Hardware C)

1. Place the stud pins in holes in upper handle

(head of pins go to the inside of handle). Secure

pins with push-on speed nuts by holding speed

nut with box wrench and tapping pin with ham-

--------

mer. See figure 7.

2. Assemble the bag by slipping the top straps on

bag over upper handle. Hook two small straps

over stud pins on handle. Slip elastic opening of

bag over air duct assembly. Be certain elastic on

bag is placed over the flanges on air duct assem-

— bly. See figure 8.

FIGURE 8.

Page 5

*\

FIGURE 10.

Rod

AHACHING THE CLUTCH ROD (Hardware D)

(Self-Propelled Models Only)

1. Assemble the clutch grip to the left hand side of

upper handle. Secure in place with clevis pin and

---------

hairpin clip. See figure 9. Head of clevis pin

should be to the outside of handle.

2. Slide the extension spring onto clutch rod as

— shown in figure 10. Thread hex lock nut onto

clutch rod approximately 2-1/2 inches.

N

■N

Clutch Bracket

Assembly

FIGURE 11.

FIGURE 12.

Hand

Knob

3. Hook top (hooked end) of clutch rod into upper

hole on clutch grip. See figure 9. Hook spring into

— clutch bracket assembly. See figure 11. Adjust

nut on the clutch rod so that when the clutch grip

is all the way up, there is no slack in the spring.

4. Thread hex jam nut (thinner nut) onto clutch rod,

and lock it against the lock nut.

CONVERTING VACUUM TO A LEAF BLOWER

WARNING: Be sure to stop engine and

A

1. Remove the bag. Remove the air duct assembly

3.

disconnect spark plug wire.

by removing the hand knob, cupped washer and

flat washer from the front of the air duct assem

bly, and the thumb screw and cupped washer

from behind the air duct assembly. Refer to figure

6.

Remove the nozzle by removing one hand knob

and cupped washer. Refer to figure 4.

Remove the hand knob and cupped washer

■which hold the housing to engine brace. See fig

ure 12.

Page 6

Cupp^ Washen

Flat Washer

I I

4. Lift up and out on the housing and rotate it 105°

clockwise. Chute opening should be to the right

hand side when viewed from the front of unit. See

— figure 13.

5. Place the impeller guard into flanges on front of

housing. Line up hole in guard with hole on hous

ing. Secure with one hand knob and cupped

washer (cupped side of washer against the

impeller guard). See figure 13.

Place the directional discharge assembly over

chute opening. Secure with one hand knob,

cupped washer and flat washer, and the thumb

screw and cupped washer. The cupped side of

washer goes against the flat washer. See figure

14.

Hand Knob

FIGURE 14.

Truss

Machine

Hex Nut

(C)

Screw (D),

Hex

Bolt (A)

Shouider

Spacers (B)

Lock

Washer (E) yt ■

FiGURE 15.—Optionai Tow Bar

Direc’ional

Disci large

Assembly

Cupped

Washer (H)

^^Shouider

Nut (F) Bon (Q)

Waiiher (H)

INSTALLATION OF OPTIONAL TOW BAR

1. Remove the self-tapping screws on each side of

frame. Refer to illustration on page 10, reference

number 42.

2. Place one bar half in position on frame of vacu

um. Place one shoulder spacer (B) between

frame and tow bar. Next, place shoulder spacer

(B) and hex bolt (A) through tow bar and frame.

--------

Secure with hex nut (C). See figure 15. Repeat

on other side.

3. Secure the two tow bar ends together with truss

machine screw (D), lock washer (E) and hex nut

(F). See figure 15.

To attach the tow bar to a hitch, place the shoulder

bolt (G) up through the tow bar. Place one cupped

washer (H) on the shoulder bolt, then the hitch plate

Clipped

and the other cupped washer. Cupped side of the

washers must be against the hitch plate. Secure with

hex jam lock nut (I). See figure 15.

OPERATION

BEFORE STARTING ENGINE

Service engine with gas and oil. See engine manual

packed with vacuum for complete instructions for care

and maintenance of engine. Read directions c irefully.

WARNING: Revolving blades -- keep

▲

hands away from all openings.

TO START ENGINE

After the engine has been properly fueled and oiled

(refer to engine operating and maintenance instruc

tions), start engine as follows.

1. Move choke lever on engine to CHOKE position.

(A warm engine may not require choking.)

2. Move throttle control lever on engine to FAST

position.

Page 7

3. Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

N

will pull slightly harder at this point). Let the rope

rewind slowly.

4. Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope

rewind slowly. Do not let starter handle snap back

against starter.

5. Repeat instructions 3 and 4 until engine fires.

When engine starts, move choke control gradual

ly to RUN position.

6. Self-Propelled Models Only—To engage the

drive mechanism, squeeze the clutch grip against

the upper handle. Release the clutch grip to stop

the forward motion.

TO STOP ENGINE

1. To stop engine, move throttle control lever to OFF

position.

2. Disconnect spark plug wire and ground to prevent

accidental starting while equipment is unattended.

IMPORTANT: The vacuum bag may have an air

escape located on the upper right hand side. See

figure 16. The air escape can be opened if the

vacuum is operated in wet, sandy or muddy

conditions.

The bag may be emptied using the large zipper as

shown in figure 16. Be certain the zipper is closed

when operating the unit.

FIGURE 16

ADJUSTMENTS

WARNING: Do not at any time make any

adjustment to the unit without first stop

A

HEIGHT ADJUSTMENT

The height adjustment crank is located on the right

hand side of the vacuum. See figure 17. Turn the

crank clockwise to raise the nozzle. Turn the crank

counterclockwise to lower.

FIGURE 17.

ping engine and disconnecting spark

piug wire.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

to the engine while the engine is running

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load.

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

Do not make unnecessary adjustments. Factory set

tings are satisfactory for most applications and condi

tions. If adjustment is needed, refer to the separate

engine manual packed with your vacuum.

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

CLUTCH ROD ADJUSTMENT

(Self-Propelled Models Only)

To adjust the clutch rod, refer to step numbers 3 and

4 under “Attaching the Clutch Rod” in Assembly

Instructions.

A

MAINTENANCE

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

lubricating or performing any repairs or

maintenance.

LUBRICATION

Wheels—Rear wheels are provided with light oil bear

ings. Place a few drops of SAE 30 oil on each bearing

once a season.

Page 8

Gear Box (Self-Propelled Models Only)—The gear

box is lubricated with 3 ounces of High Tenp. (450°

F.) grease. Order part number 737-0223. Pf riodically

check lubricant level by removing the two se f-tapping

screws on the gear box cover and lifting off t ie cover.

Do not change grease; simply add if necessary.

ENGINE

Refer to the separate engine manual fo' engine

maintenance instructions.

Maintain engine oil as instructed in the ¡separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under noi mal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement i;; recom

mended at the start of each season; chec< engine

manual for correct plug type and gap specific itions.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to

permit proper air circulation which is essential to

engine performance and life. Be certain to re ¡move all

dirt and combustible debris from muffler area

BELT REPLACEMENT (Self-Propelled Models Only)

1. Remove the nozzle or impeller guard from front of

blower housing.

2. Remove hex bolt and lock washer from center of

impeller. See figure 18. A 9/16" socket wrench

with extension is needed.

11

FIGURE 19.

5. Slide belt off the impeller pulley. Slide housing

and impeller off engine crankshaft. Be careful to

not lose square key. See figure 20.

Engine

Crankshaft

P.T.O.

Pulley Square

Key

FIGURE 20.

6. Slide impeller and blower housing assemblies off

crankshaft.

7. Remove belt from P.T.O. pulley and install new

belt. See figure 20.

3.4.Remove hand knob and cupped washer from top

of housing.

Remove two self-tapping screws which hold the

belt guard. See figure 19. A 3/8” wench is

required. Lift off belt guard.

NOTE: When reassembling the new belt, the aid of

another person will be helpful.

8. Turn the crankshaft until the keyway on shaft is

directly on top. While holding housing assembly

and impeller assembly, line up the keyway on the

pulley with the key on the crankshaft, and slide

housing and impeller assemblies onto crankshaft.

9. Secure impeller to crankshaft with hex bolt and

lock washer, removed in step 2. Tighten securely.

10. Slip belt over impeller pulley. Reassemble the

belt guard.

11. Secure blower housing with hand knob and wash

er.

12. Reassembie the nozzle or impeller guard.

Page 9

OFF-SEASON STORAGE

The following steps should be taken to prepare your

N

vacuum for storage.

1. Clean and lubricate the vacuum thoroughly as

described in the lubrication instructions.

2. Refer to engine manual for correct engine storage

instructions.

3. If storing in an unventilated or metal storage

shed, coat metal parts with a light oil or silicone to

prevent rust.

4. Store in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

OPTIONAL EQUIPMENT^

Hose

Attachment

Kit

Hose Attachment Kit Model 290-204-000 is available

as optional equipment. See figure 21.

TROUBLE SHOOTING

PROBLEM

Engine fails to start

Loss of power;

operation erratic

Engine overheats

Too much vibration

POSSIBLE CAUSE(S)

1. Fuel tank empty, or stale fuel.

2. Spark plug wire disconnected.

3. Faulty spark plug.

1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line (if so equipped)

or stale fuel.

4. Water or dirt in fuel system.

5. Carburetor out of adjustment.

6. Dirty air cleaner.

1. Carburetor not adjusted

properly.

2. Engine oil level low.

Loose parts or damaged

crankshaft.

FIGURE 21.

CORRECTIVE ACTION

1. Fill tank with clean, fresh fuel.

2. Connect wire to spark plug.

3. Clean, adjust gap or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean

fresh gasoline.

4. Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

5. Adjust carburetor.f

6. Service air cleaner.t

1. Adjust carburetor.f

2. Fill crankcase with proper oil.

Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration continues,

have unit serviced by an authorized service

dealer.

Unit does not

discharge

tRefer to the engine manual packed with your unit.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service dealer.

1. Directional discharge or

nozzle clogged.

2. Foreign object or dirt lodged in

air vane plate assembly.

3. Vacuum bag is full.

4. Belt worn and/or stretched.

1. Stop engine immediately and disconnect

spark plug wire. Clean directional discharge

or nozzle.

2. Stop engine immediately and disconnect

spark plug wire. Remove lodged object or dirt.

3. Empty bag.

4. Replace belt. See maintenance section of

this manual.

Page 10

11

Page 11

N

Page 12

11

For Replacement Parts, Contact:

SERVICE DEPARTMENT • P.O. BOX 368022 • CLEVELAND, OHIO 44136-9722

Loading...

Loading...