Page 1

TM

MC

OPERATOR’S MANUAL

60-2310-6 / 60-2311-4 / 60-2312-2

FOR QUESTIONS, CALL 1-866-523-5218

IMPORTANT MANUAL DO NOT THROW AWAY

2-Cycle Gas Trimmer / Brushcutter

Page 2

2

INTRODUCTION

Copy the serial number

here:

THANK YOU

Thank you for buying this quality product. This modern

outdoor power tool will provide many hours of useful

service. You will find it to be a great labor-saving device.

This operator’s manual provides you with easy-tounderstand operating instructions. Read the whole

manual and follow all the instructions to keep your new

outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS

AND SPECIFICATIONS

All information, illustrations, and specifications in this

manual are based on the latest product information

available at the time of printing. We reserve the right to

make changes at any time without notice.

Copyright© 2003 MTD SOUTHWEST INC, All Rights

Reserved.

Bump Head™ is a trademark of MTD SOUTHWEST INC.

SplitLine™ is a trademark of MTD SOUTHWEST INC.

SERVICE INFORMATION

Service on this unit both within and after the warranty

period should be performed only by an authorized and

approved service dealer.

For service call 1-866-523-5218 to obtain a listing of

authorized service dealers near you.

DO NOT RETURN THE UNIT TO THE RETAILER.

PROOF OF PURCHASE WILL BE REQUIRED FOR

WARRANTY SERVICE.

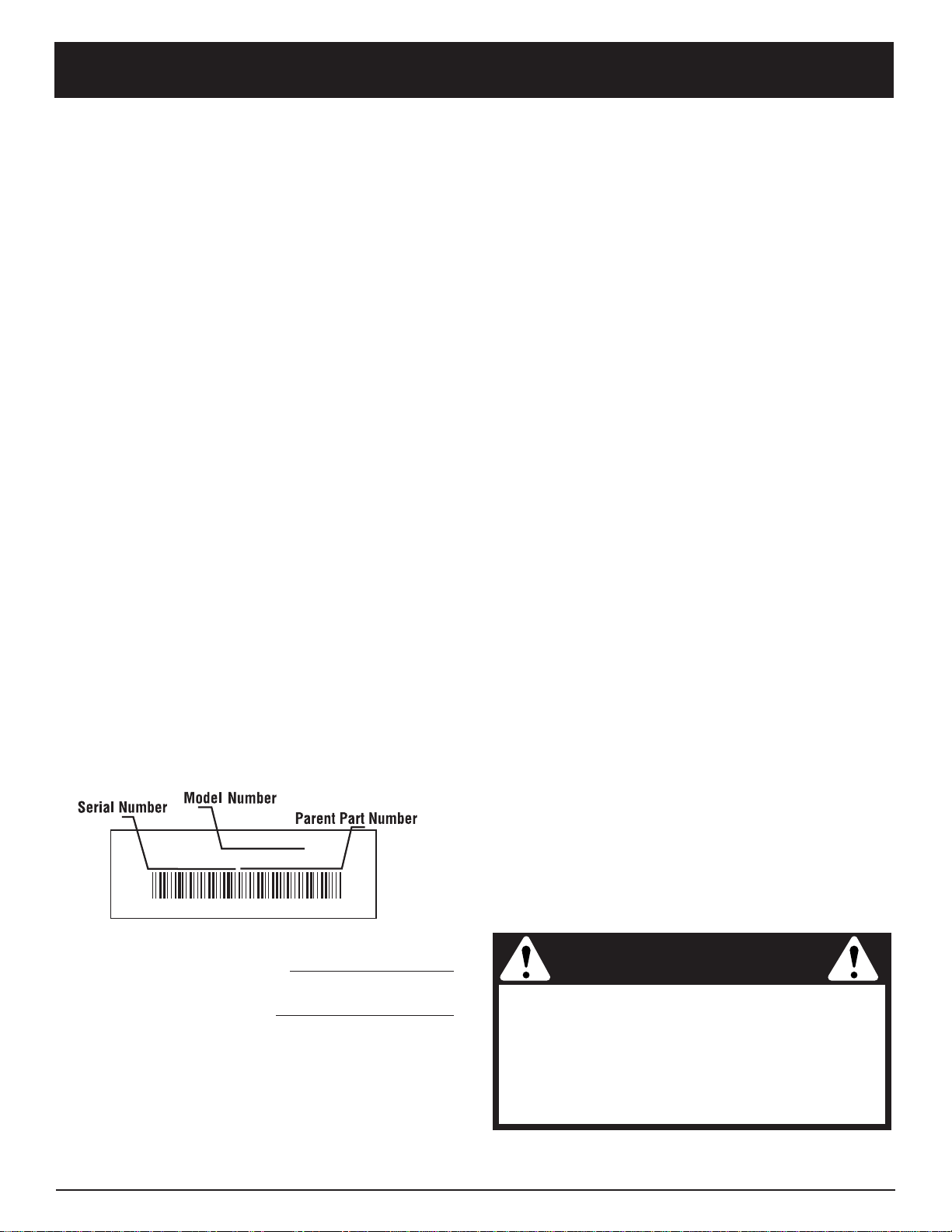

Before beginning, locate the unit’s model plate. It lists

the model and serial numbers of your unit. Refer to the

sample plate below and copy the information for future

reference.

Make sure you carefully read and understand this manual

before starting or operating this equipment.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S.

PATENTS. OTHER PATENTS PENDING.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . .2

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . .3

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . .9

Brushcutter Assembly Instructions . . . . . . . . . . . .10

Oil and Fuel Information . . . . . . . . . . . . . . . . . . . . .12

Starting/Stopping Instructions . . . . . . . . . . . . . . . .13

Operating Instructions . . . . . . . . . . . . . . . . . . . . . .14

Maintenance and Repair Instructions . . . . . . . . . . .17

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . .25

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . .26

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Warranty Information . . . . . . . . . . . . . . . . . . . . . . .30

Parts List . . . . . . . . . . . . . . . . . . . .Inside Back Cover

Copy the model and parent

part number here:

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the

states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public

Resources Codes 4442 and 4443), Oregon and

Washington require, by law that certain internal

combustion engines operated on forest brush and/or

grass-covered areas be equipped with a spark arrestor,

maintained in effective working order, or the engine be

constructed, equipped and maintained for the prevention

of fire. Check with your state or local authorities for

regulations pertaining to these requirements. Failure to

follow these requirements could subject you to liability or

a fine. This unit is factory equipped with a spark

arrestor. If it requires replacement, ask your LOCAL

SERVICE DEALER to install the Accessory Part

#182747 Spark Arrestor Kit.

CALIFORNIA PROPOSITION 65 WARNING

WARNING

THE ENGINE EXHAUST FROM THIS

PRODUCT CONTAINS CHEMICALS

KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER, BIRTH DEFECTS

OR OTHER REPRODUCTIVE HARM.

MODEL :

S/N :

ITEM :

Page 3

3

RULES FOR SAFE OPERATION

READ ALL INSTRUCTIONS

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

• Do not operate this unit when tired, ill, or under the

influence of alcohol, drugs, or medication.

• Children and teens under the age of 15 must not use

the unit, except for teens guided by an adult.

• All guards and safety attachments must be installed

properly before operating the unit.

• Inspect the unit before use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are in

place and secure. Replace parts that are cracked,

chipped, or damaged in any way. Do not operate the

unit with loose or damaged parts.

• Carefully inspect the area before starting the unit.

Remove all debris and hard or sharp objects such as

glass, wire, etc.

• Be aware of the risk of injury to the head, hands and

feet.

• Clear the area of children, bystanders, and pets. At a

minimum, keep all children, bystanders, and pets

outside a 50 feet (15 m.) radius; there still may be a

risk to bystanders from thrown objects. Bystanders

should be encouraged to wear eye protection. If you

are approached, stop the unit immediately.

• Use only 0.095 inch,

2.41 mm (for brushcutter

60-2312-2), or 0.080 inch, 2.03 mm (for trimmers

60-2310-6 & 60-2311-4), diameter original equipment

manufacturer replacement line. Never use metalreinforced line, wire or rope. These can break off and

become dangerous projectiles.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments

or repairs before using unit.

•

Trimmer models 60-2310-6 & 60-2311-4 only:

This unit was not designed to be used as a

brushcutter. Do not attach or operate this unit with any

type of brushcutting blade or brushcutting attachment.

SAFETY WARNINGS FOR GAS UNITS

• Store fuel only in containers specifically designed and

approved for the storage of such materials.

• Avoid creating a source of ignition for spilled fuel. Do

not start the engine until fuel vapors dissipate.

SYMBOL MEANING

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

NOTE: Advises you of information or instructions vital to

the operation or maintenance of the equipment.

SYMBOL MEANING

When using the unit,

you must follow the

safety rules. Please read these instructions

before operating the unit in order to ensure

the safety of the operator and any bystanders.

Please keep these instructions for later use.

WARNING:

• IMPORTANT SAFETY INSTRUCTIONS •

Failure to obey a

safety warning can

result in injury to yourself and others.

Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

WARNING:

Failure to obey a

safety warning will

result in serious injury to yourself or to

others. Always follow the safety precautions

to reduce the risk of fire, electric shock and

personal injury.

DANGER:

Failure to obey a

safety warning may

result in property damage or personal injury

to yourself or to others. Always follow the

safety precautions to reduce the risk of fire,

electric shock and personal injury.

CAUTION:

Indicates

danger,

warning or caution. Attention is required in

order to avoid serious personal injury. May

be used in conjunction with other symbols

or pictographs.

SAFETY ALERT:

Gasoline is highly

flammable, and its

vapors can explode if ignited. Take the

following precautions:

WARNING:

Read the Operator’s Manual(s) and follow all

warnings and safety instructions.

Failure to do so can result in serious injury to the

operator and/or bystanders.

FOR QUESTIONS, CALL 1-866-523-5218

Page 4

4

• Always stop the engine and allow it to cool before

filling the fuel tank. Never remove the fuel tank cap or

add fuel when the engine is hot. Never operate the unit

without the fuel cap securely in place. Loosen the fuel

tank cap slowly to relieve any pressure in the tank.

• Add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. Remove the fuel cap

slowly, and only after the engine stops. Do not smoke

while fueling or mixing fuel. Wipe up any spilled fuel

from the unit immediately.

• Avoid creating a source of ignition for spilled fuel. Do

not start the engine until fuel vapors dissipate.

• Move the unit at least 30 feet (9.1 m) from the fueling

source and site before starting the engine. Do not

smoke. Keep sparks and open flames away from the

area while adding fuel or operating the unit.

WHILE OPERATING

• Never start or run the unit inside a closed room or

building. Breathing exhaust fumes can be fatal.

Operate this unit only in a well-ventilated outdoor area.

• Wear safety glasses or goggles that meet ANSI Z87.1

standards and are marked as such. Wear ear/hearing

protection when operating this unit. Wear a face or

dust mask if the operation is dusty.

• Wear heavy long pants, boots, gloves and a long

sleeve shirt. Do not wear loose clothing, jewelry, short

pants, sandals or go barefoot. Secure hair above

shoulder level.

• The cutting attachment shield must always be in place

while operating the unit as a trimmer. Do not operate

unit without both trimming lines extended, and the

proper line installed. Do not extend the trimming line

beyond the length of the shield.

• This unit has a clutch. The cutting attachment remains

stationary when the engine is idling. If it does not, have

the unit adjusted by an authorized service technician.

• Adjust the J-handle to your size in order to provide the

best grip.

• Be sure the cutting attachment is not in contact with

anything before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position

whenever pulling the starter rope. The operator and

unit must be in a stable position while starting. Refer

to Starting/Stopping Instructions.

• Use the right tool. Only use this tool for its intended

purpose.

• Do not overreach. Always keep proper footing and

balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on both handles or grips.

• Keep hands, face, and feet at a distance from all

moving parts. Do not touch or try to stop the cutting

attachment when it rotates.

• Do not touch the engine, gear housing or muffler.

These parts get extremely hot from operation, even

after the unit is turned off.

• Do not operate the engine faster than the speed

needed to cut, trim or edge. Do not run the engine at

high speed when not cutting.

• Always stop the engine when cutting is delayed or

when walking from one cutting location to another.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do

not operate the unit with loose or damaged parts.

• Stop the unit, switch the engine to off, and disconnect

the spark plug for maintenance or repair.

• Use only original equipment manufacturer replacement

parts and accessories for this unit. These are available

from your authorized service dealer. Use of any

unauthorized parts or accessories could lead to

serious injury to the user, or damage to the unit, and

void your warranty.

• Keep unit clean of vegetation and other materials.

They may become lodged between the cutting

attachment and shield.

• To reduce fire hazard, replace a faulty muffler and

spark arrestor. Keep the engine and muffler free from

grass, leaves, excessive grease or carbon build up.

BRUSHCUTTER 60-2312-2 ONLY:

WHILE OPERATING WITH CUTTING BLADE

• Read and understand all safety warnings before

operating this unit.

• Always use the shoulder harness when using the

brush blade accessory.

• Keep the J-handle between the operator and cutting

attachment or blade at all times.

• NEVER cut when the cutting blade is 30 inches

(76 cm) or more above the ground level.

• Blade thrust may occur when the spinning blade

contacts an object that it does not immediately cut.

Blade thrust can be violent enough to propel the unit

and/or operator in any direction, possibly causing a

loss of control. Blade thrust can occur without warning

if the blade snags, stalls or binds. This is more likely to

occur in areas where it is difficult to see the material

being cut.

• For operation with the brush blade, do not cut

anything thicker than 1/2 inch or a violent kickback

could occur.

RULES FOR SAFE OPERATION

Page 5

5

• Do not attempt to touch or stop the blade when it is

rotating.

•A coasting blade can cause injury while it continues to

spin after the engine is stopped or the throttle trigger

is released. Maintain proper control until the blade has

completely stopped rotating.

• Do not run the unit at high speed when not cutting.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Have any damage repaired before attempting

further operations. Do not operate unit with a bent,

cracked or dull blade. Discard blades that are bent,

warped, cracked or broken.

• Do not sharpen the cutting blade. Sharpening the blade

can cause the blade tip to break off while in use. This

can result in severe personal injury. Replace the blade.

• Do not use the cutting blade for edging or as an edger;

severe personal injury to yourself or others may incur.

Use the cutting blade only for the purpose described

in this manual.

• Stop the engine IMMEDIATELY if you feel excessive

vibration. Vibration is a sign of trouble. Inspect

thoroughly for loose nuts, bolts or damage before

continuing. Repair or replace affected parts as

necessary.

RULES FOR SAFE OPERATION

After Use

• Clean cutting blades with a household cleaner to

remove any gum buildup. Oil the blade with machine

oil to prevent rust.

• Lock up and store the cutting blade in an appropriate

area to protect the blade from unauthorized use or

damage.

OTHER SAFETY WARNINGS

• Never store a fueled unit inside a building where fumes

may reach an open flame or spark.

• Allow the engine to cool before storing or transporting.

Be sure to secure the unit while transporting.

• Store the unit in a dry area, locked up or up high to

prevent unauthorized use or damage, out of the reach

of children.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use, see Cleaning and Storage

instructions.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

SAVE THESE

INSTRUCTIONS

Page 6

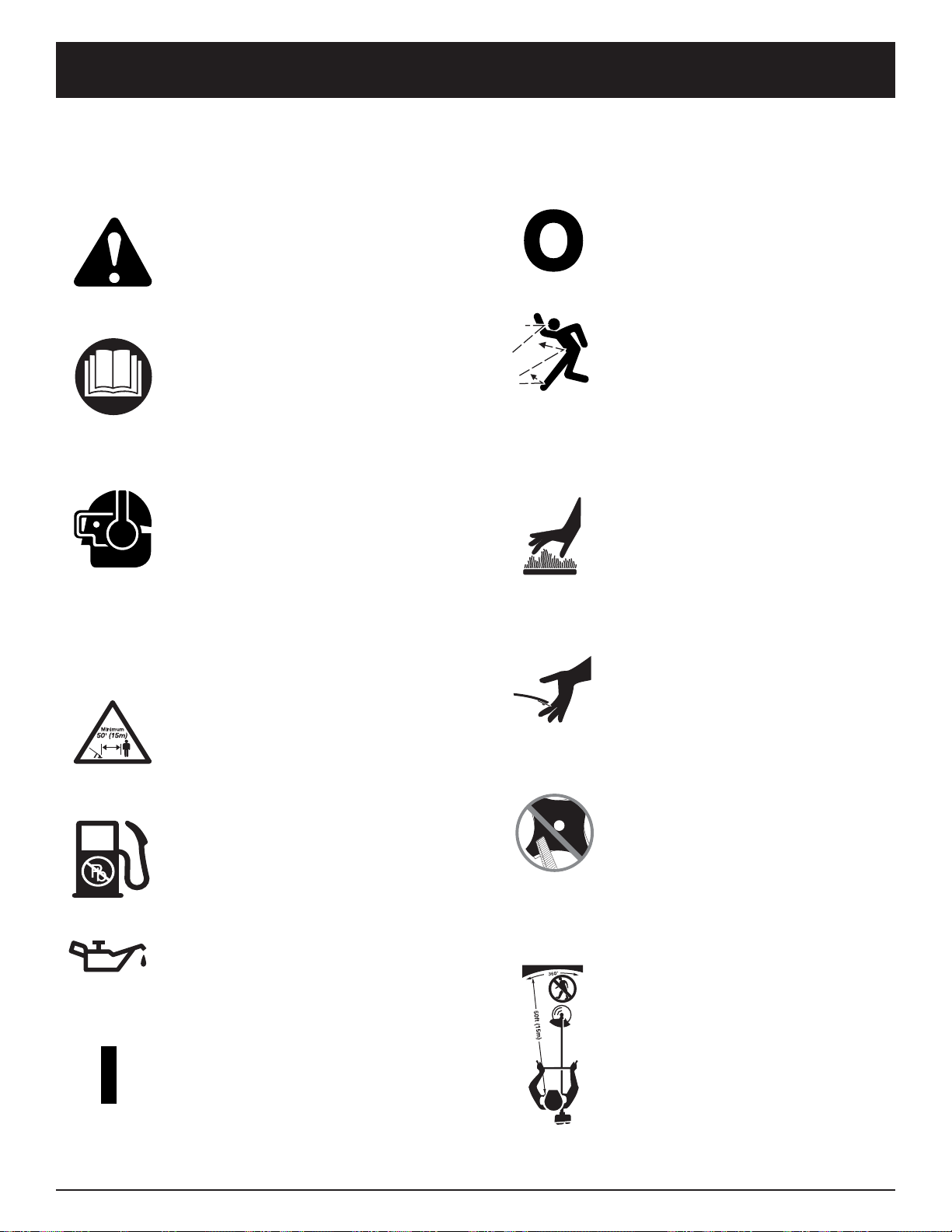

SYMBOL MEANING

• ON/OFF STOP CONTROL

OFF or STOP

• THROWN OBJECTS AND

ROTATING CUTTER CAN CAUSE

SEVERE INJURY

WARNING:Do not

operate without the cutting

attachment shield in place.

Keep away from the rotating cutting

attachment.

• HOT SURFACE WARNING

Do not touch a hot muffler, gear housing

or cylinder. You may get burned. These

parts get extremely hot from operation.

They remain hot for a short time after the

unit is turned off.

• SHARP BLADE

WARNING:Sharp blade

on cutting attachment shield. To

prevent serious injury, do not touch

line cutting blade.

• Brushcutter ONLY:

REPLACE DULL BLADE

Do not sharpen the cutting blade.

Sharpening the blade can cause the

blade tip to break off while in use. This

can result in severe personal injury.

• Brushcutter ONLY: TRIMMER/

BRUSHCUTTER SAFETY

WARNING:Thrown

objects and rotating cutter can cause

severe injury. Keep bystanders,

especially children and pets, at least

50 feet (15 m) away from the cutting

area. The cutting attachment shield

must be used when using the trimmer

cutting attachment.

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or

caution. May be used in conjunction

with other symbols or pictographs.

•WARNING - READ

OPERATOR'S MANUAL

Read the operator’s manual(s) and

follow all warnings and safety

instructions. Failure to do so can result

in serious injury to the operator and/or

bystanders.

• WEAR EYE AND HEARING

PROTECTION

WARNING:Thrown

objects and loud noise can cause

severe eye injury and hearing loss.

Wear eye protection meeting ANSI

Z87.1 standards and ear protection

when operating this unit. Use a full

face shield when needed.

•KEEP BYSTANDERS AWAY

WARNING:Keep all

bystanders, especially children and

pets, at least 50 feet (15 m) from the

operating area.

• UNLEADED FUEL

Always use clean, fresh unleaded

fuel.

• OIL

Refer to operator's manual for the

proper type of oil.

•ON/OFF STOP CONTROL

ON / START / RUN

6

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

RULES FOR SAFE OPERATION

Page 7

7

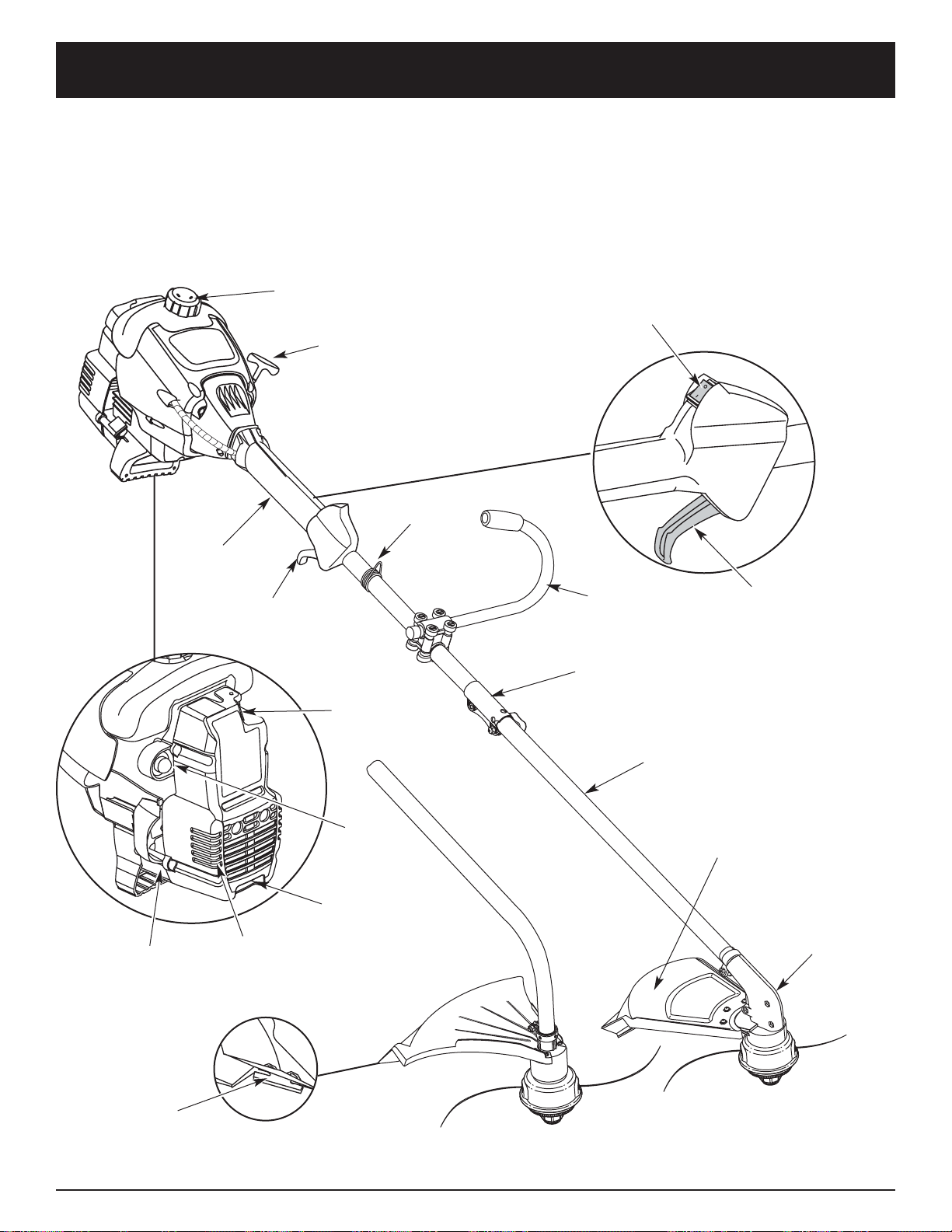

KNOW YOUR UNIT

APPLICATIONS

As a trimmer:

• Cutting grass and light weeds

• Edging

• Decorative trimming around trees, fences, etc.

Other optional accessories may be used with these units.

Refer to Operating the EZ-Link System for a list of add-ons.

Cutting

Attachment

Shield

Fuel Cap

Throttle

Control

J-Handle

60-2311-4 Cutting

Attachment

Gear Housing

Shaft Grip

Primer

Bulb

Air Filter/Muffler

Cover

Spark Plug

On/Off Stop Control

Shaft

Housing

Starter Rope

Grip

Line Cutting

Blade

Muffler

Support Fitting

Throttle Control

EZ-Link™

EZ-Start

Lever

60-2310-6 Cutting

Attachment

TRIMMER MODELS 60-2310-6 & 60-2311-4 ONL Y (Model 60-2312-2 is on the next page)

Page 8

8

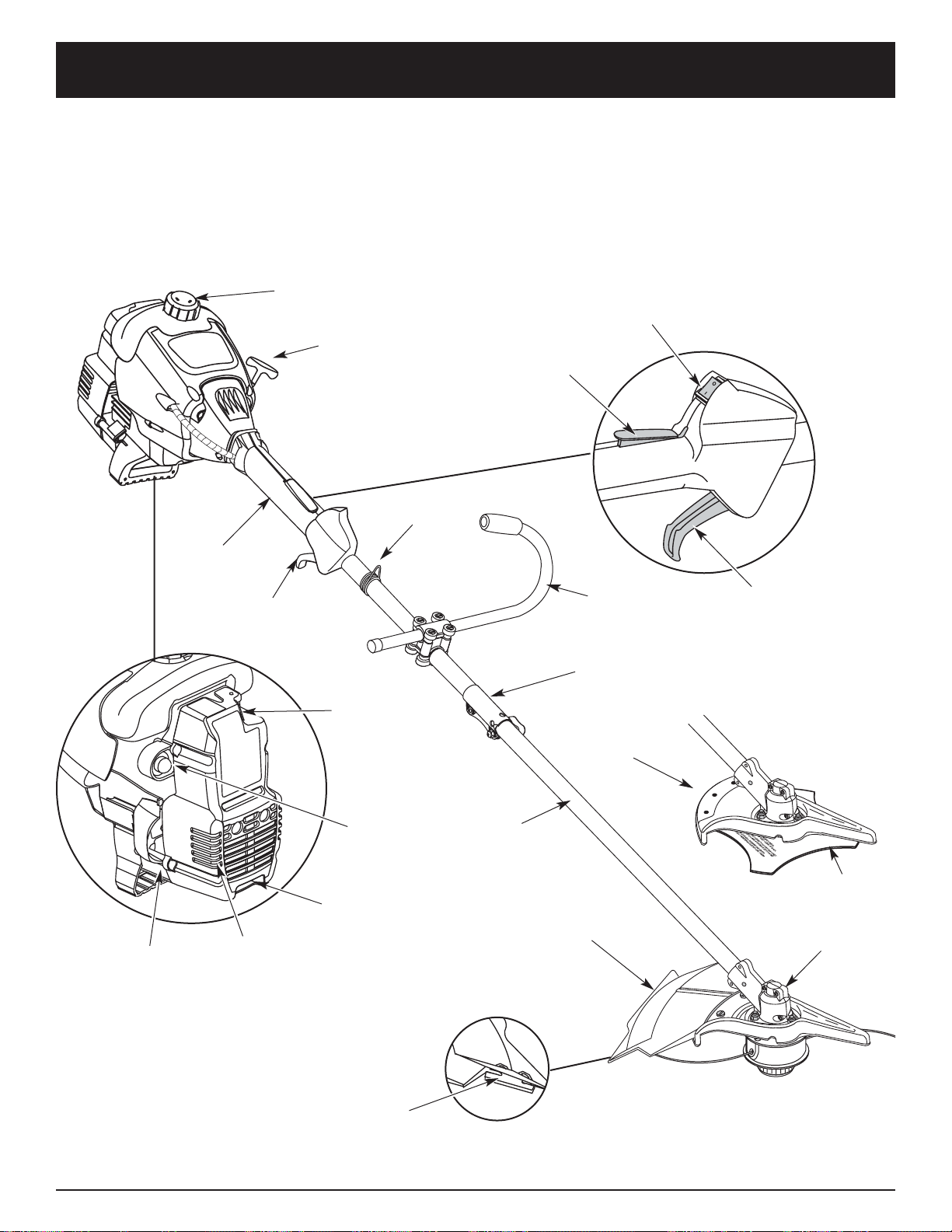

KNOW YOUR UNIT

APPLICATIONS

As a trimmer:

• Cutting grass and light weeds

• Edging

• Decorative trimming around trees, fences, etc.

As a brushcutter:

• Cutting weeds and light bush of up to 1/2 inch in

diameter

Other optional accessories may be used with this unit.

Refer to Operating the EZ-Link System for a list of add-ons.

Cutting

Attachment

Shield

Fuel Cap

Throttle

Control

J-Handle

Cutting Attachment

Gear Housing

Shaft Grip

Primer Bulb

Air Filter/Muffler

Cover

Spark Plug

On/Off Stop Control

Shaft

Housing

Starter Rope

Grip

Blade Shield /

Shield Mount

Cutting Blade

Line Cutting

Blade

Muffler

Support Fitting

Throttle Lock-Out

Throttle Control

EZ-Link™

EZ-Start

Lever

BRUSHCUTTER MODEL

60-2312-2 ONLY

Page 9

9

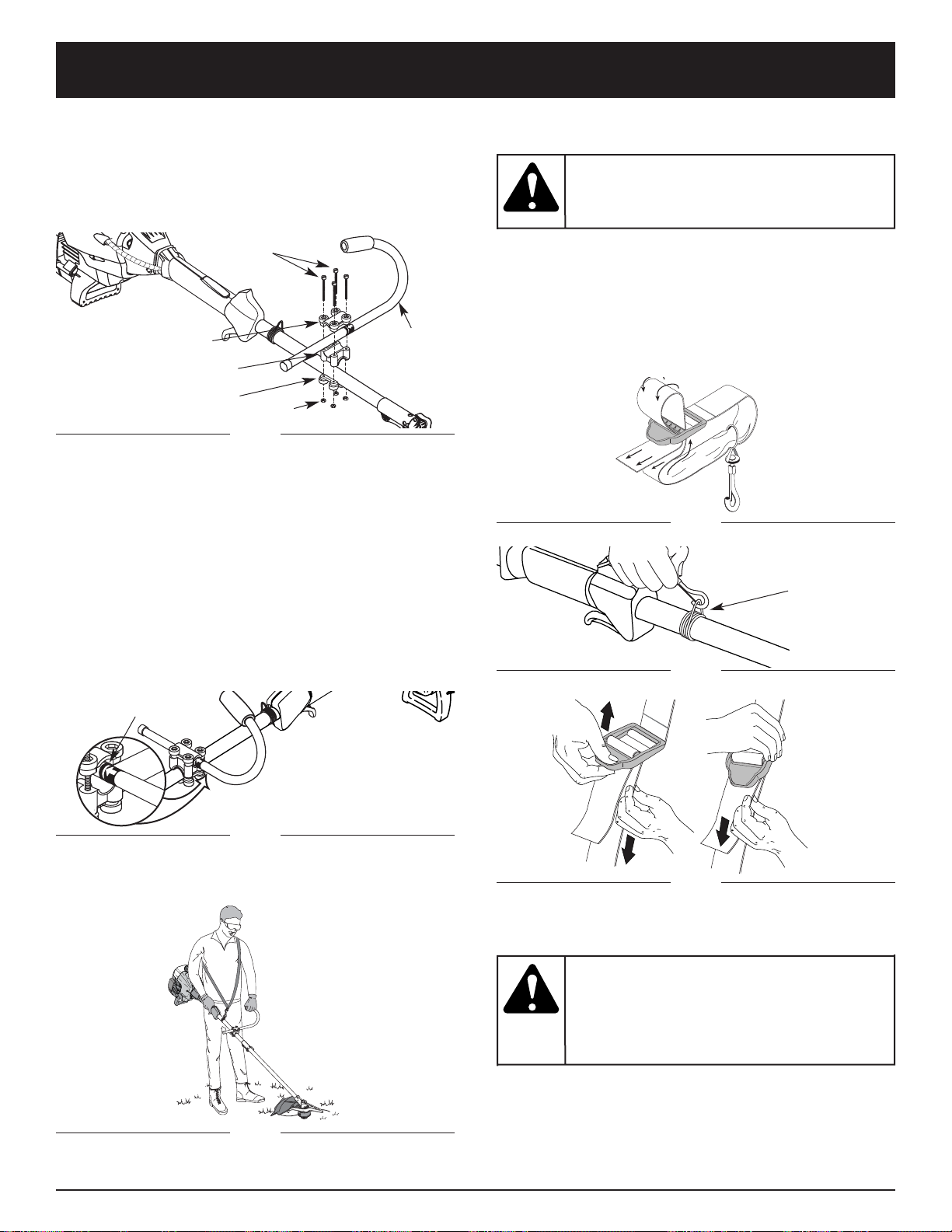

ASSEMBLY INSTRUCTIONS

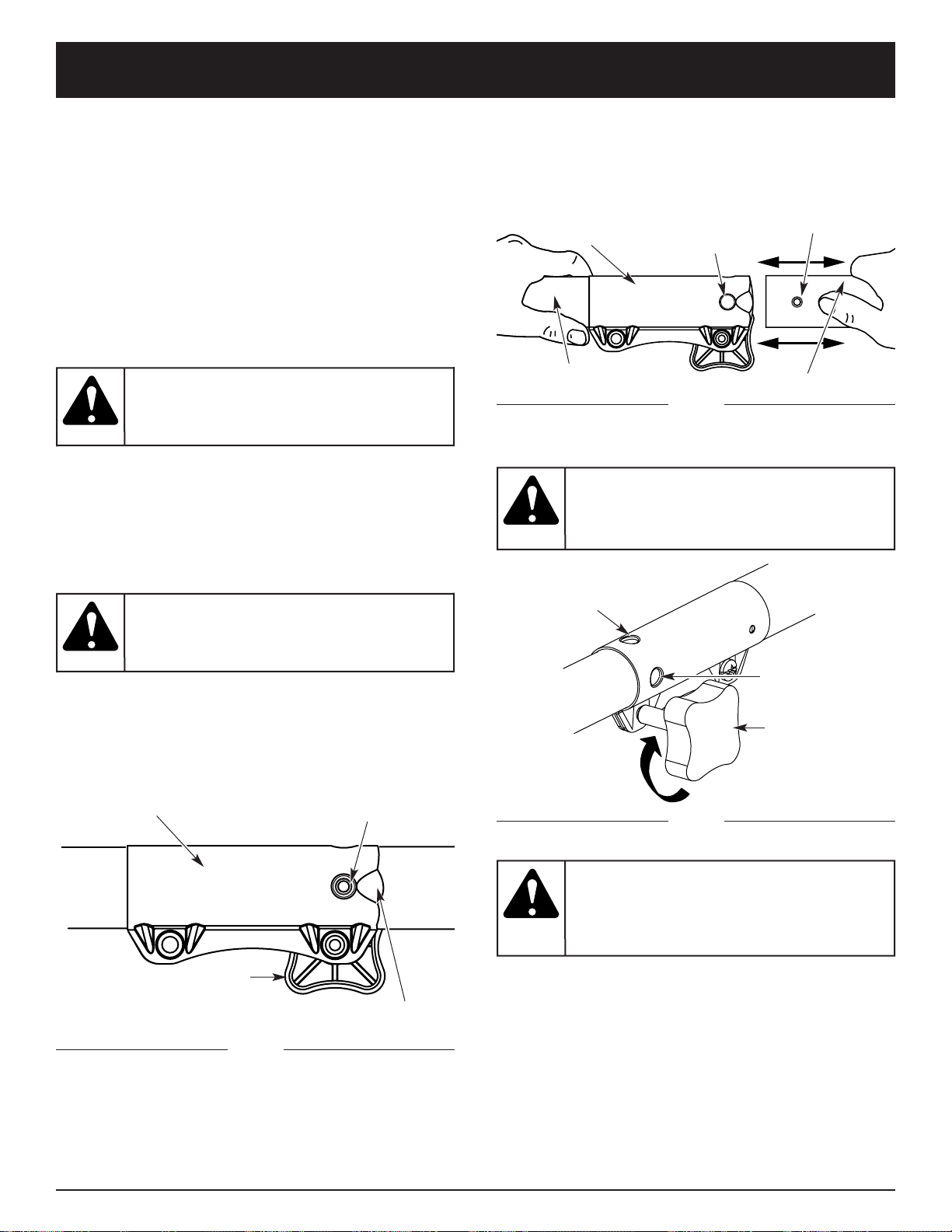

On some units, the J-handle may be pre-installed. In this

case you must loosen screws and adjust the handle to fit

the operator. Go to step 5 if the J-handle is pre-installed.

INSTALL AND ADJUST THE J-HANDLE

1. Place the J-handle between the top and middle

clamp pieces (Fig. 1).

(4) Screws

Top Clamp

J-Handle

Middle Clamp

Bottom Clamp

Nuts

2. While holding the three pieces together, install the four

(4) screws through the top clamp and into middle clamp.

NOTE: The holes in the top and middle clamp will line up

only when assembled correctly.

3. Place the clamps and the J-handle over the shaft

housing and onto the bottom clamp.

4. Hold each hex nut in the bottom clamp recess with a

finger. Start screws with a large Phillips screwdriver.

Do not tighten until you make the handle adjustment.

5. Slide the J-handle in or out until the arrow/white line on

the decal touches the clamp assembly (Fig. 2). You must

first loosen the screws if the handle is pre-installed.

Fig. 1

Fig. 2

Fig. 3

6. While holding the unit in the operating position (Fig. 3),

position the J-handle to the location that provides you

the best grip.

7. Tighten the clamp screws evenly, until the J-handle

is secure.

Decal

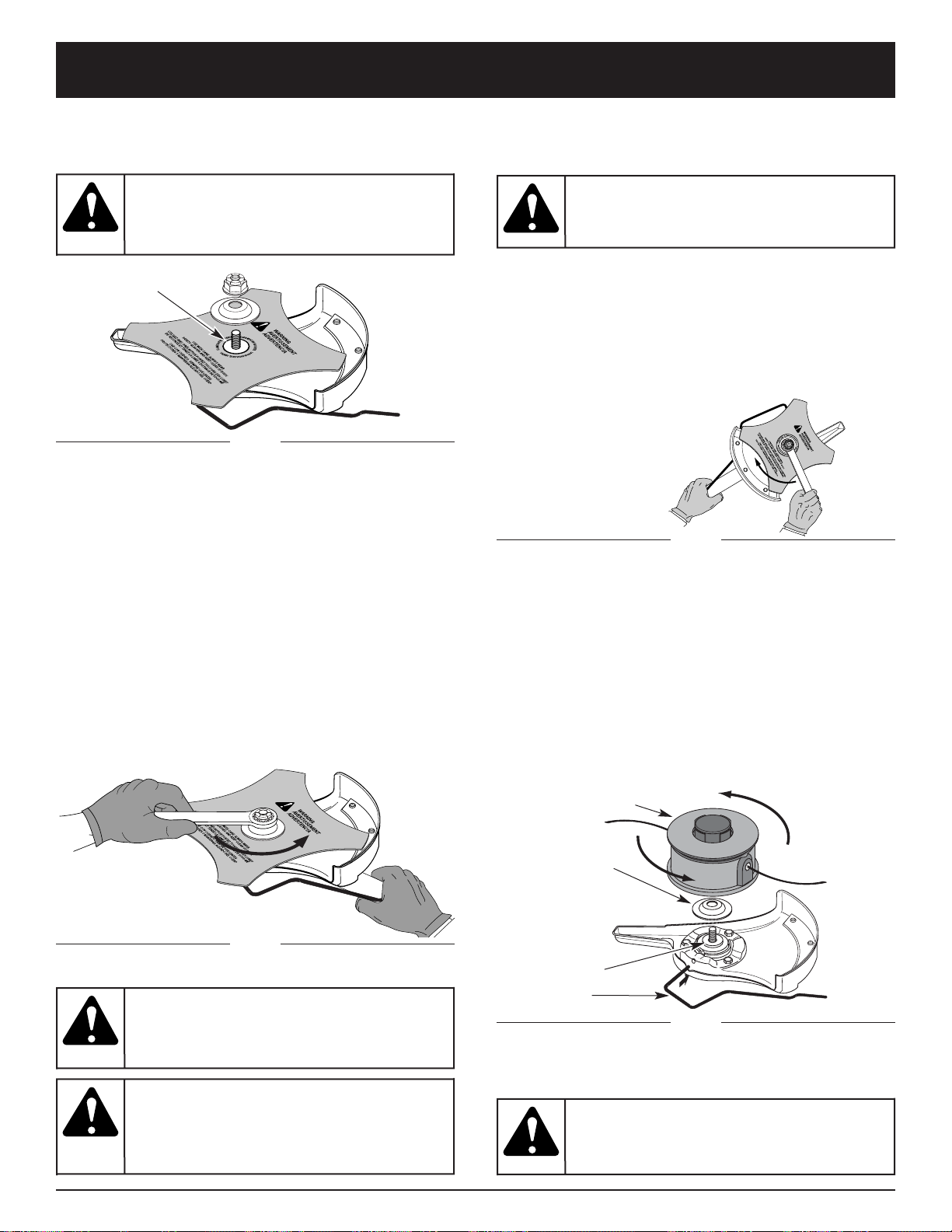

BRUSHCUTTER ONLY:INSTALL THE

HARNESS

1. Push the strap through the center of the buckle.

2. Pull the strap over the cross bar and down through

the slot in the buckle (Fig. 4).

3. Put the harness on over head and onto shoulder.

Snap it on to the support fitting (Fig. 5).

4. Adjust length to fit the operator’s size. Pull tab to

lengthen, pull strap to shorten (Fig 6).

Support Fitting

Fig. 4

Fig. 5

Fig. 6

BRUSHCUTTER ONLY: REMOVE AND

INST ALL THE CUTTING ATTACHMENT SHIELD

Remove the cutting attachment shield when

using the unit as a brushcutter

Remove the cutting attachment shield from the shield

mount by removing the three (3) screws with a flat blade

screwdriver (Fig. 7). Store parts for future use.

The cutting

attachment shield

should NOT be installed when operating the

unit with a blade. Remove the cutting

attachment shield before removing or

installing the blade.

WARNING:

Always use the

shoulder harness

when using the cutting blade to avoid

serious personal injury.

WARNING:

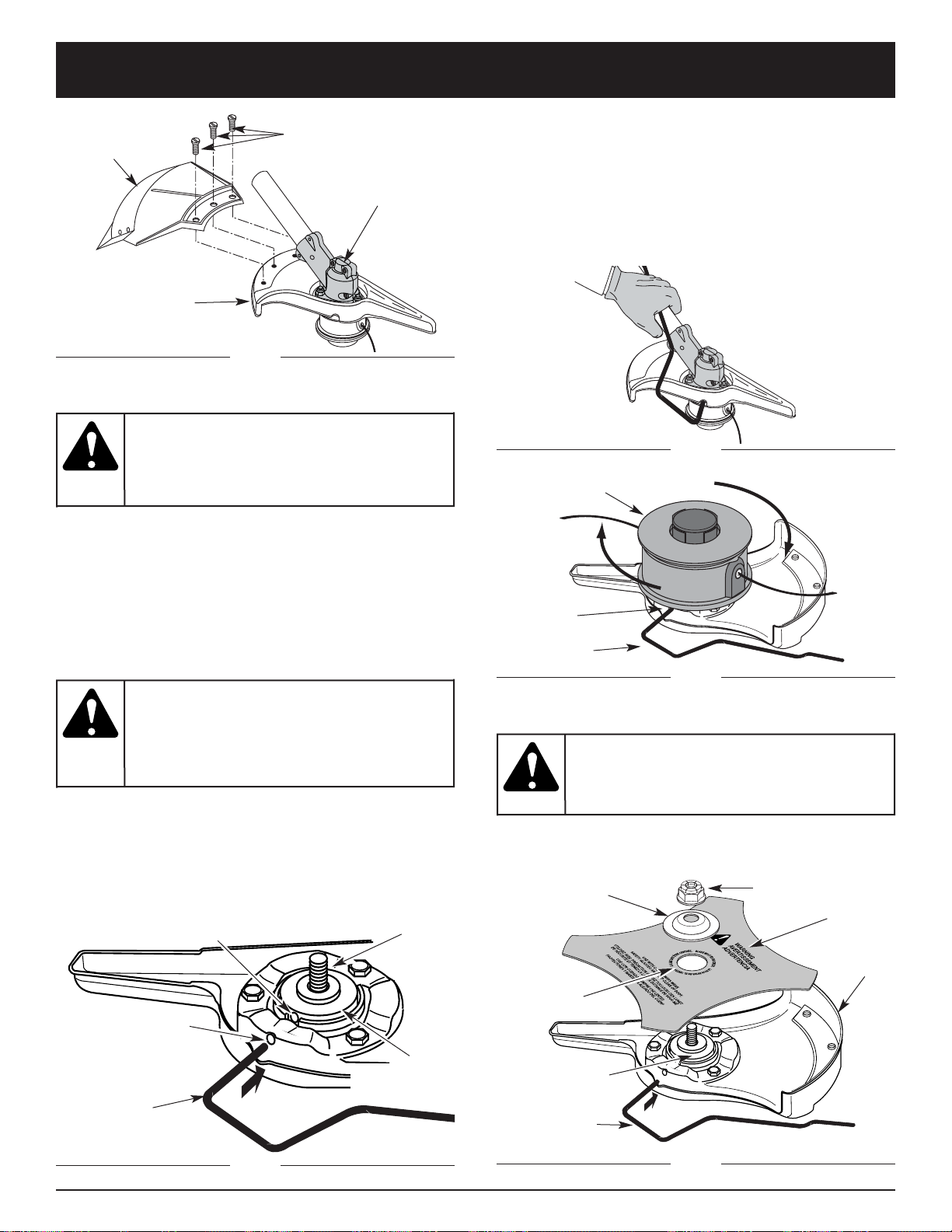

Page 10

10

Install the cutting attachment shield when using

the unit as a grass trimmer

Install the cutting attachment shield on the shield mount

by inserting the three (3) screws into the shield mount.

Tighten securely with a flat blade screwdriver (Fig. 7).

BRUSHCUTTER ONLY:

REMOVE THE

CUTTING A TTACHMENT AND INSTALL THE

CUTTING BLADE

NOTE: To make cutting blade removal and installation easier,

place the unit on the ground or on a work bench

.

Remove the Cutting Attachment Shield

See Remove and Install the Cutting Attachment Shield.

Remove the Cutting Attachment

1.

Align the shaft bushing hole with the locking rod slot and

insert the locking rod into the shaft bushing hole (Fig. 8).

(3) Screws

Cutting

Attachment

Shield

Shield Mount

Gear Housing

Fig. 7

BRUSHCUTTER ASSEMBLY INSTRUCTIONS

Cutting Attachment

Locking Rod

Slot

Locking Rod

Shaft Bushing Hole

Locking Rod Slot

Output Shaft

Bushing

Locking Rod

Output Shaft

2. Hold the locking rod in place by grasping it next to

the boom of the unit (Fig. 9).

3. While holding the locking rod, remove the cutting

attachment by turning it clockwise off of the output shaft

(Fig. 10). Store the cutting attachment for future use.

NOTE: The blade retainer under the cutting attachment

will be used when installing the cutting blade.

Fig. 8

Fig. 10

Fig. 9

Install the Cutting Blade

4. Place the cutting blade on the output shaft bushing

(Fig. 11).

Shield

Mount

Locking Rod

Cutting

Blade

Blade Retainer

Nut

Output Shaft

Bushing

Pilot Hole

Fig. 11

The gear housing

gets hot with use. It

can result in injury to the operator. The

housing remains hot for a short time even

after the unit is turned off. Do not touch the

gear housing until it has cooled.

WARNING:

To avoid serious

personal injury, the

cutting attachment shield MUST be in place

at all times while operating the unit as a

grass trimmer.

WARNING:

To avoid serious

personal injury,

always wear gloves while handling or

installing the blade.

WARNING:

Page 11

11

Fig. 15

Fig. 12

Pilot Step

BRUSHCUTTER ONLY: REMOVE THE

CUTTING BLADE AND INSTALL THE

CUTTING ATTACHMENT

Remove the Cutting Blade

1. Align the shaft bushing hole with the locking rod slot

and insert the locking rod into the bushing hole (Fig. 8).

2. Hold the locking rod in place by grasping it next to

the boom of the unit (Fig. 14).

3. While holding the locking rod, loosen the nut on the

blade by turning it clockwise with a 5/8 inch closedend or socket wrench (Fig. 14).

Fig. 13

9. Remove the locking rod from the locking rod slot.

1/4-1/2 turn

Counterclockwise

6. Align the shaft bushing hole with the locking rod

slot and insert the locking rod into the bushing hole

(Fig. 8).

7. Put the blade retainer and nut on the output shaft.

Make sure that the blade is installed correctly.

8. Tighten nut counterclockwise against the blade while

holding the locking rod:

• If using a torque wrench and an 5/8 inch socket tighten

to: 325 - 335 in•lb, 27 - 28 ft.•lb, 37 - 38 N•m.

•Without a torque wrench, use a 5/8 inch closed-end or

socket wrench, turning the nut until the blade retainer

is snug against the shaft bushing. Make sure that the

blade is installed correctly, then rotate the nut an

additional 1/4 to 1/2 turn counterclockwise (Fig. 13).

Cutting Attachment

Locking Rod

Clockwise

6. Remove the locking rod.

7. Install the cutting attachment shield. Refer to Remove

and Install the Cutting Attachment Shield.

Blade Retainer

Output Shaft

Bushing

Fig. 14

BRUSHCUTTER ASSEMBLY INSTRUCTIONS

5. Make sure that the cutting blade is centered on the

pilot step and sitting flat against the output shaft

bushing (Fig. 12).

4. Remove the nut, blade retainer and blade. Store the

nut and blade together for future use in a secure

place. Store out of children’s reach.

Install the Cutting Attachment

5.

Align the shaft bushing hole with the locking rod slot and

insert the locking rod into the shaft bushing hole (Fig. 8).

Place the blade retainer on the output shaft with the flat

surface against the output shaft bushing (Fig. 15). Screw

the cutting attachment counterclockwise onto the output

shaft. Tighten securely.

NOTE: The blade retainer must be installed on the output

shaft in the position shown for the cutting

attachment to work correctly.

If the cutting blade

is off-center, the

unit will vibrate and the blade may fly off,

causing possible serious personal injury.

WARNING:

To avoid serious

personal injury,

always wear gloves while handling or

installing the blade.

WARNING:

Do not sharpen the

cutting blade.

Sharpening the blade can cause the blade tip

to break off while in use. This can result in

severe personal injury. Replace the blade.

WARNING:

To avoid serious

personal injury or

damage to the unit, do not start or operate this

unit with the locking rod in the locking rod slot.

WARNING:

To avoid serious

personal injury, the

cutting attachment shield MUST be in place at

all times while operating the unit as a trimmer.

WARNING:

Page 12

12

OIL AND FUEL INFORMATION

NOTE: Dispose of the old fuel/oil mix in accordance to

Federal, State and Local regulations.

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons

for the unit not running properly. Be sure to use fresh,

clean unleaded fuel. Follow the instructions carefully for

the proper fuel/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and

oxygenates such as ethanol, methanol, or MTBE (ether).

Alcohol-blended fuel absorbs water. As little as 1%

water in the fuel can make fuel and oil separate. It forms

acids when stored. When using alcohol-blended fuel,

use fresh fuel (less than 60 days old).

Using Blended Fuels

If you choose to use a blended fuel, or its use is

unavoidable, follow recommended precautions:

• Always use the fresh fuel mix explained in your

operator's manual

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing

the unit

Using Fuel Additives

The bottle of 2-cycle oil that came with your unit

contains a fuel additive which will help inhibit corrosion

and minimize the formation of gum deposits. It is

recommended that you use our 2-cycle oil with this unit.

If unavailable, use a good 2-cycle oil designed for

air-cooled engines along with a fuel additive, such as

STA-BIL®Gas Stabilizer or an equivalent. Add 0.8 oz.

(23 ml.) of fuel additive per gallon of fuel according to the

instructions on the container. NEVER add fuel additives

directly to the unit's fuel tank.

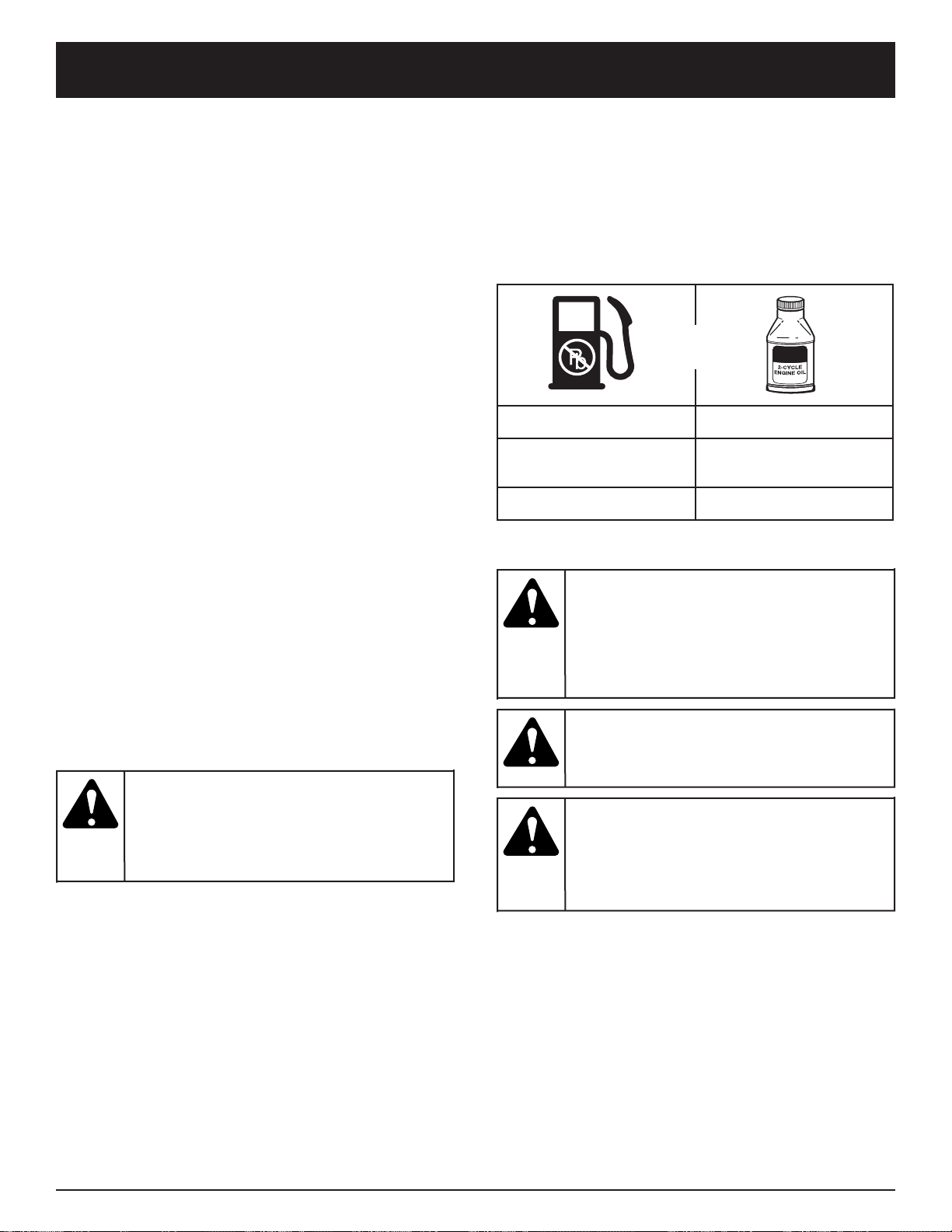

Thoroughly mix the proper ratio of 2-cycle engine oil

with unleaded gasoline in a separate fuel can. Use a 40:1

fuel/oil ratio. Do not mix them directly in the engine fuel

tank. See the table below for specific gas and oil mixing

ratios.

NOTE: One gallon (3.8 liters) of unleaded gasoline mixed

with one 3.2 oz. (95 ml.) bottle of 2-cycle oil

makes a 40:1 fuel/oil ratio.

UNLEADED GAS 2 CYCLE OIL

1 GALLON US

(3.8 LITERS)

3.2 FL. OZ.

(95 ml)

1 LITER 25 ml

+

MIXING RATIO - 40:1

Add fuel in a clean,

well ventilated

outdoor area. Wipe up any spilled fuel

immediately. Avoid creating a source of

ignition for spilt fuel. Do not start the engine

until fuel vapors dissipate.

WARNING:

Gasoline is

extremely

flammable. Ignited Vapors may explode.

Always stop the engine and allow it to cool

before filling the fuel tank. Do not smoke

while filling the tank. Keep sparks and open

flames at a distance from the area.

WARNING:

Remove fuel cap

slowly to avoid injury

from fuel spray. Never operate the unit

without the fuel cap securely in place

.

WARNING:

For proper engine

operation and

maximum reliability, pay strict attention to

the oil and fuel mixing instructions on the

2-cycle oil container. Using improperly mixed

fuel can severely damage the engine.

CAUTION:

Page 13

13

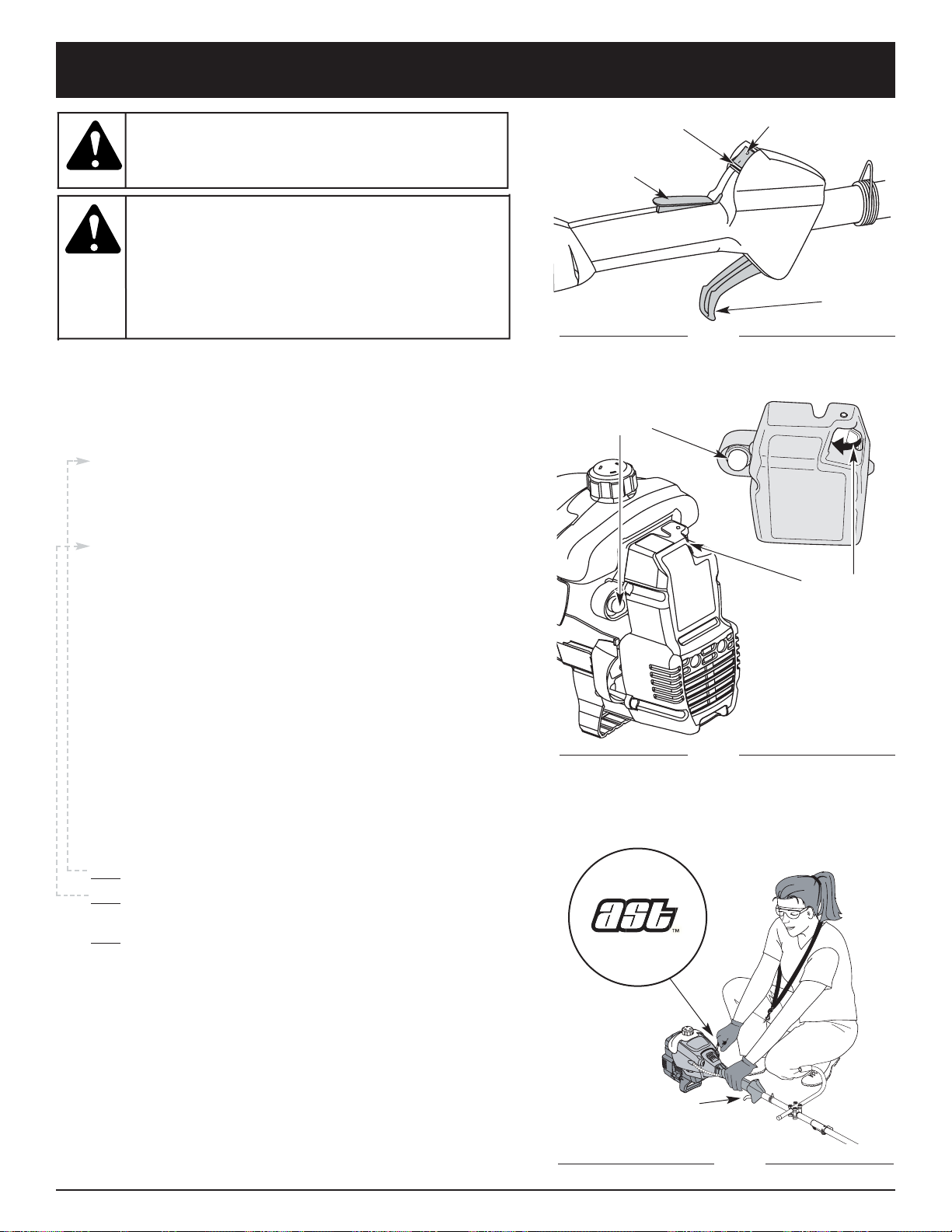

STARTING/STOPPING INSTRUCTIONS

STARTING INSTRUCTIONS

STOPPING INSTRUCTIONS

1. Release your hand from the throttle control. Allow the engine

to cool down by idling.

2. Put the On/Off Stop Control in the OFF (O) position (Fig. 16).

Primer

Bulb

EZ-Start™

Lever

Fig. 18

1. Mix gas with oil. Fill fuel tank with fuel/oil mixture. See

Oil and Fuel Mixing Instructions.

2. Make sure the On/Off Stop Control in the ON (I)

position (Fig. 16).

3. Fully press and release the primer bulb 10 times,

slowly. Some amount of fuel should be visible in the

primer bulb and fuel lines (Fig. 17). If you can’t see

fuel in the bulb, press and release the bulb as many

times as it takes before you can see fuel in it.

4. Push the EZ-Start™ Lever towards the primer bulb

until it clicks and locks into place (Fig. 17).

5. Crouch in the starting position and do not squeeze the

throttle control (Fig. 18). Pull the starter rope out with a

controlled and steady motion until the engine attempts

to start. Repeat until the engine starts.

NOTE: The unit uses Advanced Starting Technology™,

which significantly reduces the effort required to start

the engine. You must pull the starter rope out far

enough to hear the engine attempt to start. There is

no need to pull the rope briskly-- there is no harsh

resistance when pulling. Be aware that this starting

method is vastly different from (and much easier

than) what you may be used to.

6. When the engine starts, (for the 60-2312-2 brushcutter

only, hold down the throttle lock-out) squeeze the

throttle control for 15 to 30 seconds. This will warm up

the unit. The EZ-Start™ Lever will click off

automatically when you squeeze the throttle control.

IF

...

The engine does not start, go back to step 3.

IF... The engine stops while you are squeezing the throttle,

go back to step 4.

IF... The engine stops before you squeeze the throttle

control, hold the throttle control and pull the starter

rope until the trimmer starts.

NOTE: If you are having trouble starting the unit or are

operating in extreme temperatures (below 40º F,

above 90º F), refer to the Troubleshooting section.

Operate this unit only in a

well- ventilated outdoor

area. Carbon monoxide exhaust fumes can be lethal in

a confined area.

WARNING:

Avoid accidental starting.

Make sure you are in the

starting position when pulling the starter rope

(Fig. 18).

To avoid serious injury, the operator and unit

must be in a stable position while starting.

To avoid serious personal injury, ensure any AddOn being used is installed correctly and secure

before starting the unit.

WARNING:

Start/On (I) Stop/Off (O)

Throttle

Lock-Out

(Brushcutter

Only)

Throttle

Control

Fig. 16

Throttle Control

(Do NOT squeeze during

a standard start)

Starting Position

Trimmer

Equipped With

Advanced Starting

Technology™

Fig. 17

Page 14

14

For edging (when using the line head cutting attachment

with EZ-Link™ models), lock the release button of the

cutting attachment into the 90° edging hole or the 180°

edging hole (Fig. 21).

OPERATING THE EZ-LINK™SYSTEM

The EZ-Link™ system enables the use of these optional

Add-Ons:

Blower/Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . BV720r

Cultivator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GC720r

Edger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LE720r

Hedge Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . HS720r

Snow Thrower . . . . . . . . . . . . . . . . . . . . . . . . . . . ST720r

Straight Shaft Trimmer . . . . . . . . . . . . . . . . . . . . SS725r

Tree Pruner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TP720r

Turbo Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . TB720r

Removing the Cutting Attachment or Add-Ons

1. Turn the knob counterclockwise to loosen (Fig. 19).

2. Press and hold the release button (Fig. 19).

3. While firmly holding the upper shaft housing, pull

the cutting attachment or add-on straight out of the

EZ-Link™ coupler (Fig. 20).

Installing the Cutting Attachment or Add-On

NOTE: Place the unit on the ground or on a work bench

to make add-on installation or removal easier.

1. Turn knob counterclockwise to loosen (Fig. 19).

Fig. 19

EZ-Link™ Coupler

Release Button

Guide Recess

Knob

Primary Hole

Upper Shaft Housing

EZ-Link™ Coupler

2. While firmly holding the add-on, push it straight into

the EZ-Link™ coupler (Fig. 20).

NOTE: Aligning the release button with the guide recess

will help installation (Fig. 19).

3. Turn the knob clockwise to tighten (Fig. 21).

Fig. 20

Fig. 21

Knob

Lower Shaft Housing

Release Button

90˚ Edging Hole

(Trimmer Only)

180˚ Edging Hole

(Trimmer Only)

OPERATING INSTRUCTIONS

Prior to operation,

read and understand

the operator’s manual for the add-on to be

used with this unit.

WARNING:

To avoid serious

personal injury and

damage to the unit, shut the unit off before

removing or installing add-ons.

WARNING:

The add-ons with the

coupler system is to

be used in the primary hole only. Using the

wrong hole could lead to personal injury or

damage to the unit.

CAUTION:

Lock the release

button in the primary

hole (Fig. 20) and securely tighten the knob

before operating this unit.

CAUTION:

Page 15

15

HOLDING THE TRIMMER

Before operating the unit, stand in the operating position

(Fig. 22). Check for the following:

• The operator is wearing eye protection and proper

clothing

• With a slightly-bent right arm, the operator’s right hand

is holding the shaft grip

• The operator’s left arm is straight, the left hand holding

the J-handle

• The unit is at waist level

• The cutting attachment is parallel to the ground and

easily contacts the grass without the need to bend over

Once you are in the operating position, hook the

shoulder strap to the unit (brushcutter only).

OPERATING INSTRUCTIONS

Fig. 22

ADJUSTING TRIMMING LINE LENGTH

The Bump Head™ cutting attachment allows you to

release trimming line without stopping the engine. To

release more line, lightly tap the cutting attachment on the

ground (Fig. 23) while operating the trimmer at high speed.

NOTE: Always keep the trimming line fully extended.

Line release becomes more difficult as the cutting

line becomes shorter.

Each time the head is bumped, about 1 inch (25.4 mm) of

trimming line is released. A blade in the cutting

attachment shield will cut the line to the proper length if

excess line is released.

For best results, tap the Bump Head™ on bare ground or

hard soil. If line release is attempted in tall grass, the

engine may stall. Always keep the trimming line fully

extended. Line release becomes more difficult as the

cutting line becomes shorter.

NOTE: Do not rest the Bump Head™ on the ground

while the unit is running.

Fig. 23

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects such as walls or fence posts

TIPS FOR BEST TRIMMING RESULTS

• For best trimming results, operate unit at full throttle.

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip of

the line to do the cutting, especially along walls.

Cutting with more than the tip will reduce cutting

efficiency and may overload the engine.

• Cut grass over 8 inches (200 mm) by working from top

to bottom in small increments to avoid premature line

wear or engine drag.

• Cut from left to right whenever possible. Cutting to the

right improves the unit's cutting efficiency. Clippings

are thrown away from the operator.

• Slowly move the trimmer into and out of the cutting

area at the desired height. Move either in a forwardbackward or side-to-side motion. Cutting shorter

lengths produces the best results.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

• Proper adherence of explained trimming techniques

• What vegetation is cut

• Where vegetation is cut

For example, the line will wear faster when trimming against

a foundation wall as opposed to trimming around a tree.

Do not remove or alter

the line cutting blade

assembly. Excessive line length will make the

clutch overheat. This may lead to serious

personal injury or damage to the unit.

CAUTION:

Always wear eye,

hearing, foot and

body protection to reduce the risk of injury

when operating this unit.

WARNING:

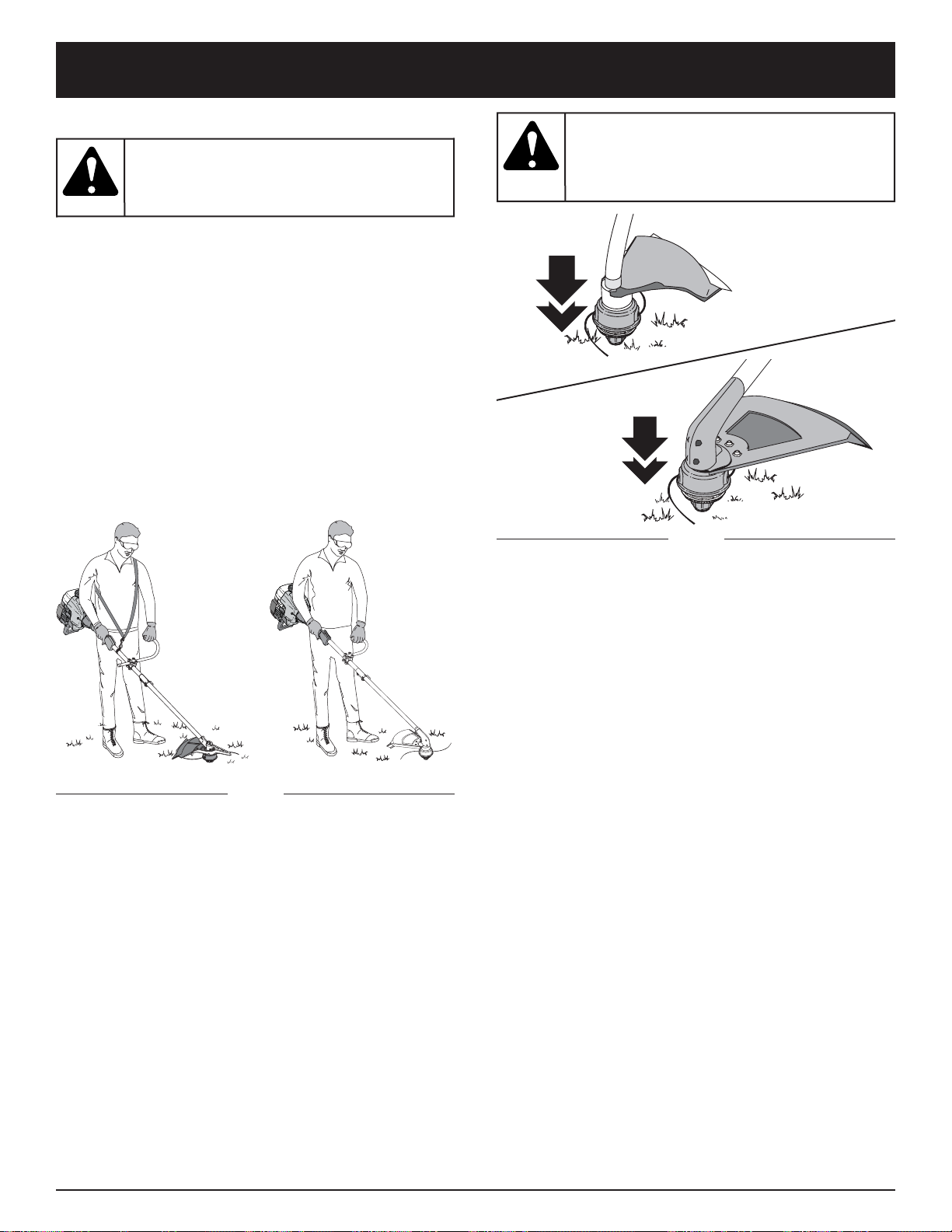

Trimmer

Brushcutter

Curved

Trimmer

Straight

Trimmer

Page 16

16

Fig. 24

Fig. 25

Fig. 26

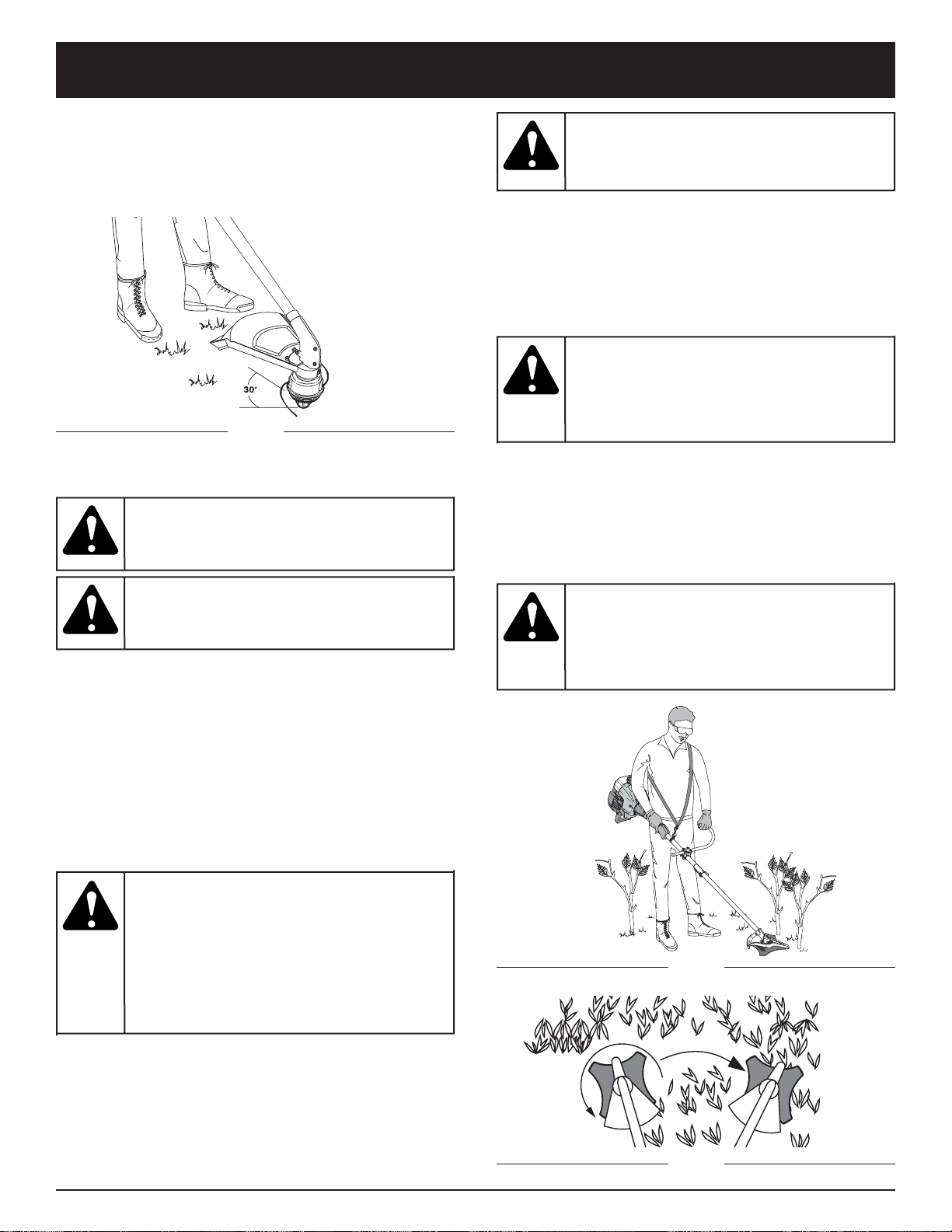

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences and more.

Rotate the whole unit so that the cutting attachment is at

a 30° angle to the ground (Fig. 24).

BRUSHCUTTER ONLY:USING THE

CUTTING BLADE

Before operating the unit with the cutting blade, stand in

the operating position (Fig. 25). Refer to Holding the

Trimmer.

Cutting Blade Operating Tips

To establish a rhythmic cutting procedure:

• Plant feet firmly, comfortably apart.

• Bring the engine to full throttle before entering the

material to be cut. At full throttle the blade has

maximum cutting power and is less likely to bind, stall

or cause blade thrust (which can result in serious

personal injury to the operator or others).

• Cut while swinging the upper part of your body from

left to right.

• Always release the throttle trigger and allow the engine

to return to idle speed when not cutting.

• When you are finished, always unsnap the unit from

the harness before taking off the harness.

• Swing the unit in the opposite direction as the blade

spins, which increases the cutting action.

• After the return swing, move forward to the next area

to be cut plant your feet again.

• The cutting blade is designed with a second cutting

edge. You can use it by removing the blade, turning it

upside down, and reinstalling it.

To reduce the chance of material wrapping around the

blade, follow these steps:

• Cut at full throttle

• Swing the unit into material to be cut from your left to

your right (Fig. 26)

• Avoid the material just cut as you make the return swing

OPERATING INSTRUCTIONS

Always wear eye,

hearing, foot, body

protection and the shoulder strap to reduce the

risk of injury when operating this unit.

WARNING:

Do not use the

cutting blade for

edging or as an edger. Severe personal injury

to yourself or others can result.

WARNING:

The blade continues

to spin after the

engine is turned off. The coasting blade can

seriously cut you if accidentally touched.

WARNING:

Do not sharpen the

cutting blade.

Sharpening the blade can cause the blade tip

to break off while in use. This can result in

severe personal injury to yourself or others.

Replace the blade.

WARNING:

Bl

ade thrust may

occur when the

spinning blade contacts an object that it does

not immediately cut. Blade thrust can be violent

enough to cause the unit and/or operator to be

propelled in any direction, and possibly lose

control of the unit. Blade thrust can occur

without warning if the blade snags, stalls or

binds. This is more likely to occur in areas where

it is difficult to see the material being cut.

WARNING:

Do not clear away

any cut material with

the engine running or blade turning. To avoid

serious personal injury, turn off the engine.

Allow the blade to stop before removing

materials wrapped around the blade shaft.

WARNING:

Page 17

17

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should

also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require

special tools or skills. If you are unsure about

these procedures take your unit to any non-road

engine repair establishment, individual or

authorized service dealer.

NOTE: Maintenance, replacement, or repair of the

emission control devices and system may be

performed by any non-road engine repair

establishment, individual or authorized service

dealer.

In order to assure peak performance of your engine,

inspection of the engine exhaust port may be necessary

after 50 hours of operation. If you notice lost RPM, poor

performance or general lack of acceleration, this service

may be required. If you feel your engine is in need of this

inspection, refer service to any non-road engine repair

establishment, individual or authorized service dealer for

repair. DO NOT attempt to perform this process yourself

as engine damage may result from contaminants

involved in the cleaning process for the port.

FREQUENCY MAINTENANCE REQUIRED REFER TO

Before starting engine Fill fuel tank with fresh fuel Page 12

Every 10 hours Clean and re-oil air filter Page 22

Every 25 hours

Check and clean spark arrestor

Check spark plug condition and gap

Page 23

Page 24

Every 50 hours

Inspect exhaust port and spark arrestor screen for clogging or

obstruction to assure maximum performance levels

Page 23

MAINTENANCE AND REPAIR INSTRUCTIONS

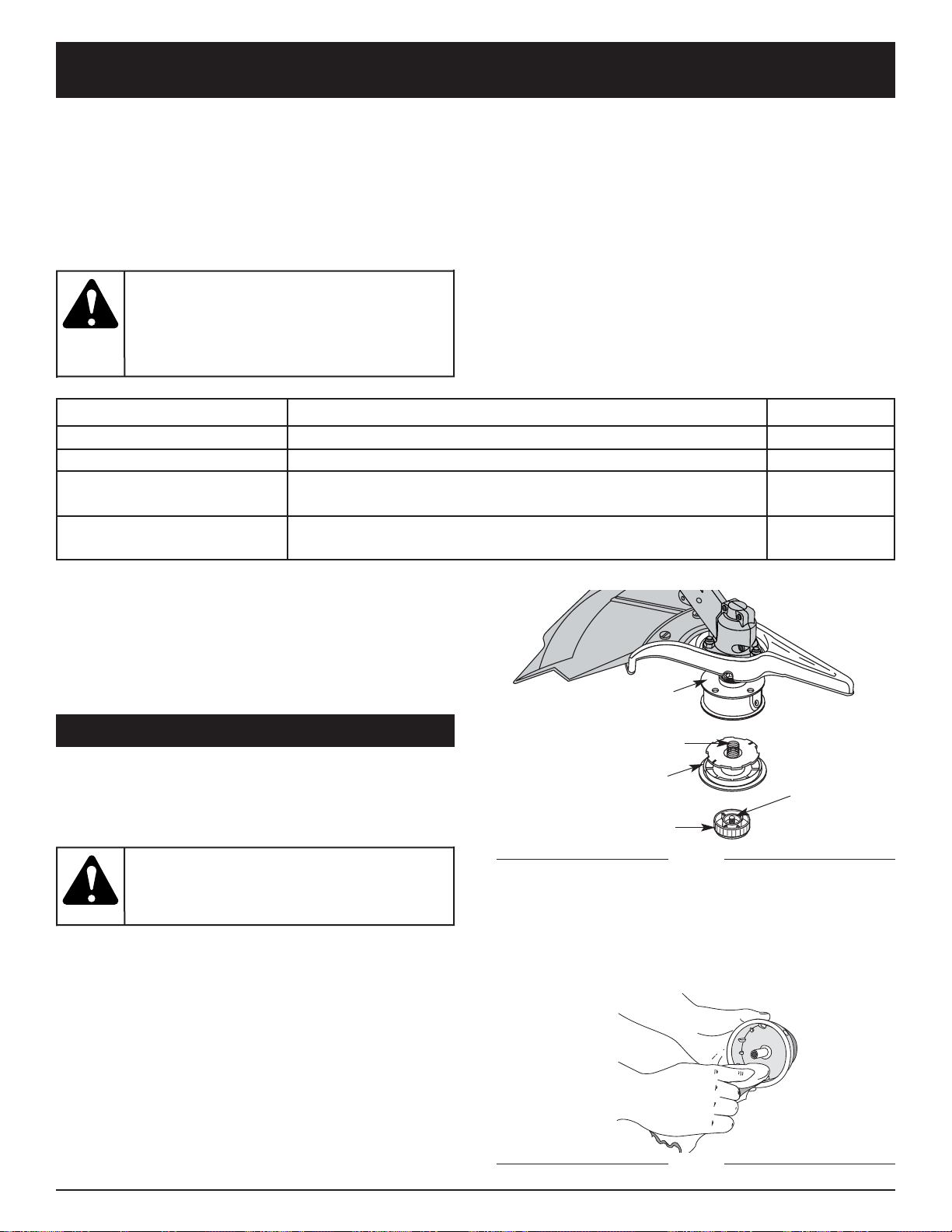

Fig. 28

This section covers both SplitLine™ and standard single

line installation.

Always use original equipment manufacturer 0.095 in.

(2.41 mm) replacement line. Line other than the specified

may make the engine overheat or fail.

There are two methods to replace the trimming line:

• Wind the inner reel with new line

• Install a prewound inner reel

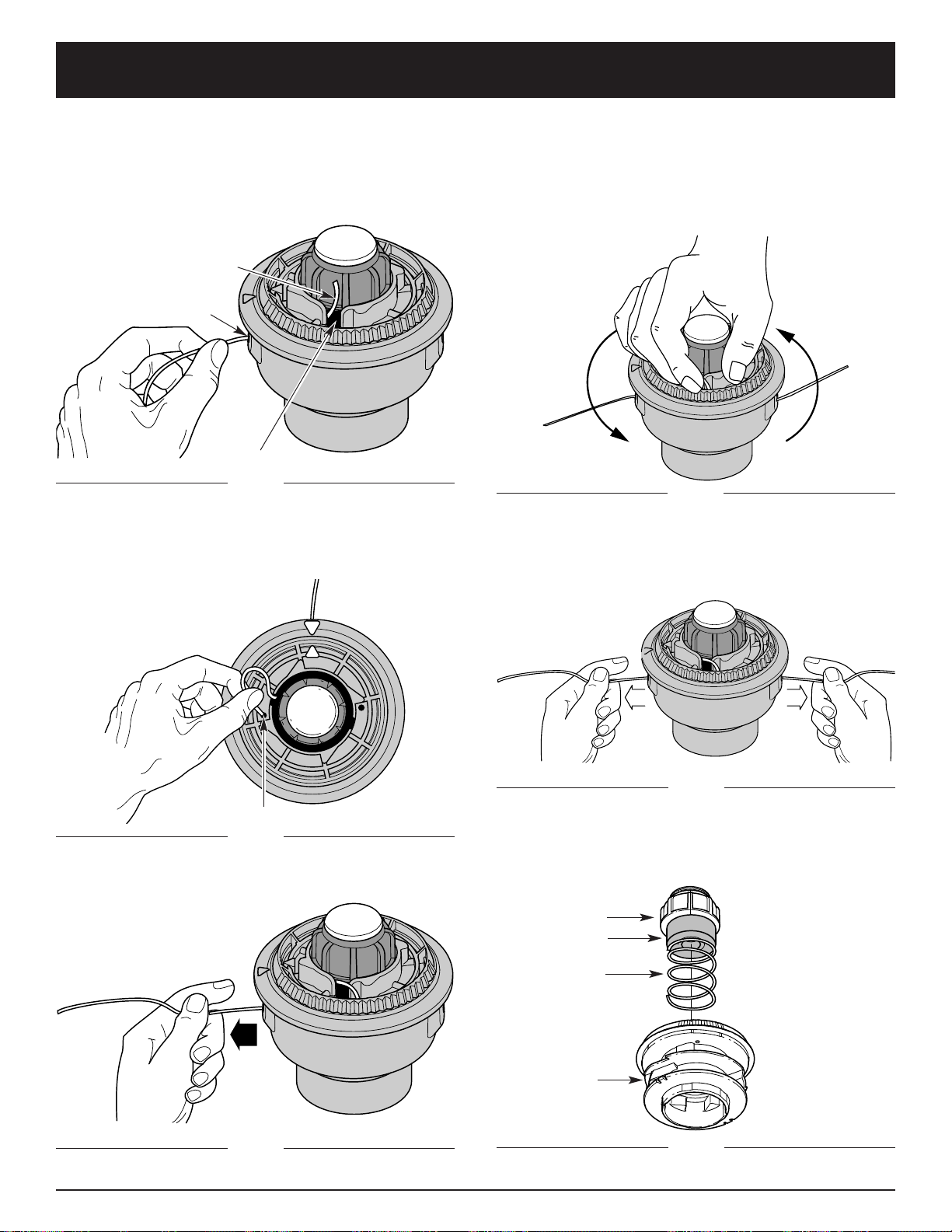

Winding the Existing Inner Reel

1. Hold the outer spool with one hand and unscrew the

Bump Knob clockwise (Fig. 27). Inspect the bolt inside

the bump knob to make sure it moves freely. Replace

the bump knob if damaged.

2. Remove the inner reel from the outer spool (Fig. 27).

3. Remove spring from the inner reel (Fig. 27).

4. Use a clean cloth to clean the the inner reel, spring,

shaft and inner surface of the outer spool (Fig. 28).

5. Check the indexing teeth on the inner reel and outer

spool for wear (Fig. 29). If necessary, remove burrs or

replace the reel and spool.

Inner Reel

Spring

Outer Spool

Bump Knob

Bolt

Fig. 27

LINE INSTALLATION

Your trimmer is equipped with one of two cutting

attachments. The trimmers (60-2310-6 & 60-2311-4) use

a SpeedSpool, while the 60-2312-2 brushcutter uses a

large bump head. Refer only to the section that applies

to the type of cutting attachment that your unit is

equipped with.

BRUSHCUTTER LINE INSTALLATION: BUMP HEAD

To prevent serious

injury, never perform

maintenance or repairs with unit running.

Always service and repair a cool unit.

Disconnect the spark plug wire to ensure that

the unit cannot start.

WARNING:

Never use metal-

reinforced line, wire,

chain or rope. These can break off and

become dangerous projectiles.

WARNING:

Page 18

18

MAINTENANCE AND REPAIR INSTRUCTIONS

Fig. 31

Fig. 34

Fig. 30

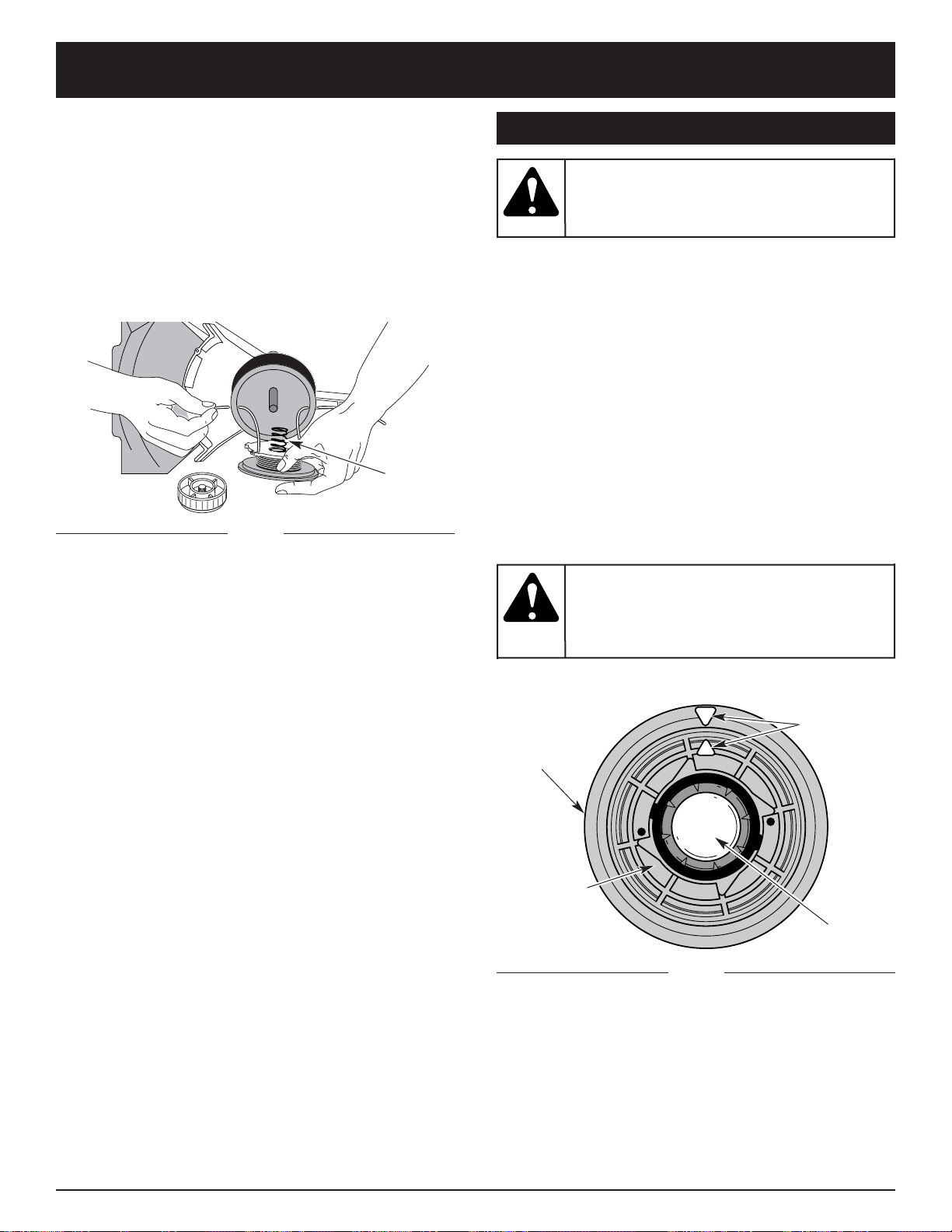

NOTE: SplitLine™ can only be used with the inner reel

with the slotted holes. Single line can be used on

either type of inner reel. Use Figure 30 to identify

the inner reel you have.

NOTE: Always use the correct line length when installing

trimming line on the unit. The line may not release

properly if the line is too long.

Single Line Installation

Go To Step 8 for SplitLine™ Installation

6. Take approximately 16 feet (5 m) of new trimming

line, loop it into two equal lengths. Insert each end of

the line through one of the two holes in the inner reel

(Fig. 31). Pull the line through the inner reel so that

the loop is as small as possible.

7. Wind the lines in tight even layers, onto the reel

(Fig. 32). Wind the line in the direction indicated on

the inner reel. Place your index finger between the

two lines to stop the lines from overlapping. Do not

overlap the ends of the line. Proceed to step 11.

SplitLine™ Installation

8. Take approximately 8 feet (2.5 m) of new trimming

line. Insert one end of the line through one of the two

holes in the inner reel (Fig. 33). Pull the line through

the inner reel until only about 4 inches is left out.

9. Insert the end of the line into the open hole in the

inner reel and pull the line tight to make the loop as

small as possible (Fig. 33).

10. Before winding, split the line back about 6 inches.

11. Wind the line in tight even layers in the direction

indicated on the inner reel.

NOTE: Failure to wind the line in the direction indicated will

cause the cutting attachment to operate incorrectly.

12. Insert the ends of the line into the two holding slots

(Fig. 34).

Loop

Slotted

Holes

For Use with SplitLine™

or Single Line

For Use with Single

Line ONLY

Loop

Holding Slots

Fig. 33

Indexing Teeth

Fig. 29

Fig. 32

Page 19

19

Fig. 35

Spring

13. Insert the ends of the line through the eyelets in the

outer spool and place inner reel with spring inside the

outer spool (Fig. 35). Push the inner reel and outer

spool together. While holding the inner reel and outer

spool, grasp the ends and pull firmly to release the

line from the holding slots in the reel.

NOTE: The spring must be assembled on the inner reel

before reassembling the cutting attachment.

14. Hold the inner reel in place and install the bump knob

by turning counterclockwise. Tighten securely.

MAINTENANCE AND REPAIR INSTRUCTIONS

Installing a Prewound Wheel

1. Hold the outer spool with one hand and unscrew the

bump knob clockwise (Fig. 27). Inspect the bolt inside

the bump knob to make sure it moves freely. Replace

the bump knob if damaged.

2. Remove the old inner reel from the outer spool

(Fig. 27).

3. Remove the spring from the old inner reel

(Fig. 27).

4. Place the spring in the new inner reel.

NOTE:The spring must be assembled on the inner reel

before reassembling the cutting attachment.

5. Insert the ends of the line through the eyelets in the

outer spool (Fig. 35).

6. Place the new inner reel inside the outer spool. Push the

inner reel and outer spool together. While holding the

inner reel and outer spool, grasp the ends and pull firmly

to release the line from the holding slots in the spool.

7. Hold the inner reel in place and install the bump knob

by turning counterclockwise. Tighten securely.

Replacement Parts

See Accessories / Replacement Parts.

Always use original equipment manufacturer ™ 0.080

inch (2.03 mm) replacement line. Lines other than those

specified may make the engine overheat or fail.

There are two methods to replace the SpeedSpool

®

trimming line:

• Wind the inner reel with new line

• Install a pre-wound inner reel

Winding the Inner Reel With New Line

NOTE: It Is unnecessary to remove the bump knob to

install a new trimming line.

1. Cut two pieces of 0.080 inch (2.03 mm) trimming

line, 10 feet (3 m) long.

2. Hold the outer spool and turn the inner reel

counterclockwise to line up the arrows on the outer

spool and inner reel (Fig. 36).

Top View Of The SpeedSpool

®

Outer Spool

Inner Reel

Fig. 36

Bump Knob

Arrows

TRIMMER LINE INST ALLATION:

SPEEDSPOOL

Never use metal-

reinforced line, wire,

chain or rope. These can break off and

become dangerous projectiles.

WARNING:

Always use the

correct line length

when installing trimming line on the unit.

The line may not release properly if the line

is too long.

WARNING:

Page 20

20

Line Locking Hole

Trimming Line

Line Loading Hole

Eyelet

5. Insert the line into the locking hole (Fig. 38). Do not

push the line more than a 1/2 inch (12.7 mm) into the

line locking hole. The line will form a small loop

(Fig. 38) when it is inserted correctly.

3. Pull old line out of the line loading and line locking

holes (Fig. 37 and 38).

4. Insert a piece of trimming line straight into one of the

two eyelets in the outer spool. Push it up through the

line loading hole in the inner reel (Fig. 37). Do not

bend the line when inserting it into the eyelet.

Fig. 37

Fig. 38

6. Pull the line from the outer spool until the line is tight

against the inner reel (Fig. 39).

Fig. 39

INSTALLING A PRE-WOUND REEL

1. Turn the bump knob counterclockwise and remove

the bump knob, spring and foam seal (Fig. 42).

9. If winding the line becomes difficult or if the line

jams, pull the ends of the line from the spool

(Fig. 41). Continue winding the inner reel

counterclockwise.

Fig. 40

Fig. 41

7. Repeat procedures 4-6 with the second piece of line.

8. Hold the outer spool. Wind the inner reel

counterclockwise until approximately four (4) inches

(102 mm) of line remain (Fig. 40).

NOTE: Do not wind the inner reel before installing the

second piece of line.

Bump Knob

Foam Seal

Spring

Inner Reel

Fig. 42

MAINTENANCE AND REPAIR INSTRUCTIONS

Page 21

21

MAINTENANCE AND REPAIR INSTRUCTIONS

SPEEDSPOOL®REPLACEMENT PARTS

Replacement Line . . . . . . . . . . . . . . . . . . . . . . . . 181472

Replacement Line Cartridge . . . . . . . . . . . . . . . . 181460

Inner Reel Spring . . . . . . . . . . . . . . . . . . . . . . . . 181465

Foam Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181467

Inner Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181464

Bump Knob Assembly . . . . . . . . . . . . . . . . . . . . 181468

These SpeedSpool

®

replacement parts can be

purchased from your local authorized dealer.

4. Hold the inner reel in place and install the bump

knob, spring and foam seal. Press down and turn the

bump knob clockwise. Grasp the ends and pull

firmly to release the line from the holding slots in the

inner reel (Fig. 42).

Releasing the Inner Reel

If the SpeedSpool®does not release line correctly, pull

the ends of the line firmly from the spool (Fig. 41). If this

does not the release line, follow the Cleaning the

SpeedSpool®instructions.

2. Pull the old inner reel with existing line from the outer

spool.

3. Insert the ends of the prewound inner reel line into

the outer spool eyelets (Fig. 43). Push the new inner

reel, arrow side up, into the outer spool.

Fig. 43

4. Remove any existing line from the inner reel before

cleaning. Remove any debris or grass from the knob,

spring, inner reel and foam seal. Wash the inner reel

with warm soapy water (Fig. 45).

Fig. 44

CLEANING THE SPEEDSPOOL

®

Cleaning the SpeedSpool®may be necessary if:

•A jammed or excessive line must be removed

• The SpeedSpool®becomes difficult to wind or does

not operate correctly when bumping the head on the

ground

1. Hold the outer spool, and unscrew the bump knob

counterclockwise (Fig. 44).

2. Pull out the bump knob, spring and foam seal (Fig. 42).

Shaft

Plunger

NOTE: The inner reel must be totally dry before

reinstalling it into the outer spool. Do not lubricate

the inner reel or outer spool assembly.

6. Place the inner reel into the outer spool.

7. Place the bump knob, spring and foam seal into the

inner reel (Fig. 42).

8. Press the bump knob down and tighten clockwise.

9. Install new line as described in Line Installation for

the SpeedSpool®.

5. Clean the shaft and the inner surface of the outer

spool. To clean the shaft underneath the plunger,

press down on the plunger (Fig. 46). Remove any dirt

or debris from the shaft.

Fig. 46

Inner Reel

Fig. 45

3. Pull the inner reel with existing line from the outer

spool (Fig. 43).

Page 22

22

MAINTENANCE AND REPAIR INSTRUCTIONS

Fig. 47

AIR FILTER MAINTENANCE

Removing the Air Filter/Muffler Cover

1. Remove the four (4) screws securing the air

filter/muffler cover (Fig. 47). Use a flat blade or

T20 Torx bit screwdriver.

2. Pull the cover from the engine. Do not force.

Screws

Screws

Cleaning the Air Filter

Clean and re-oil the air filter every 10 hours of operation.

It is an important item to maintain. Failure to maintain the

air filter will VOID the warranty.

1. Remove air filter/muffler cover. Refer to Removing

the Air Filter/Muffler Cover.

2. Turn cover over and look inside to locate the air filter.

Remove the air filter from inside the air filter/muffler

cover (Fig. 48).

3. Wash the filter in detergent and water (Fig. 49). Rinse

the filter thoroughly. Squeeze out excess water. Allow

it to dry completely.

4. Apply enough clean SAE 30 oil to lightly coat the filter

(Fig. 50).

5. Squeeze the filter to spread and remove excess oil

(Fig. 51).

Fig. 48

Fig. 49

Fig. 50

Fig. 51

6. Replace the air filter inside the air filter/muffler cover

(Fig. 48).

NOTE: Operating the unit without the air filter and air

filter/muffler cover assembly will VOID the

warranty.

Reinstalling the Air Filter/Muffler Cover

1. Place the air filter/muffler cover over the back of the

carburetor and muffler. Align the screw holes.

2. Insert the four (4) screws into the holes in the air

filter/muffler cover (Fig. 47) and tighten.

Do not over tighten.

Air Filter

Inside Muffler

Cover

EZ-Start™

Lever

To avoid serious

personal injury ,

always turn your unit off and allow it to cool

before you clean or service it.

WARNING:

Page 23

23

SPARK ARRESTOR MAINTENANCE

1. Remove air filter/muffler cover. Refer to Removing

the Air Filter/Muffler Cover.

2. Locate muffler front and the two (2) bolts securing it

to the engine (Fig. 52). Remove the two (2) bolts

using a flatblade screwdriver or 5/16-inch socket or

nut driver. Pull muffler off of the engine.

3. Turn muffler over to the back side and locate the

exhaust gasket. Remove the muffler gasket from the

muffler (Fig. 52).

NOTE: If the exhaust gasket is torn or damaged, replace

it with a new gasket before reassembling muffler.

4. Using a small flatblade screwdriver, carefully pry up

the spark arrestor from the recessed hole (Fig. 53).

Remove the spark arrestor from the muffler.

5. Clean the spark arrestor with a wire brush. Replace it

if it is damaged or if it is impossible to clean

thoroughly (Fig. 53).

6. Reinstall the spark arrestor by pressing it into the

recessed hole on the muffler's back side. Make sure

it fits tightly against the muffler and is not raised up.

7. Place the exhaust gasket against muffler's back side.

Align the gasket bolt holes with the bolt holes in the

muffler. While holding exhaust gasket in place, insert

the bolts into the muffler's front side (Fig. 52).

8. Place the muffler (with the exhaust gasket in place

and bolts inserted), against the engine, aligning the

bolt holes. Tighten the bolts to secure the muffler to

the engine.

If using a torque wrench, torque to:

80-90 in.•lb. (9-10.2 N•m)

9. Reinstall the air filter/muffler cover.

Fig. 53

Fig. 52

Muffler - Front Side

Muffler - Back Side

Bolts

Exhaust

Gasket

Spark

Arrestor

Muffler - Back Side

Spark

Arrestor

Flatblade

Screwdriver

Spark Arrestor

MAINTENANCE AND REPAIR INSTRUCTIONS

If the muffler is not

tightened securely, it

could fall off causing damage to the unit and

possible serious personal injury.

WARNING:

Page 24

24

Check Fuel Mixture

Old and/or improperly mixed fuel is usually the reason

for improper unit performance. Drain and refill the tank

with fresh, properly-mixed fuel prior to making any

adjustments. Refer to Oil and Fuel Information.

Clean Air Filter

The condition of the air filter is important to the operation

of the unit. A dirty air filter will restrict air flow and

change the air/fuel mixture. This is often mistaken for an

out of adjustment carburetor. Check the condition of the

air filter before adjusting the idle speed screw. Refer to

Air Filter Maintenance.

Adjust Idle Speed Screw

If, after checking the fuel mixture and cleaning the air

filter, the engine still will not idle, adjust the idle speed

screw as follows:

1. Start the engine and let it run at a high idle for a

minute to warm up. Refer to Starting/Stopping

Instructions.

2. Release the throttle trigger and let the engine idle. If

the engine stops, insert a small phillips or flat blade

screwdriver into the hole in the air filter/muffler cover

(Fig. 54). Turn the idle speed screw in, clockwise,

1/8 of a turn at a time (as needed) until the engine

idles smoothly.

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable through the air

filter/muffler cover (Fig. 54).

NOTE: Careless adjustments can seriously damage your

unit. An authorized service dealer should make

carburetor adjustments.

Fig. 54

Idle Speed Screw

NOTE: The cutting attachment should not rotate when

the engine idles.

3. If the cutting attachment rotates when the engine

idles, turn the idle speed screw counterclockwise

1/8 of a turn at a time (as needed), to reduce idle

speed.

Checking the fuel mixture, cleaning the air filter, and

adjusting the idle speed should solve most engine

problems. If not and:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

Have the carburetor adjusted by an authorized service

dealer.

REPLACING THE SPARK PLUG

Use a Champion RDJ7Y spark plug, or equivalent. The

correct air gap is 0.020 inch (0.5 mm). Remove the plug

after every 25 hours of operation and check its condition.

1. Stop the engine and allow it to cool. Grasp the plug

wire firmly and pull it from the spark plug.

2. Clean around the spark plug. Remove the spark plug

from the cylinder head by turning a 5/8-inch socket

counterclockwise.

3. Replace a cracked, fouled or dirty spark plug. Set

the air gap at 0.020 in. (0.5 mm) using a feeler gauge

(Fig. 55).

4. Install a correctly-gapped spark plug in the cylinder

head. Tighten by turning the 5/8-inch socket

clockwise until snug.

If using a torque wrench torque to:

110-120 in.•lb. (12.3-13.5 N•m)

Do not over tighten.

0.020 in.

(0.5 mm)

Fig. 55

MAINTENANCE AND REPAIR INSTRUCTIONS

The cutting

attachment may spin

during idle speed adjustments. Wear

protective clothing and observe all safety

instructions to prevent serious personal injury.

WARNING:

To prevent serious

personal injury,

make sure the cutting attachment has

stopped rotating before you turn it off and

set it down.

WARNING:

Do not sand blast,

scrape or clean

electrodes. Grit in the engine could damage

the cylinder.

WARNING:

Page 25

25

MAINTENANCE AND REPAIR INSTRUCTIONS

CLEANING

Use a small brush to clean off the outside of the unit.

Do not use strong detergents. Household cleaners that

contain aromatic oils such as pine and lemon, and

solvents such as kerosene, can damage plastic housing

or handle. Wipe off any moisture with a soft cloth.

STORAGE

• Never store a fueled unit where fumes may reach an

open flame or spark.

• Allow the engine to cool before storing.

• Store the unit locked up to prevent unauthorized use

or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

LONG TERM STORAGE

If you plan on storing the unit for an extended time, use

the following storage procedure:

1. Drain all fuel from the fuel tank into a container with

the same 2-cycle fuel mixture. Do not use fuel that

has been stored for more than 60 days. Dispose of

the old fuel/oil mix in accordance to Federal, State

and Local regulations.

TRANSPORTING

• Allow the engine to cool before transporting.

• Drain fuel from unit.

• Tighten fuel cap before transporting.

• Secure the unit while transporting.

To avoid serious

personal injury,

always turn your trimmer off and allow it to

cool before you clean or service it.

WARNING:

2. Start the engine and allow it to run until it stalls. This

ensures that all fuel has been drained from the

carburetor.

3. Allow the engine to cool. Remove the spark plug and

put 1 oz. (30 ml) of any high quality motor oil or

2-cycle oil into the cylinder. Pull the starter rope

slowly to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil

from the cylinder before attempting to start the

trimmer after storage.

4. Thoroughly clean the unit and inspect it for any loose

or damaged parts. Repair or replace damaged parts

and tighten loose screws, nuts or bolts. The unit is

ready for storage.

Page 26

26

TROUBLESHOOTING

CAUSE ACTION

Cutting attachment bound with grass Stop the engine and clean cutting attachment

Cutting attachment out of line Refill with new line

Inner reel bound up Replace the inner reel

Cutting head dirty Clean inner reel and outer spool

Line welded Disassemble, remove the welded section and rewind

Line twisted when refilled Disassemble and rewind the line

Not enough line is exposed Push the bump knob and pull out line until 4 inches

(102 mm) of line is outside of the cutting attachment

CAUSE ACTION

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Improper carburetor adjustment Take to an authorized service dealer for an adjustment

Fouled spark plug Replace or clean the spark plug

Plugged spark arrestor Clean or replace spark arrestor

CAUSE ACTION

Empty fuel tank Fill fuel tank with properly mixed fuel

Primer bulb wasn't pressed enough Press primer bulb fully and slowly 10 times

Engine is flooded Squeeze the trigger and pull the starter rope

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Fouled spark plug Replace or clean the spark plug

Plugged spark arrestor Clean or replace spark arrestor

EZ-Start lever wasn’t flipped/set Move lever to the starting position

The outside temperature is below 40º F Pull the starter rope up to 10-15 times

The outside temperature is above 90º F Squeeze the throttle control and pull the starter rope

ENGINE WILL NOT START

ENGINE WILL NOT IDLE

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STALLS WHEN CUTTING

CAUSE ACTION

Air filter is plugged Replace or clean the air filter

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Improper carburetor adjustment Adjust according to the Carburetor Adjustments section

CAUSE ACTION

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Improper carburetor adjustment Take to an authorized service dealer for an adjustment

Cutting attachment bound with grass Stop the engine and clean the cutting attachment

Dirty air filter Clean or replace the air filter

Plugged spark arrestor Clean or replace spark arrestor

CUTTING ATTACHMENT WILL NOT ADVANCE LINE

CAUSE ACTION

Oil, cleaner or lubricant in cutting head Clean and thoroughly dry the cutting head

CUTTING LINE ADVANCES UNCONTROLLABLY

If further assistance is required, contact your authorized service dealer.

Page 27

27

SPECIFICATIONS

Engine Type........................................................................................................................................... Air-Cooled, 2-Cycle

Stroke..................................................................................................................................................... 1.25 in. (31.75 mm)

Displacement.............................................................................................................................................. 1.9 cu in. (31 cc)

Clutch Type ......................................................................................................................................................... Centrifugal

Idle Speed RPM ....................................................................................................................................... 2,800 - 4,000 rpm

Operating RPM .................................................................................................................................................. 7,200+ rpm

Ignition Type.......................................................................................................................................................... Electronic

Ignition Switch............................................................................................................................................... Rocker

Switch

Spark Plug Gap........................................................................................................................................ 0.020 in. (0.5 mm)

Lubrication................................................................................................................................................... Fuel/Oil Mixture

Fuel/Oil Ratio.................................................................................................................................................................. 40:1

Carburetor....................................................................................................................................... Diaphragm, All-Position

Starter............................................................................................................................................................... Auto Rewind

Muffler..................................................................................................................................................... Baffled with Guard

Throttle............................................................................................................................................... Manual Spring Return

Fuel Tank Capacity........................................................................................................................................ 12 oz. (355 ml)

ENGINE*

DRIVE SHAFT and CUTTING ATTACHMENT*

Drive Shaft Housing .......................................................................................................................... Steel Tube, EZ-Link™

Throttle Control.......................................................................................... Finger-Tip Trigger (Brushcutter: with Lock-Out)

Brushcutter Approximate Unit Weight (No fuel, with cutting attachment, shield and J-handle)...................... 15 lbs. (7 kg)

Trimmer Approximate Unit Weight (No fuel, with cutting attachment, shield and J-handle)........................... 13 lbs. (6 kg)

Brushcutter Cutting Mechanism ............................................................. 4-Tooth Cutting Blade, Dual String Cutting Head

Trimmer Cutting Mechanism.................................................................................. SpeedSpool®Dual String Cutting Head

Line Spool............................................................................................................................................. Bump Line Releaser

Line Spool Diameter ................................................... 4 inches, 101.6 mm (Brushcutter) or 3 inches, 76.2 mm (Trimmers)

Trimming Line Diameter...................................... 0.095 inch, 2.41 mm (Brushcutter) or 0.080 inches, 2.03 mm (Trimmers)

Cutting Path Diameter, Cutting Attachment ............ 18 inches, 45.7 cm (Brushcutter) or 17 inches, 43.18 cm (Trimmers)

Brushcutter: Cutting Path Diameter, Cutting Blade ................................................................................ 8 inches (204 mm)

Shoulder Harness ................................................................................................................................... Single Quick-Snap

*All specifications are based on the latest product information available at the time of printing. We reserve the right to

make changes at any time without notice.

Page 28

28

SPECIFICATIONS

Page 29

29

EPA Emission Control Warranty Statement

Your Warranty Rights and Obligations

The Environmental Protection Agency and MTD LLC (MTD) are pleased to explain the emission control system warranty

on your 2002 and later small off-road engine. New small off-road engines must be designed, built and equipped to meet

stringent anti-smog standards. Yard Works must warrant the emission control system on your small off-road engine for

the periods of time listed below provided there has been no abuse, neglect or improper maintenance of your small offroad engine.

Your emission control system may include parts such as the carburetor or fuel-injected system, the ignition system, and

catalytic converter. Also included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Yard Works will repair your small off-road engine at no cost to you including

diagnosis, parts and labor.

The 2002 and later small off-road engines are warranted for two years. If any emission-related part on your engine is

defective, the part will be repaired or replaced by Yard Works.

Owners Warranty Responsibilities

• As the small off-road engine owner, you are responsible for the performance of the required maintenance listed in your

operator’s manual. Yard Works recommends that you retain all receipts covering maintenance on your small off-road

engine, but Yard Works cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance

of all scheduled maintenance.

• As the small off-road engine owner, you however should be aware that Yard Works may deny you warranty coverage if

your small off-road engine or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

• You are responsible for presenting your small off-road engine to a Yard Works Authorized Service Center as soon as a