Page 1

Safety • Setup • Operation • Maintenance • Troubleshooting • Parts Lists • Warranty

OPERATOR’S MANUAL

Log Splitter — Model Series 5DM

IMPORTANT:

READ SAFETY RULES AND INSTRUCTIONS

CAREFULLY BEFORE OPERATING EQUIPMENT.

PRINTED IN U.S.A. MTD Products Ltd., P. O. Box 1386, KITCHENER, ONTARIO N2G 4J1

769-03483

9/25/07

Page 2

This Operator’s Manual is an important part of your new log splitter. It will help you assemble,

-4$02/$5#43,)-)4%$

+)4#(%.%2/..'*

8888888888

88888888888

-ODEL.UMBER

.UM£RODEMODÞLE

3ERIAL.UMBER

.UM£RODES£RIE

WWWMTDCANADACOM

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety Labels ......................................................3

Safe Operation Practices .................................. 4

Setting Up Your Log Splitter ............................. 6

Operating Your Log Splitter .............................. 8

Maintaining Your Log Splitter ......................... 12

Troubleshooting ................................................ 14

Finding and Recording Model Number

BEFORE YOU START ASSEMBLING

YOUR NEW EQUIPMENT,

please locate the model plate on the equipment and copy the

model number and the serial number to the sample model

plate provided to the right. You can locate the model plate by

standing at the operating position and looking down at the rear

of the machine.

Engine Appendix .............................................. 16

Engine Safe Operation Practices ................. 16

Operating Your Engine .................................. 18

Maintaining Your Engine ............................... 20

Warranty ............................................................ 23

Illustrated Parts List ........................................ 24

Emission Control System Warranty

Statement ...................................................... 26

Customer Support

Please do

purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of this unit,

you can seek help from the experts. Choose from the options below:

1. Visit www.mtdcanada.ca for many useful suggestions, click on Customer Support button.

2. Call a Customer Support Representative at 1-800-668-1238.

Please have your unit’s model number and serial number ready when you call. See previous section to locate this information.

You will be asked to enter the serial number in order to process your call.

NOT

return the unit to the retailer from which it was

2

Page 3

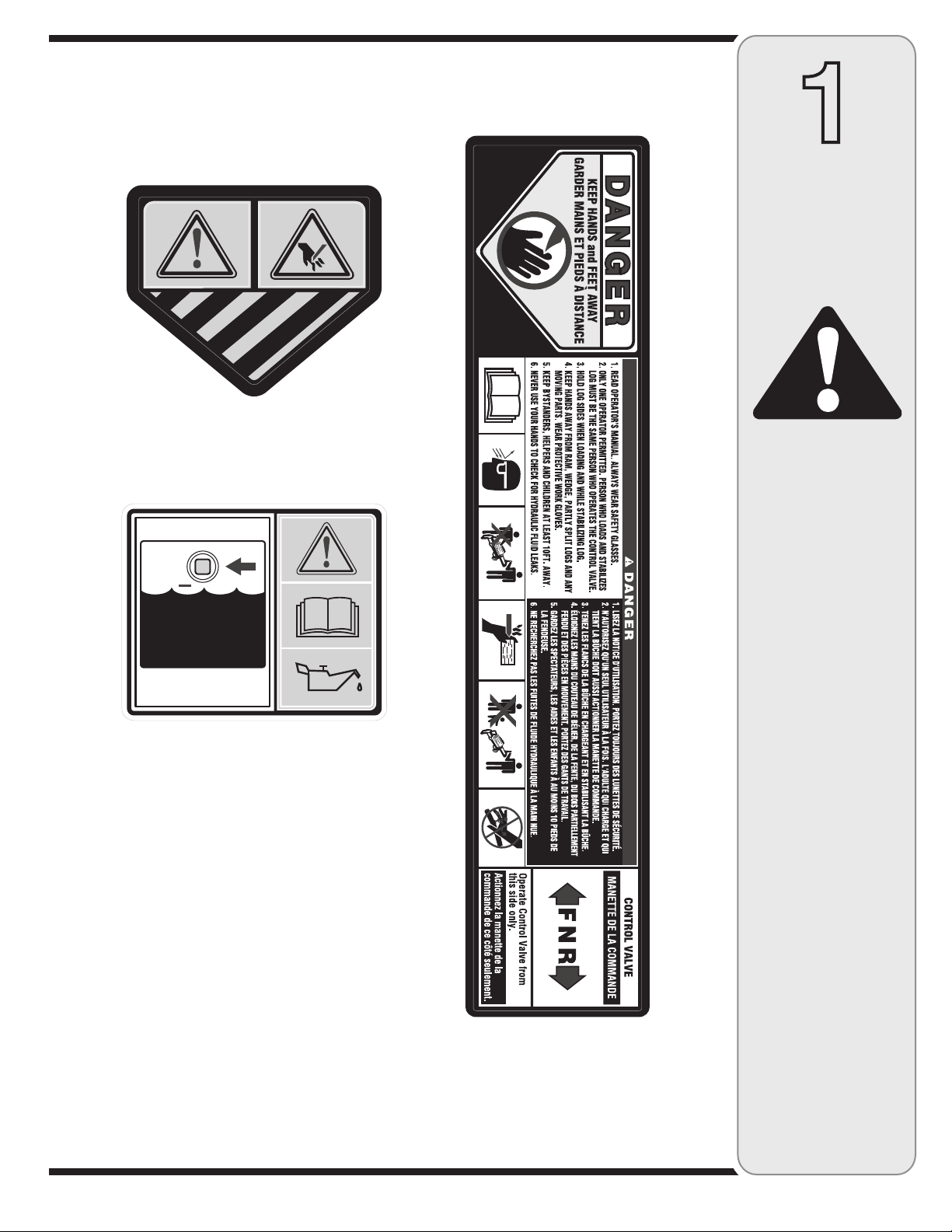

Safety Labels Found On Your Log Splitter

I22871

max.

DEXRON III

1

Safety

Labels

WARNING

DO NOT remove safety

(or any) labels from log

splitter for any reason.

3

Page 4

2

Safe

Operation

Practices

WARNING

This symbol points

out important safety

instructions which, if

not followed, could

endanger the personal

safety and/or property

of yourself and others.

Read and follow all

instructions in this

manual before attempting to operate

this machine. Failure

to comply with these

instructions may result

in personal injury. When

you see this symbol,

HEED ITS WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or

emit chemicals known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with

any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This

machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting

to assemble and operate. Keep this manual in a

safe place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper opera

tion. Know how to stop the machine and disengage

them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained and

supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Many accidents occur when more than one person

operates the machine. If a helper is assisting in loading logs, never activate the control until the helper is

a minimum of 10 feet from the machine.

6. Keep bystanders, helpers, pets, and children at least

20 feet from the machine while it is in operation.

7. Never allow anyone to ride on this machine.

8. Never transport cargo on this machine.

9. Hydraulic log splitters develop high fluid pressures

during operation. Fluid escaping through a pin hole

opening can penetrate your skin and cause blood

poisoning, gangrene, or death. Give attention to the

following instructions at all times:

a. Do not check for leaks with your hand.

b. Do not operate machine with frayed, kinked,

cracked, or damaged hoses, fitting, or tubing.

c. Stop the engine and relieve hydraulic system

pressure before changing or adjusting fittings,

hoses, tubing, or other system components.

d. Do not adjust the pressure settings of the pump

or valve.

10. Leaks can be detected by passing cardboard or

wood, while wearing protective gloves and safety

glasses, over the suspected area. Look for discoloration of cardboard or wood.

11. If injured by escaping fluid, see a doctor immediately.

Serious infection or reaction can develop if proper

medical treatment is not administered immediately.

12. Keep the operator zone and adjacent area clear for

safe, secure footing.

13. If your machine is equipped with an internal combustion engine and it is intended for use near any

unimproved forest, brush, or grass covered land,

the engine exhaust should be equipped with a spark

-

arrester. Make sure you comply with applicable local,

state, and federal codes. Take appropriate firefighting

equipment with you.

14. This machine should be used for splitting wood only,

do not use it for any other purpose.

15. Follow the instructions in the manual(s) provided with

any attachment(s) for this machine.

PREPARATION

1. Always wear safety shoes or heavy boots.

2. Always wear safety glasses or safety goggles during

operating this machine.

3. Never wear jewelry or loose clothing that might

become entangled in moving or rotating parts of the

machine.

4. Make sure this machine is on level surface before

operating.

5. Always block the machine as required to prevent

unintended movement, and lock in either the horizontal or vertical position.

6. Always operate this machine from the operator

zone(s) specified in the manual.

7. Logs should be cut with square ends prior to splitting.

8. Use your log splitter in daylight or under good artificial

light.

9. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine

is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

4

Page 5

f. Never overfill the fuel tank. Fill tank to no more than

1/2 inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light as

on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

j. Allow machine to cool at least 5 minutes before

storing.

OPERATION

1. Before staring this machine, review the “Safety

Instructions”. Failure to follow these rules may result in

serious injury to the operator or bystanders.

2. Never leave this machine unattended with the engine

running.

3. Do not operate machine while under the influence of

alcohol, drugs, or medication.

4. Never allow anyone to operate this machine without

proper instruction.

5. Always operate this machine with all safety equipment

in place and working. Make sure all controls are

properly adjusted for safe operation.

6. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

7. When loading a log, always place your hands on the

sides of the log, not on the ends, and never use your

foot to help stabilize a log. Failure to do so, may result

in crushed or amputated fingers, toes, hand, or foot.

8. Use only your hand to operate the controls.

9. Never attempt to split more than one log at a time

unless the ram has fully extended and a second log is

needed to complete the separation of the first log.

10. For logs which are not cut square, the least square

end and the longest portion of the log should be

placed toward the beam and wedge, and the square

end placed toward the end plate.

11. Always keep fingers away from any cracks that open

in the log while splitting. They can quickly close and

pinch or amputate your fingers.

12. Keep your work area clean. Immediately remove split

wood around the machine so that you do not stumble

over it.

13. Never move this machine while the engine is running.

14. This machine should not be towed on any street,

highway, or public road behind a vehicle.

MAINTENANCE AND STORAGE

1. Stop the engine, disconnect the spark plug and

ground it against the engine before cleaning, or

inspecting the machine.

2. Stop the engine and relieve hydraulic system

pressure before repairing or adjusting fittings, hoses,

tubing, or other system components.

3. To prevent fires, clean debris and chaff from the

engine and muffler areas. If the engine is equipped

with a spark arrester muffler, clean and inspect it

regularly according to manufacturers instructions.

Replace if damaged.

4. Periodically check that all nuts and bolts, hose

clamps, and hydraulic fittings are tight to be sure

equipment is in safe working condition.

5. Check all safety guards and shields to be sure they

are in the proper position. Never operate with safety

guards, shields, or other protective features removed.

6. The pressure relief valve is preset at the factory. Do

not adjust the valve.

7. Never attempt to move this machine over hilly or

uneven terrain without a tow vehicle or adequate help.

8. For your safety, replace all damaged or worn parts

immediately with original equipment manufacturer’s

(O.E.M.) parts only. “Use of parts which do not meet

the original equipment specifications may lead to

improper performance and compromise safety! ”

9. Do not alter this machine in any manner, alterations

such as attaching a rope or extension to the control

lever, or adding to the width or height of the wedge

may result in personal injury.

Spark Arrestor

Warning: This machine is equipped

with an internal combustion engine

and should not be used on or near any

unimproved forest-covered, brushcovered or grass-covered land unless the

engine’s exhaust system is equipped

with a spark arrester meeting applicable local or provincial laws (if any).

If a spark arrester is used, it should be maintained in

effective working order by the operator.

A spark arrester for the muffler is available through your

nearest engine authorized service dealer.

Average Useful Life

According to the Consumer Products Safety Commission (CPSC) and the U.S. Environmental Protection

Agency (EPA), this product has an Average Useful Life of

seven (7) years, or 60 hours of operation. At the end of

the Average Useful Life, buy a new machine or have the

machine inspected annually by an authorized service

dealer to ensure that all mechanical and safety systems

are working properly and not worn excessively. Failure

to do so can result in accidents, injuries or death.

2

Safe

Operation

Practices

WARNING

This symbol points

out important safety

instructions which, if

not followed, could

endanger the personal

safety and/or property

of yourself and others.

Read and follow all

instructions in this

manual before attempting to operate

this machine. Failure

to comply with these

instructions may result

in personal injury. When

you see this symbol,

HEED ITS WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

5

Page 6

3

WARNING: Use extreme caution

unpacking this machine. Some

components are very heavy and will

require additional people or mechanical

handling equipment.

Setting Up

Your Log

Splitter

WARNING

Use extreme caution unpacking this

machine. Some

components are very

heavy and will require

additional people or

mechanical handling

equipment.

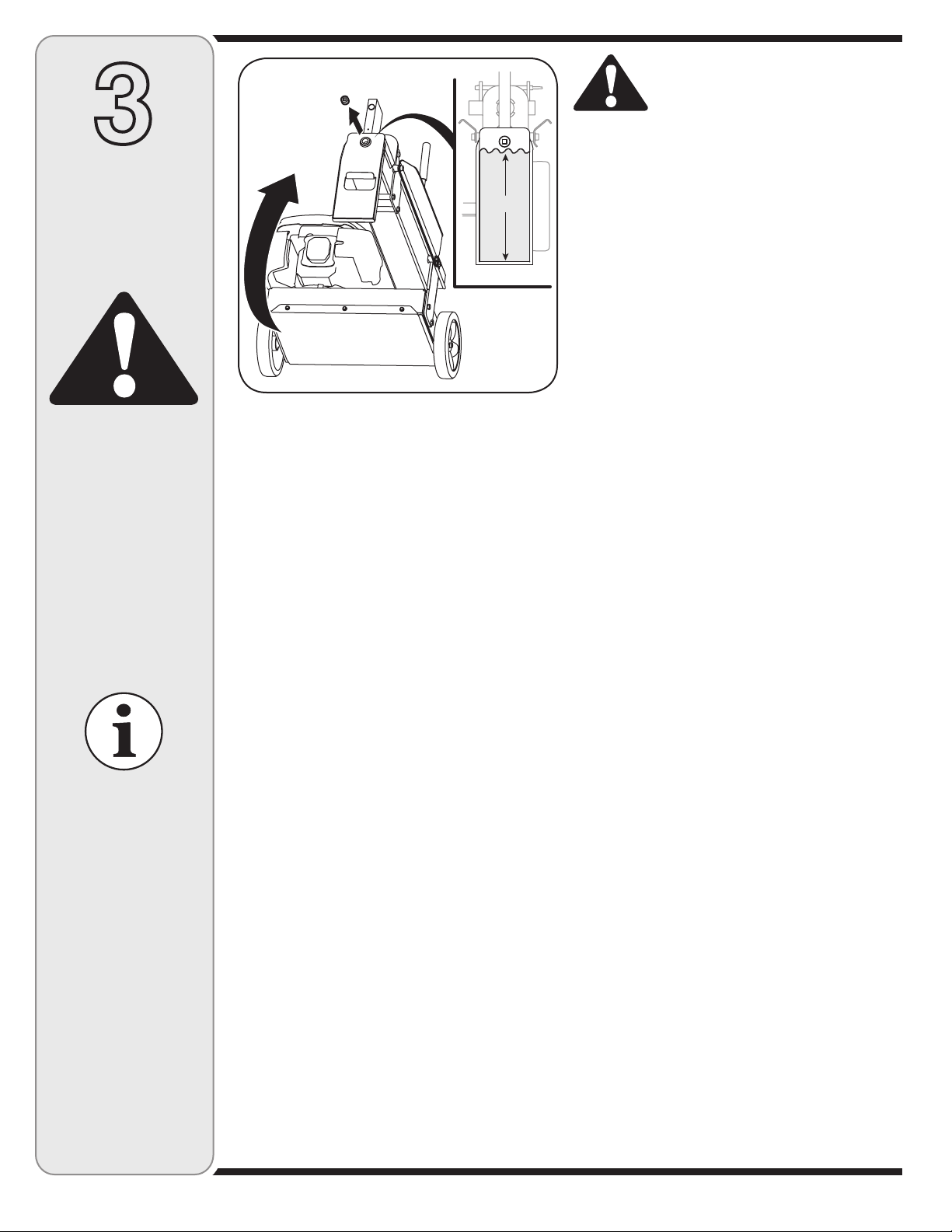

Figure 3-1

max.

Do not overfill

NOTE: All references in this manual to the left or right

side of the log splitter is from the operating position only.

Exceptions, if any, will be specified.

Preparing the Log Splitter

IMPORTANT: The log splitter is shipped without hydraulic

fluid in the reservoir tank. You MUST add fluid before

operating. Proceed with the following steps:

1. Remove oil plug, which is located on the end of the

beam assembly. See Figure 3-1.

2. Tilt unit back and add 1.5 gallons of hydraulic fluid

(Dexron® III, or 10 weight AW hydraulic oil).

3. Replace and tighten oil plug.

4. Lower unit to level ground.

IMPORTANT: Maximum fluid level will not be achieved

until cylinder is cycled (See Operating Your Log Split-

ter). Check when fluid is cold and with unit level. Never

run below this level - pump will be ruined.

NOTE: This Operators

Manual covers a range

of product specifications

for various models.

Characteristics and

features discussed

and/or illustrated in

this manual may not be

applicable to all models.

MTD reserves the right

to change product

specifications, designs

and equipment without

notice and without incurring obligation.

6

Page 7

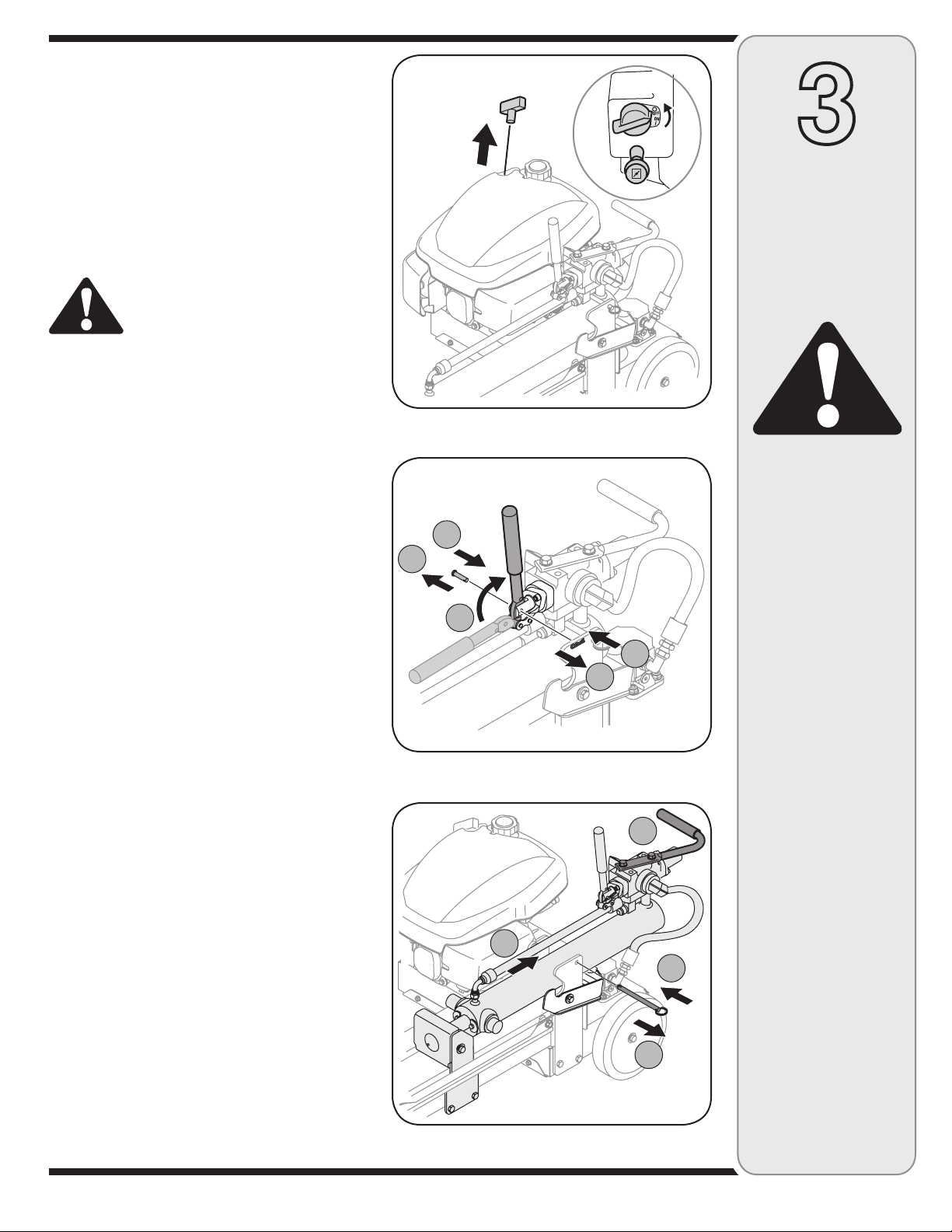

IMPORTANT: This unit is shipped without gasoline or oil

in the engine. Fill up gasoline and oil BEFORE priming

pump or operating your log splitter.

5. Add oil provided before priming pump or starting unit

for the first time out of the box. See Engine Operation

section for this and for location of the oil fill.

6. Service the engine with gasoline as instructed in the

Engine Operation section. See Engine Operation

section for location of gas fill.

WARNING: Use extreme care when handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel the machine indoors or while

the engine is hot or running. Extinguish cigarettes,

cigars, pipes and other sources of ignition.

7. Make sure that the engine switch is off. See Figure

3-2. Prime the hydraulic pump by pulling the recoil

starter as far as it will go. Repeat approximately 4-6

times.

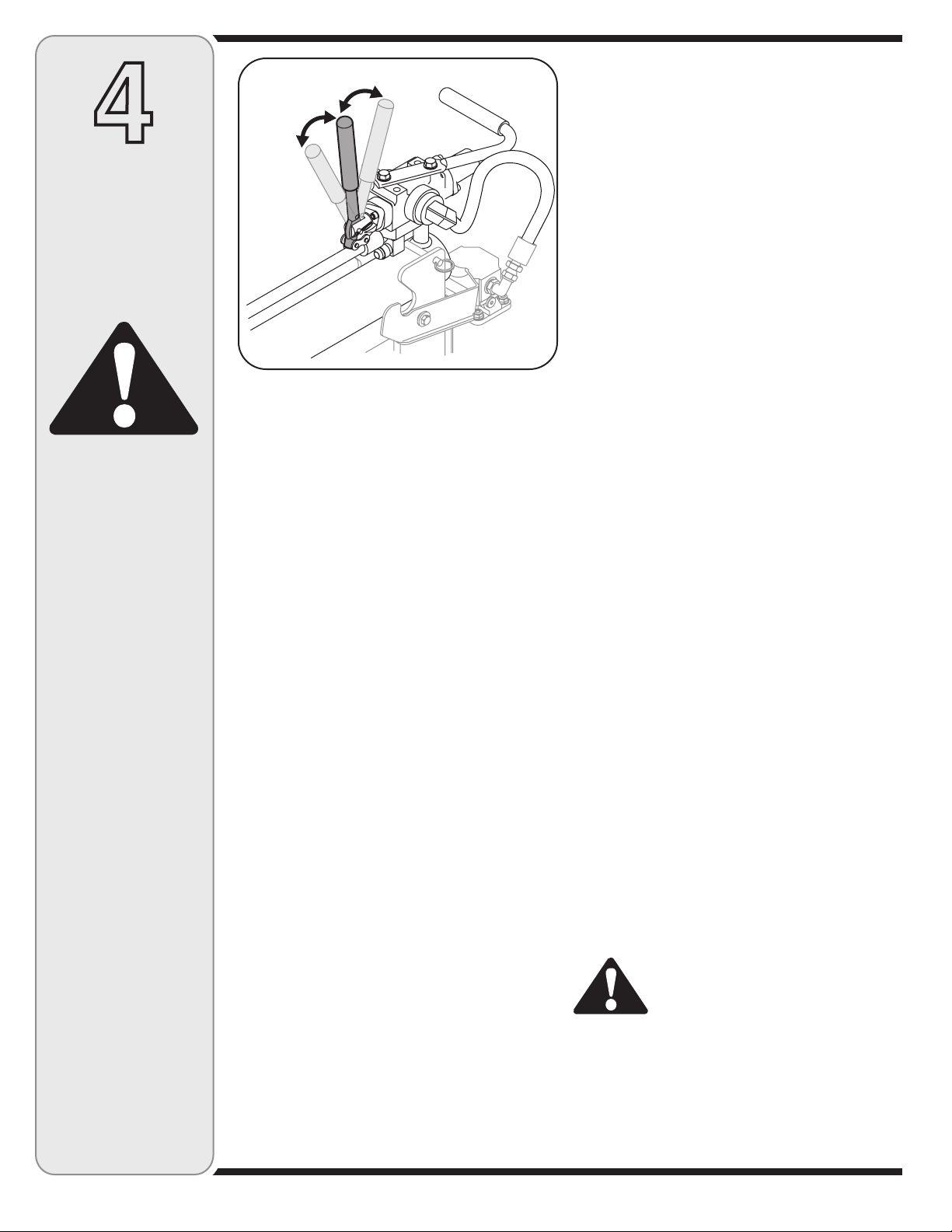

8. a. Remove clevis pin and hairpin clip. See Figure 3-3.

b. Pivot hydraulic valve control back into slot of valve.

c. Align holes and reinstall clevis pin and hairpin clip.

9. a. Pull locking pin from cylinder base. See Figure 3-4.

b. Use handle to slide cylinder back to lock in place.

c. Reinstall pin.

10. Lubricate the beam area (where the cylinder will slide)

with engine oil; do not use grease.

3

Setting Up

Your Log

Splitter

Figure 3-2

WARNING

Use extreme care

C

A

B

C

A

Figure 3-3

when handling

gasoline. Gasoline is

extremely flammable

and the vapors are

explosive. Never fuel

the machine indoors

or while the engine

is hot or running.

Extinguish cigarettes, cigars, pipes

and other sources of

ignition.

B

B

C

A

Figure 3-4

7

Page 8

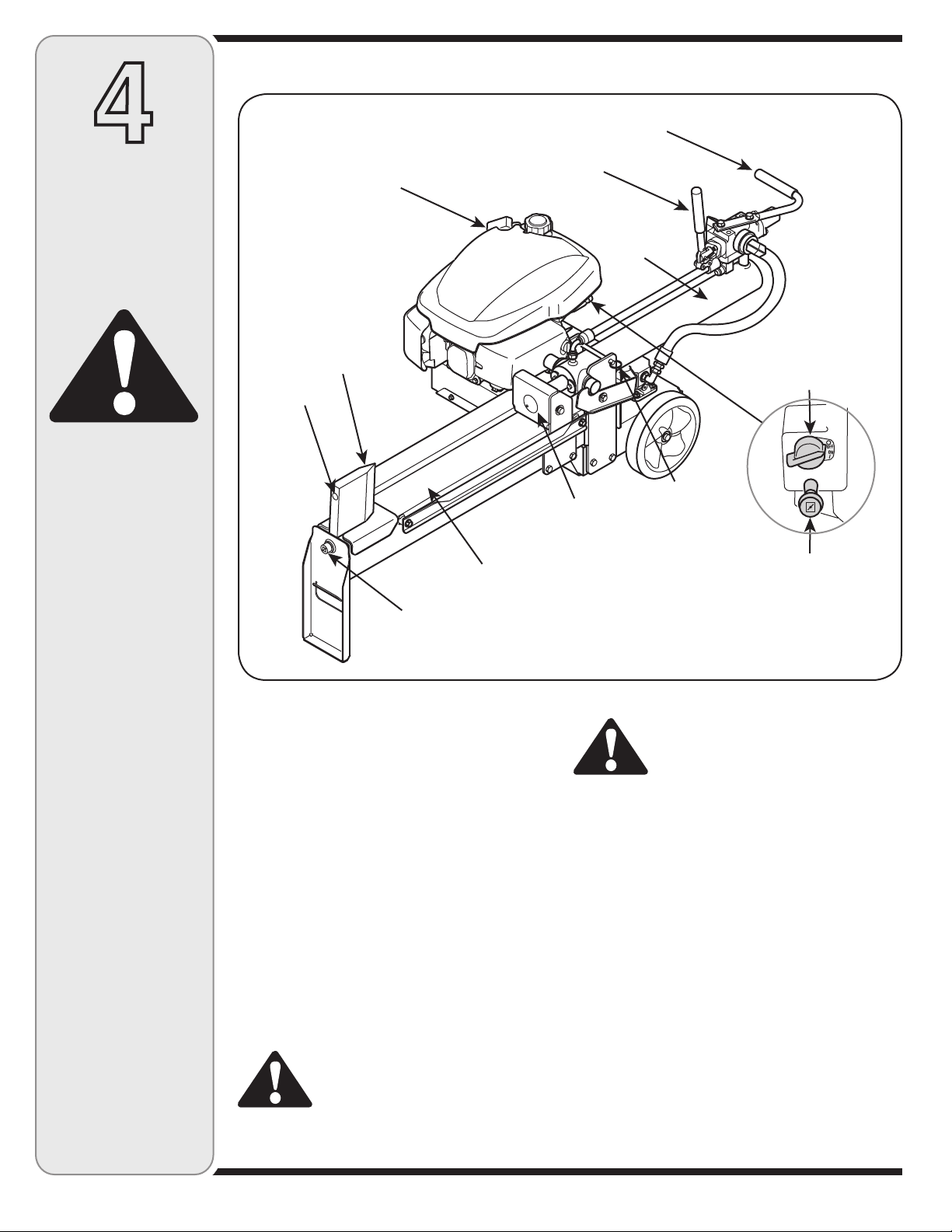

4

Starter Rope

Hydraulic

Valve Control

Wedge

Air Vent

Beam

Hydraulic Oil Fill

Engine Switch

Cylinder

Choke

Ram

Locking

Pin

Handle

Operating

Your Log

Splitter

WARNING

Read, understand, and

follow all instructions

and warnings on the

machine and in this

manual before operating.

Know Your Log Splitter

Wear leather work

gloves, safety shoes,

ear protection, and

safety glasses when

operating a log splitter.

Ensure safe footing.

Hydraulic Valve Control

The hydraulic valve control has three positions.

• FORWARD: Move control FORWARD toward wedge

to split wood.

NOTE: Control handle will return to neutral position as

soon as handle is released.(Forward Position only)

NEUTRAL: Release the control or move the lever to

•

neutral position to stop movement.

• REVERSE: Move control BACK to return toward

the cylinder base. The control stays in the return

(Reverse) position and returns to neutral automatically when fully retracted.

NOTE: Reverse position may also be operated back to

neutral position manually, if necessary.

WARNING: Read, understand, and

follow all instructions and warnings on

the machine and in this manual before

operating.

Figure 4-1

WARNING: Wear leather work gloves,

safety shoes, ear protection, and safety

glasses when operating a log splitter.

Ensure safe footing.

Handle

The handle is used to slide the cylinder into operating

position.

Air Vent

The air vent is located on the rear of the wedge and is

used to help vent air out of the hydraulic fluid reservoir. To

prevent fluid from escaping out of this hole, the log splitter

must always be operated on level ground.

Safety Switch

The safety switch is intended to prevent the operator

from starting the engine without the cylinder being in the

operating “lock” position. See Figure 4-3 for the location

of the safety switch.

8

Page 9

Starter Rope

The starter rope is located on the engine. See Figure 4-1.

Pull the recoil starter rope to start the unit.

Engine Switch

The engine switch is located on the engine. Turn it on

when starting the engine and use it to turn off the engine.

Choke

The choke is located on the engine and when activated,

closes the choke plate on the carburetor and aids in

starting the engine.

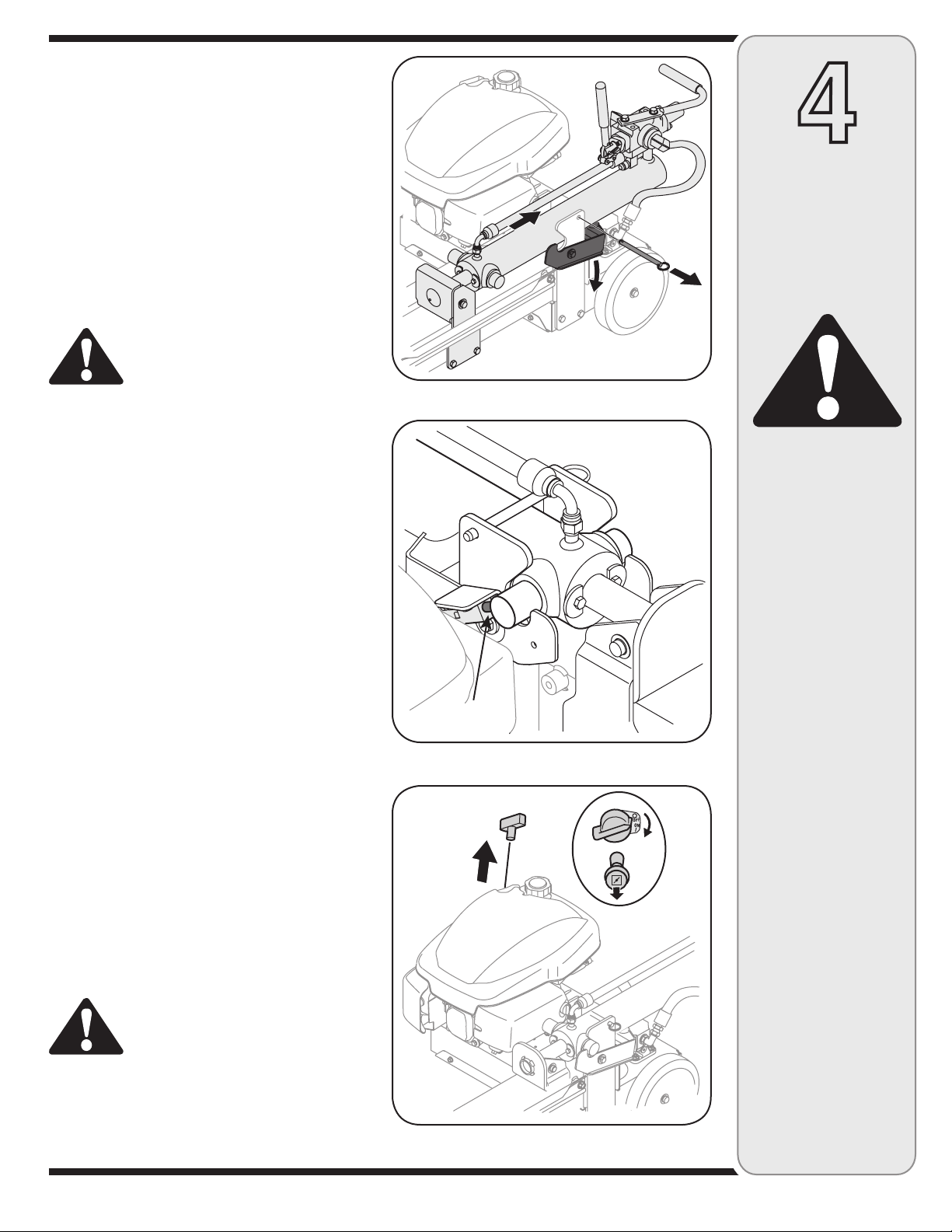

Starting Log Splitter

WARNING: Always keep hands and feet

clear of equipment moving parts. Do not

use a pressurized starting fluid. Vapors

are flammable.

NOTE: Make sure hydraulic pump is primed as instructed

in the “Setting Up Your Log Splitter” section.

1. Remove locking pin from cylinder storage position.

See Figure 4-2.

2. Use handle to slide cylinder rearward into the operating “Lock” position, engaging the safety switch, and

reinsert locking pin. See Figure 4-3.

3. Place the log splitter on level, dry, and solid ground.

4. Pull out the choke knob located on the engine. See

Figure 4-4 inset.

4

Operating

Your Log

Splitter

Figure 4-2

WARNING

Always keep hands

and feet clear of equipment moving parts. Do

not use a pressurized

starting fluid. Vapors

are flammable.

NOTE: Use of the choke may not be necessary if the

engine is warm or the air temperature is high.

5. Turn engine switch to on. See Figure 4-4 inset.

6. Pull the starter grip lightly until resistance is felt,

then pull rapidly to overcome compression, prevent

kickback and start engine. See Figure 4-4. If engine

does not start after ten seconds of repeated pulls, wait

a few minutes and repeat.

IMPORTANT: Do not allow the starter grip to snap

back against the rope guide. Return it gently to prevent

damage to the starter.

7. When engine warms up, push in the choke knob.

8. Use the hydraulic valve control to extend and retract

cylinder 4-6 cycles to remove trapped air in the

system.

WARNING: When starting a warm

engine, the muffler and surrounding

areas are hot and can cause a burn. Do

not touch.

Safety Switch

Figure 4-3

When starting a warm

engine, the muffler and

surrounding areas are

hot and can cause a

burn. Do not touch.

Figure 4-4

9

Page 10

4

Operating

Neutral

Forward

Reverse

Stopping Log Splitter

1. Turn off the engine switch.

2. Disconnect spark plug wire and ground against the

engine to prevent unintended starting.

3. Remove locking pin.

4. Return cylinder back to original position.

5. Place locking pin back into cylinder base to lock unit.

Your Log

Splitter

WARNING

Never remove partially

split wood from the

wedge with your

hands. Fingers may become trapped between

split wood.

Figure 4-5

Before Each Use

1. Remove the oil plug and check hydraulic fluid level on

level ground. Maintain fluid level to just below oil plug.

Refill if necessary. Approved fluids include Dexron®

III, or 10 weight AW hydraulic oil.

2. Check engine oil level. Refill if necessary.

3. Fill up gasoline if necessary.

4. Lubricate the beam area where cylinder will slide with

engine oil. Do not use grease to lubricate. Make sure

to lubricate both the top and bottom of the beam face.

5. Attach spark plug wire to the spark plug.

Using the Log Splitter

IMPORTANT: Always operate on level ground, otherwise

fluid may be forced out through the air vent hole.

1. Block the front and back of both wheels.

2. Place the log against the splitting wedge. Only split

wood in the direction of the grain.

3. Stabilize log, if needed, with your left hand on the

side of the log only. Never place hand on the end

between the log and the ram.

IMPORTANT: Only one adult should stabilize the log and

operate the hydraulic valve control, so the operator has

full control over the log and the ram.

4. Move hydraulic valve control FORWARD until ram

touches log. Release the hydraulic valve control to

NEUTRAL position to stop the ram movement. See

Figure 4-5.

5. Remove your left hand from log. Move hydraulic valve

control FORWARD to split log.

6. Move hydraulic valve control BACK to fully retract the

ram to the locked position.

WARNING: Never remove partially split

wood from the wedge with your hands.

Fingers may become trapped between

split wood.

10

Page 11

Operating Tips

Always:

1. Use clean fluid and check fluid level regularly.

2. Use an approved hydraulic fluid. Approved fluids

include Dexron® III, or a 10 Weight AW hydraulic oil.

3. Keep hoses clear and unblocked.

4. Use the hydraulic valve control to extend and retract

cylinder 4-6 cycles to remove trapped air in the system

before operating.

5. Flush and clean hydraulic system before restarting

after servicing.

6. Use “pipe dope” on all hydraulic fittings.

7. Operate on level ground.

8. Allow time for warm-up before splitting wood.

9. Prime the pump before initial start-up by pulling the

recoil starter on the engine 4-6 times with engine

switch in OFF position and spark plug disconnected.

10. Split wood along the grain (lengthwise) only.

11. Keep log centered in front of ram.

Never:

1. Use when fluid is below 20° F or above 150° F.

2. Operate in FORWARD or REVERSE position with

ram stopped for extended period.

3. Attempt to adjust unloading or relief valve settings.

4. Operate with air in hydraulic system.

5. Use teflon tape on hydraulic fittings.

6. Attempt to cut wood across the grain.

7. Attempt to remove partially split wood from the

wedge with your hands.

4

Operating

Your Log

Splitter

11

Page 12

5

Maintaining

Hydraulic Fluid

• Check the hydraulic fluid level in the log splitter

reservoir tank before each use. Maintain fluid level to

just below the oil plug.

• Have the hydraulic fluid in the reservoir changed every

100 hours of operation. See your authorized service

dealer to have the hydraulic fluid changed.

Your Log

Splitter

WARNING

Do not at any time

make any adjustments

without first stopping

engine, disconnecting

spark plug wire, and

grounding it against

the engine. Always

wear safety glasses

during operation or

while performing any

adjustments or repairs.

Higher pressure could

cause the hoses to

burst, cylinder to rupture, and intense fluid

to be released, which

could result in serious

personal injury.

Figure 5-1

WARNING: Before cleaning,

lubricating, repairing, or inspecting,

disengage the control lever and stop

engine. Disconnect the spark plug

wire and ground it against the engine to prevent

unintended starting. Always wear safety glasses

during operation or while performing any adjustments or repairs.

Conditions that Will Void Warranty

1. Failure to maintain proper fluid level in reservoir

2. Changing the relief valve setting or pressure adjust

ment of control valve without proper knowledge and

instruction from the factory

WARNING: Higher pressure could

cause the hoses to burst, cylinder

to rupture, and intense fluid to be

released, which could result in serious personal

injury.

3. Disassembling the pump

4. Use of incorrect hydraulic fluid

5. Lack of lubrication or improper lubrication of the

beam or unit

6. Excessive heating of the hydraulic system

7. Attempting to start unit in temperatures under 20°F

without pre-heating fluid in reservoir

8. Unattended leaks in hydraulic system

Beam and Splitting Wedge

• Lubricate top and bottom of the beam (where it comes

into contact with the cylinder), before each use, with

engine oil.

Hose Clamps (If Equipped)

• Check, before each use, if hose clamps on the suction

hose (attached to the side of the pump) are tight.

Check the hose clamps on the return hose at least

once a season.

Engine

Refer to the Engine maintenance section for all maintenance instructions.

Changing the Belt

WARNING: Be sure to shut the engine

off, disconnect the spark plug wire(s)

and ground against the engine to

prevent unintended starting before

removing the belt.

The belt on your log splitter is subject to wear and should

be replaced if any signs of wear are present.

IMPORTANT: The V-belt found on your log splitter is a

non-clutching, constant tension belt. A substitute (nonOEM) V-belt can be dangerous. For a proper working

machine, use factory approved belts.

To change or replace the belt on your log splitter, proceed

as follows:

NOTE: This procedure requires the assistance of a

second person.

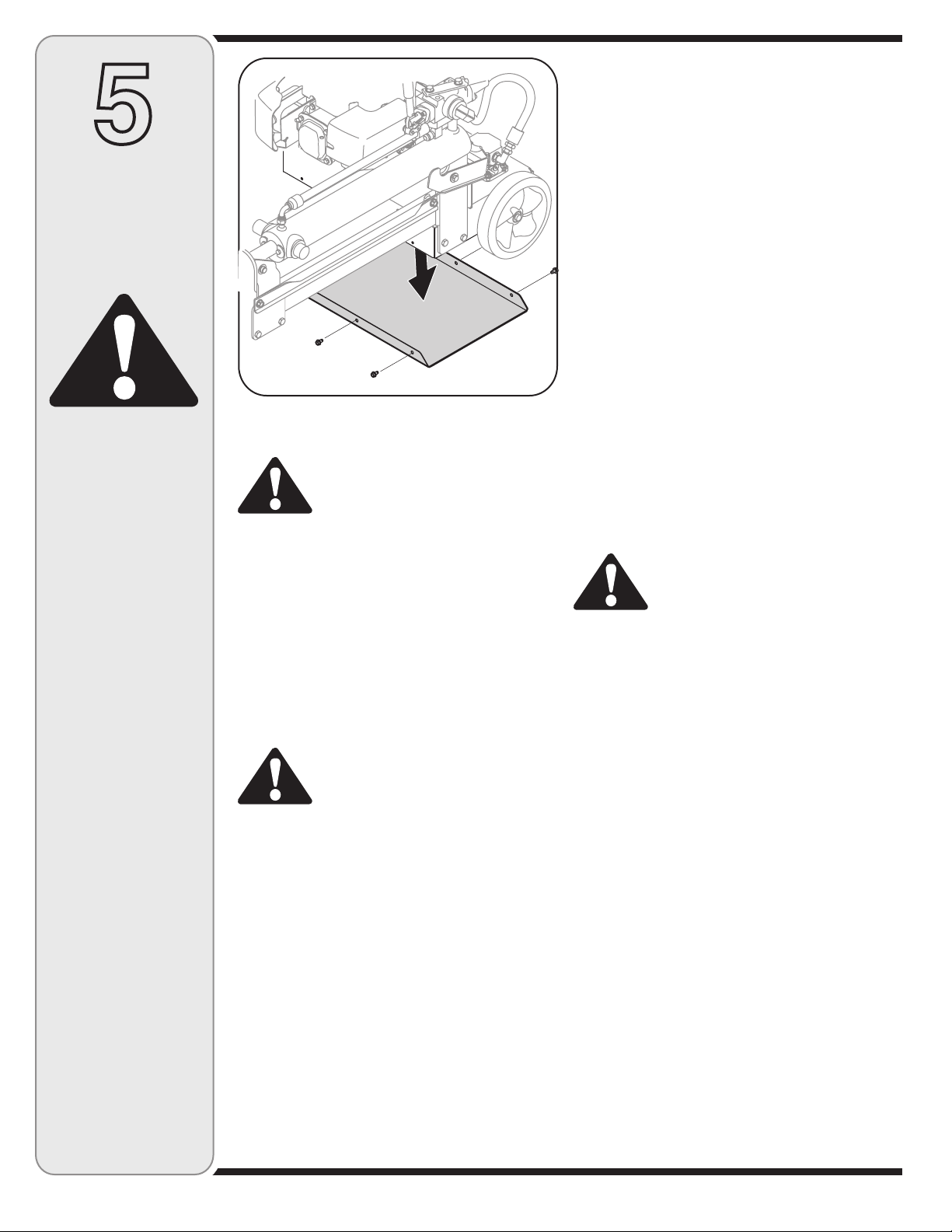

1. Place the unit in the transport position on level ground

as shown in Figure 5-1.

2. Disconnect the spark plug wire and ground it against

the engine.

3. Drain gasoline or place a piece of plastic beneath the

gas cap to prevent gasoline leakage.

4. Remove the belt cover by removing the six self-tap-

ping screws that fasten it to the frame. See Figure 5-1.

12

Page 13

5. Chock both wheels, front and rear, and have your

helper grasp the front of the unit and carefully tilt it

back to expose the belt drive underneath.

IMPORTANT: To prevent engine oil from entering

carburetor and/or hydraulic oil from escaping through the

air vent hole, do not tilt unit to the side.

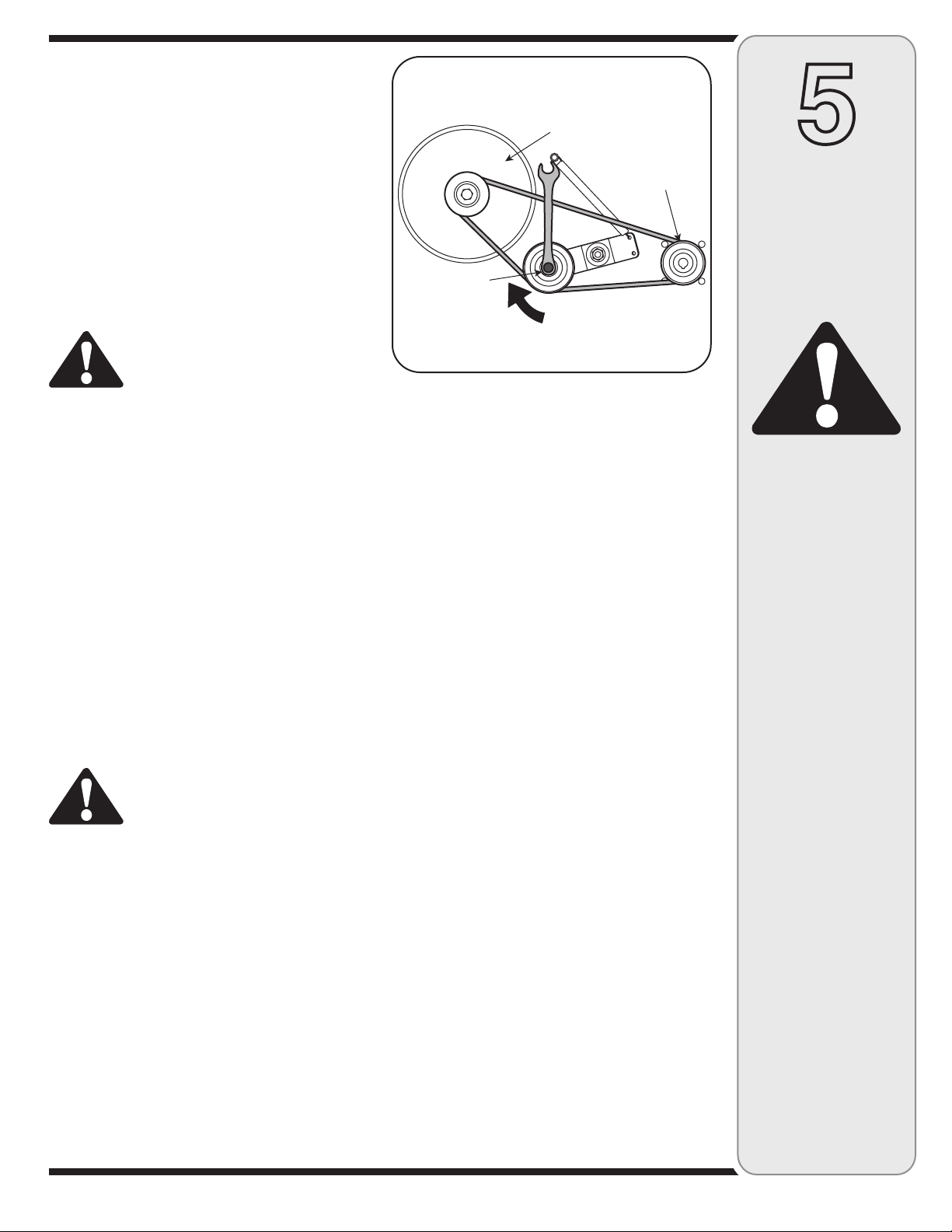

6. While your partner continues to hold the unit up, grasp

the idler pulley nut with a 9/16 hex wrench or socket

and pivot the idler bracket as shown in Figure 5-2.

This will enable the belt to be easily removed from the

idler pulley.

WARNING: Avoid the possibility of

a pinching injury. Do not place your

fingers on the idler spring or between

the belt and a pulley while removing the

belt.

7. Remove the belt from around the engine and pump

pulleys.

8. Route the new belt around the three pulleys as shown

in Figure 5-2.

NOTE: Idler bracket must pivot freely.

9. Have your partner lower unit and remount the belt

cover removed earlier. Do not over tighten.

10. Remove piece of plastic from gas cap (if used).

11. Reconnect spark plug.

Storing Your Log Splitter

Prepare your log splitter for storage at the end of the

season or if the log splitter will not be used for 30 days or

more.

WARNING: Never store machine with

fuel in the fuel tank inside of building

where fumes may reach an open flame

or spark, or where ignition sources

are present such as hot water and space heaters,

furnaces, clothes dryers, stoves, electric motors, etc.

Engine

Pulley

Pump

Pulley

Idler Pulley

Nut

Figure 5-2

2. Wipe unit with an oiled rag to prevent rust, especially

on the wedge and the beam.

3. Drain fuel tank. Always drain fuel into approved

container outdoors, away from open flame. Be sure

that engine is cool before draining the fuel. Do not

smoke while handling fuel.

4. Start the engine and let it run until the fuel lines and

carburetor are empty.

5. Remove spark plug. Holding a rag over the cylinder

hole, pour approximately 1/2 ounce (approximately

one tablespoon) of engine oil into cylinder and crank

slowly to distribute the oil.

6. Replace spark plug.

7. Do not store gasoline from one season to another.

8. Replace your gasoline can if it starts to rust. Rust

and/or dirt in the gasoline will cause problems.

NOTE: For more information on storing the engine, refer

to the Engine Maintenance section.

9. Store unit in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer. DO NOT store

unit in upright position.

5

Maintaining

Your Log

Splitter

WARNING

Avoid the possibility of

a pinching injury. Do

not place your fingers

on the idler spring or

between the belt and a

pulley while removing

the belt.

Avoid the possibility of

a pinching injury. Do

not place your fingers

on the idler spring or

between the belt and a

pulley while removing

the belt.

1. Clean the log splitter thoroughly.

NOTE: We do not recommend the use of pressure washers or garden hose to clean your unit. They may cause

damage to bearings or the engine. The use of water will

result in shortened life and reduce serviceability.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coating

with a light oil or silicone.

13

Page 14

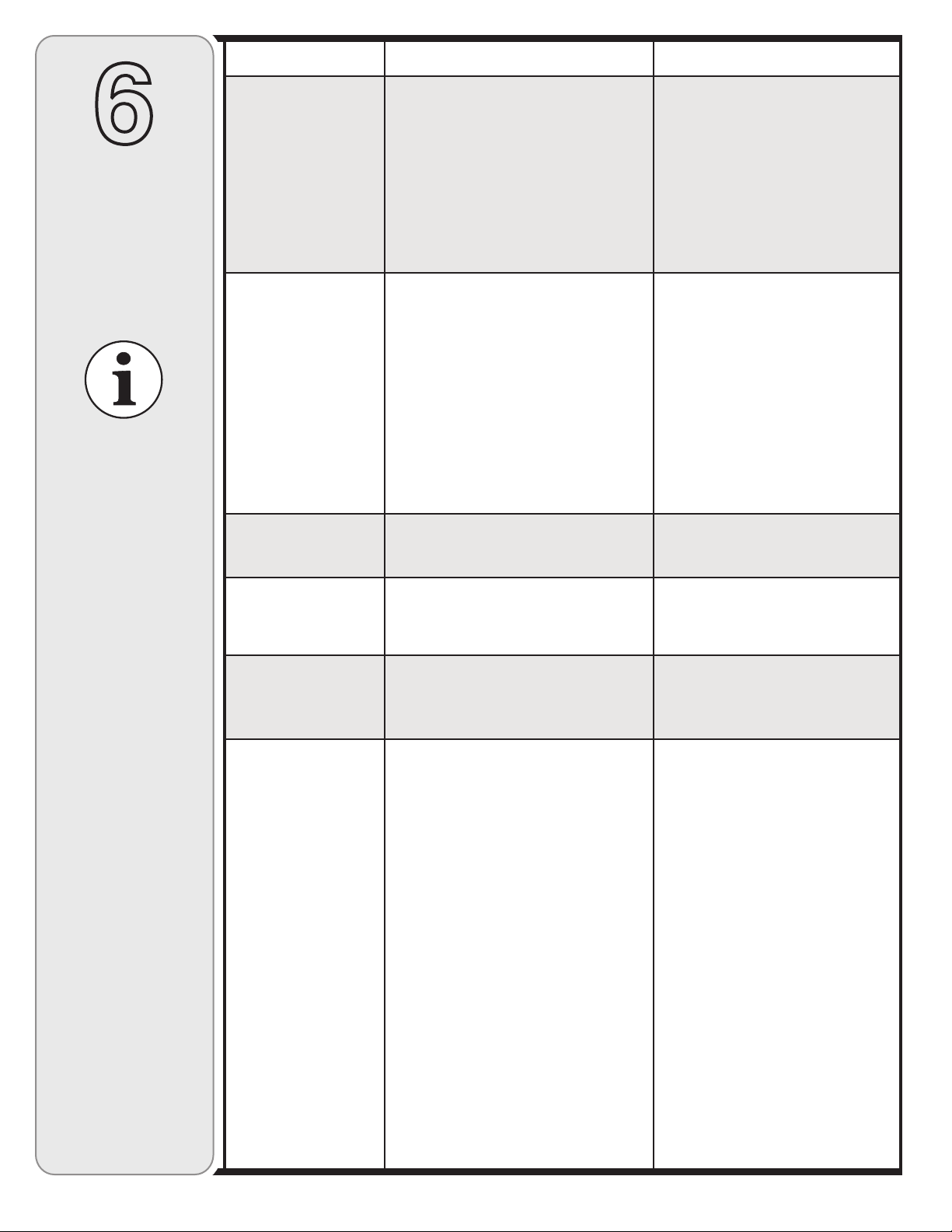

6

Trouble

Shooting

For repairs beyond

the minor adjustments listed here,

contact an authorized

service dealer.

Engine fails to start

Engine runs erratic

Engine Overheats

Occasional skips

(hesitates) at

CauseProblem Remedy

1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Choke, if equipped, not in CHOKE

position.

4. Trunnions not depressing safety switch.

5. Faulty spark plug.

6. Blocked fuel line.

7. Engine Flooded.

1. Unit running on CHOKE, if equipped.

2. Spark plug wire loose.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Vent in gas cap plugged.

1. Engine oil level low.

2. Air flow restricted.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move choke to CHOKE position.

4. Move cylinder into locked position.

5. Clean, adjust gap, or replace.

6. Clean fuel line.

7. Wait a few minutes to start.

1. Push CHOKE knob in.

2. Connect and tighten spark

plug wire.

3. Clean fuel line; fill tank with clean,

fresh (less than 30 days old)

gasoline.

4. Drain fuel tank. Refill with

fresh fuel.

5. Refer to engine maintenance

section.

6. Clear vent.

1. Fill crankcase with proper oil.

2. Remove blower housing

and clean.

1. Adjust gap to .030”.1. Spark plug gap too close.

Hydraulic

Trouble

Shooting

high speed

Idles poorly

Cylinder rod will not

move

1. Spark plug fouled, faulty or gap

too wide.

2. Dirty air cleaner.

CauseProblem Remedy

1. Broken or worn belt.

2. Shipping plugs left in hydraulic hoses.

3. Set screws in pump pulley not

adjusted properly.

4. Loose pulley.

5. Pump gear sections damaged.

6. Damaged relief valve.

7. Hydraulic lines blocked.

8. Incorrect oil level.

9. Damaged directional valve.

10. Blocked directional valve.

11. Unlevel ground; hydraulic fluid not

reaching pump.

1. Reset gap to .030” or replace

spark plug.

2. Refer to engine maintenance

section.

1. Replace belt.

2. Disconnect hydraulic hoses,

remove shipping plugs, reconnect

hoses.

3. See authorized service dealer.

4. Correct engine/pump alignment as

necessary.

5. See authorized service dealer.

6. See authorized service dealer.

7. Flush and clean hydraulic system.

8. Check oil level.

9. See authorized service dealer.

10.Flush and clean hydraulic system.

11. Move log splitter to level ground.

14

Page 15

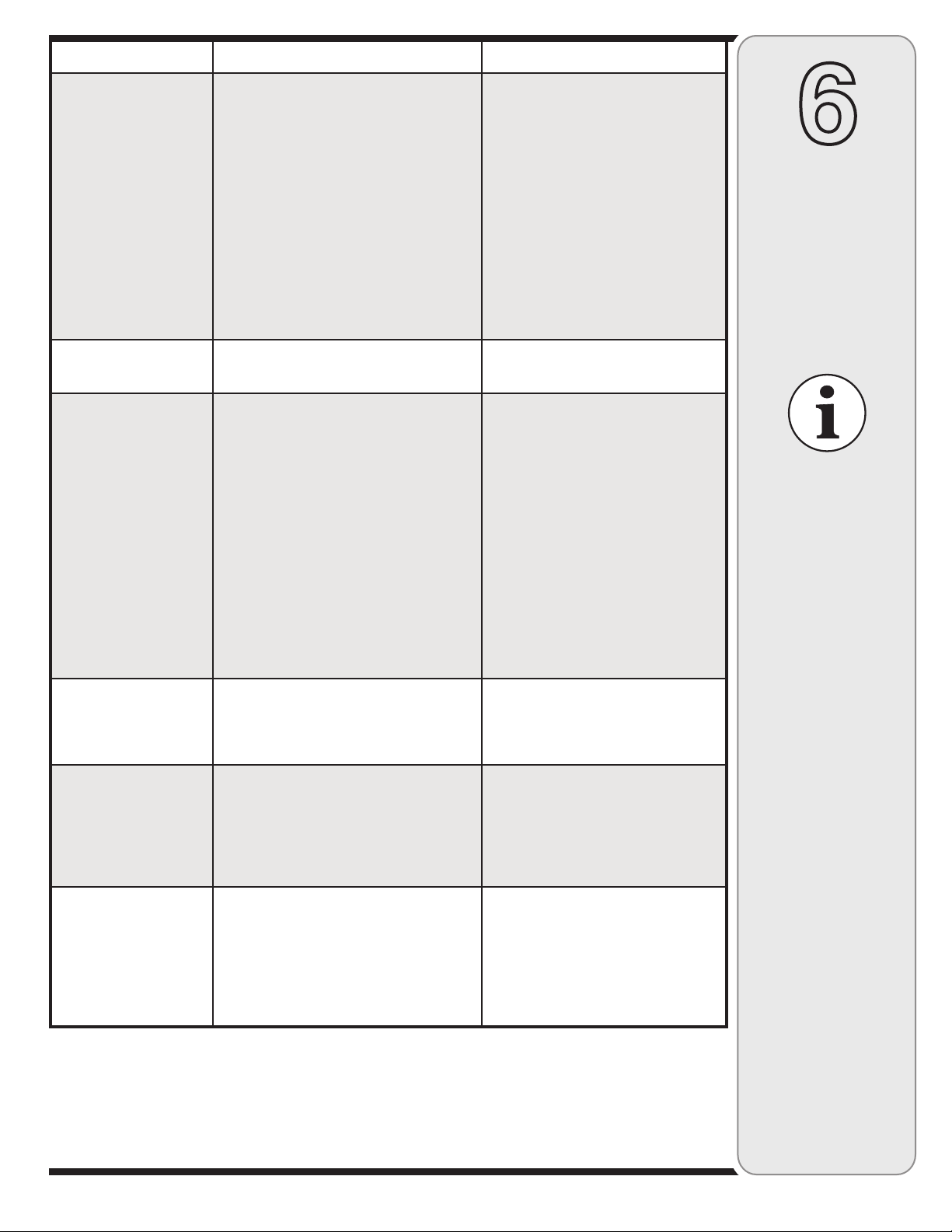

Slow cylinder shaft

speed while extending

and retracting.

Leaking Cylinder

CauseProblem Remedy

1. Gear sections damaged.

2. Excessive pump inlet vacuum.

3. Slow engine speed.

4. Damaged relief valve.

5. Incorrect oil level.

6. Contaminated oil.

7. Directional valve leaking internally.

8. Internally damaged cylinder.

9. Unit not on level ground.

1. Broken seals.

2. Scored cylinder.

1. See authorized service dealer.

2. Make certain pump inlet hoses are

clear and unblocked-use short,

large diameter inlet hoses.

3. See authorized service dealer.

4. See authorized service dealer.

5. Check oil level.

6. Drain oil, clean reservoir, and refill.

7. See authorized service dealer.

8. See authorized service dealer.

9. Move log splitter to level ground.

1. See authorized service dealer.

2. See authorized service dealer.

6

Hydraulic

Trouble

Shooting

Engine runs but wood

will not split or wood

splits too slowly

Engine stalls during

splitting

Engine will not turn or

stalls under low load

conditions

Leaking pump shaft

seal

1. Small gear section damaged.

2. Pump check valve leaking.

3. Excessive pump inlet vacuum.

4. Incorrect oil level.

5. Contaminated oil.

6. Directional valve leaking internally.

7. Overloaded cylinder.

8. Internally damaged cylinder.

9. Worn belt.

10. Unit not on level ground.

1. Low horsepower/weak engine.

2. Overloaded cylinder.

1. Engine/pump misalignment.

2. Frozen or seized pump.

3. Low horsepower/weak engine.

4. Hydraulic lines blocked.

5. Blocked directional valve.

1. Broken drive shaft.

2. Engine/pump misalignment.

3. Gear sections damaged.

4. Poorly positioned shaft seal.

5. Plugged oil breather.

1. See authorized service dealer.

2. See authorized service dealer.

3. Make certain pump inlet hoses are

clear and unblocked.

4. Check oil level.

5. Drain oil, clean reservoir, and refill.

6. See authorized service dealer.

7. Do not attempt to split wood

against the grain.

8. See authorized service dealer.

9. Replace belt.

10. Move log splitter to level ground.

1. See authorized service dealer.

2. Do not attempt to split wood

against the grain or see authorized

service dealer.

1. Correct alignment as necessary.

2. See authorized service dealer.

3. See authorized service dealer.

4. Flush and clean hydraulic system.

5. Flush and clean hydraulic system.

1. See authorized service dealer.

2. Correct alignment as necessary.

3. See authorized service dealer.

4. See authorized service dealer.

5. Make certain reservoir is properly

vented.

For repairs beyond

the minor adjustments listed here,

contact an authorized

service dealer.

15

Page 16

8

WARNING: Gasoline and its vapors are extremely flammable and explosive. Fire or

explosion can cause severe burns or death. If gasoline is spilled on yourself or your

clothes, wash your skin and change clothes immediately.

Engine

Safe

Operation

Practices

WARNING

Gasoline and its vapors

are extremely flammable and explosive.

Fire or explosion can

cause severe burns

or death. If gasoline is

spilled on yourself or

your clothes, wash your

skin and change clothes

immediately.

Starting engine creates

sparking. Sparking can

ignite nearby flammable gases. Explosion

and fire could result.

Unintentional sparking

can result in fire or

electric shock. Unintentional start-up can

result in entanglement,

traumatic amputation,

or laceration.

Gasoline and its vapors are

extremely flammable and

explosive. Fire or explosion can

cause severe burns or death. If

gasoline is spilled on yourself

or your clothes, wash your skin

and change clothes immediately.

• When adding fuel, turn engine OFF and let engine

cool at least 2 minutes before removing gas cap.

• Fill fuel tank outdoors or in well ventilated area.

• Use only an approved gasoline container.

• Never fill containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers on the ground away from your vehicle before

filling.

• If possible, remove gas-powered equipment from the

truck or trailer and refuel it on the ground. If this is

not possible, then refuel such equipment on a trailer

with a portable container, rather than from a gasoline

dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

• Do not overfill fuel tank. Fill tank to approximately

2 cm below lowest portion of neck to allow for fuel

expansion.

• Keep gasoline away from sparks, open flames, pilot

lights, heat, and other ignition sources.

• Never fuel equipment indoors because flammable

vapors will accumulate in the area.

• Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

• Check fuel line, tank, cap, and fittings frequently for

cracks or leaks. Replace if necessary.

• When starting engine, make sure spark plug, muffler,

fuel cap and air cleaner are in place.

• Do not crank engine with spark plug removed.

• If fuel spills, wait until it evaporates before starting

engine.

• When operating equipment, do not tip engine or

equipment at angle which causes gasoline to spill.

• Do not choke carburetor to stop engine.

• When transporting equipment, transport with fuel tank

EMPTY.

• When storing gasoline or equipment with fuel in tank,

store away from furnaces, stoves, water heaters or

other appliances that have pilot light or other ignition

source because they can ignite gasoline vapors.

Starting engine creates sparking. Sparking can ignite nearby

flammable gases. Explosion and

fire could result.

• If there is a natural or LP gas leakage in area, do not

start engine.

• Do not use pressurized starting fluids because vapors

are flammable.

Engines give off carbon monoxide, an odorless, colorless,

poisonous gas. Breathing carbon

monoxide can cause nausea,

fainting, or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area, even if

doors or windows are open.

Unintentional sparking can result

in fire or electric shock. Unintentional start-up can result in

entanglement, traumatic amputation, or laceration.

• Before peforming adjustments or repairs, disconnect

spark plug wire and keep it away from spark plug.

• When testing for spark, use approved spark plug

tester.

• Do not check for spark with spark plug removed.

16

Page 17

Running engine produces heat.

2UN

3TART

4OXIC&UMES

(OT3URFACE

3AFETY!LERT

5NLEADED&UEL

-ANUAL

2EAD/WNERS

'ASOLINE)S

&LAMMABLE

0 "

Engine parts, especially muffler,

become extremely hot. Severe

thermal burns can occur on

contact. Combustible debris,

such as leaves, grass, brush, etc.,

can catch fire.

• Allow muffler, engine cylinder, and fins to cool before

touching.

• Keep children away from hot or running engines. They

can suffer burns from a hot muffler.

• Remove accumulated combustibles from muffler and

cylinder area.

Rotating engine parts can

contact or entangle hands, feet,

hair, clothing, or accessories.

Traumatic amputation or severe

laceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

Pb

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling draw

strings or items that could become caught.

Rapid retraction of starter cord

(kickback) will pull hand and

arm toward engine faster than

you can let go. Broken bones,

fractures, bruises or sprains

could result.

• When starting engine, pull cord slowly until resistance is felt, then pull rapidly.

• Remove all external equipment/engine loads before

starting engine.

• Direct coupled equipment components such as, but

not limited to blades, impellers, pulleys, sprockets,

etc., must be securely attached.

Safety Label Location

This label warns you of potential hazards that can cause

serious injury. Read it carefully. See Figure 8-1 for

explanation of symbols.

If the label comes off or becomes hard to read, contact

the dealer for replacement.

-

8

Engine

Safe

Operation

Practices

WARNING

Running engine

produces heat. Engine

parts, especially muffler, become extremely

hot. Severe thermal

burns can occur on

contact. Combustible

debris, such as leaves,

grass, brush, etc., can

catch fire.

International Symbols and Meanings

Figure 8-1

17

Rotating engine parts

can contact or entangle

hands, feet, hair, clothing, or accessories.

Traumatic amputation

or severe laceration

can result.

Rapid retraction of

starter cord (kickback)

will pull hand and

arm toward engine

faster than you can

let go. Broken bones,

fractures, bruises or

sprains could result.

Page 18

9

Know Your Engine

Fuel Cap

Operating

Your

Engine

WARNING

This engine is

shipped without

gasoline or oil in

the engine. Running

the engine with

insufficient oil can

cause serious engine

damage and void the

engine warranty.

Using nondetergent

oil or 2-stroke engine

oil could shorten the

engine’s service life.

Air Cleaner

Starter

Grip

Oil Fill Cap

Oil Drain

Muffler

Figure 9-1: The major components of the engine. The shroud on your engine may differ.

Read this section before starting your log splitter engine. Compare the illustrations in Figure 9-1 with your log splitter

engine to familiarize yourself with the location of various controls and adjustments.

Spark Plug

Pre-Operation Check

Oil Recommendations

IMPORTANT: This engine is shipped without gasoline or

oil in the engine. Running the engine with insufficient oil

can cause serious engine damage and void the engine

warranty.

• Before starting engine, fill with oil. Do not over-fill. Oil

capacity is about 20 oz.

Use a 4-stroke, or an equivalent high detergent,

premium quality motor oil certified to meet or exceed

U.S. automobile manufacturer’s requirements for service

classification SG/SF. Motor oils classified SG/SF will

show this designation on the container.

SAE 10W-30 is recommended for general, all temperature use. If single viscosity oil is used, select the

appropriate viscosity for the average temperature in your

area from the chart to the right.

NOTE: A 5w30 synthetic oil may be used to improve

startability for cold weather (temperatures below 40

degrees F).

IMPORTANT: Using nondetergent oil or 2-stroke

engine oil could shorten the engine’s service life.

1

20w40, 20w50

15w40, 15w50

2

10w40

10w30

(ºC)

-30º -20º

(ºF)

-20º

Ambient Temperature

1. Single Viscosity

2. Multi Viscosity

-10º 0º

0º 20º 40º 60º 80º 100º

10w

20w

20

40

10º 20º 30º 40º

30

Check Oil Level

IMPORTANT: Be sure to check the engine on a level

surface with the engine stopped.

1. Remove the oil filler cap and wipe the dipstick clean.

18

Page 19

2. Insert the dipstick into the engine block, but do not

screw it in. See Figure 9-2.

3. If the level is low, slowly add oil to the upper limit on

the dipstick.

4. Tighten dipstick firmly before starting engine.

9

IMPORTANT: Do not overfill. Overfilling with oil may

cause smoking, hard starting, spark plug fouling, or oil

saturation of air cleaner.

Fuel Recommendations

Use automotive gasoline (unleaded or low leaded to

minimize combustion chamber deposits) with a minimum

of 87 octane. Gasoline with up to 10% ethanol or 15%

MTBE (Methyl Tertiary Butyl Ether) can be used. Never

use an oil/gasoline mixture or dirty gasoline. Avoid

getting dirt, dust, or water in the fuel tank. DO NOT use

E85 gasoline.

WARNING: Gasoline is extremely flammable and is explosive under certain

conditions.

Refuel in a well-ventilated area with the engine

stopped. Do not smoke or allow flames or sparks

in the area where the engine is refueled or where

gasoline is stored.

Do not overfill the fuel tank (there should be no fuel

in the filler neck). After refueling, make sure the tank

cap is closed properly and securely.

Oil Fill Cap/

Dipstick

Upper Level

Figure 9-2: Checking the oil level.

Operating

Your

Engine

WARNING

Gasoline is extremely

flammable and is

explosive under

certain conditions.

Be careful not to spill fuel when refueling. Spilled

fuel or fuel vapor may ignite. If any fuel is spilled,

make sure the area is dry before starting the engine.

Avoid repeated or prolonged contact with skin or

breathing of vapor.

Check Fuel Level

1. Clean around fuel fill before removing cap to fuel.

2. Fill tank to approximately one inch below lowest

portion of neck to allow for fuel expansion. Be careful

not to overfill.

IMPORTANT: Before refueling, allow engine to cool two

minutes.

Starting The Engine

WARNING: Always keep hands and

feet clear of equipment moving parts.

Do not use a pressurized starting fluid.

Vapors are flammable.

1. Check to make sure that cylinder is in the operating

“Lock” position, engaging safety switch.

2. Pull out the choke knob located on the engine. See

Figure 9-3 inset.

Figure 9-3: Starting the log splitter.

NOTE: Use of the choke may not be necessary if the

engine is warm or the air temperature is high.

3. Turn engine switch to on.

4. Pull the starter grip lightly until resistance is felt,

then pull rapidly to overcome compression, prevent

kickback and start engine. See Figure 9-3. If engine

does not start after ten seconds of repeated pulls, wait

a few minutes and repeat.

IMPORTANT: Do not allow the starter grip to snap

back against the rope guide. Return it gently to prevent

damage to the starter.

5. When engine warms up, push in the choke knob.

Stopping The Engine

1. Turn off the engine switch.

Always keep hands

and feet clear of

equipment moving

parts. Do not use a

pressurized starting

fluid. Vapors are flammable.

19

Page 20

10

Maintaining

Your

Engine

WARNING

Shut off the engine

before performing

any maintenance. To

prevent accidental

start-up, disconnect

the spark plug boot.

WARNING: Shut off the engine before

performing any maintenance. To

prevent accidental start-up, disconnect

the spark plug boot.

IMPORTANT: If engine must be tipped to transport

equipment or to inspect, keep spark plug side of engine

up. Transporting or tipping engine spark plug down may

cause smoking, hard starting, spark plug fouling, or oil

saturation of air cleaner.

Maintenance Schedule

Tasks

Check Engine

Oil

Change Engine

Oil

Check Air

Cleaner

Service Air

Cleaner

Check Spark

Plug

Service Spark

Plug

Clean Finger

Guard

Clean Around

Muffler

First 5 hours

Each use or

every 5 hours

Every season

or 25 hours

Periodic inspection and adjustment of the engine is

essential if high level performance is to be maintained.

Regular maintenance will also ensure a long service life.

The required service intervals and the kind of maintenance to be performed are described in the table below.

Follow the hourly or calendar intervals, whichever occur

first. More frequent service is required when operating in

adverse conditions.

Every season

or 50 hours

Every season

or 100 hours

Service Dates

IMPORTANT

Be sure to check

engine on a level

surface with the engine

stopped. Drain the oil

while the engine is still

warm to assure rapid

and complete draining.

† Service more frequently when used in dusty areas.

†† If operating under heavy load or high ambient temperature.

Oil Service

Oil Fill Cap

Oil

Drain

• Check oil level regularly.

• Be sure correct oil level is maintained. Check every five

Oil Change

IMPORTANT: Be sure to check engine on a level surface

with the engine stopped. Drain the oil while the engine is

still warm to assure rapid and complete draining.

1. Remove drain plug and allow oil to drain into a suitable

Level

2. Reinstall the drain plug and tighten it securely.

3. Refill with the recommended oil (see Operation

Figure 10-1: Changing the oil.

4. Reinstall the oil fill cap securely.

hours or daily before starting engine. See oil checking

procedure in the Operation section.

container. See Figure 10-1.

section) and check the oil level. See Figure 10-1.

20

Page 21

IMPORTANT: Used motor oil may cause skin cancer

if repeatedly left in contact with the skin for prolonged

periods. Although this is unlikely unless you handle used

oil on a daily basis, it is still advisable to thoroughly wash

your hands with soap and water as soon as possible

after handling used oil.

Paper Element

10

NOTE: Please dispose of used motor oil in a manner that

is compatible with the environment. We suggest you take

it in a sealed container to your local service station for

reclamation. Do not throw it in the trash or pour it on the

ground.

Air Cleaner Service

Paper filters cannot be cleaned and must be replaced

once a year or every 100 operating hours; more often if

used in extremely dusty conditions.

WARNING: Never use gasoline or low

flash point solvents for cleaning the

air cleaner element. A fire or explosion

could result.

IMPORTANT: Never run the engine without the air

cleaner. Rapid engine wear will result.

1. Remove the wing bolt and the air cleaner cover.

Remove the elements and separate them. See Figure

10-2. Replace paper element when dirty or damaged.

Replace foam element when damaged.

2. To clean foam element, separate it from the paper

element and wash in liquid detergent and water. Allow

to dry thoroughly before using. Do not oil the foam

element.

Spark Plug Service

WARNING: DO NOT check for spark

with spark plug removed. DO NOT

crank engine with spark plug removed.

Foam Element

Figure 10-2: Servicing the air cleaner.

Spark Plug

Spark Plug Boot

Figure 10-3: The spark plug and boot.

Maintaining

Your

Engine

WARNING

Never use gasoline

or low flash point solvents for cleaning the

air cleaner element.

A fire or explosion

could result.

DO NOT check for

spark with spark plug

removed. DO NOT

crank engine with

spark plug removed.

To ensure proper engine operation, the spark plug must

be properly gapped and free of deposits.

1. Remove the spark plug boot and use a spark plug

wrench to remove the plug. See Figure 10-3.

WARNING: If the engine has been

running, the muffler will be very hot. Be

careful not to touch the muffler.

2. Visually inspect the spark plug. Discard the spark

plug if there is apparent wear, or if the insulator is

cracked or chipped. Clean the spark plug with a wire

brush if it is to be reused.

3. Measure the plug gap with a feeler gauge. Correct

as necessary by bending side electrode. See Figure

10-4. The gap should be set to 0.030 in.

Electrode

0.030 in.

Figure 10-4: Measure the plug gap with a feeler gauge.

21

If the engine has

been running, the

muffler will be very

hot. Be careful not to

touch the muffler.

Page 22

10

Maintaining

Your

Engine

WARNING

Accumulation of

debris around muffler

could cause a fire.

Inspect and clean

before every use.

IMPORTANT

Do not spray engine

with water to clean

because water could

contaminate fuel.

Using a garden hose

or pressure washing

equipment can also

force water into the

air cleaner or muffler

opening. Water in the

air cleaner will soak

the paper element,

and water that passes

through the element

or muffler can enter

the cylinder, causing

damage.

4. Check that the spark plug washer is in good condition and thread the spark plug in by hand to prevent

cross-threading.

5. After the spark plug is seated, tighten with a spark

plug wrench to compress the washer.

NOTE: When installing a new spark plug, tighten 1/2

turn after the spark plug seats to compress the washer.

When reinstalling a used spark plug, tighten 1/8-1/4 turn

after the spark plug seats to compress the washer.

IMPORTANT: The spark plug must be securely tightened. An improperly tightened spark plug can become

very hot and may damage the engine.

Clean Engine

If the engine has been running, allow it to cool for at

least half an hour before cleaning. Periodically remove

dirt build-up from engine. Clean finger guard and around

muffler. Clean with a brush or compressed air.

IMPORTANT: Do not spray engine with water to clean

because water could contaminate fuel. Using a garden

hose or pressure washing equipment can also force

water into the air cleaner or muffler opening. Water in

the air cleaner will soak the paper element, and water

that passes through the element or muffler can enter the

cylinder, causing damage.

WARNING: Accumulation of debris

around muffler could cause a fire.

Inspect and clean before every use.

Storage

Engines stored over 30 days need to be drained of fuel

to prevent deterioration and gum from forming in fuel

system or on essential carburetor parts. If the gasoline in

your engine deteriorates during storage, you may need to

have the carburetor, and other fuel system components,

serviced or replaced.

1. Remove all fuel from tank by running engine until it

stops from lack of fuel.

2. Change oil. See Oil Change section.

3. Remove spark plug and pour about 1/2 an ounce of

engine oil into cylinder. Replace spark plug and crank

slowly to distribute oil.

4. Clean debris from around engine, under finger guard,

and under, around and behind muffler. Touch up any

damaged paint, and coat other areas that may rust with

a light film of oil.

5. Store in a clean, dry and well ventilated area away from

any appliance that operates with a flame or pilot light,

such as a furnace, water heater, or clothes dryer. Also

avoid any area with a spark producing electric motor,

or where power tools are operated.

6. If possible, also avoid storage areas with high humidity,

because that promotes rust and corrosion.

7. Keep the engine level in storage. Tilting can cause fuel

or oil leakage.

Removing From Storage

1. Check your engine as described in the Pre-Operation

Check section of this manual.

2. If the fuel was drained during storage preparation, fill

the tank with fresh gasoline. If you keep a container

of gasoline for refueling, make certain it contains only

fresh fuel. Gasoline oxidizes and deteriorates over

time, causing hard starting.

3. If the cylinder was coated with oil during storage

preparation, the engine will smoke briefly at startup.

This is normal.

22

Page 23

TWO YEAR LIMITED WARRANTY

The limited warranty set forth below is given by MTD Products Limited with respect to new merchandise purchased and used in

Canada and/or its territories and possessions (either entity respectively, “MTD”).

MTD warrants this product (excluding its normal wear parts as described below) against defects in material and workmanship for

a period of two (2) years commencing on the date of original purchase and will, at its option, repair or replace, free of charge, any

part found to be defective in materials or workmanship. This limited warranty shall only apply if this product has been operated

and maintained in accordance with the Operator’s Manual furnished with the product, and has not been subject to misuse, abuse,

commercial use, neglect, accident, improper maintenance, alteration, vandalism, theft, fire, water, or damage because of other peril

or natural disaster. Damage resulting from the installation or use of any part, accessory or attachment not approved by MTD for use

with the product(s) covered by this manual will void your warranty as to any resulting damage.

Normal wear parts are warranted to be free from defects in material and workmanship for a period of thirty (30) days from the date of

purchase. Normal wear parts include, but are not limited to items such as: batteries, belts, blades, blade adapters, grass bags, rider

deck wheels, seats, snow thrower skid shoes, friction wheels, shave plates, auger spiral rubber, tires engine oil, air filters and spark

plugs.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH PROOF OF PURCHASE, through your local authorized service

dealer. To locate the dealer in your area contact MTD Products Limited, Kitchener, ON N2G 4J1, or call 1-800-668-1238 or log on to

our Web site at www.mtdcanada.com.

This limited warranty does not provide coverage in the following cases:

a. The engine or component parts thereof. These items may carry a separate manufacturer’s warranty. Refer to applicable

manufacturer’s warranty for terms and conditions. The Powermore engine is not excluded under this agreement.

b. Log splitter pumps, valves, and cylinders have a separate one-year warranty.

c. Routine maintenance items such as lubricants, filters, blade sharpening, tune-ups, brake adjustments, clutch adjustments, deck

adjustments, and normal deterioration of the exterior finish due to use or exposure.

d. Service completed by someone other than an authorized service dealer.

e. MTD does not extend any warranty for products sold or exported outside of Canada, including possessions and territories.

f. Replacement parts that are not genuine MTD parts.

g. Transportation charges and service calls.

h. If Products are used commercially. (MTD may separately offer Limited Commercial Warranties on certain select products. Ask

your dealer or retailer for details or contact MTD Service for more information.)

No implied warranty, including any implied warranty of merchantability of fitness for a particular purpose, applies after

the applicable period of express written warranty above as to the parts as identified. No other express warranty, whether

written or oral, except as mentioned above, given by any person or entity, including a dealer or retailer, with respect to any

product, shall bind MTD. During the period of the warranty, the exclusive remedy is repair or replacement of the product as

set forth above.

The provisions as set forth in this warranty provide the sole and exclusive remedy arising from the sale. MTD shall not

be liable for incidental or consequential loss or damage including, without limitation, expenses incurred for substitute or

replacement lawn care services or for rental expenses to temporarily replace a warranted product.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions or limitations may not apply to you.

In no event shall recovery of any kind be greater than the amount of the purchase price of the product sold. Alteration of safety

features of the product shall void this warranty. You assume the risk and liability for loss, damage, or injury to you and your

property and/or to others and their property arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the original purchaser or to the person for whom it was purchased as a

gift.

HOW LOCAL LAWS RELATE TO THIS WARRANTY: This limited warranty gives you specific legal rights, and you may also have

other rights that vary in different jurisdictions.

IMPORTANT: Owner must present Original Proof of Purchase to obtain warranty coverage.

MTD Products Ltd., P. O. BOX 1386, KITCHENER, ON N2G 4J1; Phone: 1-800-668-1238

12.16.06

23

Page 24

Model Series 5DM

33

2936

38

22

25

24

47

57

35

27

26

17

20

7

46

49

50

52

7

4

33

30

34

32

41

42

8

43

44

39

40

31

55

42

19

21

37

23

18

51

56

58

28

7

A

8

48

2

5

A

15

8

12

7

16

B

14

59

10

8

8

11

13

3

9

6

B

45

1

4

48

53

54

42

24

Page 25

REF PART

NO. NO.

N° DE N° DE

RÉF PIÈCE DESCRIPTION DESCRIPTION

1 656-04037 Pulley .50 ID x 2.38 OD Poulie 0,50 x 2,38

2 681-04065 Frame Assembly Bâti

3 710-0191 Hex Screw 3/8-24 x 1.25 Vis à tête hexagonale 3/8-24 x 1,25

4 710-0653 Hex Wash HD Tapp Scr 1/4-20 x .375 Vis auto-taraudeuse hexagonale 1/4-20 x 0,375

5 710-0654A Hex Wash HD Tap Scr 3/8-16 x .88 Vis autotaraudée 3/8-16 x 0,88

6 710-1650 Self-tapping Screw, 5/16-18 x .875 Vis autotaraudeuse de 5/16-18 x 0,875 po

7 710-3005 Hex Bolt 3/8-16 x 1.25 Boulon hex. 3/8-16 x 1,25

8 712-04065 Flange Lock-Nut 3/8-16 Gr. F Nylon Contre-écrou à embase 3/8-16 Qual. F nylon

9 732-04217 Extension Spring .375 x 2.95 Ressort d’extension 0,375 x 2,95

10 736-0452 Belleville Washer Rondelle Belleville

11 748-04125 Shoulder Spacer .30 x .46 Entretoise 0,30 x 0,46

12 754-04128 Belt, V-Type, 3L, 33.92" Lg. Courroie 33,92 po de lg.

13 756-04133 Pulley, V-idler, 2 x 2.75 x .625-3L Poulie 2 x 2,75 x 0,625-3L

14 756-04304 Idler Pulley Poulie tendeur

15 781-04132 Belt Idler Bracket Support de tendeur de courroie

16 781-04161 Belt Cover Couvercle du courroie

17 629-04161 Harness, Interlock Faisceau

18 681-04064 Tank Assembly Réservoir

19 738-04237 Shoulder Screw #10-16 x .50 Vis à épaulement no. 10-16 x 0,50

20 711-04772 Pin, locking Goupille de blocage

21 725-04363 Switch, Interlock Contacteur

22 726-3046 Foot Pad Clips (Not Shown) Attaches de pédale (non représentées)

23 732-04085 Extension Spring .480 OD x 5.0 Ressort d’extension 0,480 x 5,0

24 736-04178A Washer, slotted, felt Rondelle

25 737-04148 Drain Plug Bouchon

26 738-0930 Shoulder Bolt Vis à épaulée

27 781-04168 Bracket, Lock, Cylinder Support

28 718-04241 Cylinder Cylindre

29 710-0870 Hex Tap Scr. 3/8-16 x .62 Vis taraudée 3/8-16 x 0,62 po de lg

30 711-04585 Clevis Pin Axe de chape

31 713-04036 Link, Handle, Valve Maillon

32 714-0104 Int. Cotter Pin .072 x 1.13" Lg. Goupille fendue int. 0,072 x 1,13 po de lg.

33 720-04088 Grip Poignée

34 727-04182 Hose, Valve, Cylinder Tuyau

35 737-04155 Adapter, Hydraulic Adaptateur

36 737-04154 Adapter, Hydraulic Adaptateur

37 747-04539 Control, Valve, Hydraulic Soupape de commande

38 747-04707 Handle, Rod Manette de tige

39 681-04087 Assembly Bracket, Push Support

40 710-0615A Hex Cap Screw, 3/8-16 x 5.0 Vis à chapeau hex., 3/8-16 x 5,0 po

41 711-04762 Pivot Rod .497 x 4.160 Tige de pivot 0,497 x 4,160

42 726-0299 Push Cap x 1/2" Rod Écrou pour tige de 1/2 po

43 750-04668 Spacer .385 x .625 x 4.07 Entretoise 0,385 x 0,625 x 4,07

44 750-04886 Spacer .525 x .775 x .852 Entretoise 0,525 x 0,775 x 0,852

45 710-0376 Hex Scr 5/16 x 1,00 Gr. 5 Vis à tête hex. 5/16 x 1,00 Qual. 5

46 712-04063 Flange Locknut 5/16-18 Gr. F, Nylon Contre-écrou à embase 5/16-18 Qual. F, nylon

47 718-04243 Pump, gear Pompe

48 726-04079 Hose Clamp Collier de tuyau

49 727-04154 Hose Tuyau

50 727-04156 Hose, return Tuyau de retour

51 727-04157 Hose, Inlet Tuyau

52 737-04187 Fitting, elbow Raccord

53 711-04575 Axle Essieu

54 734-1987 Wheel Assembly 8 x 1.8 Spoke Bar Grey Ensemble de roue 8 x 1,80 gris

55 710-04484 Hex Wash Hd. Tapp Scr. 5/16-18 x .75 Vis taraudée 5/16-18 x 0,75

56 781-04124 Bracket, Support Support

57 718-0481A Valve Soupape

58 737-0192 90o Solid Male Adaptor Adaptateur male a 90

o

59 714-0122 Square Key 3/16 X 3/4 Clavette carrée 3/16 X 3/4

25

7

Parts List

Pièces

détachées

For parts and/or

accessories refer to

customer support on

page 2.

Adressez-vous au

«Service aprèsvente» à la page 2

pour ce qui concerne

les pièces et/ou

accessoires.

Page 26

MTD LLC (MTD), The United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner’s Defect Warranty Rights and Obligations)

The U. S. EPA and MTD are pleased to explain the emissions control system warranty on your model year 2005 and later small off-road engine.

New small off-road engines must be designed, built and equipped to meet the stringent anti-smog standards. MTD must warranty the emission

control system on your engine for the period of time listed below, provided there has been no abuse, neglect or improper maintenance of your small

off-road engine.

Your emission control system may include parts such as the carburetor, air cleaner, ignition system, exhaust system, and other associated emission-related components.

Where a warrantable condition exists, MTD will repair your small off-road engine at no cost to your including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emission-related part on your engine is defective, the part will be repaired or

replaced by MTD.

OWNER’S WARRANTY RESPONSIBILITIES:

As the small off-road engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual. MTD

recommends that you retain all your receipts covering maintenances on your small off-road engine, but MTD can not deny warranty solely for the

lack of receipts or for your failure to ensure the performance to all scheduled maintenance.

As the small off-road engine owner, you should however be aware that MTD may deny your warranty coverage if your small off-road engine or part

has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to an Authorized MTD Service Dealer as soon as a problem exists. The warranted

repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact a MTD Service Representative at 1-800-668-1238

and address is MTD Products Ltd., P. O,. Box 1386, 97 Kent Avenue, Kitchener, Ontario Canada N2 G 4J1.

DEFECTS WARRANTY REQUIREMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENGINES:

This section applies to 1995 and later small off-road engines. The warranty period begins on the date the engine or equipment is delivered to an

ultimate purchaser.

(a) General Emissions Warranty Coverage

MTD must warrant to the ultimate purchaser and each subsequent purchaser that the engine is:

(1) Designed, built, and equipped so as to conform with all applicable regulations adopted by the Air Resources Board pursuant to its authority in

Chapters 1 and 2,Part 5, Division 26 of the Health and Safety Code; and

(2) Free from defects in materials and workmanship that cause the failure of a warranted part to be identical in all material respects to the part as

described in the engine manufacturer’s application for certification for a period of two years.

(b) The warranty on emissions-related parts will be interpreted as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in the written instructions required by Subsection (c)

must be warranted for the warranty period defined in Subsection (a)(2). If any such part fails during the period of warranty coverage, it must be

repaired or replaced by MTD according to Subsection (4) below. Any such part repaired or replaced under the warranty must be warranted for

the remaining warranty period.

(2) Any warranted part that is scheduled only for regular inspection in the written instructions required by Subsection (c) must be warranted for

the warranty period defined in Subsection (a)(2). A statement in such written instructions to the effect of “repair or replace as necessary” will

not reduce the period of warranty coverage. Any such part repaired or replaced under warranty must be warranted for the remaining warranty

period.

(3) Any warranted part that which is scheduled for replacement as required maintenance in the written instructions required by Subsection (c)

must be warranted for the period of time prior to the first scheduled replacement point for that part. If the part fails prior to the first scheduled

replacement, the part must be repaired or replaced by MTD according to Subsection (4) below. Any such part repaired or replaced under

warranty must be warranted for the remainder of the period prior to the first scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions of this article must be performed at no charge to the owner at a

warranty station.

(5) Notwithstanding the provisions of Subsection (4) above, warranty services or repairs must be provided at all MTD distribution centers that

are franchised to service the subject engines.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is in fact defective, provided that

such diagnostic work is performed at a warranty station.

26

EPA-1-CA

Page 27

(7) The engine manufacturer is liable for damages to other engine components proximately caused by a failure under warranty of any warranted

part.

(8) Throughout the engine’s warranty period defined in Subsection (a)(2), MTD will maintain a supply of warranted parts sufficient to meet the

expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to the

owner. Such use will not reduce the warranty obligations of MTD.