Page 1

OPERATOR’S MANUAL

Chipper Shredder

Model Series

462 thru 465

Model 465 Shown

IMPORTANT:

READ SAFETY RULES

AND INSTRUCTIONS CAREFULLY.

P. O. BOX 1386, KITCHENER, ONTARIO N2G 4J1

PRINTED IN U.S.A.

772C0505C

(07/04)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Assembling Your Chipper Shredder...................................................................5

Know Your Chipper Shredder ............................................................................7

Operating Your Chipper Shredder ....................................................................8

Maintaining Your Chipper Shredder ..................................................................9

Troubleshooting.................................................................................................12

Warranty............................................................................................................13

Parts List............................................................................................................14

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new chipper shredder. It will help you assemble,

prepare and maintain the unit for best perf ormance. Please read and under stand what it says.

Before you start assembling your new equipment, please locate the model pla te on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by standing behind the unit and lookin g down at the frame below

the engine. A sample model plate is explained below. For future reference, please copy the model

number and the serial number of the equipment in the space be low.

Model Number

Numéro de modèle

XXXXXXXXXX

www.mtdcanada.com

Serial Number

Numéro de série

XXXXXXXXXXX

MTD PRODUCTS LIMITED

KITCHENER, ON N2G 4J1

1-800-668-1238

Copy the model number here:

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine- related issues with regards t o performance, powerrating, specifications, warranty and service. Plea se refer to the engine manufacturer’s Owner’s/Operator’s

Manual packed separately with your unit for more information.

CALLING CUSTOMER SUPPORT

Please do NOT return the unit to the retailer from which it was purchase d, without first contacting

Customer Support.

Should you have difficulty assembling this product or have any questions regarding the cont rols, operation

or maintenance of this unit, please call the Customer Support Departm ent.

Call 1- 800-668-1238 to reach a Customer Support representative. Please have your unit’s

model number and serial number ready when you call. See previous section to locate this

information. You will be asked to enter the serial number in order to process your call.

For more details about your machine, visit our website at www.mtdcanada.com

2

Page 3

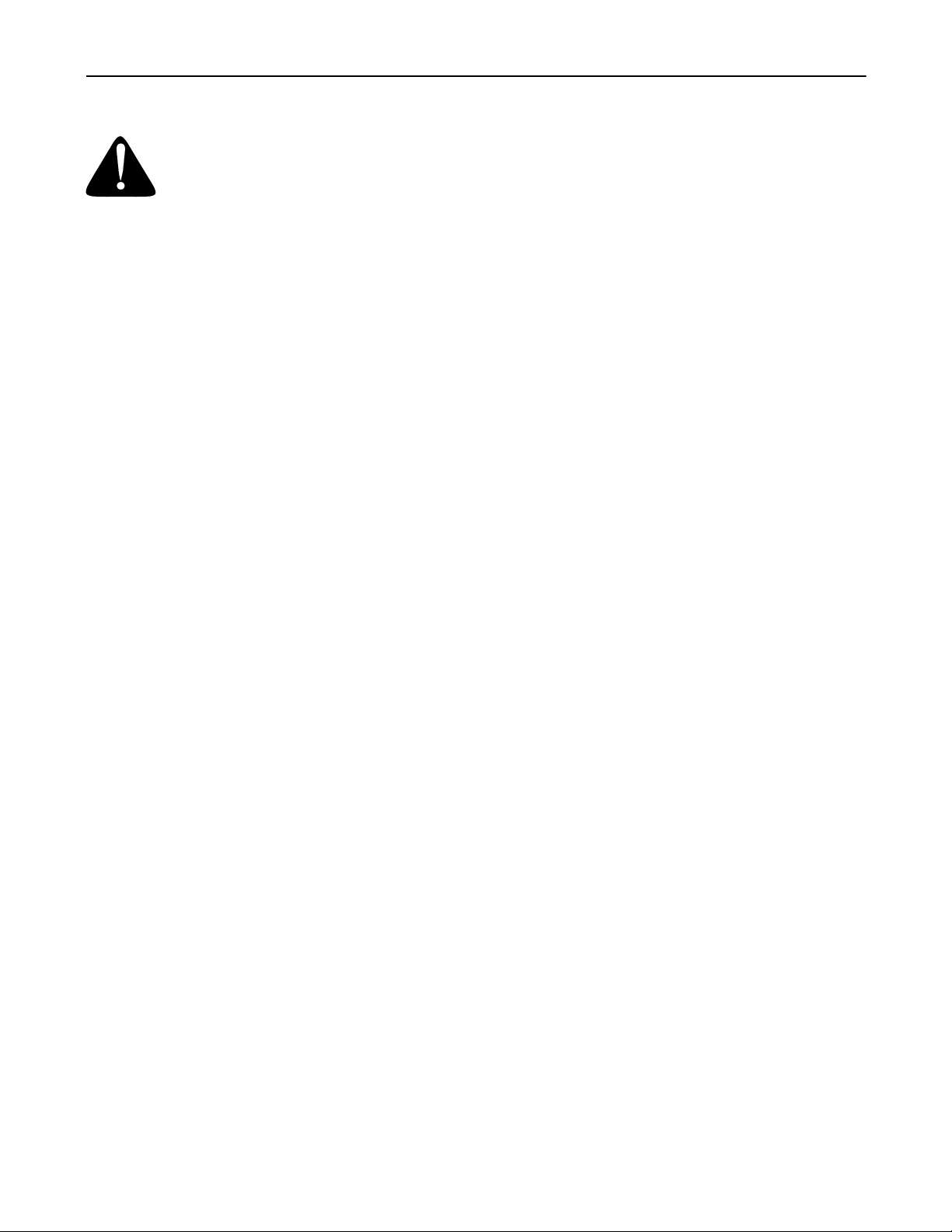

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of your self and others. Read and follow all instructions in

this manual before attempting to operate this machine. Failur e to comply with these instructions may

result in personal injury. When you see this symbol - heed its warning.

DANGER: This machine was built to be operated according to the rules for safe oper ation in this

manual. As with any type of power equipment, carelessne ss or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and thro wing objects.

Failure to observe the following safety instructions could result in serious injury or death.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regu lar reference a nd for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 16 years old to operate

this machine. Children 16 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate t his machine without

proper instruction.

5. Keep bystanders, helpers, pets, and childre n at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

6. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in

the feeding chambers and discharg e opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog either th e feed intake or

discharge opening, remove or empty bag, or

inspect and repair the machine while the engine is

running. Shut the engine off and wait until all

moving parts have come to a complete stop.

Disconnect the spark plug wire and ground it

against the engine.

PREPARATION

1. Thoroughly inspect the area where the equipment

is to be used. Remove all rocks, bottles, cans, or

other foreign objects which could be picked up or

thrown and cause personal injury or damage to the

machine.

2. Always wear safety glasses or safety goggles

during operation or while performing an adjustment

or repair, to protect eyes. Thrown objects which

ricochet can cause serious injury to the eyes.

3. Wear sturdy, rough-soled work shoes a nd closefitting slacks and shirts. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals. Wear

leather work gloves when feeding material in the

chipper chute.

4. Before starting, check all bolts and screws for

proper tightness to be sure the machine is in safe

working condition. Also, visually inspect machine

for any damage at frequent intervals.

5. Maintain or replace safety and instructions labels,

as necessary.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline containe r.

b. Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark,

or pilot light (e.g. furnace, water heater,

space heater, clothes dryer, etc.)

j. To reduce a fire hazard, keep machine free

of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage and remove any

fuel soaked debris.

k. Allow machine to cool at least 5 minutes

before storing.

3

Page 4

OPERATION

1. Do not put hands and feet near rotating parts or in

the feeding chambers and discharg e opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

2. Bef ore starting the machine, make su re the chipper

chute, feed intake, and cutting chamber are empt y

and free of all debris.

3. Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other

foreign objects which could cause personal injury

or damage to the machine.

4. If it becomes necessary to push mater ial through

the shredder hopper, use a small diameter stick. Do

not use your hands or feet.

5. If the impeller strikes a foreign object or if your

machine should start making an unusual noise or

vibration, immediately shut the engine off. Allow the

impeller to come to a complete stop. Disconnect

the spark plug wire, ground it against the engine

and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to

assure continued safe operation.

6. Do not allow an accumulati on of processed

material to build up in the discharge area. This can

prevent proper discharge and result in kickback of

material through the feed opening.

7. Do not attempt to shred or chip material larger than

specified on the machine or in this manual.

Personal injury or machine damage could re sult.

8. Never attempt to unclog either th e feed intake or

discharge opening while the engine is running.

Shut the engine off, wait until all moving parts have

stopped, disconnect the spark plug wire and

ground it against the engine before clearing debris.

9. Never operate without the shredd er hopper,

chipper chute, or discharge chute properly at tached

to the machine. Never empty or change discharge

bag while the engine is running.

10. Keep all guards, deflectors and safety devices in

place and operating properly.

11. Keep your face and body back and to the side of

the chipper chute while feeding material into the

machine to avoid accidental kickback injuries.

12. Never operate this machine without good visibility

or light.

13. Do not operate this machine on a paved, gravel or

non-level surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a

burn. Do not touch.

16. Never pick up or carry machine while the engine is

running.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the mach ine in safe

working condition. Also, visually inspect machine

for any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, sto p the

engine and make certain the impeller and all

moving parts have stopped. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

4. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoor s.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

WARNING: - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this ma nual and on the mac hine.

4

Page 5

>12mm

S30039

>76mm

S30186

SECTION 2: ASSEMBLING YOUR CHIPPER SHREDDER

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL in the engine. Be certain to service

engine with gasoline and oil as instructed in the

separate engine manual before operating your

machine.

NOTE: Reference to right or left hand side of the

chipper shredder is observed from the operating

position.

Removing Unit From Carton

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton.

• Remove loose parts if included with unit (i.e.,

operator’s manual, etc.)

• Cut along corners, lay carton down fl at, and remove

packing material.

• Roll or slide unit out of carton and check carton

thoroughly for loose parts.

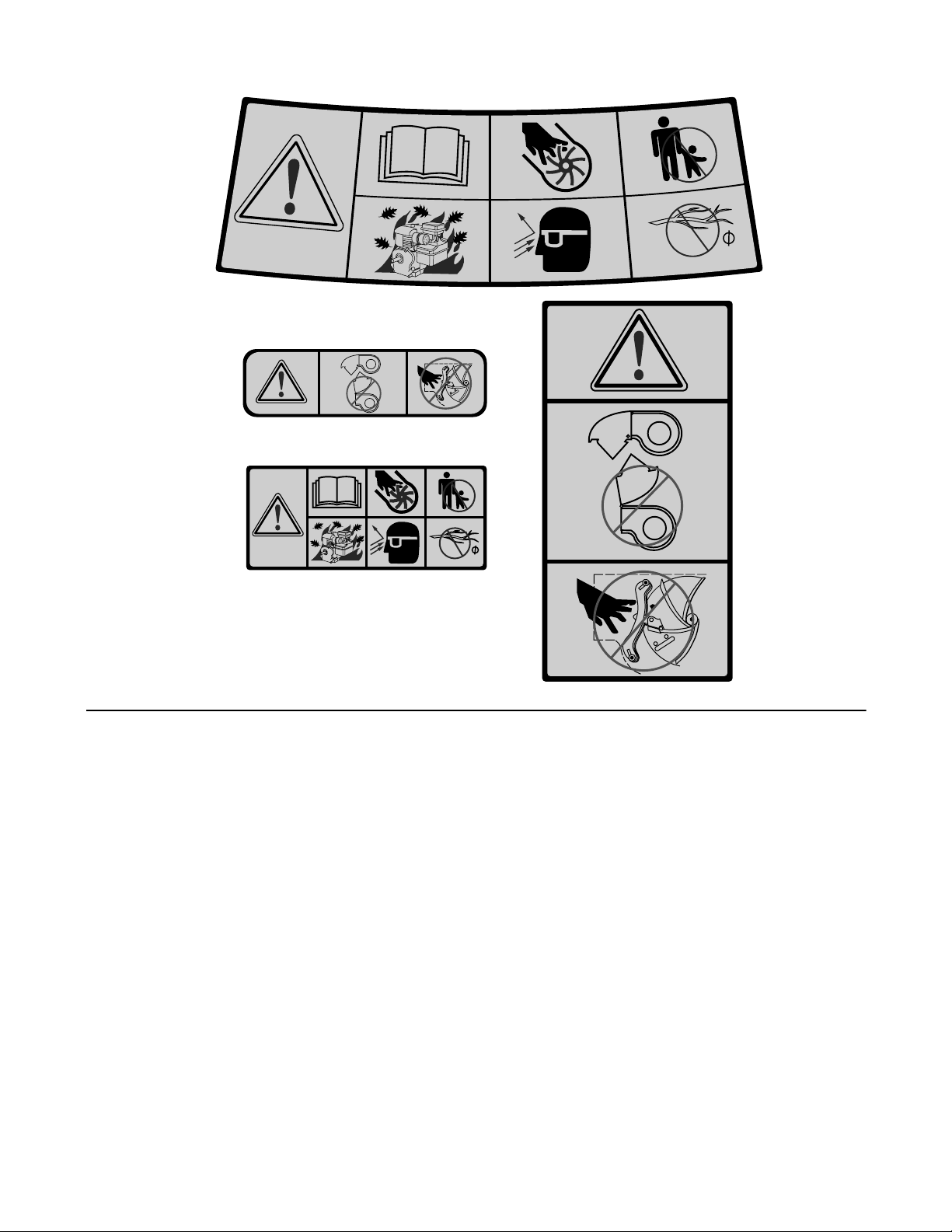

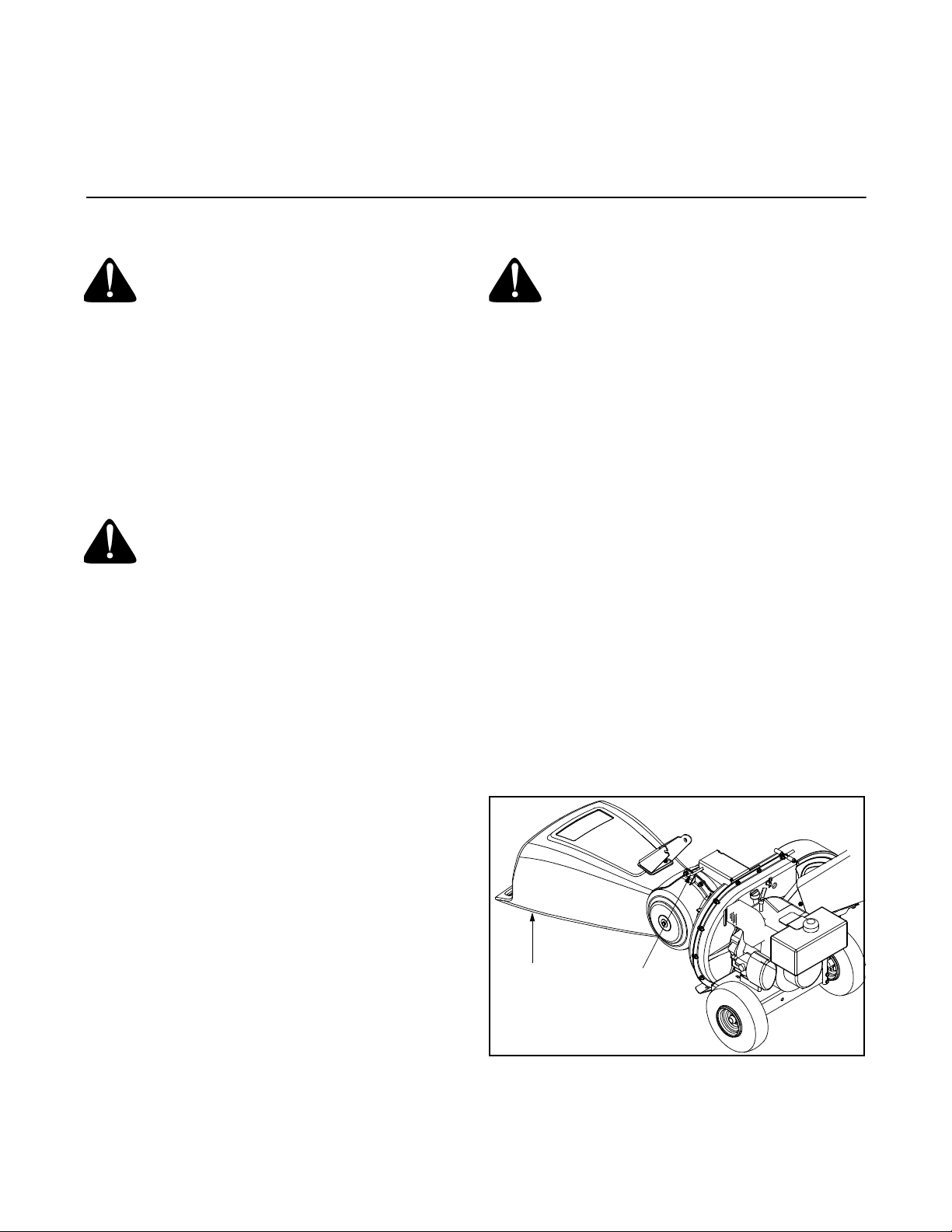

Loose Parts In Carton (See Figure 1)

• Hopper Assembly

• Discharge Chute

• Chipper Chute (462 thru 465)

• Bag (Not Shown)

• Tamper Plug (If Equipped)

• Safety Glasses (Not Shown)

Disconnecting Spark Plug Wire

Before setting up your chipper shredder , disconnect the

spark plug wire from the spark plug and g round against

the engine.

5

Page 6

Attaching The Discharge Chute (All Models)

• Remove the wing knobs from each side of the lower

impeller housing. See Figure 3.

Hex Lock Nut

Discharge

Chute

Hopper

Assembly

Chipper

Chute

Figure 1

Attaching The Hopper Assembly (All Models)

• Remove six hex nuts and washers f rom the weld

studs on the impeller housing. Do not remove the

support plate. See Figure 2.

• Place hopper assembly into position in fr ont of

impeller housing, aligning holes in hopper

assembly collar with weld studs.

Impeller Housing

Washer

Hex Nut

Hopper

Bracket

Weld Stud

Hopper

Assembly

Figure 2

• Slide hopper assembly onto weld studs and replace

washers and hex nuts. Do not tighten completely.

• Lift hopper assembly up to impeller bracket

assembly and slide the release rod out slightly to

hook the hopper bracket onto the rod. See Fi gure 2.

• Tighten the six hex nuts that secure ho pper

assembly to impeller housing and also tighten the

hex nuts that secure hopper bracket to hopper

assembly.

Impeller

Bracket

Release

Rod

Support

Plate

Spacer

Hex Bolt

Wing Knob

Discharge Chute

Figure 3

• Remove the hex lock nut, spacers, and hex bolt

from the top of the impeller housing.

• Align the discharge chute in position on the

discharge opening and insert hex bolt with spacer

through hinge on discharge chute (spacers fit inside

of hinges). See Figure 3.

• Place second spacer over hex bolt inside other

hinge and secure with hex lock nut.

• Secure both sides of discharge chute to impeller

housing using wing knobs previously removed.

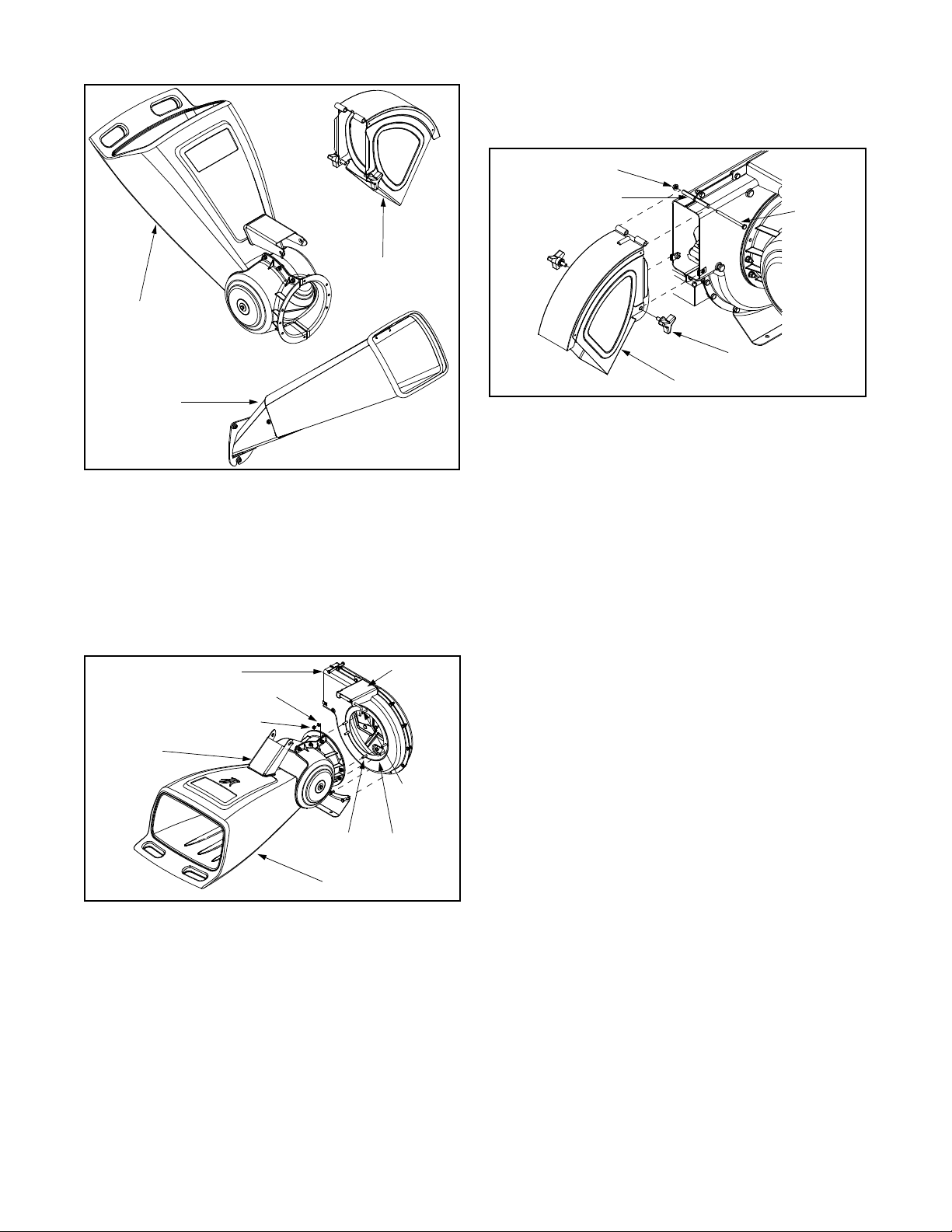

Attaching The Chipper Chute

(Select Models 462 Thru 465 Only)

• Remove the three cupped washers and hex nuts

from weld studs around the opening on the side of

the impeller housing. See Figure 4.

• Remove the hex bolts, flat washers, and lock nuts

from the two holes on the upper end of the support

brace.

• Align the chipper chute over the weld studs, so the

slot in the bottom of the chute is facing down.

• Secure chipper chute with the three cupped

washers (cupped side against the chipper chute)

and hex nuts previously removed. Do not tighten

the nuts at this time.

• The chipper shredder was shipped with one end of

the support brace already secured to the lower

frame. Loosen but do not remove the bolt s

securing the brace to the frame.

• Align the holes in the chute with the holes in the top

of the brace and attach brace to chipper chute with

hardware previously removed. Tighten securely.

• Tighten the bolts securing the support brace to the

frame.

• Tighten the three nuts on the weld studs holding the

chipper chute to the impeller housing.

NOTE: Engine is not shown for clarity in Figure 4.

6

Page 7

Weld Stud

Discharge

Chute

Slot

Chipper

Chute

Hex Nut

Cupped

Washer

Figure 4

Hex Bolt

Support Brace

Flat

Washer

Lock Nut

• Pull on the drawstring until the bag is tight around

chute opening.

• Clip the drawstring back onto inself, tight against

the discharge chute to secure into position. See

Figure 5.

Clip

Chipper Bag

Attaching The Bag (All Models)

Figure 5

• To attach the bag, place the opening of the bag

completely over the discharge chute.

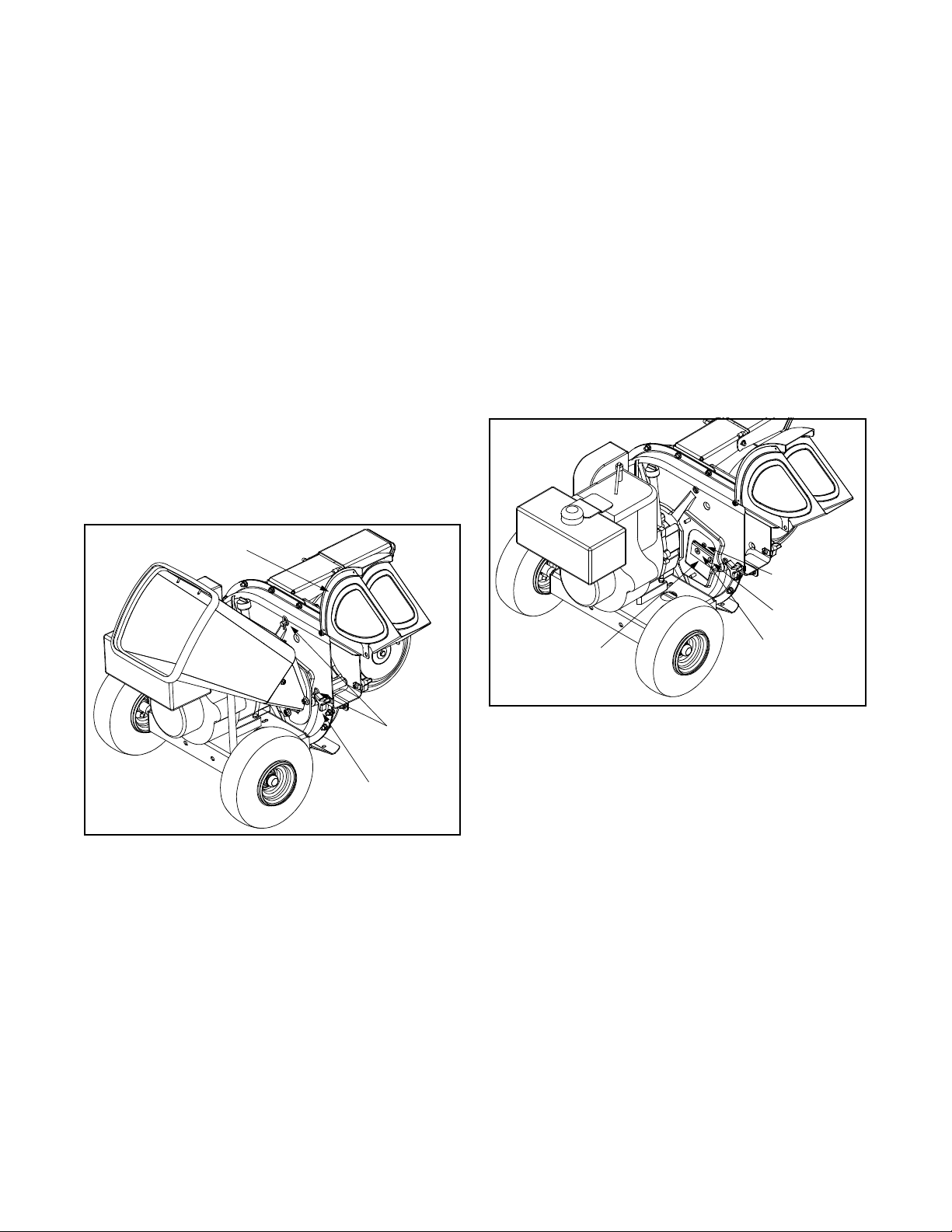

SECTION 3: KNOW YOUR CHIPPER SHREDDER

Read this operator’s manual and safety rules before operating your chipper shredder. Compare the illustrations in

Figure 6 with your unit to familiarize yourself with the location of various controls and adjustments. Save this manual

for future reference.

Chipper

Chute

Hopper

Assembly

Release

Rod

Model 465 Shown

Starter Handle

The starter handle is located on the engine. Pull the

starter handle to start engine. See Figure 6.

Engine Controls

See the separate engine manual for the locat ion and

function of the controls on the engine.

Bag (Not Shown)

Collects shredded or chipped material fed through the

chipper chute or hopper assembly.

Starter Handle

Tamper Plug

Figure 6

Release Rod

The release rod is located on the impeller bracket

assembly and it is used to release or lock the hopper

when raising or lowering. See Figure 6.

Chipper Chute

Allow twigs and small branches up to 3” in diameter on

models 462 thru 465 and 2” in diameter on models 463

to be fed into the impeller for chipping. See Figure 6.

7

Page 8

Hopper Assembly

Allow leaves and small branches up to 1/2 diameter to

be fed into the impeller for chipping and shredding.

Material can be raked into hopper assembly by

lowering the hopper assembly. See Figure 6.

Tamper Plug (If Equipped)

The tamper plug is designed to insert in the chipper

chute to push material toward the impeller.

See Figure 6.

SECTION 4: OPERATING YOUR CHIPPER SHREDDER

WARNING: The operation of any chipper

shredder can result in foreign objects

being thrown into the eyes, which can

damage your eyes severely. Always wear

the safety glasses provided with this unit

or eye shields before chipping or shredding and while performing any

adjustments or repairs.

Gas And Oil Fill-Up

Service the engine with gasoline and oil as instr ucted in

the separate engine manual packed with your chipper

shredder. Read instructions carefully.

WARNING: Never fill fuel tank indoors with

engine running or until the engine has

been allowed to cool for at least two

minutes after running.

Starting Engine

• Attach spark plug wire to spark plug. Make certain

the metal cap on the end of the spark plug is

fastened securely over the metal tip on the spark

plug.

• Engines with choke lever:

Move choke lever on engine to CHOKE position. (A

warm engine may not require choking).

• Engines with primer:

Prime engine as instructed in separate engine

manual.

• The throttle control lever is located on the engine.

Move engine throttle control lever to FAST or

START position.

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

will pull slightly harder at this point).

WARNING: Never run the engine indoors

or in a poorly ventilated area. Engine

exhaust contains carbon monoxide, an

odorless and deadly gas.

Stopping Engine

• Move throttle control lever to STOP or OFF

position.

• Disconnect spark plug wire from spark plug a nd

ground against the engine.

NOTE: See your engine manual packed with your unit

for more detailed instructions.

To Empty Bag

• Un-clip drawstring and loosen bag from discharge

chute opening.

• Empty bag and reattach to the discharge ch ute

opening. Pull on the drawstring until the bag is tight

around the chute opening and clip the d rawstring

tight against the discharge chute.

Lowering The Hopper Assembly

• With one hand grasp the handle at the top of the

hopper assembly and lift slightly.

• With the other hand pull out on the release rod and

lower the hopper assembly to the ground.

See Figure 7.

NOTE: A noise will be heard when finding the start of

the compression cycle. This noise is caused by the

flails and fingers, which are part of the sh redding mechanism, and it should be expected until the impeller

reaches full speed.

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope rewind

slowly.

• Repeat the previous steps until engine fires. When

engine starts, move choke control (if equipped)

gradually to RUN position.

8

Hopper

Assembly

Release

Rod

Figure 7

Page 9

Using The Chipper Shredder

Yard waste such as leaves and pine needles can be

raked up through the hopper assembly for shredding.

After material has been shredded by the flail blades on

the impeller assembly, it will be discharged out of

opening or into catcher bag. Do not attempt to shred or

chip any material other than vegetati on found in a

normal yard (i.e. branches, leaves, twigs, etc.) Avoid

fibrous plants such as tomato vines until they are

thoroughly dried out. Twigs and small branches up to 3”

Hopper

Assembly

in diameter on models 462 thru 465 and 2” in diameter

on models 463 can be fed into the chipper chute. If

equipped, use the tamper plug to push material into the

Model 465 Shown

chipper chute. See Figure 8.

IMPORTANT: The flail screen is located inside the

housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

SECTION 5: MAINTAINING YOUR CHIPPER

SHREDDER. For best performance, it is also important

to keep the chipper blade sharp.

SECTION 5: MAINTAINING YOUR CHIPPER SHREDDER

Customer Responsibilities

MAINTENANCE

SCHEDULE

Lubricate Release Bracket

T

C

Lubricate Hopper Assembly

U

D

Lubricate Discharge Chute

O

R

P

Check Chipper Blade

e

s

u

h

c

a

e

e

r

o

f

e

B

E

s

r

u

o

h

5

2

y

r

e

v

E

s

r

u

o

h

0

5

1

y

r

e

v

y

r

e

v

E

s

r

u

o

h

0

0

n

O

n

o

s

r

a

o

e

t

s

s

a

e

r

e

o

c

f

e

B

Discharge

Chute

Figure 8

e

g

a

Chipper

Chute

SERVICE

DATES

Check Oil

Change Oil

E

N

I

Clean Air Filter

G

EN

Clean Engine

Check Spark Plug

WARNING: Always stop engine,

disconnect spark plug, and ground

against engine before cleaning,

lubricating or doing any kind of

maintenance on your machine.

Lubrication

Release Rod: Lubricate the release rod and spring with

light oil once a season.

Hopper Assembly: Lubricate the pivot points on the

hopper assembly with light oil once a season.

Discharge Chute: Lubricate the pivot points on the

chute deflector with light oil once a season.

Engine: Follow the separate engine manual packed

with you unit for lubrication instructions.

Maintenance

Engine

Refer to the separate engine manual for all engine

maintenance instructions.

9

Page 10

• Check engine oil leve l before each use as

instructed in the separate engine manual packed

with your unit. Read and follow instructions

carefully.

• Clean air cleaner ever y 25 hours under normal

conditions or once a season. Clean every few hours

under extremely dusty conditions. To service the air

cleaner, refer to the separate engine manual

packed with your unit.

• The spark pl ug should be cleaned and the gap

reset once a season. Check engine manual for

correct plug type and gap specifications.

Removing The Flail Screen

If the discharge area becomes clogged, remove t he flail

screen and clean area as follows:

• Stop the engine and make certain the chipper

shredder has come to a complete stop.

• Disconnect spark plug wire from spark pl ug and

ground against the engine.

• Remove the bag and two wing knobs on each side

of the discharge chute and lift the discharge chute

up to keep it out of the way. See Figure 9.

Sharpening Or Replacing Chipper Blades

• Disconnect the spark plug wire and ground against

the engine.

• Remove the flail screen as instructed in the

previous section.

• Remove the chipper chute by removing three he x

nuts and washers.

Models 462 or 465

• Remove the chipper chute support brace from t he

frame by removing the hex bolts.

All Models

• Rotate the impeller assembly by hand until you

locate one of the two chipper blades in the chipper

chute opening.

• Remove the blade by removing the internal hex

screws, lock washers and hex nuts which secure it

to the impeller. Retain the hardware. See Figure 10.

Discharge

Chute

Hairpin

Clips

Wing Knobs

Figure 9

• Remove the two hairpin clips from each clevis pin

which extend through the housing and remove the

pins. See Figure 9.

• Remove the flail screen from inside the housing

and clean the screen by scraping or washing with

water.

• Reinstall the screen, making certain to reassemble

the flail screen with the curve side down.

• Reattach the discharge chute with the har dware

previously removed and connect the bag (if

equipped) to unit.

Lock Washer

& Nut

Internal Hex

Screw

Impeller

Chipper Blade

Figure 10

NOTE: Use a 3/16” hex key (Allen) wrench on the

outside of the blade and a 1/2” box (or socket) wrench

on the inside of the impeller. Hold the Allen wrench

stationary and rotate the box (or socket) wrench to

loosen the nut.

• Install a replacement blade (Part No. 781-0490)

with the hardware removed earlier or sharpen.

IMPORTANT:

When sharpening the blade, protect

hands by using gloves. Follow the original angle of

grind and make sure to remove an equal amount f rom

each blade.

• To replace the other blade, rotate th e impeller to

expose the second blade and repeat the steps

above.

NOTE: Make certain blades are reassembled with the

sharp edge facing upward. Torque hardware to 250 300 in. lbs.

10

Page 11

Sharpening Or Replacing The Shredder

Blade

WARNING: The impeller’s chipper blades

are sharp. Wear leather work gloves to

protect your hands.

• Stop the engine and make certain that all moving

parts have come to a complete stop.

• Disconnect the spark plug wire and g round against

the engine.

• Lower the hopper assembly and block u p the

housing.

• Remove the six hex lock nuts and flat washers from

the weld studs on the flail housing. Retain the

hardware.

• Carefully separate the hopper assembly from t he

impeller assembly and remove the support plate.

NOTE: When reassembling the support plate, make

certain the embossed tab faces inward towards the

impeller.

• Remove the two wing knobs and cupped washers

that secure the discharge chute and raise the

chute.

• Insert a 1/2” or 3/4” diameter pipe through the flail

screen into the impeller to keep it from turning or

remove the flail screen and insert a piece of wood

into the chute opening.

• Remove the two internal hex screws which secure

the shredder blade to the impeller. See Figure 11.

NOTE: Use caution when removing the blade to avoid

contacting the weld studs on the housing.

IMPORTANT:

original angle of grind as a guide. It is extremely

important that each cutting edge receives an equal

amount of grinding to prevent an unbalance d blade. An

unbalanced blade will cause excessive vibration when

rotating at high speeds and may cause damage to the

unit. The blade can be tested by balancing it on a

screwdriver or nail. Remove metal from the heavy side

until it is balanced evenly.

IMPORTANT:

center bolt to between 550 and 700 in.-lbs. and the two

outer bolts to between 250 and 350 in.-lbs.

When sharpening the blade , follow the

When reassembling the blade, tighten

Storing Your Chipper Shredder

• Clean the equipment thoroughly.

• Wipe equipment with an oiled rag to prevent rust.

• Refer to engine manual for correct engine storage

instructions.

• Store unit in a clean, dry area. Do not store next to

corrosive materials such as fertilizer.

Discharge Chute

Shredder

Blade

Internal

Hex Screw

Hex Bolt,

Lock Washer &

Flat Washer

Impeller

Figure 11

NOTE: Use a 3/16” hex key (Allen) wrench on the

outside of the shredder blade and a 1/2” box (or socket)

wrench on the inside of the shredder blade. Hold the

Allen wrench stationary and rotate the box (or socket)

wrench to loosen the nut.

• Remove the hex bolt, lock washer and flat washer

to completely free the shredder blade.

Weld Stud

11

Page 12

SECTION 6: TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start. 1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Throttle control lever not in correct

starting position. (If Equipped)

4. Choke not in CHOKE position.

(If Equipped)

5. Engine not primed.

6. Blocked fuel line.

7. Faulty spark plug.

Engine runs erratic. 1. Spark plug wire loose.

2. Unit running on CHOKE.

(If Equipped)

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Carburetor out of adjustment.

Too much vibration. 1. Loose parts or damaged impeller. 1. See authorized service dealer.

Engine overheats. 1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted p roperly.

Occasional skip (hesitates)

at high speed.

Unit does not discharge. 1. Discharge chute clogged.

Rate of discharge slows

considerably or

composition of discharged

material changes.

1. Spark plug gap too close. 1. Adjust gap to.030”.

2. Foreign object lodged in impeller.

3. Low engine RPM.

1. Low engine RPM.

2. Chipper blade dull.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move throttle lever to FAST position.

4. Move choke to CHOKE position.

5. Prime engine.

6. Clean fuel line.

7. Clean, adjust gap, or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean, fresh

gasoline. The gasoline must be u sed

within 30 days unless using a fuel

stabilizer.

4. Drain fuel tank. Refill with fresh fuel.

5. Clean or replace air cleaner.

6. See authorized service dealer.

1. Fill crankcase with proper oil.

2. Clean or replace air cleaner.

3. See authorized service dealer.

1. Stop engine immediately and

disconnect spark plug wire. Clean flail

screen and inside of discharge opening.

2. Stop engine and disconnect spark plug

wire. Remove lodged object.

3. Always run engine at full throttle.

1. Always run engine at full throttle.

2. Replace chipper blade or see your

authorized service dealer.

NOTE: For repairs beyo nd the minor a djustments listed above, contact your neare st authorized service dealer .

12

Page 13

TWO YEAR LIMITED WARRANTY

For TWO YEARS from the date of retail purchase within Canada, MTD PRODUCTS LIMITED will, at its option, re

pair or replace, for the original purchaser, free of charge, any part or parts found to be defective in material or

workmanship.

This warranty does not cover:

1. Any part which has become inoperative due to misuse, commercial use, abuse, neglect, accident, im

proper maintenance or alteration; or

2. The unit if it has not been operated and/or maintained in accordance with the owner’s instructions fur

nished with the unit; or

3. The engine or motor or component parts thereof which carry separate warranties from their manufac

turers. Please refer to The applicable manufacturer’s warranty on these items; or

4. Batteries and normal wear parts except as noted below. Log splitter pumps, valves and cylinders or

component parts thereof are covered by a one year warranty; or

5 Routine maintenance items such as lubricants, filters, blade sharpening and tune-ups, or adjustments

such as brake, clutch or deck; or

6. Normal deterioration of the exterior finish due to use or exposure.

Full Ninety Day Warranty on Battery: For ninety (90) days from the date of retail purchase, if any battery included

with this unit proves defective in material or workmanship and our testing determines the battery will not hold a

charge, MTD PRODUCTS LIMITED will replace the battery at no charge to the original purchaser.

Additional Limited Thirty Day Warranty on Battery: After ninety (90) days but within one hundred twenty (120)

days from the date of purchase, MTD PRODUCTS LIMITED will replace the defective battery, for the original purchaser, for a cost of one-half (1/2) of the current retail price of the battery in effect at the date of return.

Full Sixty Day Warranty on Normal Wear Parts: Normal wear parts are defined as belts, blade adapters, blades,

grass bags, seats, tires, rider deck wheels and clutch parts (friction wheels). These parts are warranted to the original purchaser to be free from defects in material and workmanship for a period of sixty (60) days from the date of

retail purchase.

How to Obtain Service: Warranty service is available, with proof of purchase, through your local authorized service dealer or distributor. If you do not know the dealer or distributor in your area, please write to the Service

Department of MTD PRODUCTS LIMITED, P. O. BOX 1386, KITCHENER, Ontario, N2G 4J1. The return of a com

plete unit will not be accepted by the factory unless prior written permission has been extended by MTD

PRODUCTS LIMITED.

Transportation Charges: Transportation charges for the movement of any power equipment unit or attachment

are the responsibility of the purchaser. Transportation charges for any part submitted for replacement under this

warranty must be paid by the purchaser unless such return is requested in writing by MTD PRODUCTS LIMITED.

Other Warranties: All other warranties, express or implied, including any implied warranty of merchantability is lim

ited in its duration to that set forth in this express limited warranty. The provisions as set forth in this warranty

provide the sole and exclusive remedy of MTD PRODUCTS LIMITED obligations arising from the sale of its prod

ucts.

MTD PRODUCTS LIMITED will not be liable for incidental or consequential loss or damage.

-

-

-

-

-

-

-

13

Page 14

67

1

3

4

18

49

20

15

57

21

29

17

16

56

15

48

60

19

6

39

38

42

2

7

73

56

9

10

7

8

11

12

36

40

8

20

53

37

32

41

55

54

68

35

52

13

30

10

8

9

31

33

24

51

21

29

32

5

22

25

23

24

27

23

28

23

3

4

43

26

44

69

47

45

46

23

11

60

56

59

56

61

60

56

62

58

65

60

64

59

63

61

60

60

50

56

60

56

59

57

56

14

Page 15

REF.

NO.

N°. DE

RÉF.

1 728-0175 Pop Rivet Rivet

2 731-1899 Chipper Chute Goulotte de déchiquetage

3 735-0249 Chipper Flap Rabat de la goulotte

4 781-0633 Flat Strip Baguette plate

5 681-0095 Chipper Chute Ass'y Goulotte de déchiquetage

6 681-0068A Chipper Chute Assembly Goulotte de déchiquetage

7 710-0751 Hex Bolt 1/4-20 x .62 Gr. 5 Boulon hexagonale 1/4-20 x 0,62 Qual. 5

8 712-3027 Hex L-Flanged Nut Contre-écrou à embase

9 710-0106 Hex Screw 1/4-20 x 1.25 Vis à tête hexagonale 1/4-20 x 1,25

10 736-0173 Flat Washer .28 ID x .74 DE x .063 Rondelle plate 0,28 DI x 0,74 DE x 0,063

11 736-0242 Cupped Washer .345 ID x .88 OD x .060 Rondelle creuse 0,345 DI x 0,88 DE x 0,060

12 712-3010 Hex Nut 5/16-18 hd. (Gr. 5) Écrou hexagonal 5/16-18 Qual. 5

13 749-1004 Chute Support Support de la goulotte

15 714-0149B Internal Cotter Pin Goupille fendue interne

16 681-0048 Hand Knob Ass'y Bouton à oreilles

17 681-0094 Chute Deflector Ass'y Déflecteur de la goulotte

18 711-0835 Clevis Pin .5" Dia. x 4.62" Lg. Axe de chape 0,50 dia x 4,62 po de lg.

19 781-0457 Shredder Screen Tamis à broyeuse

20 726-0211 "U" Nut 5/16-18 Écrou en «U» 5/16-18

21 750-0793 Chute Hinge Spacer 1.66" Lg. Cales d'écartement 1,66 po de lg.

22 712-3027 Hex L-Flanged Nut Contre-écrou à embase

23 712-3004A He x Flange L-Nut 5/16-18 Contre-écrou à embase 5/16-18

24 736-0119 L-Washer 5/16 ID Rondelle frein 5/16 DI

25 681-0184 Frame Châssis

26 710-0805 Hex Bolt 5/16-18 x 1,50" Lg. Gr. 5 Boulon hex. 5/16-18 x 1,50 po de lg Qual. 5

27 736-0170 Special L-Wash 5/16" ID x .88 Rondelle frein - spéciale 5/16 DI x 0,88

28 681-0117 Flail Housing Ass'y - RH Boîtier de fléaux - droit

29 710-3025 Screw-Hex Cap Vis à tête hex.

30 710-0157 Hex Screw 5/16-24 x .75 Vis à tête hex. 5/16-24 x 0,75

31 781-0490 Chipper Blade Lame de déchiquetage

32 710-1054 Flat Hd. Screw 5/16-24 x .75" Lg. Vis à tête plate 5/16-24 x 0,75 po de lg.

33 681-0030 Impeller Assembly Turbine

34 736-0366 Flat Washer .63 ID x .12 OD x .12 Rondelle plate 0,63 DI x 0,12 DE x 0,12

35 712-0411 Hex Top L-Nut 5/16-24 Écrou de blocage hex. 5/16-24

36 781-0735 Spring Clip Attache à ressort

37 719-0329 Flail Blade Fléau

38 711-0833B Cle vis Pin .496" Dia. Axe de chape 0,496 dia.

39 715-0166 Spring Roll Pin 1.0" Lg. Goupille ronde ressort de 1,00 po de lg.

40 736-0247 Flat Washer .40 ID x 1.25 OD x .160 Rondelle plate 0,40 DI x 1,25 DE x 0,160

41 742-0571 Blade Lame

42 710-1254 Hex Patch Bolt 3/8-24 x 2.25" (Grade 8) Boulon hex 3/8-24 x 2,25 po de lg. Qual. 8

43 738-0813 Shredder Axle .625 x 22.47 Essieu de la déchiqueteuse 0,625 x 22,47

†43 738-0814 Shredder Axle .625 x 21.21 Essieu de la déchiqueteuse 0,625 x 21,21

44 750-0786 Spacer .64" ID x 1.24 Entretoise 0,64 DI x 1,24

45 734-1845 Wheel Assembly 10.0 x 4.0 x 4.0 Gray Roue complète 10,0 x 4,0 x 4,0 gris

46 726-0214 Push Cap 5/8" Dia Rod Chapeau à enfoncer dia. 5/8 po

47 634-04009 Wheel assembly 10 x 4 x 4 Plastic-Gray Ensemble de roue 10,0 x 4,0 x 4,0 plastique - gris

†47 734-1600 Wheel Assembly Complete Ensemble de roue complet

48 681-0004A Flail Housing Ass'y - LH Boîtier des fléaux - gauche

49 710-0825 Hex Bolt 1/4-20 x 3.75" Lg. Boulon hex. 1/4-20 x 3,75 po de lg.

50 781-0515 Front Support Brkt. Support - avant

51 781-0574 Back Up Plate Plaque de renfort

52 681-0104 Bracket Ass'y - R.R. Support - arrière droit

53 732-0306 Compression Spring Ressort de compression

54 736-0117 Flat Washer .385 ID x .62 OD x .033 Rondelle plate 0,385 DI x 0,62 DE x 0,033

55 714-0104 Int. Cotter Pin .072 x 1.13" Lg. Goupille fendue int. 0,072 x 1,13 po de lg.

56 736-0264 Flat Washer .344 ID x .625 OD x .063 Rondelle plate 0,344 DI x 0,625 DE x 0,063

57 710-0376 Hex Scr 5/16 x 1,00 Gr. 5 Vis à tête hex. 5/16 x 1,00 Qual. 5

58 748-0453 Spacer .375 x 2.50 Lg. Entretoise 0,375 x 2,50 po de lg.

59 736-0362 Flat Washer .22 ID x 1.25 Rondelle plate 0,22 DI x 1,25

60 712-0429 Hex Ins. L-Nut 5/16-18 Contre-écrou de blocage 5/16-18

61 731-1710 Collar-Hopper Collier de la trémie

62 681-0123 Bracket Ass'y - Frt. Support - avant

63 711-1128 Lock Rod Tige de blocage

64 731-1707 Hopper Trémie

65 710-3008 Hex Bolt 5/16-18 x .75" Lg. Gr. 5 Boulon hex. 5/16-18 x 0,75 po de lg. Qual. 5

67 731-1617 Tamper Plug Bouchon

68 736-0451 Saddle Wash. .320 ID x .937 OD Rondelle selle 0,320 DI x 0,937 DE

- 723-0400 Safety Glasses (Not Shown) Lunettes de sécurité (non illustré)

- 764-0199A Bag 23.5 x 36 White (Not Shown) Sac 23,5 x 36 blanc (non illustrée)

- 664-04022 Chipper Bag Assembly 23.5 x 36 (Not Shown) Sac de déchiqueteuse-broyeuse 23,50 x 36 (non-illustré)

- 664-04023 Chipper Bag Assembly 23.5 x 58 (Not Shown) Sac de déchiqueteuse-broyeuse 23,50 x 58 (non-illustré)

† Model 462 Only/Modèle 462 seulement

PART

NO.

N° DE

PIÈCE DESCRIPTION DESCRIPTION

15

462-465

07.14.04

Page 16

Notes

16

Page 17

Notes

17

Page 18

Notes

18

Page 19

14

rect.

-

MTD PRODUCTS LIMITED ne peut être tenue responsable pour toute perte ou tout dommage accidentel ou indi

découlant de la vente de ses produits.

dans cette garantie constituent le recours unique et exclusif quant aux obligations de MTD PRODUCTS LIMITED

de qualité marchande, se limitent à la durée stipulée dans cette garantie limitée expresse. Les conditions stipulées

Autres garanties: Toutes les autres garanties, qu’elles soient expresses ou tacites, y compris les garanties tacites

par MTD PRODUCTS LIMITED.

de cette garantie doivent être pris en charge par l’acheteur, sauf si le renvoi de la machine est demandé par écrit

charge de l’acheteur. Les frais de transport d’une pièce quelconque envoyée à des fins de remplacement en vertu

Frais de transport: Les frais relatifs au transport de toute machine motorisée ou de tout accessoire sont à la

LIMITED.

accepter le renvoi d’une machine complète si une autorisation n’a pas été accordée par écrit par MTD PRODUCTS

service après-vente de MTD PRODUCTS LIMITED, C.P. 1386, Kitchener (Ontario) N2G 4J1. L’usine ne peut

vous ne connaissez pas l’adresse de l’atelier de réparations ou du distributeur de votre région, adressez-vous au

Pour faire honorer la garantie: Présentez une preuve d’achat à l’atelier de réparations ou au distributeur agréé. Si

détail.

matière et de fabrication à l’acheteur initial pour une période de soixante (60) jours à partir de la date d’achat au

frottement) sont considérés comme des pièces à usure normale. Elles sont garanties exemptes de vices de

sacs à herbe, sièges, pneus, roues du plateau de coupe des tondeuses à siège, et pièces d’embrayage (roues de

Garantie complète de soixante jours des pièces à usure normale: Les courroies, adaptateurs de lame, lames,

vigueur au moment du retour de la batterie.

remplacer la batterie défectueuse à l’acheteur initial pour la moitié du prix de vente au détail de la batterie, en

jours, mais dans un délai de cent vingt (120) jours de la date d’achat, MTD PRODUCTS LIMITED s’engage à

Garantie limitée supplémentaire de trente jours de la batterie: A l’expiration du délai de quatre-vingt-dix (90)

délai de quatre-vingt-dix (90) jours à partir de la date d’achat au détail.

vice de matière ou de fabrication et si nos essais confirment qu’elle ne peut pas maintenir une charge, dans un

gratuitement la batterie à l’acheteur initial, si la batterie fournie avec la machine s’avère défectueuse en raison d’un

Garantie complète de quatre-vingt-dix jours de la batterie: MTD PRODUCTS LIMITED s’engage à remplacer

tion aux intempéries.

-

6. La détérioration normale de la finition extérieure du fait de l’utilisation de la machine et de son exposi

réglages des freins, de l’embrayage ou du plateau de coupe;

5. Les articles d’entretien courant tels que les lubrifiants, filtres, aiguisage de lames et révisions, ou les

soupapes et cylindres des fendeuses à bois sont garantis pendant un an;

4. Les batteries et les pièces présentant une usure normale énumérées plus bas. Les pompes,

respectifs. Veuillez consulter la garantie qui s’applique à la pièce en particulier;

3. Le moteur, le moteur électrique ou l’un de ses composants car ils sont garantis par leurs fabricants

l’accompagnaient;

2. La machine si elle n’a pas été utilisée et/ou entretenue conformément aux instructions qui

abusif, une négligence, un entretien incorrect ou une modification;

1. Les pièces rendues inutilisables par un emploi incorrect, une utilisation commerciale, un emploi

Cette garantie ne couvre pas:

de DEUX ANS à partir de la date d’achat au détail au Canada.

pièce ou partie de pièce qui s’avère défectueuse en raison d’un vice de matière ou de fabrication, dans un délai

MTD PRODUCTS LIMITED s’engage à réparer ou à remplacer gratuitement, à son choix, à l’acheteur initial, toute

PIÈCES SOUS GARANTIE ET SERVICE APRÈS-VENTE

Page 20

broyeuse ou adressez-vous à la station technique.

2. Remplacez la lame de la déchiqueteuse ou de la

1. Le moteur doit toujours tourner à plein régime.

3. Le moteur doit toujours tourner à plein régime.

de la bougie. Dégagez l’objet.

2. Arrêtez immédiatement le moteur et débranchez le fil

l’entretien dans cette notice.

du logement du ventilateur. Voir le chapitre de

de la bougie. Nettoyez le tamis à fléaux et l’intérieur

1. Arrêtez immédiatement le moteur et débranchez le fil

1. Ajustez l’écartement à 0,030 po.

agréée.

3. Faites vérifier la machine par une station technique

2. Nettoyez ou remplacez le filtre à air.

1. Faites le plein d’huile du carter.

agréée.

1. Faites vérifier la machine par une station technique

agréée.

6. Faites vérifier la machine par une station technique

5. Nettoyez ou remplacez le filtre à air.

propre et fraîche.

videz le réservoir. Faites le plein avec une essence

4. Débranchez la conduite d’essence au carburateur et

stabilisateur de carburant.

utilisée dans les 30 jours à moins d’utiliser un

une essence propre et fraîche. L’essence doit être

3. Nettoyez la conduite d’essence. Faites le plein avec

2. Ouvrez le volet de départ.

1. Branchez et serrez le fil de la bougie.

bougie.

7. Nettoyez, réglez l’écartement ou remplacez la

6. Nettoyez la conduite d’essence.

5. Amorcez le moteur.

4. Ouvrez le volet de départ.

démarrage.

3. Placez la commande des gaz à la position de

d’utiliser un stabilisateur de carburant.

L’essence doit être utilisée dans les 30 jours à moins

2. Faites le plein avec une essence propre et fraîche.

1. Branchez le fil à la bougie.

13

de la broyeuse est émoussée.

2. La lame de la déchiqueteuse ou

1. Régime du moteur trop bas.

3. Régime du moteur trop bas.

2. Objet dans la turbine.

petit.

1. Écartement de la bougie est trop

3. Carburateur mal réglé.

2. Filtre à air sale.

endommagée.

6. Carburateur mal réglé.

5. Filtre à air sale.

carburant.

4. Eau ou saleté dans le système de

essence éventée.

3. Conduite d’essence bouchée ou

2. Volet de départ fermé.

1. Fil de la bougie desserré.

7. Bougie défectueuse.

6. Conduite d’essence bouchée.

5. Moteur non amorcé.

4. Volet de départ fermé.

démarrage.

trouve pas en position de

3. La commande des gaz ne se

est éventée.

2. Le réservoir est vide ou l’essence

la station technique agréée.

REMARQUE: Pour toute réparation plus importante que les ajustements mentionnés ci-dessus, adressez-vous à

matériau broyé change.

ou la consistance du

ralentit considérablement

Le débit d’évacuation

La machine n’éjecte rien. 1. Goulotte d’éjection bouchée.

à vitesse élevée

Ratés possible (hésitations)

Le moteur surchauffe. 1. Niveau d’huile trop bas.

Vibrations excessives. 1. Pièces desserrées ou turbine

fonctionnement irrégulier.

Perte de puissance;

Le moteur ne démarre pas. 1. Fil de la bougie débranché.

Problème Cause(s) Possible(s) Solution

CHAPITRE 6: DÉPANNAGE

Page 21

12

boulons soudés sur l’habitacle en retirant la lame.

REMARQUE: Faites attention de ne pas toucher les

boulon hex., la rondelle-frein et la rondelle plate.

• Dégagez la lame de broyage après avoir retiré le

l’écrou.

fixe et faites tourner la clé polygonale pour desserrer

polygonale de 1/2 po sur l’intérieur. Gardez la clé Allen

comme des engrais.

la remisez pas à proximité de matériaux corrosifs

• Remisez la machine dans un abri propre et sec. Ne

remisage hors saison.

• Consultez la notice d’utilisation du moteur quant au

pour empêcher la rouille.

• Essuyez la machine avec un chiffon imbibé d’huile

broyeuse.

• Nettoyez complètement la déchiqueteuse-

Remisage hors saison

po-lb.

po-lb et les deux boulons extérieurs entre 250 et 350

Serrez le boulon central entre 550 et 700

Suivez l’angle d’aiguisage d’origine pour

Figure 11

IMPORTANT:

lourd jusqu’à ce que la lame soit bien équilibrée.

ou d’un clou. Éliminez davantage de métal du côté plus

équilibre en la plaçant sur la tige ronde d’un tournevis

elle risque d’endommager la machine. Vérifiez son bo n

vibrer excessivement en tournant à grande vitesse et

non équilibrée. Une lame mal équilibrée a tendance à

tranchant de façon égale pour évit er d’obtenir une lame

affûter la lame. Il est très import ant d’aiguiser chaqu e

IMPORTANT:

sur l’extérieur de la lame de déchiquetage et une clé

REMARQUE: Placez une clé hex. (Allen) de 3/16 po

la lame de broyage sur la turbine. Voir la Figure 11.

• Enlevez les deux vis hex. internes qui maintiennent

goulotte.

insérez un morceau de bois dans l’ouverture de la

l’empêcher de tourner, ou démontez l e tamis et

travers le tamis des fléaux dans la turbine pour

• Enfoncez un tuyau de 1/2 po ou de 3/4 de po à

d’éjection. Relevez celle-ci.

rondelles creuses qui retiennent la goulot te

• Enlevez les deux boutons à oreilles et et les

turbine).

placer l’attache bosselée vers l’intérieur (vers la

REMARQUE: Assurez-vous, lors du remontage, de

enlevez la plaque de soutien.

• Séparez soigneusement la trémie de la turbine et

des fléaux. Gardez la boulonnerie.

rondelles plates des boulons soudés sur l’habitacle

• Enlevez les six contre-écrous à six pans et les six

• Abaissez la trémie et calez l’habitacle.

contre le moteur.

• Débranchez le fil de la bougie et mettez-le à la terre

immobilisées.

en mouvement se sont complètement

• Arrêtez le moteur et vérifiez que toutes les pièces

cuir en guise de protection.

Turbine

rondelle plate

rondelle frein et

Boulon hex.,

interne

Vis hex.

Goujon soudé

broyage

Lame de

Goulotte d’éjection

coupantes. Portez des g ants de travail en

déchiquetage de la turbine sont très

AVERTISSEMENT: Les lames de

de broyage

Aiguisage ou remplacement de la lame

po-lb.

le haut. Serrez la boulonnerie à un couple de 250-300

REMARQUE: Installez les lames le côté tranchant vers

étapes ci-dessus.

main pour exposer la deuxième lame et répéter les

• Pour rem placer l'autre lame, tournez la turbine à la

Page 22

11

interne

Vis hex.

six pans

écrou à

frein et

Rondelle-

oreilles

Bouton à

épingles

Goupille-

déchiquetage

Lame de

chaque lame.

attention de retirer une quantité éga le de métal de

de l’aiguisage. Suivez l’angle d’origine et faites

Portez des gants pour vous protéger lors

Figure 10

Turbine

IMPORTANT:

boulonnerie retirée plus tôt ou aiguissez la lame.

• Installez la lame de rechange (nº 781-0490) avec la

l’écrou.

fixe et faites tourner la clé polygonale pour desserrer

polygonale de 1/2 po sur l’intérieur. Gardez la clé Allen

sur l’extérieur de la lame de déchiquetage et une clé

REMARQUE: Placez une clé hex. (Allen) de 3/16 po

Voir la Figure 10.

maintiennent sur la turbine. Garder la boulonne rie.

les rondelles-frein et les écrous à six pans qui la

• Démontez la lame en enlevant les vis hex. internes,

la turbine à la main.

l’ouverture de la trappe d’accès en faisa nt tourner

• Localisez une des lame de déchiquetage dans

Tous les modèles

Figure 9

boulons hex.

déchiquetage sur le châssis en enlevant les

• Démonter le support qui retient la go ulotte de

Modèles 462 ou 465

les trois écrous à six pans et les trois rondelles.

• Démonter la goulotte de déchiquetage et enlevez

du passage précédent.

• Démontez le tamis des fléaux selon les instructions

contre le moteur.

• Débranchez le fil de la bougie et mettez-le à la terre

de déchiquetage

Aiguisage ou remplacement des lames

cas échéant).

d’origine et serrez les boutons. Installez le sac (le

• Replacez la goulotte d’éjection à sa position

remonter le tamis le côté arrondi vers le bas.

• Remettez le tamis en place. Assurez-vou s de

grattant et en le lavant à l’eau.

• Sortez le tamis des fléaux. Nettoyez le tamis en le

aussi les axes de chape.

chape qui dépassent de la carrosserie. Enlevez

• Enlevez les deux goupilles-épingles des axes de

écartez-la. Voir la Figure 9.

de la goulotte). Redressez la goulotte d’éjection et

chaque côté de la goulotte d’éjectio n (ou déflecteur

• Enlevez le sac et les deux boutons à oreilles de

masse contre le moteur.

• Débranchez le fil de la bougie et mettez-le à la

déchiqueteuse-broyeuse soit tout à fait immobile.

• Arrêtez le moteur et attendez que la

des fléaux et nettoyez comme suit:

Si la zone d’éjection se bouche, démontez le tamis

Démontage du tamis des fléaux

l’écartement conseillé.

moteur pour déterminer le type de bougie requ is et

par saison. Consultez la notice d’utilisation du

• Nettoyez la bougie et réglez l’écartement une fois

à air.

moteur fournie séparément pour l’entretien du filtre

poussiéreuses. Consultez la notice d’utilisation du

Nettoyez-le plus souvent dans des conditions très

d’utilisation dans des conditions normales.

• Nettoyez le filtre à air toutes les 25 heures

instructions.

Veuillez lire attentivement et bien suivre ces

recommandé dans la notice d’utilisation du moteur.

• Maintenez le niveau d’huile à moteur au niveau

est de l’entretien du moteur.

Consultez la notice d’utilisation du moteur pour ce qui

Moteur

déchiquetage

Goulotte de

Entretien

Page 23

10

le ressort avec une huile légère une fois par saison.

Tringle de blocage : Lubrifiez la t ringle de blocage et

Lubrication

du moteur fournie séparément.

Moteur : Suivez les instructions de la notice d'utilisation

légère une fois par saison.

pivotement du déflecteur de la goulotte avec une huil e

Goulotte d'éjection : Lubrifiez les points de

avec une huile légère une fois par saison.

Trémie : Lubrifiez les points de pivotement de la trémie

U

r

e

s

A

m

ENTRETIENS

a

DATES DES

g

e

a

v

i

s

i

a

s

f

o

o

n

n

i

t

s

l

e

p

a

r

n

h

e

u

e

t

e

u

s

r

e

l

e

s

s

1

0

0

T

o

o

h

u

e

t

e

u

s

r

e

l

e

s

s

5

0

T

T

o

h

u

e

t

e

u

s

r

e

l

e

s

s

2

5

A

v

e

a

m

n

p

t

l

c

o

h

i

a

q

u

e

la machine.

d'effectuer toute opération d'entretien de

tout nettoyage, toute lubrificat ion ou avant

mettez-le à la terre contre le moteur avant

moteur, débranchez le fil de la bougie et

AVERTISSEMENT: Arrêtez toujours le

Vérification de la bougie

Nettoyage du moteur

M

O

T

Nettoyage du filtre à air

E

U

R

Vidange d’huile

Vérification - niveau d’huile

déchiqueteuse

Vérification lame de la

d’éjection

M

A

Lubrifiez la goulotte

C

H

I

Lubrifiez la trémie

N

E

Lubrifiez la tringle de blocage

D’ENTRETIEN

CALENDRIER

Responsibilités du client

CHAPITRE 5: ENTRETIEN DE LA DÉCHIQUETEUSE-BROYEUSE

Figure 8

Modèle 465 Illustrée

Trèmie

aiguisée.

aussi de meilleurs résultats si la lame est toujours bien

DÉCHIQUETEUSE/BROYEUSE. Vous obtiendrez

les instructions du CHAPITRE 5 : ENTRETIEN DE LA

tamis se bouche, démontez-le et nettoyez-le en suivant

l'intérieur du boîtier dans la zone d'évacuation. Si le

IMPORTANT: Le tamis des fléaux se trouve sur

déchiquetage

Goulotte de

d’éjection

Goulotte

Page 24

9

plus détaillées.

moteur founie avec la machine pour des instructions

REMARQUE: Consultez la notice d’utilisation du

masse contre le moteur.

• Débranchez le fil de la bougie et mettez-le à la

de la déchiqueteuse. Voir la Figure 8.

le tasse-débris pour pousser les débris dans la go ulotte

dans la trémie du modèle 463. Le cas échéant, utilisez

trémie des modèles 462 à 465 et d'u n diamètre de 2 po

branches d'un diamètre maximum de 3 po dans la

desséchés. Vous pouvez placer des brindilles et petites

plants de tomates tant qu'ils ne sont pas complètement

Évitez de broyer des plantes fibreuses comme les

jardin ordinaire (branches, feuilles, brindilles, etc.).

de broyer des débris autres que de la végétation d'un

projetés dans un sac. N'essayez pas de déchiquete r ou

fléaux de la turbine, ils sont éjectés par l'ouverture ou

seront broyés. Quand les débris ont été broyés par les

exemple) peuvent être ratissés dans la trémie oû ils

Les débris végétaux (feuilles et aiguilles de pin par

Utilisation de la déchiqueteuse/broyeuse

«STOP»ou «OFF» (Arrêt).

• Placez la commande de l’obturateur à la position

Arrêt du moteur

gaz inodore et mortel.

contiennent du monoxyde de carbone, un

car les gaz d’échappement du moteur

fonctionner la machine dans un local clos

AVERTISSEMENT: Ne faites jamais

position «RUN» (Marche).

manette du volet de départ (le cas échéant) à la

le moteur démarre, déplacez progressivement la

• Répétez jusqu’à ce que le moteur démarre. Quand

corde revenir lentement.

continu. Tenez fermement la poignée et laissez la

• Tirez sur la corde d’un mouvement rapide et

Figure 7

blocage

Tringle de

Trèmie

au sol. Voir la Figure 7 .

• Tirez sur la tringle de blocage et abaissez la trémie

légèrement l’ensemble.

haut de la trémie d’une main et soulevez

• Pour abaisser la trémie, tenez la p oignée sur le

Pour abaisser la trémie

goulotte d’éjection.

goulotte et bouclez àfond la cordelière contre la

sac soit bien ajusté autour de l’ouverture de la

goulotte. Tirez sur la cordelière jusqu’à ce que le

• Videz le sac et replacez-le sur l’ouverture de la

dégager de l’ouverture de la goulotte d’éjection.

• Déboucler la cordelière pour desserrer le sac et le

Pour vider le sac

minutes.

Laissez-le refroidir pendant au moins deux

moteur tourne ou si le moteur est chaud.

d’essence à l’intérieur, pendant que le

AVERTISSEMENT: Ne faites jamais le plein

que la turbine atteigne sa vitesse maximale.

seront assez bruyants après le démarrage et jusqu’à ce

mécanisme de broyage. De plus, les fléaux et lames

la mise en place des fléaux et lames qui constituent le

début du cycle de compression. Ce bruit est causé par

REMARQUE: Vous entendrez peut-être un bruit au

corde revenir lentement.

(vous sentirez une légère résistance). Laissez la

ce que le moteur atteigne le cycle de compression

• Tirez lentement sur la corde du démarreur jusqu’à

«START» (Démarrage).

Placez-la à la position «FAST» (Rapide) ou

• La manette de l’obturateur se trouve sur le moteur.

accompagne la machine.

figurent dans la notice d’utilisation du moteur qui

Amorcez le moteur en suivant les instructions qui

• Moteur à amorceur:

fermer le volet de départ si le moteur est chaud).

tion «CHOKE» (Fermé). (Il n’est pas nécessaire d e

Déplacez la manette du volet de dépar t à la po si-

• Moteur à volet de départ:

bien l’embout métallique de la bougie.

que le capuchon métallique de la bougie recouvre

• Raccordez le fil de la bougie à la bougie. Vérifiez

Mise en marche du moteur

Page 25

8

instructions.

accompagne la machine. Veuillez lire attentivement les

instructions fournies dans la notice d’utilisation qui

Faites les pleins d’essence et d’huile selon les

Pleins d’huile et d’essence

moteur.

l’emplacement et au rôle des diverses commandes du

Consultez la notice d’utilisation du moteur quant à

Commandes du moteur

Voir la Figure 6.

déchiquetage pour pousser les débris vers la turbine.

Le tasse-débris doit être inséré dans la goulotte de

Tasse-débris (le cas échéant)

matériaux ratissés pour les broyer. Voir la Figure 6.

broyées. Abaissez la trémie pour charger les

dans la turbine où elles seront déchiquetées et

branches d’un demi-pouce de diamètre maximum

Elle permet le chargement de feuilles et de petites

Trémie

ajustement à la machine.

en effectuant toute réparation ou tout

machine ou un masque en travaillant ou

lunettes de sécurité fournies avec la

atteignent les yeux. Portez toujours les

causer des blessures graves s'ils

la projection d'objets divers qui peuvent

déchiqueteuse/broyeuse peut provoquer

AVERTISSEMENT: L'utilisation d'une

CHAPITRE 4: UTILISATION DE LA DÉCHIQUETEUSE-BROYEUSE

Pour récupérer les matériaux broyés.

Sac (non représenté)

Voir la Figure 6.

po sur les modèles 462 à 465 et 2 po sur le modèle 463.

elle sera déchiquetée et broyée. Diam ètre maximal: 3

(tiges ou branches plus épaisses) dans la turbine où

Elle permet le chargement de végétation plus gr ossière

Goulotte de déchiquetage:

l'abaisser. Voir la Figure 6.

bloquer ou à dégager la trémie pour la relever ou

Elle se trouve sur le support de la turbine et sert à

Tringle de blocage

mettre le moteur en marche. Voir la Figure 6.

Elle se trouve sur le moteur. Tirez sur la poignée pour

Poignée du démarreur

Figure 6

Tasse-débris

démarreur

Poignée de

déchiquetage

Goulotte de

Modèle 465 illustrée

de blocage

Tringle

Trémie

ultérieure.

commandes et ajustements divers. Conservez cette notice d’utilisation à un endroit sûr pour toute consultation

broyeuse. Comparez l’illustration à la Figure 6 avec votre machine pour vous familiariser avec l’emplacement des

Veuillez lire attentivement la notice d’utilisation et les consignes de sécurité avant d’utiliser la déchiqueteuse-

CHAPITRE 3: DESCRIPTION DE LA DÉCHIQUETEUSE-BROYEUSE

Page 26

7

Goulotte

d'éjection

Figure 5

Sac

précédemment. Serrez à fond.

déchiquetage avec la boulonnerie retirée

support. Attachez le support sur la goulotte de

• Alignez les trous de la goulotte avec les trous du

support sur le châssis.

n’enlever pas les boulons qui maintiennent le

été attachée au châssis inférieur. Desserrez mais

• Pour l’expédition, l’une des extrémités du support a

Boucle

déchiquetage.

rondelles se trouve contre la goulo tte de

encore les écrous. Vérifiez que le côté creux des

six pans enlevés au paragraphe 1. Ne serrez pas

Voir la Figure 5.

maintenir bien serrée contre la goulotte d’éjection.

• Faites une boucle avec la cordelière pour la

bien ajusté autour de l’ouverture de la goulotte .

• Tirez sur la cordelière jusqu’à ce que le sac soit

entièrement recouverte.

déflecteur de la goulotte pour qu’elle soit

• Installez le sac en plaçant son ouverture sur le

Installation du sac (Tous les modèles)

contre la goulotte de déchiquetage) et les écrous à

• Replacez les trois rondelles creuses (côté creux

goulotte avec les trois goujons soudés.

orientée vers le bas. Alignez les trois trous de la

goujons soudés pour que la fente de la goulotte soit

• Positionnez la goulotte de déchiquetage sur les

l’extrémité supérieure du support.

plates et les deux contre-écrous des deux trous d e

• Enlevez les deux boulons hex., les deux rondelles

sur la gauche de la carrosserie. Voir la Figure 4.

six pans des goujons soudés autour de l’ouverture,

• Enlevez les trois rondelles creuses et les écrous à

déchiquetage

Installation de la goulotte de

précédemment.

Figure 4

creuse

Rondelle

Écrou à six pans

Fente

représenté à la Figure 4.

REMARQUE: Pour plus de clarté, le moteur n’est pas

(Modèles sélects 462 à 465 seulement)

de la turbine avec les boutons à oreilles retirée

Support

Contre-écrou

Figure 3

• Attachez les deux côtés de la goulotte sur le boîtier

plate

Rondelle

Goulotte d’éjection

Bouton à oreilles

Boulon hex.

déchiquetage

Goulotte de

Goujon soudé

des fléaux.

retiennent la goulotte de déchiquetage sur le boîtier

• Serrez les trois écrous sur les goujons soudés qui

le châssis.

• Serrez les boulons qui maintiennent le support sur

hex.

Boulon

Entretoise

à six pans

Contre-écrou

Page 27

6

blocage

Tringle de

la turbine

Support de

soutien

Plaque de

avec le contre-écrou à six pans.

boulon hex., dans la charnière. Maintenez en place

• Placez la deuxième rondelle d’écartement sur le

la charnière). Voir la Figure 3.

le boîtier (les rondelles se trouvent sur l’intérieur de

dans la charnière de la goulotte d’éjection et dans

Insérez le boulon hex. et la rondelle d’écartement

• Placez la goulotte d’éjection sur l’ouverture.

boîtier.

d’écartement, et les boulons hex. du haut du

• Enlevez les contre-écrous à six pans, les rondelles

Figure 3.

chaque côté du boîtier de la turbine inférieur. Voir la

• Enlevez les boutons à oreilles qui se trouven t de

(Tous les modèles)

Installation de la goulotte d’éjection

Figure 2

Trémie

la trémie

Support de

Écrou à six pans

Rondelle

Goujon soudé

Habitacle de la turbine

Figure 1

trémie sur cette dernière.

écrous à six pans qui maintiennent le support de la

trémie sur le boîtier de la turbine, puis serrez les

• Serrez les six écrous à six pans qui maintiennent la

Figure 2.

pouvoir y accrocher le support de la trémie. Voir la

poussez légèrement la tringle de blocage pour

• Relevez la trémie jusqu’au support de la turbine et

place. Ne les serrez pas à fond.

remettez les rondelles et les écrous à six pans en

• Glissez la trémie sur les goujons soudés, puis

avec les goujons soudés.

turbine et alignez les trous du collier de la trémie

• Positionnez la trémie sur l’avant de l’habitacle de la

goujons. Voir la Figure 2.

turbine. Laissez la plaque de soutien su r les

rondelles des goujons soudés sur l’habitacle de la

• Enlevez les six écrous à six pans et les six

Installation de la trémie (Tous les modèles)

contre le moteur.

débranchez le fil de la bougie et mettez-le à la terre

Avant de régler la déchiqueteuse/broyeuse,

Débranchement du fil de la bougie

• Lunettes de sécurité (non représenté)

• Tasse-débris (le cas échéant)

• Sac (non représenté)

• Goulotte de déchiquetage (462 à 465)

• Goulotte d’éjection

•Trémie

(Voir la Figure 1 )

Pièces détachées dans le carton

d’éjection

Goulottte

déchiquetage

Goulotte de

Trémie

dans le carton.

Vérifiez qu’il ne reste plus de pièces détachées

• Faites rouler ou glisser la machine hors du carton.

le et sortez les garnitures d’emballage.

• Découpez le carton le long des coins et aplatissez(notice d’utilisation par ex.).

• Sortez les pièces qui accompagnent la machine

carton.

carton ou coupez le ruban adhésif pour ouvrir le

• Enlevez les agrafes, décollez les rabats du haut du

Sortez la machine du carton

derrière la machine, en position de conduite.

gauche de la déchiqueteuse-broyeuse, placez-vous

REMARQUE: Pour déterminer les côtés droit et

quant au carburant et à l’huile à moteur recommandés.

terminé, veuillez lire la notice d’utilisation du moteur

ESSENCE ni HUILE. Lorsque l’assemblage est

IMPORTANT: Cette machine est expédiée SANS

CHAPITRE 2: ASSEMBLAGE

Page 28

5

S30186

>76mm

S30039

>12mm

qui figurent dans cette notice d’utilisation et sur la machine.

des personnes qui ont lu, qui comprennent et qu i respectent les avertissements e t les instructions

AVERTISSEMENT: — VOTRE RESPONSABILITÉ: Ne permettez l’utilisation de cette machine qu’à

mobiles de la machine.

nature et à l’environnement.

des déchets et liquides qui risquent de nuire à la

10. Respectez les règlements concernant l’élimination

l’extérieur.

9. Le cas échéant, videz le réservoir d’essence à

instructions de remisage hors-saison.

8. Consultez toujours la notice d’utilisation quant aux

etc.)

étincelle (chauffe-eau à gaz, radiateur, sèch e-linge,

d’essence à l’intérieur s’il y a une flamme, une

7. Ne remisez jamais la machine ou les bidons

danger de cette machine.

déchargement, le transport et le remisage sans

d’utilisation pour ce qui concerne le chargement, le

6. Suivez les conseils fournis dans cette notice

d’instructions et remplacez-les au besoin.

5. Prenez soin des étiquettes de sécurité et

risque de l’endommager ainsi que d’autres pièces

dangereux de laisser le moteur s’emballer, ce qui

un régime optimum sans présenter de danger. Il est

4. Ne modifiez pas le réglage du régulateur qui assure

celle-ci pour empêcher tout démarrage accidentel.

Débranchez le fil de la bougie et él oignez-le de

pièces en mouvement se sont immobilisées.

machine, assurez-vous que la turbine et autres

3. Avant de nettoyer, de réparer ou d’examiner la

pas besoin d’être réparée.

vous assurer qu’elle n’est pas endommagée et n’a

marche. Examinez soigneusement la machine pour

bien serrés et maintenez la machine en bon état de

2. Vérifiez régulièrement que les boulons et vis sont

Vérifiez souvent qu’ils fonctionnent correctement.

1. Ne modifiez jamais les dispositifs de sécurité.

ENTRETIEN ET REMISAGE

Page 29

4

quand le moteur tourne.

16. Ne soulevez jamais la machine et ne la portez pas

pas.

et peuvent causer des brûlures. Ne les touchez

15. Le silencieux et le moteur deviennent très chauds

médicaments.

des boissons alcoolisées ou après avoir pris des

14. Ne vous servez pas de la machine après avoir bu

goudronnée, recouverte de gravier ou accidentée.

13. N'utilisez pas cette machine sur une surface

mauvaise ou si la lumière est insuffisante.

12. N’utilisez pas la machine si la visibilité est

matériaux.

déchiquetage pour éviter tout rejet accidentel des

11. Ne vous approchez jamais de la goulotte de

et en bon état.

déflecteurs et autres dispositifs de sé curité en place

10. Laissez tous les dispositifs de protection, les

fonctionne.

toujours être fermée pendant que la machine

L’extrémité à fermeture à glissière du sac doit

l’aspirateur pendant que le moteur tourne.

N’essayez jamais de retirer et de vider le sac de

et la goulotte d’éjection ne sont pas installés.

9. N’utilisez jamais la machine si le sac de l’aspirateur

les débris.

mettez-le à la terre contre le moteur avant de retirer

immobilisées. Débranchez le fil de la bougie et

toutes les pièces en mouvement se soient

le moteur tourne. Arrêtez le moteur et attendez que

d’alimentation ou l’ouverture d’éjectio n pendant que

8. N’essayez jamais de déboucher le compartiment

d’endommager la machine.

d’utilisation. Vous risquez de vous blesser ou

diamètre précisé sur la machine ou dans la noti ce

matériaux d’un diamètre plus important que le

7. N’essayez jamais de broyer ou de déchiqueter des

déchiquetage.

de provoquer des rejets par la goulotte de

empêcheront une éjection satisfaisante et risqu ent

s’accumuler à proximité de la goulotte car ils

6. Ne laissez pas les matériaux déchiquetés

fonctionnement sans danger.

resserrez-les pour bénéficier d’un

c. Vérifiez s’il y a des pièces desserrées et

endommagées.

b. Réparez ou remplacez les pièces

a. Recherchez les dégâts éventuels;

contre le moteur. Procédez comme suit :

Débranchez le fil de la bougie et mettez-le à la terre

Attendez que la turbine s’immobilise complètement.

anormalement, arrêtez immédiatement le moteur.

produit des bruits inhabituels ou vibre

5. Si la turbine frappe un objet dur ou si la machine

N’utilisez jamais vos mains ou pieds.

travers la trémie, utilisez un bâton de petit diamètre.

4. S’il devient nécessaire de pousser le matériel â

blessures graves ou d’endommager la machine.

métallique ou autre objet qui risque de causer des