MTD 41AD251G900 Owner’s Manual

Operator'

Y25

2-Cycle Trimmer

®

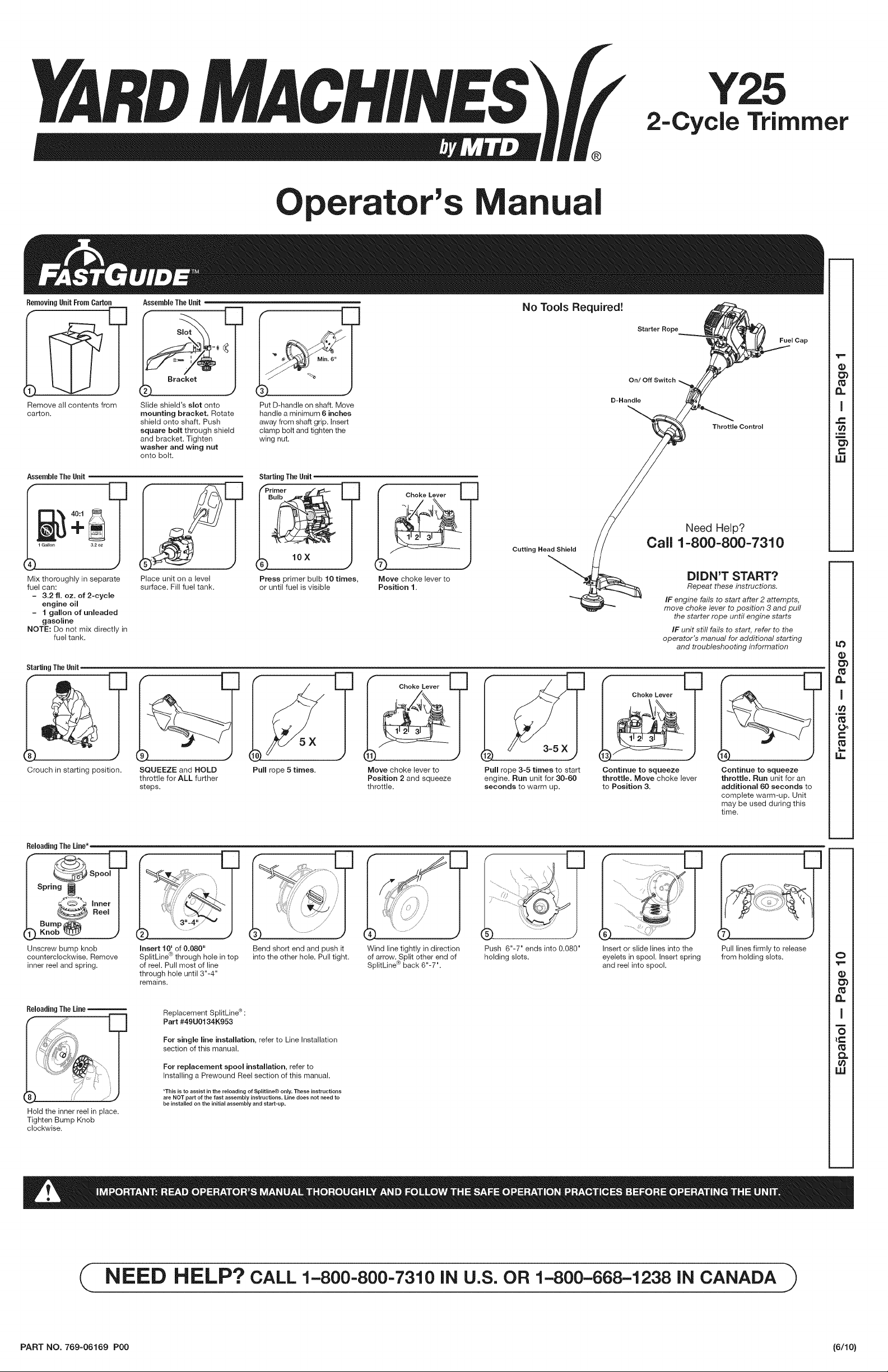

RemovingUnitFrom Carton

Remove all contents from

carton.

AssembleThe Unit

f

E]

1 Gallon 3.2 oz

1 J

Mix thoroughly in separate

fuel can:

- 3.2 ft. oz. of 2-cycle

engine oil

- 1 galmon of unleaded

gasoline

NOTE: Do not mix directly in

fuel tank.

AssembleThe Unit

Bracket

Slide shield's slot onto

mounting bracket. Rotate

shield onto shaft. Push

square bolt through shield

and bracket. Tighten

washer and wing nut

onto bolt.

Place unit on a level

surface. Fill fuel tank.

]

Put D-handle on shaft. Move

handle a minimum 6 inches

away from shaft grip. Insert

clamp bolt and tighten the

wing nut.

Starting The Unit

]

_rimer '=frACL" L

Bu_ ......

10X

Press primer bulb 10 times,

or until fuel is visible

L

]

]

Move choke lever to

Position 1.

ChokeLever i

1--

No Tools Required!

Starter Rope

On/Off Switch

D-Handle

Throttle Control

n

I

,,C

_m

C

uJ

]

Need Help?

Call 1-800-800-7310

DIDN'T START?

Repeat these instructions.

IF engine fails to start after2 attempts,

move choke lever to position 3 and pull

the starter rope until engine starts

IF unit still fails to start, refer to the

operator's manual for additional starting

and troubleshooting information

m

m

LO

Starting The Unit

Crouch in starting position.

Reloading The Line*

f _ SP oolE

Spring

_ nner

Unscrew bump knob

counterclockwise. Remove

inner reel and spring.

Reloading The Line

Hold the inner reel in place.

Tighten Bump Knob

clockwise.

Reem

[--1

SQUEEZE and HOLD

throttle for ALL further

steps.

f

insert 10' of 0,080"

SplitLine ® through hole in top

of reel. Pull most of line

through hole until 3"-4"

remains.

Replacement SplitLine c_:

Part #49U0134K953

For single line installation, refer to Line Installation

section of this manual

For replacement spool installation, refer to

Installing a Prewound Reel section of this manual.

*This is to assist in the reloading of Splitline® only. These instructions

are NOT part of the fast assembly instructions. Line does not need to

be installed on the initial assembly and start-up.

E]

Pull rope 5 times.

Bend short end and push it

into the other hole. Pull tight.

]

Move choke lever to

Position 2 and squeeze

throttle.

Wind line tightly in direction Push 6"-7" ends into 0.080" Insert or slide lines into the Pull lines firmly to release

of arrow. Split other end of holding slots, eyelets in spool. Insert spring from holding slots.

®

SplitLine back 6"-7". and reel into spool.

]

j

: 35xj

Pull rope 34 times to start

engine. Run unit for 30-60

seconds to warm up.

F]

j ) J

r E

Choke Lever

Continue to squeeze

throttle. Move choke lever

to Position 3.

]

Continue to squeeze

throttle. Run unit for an

additional 60 seconds to

complete warm-up. Unit

may be used during this

time.

F]

n

I

C

U,

m

O

n

I

m

O

_C

o_

¢0

uJ

NEED HELP? CALL 1-800-800-7310 iN U.S. OR 1-800-668-1238 iN CANADA

PART NO. 769=06169 P00 (6/10}

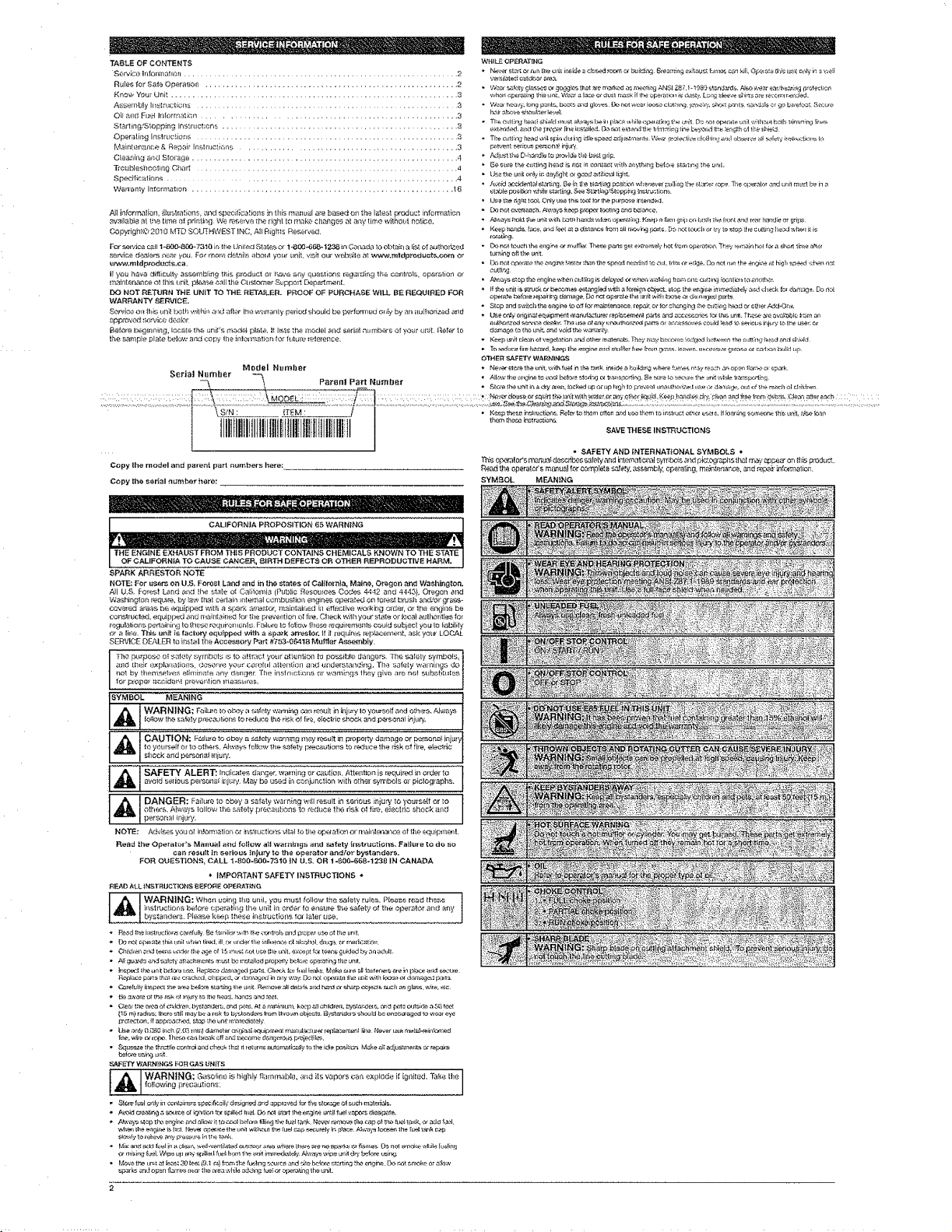

TABLE OF CONTENTS

Serv;cP. Info_mafFo_ ....................................................... 2

Rules for Sa_e Operatio£ ........................................................... 2

Know Your Unit .................................................. 3

AsseTnbly tfl_[r[_cUc[Is ............................................................. 3

O[_ _ld F[Je] !fflormabcn ............................................... 3

ttort i¢_g.'Stopping Instruct;arts ........................................... 3

Operating Inslruc_ions ......................................................... 3

f,,,laintefl?.nr_e & Repair Instruc[}_ms ................................................. 3

C[eaniP.g aP.d Storage .............................................................. 4

Tro_blesiloot_P.g Chad ............................................................. 4

Specific_t Jot_s ......................................................... 4

Warl_nty Intorm£-tlo r_ ............................................................ 16

All informaf[om iiluslra_ion s. a_d spe¢it_ca lion s in this ma;mal are based o.q the latest pR>duc_ information

avaiI_hie at the lime. or prk_ting We _s_ g_e right to make tha_ge._ at airy time _ithebl notice.

Copyrig!t_© 2010 MTD SOUTHW£ST _NC,All Rights Resel_ed.

Per se_Aee call I _80£--80_3W31a in the [Jniled _etee or 14_00-66_ 12,38 in C.31lr_da to obtain a li_ Of auth0 rLzerJ

se_,ice dealers ne.3t _!ou Pot m_ det_i!s abo_ your uniL v%it o_Jrwebt_'le at _.mtdproduc_.com or

www.mldp_oduc_s.ca.

ir you h_ve diffict_lty assembli_g this p_duCl 01¸Iiave any questions reg_din_ the cGnh_s, ope_tio_ o_

m_ nth.rlan ce ot thit_ _lnR,p!ea ._e_tll the C_l_ome_ Support Deparlrnent.

DO NOT R£'_RN THE UNIT TO THE RETAILER. PROOP OF PURCHASE WII_ BE REQUIRED FOR

WARRANTY 8ZRVICiZ.

S(_vioe o_}this _A;t _3U1 within an(} r_tter bhewarranty Feq-iud should be perfomled o_y by ar_ m_if_nzed afld

Before D_z31hhq #. [GCO_eth_ _nifs modei p_ate, it I_ststhe model al_d serm_number_ ot your uP._t[_efer to

IRe sample p_ate below and ¢-opy _h÷ i_llo__l_etiot_ Ior ft_t_l>__4@_nge.

Serial Number

Copy the model and parenl part numbers here: R e."_Ithe operator's m_uaJ for c_mplet esafe_. _ss_mbly, operating, m_nteear,.ce, and repak _fc_malien.

COpy il_e ssriaI humped' here," SYMBOL MF,AN_NG

SPARK ARRESTOR NOTE

NOTE: For users or_ U.S, Foreel La_,d arid in the states of Colgorrfla, Maine, Oregon and Wa_lllngto_.

All U.S. Forest Land and the _;tate ot Calitorni_ (Public Resoulees Codes 4442 and 4443}. Oregon and

1_,%_3_hingtorz re_ulre, by ]_w 1_3t Cert_h illtem_] COr_bustioll _llgiP_ee operated on toilet brg £11and/or gr a£.s-

COnSttU¢l_d_ equi_p_d altd nl._il_ta illt-d _or {lie [srd_'eotJsq OI fire. alack Withyour state Or _ee_!lfa_thorit le_for

mg_lalion s perk_bing to th_se r(_qukem _-rlls. Failure to fol!ow lh_ _ quir_Rt_ZI_SCould s_b_ec[ yo_ to liability

o_ a line TI_is unit is factory equipped with a _pa_k arrestor. 11it_'4uiree _eplacement. ask ym=_ LOCAL

SERVICE DD\LER toibstal_ tile Acces._oty Part #753436418 Muffler As,notably

a_d [heir explanations, deserve you. _carolal a_ten{iorl and underatandirlg. The safely' warning_ do

I R_e p_._rMoS,:'0t SaKW _ymbui_ is _o al_ract y_.a_ralt_nii:_ll Io possible dangers. Tile safely symbols,

for p=ope_ _ccideni prevention nleasure_, t

SYMBOL M'_ANING

t WARNING; _ellu_e Io ob_.,ya s;_f_,, _,,,am_g ca.._result in injt_i =o yourself a,qd oth_._. Always [

toltow the safety p_cau_ions 1o_educe the risk of fire, electric shOCk and paschal [njtw'.

,_ CAUTION: Fa!k:_e to obey a s_.lety worrying moy result in property damage or persona! i_juty

tO y_hl_ell or to othe_.. Ab:¢ays fallow the SafeIy pre_LMons to red_._ce the dsk af fire, eleclr_c

I ! sho_:k and p ..... I injury, t

1_ SAFETY ALER Tf lr_dlcates danger, warning or cautio n, Altelnien is required in o_JeHoavoid sedous pe_'son aHnjury. May be used in co_ju r.ction with ot he_'symbols ol' piclogr aphs. I

othe.%. Always tallcev me safety precautions to rodlike el_lris_ o_ _ire, e_ectMo shock and

persoP.a_ inlury.

NOTE: iVJ,Jises you ot iulom_._tiol5 or in_l_uctio!% _11.%1_oti_e ope_alio_l or rnail-4_tance of _ll@_q_iplll_/l.

]qead the Operator% Manual and follow atl Warntn_]s and safety _nst_'ucti0ns. ?aEl_re _0 do so

READ ALL _NOTRUCTIOHS _ £_ORE OPIZRA3"a_G

_ ARNING: _#hel_ usil/g me urtil! you must fotlow _he safety rules. Please read th_se ]

• _ad1hek_`_1r_c_s_aretu_f8ef?_r_i_i:_r_`_b_e`_r_s_ndp_Fe_`_t_he_:t_

. _r_ono[ul_te_hi_Hn#w_t_t_r_J, al {*ur_Jer_he_fl*_e_c_ol_lc_I_l 4_3s _zm_di4mn_

* `Ch_d_en_:_teenc_*je_@_e_[L5_3_s;_1t_eu``1t,ex_:ep[_';_teer_£ukjedb73r_adu_

• Aj_gu_duar_satc4yat_hmc_tsmustt`_nsta_d_r_P_t_``t_;_£_P_:_i_th_`_n_t_

• _re|#l_ in_4>ec[_hem_eabe{ore sta,tNg _beu_li_Remo_e all dehd_ al_d b2rd _ sharp ebjec_ _h as gla_s, wir_.e[c

. Ee awareot tP,#_mkr_tmj_y _othehead. honesan,J_em,

tl 5m@faders, there stZ ma_"be a r_s__ob_'sta_d_s _rumt _o':_ a_c_. ]_t_de_ £.h_JIdbe _zo_a#_ lo wea_eye

_i_n_ tf _pp_oacbed._tc,__heun,Lm_medtatetf

• 8q._ze_e the _P.fcttk,c_e_{ciand ch_k _ at __etums_a_r_i_ly t_ the _# _@_c_ M_kea]__dfJstment_ _r repa_

_Lc_t WARN}NGS FORGAS UNITS

. _ret_1yin¢_t_s_s_pe_i_¢_yd_s_nedandap_ved_rthes[_age_su_mate5ajs_

• Avoid c_e_st_tx-_._._c_r¢.eof ion_ti_nIo_ ._pilledh[¢1._.3r_ _1atl lhe er..3if,eun_iift_elva_s d_nte.

Ahva}_ step t_k_8neil_ and al_w il t__o_q [_.fuw¢.t,]_._ lJ..eluel _aqk._¢ev(.t._qI_Qe _hecap ot me -_e}tal_k,or ade 9ok

_h_ LI_eeagb_eis hsl b..X__ r-pelage_bet_t.i_w_L_-_ulthe.filel cap _ur_y imp_aueO_¢,_ ]od_en_he tooli_¢I_c_p

s_dy torel:eveany _zes_u_e],Ilhe I_k

. Mix and ado lull _ _dea_, w_Jl.venli_.t_ _.atm;_x3rar_l where _h_ze:ere_.__par_ _ l]m_e& D_ :_ _moke Mfile[ue_o£

_- m&i_] t,._llWr#e up _r_y_[,4_le_if,._ f_n 1he_r_i_i_d_lei2 Alway_ wipe ur_i!eP_before _sing

• Movetheu_atbas;3Otee;@,_r4).f_m1_;_n_sou_eand@_bd¢_estz_t[r, Othee_9_e Do_at_raokeerd,]ew

sl'_r kse_.t o_en flam_ _lea:_he area'A'l_i_eadding iue; orol_m_Jng _he ,_.

can result tn seriou_ Injury to the operator and/or bystanders.

FOR QUESTIONS, CALL 1-800-800-73t0 IN U.S, OR 1-80@-558-1238 IN CANADA

i:_structions b_./ore cpe_aliqg the u_!itin Order _o erasure the satet_j of the operator at_d _ny

WARNING: Gasotine is highly flarr, mable. 4rod it s vapors _;an explode il [gnilsd. Take Ihe

o owng preca_ ann: I

Model N_mber

IIIHII HII' ,.o,............,....I I _ sAvET.ESE,NS_UC_,D_S

* IMPORTANT SAFELY INSTRUCTIONS *

,IIIH{[I]II

TIiS0Z4r31sr's ma_;ua_<l_,.cr_L_ safety and _ltematic_lal sylnlao_ a_d F-ictogra_s {hal may aRsear on Itlis grOduct.

I

• SAFETY AND NT_RNAT ONAL SYMBOLS *

1bystande_-s Please keep t_ese Jnstructlon_ tot _ater use,

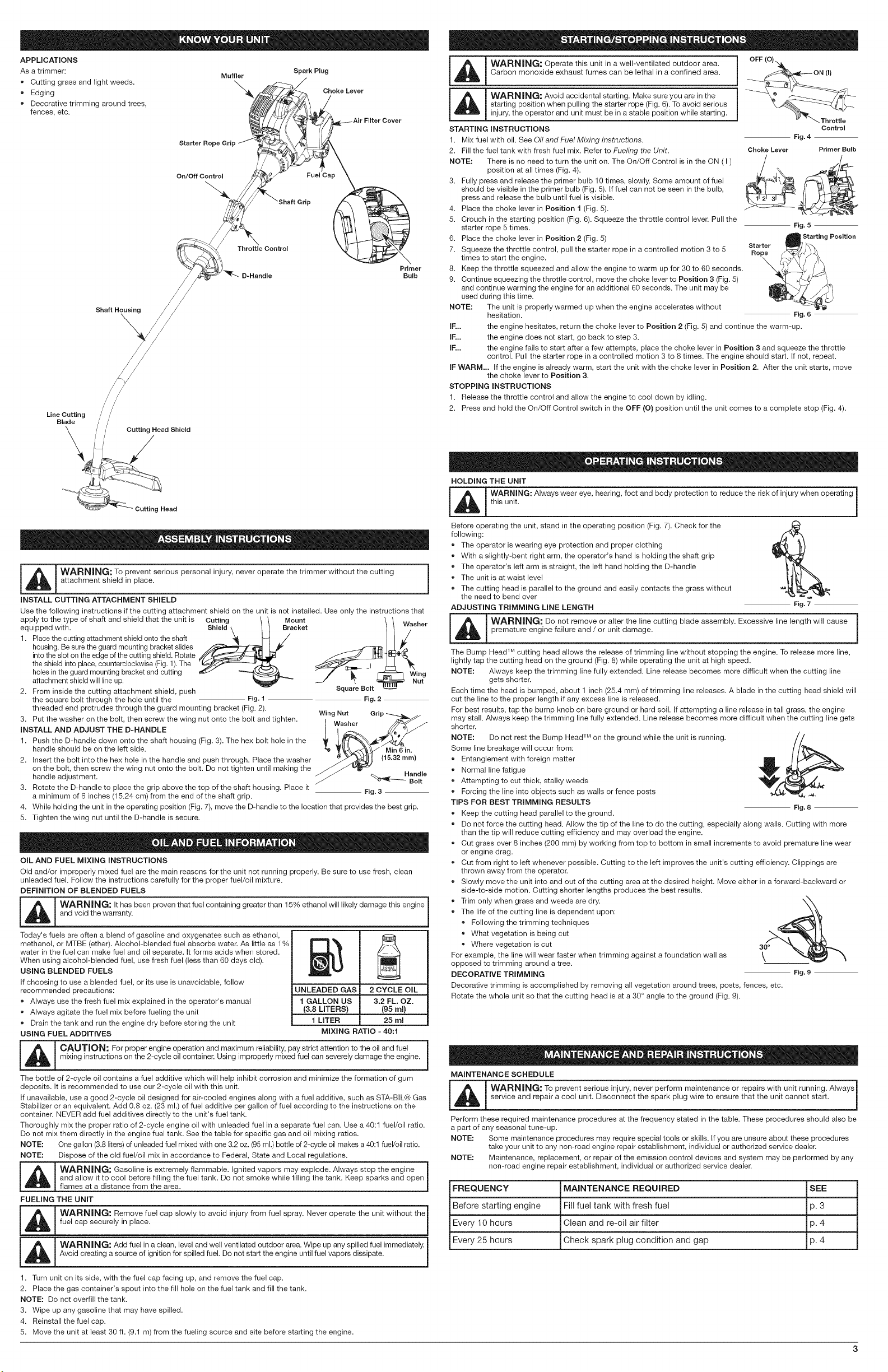

APPLICATIONS

As a trimmer: Muffler Spark PJug

• Cutting grass and light weeds.

Edging _' Choke Lever

Decorative trimming around trees,

fences, etc.

On/Off Control Fuel Cap

Throttle Control

D-Handle

Shaft Housin_

\

Line Cutting

Blade

Cutting Head Shield

Primer

Bulb

m

_ WARNING: Operate this unit in a well-ventilated outdoor area.

_L_ ARNING; Avoid accidental starting. Make sure you are in the

STARTING INSTRUCTIONS

1. Mix fuel with oil. See Oil and Fuel Mixing Instructions.

2. Fill the fuel tank with fresh fuel mix. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off Control is in the ON ( I )

3. Fully press and release the primer bulb 10 times, slowly. Some amount of fuel

4. Place the choke lever in Position 1 (Fig. 5).

5. Crouch in the starting position (Fig. 6). Squeeze the throttle control lever. Pull the

6. Place the choke lever in Position 2 (Fig. 5)

7. Squeeze the throttle control, pull the starter rope in a controlled motion 3 to 5

8. Keep the throttle squeezed and allow the engine to warm up for 30 to 60 seconds.

9. Continue squeezing the throttle control, move the choke lever to Position 3 (Fig. 5)

NOTE: The unit is properly warmed up when the engine accelerates without

IF... the engine hesitates, return the choke lever to Position 2 (Fig. 5) and continue the warm-up.

IF... the engine does not start, go back to step 3.

IF... the engine fails to start after a few attempts, place the choke lever in Position 3 and squeeze the throttle

IF WARM... If the engine is already warm, start the unit with the choke lever in Position 2. After the unit starts, move

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to cool down by idling.

2. Press and hold the On/Off Control switch in the OFF (O} position until the unit comes to a complete stop (Fig. 4).

Carbon monoxide exhaust fumes can be lethal in a confined area.

starting position when pulling the starter rope (Fig. 6). To avoid serious

injury, the operator and unit must be in a stable position while starting.

Choke Lever Primer Bulb

position at all times (Fig. 4).

should be visible in the primer bulb (Fig. 5). If fuel can not be seen in the bulb,

press and release the bulb until fuel is visible.

starter rope 5 times.

Starter _] _%,

times to start the engine.

and continue warming the engine for an additional 60 seconds. The unit may be

used during this time.

hesitation. Fig.6

control. Pull the starter rope in a controlled motion 3 to 8 times. The engine should start. If not, repeat.

the choke lever to Position 3.

"_.Throttle

ControJ

Fig.4

Fig. 5

m Starting Position

Cutting Head

m

_1_ ARNING: To prevent serious personal injury, never operate the trimmer without the cutting

INSTALL CUTTING ATTACHMENT SHIELD

Use the following instructions if the cutting attachment shield on the unit is not installed. Use only the instructions that

apply to the type of shaft and shield that the unit is Cutting \ / Mount

1. Place the cutting attachment shield onto the shaft

equipped with. _eket

2. From inside the cutting attachment shield, push

3. Put the washer on the bolt, then screw the wing nut onto the bolt and tighten. Washer

INSTALL AND ADJUST THE D-HANDLE _. _

1. Push the D-handle down onto the shaft housing (Fig. 3). The hex bolt hole in the

2. Insert the bolt into the hex hole in the handle and push through. Place the washer

3. Rotate the D-handle to place the grip above the top of the shaft housing. Place it Fig. 3

4. While holding the unit in the operating position (Fig. 7), move the D-handle to the location that provides the best grip.

5. Tighten the wing nut until the D-handle is secure.

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons for the unit not running properly. Be sure to use fresh, clean

unleaded fuel. Follow the instructions carefully for the proper fuel/oil mixture.

DEFINITION OF BLENDED FUELS

_L_ ARN ING, It has been proven that fuel containing greater than 15% ethanol will likely damage this engine

Today's fuels are often a blend of gasoline and oxygenates such as ethanol,

methanol, or MTBE (ether). Alcohol-blended fuel absorbs water. As little as 1% _

water in the fuel can make fuel and oil separate. It forms acids when stored.

When using alcohol-blended fuel, use fresh fuel (less than 60 days old).

USING BLENDED FUELS °

If choosing to use a blended fuel, or its use is unavoidable, follow

recommended precautions: UNLEADED GAS 2 CYCLE OIL

USING FUEL ADDITIVES MIXING RATIO - 40:1

attachment shield in place,

housing. Be sure the guard mounting bracket slides

into the slot on the edge of the cutting shield. Rotate

the shield into place, counterclockwise (Fig.1).The

holes in the guard mounting bracket and cutting

attachment shield will line up.

the square bolt through the hole until the Fig. 1

threaded end protrudes through the guard mounting bracket (Fig. 2).

handle should be on the left side.

on the bolt, then screw the wing nut onto the bolt. Do not tighten until making the _ Handle

handle adjustment. J "_-'_---- Bolt

a minimum of 6 inches (15.24 cm) from the end of the shaft grip.

and void the warranty.

Always use the fresh fuel mix explained in the operator's manual 1 GALLON US 3.2 FL OZ.

Always agitate the fuel mix before fueling the unit (3.8 LITERS) (95 ml)

Drain the tank and run the engine dry before storing the unit 1 LITER 25 ml

Wing Nut Grip _

/_ Washer

Fig. 2

HOLDING THE UNIT

-- i_L_ ARNING: Always wear eye, hearing, foot and body protection to reduce the risk of injury when operating

Before operating the unit, stand in the operating position (Fig. 7). Check for the

following:

i

ADJUSTING TRIMMING LINE LENGTH Fig, 7

_ ARNING: Do not remove or alter the line cutting blade assembly. Excessive line length will cause /

The Bump Head TM cutting head allows the release of trimming line without stopping the engine. To release more line,

lightly tap the cutting head on the ground (Fig. 8) while operating the unit at high speed.

NOTE: Always keep the trimming line fully extended. Line release becomes more difficult when the cutting line

Each time the head is bumped, about 1 inch (25.4 mm) of trimming line releases. A blade in the cutting head shield will

cut the line to the proper length if any excess line is released.

For best results, tap the bump knob on bare ground or hard soil. If attempting a line release in tall grass, the engine

may stall. Always keep the trimming line fully extended. Line release becomes more difficult when the cutting line gets

shorter.

NOTE: Do not rest the Bump Head on the ground while the unit is running.

Some line breakage will occur from:

TIPS FOR BEST TRIMMING RESULTS

For example, the line will wear faster when trimming against a foundation wall as

opposed to trimming around a tree.

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all vegetation around trees, posts, fences, etc.

Rotate the whole unit so that the cutting head is at a 30° angle to the ground (Fig. 9).

this unit.

The operator is wearing eye protection and proper clothing

With a slightly-bent right arm, the operator's hand is holding the shaft grip

The operator's left arm is straight, the left hand holding the D-handle

The unit is at waist level

The cutting head is parallel to the ground and easily contacts the grass without

the need to bend over

premature engine failure and / or unit damage.

gets shorter.

TM

Entanglement with foreign matter

Normal line fatigue

Attempting to cut thick, stalky weeds

Forcing the line into objects such as walls or fence posts

Keep the cutting head parallel to the ground. Fig. 8

Do not force the cutting head. Allow the tip of the line to do the cutting, especially along walls. Cutting with more

than the tip will reduce cutting efficiency and may overload the engine.

Cut grass over 8 inches (200 mm) by working from top to bottom in small increments to avoid premature line wear

or engine drag.

Cut from right to left whenever possible. Cutting to the left improves the unit's cutting efficiency. Clippings are

thrown away from the operator.

Slowly move the unit into and out of the cutting area at the desired height. Move either in a forward-backward or

side-to-side motion. Cutting shorter lengths produces the best results.

Trim only when grass and weeds are dry. _X

The life of the cutting line is dependent upon:

Following the trimming techniques

What vegetation is being cut

Where vegetation is cut

30°

Fig. g

J

_L_ CAUTION: For proper engine operation and maximum reliability, pay strict attention to the oil and fuel

The bottle of 2-cycle oil contains a fuel additive which will help inhibit corrosion and minimize the formation of gum

deposits. It is recommended to use our 2-cycle oil with this unit.

If unavailable, use a good 2-cycle oil designed for air-cooled engines along with a fuel additive, such as STA-BIL® Gas

Stabilizer or an equivalent. Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel according to the instructions on the

container. NEVER add fuel additives directly to the unit's fuel tank.

Thoroughly mix the proper ratio of 2-cycle engine oil with unleaded fuel in a separate fuel can. Use a 40:1 fuel/oil ratio.

Do not mix them directly in the engine fuel tank. See the table for specific gas and oil mixing ratios.

NOTE: One gallon (3.8 liters) of unleaded fuel mixed with one 3.2 oz. (95 ml.) bottle of 2-cycle oil makes a 40:1 fueVoil ratio.

NOTE: Dispose of the old fuel/oil mix in accordance to Federal, State and Local regulations.

-- i

_[_ ARNING: Gasoline is extremely flammable. Ignited vapors may explode. Always stop the engine

FUELING THE UNIT

_[_ ARNING: Remove fuel cap slowly to avoid injury from fuel spray. Never operate the unit without the

_[_ WARNING: Add fuel in a clean, level and well ventilated outdoor area. Wipe up any spilled fuel immediately.

1. Turn unit on its side, with the fuel cap facing up, and remove the fuel cap.

2. Place the gas container's spout into the fill hole on the fuel tank and fill the tank.

NOTE: Do not overfill the tank.

3. Wipe up any gasoline that may have spilled.

4. Reinstall the fuel cap.

5. Move the unit at least 30 ft. (9.1 m) from the fueling source and site before starting the engine.

mixing instructions on the 2-cycle oil container. Using improperly mixed fuel can severely damage the engine.

and allow it to cool before filling the fuel tank. Do not smoke while filling the tank. Keep sparks and open

flames at a distance from the area.

fuel cap securely in place.

Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel vapors dissipate.

MAINTENANCE SCHEDULE

_[_ WARNING: To prevent serious injury, never perform maintenance or repairs with unit running. Always

Perform these required maintenance procedures at the frequency stated in the table. These procedures should also be

a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these procedures

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be performed by any

service and repair a cool unit. Disconnect the spark plug wire to ensure that the unit cannot start, j

take your unit to any non-road engine repair establishment, individual or authorized service dealer.

non-road engine repair establishment, individual or authorized service dealer.

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting engine Fill fuel tank with fresh fuel p. 3

Every 10 hours Clean and re-oil air filter p. 4

Every 25 hours Check spark plug condition and gap p. 4

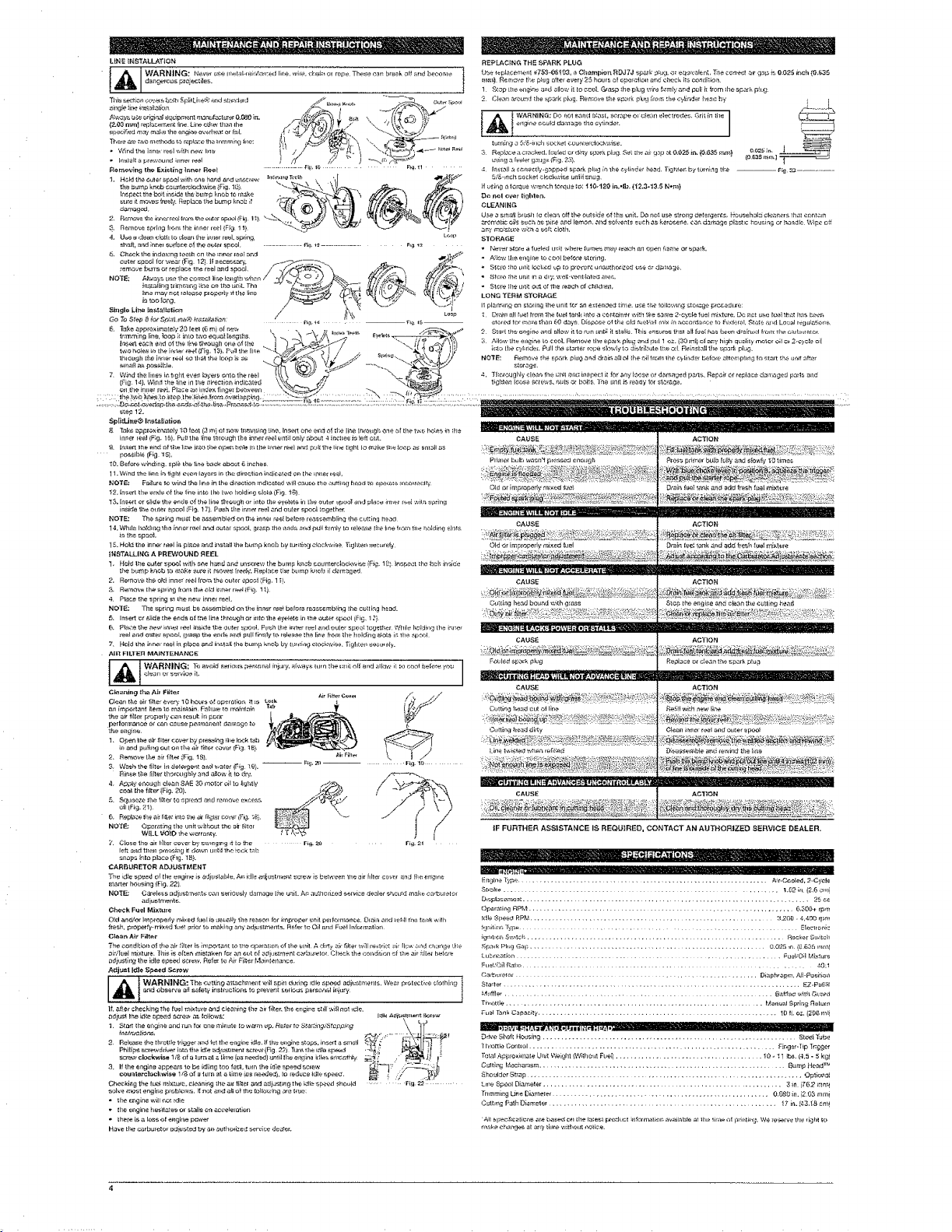

$p(illJntO I_lltl ilion

inper _eel (Fig, 15}, P_I_ lt_e Iin_ lh(o_gh the inn_ _eel until o_ly _bout 4 __,c1_e_ is _eff m_t.

.... po&_ible (fig 151,

_0. Before windin 9 lplll Ihe gne ba_k _bout 6 incha_

11. Wind the lee i_ tighl e,,,e_ layel_ i# the dir_ctla_ i_d k'_te_ on _he mitre _eel,

NOT_ Faifure Io wind tt_e hne _rHhe d r_tio# mdicat_d w_ll c_use rh# cudil_g heed t_ e+pa,_+ mcm_ecibi

12. Insert Ihe end_ of lbe llne illlo lhe lwo holdi,_g slo_ (Fk 3 18)

13, laded or _lide the ends of the Ii_e Q,tough o_ i_tlo _lle eyelets in lhe outer _t_oo_ end ;;lace impel f_ei wiU_ spring

ins_e lbe ou_e_ _p_l _FI#. t _). P#_h _he inn_ reel_nd outer _=_o_ _ogeth_

NOT_; ?he Sp_P4_ m_t be _ssem bled on the i<nn_ reef betore re,_ssemblin# the cul:ia9 h_o

14. WM_ I_o[dlag _h _ _n er m_l and out_l _+po_l. g_p _ha and_ m_d ?Ult t:rmly V_ relesse lh_ tin÷ l r.'_ l_e h¢_Idi_g NOts

_# me spool.

15. Held Ib8 innor T_el i_ #lace and _nstml _he bump kaoh by _urAlrR! clockwig÷ T_Jl_lt_ _e< ure_y

tNBTAU=ING A PREWOUND REEL

I. Hotdtheo_ters_iwitboneh#_ar, duns¢_ewlhebumpk_cl_counterclockv+i_e(F_g, lO_ Ir,spect,_he#ehin_ide

tt_e bump hob to m_Re ._ute il l_lr'.v_S freet# R epl_lce lhe bump knob iI d_m_ged

2. Remov_ lhe okt ina_ reel fto,_, the ouler _p_J (Fig. 1 t),

_. Rem_vethe_#,iagl_on_[he_ldi_m,_rr_Fi 0 It)

4. Placethespringmihenewlanerreel.

NOTE: The 5pdng mull b8 assembled on d!_ inner zeeF before reassembling _he cldli_g he_d.

5. Inse_t _r _Jide _he ends el the lint !hrotx3h or into the e_,el_ in me ouler spo_l (fig. 1 _}

6. Place the t_e_ M_et ,eel il_id ÷ th÷ o,aer sp¢,,;4,Push lhe i_rl_r re_l end outer _poo[ Iog_tl_e_ £%¢hlie hslding ihe ial_er

zenl and otlto_ 8p_#l, grasp t_e e_r[_ _l_d p_lll firmly to, releaDe !h÷ lie e _r_m the h _ld[t_g _o!_ [it lhe s13ool

_. Hold the _nnel re#t i1_£1_¢e _ in&lall ;he bump knob by tut_h_,# e_kwi_e, Tight er_ _8#t_,efy.

AIR FILTER MAINT£NA_C_

I_!

Glean the a_rfillerever), I0 bouts O! op_rsllo_ It _s L_=_ _AirFi_l ,Co_ /._+ ._./I,/ --

_n [mpodant item to m_iBl_in, F_Ibu_e to mainloi_ _'_ ti /._. i_t/f

r_r [O¢l_61_ice ILl' can cause _il_tll l _t11_ f to {

_h_ oir flll_f _rO_#ll 7 o_1_ leou_ in poor __ '_

1. Open It,.e ak filter cc+_er b7 poe_._ng ,be Ioct_ ta_b

in and pu:t_g out on tha alr fit_ cover (_g. 1 B)

1he o_ine.

2. R_move the mr filt_ _Fig 18) ai, FII*_ _ /

,_. WOSN lhe lilI_ in _eIeNe,_t _ad roarer t'_g. ig',,. _,_. m r_<i 1_

£in_._ ti;_ 5fief lho_Oklghly 3tld allow h Io ctry, I_--,---...

4. Apply enough cle_n SAE 30 m,tot oil to lighlly _---_.

¢o_1 tile filter (Fig. 20).

E Squ0eze lhe flit er io nplead _ld remove e_e_n_

,all IFig. 21)

NOTI_ Opo_at_ng the unhw_thout the _ l_;tor

8. ReN0¢e lh _.a_ f_et _nt* ;_'4 ak li!gL*r ¢0¢_: I'FN. _8i. _ v

"g_[L L VOID the _ar rarity.

2. CNse the aiH3ter cover by _'e,<mglr._ _ to th_ F_ .... Fi_. 2_

le_ alld tllt-,ll pr_asiag it down ul_lil lhe _ocR tnh

s _.aps inl_ place [lzlg. 1m.

_;ARBLiRETOR AD.JUSTNE NT

_=hu idle speed o{ lhe er:_[ll_ i_ adj_lgt_ble. A=; kin ed;uslmen_ ucrew is b_t a'ee_ ltle air [liter eo'w.r and tie engine

mane_ h_us_ng fFi 9. 22)

NOTE; C_eles 5 adjllslment_ earl _ed_u_ly rJam_ge lile u_iI. At: amh_dzed _er_ice deale_ sr_c_/_,.I make c a,_u_e_c_

adiu_lme_t_

Check Fuel MixltlTe

O_d and/e_ Improperly mixed £1el _sLl_ually titl_ r_<'Isorlfor _mprope_ imil _el forn;_ce _ t._11__nd le_i[I ?ha tol_ w{lh

fresh, pToI_¢y mixed £,e_ p_ior lo m_kin_ _ny adiu_lmenls. Refer tc Oil an_ Feel InfNmallon

Cl_ai_ Air Filt_r

_he don dillon el the air f_iler i_ }n_pOrI_nt IO In* opat_[iOrl Of lhe Ullll, A dkr[ :, ai_ 5ke, w;ll reslde_ _ik [l_w .?;_d_'11[tr't{_* th÷

_]:g[tl_l mixture, lMs is ofte_, mistaken re, an _t of _*ju _tment c;_rbtlr_lo, Check the i]ol_d_l_ol_ _f I_le a{r ill[el bete_ e

adjustlng Ihe idb _peed _¢_ev+, Refe_ to Ak Fi_ler M,_inlerlance,

ANu_I I_le S_,ee_l Screw

l_i WARNING: The cuIlhg almchmen_ will spin d_dng Idl* _ adiusm_enl*. W<,m proleCtlve *!olhi_ 1

and obsea,a a1 sa etV nsl_ucllons to p_e_ent so{io_ p_rs_M _j_:_y t

If. alter cl_ecki ng the lull mixture and €leading Ihe o ir fitter, lh e engTne s_llfwill not *dl e.

adjus_ lhe _d_ cp_ad sc_co,_a_ Ioltow_: faie aiti_lln_nt £_ Ie'_"

1. Start lhe engine and Tu_f_ one minule [o ',v,_m up.R_lerteNtad_ngiSfcp#_Lq "\ _

fr,_tructmr_, ,"2"4'_ " ..... _.,_t T_,.."

Phil_]p'_ tx_e.vdd_<er hltr_ the idle a@u51m_l _x_re,,v{Fig 22) TL_t_llle _dta _f_d -_

3. If the engine 0ppear_ Io be _dlTng too fa_l. ILff_l the i01e spe.sd ._c_ew _::

co_rll_clock_dse I Y8 of a t_m al e lie e ias needed]. Io reduc# iGle r_£_d, l_ ' . / .p_u,

Gheckiaglheluolmi_¢Lure._leani_g_heal_tiller_r_dadj_stmgth£bdlesp_ed_ho_ld ...... Fig. 22 .............

5o_.,e _3st er_ige pmhlcn_s. It _ot an# ell of the t ollo_='ir_g are l{tio:

• t he engine will r.o_ _81e

• lheoag_ehesil_te_o[5_allsoaacceleratie#

- lhere {S _ I_e el e_lgit_e p_wer

Have lhe carb_reto_ odiusted by a# a_tho_ized semite dea_er.

R_PLACfNG THE SPARK PLUG

b_e _pla_ement _,753-0_1 e3, a Champion RDJ7J spall, ¸ p_ug. o: eq_valent. The ¢+o_+cl air g_p is O.O25 i_ch {O,635

i_:_) _emcv_ _he plug after every 25 hour_ el operation1 and ci_c_k Its con di;_l_.

1 St_.p u_ _n_n_ a_,d allo_ it to cool. G_sp the plug wire !_mly _d p_lH_ _om the spa_k p!ug

2 Clean a_e:und d_e _pa_k i_l_. Rem,_ve g_e _p_,rk pk,_ from _he ,;ginde_ he_ _. by

fuming a 5i_-iuch _>L v,el _._u_ eret_+_kwis e.

S Repkv:eac_a.cke_.fotf, e_d._y_x{r_pklg_tm_ak,4:,#atO.O25m.(O.635mm}

cF_ina _ feeler [_a,J_ e._ig. 22_,

4 D_Sl#ll¢_ccl_dy.g,_ppe_parkphlgin_he¢_lJndethead. T_gt1_e_bytom_ngt_:e --#19_# ........

5/8-mob +_o_ ket clockwise urdii s_ug

fl u_g .1 Iorque ,vl#l_¢ h torque _o: 'f_0-120 i_..tb, (t2.3-13,5 N*m}

De li_l aver li#hles.

CLEAktlNG

Use _ 5matl b_lJsh lo ¢1e3_ otf lhe outside of _h_ _nit+ DO nol tee strong de_rgenl#, Noussho_d cle_er_ _hat _znntmn

s_on",atic oils su¢_ _s #l_e m_d lem_n. _nd so0.,ents ouch as kerose_,e. {_ d_l_,age plastic housing e_ _a_le Wipe off

ar:_ mo_swre w;b>_ a _3N cloth,

STORAGE

OAUSE

Rlimel b,_lb WaSl_'¢ press_'J enough

' ;;;::_+;_ 'G,,_g<i;t_':<_:=!7"_4 ) {G<g;rt 'c _:/,:_Tftff,7;!,_ :: #:i

Old or improperly ml_ed tuof

ACTIOI_

Ples_ pdmc_ bulb luHy and stowly 10 timss

D{aln tue_ ta_R and odd ba_h t_=el mixtoTe

7

'llfl'l_ll_l_li i I '"

CAUSE

Old or impsopelly mixed fuel

CAUS_

C_iti#g head bound _i[h 9_ss

! t_ [_t: I=I IL=T_ ;_:t _,t,t JI; [,);_it f:%II"

CAUS£

Fo_le_ spark plvg

CAUSE

Cuttiq 9 head _ul ol line

Culling tlead dlr{y

CAUSE ACG[ION

IF FURTHER ASSISTANCE I$ REQt.JlRED, CONTAGT AN AUTHORIZKD SERVICE DI_ALER.

E_gh_e I}'pe ................................................................... A r-Ceoled, 2 -Cycle

Dlsplac_me _[ ......................................................................... 25¢c

Operating RPM .............................. 6,30g÷ rpm

ldle 8gee_ RP}_ .................................................................. .3,2f_B. 4,400 rpm

ig_ll:61_ Sv,'l!¢ h ...................................................................... Recke f S'._itcl/

Spmk Pk_g Gap .......................................................... 0 02S ,n (I)635 ilm_)

t u h_l_2_i,Dl_ ................... 7ufl,'Oit k4f_tofl

f uel/TJit R,lim ........................................................................ 4011

C_rbul e[of ................... i_lJ_'lphr_Tm, All Podt r3_

_lorler ................................................................................. _Z -p ill1{_D

t

KLlel T_nk Ca p_ity .................................... fD fh _;. (296 _ldi

I*);tl,i!llf_lmI!_t:t=lltlJillfl411_i!l|l !11',"'""'""' ,

Ddve 5ha(l tto0f_n*.3 ..................................................................... stal Tube

7hfoltle I._ontlol ........................................................... Pir, ge:-TipTRgg(_

"R.'tal Appro<imate UM W_ighI _Aqlh oul Pt,efl ........................................ 1g - 11 Ibm. (-I,5 - 5 kg)

Cultlng M._hamsm ..................................................... Bump Head"

_,heulder St:ap ...................................... Optio_ al

tll!e S.OO01Diameler ................................................................. 3 _a (',6,2 m_)

Trim m{_!g Une Diaale[er ........................................... 0,080 in. €203 mini

Cmlln_PalhDiameler .............................................................. 7 6 N3 8€n_

'All 5pec;£cal{_r,_ are baseel on ihe I_est _educt i_dot mat_l_ aw_il:_b4e al the lln_ of pH nlh,_, We Tet_,rve lh_ ,k]hl I_

Draln I_e: tank m_d add fresh t_l m_xtu_e

ACTION

Stop the el_gii_e _nd cte_n the outli{_g head

AClqON

Replace c_ clean the _p_rk p_ug

AOTIOf_I

Nef¢ll wi;h new I_ne

_.1_ irl_ 11 t@#l a_fl outer 1 7}

D;_a sselt_ble a_d _ewiqd the ling

!: ,: [:

Y25

D sherbeuse

2-temps

®

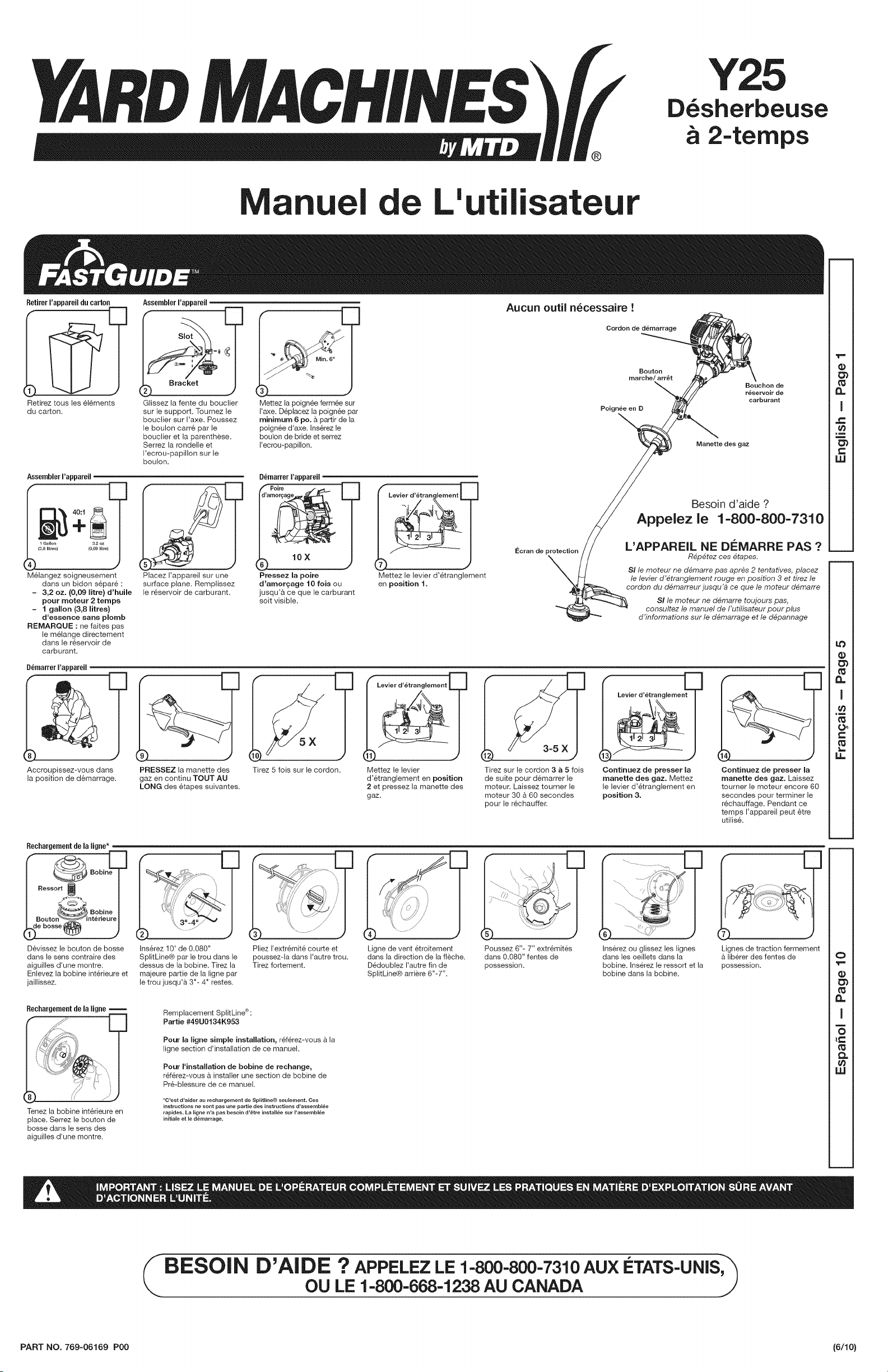

Retirnr I'appareil du carton

Retirez tous lea 616ments

du carton.

AssemblerI'appareil

E]

AssemblerI'appareil

Bracket

Glissez la fente du bouclier

sur le support. Tournez le

bouclier sur I'axe. Poussez

le boulon carr& par le

bouclier et la parenthese.

Serrez la rondelle et

I'ecrou-papillon sur le

boulon.

]

Mettez la poign6e ferm&e sur

I'axe. D_placez la poign&e par

minimum 6 po. & partir de la

poign_e d'axe. Ins@ez le

boulon de bride st serrez

I'ecrou-papillon.

D_marrer I'appareil

f Poire j

I de L'utilisate

Aucun outil n_cessaire !

]

" Levi:r d'_trang,.... th-]

I"

Cordon de d_marrage

Bouton

marehe/arr_t

Poign_e en D

Appelez ie 1-800-800-7310

Bouchon de

r_servoir de

carburant

Manette des gaz

Besoin d'aide ?

0=

J_

_m

uJ

03

00

03

C

I

1 Gallon 3.2 oz

(3,8 lit res) (0,09 lit re)

M&langez soigneusement

dans un bidon s&par6 :

- 3,2 oz. (0,09 litre} d'huile

pour rnoteur 2 temps

- 1 gallon (3,8 litres}

d'essence sans plornb

REMARQUE : ne faites pas

le m6lange directement

dans le r6servoir de

carburant.

D_marrnrI'appareil

Accroupissez-vous dana

la position de d6marrage.

Rechargementde la ligne*

Bobine

Ressort 8

_ Bobine

Placez I'appareil sur une

surface plane. Remplissez

le r6servoir de carburant.

PRESSEZ la manette des

gaz en continu TOUT AU

LONG des 6tapes suivantes.

--]

L

Pressez la poire

d'arnor_age 10 fois ou

jusqu'& ce que le carburant

soit visible.

Tirez 5 fois sur le cordon.

Mettez le levier d'6tranglement

en position 1.

]

Mettez le levier

d'6tranglement en position

2 et pressez la manette des

gaz.

_:cran de protection

]

Tirez sur le cordon 3 _ 5 fois

de suite pour d&marrer Is

moteur. Laissez tourner Is

moteur 30 &60 secondes

pour le r6chauffer.

3-5 X

L'APPAREIL NE DEMARRE PAS ? m

R6p6tez ces 6tapes.

SIle moteur ne d6marre pan apres 2 tentatives, placez

le levier d'6trangternent rouge en position 3 et tirez le

cordon du d6marreur jusqu'a ce que le moteur d6marre

St le moteur ne d6marre toujours pan,

consultez le manuel de I'utilisateur pour plus

d'informations sur le d6marrage et le d6pannage

" E

Levierd'_tranglement

]

@

Continuez de presser la

rnanette des gaz. Mettez

le levier d'6tranglement en

position 3.

j_,==

" L

Continuez de presser la

rnanette des gaz. Laissez

tourner Is moteur encore 60

secondes pour terminer Is

r6chauffage. Pendant ce

temps I'appareil pout _tre

utilis&

" E]

]

_o

03

0=

I

O_

m

m

_Be°bt'ot °sei_%-_ 'e t er'e u_

Devissez le bouton de bosse

dans le sens contraire des

aiguilles d'une montre.

Enlevez la bobine int@ieure et

jaillissez.

Rechargementde la lignn

Tenez la bobine int@ieure en

place. Serrez le bouton de

bosse dans lesens des

aiguilles d'une montre.

Ins@ez 10' de 0.080"

SplitLine® par le trou dans le

dessus de la bobine. Tirez la

majeure pattie de la ligne par

le trou jusqu'a 3"- 4" testes.

Remplacement SplitLine c_:

]

Partie #49U0134K953

Pour la ligne simple installation, ref@ez-vous & la

ligne section d'installation de ce manuel.

Pour I'installation de bobine de rechange,

r6f@ez-vous & installer une section de bobine de

Pr6-blessure de ce manuel.

*C_est d_aider au rechargement de Splitline® seulement. Ces

instructions ne sont pas une partie des instructions d_assembl6e

rapides. La ligne n_a pan besoin d_6tre installee sur Passembl_e

initiale et le d6marrage,

Pliez I'extr6mit6 courte et

poussez-la dans I'autre trou.

Tirez fortement.

Ligne de vent 6troitement

dans la direction de la fleche.

D6doublez I'autre fin de

SplitLine® arri@e 6"-7".

Poussez 6"- 7" extr6mit6s

dans 0.080" fentes de

possession.

J

Ins@ez ou glissez les lignes

darts les oeillets dans la

bobine. Ins@ez le ressort et la

bobine dans la bobine.

Lignes de traction fermement

& lib@er des fentes de

possession.

O

03

0=

I

m

O

o_

¢0

uJ

m

BESOIN D'AIDE ?APPELEZ LE 1-800-800-7310 AUX I TATS-UNIS,"

PART NO. 769=06169 P00 (6/10}

OU LE 1-800-668-1238 AU CANADA

J

Loading...

Loading...