Page 1

OWNEirS GUIDE

AMERICAN AMERICAN

MADE OWNED

OUTDOOR POWER EQUIPMENT

Important: Read Safety Rules and Instructions Carefully

REAR TINE

TILLER

Model 406

(With Reverse Drive)

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped

with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be

maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is avail

able through your nearest engine authorized service dealer or contact the service department, P.O. Box 368022,

Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC • P.O. BOX 368022 • CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 770-8563J

Page 2

INDEX

Safe Operation Practices

Assembly...................................................................... 3

Controls

Operation...................................................................... 9

How To Use Your Tiller

........................................................................

...........................................

................................................

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE

PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS

A

MANUAL BEFORE ATTEMPTING TO OPERATE YOUR TILLER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL- ^ HEED ITS WARNING.

Your tiller was built to )e operated according to the rules for safe operation in this manual. As with

DANGER: type of power equi )ment, carelessness or error on the part of the operator can result in serious

A

1. It is suggested that this manual be rt ad in its

entirety before attempting to assemble cr operate

this unit. Keep this manual in a safe Diace for

future and regular reference and for ordering

replacement parts.

2. Your tiller is a precision piece of powar equip

ment, not a plaything. Therefore, axercise

extreme caution at ail times.

3. Read this owner’s manual carefully. Be horoughly familiar with the controls and the prof er use of

the equipment.

4. Never allow children to operate a power tiller.

Only persons well acquainted with thes a rules of

safe operation should be allowed to use your

tiller.

5. No one should operate this unit while ir toxicated

or while taking medication that impairs tfie senses

or reactions.

6. Keep the area of operation clear of all persons,

particularly small children and pets.

7. Do not operate equipment when barefoot or

wearing open sandals. Always wear s jbstantial

footwear.

8. Do not wear loose fitting clothing that could get

caught on the tiller.

9. Do not start the engine unless the shift ever is in

the neutral (N) position.

10. Do not stand in front of the tiller while slarting the

engine.

11. Do not place feet and hands on or neai the tines

when starting the engine or while the engine is

running.

12. Never attempt to make a wheel or depth bar

adjustment while the engine is running.

13. Do not leave the tiller unattended with t ie engine

running.

injury. If you violate an f of these rules, you may cause serious injury to yourself or others.

2

8

9

Adjustments

Lubrication

Maintenance

Off-Season Storage

Trouble Shooting Guide

................................................................

..................................................................

................................................................

....................................................

.............................................

RULES FOR SAFE OPERATION

Do not walk in front of the tiller while the engine

14.

is running.

Check the fuel before starting the engine.

15.

Gasoline is an extremely flammable fuel. Do not

fill gasoline tank indoors, while the engine is run

ning, or while the engine is still hot. Replace

gasoline cap securely, and wipe off any spilled

gasoline before starting the engine as it may

cause a fire or explosion.

Do not run the engine while indoors. Exhaust

16.

gases are deadly poisonous.

Be careful not to touch the muffler after the

17.

engine has been running. It is hot.

Do not change the engine governor settings or

18.

overspeed the engine. Excessive engine speeds

are dangerous.

Before any maintenance work is performed or

19.

adjustments are made, remove the spark plug

wire and ground it on the engine block for added

safety.

Use caution when tilling near buildings and

20.

fences. Rotating tines can cause damage or

injury.

Before attempting to remove rocks, bricks and

21.

other objects from tines, stop the engine and be

sure the tines have stopped completely.

Disconnect the spark plug wire and ground to

prevent accidental starting.

Check the tine and engine mounting bolts at fre

22.

quent intervals for proper tightness.

Keep all nuts, bolts and screws tight to be sure

23.

the equipment is in safe working condition.

Never store the equipment with gasoline in the

24.

tank inside of a building where fumes may reach

an open flame or spark. Allow the engine to cool

before storing in any enclosure.

10

12

12

14

15

A

Page 3

FIGURE 1.

ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT GASO

LINE or OIL. After assembly, see separate engine

manual for proper fuel and engine oil recommenda

tions.

NOTE: Left and right is determined from the opera

tor’s position, standing behind the tiller.

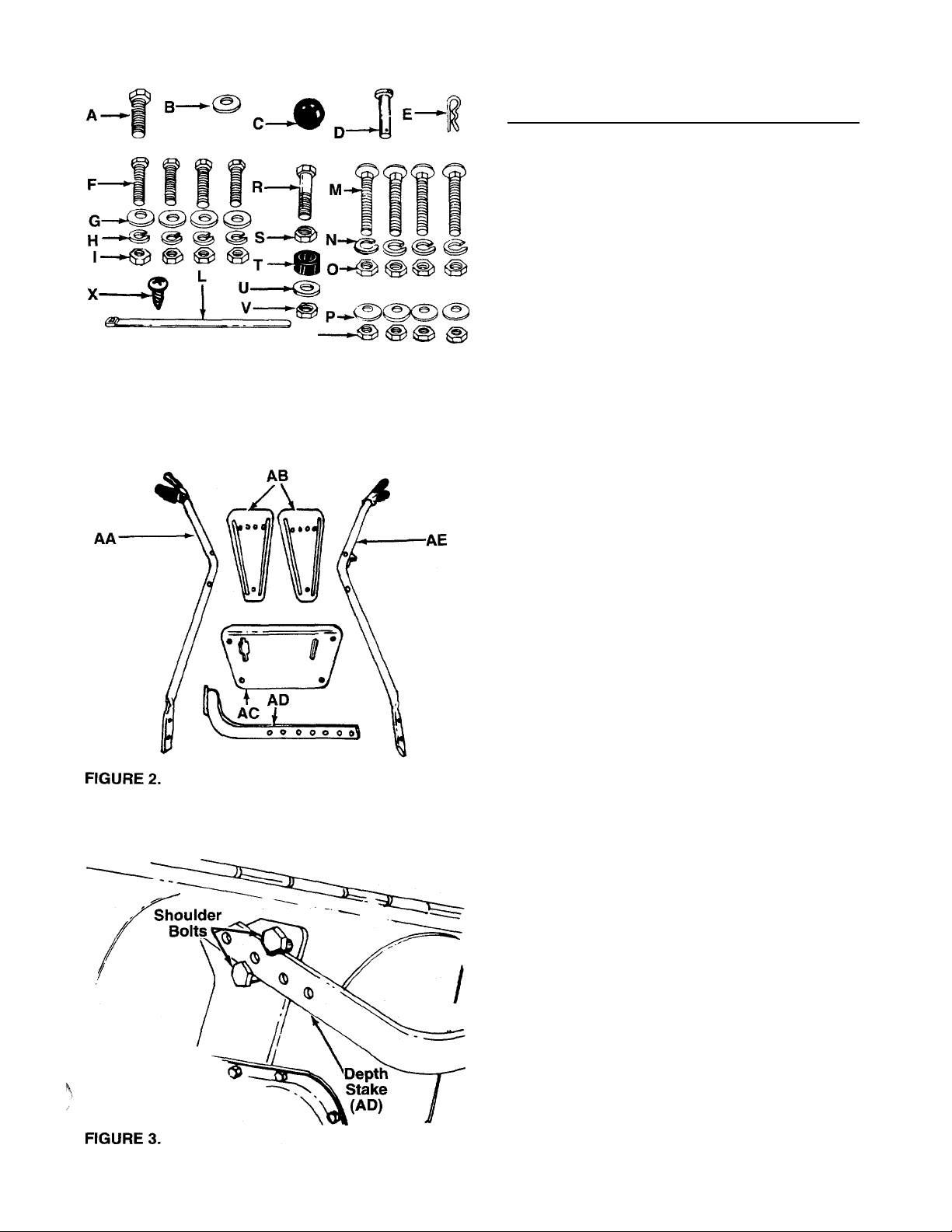

-Contents of Hardware Pack: (See Figure 1)

(Part numbers are shown in parentheses.)

A

B

C

D

E

F

G

H

I

L

M

N

O

P

Q

R

S

T

u

V

w

X

-Loose Parts in Carton: (See figure 2)

(Part numbers are shown in parentheses.)

AA (1) Handle—R.H. (749-0642A)

AB

AC

AD

AE

1. Remove tiller, loose parts and hardware pack

2. Extend the control cables attached to the tiller

Hex Bolt 3/8-16 X 3/4" Long (710-0216)

(1)

Flat Washer 3/8" I.D. (736-0117)

(1)

Ball Knob (720-0165)

(1)

Clevis Pin (711-0415)

(1)

Hairpin Cotter (714-0149B)

(1)

Hex Bolts 3/8-16 X 1.0" Long (710-0253)

(4)

Belleville Washers 3/8" I.D. (736-0105)

(4)

Lock Washers 3/8" I.D. (736-0169)

(4)

Hex Nuts 3/8-16 Thread (712-0798)

(4)

Cable Ties (725-0157)

(2)

Carriage Bolts 5/16-18 x 1.75" Long

(4)

(710-0458)

Lock Washers 5/16" I.D. (736-0119)

(4)

Hex Nuts 5/16-18 Thread (712-0267)

(4)

Belleville Washers 5/16" I.D. (736-0242)

(4)

Hex Nuts 5/16-18 Thread (712-0267)

(4)

Hex Bolt 1/4-28 x .75" Long (710-0412)

(1)

Hex Lock Nut 1/4-28 Thread (712-0117)

(1)

Rubber Washer (735-0126)

(1)

Flat Washer 5/16" I.D. x 7/8" O.D. (736-0159)

(1)

Hex Lock Nut 5/16-18 Thread (712-0158)

(1)

Reverse Drive Clutch Lever (Not Shown—

(1)

747-0517, Grip—720-0143)

Self-Tapping Screw (710-0779A)

(1)

Side Shields (15390)

(2)

Handle Panel (784-0271)

(1)

Depth Stake Assembly (14992)

(1)

Handle—L.H. (749-0643A)

(1)

from carton. Make certain all parts and literature

have been removed from the carton before the

carton is discarded.

and place on the floor. Be careful not to bend or

kink the cables.

DEPTH STAKE INSTALLATION

1. Raise the tine shield hinge flap assembly. Insert

the depth stake assembly (AD) between the two

shoulder bolts and up through the tine shield

i

-----

assembly as shown in figure 3. Depth stake

points toward the rear of the unit.

NOTE: For clarity, figure 3 was taken with tiller raised

on end. It is not necessary to raise the tiller.

Page 4

I I

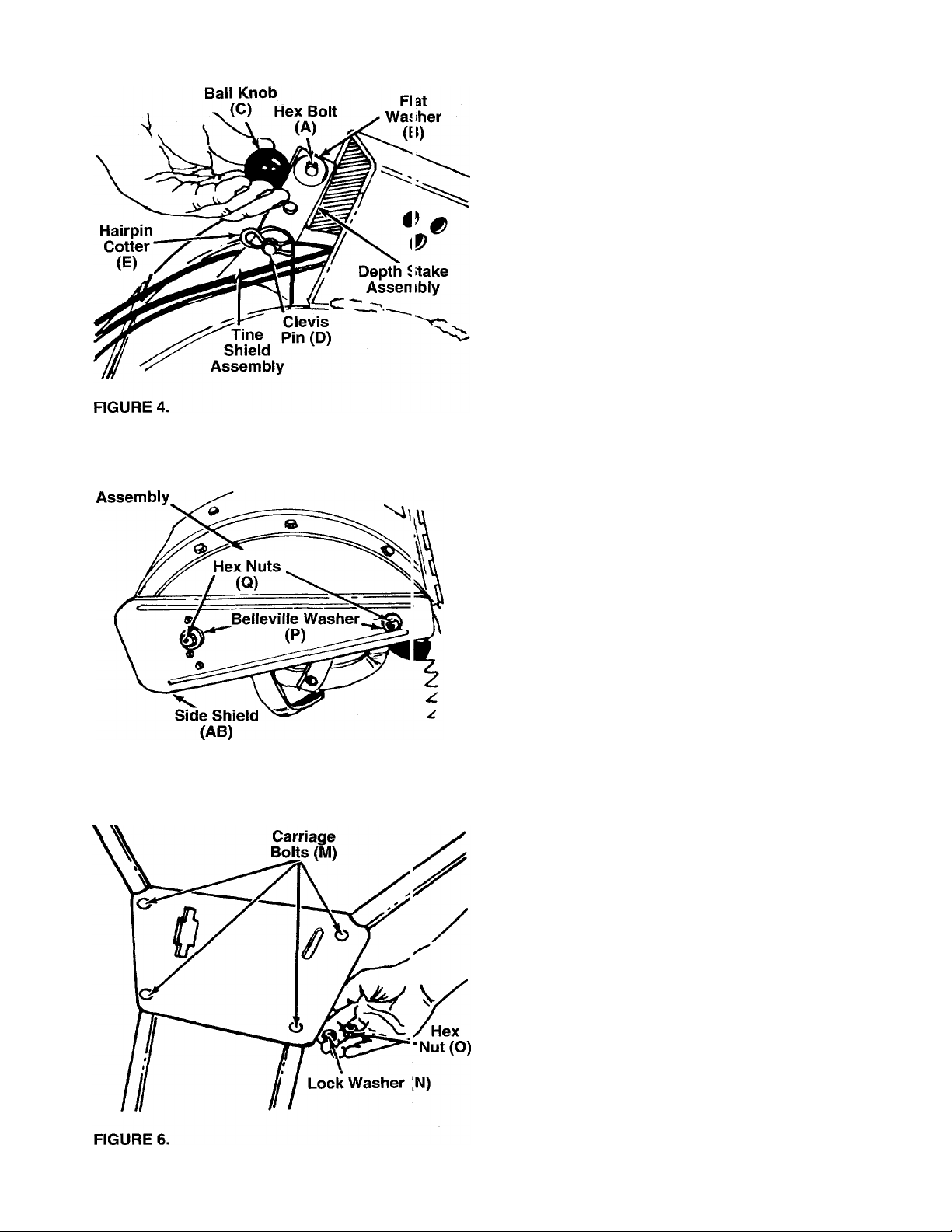

2. Insert clevis pin (D) through the tine shield and

depth stake assemblies. Secure with hairpin cot-

— ter (E). See figure 4.

3. Insert hex bolt (A) into the upper hole of the depth

stake assembly. Place flat washer (B) onto the

hex bolt and thread ball knob (C) onto the hex

bolt. See figure 4. Tighten securely.

End Cover

FIGURE 5.

SIDE SHIELD INSTALLATION

Mount side shields (AB) over the weld bolts on the

end cover assemblies. Secure with belleville washers

(P) and hex nuts (Q). Crowned side of washers go

-against the hex nuts. See figure 5.

HANDLE ASSEMBLY

1. Attach the handle panel to the handles using car

riage bolts (M), lock washers (N) and hex nuts

------

(O). See figure 6. Do not tighten.

NOTE: To align the holes in the handle panel and the

handle, it may be necessary to loosen the cable

brackets which are mounted to the back of the han

dles with self-tapping screws.

Page 5

FIGURE 7.

A B

¥

!

Washers (G)

1

Belleville

y

Screw

D \

(X)

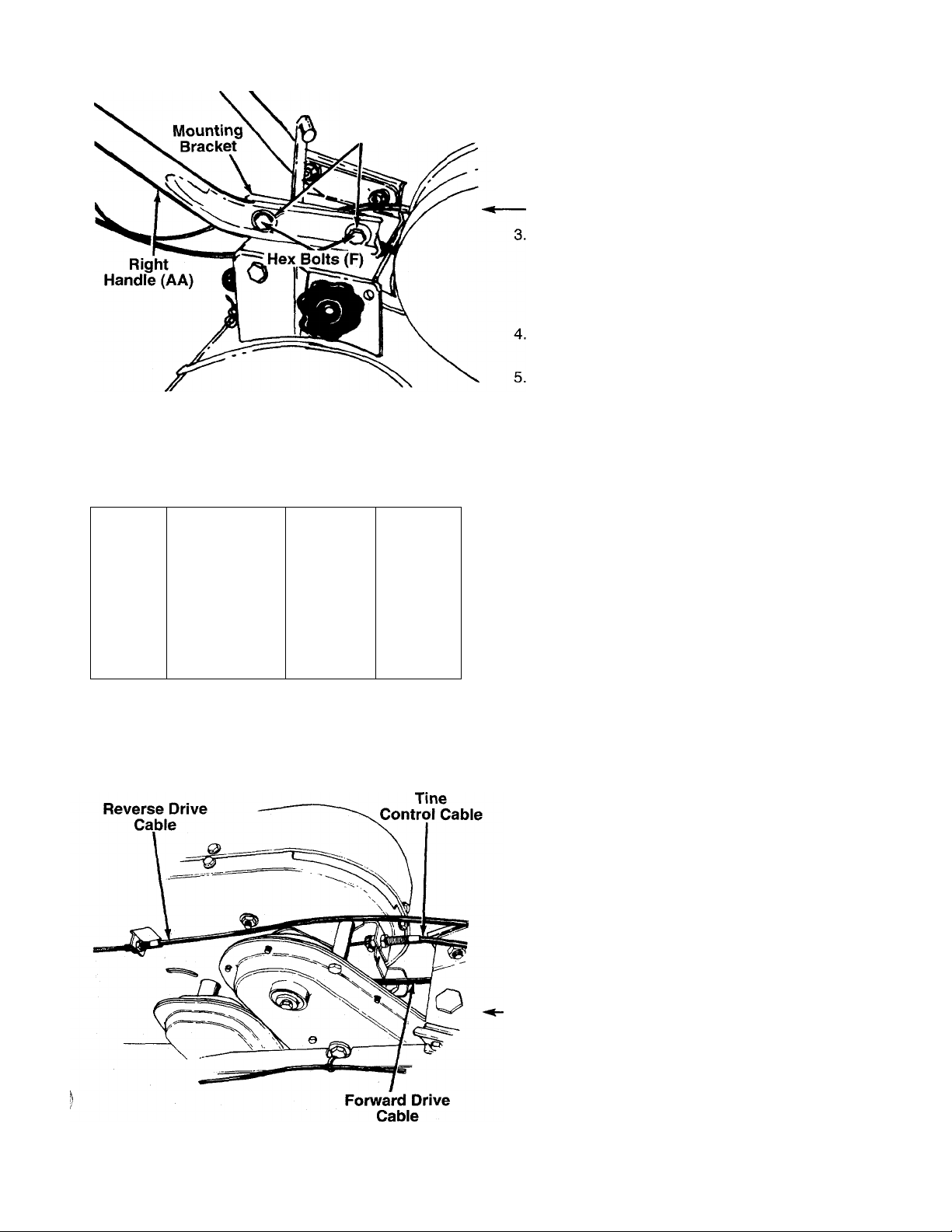

2. Place handle assembly in position on the tiller.

Working on one side of the unit, insert one hex

bolt (F) through belleville washer (G) (crowned

side of washer goes against head of bolt), then

through bottom hole of handle and handle mount

ing bracket. Secure loosely with lock washer (H)

-and hex nut (I). See figure 7.

Align the other side of the handle with the handle

mounting bracket. It may be necessary to use

force to spring the handle over the handle mount

ing bracket. Secure loosely with hex bolt,

belleville washer, lock washer and hex nut.

Secure upper hole in handle to handle mounting

bracket (both sides) in the same manner.

Tighten securely all four nuts and bolts which

secure the handles to the handle mounting brack

ets. Then tighten the four nuts at the handle

panel.

THROTTLE CONTROL INSTALLATION

Assemble the throttle control to the handle panel as

follows.

1. Hold the throttle control assembly beneath the

handle panel. Turn the control sideways and

insert the lever up through the wide portion of the

------

slot on the handle panel. See figure 8A.

2. After the end of the lever is through the slot, turn

and then tip the control forward as shown in fig

ure 8B to slide it through the slot.

FIGURE 8.

FIGURE 9.

NOTE: The lever must be all the way to the back of

the control housing as shown in figure 8B.

Push the control back into the slot in the handle

panel and press in place. Be certain the control is

locked securely into the slot.

4.

Secure the throttle control to the handle panel

using the self-tapping screw (X). See figure 8D.

ATTACHING THE CONTROL CABLES

The control cables are already attached to the unit.

The tine control cable and the forward drive cable

have “2” fittings on the loose end. Refer to figure 9 for

cable identification when attaching the cables.

NOTE: Both the drive control cables and the tine con

trol cable are attached to springs, which are hooked

to bolts. If either the cable or spring has come loose in

shipping, it must be reassembled. Refer to page 18,

reference numbers 2, 5, 11, 12, 15 and 17.

Page 6

Tine Control Cable (Attaches to Left Handle)

1. Remove one nut and the lock washer from the

end of the tine control cable. Slip the cable up

through the slot on the cable bracket on the left

handle. Rethread hex nut and lock washer on the

------

end of the cable. See figure 10. Do not tighten at

this time.

2. Hook the “Z” end of tine control cable into the

hole in tine clutch lever.

3. With the clutch lever released (in the “up” posi

tion), adjust the bottom nut at the cable bracket

so there is only a slight amount of slack in the

control wire. Tighten the upper nut against the

bracket. Squeeze the clutch lever against the

handle. The control wire should now be straight.

------

See figure 11.

NOTE: Do not overtighten control wire. Too much ten

sion may cause it to break.

FIGURE 11.

Flat End of

Reverse Clutch

Forward Drive Control Cable

(Attaches to Right Handle)

Attach the forward drive control cable (refer to figure

9) to the right handle in the same manner in which the

tine control cable was attached.

WARNING: Final adjustment of the for

ward and reverse drive cables must be

A

made as instructed in the Final Adjust

ment section before operating the tiller.

Reverse Drive Control Cable

1. Push the flat end of reverse drive clutch lever

through the slot in the handle panel. See figure

--------

12.

2. Attach the end of drive control cable to the upper

hole of reverse drive clutch lever (W), using hex

bolt (R) and hex lock nut (S). See figure 13.

3. Remove one nut and the lock washer from the

end of the reverse drive control cable. Thread the

other hex nut all the way down the cable as far as

-------

it will go as shown in figure 13.

4. Slip the wire on the cable through the inside slot

In the cable bracket as shown in figure 12. Push

the ends of the cable up through the holes in the

bracket. Rethread hex nut and lock washer on the

end of the cable. Do tighten at this time.

5. Place end of reverse drive clutch lever over weld

bolt on handle panel. See figure 12.

Page 7

FIGURE 14.

6. Secure reverse drive clutch lever to weld bolt with

rubber washer (T), flat washer (U) and hex lock

— nut (V). See figure 14. Tighten hex lock nut until

snug. Do not overtighten.

7.

With the reverse drive clutch lever in the neutral

(N) position, adjust the reverse cable as follows.

Adjust the hex nuts at the cable bracket on the

handle panel so that the cable is tight, and the

bolt on the reverse idler pulley is in the center of

the slot (approximately 1" from either end of the

slot) as shown in figure 15.

Secure the cables to the right hand handle with

8

two cable ties (L), one near the top and one near

the bottom of handle. Trim excess ends of cable

ties.

9. Check the adjustment of the drive clutch controls

as follows.

FIGURE 15.

Cable

Bracket

FINAL ADJUSTMENTS

First check the adjustment of the drive clutch controls

with the engine off as follows.

1. Disconnect the spark plug wire from the spark

plug and ground against the engine.

2. Make certain the forward drive and tine clutch

levers are released, and the reverse drive clutch

lever is in the neutral (N) position.

3. Pull the recoil starter rope several times. If the

unit moves forward, adjust the forward cable as

instructed in step A which follows. If the unit

moves backward, adjust the reverse cable as

instructed in step B which follows.

IMPORTANT: Service engine with oil and gasoline

before starting the engine. Refer to the separate

engine manual packed with your tiller.

Now check the adjustment of the drive clutch controls

with the engine running. Place the unit against a solid

object (wall, fence, etc.). With the forward drive clutch

lever and tine clutch lever released and the reverse

drive clutch lever in the neutral position, carefully start

the engine.

WARNING: BE PREPARED TO STOP

ENGINE IMMEDIATELY, as tiller may go

A

in reverse motion.

NOTE: The unit moves faster in reverse than in for

ward.

Page 8

Note which (if any) of the following conditions exist in

your unit. Adjust the cable(s) at the cable brackets by

following the appropriate instructions.

WARNING: Stop the engine before mak

A

A. TILLER HAS FORWARD MOTION with forward

B. TILLER HAS REVERSE MOTION with reverse

C. TILLER DOES NOT HAVE FORWARD MOTION

ing any cable adjustments.

drive clutch lever released. Adjust the forward

cable (right hand handle) by loosening the hex nut

on top of the cable bracket three or four turns,

then tightening the hex nut beneath tha cable

bracket.

drive clutch lever in neutral. Adjust the reverse

cable (beneath the handle panel) by loosening the

nut beneath the cable bracket three or four turns,

then tightening the hex nut on top of the cable

bracket.

with forward drive clutch lever in forward. Adjust

the forward cable by loosening the hex nut beneath

the cable bracket three or four turns, then tighten

ing the hex nut on top of the cable bracket.

D. TILLER DOES NOT HAVE REVERSE MOTION

with the reverse drive clutch lever in reverse.

Adjust the reverse cable by loosening the hex nut

on top of the cable bracket three or four turns, then

tightening the hex nut beneath the cable bracket.

TIRE PRESSURE

The tires on your unit may be over-inflated for ship

ping purposes. Reduce the tire pressure before oper

ating the unit. Recommended operating tire pressure

is approximately 12 p.s.i. (check sidewall of tire for tire

manufacturer’s recommended pressure).

WARNING: Maximum tire pressure under

any circumstances is 30 p.s.i. Equal tire

A

pressure shouid be maintained on both

tires.

CONTROLS

THROTTLE CONTROL

The throttle control lever is located on the right hand

side of handle panel and controls the engints speed.

See figure 16.

1. Start—Push throttle control lever forwarpi (down)

to FAST position.

2. Stop—Pull lever back (upward) to stop th(i engine.

figure 16. Squeeze the lever against the handle to

engage the tines. Release the lever to stop the tines

from turning.

FORWARD DRIVE CLUTCH LEVER

The forward drive clutch lever is located on the left

handle. See figure 16. Squeezing the lever against

the handle engages the forward wheel drive. Release

the lever to stop the forward motion.

REVERSE DRIVE CLUTCH LEVER

The reverse drive clutch lever is located on the left

hand side of handle panel. See figure 16.

The reverse drive clutch lever may be placed in one

of two positions.

1. Neutral (N)—Be certain lever is in neutral position

when starting the engine.

2. Reverse (R)—Raise up on the handles to lift the

tines out of the ground and pull the drive clutch

lever back (upward) slowly to obtain reverse.

Always use caution when using the reverse.

When using reverse, if reverse drive clutch lever

is released it will snap back into neutral (N).

TINE CLUTCH LEVER

The tine clutch lever is located on the left handle. See

NOTE: A/ever engage both the forward and reverse

drive at the same time, or the engine will stall.

Page 9

•V

IMPORTANT: Engine is shipped without oil.

BEFORE STARTING

1. Before operating tiller for the first time or if tines

have been removed and reassembled for any

reason, check to be certain the tines are assem

bled correctly. The sharp edge of the tines must

enter the soil first as shown in figure 17. (Figure

17 illustrates the left hand tines, viewed from the

left hand side of the tiller. Right hand tines rotate

in the same direction as the left hand tines.)

OPERATION

TO START ENGINE

A

1. Place the throttle control lever in START position.

2. Move choke lever to CHOKE position.

NOTE: A warm engine may not require choking.

3.

Stand at side of tiller. Grasp the starter handle

and pull out slowly, until it pulls slightly harder.

Let rope rewind slowly.

4.

Pull starter handle rapidly. Do not allow handle to

snap back. Allow it to rewind slowly while keeping

a firm hold on the starter handle.

5. Repeat steps 3 and 4 until engine starts.

6. As engine warms up and begins to operate even

ly, move choke lever gradually to OFF position. If

engine falters, return to choke position, then slow

ly move to OFF position.

Refer to engine manual for additional engine informa

tion.

WARNING: BE SURE NO ONE IS STAND

ING IN FRONT OF THE TILLER WHILE

THE ENGINE IS RUNNING OR BEING

STARTED.

2. Service engine with oil as instructed in the sep

arate engine manuai packed with your unit.

3. Fill fuel tank with clean, fresh, lead-free, low-lead

or regular grade leaded gasoline.

HOW TO USE YOUR TILLER

WARNING: When operating the tiller for

A

Tilling depth is controlled by the depth stake which

can be adjusted to five different settings. See figure

18. Adjust the side shields as shown in figure 19, as

you adjust the depth stake. Be certain spark plug wire

is disconnected and grounded against the engine.

1. When using the tiller for the first time, use the

the first time, use the depth bar setting

that gives 11/2 inches of tilling depth

(second hole from the top). Refer to fig

ure 18. Use slow speed only.

second adjustment hole from the top (1-1/2” of till

ing depth). See figure 18.

TO STOP ENGINE

1. Move throttle control to OFF position.

2. Disconnect spark plug wire and ground to prevent

accidentally starting while equipment is un

attended.

Page 10

2. When breaking up sod and for shallow cul Jvation,

use the setting which gives 11/2” of tillinj depth

(second hole from the top). Place the side shields

in their lowest position. For further depti, raise

the depth stake and side shields and make one

or two more passes over the area.

3. When tilling loose soil, depth stake may b 3 raised

to its highest position (use bottom adjustment

hole) to give the deepest tilling depth. Raise the

side shields to their highest position.

4. To transport tiller, lower the depth stake [use top

adjustment hole).

To adjust the depth stake, remove the clevis pin and

hairpin cotter. See figure 18. Move the depth stake to

the desired setting.

To adjust the side shields, remove the hex nut and

belleville washer from the front and loosen the rear

nut. See figure 19. Pivot the side shield to the desired

position. Replace hex nut and belleville washer.

Tighten securely.

To operate the tiller;

1. Select the depth stake setting.

2. Start engine as instructed on page 9.

3. Engage either the forward drive clutch lever or

the reverse drive clutch lever.

4. Engage tine clutch lever.

ADJUSTMENTS

WARNING: Disconnect the spark plug

wire and ground against the engine

A

HANDLE ADJUSTMENT

The handle may be placed in one of nine different

positions. The handle may be adjusted to one of three

height positions, and also may be adjusted to be in

line with the tiller, or swung to the left or right so the

operator is not walking in the freshly tilled soil.

To adjust the handle height, remove the hand knob

and locking pin shown in figure 20. Select one of the

three adjustment holes and reassemble.

FIGURE 20.

To adjust the handle position from side to side, loosen

the adjustment handle by turning it counterclockwise

several turns. Pull the adjustment handle backward

and pivot the tiller handle to desired position. Release

and tighten the adjustment handle. See figure 21.

before performing any adjustments,

repairs, or maintenance.

WARNING: Engage wheel driv j before

engaging the tine clutch lever.

NOTE: To transport tiller, do not engage the tine

A

clutch lever. Engage the wheel drive only.

WARNING: Do not push down on the

handles so that the wheels are lifted off

A

For best results, it is recommended the garden be

tilled twice (lengthwise, then widthwise) to pulverize

the soil.

the ground while the tine clutch is

engaged, or the tiller could mc ve back

ward and cause personal injury.

10

Page 11

DEPTH STAKE ADJUSTMENT

To adjust the depth stake, refer to “How To Use Your

V,

Tiller” on pages 9 and 10.

When making either of the above adjustments (a or

b), be certain to recheck the neutral adjustments on

the tiller (steps A and B in first column on page 8).

BELT TENSION ADJUSTMENT

Tine Clutch

Periodic adjustment of the belt tension may be

required due to normal stretch and wear on the belt.

Adjustment is needed if the tines seem to hesitate

while tilling, but the engine maintains the same speed.

To adjust, loosen the hex nuts at the cable bracket on

the handle. See figure 22. With the clutch lever

released as shown in figure 16, adjust the bottom nut

so that there is only a slight amount of slack in the

control wire. Tighten the upper nut against the brack

et.

NOTE: Do not overtighten control wire. Too much ten

sion may cause it to break.

Drive Clutch

if adjustment is needed, refer to final adjustment sec

tion of Assembly instructions.

If through normal operation the belts become

stretched or worn, and there is no adjustment left at

the cable brackets on the handles and handle panel,

the other end of the cables may be adjusted as fol

lows.

a. If the tiller does not have forward motion with the

forward drive clutch lever engaged, adjust the for

ward drive cable by loosening the hex nut in back

of the cable bracket on the tiller a few turns, then

tightening the hex nut in front of the bracket. Refer

to figure 9.

b. If the tiller does not have reverse motion with the

reverse drive clutch lever in reverse, adjust the

reverse cable by loosening the hex nut in front of

the cable bracket on the tiller a few turns, then

tightening the hex nut in back of the bracket. When

correctly adjusted, the reverse idler should be

toward the middle of the slot as shown in figure 15.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load. If adjustments are needed, refer to the engine

manual packed with the tiller.

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Do not

make unnecessary adjustments. Factory settings are

satisfactory for most applications and conditions.

to the engine while the engine is running,

(e.g. carburetor), disengage all clutches

and tines. Keep ciear of ali moving parts.

Be careful of heated surfaces and muf

fler.

THROTTLE CONTROL ADJUSTMENT

To obtain satisfactory engine performance, the engine

throttle control must be adjusted properly. If it is nec

essary to check the engine control adjustments, pro

ceed as follows.

1. Loosen the cable clamp screw. See figure 23.

2. With the throttle control in FAST position and the

cable connected to the adapter lever, push the

cable through the cable clamp in the direction

shown in figure 23 until the adapter lever is as far

up as it will go.

3. Tighten the cable clamp screw.

4. Check that the engine stops when throttle control

is moved to STOP position. If engine does not

stop, loosen the cable clamp screw and readjust

by pulling cable backward slightly until engine

stops. Retighten cable clamp screw.

Adapter

Lever

Cable Clamp

Screw

FIGURE 23.

11

Page 12

LUBRICATION

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

A

Chain Cases—The chain cases are pre-lu jricated

and sealed at the factory. They require no < becking

unless the chain cases are disassembled. Tci fill with

grease, lay the left half of the chain case on its side.

Add 12 ounces of plastilube #0 grease to the tine

chain case or 10 ounces to the wheel chain case.

Assemble the right half to it. This grease can be

obtained through your nearest authorized dealer.

Order part number 737-0133 (14 oz. tube).

Wheels—Lubricate the wheel bearings with a light oil

after each fifteen hours of operation.

Ciutch Controls—Lubricate the pivot points on the

clutch levers and the cables at least once a season

with light oil. The controls must operate freely in both

directions.

Pivot Points—Lubricate all pivot points and linkages

at least once a season with light oil.

lubricating or doing any kind of v/ork on

tiiler.

usually indicates that the air cleaners should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each tilling season; check

engine manual for correct plug type and gap specifi

cations.

CLEANING THE TINE AREA

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed immedi

ately instead of after if dries.

TIRES

Recommended operating tire pressure is approxi

mately 12 p.s.i. (check sidewall of tire for tire manu

facturer’s recommended pressure). Maximum tire

pressure under any circumstances is 30 p.s.i. Equal

tire pressure should be maintained on both tires.

When installing a tire to the rim, be certain rim is

clean and free of rust. Lubricate both the tire and rim

generously. Never inflate to over 30 p.s.i. to seat

beads.

MAINTENANCE

WARNING: Disconnect the spark piug

wire and ground it against the engine

A

IMPORTANT: If for any reason the tines are removed

from the tiller, be certain the tines are reassrsmbled so

that the sharp edge of the tines enter the soil first.

Refer to item number one under “Operation. ’

TROUBLE SHOOTING

Refer to page 15 of this manual for troubk shooting

information.

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cieaner every 25 hours under n Drmal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

before performing any repairs o' mainte

nance.

WARNING: Excessive pressure (over 30

A

BELT REPLACEMENT

Your tiller has been engineered with belts made of

special material (Kevlar Tensile) for longer life and

better performance. They should not be replaced with

an off-the-shelf belt.

If belt replacement is required, order belt or belts by

part number from your nearest authorized dealer.

1. Remove belt cover by removing the four self-tap

p.s.i.) when seating beads may cause

tire/rim assembiy to burst with force suf

ficient to cause serious injury.

ping screws. See figure 24.

12

Page 13

2. To remove the tine belt, lift up on the idler pulley,

and slip belt off tine chain case pulley as shown

in figure 25. Remove belt from the two-step

engine pulley.

B. Pull bottom of wire belt keeper out and then

upward, pivoting it away from the forward

engine pulley. See figure 27.

Tine Belt

Idler

Pulley

Two-Step

Engine Pulley

FIGURE 25.

3. To remove the reverse drive belt, lift up on small

idler pulley as shown in figure 26. Slip belt off out

side sheave of wheel chain case pulley. Then

remove belt from two-step engine pulley.

Wheel Chain

FIGURE 27.

C. Lift belt off the forward engine pulley. See fig

ure 28.

D. Remove belt from inside sheave of wheel

chain case pulley.

Wheel Chain

Case Pulley Forward

J3rive Belt Forward

Engine Pulley

FIGURE 26. FIGURE 28.

4. To remove the forward drive belt, proceed as fol

lows.

5. Reassemble new belts, following instructions in

reverse order.

IMPORTANT: When reassembling belts, be certain

A. Loosen (do not remove) the hex nut at the top

of the wire belt keeper.

belts are routed around all belt keeper pins as shown

in figure 29.

13

Page 14

Forward BeltKeoper

Drive Belt Pins

FIGURE 29.

NOTE: If the “V”-idler or flat idler pulleys are removed

for any reason, be sure to install with hub side against

the idler bracket. See figure 30.

Hub

OFF-SEASON STORAGE

If the tiller is to be inoperative for a period longer than

30 days, the following precautions are recommended.

1. Working outdoors, drain all fuel from the fuel tank.

Run the engine until it stops from lack of fuel.

WARNING: DO NOT DRAIN FUEL WHILE

A

2. Drain all the oil from the crankcase (this should

3. Protect the inside of the engine for storage as

4. Clean the exterior of engine and the entire tiller

5. Wipe tines with oiled rag to prevent rust.

NOTE: When storing any type of power equipment in

an unventiiated or metal storage shed, care should be

taken to rustproof the equipment. Using a light oil or

silicone, coat the equipment, especially any springs,

bearings and cables.

SMOKING, OR IF NEAR AN OPEN FIRE.

be done after the engine has been operated and

is still warm) and refill the crankcase with fresh

oil.

instructed in the separate engine manual packed

with your unit.

thoroughly.

FIGURE 30.

6. Store in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

14

Page 15

TROUBLE SHOOTING GUIDE

Trouble

Engine fails to start

Engine runs erratic 1. Unit running on CHOKE.

Possible Cause(s) Corrective Action

1. Fuel tank empty, or stale fuel.

2. Throttle control lever not in

starting position.

3. Spark plug wire disconnected.

4. Faulty spark plug.

5. Engine flooded.

2. Spark plug wire loose.

3. Stale fuel.

4. Vent in gas cap plugged.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Carburetor out of adjustment.

Engine overheats 1. Engine oil level low.

2. Air flow restricted.

3. Carburetor not adjusted

properly.

1. Fill tank with clean, fresh gasoline.

2. Move throttle lever to START position.

3. Connect wire to spark plug.

4. Clean, adjust gap or replace.

5. Remove spark plug, dry the plug,

and crank engine with plug removed

and throttle in OFF position. Replace

spark plug, connect wire and resume

starting procedures.

1. Move choke lever to OFF position.

2. Connect and tighten spark plug wire.

3. Fill tank with clean, fresh gasoline.

4. Clear vent.

5. Drain fuel tank. Refill with fresh fuel.

6. Clean air cleaner as instructed in

separate engine manual.

7. Adjust carburetor as instructed in

separate engine manual.

1. Fill crankcase with proper oil.

2. Remove blower housing and clean as

instructed in separate engine manual.

3. Adjust carburetor as instructed in

separate engine manual.

Tines do not engage 1. Foreign object lodged in tines.

2. Tine clevis pin(s) missing.

3. Control cable not adjusted

properly.

4. Belt worn and/or stretched.

Wheels do not engage

NOTE; For repairs beyond the minor adjustments listed above, please contact your local service dealer.

1. Control cable not adjusted

properly.

2. Belt worn and/or stretched.

1. Dislodge foreign object.

2. Replace tine clevis pin(s).

3. Adjust control cable (see assembly

instructions).

4. Replace belt.

1. Adjust control cable (see assembly

instructions).

2. Replace belt.

15

Page 16

Copy ihc inform«i#ion from

your model piede here:

Model No. -406-

Engine Oil (SAE 30)

Air Filter 491588

Air Pre-Cleaner 491435

Spark Plug

Throttle Cable

Forward Drive Clutch C :able 746-0496

Reverse Drive Clutch (;able

Tine Clutch Cable

Forward Drive Belt

Reverse Drive Belt

Tine Drive Belt

Forward Drive Idler Pi lley

Reverse Drive Idler Pi lley 756-0166

Tine Drive Idler Pulley

Wheel Chain Case Grsase (10 oz. req’d.)

Tine Chain Case Grei se (12 oz. req’d.)

737-0208 (21 oz. req’d.)

737-0223 (16 oz. bottle)

737-0223 (16 oz. bottle)

RJ19LM

746-0502

746-0571

746-0535

754-0190

754-0109

754-0195A

756-0313

756-0405

\

is/

u ^

Have your

model number

available

when you call

Fpr Paris» Acceissorles or Service Ififormatioii»

VISA

CALL NOW!

MC

DISC

The only way to insure the performance of your product

is to use original equipmeni; parts and accessories.

MTD designs and engineers quality parts to exacting

specifications. When you substitute, you take a chance

on quality, reliability, safety and performance. Use MTD

original equipment, the be st buy on the American

Landscape—American Made and American Owned!

1

(

800

9:00 AM to Miijlnigfit Monday through Friday

9:00 AiIa to 8:00 PM Saturday

Ecffitem Tiiiiie (winter hours may vary)

)

800-7310

Loading...

Loading...