Page 1

OPERATOR’S MANUAL

Front Tine Tillers

Models

340 Thru 390

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO.

770-10135B.fm

(11/01)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Assembling Your Tiller.......................................................................................5

Know Your Tiller.................................................................................................7

Operating Your Tiller..........................................................................................8

Making Adjustments ..........................................................................................11

Maintaining Your Tiller .......................................................................................11

Troubleshooting.................................................................................................14

Parts List............................................................................................................16

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new tiller. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by standing in the operating position behind the unit and looking

down at the frame on the right side. A sample model plate is explained below. For future reference,

please copy the model number and the serial number of the equipment in the space below.

Copy the model number here:

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, powerrating, specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s

Manual packed separately with your unit for more information.

CONTACTING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call Customer Support Department.

Call 1- (330) 220-4MTD (4683) or 1- (800)-800-7310 to reach a Customer Support

representative. Please have your unit’s model number and serial number ready when you

call. See previous section to locate this information. You will be asked to enter the serial

number in order to process your call.

For more details about your unit, visit our website at www.mtdproducts.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this

manual before attempting to operate this machine. Failure to comply with these instructions may result

in personal injury. When you see this symbol— heed its warning.

WARNING: Engine exhaus t, s om e o f it s con st itu ents , a nd certain vehicle c om ponents contain or e m it

chemicals known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet. Failure to observe the

following safety instructions could result in serious injury or death.

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and ov er should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, pets and children at least

75 feet from the machine while it is in operation.

Stop machine if anyone enters the area.

Preparation

1. Thoroughly inspect the area where the equipment is

to be used. Remove all stones, sticks, wire, and

other foreign objects which could be tripped over

and cause personal injury.

2. Wear sturdy, rough-soled work shoes and close

fitting slacks and shirt. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals.

3. Disengage clutch levers and shift (if provided) into

neutral (“N”) before starting the engine.

4. Never leave this machine unattended with the

engine running.

5. Never attempt to make any adjustments while

engine is running, except where specifically

recommended in the operator’s manual.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

7. Use only an approved gasoline container.

8. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

9. Never fuel machine indoors.

10. Never remove gas cap or add fuel while the engine

is hot or running.

11. Allow engine to cool at least two minutes before

refueling.

12. Never over fill fuel tank. Fill tank to no more than ½

inch below bottom of filler neck to provide space for

fuel expansion.

13. Replace gasoline cap and tighten securely.

14. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

15. Never store the machine or fuel container inside

near an open flame, spark or pilot light (e.g.

furnace, water or space heater, clothes dryer etc.).

16. Allow machine to cool 5 minutes before storing.

Operation

1. Do not put hands or feet near rotating parts. Contact

with the rotating parts can amputate hands and feet.

2. Do not operate machine while under the influence

of alcohol or drugs.

3. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles.

4. Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation. Stop the machine if anyone enters the

area.

5. Be careful when tilling in hard ground. The tines

may catch in the ground and propel the tiller

forward. If this occurs, let go of the handle bars and

do not restrain the machine.

6. Exercise extreme caution when operating on or

crossing gravel surfaces. Stay alert for hidden

hazards or traffic. Do not carry passengers.

7. Never operate the machine at high transport

speeds on hard or slippery surfaces.

8. Exercise caution to avoid slipping or falling.

3

Page 4

9. Look down and behind and use care when in

reverse or pulling machine towards you.

10. Start the engine according to the instructions found

in this manual and keep feet well away from the

tines at all times.

11. After striking a foreign object, stop the engine,

disconnect the spark plug wire and ground against

the engine. Thoroughly inspect the machine for any

damage. Repair the damage before starting and

operating.

12. Disengage all clutch levers and stop engine before

you leave the operating position (behind the

handles). Wait until the tines come to a comple te

stop before unclogging the tines, making any

adjustments, or inspections.

13. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

14. Muffler and engine become hot and can cause a

burn. Do not touch.

15. Use caution when tilling near fences, buildings and

underground utilities. Rotating tines can cause

property damage or personal injury.

16. Do not overload machine capacity by attempting to

till soil to deep at to fast of a rate.

17. If the machine should start making an unusual noise

or vibration, stop the engine, disconnect the spark

plug wire and ground it against the engine. Inspect

thoroughly for damage. Repair any damage before

starting and operating.

18. Keep all shields, guards and safety devic es in place

and operating properly.

19. Never pick up or carry machine while the engine is

running.

20. Use only attachments and accessories approved by

the manufacturer. Failure to do so, can result in

personal injury.

21. If situations occur which are not covered in this

manual, use care and good judgment. Contact your

dealer or telephone 1-800-800-7310 for assistance

and the name of your nearest servicing dealer.

4. Do not change the engine governor settings or

over-speed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

Y our Responsibility

1. Restrict the use of this power machine to persons

who read, understand and follow the warnings and

instructions in this manual and on the machine.

2. The safety label on the tiller is reproduced below for

your review. To ensure safe operation of the tiller,

follow the instructions on all labels closely.

Maintenance & Storage

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine for

any damage.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the tines and all moving

parts have stopped. Disconnect the spark plug wire

and ground it against the engine to prevent

unintended starting.

4

Page 5

SECTION 2: ASSEMBLING YOUR TILLER

NOTE: This operator’s guide covers three different

model tillers. Models 340 thru 345 have forward tine

drive only. Model 390 has both forward and reverse tine

drive. Follow only the in st ruct ions which pertain to your

model tiller. See the mode l plate on your tiller for the

correct model number.

NOTE: References to right or left side of the tiller are

determined from behind the unit in the operating

position.

Removing Unit From Carton

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton.

• Remove all loose parts included with unit (i.e.,

operator’s manual, etc.)

• Cut corners and lay carton down flat.

• Remove packing material.

• Roll or sl ide u nit o ut of c art on. Ch eck car ton

thoroughly for loose parts.

• Extend control cable(s) to the rear of the tiller and

lay them on the floor. Be careful not to bend or kink

control cable(s).

IMPORT ANT :

in the engine. Be certain to service engine with gasoline

and oil as instructed in the separate engine manual

before operating your machine.

This unit is shipped without gasoline or oil

Before Assembly

WARNING: Disconnect the spark plug wire

and ground it against the engine to prevent

unintended starting.

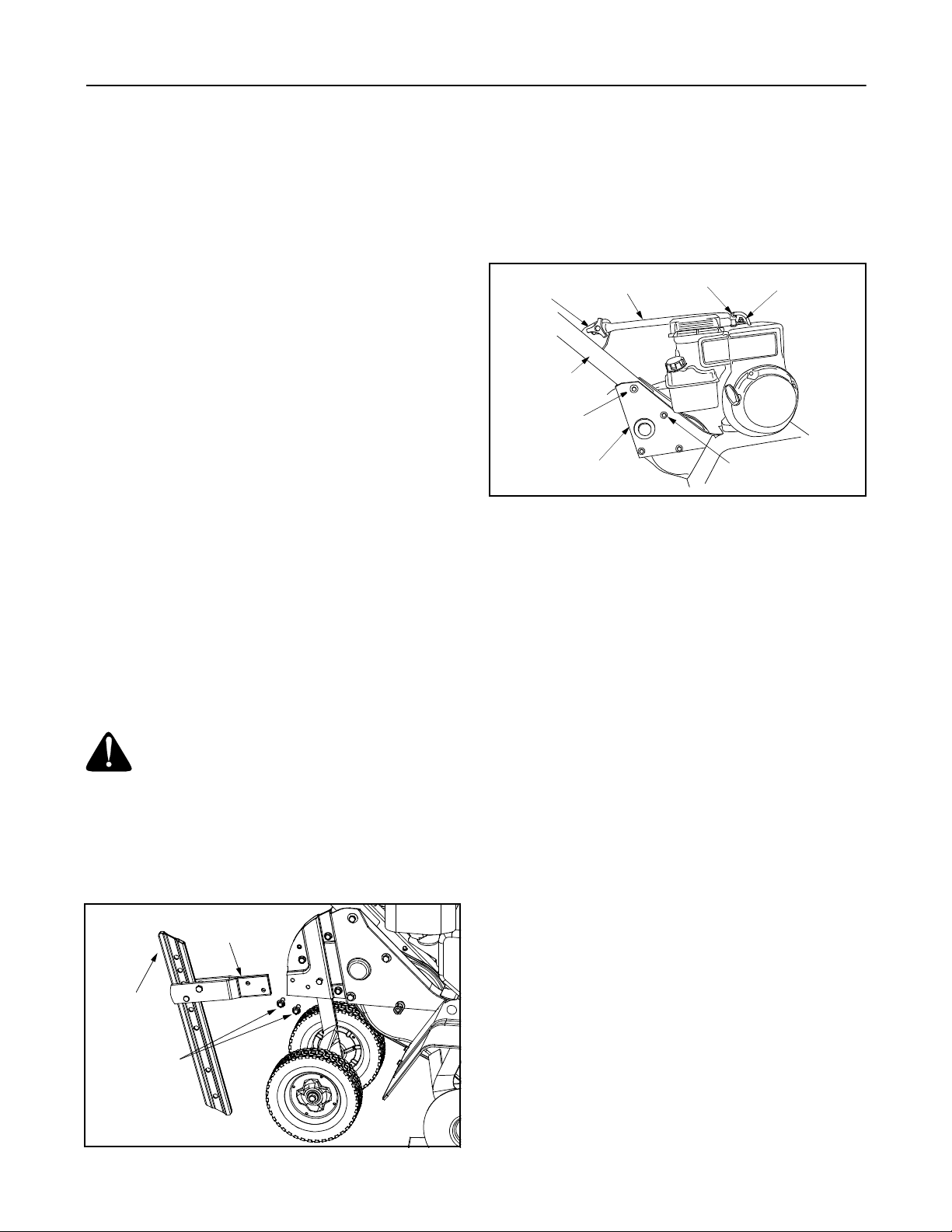

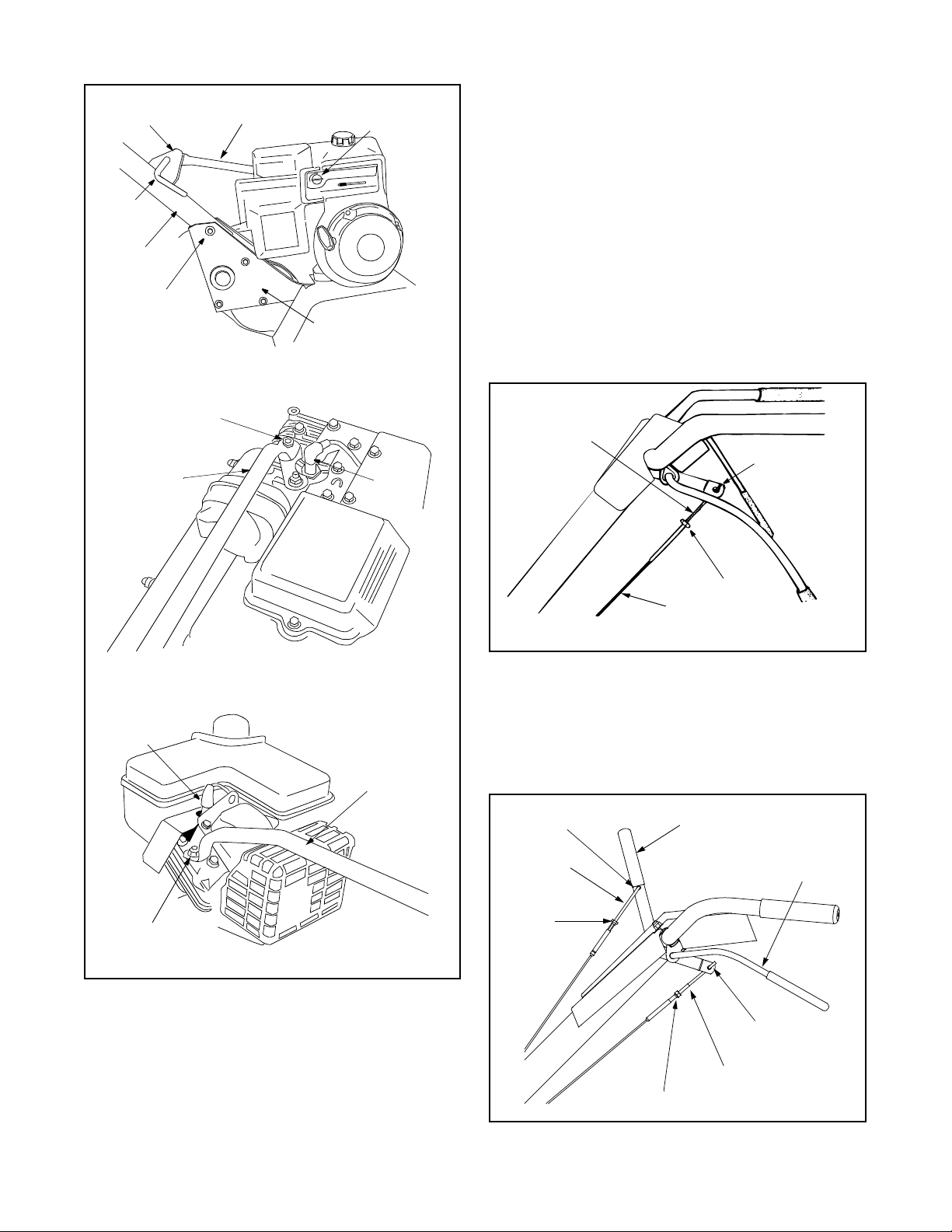

Attaching Tailpiece And Depth Stake

Remove the two self-tapping screws on the frame.

Slide the tailpiece into the frame with the lower hole in

the tailpiece toward the front. Secure with screws just

removed. See Figu re 1.

Tailpiece

Depth

Stake

Attaching Handle Assembly

• Remove the hex bolt and cupped washer from the

top right sid e of the fra me halves . Hold the ca ble

guide bracket on the left side of the frame as it will

fall when the bolt is removed. See Figure 2.

Handle

Hand Knob

Handle

Hex Bolt &

Cupped Washer

Frame Half

• Insert the handle assembly between the two frame

halves. Insert the hex bolt just removed through the

frame halves, handle assembly, and into the cable

guide bracket (notch in cable guide bracket goes

over the flange on the frame). Tighten securely.

• Loosen the hand knob which secures the handle

brace to the handle assembly. (Standard Briggs &

Stratton & Tecumseh Engines).

• Remove handle crank from the handle brace.

(Briggs & Stratton Intek Only).

• Remove the hex lock nut from on top of the engine,

just to the left of the spark plug. Attach the curved

end of the handle brace to the top of the engine,

using hex lock nut ju st removed. Tig hten securely .

See Figure 3.(Standard Briggs & Stratton &

Tecumseh engines).

• Insert handle crank through the welded bracket on

the handle and into the threaded u-nut on the end

of the handle brace. (Briggs & Stratton Intek

only).

• Select one of the three handle height positions

(three notches in welded bracket), and tighten the

hand knob to secure the handle in desired position.

Make certain carriage bolt is seated securely into

one of the three positions provided.

Brace

Spark

Plug

Figure 2

Hex Lock Nut

Shoulder Bolt

Self-Tapping

Screws

Figure 1

5

Page 6

Welded

Bracket

Handle

Crank

Handle

Hex Bolt &

Cupped Washer

Briggs and Stratton Intek Engine

Hex Lock Nut

Handle Brace

Handle

Brace

Fuel Shut-Off

Valve

Frame Half

Spark

Plug

• Loosen the hex nut on the threaded rod near the

end of the cable, and move it up the rod as far as it

will go.

• Unthread the rod from the rest of the cable. Hook

the “Z” end of the rod into the bracket underneath

the handle assembly from the right hand side. See

Figure 4.

• Thread the rod back into the cable until the cable is

straight. Do not tighten it enough to put any tension

on the spring.

• Thread the hex nut down against the end of cable.

Use a pair of pliers and a wrench to lock the nut

against th e rod.

NOTE: Do not overtighten control cable. Too much

tension may cause it to break when engaged.

Threaded Rod

“Z” End

Hooked In

Bracket

Briggs and Stratton Standard Engine

Spark

Plug

Handle

Brace

Hex Lock

Nut

Tecumseh Engine

Figure 3

Attaching Clutch Control Cable(s)

Forward Cable

Attach the end of the forward cable to the bracket

underneath the handle assembly as follows. (On model

390, the forward clutch cable is the cable which is

attached closer to the rear of the tiller).

Hex Nut

Cable

Models 340 thru 345

Figure 4

Reverse Cable (Model 390 Only)

The reverse clutch cable is the cable which is attached

closer to the front of the tiller. Attach the end of the

reverse cable to the reverse tine drive clutch lever,

above the handle assembly, in the same manner as

you attached the forward cable. See Figure 5.

Z End Hooked

in Bracket

Threaded

Rod

Hex Nut

Reverse Tine

Engagement Lever

Hex Nut

Figure 5

Forward Tine

Engagement Handle

Z End Hooked

in Bracket

Threaded

Rod

6

Page 7

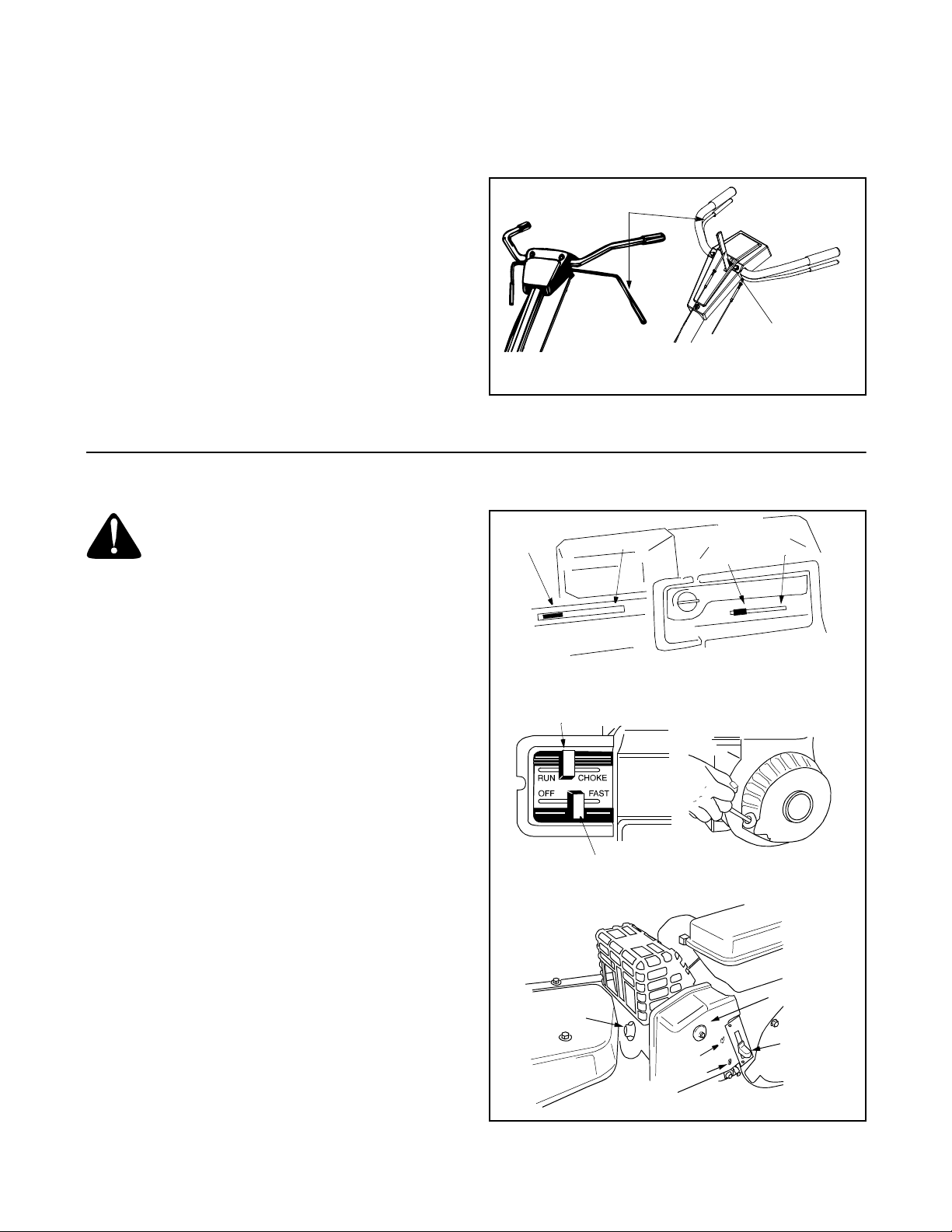

Final Clutch Adjustme nt

To check the clutch cable adjustment, proceed as

follows.

• Disconnect the spark plug wire and move it away

from the spark plug to prevent accidental starting.

• Engage and release the tine engagement handle,

then the reverse tine engagement lever (model 390

only). If an excessive noise is heard when releasing

either the tine drive clutch handle or lever, the cable

may be too loose. Adjust either the forward or

reverse clutch cable by loosening the hex nut,

threading the rod into the cable one or two turns,

then retightening the nut.

• With tine engagement handle in neutral (released)

as shown in Figure 6, pull the starter rope several

times. The tines should not turn. If they turn

forward, loosen the hex nut on the forward cable

(underneath the handle assembly). If they turn

SECTION 3: KNOW YOUR TILLER

WARNING: Read, understand, and follow

all instructions and warnings on the

machine and in this manual before

operating.

toward the rear (model 390 only), loosen the hex

nut on the reverse cable (above the handle

assembly). Unthread the rod from the cable 2 or 3

turns. Retighten the hex nut, and check again for

correct adjustment. See Figure 6.

Forward Tine

Engagement Lever

Reverse Tine

Engagement Lever

Models 340 thru 345

Model 390

Figure 6

Run

Choke

Stop

Fast

Throttle Control

The throttle control lever is located on the engine. It

controls the engine speed and stops the engine. See

Figure 7.

Choke Lever (Model 340/390)

The choke lever is located above the throttle control. It

is used to enrich the fuel mixture when starting a cold

engine. See Figure 7.

Primer Button (Model 345)

The primer button is located behind the air cleaner. It is

used to enrich the fuel mixture in the carburetor when

starting a cold engine. See Figure 7

Forward Tine Enga gement Handle

The forward tine engagement handle is located

beneath the tiller handle. Squeezing the handle up

against the tiller handle engages the tines. Release the

handle to stop the tines. See Figure 8

Reverse Tine Drive Clutch Lever

(Model 390 Only)

The reverse tine drive clutch lever is located on top of

the handle panel. Pull the lever to the rear to move the

tines in reverse. Release the lever to stop the reverse

tine drive. See Figure 8

NOTE: Never engage both the forward and reverse tine

drives at the same time. Engaging both forward and

reverse tine drives at the same ti me co uld da mag e the

belt drives and cause the engine to stall.

Briggs and Stratton Intek

Choke

Throttle Control

Briggs and Stratton Standard

Primer

Fast

Stop

Tecumseh

Figure 7

Air

Cleaner

Throttle

Control

7

Page 8

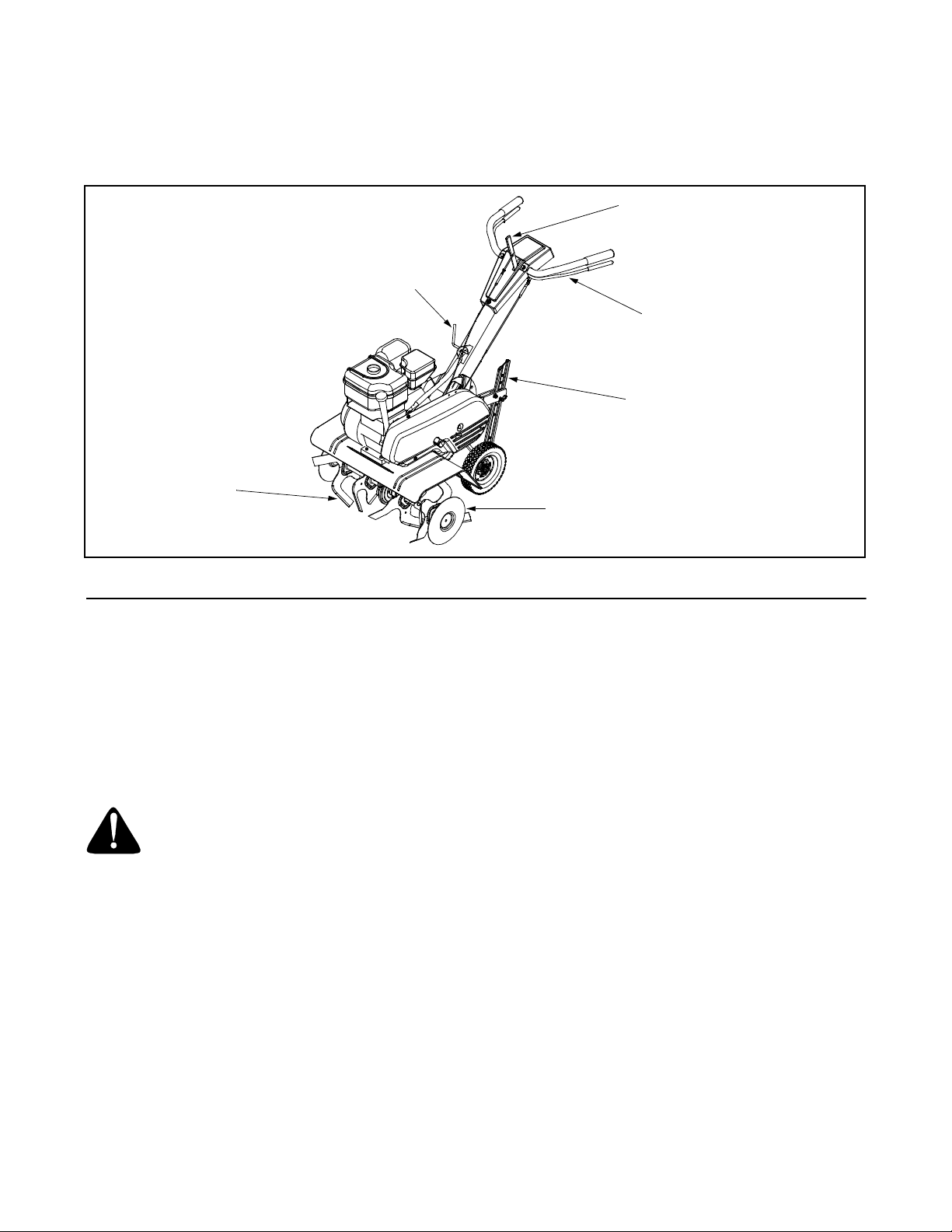

Depth Stake

The depth stake controls the tilling depth. Refer to

OPERATING YOUR TILL ER in Sectio n 4.

Handle

Crank

Tines

Model 390 Shown

Tines And End Caps

The tilling tines and end caps (are used to cultivate,

furrow, and preapre yoru garden for seeding. The end

caps (Model 390 only) are used to avoid tilled soil from

overflowi ng onto un wante d areas.

Reverse Tine

Engagement

Handle

Forward Tine

Engagement

Handle

Depth

Stake

End Cap

Figure 8

SECTION 4: OPERATING YOUR TILLER

Gas and Oil Fill up

Service the engine with gasoline and oil as instructed in

the separate engine manual packed with your tiller.

Read ins tructi ons caref ully .

Starting Engine

WARNING: Be sure no one is standing in

front of the tiller while the engine is

running or being started.

Models 340, 342, & 390

• Attach spark plug wire to spark plug. Make certain

the metal loop on the end of the spark plug wire

(inside the boot) is fastened securely over the metal

tip on th e spar k plug .

• Make certain all controls are in the neutral position

(released). See Figure 6.

• Place the throttle control lever in FAST position.

See Figure 7.

• Move chok e leve r to C HOKE p ositi on. (A war m

engine requires little or no choke.)

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

will pull slightly harder at this point). Let the rope

rewind slowly.

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope rewind

slowly. Do not let starter handle snap back against

starter.

• Repeat preceding instructions until engine starts.

When engine starts, move choke lever on engine

halfway between CHOKE and RUN.

• Move throttle control to IDLE position for a few

minutes warm-up. Move choke lever to RUN

position as engine warms up.

Models 343 & 345

• Attach spark plug wire to spark plug. Make certain

the metal loop on the end of the spark plug wire

(inside the boot) is fastened securely over the metal

tip on th e spar k plug .

• Make certain all controls are in the neutral position

(released). See Figure 8.

• Place the engine speed control in the START

position.

• Push primer two (2) or three (3) times. Wait about

two (2) seconds between each push.

NOTE: Primer may be needed to restart a warm engine

after a short shutdown.

8

Page 9

• Stand at side of tiller. Grasp the starter handle and

pull out slowly, until it pulls slightly harder. Let rope

rewind slowly.

• Pull rope with a rapid full arm stroke. Do not allow

handle to snap back. Allow it to rewind slowly while

keeping a firm hold on the starter handle.

NOTE: If engine fail s to start afte r thre e (3) p ulls , pu sh

primer two (2) times and pull starter rope again.

• Repeat previous steps until engine starts. Refer to

engine manual for additional engine information.

To Stop Engine

• Move throttle control lever to STOP or OFF

position.

• Disconnect spark plug wire from spark plug and

ground against the engine to prevent accidental

starting while equipment is unattended.

Removing End Caps (Model 390 only)

The end cap, which are used to avoid tilled soil from

overflowing onto unwanted areas, are removable from

the outer axle. Remove the hairpin clip and clevis pin

that is securing each end cap and slide end cap off the

axle. See Figure 10.

End Cap

Using Y our Tiller

Your tiller is a precision built machine designed for seed

bed preparation, cultivating, furrowing and mulching. It

is engineered to minimize the hardest work in the

vegetable or flower garden, to till the soil for planting

and cultivating, and to perform many other useful labor

saving tasks in the garden.

With the proper amount of care and maintenance, this

machine will provide the owner with many years of

service.

Wheel Position

The tiller is shipped with the wheels adjusted such that

the unit sits level. While tilling, as the tines enter the

ground and the front of the tiller lowers, the wheels

must be raised to level the unit, which is essential for

proper engine operation. This adjustment is made by

removing the clevis pin and hairpin clip from wheel

yoke, rai sing the w heel s to t he de sire d hei ght, a nd

replacing the clevis pin and hairpin clip. See Figure 9.

Depth Stake

Clevis Pin

Hairpin Clip

Figure 10

Controlling Speed And Tilling Depth

Wheel Yoke Adjustment

Place wheel yoke so that the wheels are forward

(nearest point between wheels and tines) for shallow

tilling, cultivating and transport. The forward speed will

increase. Turn yoke around (farthest point between

wheels and tines) for deep tilling. Forward speed will

decrease. See Figure 11.

Wheel Yoke

Hairpin Clips

& Clevis Pins

Figure 9

Position Wheel Yoke

For Shallow Tilling

Figure 11

Position Wheel Yoke

For Deep Tilling

Depth Stake Adjustment

The depth stake acts as a brake for the tiller and

controls the depth and speed at which the machine will

operate. Remove the clevis pin and hairpin clip to raise

or lower depth stake. See Figure 9.

.

9

Page 10

Transport

Position

Depth Stake

Shallow Tilling

Wheel Setting For

Deep Tilling

Deep Tilling

Figure 12

By increasing the depth of the depth stake, the forward

speed of the machine is reduced and the working depth

is increased. When the depth stake is raised, the

working depth of the machine is reduced and the

forward speed is increased. The working depth of the

machine may be predetermined by setting the depth

stake and wheels so that the wheels are about four

inches from the ground when the tines and depth stake

are resting on the ground. This setting will permit a

working depth of about four inches. When presetting

the working depth, the handles should be adjusted so

the hand grips are a little above waist. The tiller will be

lower when the tines and depth stake penetrate the

ground. See Figure 12.

Figure 13

When tilling, leave approximately 8 inches of untilled

soil betw een the fi rst and second ti llin g paths, then

make the third path between the first and second. In

some soils, the desired depth is obtained the first time

over the garden. In other soils, the desired depth is

obtained by going over the garden two or three times. In

the latter case, the depth stake should be lowered

before each succeeding pass over the garden. Passes

should be made across the length and width of the

garden alternately. Rocks which are turned up should

be removed from the garden area. See Figure 13.

Handle Pressure

Further control of tilling depth and travel speed can be

obtained by variation of pressure on the handles.

• A downward pressure on the handles will reduce

the working depth and increase the forward speed.

• An upward pressure on the handles will increase

the working depth and reduce the forward speed.

The type of soil and working conditions will determine

the actual setting of the depth stake and the handle

pressure required.

Throttle Control

The throttle control lever adjusts the engine speed and

stops the engine. With the throttle control lever pushed

completel y forw ard, t he ca rburet or i s in ST ART

position. Pulling the throttle control back slightly adjusts

the engine speed to FAST. Pulling the throttle back

further reduces the engine speed to SLOW. Pull the

throttle completely back to stop the engine.

Use maximum engine speed for deep tilling. Move the

throttle control to SLOW when transporting the tiller.

Transporting The Tiller

To transport the tiller to or from the garden, pivot the

depth stake forward, out of the way. See Figure 12.

With the throttle control in SLOW position, the unit will

walk freely on top of the lawn. If the operator does not

allow the tiller to move freely, the unit will start to till the

surface.

Cultivating

For cultivating, a two to three inch depth is desirable.

Setting the wheels and depth stake so that the wheels

are about two inches above the ground while the tiller is

resting on the tines and depth stake will allow the

machine to work at cultivating depth. The throttle

should be set to control forward movement to a slow

walking speed. With the outer tines installed, the

working wid th of the machine is 22 or 24 inches . For

cultivation, this may be reduced to 13 inches by

removing the outer tines. Refer to the Adjustment

Section. Wh en laying ou t plant rows , be sure to al low

enough width to permit cultivation between the rows. In

growing corn or similar crops, check-row planting will

permit cross cultivation and practically eliminate hand

hoeing. Se e Figur e 14.

The tiller has many uses other than tilling and

cultivating a garden. One of these is the preparation of

lawn area for seeding. The tiller will prepare a deep

seed bed which will be free of hard untilled spots,

allowing a better stand of grass to grow. The tiller is

very useful for loosening hard soil for excavation with a

shovel. No tedious handwork will be necessary. Your

tiller may be us ed fo r mi xing c ompos t in th e pile , or for

mixing it with the soil in your garden. This should be

done after the soil has been broken to the full working

depth. The compost should be worked in to a depth of

six to seven inches. This may be done by working the

length of the garden and then by making separate

10

Page 11

passes across its width. The addition of decayed

organic matter will substantially increase the fertility of

your garden. For proper decaying action, fertilizer

should be applied and worked in with the mulch

materials. Breaking up leaves and straw and mixing it

with several in ches of soil causes the so il to h old

moisture longer and allows proper aeration of the plant

root system. This also retards the growth of weeds.

SECTION 5: MAKING ADJUSTMENTS

WARNING: Disconnect the spark plug wire

and ground it against the engine before

performing any adjustments.

Engine Adjustment

Refer to the separate engine manual for engine

adjustment instructions.

Wheel Adjustments

To adjust the wheel yoke and wheel position, refer to

the Operating Section.

Figure 14

22”

Clutch Control Adjustments

To adjust the clutch controls, refer to the Final

Adjustment sec tion o f asse mbly i nstructio ns.

Depth Stake Adjustment

To adjust the depth stake, refer to the Operating

Section.

Tine Width Adjustment

The tilling width of the unit is 22 inches. Tilling width can

be increased to 24 inches by removing the clevis pins

and hairpin clips, sliding the outer tines out one inch,

and securing in this position with the clevis pins and

hairpin clips. For cultivation, reduce the tine width to 13

inches by removing the outer tines completely.

See Figure 15.

SECTION 6: MAINTAINING YOUR TILLER

WARNING: Disconnect the spark plug wire

and ground it against the engine before

performing any repairs or maintenance.

Engine

Refer to the separate engine manual for engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions ca refully .

Service air cleaner every ten hours under normal

conditions. Clean every hour under extremely dusty

11

24”

13”

Figure 15

Page 12

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be

serviced. To service the air cleaner, refer to the

separate engine manual packed with your unit.

Hex Washer

Screw

Lock Nut &

Flat Washer

Belt Cover

IMPORT ANT :

completely as sembled .

The spark plug should be cleaned and the gap reset

every 25 hours of engine operation. Spark plug

replacement is recommended at the start of each tiller

season; check engine manual for correct plug type and

gap specification.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to

permit proper air circulation which is essential to engine

performance and life. Be certain to remove all dirt and

combustible debris from muffler area.

Never run your engine without air cleaner

Lubrication

Pivot Points

Remove the belt cover and lubricate all moving parts

and pivot points at least once a season using SAE 30

engine oil.

Chain Drive

The chain case is pre-lubricated and sealed at the

factory.

Figure 16

• Lift the belt off the transmission pulley.

• Remove the hex nut which secures t he reve rse

idler pulley to the idler bracket. Slide idler pulley out

and remove the belt. See Figure 17.

Reverse Idler

Pulley

Hex Nut

Forward

Belt

Cleaning Tine Ar ea

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if rinsed off

immediately instead of after it dries. Always towel dry

the tiller afterwards and apply a light coat of oil or

silicone to prevent rusting or water damage.

IMPORT ANT :

your tiller. Water can penetrate tight areas of the tiller

and its chain case and cause serious damage to the

unit.

Never use a "pressure washer” to clean

Belt Replacement

Your tiller has been engineered with belts made of

special material (Kevlar Tensile). They should not be

replaced with an off-the-shelf belt. If belt replacement is

required, order belt or belts by part number from your

nearest aut horized service de aler. Se e parts list.

Reverse Drive Belt (Model 390 Only)

• Disconnect and ground the spark plug wire against

the engine. Remove the belt cover from the left side

of the tiller as follows.

• Remove two self-tapping screws and flat washers

from the front of belt cover. See Figure 16.

• Remove the he x stop nut and flat was her from th e

side of the belt cover. Remove belt cover.

Engine Pulley

Model 390 Show n

• Reassemble the new belt, following instructions in

reverse order. Make certain the reverse drive belt is

assembled with the wide side of the belt against the

transmission and engine pulleys.

Be certain to adjust the clutch control as instructed

in the final clutch adjustment section of assembly

instructions.

Reverse Belt

Transmission

Pulley

Figure 17

Forward Drive Belt

• Models 340 thru 345: Remove the belt cover by

following steps 1 thru 3 of the previous section.

Model 390: Remove the reverse drive belt as

instructe d in the prev ious secti on.

• Remove the belt keeper fro m the idler pu lley by

removing the idler pulley nut.

• Lift belt off the idler pulley and transmission pulley.

See Figure 18.

• Using a 9/16" wrench, remove bolt from engine

pulley.

• Push reverse idler pulley bracket forward, and

remove engine pulley and belt. See Figure 18.

• Reassemble the new belt, following instructions in

reverse order. Make certain the forward drive belt is

12

Page 13

assembled with the wi de side of the belt aw ay from

the transmission and engine pulleys.

Reverse Idler

Pulley

Engine

Pulley

Forward

Belt

Transmission

Pulley

Idler Pulley Nut

Figure 18

• Be certain to adjust the clutch control as instructed

in the final clutch adjustment section of assembly

instructions.

Off-Season Storage

If the tiller will not be used for a period longer than 30

days, the following steps should be taken to prepare the

tiller for storage.

• Clean the exterior of engine and the entire tiller

thoroughly. Lubricate the tiller as described in the

lubrication instructions.

• We do not r ecom mend t he us e of pres sure

washers to clean your unit. They may cause

damage to electric components, spindles, pulleys,

bearings or the engine. The use of pressure

washers will result in shortened life and reduce

serviceability.

• Refer to the engine manual for correct engine

storage instructions.

• Wipe tines with oiled rag to prevent rust.

• Store tiller in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

NOTE: When storing any type of power equipment in

an unventilated or metal sto rage shed, care shou ld be

taken to rustproof the equipment. Using a light oil or

silicone, coat the equipment and especially any

springs, bearings, and cables.

13

Page 14

SECTION 7: TROUBLE SHOOTING GUIDE

T rouble Possible Cause(s) Corrective Action

Engine fails to

start

Engine runs

erratic

Engine overheats

Tines do not

engage

Fuel tank empty, or stale fuel.

Throttle control lever not in correct

starting position (if so equipped).

Blocked fuel line.

Dirty aircleaner.

Choke not in ON position.

Spark plug wire disconnected.

Faulty spark plug.

Engine flooded.

Unit running on CHOKE.

Spark plug wire loose.

Blocked fuel line or stale fuel.

V ent in gas cap plu gge d.

Water or dirt in fuel system.

Dirty air cleaner.

Carburetor out of adjustment.

Engine oil level low.

Dirty air cleaner.

Air flow restricted.

Carburetor not adjusted properly.

Foreign object lodged in tines.

Tine clevis pin(s) missing.

Pulley and idler not in correct

adjustment.

Control cable not adjusted properly.

Belt worn and/or stretched.

Fill tank with clean, fresh gasoline. Fuel will not last over

thirty days unless a fuel stabilizer is used.

Move throttle lever to start position.

Clean fuel line.

Refer to the engine manual packed with your unit.

Move switch to ON position.

Connect wire to spark plug.

Clean, adjust gap or replace.

Refer to the engine manual packed with your unit.

Move choke lever to OFF position.

Connect and tighten spark plug wire.

Clean fuel line; fill tank with clean, fresh gasoline. Fuel will

not last over thirty days unless a fuel stabilizer is used.

Clear vent.

Drain fuel tank. Refill with fresh fuel.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Fill crankcase with proper oil.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Adjust carburetor as instructed in separate engine manual.

Dislodge foreign object.

Replace tine clevis pin(s).

Take unit to authorized service dealer.

Adjust control cable (see assembly instructions).

Replace belt.

14

Page 15

Notes

15

Page 16

Model 340 Thru 345

1

2

5

3

2

9

4

6

8

10

Standard Briggs & Stratton

Tecumseh Engines

7

48

32

37

32

25

15

12

33

31

30

16

24

25

35

13

14

26

29

27

34

23

11

28

22

20

44

21

45

19

17

18

50

47

49

46

25

38

39

36

40

41

42

43

16

Page 17

Model 340 Thru 345

Ref.

No.

1. 712-0442 Acorn Lock Nut 1/4-20

2. 736-3020 Flat Washer .271” I.D. x .630” O.D.

3. 731-1599 Handle Cover

4. 712-0287 Hex Nut 1/4-20 Gr.2

5. 720-0274 Handle Grip

6. 686-0083 Clutch Handle Assembly

7. 720-0269 Clutch Grip

8. 710-0641 Hex Bolt 1/4-20 x 2.25” Lg. Gr.5

9. 731-1645A Clutch Handle Holder

10. 736-0140 Flat Washer .385” I.D. x .62” O.D.

11. 649-0039 Handle Assembly Comp. †

12. 647-0042 Adjustment Crank †

13. 726-0211 U Nut 5/16-18 †

14. 749-1101 Handle Brace †

15. 736-0921 Lock Washer 1/2 †

16. 710-3194 Hex Bolt 1/2-20 Gr. †

17. 786-0005 Depth Bar

18. 714-0149B Cotter Pin

19. 712-3004A Hex Flange L-Nut 5/16-18

20. 786-0003 Tail Piece Bracket (L.H.)

21. 786-0004 Tail Piece Bracket (R.H.)

22. 711-0415 Clevis Pin

23. 710-0805 Hex Bolt 5/16-18 x 1.5” Lg.

24. 710-0189 Hex Bolt 5/16-18 x 3” Lg.

25. 736-0242 Wash. Bell. .340” I.D. x .872” O.D.

Part No. Part Description

649-0022B Handle Assembly Comp. ††

Ref.

No.

26. 711-1036 Spec. Hex Nut

27. 736-0119 L-Wash. 5/16” I.D.

28. 710-3008 Hex Bolt 5/16-18 Gr. 5

29. 786-0129 Cable Guide Bracket

30. 710-0604 Hex Wash Screw 5/16-18 x .6 2”

31. 710-0602 Hex Wash. Hd. TT-Tap Scr.

32. 738-0934 S hdl. Bolt 5/16-18

33. 786-0138A Frame (R.H.)

34. 786-0139A Frame (L.H.)

35. 736-0171 Lock Washer 7/16

36. 712-02 40 Jam Nut 7/16 -20 Gr. 2

37. 710-0176 Hex Bolt 5/16-18 x 2.75” Lg.

38. 712-0429 Hex Nyloc Nut 5/16-18 Thd.

39. 711-0415 Clevis Pin

40. 714-0149B Cotter Pin

41. 686-0081A Wheel Hanger Brkt. Assy

42. 734-1566 Wheel Ass’y 8” x 1.75”

43. 738-09 29 Shoulder Screw .496 x 1.445

44. 750-0890 Spacer

45 712-3004A Hex Flange L-Nut 5/16-18 Thd. ††

46 720-0195 Hand Knob ††

47 749-0915A Engine Tube Brace (Std. B&S)

48 710-1236 Carr. Bolt 5/16-18 x 1 ††

49 736-0242 Bell. Wash. .34” I.D. ††

50 786-0159 Engine Brkt. (Std B&S)

Part No. Part Description

749-1082 Engine Tube Brace (Tec. )

† Briggs & Stratton Intek Engine

†† Standard Briggs & Stratton and Tec. Engine

17

Page 18

Model 340 Thru 345

27

13

14

12

15

28

31

41

29

23

10

40

33

30

42

39

38

37

32

36

34

22

35

9

8

6

26

16

21

19

18

25

24

19

7

4

5

3

20

11

1

2

18

Page 19

Model 340 Thru 345

Ref.

No.

1. 712-0392 Hex L-Stop nut 1/4-28

2. 736-3020 Flat Wash. .266” I.D. x .625” O.D.

3. 710-0599 Hex Washer Screw 1/4-20 x .5”

4. 711-0920 Belt Cover Bolt

5. 712-3004A Hex Flange Top L-Nut 5/16-18

6. 710-0723 Hex Hd. Scr. 3/8-16 x 1.25” Lg.

7. 756-0313 Fl-Idler 2.12” O.D.

8. 786-0149 Idler Belt Keeper

9. 786-0144 Idler Bracket

10. 712-0266 Hex Cent. Jam Nut 3/8-16 Thd.

11. 786-0056 Belt Cover

12. 710-0599 Hex Washer Screw 1/4-20 x .5”

13. 786-0035A Tine Shield

14. 710-3008 Hex Hd. Cap Scr. 5/16-18 x .75” Lg

15. 712-3004A Hex Flange Top L-Nut 5/16-18

16. 686-0091 Chain Case Assembly Complete

18. 714-0149B Internal Cotter Pin

19. 711-0415 Clevis Pin

20. 642-0005 Outer Tine Assembly L.H.

21. 642-0003 Inner Tine Assembly L.H.

Part No. Part Description

642-0004 Outer Tine Assembly R.H.

642-0002 Inner Tine Assembly R.H.

Ref.

No.

22. 746-0918 Forward Clutch Cable

23. 786-0053 Tine Shield Bracket

24. 736-0171 L-Wash. 7/16” I.D.

25. 712-0240 Hex Nut 7/16-20 Thd.

26. 710-0502A Hex Washer Screw 3/8-16 x 1.25”

27. 786-0145A Engine Plate

28. 786-0039B Bracket Cover

29. 736-0119 Lock Washer 5/16

30. 710-0107 Hex Bolt 5/16-24 x .5”

31. 756-0971 Inner Engine Pulley Half

32. 756-0972 Outer Engine Pulley Half

33. 736-0258 Flat Washer .385 ID x 1.0 OD

34. 736-0169 Lock Washer 3/8

35. 710-0191 Hex Bolt 3/8-24 x 1.25”

36. 736-0112 Bell-Wash. .525” I.D. x 1.5” O.D.

37. 712-3029 Hex Jam Nut 1/2-20 Thd. (Gr. 5)

38. 736-0312 Retainer Washer Bearin g

39. 756-0585 Fl-Pulley 6” Dia.

40. 754-0428 V-Belt (Forward)

41. 750-0892 Spacer .64” Dia. x 2.4” Lg.

42. 748-0350 Pulley Mounting Adapter

Part No. Part Description

19

Page 20

Model 390

3

1

2

5

20

37

7

2

17

35

36

4

8

21

29

19

30

6

10

9

11

12

16

31

14

18

32

13

15

49

26

2728

Standard Briggs & Stratton

Tecumseh Engines

51

52

53

22

23

50

54

55

37

42

30

38

30

43

44

40

34

41

39

33

20

46

25

24

45

47

48

Page 21

Model 390

REF.

NO.

10. 720-0269 Grip-Clutch

11. 710-0641 Hex Bolt 1/4-20 x 2.25” Lg. Gr .5

12. 731-1645A Clutch Handle Holder

13. 736-0140 Flat Washer .385” I.D. x .62” O.D.

14. 686-0014A Reverse Handle Ass’y

15. 736-0264 Flat Washer .344” I.D. x .62” O.D.

16. 649-0039 Handle Assembly C omp. †

17. 647-0042 Adjustment Crank †

18. 726-0211 U Nut 5/16 -18 †

19. 749-1101 Handle Brace †

20. 736-0921 Lock W as her 1/2 †

21. 710-3194 Hex Bolt 1/2-20 Gr. 5 †

22. 786-0005 Depth Bar

23. 714-0149B Cotter Pin

24. 712-3004A Hex Flange L-Nut 5/16-18 Thd. Gr.5

25. 786-0003 Tail Piece Bracket (L.H.)

26. 786-0004 Tail Piece Bracket (R.H.)

27. 711-0415 Clevis Pin

28. 710-0805 Hex Bolt 5/16-18 x 1.5” Lg.

PART NO. DESCRIPTION

1. 712-0442 Acorn Lock Nut 1/4-20

2. 736-3020 Flat Washer .271” I.D. x .630” O.D.

3. 720-0270A Reverse Handle Grip

4. 731-1600 Handle Cover w/o throttle

5. 710-0779A Truss Mach. Scr. #10 x 1/2” Lg.

6. 720-0274 Grip-Handle

7. 712-0287 Hex Nut 1/4-20 Gr.2

8. 726-0135 Cap Speed Nut

9. 686-0083 Clutch Handle Assembly

649-0022B Handle Assembly Comp. ††

REF.

NO.

29. 710-0189 Hex Bolt 5/16-18 x 3” Lg.

30. 736-0242 Wash. Bell. .340” I.D. x .872” O.D.

31. 711-1036 Spec. Hex Nut

32. 736-0119 L-Was h. 5/16 ” I.D.

33. 710-3008 Hex Bolt 5/16-18 Gr. 5

34. 786-0129 Cable Guide Bracket

35. 710-0604A Hex Washer Screw 5/16-18 x .62” Lg.

36. 710-0602 Hex Wash. Hd. TT-Tap Scr.

37. 738-0934 Shdl. Bolt 5/16-18

38. 786-0138A Frame (R.H.)

39. 786-0139A Frame (L.H.)

40. 736-0171 Lock Washer 7/16

41. 712-0240 Jam Nut 7/16-20 Gr. 2

42. 710-0176 Hex Bolt 5/16-18 x 2.75 ” Lg.

43. 712-0429 Hex Nylon Nut 5/16-18 Thd.

44. 711-0415 Clevis Pin

45. 714-0149B Cotter Pin

46. 686-0081A Wheel Hanger Bracket Assembly

47. 734-1566 Wheel Ass’y 8” x 1.75”

48. 738-0929 Shoulder Screw .496 I.D. x 1.445 O.D.

49. 750-0890 Spacer

50. 710-1236 Carr. Bolt 5/16-18 x 1 ††

51. 749-0915A Engine Tube Brace (Std. B&S)

52. 712-3004A Hex Flange L-Nut 5/16-18 Thd. ††

53. 786-0159 Engine Brkt. (Std. B&S)

54. 736-0242 Bell. Wash. .34” I.D. ††

55. 720-0195 Hand Knob††

PART NO. DESCRIPTION

749-1082 Engine Tube Brace (Tec.)

† Briggs & Stratton Intek Engine

†† Standard Briggs & Stratton and Tec. Engine

21

Page 22

Model 390

13

12

14

15

29

25

48

30

33

31

45

39

26

32

38

49

34

50

35

24

24

23

27

28

36

42

40

22

41

9

51

43

16

44

21

19

46

47

10

7

4

5

20

3

17

8

6

11

1

2

18

22

Page 23

Model 390

REF.

NO.

10. 712-0266 Hex Cent. Jam Nut 3/8-16 Thd.

11. 786-0057 Belt Cover

12. 710-0599 Hex Wash. TT-Tap Scr. 1/4-20 x .5” Lg.

13. 786-0043A Tiner Shield

14. 710-3008 Hex Hd. Cap Scr. 5/16-18 x .75” Lg

15. 712-3004A Hex Flange Top L-Nut 5/16-18 (Gr. 5)

16. 686-0091 Chain Case Assembly Complete

17. 686-0106 Tine Disc Ends

18. 714-0149B Internal Cotter Pin

19. 711-0415 Clevis Pin

20. 642-0023 Outer Tine Assembly L.H.

21. 642-0003 Inner Tine Assembly L.H.

22. 746-0918 Forward Clutch Cable

23. 746-0953 Revers e Clutc h Cable

24. 756-0585 Fl-Pulley 6” Dia.

PART NO. DESCRIPTION

1. 712-0392 Hex L-Stop nut 1/4-28

2. 736-3020 Flat Wash. .266” I.D. x .625” O.D.

3. 710-0599 Hex Washer TT-Tap Scr. 1/4-20 x .5”

4. 711-0920 Belt Cover Bolt

5. 712-3004A Hex Flange Top L-Nut 5/16-18 (Gr.5)

6. 710-0723 Hex Hd. Scr. 3/8-16 x 1.25” Lg. (Gr.5)

7. 756-0313 Fl-Idler 2.12” O.D.

8. 786-0149 Idler Belt Keeper

9. 786-0144 Idler Bracket

642-0024 Outer Tine Assembly R.H.

642-0002 Inner Tine Assembly R.H.

REF.

NO.

25. 750-0892 Spacer .64” Dia. x 2.4” Lg.

26. 748-0350 Pulley Mounting Adapter

27. 736-0112 Bell-Wash. .525” I.D. x 1.5” O.D.

28. 712-3029 Hex Jam Nut 1/2-20 Thd. (Gr. 5)

29. 732-0697 Return Spring

30. 786-0040B Reverse Bracket

31. 736-0119 Lock Washer 5/16

32. 710-0107 Hex Bolt 5/16-24 x .5”

33. 756-0971 Inner Engine Pulley Half

34. 756-0600 Outer Engine Pulley Half

35. 736-0452 Bell Washer .396” I.D. x 1/14” O.D.

36. 710-0191 Hex Bolt 3/8- 24 x 1.25”

38. 686-0013 Reverse Arm Assembly

39. 712-0266 Hex Cent. J am Nut 3/8-16 Thd.

40. 710-0723 Hex Cap Bolt 3/8-16 x 1.25” Lg. (Gr. 5)

41. 756-0313 Fl-Idler 2.12” O.D.

42. 786-0041 Keeper Plate

43. 710-0502A Hex L-Wash. TT-Tap 3/8-16 x 1.25”

44. 786-0145A Engine Plate

45. 786-0053 Tine Shield Bracket

46. 736-0171 L-Was h. 7/16 ” I.D.

47. 712-0240 Hex Nut 7/16-20 Thd.

48. 754-0428 V-Belt (Forward)

49. 754-0429 V-Belt (Reverse)

50. 738-0102 Shld. Bolt

51. 738-0930 Shld. Bolt

PART NO. DESCRIPTION

23

Page 24

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warran ty set fo rth below is given by MTD LLC wit h

respect to new merchandise purchased and used in the

United States, its possessions and territories.

MTD LLC warra nts this prod uct agai nst def ects fo r a period of

two (2) years commencing on the date of original purchase

and will, at its option, repair or replace, free of charge, any

part found to be defective in materials or workmanship. This

limited warr anty shall only apply if th is pro duct h as bee n oper ated and maintained in accordance with the Operator’s Man-

ual furnished with the product, and has not been subject to

misuse, abuse, comm ercial use, neglect, accident, improper

maintenance, alteration, vandalism, theft, fire, water, or damage because of other peril or natural disaster. Damage

resulting from the installation or use of any accessory or

attachment not approved by MTD LLC for use with the product(s) covered by this manual will void your warranty as to

any resulting damage.

Normal wear parts or components thereof are subject to separate terms as follows: All normal wea r parts or component

failures will be c o vered on the product for a period o f 90 days

regardless of cause. After 90 days, but within the two year

period, normal wear part failures will be covered ONLY IF

caused by defects in materials or workmanship of OTHER

component parts. Normal wear parts and components

include, but are not limited to: batteries, belts, blades, blade

adapters, gr ass b ags , rider dec k wheels , s eats , sn ow thro wer

skid shoes, shave plates, auger spiral rubber, tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized service dealer. To l oc ate t he d eal er in your area, check

your Yellow Pages, or contact MTD LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, 1-800-800-7310, 1-330-2204683 or log on to our Web site at www.mtdproducts.com.

This limited warranty does not provide coverage in the following cases:

a. The engine or component parts thereof. These items

carry a separate manufacturer’s warranty. Refer to the

applicable manufacturer’s warranty for terms and conditions.

b. Log splitter pumps, valves, and cylinders have a sepa-

rate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening, tune-ups, brake adjustments, clutch

adjustments, de ck adjustments , and normal deterioration

of the exterior finish due to use or exposure.

d. MTD LLC does not extend any warranty for products

sold or exported outside of the U nit ed State s , its possessions and territories, except those sold through MTD

LLC’s authorized channels of export distribution.

e. Parts that a re not genuine MTD parts are n ot covered by

this warranty.

f. Service completed by s omeone o ther than an authoriz ed

service dealer is not covered by this warranty.

g. Transportation charges and service calls are not

covered.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, e xcept as mentioned above, given by any person or entity, including a

dealer or retailer, with respect to any product, shall bind

MTD LLC. D uring the pe riod of the warranty, the exclusive remedy is repair or replacement of the product as

set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. MTD

LLC shall not be liable for incidental or consequential

loss or damage including, without limitation, expenses

incurred for substitute or replacement lawn care services

or for rental expense s to tem poraril y replace a warranted

product.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or limitations on how long

an implied warranty lasts, so the above exclusions or limitations may not apply to y ou.

In no event shall recovery of a ny k ind be greater than the

amount of the purchase price of the pr oduct sold. Alteration

of safety features of the pr oduc t shall v oid t his warra nty.

You assume the risk and liability f o r loss , dam age , or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser or to the person for whom it was purchased as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you

may also have other ri ghts wh ich v ary fr om sta te to s tate.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 1-800-800- 7310

Loading...

Loading...