MTD 31BH97SJ799 Owner’s Manual

perator's nual

I:RRFrSMAN+

Electric Start

SNOW THROWER

Model No. 247.883980

CX

IES

,, SAFETY

, ASSEMBLY

OPERATION

MAINTENANCE

CAUTION" Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com

PARTS LIST

o ESPANOL

Form No.769-08169

(June 15,2012)

Warranty Statement .................................. Page 2

Safe Operation Practices .......................... Page 3

Safety Labels ............................................ Page 7

Assembly .................................................. Page 8

Operation .................................................. Page 14

Service and Maintenance ......................... Page 19

Off-Season Storage .................................. Page 27

Troubleshooting ........................................ Page 28

Parts List ................................................... Page 29

Repair Protection Agreement ................... Page 48

Espa_ol ..................................................... Page 49

Service Numbers ...................................... Back Cover

CRAFTSMANCXTWOYEARFULLWARRANTY

FORTWOYEARSfromthe dateofpurchase,thisproductiswarrantedagainstanydefectsin materialor workmanship.A defective

productwillreceivefree repairorreplacementif repairisunavailable.

Forwarranty coveragedetails to obtain free repairor replacement,visitthe website: www.craftsman.com

Thiswarranty coversONLYdefects in material andworkmanship. Warranty coveragedoes NOTinclude:

• Expendableitemsthatcan wearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddles,

driftcutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

Tirereplacementor repaircausedby puncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedto damagecausedbyover-speedingtheengine,orfrom

impactingobjectsthatbendthe frame,augershaft,etc.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricaland mechanicaldamagecausedby

improperstorage,failureto usethepropergradeandamountof engineoil,or failuretomaintaintheequipmentaccordingtothe

instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedtobecontaminatedor oxidized(stale).Ingeneral,fuelshouldbe

usedwithin30 daysofitspurchasedate.

• Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidif thisproductiseverusedwhileprovidingcommercialservicesor if rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

SearsBrands ManagementCorporation, Hoffman Estates,IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 37ounces

FuelCapacity: Approx.5 Quarts

SparkPlug: F6RTC(951-10292)

SparkPlugGap: .020"to.030"

©SearsBrands,LLC

Model Number.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualin asafeplaceforfutureand

regularreferenceandfororderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscan causeseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon themachine.

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

• Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledin movingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheightto cleargravelorcrushedrock

surfaces.

• Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedinthe operator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhiletheengineishotor

running.

• Allowengineto coolat leasttwo minutesbeforerefueling.

• Neveroverfill fueltank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto providespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineis spilled,wipeitofftheengineandequipment.Move

machinetoanotherarea.Wait5 minutesbeforestartingthe

engine.

• Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkor pilotlight(e.g.furnace,waterheater,space

heater,clothesdryeretc.).

• Allowmachinetocoolat least5minutesbeforestoring.

• Neverfillcontainersinsideavehicleor ona truckortrailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthe truckor

trailerandrefuelitonthe ground.Ifthis isnotpossible,thenrefuel

suchequipmenton a trailerwithaportablecontainer,ratherthan

froma gasolinedispensernozzle.

• Keepthenozzlein contactwiththerimofthefueltankor

containeropeningatalltimes untilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

OPERATION

• Donot puthandsorfeetnearrotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisa safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.Do notoperateonsteepslopes.

Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby aricochet.

Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontof themachine.

Donot overloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingand keepafirmholdon the handles.Walk,

neverrun.

Disengagepowertotheauger/impellerwhentransportingor not

in use.

Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindandusecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwire andgrounditagainsttheengine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,or inspections.

Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.). Forinformation

concerningtheseitems,call1-800-469-4663.

Whenstartingengine,pullcord slowlyuntilresistanceis felt,then

pull rapidly.Rapidretractionof startercord(kickback)willpull

handandarmtowardenginefasterthanyoucanletgo.Broken

bones,fractures,bruisesorsprainscouldresult.

Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.

Toorderpartsor scheduleserviceforthisproduct,call 1-800-

469-4663.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe surethe impellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothe maintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonlyaslistedinthe Partspagesof thisoperator's

manual.Useofpartswhichdonot meettheoriginalequipment

specificationsmayleadto improperperformanceandcompro-

misesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertothe adjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsfor gas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupof auger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchasawaterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60hoursof

operation.Atthe endoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodoso canresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththe governorsettingcanleadto arunawayengineand

causeitto operateatunsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,itshouldbe maintainedineffectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorfor themufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

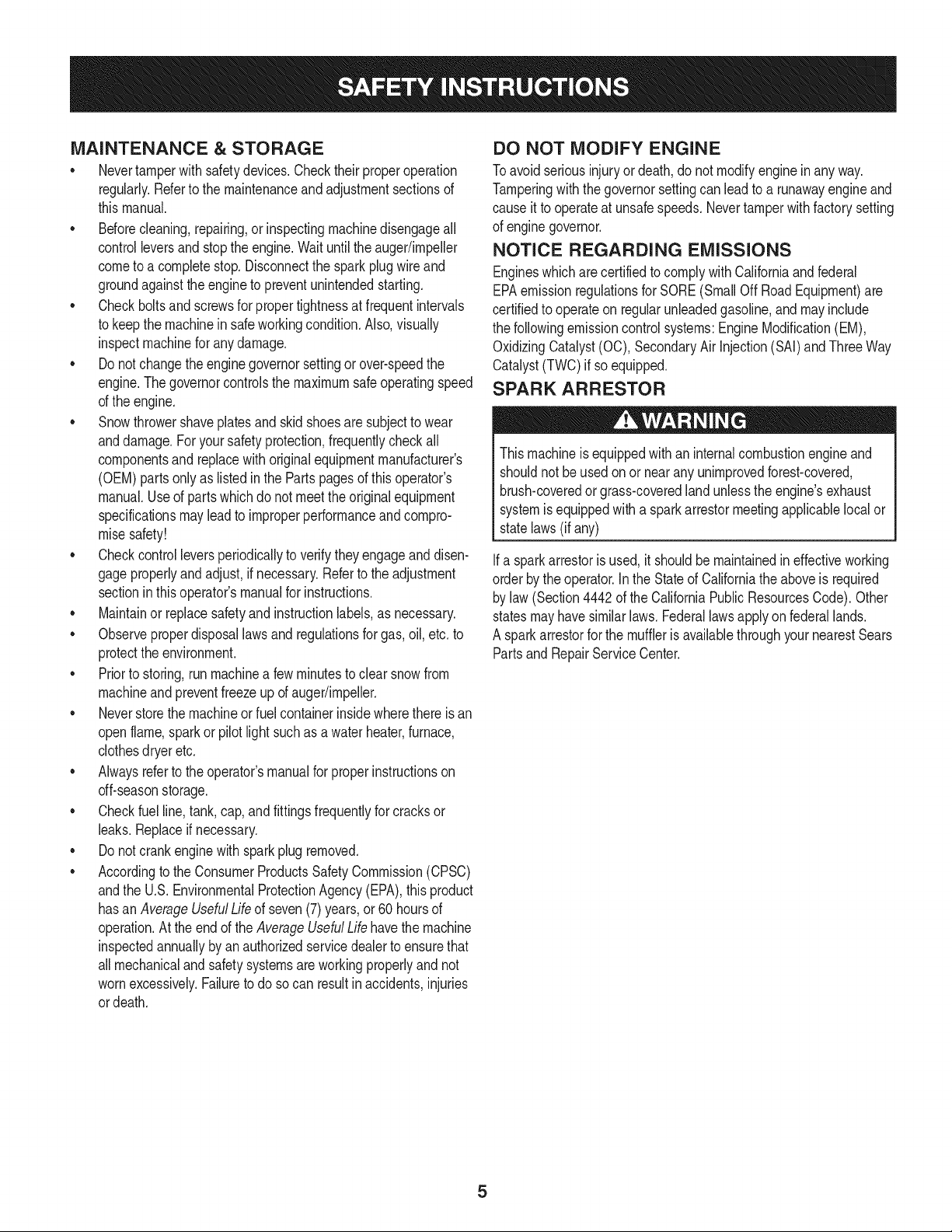

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson the machine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

"JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

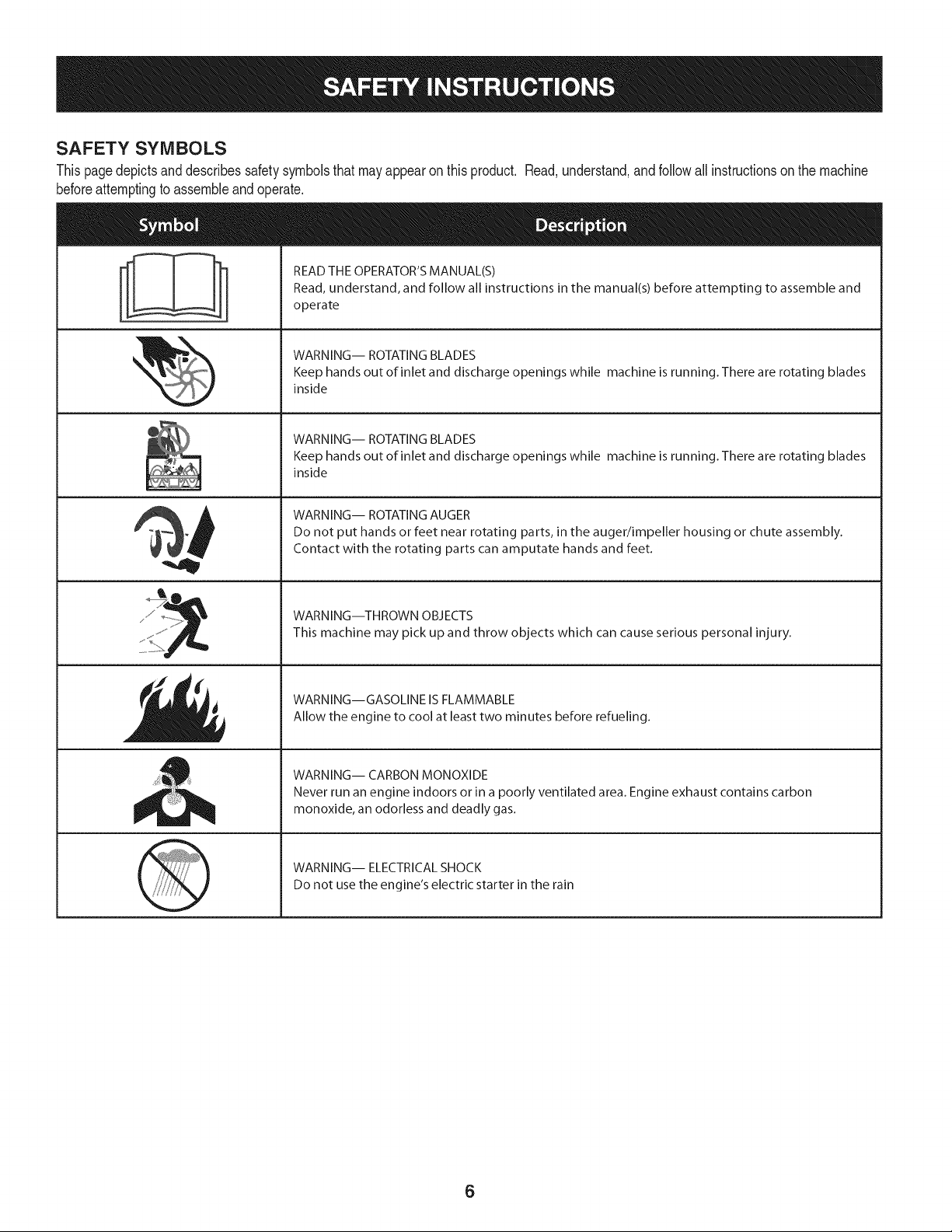

r

100/.LIIO-NV:IIO

"lVflNV_ S,UOIVU3dOQV3H"G

"S3OV_IJflS]3AVUONO9NIIV_J3dO

N3HMNOIIflVOVSIX]qsfl"S9]ONVIS181V]98VHOSIO

10381083A3N'S]IUflrNI SI03PgoNMOUHIQIOAV01"_

"3NIHOV_ONIOIA83SUOONIOOO]ONfl

]UO_38O3ddOIS]AVHSlHPd9NIAOW11VlllNfl S]IQNVH

ONIH]8NIVW3UONV']NION]dOlS'88]A]1HOlnlo]9VON]SIO"8

"]lnHg ]gHVHOSIO9010Nfl01 1001lflO-NP]lO ]Sfl "Z

"l]]d ONVSONVH]lPlnd_P NVOH3onvuoHq]l]d_JIHIIM

IOVINO0"u39npONV_J3113dWI9NllVIOU_JOH_IVMVd]3H "L

7

NOTE:Referencesto rightorleft sideof thesnowthrowerare

determinedfromthe operatingpositionlookingforwardtothe frontof

themachine.

REMOVING FROM CRATE

1. Removescrewsfromthebottomof thecratesecuringthesides,

andendsof theshippingcrate.

2. Liftoff thetopoff ofthe crateandsetoutof thewayof the

assemblyarea.

3. Removeanddiscardplasticbagthatcoversunit.

4. Removeanyloosepartsincludedwithunit(e.g.,Operator's

Manual,etc.).

5. Pushdownonthelowerhandleandpullunitbackout ofcrate.

6. Makecertainthecratehas beencompletelyemptiedbefore

discardingit.

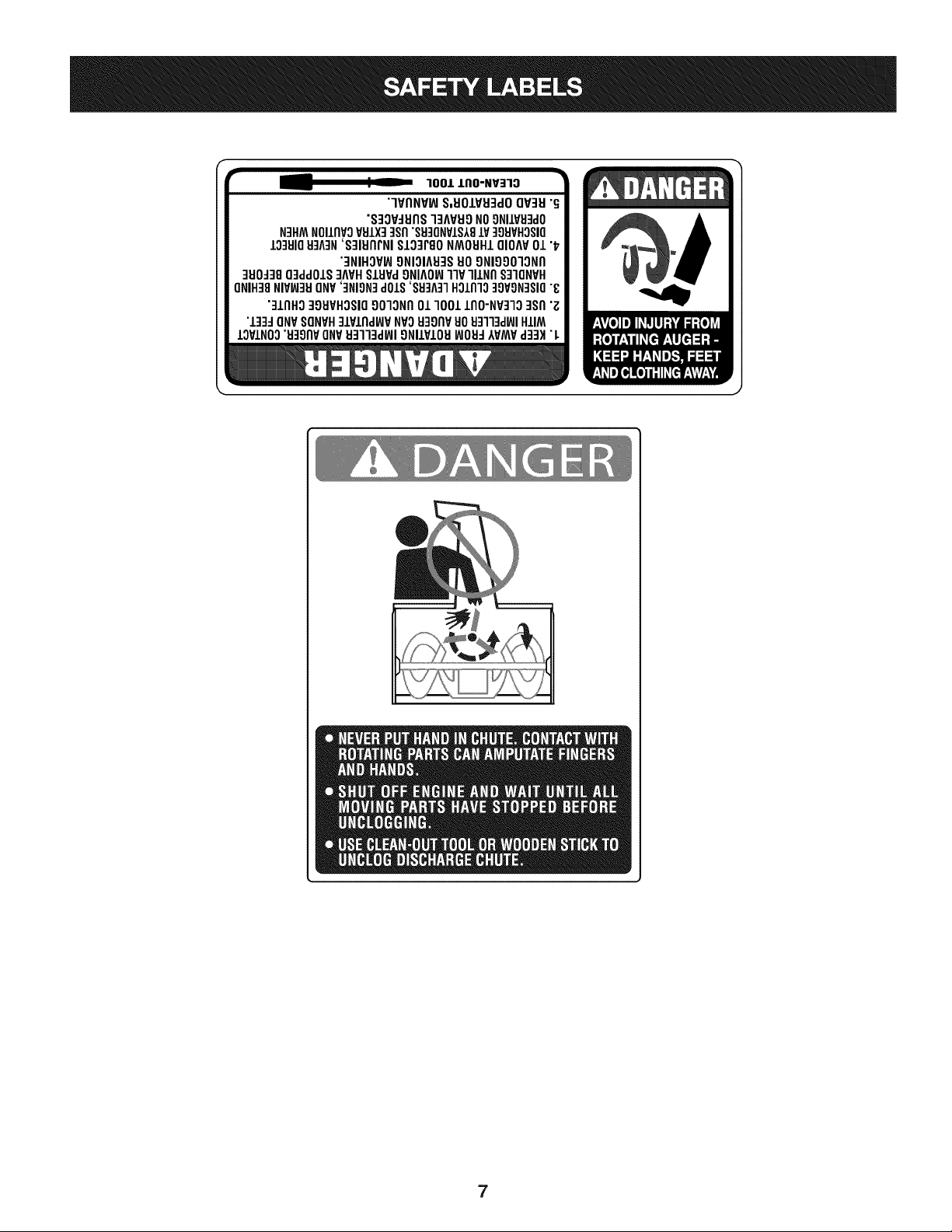

ASSEMBLY

1. Makecertainthe springsatthelowerendofthe augeranddrive

cablesaresecurelyhookedintotheir respectiveactuator

bracketsbeforepivotingthehandleupward.Referto Fig. 10.

a. Placethe speedselectorshiftleverin theF6 position.

b. Cutthecabletiesecuringthetwo piecechutecrankto the

lowerhandle.Thecable tieisusedforshippingpurposes.

c. Removethe upperwingknobandcarriageboltfromeach

sideof thelowerhandle.Pulluponupperhandleasshown

in Fig.1.Alignupperhandlewiththelowerhandle.Again,

makecertainthespringsat thelowerendoftheaugerand

drivecablesaresecurelyhookedintotheirrespective

actuatorbrackets.Also,removeanyrubberbandssecuring

thecablesto thewingnuts.

Tightenthetwowingknobsalreadyinstalledinthe upper

holesto firmlysecuretheupperhandleandsupporttubes.

See Fig.2.

f

!

{

/

/

Figure2

NOTE:Ifthe fullrangeofspeeds(forwardandreverse)cannotbe

achieved,refertothe "MakingAdjustments"section.

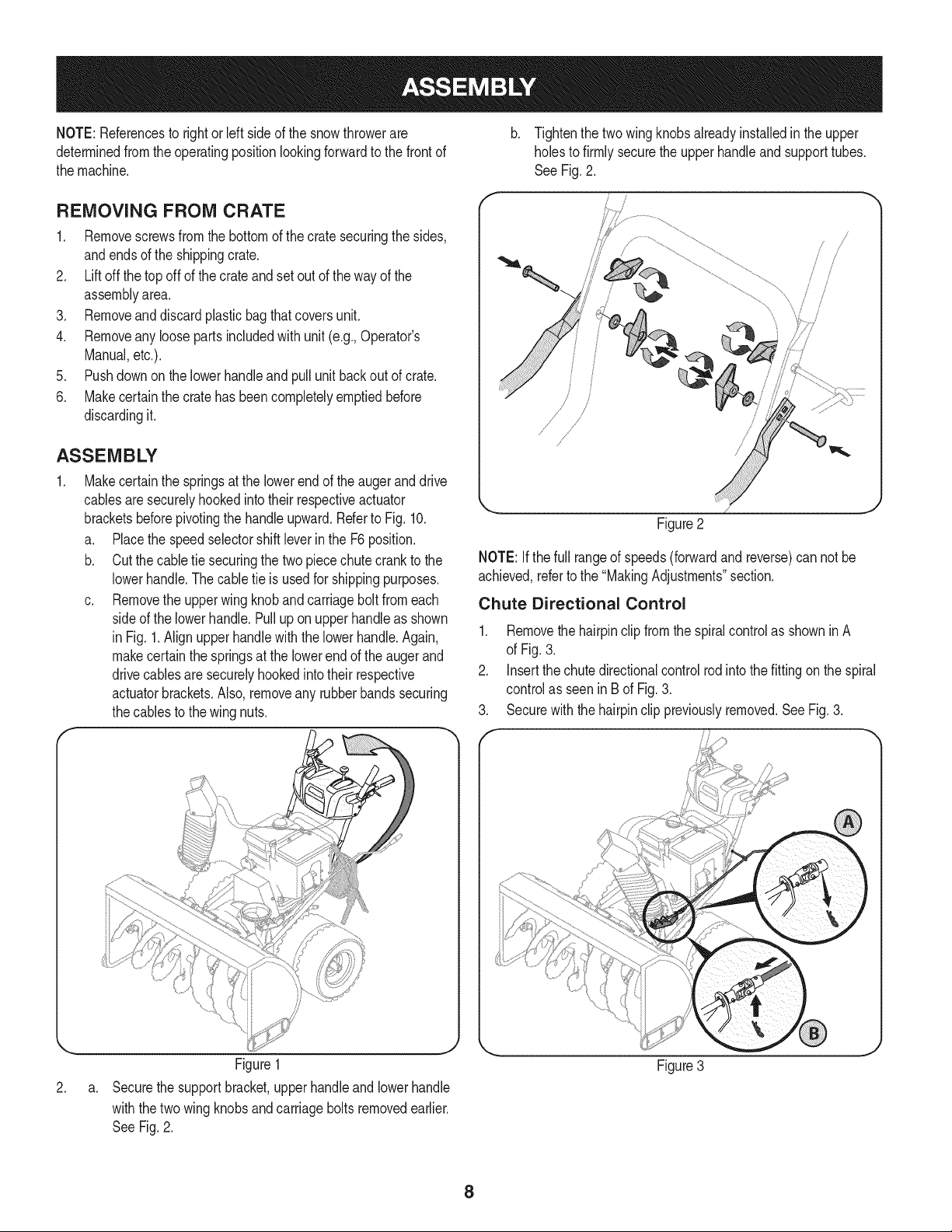

Chute Directional Control

1. Removethehairpinclipfromthespiralcontrolas showninA

of Fig.3.

2. Insertthechutedirectionalcontrolrodintothefittingonthe spiral

controlas seeninBof Fig.3.

3. Securewiththe hairpinclippreviouslyremoved.SeeFig.3.

\

Figure1

2.

a.

Securethesupportbracket,upperhandleandlowerhandle

Figure3

withthetwo wingknobsandcarriageboltsremovedearlier.

SeeFig.2.

8

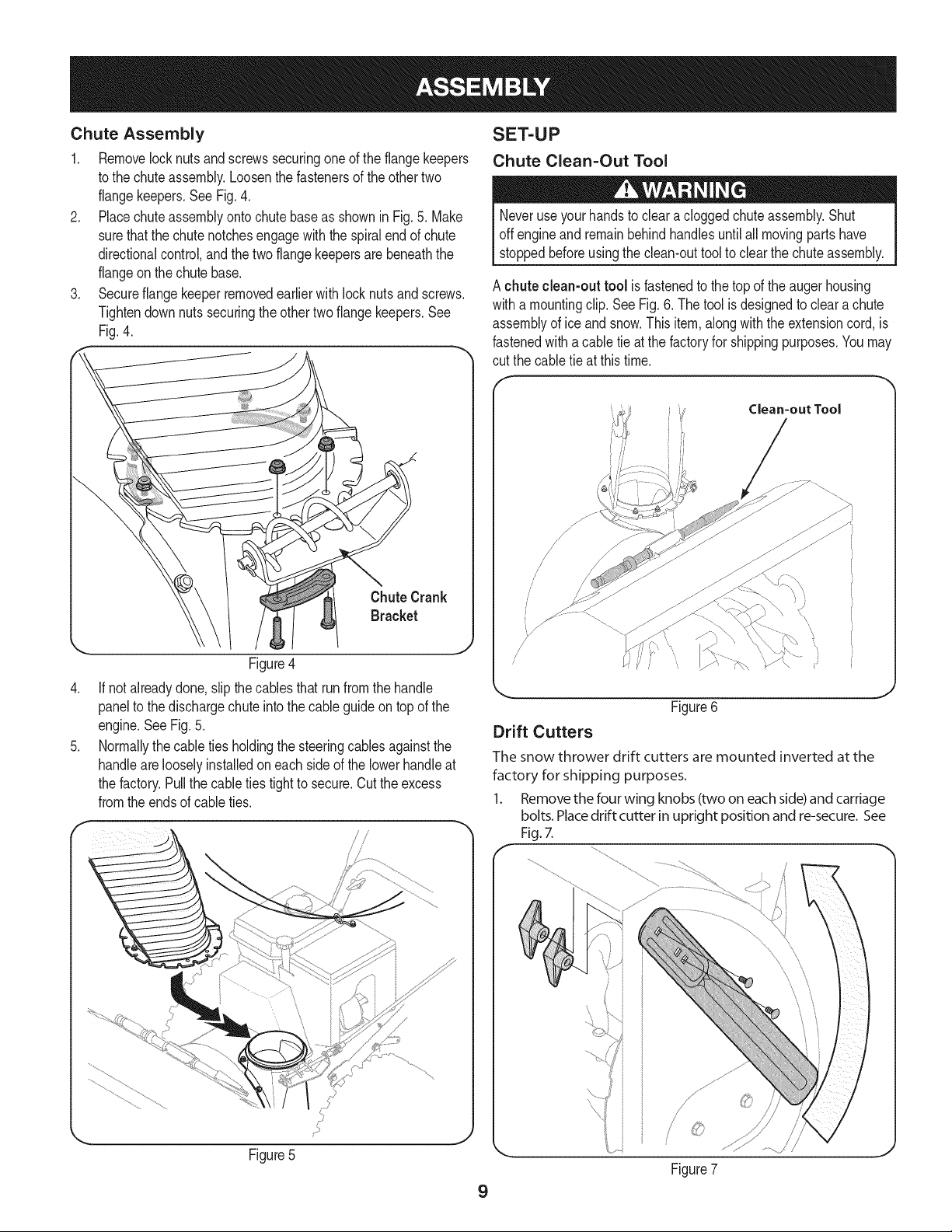

Chute Assembly

1, Removelocknutsandscrewssecuringoneof theflangekeepers

tothe chuteassembly,Loosenthefastenersoftheothertwo

flangekeepers,SeeFig,4,

2, Placechuteassemblyontochutebaseas showninFig,5,Make

surethatthe chutenotchesengagewiththespiralendofchute

directionalcontrol,andthe twoflangekeepersarebeneaththe

flangeonthe chutebase,

3, Secureflangekeeperremovedearlierwithlocknutsandscrews,

Tightendownnutssecuringtheothertwoflangekeepers.See

Fig.4.

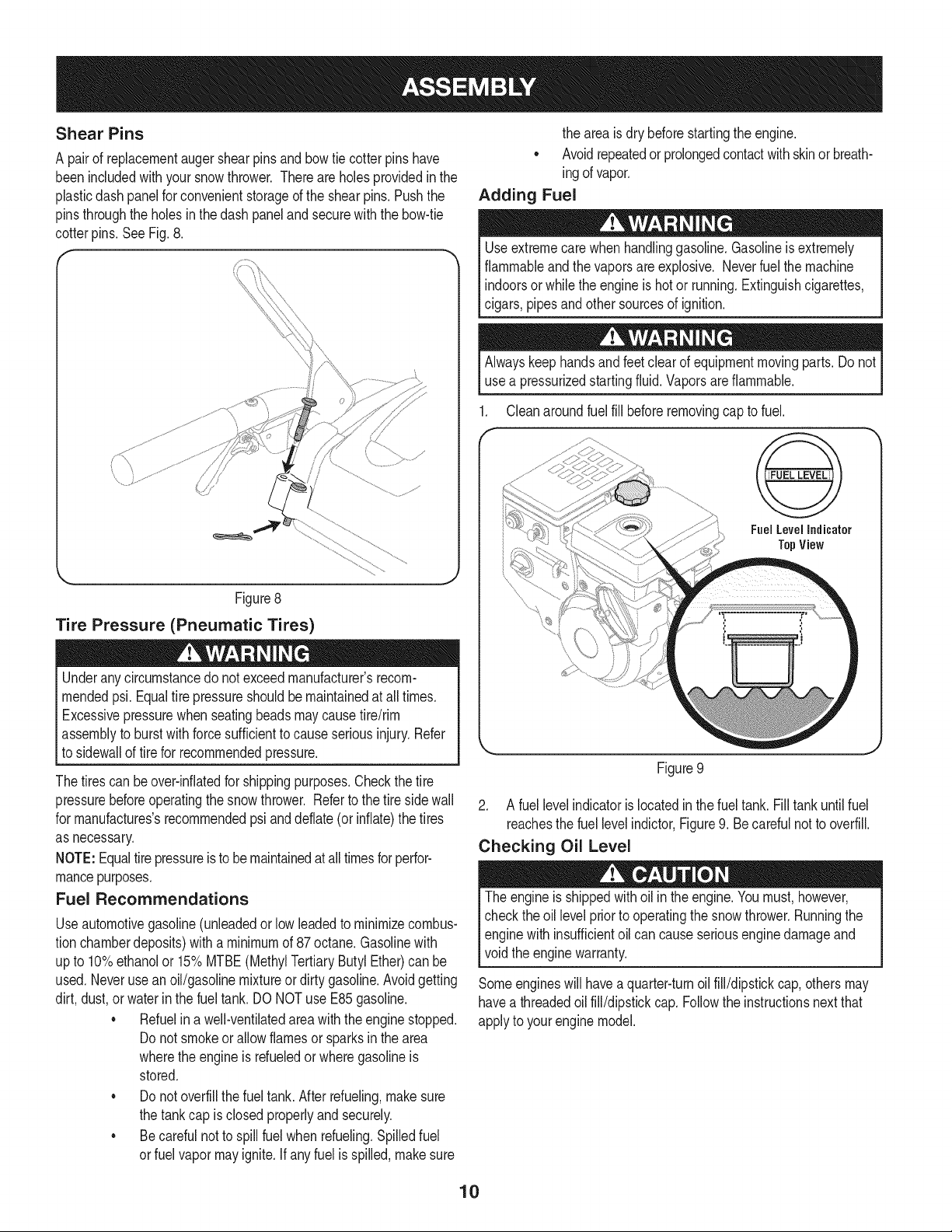

SET-UP

Chute Clean=Out Tool

Neveruseyourhandsto cleara cloggedchuteassembly.Shut

offengineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeusingtheclean-outtooltoclearthechuteassembly,

A chuteclean-outtool is fastenedtothetop oftheaugerhousing

witha mountingclip. SeeFig.6. Thetoolisdesignedtoclearachute

assemblyofice andsnow.Thisitem,alongwiththeextensioncord,is

fastenedwitha cabletieatthefactoryforshippingpurposes.Youmay

cut thecabletieatthistime.

Clean=out Tool

Figure4

.

If notalreadydone,slipthecablesthat runfromthehandle

paneltothe dischargechuteintothecableguideontopof the

engine.SeeFig.5.

.

Normallythecabletiesholdingthe steeringcablesagainstthe

handlearelooselyinstalledoneachsideofthe lowerhandleat

thefactory.Pullthecableties tighttosecure.Cuttheexcess

fromtheendsof cableties.

\,

//

//

(,

Figure6

Drift Cutters

The snow thrower drift cutters are mounted inverted at the

factory for shipping purposes.

1. Removethe four wing knobs (twooneachside)andcarriage

bolts.Placedrift cutter in upright positionand re-secure.See

Fig.7.

ii

J

J

Figure7

9

Shear Pins

A pairof replacementaugershearpinsandbowtiecotterpinshave

beenincludedwithyour snowthrower.Thereareholesprovidedinthe

plasticdashpanelforconvenientstorageofthe shearpins.Pushthe

pinsthroughtheholesin thedashpanelandsecurewiththebow-tie

cotterpins.See Fig.8.

theareais drybeforestartingtheengine.

• Avoidrepeatedor prolongedcontactwithskinorbreath-

ingofvapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelthemachine

indoorsorwhile theengineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

Alwayskeephandsandfeetclear ofequipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsareflammable.

Cleanaroundfuel fillbeforeremovingcap tofuel.

Fuel Level Indicator

TopView

Figure8

Tire Pressure (Pneumatic Tires)

Underanycircumstancedo notexceedmanufacturer'srecom-

mendedpsi.Equaltire pressureshouldbemaintainedatalltimes.

Excessivepressurewhenseatingbeadsmaycausetire/rim

assemblytoburstwithforcesufficienttocauseseriousinjury.Refer

to sidewalloftireforrecommendedpressure.

Thetirescan beover-inflatedforshippingpurposes.Checkthetire

pressurebeforeoperatingthesnowthrower. Refertothetiresidewall

for rnanufactures'srecommendedpsianddeflate(or inflate)thetires

as necessary.

NOTE:Equaltirepressureisto bemaintainedatalltimesforperfor-

mancepurposes.

Fuel Recommendations

Useautomotivegasoline(unleadedor lowleadedto minimizecombus-

tionchamberdeposits)witha minimumof87 octane.Gasolinewith

upto 10%ethanolor15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirtygasoline.Avoidgetting

dirt, dust,or waterinthefueltank.DO NOTuseE85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.

Donot smokeorallowflamesor sparksinthearea

wherethe engineis rdueledor wheregasolineis

stored.

• Donotoverfillthefueltank.Afterrefueling,makesure

thetankcap isclosedproperlyandsecurely.

• Becarefulnottospillfuel whenrefueling.Spilledfuel

or fuelvapormayignite.Ifanyfuelis spilled,makesure

Figure9

2. A fuellevelindicatorislocatedinthe fueltank. Filltankuntilfuel

reachesthefuel levelindictor,Figure9.Becarefulnottooverfill.

Checking Oil Level

Theengineis shippedwithoil in theengine.Youmust,however,

checkthe oillevelpriorto operatingthesnowthrower.Runningthe

enginewith insufficientoil cancauseseriousenginedamageand

voidtheenginewarranty.

Someengineswillhavea quarter-turnoil fill/dipstickcap,othersmay

havea threadedoilfill/dipstickcap.Followthe instructionsnextthat

applyto yourenginemodel.

10

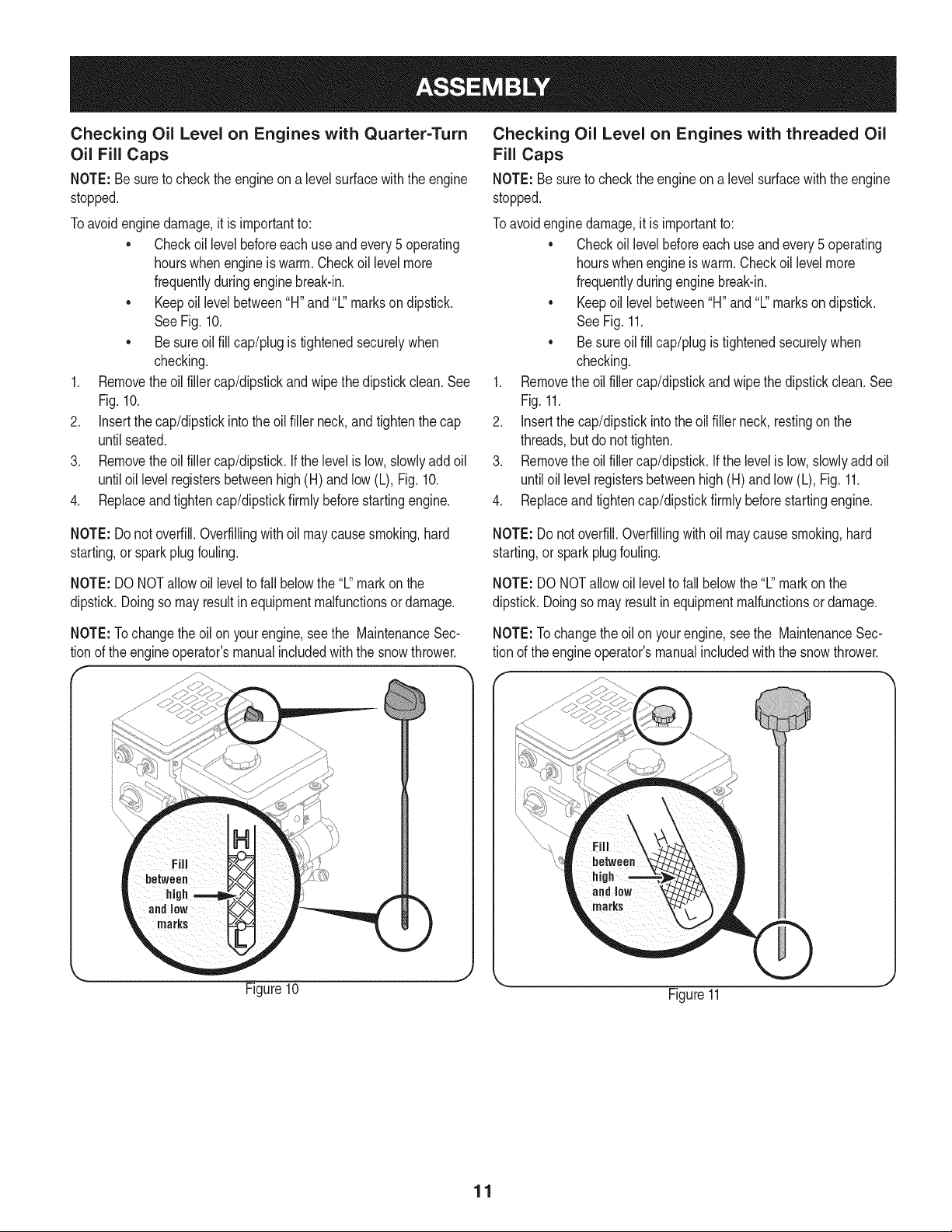

Checking Oil Level on Engines with Quarter=Turn

Oil Fill Caps

NOTE:Besuretochecktheengineona levelsurfacewiththeengine

stopped.

Toavoidenginedamage,itisimportantto:

• Checkoillevelbeforeeachuseandevery5 operating

hourswhenengineiswarm.Checkoillevelmore

frequentlyduringenginebreak-in.

• Keepoil levelbetween"H"and'%'marksondipstick.

SeeFig.10.

• Besureoil fillcap/plugistightenedsecurelywhen

checking.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Fig.10.

2. Insertthe cap/dipstickintotheoil fillerneck,andtightenthecap

untilseated.

3. Removetheoil fillercap/dipstick.Ifthelevelislow,slowlyaddoil

untiloil levelregistersbetweenhigh(H)andlow(L), Fig.10.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Checking Oil Level on Engines with threaded Oil

Fill Caps

NOTE:Besuretochecktheengineon a levelsurfacewiththeengine

stopped.

Toavoidenginedamage,itis importantto:

• Checkoillevelbeforeeachuseandevery5 operating

hourswhenengineiswarm.Checkoil levelmore

frequentlyduringenginebreak-in.

• Keepoillevelbetween"H"and"L"markson dipstick.

SeeFig.11.

• Besureoilfillcap/plugistightenedsecurelywhen

checking.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.See

Fig.11.

2. Insertthecap/dipstickintothe oilfillerneck,restingon the

threads,butdo nottighten.

3. Removethe oilfillercap/dipstick.Ifthe levelislow,slowlyaddoil

untiloillevel registersbetweenhigh(H)andlow (L),Fig.11.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:Donotoverfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

NOTE:DONOTallowoil leveltofallbelowthe"L"markonthe

dipstick.Doingsomayresultinequipmentmalfunctionsordamage.

NOTE:Tochangethe oilonyourengine,seethe MaintenanceSec-

tionof theengineoperator'smanualincludedwiththesnowthrower.

NOTE:Do notoverfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

NOTE:DO NOTallowoil leveltofallbelowthe"L"markon the

dipstick.Doingsomayresultinequipmentmalfunctionsor damage.

NOTE:Tochangetheoil onyourengine,seethe MaintenanceSec-

tionof theengineoperator'smanualincludedwiththe snowthrower.

Figure10

Figure11

11

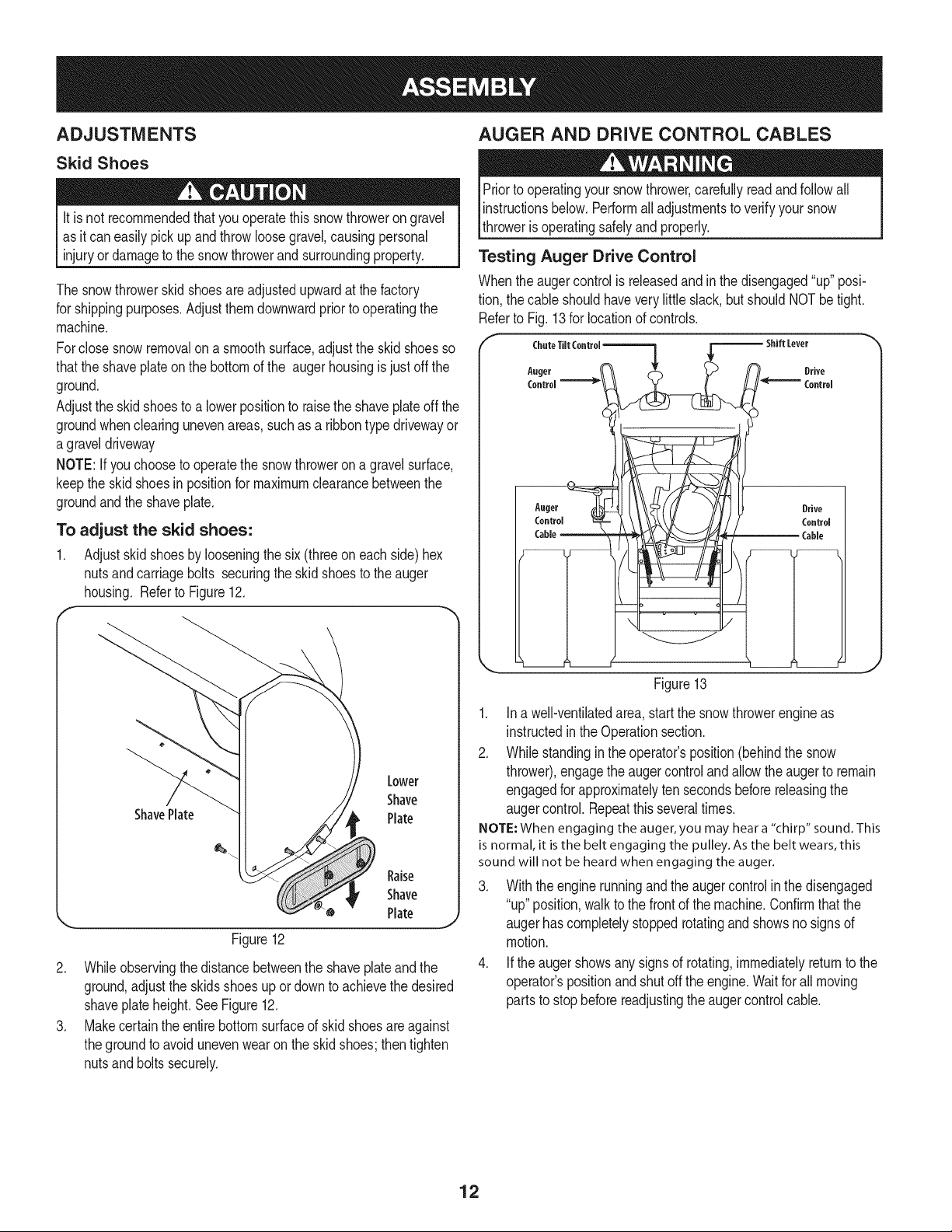

ADJUSTMENTS

Skid Shoes

Itisnot recommendedthatyouoperatethissnowthrowerongravel

asit caneasilypickupandthrowloosegravel,causingpersonal

injuryor damagetothesnowthrowerandsurroundingproperty.

Thesnowthrowerskidshoesareadjustedupwardatthefactory

forshippingpurposes.Adjustthemdownwardpriortooperatingthe

machine.

Forclosesnowremovalona smoothsurface,adjustthe skidshoesso

thattheshaveplateonthebottomof the augerhousingisjustoffthe

ground.

Adjusttheskidshoesto alowerpositiontoraisetheshaveplateoff the

groundwhenclearingunevenareas,suchas aribbontypedrivewayor

agraveldriveway

NOTE:If youchoosetooperatethesnowthrowerona gravelsurface,

keepthe skidshoesinpositionformaximumclearancebetweenthe

groundandtheshaveplate.

To adjust the skid shoes:

1. Adjustskidshoesby looseningthesix(threeon eachside)hex

nutsandcarriagebolts securingtheskidshoestotheauger

housing. RefertoFigure12.

f

AUGER AND DRIVE CONTROL CABLES

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

Testing Auger Drive Control

Whenthe augercontrolisreleasedandinthedisengaged"up" posi-

tion,thecableshouldhaveverylittleslack,butshouldNOTbetight.

RefertoFig.13for locationof controls.

r c,.,o,,,co.,°,-.--.-] :[------,,,.Levo,

,.ge, & n. D,,vo

H '°°"°'

Auter (_}J__ Drive

Lower

Shave

ShavePlate

Figure12

2. Whileobservingthedistancebetweentheshaveplateand the

ground,adjusttheskidsshoesupor downtoachievethedesired

shaveplateheight.SeeFigure12.

3. Makecertaintheentirebottomsurfaceof skidshoesareagainst

thegroundto avoidunevenwearontheskidshoes;thentighten

nutsandboltssecurely.

Plate

Raise

Shave

Plate

Figure13

1. Ina well-ventilatedarea,startthesnowthrowerengineas

instructedintheOperationsection.

2. Whilestandinginthe operator'sposition(behindthesnow

thrower),engagetheaugercontrolandallowthe augerto remain

engagedforapproximatelytensecondsbeforereleasingthe

augercontrol.Repeatthisseveraltimes.

NOTE: When engaging the auger, you may hear a "chirp" sound. This

is normal, it is the belt engaging the pulley. As the belt wears, this

sound will not be heard when engaging the auger.

3. Withtheenginerunningandthe augercontrolin thedisengaged

"up"position,walktothe frontofthe machine.Confirmthatthe

J

augerhascompletelystoppedrotatingandshowsnosignsof

motion.

4. Iftheaugershowsanysignsof rotating,immediatelyreturntothe

operator'spositionandshutofftheengine.Waitforall moving

partstostopbeforereadjustingthe augercontrolcable.

12

Testing Wheel Drive Control & Speed Selector Lever

RefertoFig.13forlocationofcontrols.

1. Movethespeedselectorshiftleverintosixth(6)position.

2. Withthewheeldrivecontrolreleased,pushthesnowthrowerforward,

thenpullitback.Themachineshouldmovefreely.

3. Engagethedrivecontrolandattempttomovethemachineboth

forwardandback,resistanceshouldbefelt.

4. Movethespeedselectorshiftleverintothefastreverse(R2)position

andrepeattheprevioustwosteps.

Ifyouexperiencedresistancerollingtheunit,eitherwhenrepositioning

thespeedselectorshiftleverfrom6toR2orwhenattemptingtomovethe

machinewiththedrivecontrolreleased,adjustthedrivecontrolimmedi-

ately.SeeAdjustingDriveandAugerControls.

Adjusting Wheel Drive & Auger Controls

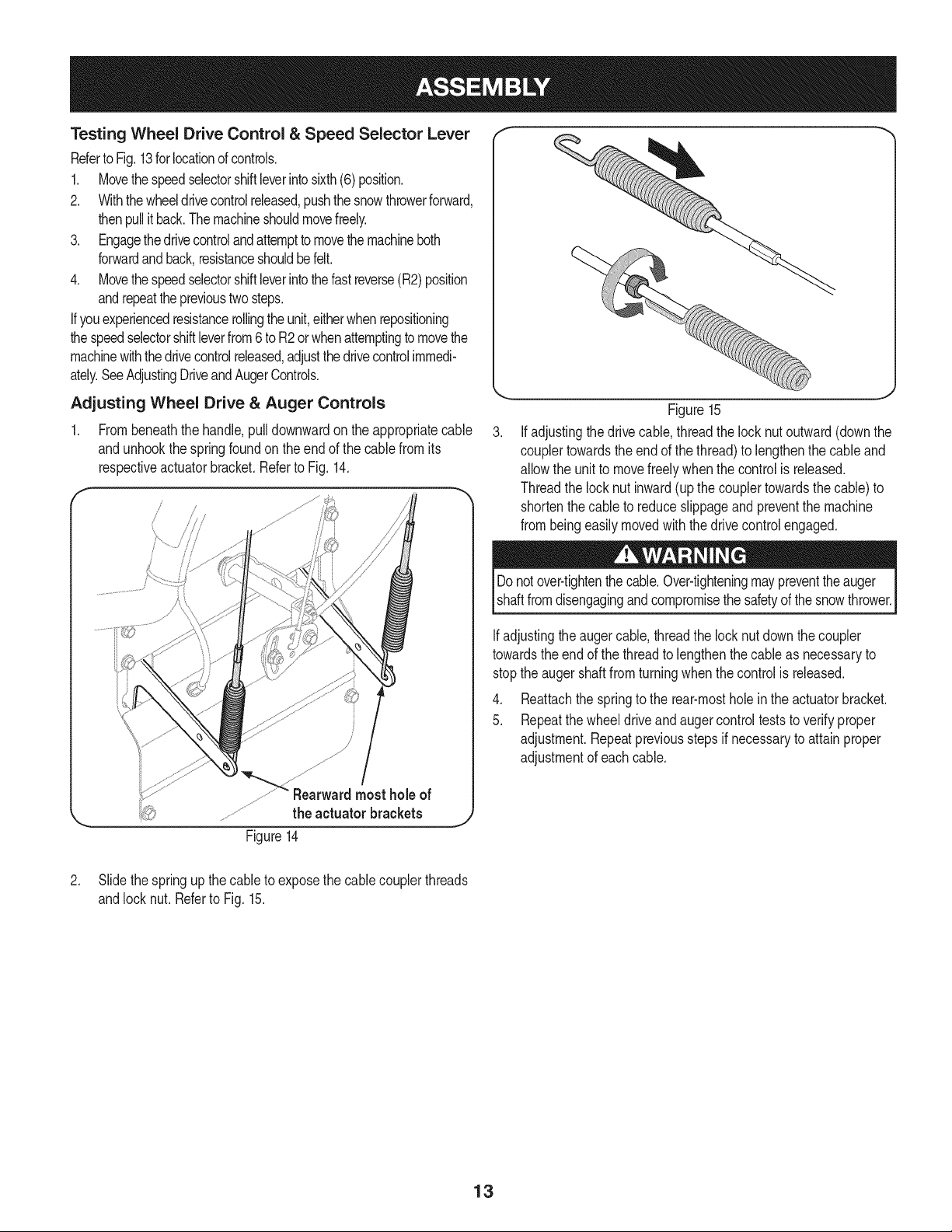

1. Frombeneaththehandle,pulldownwardontheappropriatecable

andunhookthespringfoundontheendofthecablefromits

respectiveactuatorbracket.RefertoFig.14.

J

Figure15

Ifadjustingthedrivecable,threadthelock nutoutward(downthe

couplertowardstheend ofthethread)tolengthenthecableand

allowthe unittomovefreelywhenthecontrolis released.

Threadthe locknutinward(upthecouplertowardsthecable)to

shortenthecableto reduceslippageandpreventthemachine

frombeingeasilymovedwiththedrive controlengaged.

Donotover-tightenthecable.Over-tighteningmaypreventtheauger

shaftfromdisengagingandcompromisethesafetyofthesnowthrower.

b_ Rearwardmost holeof

\.. theactuator brackets .1)

Figure14

2. Slidethespringup thecableto exposethecablecouplerthreads

andlocknut. Referto Fig.15.

Ifadjustingtheaugercable,threadthe locknutdownthecoupler

towardstheendofthe threadtolengthenthecableasnecessaryto

stoptheaugershaftfromturningwhenthecontrolis released.

4. Reattachthespringtothe rear-mostholeinthe actuatorbracket.

5. Repeatthewheeldriveandaugercontrolteststo verifyproper

adjustment.Repeatpreviousstepsifnecessarytoattainproper

adjustmentofeachcable.

13

"I- SpeedSelector '_

Lever

Drive 'Chute ControlTM

Control

Headli_

ChuteAssembly

WheelSteeringControl

Drift Cutters '_

Clean-outTool

Augers

\Auger

Housing

f

SkidShoes

Nowthat youhavesetupyoursnowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.RefertoFigure16.

SPEED SELECTOR SHIFT LEVER

Thespeedselectorshiftleveris locatedontherightside

ofthe handlepanel.Placethespeedselectorshiftlever

intoany ofeightpositionstocontrolthedirectionoftravel

andgroundspeed.

Forward

Yoursnowthrowerhassixforward(F) speeds.Position

one(1)isthe slowestand positionsix(6) isthefastest.

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is

theslowerandtwo (2) isthefaster.

6

5

4

3

t 2

F1

R1

Chute

Directional

Control

Oil Filler

Cap/Dipstick

PrimerKey

Throttle

OilDrain

Figure16

CHOKE CONTROL

Thechokecontrolisfoundon therearofthe

engineand isactivatedbyrotatingtheknob

counter-clockwise.Activatingthechokecontrol

closesthe chokeplateon thecarburetorandaids

in startingtheengine.

KEY

Thekeyis asafetydevice.It mustbefullyinserted

in orderfortheengineto start.Removethekey

whenthe snowthroweris notinuse.

NOTE:Donotturnthekeyinan attempttostart

theengine.Doingsomaycauseit tobreak.

Electric

Start

Button

Electric

Starter Outlet

RecoilStarter

Handle

J

R2

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

14

ThrottleControl

GAS CAP

Unthreadthe gascapto addgasolinetothefueltank.

OIL DRAIN

Engineoil canbedrainedthroughtheoildrain.

Thethrottlecontrolis locatedontherearoftheengine,it regulatesthe

speedof theengineandwillshutofftheenginewhenmovedintothe

STOPposition.

PRIMER

Depressingtheprimerforcesfuel directlyintotheengine'scarburetor

toaidin cold-weatherstarting.

Engineoil levelcanbecheckedandoiladded

OIL FILL I _Tp_._-

throughtheoilfill. |

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

AUGERS

Whenengaged,theaugersrotateanddrawsnowintotheauger

housing.

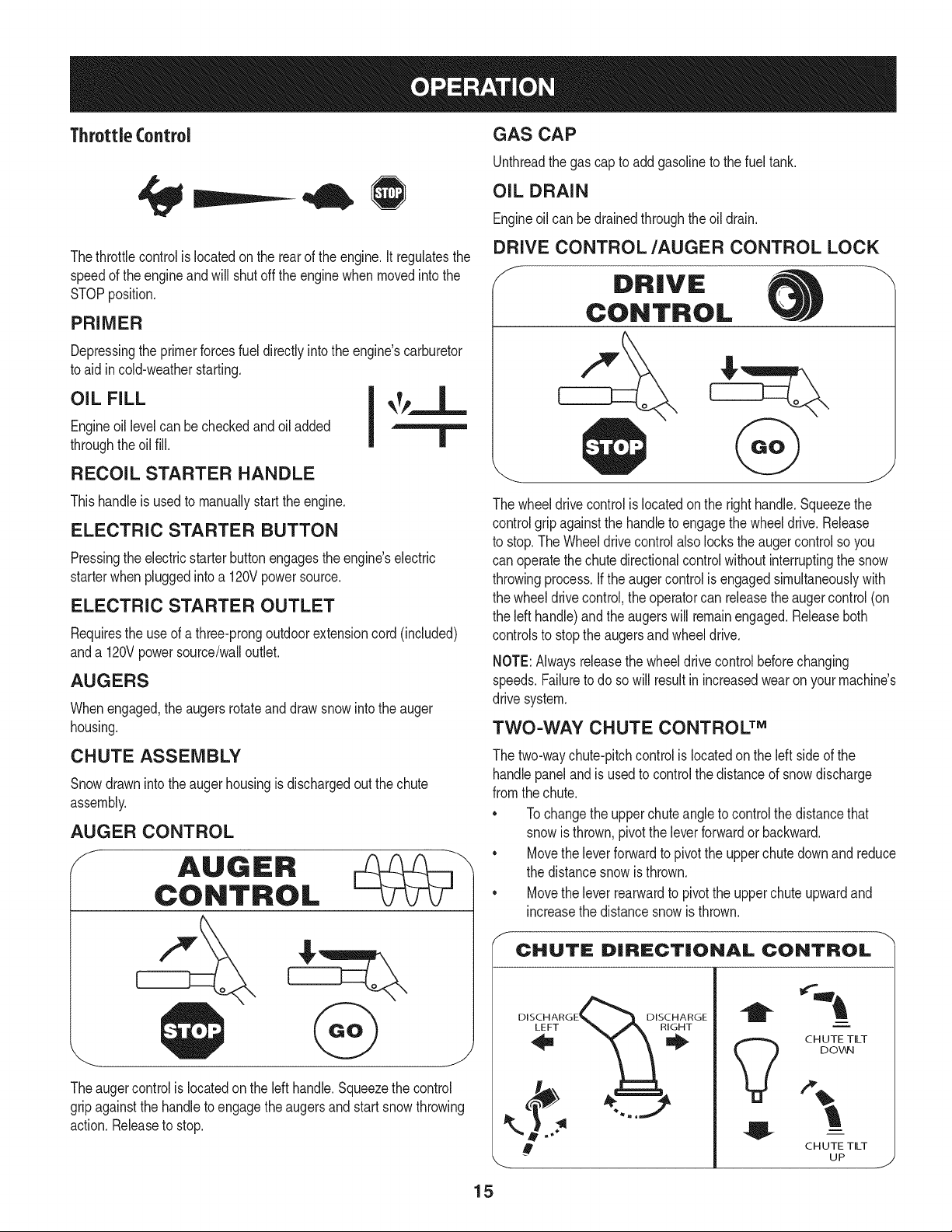

DRIVE CONTROL/AUGER CONTROL LOCK

f

DRIVE

CONTROL

Thewheeldrivecontrolis locatedonthe righthandle.Squeezethe

controlgrip againstthe handletoengagethe wheeldrive.Release

to stop.TheWheeldrivecontrolalsolockstheaugercontrolsoyou

canoperatethechutedirectionalcontrolwithoutinterruptingthe snow

throwingprocess.Iftheaugercontrolis engagedsimultaneouslywith

thewheeldrivecontrol,theoperatorcanreleasetheaugercontrol(on

theleft handle)andtheaugerswillremainengaged.Releaseboth

controlsto stoptheaugersandwheeldrive.

NOTE:Alwaysreleasethewheeldrivecontrolbeforechanging

speeds.Failuretodo sowillresultinincreasedwearonyourmachine's

drivesystem.

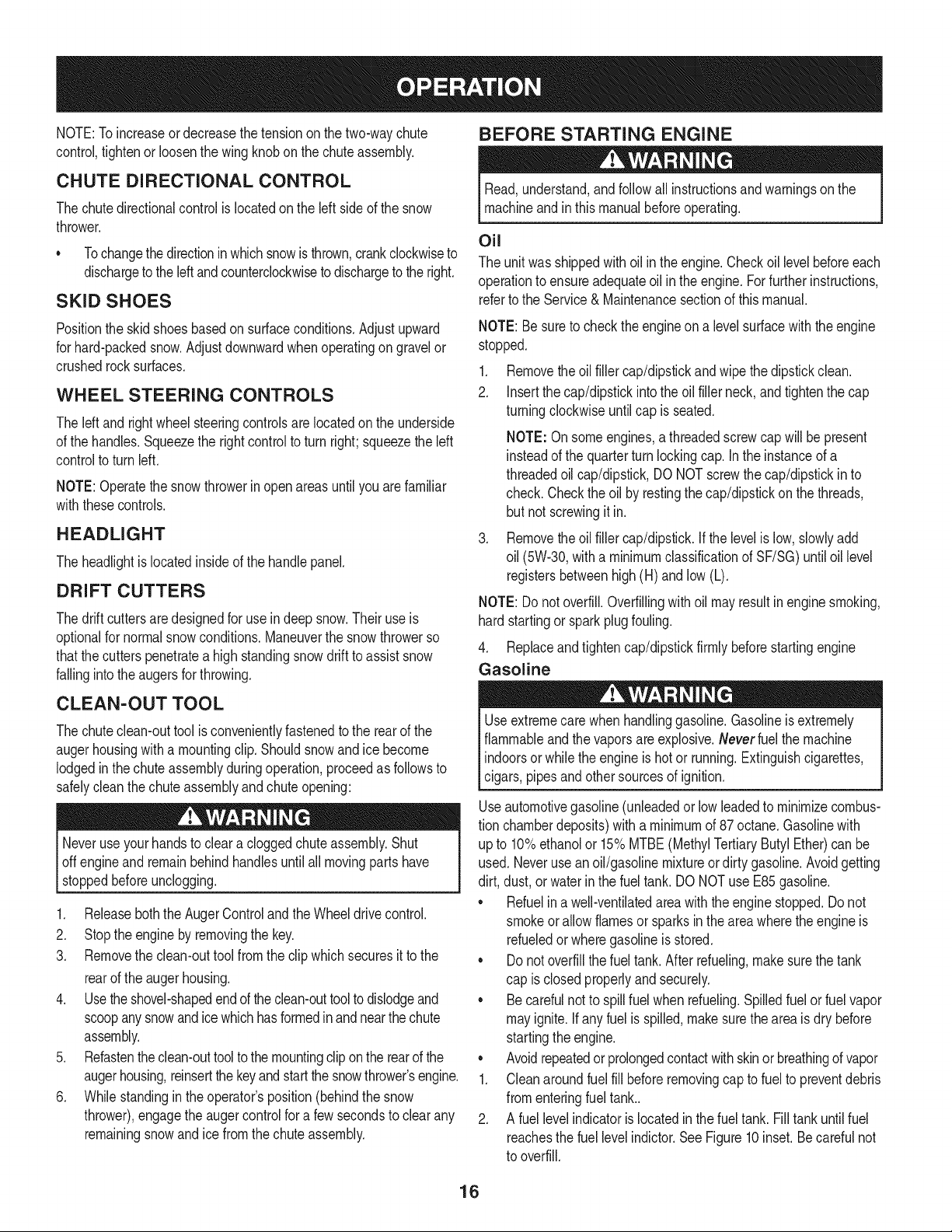

TWO-WAY CHUTE CONTROL TM

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedout thechute

assembly.

AUGER CONTROL

f

AUGER

CONTROL

Theaugercontrolis locatedontheleft handle.Squeezethecontrol

gripagainstthehandleto engagetheaugersandstartsnowthrowing

action.Releasetostop.

Thetwo-waychute-pitchcontrolislocatedonthe left sideofthe

handlepanelandisusedto controlthedistanceofsnowdischarge

fromthechute.

* Tochangetheupperchuteangleto controlthedistancethat

snowisthrown,pivottheleverforwardor backward.

* Movetheleverforwardtopivotthe upperchutedownand reduce

thedistancesnowisthrown.

* Movethelever rearwardtopivotthe upperchuteupwardand

increasethedistancesnowisthrown.

CHUTE DiRECTiONAL CONTROL

DISCHARGE_ DISCHARGE

CH UTE TILT

DOV_N

!

CH UTE TILT

UP

15

J

NOTE:Toincreaseordecreasethetensiononthe two-waychute

control,tightenorloosenthewing knobonthechuteassembly.

BEFORE STARTING ENGINE

CHUTE DIRECTIONAL CONTROL

Thechutedirectionalcontrolislocatedon theleftsideof thesnow

thrower.

• Tochangethedirectioninwhichsnowis thrown,crankclockwiseto

dischargeto theleftandcounterclockwiseto dischargeto theright.

SKID SHOES

Positiontheskidshoesbasedon surfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingongravelor

crushedrocksurfaces.

WHEEL STEERING CONTROLS

Theleftandrightwheelsteeringcontrolsarelocatedonthe underside

ofthe handles.Squeezetherightcontroltoturn right;squeezethe left

controltoturn left.

NOTE:Operatethesnowthrowerinopenareasuntilyou arefamiliar

withthesecontrols.

HEADLIGHT

Theheadlightislocatedinsideofthe handlepanel.

DRIFT CUTTERS

Thedrift cuttersaredesignedforuseindeepsnow.Theiruseis

optionalfornormalsnowconditions.Maneuverthesnowthrowerso

thatthecutterspenetrateahighstandingsnowdrifttoassistsnow

fallingintotheaugersforthrowing.

Read,understand,andfollowall instructionsand warningsonthe

machineandinthis manualbeforeoperating.

Oil

Theunitwasshippedwithoilin theengine.Checkoillevelbeforeeach

operationtoensureadequateoil inthe engine.Forfurtherinstructions,

refertotheService& Maintenancesectionofthis manual.

NOTE:Besuretochecktheengineona levelsurfacewiththeengine

stopped.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoil fillerneck,andtightenthecap

turningclockwiseuntilcap isseated.

NOTE:Onsomeengines,athreadedscrewcapwillbe present

insteadofthe quarterturnlockingcap.Intheinstanceofa

threadedoilcap/dipstick,DONOTscrewthecap/dipstickinto

check.Checktheoil byrestingthecap/dipstickonthethreads,

butnot screwingitin.

.

Removetheoilfiller cap/dipstick.Ifthelevelis low,slowlyadd

oil (5W-30,witha minimumclassificationofSF/SG)untiloil level

registersbetweenhigh(H)andlow (L).

NOTE:Donotoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingor sparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine

Gasoline

CLEAN-OUT TOOL

Thechuteclean-outtoolisconvenientlyfastenedtotherearof the

augerhousingwitha mountingclip.Shouldsnowandicebecome

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

Neveruseyourhandsto cleara cloggedchuteassembly.Shut

offengineand remainbehindhandlesuntil all movingpartshave

stoppedbeforeunclogging.

1. Releaseboththe AugerControlandtheWheeldrivecontrol.

2. Stopthe enginebyremovingthekey.

3. Removetheclean-outtoolfromtheclipwhichsecuresit tothe

rearofthe augerhousing.

4. Usetheshovel-shapedendof theclean-outtooltodislodgeand

scoopanysnowandicewhichhasformedinandnearthechute

assembly.

5. Refastentheclean-outtooltothemountingclipontherearof the

augerhousing,reinsertthe keyandstartthesnowthrower'sengine.

6. Whilestandinginthe operator'sposition(behindthesnow

thrower),engagetheaugercontrolfora fewsecondstoclearany

remainingsnowandice fromthechuteassembly.

Useextremecarewhenhandlinggasoline.Gasolineis extremely

flammableandthevaporsare explosive.Neverfuelthemachine

indoorsorwhiletheengineis hotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

Useautomotivegasoline(unleadedor lowleadedto minimizecombus-

tionchamberdeposits)witha minimumof87 octane.Gasolinewith

up to 10%ethanolor15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirtygasoline.Avoidgetting

dirt, dust,or waterinthefueltank.DO NOTuseE85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksintheareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.After refueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuel whenrefueling.Spilledfuelorfuelvapor

mayignite.Ifanyfuelis spilled,makesuretheareaisdrybefore

startingthe engine.

• Avoidrepeatedor prolongedcontactwithskinorbreathingofvapor

1. Cleanaroundfuelfillbeforeremovingcaptofueltopreventdebris

fromenteringfueltank..

2. A fuellevelindicatorislocatedinthe fueltank. Filltankuntilfuel

reachesthefuel levelindictor.SeeFigure10inset.Becarefulnot

tooverfill.

16

STARTING THE ENGINE Recoil Starter

Alwayskeephandsandfeetclearofmovingparts.Donot usea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Allowtheengineto warmupfora fewminutesafterstarting.

Theenginewill notdevelopfullpoweruntilit reachesoperating

temperatures.

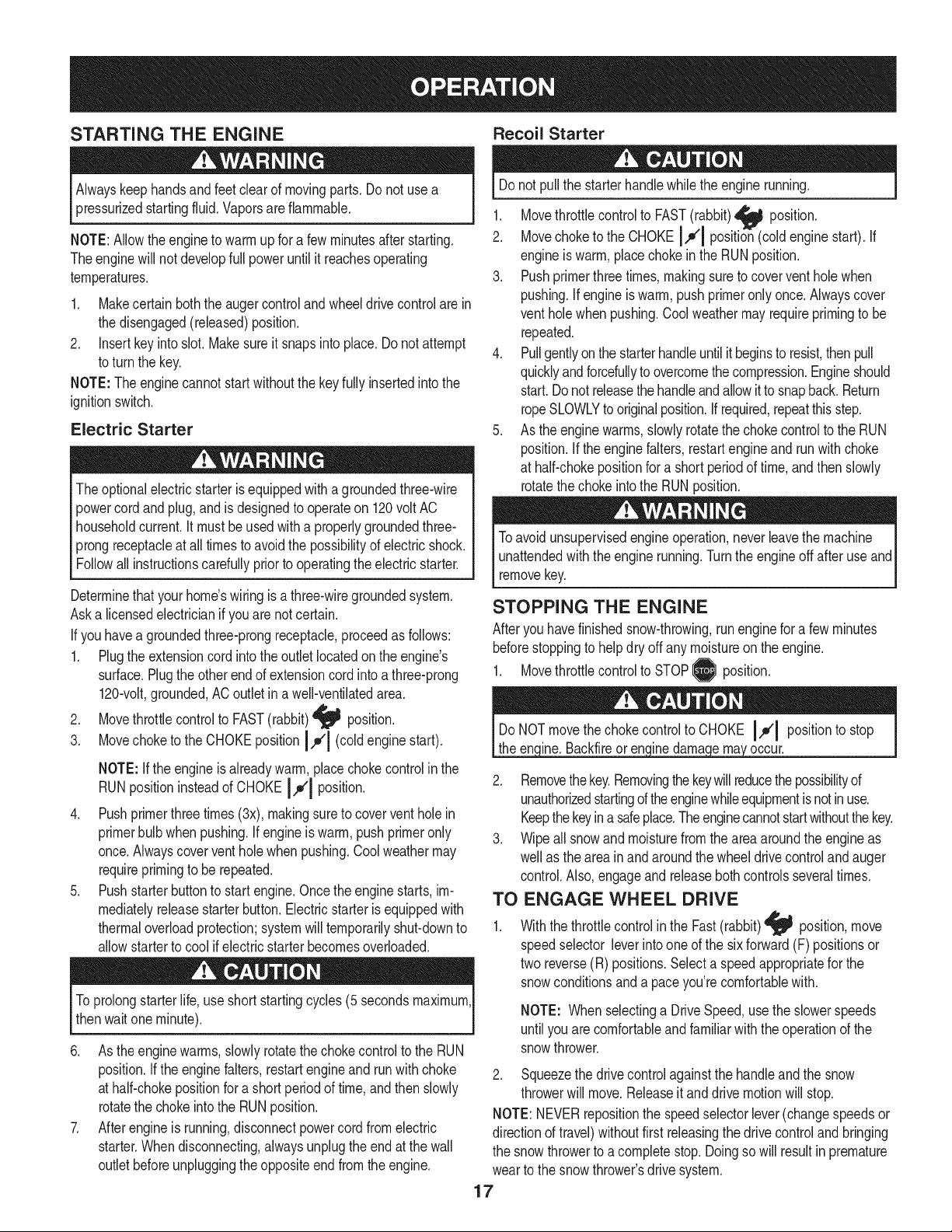

1. Makecertainboththe augercontrolandwheeldrivecontrolare in

thedisengaged(released)position.

2. Insertkeyintoslot.Makesureit snapsinto place.Donotattempt

toturnthekey.

NOTE:The enginecannotstartwithoutthekeyfullyinsertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarterisequippedwithagroundedthree-wire

powercordandplug,andis designedtooperateon 120voltAC

householdcurrent.Itmustbeusedwithaproperlygroundedthree-

prongreceptacleatalltimesto avoidthepossibilityof electricshock.

Followallinstructionscarefullypriortooperatingtheelectricstarter.

Determinethatyourhome'swiringisathree-wiregroundedsystem.

Aska licensedelectricianif youarenotcertain.

If youhaveagroundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordinto theoutletlocatedonthe engine's

surface.Plugtheotherendofextensioncordintoathree-prong

120-volt,grounded,ACoutletin awell-ventilatedarea.

2. Movethrottlecontrolto FAST(rabbit)_ position.

3. Movechoketothe CHOKEpositionI,._1 (coldenginestart).

NOTE:Ifthe engineisalreadywarm,placechokecontrolinthe

RUNpositioninsteadof CHOKEIJl position.

4. Pushprimerthreetimes(3x),makingsureto coverventholein

primerbulbwhen pushing.If engineis warm,pushprimeronly

once.Alwayscoverventholewhenpushing.Coolweathermay

requireprimingtobe repeated.

5. Pushstarterbuttontostart engine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarterisequippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocool ifelectricstarterbecomesoverloaded.

Toprolongstarterlife,useshortstartingcycles(5 secondsmaximum

thenwaitoneminute).

6. Astheenginewarms,slowlyrotatethe chokecontroltothe RUN

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfora shortperiodoftime,andthenslowly

rotatethechokeintothe RUNposition.

7. Afterengineisrunning,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendatthewall

outletbeforeunpluggingtheoppositeendfromtheengine.

Donot pullthestarterhandlewhile theenginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. MovechoketotheCHOKEIJl position'_'(coldenginestart).If

engineiswarm,placechokeinthe RUNposition.

3. Pushprimerthreetimes,makingsuretocoverventholewhen

pushing.If engineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingto be

repeated.

4. Pullgentlyonthestarterhandleuntilit beginsto resist,thenpull

quicklyandforcefullytoovercomethecompression.Engineshould

start.Donot releasethehandleandallowitto snapback.Return

ropeSLOWLYtooriginalposition.Ifrequired,repeatthisstep.

5. Astheenginewarms,slowlyrotatethe chokecontroltotheRUN

position.Ifthe enginefalters,restartengineand runwithchoke

at half-chokepositionfora shortperiodoftime,andthenslowly

rotatethechokeintotheRUNposition.

Toavoidunsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turntheengineoffafteruseand

removekey.

STOPPING THE ENGINE

Afteryouhavefinishedsnow-throwing,runenginefora fewminutes

beforestoppingto helpdry off anymoistureon the engine.

1. Movethrottlecontrolto STOPI_ position.

inc. Backfireoren( occur.

2. Removethekey.Removingthekeywillreducethepossibilityof

unauthorizedstartingof theenginewhileequipmentisnotinuse.

Keepthekeyinasafeplace.Theenginecannotstartwithoutthekey.

3. Wipeallsnowandmoisturefromtheareaaroundtheengineas

wellas theareain andaroundthewheeldrivecontrolandauger

control.Also,engageand releasebothcontrolsseveraltimes.

TO ENGAGE WHEEL DRIVE

1. Withthethrottlecontrolinthe Fast(rabbit)_ position,move

speedselector leverintooneofthesixforward(F)positionsor

two reverse(R) positions.Selecta speedappropriatefor the

snowconditionsanda paceyou'recomfortablewith.

NOTE: WhenselectingaDriveSpeed,usetheslowerspeeds

untilyouarecomfortableandfamiliarwiththeoperationofthe

snowthrower.

2. Squeezethe drivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseitanddrive motionwill stop.

NOTE:NEVERrepositionthespeedselectorlever(changespeedsor

directionoftravel)withoutfirstreleasingthedrivecontrolandbringing

thesnowthrowertoa completestop.Doingsowillresultin premature

wearto thesnowthrower'sdrivesystem.

17

TO ENGAGE AUGER

1. Toengagetheaugerandstartthrowingsnow,squeezetheauger

controlagainstthelefthandle.Releaseto stoptheaugers.

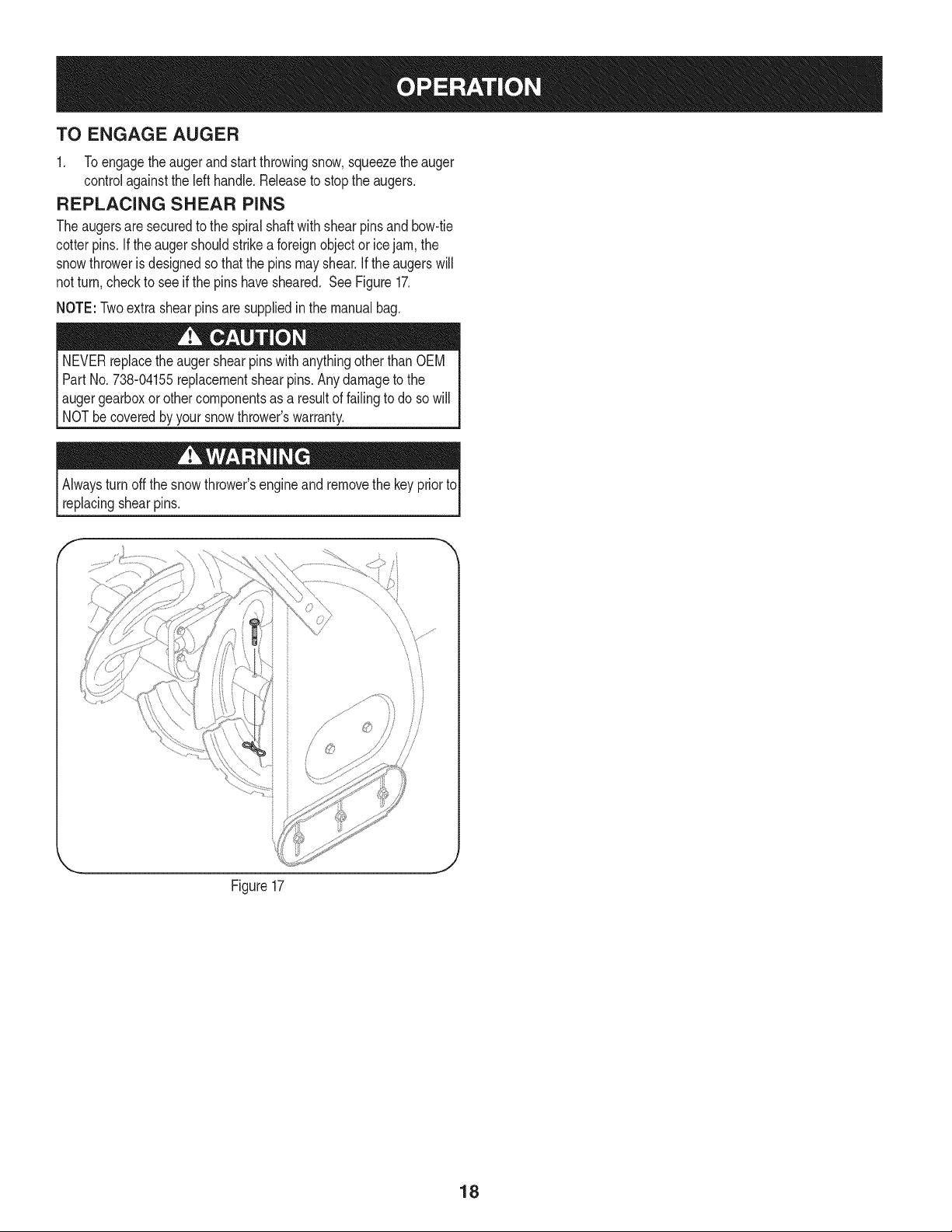

REPLACING SHEAR PINS

Theaugersaresecuredtothe spiralshaftwithshearpinsandbow-tie

cotterpins.Ifthe augershouldstrikeaforeignobjector icejam,the

snowthrowerisdesignedsothatthe pinsmayshear.If theaugerswill

notturn,checkto seeifthepinshavesheared.SeeFigure17.

NOTE:Twoextrashearpinsare suppliedinthemanualbag.

NEVERreplacetheaugershearpinswithanythingotherthanOEM

PartNo.738-04155replacementshearpins.Anydamagetothe

Iaugergearboxor othercomponentsas,a resultoffailingtodo sowill

[NOTbe coveredbyyoursnowthrowerswarranty.

Alwaysturnoff thesnowthrower'sengineand removethekeypriorto

replacingshearpins.

f-

Figure17

18

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo a

completestop.Removethekeytopreventunintendedstarting.Always

wearsafetyglassesduringoperationorwhileperforminganyadjustments

orrepairs.

EachUse

1st5 -8hours

25 hours

50 hours

Annuallyor100hours

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Engineoi11-

2. Controllinkagesand pivots

1. Engineoil

1. Sparkplug

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Lubewithlightoil

1. Change

1. Cleanandre-gap,orelse replace

withnewplug.

BeforeStorage 1. Fuelsystem

1. Runengineuntilit stopsfromlackof

fueloradda gasolineadditivetothe

gasin thetank.

Underheavyloador inhightemperatures

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocate the nearest SearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

= =

ENGINE MAINTENANCE

Checking Engine Oil

Beforelubricating,repairing,orinspecting,disengageallcontrolsand

stopengine.Waituntilallmovingpartshavecometoa completestop.

Removethekeytopreventunintendedfiringoftheengine.

NOTE: Checktheoil levelbeforeeachuseto besurecorrectoil level

ismaintained.

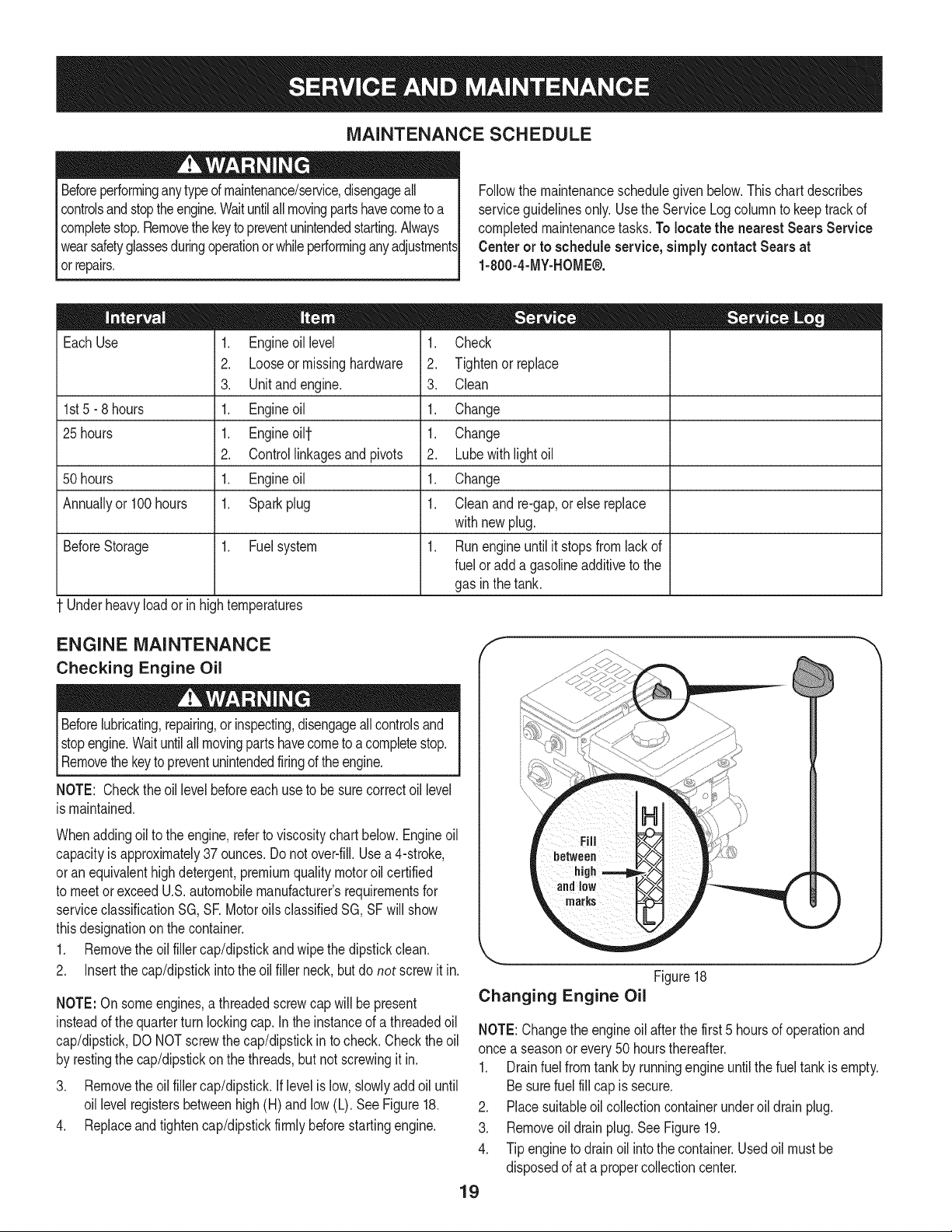

Whenaddingoilto theengine,refertoviscositychart below.Engineoil

capacityisapproximately37 ounces.Donotover-fill.Usea 4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG,SRMotoroilsclassifiedSG, SFwill show

thisdesignationonthecontainer.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthe cap/dipstickintotheoil fillerneck,butdo not screwit in.

NOTE:On someengines,athreadedscrewcapwillbepresent

insteadofthequarterturn lockingcap.Intheinstanceof a threadedoil

cap/dipstick,DONOTscrewthecap/dipstickin tocheck.Checktheoil

byrestingthe cap/dipstickonthe threads,butnotscrewingitin.

3. Removetheoilfillercap/dipstick,iflevelislow,slowlyaddoiluntil

oil levelregistersbetweenhigh(H) andlow(L). SeeFigure18.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

J

Figure18

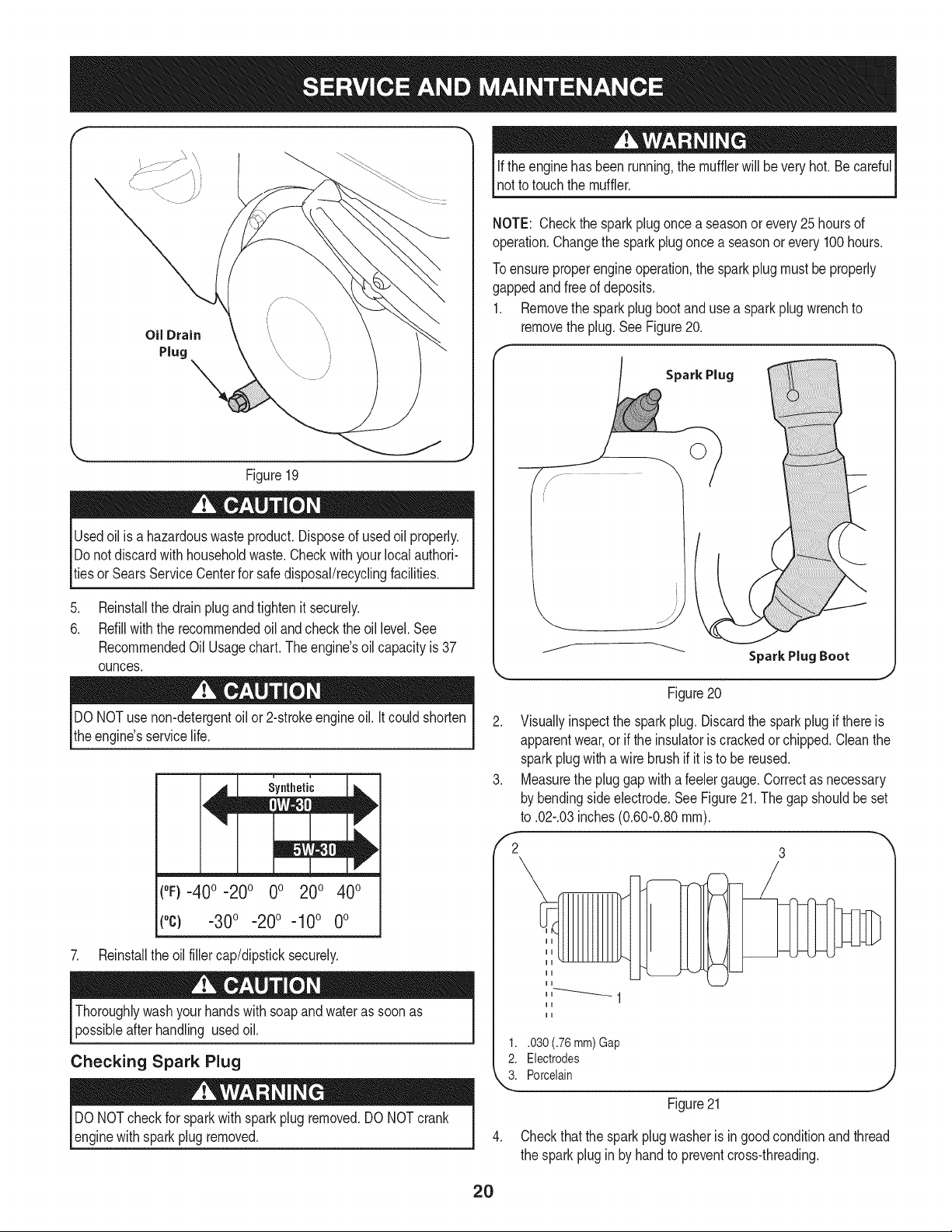

Changing Engine Oil

NOTE:Changetheengineoil afterthefirst5 hoursofoperationand

oncea seasonorevery50 hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefuel tankisempty.

Besurefuel fillcapis secure.

2. Placesuitableoilcollectioncontainerunderoil drainplug.

3. Removeoil drainplug.SeeFigure19.

4. Tipenginetodrainoil intothe container.Usedoil mustbe

disposedofat apropercollectioncenter.

19

f

Oil Drain

Plug

Figure19

Usedoil isa hazardouswasteproduct.Disposeof usedoilproperly.

Donotdiscardwith householdwaste.Checkwithyourlocalauthori-

tiesor SearsServiceCenterforsafedisposal/recyclingfacilities.

ifthe enginehasbeenrunning,themufflerwillbeveryhot.Becareful

notto touchthemuffler.

NOTE: Checkthesparkplugonceaseasonor every25 hoursof

operation.Changethe sparkplugoncea seasonorevery100hours.

Toensureproperengineoperation,the sparkplugmustbeproperly

gappedandfreeof deposits.

1. Removethesparkplugbootand usea sparkplugwrenchto

removetheplug.SeeFigure20.

Spark Plug

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoil andchecktheoil level.See

RecommendedOil Usage chart. The engine's oilcapacity is 37

ounces.

DONOTuse non-detergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

(°F}=40o =20o 0o 200 400

(°c) -30° -20° -10° 0°

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyourhandswithsoapandwateras soonas

possibleafterhandling usedoil.

Checking Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Figure20

2. Visuallyinspectthe sparkplug.Discardthe sparkplugif thereis

apparentwear,orif theinsulatoriscrackedorchipped.Cleanthe

sparkplugwithawirebrushifit istobe reused.

3. Measurethepluggapwitha feelergauge.Correctasnecessary

bybendingsideelectrode.SeeFigure21.Thegapshouldbe set

to .02-.03inches(0.60-0.80ram).

,'2 3

1..030 (.76 mm) Gap

2. Electrodes

k"_i Porcelain

Figure21

4. Checkthatthesparkplugwasheris ingoodconditionandthread

thesparkpluginby handtopreventcross-threading.

2O

5. Afterthe sparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthe washer.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthesparkplugseatsto

compressthewasher.

hotandcan ine.

CARBURETOR ADJUSTMENT

Thecarburetoris notuseradjustable.ContactSearsParts&Repairfor

adjustment.

LUBRICATION

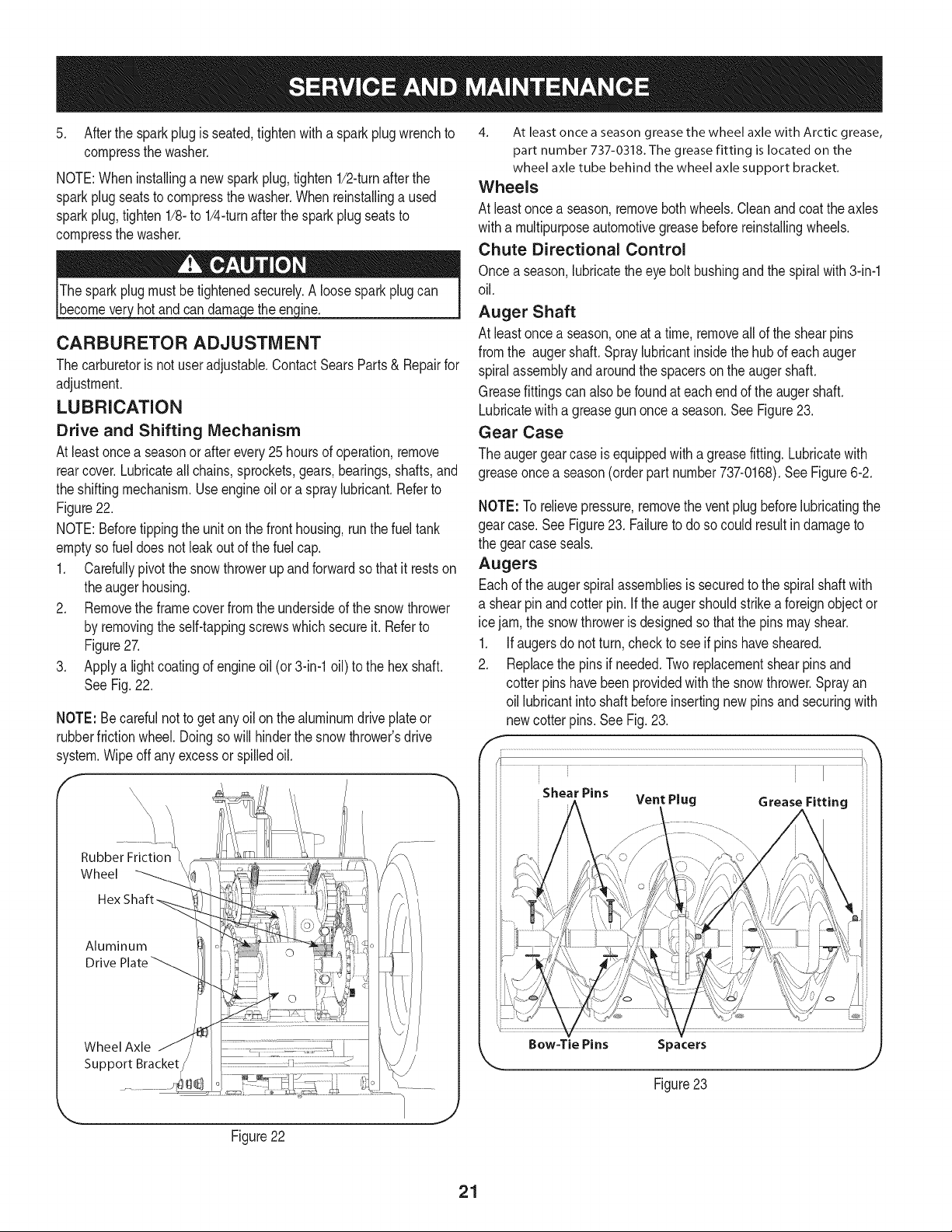

Drive and Shifting Mechanism

Atleastoncea seasonor afterevery25 hoursofoperation,remove

rearcover.Lubricateall chains,sprockets,gears,bearings,shafts,and

theshiftingmechanism.Useengineoilora spraylubricant.Referto

Figure22.

NOTE:Beforetippingtheunitonthe fronthousing,runthefueltank

emptyso fueldoesnotleakoutof thefuelcap.

1. Carefullypivotthesnowthrowerupandforwardsothat it restson

theaugerhousing.

2. Removetheframecoverfromtheundersideof thesnowthrower

byremovingtheself-tappingscrewswhichsecureit. Referto

Figure27.

3. Applya lightcoatingofengineoil (or3-in-1oil) tothehexshaft.

SeeFig.22.

NOTE:Becarefulnottoget anyoilon thealuminumdrive plateor

rubberfrictionwheel.Doingsowill hinderthesnowthrower'sdrive

system.Wipeoff anyexcessorspilledoil.

4. At least once a season grease the wheel axle with Arctic grease,

part number 737-0318. The grease fitting is located on the

wheel axle tube behind the wheel axle support bracket.

Wheels

At leastonceaseason,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Chute Directional Control

Onceaseason,lubricatetheeyeboltbushingandthespiralwith3-in-1

oil.

Auger Shaft

At leastonceaseason,oneatatime, removeallof theshearpins

fromthe augershaft.Spraylubricantinsidethehubofeachauger

spiralassemblyandaroundthe spacersontheaugershaft.

Greasefittingscan alsobe foundateachendof theaugershaft.

Lubricatewitha greasegunoncea season.SeeFigure23.

Gear Case

Theaugergearcaseis equippedwitha greasefitting.Lubricatewith

greaseoncea season(orderpartnumber737-0168).SeeFigure6-2.

NOTE:Torelievepressure,removetheventplugbeforelubricatingthe

gearcase.See Figure23. Failuretodosocouldresultindamageto

thegearcaseseals.

Augers

Eachoftheaugerspiralassembliesissecuredtothe spiralshaftwith

a shearpinandcotterpin.If theaugershouldstrikeaforeignobjector

icejam,the snowthrowerisdesignedsothatthepinsmayshear.

1. Ifaugersdonot turn,checkto seeif pinshavesheared.

2. Replacethepinsif needed.Tworeplacementshearpinsand

cotterpins havebeenprovidedwiththe snowthrower.Sprayan

oil lubricantintoshaftbeforeinsertingnewpinsand securingwith

newcotter pins.SeeFig.23.

i • i I ii

i Shear Pins ii:i

" Vent Plug Grease Fitting

Aluminum

Drive

Wheel Axle

Support Bracket

/ .............

Bow-Tie Pins Spacers

Figure23

Figure22

21

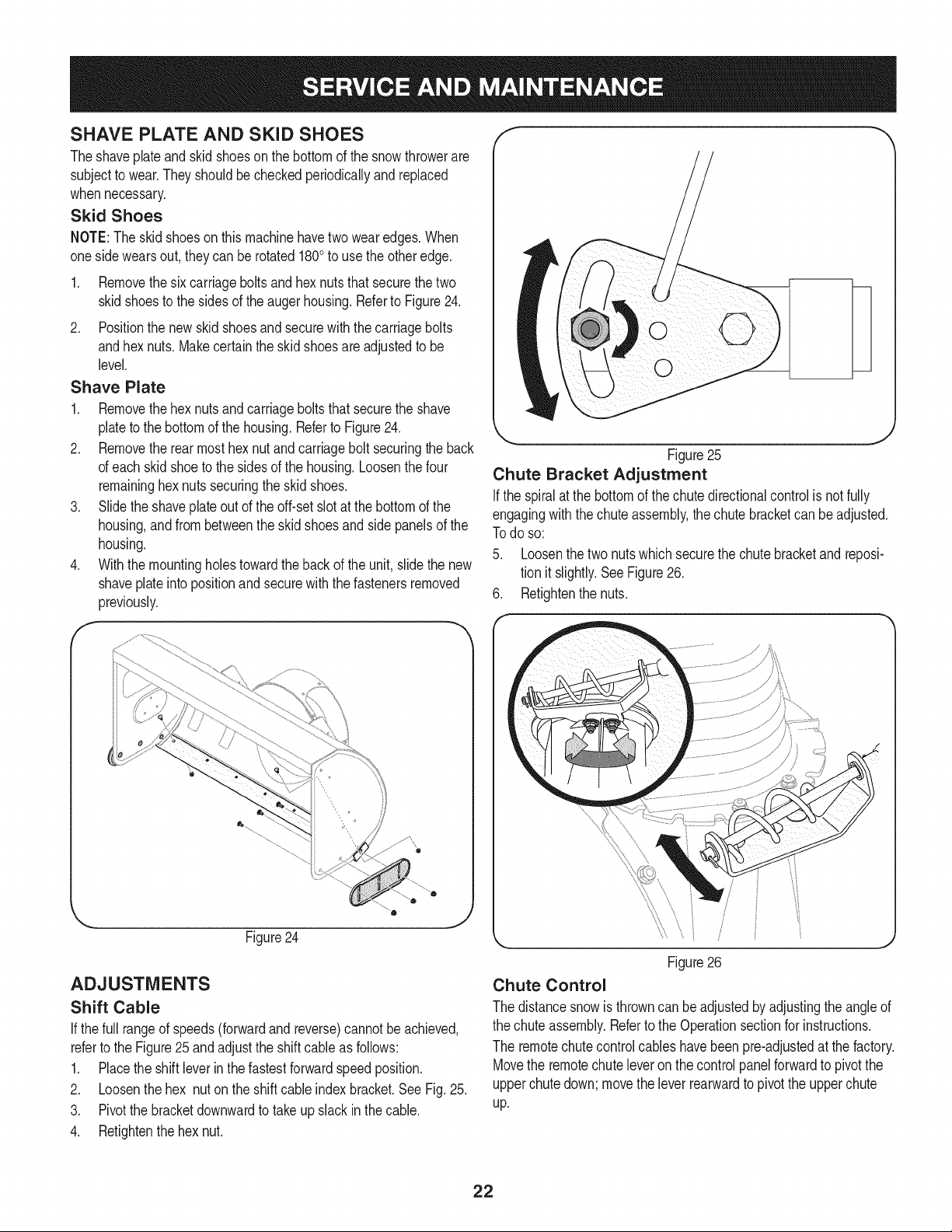

SHAVE PLATE AND SKiD SHOES

Theshaveplateand skidshoesonthebottomofthesnowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Skid Shoes

NOTE:Theskidshoesonthismachinehavetwowearedges.When

onesidewearsout, theycanberotated1800to usetheotheredge.

1. Removethesix carriageboltsandhexnutsthatsecurethetwo

skidshoestothe sidesoftheaugerhousing.RefertoFigure24.

2. Positionthenew skidshoesandsecurewiththecarriagebolts

andhexnuts.Makecertaintheskidshoesare adjustedtobe

level.

Shave Plate

1. Removethehexnutsandcarriageboltsthatsecuretheshave

plateto thebottomofthehousing.Referto Figure24.

2. Removetherearmosthexnutand carriageboltsecuringtheback

ofeachskidshoeto thesidesofthehousing.Loosenthefour

remaininghexnutssecuringtheskidshoes.

3. Slidetheshaveplateoutof theoff-setslotat thebottomofthe

housing,andfrombetweentheskidshoesandsidepanelsofthe

housing.

4. Withthemountingholestowardthebackof theunit,slidethenew

shaveplateinto positionandsecurewiththe fastenersremoved

previously.

f

k

J

Figure25

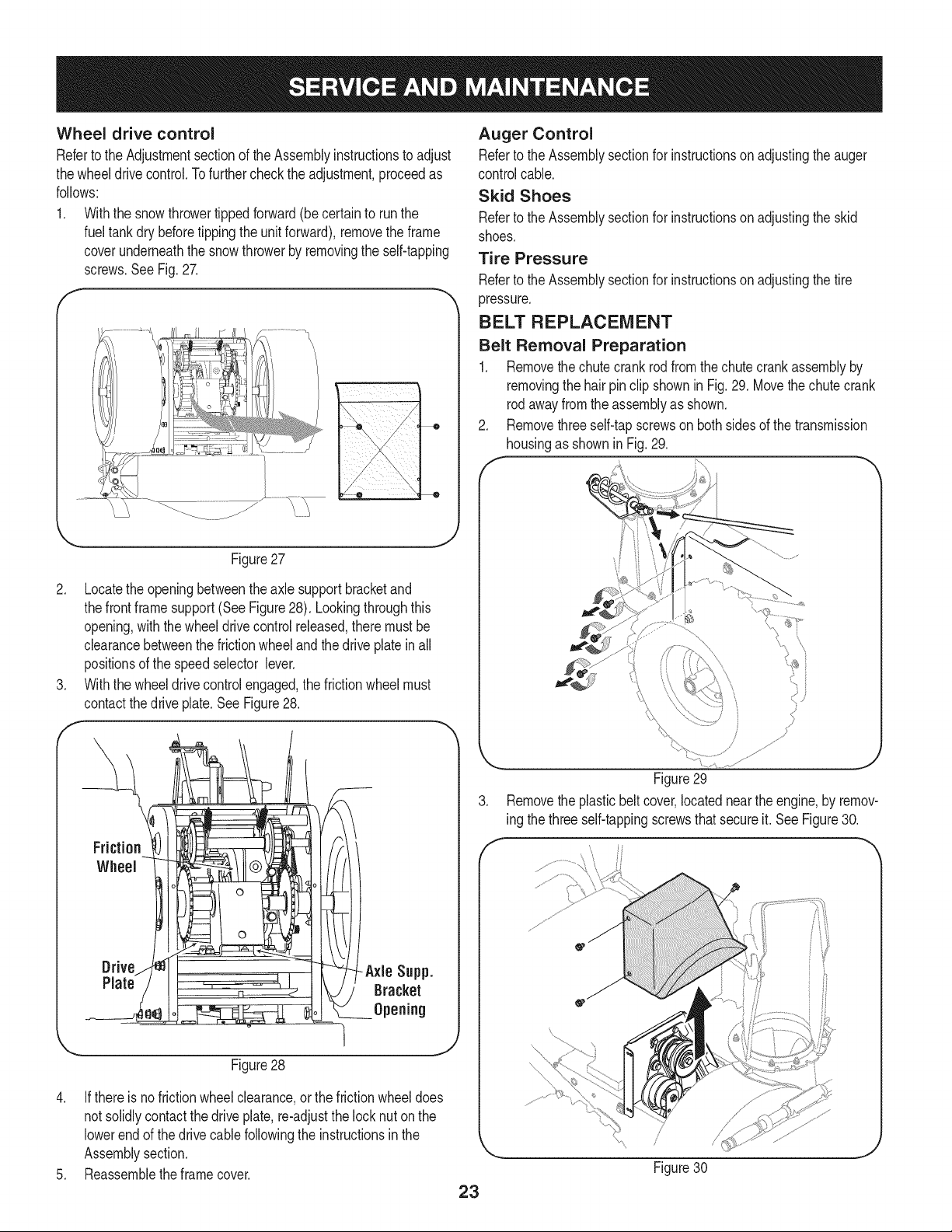

Chute Bracket Adjustment

Ifthespiralatthe bottomofthechutedirectionalcontrolis notfully

engagingwiththechuteassembly,thechutebracketcanbeadjusted.

Todo so:

5. Loosenthetwo nutswhichsecurethechutebracketandreposi-

tionit slightly.SeeFigure26.

6. Retightenthenuts.

0

Figure24

ADJUSTMENTS

Shift Cable

If thefull rangeofspeeds(forwardandreverse)cannotbeachieved,

referto theFigure25andadjusttheshiftcableasfollows:

1. Placetheshiftleverin thefastestforwardspeedposition.

2. Loosenthehex nuton theshiftcableindexbracket.SeeFig.25.

3. Pivotthebracketdownwardtotakeupslack inthecable.

4. Retightenthehexnut.

Figure26

Chute Control

Thedistancesnowisthrowncanbe adjustedbyadjustingtheangleof

thechuteassembly.Refertothe Operationsectionforinstructions.

Theremotechutecontrolcableshavebeenpre-adjustedat thefactory.

Movethe remotechuteleveronthecontrolpanelforwardtopivotthe

upperchutedown;movetheleverrearwardtopivottheupperchute

up.

22

Wheel drive control

Refertothe Adjustmentsectionofthe Assemblyinstructionsto adjust

thewheeldrivecontrol.Tofurtherchecktheadjustment,proceedas

follows:

1. Withthe snowthrowertippedforward(be certainto runthe

fueltankdry beforetippingtheunitforward),removetheframe

coverunderneaththesnowthrowerbyremovingtheself-tapping

screws.SeeFig.27.

J

Figure27

Auger Control

RefertotheAssemblysectionforinstructionson adjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionforinstructionson adjustingtheskid

shoes.

Tire Pressure

RefertotheAssemblysectionforinstructionson adjustingthetire

pressure.

BELT REPLACEMENT

Belt Removal Preparation

1. Removethechutecrankrodfromthechutecrankassemblyby

removingthe hairpinclip shownin Fig.29.Movethechutecrank

rodawayfromtheassemblyas shown.

Removethreeself-tapscrewson bothsidesof thetransmission

housingas showninFig.29.

2. Locatetheopeningbetweentheaxlesupportbracketand

thefrontframesupport(SeeFigure28). Lookingthroughthis

opening,withthe wheeldrivecontrolreleased,theremustbe

clearancebetweenthefrictionwheelandthe driveplateinall

positionsofthespeedselectorlever.

3. Withthewheeldrivecontrolengaged,thefrictionwheelmust

contactthedrive plate.SeeFigure28.

Drive -Axle Supp.

Plate Bracket

Opening

Figure29

3. Removethe plasticbeltcover,locatedneartheengine,by remov-

ing thethreeself-tappingscrewsthatsecureit.See Figure30.

f

Figure28

4. Ifthereisnofrictionwheelclearance,or thefrictionwheeldoes

notsolidlycontactthe driveplate,re-adjustthelocknuton the

lowerendof thedrivecablefollowingtheinstructionsinthe

Assemblysection.

5. Reassembletheframecover.

23

.

Loosentheboltshownin Figure31securingthebeltkeeper

bracketandremovetheotherbolt.Pushthebelt keeperand

bracketupoff theenginepulley.

Loosen

\

\

Figure31

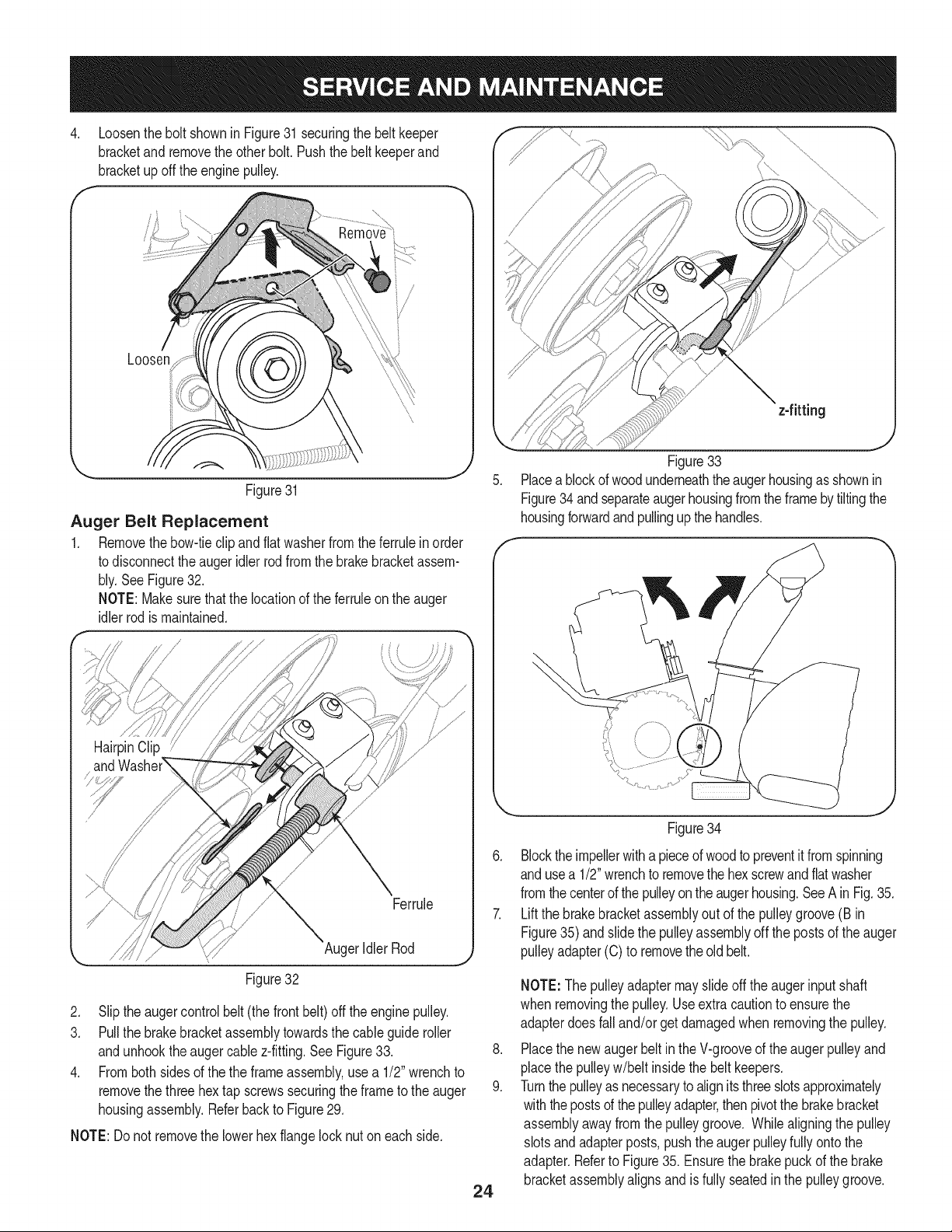

Auger Belt Replacement

1. Removethebow-tieclipandflatwasherfromtheferrulein order

todisconnecttheaugeridlerrodfromthebrakebracketassem-

bly.SeeFigure32.

NOTE:Makesurethatthelocationof theferruleontheauger

idlerrodismaintained.

HairpinClip

Ferrule

AugerIdlerRod

z-fitting

J

Figure33

Placeablockof woodunderneaththeaugerhousingasshownin

Figure34 andseparateaugerhousingfromtheframebytiltingthe

housingforwardandpullingupthehandles.

Figure34

6. Blocktheimpellerwithapieceofwoodtopreventitfromspinning

andusea 1/2"wrenchtoremovethehexscrewandflatwasher

fromthecenterofthepulleyontheaugerhousing.SeeAinFig.35.

7. Liftthebrakebracketassemblyoutofthe pulleygroove(B in

Figure35)andslide thepulleyassemblyoff the postsoftheauger

pulleyadapter(C)to removetheoldbelt.

Figure32

2. Sliptheaugercontrolbelt (thefrontbelt) offtheenginepulley.

3. Pullthebrakebracketassemblytowardsthecableguideroller

andunhooktheaugercablez-fitting.SeeFigure33.

4. Frombothsidesof thethe frameassembly,usea 1/2"wrenchto

removethethreehextap screwssecuringthe frametothe auger

housingassembly.Referbackto Figure29.

NOTE:Do notremovethelowerhexflangelocknutoneachside.

24

NOTE:Thepulleyadaptermayslideoff theaugerinputshaft

whenremovingthepulley.Useextracautionto ensurethe

adapterdoesfalland/or getdamagedwhen removingthepulley.

.

Placethenewaugerbeltin theV-grooveof theaugerpulleyand

placethepulleyw/belt insidethebeltkeepers.

9.

Turnthepulleyasnecessaryto alignitsthreeslotsapproximately

withthepostsofthepulleyadapter,thenpivotthe brakebracket

assemblyawayfromthepulleygroove. Whilealigningthepulley

slotsandadapterposts,pushtheaugerpulleyfullyontothe

adapter.RefertoFigure35.Ensurethebrakepuckofthebrake

bracketassemblyalignsandisfullyseatedin thepulleygroove.

Loading...

Loading...