MTD 31B-611D062 Owner’s Manual

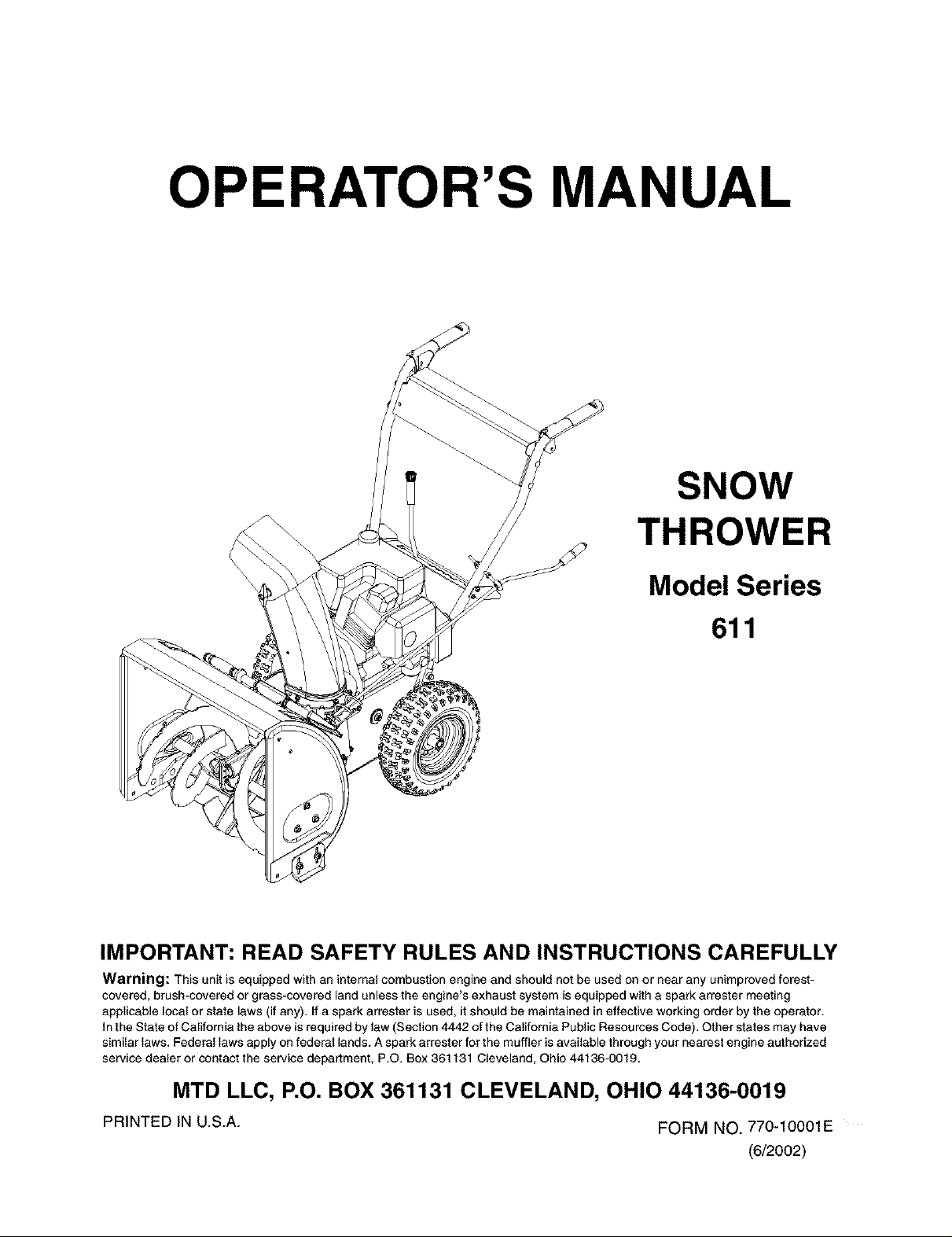

OPERATOR'S MANUAL

SNOW

THROWER

Model Series

611

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on ornear any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO. 770-10001E

(6/2002)

TABLEOFCONTENTS

Content Page

Important Safe Operation Practices ................................................................... 3

Hardware Pack .................................................................................................. 5

Assembling Your Snow Thrower ........................................................................ 6

Know Your Snow Thrower ................................................................................. 9

Operating Your Snow Thrower ........................................................................... 10

Making Adjustments .......................................................................................... 13

Maintaining Your Snow Thrower ........................................................................ 15

Service ............................................................................................................... 16

Troubleshooting ................................................................................................. 19

Parts List ............................................................................................................ 19

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new Snow Thrower. It will help you assemble, prepare

and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from ourCustomer Support Department or

an authorized dealer.

You can locate the model number by standing behind the unit in the operating position and looking

down at the dash panel. A sample model plate is explained below. For future reference, please copy

the model number and the serial number of the equipment inthe space below.

Copy the model number here:

ii ii iiii

Copy the serial number here:

www.mtdproducts.com 800-800-7310

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-

rating, specifications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's

Manual packed separately with your unit for more information.

CALLINGCUSTOMERSUPPORT

PleasedoNOTreturntheunitto theretailer fromwhichit waspurchased,withoutfirstcontactingCustomerSupport.

Should you have difficulty assembling this product or have any questions regarding the controls, operation

or maintenance of this unit, please call the Customer Support Department.

Call 1- (330) 220-4MTB (4683) or 1- (800)-800-7310 to reach a Customer Support

representative. Please have your unit's model number and serial number ready when you

call. See previous section to locate this information. You will be asked to enter the serial

number in order to process your call.

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

This symbol points out important safety instructions, which if not followed, could endanger the personal

safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symboliheed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer, birth defects or

other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation inthis

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

6.

TRAINING

1. Read, understand, and follow all instructions on the

machine and inthe manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow4hrowing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment is to

be used. Remove all doormats, newspapers, sleds,

boards, wires and other foreign objects, which could be

tripped over or thrown by the augedimpeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing, which could become entangled in moving

parts. Wear footwear which will improve footing on

slippery surfaces.

4. Use a grounded three-wire extension cord and

receptacle for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

Disengage all clutch levers before starting the engine.

7.

Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator's manual.

8.

Let engine and machine adjust to outdoor temperature

before starting to clear snow.

9.

To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes, which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasolinecontainer.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to nomore than

_/2inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline capand tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

j. Allow machine to cool at least 5 minutes before

storing.

OPERATION

1. Do not put hands or feet near rotating parts, in the auger/

impeller housing or discharge chute. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller clutch lever is a safety device. Never

bypass its operation. Doing so makes the machine

unsafe and may cause personal injury.

3. The clutch levers must operate easily in both directions

and automatically return to the disengaged position when

_leased.

4. Neveroperatewithamissingordamageddischarge

chute.Keepallsafetydevicesinplaceandworking.

5. Neverrunanengineindoorsorinapoorlyventilated

area.Engineexhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

6. Donotoperatemachinewhileundertheinfluenceof

alcoholordrugs.

7. Mufflerandenginebecomehotandcancauseaburn.Do

nottouch.

8. Exerciseextremecautionwhenoperatingonorcrossing

gravelsurfaces.Stayalertforhiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhile

operatingonslopes.

10.Planyoursnow-throwingpatterntoavoiddischarge

towardswindows,wails,carsetc.Thus,avoiding

possiblepropertydamageorpersonalinjurycausedbya

ricochet.

11.Neverdirectdischargeatchildren,bystandersandpets

orallowanyoneinfrontofthemachine.

12.Donotoverloadmachinecapacitybyattemptingtoclear

snowattoofastofarate.

13.Neveroperatethismachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfootingandkeepafirmhold

onthehandles.Walk,neverrun.

14.Disengagepowertotheauger/impellerwhen

transportingornotinuse.

15.Neveroperatemachineathightransportspeedson

slipperysurfaces.Lookdownandbehindandusecare

wheninreverse.

16.Ifthemachineshouldstarttovibrateabnormally,stopthe

engine,disconnectthesparkplugwireandgroundit

againsttheengine.Inspectthoroughlyfordamage.

Repairanydamagebeforestartingandoperating.

17.Disengageallclutchleversandstopenginebeforeyou

leavetheoperatingposition(behindthehandles).Wait

untiltheauger/impellercomestoacompletestopbefore

uncloggingthedischargechute,makingany

adjustments,orinspections.

18.Neverputyourhandinthedischargeorcollector

openings.Alwaysusetheclean-outtoolprovidedto

unclogthedischargeopening.Donotunclogdischarge

chutewhileengineisrunning.Shutoffengineandremain

behindhandlesuntilallmovingpartshavestopped

beforeunclogging.

19.Useonlyattachmentsandaccessoriesapprovedbythe

manufacturer(e.g.wheelweights,tirechains,cabsetc.).

20.Ifsituationsoccurwhicharenotcoveredinthismanual,

usecareandgoodjudgment.Contactyourdealeror

telephone1-800-800-7310forassistanceandthename

ofyournearestservicingdealer.

MAINTENANCEANDSTORAGE

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and

adjustment sections of this manual.

2. Before cleaning, repairing, or inspecting machine

disengage all clutch levers and stop engine. Wait until the

auger/impeller come to a complete stop. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original

equipment manufacturer's (OEM) parts only. "Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!"

6. Check dutch controls periodically to verify they engage

and disengage properly and adjust, ifnecessary. Refer to

the adjustment section in this operator's manual for

instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator's manual for proper

instructions on off-season storage.

power machine to persons who read,

WARNING: Restrict the use of this

understand and follow the warnings and

instructions in this manual and on the

machine.

5. READOPERATOR'SMANUAL.

C[.EAII-OUTTOOl.

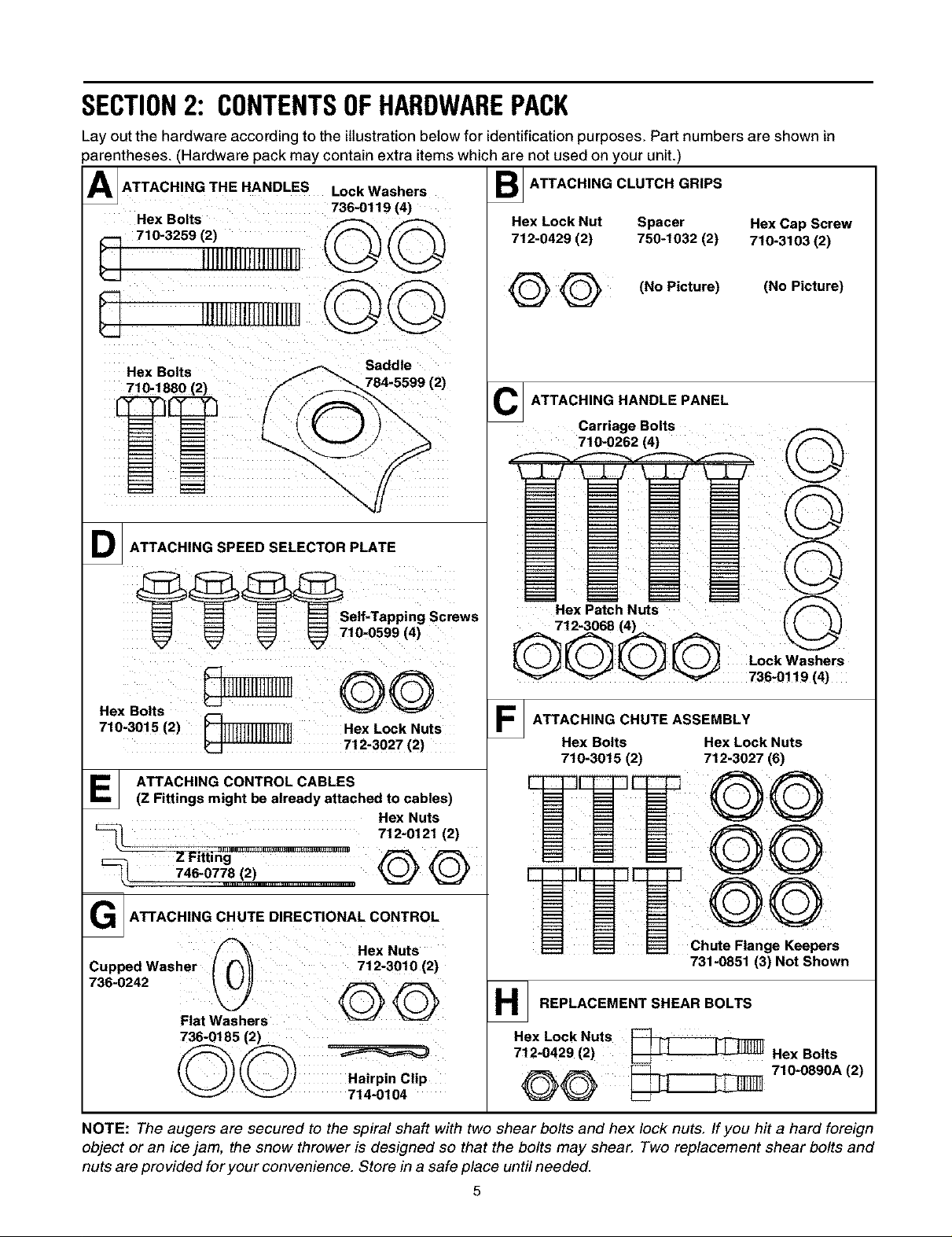

SECTION2: CONTENTSOFHARDWAREPACK

Lay out the hardware according to the illustration below for identification purposes. Part numbers are shown in

_arentheses. (Hardware pack may contain extra items which are not used on your unit.)

A_ ATTACHING THE HANDLES Lock Washers

736-0119 (4)

Hex Bolts _

ATTACHING CLUTCH GRIPS

Hex Lock Nut Spacer Hex Cap Screw

712-0429 (2) 750-1032 (2) 710-3103 (2)

8 '"'"''"""©@

Hex Bolts Saddle

7!0-!680 (2) 784.5599 (2)

D_ ATTACHING SPEED SELECTOR PLATE

Hex Bolts (--_

710.3015(2) _ Hex Lock Nuts

7!2,3027(2)

@@

C_ ATTACHING HANDLE PANEL

Carriage Bolts

710-0262 (4)

Hex Patch Nuts

712-3068 (4) i

____ Lock Washers

v _" v_ 736-0!!9 (4)

F_ ATTACHING CHUTE ASSEMBLY

Hex Bolts Hex Lock Nuts

710-3015 (2) 712-3027 (6)

(No Picture) (No Picture)

E_ ATTACHING CONTROL CABLES

(Z Fittings might be already attached to cables)

Hex Nuts

712-0121 (2)

746"0778..!2 _............................................. _

i ir-

G3 ATTAOH,NGCHUTED,REOTIONALCONTROL

Hex Nuts

Cupped Washer t ("_11 712-3010(2)

736-0242

REPLACEMENT SHEAR BOLTS

Chute Flange Keepers

731-0851 (3) Not Shown

Flatw ers

736-0185(2)

Hairpin Clip

_ 714-0104

NOTE: The augers are secured to the spiral shaft with two shear bolts and hex lock nuts. Ifyou hit a hard foreign

object or an icejam, the snow thrower is designed so that the bolts may shear. Two replacement shear bolts and

nuts are provided for your convenience. Store in a safe place until needed.

Hex Lock Nuts

712-0429 (2) _-_J__._H-J_

Hex Bolts

710-0890A (2)

SECTION3: ASSEMBLINGYOURSNOWTHROWER

NOTE: References to right or left side of the snow

thrower are determined from behind the unit in the

operating position. The "operator's position" is defined

as standing directly behind the snow thrower, facing the

handle panel

Unpacking

• Remove staples or break glue on top flaps of the

carton. Remove any loose parts included with unit

(i.e., operator's manual, etc.).

• Cut corners of the carton and lay ends down flat.

Remove packing material.

• Roll unit out of carton. Check carton thoroughly for

loose parts before discarding.

LoosePartsInCarton

Handl_ Panel ps

BeforeAssembly

WARNING: Disconnect the spark plug

wire and ground it against the engine to

prevent unintended starting.

AttachingHandles(HardwareGroupA)

• Place right handle in position against the snow

thrower so that the flat side of the handle is against

the frame. Align the bottom hole on the handle to

the corresponding hole on the snow thrower

housing.

• Insert hex bolt and lock washer through these holes

to secure the handle to the snow thrower housing.

Do not tighten at this time. See Figure 2.

Guide_

Hex Bolt & _

Clean-out \

jTool*

Figure 1

*This item is fastened with a cable tie to the rear of

the Auger Housing at the factory.

Lock Washer

Figure 2

Attach the left handle in the same manner and do

not tighten.

Place saddle washer over upper holes on handles

and secure to the frame with lock washers and hex

bolts. Do not tighten now. See Figure 2.

AttachingClutchGrips(HardwareGroupB)

• Slide spacer on each end of the clutch grip and

place the clutch grip in position on the each

respective handle. Clutch grips must sit on top of

the handles. See Figure 3.

_Hex Lock Nut

_ Hex Bolt

Spacer

Figure 3

• Secure each clutch grip with a hex bolt threaded

from the outside of each handle and tighten with

hex lock nut under handle panel. See Figure 3.

AttachingHandlePanel(HardwareGroupC)

• Position the handle panel between handles and

insert two carriage bolts on each side and secure

with lock washers and hex patch nuts.

See Figure 4.

Hex Cap Screw\

Carriage Hex Lock Nuts

Bolts

Self-Tappin_

Screws

Figure 4

ige

• Secure shift lever to the shift lever spring using two

hex bolts (G) and hex lock nuts (H). Tighten both

bolts finger tight. At this point the shift lever and

shift lever spring are not against each other. As you

tighten the bolts and nuts with two wrenches, these

will pull together.

• Tighten all hardware assembled to this point. Make

sure that clutch grips are moving freely.

AttachingControlCables(HardwareGroupE)

Z fittings with jam nuts might be already inserted in

each control lever (on the handle panel) at the factory.

To attach the cables to the Z fittings, proceed as

follows:

NOTE: Two extra jam nuts are included in the hardware

pack in the event either are lost during shipping.

• If Z fittings are not already attached, thread hex

nuts onto the "Z" fittings and insert "Z" fitting into

hole in clutch grips. See Figure 6.

• Route the left cable between engine and speed

selector plate and then between handle panel and

clutch lever pivot rod before threading onto the left

"Z" fitting.

• Assemble the right cable inthe same manner.

• Both cables should have minimal slack, but not

tight.

AttachingSpeed Selector Plate

(HardwareGroupD)

Assemble the speed selector plate to the outside

of the handles. Secure using two self-tapping

screws on each side. See Figure 5.

Shift Lever

Figure 5

AttachingShiftLever

• Insert the shift lever through slot in the speed

selector plate. See Figure 5.

NOTE: The bend in the lever should be towards the

operator.

Jam Nut

Figure 6

• If Z fittings are already attached, thread the jam

nuts all the way up each of the Z fittings, toward the

handle panel.

• Make certain all cables are inthe grooves of the

cable roller guides in the lower rear of the unit, one

on each side. Refer to Figure 2.

• Thread the coupling end of the cable onto the

threaded portion of the Z fitting until the rubber

bumper (located on the underside of the clutch

lever) only lightly contacts the upper handle.

IMPORTAWr: The cable should have very little slack, but

should NOT be tight. An overtightened cable may

prohibit the auger and drive from disengaging.

• Once properly adjusted, tighten the jam nut against

the coupling end of the cable to lock it in position.

WARNING: Over-tightening the cable

may prohibit the auger and drive from

disengaging and compromise the safety

of the snow thrower. Do NOT overtighten

the cable.

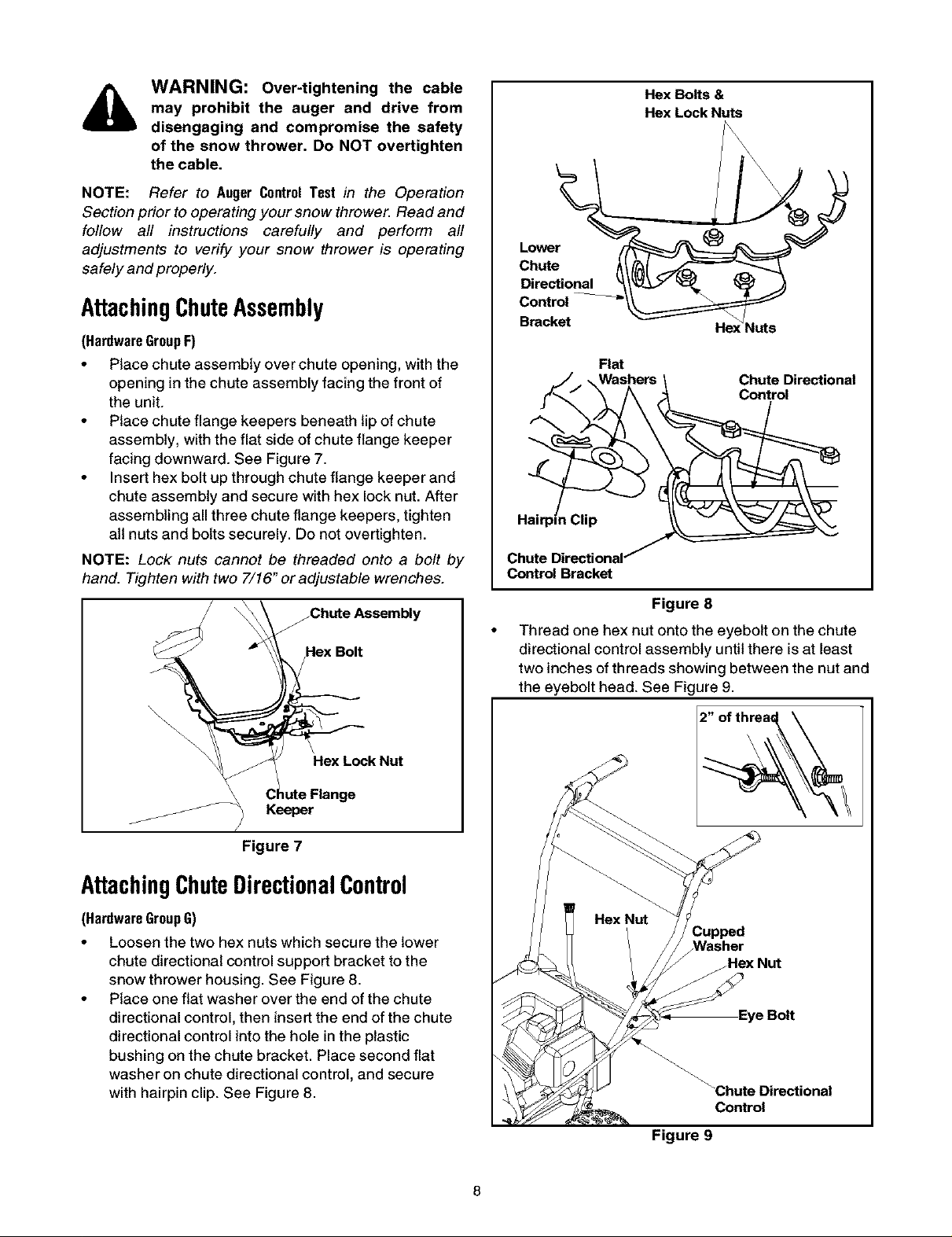

Hex Bolts &

Hex Lock Nuts

NOTE:

Refer to AugerControlTest in the Operation

Section prior to operating your snow thrower. Read and

follow all instructions carefully and perform all

adjustments to verify your snow thrower is operating

safely and properly.

AttachingChuteAssembly

(HardwareGroupF)

• Place chute assembly over chute opening, with the

opening in the chute assembly facing the front of

the unit.

• Place chute flange keepers beneath lip of chute

assembly, with the flat side of chute flange keeper

facing downward. See Figure 7.

• Insert hex bolt up through chute flange keeper and

chute assembly and secure with hex lock nut. After

assembling all three chute flange keepers, tighten

all nuts and bolts securely. Do not overtighten.

NOTE: Lock nuts cannot be threaded onto a bolt by

hand. Tighten with two 7/16" or adjustable wrenches.

Lower

Chute

Directional

Control \

Bracket He:

Flat

Washers

Control Bracket

_luts

Chute Directional

Control

Figure 8

Thread one hex nut onto the eyebolt on the chute

directional control assembly until there is at least

two inches of threads showing between the nut and

the eyebolt head. See Figure 9.

Figure 7

AttachingChuteDirectionalControl

(HardwareGroupG)

• Loosen the two hex nuts which secure the lower

chute directional control support bracket to the

snow thrower housing. See Figure 8.

• Place one flat washer over the end of the chute

directional control, then insert the end of the chute

directional control into the hole in the plastic

bushing on the chute bracket. Place second flat

washer on chute directional control, and secure

with hairpin clip. See Figure 8.

2" of threal;_

Control

Figure 9

• Place the eyebott into the hole located half way up

the left handle and secure with cupped washer and

hex nut making sure that the cupped side of the

washer is against the handle.

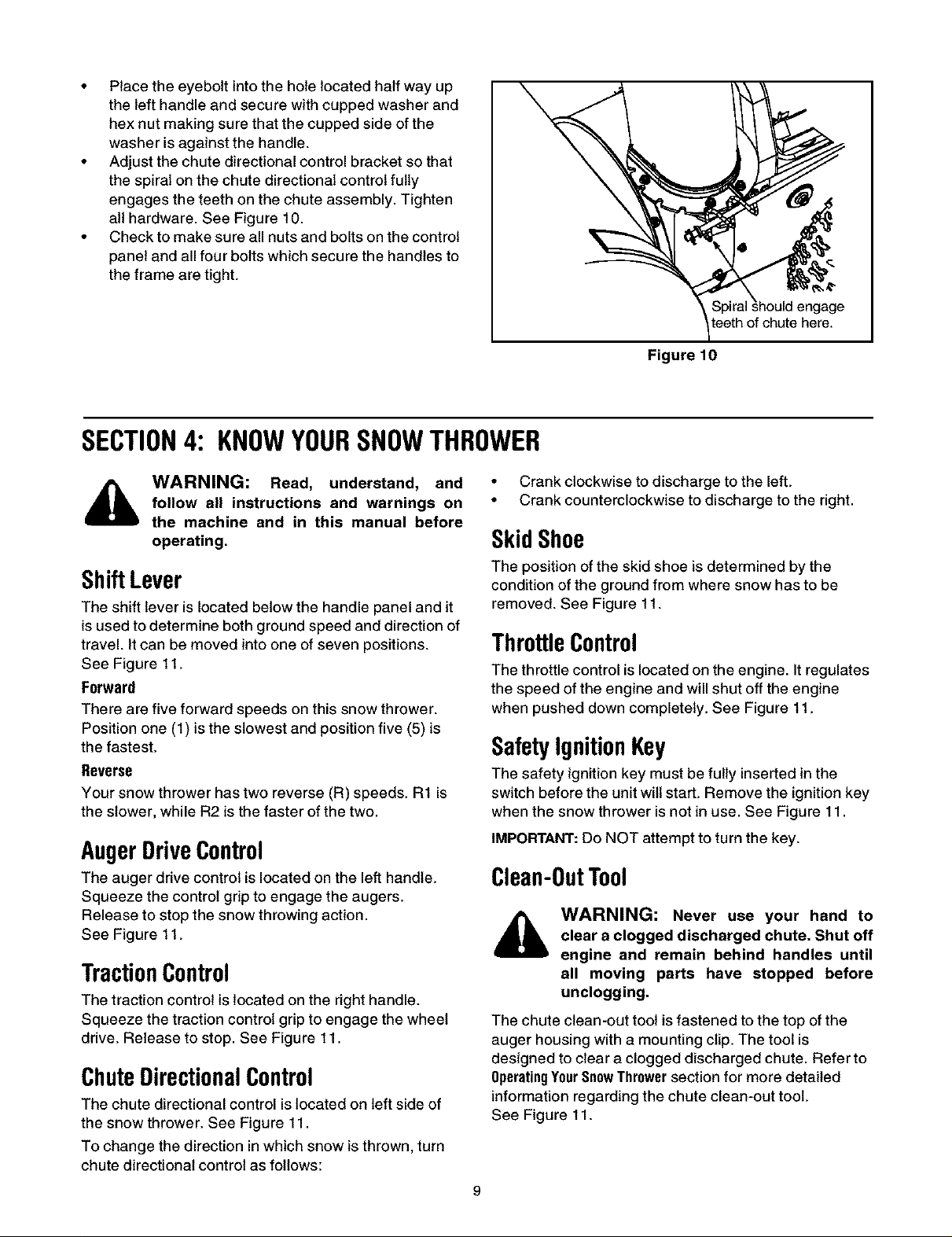

• Adjust the chute directional control bracket so that

the spiral on the chute directional control fully

engages the teeth on the chute assembly. Tighten

all hardware. See Figure 10.

• Check to make sure all nuts and bolts on the control

panel and all four bolts which secure the handles to

the frame are tight.

SECTION4: KNOWYOURSNOWTHROWER

teeth of chute here.

Figure lg

WARNING: Read, understand, and

follow all instructions and warnings on

the machine and in this manual before

operating.

ShiftLever

The shift lever is located below the handle panel and it

is used to determine both ground speed and direction of

travel. Itcan be moved into one of seven positions.

See Figure 11.

Forward

There are five forward speeds on this snow thrower.

Position one (1) is the slowest and position five (5) is

the fastest.

Reverse

Your snow thrower has two reverse (R) speeds. R1 is

the slower, while R2 is the faster of the two.

AugerDriveControl

The auger drive control is located on the left handle.

Squeeze the control grip to engage the augers.

Release to stop the snow throwing action.

See Figure 11.

TractionControl

The traction control is located on the right handle.

Squeeze the traction control grip to engage the wheel

drive. Release to stop. See Figure 11.

ChuteDirectionalControl

The chute directional control is located on left side of

the snow thrower. See Figure 11.

To change the direction in which snow is thrown, turn

chute directional control as follows:

• Crank clockwise to discharge to the left.

• Crank counterclockwise to discharge to the right.

SkidShoe

The position of the skid shoe is determined by the

condition of the ground from where snow has to be

removed. See Figure 11.

ThrottleControl

The throttle control is located on the engine. It regulates

the speed of the engine and will shut off the engine

when pushed down completely. See Figure 11.

SafetyIgnitionKey

The safety ignition key must be fully inserted in the

switch before the unit wilt start. Remove the ignition key

when the snow thrower is not in use. See Figure 11.

IMPORTANT: Do NOT attempt to turn the key.

Clean-OutTool

WARNING: Never use your hand to

clear a clogged discharged chute. Shut off

engine and remain behind handles until

all moving parts have stopped before

unclogging.

The chute clean-out toot is fastened to the top of the

auger housing with a mounting clip. The tool is

designed to clear a clogged discharged chute. Refer to

OperatingYourSnowThrowersection for more detailed

information regarding the chute clean-out tool.

See Figure 11.

Loading...

Loading...