MTD 31AS6WEG799 Owner’s Manual

Operator's Manual

CRRFTSMRN

28" SNOW THROWER

Model No. 247.88690

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-03973

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

2/4/2009

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-6

SafetyLabels......................... Page7

Assembly......................... Pages8-11

Operation........................ Pages12-15

Off-SeasonStorage................... Page24

Troubleshooting...................... Page25

PartsList......................... Pages26-38

RepairProtectionAgreement............ Page42

Espa_ol............................. Page43

Service&Maintenance.............. Pages16-23

CRAFTSMAN LiMiTED WARRANTY

Two Years on Snow Thrower

Whenoperatedand maintainedaccordingtoallsuppliedinstructions,ifthis snowthrowerfailsdueto a defectinmaterialorworkmanshipwithin

twoyearsfromthe dateor purchase,call 1-800-4-MY-HOME®toarrangefor freerepair.

Thiswarrantyappliesforonly90 daysfromthe dateof purchaseifthissnowthroweriseverusedfor commercialor rentalpurposes.

Duringthefirstyearofpurchase,therewillbe nochargefor warrantyserviceinyourhome.Foryourconvenience,in-homewarrantyservicewill

stillbeavailableafterthe firstyearof purchase,butatripchargewillapply.Thischargewillbewaivedif youtransportthe snowthrowertoan

authorizedCraftsmandrop-offlocation.Forthe nearestauthorizedlocation,call 1-800-4-MY-HOME®.

Thiswarranty coversONLYdefects in material andworkmanship. Searswill NOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnot limitedtoskidshoes,shaveplate,shearpins,sparkplug,air

cleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchas nails,thorns,stumps,or glass.

Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyimpactingobjectsthat bendtheframeor

crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedby improper

storage,failureto usethepropergradeandamountofengineoil,or failureto maintaintheequipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantyappliesonlywhilethisproductis usedinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears, RoebuckandCo.,Hoffman Estates,IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 3 Quarts

SparkPlug: Champion®RC12YC

SparkPlugGap: .030"

©SearsBrands,LLC

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingto thesafeopera-

tionpracticesin thismanual.As withanytypeofpowerequipment,

carelessnessor erroronthe partof theoperatorcanresultinserious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethe followingsafety

instructionscould resultinseriousinjuryor death.

CALIFORNIA PROPOSiTiON 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowallinstructionsonthemachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureandregularreference

andfororderingreplacementparts.

• Readthe Operator'sManualandfollowallwarningsand safety

instructions.Failuretodoso canresultinseriousinjurytothe

operatorand/orbystanders.Forquestionscall, 1-800-659-5917.

Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbetrainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscan causeseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useof this powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawherethe equipmentisto beused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

• Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairtoprotectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledin movingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptaclefor all

machineswithelectricstartengines.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

Disengageall controlleversbeforestartingtheengine.

• Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedinthe operator'smanual.

Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

SafeHandlingof Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuel whilethe engineishot

or running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltanktonomorethan1/2inch

belowbottomoffillerneckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineorfuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolatleast5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleor ona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refueliton the ground.Ifthisis notpossible,

thenrefuelsuchequipmentona trailerwithaportable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donotputhandsorfeetnear rotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleverisasafetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingor damagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancauseaburn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

• Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontof themachine.

• Donotoverloadmachinecapacitybyattemptingto clearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureof yourfootingand keepa firmholdon the handles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineathightransportspeedson slippery

surfaces.Lookdownand behindandusecarewhenbackingup.

• Ifthe machineshouldstarttovibrateabnormally,stopthe engine,

disconnectthesparkplugwire andgrounditagainsttheengine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoacompletestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverputyourhandinthedischargeor collectoropenings.

Alwaysusetheclean-outtoolprovidedtounclogthedischarge

opening.Donotunclogchuteassemblywhileengineisrunning.

Shutoff engineand remainbehindhandlesuntilallmovingparts

havestoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanletgo. Broken

bones,fractures,bruisesorsprainscould result.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyournearestservicingdealer.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstopthe engine.Waituntiltheauger/impeller

cometoacompletestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingorover-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo notmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,if necessary.Referto theadjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.Attheendof theAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failureto do socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifa sparkattesteris used,it shouldbemaintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

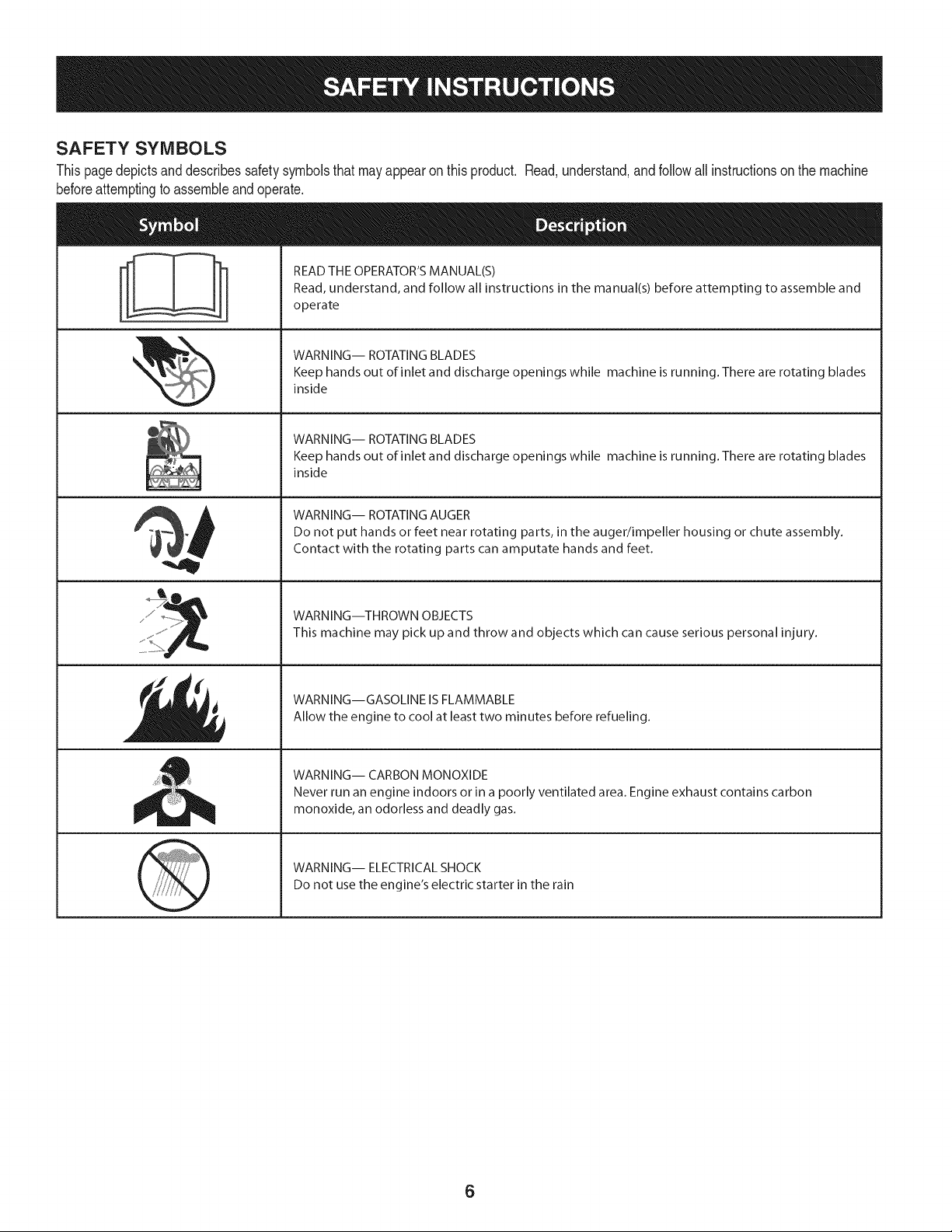

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

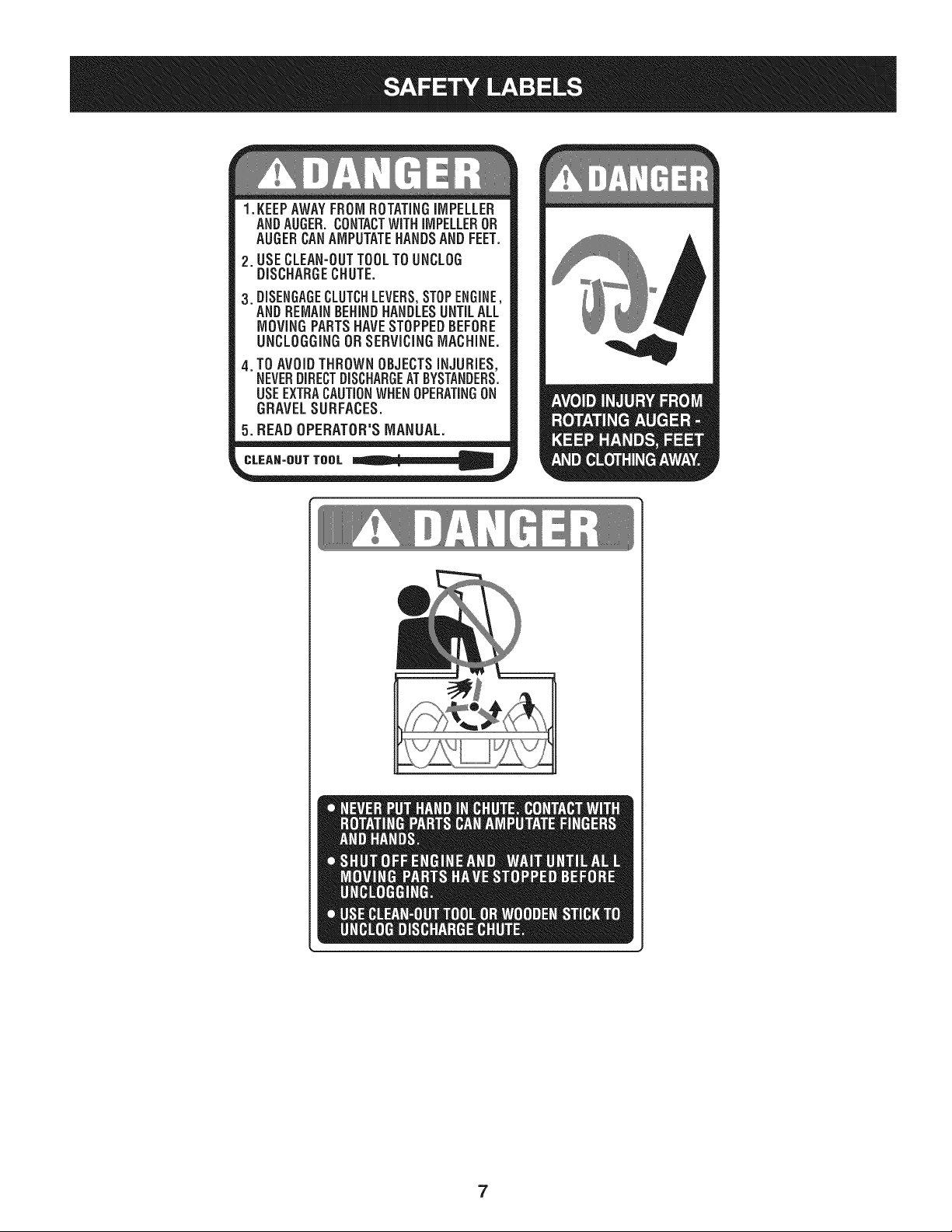

1.KEEPAWAYFROMROTATINGiMPELLER

ANDAUGER,CONTACTWiTHiMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3.DISENGAGECLUTCHLEVERS,STOPENGINE,

AND REMAINBEHINDHANDLESUNTILALL

MOVING PARTSHAVE STOPPEDBEFORE

UNCLOGGING OR SERViCiNGMACHINE.

TO AVOIDTHROWN OBJECTSiNJURiES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHEN OPERATINGON

GRAVELSURFACES.

5.BEAD OPERATOR'S MANUAL.

CLEAN-OUT TOOL

7

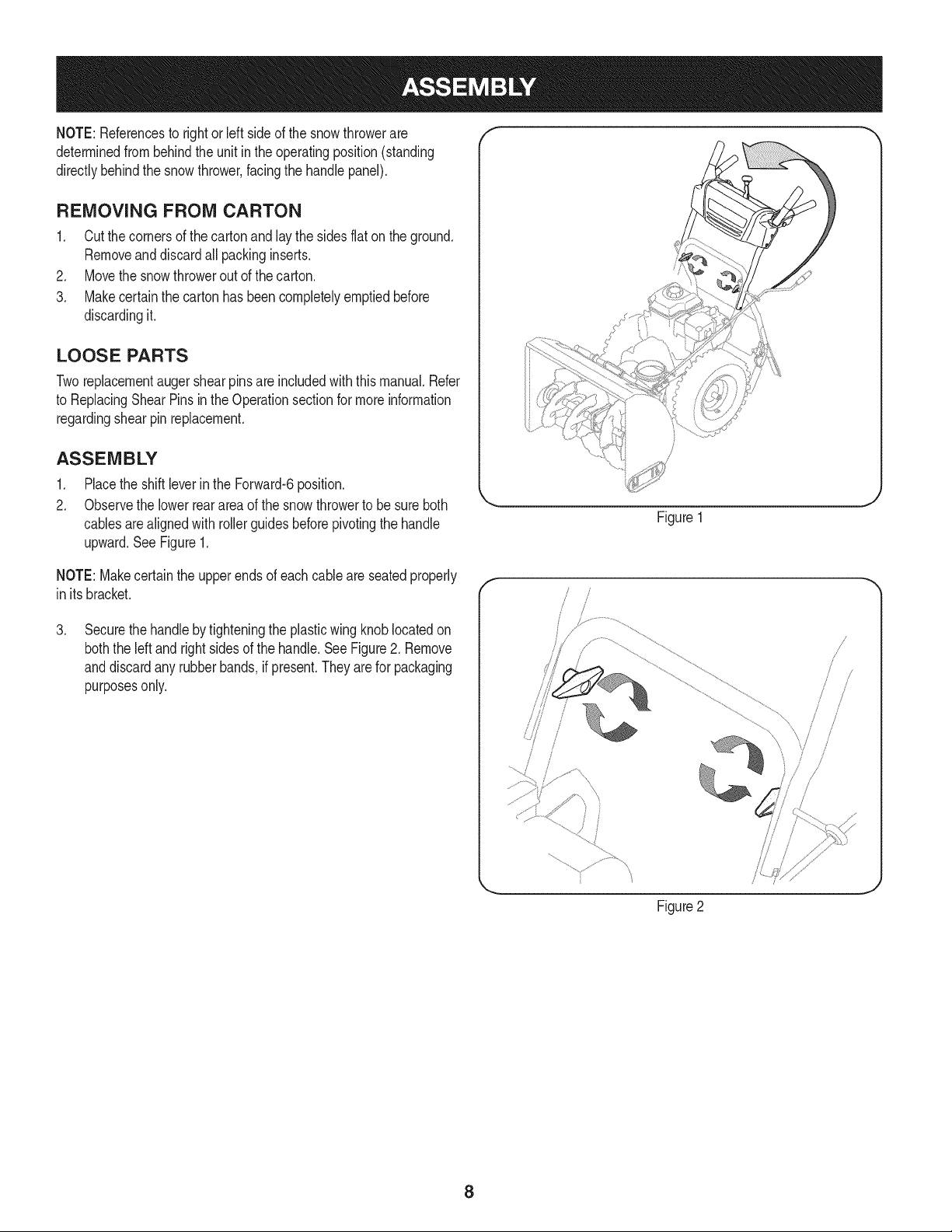

NOTE:Referencesto rightorleftsideofthesnowthrowerare

determinedfrombehindtheunitintheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthe cornersofthecartonandlay thesidesflaton the ground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutof thecarton.

3. Makecertainthecartonhas beencompletelyemptiedbefore

discardingit.

LOOSE PARTS

Tworeplacementaugershearpinsare includedwiththismanual.Refer

toReplacingShearPinsintheOperationsectionformoreinformation

regardingshearpin replacement.

ASSEMBLY

1. Placethe shiftleverin the Forward-6position.

2. Observethe lowerrearareaofthesnowthrowertobesure both

cablesarealignedwith rollerguidesbeforepivotingthehandle

upward.See Figure1.

Figure1

NOTE:Makecertainthe upperendsofeachcableare seatedproperly

in itsbracket.

.

Securethehandlebytighteningtheplasticwingknoblocatedon

boththe left andrightsidesof thehandle.SeeFigure2.Remove

anddiscardanyrubberbands,ifpresent.Theyareforpackaging

purposesonly.

f

!

/

/

/

Figure2

8

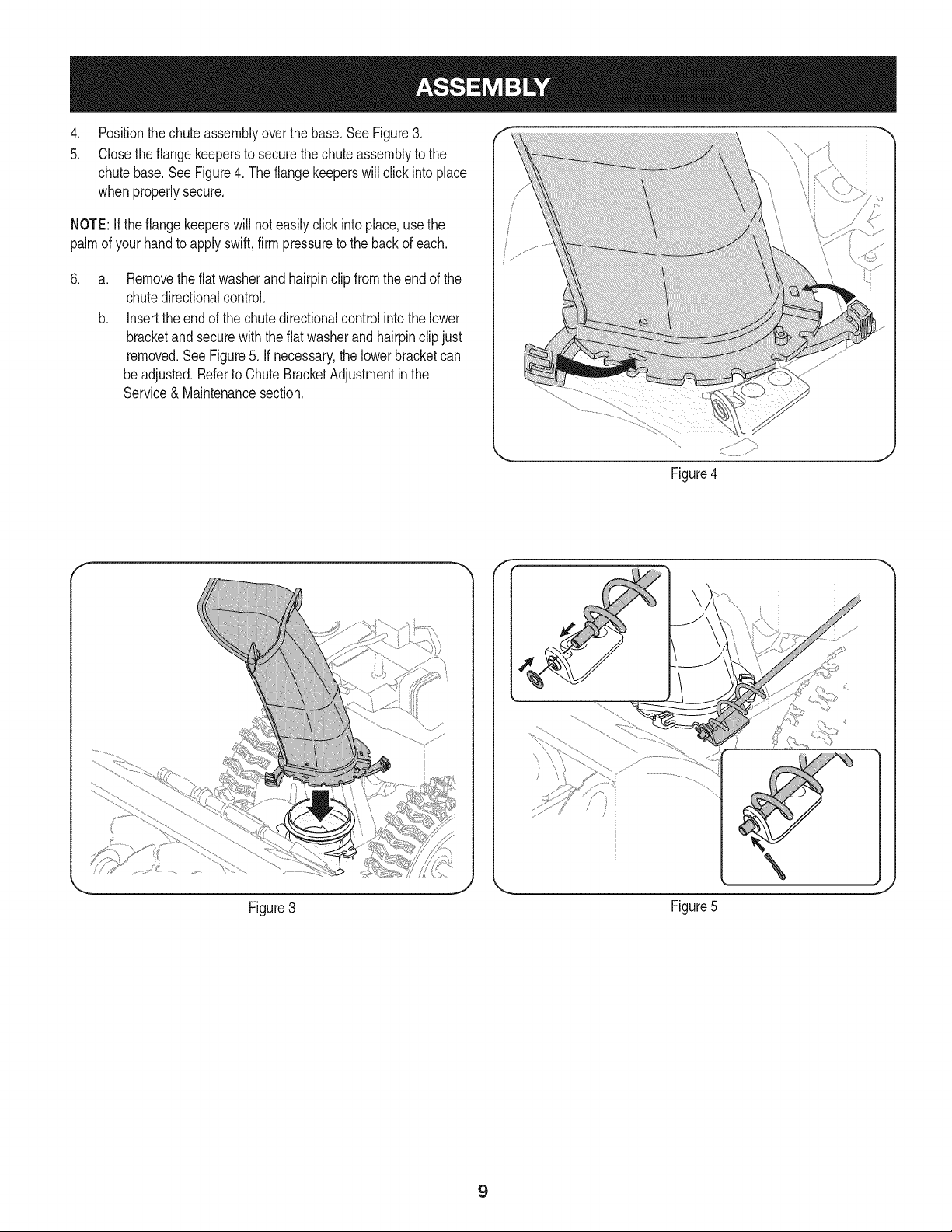

.

Positionthechuteassemblyoverthebase.SeeFigure3.

5.

Closetheflangekeepersto securethechuteassemblytothe

chutebase.SeeFigure4.Theflangekeeperswillclickintoplace

whenproperlysecure.

NOTE:Iftheflangekeeperswillnoteasilyclickintoplace,usethe

palmof yourhandtoapplyswift,firmpressuretothe backofeach.

.

a.

Removetheflatwasherand hairpinclipfromtheendof the

chutedirectionalcontrol.

b.

Insertthe endofthechutedirectionalcontrolintothelower

bracketandsecurewiththeflatwasherandhairpinclipjust

removed.See Figure5.Ifnecessary,thelowerbracketcan

beadjusted.Referto ChuteBracketAdjustmentinthe

Service& Maintenancesection.

f F

Figure4

Figure3

\

J

Figure5

9

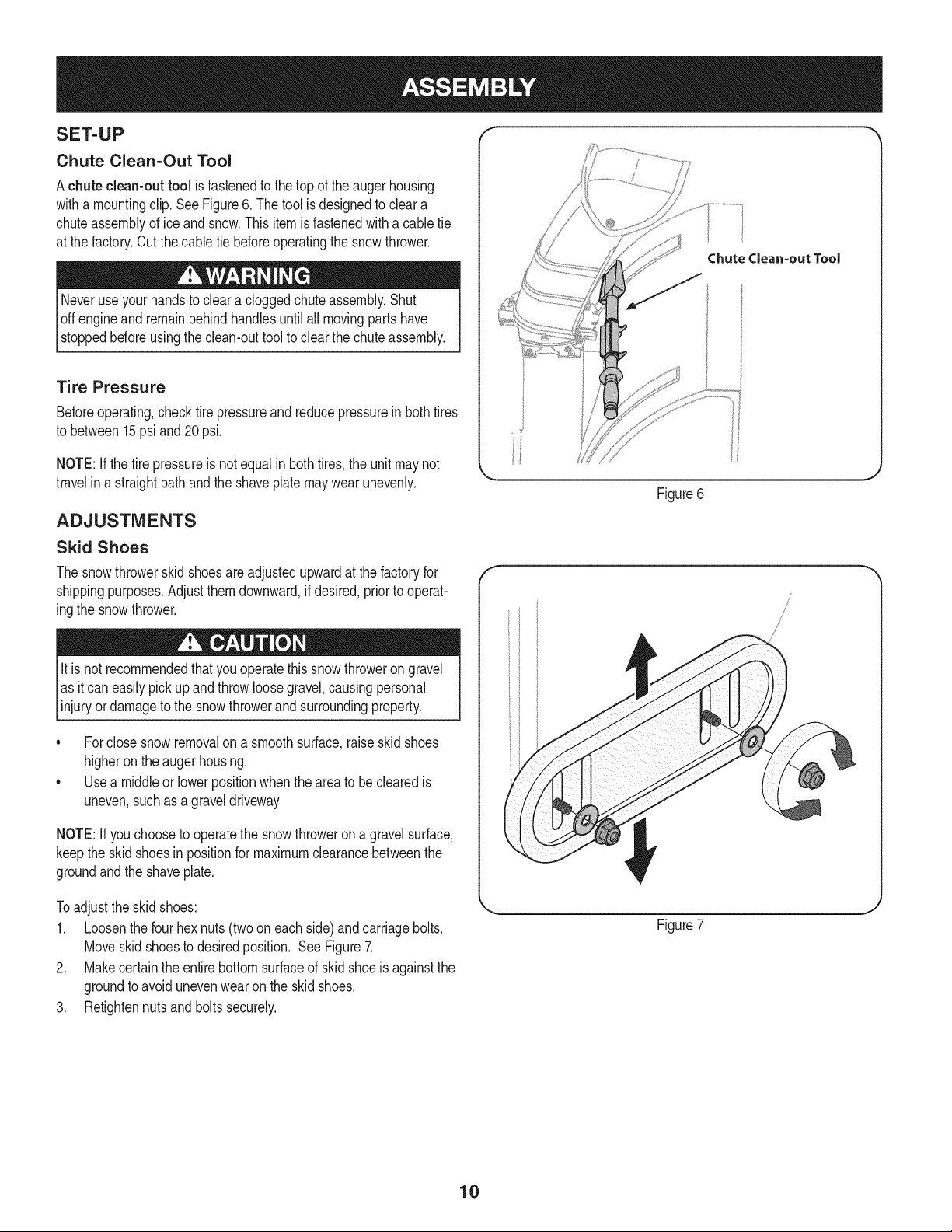

SET-UP

Chute Clean-Out Tool

Achute clean-out tool is fastenedtothetopof theaugerhousing

witha mountingclip.SeeFigure6.Thetool isdesignedtocleara

chuteassemblyoficeandsnow.Thisitemisfastenedwitha cabletie

atthefactory.Cutthecable tiebeforeoperatingthesnowthrower.

loft _1 .allmovingpartshave

stoppedbeforeusingtheclean-outtool toclearthechuteassembly.

Tire Pressure

Beforeoperating,checktirepressureandreducepressureinbothtires

tobetween15psiand20 psi.

NOTE:If thetirepressureis notequalin bothtires,theunitmaynot

travelin a straightpathandtheshaveplatemaywearunevenly.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priortooperat-

ingthesnowthrower.

ChuteClean-outTool

Figure6

f

/

It isnotrecommendedthatyouoperatethis snowthrowerongravel

asitcaneasilypickup andthrowloosegravel,causingpersonal

njuryordamageto the snowthrowerand surroundng property.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

• Usea middleorlowerpositionwhentheareatobe clearedis

uneven,suchasagraveldriveway

NOTE:If youchoosetooperatethesnowthrowerona gravelsurface,

keepthe skidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjustthe skidshoes:

1. Loosenthefour hexnuts(twooneachside)andcarriagebolts.

Moveskidshoestodesiredposition. SeeFigure7.

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsand boltssecurely.

Figure7

10

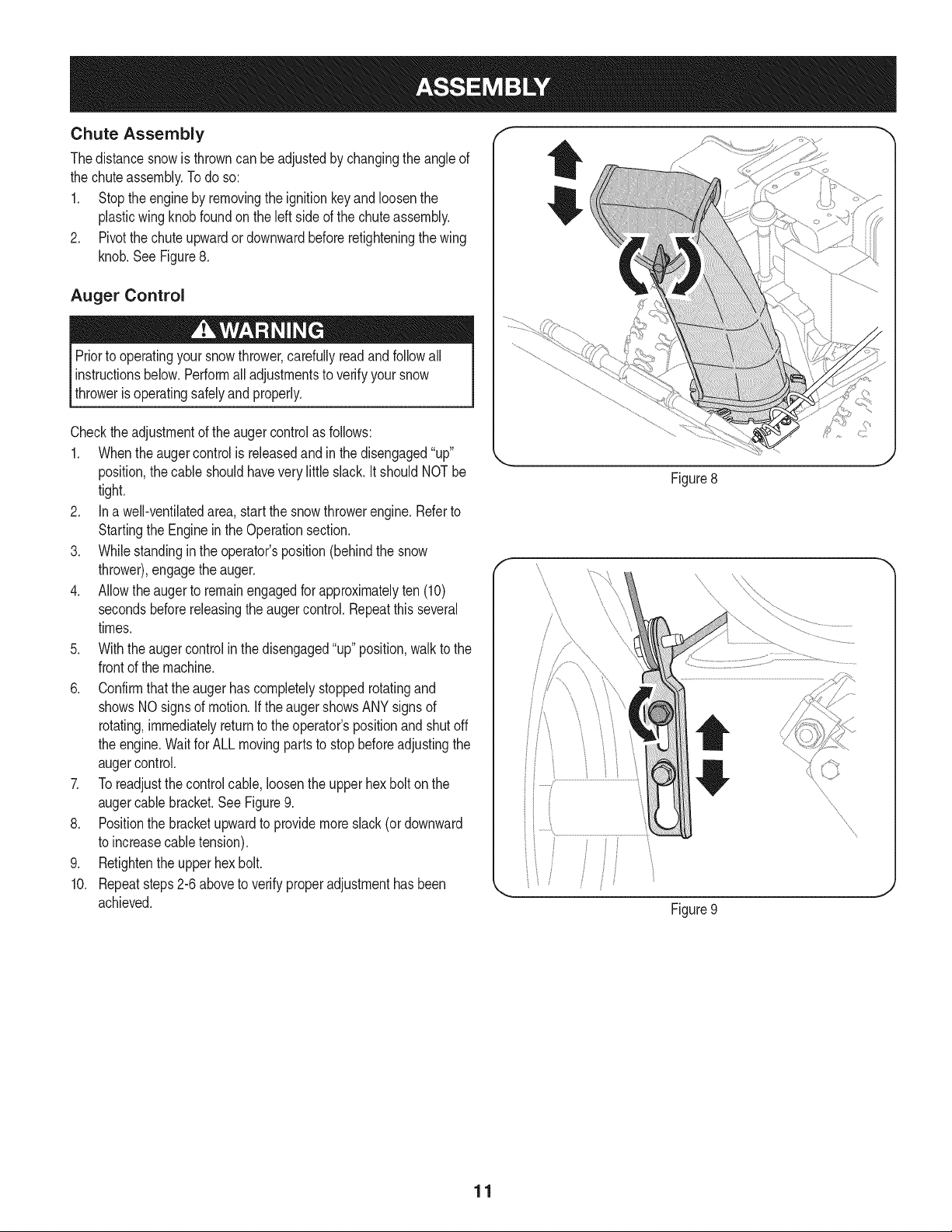

Chute Assembly

Thedistancesnowisthrowncanbeadjustedbychangingtheangleof

thechuteassembly.Todo so:

1. Stopthe enginebyremovingthe ignitionkeyandloosenthe

plasticwingknobfoundontheleft sideofthechuteassembly.

2. Pivotthechuteupwardordownwardbeforeretighteningthewing

knob.See Figure8.

Auger Control

Priorto operatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentstoverifyyoursnow

throwerisoperatingsafelyandproperly.

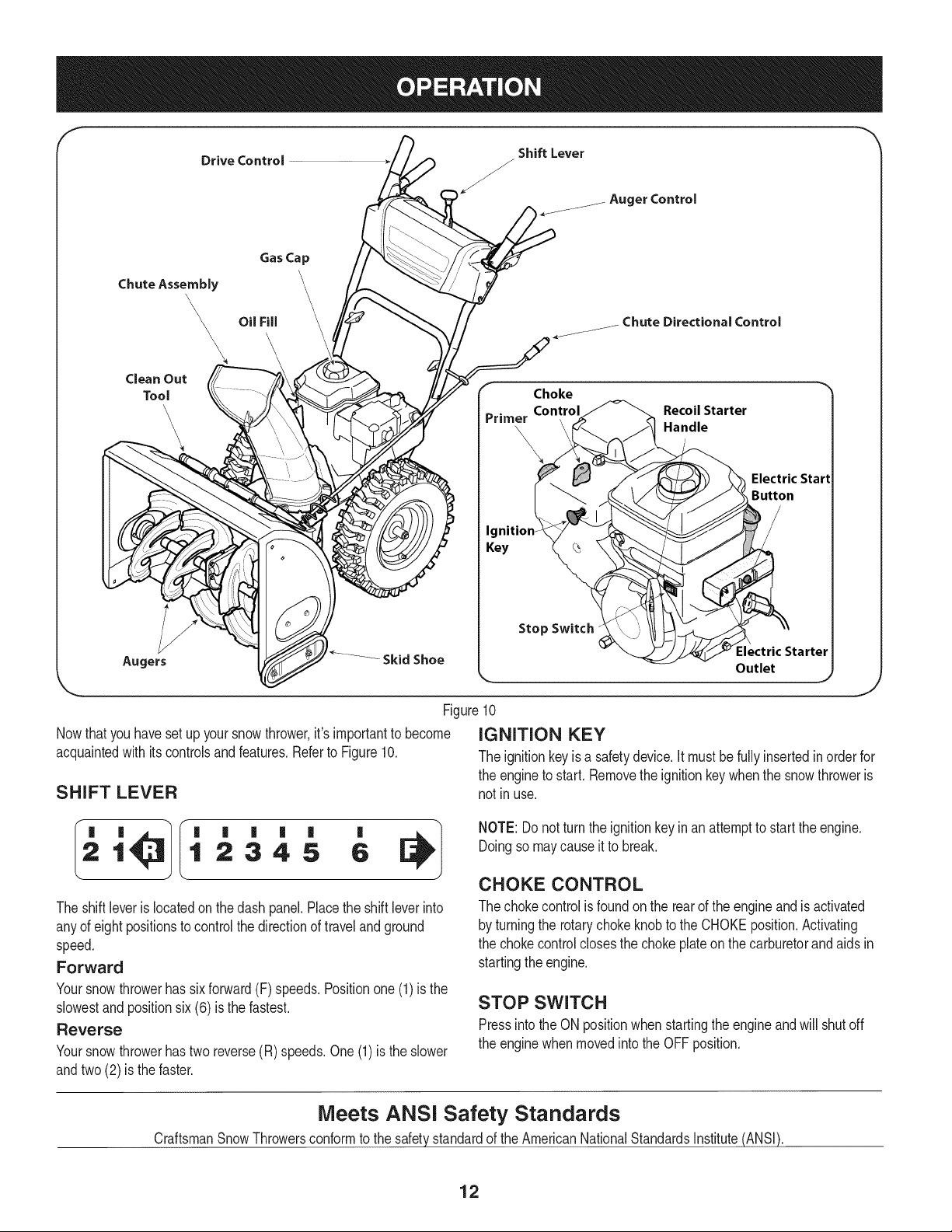

Checktheadjustmentoftheaugercontrolas follows:

1. Whentheaugercontrolis releasedandinthedisengaged"up"

position,thecableshouldhavevery littleslack.ItshouldNOTbe

tight.

2. Inawell-ventilatedarea,startthesnowthrowerengine.Referto

StartingtheEngineinthe Operationsection.

3. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe auger.

4. Allowtheaugertoremainengagedforapproximatelyten (10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheaugercontrolin thedisengaged"up"position,walktothe

frontofthemachine.

6. Confirmthatthe augerhascompletelystoppedrotatingand

showsNOsignsof motion.IftheaugershowsANYsignsof

rotating,immediatelyreturntotheoperator'spositionandshutoff

theengine.WaitforALLmovingpartstostopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexboltonthe

augercablebracket.SeeFigure9.

8. Positionthebracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

9. Retightentheupperhex bolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

Figure8

Figure9

11

ChuteAssembly

Auger Control

Gas Cap

\

\

Clean Out

Tool

'\

\

Augers _ Skid Shoe

Figure10

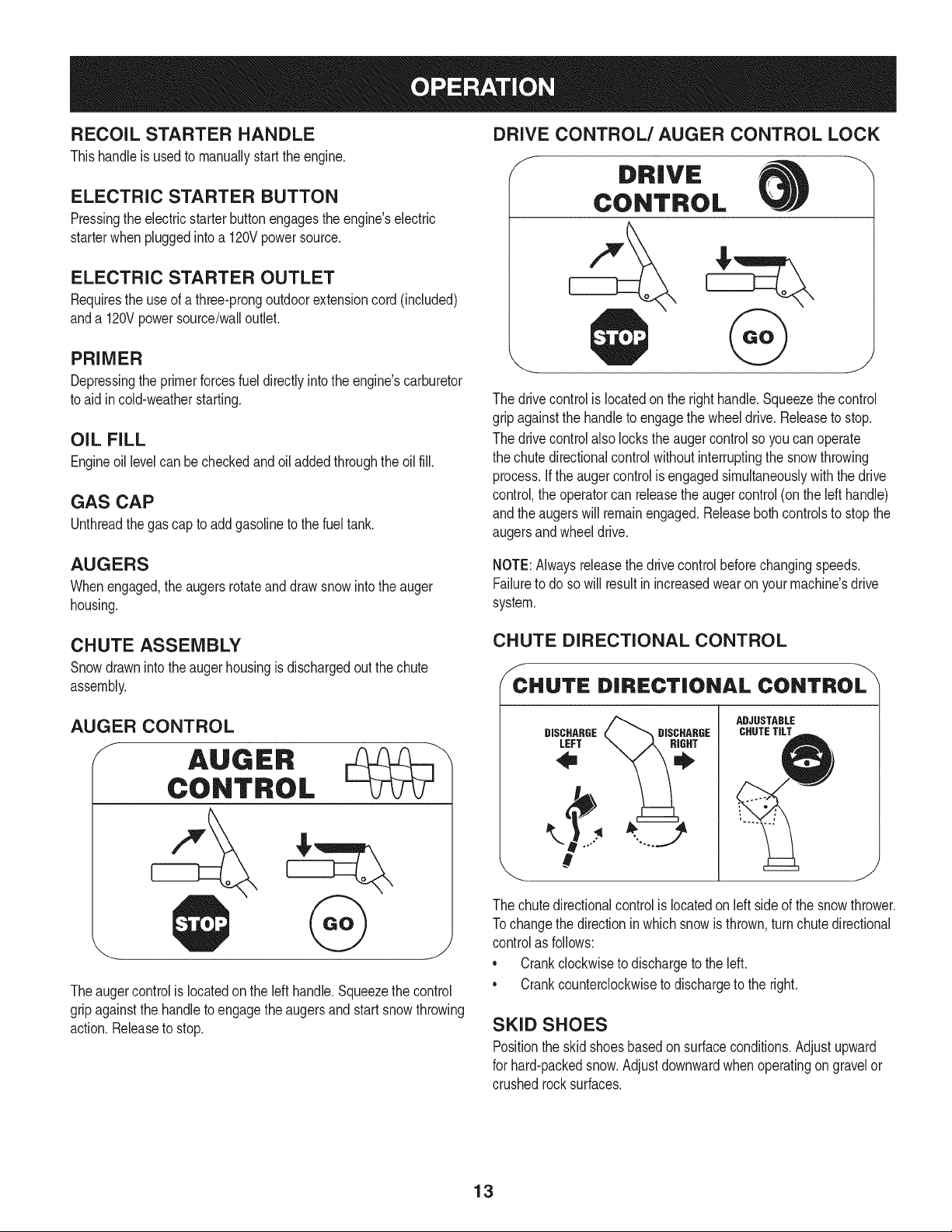

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome iGNiTiON KEY

acquaintedwith itscontrolsandfeatures.RefertoFigure10.

SHIFT LEVER

Theignitionkeyisa safetydevice.Itmustbe fullyinsertedinorderfor

theenginetostart. Removetheignitionkeywhenthesnowthroweris

notinuse.

Chute Directional Control

Recoil Starter

Handle

Electric Start

Button

Outlet

J

1 2345 6

Theshiftleverislocatedonthe dashpanel.Placetheshiftleverinto

anyof eightpositionstocontrolthedirectionoftravelandground

speed.

Forward

Yoursnowthrowerhassixforward(F) speeds.Positionone(1)is the

slowestandpositionsix(6) isthe fastest.

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)istheslower

andtwo(2) isthe faster.

'

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformtothesafetystandardofthe AmericanNationalStandardsInstitute(ANSI).

NOTE:Donotturntheignitionkeyinanattemptto starttheengine.

Doingsomaycauseitto break.

CHOKE CONTROL

Thechokecontrolisfoundon the rearoftheengineand isactivated

byturningtherotarychokeknobtotheCHOKEposition.Activating

thechokecontrolclosesthechokeplateon thecarburetorandaids in

startingthe engine.

STOP SWITCH

Pressintothe ONpositionwhen startingtheengineandwill shutoff

theenginewhenmovedintotheOFFposition.

12

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource,

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

PRIMER

Depressingthe primerforcesfueldirectlyintothe engine'scarburetor

toaidin cold-weatherstarting,

OiL FILL

Engineoil levelcanbecheckedand oiladdedthroughtheoil fill.

GAS CAP

Unthreadthegascaptoaddgasolinetothefuel tank.

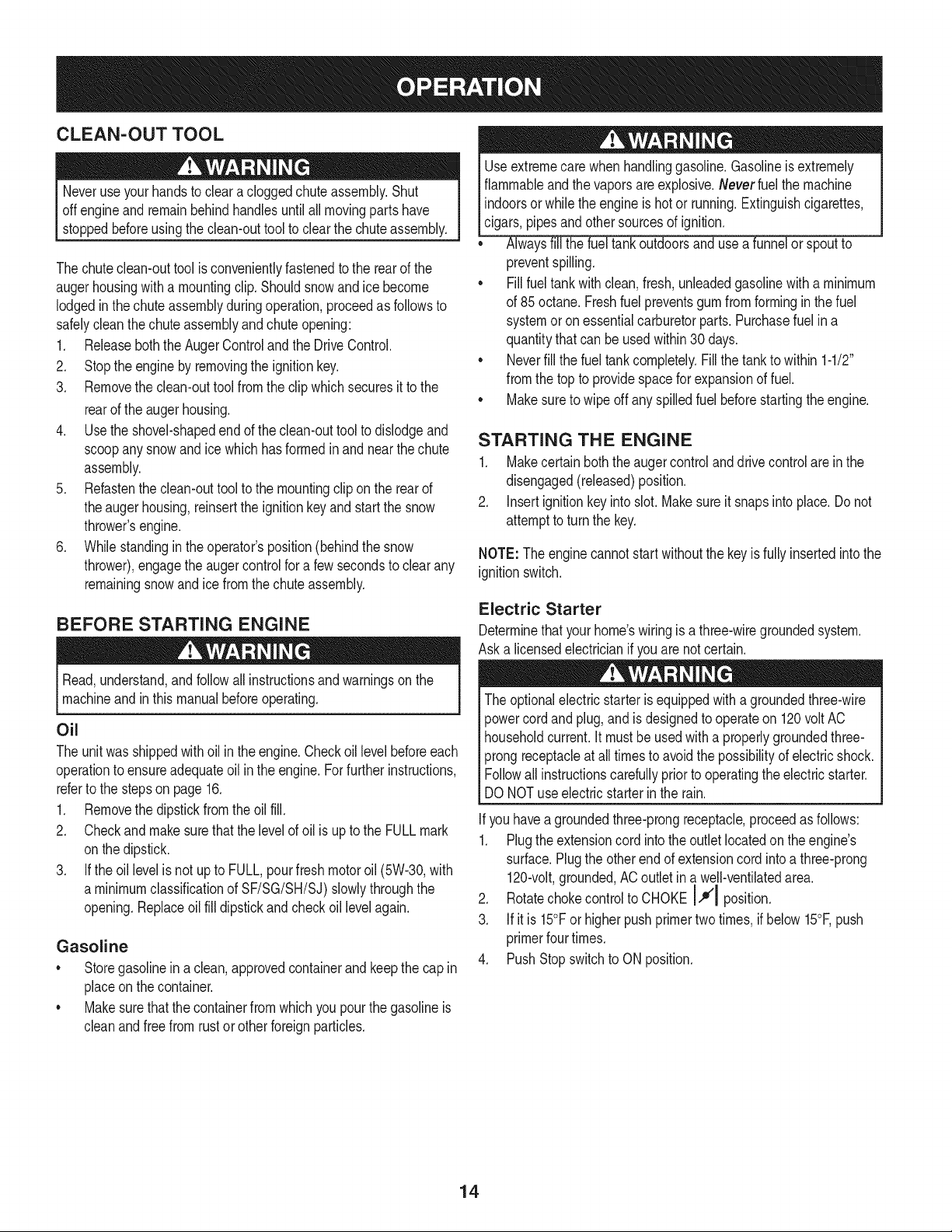

DRIVE CONTROL/AUGER CONTROL LOCK

f

Thedrivecontrolislocatedon the righthandle.Squeezethecontrol

gripagainstthehandletoengagethe wheeldrive.Releaseto stop.

Thedrivecontrolalsolockstheaugercontrolso youcan operate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process,iftheaugercontrolisengagedsimultaneouslywiththedrive

control,the operatorcan releasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releasebothcontrolstostopthe

augersandwheeldrive.

AUGERS

Whenengaged,theaugersrotateanddrawsnowintotheauger

housing.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

AUGER CONTROL

Theaugercontrolislocatedonthe left handle.Squeezethecontrol

gripagainstthehandletoengagetheaugersandstart snowthrowing

action.Releasetostop.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto dosowillresultinincreasedwearon yourmachine'sdrive

system.

CHUTE DIRECTIONAL CONTROL

f -\

CHUTE DiRECTiONAL CONTROL

ADJUSTABLE

DISCHARGE

LEFT

DISCHARGE

\

Thechutedirectionalcontrolislocatedonleft sideof thesnowthrower.

Tochangethedirectioninwhichsnowisthrown,turnchutedirectional

controlasfollows:

* Crankclockwiseto dischargeto theleft.

* Crankcounterclockwisetodischargeto the right.

SKiD SHOES

Positiontheskidshoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingon gravelor

crushedrocksurfaces.

CHUTETILT

13

CLEAN-OUT TOOL

Neveruseyour handsto clearacloggedchuteassembly.Shut

offengineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeusingtheclean-outtool toclearthechuteassembly.

Thechuteclean-outtool isconvenientlyfastenedtotherearof the

augerhousingwitha mountingclip.Shouldsnowandice become

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandthe DriveControl.

2. Stopthe enginebyremovingthe ignitionkey.

3. Removetheclean-outtoolfromthe clipwhichsecuresittothe

rearoftheaugerhousing.

4. Usethe shovel-shapedendof theclean-outtooltodislodgeand

scoopanysnowandicewhichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtoolto themountingclip ontherearof

theaugerhousing,reinsertthe ignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolfora fewsecondstoclearany

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthe machine

indoorsorwhiletheengineis hotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

Alwaysfillthefueltankoutdoorsand usea funnelor spoutto

preventspilling.

• Fillfueltankwithclean,fresh,unleadedgasolinewitha minimum

of85octane.Freshfuelpreventsgumfromforminginthe fuel

systemoronessentialcarburetorparts.Purchasefuelin a

quantitythatcanbeusedwithin30 days.

• Neverfillthefuel tankcompletely.Fillthetanktowithin1-1/2"

fromthetopto providespaceforexpansionoffuel.

• Makesuretowipeoff anyspilledfuelbeforestartingtheengine.

STARTING THE ENGINE

1. Makecertainboththe augercontrolanddrivecontrolarein the

disengaged(released)position.

2. Insertignitionkeyinto slot.Makesure itsnapsintoplace.Donot

attempttoturnthekey.

NOTE:Theenginecannotstartwithoutthe keyisfullyinsertedintothe

ignitionswitch.

Electric Starter

Determinethatyourhome'swiringisathree-wiregroundedsystem.

Aska licensedelectricianifyou arenotcertain.

Read,understand,andfollowallinstructionsandwarningson the

machineand inthismanualbeforeoperating.

Oil

Theunitwasshippedwithoil inthe engine.Checkoil levelbeforeeach

operationto ensureadequateoilin theengine.Forfurtherinstructions,

referto thestepsonpage16.

1. Removethedipstickfromtheoil fill.

2. Checkandmakesurethatthe levelof oil isupto the FULLmark

onthedipstick.

3. Ifthe oil levelis notupto FULL,pourfreshmotoroil (5W-30,with

a minimumclassificationofSF/SG/SH/SJ)slowlythroughthe

opening.Replaceoil fill dipstickandcheckoil levelagain.

Gasoline

• Storegasolineinaclean,approvedcontainerandkeepthecapin

placeonthecontainer.

• Makesurethatthecontainerfromwhichyoupourthe gasolineis

cleanandfreefromrustor otherforeignparticles.

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordandplug,and is designedto operateon 120voltAC

householdcurrent.It mustbeusedwitha properlygroundedthree-

prongreceptacleatall timesto avoidthe possibilityofelectricshock.

Followall instructionscarefullypriortooperatingtheelectricstarter.

DONOTuse electricstarterinthe rain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows:

1. Plugtheextensioncordintotheoutletlocatedontheengine's

surface.Plugtheotherendof extensioncord intoa three-prong

120-volt,grounded,ACoutletinawell-ventilatedarea.

2. RotatechokecontroltoCHOKEIJl position.

3. Ifit is 15°Forhigherpushprimertwotimes,ifbelow15°F,push

primerfourtimes.

4. PushStopswitchto ONposition.

14

5. Pushstarterbuttonto startengine.

Toprolongstarterlife,useshortstartingcycles(5 secondsmaximum

thenwaitoneminute).

6. Oncethe enginestarts,releasestarterbutton.

7. Allowtheenginetowarmup severalminutes,adjustingchoke

towardRUNposition.Waituntilenginerunssmoothlybeforeeach

chokeadjustment.

8. Whendisconnectingthe extensioncord,alwaysunplugtheend

atthethree-prongwalloutletbeforeunpluggingtheoppositeend

fromthesnowthrower.

Recoil Starter

1. Rotatechokecontrolto CHOKE IJl position.

2. Depressprimer.Ifit is 15°Forhigherpushprimertwotimes,if

below15°F,pushprimerfourtimes.

3. PushStopswitchto ONposition.

4. Graspthe recoilstarterhandleandslowlypullthe ropeout.At

thepointwhereit becomesslightlyhardertopullthe rope,slowly

allowthe ropeto recoil.

5. Pullthe starterhandlewitha firm, rapidstroke.Donotrelease

thehandleandallowittosnap back.Keepa firmholdonthe

starterhandleandallowittoslowlyrecoil.

6. Allowtheenginetowarmup severalminutes,adjustingchoke

towardRUNposition.Waituntilenginerunssmoothlybeforeeach

chokeadjustment.

NOTE:NEVERrepositiontheshiftlever(changespeedsordirection

oftravel)withoutfirstreleasingthedrivecontrolandbringingthesnow

throwertoacompletestop.Doingsowill resultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagethe augersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

REPLACING SHEAR PINS

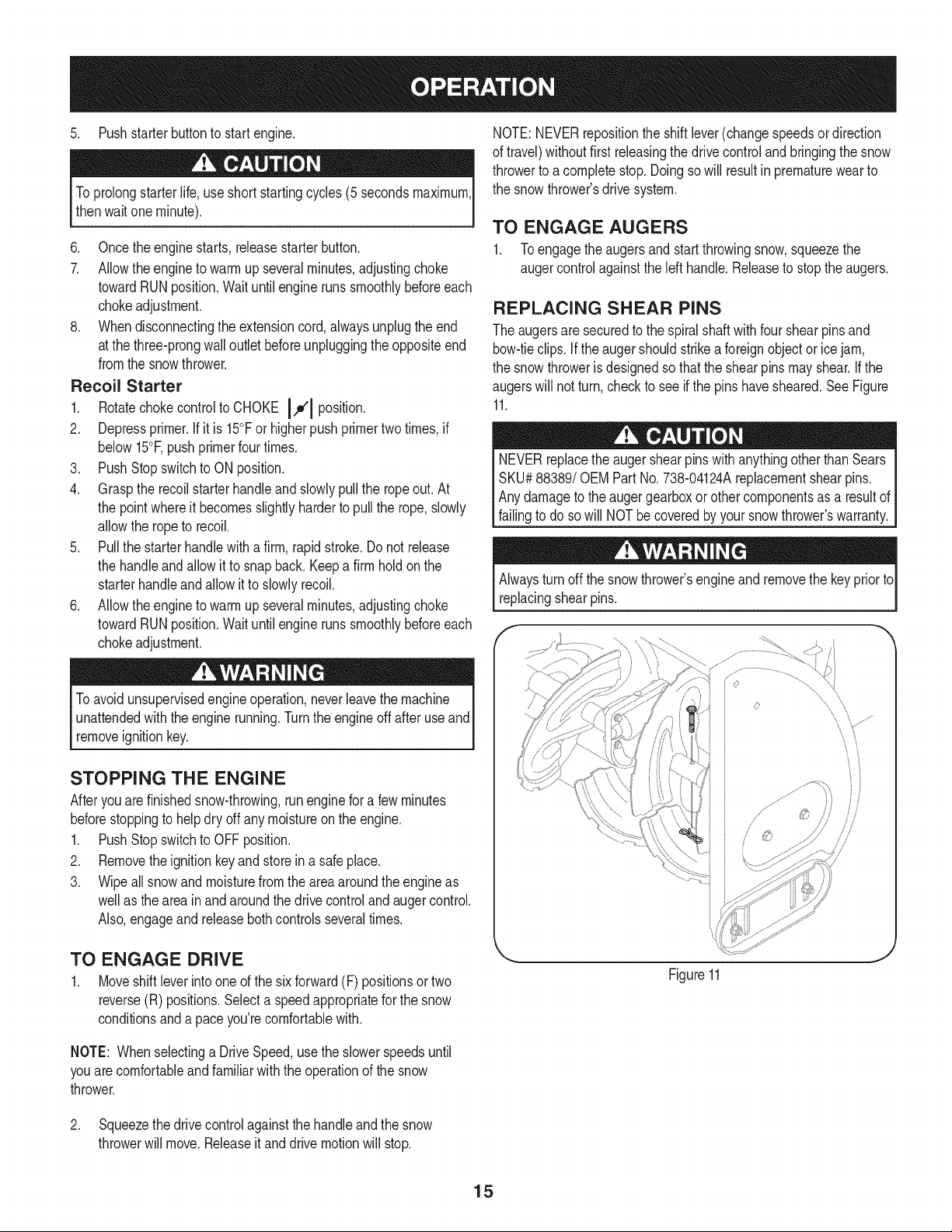

Theaugersare securedtothespiralshaftwithfourshearpinsand

bow-tieclips.Ifthe augershouldstrikea foreignobjector icejam,

thesnowthrowerisdesignedsothattheshearpinsmayshear.Ifthe

augerswill notturn,checktoseeifthepins havesheared.SeeFigure

11.

NEVERreplacetheaugershearpinswithanythingotherthanSears

SKU#88389/OEM PartNo.738-04124Areplacementshearpins.

Anydamagetotheaugergearboxorothercomponentsasaresultof

failingto do sowill NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoff thesnowthrower'sengineand removethekeypriorto

replacingshearpins.

f

Toavoidunsupervisedengineoperation,neverleavethe machine

unattendedwiththeenginerunning.Turntheengineoffafter useand

removeignitionkey.

STOPPING THE ENGINE

Afteryouarefinishedsnow-throwing,runengineforafewminutes

beforestoppingtohelpdry offanymoistureontheengine.

1. PushStopswitchto OFFposition.

2. Removetheignitionkeyandstoreina safeplace.

3. Wipeall snowandmoisturefromtheareaaroundtheengineas

wellas theareainandaroundthe drivecontrolandaugercontrol.

Also,engageand releasebothcontrolsseveraltimes.

TO ENGAGE DRIVE

1. Moveshiftleverintooneofthesixforward(F) positionsor two

reverse(R)positions.Selecta speedappropriateforthe snow

conditionsand a paceyou'recomfortablewith.

NOTE: WhenselectingaDriveSpeed,usetheslowerspeedsuntil

youarecomfortableandfamiliarwiththe operationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseit anddrivemotionwillstop.

Figure11

15

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

EachUse

1st5 to8hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage

Underheavyloadorinhightemperatures

1. Engineoillevel

2. Looseormissinghardware

3. Unitand engine.

1. Engineoil

1. Engineoi11-

2. Controllinkagesand pivots

3. Wheels

4. GearshaftandAugershaft

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

1. Change

1. Check/Change

1. Runengineuntilit stopsfromlackof

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

= =

fueloraddagasolineadditivetothe

gasinthetank.

ENGINE MAINTENANCE

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo a complete

[stop.

Checking Engine Oil

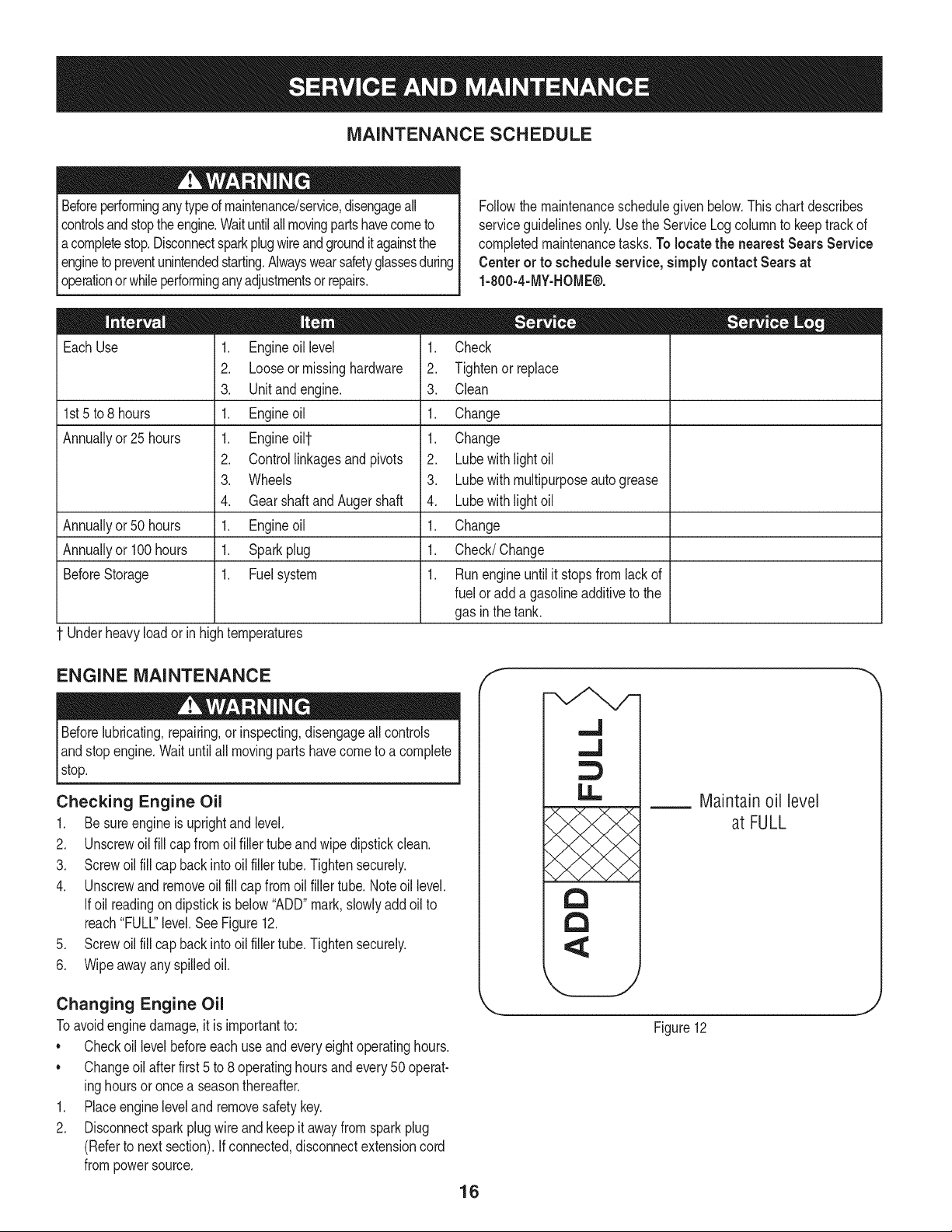

1. Besureengineis uprightandlevel.

2. Unscrewoil fillcapfromoil fillertubeandwipe dipstickclean.

3. Screwoil fillcapbackintooil fillertube.Tightensecurely.

4. Unscrewand removeoilfill capfromoilfillertube.Noteoillevel.

Ifoil readingondipstickisbelow"ADD"mark,slowlyaddoil to

reach"FULL"level.SeeFigure12.

5. Screwoil fillcapbackintooil fillertube.Tightensecurely.

6. Wipeawayanyspilledoil.

Changing Engine Oil

Toavoidenginedamage,it isimportantto:

• Checkoillevelbeforeeachuseandeveryeightoperatinghours.

• Changeoilafterfirst5 to8operatinghoursandevery50operat-

inghoursor oncea seasonthereafter.

1. Placeenginelevelandremovesafetykey.

2. Disconnectsparkplugwireandkeepitawayfromsparkplug

(Refertonextsection).Ifconnected,disconnectextensioncord

frompowersource.

16

f

..J

,,.J

U.,

Maintain oil level

at FULL

a

a

J

Figure12

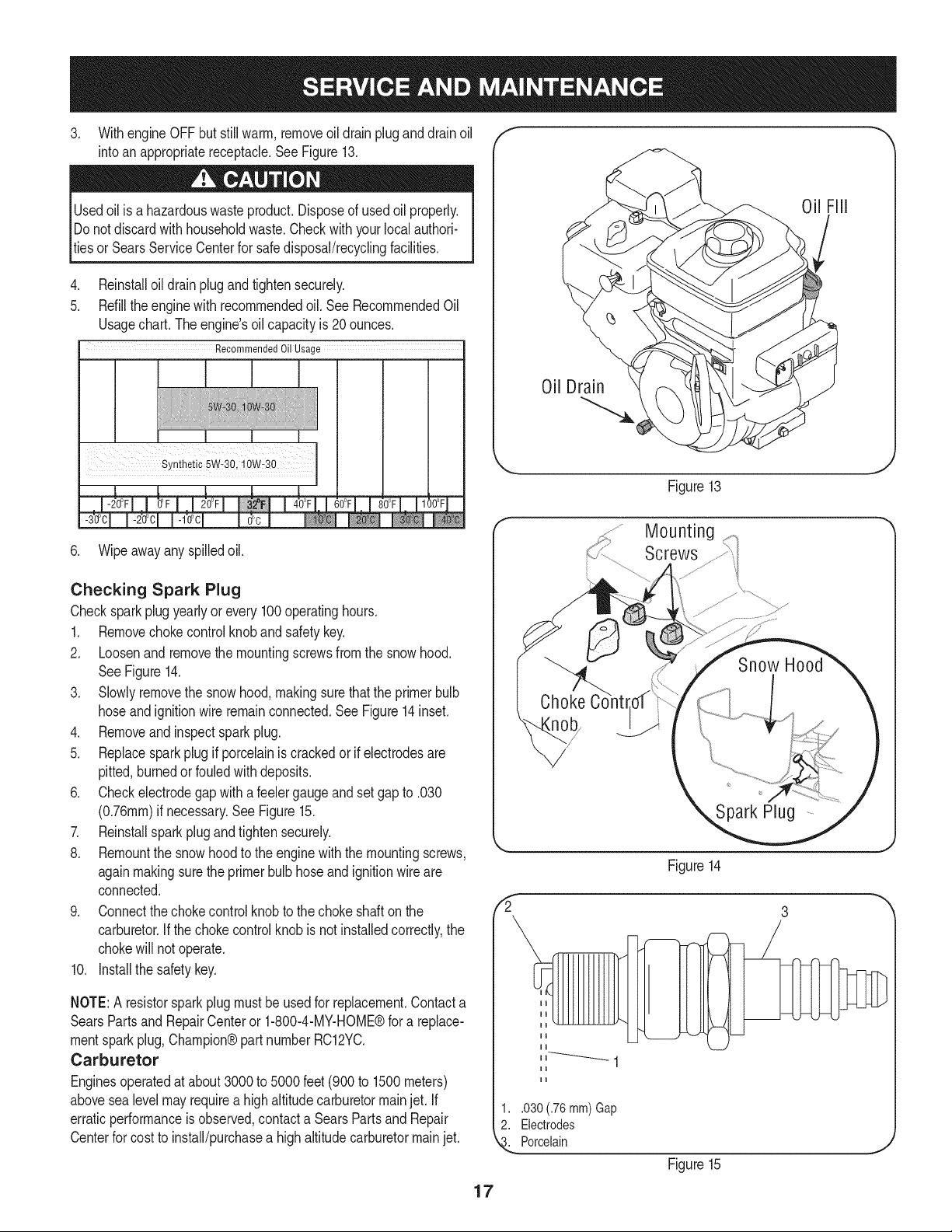

3. WithengineOFFbutstillwarm,removeoildrainpluganddrainoil

intoanappropriatereceptacle.SeeFigure13.

Usedoilisahazardouswasteproduct.Disposeofusedoilproperly.

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

ItiesorSearsServiceCenterfor safedisposal/recyclingfacilities.

4. Reinstalloildrainplugandtightensecurely.

5. Refilltheenginewithrecommendedoil.SeeRecommendedOil

Usagechart.The engine'soilcapacityis20ounces.

Recommended Oil Usage

6. Wipeawayanyspilledoil.

Checking Spark Plug

Checksparkplugyearlyorevery100operatinghours.

1. Removechokecontrolknobandsafetykey.

2. Loosenandremovethe mountingscrewsfromthesnowhood.

SeeFigure14.

3. Slowlyremovethesnowhood,makingsurethatthe primerbulb

hoseandignitionwireremainconnected.SeeFigure14inset.

4. Removeandinspectsparkplug.

5. Replacesparkplugif porcelainiscrackedorif electrodesare

pitted,burnedorfouledwithdeposits.

6. Checkelectrodegapwithafeelergaugeandsetgapto .030

(0.76ram)ifnecessary.SeeFigure15.

7. Reinstallsparkplugandtightensecurely.

8. Remountthe snowhoodtotheenginewith themountingscrews,

againmakingsurethe primerbulbhoseandignitionwireare

connected.

9. Connectthechokecontrolknobto thechokeshaftonthe

carburetor.Ifthechokecontrolknobisnotinstalledcorrectly,the

chokewillnotoperate.

10. Installthe safetykey.

0il FIll

Oil Drain

Figure13

g

Screws

Figure14

,,!

NOTE:A resistorsparkplugmustbe usedfor replacement.Contacta

SearsPartsand RepairCenteror 1-800-4-MY-HOME®forareplace-

mentsparkplug,Champion®partnumberRC12YC.

Carburetor

Enginesoperatedatabout3000to5000feet(900to1500meters)

abovesealevelmayrequireahighaltitudecarburetormainjet.If

erraticperformanceis observed,contactaSearsPartsand Repair

Centerforcosttoinstall/purchaseahighaltitudecarburetormainjet.

1..030 (.76mm)Gap

2. Electrodes

_. Porcelain

Figure15

17

Engine Speed

Toavoidseriousinjuryor death,DONOTmodifyengineinany

way.Tamperingwiththegovernorsettingcancausetheengineand

equipmenttooperateatunsafespeeds.NEVERtamperwithfactory

settingofenginegovernor.Runningtheenginefasterthanthespeed

setatthefactoryis dangerous.

LUBRICATION

Gear Shaft

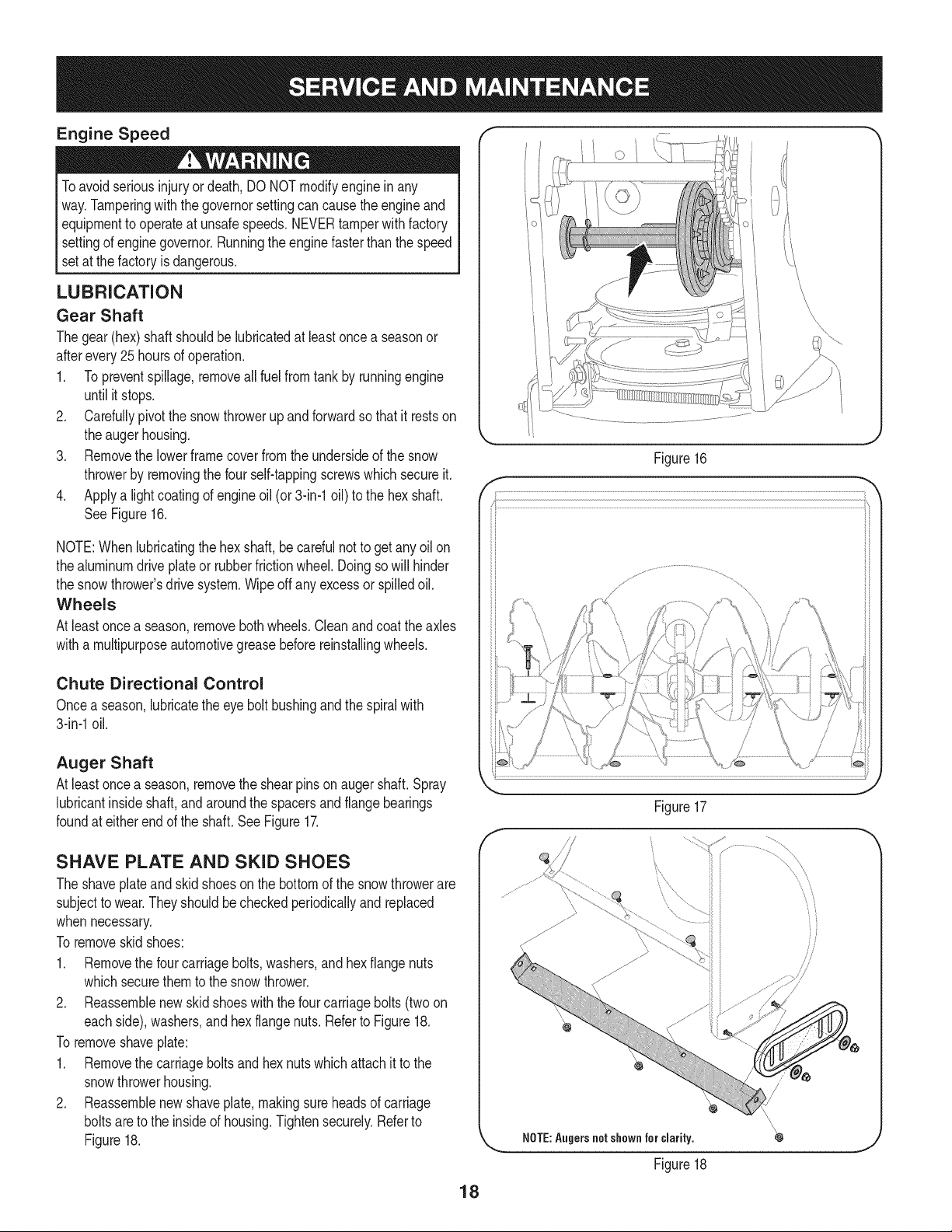

Thegear(hex)shaftshouldbe lubricatedatleastoncea seasonor

afterevery25 hoursofoperation.

1. Topreventspillage,removeall fuelfromtankbyrunningengine

untilitstops.

2. Carefullypivotthesnowthrowerupandforwardso that itrestson

theaugerhousing.

3. Removethe lowerframecoverfromtheundersideofthesnow

throwerbyremovingthe fourself-tappingscrewswhichsecureit.

4. Applya lightcoatingofengineoil(or3-in-1oil) to thehexshaft.

SeeFigure16.

NOTE:Whenlubricatingthehexshaft,be carefulnottogetanyoilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowillhinder

thesnowthrower'sdrivesystem.Wipeoff anyexcessor spilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

J

Figure16

Chute Directional Control

Oncea season,lubricatetheeyeboltbushingandthespiralwith

3-in-1oil.

Auger Shaft

Atleastoncea season,removetheshearpinson augershaft.Spray

lubricantinsideshaft,andaroundthespacersandflangebearings

foundat eitherendoftheshaft.SeeFigure17.

SHAVE PLATE AND SKID SHOES

Theshaveplateand skidshoesonthe bottomof thesnowthrowerare

subjecttowear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Toremoveskidshoes:

1. Removethefour carriagebolts,washers,andhexflangenuts

whichsecurethemto thesnowthrower.

2. Reassemblenewskidshoeswiththefourcarriagebolts(twoon

eachside),washers,andhexflangenuts.Referto Figure18.

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattachit tothe

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsof carriage

boltsareto theinsideof housing.Tightensecurely.Referto

Figure18.

,,.

Figure17

x X \

\

\

\\

NOTE:Angers notshownfor clarity.

Figure18

18

ADJUSTMENTS

Shift Cable

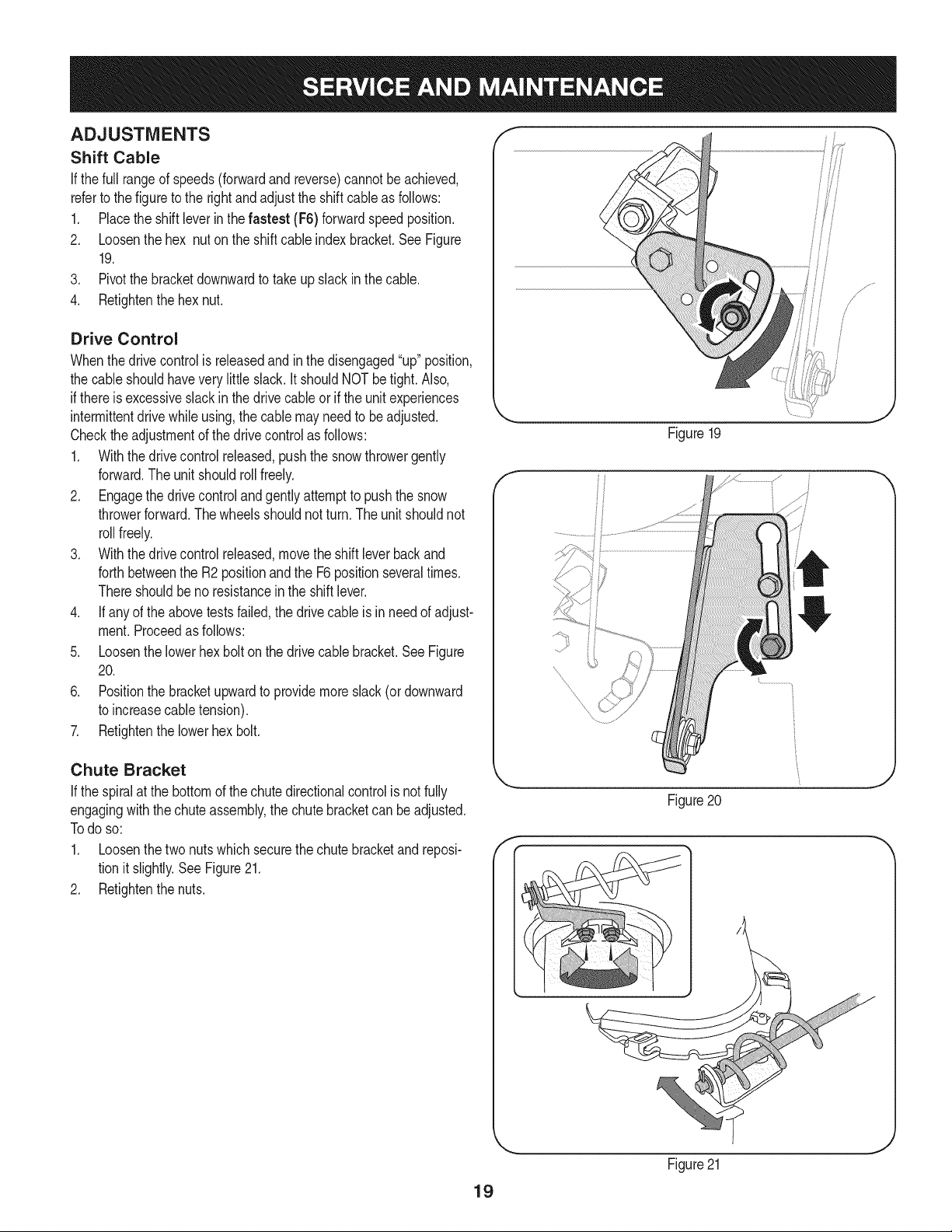

If thefull rangeofspeeds(forwardandreverse)cannotbe achieved,

referto thefiguretotherightandadjusttheshiftcableasfollows:

1. Placethe shiftleverin thefastest (F6) forwardspeedposition.

2. Loosenthehex nuton theshiftcableindexbracket.SeeFigure

19.

3. Pivotthebracketdownwardtotakeupslackinthecable.

4. Retightenthehexnut.

Drive Control

Whenthedrivecontrolis releasedandin thedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight.Also,

ifthereisexcessiveslackin thedrivecableor iftheunitexperiences

intermittentdrivewhileusing,thecablemayneedtobeadjusted.

Checktheadjustmentofthedrivecontrolas follows:

1. Withthedrivecontrolreleased,pushthesnowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattempttopushthesnow

throwerforward.Thewheelsshouldnotturn.Theunitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweenthe R2positionandthe F6positionseveraltimes.

Thereshouldbeno resistancein the shiftlever.

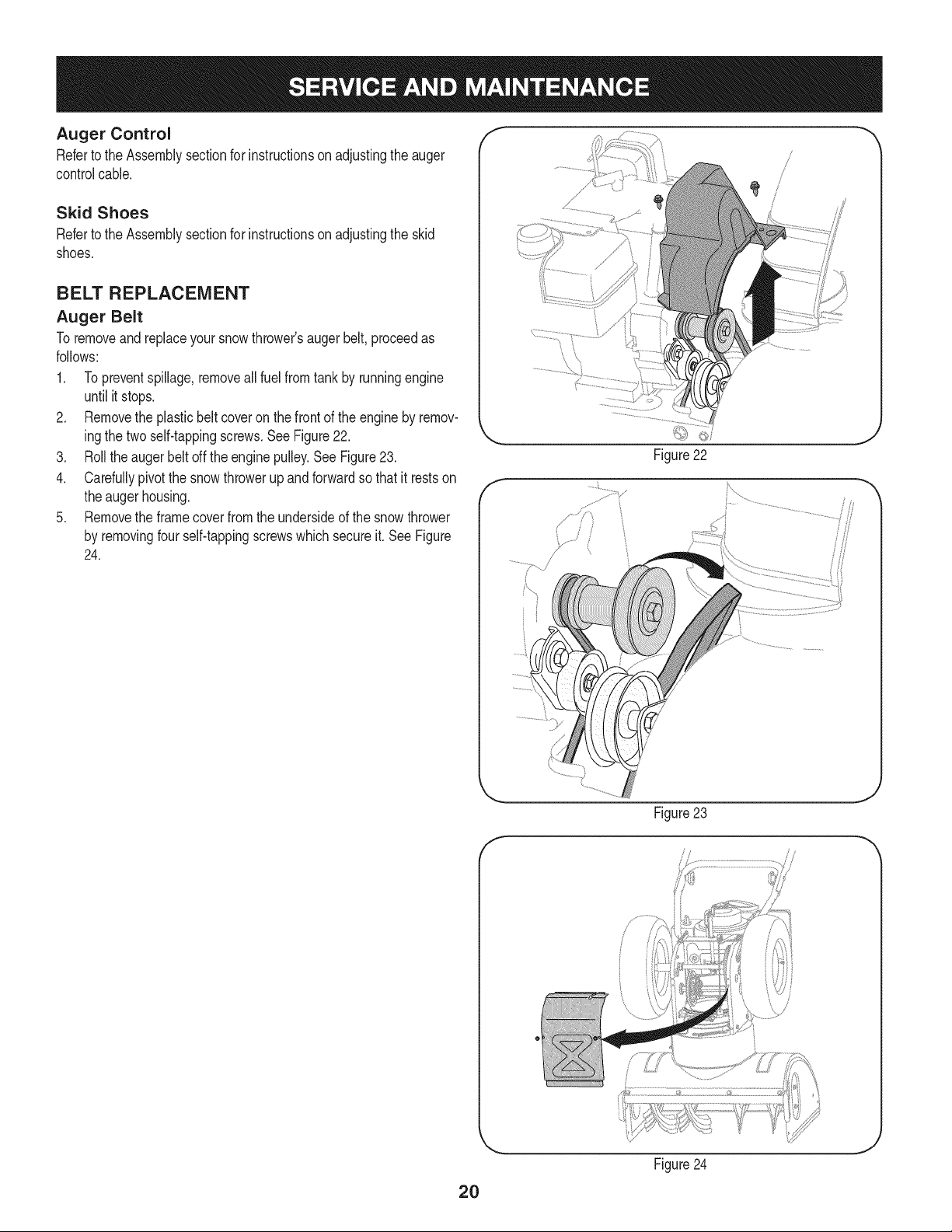

4. If anyoftheabovetestsfailed,thedrivecableisin needofadjust-

ment.Proceedasfollows:

5. Loosenthelowerhexboltonthe drivecable bracket.SeeFigure

20.

6. Positionthebracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

7. Retightenthelowerhexbolt.

Figure19

f

Chute Bracket

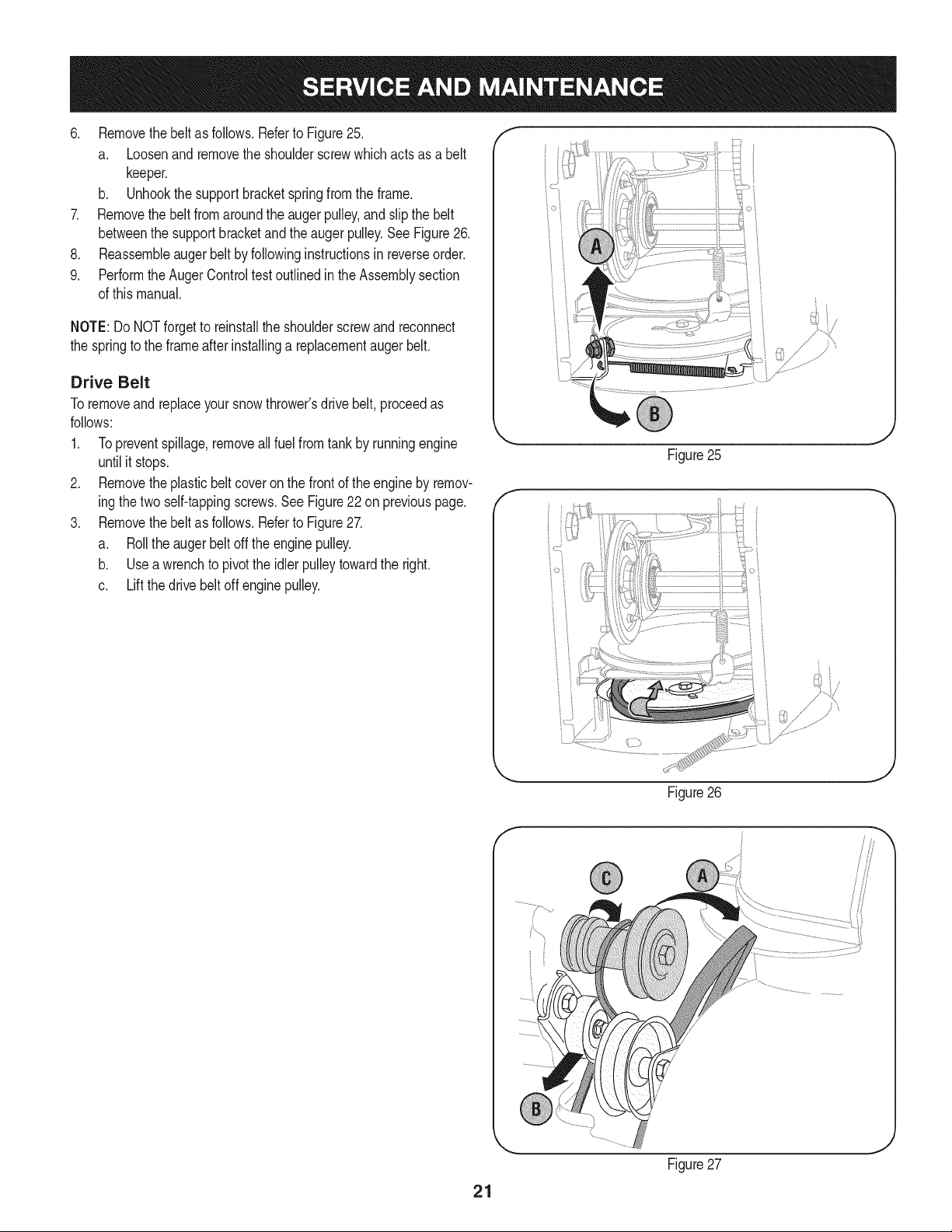

If thespiralatthe bottomofthechutedirectionalcontrolisnotfully

engagingwiththechuteassembly,thechutebracketcanbeadjusted.

Todo so:

1. Loosenthetwonutswhichsecurethechutebracketandreposi-

tionitslightly.See Figure21.

2. Retightenthenuts.

Figure20

f

Figure21

19

Auger Control f "_

RefertotheAssemblysectionforinstructionsonadjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionforinstructionsonadjustingtheskid

shoes.

BELT REPLACEMENT

Auger Belt

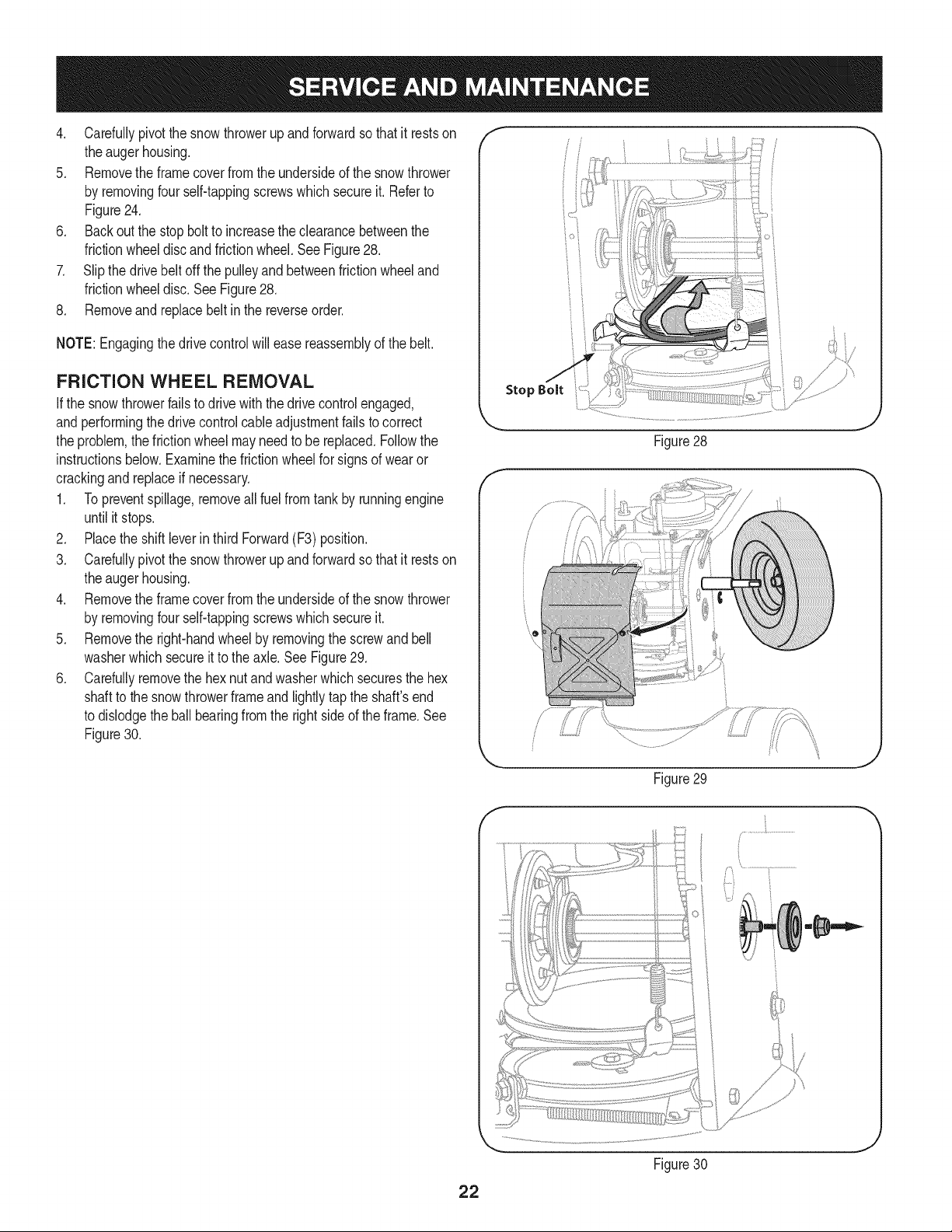

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeall fuelfromtankbyrunningengine

untilitstops.

2. Removethe plasticbeltcoveronthefrontof theenginebyremov-

ingthetwoself-tappingscrews.SeeFigure22.

3. Rolltheaugerbeltoff theenginepulley.SeeFigure23.

4. Carefullypivotthesnowthrowerupandforwardso that itrestson

theaugerhousing.

5. Removetheframecoverfromthe undersideof thesnowthrower

byremovingfourself-tappingscrewswhichsecureit.SeeFigure

24.

Figure22

f

J

2O

Figure 23

f

//

J

Figure24

6. Removethebeltasfollows.RefertoFigure25.

a. Loosenandremovetheshoulderscrewwhichactsasabelt

keeper.

b. Unhookthesupportbracketspringfromtheframe.

7. Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandtheaugerpulley.SeeFigure26.

8. Reassembleaugerbeltbyfollowinginstructionsinreverseorder.

9. PerformtheAugerControltestoutlinedintheAssemblysection

ofthismanual.

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnect

thespringtotheframeafterinstallingareplacementaugerbelt.

Drive Belt

Toremoveandreplaceyoursnowthrower'sdrivebelt,proceedas

follows:

1. Topreventspillage,removeallfuel fromtankby runningengine

untilit stops.

2. Removetheplasticbelt coveronthe frontoftheengineby remov-

ingthetwoself-tappingscrews.See Figure22on previouspage.

3. Removethebeltasfollows.Referto Figure27.

a. Rolltheaugerbeltoff theenginepulley.

b. Useawrenchto pivottheidlerpulleytowardthe right.

c. Liftthedrivebeltoffenginepulley.

/" }

Figure25

21

Figure26

Figure27

4, Carefullypivotthesnowthrowerupandforwardsothatitrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideofthesnowthrower

byremovingfourself-tappingscrewswhichsecureit.Referto

Figure24,

6. Backoutthestopbolttoincreasetheclearancebetweenthe

frictionwheeldiscandfrictionwheel,SeeFigure28,

7. Slipthedrivebeltoffthepulleyandbetweenfrictionwheeland

frictionwheeldisc,SeeFigure28,

8, Removeandreplacebeltinthereverseorder,

NOTE:Engagingthedrivecontrolwilleasereassemblyofthebelt.

FRICTION WHEEL REMOVAL

Ifthe snowthrowerfailstodrive withthedrivecontrolengaged,

andperformingthedrivecontrolcableadjustmentfailsto correct

theproblem,the frictionwheelmayneedto be replaced.Followthe

instructionsbelow.Examinethefrictionwheelfor signsofwearor

crackingandreplaceifnecessary.

1. Topreventspillage,removeall fuelfromtankbyrunningengine

untilitstops.

2. Placethe shiftleverin third Forward(F3)position.

3. Carefullypivotthesnowthrowerupandforwardso that itrestson

theaugerhousing.

4. Removetheframecoverfromthe undersideof thesnowthrower

byremovingfourself-tappingscrewswhichsecureit.

5. Removethe right-handwheelbyremovingthescrewandbell

washerwhichsecureitto theaxle.SeeFigure29.

6. Carefullyremovethehexnutandwasherwhichsecuresthe hex

shaftto thesnowthrowerframeandlightlytaptheshaft'send

todislodgetheballbearingfromtherightsideof theframe.See

Figure30.

Stop Bolt

Figure28

/ ii

J

Figure29

22

/

Figure30

Loading...

Loading...