MTD 31AS6FEE729, 31AE6LFH718, 31AE6LFG700 Owner’s Manual

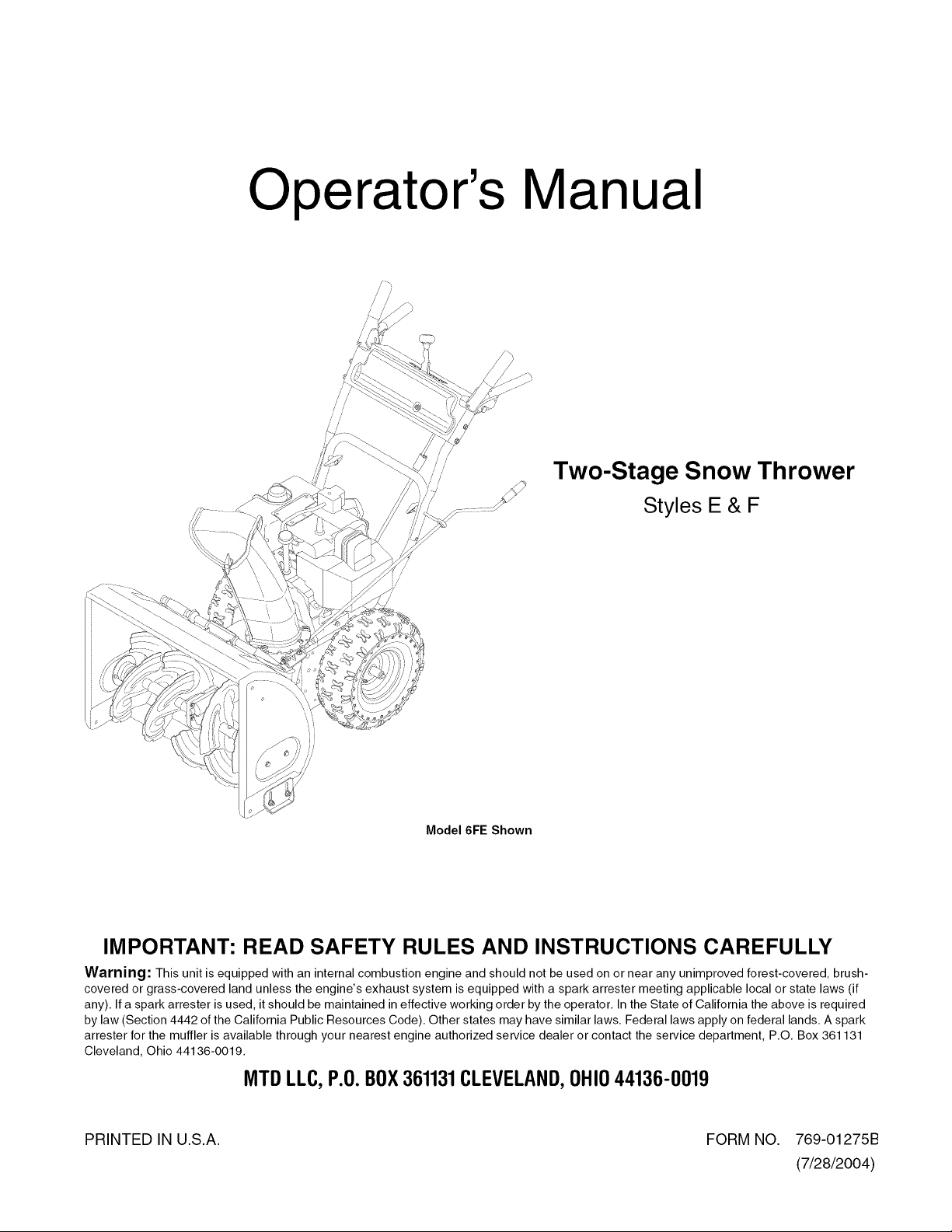

Operator's Manual

/ /'

/ /

/ !

Two-Stage Snow Thrower

Styles E & F

/

/

ii /

Model 6FE Shown

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if

any), If a spark arrester is used, it should be maintained in effective working order by the operator, In the State of California the above is required

by law (Section 4442 of the California Public Resources Code), Other states may have similar laws, Federal laws apply on federal lands, A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P,O, Box 361131

Cleveland, Ohio 44136-0019,

MTDLLC,P.O.BOX361131CLEVELAND,OHIO44136-0019

PRINTED IN U.S.A.

FORM NO. 769-01275B

(7/28/2004)

TABLEOFCONTENTS

Content

Important Safe Operation Practices

Assembling Your Snow Thrower

Know Your Snow Thrower

Operating Your Snow Thrower

Making Adjustments

Page

3

6

8

10

13

Content Page

Maintaining Your Snow Thrower 15

Servicing Your Snow Thrower 15

Troubleshooting 20

Illustrated Parts List 22

Warranty Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new snow thrower. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment

and copy the information from it in the space provided below. A sample model plate is also given below.

You can locate the model plate by standing at the operating position and looking down at the rear of the

deck. This information will be necessary to use the manufacturer's web site and/or help from the

Customer Support Department or an authorized service dealer.

Copy the model number here:

_'_ MTDLLC

_, www.rntuprouucts,com 888-888-7318

P. O. BOX 361131

CLEVELAND,OH 44136

330-228-4683

Copy the serial number here:

CUSTOMERSUPPORT

Please doNOTreturntheunitto theretailer fromwhereit waspurchased,withoutfirst contactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, you can seek help from the experts. Choose from the options below:

Visit mtdproducts.com for many useful suggestions. Click on Customer Support button and

you will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

_4_lleje "_o÷a_c_ *>_llkl_>wb!d_le base,

{idlic[ keyw{,HL _ ihh_se "

8RSWeY _Y&_?

pnfi_e

_Ser vice Locato

at_tbo_ize_ _÷_vi£e cel_t÷_s b_ yl}l_ ¢,_ea,

Manuals On_in°

To reach a Customer Support Representative, please call 1(800) 800-7310.

/ook/ng for cou/d be just

a mouse-crick aw_y!

I Eng,noI

Manual /

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer, birth defects or

other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause serious personal injury.

Plan your snow-throwing pattern to avoid discharge

of material toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

7. Exercise caution to avoid slipping or falling,

especially when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment

is to be used. Remove all doormats, newspapers,

sleds, boards, wires and other foreign objects,

which could be tripped over or thrown by the auger/

impeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or

repair to protect your eyes. Thrown objects which

ricochet can cause serious injury to the eyes.

3. Do not operate without wearing adequate winter

outer garments. Do not wear jewelry, long scarves

or other loose clothing, which could become

entangled in moving parts. Wear footwear which

will improve footing on slippery surfaces.

4. Use a grounded three-wire extension cord and

receptacle for all units with electric start engines.

5. Adjust collector housing height to clear gravel or

crushed rock surfaces.

6,

Disengage allcontrol levers beforestarting the engine.

7.

Never attempt to make any adjustments while

engine is running, except where specifically

recommended inthe operator's manual.

,

Let engine and machine adjust to outdoor

temperature before starting to clear snow.

,

To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes, which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than V2inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. Ifgasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark or

pilot light (e.g. furnace, water heater, space

heater, clothes dryer etc.).

j. Allow machine to cool at least 5 minutes

before storing.

Operation

1. Donotputhandsorfeetnearrotatingparts,inthe

auger/impellerhousingorchuteassembly.Contact

withtherotatingpartscanamputatehandsand

feet.

2. Theauger/impellercontrolleverisasafetydevice.

Neverbypassitsoperation.Doingsomakesthe

machineunsafeandmaycausepersonalinjury.

3. Thecontrolleversmustoperateeasilyinboth

directionsandautomaticallyreturntothe

disengagedpositionwhenreleased.

4. Neveroperatewithamissingordamagedchute

assembly.Keepallsafetydevicesinplaceand

working.

5. Neverrunanengineindoorsorinapoorly

ventilatedarea.Engineexhaustcontainscarbon

monoxide,anodorlessanddeadlygas.

6. Donotoperatemachinewhileundertheinfluence

ofalcoholordrugs.

7. Mufflerandenginebecomehotandcancausea

burn.Donottouch.

8. Exerciseextremecautionwhenoperatingonor

crossinggravelsurfaces.Stayalertforhidden

hazardsortraffic.

9. Exercisecautionwhenchangingdirectionand

whileoperatingonslopes.

10.Planyoursnow-throwingpatterntoavoiddischarge

towardswindows,walls,carsetc.Thus,avoiding

possiblepropertydamageorpersonalinjury

causedbyaricochet.

11.Neverdirectdischargeatchildren,bystandersand

petsorallowanyoneinfrontofthemachine.

12.Donotoverloadmachinecapacitybyattemptingto

clearsnowattoofastofarate.

13.Neveroperatethismachinewithoutgoodvisibility

orlight.Alwaysbesureofyourfootingandkeepa

firmholdonthehandles.Walk,neverrun.

14.Disengagepowertotheauger/impellerwhen

transportingornotinuse.

15.Neveroperatemachineathightransportspeedson

slipperysurfaces.Lookdownandbehindanduse

carewhenbackingup.

16.Ifthemachineshouldstarttovibrateabnormally,

stoptheengine,disconnectthesparkplugwireand

grounditagainsttheengine.Inspectthoroughlyfor

damage.Repairanydamagebeforestartingand

operating.

17.Disengageallcontrolleversandstopenginebefore

youleavetheoperatingposition(behindthe

handles).Waituntiltheauger/impellercomestoa

completestopbeforeuncloggingthechute

assembly,makinganyadjustments,orinspections.

18.Neverputyourhandinthedischargeorcollector

openings.Alwaysusetheclean-outtoolprovidedto

unclogthedischargeopening.Donotunclogchute

assemblywhileengineisrunning.Shutoffengine

andremainbehindhandlesuntilallmovingparts

havestoppedbeforeunclogging.

19.Useonlyattachmentsandaccessoriesapproved

bythemanufacturer(e.g.wheelweights,tire

chains,cabsetc.).

20.Ifsituationsoccurwhicharenotcoveredinthis

manual,usecareandgoodjudgment.Contactyour

dealerorcall1-800-800-7310forassistanceand

thenameofyournearestservicingdealer.

Maintenance& Storage

1. Never tamper with safety devices. Check their

proper operation regularly. Refer to the

maintenance and adjustment sections of this

manual.

2. Before cleaning, repairing, or inspecting machine

disengage all control levers and stop the engine.

Wait until the auger/impeller come to a complete

stop. Disconnect the spark plug wire and ground

against the engine to prevent unintended starting.

3. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any damage.

4. Do not change the engine governor setting or over-

speed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Snow thrower shave plates and skid shoes are

subject to wear and damage. For your safety

protection, frequently check all components and

replace with original equipment manufacturer's

(OEM) parts only. "Use of parts which do not meet

the original equipment specifications may lead to

improper performance and compromise safety!"

6. Check controls periodically to verify they engage

and disengage properly and adjust, if necessary.

Refer to the adjustment section inthis operator's

manual for instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear

snow from machine and prevent freeze up of auger/

impeller.

10. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer etc.

11. Always refer to the operator's manual for proper

instructions on off-season storage.

YOURRESPONSIBILITY

Restrict the use of this power machine to persons who read, understand and follow the warnings and instructions in

this manual and on the machine.

Donotmodifyengine

To avoid serious injury or death, do not modify engine

in any way. Tampering with the governor setting can

lead to a runaway engine and cause itto operate at

unsafe speeds. Never tamper with factory setting of

engine governor.

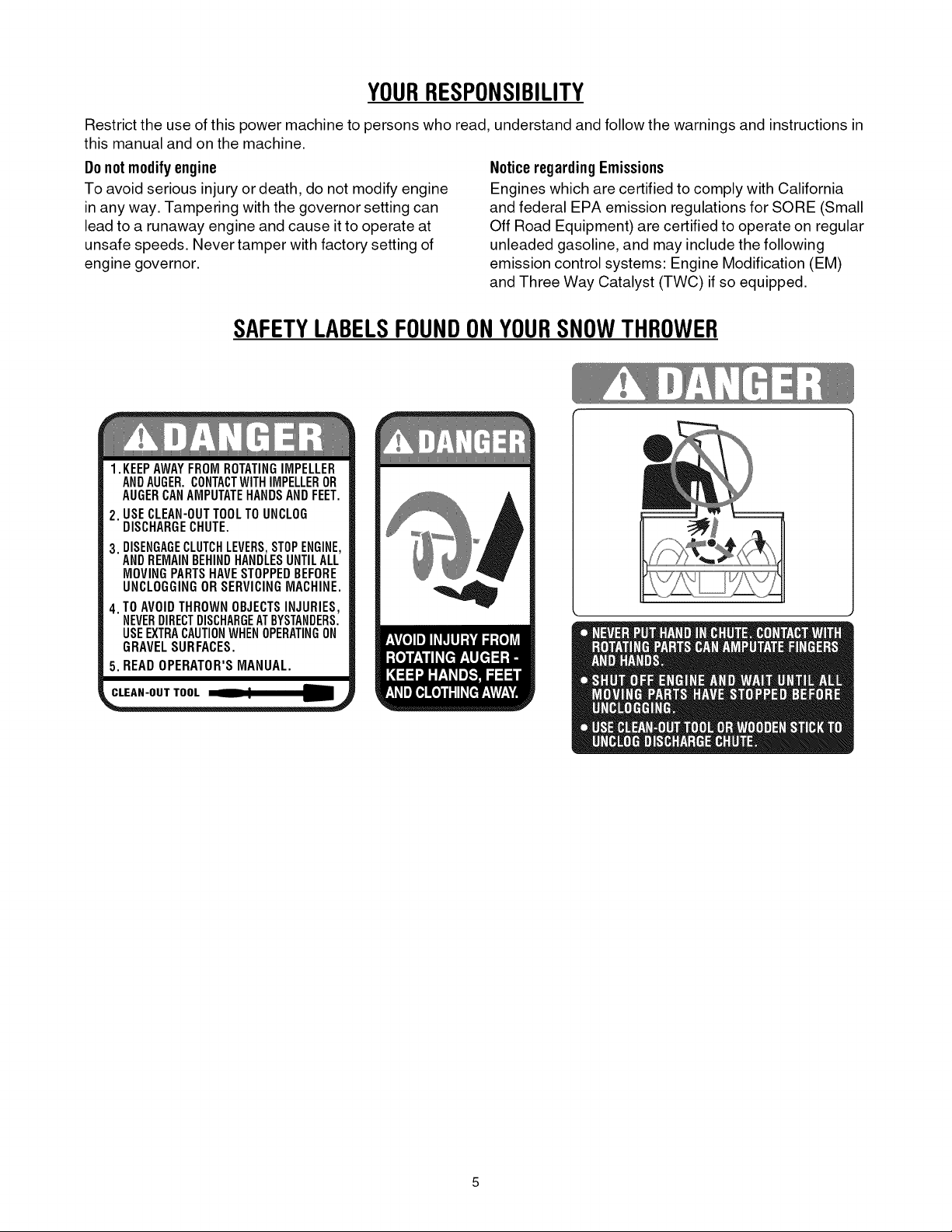

SAFETYLABELSFOUNDONYOURSNOWTHROWER

1.KEEPAWAYFROMROTATINGIMPELLER

ANDAUGER.CONTACTWITHIMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3. DISENGAGECLUTCHLEVERS,STOPENGINE,

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGORSERVICINGMACHINE.

4.TOAVOIDTHROWNOBJECTSINJURIES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

NoticeregardingEmissions

Engines which are certified to comply with California

and federal EPA emission regulations for SORE (Small

Off Road Equipment) are certified to operate on regular

unleaded gasoline, and may include the following

emission control systems: Engine Modification (EM)

and Three Way Catalyst (TWC) if so equipped.

CLEAN-OUT TOOL I1_

SECTION2: ASSEMBLINGYOURSNOWTHROWER

NOTE: References to right or left side of the snow

thrower are determined from behind the un# in the

operating position (standing directly behind the snow

thrower, facing the handle panel).

NOTE: This Operator's Manual covers several

models. Snow thrower features vary by model Not

all features referenced and pictured in this manual are

applicable to all snow thrower models.

IMPORTANT:Two replacement auger shear pins and

cotter pins are included with this manual. Refer to

Augerson page 19 for more information.

CAUTION: Prior to operating your snow

thrower, refer to AugerControlTeston page 11.

Read and follow all instructions carefully and

perform all adjustments to verify your snow

thrower is operating safely and properly.

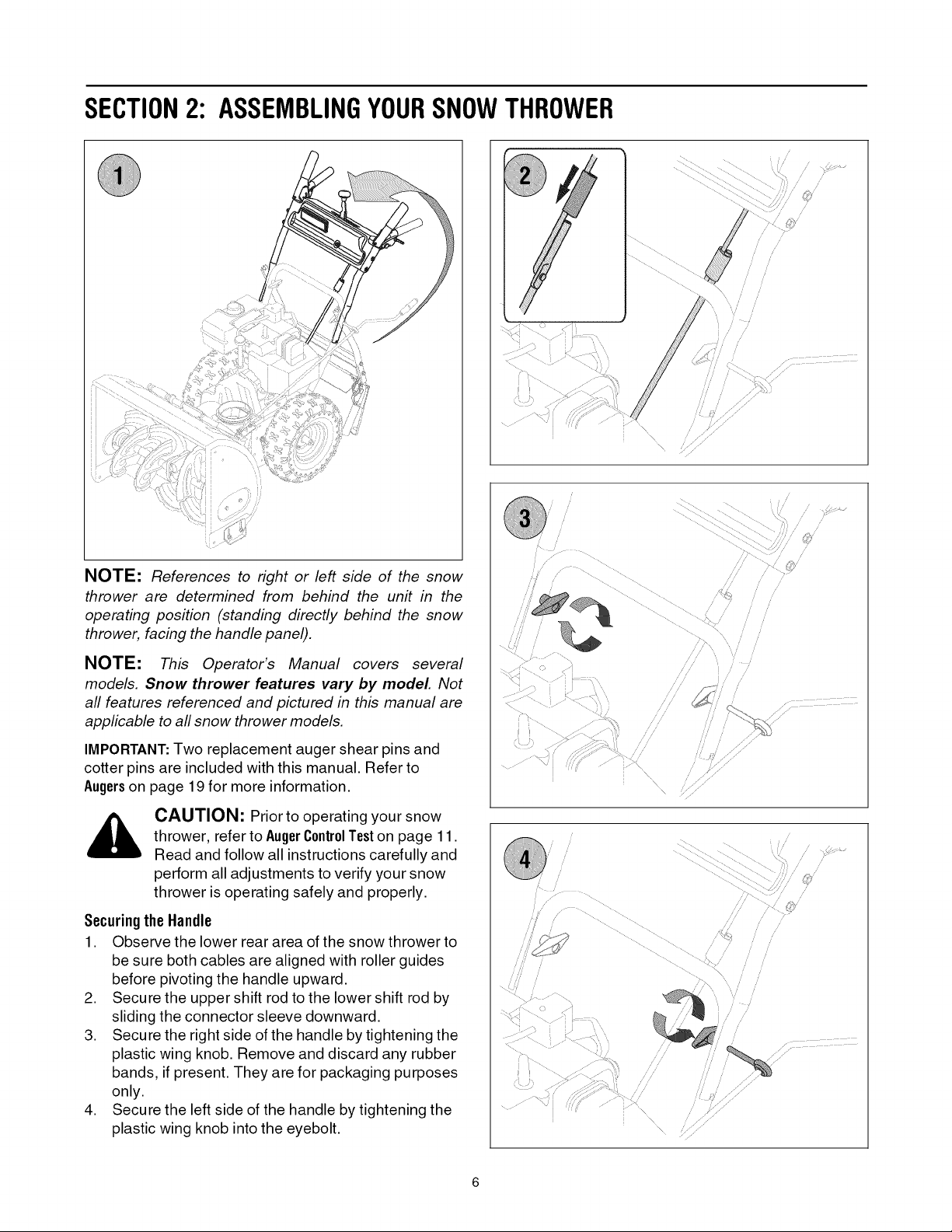

Securing the Handle

1. Observe the lower rear area of the snow thrower to

be sure both cables are aligned with roller guides

before pivoting the handle upward.

2. Secure the upper shift rod to the lower shift rod by

sliding the connector sleeve downward.

3. Secure the right side of the handle by tightening the

plastic wing knob. Remove and discard any rubber

bands, if present. They are for packaging purposes

only.

4. Secure the left side of the handle by tightening the

plastic wing knob into the eyebolt.

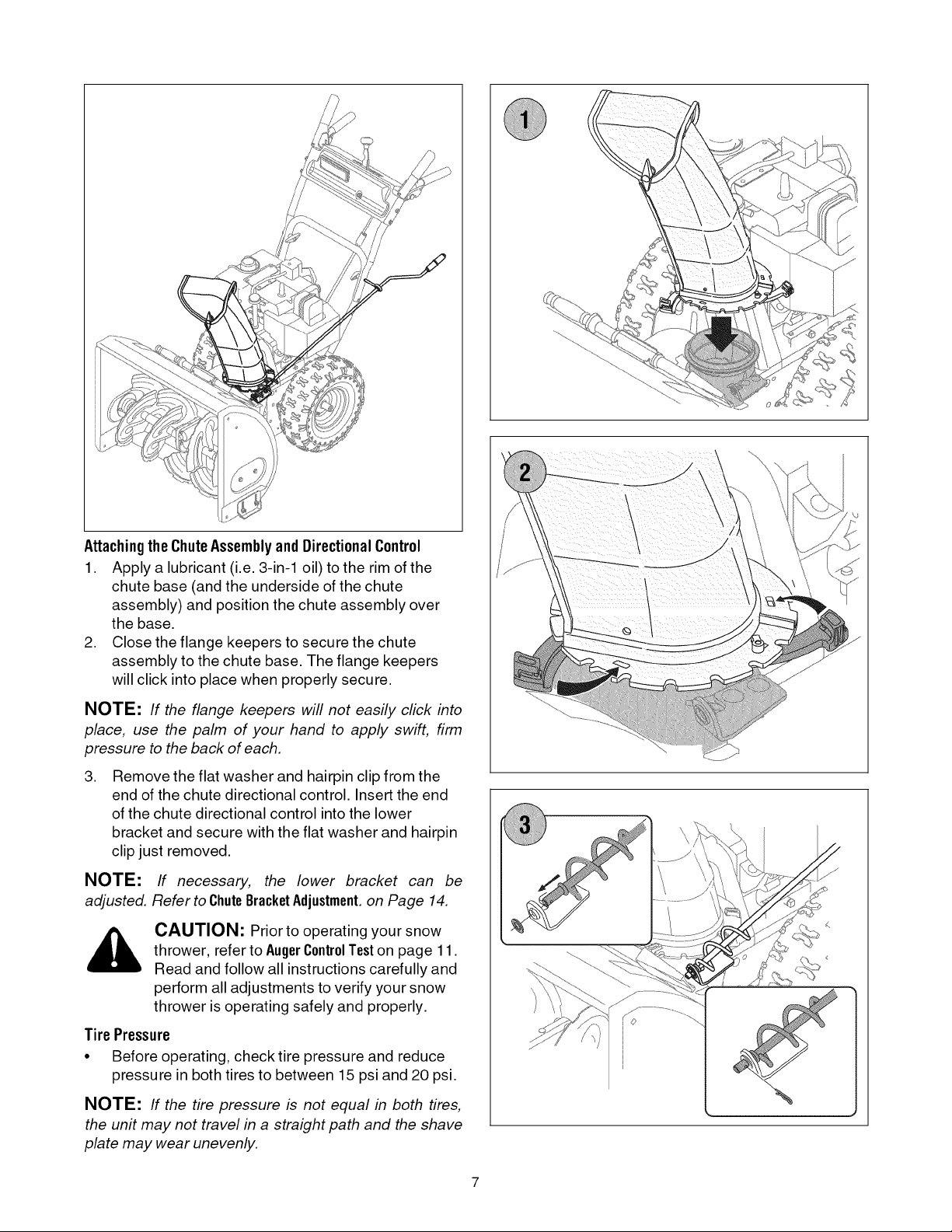

AttachingtheChuteAssemblyandDirectionalControl

1. Apply a lubricant (i.e. 3-in-1 oil) to the rim of the

chute base (and the underside of the chute

assembly) and position the chute assembly over

the base.

2. Close the flange keepers to secure the chute

assembly to the chute base. The flange keepers

will click into place when properly secure.

NOTE: If the flange keepers wifl not easily click into

place, use the palm of your hand to apply swift, firm

pressure to the back of each.

,

Remove the flat washer and hairpin clip from the

end of the chute directional control. Insert the end

of the chute directional control into the lower

bracket and secure with the flat washer and hairpin

clip just removed.

NOTE: If necessary, the lower bracket can be

adjusted. Refer to ChuteBracketAdjustment.on Page 14.

CAUTION: Prior to operating your snow

thrower, refer to AugerControlTeston page 11.

Read and follow all instructions carefully and

perform all adjustments to verify your snow

thrower is operating safely and properly.

Tire Pressure

• Before operating, check tire pressure and reduce

pressure in both tires to between 15 psi and 20 psi.

NOTE: If the tire pressure is not equal in both tires,

the unit may not travel in a straight path and the shave

plate may wear unevenly.

\

\

\

\

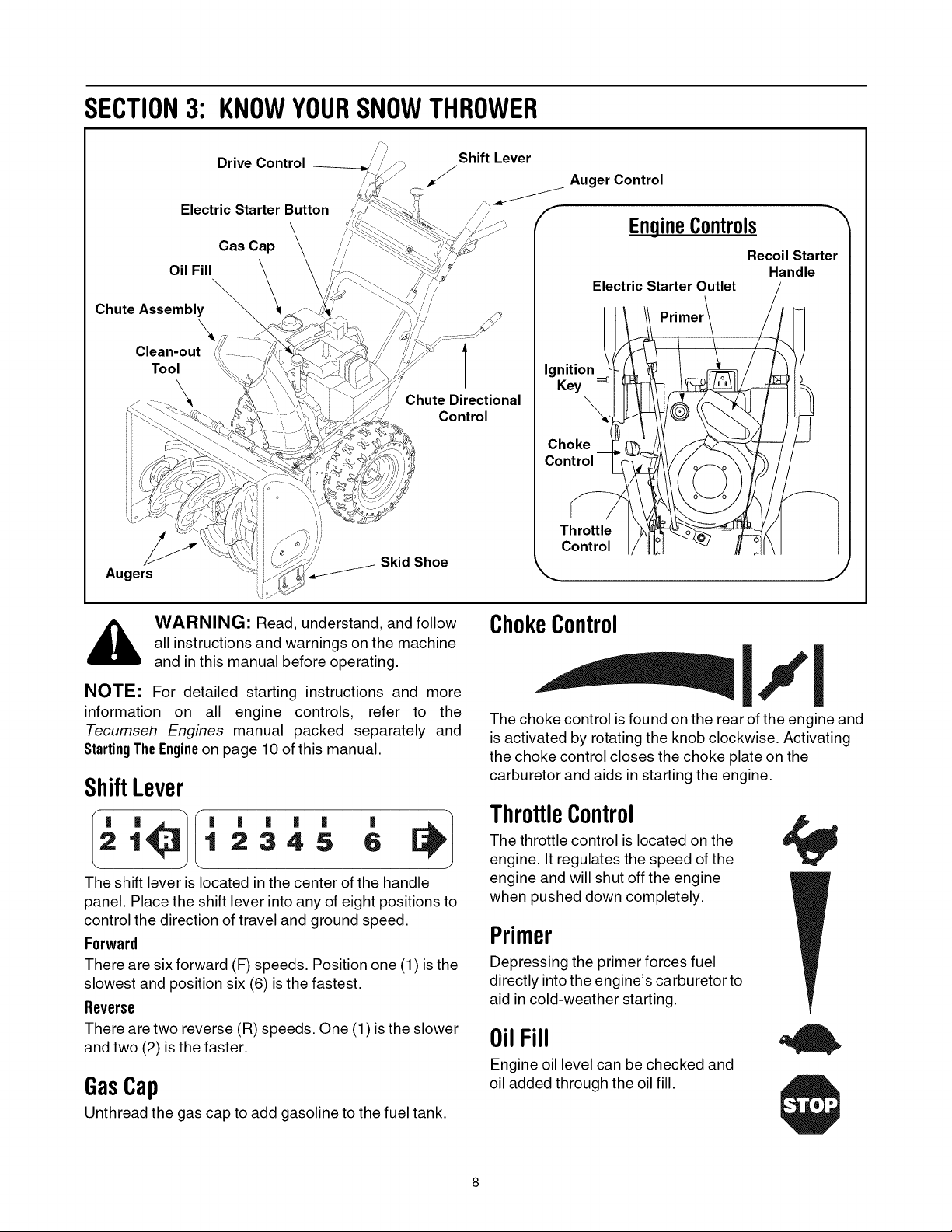

SECTION3: KNOWYOURSNOWTHROWER

Electric Starter Button

Oil Fill

Chute Assembly

Clean-out

Tool

\

Augers

Drive Control

Gas Cap

X

Shift Lever

J

Chute Directional

Control

Skid Shoe

Auger Control

f

EngineControls

Recoil Starter

Handle

Electric Starter Outlet

Ignition

Key

Choke

Control

Throttle

Control

_, WARNING: Read, understand, and follow

NOTE: For detailed starting instructions and more

information on all engine controls, refer to the

Tecumseh Engines manual packed separately and

StartingTheEngineon page 10 of this manual.

all instructions and warnings on the machine

and in this manual before operating.

ShiftLever

1 12345 6

'*lI'"" ' *1

The shift lever is located in the center of the handle

panel. Place the shift lever into any of eight positions to

control the direction of travel and ground speed.

Forward

There are six forward (F) speeds. Position one (1) is the

slowest and position six (6) is the fastest.

Reverse

There are two reverse (R) speeds. One (1) is the slower

and two (2) isthe faster.

GasCap

Unthread the gas cap to add gasoline to the fuel tank.

ChokeControl

The choke control is found on the rear of the engine and

is activated by rotating the knob clockwise. Activating

the choke control closes the choke plate on the

carburetor and aids in starting the engine.

ThrottleControl

The throttle control is located on the

engine. It regulates the speed of the

engine and will shut off the engine

when pushed down completely.

Primer

Depressing the primer forces fuel

directly into the engine's carburetor to

aid in cold-weather starting.

OilFill

Engine oil level can be checked and

oil added through the oil fill.

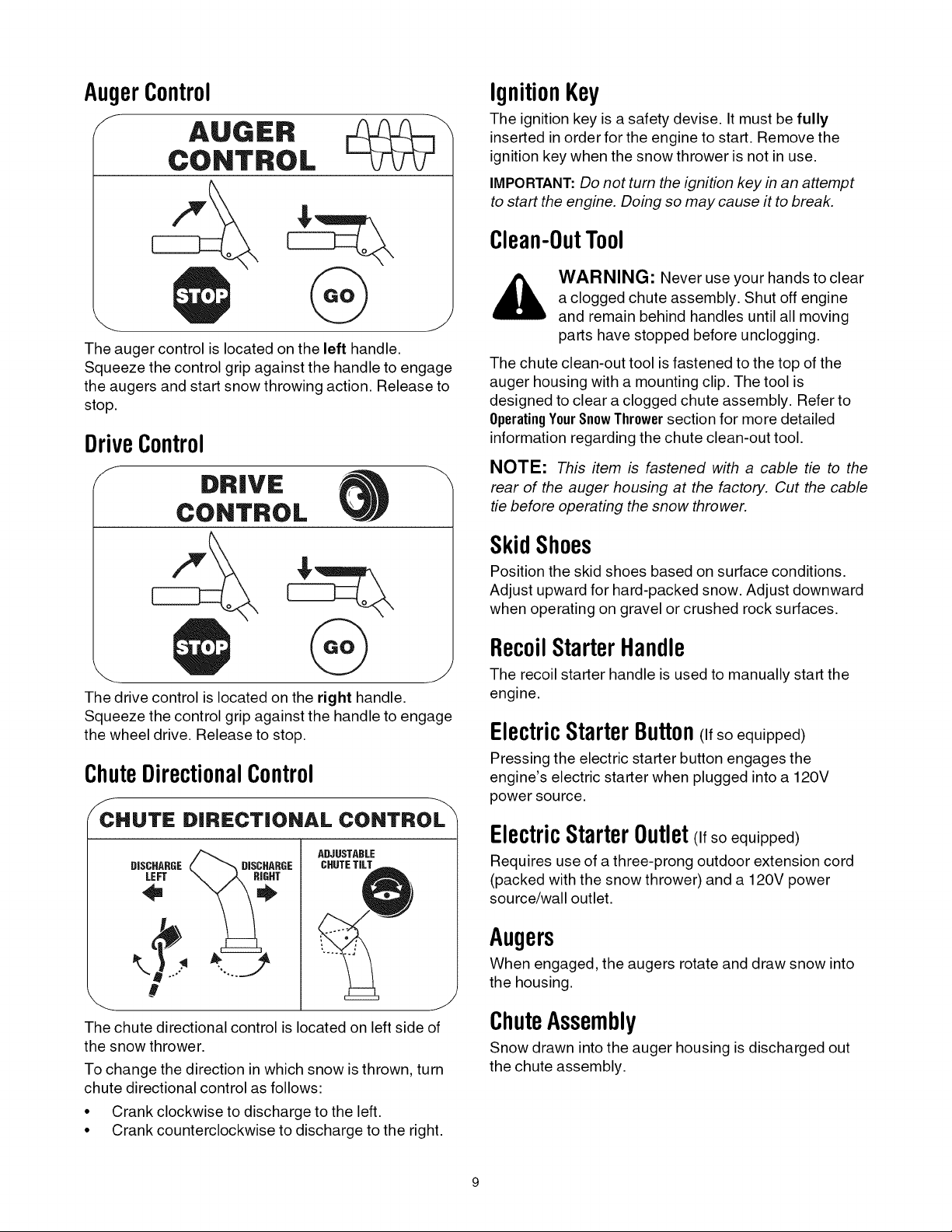

AugerControl

f

The auger control is located on the left handle.

Squeeze the control grip against the handle to engage

the augers and start snow throwing action. Release to

stop.

DriveControl

S

IgnitionKey

The ignition key is a safety devise. It must be fully

inserted inorder for the engine to start. Remove the

ignition key when the snow thrower is not in use.

IMPORTANT:Do not turn the ignition key in an attempt

to start the engine. Doing so may cause it to break.

Clean-OutTool

WARNING: Never use your hands to clear

a clogged chute assembly. Shut off engine

and remain behind handles until all moving

parts have stopped before unclogging.

The chute clean-out tool is fastened to the top of the

auger housing with a mounting clip. The tool is

designed to clear a clogged chute assembly. Refer to

OperatingYourSnowThrowersection for more detailed

information regarding the chute clean-out tool.

NOTE: This item is fastened with a cable tie to the

rear of the auger housing at the factory. Cut the cable

tie before operating the snow thrower.

SkidShoes

Position the skid shoes based on surface conditions.

Adjust upward for hard-packed snow. Adjust downward

when operating on gravel or crushed rock surfaces.

The drive control is located on the right handle.

Squeeze the control grip against the handle to engage

the wheel drive. Release to stop.

ChuteDirectionalControl

DIR CTIO.ALCO.T.O

ADJUSTABLE

LEFT

#

"-. J

The chute directional control is located on left side of

the snow thrower.

To change the direction in which snow is thrown, turn

chute directional control as follows:

• Crank clockwise to discharge to the left.

• Crank counterclockwise to discharge to the right.

CHUTETiLTDISCHARGE

RecoilStarterHandle

J

The recoil starter handle is used to manually start the

engine.

ElectricStarterButtonofso equipped)

Pressing the electric starter button engages the

engine's electric starter when plugged into a 120V

power source.

ElectricStarterOutletofso equipped)

Requires use of a three-prong outdoor extension cord

(packed with the snow thrower) and a 120V power

source/wall outlet.

Augers

When engaged, the augers rotate and draw snow into

the housing.

ChuteAssembly

Snow drawn into the auger housing is discharged out

the chute assembly.

Loading...

Loading...