MTD 31AS6BN2711 Service Manual

Service Manual

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals. These

materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals

should seek the assistance of an experienced and trained professional. Read, understand, and follow all instructions and common

sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the

equipment. No liability can be accepted for any inaccuracies or omission in this publication, although care has been taken to make

it as complete and accurate as possible at the time of publication. However, due to the variety of outdoor power equipment and

continuing product changes that occur over time, updates will be made to these instructions from time to time. Therefore, it may

be necessary to obtain the latest materials before servicing or repairing a product. The company reserves the right to make

changes at any time to this publication without prior notice and without incurring an obligation to make such changes to previously

published versions. Instructions, photographs and illustrations used in this publication are for reference use only and may not

depict actual model and component parts. © Copyright 2005 MTD Products Inc. All Rights Reserved

Model 31AS6BN2711 Two-Stage Snow Thrower

MTD Products LLC - Product Training and Education Department

FORM NUMBER 769-01420

9/2004

SERVICE MANUAL

31AS6BN-711 Snow Thrower

Tire Pressure ..............................................................................................................................1

Chute Installation .........................................................................................................................2

Discharge Chute Removal ...........................................................................................................2

Directional Control Assembly .......................................................................................................2

Chute Bracket Adjustment ...........................................................................................................2

Skid Shoe and Shave Plate Adjustment .....................................................................................2

The Shave Plate Adjustment........................................................................................................3

Drive Control Cable Adjustment ..................................................................................................3

Auger Control Testing and Adjustment .......................................................................................4

Shift Rod Adjustment .................................................................................................................5

Auger Belt Replacement .............................................................................................................5

Drive Belt Replacement .............................................................................................................7

Friction Wheel Removal........... ...................................................................................................7

Axle Shaft RemovalL ...................................................................................................................9

Splitting the Unit ........................................................................................................................10

Friction Wheel Disc Disassembly ..............................................................................................11

Auger Pulley Removal ...............................................................................................................11

Auger and Impeller Removal .....................................................................................................12

Reducer Transmission................................................................................................................13

Reduction Transmission Disassembly .......................................................................................14

Auger Idler Arm ..........................................................................................................................14

Chute Disassembly ....................................................................................................................15

1

SERVICE MANUAL

31AS6BN2-711 Snow Thrower

31AS6BN2711 (TROY-BILT AS SPECIFIED FOR

LOWE’S

SNOW THROWER MODEL NUMBER 31AS6BN2711

SERIAL # 1G144B40028

• Two Stage 5.5 HP Electric Start

• 24” Clearing Width

• 6 Forward Speeds and 2 Reverse Speeds

• X – Track Tires

GENERAL INFORMATION

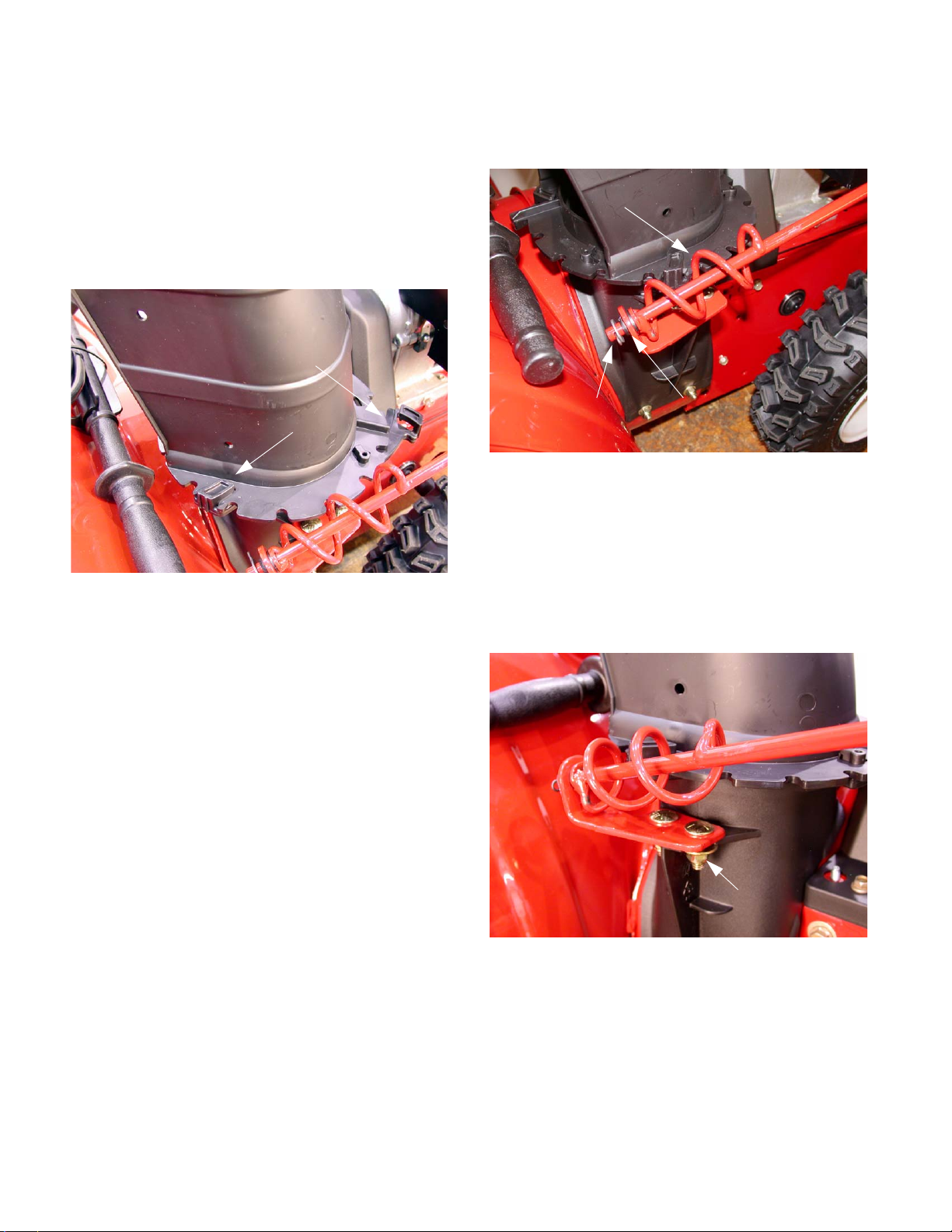

Secure it in place by placing a rubber bushing over the

top of the lower shift rod OR the upper shift rod. (A

small piece of gas line can be used as a bushing.) This

will prevent the sleeve from sliding up the shaft. See

Figure 1.

Rubber Bushing

Connecter Sleeve

Figure 1

Rubber bands hold the Auger and Drive control cables

in their respective nylon pulleys during shipping and

generally break during assembly of the handle.

Remove any pieces of rubber band after assembly.

There is a storage area in the handle panel used for

holding the spare auger shear pins. See Figure 2.

The Owner’s Manual packet includes and engine manual, extra shear pins and cotter pins as well as a packet

containing a sample of Sta-Bill fuel stabilizer that will

treat up to 2 ½ gallons of regular gas.

CAUTION: When assembling the handle for the

first time, use caution when lifting the handle.

The shift lever rod can get caught on the lower

handle cross member and if forced into position

can bend the spring shift lever. If necessary,

move the shift rod in front of the cross member

as you raise the handle into position.

There are two Supplement Sheet dated July 19, 2004,

and July 20, 2004 – Subject: Connector Sleeve on Two

Stage Snow Thrower shift rod. (Styles: E, F, H, K, L, N,

O, P and Q.)

Vibration may cause the rod connector sleeve to slide

up out of position. The remedy is to slide the connecter

sleeve fully down.

Shear Pin Storage

Figure 2

1. TIRE PRESSURE

Before operating, check tire pressure. Both tires should

be between 15 psi and 20 psi.

1

NOTE: If the tire pressure is not equal in both tires, the

unit may pull to one side or the other during operation.

2. CHUTE INSTALLATION

4.2. Insert the end of the chute directional control into

the lower bracket and secure with the flat

washer and hairpin clip. See Figure 4.

2.1. Apply a light lubricant to the rim/lip of the chute

base (and the underside of the chute assembly)

and position the chute over the base.

2.2. Close the flange keepers to secure the chute to

the base. See Figure 3.

Third flange keeper is at front of chute

Open flange keeper

Closed flange keeper

Figure 3

NOTE: If the flange keepers will not easily click

into place, use the palm of your hand to apply

swift, firm pressure to the back of each.

Directional Control Lever

Hairpin Clip Washer

Figure 4

5. CHUTE BRACKET ADJUSTMENT

If necessary the Chute Bracket can be adjusted if the

spiral at the bottom of the directional control is not fully

engaging the chute assembly.

5.1. Loosen the two nuts, which secure the chute

bracket and reposition it slightly before retightening the nuts. See Figure 5.

3. DISCHARGE CHUTE REMOVAL

3.1. To remove the discharge chute, use the bladeside of a screwdriver by wedging between the

housing and the flange keepers and with a lifting

and prying motion lift the locking flange out of

the locked position and pivot the flange keepers

outwards.

3.2. Lift the chute assembly off the mounting base of

the main housing.

4. DIRECTIONAL CONTROL ASSEMBLY

4.1. Remove the flat washer and hairpin clip from the

end of the chute directional control.

Adjustment Nuts

Figure 5

6. SKID SHOE AND SHAVE PLATE ADJUSTMENT

The space between the shave plate and the ground

can be adjusted.

For close snow removal on a smooth surface, raise

skid shoes higher on the auger housing to lower the

shave plate.

2

Loading...

Loading...