MTD 31AS615E099 Owner’s Manual

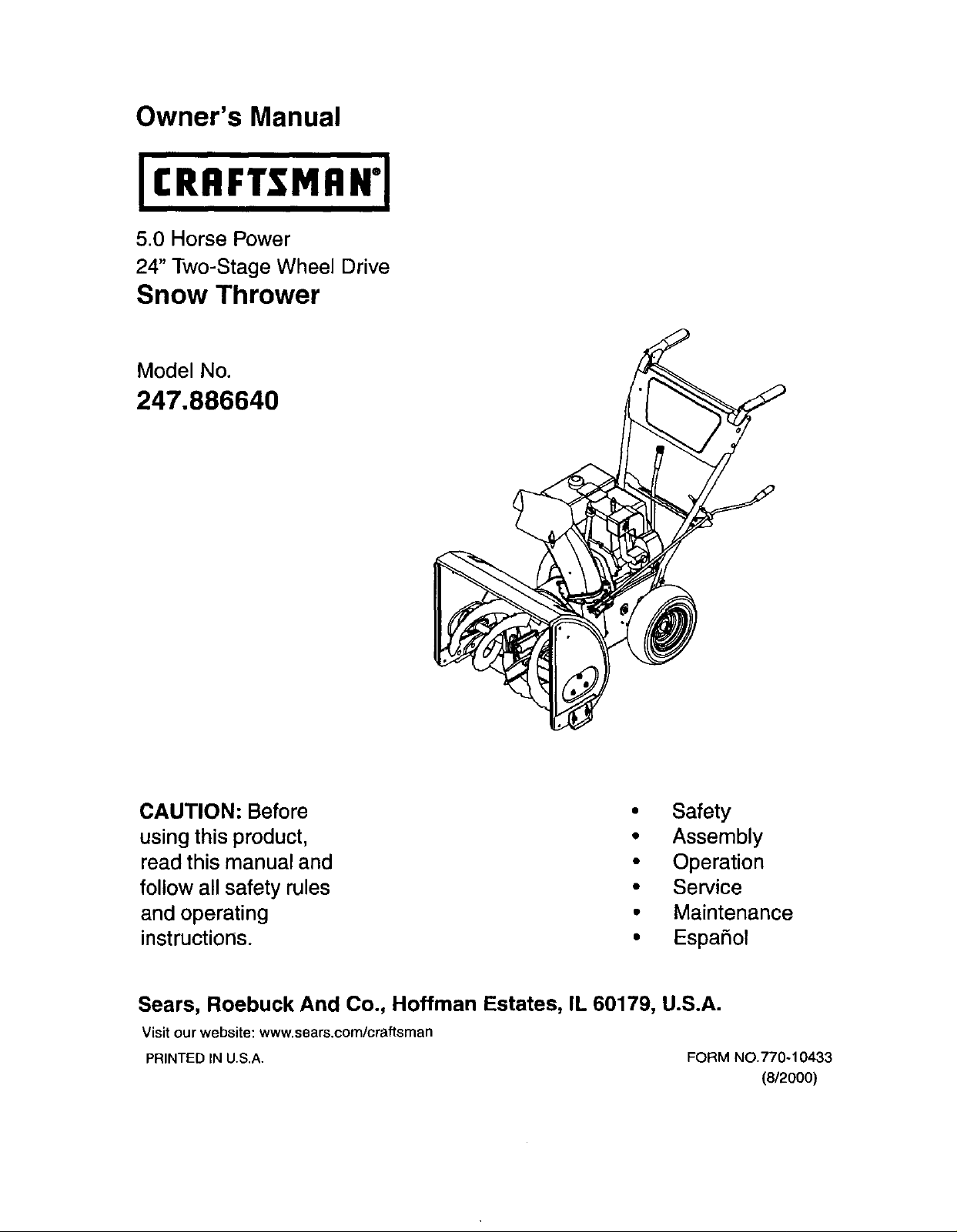

Owner's Manual

5.0 Horse Power

24" Two-Stage Wheel Drive

Snow Thrower

Model No.

247.886640

CAUTION: Before

using this product,

read this manual and

follow all safety rules

and operating

instructions.

Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craffsman

PRINTED IN U.S.A. FORM NO.770-10433

• Safety

• Assembly

• Operation

• Service

• Maintenance

• EspaSol

(8/2ooo)

Content Page

Warranty Information ......................................... 2

Safe Operation Practices ................................... 3

Hardware Pack .................................................. 5

Assembly ........................................................... 6

Operation ........................................................... 10

Maintenance ...................................................... t3

Content Page

Service & Adjustment......................................... 15

Off-Season Storage ........................................... 19

Trouble-Shooting ............................................... 20

Parts List ............................................................ 21

Espanol .............................................................. 34

Two -Year Warranty on Craftsman Snow Thrower

For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated and tuned

up according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material

and workmanship.

If this Craftsman snow thrower is used for commercial or rental purposes, this warranty applies for only 30 days

from the date of purchase.

Thls warranty does not cover:

Expendable items which become worn during normal use, such as skid shoes, shave plate and spark

plugs.

Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE ISAVAILABLE BY RETURNING THE CRAFTSMAN SNOWTHROWER TOTHE NEAREST

SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES.

Thls warranty applies only while this product Is In use In the United States.

This warranty gives you specific legalrights and you may also haveother dghtswhich may vary from stateto state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES,IL60179

Horsepower: ......................... 5.0

Engine Oil ............................. SAE 5W30 oil

Spark Plug: ........................... RJ-19LM

Engine: .................................. 143.015007

Model Number 247.886640

Serial Number ...........................................................

Date of Purchase ......................................................

Record both serial number and date of purchase and

keep in a safe place for future reference.

2

A

This symbolpoints out importantsafety instructionswhich, ifnot followed, could endangerthe personal

safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol--heed its warning.

WARNING: Engine Exhaust, some of itsconstituents, and certainvehicle components containor emit

chemicalsknown to State of Californiato cause cancerand birth defects orother reproductiveharm.

DANGER: This machine was built to be operatedaccordingto the rules for safe operation in this I

manual. As withany type ofpowerequipment, carelessnessor erroron the partof theoperator can resultI

in seriousinjury.This machine is capable of amputatinghands and feet and throwingobjects. Failureto

observe the following safety instructionscould resultinserious injuryor death.

Training

1. Read, understand, and follow all instructionson the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controlsand theirproper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years oldto operate this

machine. Children 14 years old and over shouldread and

understand the operation instructions and safetyrules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow throwingpattern to avoid discharge ofmaterial

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets andchildren at least 75

feet from the machine whileit is inoperation. Stop

machineif anyone enters the area.

7. Exercise caution to avoid slippingor falling, especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment isto

be used. Remove all door mats, newspapers, sleds,

boards, wires and other foreignobjectswhich could be

trippedover orthrown by the auger/impeller.

2. Always wear safety glasses oreye shields during

operationand while performing an adjustmentor repairto

protectyour eyes. Thrown objectswhich ricochetcan

cause serious injuryto the eyes.

3. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarvesor other

loose clothingwhich coutd become entangled inmoving

parts. Wear footwear which willimprove footingon

slipperysurfaces.

4. Use a grounded three wireextension cordand receptacle

forall units with electricstart engines.

5. Adjust collector housingheight to clear gravel or crushed

rock surfaces.

6. Disengage all clutchlevers before starting the engine.

7. Never attempt to make any adjustments while engineis

running, except where specifically recommended in the

operator's manual.

8.

Let engine and machine adjust to outdoortemperature

before stadingto clear snow.

9.

To avoidpersonal injuryor propertydamage use extreme

care inhandling gasoline. Gasoline isextremely

flammable and the vapors are explosive. Serious

personal injurycan occur when gasoline is spilledon

yourselfor your clothes which can ignite. Wash yourskin

and change clothes immediately.

a. Use onlyan approved gasoline container.

b. Extinguishall cigarettes, cigars, pipes and other

sourcesof ignition.

c. Neverfuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hotor running.

e. Allow engine to cool at least two minutes before

refueling and at least 5 minutes before storing.

f. Never over fill fuel tank. Fill tank to no more than

1,6inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc).

Operation

1. Do not put hands or feet near rotating parts,in the auger/

impellerhousing or discharge chute. Contactwith the

rotatingparts can amputate hands and feet.

2. The auger/impeller clutch lever is a safetydevice, Never

bypass itsoperation. Doing so, makes the machine

unsafe and may cause personal injury.

3. The clutch levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4. Never operate with a missing or damaged discharge

chute. Keep all safety devices in place and working.

5. Never run an engine indoors or ina poorly ventilated

area. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

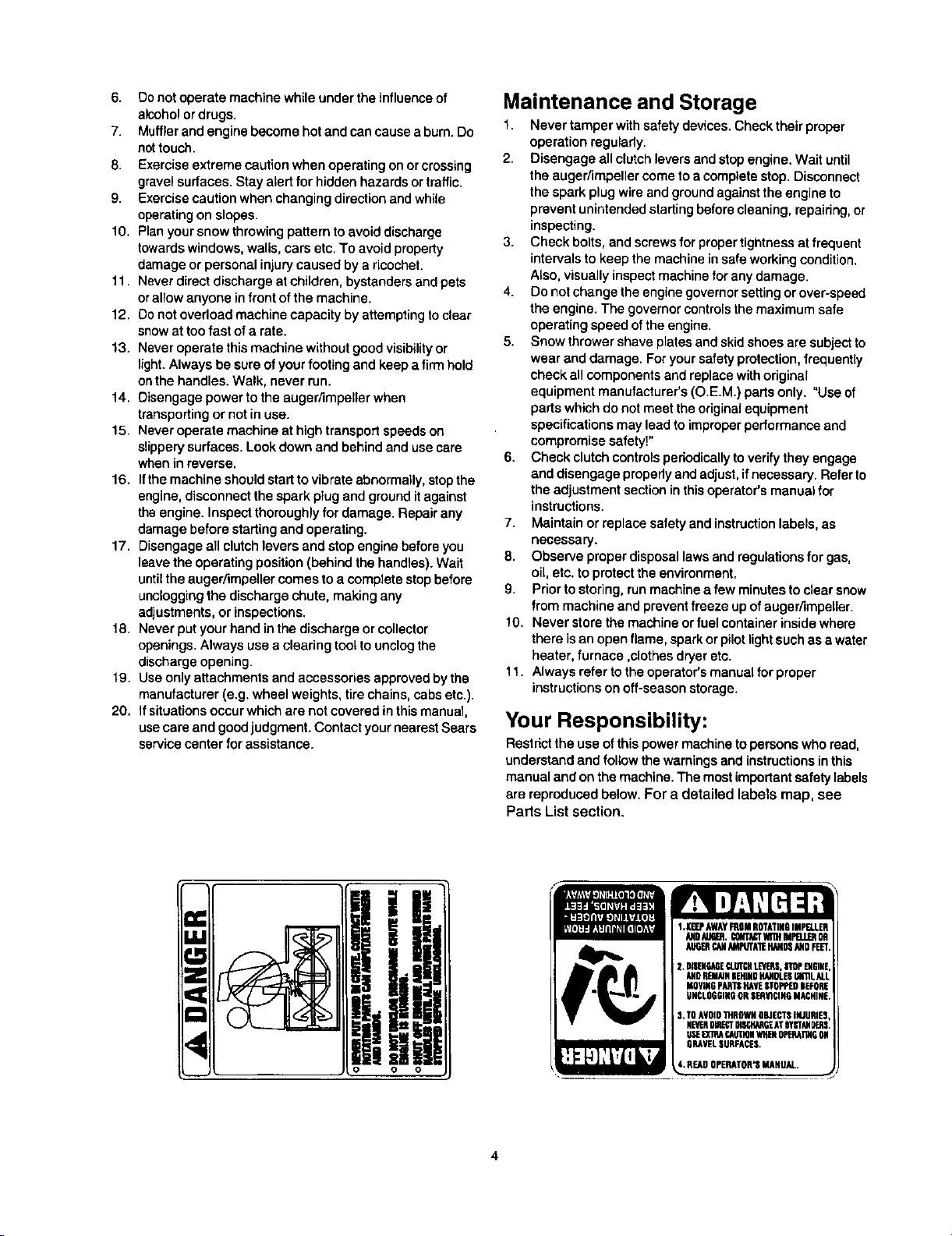

6. Donotoperate machine whileunder the influence of

alcoholor drugs.

7. Muffler and engine become hot and can cause aburn. Do

nottouch.

8. Exercise extreme caution when operating on orcrossing

gravelsurfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while

operatingon slopes.

tO. Plan your snow throwingpattern to avoid discharge

towardswindows, walls, cars etc. To avoid property

damage or personal injurycaused by a ricochet.

t1. Never direct discharge at children, bystandersand pets

orallow anyone in frontof the machine.

12. Do notoverload machine capacity by attemptingto clear

snowat too fast ofa rate.

13. Never operate thismachine without goodvisibilityor

light.Always be sure ofyour footing and keep a firmhold

onthe handles. Walk, never run.

14. Disengage power to the auger/impeller when

transportingor notin use.

15. Never operate machine at hightransport speeds on

slipperysurfaces. Lookdown and behind and use care

whenin reverse.

16. If the machine shouldstart to vibrate abnormally,stopthe

engine, disconnect the spark plug and ground itagainst

the engine. Inspect thoroughly for damage. Repair any

damage before startingand operating.

17. Disengage all clutch levers and stop engine before you

leave the operating position(behind the handles). Wait

untilthe auger/impeller comes to acomplete stopbefore

uncloggingthe discharge chute, making any

adjustments, or inspections.

18. Never put your hand inthe discharge or collector

openings. Always use a clearing toolto unclogthe

discharge opening.

19. Use onlyattachments and accessories apprcved bythe

manufacturer (e.g. wheel weights, tire chains, cabsetc.).

20. If situabonsoccur whichare not covered in thismanual,

usecare and goodjudgment. Contact your nearest Sears

servicecenter for assistance.

Maintenance and Storage

1. Never tamper with safetydevices. Check their proper

operation regularly.

2. Disengage all clutch leversand stopengine. Wait until

the auger/impeller come to a completestop. Disconnect

the spark plugwire and groundagainst the engine to

prevent unintended startingbefore cleaning, repairing,or

inspecting.

3. Check bolts, and screwsfor propertightness at frequent

intervalsto keep the machine insafe working condition,

Also,visually inspect machine forany damage.

4. Do notchange the engine governor settingor over-speed

the engine. The governorcontrolsthe maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skidshoes are subjectto

wear and damage. For your safety protection,frequently

check all componentsand replace withoriginal

equipment manufacturer's (O.EM.) parts only. "Use of

partswhich do not meet the originalequipment

specifications may lead toimproper performance and

compromise safety!"

6. Check clutch controlsperiodicallytoverify they engage

and disengage properlyand adjust,if necessary. Refer to

the adjustment sectionin thisoperator's manual for

instructions.

7. Maintain orreplace safety and instructionlabels, as

necessary.

8, Observe properdisposal laws and regulationsforgas,

oil, etc. to protectthe environment.

9. Priorto storing,runmachine afew minutes to clear snow

from machine andprevent freeze up ofauger/impeller.

tO. Never store the machine orfuel container inside where

there is an openflame, spark or pilot lightsuch asa water

heater, furnace ,clothesdryer etc.

11. Always refer to the operator'smanual forpraper

instructionson off-season storage.

Your Responsibility:

Restnct the use of this power machineto persons who read,

understand and follow the warnings andinstructionsin this

manual and on the machine. The mostimportant safety labels

are reproduced below. For a detailed labels map, see

Parts List section.

1.BENPAWAYEROMROTATINGIMPeJ,.ER

ANDS. €_OT'_TEREHENPELL_ER

ACRERCANAMPUTATElaNDSAHDFEET.

E.DISENGAGECLUTCHLEVER|.STOPENGINE.

ANDPJUIAIHIERIIiRHANOLEN6RILLALL

MOERi6PARTSHAVEOTOPPEOBEFORE

UNCLOG61i46ORSERVICINGMACHINE.

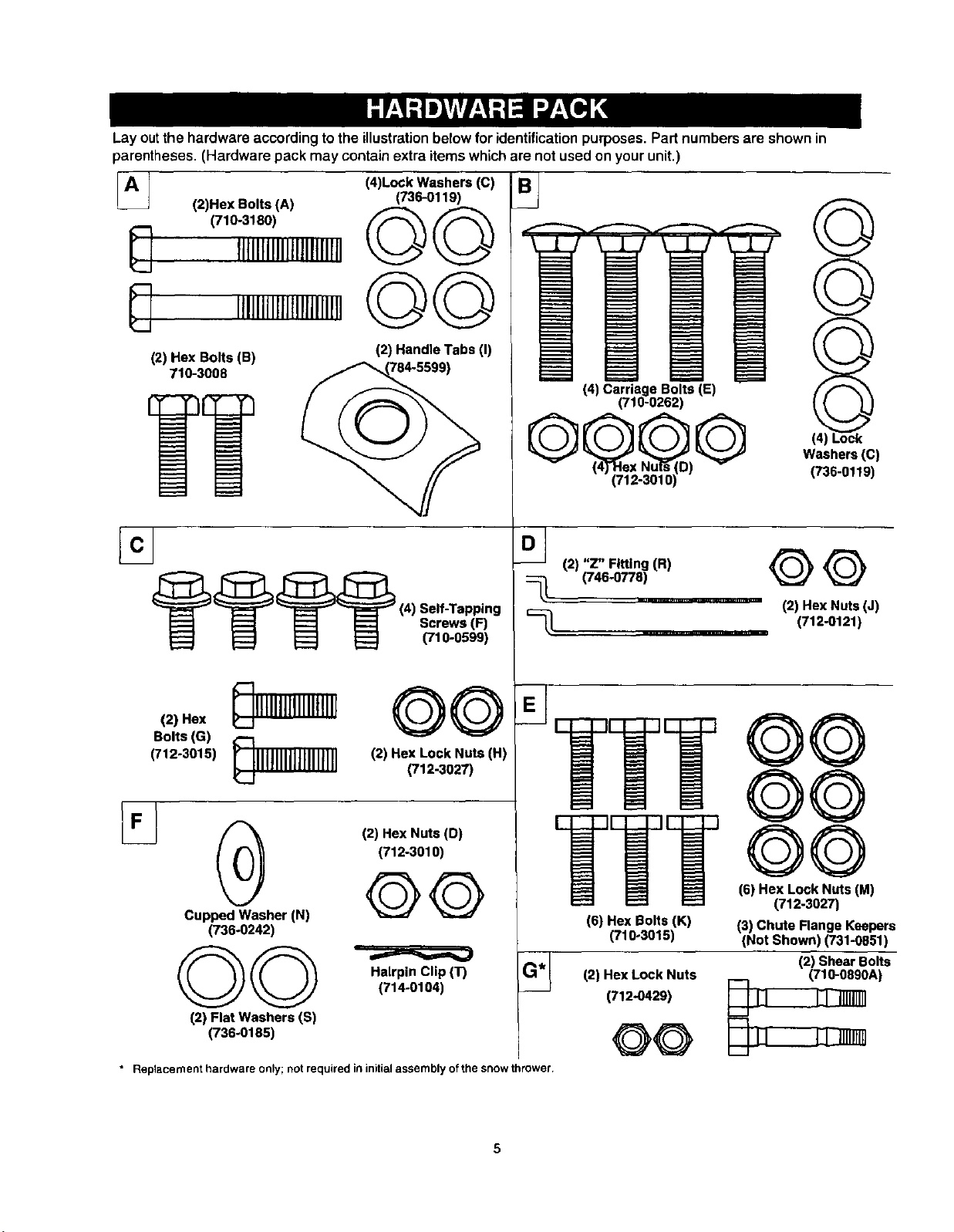

Lay outthe hardware according to the illustrationbelow for identificationpurposes. Part numbers are shown in

parentheses. (Hardware pack may contain extra items which are not used on your unit.)

(4)Lock Washers (C) I:_

A!_ (2)Hex Bolts (A)

(710-3180)

1111111111111111111111

(736-0119)

©©

©

IIIIIIIIII11i1111111II

(2) Hex Bolts(B)

710-3008

___ Screws (F)

_ t_l _ FlO-O509)

(2)Hex @11t11111111111!111

(712-3015)

Belle(G)_lllllllllllllllll]

©©

12)Handle Tabs 11)

(4) Carriage Bolts (E)

(710-0262)

G g,G

Washers (C)

(736-0119)

(7,,-'0'7%__")

(2) Hex Nuts (J)

_. .............................. (712-0121 )

88

(2) Hex Nuts (D)

(712-3010)

@

Cupped Washer (N)

(736°0242)

Q©

(2) Flat Washers IS)

(736-0185)

" Replacement hardware only; not required in initial assembly of the snow thrower.

©©

Hairpin Clip IT)

(714-0104)

(6) Hex Bolts (K)

(710-3015)

(2) Hex Lock Nuts

(7120429)

@@

oo

(6) He(_1L_.c,k2N;_ts (M)

(3) Chute Flange Keepers

(Not Shown) (731-0051)

(2) Shear Bolts

(710-0890A)

L..._r

NOTE: References to right or left side of the snow

thrower are determined from behind the unit in the

operatingposition.

Unpacking

Remove staples fromtop flaps of the carton.

Remove any looseparts included withunit (i.e.,

operator's manual, etc.).

Cut corners of the carton and lay ends down fiat,

Remove packing material.

• Roll unit out of carton. Check carton thoroughly for

loose parts before discarding.

• Take thetwo"Z" fittings from Group Dofthe

Hardware Pack and insert the Z end ofthese

throughthetwo holeson the two clutchgripson the

handle panel. The handle panel was shippedas

loosepart withyour snow thrower.

Assembly Tips:

1. For easier assembly purposes, removethe chute

from thecarton and lay iton top ofthe engine, Do

not unwrap the chute till you have installed the

handle panel and the clutch cables.

2. Lookfor stampinge of L and R respectivelyon the

bottom of the left and the right handles to identify.

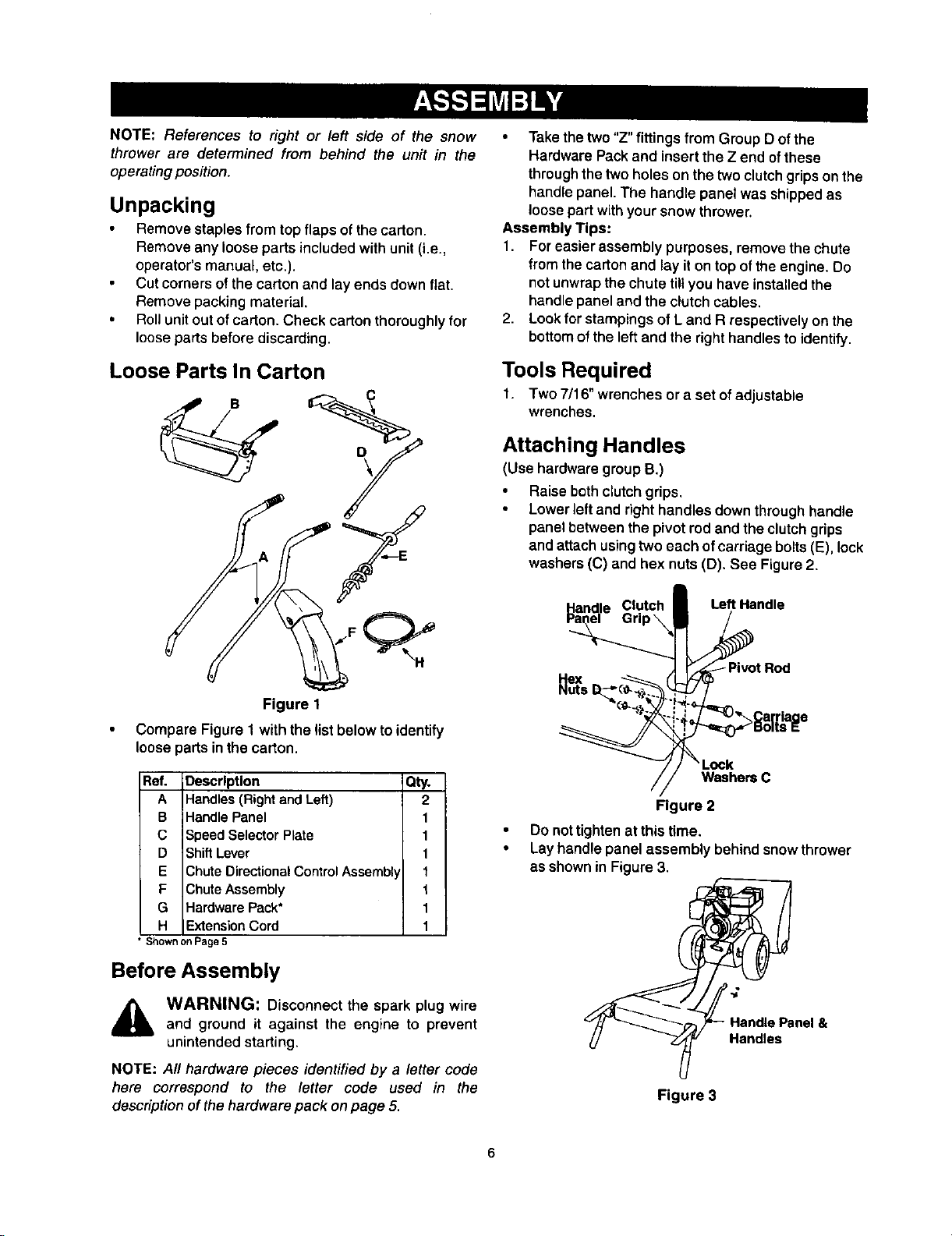

Loose Parts In Carton

Figure 1

• Compare Figure 1with the list below to identify

looseparts inthe carton.

Ref. Description Qty.

A Handles (Right and Left) 2

B Handle Panel 1

C Speed Selector Plate 1

D ShiftLever 1

E Chute Directional Control Assembl 1

F 3hute Assembly 1

G Hardware Pack* 1

H Extension Cord 1

• S_own on page 5

Tools Required

1. Two 7/16" wrenches ora set of adjustable

wrenches.

Attaching Handles

(Use hardware groupB,)

• Raise bethclutch grips,

• Lower left and right handles down throughhandle

panel between the pivot rod and theclutchgrips

and attach using two each of carriage bolts (E), lock

washers (C) and hex nuts (D). See Figure 2.

_andle Clutch • Left Handle

_1I'.._ PivotRod

_// " Lock

//

Figure 2

• Do nottighten at this time.

• Lay handle panel assembly behind snowthrower

as shown in Figure 3,

Before Assembly

WARNING: Disconnect the spark plug wireand ground it against the engine to prevent

unintendedstarting.

NOTE: All hardware pieces identified by a letter code

here correspond to the letter code used in the

descriptionof the hardware pack onpage 5.

Handle Panel &

Handles

Figure 3

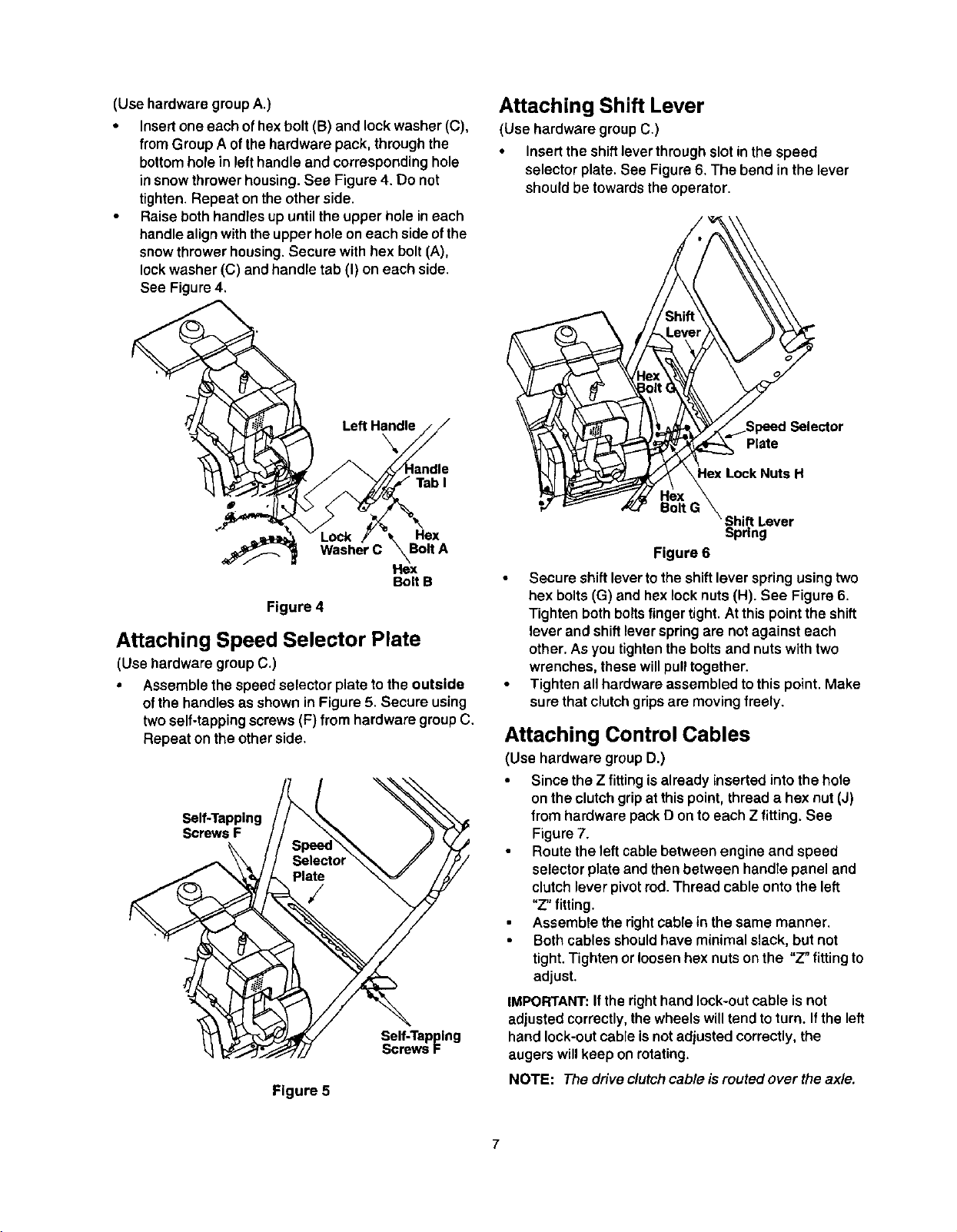

(Usehardware groupA.)

• Insert one each of hex bolt (B) and lock washer (C),

from Group A ofthe hardware pack, through the

bottomhole in left handle and correspondinghole

insnowthrower housing. See Figure 4. Do not

tighten.Repeat on the other side.

Raise both handles up until the upper hole in each

handle align with lhe upper hole on each side of the

snow thrower housing. Secure with hex bolt (A),

lock washer (C) and handle tab (I) on each side.

See Figure 4,

Left Handle

\

Attaching Shift Lever

(Use hardware groupC.)

• Insert the shiftleverthroughslotinthe speed

selectorplate. See Figure 6. The bend in the lever

shouldbe towards the operator.

Plate

Tab I

Washer C Bolt A

Figure 4

Hex

Hex

Bolt B

Attaching Speed Selector Plate

(Use hardware group C.)

• Assemble the speedselector plate to the outside

ofthe handles as shown in Figure 5. Secure using

twoself-tappingscrews (F) from hardware groupC,

Repeat on the otherside.

Self-Tapping

Screws F

Self-Tapping

Screws F

Figure 5

PlexLock Nuts H

Shift Lever

Spring

Figure 6

Secure shiftlever to the shiftlever spring usingtwo

hex bolts (G) and hex locknuts (H). See Figure 6.

Tighten both bolts finger tight. At this pointthe shift

lever and shift lever spring are not against each

other. As you tighten the bolts and nuts with two

wrenches, these will pull together.

Tighten all hardware assembled to this point. Make

sure that clutch grips are moving freely.

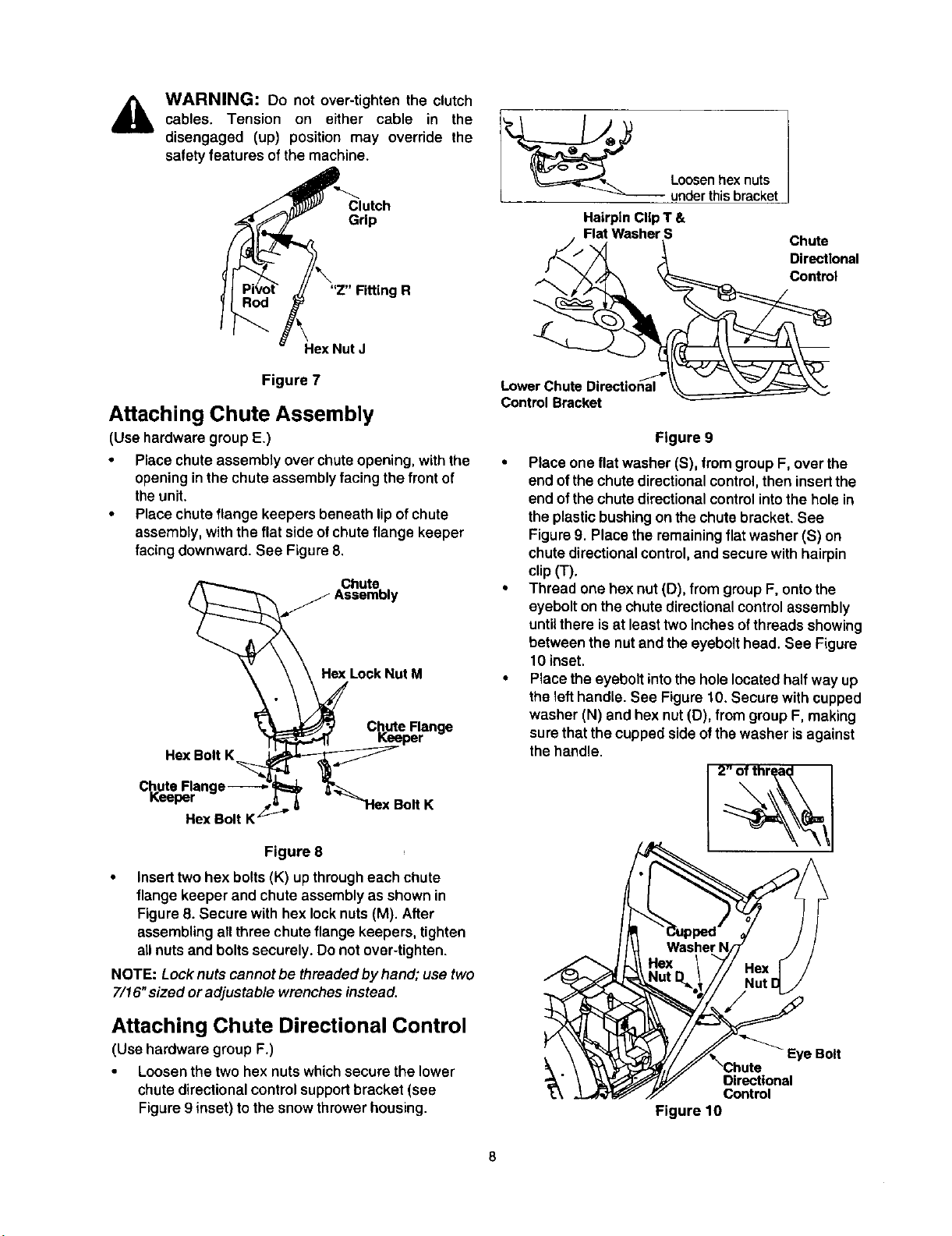

Attaching Control Cables

(Use hardware group D.)

• Since the Z fittingisalready insertedinto the hole

on the clutchgripat thispoint,thread a hex nut (J)

from hardware pack D onto each Z fitting.See

Figure7.

Route the leftcable between engine and speed

selectorplate and thenbetween handle panel and

clutchlever pivotrod.Thread cable ontothe left

"Z" fitting.

Assemble the rightcable in the same manner.

Bothcables should have minimalslack, but not

tight. Tightenor loosenhex nutson the "Z" fitting to

adjust.

IMPORTANT:Ifthe righthand lock-outcable isnot

adjusted correctly,thewheels will tend toturn. If the left

hand lock-outcable isnot adjusted correctly,the

augers will keep on rotating.

NOTE: Thedriveclutchcab/eisroutedovertheaxle.

WARNING: Do not over-tighten the clutch

A

cables. Tension on either cable in the

disengaged (up) position may override the

safetyfeatures of the machine.

Clutch

Grip

Hex Nut J

Figure 7

Attaching Chute Assembly

(Use hardware group E,)

• Race chute assembly over chuteopening, with the

opening inthe chuteassembly facingthe frontof

theunit,

• Place chute flange keepers beneath lipof chute

assembly, withthe flat sideof chute flange keeper

facingdownward, See Figure 8.

Chute

Hex Bolt K_

Cl_ute Flange -----_

r_eeper

Y

_ Loosen hex nuts

under this bracket

Hairpin Clip T &

Flat Washer S

Control Bracket

Figure 9

Place one flatwasher (S), fromgroup F, over the

end of the chute directional control, then insert the

end of the chute directional control into the hole in

the plastic bushing on the chute bracket. See

Figure 9. Place the remaining flat washer (S) on

chute directional control, and secure with hairpin

clip (T).

Thread one hex nut (D), from group F,onto the

eyebolt on the chute directional control assembly

until there is at least two inches of threads showing

between the nut and the eyeboit head. See Figure

10 inset.

Place the eyebolt intothe hole located half way up

the left handle. See Figure 10. Secure with cupped

washer (N) and hex nut (D), from group F, making

sure that the cupped side of the washer is against

the handle.

Chute

Directional

Control

Figure 8

Insert two hex bolts (K) up through each chute

flange keeper and chute assembly as shown in

Figure 8. Secure with hex lock nuts (M). After

assembling all three chute flange keepers, tighten

all nuts and bolts securely. Do not over-tighten.

NOTE: Lock nuts cannotbe threadedby hand; use two

7/16"sized oradjustable wrenches instead.

Attaching Chute Directional Control

(Usehardware group F.)

• Loosen the two hex nuts which secure the lower

chute directionalcontrol supportbracket (see

Figure9 inset) to the snow thrower housing,

e Bolt

Directional

Control

Figure 10

8

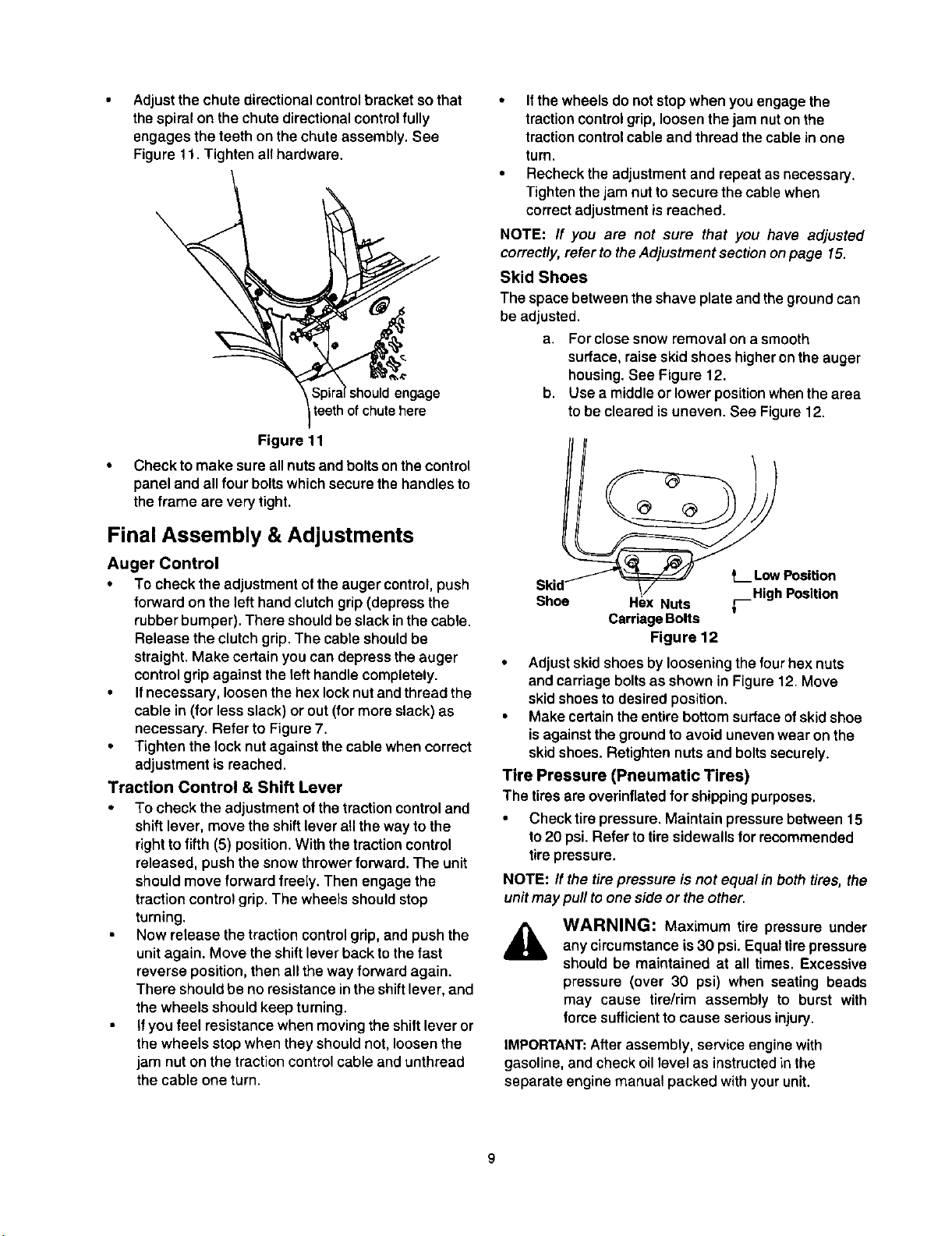

Adjustthe chute directional control bracket so that

the spiral on the chute directional control fully

engages the teeth on the chute assembly. See

Figure 11. Tighten all hardware.

_ira[should engage

teeth of chutehere

Figure 11

Check to make sure all nutsand bolts on the control

paneland all four boltswhichsecure the handles to

the frame are very tight.

Final Assembly & Adjustments

Auger Control

• To check the adjustmentof the auger control,push

forward on the left hand clutchgrip (depress the

rubberbumper). There should beslack inthe cable.

Release the clutchgrip. The cabte shouldbe

straight.Make certainyou can depress theauger

controlgrip against the left handlecompletely.

• Ifnecessary, loosenthe hex locknutand thread the

cable in (for less slack) or out(formore slack) as

necessary. Refer to Figure7.

• Tighten the locknutagainst the cablewhen correct

adjustment is reached.

Traction Control & Shift Lever

To check the adjustment of the traction control and

shift lever, move the shift lever all the way to the

right to fifth (5) position. With the traction control

released, push the snow thrower forward. The unit

should move forward freely. Then engage the

traction control grip. The wheels should stop

turning.

Now release the traction control grip, and push the

unit again. Move the shift lever back to the fast

reverse position, then all the way forward again.

There should be no resistance in the shift lever, and

the wheels should keep turning.

If you feel resistance when moving the shift lever or

the wheels stop when they should not, loosen the

jam nut on the traction control cable and unthread

the cable one turn.

• If the wheelsdo not stop when youengage the

traction controlgrip,loosen the jam nut on the

traction control cable and thread the cable in one

turn.

• Recheck the adjustment and repeat as necessary.

Tighten the jam nut to secure the cable when

correct adjustment isreached.

NOTE: If you are not sure that you have adjusted

correctly, refer tothe Adjustment section onpage 15.

Skid Shoes

The space between the shave plate and the ground can

be adjusted.

a. For close snow removal on a smooth

surface, raise skid shoes higher on the auger

housing. See Figure 12.

b. Use a middle or lower position when the area

to be cleared is uneven. See Figure 12.

oe Hex Nuts tr-

• Adjustskid shoes by loosening the four hex nuts

and carriage bolts as shown in Figure 12. Move

skid shoes to desired position.

• Make certain the entire bottom surface of skid shoe

is against the ground to avoid uneven wear on the

skid shoes. Retighten nuts and bolts securely.

Tire Pressure (Pneumatic Tires)

The tiresare overinflatedfor shipping purposes.

• Check tirepressure. Maintain pressurebetween 15

to20 psi. Refer totire sidewallsfor recommended

tire pressure.

NOTE: If the tire pressure is not equal in both tires, the

unitmay puff to one sideor theother.

A

IMPORTANT:After assembly, service enginewith

gasoline, and check oillevel as instructedinthe

separate engine manual packed with your unit.

CarriageBolts

Figure 12

WARNING: Maximum tire pressure under

any circumstance is 30 psi. Equal tirepressure

should be maintained at all times. Excessive

pressure (over 30 psi) when seating beads

may cause tire/rim assembly to burst with

force sufficient to cause serious injury.

9

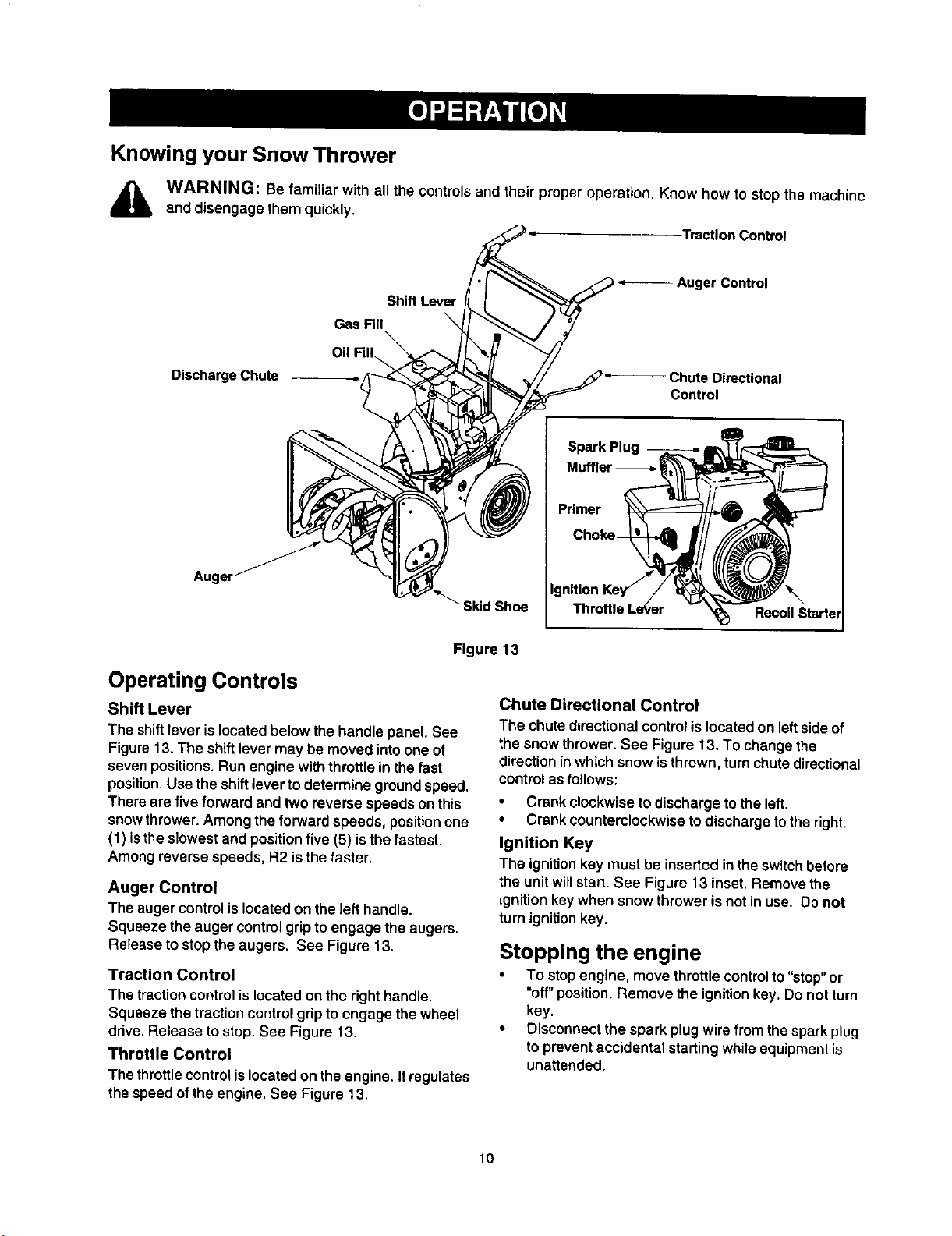

Knowing your Snow Thrower

,_ WARNING: Be familiar with all the controlsand their proper operation. Know howto stop the machine

and disengage them quickly.

Gas Fill \

Discharge Chute ---

•, --Traction Control

b_ Auger Control

Shift Lever

Chute Directional

Control

Spark Plug _ _ 1

/

Auger

IgnitionKey___X |

Skid Shoe

Figure 13

Throttle Le_er "_ RecoilStarter_

Operating Controls

Shift Lever

The shiftlever is locatedbelow the handle panel. See

Figure13. The shiftlever may be moved intoone of

seven positions.Run engine withthrottle inthe fast

position.Use the shiftlever todetermine groundspeed.

There are five forward and two reverse speedson this

snowthrower.Among the forwardspeeds, positionone

(1) isthe slowest and positionfive (5)is the fastest.

Among reverse speeds, R2 isthefaster.

Auger Control

The augercontrol islocated on the lefthandle.

Squeeze the auger controlgripto engage the augers.

Release to stopthe augers. See Figure 13.

Traction Control

The tractioncontrolis locatedon the righthandle.

Squeeze the tractioncontrolgripto engage the wheel

drive. Release tostop. See Figure 13.

Throttle Control

The throttlecontrolis locatedon the engine. Itregulates

the speed ofthe engine. See Figure 13.

Chute Directional Control

The chute directional controlislocated onleftside of

the snow thrower. See Figure 13. To change the

direction in which snow is thrown, turn chute directional

control as follows:

• Crank clockwise to discharge to the left.

• Crank counterclockwise todischarge to the right.

Ignition Key

The ignitionkeymust be inserted inthe switchbefore

the unit willstart. See Figure 13 inset. Removethe

ignition kay when snow thrower is notin use. Do not

turnignitionkey.

Stopping the engine

• To stop engine, move throttle controlto "stop" or

"off" position.Remove the ignitionkey. Donot turn

key.

• Disconnect the spark plug wirefromthe spark plug

to prevent accidental starting while equipment is

unattended.

10

Loading...

Loading...