MTD 31AS53TF799 Owner’s Manual

Operator's Manual

CRRFr MRN

26" SNOW THROWER

Model No. 247.886912

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

CAUTION: Before using

this product, read this

PARTS LIST

o ESPANOL

manual and follow all

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-05134E

7/26/2011

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-6

Assembly......................... Pages8-13

Operation........................ Pages14-17

Service&Maintenance.............. Pages18-23

Troubleshooting...................... Page25

PartsList......................... Pages26-43

RepairProtectionAgreement............ Page47

Espadol............................. Page48

ServiceNumbers................... BackPage

Off-SeasonStorage................... Page24

CRAFTSMANTWOYEARFULLWARRANTY

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwill

receivefreerepairorfreereplacementifrepairisunavailable.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesorifrentedtoanotherperson.

Forwarrantycoveragedetails to obtain repairor replacement,visit the website: www.craftsman.com

This warranty covers ONLYdefects in material andworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddles,drift

cutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementor repaircausedby puncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnot limitedto damagecausedbyover-speedingtheengine,or fromimpacting

objectsthatbendtheframe,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountofengineoil, or failureto maintaintheequipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 3 Quarts

SparkPlug: F6RTC

SparkPlugGap: .020"to .030"

©KCDIR LLC

ModelNumber.................................................................

Serial Number.................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothe safeopera-

tionpracticesinthis manual.As withanytypeof powerequipment,

carelessnessorerroron thepartofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethe followingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytothe operatorand/

orbystanders.Keepthismanualina safeplaceforfutureand

regularreferenceandfor orderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethis machinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileit is in operation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuse of thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawherethe equipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

• Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

• Neverattemptto makeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebefore

startingtoclearsnow.

3

SafeHandlingof Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

onyourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandothersources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegas capor addfuel whilethe engineis hot

or running.

• Allowenginetocoolat leasttwominutesbeforerefueling.

• Neveroverfillfueltank. Filltanktono morethan1/2inch

belowbottomoffillerneckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineor fuel containerinsidewhere

thereis anopenflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocool at least5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleor ona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refueliton theground.Ifthisisnotpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimof the fueltankor

containeropeningatalltimesuntil fuelingis complete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donotputhandsorfeetnear rotatingparts,inthe auger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyin bothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesin placeandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.Do notoperateon steepslopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc. Thus,avoidingpossibleproperty

damageorpersonalinjurycausedbya ricochet.

• Neverdirectdischargeat children,bystandersand petsor allow

anyoneinfrontof the machine.

• Donotoverloadmachinecapacityby attemptingtoclearsnowat

toofastof arate.

• Neveroperatethis machinewithoutgoodvisibilityorlight.Always

be sureof yourfootingand keepafirmholdon thehandles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineat hightransportspeedsonslippery

surfaces.Lookdownand behindand usecarewhenbackingup.

• Ifthe machineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgroundit againstthe engine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverput yourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcordslowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanletgo. Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.

• Forin-warrantysafety,operationormaintenancequestions,orto

orderpartsandscheduleservice,call 1-800-4-MY-HOME.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethe dischargechute

is themostcommoncauseof injuryassociatedwithsnowthrowers.

Neveruseyourhandto cleanout thedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothe maintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstopthe engine.Waituntiltheauger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheenginetopreventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthe machineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingorover-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjectto wear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonlyas listedinthe Partspagesof thisoperator's

manual.Useofpartswhichdonotmeetthe originalequipment

specificationsmayleadto improperperformanceandcompro-

misesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,if necessary.Referto the adjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,as necessary.

Observeproperdisposallawsand regulationsfor gas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclearsnowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.Atthe endoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do not modifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlessthe engine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(ifany)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorfor themuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

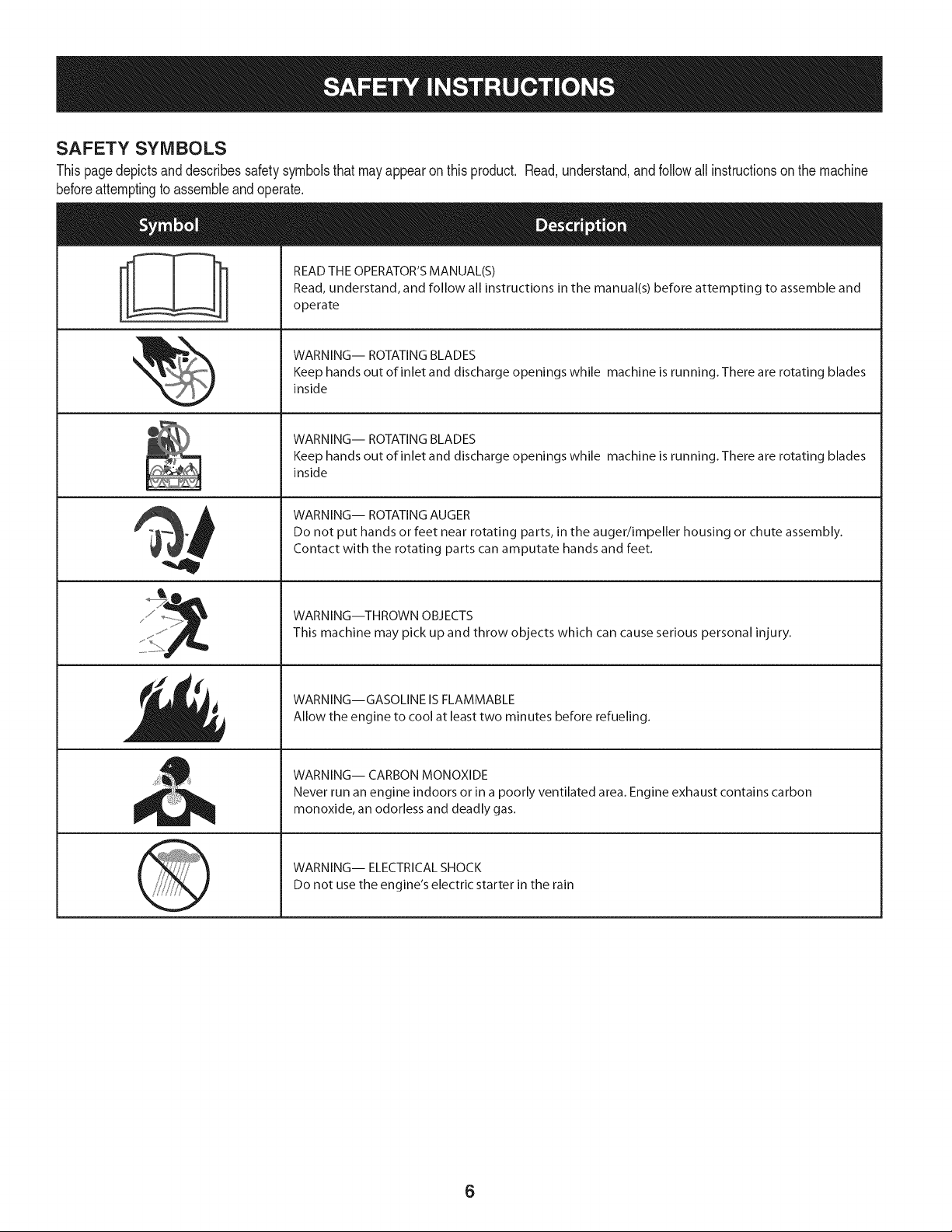

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

"JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

Thispageleftintentionallyblank.

7

NOTE:Referencesto rightorleft sideofthesnowthrowerare

determinedfrombehindtheunit intheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthe cornersof thecartonandlay the sidesflaton theground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhas beencompletelyemptiedbefore

discardingit.

ASSEMBLY

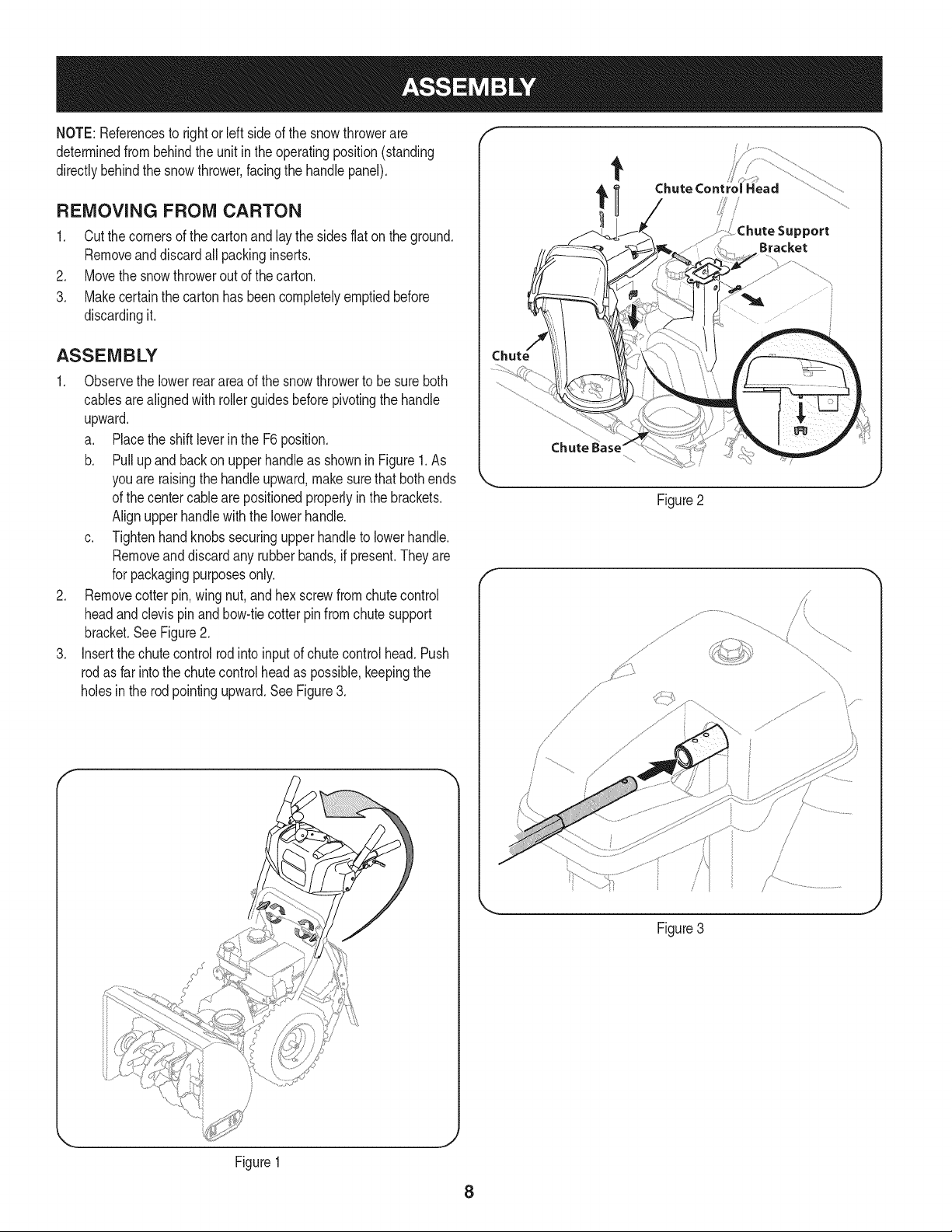

1. Observethe lowerrearareaof the snowthrowertobesureboth

cablesarealignedwith rollerguidesbeforepivotingthehandle

upward.

a. Placethe shiftleverin theF6position.

b. Pullupandbackon upperhandleasshownin Figure1.As

youare raisingthehandleupward,makesurethat bothends

ofthecentercablearepositionedproperlyinthebrackets.

Alignupperhandlewiththe lowerhandle.

c. Tightenhandknobssecuringupperhandleto lowerhandle.

Removeanddiscardany rubberbands,if present.Theyare

forpackagingpurposesonly.

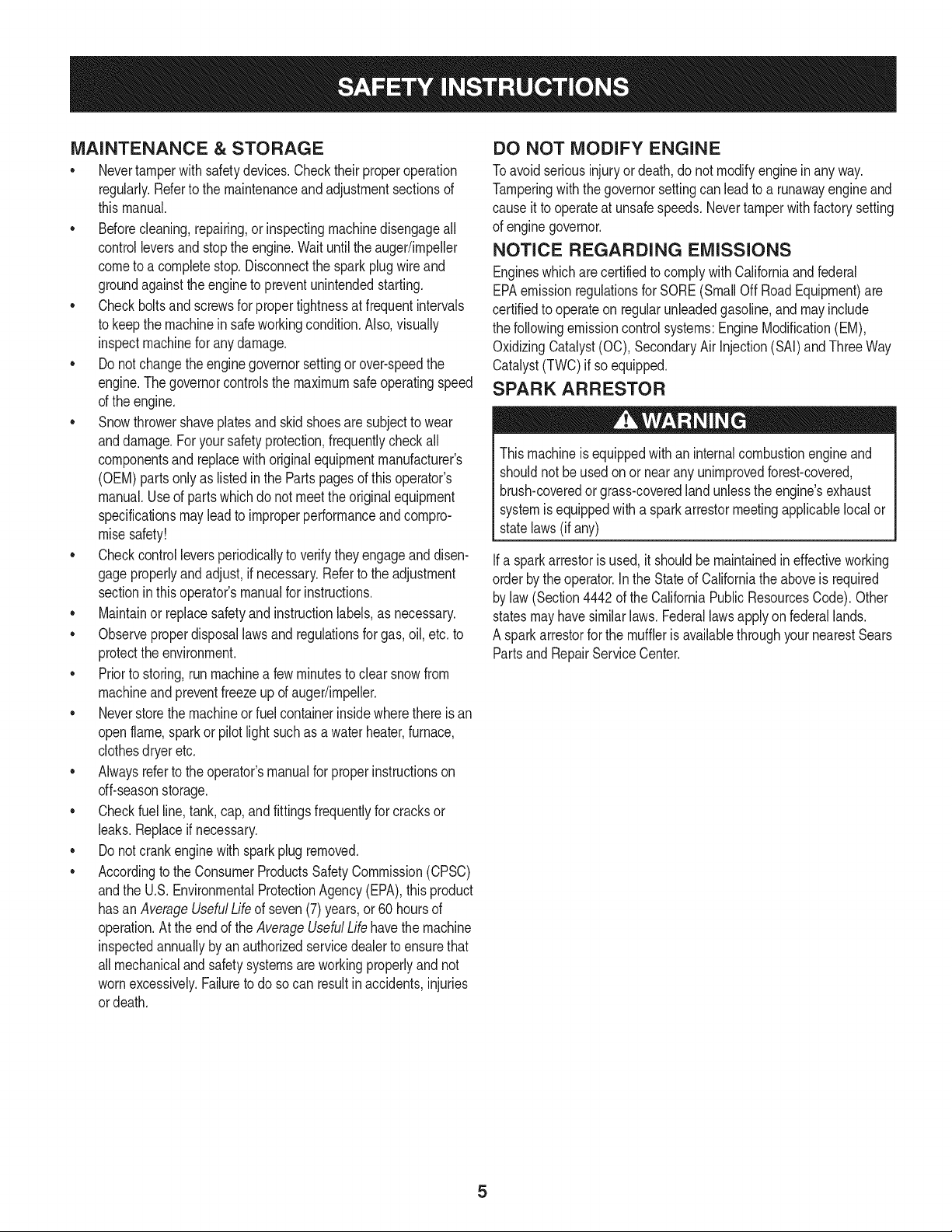

2. Removecotterpin,wing nut,andhexscrewfromchutecontrol

headandclevispinandbow-tiecotterpinfromchutesupport

bracket.SeeFigure2.

3. Insertthe chutecontrolrodintoinputofchutecontrolhead.Push

rodasfar intothechutecontrolheadaspossible,keepingthe

holesin therodpointingupward.SeeFigure3.

Chute Control Head

_ort

Bracket

Figure2

f

/

\

Figure1

_J

Figure3

8

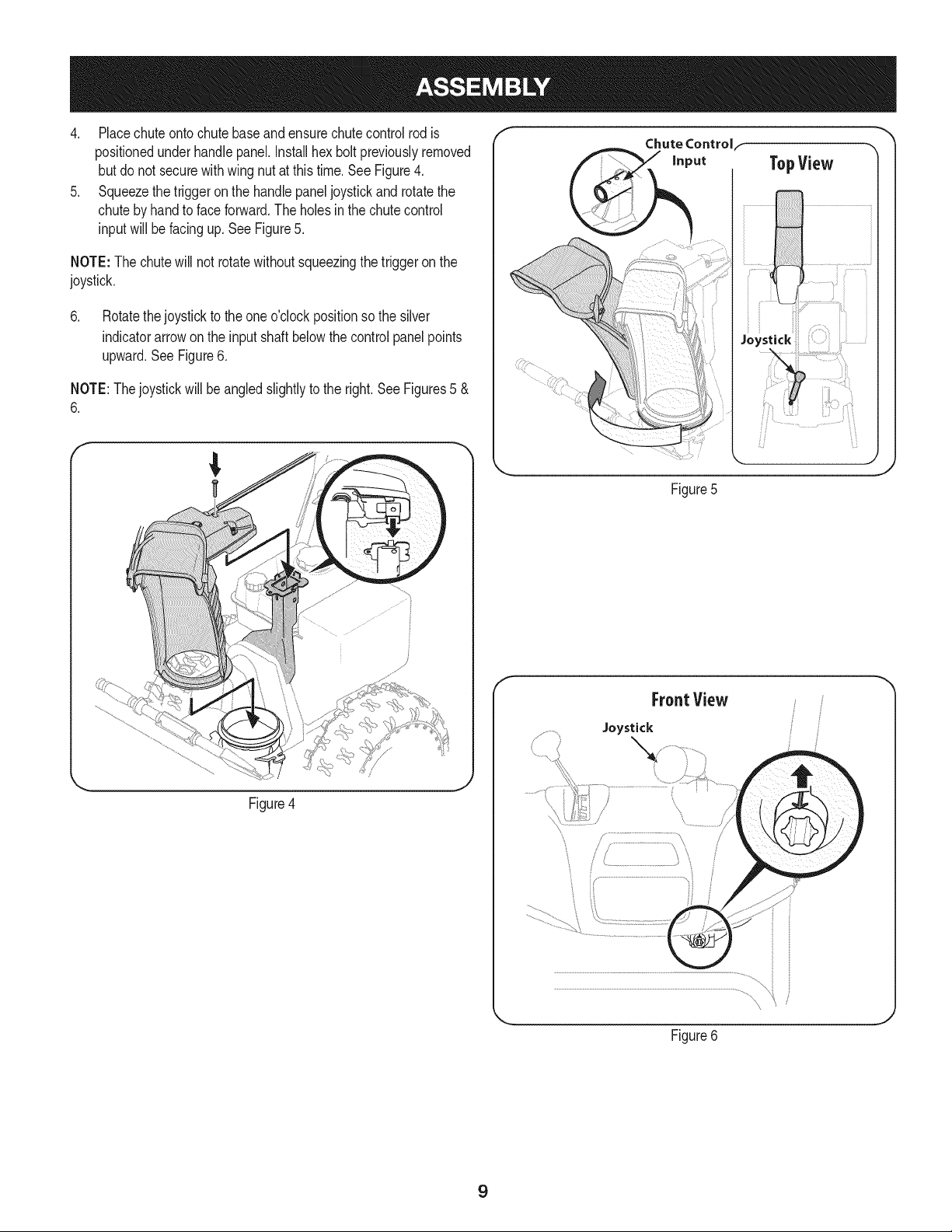

4. Placechuteontochutebaseandensurechutecontrolrodis

positionedunderhandlepanel.Installhexboltpreviouslyremoved

butdo notsecurewithwingnutatthistime.See Figure4.

5. Squeezethetriggeron the handlepaneljoystickand rotatethe

chutebyhandto faceforward.Theholesinthe chutecontrol

inputwill befacingup. SeeFigure5.

NOTE:The chutewill notrotatewithoutsqueezingthe triggeronthe

joystick.

6. Rotatethejoystickto theoneo'clockpositionsothesilver

indicatorarrowonthe inputshaftbelowthecontrolpanelpoints

upward.SeeFigure6.

NOTE:Thejoystickwillbe angledslightlyto theright.SeeFigures5 &

6.

f

Chute Controlf

Figure5

Figure4

f

FroatView

Joystick

J

Figure6

9

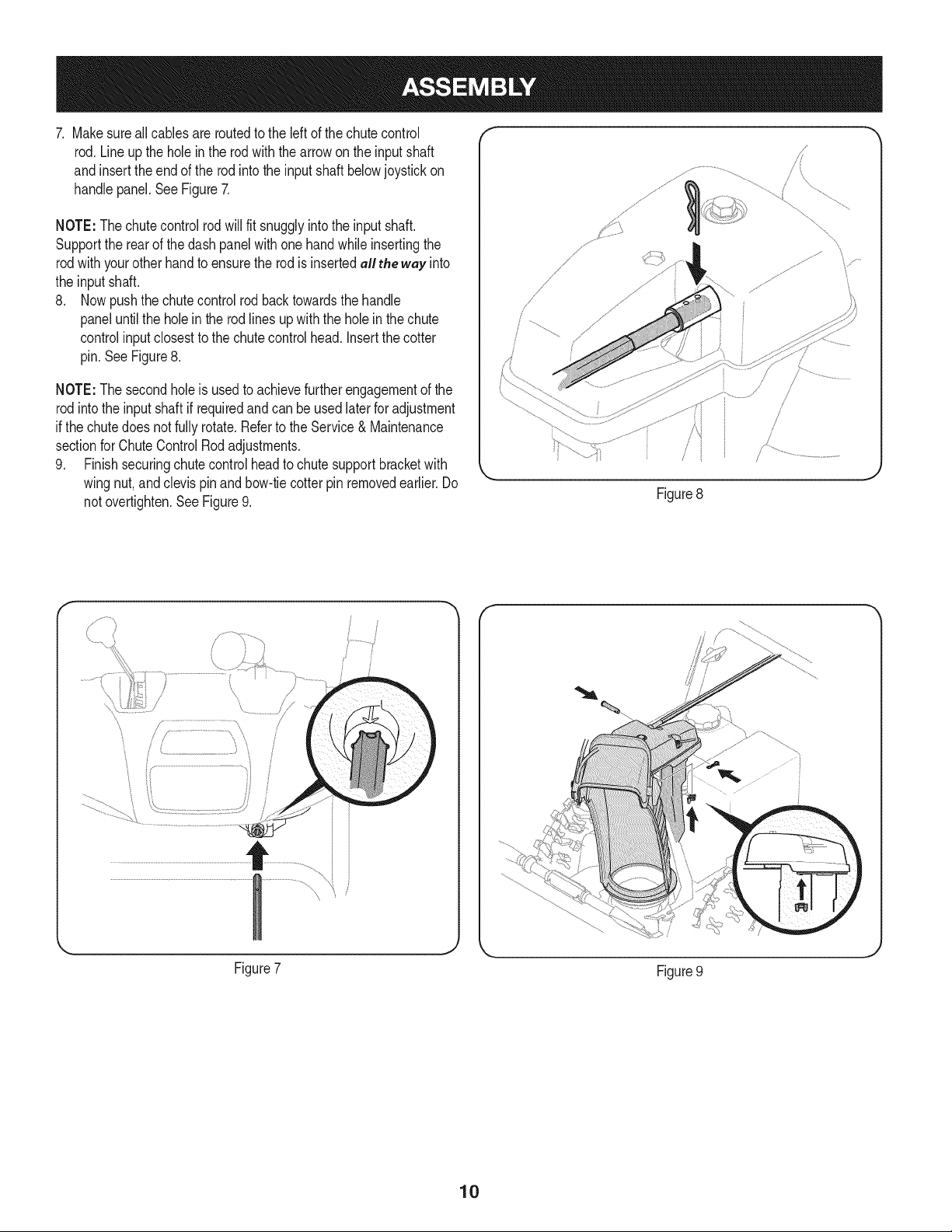

7. Makesureall cablesare routedtotheleftof thechutecontrol

rod.Lineupthe holein therodwiththearrowon theinputshaft

and insertthe endofthe rodintotheinputshaftbelowjoystickon

handlepanel.SeeFigure7.

NOTE:Thechutecontrolrodwillfit snugglyintotheinputshaft.

Supporttherearof thedash panelwithone handwhileinsertingthe

rodwithyourotherhandto ensuretherodis insertedall the way into

theinputshaft.

8. Nowpushthe chutecontrolrodbacktowardsthehandle

paneluntilthe holein therodlinesupwiththe holeinthechute

controlinputclosesttothechutecontrolhead.Insertthecotter

pin.SeeFigure8.

NOTE:The secondholeis usedtoachievefurtherengagementofthe

rodintotheinputshaftifrequiredandcanbe usedlaterfor adjustment

ifthechutedoesnotfullyrotate.Refertothe Service& Maintenance

sectionforChuteControlRodadjustments.

9. Finishsecuringchutecontrolheadto chutesupportbracketwith

wingnut,andclevispinandbow-tiecotterpinremovedearlier.Do

notovertighten.SeeFigure9.

Figure8

/

/

/

.J

' .....................................................i;"i

Figure7

/

i

}

Figure9

10

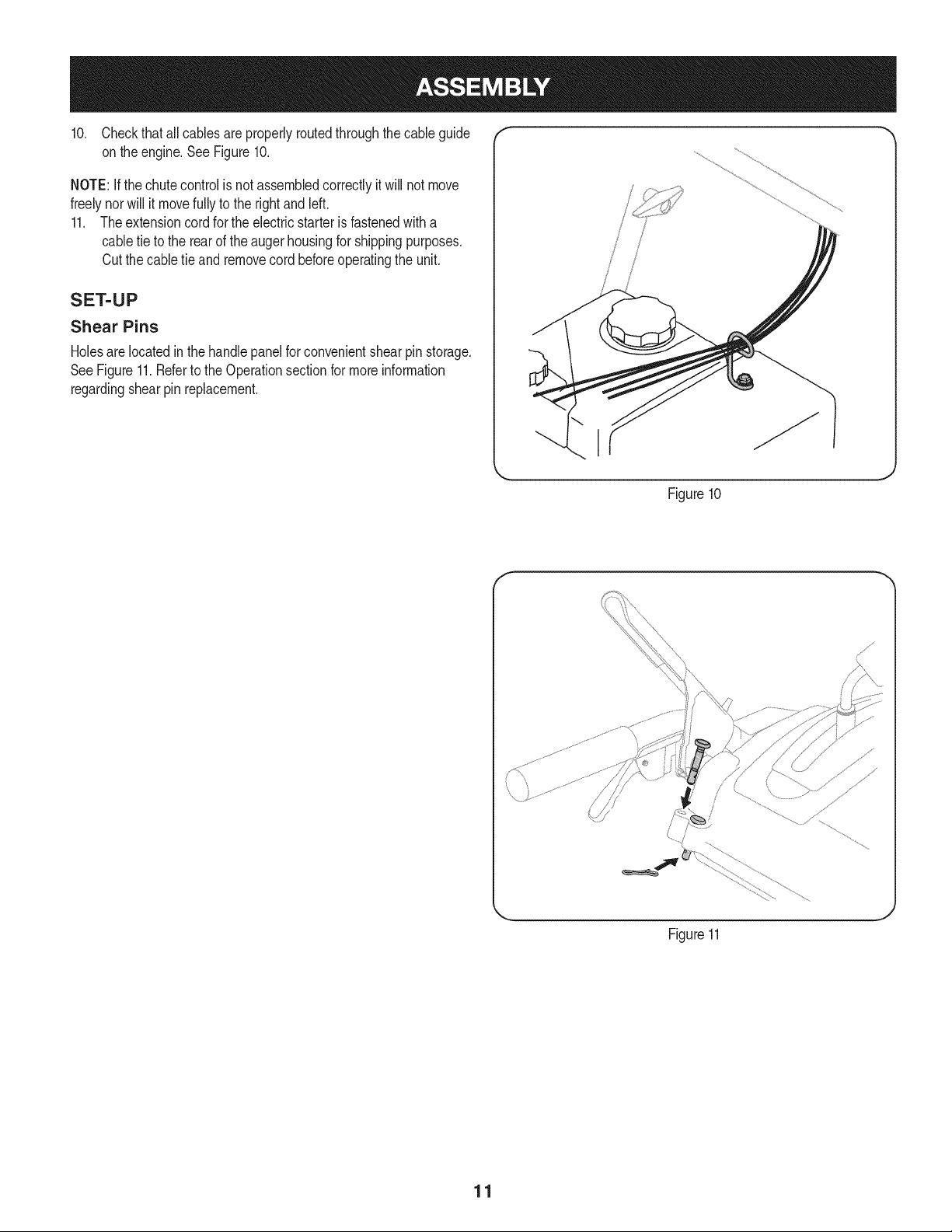

10. Checkthatallcablesareproperlyroutedthroughthecable guide "_

on theengine.SeeFigure10.

NOTE:Ifthechutecontrolis notassembledcorrectlyit willnotmove

freelynorwillit movefullyto therightandleft.

11. Theextensioncordforthe electricstarterisfastenedwitha

cabletie to therearof theaugerhousingforshippingpurposes.

Cutthecabletie and removecordbeforeoperatingthe unit.

SET-UP

Shear Pins

Holesare locatedinthehandlepanelforconvenientshearpin storage.

SeeFigure11.Refertothe Operationsectionformoreinformation

regardingshearpin replacement.

f

/

i

/

/

I

Figure10

11

J

Figure11

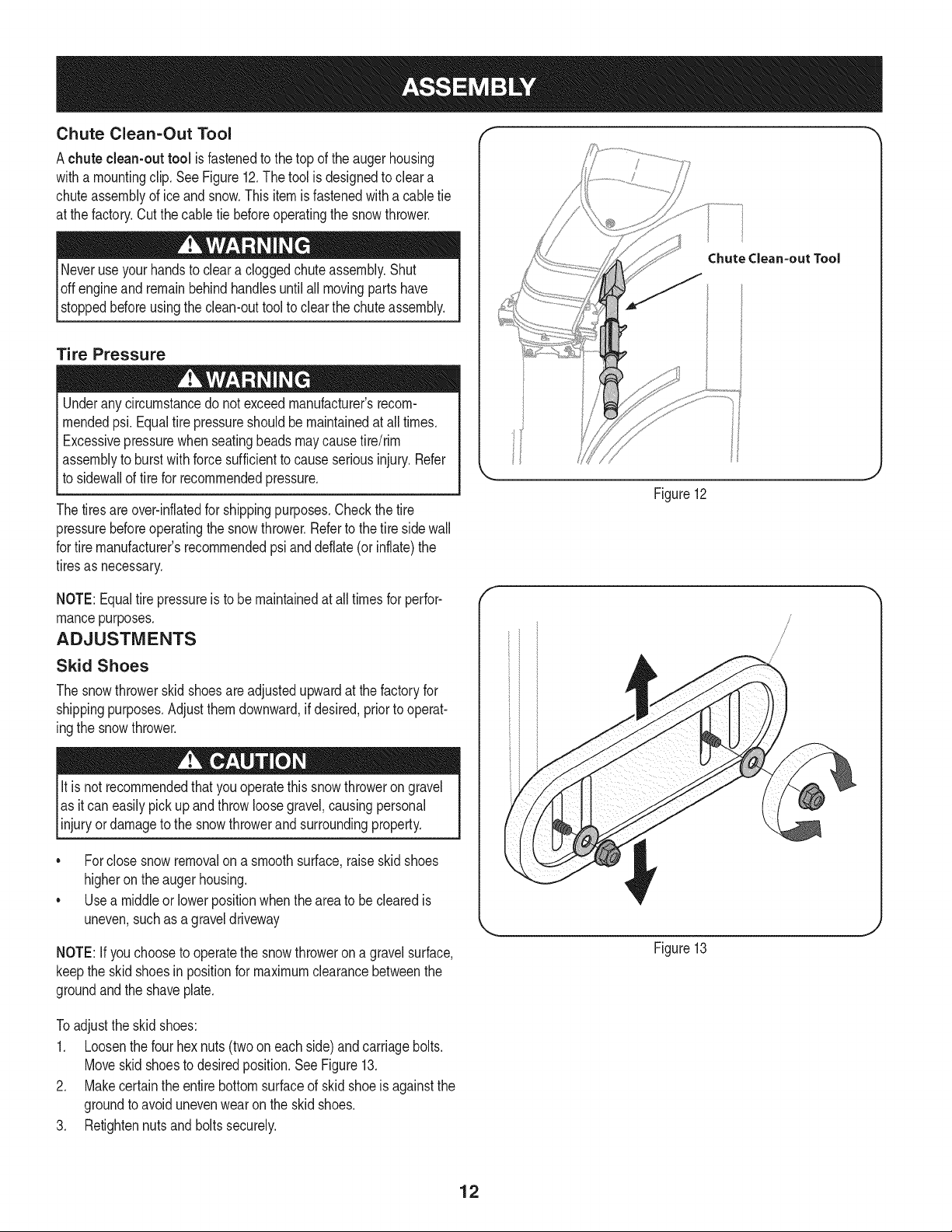

Chute Clean=Out Tool

Achute clean-out tool isfastenedtothe top oftheaugerhousing

witha mountingclip.SeeFigure12.Thetool isdesignedtocleara

chuteassemblyoficeandsnow.Thisitemisfastenedwitha cabletie

atthefactory.Cutthecable tiebeforeoperatingthesnowthrower.

loft _1 .allmovingpartshave

stoppedbeforeusingtheclean-outtoolto clearthe chuteassembly.

Tire Pressure

Underanycircumstancedo notexceedmanufacturer'srecom-

mendedpsi.Equaltire pressureshouldbe maintainedat all times.

Excessivepressurewhenseatingbeadsmaycausetire/rim

assemblytoburstwithforcesufficienttocauseseriousinjury.Refer

tosidewallof tirefor recommendedpressure.

Thetiresareover-inflatedforshippingpurposes.Checkthetire

pressurebeforeoperatingthe snowthrower.Refertothetiresidewall

fortiremanufacturer'srecommendedpsianddeflate(or inflate)the

tiresasnecessary.

Chutedean=out Tool

Figure12

NOTE:Equaltire pressureisto be maintainedat alltimesfor perfor-

mancepurposes.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthefactoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priorto operat-

ingthesnowthrower.

It is notrecommendedthatyouoperatethissnowthrowerongravel

asitcaneasilypickup andthrowloosegravel,causingpersonal

njuryordamageto thesnowthrowerand surroundng property.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousing.

• Usea middleorlowerpositionwhentheareatobe clearedis

uneven,suchas a graveldriveway

NOTE:If youchoosetooperatethesnowthrowerona gravelsurface,

keepthe skidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjustthe skidshoes:

1. Loosenthefour hexnuts(twooneachside)andcarriagebolts.

Moveskidshoestodesiredposition.SeeFigure13.

2. Makecertaintheentirebottomsurfaceof skidshoeis againstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsand boltssecurely.

Figure13

12

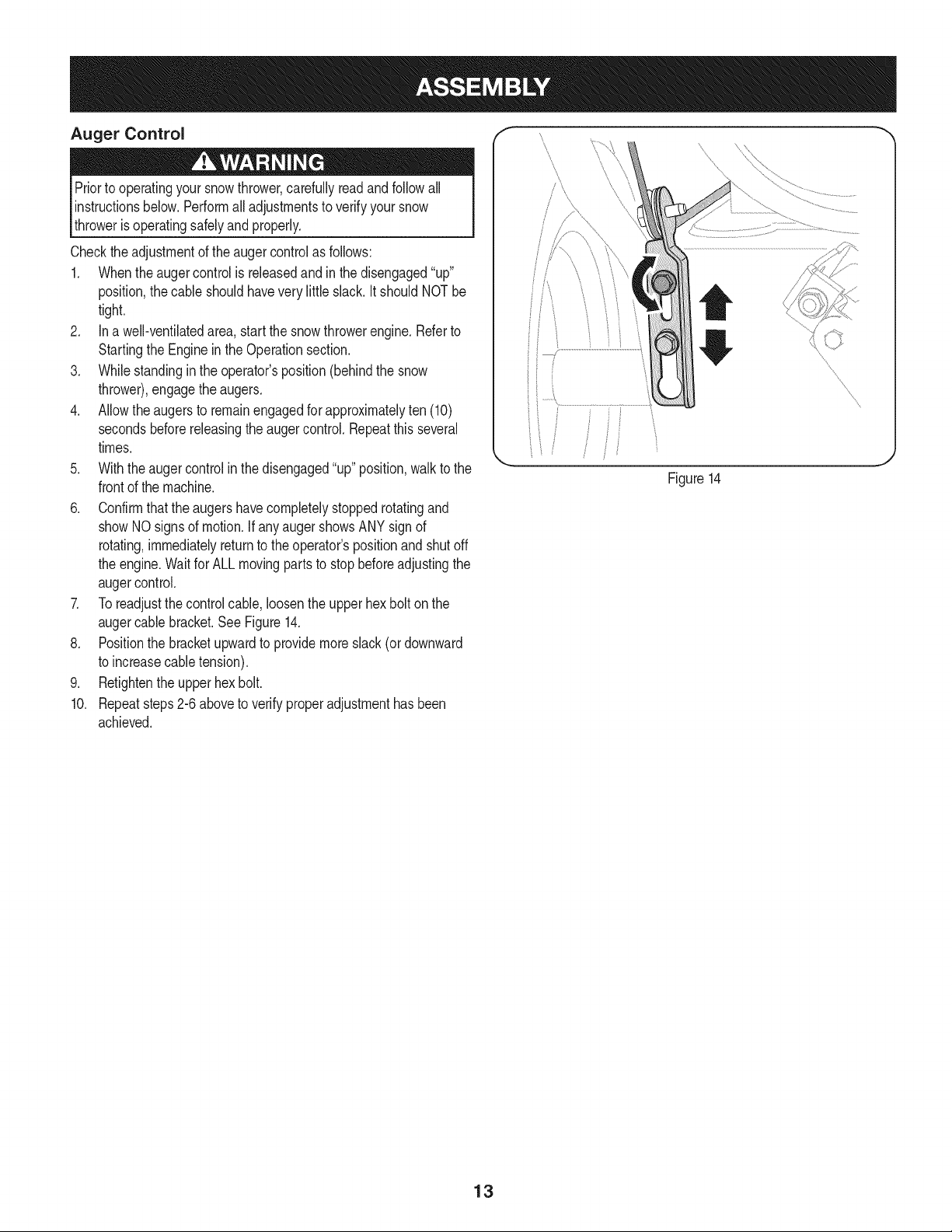

Priortooperatingyoursnowthrower,carefullyreadandfollowall

instructionsbelow.Performalladjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

Checktheadjustmentof theaugercontrolasfollows:

1. Whentheaugercontrolis releasedandin the disengaged"up"

position,thecableshouldhavevery littleslack.ItshouldNOTbe

tight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Referto

StartingtheEngineinthe Operationsection.

3. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe augers.

4. Allowtheaugersto remainengagedforapproximatelyten(10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheaugercontrolin thedisengaged"up"position,walktothe

frontofthe machine.

6. Confirmthatthe augershavecompletelystoppedrotatingand

showNOsignsof motion.If anyaugershowsANYsignof

rotating,immediatelyreturntotheoperator'spositionandshutoff

theengine.WaitforALLmovingpartstostopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexbolt onthe

augercablebracket.SeeFigure14.

8. Positionthe bracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

9. Retightentheupperhexbolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

Figure14

13

f

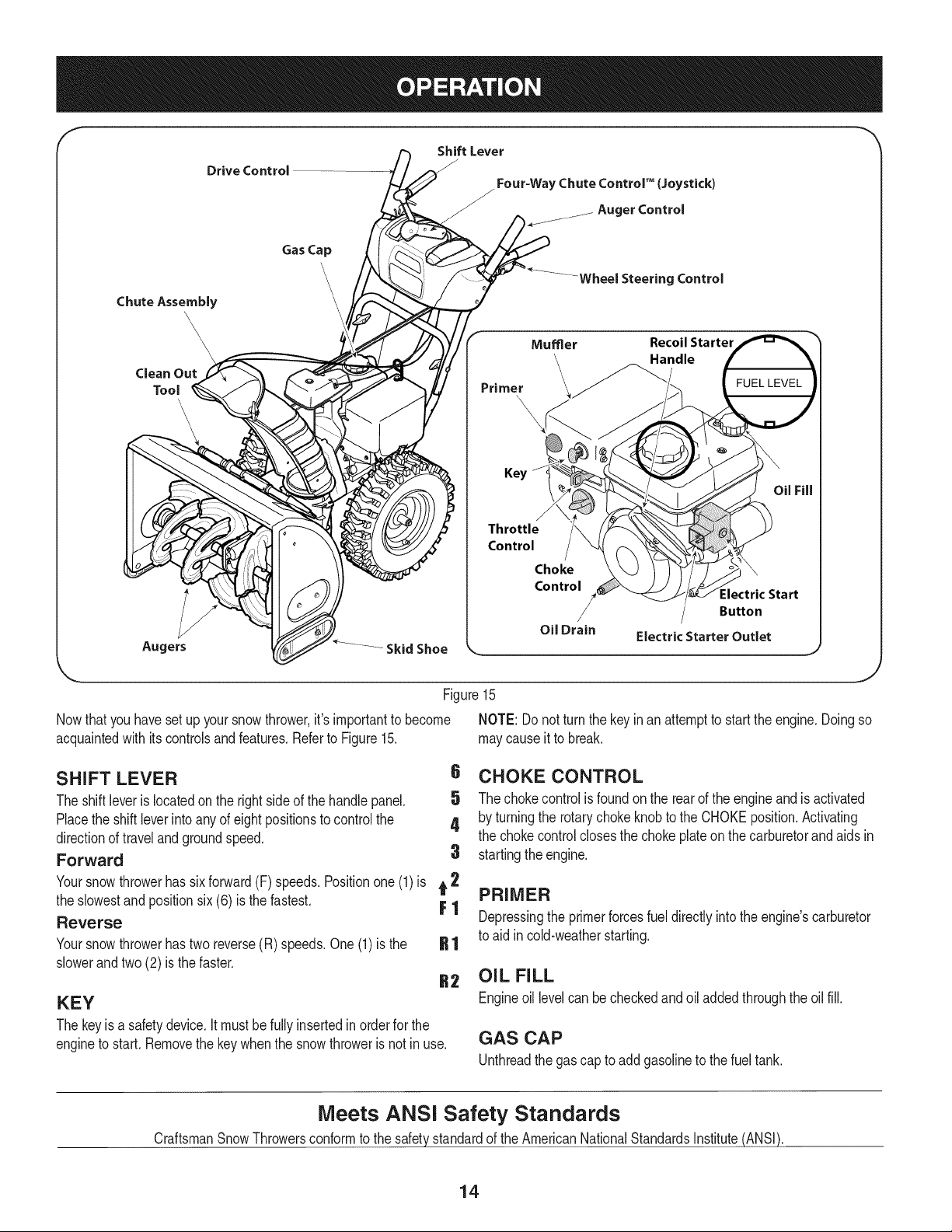

Shift Lever

J

Drive Control

Gas Cap

J

z Four=WayChuteControP (Joystick)

J

j_ Auger Control

...........WheelSteeringControl

ChuteAssembly

\\\\

Muffler Recoil Starter

Clean Out

Tool

Primer

,\\ .d e

\

Key

Fill

Throttle

Control

Choke

Control

/

Augers

Skid Shoe

Oil Drain Electric Starter Outlet

Figure15

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome NOTE:Donot turnthe keyinan attemptto starttheengine.Doingso

acquaintedwith itscontrolsandfeatures.RefertoFigure15. maycauseit to break.

SHIFT LEVER

Theshiftleveris locatedonthe rightsideofthehandlepanel.

Placethe shiftleverintoanyofeightpositionstocontrolthe

directionoftravelandgroundspeed.

Forward

Yoursnowthrowerhassixforward(F) speeds.Positionone(1)is t 2

6 CHOKE CONTROL

5 The chokecontrolisfoundon the rearof theengineand isactivated

4 by turningthe rotarychokeknobtotheCHOKEposition.Activating

thechokecontrolclosesthe chokeplateonthecarburetorandaidsin

3 startingtheengine.

PRIMER

theslowestand positionsix (6) isthe fastest. F 1

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)is the

Depressingthe primerforcesfueldirectlyintotheengine'scarburetor

toaid incold-weatherstarting.

slowerandtwo(2) is the faster.

OIL FILL

KEY

Thekeyisa safetydevice.Itmustbefully insertedin orderfor the

enginetostart.Removethekeywhenthe snowthroweris notin use.

Engineoil levelcan becheckedandoiladdedthroughtheoil fill.

GAS CAP

Unthreadthegascaptoadd gasolinetothefueltank.

:lectric Start

Button

J

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformto thesafetystandardof the AmericanNationalStandardsInstitute(ANSI).

14

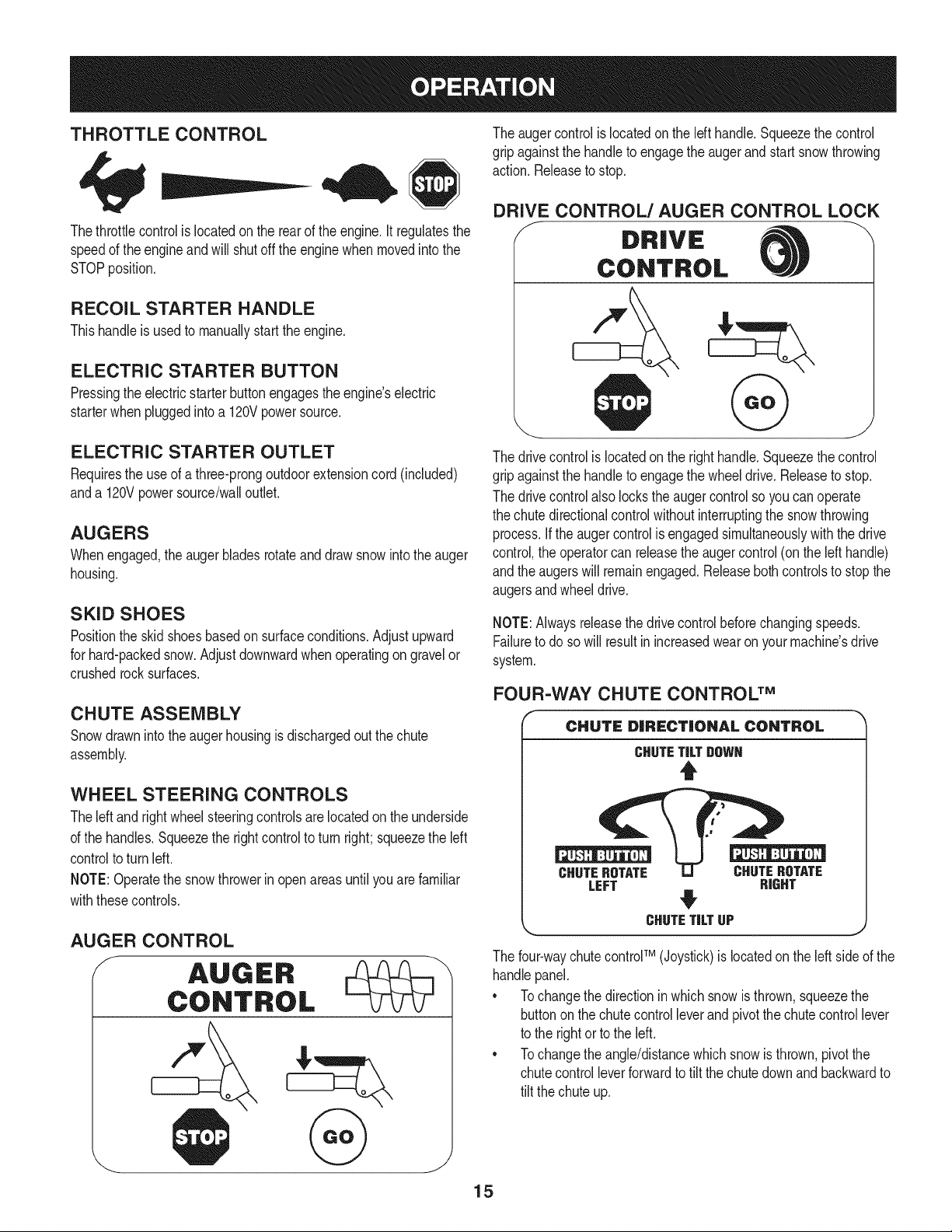

THROTTLE CONTROL

Thethrottlecontrolis locatedon therearof the engine.It regulatesthe

speedof theengineandwillshutoff theenginewhenmovedintothe

STOPposition.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystarttheengine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

Theaugercontrolis locatedonthelefthandle.Squeezethecontrol

gripagainstthehandleto engagethe augerand startsnowthrowing

action.Releaseto stop.

DRIVE CONTROL/AUGER CONTROL LOCK

DRIVE

CONTROL

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

AUGERS

Whenengaged,theaugerbladesrotateanddrawsnowintothe auger

housing.

SKID SHOES

Positiontheskid shoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingongravelor

crushedrocksurfaces.

CHUTE ASSEMBLY

Snowdrawnintotheaugerhousingisdischargedoutthechute

assembly.

WHEEL STEERING CONTROLS

Theleft andrightwheelsteeringcontrolsarelocatedon theunderside

ofthehandles.Squeezetherightcontrolto turnright;squeezetheleft

controltoturnleft.

NOTE:Operatethesnowthrowerinopenareasuntilyouarefamiliar

withthesecontrols.

AUGER CONTROL

Thedrivecontrolis locatedon therighthandle.Squeezethecontrol

gripagainstthehandleto engagethe wheeldrive.Releasetostop.

Thedrivecontrolalso lockstheaugercontrolso youcan operate

thechutedirectionalcontrolwithoutinterruptingthesnowthrowing

process.If theaugercontrolisengagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthelefthandle)

andtheaugerswillremainengaged.Releasebothcontrolstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto dosowillresultinincreasedwearon yourmachine'sdrive

system.

FOUR-WAY CHUTE CONTROL TM

CHUTE DiRECTiONAl CONTROL

CHUTETiLTgOWN

t

CHUTEROTATE CHUTEROTATE

LEFT RIGHT

#

CHUTETiLTUP J

Thefour-waychutecontroFM(Joystick)islocatedon theleft sideof the

handlepanel.

* Tochangethedirectioninwhichsnowisthrown,squeezethe

buttononthechutecontrolleverandpivotthechutecontrollever

tothe rightorto theleft.

* Tochangetheangle/distancewhichsnowisthrown,pivotthe

chutecontrolleverforwardtotiltthe chutedownandbackwardto

tilt the chuteup.

15

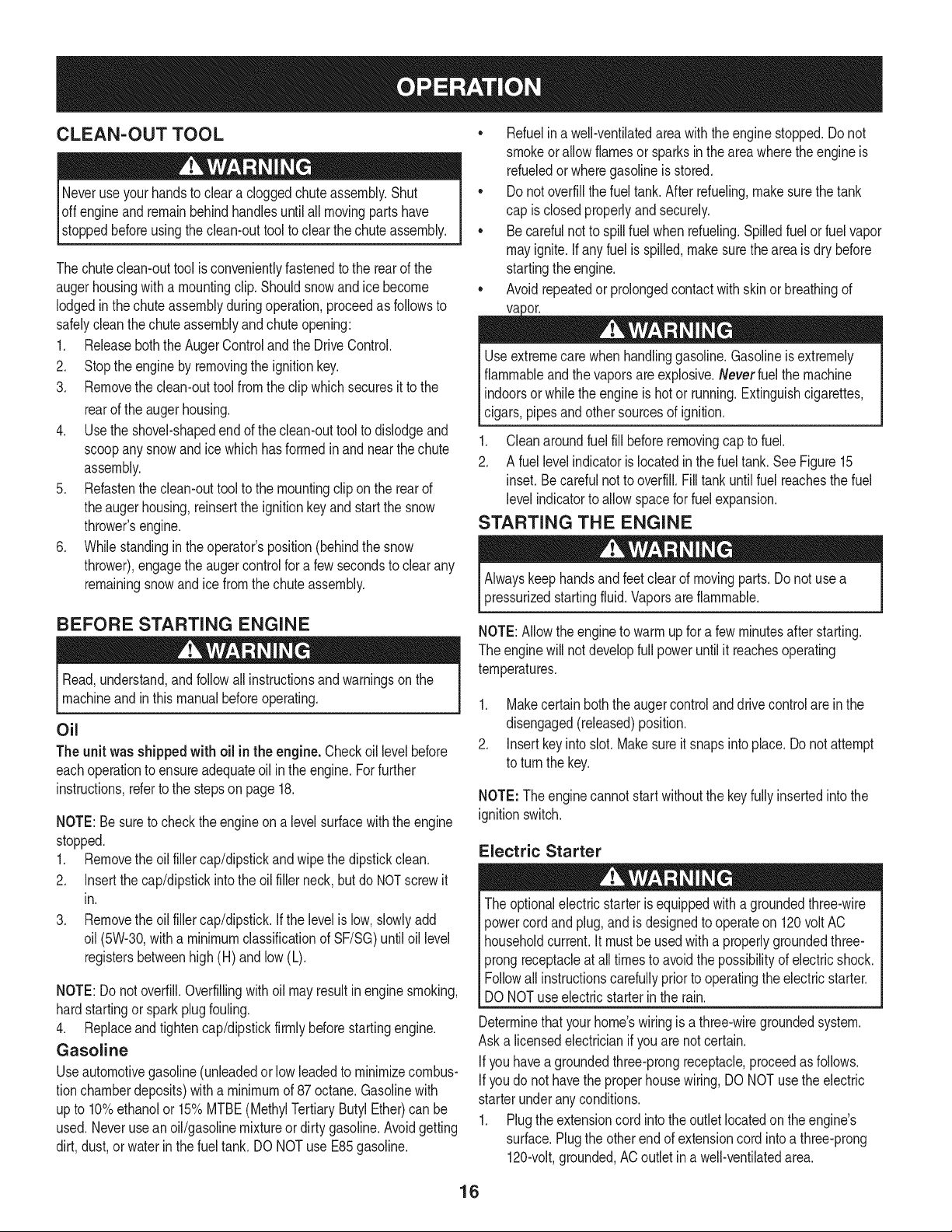

CLEAN-OUT TOOL

Neveruseyourhandstocleara cloggedchuteassembly.Shut

loft engineandremainbehindhandlesuntil allmovingpartshave

lstoppedbeforeusingtheclean-outtoolto clearthe chuteassembly.

Thechuteclean-outtoolis convenientlyfastenedtotherearofthe

augerhousingwitha mountingclip.Shouldsnowandicebecome

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandtheDriveControl.

2. Stopthe enginebyremovingthe ignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresitto the

rearofthe augerhousing.

4. Usethe shovel-shapedendof theclean-outtooltodislodgeand

scoopanysnowand icewhichhasformedin andnearthechute

assembly.

5. Refastenthe clean-outtooltothe mountingclipontherearof

theaugerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolfora fewsecondstoclear any

remainingsnowandice fromthechuteassembly.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningson the

machineand inthismanualbeforeoperating.

Oil

Theunit wasshippedwith oil inthe engine.Checkoillevelbefore

eachoperationtoensureadequateoil intheengine.Forfurther

instructions,refertothe stepson page18.

NOTE:Besureto checkthe engineon a levelsurfacewiththe engine

stopped.

1. Removetheoil fillercap/dipstickandwipethe dipstickclean.

2. insertthecap/dipstickintothe oilfillerneck,butdo NOTscrewit

in.

3. Removetheoil fillercap/dipstick,ifthelevelislow,slowlyadd

oil (5%30, witha minimumclassificationof SF/SG)untiloil level

registersbetweenhigh(H) andlow(L).

NOTE:Do notoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureor dirtygasoline.Avoidgetting

dirt,dust,or waterinthefueltank.DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksinthe areawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.After refueling,makesurethetank

capisclosedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapor

mayignite,ifany fuelis spilled,makesurethe areaisdrybefore

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

)or.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthe machine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Cleanaroundfuel fill beforeremovingcap to fuel.

2. A fuellevelindicatorislocatedin thefueltank.SeeFigure15

inset.Becarefulnottooverfill.Filltank untilfuel reachesthefuel

levelindicatorto allowspaceforfuel expansion.

STARTING THE ENGINE

Alwayskeephandsandfeetclearof movingparts.Donotusea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Allowtheengineto warmupfor a fewminutesafter starting.

Theenginewillnotdevelopfullpoweruntilit reachesoperating

temperatures.

1. Makecertainboththe augercontrolanddrivecontrolarein the

disengaged(released)position.

2. insertkeyinto slot.Makesureit snapsintoplace.Donotattempt

toturnthekey.

NOTE:Theenginecannotstartwithoutthe keyfullyinsertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarteris equippedwitha groundedthree-wire

powercordandplug,and isdesignedto operateon 120voltAC

householdcurrent.It mustbeusedwitha properlygroundedthree-

prongreceptacleatall timesto avoidthe possibilityofelectricshock.

Followall instructionscarefullypriorto operatingtheelectricstarter.

DONOTuse electricstarterinthe rain.

Determinethatyourhome'swiringis a three-wiregroundedsystem.

Aska licensedelectricianifyou arenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows.

Ifyoudonothavetheproperhousewiring,DONOTusethe electric

starterunderanyconditions.

1. Plugtheextensioncordintotheoutletlocatedontheengine's

surface.Plugtheotherendof extensioncordintoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

16

2. Movethrottlecontrolto FAST(rabbit)_J_" position.

3. MovechoketotheCHOKEI,'_1 position(coldenginestart).If

engineiswarm,placechokein RUNposition.

4. Pushprimerthree(3)times,makingsuretocoverventholein

primerbulbwhen pushing.Ifengineiswarm,pushprimeronly

once.Alwayscoverventholewhenpushing.Coolweathermay

requireprimingtobe repeated.

5. Pushstarterbuttonto start engine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarteris equippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocool if electricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethe chokecontroltoRUN

position.Iftheenginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthen slowly

rotatethechokeintoRUNposition.

7. Afterengineis running,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendat the wall

outletbeforeunpluggingtheoppositeendfromthe engine.

Recoil Starter

Donotpullthestarterhandlewhiletheenginerunning.

1. Movethrottlecontrolto FAST(rabbit)_J_ position.

2. MovechoketotheCHOKEI_¢1 position(coldenginestart).If

engineiswarm,placechokein RUNposition.

3. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.Ifengineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingtobe

repeated.

4. Pullgentlyonthe starterhandleuntilitbeginstoresist,then

pullquicklyandforcefullytoovercomethecompression.Engine

shouldstart.Donot releasethehandleandallow ittosnapback.

ReturnropeSLOWLYtooriginalposition.If required,repeatthis

step.

5. Astheenginewarms,slowlyrotatethe chokecontroltoRUN

position.Iftheenginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthen slowly

rotatethechokeintoRUNposition.

TO ENGAGE DRIVE

1. Withthethrottlecontrolinthe Fast(rabbit) position,moveshift

leverintooneof thesixforward(F) positionsor tworeverse(R)

positions.Selecta speedappropriatefor the snowconditionsand

a paceyou'recomfortablewith.

NOTE:Whenselectinga DriveSpeed,use the slowerspeedsuntil

youarecomfortableandfamiliarwiththe operationofthesnow

thrower.

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseit anddrivemotionwillstop.

NOTE:NEVERrepositionthe shiftlever(changespeedsordirection

oftravel)withoutfirst releasingthe drivecontrolandbringingthesnow

throwertoa completestop.Doingsowill resultinprematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagethe augersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

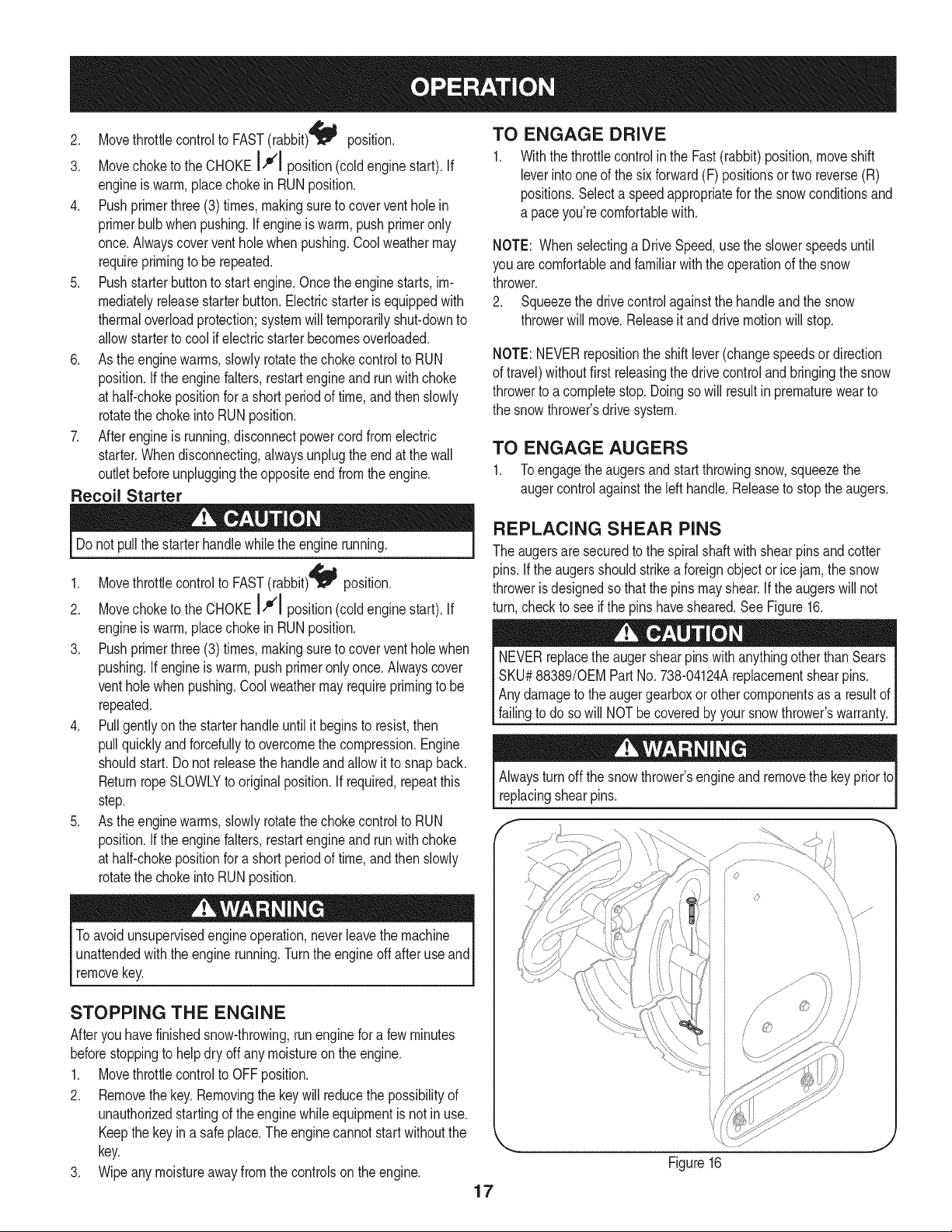

REPLACING SHEAR PiNS

Theaugersaresecuredto thespiralshaftwith shearpinsandcotter

pins.If the augersshouldstrikeaforeignobjectorice jam,thesnow

throwerisdesignedsothatthepinsmayshear.If theaugerswill not

turn,checktoseeifthe pins havesheared.SeeFigure16.

NEVERreplacetheaugershearpinswithanythingotherthanSears

SKU#88389/0EM PartNo.738-04124Areplacementshearpins.

Anydamagetotheaugergearboxorothercomponentsas a resultof

failingto do sowill NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoff thesnowthrower'sengineand removethe keypriorto

replacingshearpins.

f "

Toavoidunsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turntheengineoffafteruse and

removekey.

STOPPING THE ENGINE

Afteryouhavefinishedsnow-throwing,runenginefora few minutes

beforestoppingtohelpdry offanymoistureontheengine.

1. Movethrottlecontrolto OFFposition.

2. Removethekey.Removingthe keywillreducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentisnotin use.

Keepthekeyina safeplace.Theenginecannotstartwithoutthe

key.

3. Wipeanymoistureawayfromthecontrolsontheengine.

",,,\ _V_¸................

\\

_f

/

Figure16

17

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgroundit againstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

EachUseandevery5

hours

1st5 hours

Annuallyor25 hours

Annuallyor50 hours

Annuallyor100hours

BeforeStorage

1. Engineoil level

2. Looseor missinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesandpivots

3. Wheels

4. GearshaftandAugershaft

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlight oil

3. Lubewithmultipurposeautogrease

4. Lubewithlight oil

1. Change

1. Change

1. Runengineuntilit stopsfromlack

ENGINE MAINTENANCE

Checking Engine Oil

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.Usethe ServiceLogcolumntokeeptrackof

completedmaintenancetasks.To locate the nearestSearsService

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

d fuel

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo acomplete

_stop.

NOTE: Checktheoil levelbeforeeachuseto besurecorrectoil level

ismaintained.

Whenaddingoiltotheengine,referto viscositychart below.Engine

oilcapacityis 600 ml(approx.20 oz.). Donot over-fill.Usea 4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SR MotoroilsclassifiedSG, SFwill show

thisdesignationonthecontainer.

1. Removetheoil fillercap/dipstickandwipethe dipstickclean.

2. Insertthe cap/dipstickintothe oilfillerneck,andtightenthe cap

untilseated.

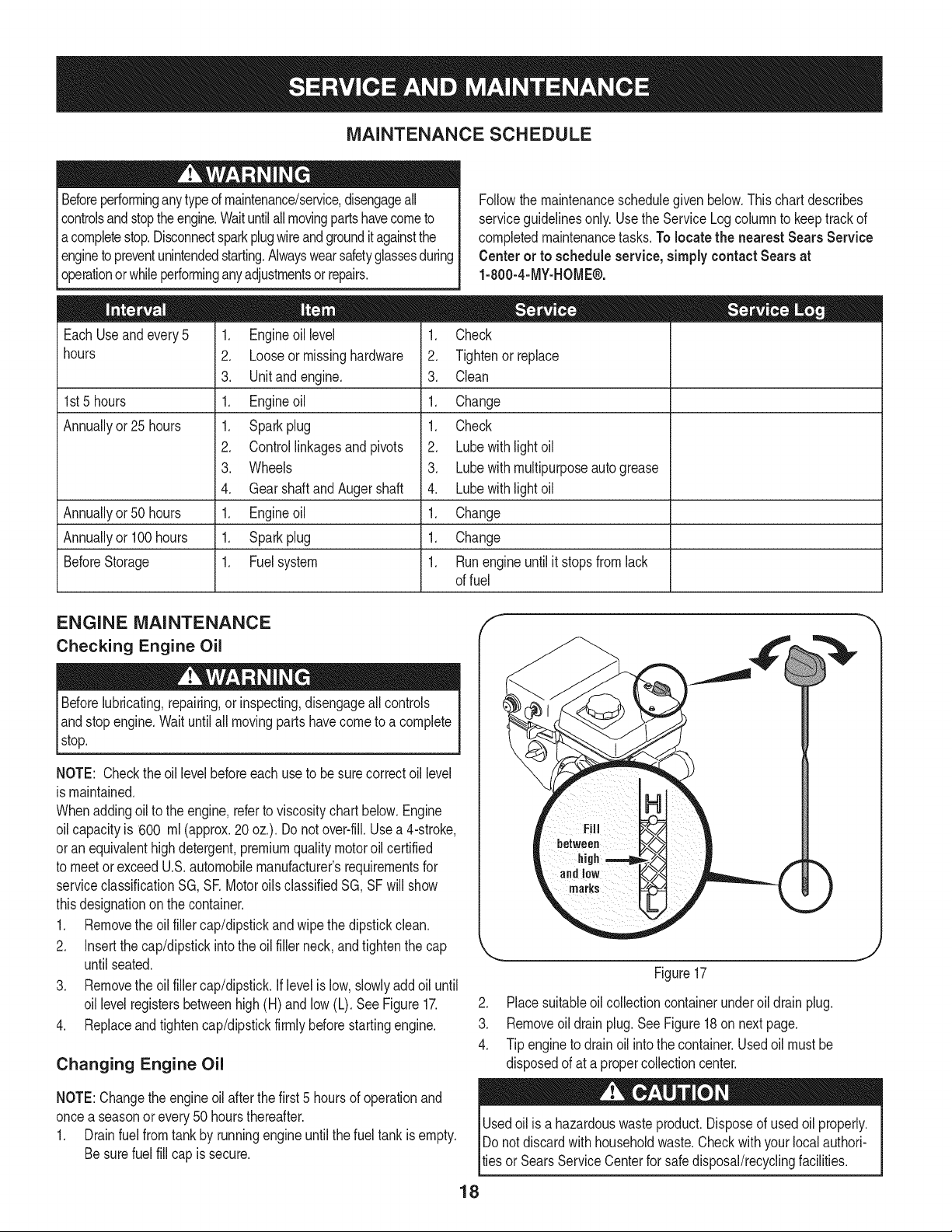

3. Removetheoil fillercap/dipstick.Iflevelis low,slowlyaddoiluntil

oil levelregistersbetweenhigh(H) andlow(L).SeeFigure17.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Changing Engine Oil

NOTE:Changetheengineoilafterthefirst5 hoursof operationand

oncea seasonorevery50 hoursthereafter.

1. Drainfuelfromtankby runningengineuntilthefuel tankisempty.

Besurefuelfillcapis secure.

J

Figure17

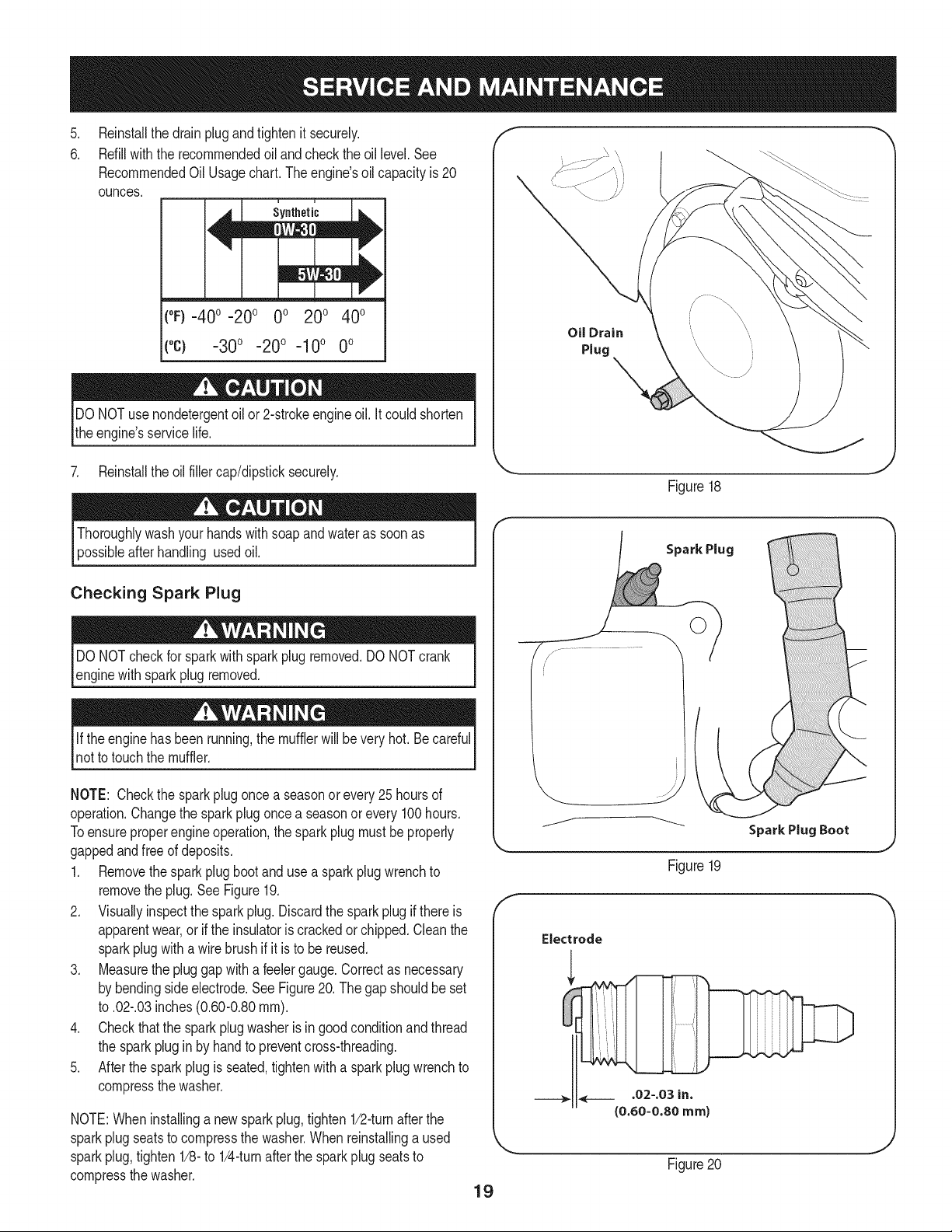

2. Placesuitableoilcollectioncontainerunderoil drainplug.

3. Removeoil drainplug.SeeFigure18on nextpage.

4. Tipenginetodrainoil intothe container.Usedoil mustbe

disposedofata propercollectioncenter.

Usedoil is a hazardouswasteproduct.Disposeof usedoil properly.

IDo notdiscardwithhouseholdwaste.Checkwithyour localauthori-

lties or SearsServiceCenterfor safedisposal/recyclingfacilities.

18

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoil andchecktheoil level.See

RecommendedOil Usagechart.Theengine'soil capacityis 20

ounces.

i u

[

(%-40 °-20 o 0o 200 400

("c) -300 -200 -10° 0°

DONOTusenondetergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

Oil Drain

Plug

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyourhandswithsoapandwateras soonas

possibleafterhandling usedoil.

Checking Spark Plug

DONOTcheckfor sparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Iftheenginehas beenrunning,themufflerwillbevery hot.Becareful

notto touchthemuffler.

NOTE: Checkthesparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonor every100hours.

Toensureproperengineoperation,the sparkplugmustbe properly

gappedandfreeofdeposits.

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.See Figure19.

2. Visuallyinspectthesparkplug.Discardthesparkplugifthereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrushif it isto be reused.

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure20.Thegap shouldbeset

to.02-.03inches(0.60-0.80ram).

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin byhandto preventcross-threading.

5. Afterthesparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatstocompressthe washer.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthesparkplugseatsto

compressthewasher.

Figure18

Spark Plug

O

J

Figure19

Electrode

.02-.03 in.

{0.60-0.80 ram)

Figure20

19

hotandcan ine.

LUBRICATION

Gear Shaft

Thegear(hex)shaft shouldbelubricatedatleastoncea seasonor

afterevery25 hoursofoperation.

1. Topreventspillage,removeall fuel fromtank by runningengine

untilitstops.

2. Carefullypivotthesnowthrowerupandforwardsothat it restson

theaugerhousing.

3. Removethe lowerframecoverfromtheundersideofthe snow

throwerbyremovingtheself-tappingscrewswhichsecureit.

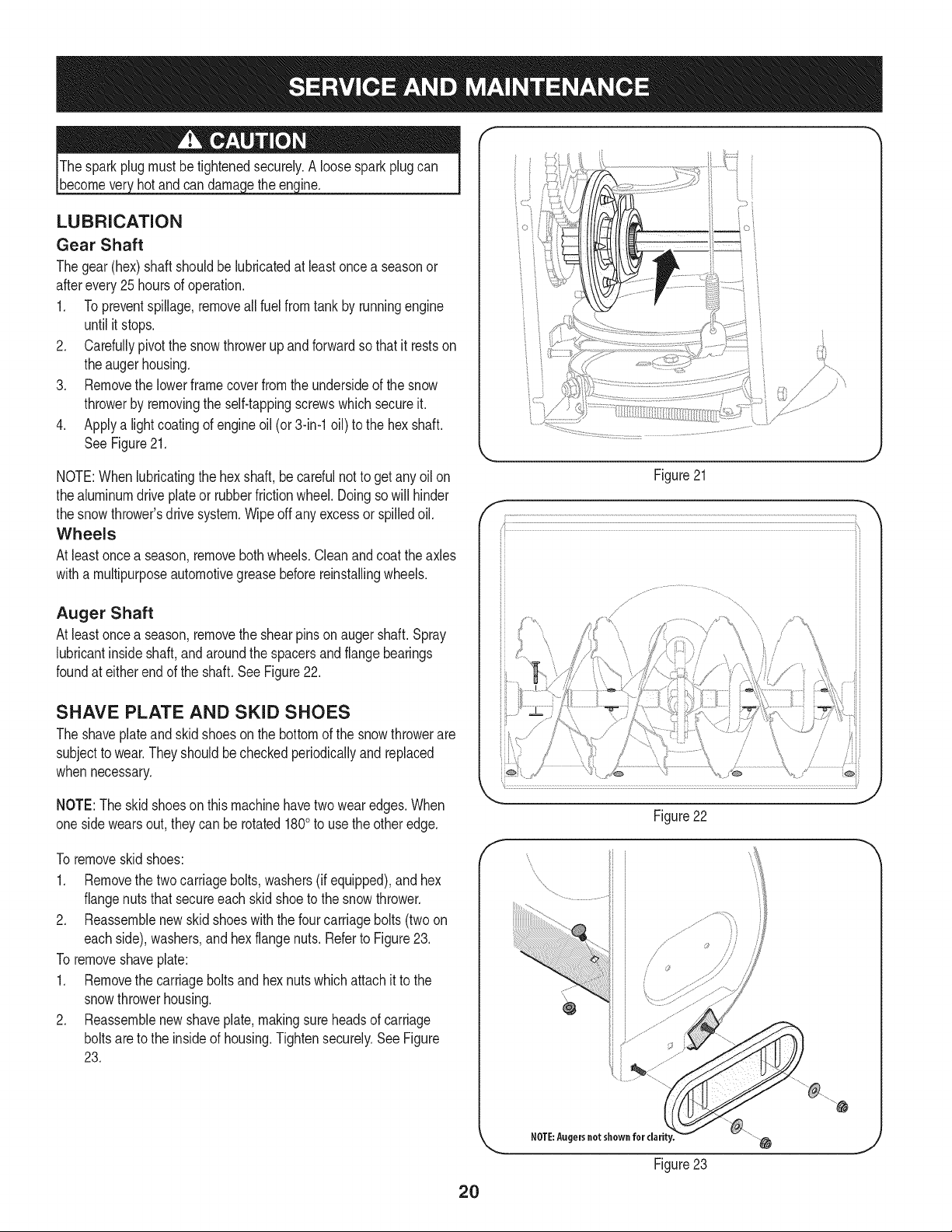

4. Applya lightcoatingofengineoil (or3-in-1oil) to thehexshaft.

SeeFigure21.

NOTE:Whenlubricatingthehexshaft,be carefulnottogetany oilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowillhinder

thesnowthrower'sdrivesystem.Wipeoffanyexcessor spilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

Auger Shaft

Atleastoncea season,removethe shearpinson augershaft.Spray

lubricantinsideshaft,andaroundthespacersandflangebearings

foundat eitherendoftheshaft.SeeFigure22.

Figure21

O i

X" "?X

/ .... )

{;:7X

7/'................

)

SHAVE PLATE AND SKID SHOES

Theshaveplateandskidshoesonthebottomofthesnowthrowerare

subjecttowear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

NOTE:Theskidshoeson thismachinehavetwowearedges.When

onesidewearsout,theycanbe rotated1800to usetheotheredge.

Toremoveskidshoes:

1. Removethetwocarriagebolts,washers(ifequipped),andhex

flangenutsthat secureeachskidshoetothe snowthrower.

2. Reassemblenewskidshoeswiththefourcarriagebolts(twoon

eachside),washers,andhexflangenuts.Referto Figure23.

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattachit tothe

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsof carriage

boltsareto theinsideof housing.Tightensecurely.SeeFigure

23.

/

J

Figure22

f

2O

Figure23

ADJUSTMENTS

Shift Cable

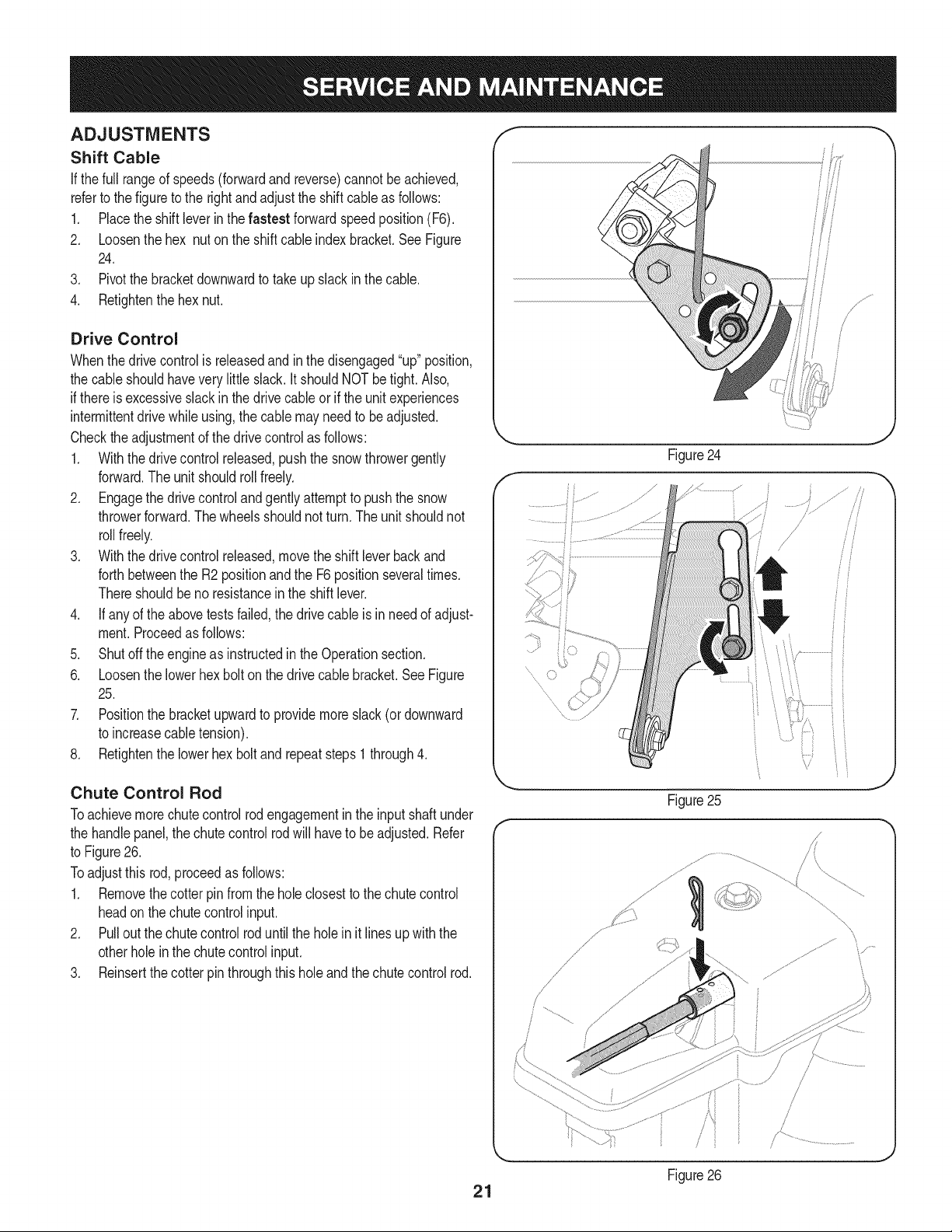

If thefull rangeofspeeds(forwardandreverse)cannotbe achieved,

referto the figureto the rightandadjusttheshiftcableasfollows:

1. Placethe shiftleverin thefastest forwardspeedposition(F6).

2. Loosenthehex nuton theshiftcableindexbracket.SeeFigure

24.

3. Pivotthebracketdownwardtotakeupslackinthe cable.

4. Retightenthehexnut.

Drive Control

Whenthedrivecontrolis releasedandin thedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight.Also,

ifthereis excessiveslackin thedrive cableor ifthe unitexperiences

intermittentdrivewhileusing,thecablemayneedtobeadjusted.

Checktheadjustmentof thedrivecontrolas follows:

1. Withthedrivecontrolreleased,pushthesnowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethe drivecontrolandgentlyattempttopushthesnow

throwerforward.Thewheelsshouldnotturn.The unitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweenthe R2positionandthe F6positionseveraltimes.

Thereshouldbeno resistancein theshiftlever.

4. If anyof theabovetestsfailed,the drivecable is in needof adjust-

ment.Proceedasfollows:

5. Shutoff theengineas instructedintheOperationsection.

6. Loosenthelowerhexboltonthe drivecable bracket.SeeFigure

25.

7. Positionthe bracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

8. Retightenthelowerhex boltand repeatsteps1 through4.

J

f

.........

Chute Control Rod

Toachievemorechutecontrolrodengagementinthe inputshaftunder

thehandlepanel,thechutecontrolrodwillhavetobeadjusted.Refer

toFigure26.

Toadjustthis rod,proceedasfollows:

1. Removethecotterpin fromtheholeclosesttothechutecontrol

headon thechutecontrolinput.

2. Pulloutthechutecontrolroduntilthe holein it lines upwiththe

otherholeinthe chutecontrolinput.

3. Reinsertthecotterpinthroughthis holeandthechutecontrolrod.

21

Figure25

/

/ ,

Figure26

J

J

\

\

Auger Control f "_

RefertotheAssemblysectionforinstructionsonadjustingtheauger

controlcable.

/

/

/

/

/

/

Skid Shoes

RefertotheAssemblysectionforinstructionsonadjustingthe skid

shoes.

BELT REPLACEMENT

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeall fuel fromtank by runningengine

untilitstops.

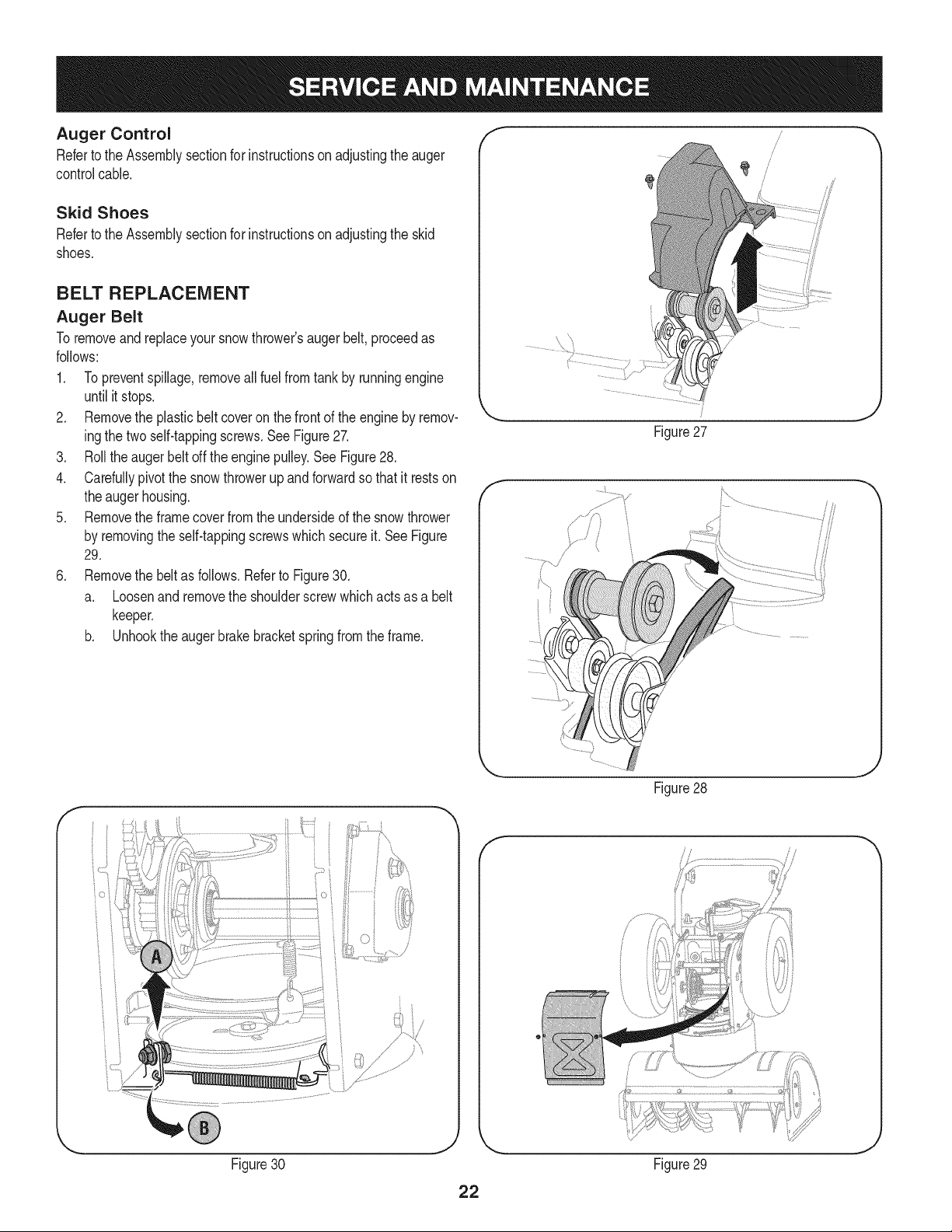

2. Removethe plasticbeltcoveronthefrontoftheenginebyremov-

ingthetwoself-tappingscrews.SeeFigure27.

3. Rolltheaugerbeltoff theenginepulley.See Figure28.

4. Carefullypivotthesnowthrowerupandforwardsothat itrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideofthesnowthrower

byremovingthe self-tappingscrewswhichsecureit.SeeFigure

29.

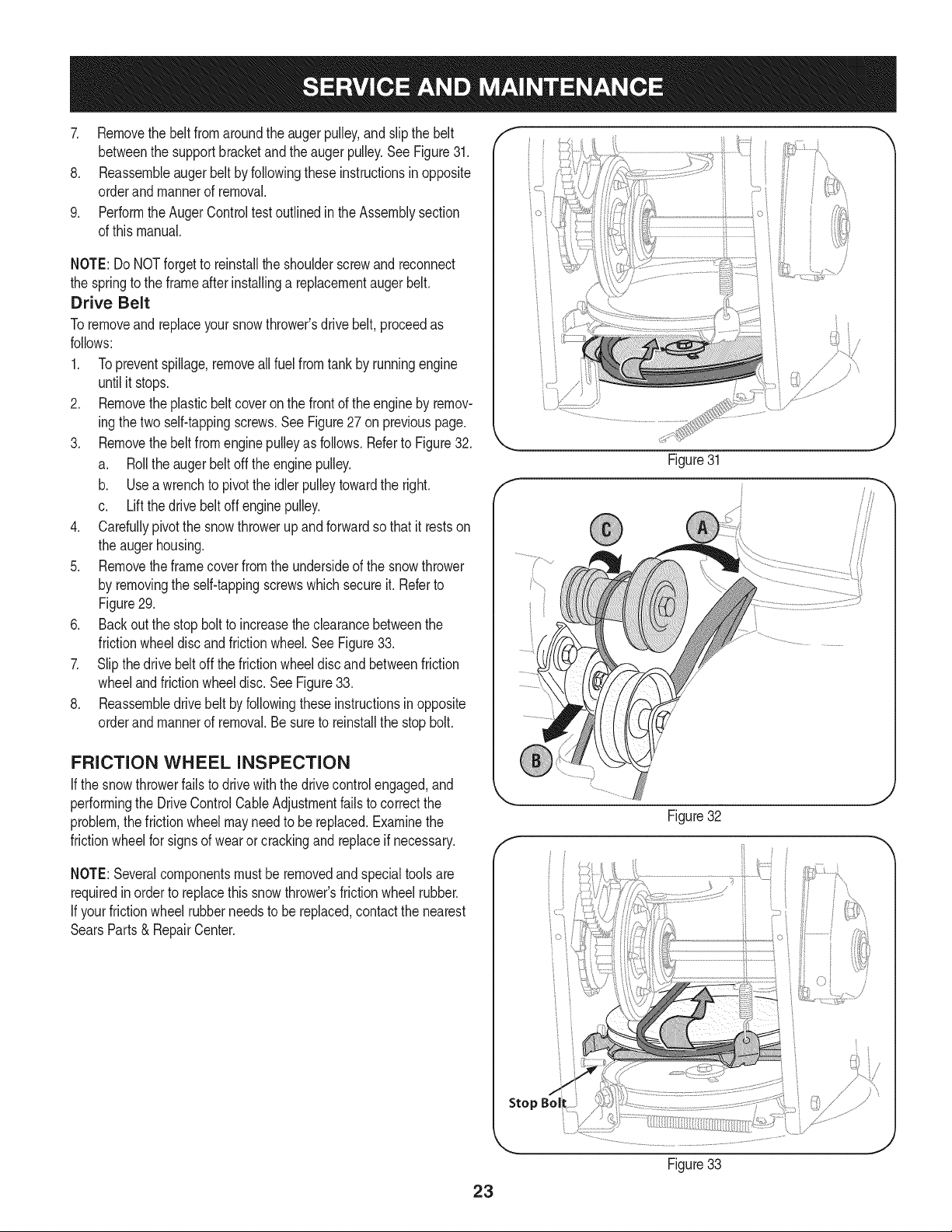

6. Removethe beltasfollows.RefertoFigure30.

a. Loosenandremovethe shoulderscrewwhichactsasa belt

keeper.

b. Unhookthe augerbrakebracketspringfromthe frame.

Figure27

f

J

Figure28

f

i I

Figure30 Figure29

J

J

7. Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandtheaugerpulley.SeeFigure31.

8. Reassembleaugerbeltbyfollowingtheseinstructionsinopposite

orderandmannerofremoval.

9. PerformtheAugerControltestoutlinedintheAssemblysection

ofthismanual.

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnect

thespringtotheframeafterinstallingareplacementaugerbelt.

Drive Belt

Toremoveandreplaceyoursnowthrower'sdrivebelt,proceedas

follows:

1. Topreventspillage,removeallfuel fromtankby runningengine

untilit stops.

2. Removetheplasticbelt coveronthefrontoftheenginebyremov-

ingthetwoself-tappingscrews.See Figure27on previouspage.

3. Removethebeltfromenginepulleyasfollows.Referto Figure32.

a. Rolltheaugerbeltoff theenginepulley.

b. Useawrenchto pivotthe idlerpulleytowardthe right.

c. Liftthedrivebeltoff enginepulley.

4. Carefullypivotthesnowthrowerupand forwardsothat itrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideofthe snowthrower

byremovingthe self-tappingscrewswhichsecureit.Referto

Figure29.

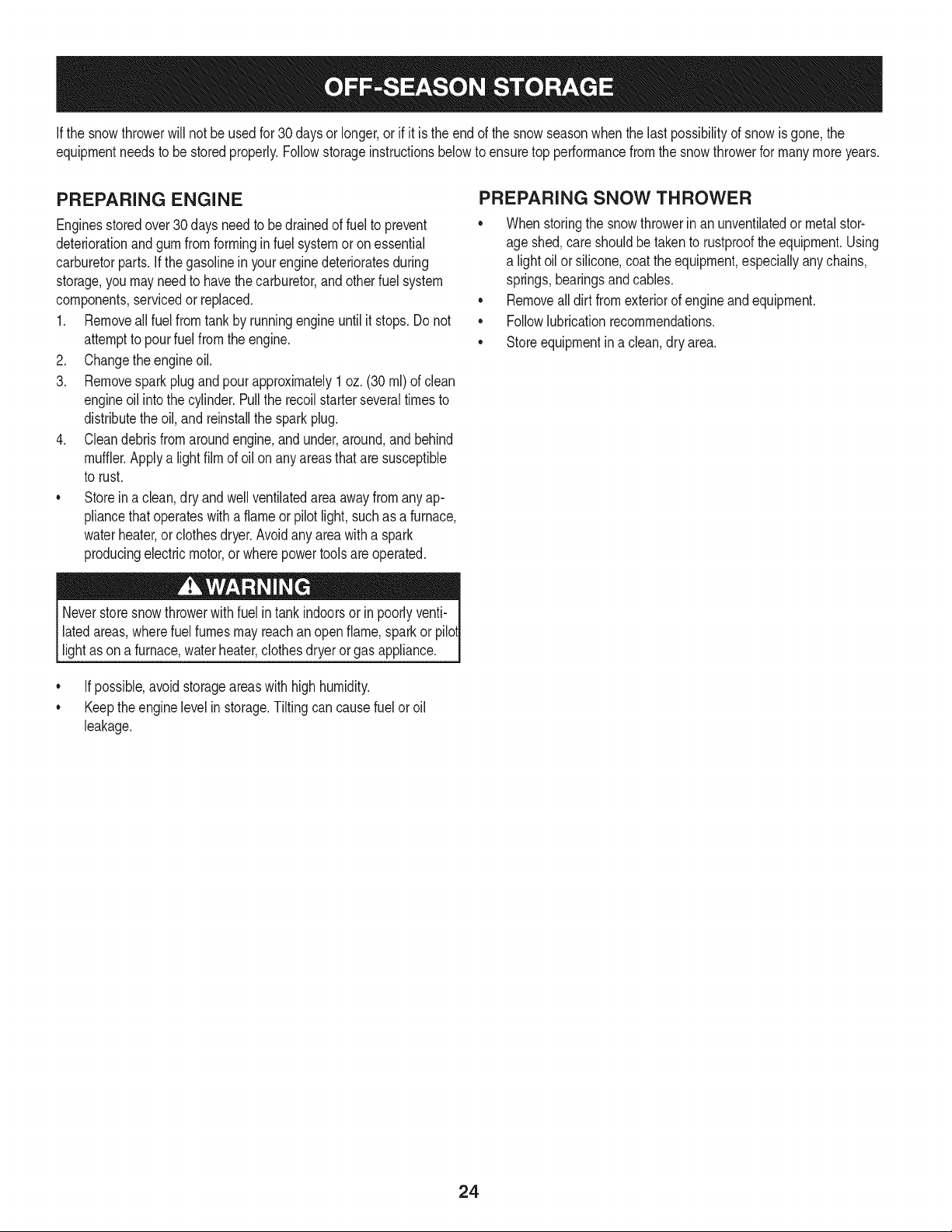

6. Backoutthestopbolttoincreasethe clearancebetweenthe

frictionwheeldiscandfrictionwheel.SeeFigure33.

7. Slipthedrivebeltoffthefrictionwheeldiscandbetweenfriction

wheelandfrictionwheeldisc.SeeFigure33.

8. Reassembledrivebeltbyfollowingtheseinstructionsinopposite

orderand mannerofremoval.Besureto reinstallthestopbolt.

iO i

Figure31

FRICTION WHEEL INSPECTION

If the snowthrowerfailsto drivewith thedrivecontrolengaged,and

performingtheDriveControlCableAdjustmentfailsto correctthe

problem,thefrictionwheelmayneedtobe replaced.Examinethe

frictionwheelforsignsof wearor crackingandreplaceifnecessary.

NOTE:Severalcomponentsmustbe removedandspecialtoolsare

requiredinorderto replacethissnowthrower'sfrictionwheelrubber.

If yourfrictionwheelrubberneedsto bereplaced,contactthenearest

SearsParts& RepairCenter.

J

Figure32

f

Stop Bol

Figure33

23

Ifthe snowthrowerwillnotbe usedfor30 daysor longer,orifit istheendofthesnowseasonwhenthelastpossibilityof snowisgone,the

equipmentneedstobestoredproperly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerfor manymoreyears.

PREPARING ENGINE

Enginesstoredover30daysneedtobedrainedoffueltoprevent

deteriorationandgumfromforminginfuelsystemoronessential

carburetorparts.If thegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedor replaced.

1. Removeall fuel fromtank by runningengineuntilit stops.Donot

attempttopourfuelfromthe engine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30 rnl)ofclean

engineoil intothe cylinder.Pullthe recoilstarterseveraltimesto

distributetheoil,and reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehind

muffler.Applya lightfilmof oilon anyareasthatare susceptible

torust.

• Storeina clean,dry andwellventilatedareaawayfromanyap-

pliancethatoperateswithaflameor pilotlight,suchasa furnace,

waterheater,or clothesdryer.Avoidanyareawitha spark

producingelectricmotor,orwherepowertoolsareoperated.

Neverstoresnowthrowerwithfuelintank indoorsor inpoorlyventi-

latedareas,wherefuelfumesmayreachanopenflame,sparkor pilol

lightas ona furnace,waterheater,clothesdryerorgasappliance.

PREPARING SNOW THROWER

Whenstoringthe snowthrowerin anunventilatedormetalstor-

age shed,careshouldbetakentorustprooftheequipment.Using

a light oilor silicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

• Removealldirt fromexteriorofengineandequipment.

• Followlubricationrecommendations.

• Storeequipmentina clean,dryarea.

• If possible,avoidstorageareaswithhighhumidity.

• Keeptheenginelevelin storage.Tiltingcancausefueloroil

leakage.

24

Loading...

Loading...