Page 1

Safety ,, Assembly ,, Operation ,,Tips & Techniques ,, Maintenance ,,Troubleshooting ,, Parts Lists ,,Warranty

OF A O A AL

i I

i I I

i I l /

r I

III j '

II/

rI /

I /

/

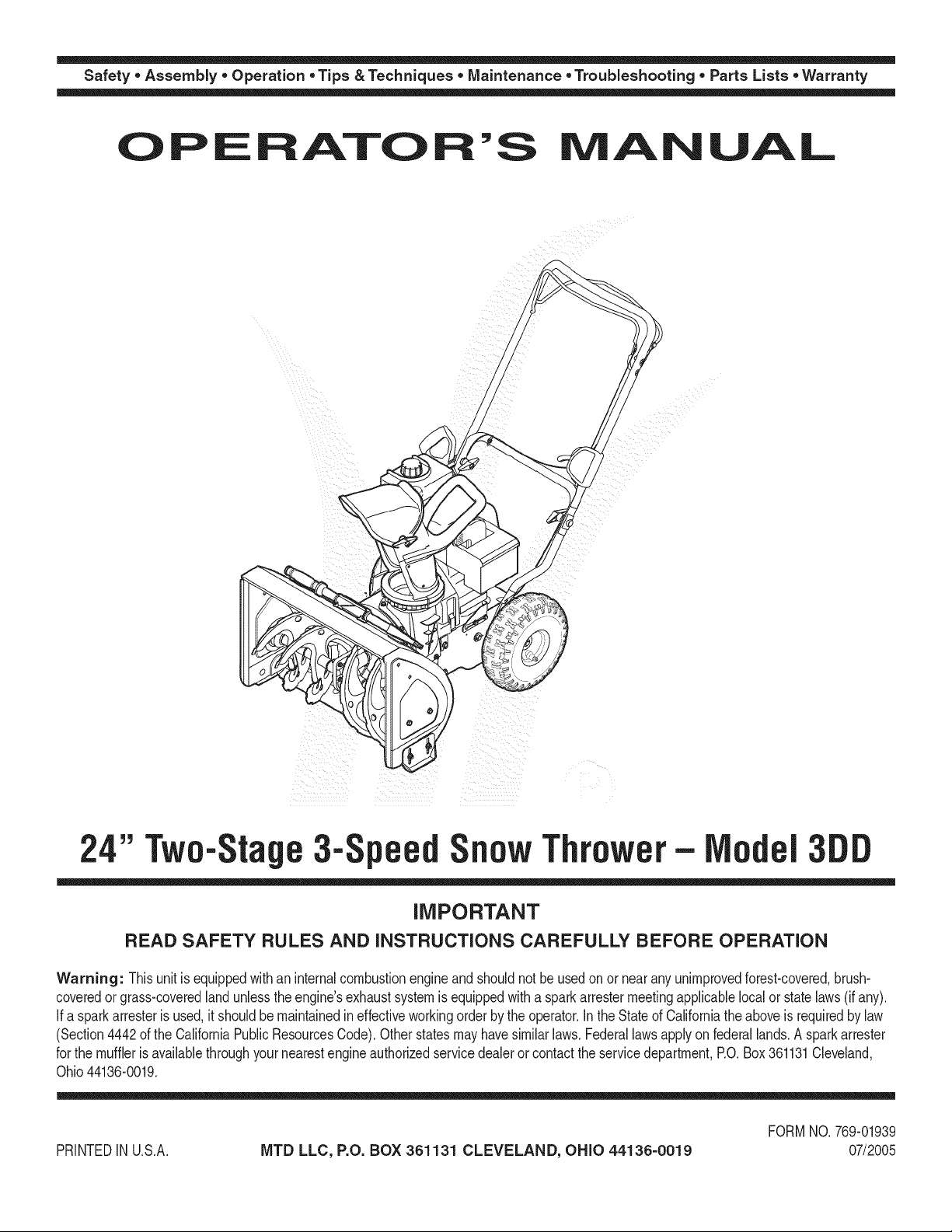

"Tw0-Stage 3- peed n0wThr0wer- el

iMPORTANT

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunit isequippedwithan internalcombustionengineandshouldnot beusedon or nearanyunimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwithasparkarrestermeetingapplicablelocalorstatelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderbytheoperator.IntheStateofCaliforniatheaboveisrequiredbylaw

(Section4442ofthe CaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthe mufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

FORMNO.769-01939

PRINTEDIN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

07/2005

Page 2

This Operator's Manual is an important part of your new snow thrower, it will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

.

Safety Labels ............................................... 3

2.

Safe Operation Practices ........................... 4

3.

Setting Up Your Snow Thrower .................. 6

4.

Know Your Snow Thrower .......................... 8

5.

Operating Your Snow Thrower ................. 10

6.

Maintenance & Service ............................ 13

7. Off-Season Storage .................................. 16

8. Troubleshooting ........................................ 17

g. Parts List ................................................... 18

10. Notes .......................................................... 22

Warranty .................................... Back Cover

Finding and Recording Model Number

BEFOREYOU STARTASSEMBLING

YOURNEW EQUIPMENT,

please locatethe modelplate onthe equipmentand copy the

informationto the sample modelplate providedtothe right.

Youcan locatethe model plateby standingat the operating

position and lookingdown atthe rearofthe snow thrower.

Thisinformationwill be necessaryto use the manufacturer's

website and/or obtain assistancefromthe CustomerSupport

Departmentoran authorizedservice dealer.

Model Number

_www. rntdprod ucts.corn

Serial Number

MTD LLC

P.O. BOX 361131

CLEVELAND, OH 44136

330-220-4683

800-800-7310j

Customer Support

Please do NOTreturn the unit to the retailer from which it was

purchased, without first contacting Customer Support.

If you have difficulty assemblingthis product orhave any questions regardingthe controls, operation,ormaintenanceof this

unit,you canseek help fromthe experts.Choose from the options below:

1. Visit mtdproducts.com Clickonthe Service & Support menuoption.

2. Phonea Customer Support Representative at 1 (800) 800-7310.

3. The engine manufacturer is responsiblefor all engine-relatedissueswith regardsto performance,power-rating,specifica-

tions,warranty andservice. Pleasereferto theengine manufacturer'sOwner's/Operator's Manual,packedseparatelywith

your unit, for moreinformation.

MTD _rit_r_fi_a_

Award Winning _rod_f_ O,_rCc,mp_y

Ser,_ice 8_Supper±

Product. Registration

Priwey P_y

2

Page 3

1.KEEPAWAYFROMROTATINGIMPELLER

ANDAUGER.CONTACTWITHIMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

USECLEAN-OUTTOOLTOUNCLOG

,

DISCHARGECHUTE.

DISENGAGECLUTCHLEVERS,STOPENGINE,

3.

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGORSERVICINGMACHINE.

TOAVOIDTHROWNOBJECTSINJURIES,

,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

WARNING

Thissymbolpoints

out importantsafety

instructionswhich,if

notfollowed,could

endangerthepersonal

safetyand/or property

of yourselfandothers.

Readandfollowall

instructionsinthis

manualbeforeat-

temptingto operate

this machine.Failure

to complywiththese

instructionsmayresult

in personalinjury.When

youseethis symbol.

HEED ITS WARNING!

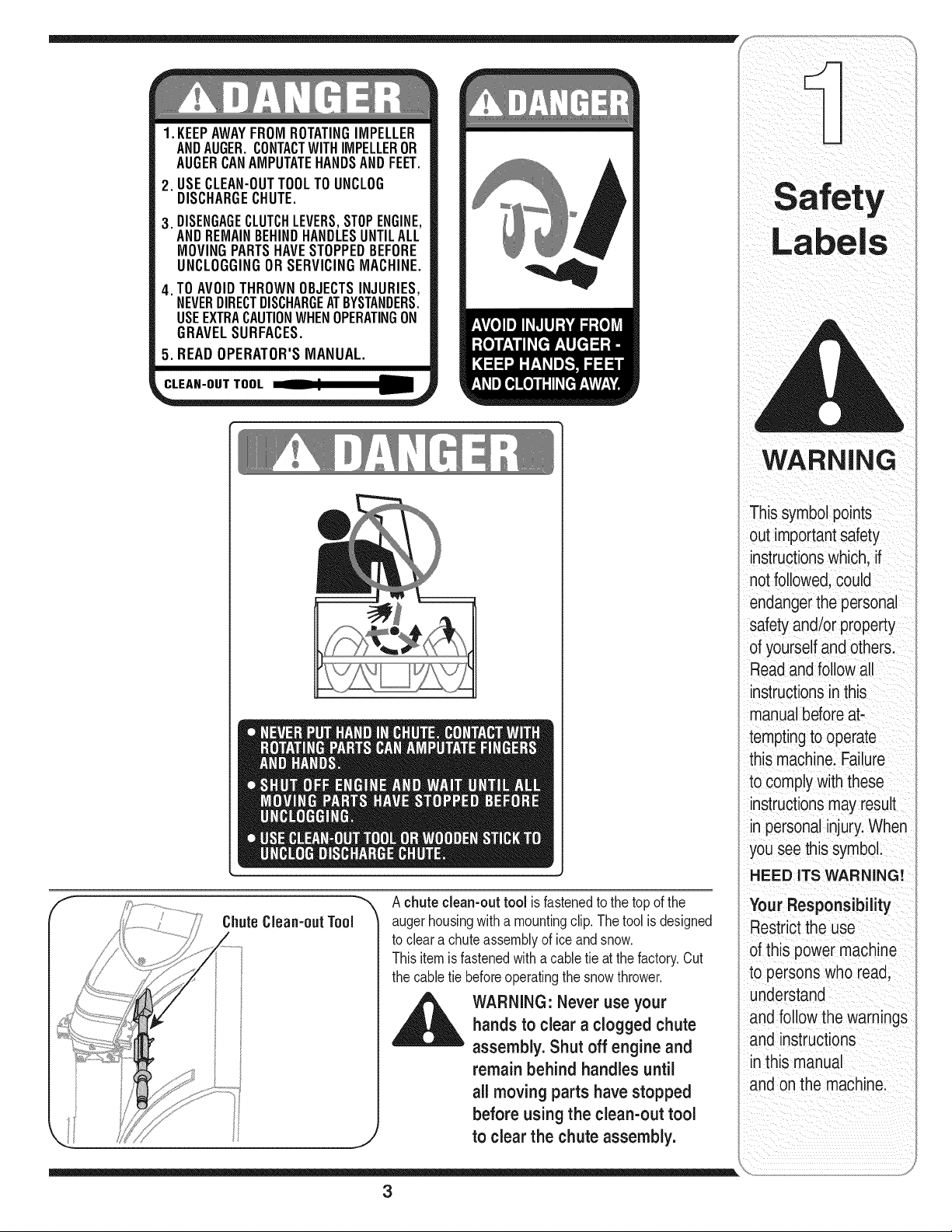

ChuteClean-out Tool

Achuteclean-outtool is fastenedtothetop ofthe

augerhousingwitha mountingclip.Thetoolis designed

tocleara chuteassemblyofice andsnow.

Thisitemisfastenedwitha cabletie atthe factory.Cut

thecabletiebeforeoperatingthesnowthrower.

_ ARNING: Never use your

hands to clear a clogged chute

assembly. Shut off engine and

remain behind handles until

all moving parts have stopped

before using the clean-out tool

to clear the chute assembly.

3

Your Responsibility

Restrictthe use

ofthis power machine

to persons who read,

understand

and follow thewarnings

and instructions

in this manual

and onthe machine.

Page 4

WARNING: EngineExhaust,some of itsconstituents,andcertain vehiclecompo-

nentscontain or emit chemicals knownto State of Californiato cause cancer and

birth defects or other reproductiveharm.

DANGER: This machinewas builtto be operatedaccordingto the rulesfor safe operationinthis

manual.As with anytype of powerequipment,carelessness or erroronthe part ofthe operatorcan

result in seriousinjury.This machineiscapableof amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafety instructionscould resultin serious injury or death.

WARNING

Thissymbolpoints

out importantsafety

instructionswhich,if

notfollowed,could

endangerthe personal

i safetyand/or property

I ofyourselfand others.

Readandfollowall

instructionsinthis

manualbeforeat-

temptingto operate

i this machine.Failure

I to complywiththese

instructionsmayresult

i inpersonalinjury.When

youseethis symbol.

i HEED ITS WARNING!

Your Responsibility

Restrictthe use

ofthis powermachine

to personswho read,

_understand

ano followthe warnings

and instructions

inthis manual

and on the machine.

Training

1. Read,understand,andfollowall instructionson the 1.

machineandin themanual(s)beforeattemptingto

assembleandoperate.Keepthis manualina safe placefor

futureandregularreferenceandfor orderingreplacement

parts. 2.

2. Befamiliarwithall controlsandtheirproperoperation.

Knowhowto stopthe machineanddisengagethemquickly.

3. Neverallowchildrenunder14yearsoldto operatethis

machine.Children14yearsold andovershouldreadand

understandtheoperationinstructionsand safetyrulesin 3.

thismanualand shouldbetrainedand supervisedbya

parent.

4. Neverallowadultsto operatethis machinewithoutproper

instruction.

5. Thrownobjectscancauseseriouspersonalinjury.Plan 4.

yoursnow-throwingpatternto avoiddischargeof material

towardroads,bystandersandthe like.

6. Keepbystanders,helpers,petsandchildrenat least75feet 5.

fromthe machinewhileit isin operation.Stopmachineif

anyoneentersthearea. 6.

7. Exercisecautiontoavoidslippingor falling,especially 7.

whenoperatingin reverse.

Preparation

Thoroughlyinspecttheareawheretheequipmentisto be

used.Removealldoormats,newspapers,sleds,boards,

wiresand otherforeignobjects,whichcouldbetripped over

orthrownbythe auger/impeller.

Alwayswearsafetyglassesor eyeshieldsduringoperation

andwhile performinganadjustmentorrepairto protectyour

eyes.Thrownobjectswhichricochetcancause serious

injurytothe eyes.

Do notoperatewithoutwearingadequatewinterouter

garments.Donotwearjewelry,longscarvesorother

looseclothing,whichcould becomeentangledin moving

parts.Wearfootwearwhich willimprovefootingonslippery

surfaces.

Useagroundedthree-wireextensioncordand receptacle

forall unitswithelectric startengines.

Adjustcollectorhousingheighttocleargravelorcrushed

rocksurfaces.

Disengageallcontrolleversbeforestartingthe engine.

Neverattemptto makeanyadjustmentswhileengineis

running,exceptwherespecificallyrecommendedinthe

operator'smanual.

8,

Letengineandmachineadjusttooutdoortemperature

beforestartingtoclearsnow.

9.

Toavoidpersonalinjuryorpropertydamageuseextreme

careinhandlinggasoline.Gasolineisextremelyflammable

andthe vaporsare explosive.Seriouspersonalinjurycan

occurwhengasolineis spilledonyourselforyourclothes,

whichcanignite.Washyourskinand changeclothes

immediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars, pipesandothersources

ofignition.

c. Neverfuel machineindoors.

d. Neverremovegascap oradd fuelwhilethe engineis hot

or running.

e. Allowengineto coolat leasttwo minutesbeforerefuel-

ing.

f. Neveroverfillfuel tank.Filltankto nomorethanY2inch

belowbottomoffiller neckto providespacefor fuel

expansion.

g. Replacegasolinecap andtightensecurely.

h. If gasolineis spilled,wipe itoff theengineandequip-

ment.Movemachinetoanotherarea.Wait5minutes

beforestartingtheengine.

i. Neverstorethe machineorfuel containerinsidewhere

there isan openflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

j. Allowmachinetocool at least5 minutesbeforestoring.

4

Page 5

Operation

1. Donot puthandsorfeetnearrotatingparts,inthe

auger/impellerhousingor chuteassembly.Contactwiththe

rotatingpartscanamputatehandsandfeet.

2. The auger/impellercontrolleveris asafetydevice.Never

bypassitsoperation.Doingso makesthe machineunsafe

andmaycausepersonalinjury.

3. The controlleversmustoperateeasilyin bothdirections

andautomaticallyreturntothe disengagedpositionwhen

released.

4. Neveroperatewitha missingor damagedchuteassembly.

Keepall safetydevicesinplaceandworking.

5. Neverrunan engineindoorsor in apoorlyventilatedarea.

Engineexhaustcontainscarbonmonoxide,anodorlessand

deadlygas.

6. Donotoperatemachinewhileunderthe influenceofalcohol

or drugs.

7. Mufflerandenginebecomehotandcan causea burn.Do

nottouch.

8. Exerciseextremecautionwhenoperatingonorcrossing

gravelsurfaces.Stayalertfor hiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhileoperat-

ingonslopes.

10.Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageor personalinjury causedby aricochet.

11.Neverdirectdischargeatchildren,bystandersand petsor

allow anyoneinfrontofthe machine.

12.Donotoverloadmachinecapacitybyattemptingto clear

snowattoofast of arate.

13.Neveroperatethis machinewithoutgoodvisibility or light.

Alwaysbe sureofyourfootingandkeepa firmholdonthe

handles.Walk,neverrun.

14.Disengagepowerto the auger/impellerwhentransportingor

notinuse.

15.Neveroperatemachineat hightransport speedsonslippery

surfaces.Lookdownand behindandusecare when

backingup.

16.Ifthe machineshouldstartto vibrateabnormally,stopthe

engine,disconnectthesparkplugwireandgroundit against

the engine.Inspectthoroughlyfordamage.Repairany

damagebeforestartingandoperating.

17.Disengageallcontrolleversandstopenginebeforeyou

leavethe operatingposition(behindthe handles).Wait

untilthe auger/impellercomestoa completestop before

uncloggingthe chuteassembly,makinganyadjustments,or

inspections.

18.Neverputyourhandin thedischargeor collectoropenings.

Alwaysuse theclean-outtoolprovidedtounclogthe dis-

chargeopening.Donot unclogchuteassemblywhileengine

isrunning.Shut offengineandremainbehindhandlesuntil

all movingpartshavestoppedbefore unclogging.

19.Useonly attachmentsandaccessoriesapprovedbythe

manufacturer(e.g.wheelweights,tirechains,cabsetc.).

20. Ifsituationsoccurwhichare notcoveredinthis manual,

usecareand goodjudgment.Contactyourdealeror call

(800)800-7310forassistanceandthe nameofyournearest

servicingdealer..

Maintenance & Storage

1. Nevertamperwithsafetydevices.Checktheir proper

operationregularly.Refertothe maintenanceandadjust-

mentsectionsofthis manual.

2. Beforecleaning,repairing,orinspectingmachinedisen-

gageall controlleversandstopthe engine.Wait untilthe

auger/impellercometoa completestop. Disconnectthe

sparkplugwireand groundagainstthe engineto prevent

unintendedstarting.

3. Checkbolts andscrewsfor propertightnessatfrequent

intervalstokeepthe machineinsafeworkingcondition.

Also,visuallyinspectmachinefor anydamage.

4. Do notchangetheenginegovernorsettingor over-speed

theengine.The governorcontrolsthemaximumsafe

operatingspeedoftheengine.

5. Snowthrowershaveplatesandskidshoesaresubjectto

wearanddamage.Foryoursafetyprotection,frequently

checkallcomponentsandreplacewith originalequipment

manufacturer's(OEM) partsonly."Useof partswhichdo

notmeetthe originalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

6. Checkcontrolsperiodicallytoverify theyengageand

disengageproperlyandadjust,if necessary.Referto the

adjustmentsectioninthis operator'smanualfor instructions.

7. Maintainor replacesafetyandinstructionlabels,as neces-

sary.

8. Observeproperdisposallawsandregulationsfor gas,oil,

etc.toprotectthe environment.

9. Priorto storing,run machineafew minutestoclearsnow

frommachineandpreventfreezeupof auger/impeller.

10.Neverstorethemachineorfuel containerinsidewhere

thereisan openflame,sparkor pilotlightsuchas a water

heater,furnace,clothesdryeretc.

11.Alwaysreferto theoperator'smanualforproperinstructions

onoff-seasonstorage.

Do not modify engine

Toavoidseriousinjuryordeath,donot modifyengineinany

way.Tamperingwiththegovernorsettingcan leadto a runaway

engineandcauseit tooperateat unsafespeeds.Nevertamper

withfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)

arecertifiedto operateonregularunleadedgasoline,andmay

includethefollowingemissioncontrolsystems:EngineModifica-

tion(EM)andThreeWayCatalyst(TWO)ifso equipped.

Your Responsibility

Restrictthe useofthis powermachineto personswhoread,un-

derstandandfollowthe warningsandinstructionsin thismanual

andon themachine.

Operation

WARNING

Thissymbol points

out importantsafety

instructions,which if

notfollowed,could

endangerthe personal

safety and/or property

of yourselfand others.

Readand followall

instructions inthis man-

ual before attemptingto

operatethis machine.

Failureto comply with

these instructionsmay

result in personalinjury.

Whenyou seethis

symbol.

HEED IT'S WARNING!

YourResponsibility

Restrictthe use

of this powermachine

to personswho read.

understand

and followthe warnings

and instructions

in this manua

and on the machine.

5

Page 6

Adjustment

IMPORTANT:Thisunit isshippedwiththeenginefull of

oil.Afterassembly,seethe EngineOwner'smanualfor

fuelandoil details.

Removing From Carton

1. Cutthecornersofthecartonandlaythesidesfiaton

theground. Removeall packinginserts.

2. Theupperhandleispackagedunattachedtothe

snowthrower,thoughconnectedbycanes. Move

thesnowthrowerandupperhandleout ofthecarton.

3. Makecertainthecartonhasbeencompletely

emptiedbeforediscardingit.

Before Assembly

WARNING

Disconnectthe

sparkplugwire

and ground

itagainst the

engine to prevent

unintended starting.

Do not lift the

snowthrower at

any time by the

i chute handle.

CAUTION:

Be careful not to

bend or kink the

cables.

__lh WARNING:Disconnectthe sparkplug

NOTE:Referencetoright,left,frontor rearofthe unitis

fromtheoperatingpositionunlessotherwisestated.

wireand Ground it againstthe engine

to preventunintendedstarting.

Setting Up The Handle

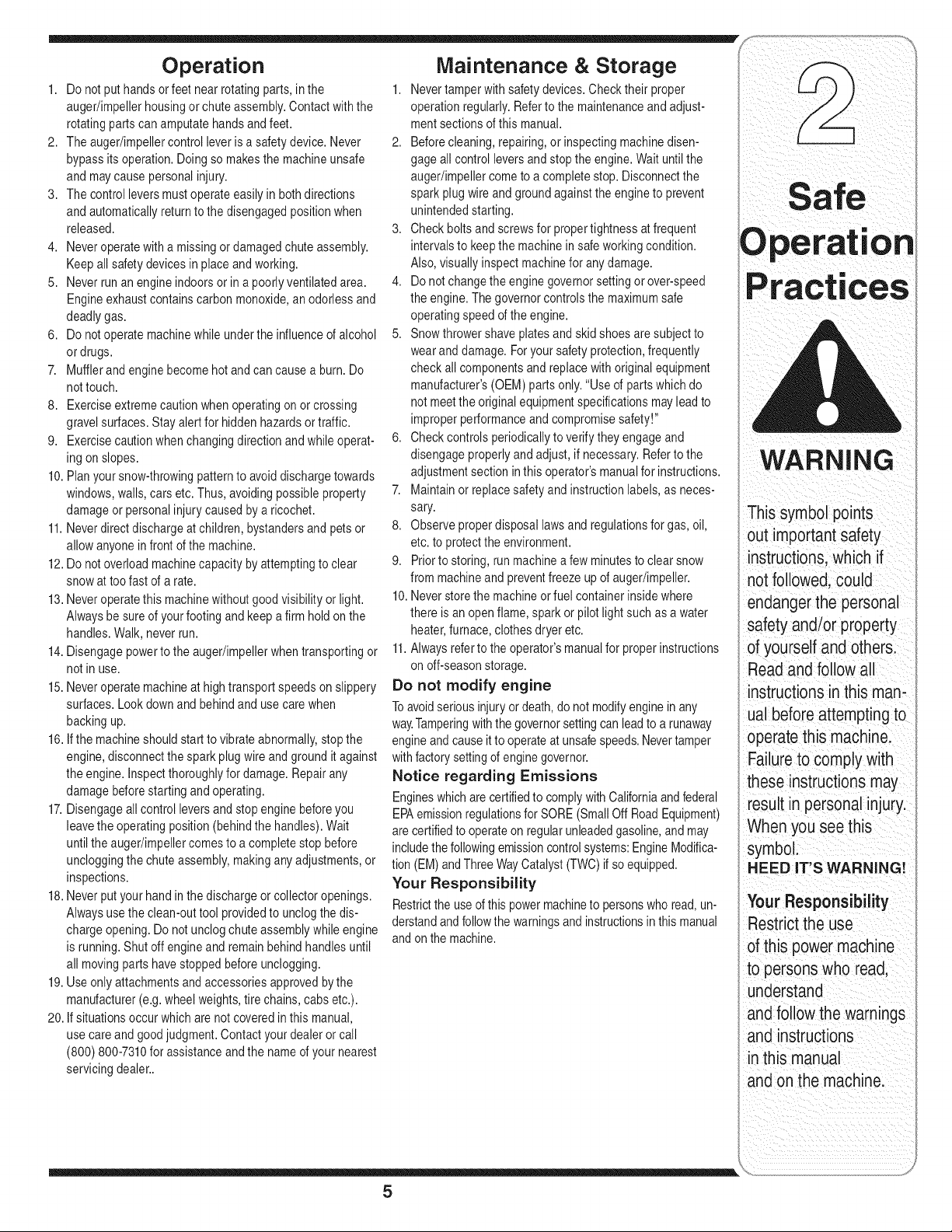

1. Loosenandremovethewingknob,saddlewasher,

handletabandcarriagescrewoneach sideof the

lowerhandle.SeeFigure1.

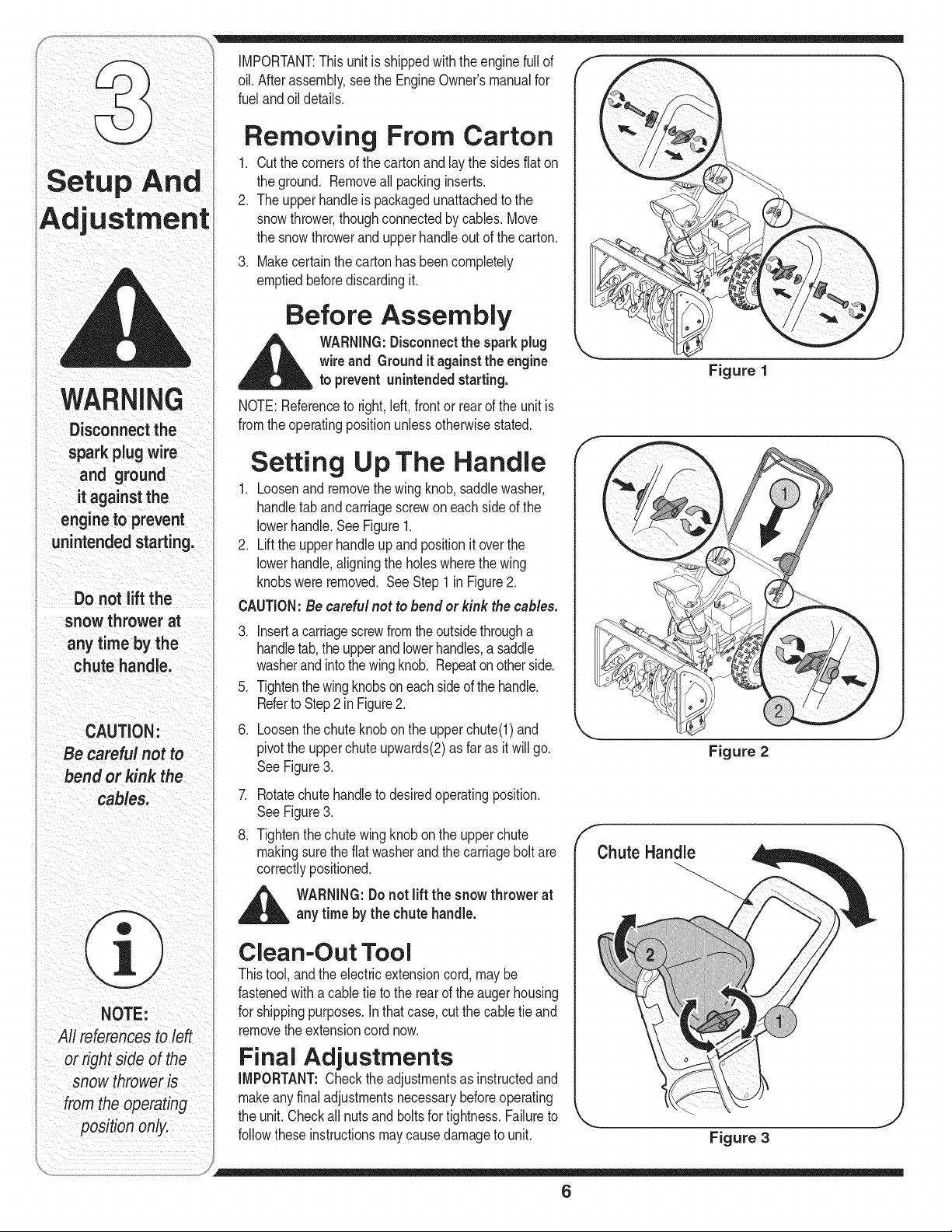

2. Liftthe upperhandleupandpositionitoverthe

lowerhandle,aligningtheholeswherethewing

knobswereremoved.SeeStep1inFigure2.

CAUTION:Be careful not to bendor kink the cables.

.

Insertacarriagescrewfromtheoutsidethrougha

handletab,theupperandlowerhandles,a saddle

washerandintothewingknob. Repeatonotherside.

.

Tightenthewingknobsoneachsideofthe handle.

Referto Step2 inFigure2.

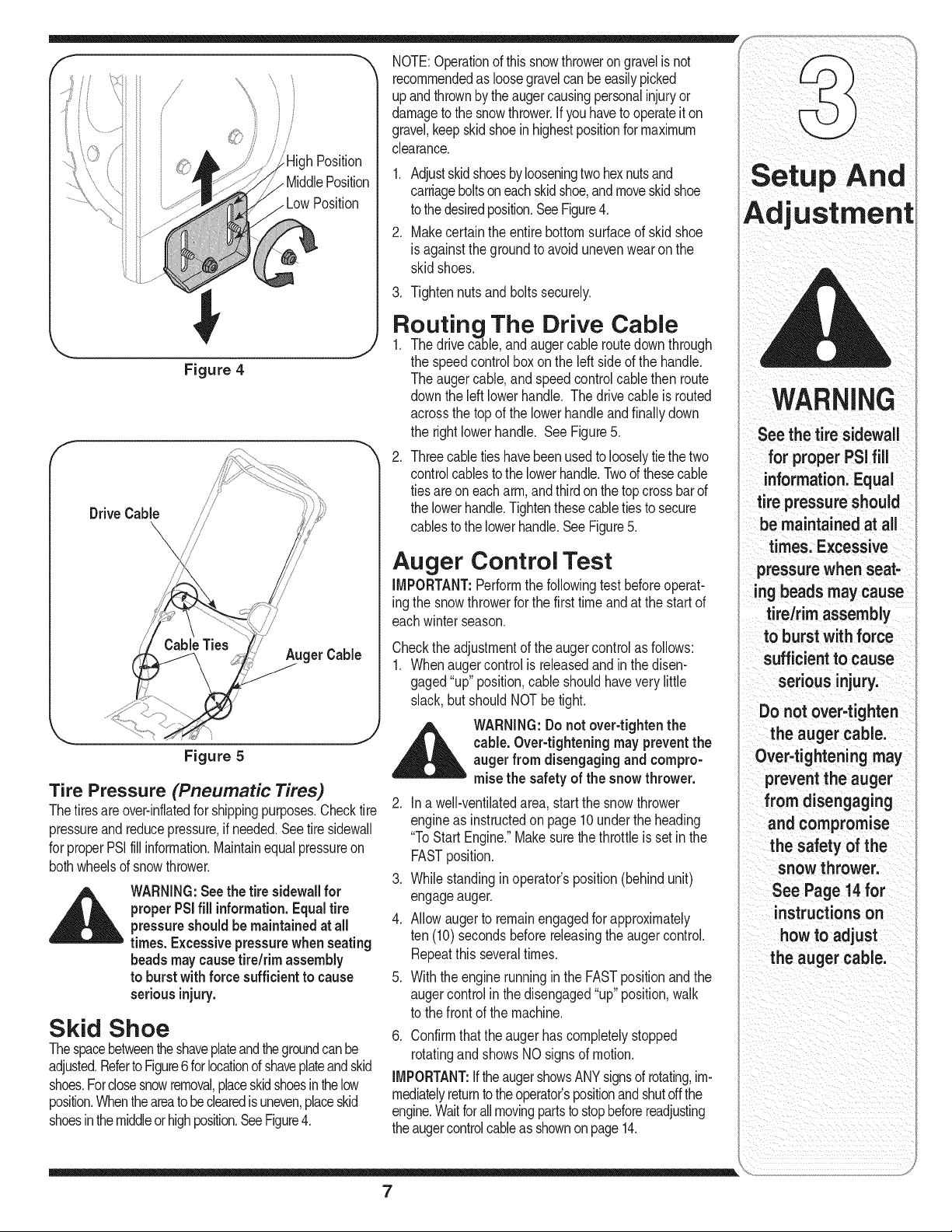

6.

Loosenthechuteknobonthe upperchute(l)and

pivottheupperchuteupwards(2)as faras itwillgo.

SeeFigure3.

7. Rotatechutehandletodesiredoperatingposition.

SeeFigure3.

8. Tightenthechutewingknobon theupperchute

makingsurethe flatwasherandthecarriageboltare

correctlypositioned.

Figure 1

f

Figure 2

f

Chute Handle

NOTEI

AIi referencestoleft

orright Sideof the

snow thrower is

theopera#g

position on8

,d_ WARNING:Donot liftthe snow thrower at

any time by thechute handle.

Clean-Out Tool

Thistool,andtheelectricextensioncord,maybe

fastenedwithacable tieto therearof theaugerhousing

forshippingpurposes.Inthatcase,cutthecabletieand

removetheextensioncordnow.

Final Adjustments

IMPORTANT:Checktheadjustmentsasinstructedand

makeanyfinaladjustmentsnecessarybeforeoperating

theunit.Checkall nutsandboltsfortightness.Failureto

followtheseinstructionsmaycausedamagetounit.

'_. j

Figure 3

6

Page 7

F

f

DriveCable

//

J

Figure 4

Figure 5

\\

i j

i '

; i

HighPosition

MiddlePosition

LowPosition

Tire Pressure (Pneumatic Tires)

Thetiresareover-inflatedforshippingpurposes.Checktire

pressureandreducepressure,ifneeded.Seetiresidewall

forproperPSIfillinformation.Maintainequalpressureon

bothwheelsofsnowthrower.

WARNING:Seethe tire sidewallfor

properPSIfill information.Equaltire

pressureshouldbemaintainedat all

times. Excessivepressurewhen seating

beadsmaycausetire/rim assembly

to burstwith force sufficientto cause

seriousinjury.

Skid Shoe

Thespacebetweentheshaveplateandthegroundcanbe

adjusted.Referto Figure6forlocationd shaveplateandskid

shoes.Forclosesnowremoval,placeskidshoesinthelow

position.Whentheareatobeclearedisuneven,placeskid

shoesinthemiddleorhighposition.SeeFigure4.

NOTE:Operationofthissnowthrowerongravelisnot

recommendedas loosegravelcanbeeasilypicked

upandthrownbythe augercausingpersonalinjuryor

damageto thesnowthrower.If youhavetooperateiton

gravel,keepskidshoeinhighestpositionformaximum

clearance.

1. Adjustskidshoesbylooseningtwohexnutsand

carriageboltsoneachskidshoe,andmoveskidshoe

tothedesiredposition.SeeFigure4.

2. Makecertainthe entirebottomsurfaceof skidshoe

isagainstthe groundtoavoidunevenwearonthe

skidshoes.

3. Tightennutsandboltssecurely.

Routing The Drive Cable

1. Thedrivecable,andaugercable routedownthrough

thespeedcontrolboxonthe leftsideofthe handle.

Theaugercable,andspeedcontrolcablethenroute

downthe leftlowerhandle.The drivecable isrouted

acrossthetopof thelowerhandleandfinallydown

therightlowerhandle. SeeFigure5.

.

Threecabletieshavebeenusedtolooselytiethetwo

controlcablestothe lowerhandle.Twoofthesecable

tiesareoneacharm,andthirdonthetopcrossbarof

thelowerhandle.Tightenthesecabletiestosecure

cablestothe lowerhandle.SeeFigure5.

Auger Control Test

IMPORTANT:Performthefollowingtestbeforeoperat-

ingthesnowthrowerfor thefirsttimeandatthestartof

eachwinterseason.

Checktheadjustmentofthe augercontrolasfollows:

1. Whenaugercontrolisreleasedand inthedisen-

gaged"up"position,cableshouldhaveverylittle

slack,butshouldNOTbetight.

WARNING:Do notover-tighten the

cable.Over-tightening maypreventthe

auger from disengagingand compro-

misethe safetyof thesnowthrower.

2. In a well-ventilatedarea,start thesnowthrower

engineasinstructedonpage10undertheheading

"ToStartEngine."Makesurethethrottleissetin the

FASTposition.

3. Whilestandinginoperator'sposition(behindunit)

engageauger.

4. Allowaugerto remainengagedforapproximately

ten(10)secondsbeforereleasingtheaugercontrol.

Repeatthisseveraltimes.

5. WiththeenginerunningintheFASTpositionandthe

augercontrolinthedisengaged"up"position,walk

tothe frontofthe machine.

6. Confirmthattheaugerhas completelystopped

rotatingandshowsNOsignsofmotion.

IMPORTANT:IftheaugershowsANYsignsofrotating,im-

mediatelyreturntotheoperator'spositionandshutoffthe

engine.Waitforallmovingpartstostopbeforereadjusting

theaugercontrolcableasshownonpage14.

WARNING

See the tire sidewall

for proper PSifill

information.Equal

tire pressureshould

be maintained at all

times. Excessive

pressurewhen seat-

ingbeads may cause

tire/rim assembly

to burstwith force

sufficientto cause

seriousinjury.

Do not over-tighten

the auger cable.

Over-tightening may

preventthe auger

from disengaging

and compromise

the safety of the

snowthrower.

See Page 14for

instructionson

how to adjust

the auger cable.

7

Page 8

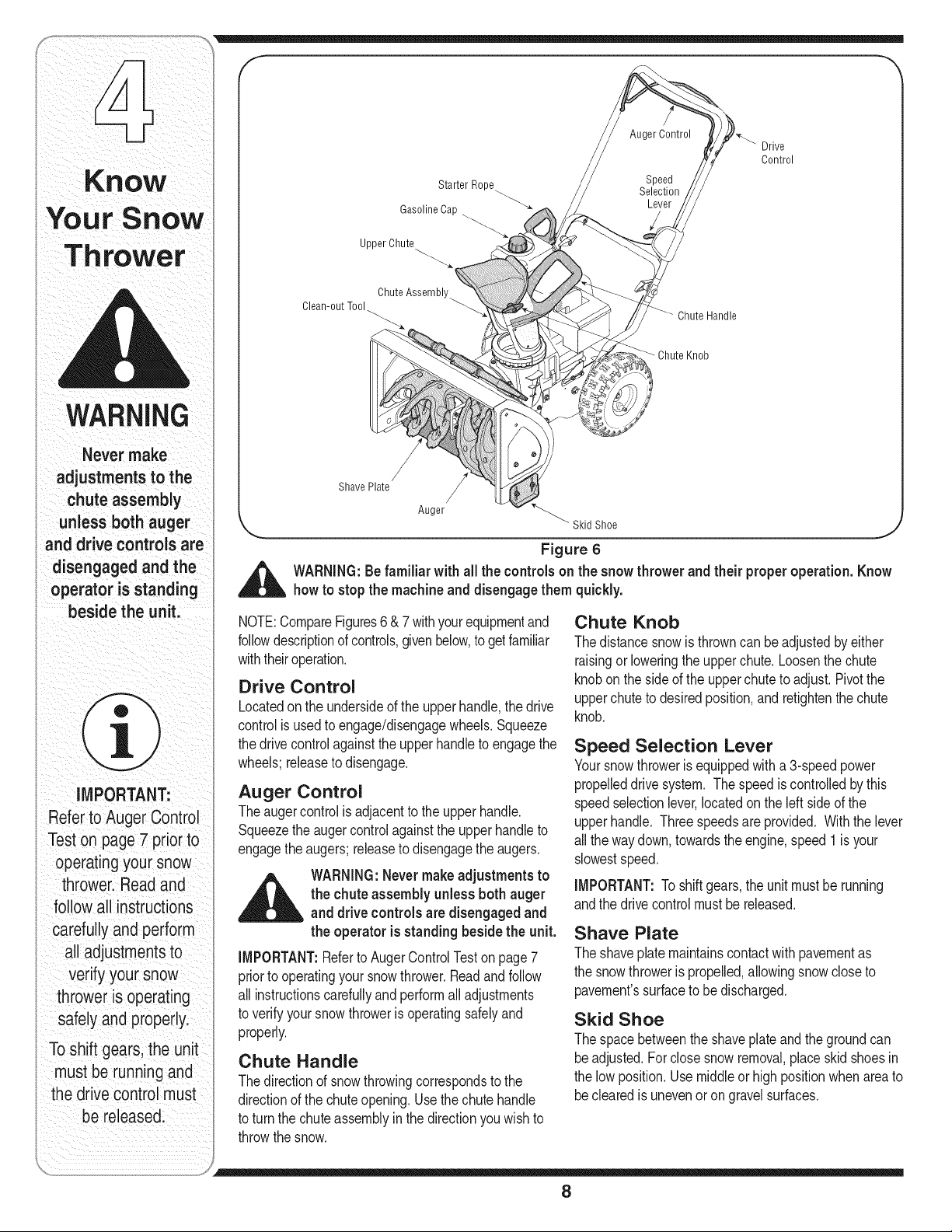

Gasoline Cap

Upper Chute

IMPORTANT:

Refer tOAuger Control

TeSton page7 priorto

operatng your snoW

throweriRead and

folloW aii instructions

Carefullyandperform

all adjuStmentsto

verifyyoursnow

thrower iSoperating

safey and properly;

l

sh ft gears;theun t

must be runningand

the drive control must

bereleased:

I

Clean-out Tool

ChuteAssembly.

_- Chute Handle

Knob

//

Shave Plate

Auger

SkidShoe

Figure 6

_ ARNING:Befamiliar with all the controls on the snowthrower andtheir properoperation. Know

NOTE:CompareFigures6&7 withyourequipmentand

followdescriptionof controls,givenbelow,togetfamiliar

withtheiroperation.

Drive Control

Locatedon theundersideof the upperhandle,thedrive

controlisusedtoengage/disengagewheels.Squeeze

thedrivecontrolagainsttheupperhandletoengagethe

wheels;releasetodisengage.

Auger Control

Theaugercontrolis adjacenttothe upperhandle.

Squeezethe augercontrolagainsttheupperhandleto

engagetheaugers;releasetodisengagetheaugers.

_lll/i ARNING:Nevermakeadjustments to

IMPORTANT:Referto AugerControlTestonpage7

priortooperatingyoursnowthrower.Readandfollow

all instructionscarefullyandperformalladjustments

toverifyyoursnowthroweris operatingsafelyand

properly.

Chute Handle

Thedirectionof snowthrowingcorrespondsto the

directionof the chuteopening.Usethe chutehandle

how to stop the machineand disengage themquickly.

Chute Knob

Thedistancesnowisthrowncan beadjustedbyeither

raisingorloweringtheupperchute.Loosenthechute

knobon thesideof theupperchutetoadjust.Pivotthe

upperchutetodesiredposition,andretightenthechute

knob.

Speed Selection Lever

Yoursnowthrowerisequippedwitha3-speedpower

propelleddrivesystem.The speedis controlledbythis

speedselectionlever,locatedontheleft sideofthe

upperhandle. Threespeedsareprovided.Withthelever

allthewaydown,towardstheengine,speed1isyour

slowestspeed.

the chute assembly unless both auger

and drive controlsare disengaged and

the operator isstanding beside the unit.

IMPORTANT:Toshiftgears,the unitmustberunning

andthedrivecontrolmustbe released.

Shave Plate

Theshaveplate maintainscontactwithpavementas

thesnowthroweris propelled,allowingsnowcloseto

pavement'ssurfaceto bedischarged.

Skid Shoe

Thespacebetweentheshaveplateandthegroundcan

beadjusted.Forclosesnowremoval,placeskidshoesin

thelowposition.Usemiddleor highpositionwhenareato

beclearedis unevenoron gravelsurfaces.

toturnthechuteassemblyinthe directionyouwishto

throwthesnow.

8

Page 9

/_Muffler Spark Oil Fill GasolineCap

Ign,tionl \b/Y \Starter

Key/ "Handle

Figure7

Clean Out Tool

Thecleanouttool isprovidedto unclogthedischarge

opening.Donotunclogdischargechutewhileengineis

running.

,_llhlk WARNING:Before unclogging, shut

Choke Control

Activatingchokecontrolclosesthechokeplateon

carburetorandaidsin startingengine.Theimagebelow

representsthe speedsof thethrottlecontrol. Forinforma-

tiononchokeusage,see page10ofthismanual.

off engineandremain behind handles

until all movingpartshavestopped

completely.Neverput yourhandinthe

discharge or collectoropenings.Always

usethe clean-outtool provided.

iii

Recoil Starter & Starter Handle

Thismotorisfitted witha recoilactionpull startanda

mittengriphandlefor easyaccesswhilewearinggloves

or mittens.

Electric Starter Button

Pressingtheelectricstarterbuttonengagesthe

engine'selectricstarterwhenpluggedintoa 120V

powersource

Electric Starter Plug

Requiresuseof atwo-prongoutdoorextensioncord

(packedwiththe snowthrower)anda 120Vpower

source/walloutlet.

Ignition Key

Theignitionkeyisnecessaryfortheengineto start.

Insertkeyandsnapin place;do notturn it to start/stop

theunit.Removekeywhenthe unitisnotinuse.

Primer

Depressingprimerforcesfueldirectlyinto

engine'scarburetortoaid incold-weather

starting.Refertothe startinginstructions

inthe Operationsectionof thismanualfor

properprimerusage.

Oil Fill

Removeoil cap toaddoil. Refertothe EngineOwner's

manualforcheckingandaddingoil instructions.

Gasoline Cap

Removegas capto addfuel.Unitrunson regulargas.

NOTE:Thisunit mayincludea fuel plug,whichisonly

usedduringassemblyto keepdirt anddebrisoutof fuel

tank. Discardthefuelplugbeforefillingthefueltank.

Throttle Control

Thethrottlecontrolislocatedonthe engine.

It regulatesthespeedofthe engineandalso

stopsthe engine.The imageto the right

representsthe speedsofthe throttlecontrol.

O

PUSH FOR A

©

WARNING

Before unclogging,

shut off engine

and remain behind

handles untilall

moving parts have

stopped completely.

Never put your hand

in the discharge or

collector openings.

Always use the clean-

out tool provided.

@

9

Page 10

WARNING

Gasolineisflammable

i and cautionmust be

used when handling

or storing it. Donot

fill fuel tank while

the snowthrower is

running,when it is

hotor when itis inan

enclosed area.

Keepyour snow

thrower awayfrom

any openflame or an

electricalsparkand

do notsmokeduring

fueling.

Besurenooneother

thanthe operatoris

standingnearthe

snowthrowerwhile

startingoroperating,

Donotoperatethis

i snowthrowerunless

i thechuteassembly

hasbeenproperly

installedandis

secured.

The electricstarter

must be properly

groundedat all

i times to avoidthe

i possibilityofelectric

i shock to the operator.

i if your house wiring

systemis nota

i three=wire grounded

system,do not use

this electricstarter

underanyconditions.

Before Starting Engine

Engine Oil

Theengineisshippedwithoil init.Checktheoillevel

beforefirstuse.

Stopengineandwaitseveralminutesbeforecheck-

ingoillevel.Removeoilfillcap anddipstick.

.

Wipedipstickclean,insertitintooil fillholeand

tightensecurely.

.

Withengineonlevelground,oil mustbe to FULL

markon dipstick.Ifoil levelislow,addoil.

FULL MaintainOilLevel

_ BetweenFULLandADD

ADD

Adding Engine Oil

Besureto usethegradeofengineoilspecifiedin

enginemanual.Toaddoil:

1. Removethedipstickfromtheoilfill.Pourfreshoil

slowlythroughtheplug.Replacedipstick.

2. Checkandmakesurethatthe levelof oil isupto the

FULLmarkonthedipstick.

IMPORTANT:Forcompletedetailedengineinformation,

seetheseparateengineowner'smanualincludedwith

thisunit.

Gasoline

,_ WARNING:Gasolineis flammable and

__L WARNING:Keepyoursnowthrower

1. Neverfillthefueltankcompletely.Fill thetankto

nomorethan 1/2inchbelowbottomoffiller neckto

providespaceforexpansionoffuel.

NOTE:Thisunit mayincludea fuel plug,whichis only

usedduringassemblyto keepdirt anddebrisoutoffuel

tank. Discardthefuelplugbeforefillingthefueltank.

2. Alwaysuseclean,fresh,unleadedgradeautomotive

gasoline.Fillthe fueltankoutdoorsanduseafunnel

orspouttopreventspilling.Makesurethatthe

containerfromwhichyoupourthegasolineisclean

andfreefromrustor otherforeignparticles.Make

caution must be usedwhen handling

or storing it.Donot fill fuel tank while

the snow thrower is running, when itis

hot or when it is inanenclosedarea.

awayfrom anyopenflameoranelectrical

sparkanddo notsmokeduringfueling.

sureto wipeoff any spilledfuelbeforestartingthe

engine.

3. At theendof thejob, emptythefueltank ifthesnow

throwerisnotgoingtobe usedfor30daysorlonger.

Storegasolineina cleancontainerandkeepthecap

in placeonthe container.

CAUTION:Never useengine or carburetor cleaner

products in thefuel tank.

To Start Engine

_ ARNING:Be sure nooneother than

NOTE:Forlocationofallthe enginecontrolsreferredtoin

thissection,referto Figure7.

the operator is standing near thesnow

thrower while starting or operating. Do

not operate this snow thrower unless

the chute assembly has beenproperly

installed andis secured.

For A Cold Start

Electric Starter

Somemodelsof thesnowthrowermaybeequipped

withanoptional120voltA.C.electricstarter.This

electricstarter,witha three-wirepowercordandplug, is

designedtooperateon120voltAC householdcurrent.

Followthestepsbelowto usethe electricstarter.

_ ARNING:Theelectricstarter must

-- avoid the possibilityof electric shock.

.

Determinethatyour housewiringisa three-wire

groundedsystem.Aska licensedelectricianifyouare

notcertain.

2. If your homewiring system is not a three-wire

grounded system, do notusethiselectricstarter

underanyconditions.

3. If your homeelectricalsystem isgrounded, but

a three-holereceptacleisnot available,oneshould

beinstalledby a licensedelectricianbeforeusingthe

electricstarter.

4. If youhavea grounded three-prong receptacle,

proceedasfollows.

5. MoveChokeControlto the"Full"position.

6. PushPrimerthree(3)times,makingsureto cover

ventholewhenpushing.

7. Connectpowercordtoswitchboxondashpanel.

Plugtheotherendof powercordintoa three-prong

120-volt,grounded,ACreceptacle.

8. Pushstarterbuttonto crankengine.

9. Whenenginestarts,releasestarterbutton,andmove

chokegraduallyto 1/2Chokeuntil theengineruns

smoothly.NextmoveChoketoOFE If enginefalters,

be used with a properlygrounded

three-prong receptacleat all times to

Followall instructionscarefullypriorto

operating the electric starter.

10

Page 11

movechokeimmediatelyto FULLandthengradually

to 1/2thento OFF.

10.Disconnectthepowercord.Alwaysunplugfromthe

outletfirst,andthenfromthe snowthrower.

Recoil Starter

1. MovechokelevertoFULLchokeposition(coldengine

start).

2. Ifengineiswarm,placechokeinOFFpositioninstead

of FULL.

3. PushPrimerthree(3) times,makingsureto cover

ventholewhenpushing.

4. Ifengineiswarm,push primerbuttononlyonce.

NOTE:Alwayscoverventholein primerbuttonwhen

pushing.Additionalprimingmaybenecessaryforfirst

startif temperatureis below15degreesFahrenheit.

5. Graspstarterhandleand pullropeout slowly,untilit

pullsslightlyharder.Letroperewindslowly.

6. Pullstarterhandlerapidly.Donotallowhandleto snap

back.Allow itto rewindslowlywhilekeepinga firm

holdon thestarterhandle.

7. Asenginewarmsupandbeginstooperateevenly,rotate

chokeleverslowlytothe 1/2Chokeposition.Whenthe

enginebeginsto runsmoothly,movethechoketothe

OFFposition.Ifenginefalters,returntoFULLchoke,then

slowlymoveto 1/2thenOFFposition.

For A Warm Start:

1. If restartingan engineafteratemporaryshut-down,

rotatechoketoOFFinsteadof FULLanddonotprime.

Useelectricstart featureor pullthestarterhandleas

instructedbefore.

Clearing The Snow

CAUTION:Checkthearea tobe clearedfor foreign

objects. Removeforeign objects, if any.

1. Startthe enginefollowingstartinginstructions.

2. Allowtheengineto warmup fora fewminutesas

theenginewill notdevelopfullpoweruntilit reaches

operatingtemperature.

3. Rotatethechuteassemblytothedesireddirection,

awayfrombystandersand/orbuildings.

4. Makingcertainno bystandersor obstaclesarein

frontof the unit,squeezetheaugercontrolcom-

pletelyagainsttheupperhandleto fullyengagethe

augers.

5. Whiletheaugercontrolisengaged,squeezethedrive

controlcompletelyagainsttheupperhandletoengage

thewheels.Donot"feather"thedrivecontrol.

6. As thesnowthrowerstartsto move,maintaina firm

holdonthehandle,andguidethesnowthrower

alongthepathto becleared.

7. Releasetheaugeranddrivecontrolstostopthe

snowthrowingactionandforwardmotion.

NOTE:Yourunitisequippedwithaclutch inthe

transmission.If thewheelsstopturningwhiletryingto

dischargelargevolumesofsnow,immediatelydisen-

gagethedrivecontrolandallowthe rotatingaugersto

dischargesnowfromthehousing.Reducetheclearing

widthandcontinueoperation.

8. Oneach succeedingpass,readjustthechute

assemblytothe desiredpositionandslightlyoverlap

thepreviouslyclearedpath.

WARNING

temperature

of muffler and the

surrounding areas

may exceed 150° F.

Avoidthese areas:

Before Stopping

1. Runengineforafew minutesto helpdryoff any

moistureonengine.

2. Toavoidpossiblefreeze-upof thestarter,followthese

steps:

Recoil Starter

a. Withtheenginerunning,pullthe starterropewitha

rapid,continuousfullarm strokethreeorfourtimes.

To Stop The SnowThrower

1. Tostopthewheels,releasethedrivecontrol.

2. To stopthrowingsnow,releasetheaugercontrol.

3. To stopengine,pushthrottlecontrollevertoOFFand

pulloutthe key.Do notturn key.

_ WARNING:Thetemperatureof muffler

andthesurroundingareasmayexceed

150°F.Avoidtheseareas.

11

Page 12

WARNING

Stopengine by

movingthrottle lever

to stop position and

wait for all moving

parts to stop before

usingthe

cleanoout tool.

Never use your

handsto clean snow

and ice from the

chute assembly or

auger housing.

Speed Selector Lever

Yourunitisequippedwitha 3-speedpowerpropelled

drivesystem. Speedposition1,whentheleveris

depressedallthewaydowntowardthe motor,isslow.

Speedposition2 isa littlefasterand3 isthe fastest.

SeeFigure8.

Tooperatethisfunction,followtheseinstructions:

1. Shiftyoursnowthroweronlywhileengineisrunning.

2. Releasedrivecontrolhandlebeforeshifting.

Operating Tips

1. Formostefficientsnowremoval,removesnow

immediatelyafteritfalls.

2. Dischargesnowdownwindwheneverpossible.

Slightlyoverlapeachpreviousswath.

3. Settheskidshoes1/4"belowtheshaveplatefor

normalusage.Theskidshoesmaybeadjusted

upwardforhard-packedsnow.

NOTE:Itis notrecommendedthatyouoperatethis

snowthrowerongravelas loosegravelcanbeeasily

pickedupandthrownbythe augercausingpersonal

injuryand/or damagetothesnowthrower.

.

Iffor somereason,youhavetooperatethesnow

throweron gravel,keepthe skidshoeinthe highest

positionformaximumclearancebetweentheground

andtheshaveplate.

5. Cleanthesnowthrowerthoroughlyaftereach use.

Cleaning The

/

Speed

Selector

Lever

Figure8

Chute

Clean-out

Tool

Chute Assembly

Theclean-outtool isconvenientlyfastenedtothe auger

housingwitha mountingclip.

Whensnowandice collectin the chuteassemblyduring

operation,usethis toolto safelycleanthe chuteand

chuteopening.Followthestepsbelowtooperateit.

__k WARNING:Stop engineby moving

1. Releasebothaugeranddrivecontrols.

2. Stoptheengineby movingthrottleleverto stop

position.

3. Removetheclean-outtool fromtheclip which

securesittothe rearoftheaugerhousing.

4. Usethe shovel-shapedendof theclean-outtool to

dislodgeandscoopanysnowandicewhichhas

formedinand nearthechuteassembly.

_ ARNING:Neveruse yourhands to

throttle leverto stop positionandwait

for all moving partsto stop before

using the clean-outtool.

clean snow and icefrom thechute

assembly oraugerhousing.

\

Figure9

5. Re-fastentheclean-outtoolto themountingclipon

theaugerhousing.Youcan startoperatingyoursnow

throwernow. SeeFigure9.

NOTE:The handleofthe clean-outtoolshouldbeplaced

withthehandleto theRightsideonthesnowthrower

augerhousing.

Housing

J

12

Page 13

ShearPin

Cotter Pin

.

Toreplace,removetwocarriageboltsand hexnuts

securingeachskidshoetothe augerhousing. See

Figure10.

2. Reassemblenewskid shoeswith hardwarejust

removed.Makesure shoesareadjustedtobe level.

3. To removeshave plate: Removeboth skidshoes

andhardwareincludingcarriagebolts,andhex

nutswhichattachshaveplateto thesnowthrower

housing.Forlocationof shaveplate,seeFigure10.

4. Reassemblenewshaveplate,makingsureheads

ofthe carriageboltsareto theinsideofthehousing.

Reinstallskidshoes.Tightensecurely.

Bolt HexNut

Figure10

Lubricate

Figure 11

General Recommendations

1. Alwaysobservesafetyruleswhenperformingany

maintenance.

2. The warrantyonthis snowthrowerdoesnotcover

itemsthat havebeensubjectedtooperatorabuseor

negligence.Toreceivefullvaluefromthe warranty,

operatormustmaintainthesnowthroweras instructed

in thismanual.

3. Periodicallycheckallfastenersandhardwareto make

surethesearetight.

lubricatingor inspecting,disengage all

_ WARNING: Before servicing, repairing,

controls and stop engine. Wait until all

moving parts have come to a complete

stop. Disconnect spark plug wire and

ground it against the engine to prevent

unintended starting. Alwayswearsafety

glassesduring operation or while per-

forming anyadjustments or repairs.

Replacing the Shave

Plate and Skid Shoes

Theshaveplateandskidshoeson thebottomofthe

snowthrowerare subjecttowear.Theseshouldbe

checkedperiodicallyand replacedwhennecessary

Servicing Augers

Theaugersaresecuredtothe spiralshaftwithfour

shearpinsandcotterpins.If youhita foreignobjector

icejam,the snowthrowerisdesignedsothatthepins

mayshear.Referto Figure10.

If theaugersdo notturn,checkifthe pinshavesheared.

Replace,ifneeded,withpropershearpins. Referto

item42on page19forpart number.

IMPORTANT:NEVERreplacetheaugershearpinswith

standardpinsorfasteners.Anydamagetotheauger

gearboxorothercomponents,as a resultofdoingso,

willNOTbecoveredby yoursnowthrower'swarranty.

Lubrication

Fora viewof thelubricationpointsonthe snowthrower,

seeFigure11.

1. Lubricatepivotpointsonthe augercontrolanddrive

controlwitha lightengineoiloncea season.

2. Lubricatetheaugeridlerbracketwithalight engine

oiloncea season.

Engine

Listedbelowaregeneralrecommendationsabout

maintainingyoursnowthrowerengine.Forfurther

details,refertothe accompanyingenginemanual.

1. Beforeoperatingsnowthrower,checkthe oil level.

2. Changeengineoil afterfirsttwo hoursofoperation

andevery25 hoursthereafter.

3. Cleansparkplugand resettheelectrodegapto

0.030"atleastonceaseasonorevery100hoursof

operation;replaceevery200hoursofoperation

Check V-Belts

Followinstructionsbelowtocheckconditionofdrive

beltsevery50 hoursofoperation.

1. Removetheplasticbeltcoveronthe frontofthe

enginebyremovingthe self-tappingscrewand

pressingtheplastictabsto releasethebeltcover.See

Figure13.

2. Visuallyinspectforfrayed,cracked,orexcessivelyworn

outbelts.Replace,ifnecessary,followinstructions

beginningonpage14.

WARNIN

Beforeservicing

repairing,lubricating

or inspecting,

disengage allcontrols

and stop engine.

Wait until all moving

parts havecome

to a completestop,

DisconneCt spark

plug wire and ground

it aga!nst the engine

to preventunintended

starting: Alwayswear

safety glassesduring

OpEration or

while performing

any adjustments

NOTE:

NEVERreplacethe

auger shear pins

with standardpinsor

fasteners.Anydamage

totheaugergearboxor

other components,as

a resultofdoingsO;Wil

NOT beCoveredbyyour

snowthrower'swarrantyl

13

Page 14

Maintenance

Replacing Belts

NOTE:Therearetwo beltson thissnowthrower:an

augerbeltanddrivebelt. Itis recommendedthat both

beltsbe replacedat thesametime.

1. Removethesparkplugwirefromsparkplugandground

itagainsttheenginetopreventaccidentalstarting.

2. Draingasolinefromthe gastankbelow1/2tankor

runthemachinebelowhalfa tank,or placea piece

ofplasticsheetunderneaththe gascap toprevent

gasolineleakage.

Bracket

\

WARNING

Performbelt

maintenanceoutdoors

assomegasmay

possiblyleakfrom

thecarburetoreven

thoughyouplaced

asheetof plastic

underneath the gas

i capto preventthe gas

capfrom leaking.

_|11 ARNING: Performbelt maintenance

outdoors assomegas maypossibly

leakfrom the carburetoreventhough

you placedasheetof plasticunder-

neaththe gascapto preventthe gas

capfrom leaking.

Adjusting The Auger Cable

Periodicadjustmentto theaugercontrolcablemaybe

requireddueto normalstretchandwearon the belt.

Adjustmentisneededif theaugersseemtohesitate

whileturning,buttheenginemaintainsspeed,or

continueturningwiththe augercontroldisengaged.

1. Loosentherearhexboltonthe cableadjustment

bracket.SeeFigure12.

2. Slidethecableadjustmentbracketbackwardstaking

outthe slackin theaugercable.

3. Retightenthe rearhexbolt

4. Startengineandverifyaugercontrolengagesand

disengagesproperly.

NOTE:if augercontinuesto rotatewiththecontrol

disengaged,shutoff engineandreadjust.

Auger Belt

1. Loosentherearscrewontheaugercableadjustment

bracketusinga 3/8" wrenchand slidethebracket

allthewayforwardto providemaximumslackinthe

augercable. SeeFigure12.

2. Removethebelt coverscrewusinga 5/16socket

withextensionand slightlyraisebeltcover.Youmust

alsouncliptheplastictabonthe othersidetoraise

thisup.Do notattemptto removethebeltcoverfrom

theunitatthistime. SeeFigure13.

3. Loosenthebottomaugerhousingmountingscrew

oneachsideonefullturn usinga 1/2"socket.See

Figure12.

4. Usingthe samesocketwrench,removethetopauger

housingmountingscrewsoneach side.

NOTE:The topaugerhousingscrewonthe leftside

alsosecurestheaugercablebracketandcableroller.

Payattentiontoits locationandhowit is positionedfor

referenceduringreassembly.SeeFigure12.

5. Pushdownonthe unit'shandle,thiswillallowthe

beltcoverto beeasilyremovedandwillgiveaccess

forthefollowingbeltmaintenanceprocedures.

Figure12

Figure 13

WoodBlock

J

Figure14

14

Page 15

fControl

Ar

Figure15

Belt LocatorPin

6. Afterremovingthebeltcover,slipthe frontauger

beltoff of theenginepulleybypushingit forwardand

rollingin offof the pulley.

7. Pushdownonthe unit'shandlefurtheropeningthis

areaand providingbetteraccesstotheaugerpulley.

Youmaywishtoplaceawoodblockundertheauger

housingtoholdtheunit open.SeeFigure14 Maintenance

8. Pushtheaugerbelt idlerpulleyin releasingthe

augerbrake,whichisthe tabthatholdsthebeltonto

theaugerpulley.Removethebelt.

9. Replacewithnewbeltafter replacingthedrivebelt.

NOTE: Ifnot replacingdrivebelt,thenproceedtoStep

5 inthe DriveBeltsection.

Drive Belt

NOTE:ToreplacetheDriveBelt,youmustfirstfollow

AugerBeltinstructions.Replacethe drivebelt before

reassemblingthe newaugerbelt.

1. Removehairpinclipand pivotrodfromunit. See

Steps1and2 in Figure15.

2. Maneuvercontrolarmoutanddisconnectdrive

cable.SeeStep3.

3. Pullidlerpulleyon righthandside out,releasing

tensionondrivebelt. Removedrivebeltfromidler

pulleyandtransmissionpulley. SeeSteps1thru3 in

Figure15.

4. Rotatecontrolarminorderto maneuverbeltfrom

unit. Removebeltandreplacewithnewbelt.

NOTE: Besuretomaintainpositionof themulti-speed

pulleyassemblysothatthebelt Iocatorpininthetop

position. SeeFigure16.

5. Reassembleinthe exactoppositeorder.

6. Afterreassemblyiscompleted,be sureto adjustthe

augercable.Refertothe "AdjustingAugerCable"

instructionson Page14of this manual.

ToreplacetheDrive

Belt,youmustfirstfollow

AugerBeltinstructions.

Replacethe drivebelt

beforereassemblingthe

Besureto maintain

positionofthe multi-

speedpulleyassembly

sothat thebeltIocator

pin inthetopposition.

NOTE:

newaugerbelt.

Figure16

15

Page 16

WARNING

Never store snow

thrower withfuel

in tank indoors or

in poorlyventilated

areas, where fuel

fumes may reach an

open flame, spark

or pilot light as on a

furnace, water heater,

clothes dryer or

gas appliance.

Drainfuel intoan

, approved container

i outdoors, away from

any open flame. Be

certain engine is

cool. Do notsmoke.

Fuelleft in engine

duringwarmweather

deteriorates and

i will causeserious

starting problems.

Donot drain

carburetor if using

fuel stabilizer.

Never use engine or

I carburetor cleaning

products inthe fuel

tank or permanent

damage may occur.

Ifthe snowthrowerwillnotbe usedfor30 daysor

longer,orifitistheendof thesnowseasonwhenthe

lastpossibilityof snowis gone,the equipmentneedsto

bestoredproperly.Followstorageinstructionsbelowto

ensuretopperformancefromthe snowthrowerformany

moreyears.

Preparing Engine

NOTE:Referto theenginemanualformoredetailed

informationon preparingthesnowthrowerenginefor

storage.

_ ARNING:Neverstore snowthrower

NOTE:Itis importantto preventgumdepositsfrom

forminginessentialfuelsystempartsof theenginesuch

asthe carburetor,fuel filter,fuelhoseor tankduring

storage.

CAUTION:Alcohol blended fuels (calledgasohol

or using ethanol ormethanol) canattract moisture

which leads to separation andformation ofacids

during storage.Acidic gas can damagethe fuel

system of anenginewhile in storage.

Toavoidengineproblems,thefuelsystemshouldbe

emptiedbeforestoragefor30daysor longer.Follow

theseinstructionstoprepareyoursnowthrowerfor

storage:

_ ARNING:Drainfuel intoan approved

1. Removeallgasolinefromthecarburetorandthefuel

tanktopreventgumdepositsfromformingonthese

partsandharmingtheengine.

2. Runtheengineuntilthefuel tankisemptyandit

stopsdueto lackoffuel.

3. Draincarburetorbypressingupwardon bowldrain,

locatedbelowthecarburetorcover. SeeFigure17.

f Carburetor _"

with fuel intank indoorsor in poody

ventilated areas,wherefuel fumes

may reachan open flame, spark or

pilotlightas on a furnace, water

heater,clothes dryer or gas appliance.

container outdoors, awayfrom any

openflame. Becertain engineiscool.

Donot smoke.Fuelleft in engine

during warmweatherdeteriorates and

will cause serious starting problems.

0ow0 anv =,r --

Figure17

_ ARNING:Donotdrain carburetorif

NOTE:Fuelstabilizer(suchas STA-BIL)is anaccept-

ablealternativein minimizingtheformationoffuelgum

depositsduringstorage.Addstabilizertogasolineinfuel

tankorstoragecontainer.Alwaysfollowmixratiofound

onstabilizercontainer.Runengineat least10minutes

afteraddingstabilizertoallowit to reachthecarburetor.

Donotdraincarburetorifusingfuelstabilizer.

4. Removethesparkplugandpourone(1)ounce

ofengineoil throughthesparkplugholeintothe

cylinder.Coversparkplugholewitha ragandcrank

theengineseveraltimestodistributetheoil. Replace

sparkplug.

NOTE:Referto theenginemanualformoreinformation

onpreparingthe snowthrowerenginefor storage.

usingfuel stabilizer.Neveruse engineor

carburetorcleaningproducts in thefuel

tankor permanentdamagemayoccur.

Preparing Snow Thrower

1. Whenstoringthesnowthrowerinan unventilatedor

metalstorageshed,careshouldbetakento rustproof

theequipment.Usinga lightoilor silicone,coatthe

equipment,especiallyanychains,springs,bearings

andcables.

2. Removealldirtfromexteriorof engineandequipment.

3. Followlubricationrecommendationson page13.

4. Storeequipmentina clean,dryarea.

16

Page 17

Problem Possible Cause(s) Solution

Engine fails tostart tankempty,or stalefuel tankwith cleanfreshgasoline:

21 Blockedfuelline 2: Cleanfuelline:

& Keynotsnappedintopiace

4. Spark plugw redisconnected 4, Connectwireto sparkp!ug.

& Fau!tyspaikplug c!ean sparkplug, readjustgap;or

replace:

6: Enginenotprimed 61Prime enginefourtimeSl

7:Eng nefoodedfromexcessive 7: waitat easttenminutesbefore

priming starting.

Enginerunserratic

1. Unitrunningonchoke

2. Fuellineblocked,orstalefuel

3. Waterordirt in fuelsystem

4. Carburetoroutofadjustment

1. MovechokelevertoOFFposition.

2. Cleanfuellineandfill tankwith

fresh,cleangasoline.

3. Referto enginemanualfor remedy.

4. Referto enginemanualfor remedy.

I Engineoverheats 1. Carburet rout ofadjustment-- 1. Referto enginemanualfor instructio.i

Lossof power 1. Sparkplugwireloose 1. Firmlyconnectsparkplugwire.

2. Ventingascap plugged 2. Clearvent.

Excessivevibration

Unitfails to self-propel

Augerscontinueto rotate

Unit fails to discharge

snow

1. Loosepartsor damagedauger 1. Stopengineimmediatelyand

disconnectsparkplugwire.Check

forpossibledamage.Tightenall

boltsand quts.Repairasneeded.If

theproblempersists,takeunitto an

authorizedservicedealer.

1. Drivebelt looseordamaged 1. Replacedrivebelt.

1. Cableoutof adjustment. 1. Adjustaugercontrolcableas

shownin "AdjustingTheAuger

Cable"on page14.

1 Chuteassemblyclogged.

2. Shearpinsheared.

3. Foreignobjectlodgedinauger

4 Augercontrolcableoutof

adjustment.

5. Augerbelt looseordamaged.

1. Stopengineanddisconnectspark

plugwire.Cleanchuteandinside

ofaugerhousingwithclean-out

toolor stick.

2. Replaceshearpin.

3. Stopengineimmediatelyand

disconnectthesparkplugwire.

Removeobjectfromauger.

4. Adjustaugercontrolcable

5. Replaceaugerbelt.

P easeao,VOr

returntheunit to the

retailerfrom which it

was purchase&

without first contacting

Customer Sup_rti

onto

www,mtdproducts;com

or call a customer

service representative

at 1(800)800,7310 or

(330)220,4683,

You wi// need the

model number and

serial number ff

and when calling

Customer Support,

loggingonto

manual

NOTE:Forrepairsbeyondtheminoradjustmentslistedabove,contactyournearestauthorizedservicerepresentativeor

call1-800-800-7310fortheCustomerSupportCenter.Refertotheenginemanualformoreenginerelatedinformation.

17

regarding locating

and recording your

model and serial

number&

Page 18

For parts and/or

accessories

please call

1-800-800-7310,or

1-330-220-4683.

www.mtdproducts.com

18

Page 19

1 684-04037 ChuteAssembly 1

2 710-04071 CarriageBolt5/16-18x1.0" 1

3 710-0451 CarriageBolt5/16-18 11

4 712-3068 FlangeLockNut,5/16-18 1 28 738-0281

5 720-04032 NutKnob5/16-18 1 29 741-0245

6 731-04388A ChuteHandle 1 30 741-0309

7 731-04426A UpperChute 1 31 750-04191

8 736-0159 FiatWasher.349x .879x .063 2 32 756-04035

9 731-04127 LowerChute 1 33 784-0434

10 731-04353 ChuteRing 1 34 790-00075

11 731-2636A ChuteAdapter5" Dia. 1 35 618-04293

12 732-04111 ChuteAdjustmentSpring 1 36 684-04113

13 712-04064 FlangeLockNut1/4-20 5 37 684-04114

14 731-2643 Clean-outTool 1 38 684-04165

15 731-2635 Clean-outToolMount 1 39 714-04040

16 725-0157 CableTie 1 40 731-04870

17 710-0134 CarriageScrew1/4-20x 0.62" 5 41 736-0351

18 710-0520 HexBolt3/8-16x 1.50" 1 42 738-04124A

19 710-0604A ABScrew5/16-18x.625 4 43 741-0493A

20 712-04063 FlangeLockNut,5/16-18 10 44 790-00087A

21 712-04065 FlangeLockNut,3/8-16 1 45 790-00120

22 712-0266 HexLockNut3/8-16 1 46 784-5580

23 715-04020 Spiral Pin 2 47 746-04246

24 726-04012 PushOnNut 2 48 736-0258

25 731-04218B Impeller 1

26 732-0611 ExtensionSpring 1

27 736-0174 WaveWasher 1

ShoulderScrew3/8-16 1

Hex FlangeBearing 2

BallBearing 1

Spacer 1

FlatIdler 1

AugerIdler Bracket 1

BearingHousing 1

AugerGearboxAssembly 1

AugerAssembly- LH 2

AugerAssembly- RH 2

AugerHousing,24" 1

BowTieCotterPin72 4

Spacer,1.25x.75x 1.00 4

FlatWasher 2

ShearPin,.25x 1.50 4

FlangeBushing 8

HexBearingHousing 2

ShavePlate2.25x23.66 LG 1

SkidShoe 2

AugerCable 1

FlatWasher 1

For parts and/or

accessories

please call

1-800-800-7310,or

1-330-220-4683.

www.mtdproducts.com

19

Page 20

Model Series 3DD

i i

[]

[]

2O

Page 21

1 710-0449 CarriageScrew5/16-18x2.25" 2

2 710-0106 HexScrew1/4-20x 1.25" 2

3 710-1260A Screw,5/16-18x .75" 4

4 712-04064 FlangeLockNut 1/4-20 2

5 720-0284 Lock NutKnob5/16-18 2

6 725-0157 CableTie 3

7 746-04256 DriveCable

8 746-04246 AugerCable

9 711-04478 PivotRod

10 747-04405 DriveControl

11 749-04147 LowerHandle

12 749-04236 UpperHandle 1

13 790-00053 HandleTab 2

14 618-04296 TransmissionAssembly 1

15 710-0604A ABScrew5/16-18x.625 4

16 710-0809 Screw,1/4-20x 1.25" 2

17 711-1364 ClevisPin

18 714-0115 CotterPin,1/8x 1.0

19 714-04040 BowTie CotterPin72

20 715-0249 RollPin

21 717-04066 Pinion14T

22 717-04073A Gear70T 1

23 732-0409 ExtensionSpring 1

24 736-0192 FiatWasher 2

25 738-04184 ShoulderScrew1/4-20 1

26 738-0924 CarriageScrew1/4-28 1

27 741-0245 HexFlangeBearing 2

28 741-04108 HexFlangeBearing 2

29 756-0625 CableRoller 1

30 784-0419B DriveHousingFrame 1

31 790-00223 AugerCableBracket 1

32 790-00224 AugerCableAdj.Bracket 1

33 634-0232A WheelAssblySnowHogGray 2

34 710-0627 LockBolt5/16-24x0.75" 5

35 736-0242 BellWasher 2

36 738-1231 Axle 1

37 710-0224 HexScrew,#10-16x.500 1

38 710-0654A TTSemsScrew3/8-16x 1.0" 4

39 710-0696 HexBolt3/8-24x 0.875" 1

40 710-1245B LockBolt5/16-24x0.875" 1

41 731-05364 BeltCover 1

42 736-0247 FlatWasher,.4061Dx 1.250D 1

43 736-0505 FiatWasher,.341Dx 1.500D 1

44 748-04067 Pulley:Adapter,.75Dia. 1

45 748-0234 ShoulderSpacer 1

1

46 750-04568 ShoulderSpacer 1

1

47 754-04102 V-Belt,3Lx 25.00LG 1

1

48 754-04014 V-Belt,3/8 x 26.680Lg. 1

1

49 756-04024 Auger Pulley 1

50 756-0569 PulleyHalf 2

51 710-0456 Screw,#10-16x.500 1

52 790-00064 HeatShield 1

53 710-1667A Screw#10-16 3

54 731-05358 SpeedSelectorHousing- Lwr 1

1

55 731-05359 SpeedSelectorHousing- Upr 1

2

56 731-05360 SpeedSelectorHousing-Lever 1

2

57 732-0627 6 SpeedShiftLeverSpring 1

1

58 746-04244 SpeedControlCable 1

59 710-04329 Screw.159x.610 2

1

60 736-3092 FiatWasher.265x1.0x .030 2

61 782-7596A 6-SpeedControlArm 1

62 790-00234 ActuatorMountingBracket 1

63 790-00235 DriveWheel IdlerBracket 1

64 656-0613 Multi-SpeedPulleyAssembly 1

65 682-7527 6 SpeedAssemblyCup 1

66 741-0545 BallBearing 1

67 756-0613 PulleyHalf 1

68 756-0612A DrivePulleyHalf 1

69 684-04168 IdlerPulleyAssembly 2

70 747-04394 AugerControlBail 1

71 736-0451 SaddleWasher 2

72 736-0232 WaveWasher.531x .781x .013 1

73 750-04571 ShoulderSpacer.60x.790x.538 2

74 710-1652 Screw,1/4-20x 1.25" 1

75 753-05426 PressureLimitingValveKit

PartList:

Stage

lOW

Thrower

For parts and/or

accessories

please call

1-800-800-7310,or

1-330-220-4683.

www.mtdproducts.com

21

Page 22

For parts and/or

accessories

please call

1-800-800-7310,or

1-330-220-4683.

www.mtdproducts.com

22

Page 23

iii!iiiii _ i!il _ i

NOTES:

Use this page to make

notes and write down

For parts and/or

accessories

please call

1-800-800-7310,or

1-330-220-4683.

www.mtdproducts.com

23

Page 24

MANUFACTURER'S LiMiTED WARRANTY FOR

Thelimitedwarrantysetforthbelowisgivenby MTDLLCwithrespectto

newmerchandisepurchasedandusedin the UnitedStates,itsposses-

sionsandterritories.

"MTD"warrantsthisproductagainstdefectsin materialandworkmanship

fora periodof two(2) yearscommencingonthedateoforiginalpurchase

andwill,atits option,repairor replace,freeofcharge,anypartfoundto

bedefectiveinmaterialsorworkmanship.Thislimitedwarrantyshallonly

applyif this producthasbeenoperatedandmaintainedinaccordance

withtheOperator'sManualfurnishedwiththeproduct,andhasnotbeen

subjectto misuse,abuse,commercialuse,neglect,accident,improper

maintenance,alteration,vandalism,theft,fire,water,ordamagebecause

ofotherperilor naturaldisaster.Damageresultingfromthe installationor

useof anypart,accessoryorattachmentnotapprovedbyMTDforuse

withtheproduct(s)coveredbythis manualwillvoidyourwarrantyasto

anyresultingdamage.

Normalwearpartsarewarrantedto befreefromdefectsinmaterialand

workmanshipfora periodof thirty(30)daysfromthe dateof purchase.

Normalwearpartsinclude,butare notlimitedto itemssuchas: batteries,

belts,blades,bladeadapters,grassbags,riderdeckwheels,seats,snow

throwerskidshoes,shaveplates,augerspiralrubberandtires.

HOW TO OBTAIN SERVICE: Warrantyservice isavailable,WITH

PROOFOF PURCHASE, throughyour localauthorized service

dealer.To locate the dealer in your area, check yourYellowPages,or

contact MTD LLC at RO. Box 361131,Cleveland,Ohio 44136-0019,or

call 1-800-800-7310or 1-330-220-4683or log on to ourWeb site at

www.mtdproducts.com.

Thislimitedwarrantydoesnot providecoverageinthefollowingcases:

a. Theengineor componentpartsthereof.Theseitemsmaycarrya

separatemanufacturer'swarranty.Refertoapplicablemanufacturer's

warrantyfortermsandconditions.

b. Logsplitterpumps,valves,andcylindershavea separateoneyear

warranty.

c. Routinemaintenanceitemssuchaslubricants,filters,blade

sharpening,tune-ups,brakeadjustments,clutchadjustments,deck

adjustments,andnormaldeteriorationof theexteriorfinishdueto use

orexposure.

d. Servicecompletedbysomeoneotherthananauthorizedservice

dealer.

e. MTDdoesnotextendanywarrantyforproductssoldor exported

outsideofthe UnitedStates,itspossessionsandterritories,except

thosesoldthroughMTD'sauthorizedchannelsofexportdistribution.

f. ReplacementpartsthatarenotgenuineMTDparts.

g. Transportationchargesandservicecalls.

No impliedwarranty,includinganyimpliedwarranty of merchant-

ability of fitness for aparticularpurpose,applies after the applicable

periodof expresswritten warranty above as to the partsas identi-

fied. Noother expresswarranty, whether written or oral, exceptas

mentionedabove,givenby any personor entity,includinga dealer

or retailer,with respect to anyproduct,shallbind MTD.Duringthe

periodof the warranty, the exclusiveremedyisrepairor replacement

of the productassetforth above.

Theprovisionsas set forth inthis warranty providethe sole and

exclusive remedyarising from the sale.MTDshall not be liable

for incidentalorconsequential loss or damageincluding,without

limitation, expensesincurredfor substitute or replacementlawncare

services or for rentalexpensesto temporarily replaceawarranted

product.

Somestatesdo not allowtheexclusionorlimitationofincidentalor

consequentialdamages,or limitationson howlonganimpliedwarranty

lasts,sothe aboveexclusionsor limitationsmaynotapplyto you.

Innoeventshall recoveryof anykind begreaterthantheamountof the

purchasepriceof theproductsold.Alterationof safetyfeatures of the

productshall void this warranty. Youassumetheriskandliabilityfor

loss,damage,orinjurytoyouandyourpropertyand/ortoothersandtheir

propertyarisingout ofthe misuseorinabilityto usetheproduct.

Thislimitedwarrantyshallnotextendto anyoneotherthantheoriginal

purchaseror tothe personforwhomitwaspurchasedasa gift.

HOWSTATELAWRELATESTOTHISWARRANTY: Thislimitedwar-

rantygivesyouspecificlegalrights,andyoumayalsohaveotherrights

whichvaryfromstateto state.

IMPORTANT:OwnermustpresentOriginalProofofPurchasetoobtain

warrantycoverage.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-800-800-7310, 1-330-220-4683

Loading...

Loading...