MTD 31AM63TF799 Owner’s Manual

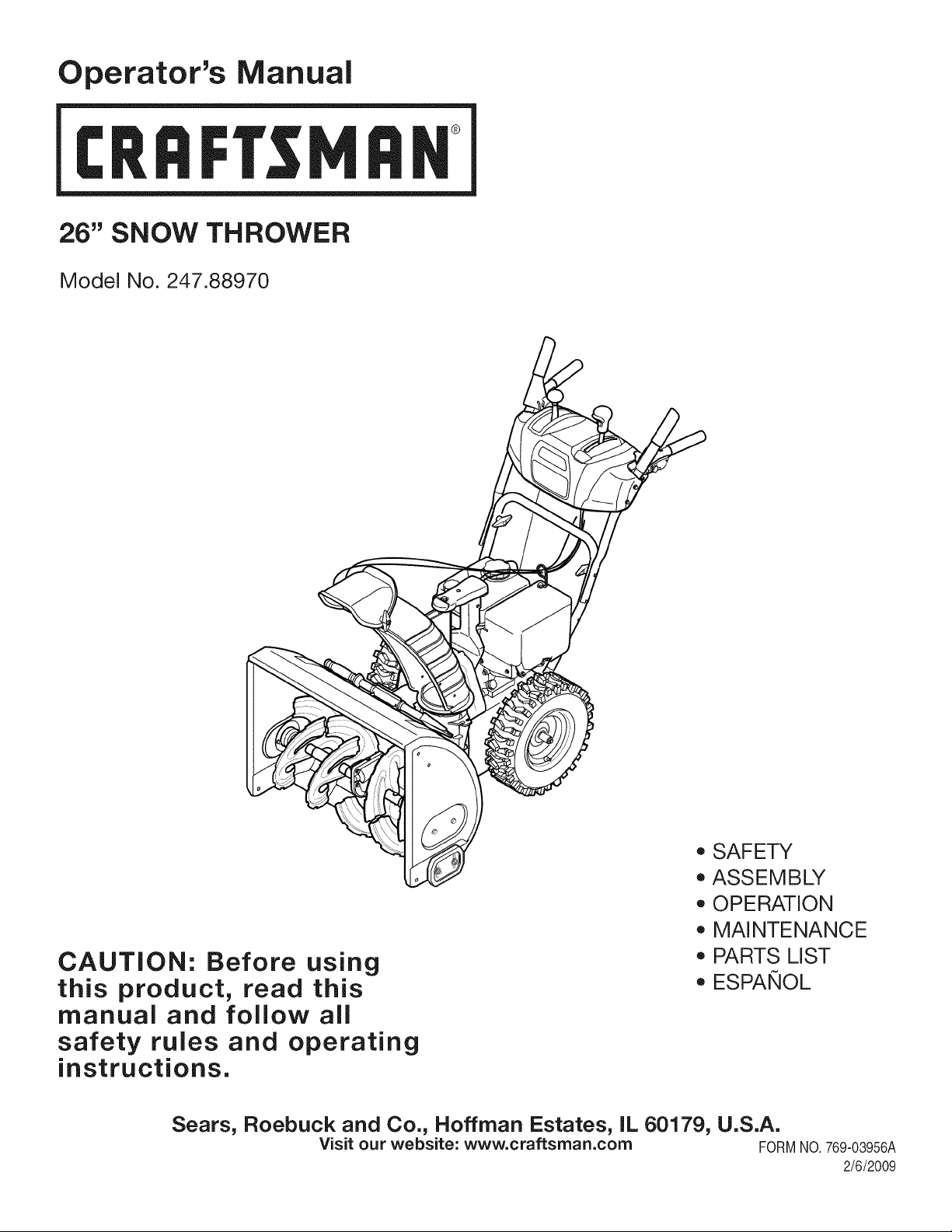

Operator's Manual

CRRFTSMRH

26" SNOW THROWER

Model No. 247.88970

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORM1/0.769-03956A

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

2/6/2009

WarrantyStatement.................... Page2

SafeOperationPractices.............. Pages3-6

SafetyLabels......................... Page7

Assembly......................... Pages8-11

Operation........................ Pages12-15

Off-SeasonStorage................... Page24

Troubleshooting...................... Page25

PartsList......................... Pages26-35

RepairProtectionAgreement............ Page39

Espadol............................. Page40

Service&Maintenance.............. Pages16-23

CRAFTSMANLiMiTED WARRANTY

Two Years on Snow Thrower

Whenoperatedand maintainedaccordingto allsuppliedinstructions,if this snowthrowerfailsdueto a defectinmaterialorworkmanshipwithin

twoyearsfromthe dateorpurchase,returnittoanyauthorizedCraftsmandrop-offlocationforfreerepair.Forthe nearestauthorizedlocation,

call1-800-4MYHOME.

Thiswarrantyappliesforonly90 daysfromthedateof purchaseifthissnowthroweriseverusedforcommercialor rentalpurposes.

Thiswarranty coversONLYdefects in material andworkmanship. SearswillNOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedtoskidshoes,shaveplate,shearpins,sparkplug,air

cleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbyimpactingobjectsthatbendtheframeor

crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedby improper

storage,failureto usethe propergradeandamountof engineoil, or failureto maintaintheequipmentaccordingtotheinstructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearofthe exteriorfinishes,orproductlabelreplacement.

Thiswarrantyappliesonlywhilethisproductisusedinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears, Roebuck and Co.,NoffmanEstates,IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2.3Quarts

SparkPlug: TorchF6RTC(F6TC)

SparkPlugGap: .020"to.030"

©SearsBrands,LLC

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsoutimportantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultinpersonalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethe followingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingto assembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfororderingreplacementparts.Forques-

tionscall,1-800-659-5917.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultsto operatethis machinewithoutproper

instruction.

• Thrownobjectscan causeseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

• Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useofthis powermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbytheauger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairtoprotectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjuryto the

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptaclefor all

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheightto cleargravelorcrushedrock

surfaces.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandlingof Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascaporaddfuel whiletheengineishot

or running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltanktono morethan1/2inch

belowbottomoffiller neckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineor fuelcontainerinsidewhere

thereis anopenflame,sparkor pilotlight (e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocool at least5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleorona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerandrefueliton theground.Ifthisisnotpossible,

thenrefuelsuchequipmentona trailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donotputhandsorfeetnear rotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingsomakesthemachineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesin placeandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea. Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcan causea burn.Do not

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsor traffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

• Neverdirectdischargeatchildren,bystandersand petsor allow

anyoneinfrontofthemachine.

• Donotoverloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureofyourfootingandkeepafirmholdon the handles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindand usecarewhenbackingup.

• Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

• Neverputyourhandinthedischargeor collectoropenings.Do

notunclogchuteassemblywhileengineisrunning.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcord slowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthan youcanletgo.Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgment.ContactCustomerSupportforassistance

andthenameof your nearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethe dischargechute

is themostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanout thedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthe machineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

oftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo not meetthe original

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertothe adjustment

sectioninthisoperator'smanualforinstructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsfor gas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclearsnowfrom

machineand preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkorpilotlightsuchasa waterheater,furnace,

clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.AttheendoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failureto do socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do not modifyengineinany way.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateon regularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(ifany)

Ifa sparkattesterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson the machine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

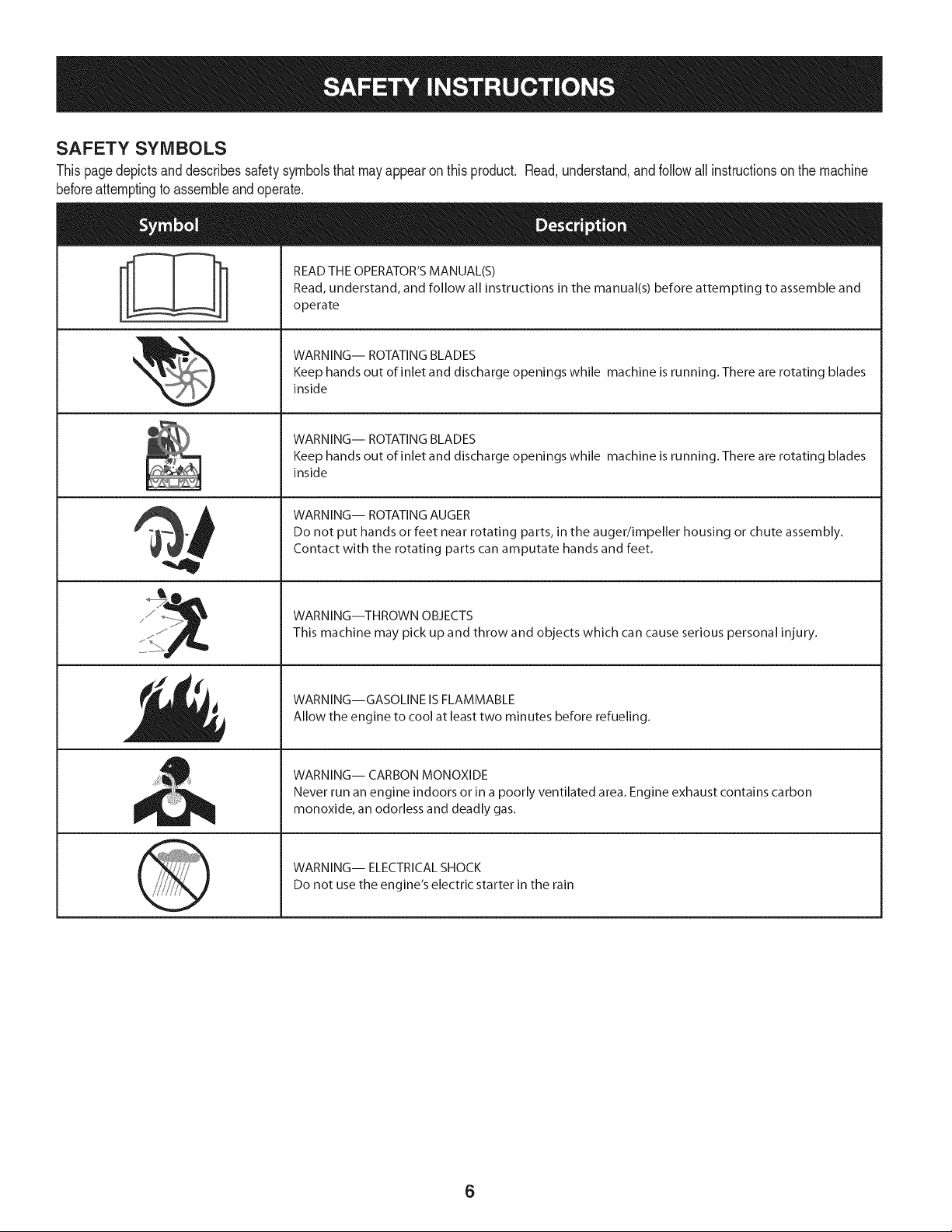

1.KEEPAWAYFROMROTATINGiMPELLER

ANDAUGER,CONTACTWiTHiMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3.DISENGAGECLUTCHLEVERS,STOPENGINE,

AND REMAINBEHINDHANDLESUNTILALL

MOVING PARTSHAVESTOPPEDBEFORE

UNCLOGGING OR SERViCiNGMACHINE.

TO AVOIDTHROWN OBJECTSiNJURiES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHEN OPERATINGON

GRAVELSURFACES.

5.BEAD OPERATOR'S MANUAL.

CLEAN-OUT TOOL

7

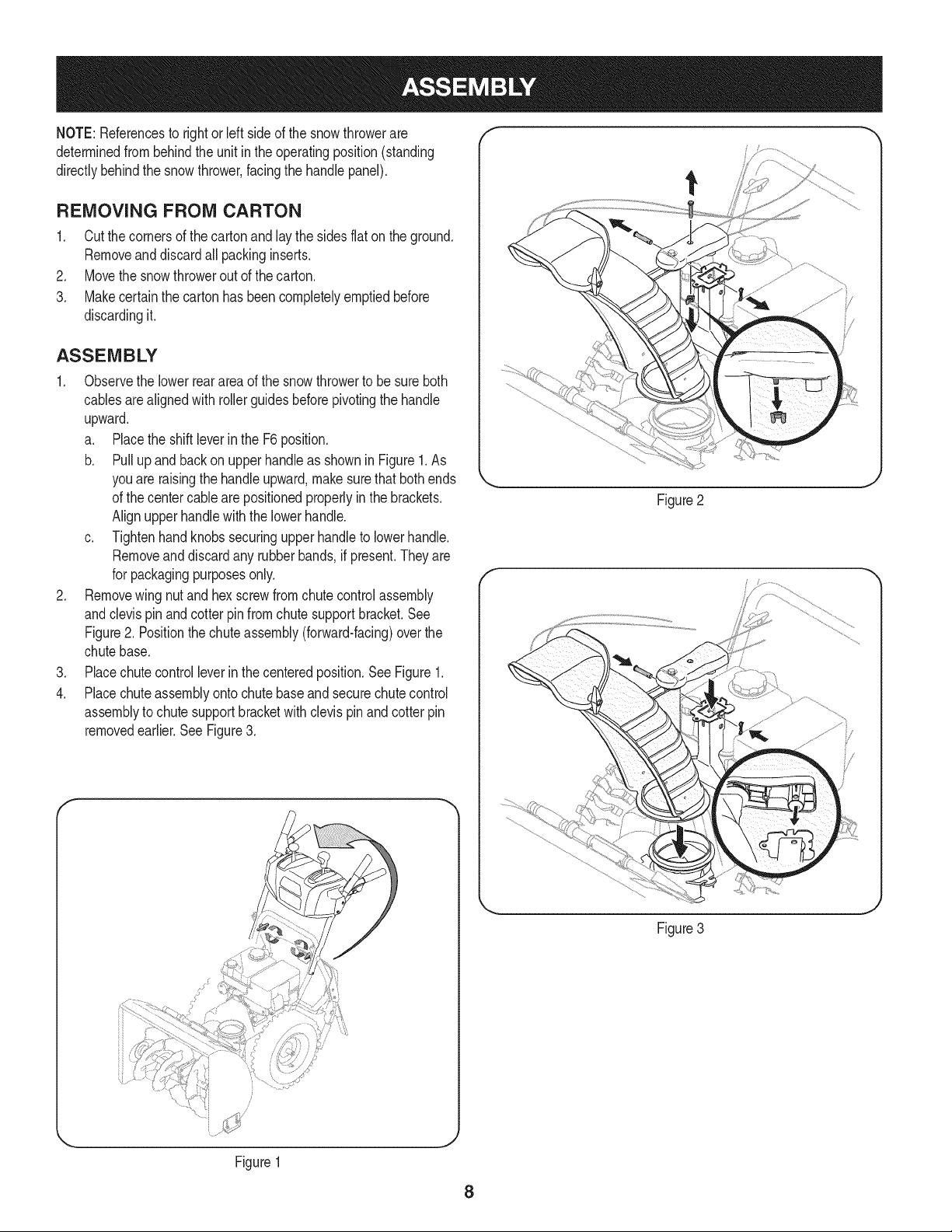

NOTE:Referencesto rightorleft sideofthesnowthrowerare

determinedfrombehindtheunitintheoperatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthecornersofthecartonandlaythesidesflaton theground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

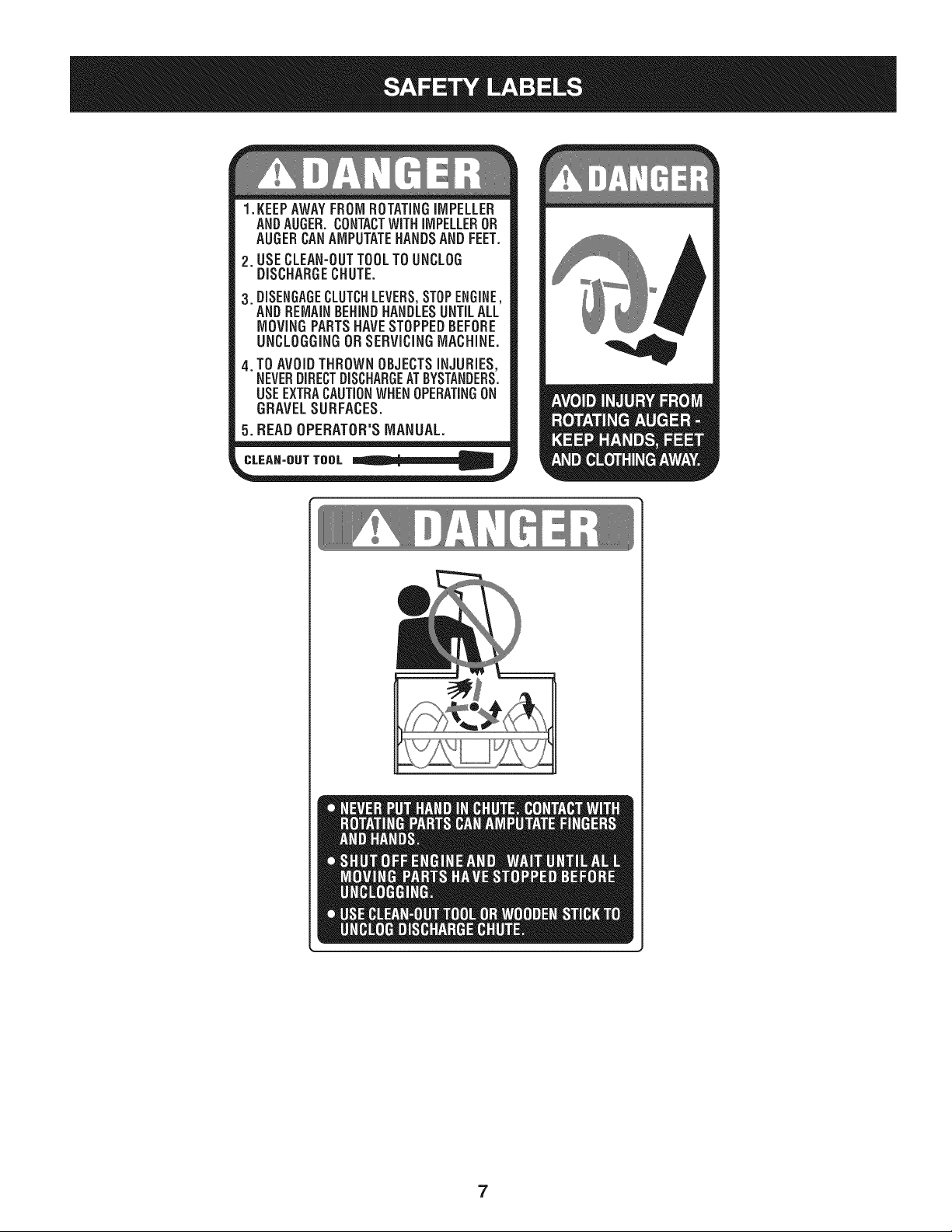

ASSEMBLY

1. Observethe lowerrearareaofthesnowthrowertobesureboth

cablesarealignedwith rollerguidesbeforepivotingthehandle

upward.

a. Placethe shiftleverin the F6position.

b. Pullupandbackon upperhandleasshownin Figure1.As

youare raisingthehandleupward,makesurethatbothends

ofthecentercablearepositionedproperlyinthebrackets.

Alignupperhandlewiththelowerhandle.

c. Tightenhandknobssecuringupperhandletolowerhandle.

Removeanddiscardanyrubberbands,ifpresent.Theyare

forpackagingpurposesonly.

2. Removewingnutandhexscrewfromchutecontrolassembly

andclevispinandcotterpinfromchutesupportbracket.See

Figure2. Positionthechuteassembly(forward-facing)overthe

chutebase.

3. Placechutecontrolleverinthecenteredposition.SeeFigure1.

4. Placechuteassemblyontochutebaseand securechutecontrol

assemblytochutesupportbracketwithclevispinand cotterpin

removedearlier.SeeFigure3.

Figure2

Figure1

Figure3

J

8

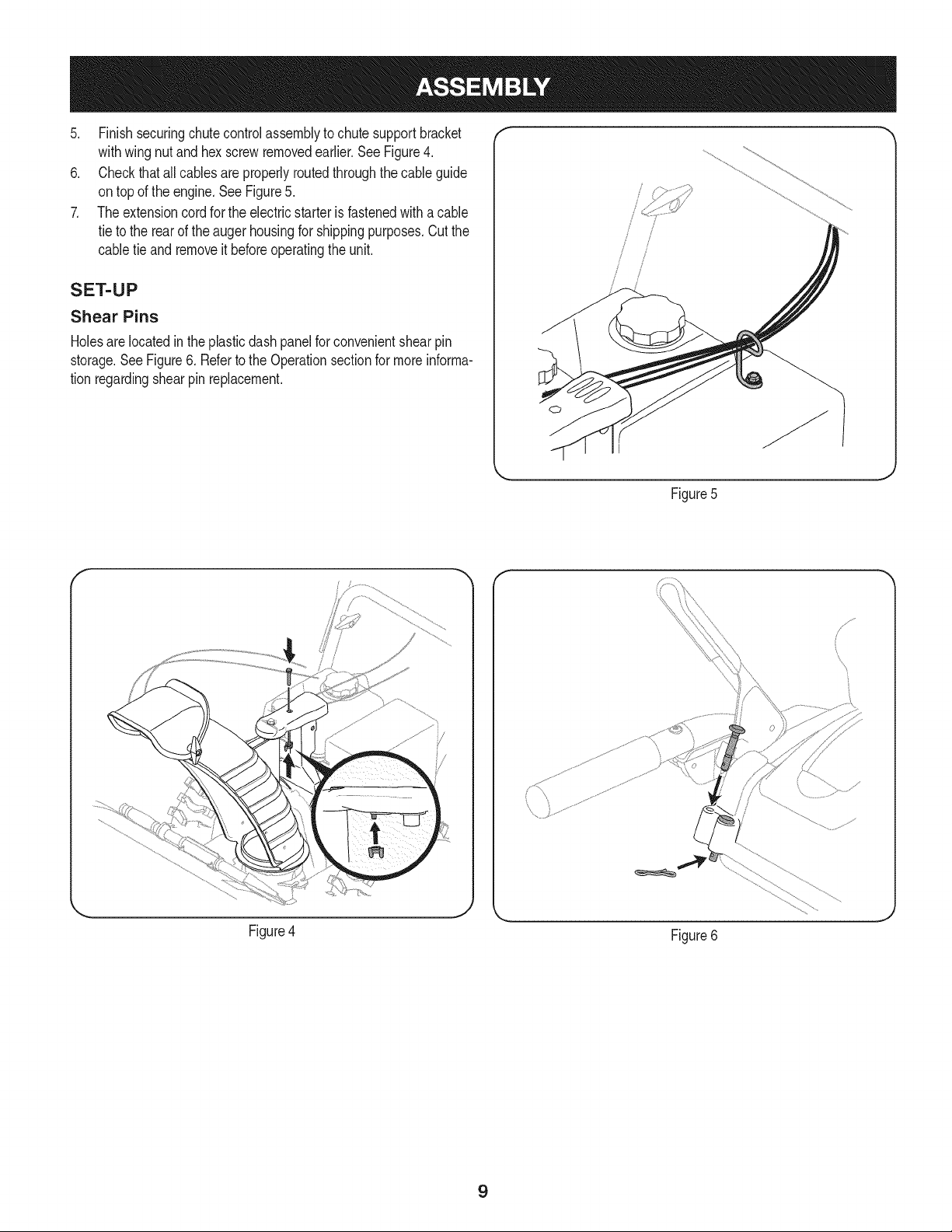

5. Finishsecuringchutecontrolassemblytochutesupportbracket

withwingnutandhexscrewremovedearlier.SeeFigure4.

6. Checkthatallcablesareproperlyroutedthroughthecableguide

ontopoftheengine.SeeFigure5.

7. Theextensioncord fortheelectricstarterisfastenedwitha cable

tietotherearoftheaugerhousingforshippingpurposes.Cutthe

cabletie and removeitbeforeoperatingtheunit.

SET-UP

Shear Pins

Holesare locatedinthe plasticdashpanelforconvenientshearpin

storage.SeeFigure6. Refertothe Operationsectionfor moreinforma-

tionregardingshearpinreplacement.

f

Figure5

Figure4

Figure6

9

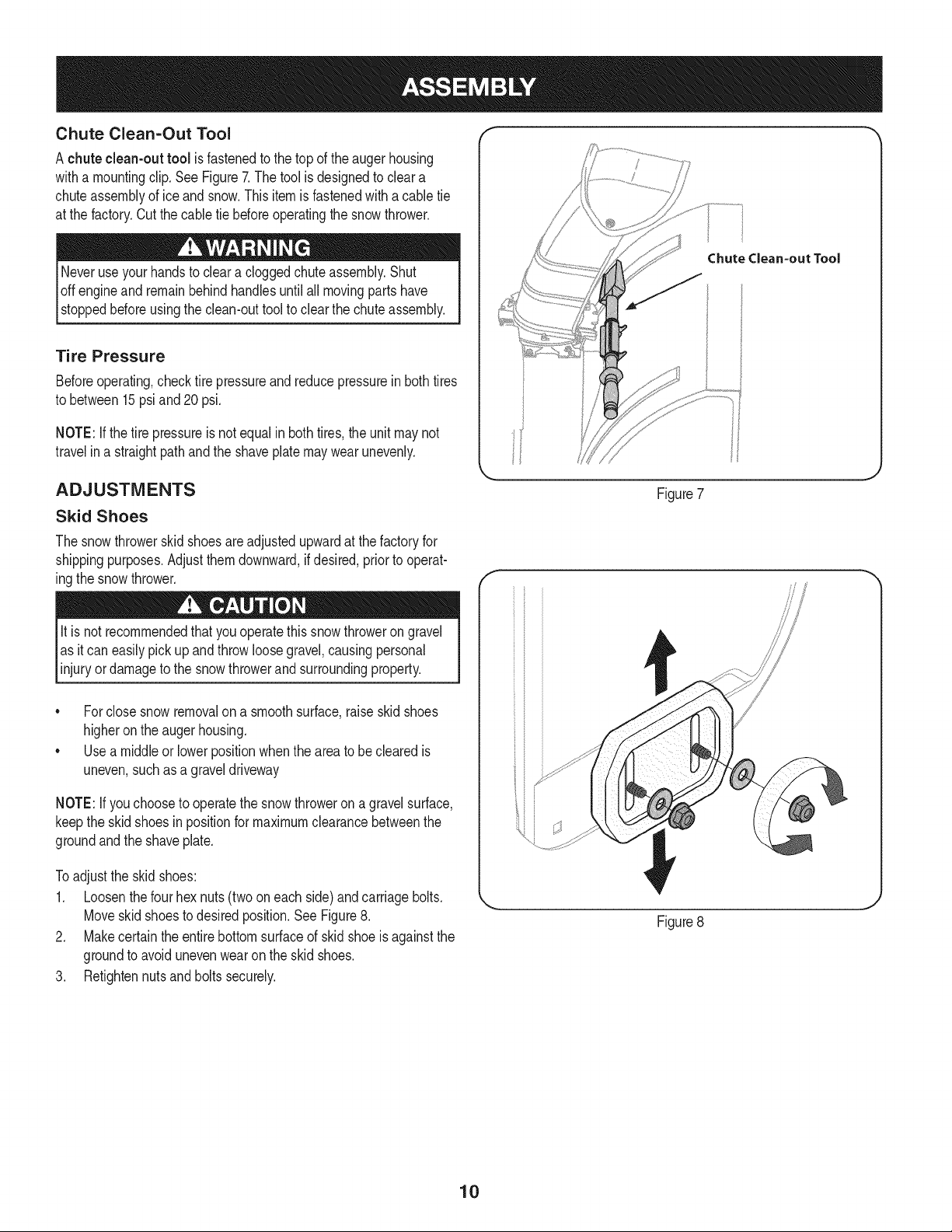

Chute Clean=Out Tool

A chute clean-out tool isfastenedtothe topoftheaugerhousing

witha mountingclip.SeeFigure7.Thetoolisdesignedtocleara

chuteassemblyoficeandsnow.Thisitemis fastenedwithacable tie

atthefactory.Cutthe cabletie beforeoperatingthesnowthrower.

Ioff_1 .allmoving}oartshave

stoppedbeforeusingtheclean-outtooltoclearthechuteassembly.

Tire Pressure

Beforeoperating,checktirepressureandreducepressurein bothtires

to between15psiand20 psi.

NOTE:Ifthetirepressureisnotequalinbothtires,theunitmaynot

travelina straightpathandtheshaveplatemaywearunevenly.

ADJUSTMENTS

Skid Shoes

Thesnowthrowerskidshoesareadjustedupwardatthe factoryfor

shippingpurposes.Adjustthemdownward,ifdesired,priorto operat-

ingthesnowthrower.

youoperate

as itcaneasilypickupandthrowloosegravel,causingpersonal

lit is notrecommendedthat this thrower

injuryordamagetothe snowthrowerandsurroundingproperty.

snow on

• Forclosesnowremovalon asmoothsurface,raiseskidshoes

higherontheaugerhousing.

• Useamiddleorlowerpositionwhenthe areatobeclearedis

uneven,suchasagraveldriveway

NOTE:Ifyouchooseto operatethesnowthrowerona gravelsurface,

keeptheskidshoesin positionformaximumclearancebetweenthe

groundandtheshaveplate.

Toadjusttheskidshoes:

1. Loosenthefourhexnuts(twoon eachside)andcarriagebolts.

Moveskidshoestodesiredposition.SeeFigure8.

2. Makecertaintheentirebottomsurfaceofskidshoeisagainstthe

groundtoavoid unevenwearon theskidshoes.

3. Retightennutsandboltssecurely.

gravel

Figure7

Figure8

10

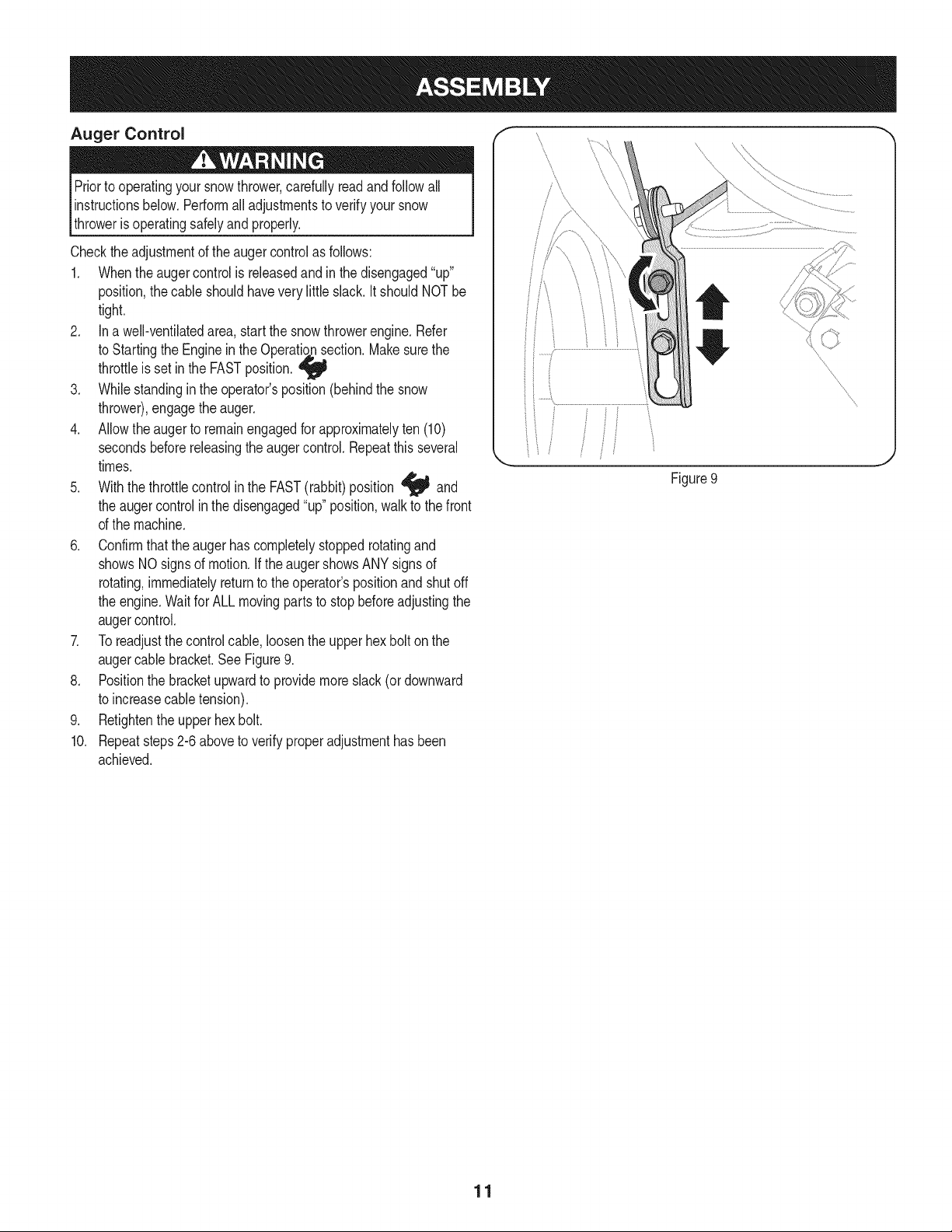

Auger Control

Priortooperatingyoursnowthrower,carefullyreadand followall

instructionsbelow.Performalladjustmentstoverifyyour snow

throwerisoperatingsafelyand properly.

Checktheadjustmentoftheaugercontrolasfollows:

1. Whentheaugercontrolis releasedandin the disengaged"up"

position,thecableshouldhaveverylittleslack.ItshouldNOTbe

tight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Refer

toStartingtheEngineintheOperati_ection. Makesurethe

throttleis setin the FASTposition.

3. Whilestandingintheoperator'sposition(behindthe snow

thrower),engagethe auger.

4. Allowtheaugerto remainengagedforapproximatelyten (10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withthethrottlecontrolin theFAST(rabbit)position _J_ and

theaugercontrolin the disengaged"up"position,walktothefront

ofthemachine.

6. Confirmthatthe augerhas completelystoppedrotatingand

showsNOsignsofmotion.IftheaugershowsANYsignsof

rotating,immediatelyreturntothe operator'spositionandshutoff

theengine.WaitforALLmovingpartsto stopbeforeadjustingthe

augercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexbolt onthe

augercablebracket.SeeFigure9.

8. Positionthebracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

9. Retightentheupperhexbolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

f

J

Figure9

11

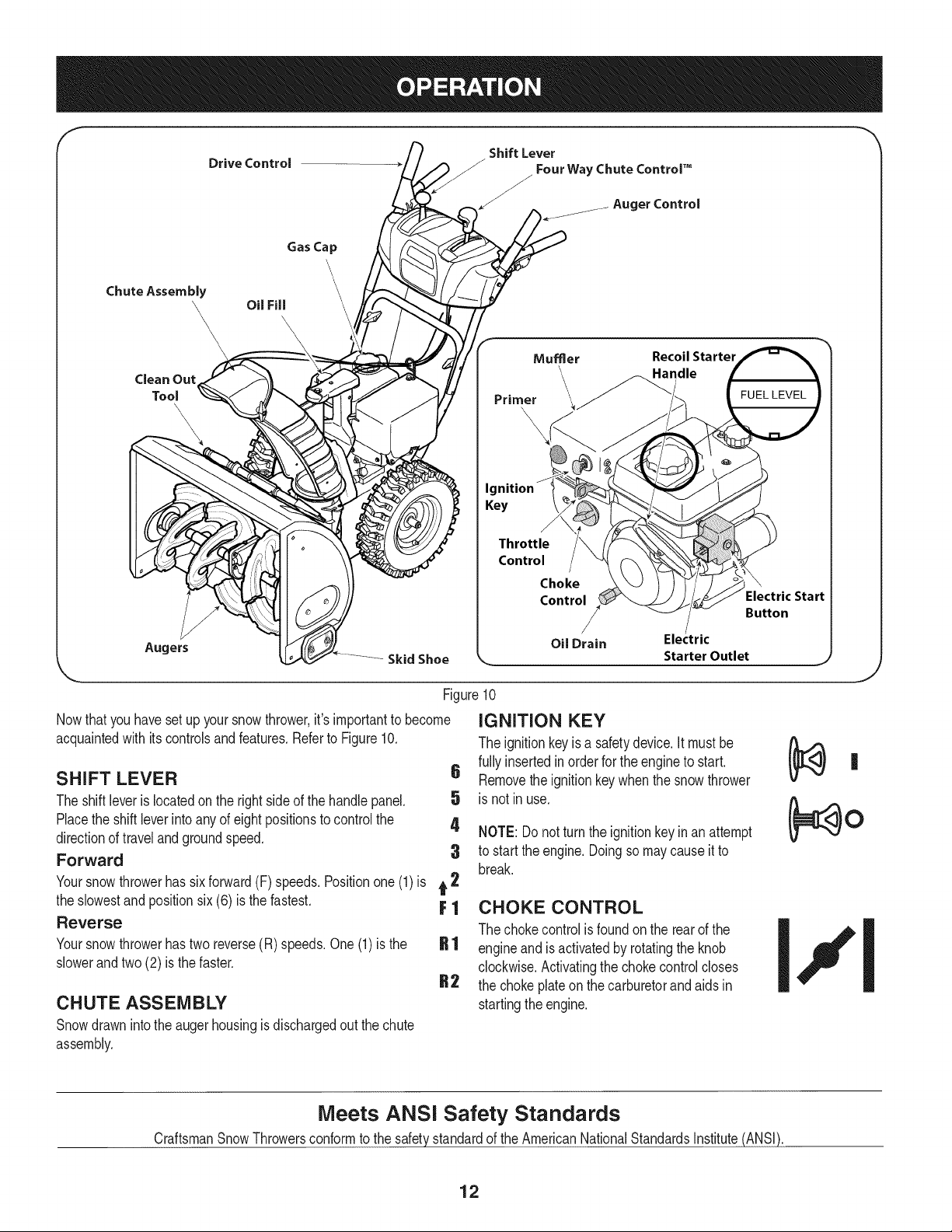

f

Drive Control

ShiftLever

J FourWayChuteControP

J j

J AugerControl

GasCap

\

ChuteAssembly

\

OUFUl

\\

\\

\

CleanOut

Tool

'\\

\\

\

Augers

Nowthat youhavesetup yoursnowthrower,it'simportanttobecome

acquaintedwith itscontrolsandfeatures.Referto Figure10.

Skid Shoe

Figure10

SHIFT LEVER 6

Theshiftleverislocatedonthe rightsideof the handlepanel. 5

Placethe shiftleverinto anyofeightpositionstocontrolthe 4

directionoftravelandgroundspeed.

Forward 3

Yoursnowthrowerhassixforward(F)speeds.Positionone(1)is t 2

theslowestand positionsix(6) is the fastest. F 1

Reverse

Yoursnowthrowerhastwo reverse(R)speeds.One(1)isthe

slowerandtwo(2) isthe faster.

CHUTE ASSEMBLY

Snowdrawnintothe augerhousingisdischargedoutthechute

assembly.

Mumer Recoil Starter

Handle

Primer

Key

Throttle

Control

Choke

Control

Oil Drain Electric

.. Starter Outlet ,j

Electric Start

Button

IGNITION KEY

Theignitionkeyisa safetydevice.Itmustbe

fullyinsertedin orderfortheenginetostart.

Removethe ignitionkeywhenthesnowthrower

is notinuse.

NOTE:Donot turntheignitionkeyinan attempt

to startthe engine.Doingso maycauseit to

break.

CHOKE CONTROL

Thechokecontrolisfoundon therearof the

engineand is activatedbyrotatingtheknob

clockwise.Activatingthechokecontrolcloses

thechokeplateonthecarburetorandaids in

startingthe engine.

,J

Meets ANSi Safety Standards

CraftsmanSnowThrowersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSi).

12

THROTTLE CONTROL

Thethrottlecontrolis locatedon therearoftheengine.It regulatesthe

speedof theengineandwill shutoff theenginewhenmovedintothe

STOPposition.

PRIMER

Depressingthe primerforcesfuel directlyinto

theengine'scarburetortoaid incold-weather

starting.

RECOIL STARTER HANDLE

Thishandleisusedto manuallystartthe engine.

ELECTRIC STARTER BUTTON

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

ELECTRIC STARTER OUTLET

Requirestheuseof athree-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

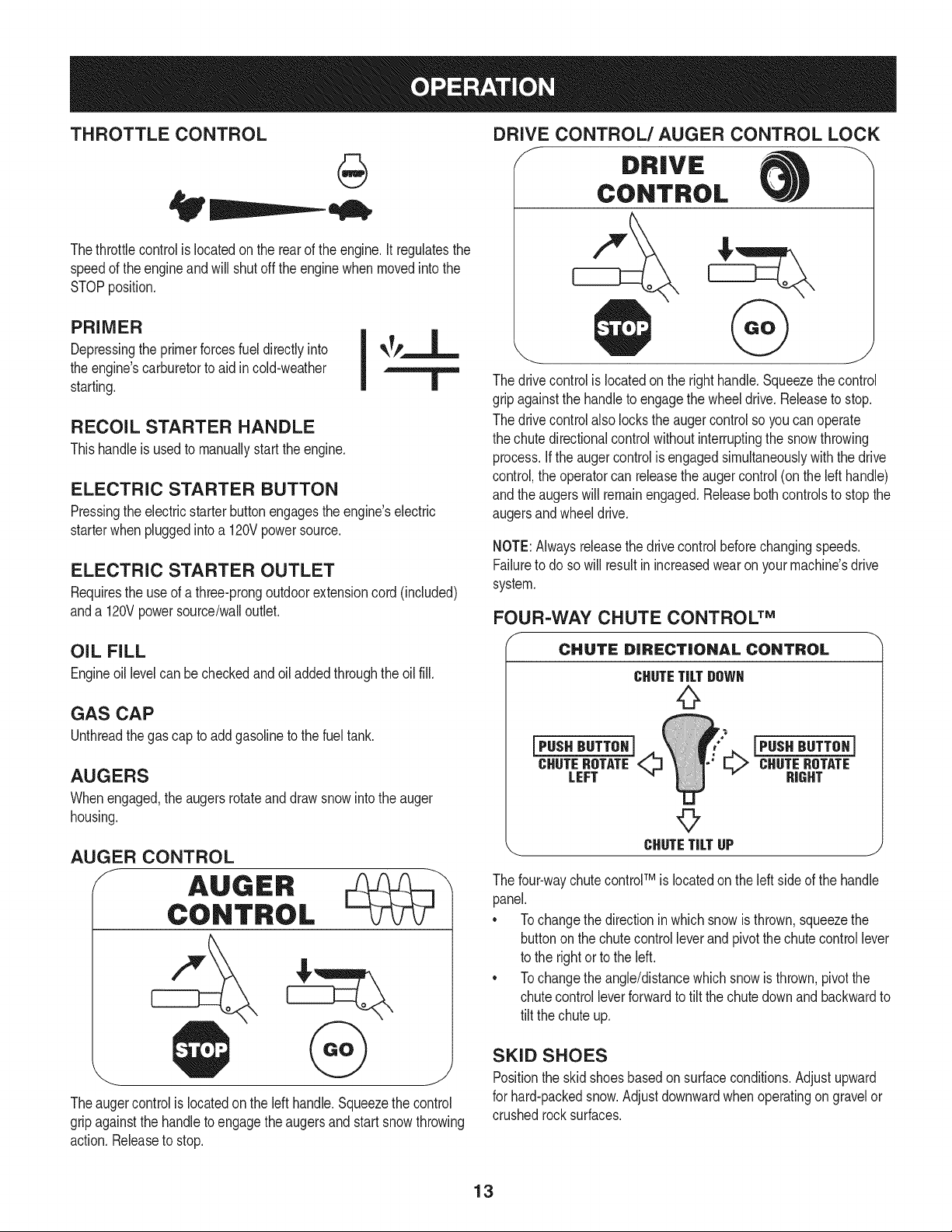

DRIVE CONTROL/AUGER CONTROL LOCK

DRIVE

CONTROL

Thedrivecontrolis locatedonthe righthandle.Squeezethecontrol

gripagainstthehandletoengagethewheeldrive.Releasetostop.

Thedrivecontrolalso lockstheaugercontrolsoyoucan operate

thechutedirectionalcontrolwithoutinterruptingthe snowthrowing

process.If the augercontrolis engagedsimultaneouslywiththedrive

control,the operatorcanreleasetheaugercontrol(onthe lefthandle)

andtheaugerswill remainengaged.Releasebothcontrolstostopthe

augersandwheeldrive.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.

Failureto dosowillresultinincreasedwearonyourmachine'sdrive

system.

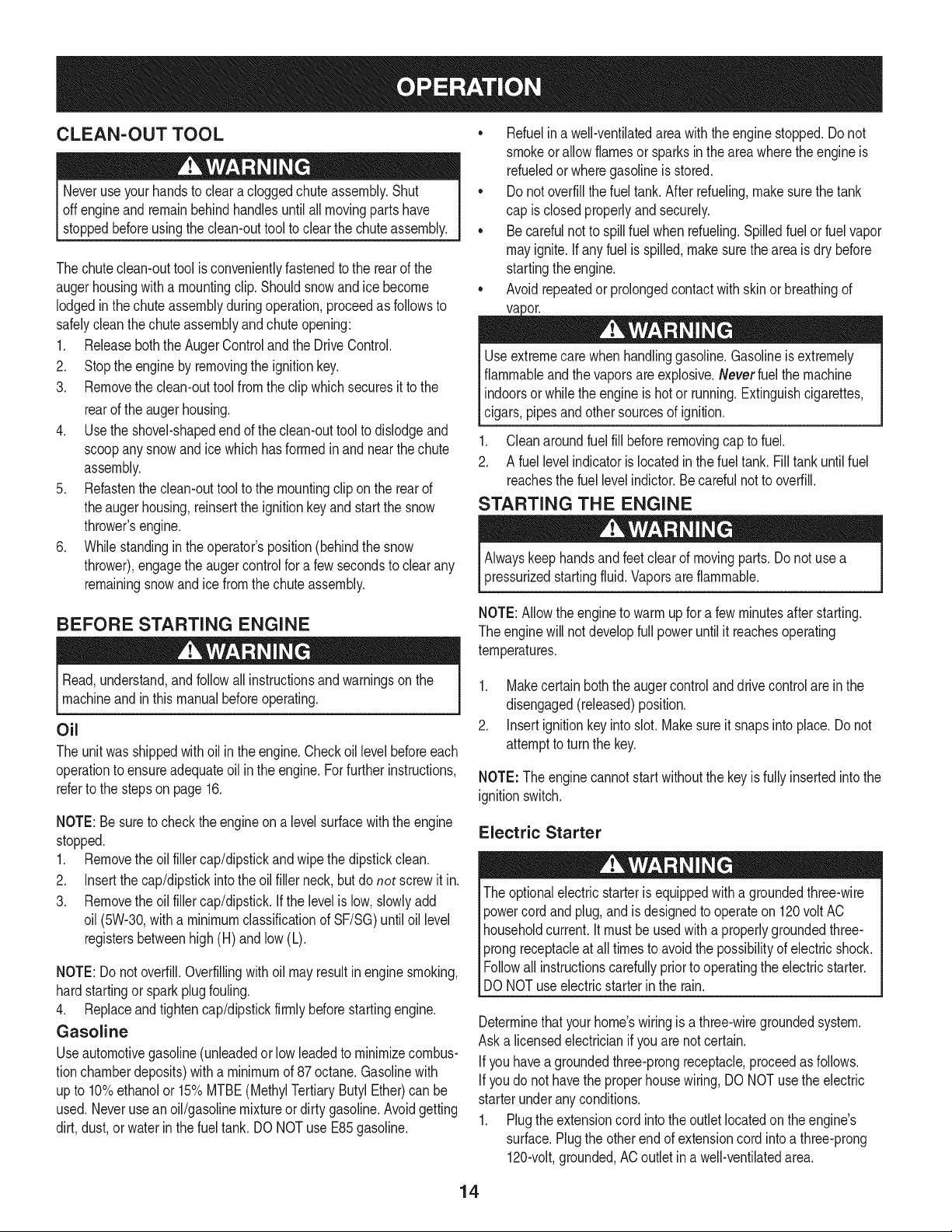

FOUR=WAY CHUTE CONTROL TM

OIL FILL

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

GAS CAP

Unthreadthegascap to addgasolinetothefueltank.

AUGERS

Whenengaged,theaugersrotateanddrawsnowintotheauger

housing.

AUGER CONTROL

f AUGER

CONTROL

&

Theaugercontrolis locatedontheleft handle.Squeezethecontrol

gripagainstthehandletoengagetheaugersandstart snowthrowing

action.Releasetostop.

CHUTE DiRECTiONAL CONTROL

CHUTETILTDOWN

iPus. ",. iPus.HUTTO.]

_E ROTATE L,.,,,>CHUTEROTATE

LEFT _ W " HIGHT

L,J

©

_. CHUTETILTUP j

Thefour-waychutecontrolTM iSlocatedontheleft sideofthehandle

panel.

* Tochangethedirectioninwhichsnowisthrown,squeezethe

buttononthechutecontrolleverandpivotthechutecontrollever

tothe rightortotheleft.

* Tochangetheangle/distancewhichsnowisthrown,pivotthe

chutecontrolleverforwardto tiltthechutedownandbackwardto

tilt the chuteup.

SKiD SHOES

Positiontheskidshoesbasedonsurfaceconditions.Adjustupward

forhard-packedsnow.Adjustdownwardwhenoperatingongravelor

crushedrocksurfaces.

13

CLEAN-OUT TOOL

Neveruseyourhandstoclearacloggedchuteassembly.Shut

off engineandremainbehindhandlesuntilall movingpartshave

stoppedbeforeusingtheclean-outtooltoclearthechuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedtothe rearof the

augerhousingwitha mountingclip. Shouldsnowandice become

lodgedin thechuteassemblyduringoperation,proceedasfollowsto

safelycleanthechuteassemblyandchuteopening:

1. Releaseboththe AugerControlandtheDriveControl.

2. Stopthe engineby removingtheignitionkey.

3. Removetheclean-outtoolfromtheclipwhichsecuresitto the

rearoftheaugerhousing.

4. Usetheshovel-shapedendof theclean-outtool to dislodgeand

scoopanysnowand icewhichhasformedin andnearthechute

assembly.

5. Refastentheclean-outtooltothemountingclipontherearof

theaugerhousing,reinserttheignitionkeyandstartthesnow

thrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnow

thrower),engagethe augercontrolfora fewsecondstoclearany

remainingsnowandice fromthechuteassembly.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthe fueltank.Afterrefueling,makesurethetank

capisclosedproperlyandsecurely.

• Becarefulnotto spillfuel whenrefueling.Spilledfuelorfuelvapor

mayignite.Ifany fuelis spilled,makesuretheareaisdrybefore

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

)or.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuelthemachine

indoorsorwhilethe engineis hotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Cleanaroundfuel fill beforeremovingcaptofuel.

2. A fuellevelindicatorislocatedin the fueltank.Filltankuntilfuel

reachesthefuellevelindictor.Becarefulnotto overfill.

STARTING THE ENGINE

Alwayskeephandsandfeetclearof movingparts.Donotusea

pressurizedstartingfluid.Vaporsareflammable.

BEFORE STARTING ENGINE

Read,understand,andfollowall instructionsandwarningsonthe

machineand inthismanualbeforeoperating.

Oil

Theunitwasshippedwithoil intheengine.Checkoil levelbeforeeach

operationto ensureadequateoilin theengine.Forfurtherinstructions,

referto the stepsonpage16.

NOTE:Besureto checktheengineon a levelsurfacewiththeengine

stopped.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. Insertthe cap/dipstickintotheoil filler neck,butdonot screwit in.

3. Removetheoil fillercap/dipstick.Ifthelevelislow,slowlyadd

oil (5%30, witha minimumclassificationof SF/SG)untiloil level

registersbetweenhigh(H) andlow(L).

NOTE:Do notoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,orwaterin thefueltank.DONOTuseE85gasoline.

NOTE:Allowtheenginetowarmupfor a fewminutesafterstarting.

Theenginewillnotdevelopfullpoweruntilit reachesoperating

temperatures.

1. Makecertainboththe augercontrolanddrivecontrolarein the

disengaged(released)position.

2. Insertignitionkeyinto slot.Makesureitsnapsintoplace.Donot

attempttoturn the key.

NOTE:Theenginecannotstartwithoutthekeyis fullyinsertedintothe

ignitionswitch.

Electric Starter

Theoptionalelectricstarteris equippedwitha groundedthree-wire

powercordand plug,andisdesignedtooperateon 120voltAC

householdcurrent.Itmustbe usedwitha properlygroundedthree-

prongreceptacleat all timesto avoidthepossibilityofelectricshock.

Followall instructionscarefullypriorto operatingtheelectricstarter.

DONOTuseelectricstarterinthe rain.

Determinethatyourhome'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouarenotcertain.

Ifyouhaveagroundedthree-prongreceptacle,proceedasfollows.

Ifyoudonothavetheproperhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncord intotheoutletlocatedonthe engine's

surface.Plugtheotherendof extensioncordintoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

14

2. Movethrottlecontrolto FAST(rabbit)_ position.

3. MovechoketotheONposition I#1 (c_d enginestart).If

engineiswarm,placechokein OFFposition.

4. Pushprimerthreetofive(3-5)times,makingsureto covervent

holewhenpushing.Ifengineiswarm,pushprimeronlyonce.

Alwayscoverventholewhenpushing.Coolweathermayrequire

primingto berepeated.

5. Pushstarterbuttontostartengine.Oncetheenginestarts,im-

mediatelyreleasestarterbutton.Electricstarterisequippedwith

thermaloverloadprotection;systemwilltemporarilyshut-downto

allowstartertocod if electricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethechokecontrolto OFF

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeinto OFFposition.

7. Afterengineisrunning,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendatthewall

outletbeforeunpluggingtheoppositeendfromtheengine.

Recoil Starter

Donotpullthestarterhandlewhiletheenginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. MovechoketotheONposition I,,9"1(coldenginestart).If

engineiswarm,placechokein OFFposition.

3. Pushprimerthreetofive(3-5)times,makingsureto covervent

holewhenpushing.Ifengineiswarm,pushprimeronlyonce.

Alwayscoverventholewhenpushing.Coolweathermayrequire

primingto berepeated.

4. Pullgentlyonthe starterhandleuntilitbeginsto resist,then

pullquicklyandforcefullytoovercomethe compression.Do

notreleasethehandleandallowitto snapback.Returnrope

SLOWLYto originalposition.Ifrequired,repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontrolto OFF

position.Ifthe enginefalters,restartengineandrunwithchoke

athalf-chokepositionfor a shortperiodoftime,andthenslowly

rotatethechokeinto OFFposition.

TO ENGAGE DRIVE

1. Withthethrottlecontrolinthe Fast(rabbit)'_ position,move

shiftleverintooneof thesix forward(F)positionsortworeverse

(R)positions.Selecta speedappropriateforthesnowconditions

anda paceyou'recomfortablewith.

NOTE:Whenselectinga DriveSpeed,usethe slowerspeedsuntil

youarecomfortableandfamiliarwiththeoperationofthe snow

thrower.

2. Squeezethedrivecontrolagainstthehandleandthesnow

throwerwillmove.Releaseitanddrivemotionwillstop.

NOTE:NEVERrepositionthe shiftlever(changespeedsordirection

oftravel)withoutfirst releasingthedrivecontrolandbringingthesnow

throwertoa completestop.Doingsowill resultin prematurewearto

thesnowthrower'sdrivesystem.

TO ENGAGE AUGERS

1. Toengagethe augersandstartthrowingsnow,squeezethe

augercontrolagainstthelefthandle.Releasetostoptheaugers.

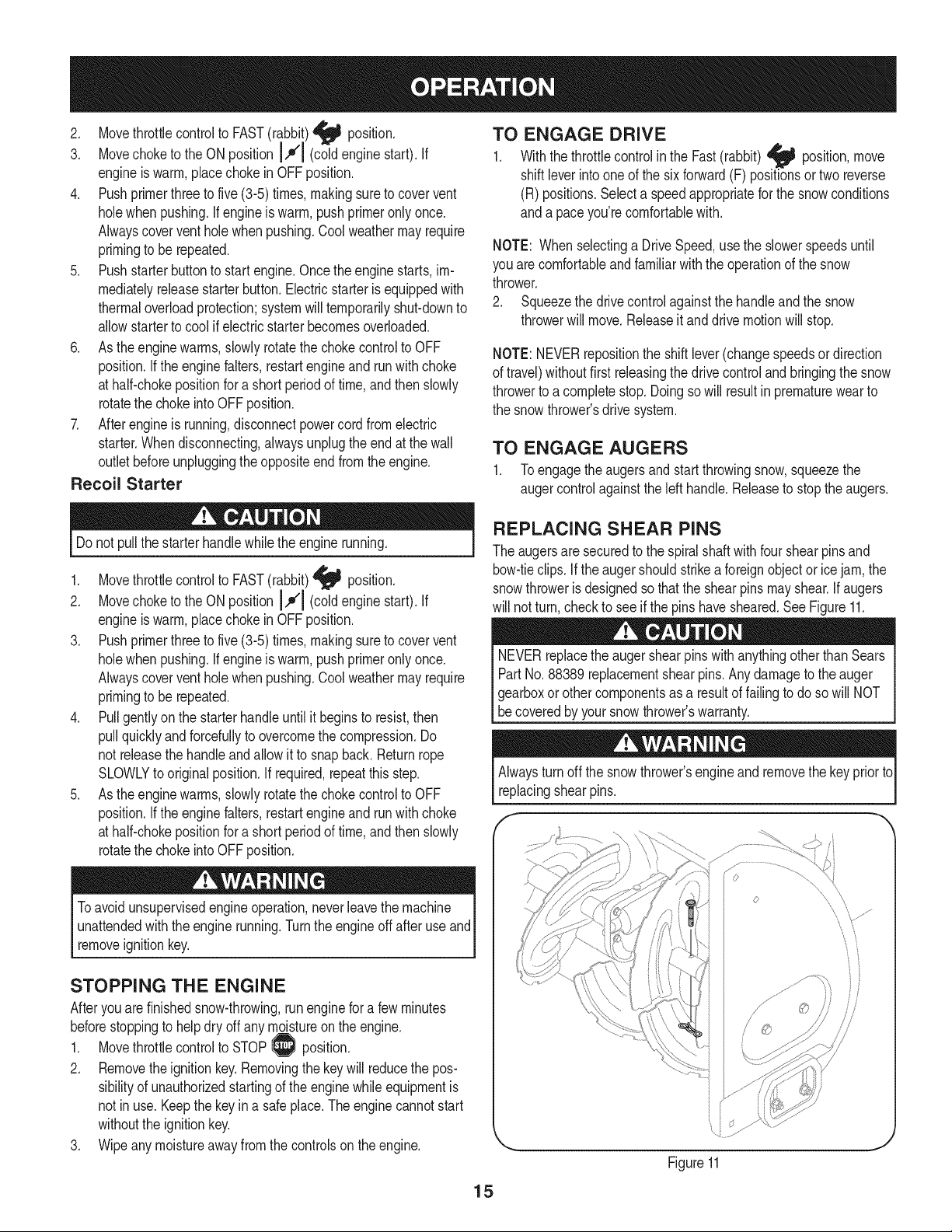

REPLACING SHEAR PINS

Theaugersaresecuredtothespiralshaftwithfourshearpinsand

bow-tieclips.Iftheaugershouldstrikea foreignobjector icejam,the

snowthrowerisdesignedsothatthe shearpinsmayshear.If augers

willnotturn,checkto seeif thepinshavesheared.SeeFigure11.

NEVERreplacethe augershearpinswithanythingotherthanSears

PartNo.88389replacementshearpins.Anydamageto theauger

j gearboxorothercomponentsas,aresultoffailingto do sowill NOT

[be coveredbyyoursnowthrowerswarranty.

Alwaysturnoff the snowthrower'sengineandremovethekeypriorto

replacingshearpins.

Toavoid unsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turntheengineoffafteruse and

removeignitionkey.

STOPPING THE ENGINE

Afteryouarefinishedsnow-throwing,runenginefora fewminutes

beforestoppingtohelpdryoffany m_sture ontheengine.

1. Movethrottlecontrolto STOP_ position.

2. Removetheignitionkey.Removingthekeywill reducethepos-

sibilityof unauthorizedstartingof theenginewhileequipmentis

notinuse.Keepthekeyin a safeplace.The enginecannotstart

withouttheignitionkey.

3. Wipeanymoistureawayfromthecontrolsontheengine.

iJ

Figure11

15

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsor repairs.

EachUseandevery5

hours

1st5 hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesand pivots

3. Wheels

4. GearshaftandAugershaft

5. 4-WayChuteControlTM

1. Engineoil

1. Sparkplug

1. Fuelsystem

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

5. Checkfor cableslackness

1. Change

1. Change

1. Runengineuntilit stopsfromlack

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.Tolocate the nearestSearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

offuel

ENGINE MAINTENANCE

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo a complete

_stop.

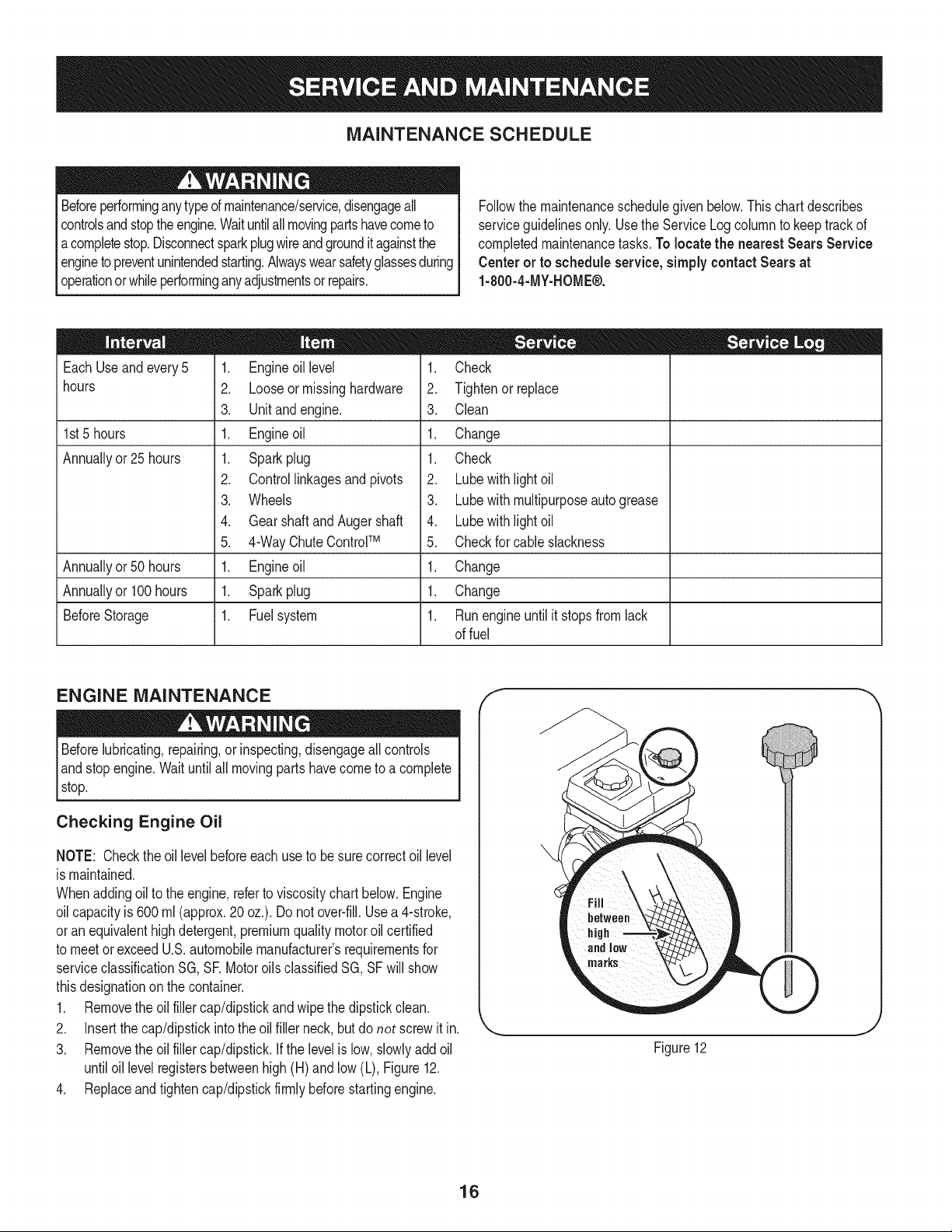

Checking Engine Oil

NOTE: Checktheoil levelbeforeeachuseto besurecorrectoil level

ismaintained.

Whenaddingoilto the engine,referto viscositychartbelow.Engine

oilcapacityis 600ml(approx.20oz.). Donotover-fill.Usea4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SR MotoroilsclassifiedSG,SFwillshow

thisdesignationonthecontainer.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. Insertthe cap/dipstickintotheoil filler neck,butdonot screwit in.

3. Removetheoil fillercap/dipstick.Ifthelevelislow,slowlyaddoil

untiloil levelregistersbetweenhigh(H)and low(L),Figure12.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

f

Figure12

16

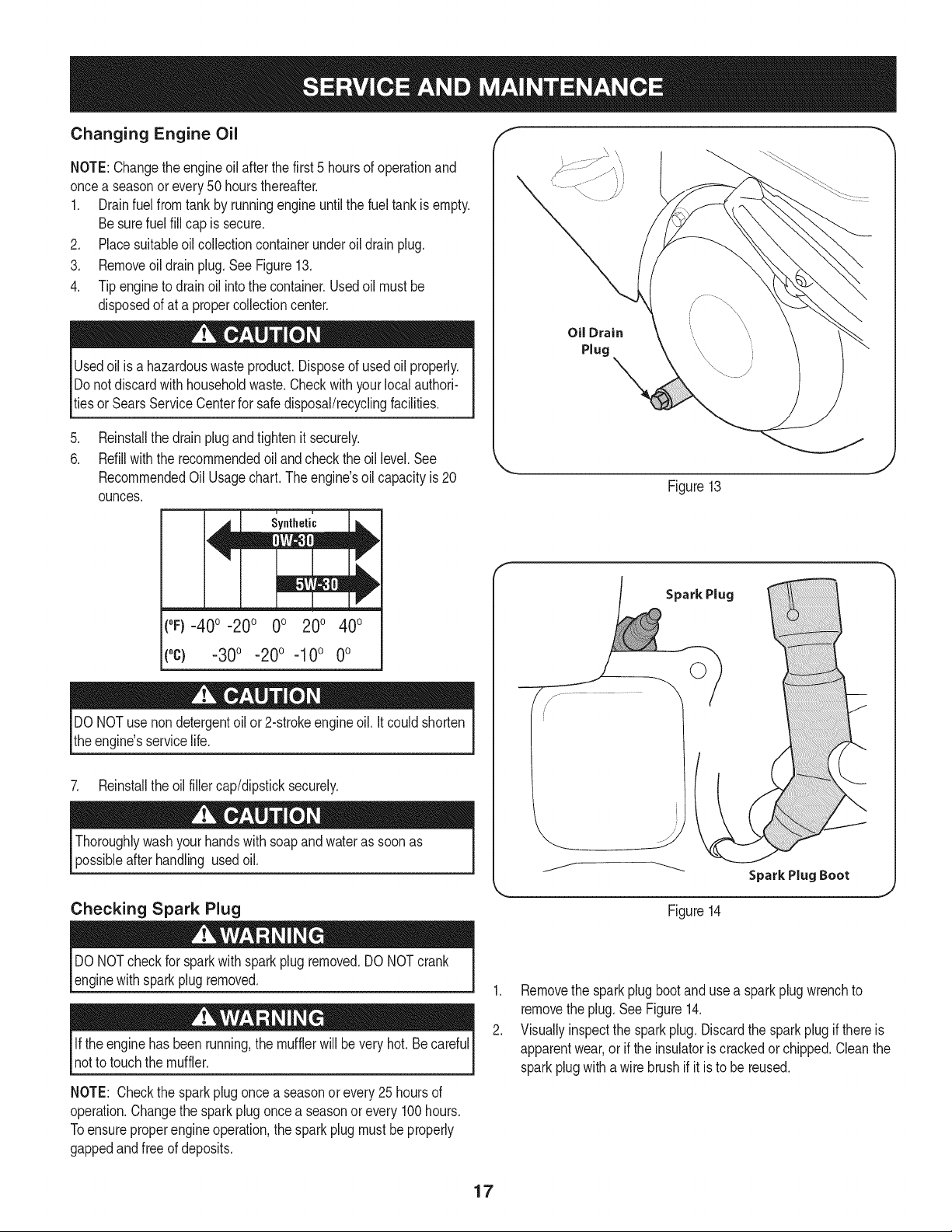

Changing Engine Oil

NOTE:Changetheengineoilafterthefirst5 hoursofoperationand

oncea seasonorevery50hoursthereafter.

1. Drainfuelfromtankby runningengineuntilthefueltankisempty.

Besurefuelfill cap is secure.

2. Placesuitableoilcollectioncontainerunderoildrainplug.

3. Removeoildrainplug.SeeFigure13.

4. Tipenginetodrainoil intothecontainer.Usedoilmustbe

disposedofata propercollectioncenter.

Usedoil is a hazardouswasteproduct.Disposeof usedoil properly.

Donotdiscardwith householdwaste.Checkwithyourlocalauthori-

tiesor SearsServiceCenterforsafedisposal/recyclingfacilities.

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoilandchecktheoil level.See

RecommendedOil Usagechart.Theengine'soil capacityis20

ounces.

u i

Synthetic

Oil Drain

Plug

Figure13

(0F)-40o-20 o 0o 200 400

("c) -30° -20° -10° 0°

DONOTuse nondetergentoilor 2-strokeengineoil.It couldshorten

theengine'sservicelife.

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyourhandswithsoapandwateras soonas

possibleafterhandling usedoil.

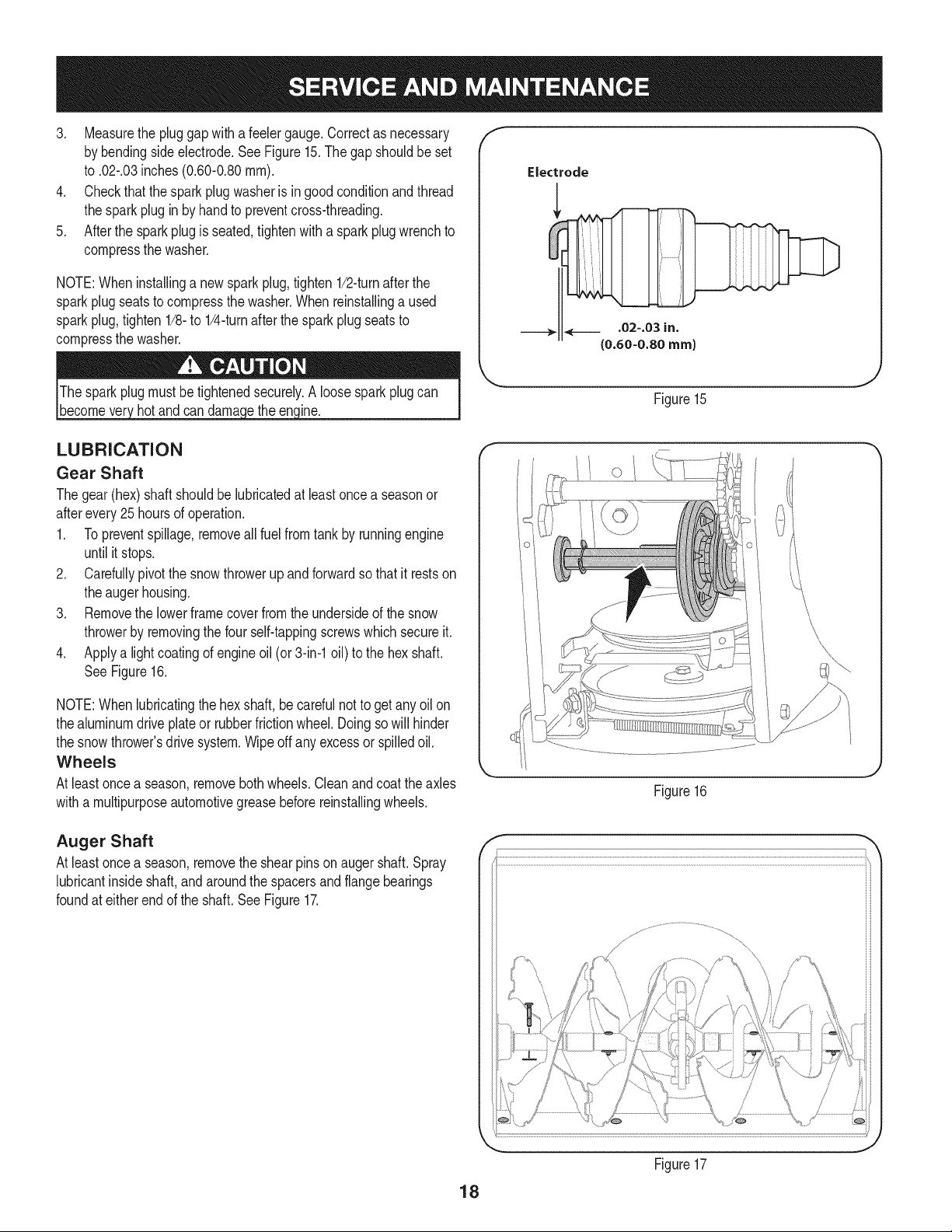

Checking Spark Plug

DONOTcheckfor sparkwithsparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Iftheenginehasbeenrunning,themufflerwillbevery hot.Becareful

notto touchthe muffler.

NOTE: Checkthe sparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonorevery100hours.

Toensureproperengineoperation,thesparkplugmustbe properly

gappedandfreeof deposits.

Spark Plug

©

SparkPlugBoot

J

Figure14

1. Removethesparkplugbootand usea sparkplugwrenchto

removetheplug.SeeFigure14.

2. Visuallyinspectthe sparkplug. Discardthe sparkplugifthereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwithawire brushifit istobe reused.

17

3. Measurethepluggapwitha feelergauge.Correctasnecessary

bybendingsideelectrode.SeeFigure15.Thegapshouldbeset

to.02-.03inches(0.60-0.80ram).

4. Checkthatthesparkplugwasherisingoodconditionandthread

thesparkplugin byhandtopreventcross-threading.

5. Afterthe sparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthe sparkplugseatsto

compressthewasher.

hotandcan ine.

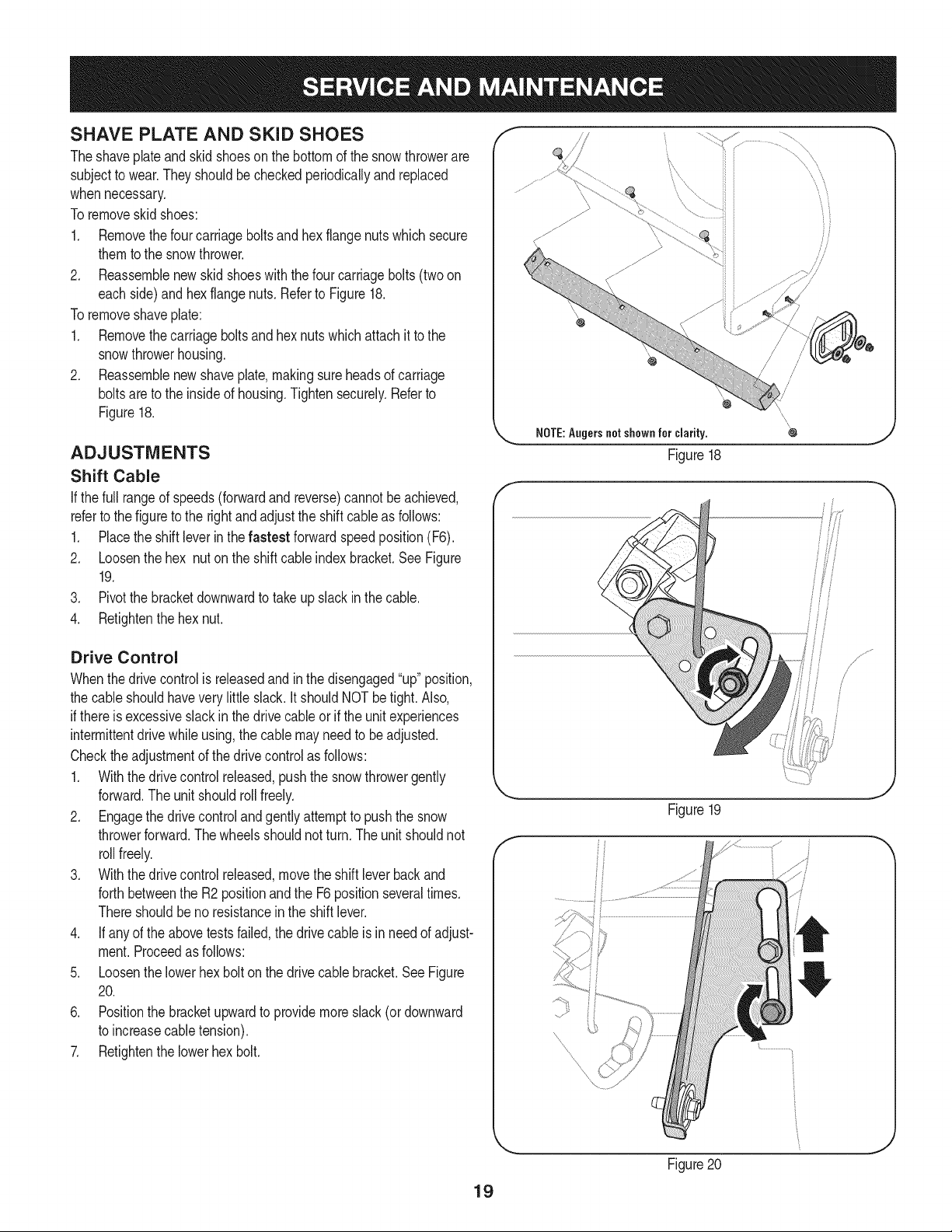

LUBRICATION

Gear Shaft

Thegear(hex)shaftshouldbelubricatedatleastoncea seasonor

afterevery25 hoursofoperation.

1. Topreventspillage,removeallfuelfromtank byrunningengine

untilitstops.

2. Carefullypivotthesnowthrowerupandforwardso that itrestson

theaugerhousing.

3. Removethe lowerframecoverfromtheundersideofthe snow

throwerbyremovingthefourself-tappingscrewswhichsecureit.

4. Applya lightcoatingof engineoil (or3-in-1oil) tothe hexshaft.

SeeFigure16.

f

Electrode

.02=.03 in.

(0.60=0.80 rnrn)

J

Figure15

NOTE:Whenlubricatingthehexshaft,be carefulnotto get any oilon

thealuminumdriveplateor rubberfrictionwheel.Doingsowillhinder

thesnowthrower'sdrivesystem.Wipeoff anyexcessor spilledoil.

Wheels

Atleastoncea season,removebothwheels.Cleanandcoattheaxles

witha multipurposeautomotivegreasebeforereinstallingwheels.

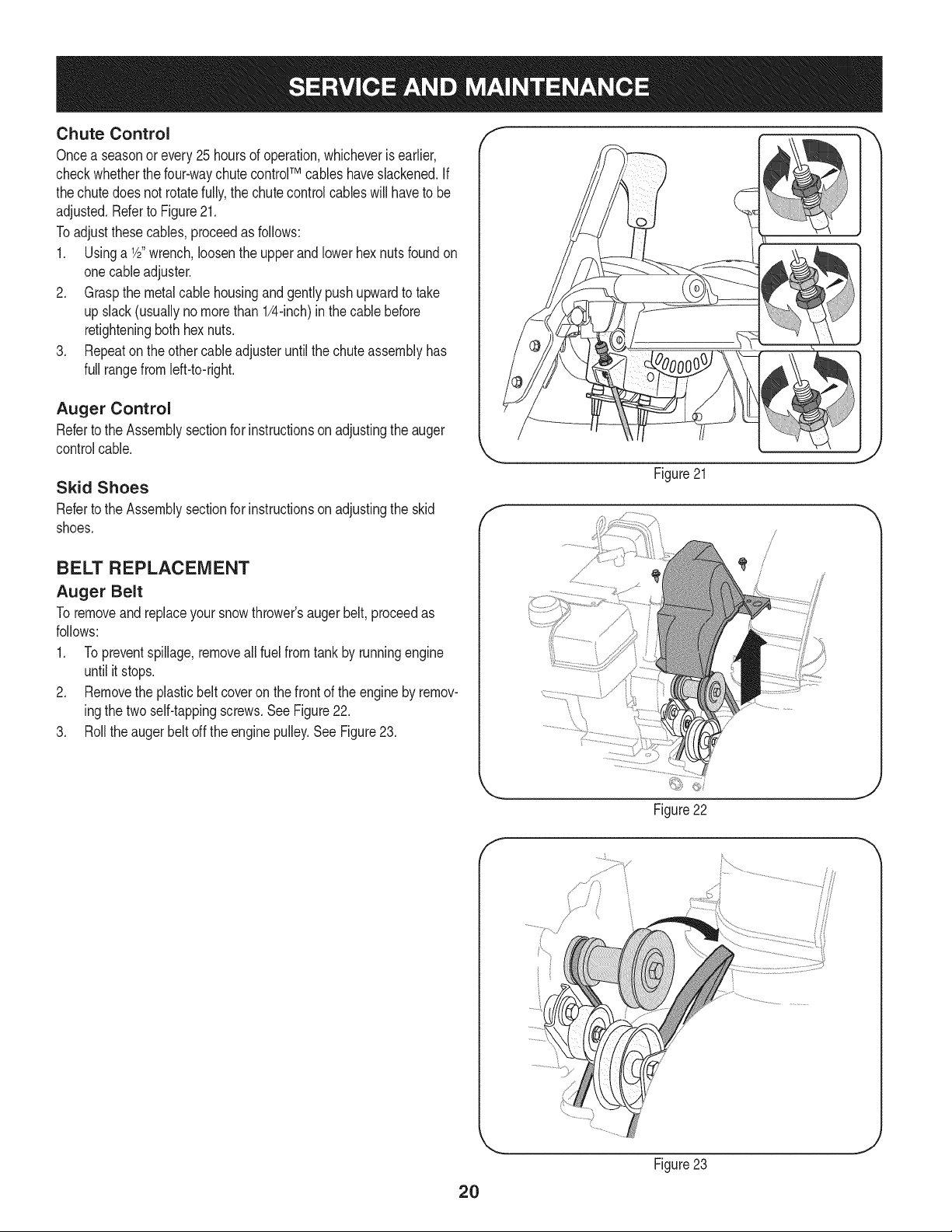

Auger Shaft

Atleastoncea season,removetheshearpinson augershaft.Spray

lubricantinsideshaft,andaroundthe spacersandflangebearings

foundat eitherendoftheshaft.SeeFigure17.

Figure16

f

\

J

Figure17

18

SHAVE PLATE AND SKiD SHOES

Theshaveplateand skidshoesonthebottomofthe snowthrowerare

subjectto wear.Theyshouldbecheckedperiodicallyandreplaced

whennecessary.

Toremoveskidshoes:

1. Removethefourcarriageboltsandhexflangenutswhichsecure

themtothe snowthrower.

2. Reassemblenewskidshoeswiththefourcarriagebolts(twoon

eachside)and hexflangenuts.Referto Figure18.

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattachit tothe

snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsof carriage

boltsaretotheinsideofhousing.Tightensecurely.Referto

Figure18.

ADJUSTMENTS

Shift Cable

If thefull rangeofspeeds(forwardandreverse)cannotbe achieved,

referto the figuretotherightandadjusttheshiftcableas follows:

1. Placethe shiftleverinthefastest forwardspeedposition(F6).

2. Loosenthehex nuton theshiftcableindexbracket.SeeFigure

19.

3. Pivotthebracketdownwardto takeupslackinthe cable.

4. Retightenthehexnut.

NOTE:Augersnot shown for clarity.

Figure18

Ji

i/

Drive Control

Whenthedrivecontrolisreleasedandin thedisengaged"up"position,

thecableshouldhaveverylittle slack.It shouldNOTbetight. Also,

ifthereis excessiveslackin thedrive cableor iftheunitexperiences

intermittentdrivewhileusing,thecable mayneedtobeadjusted.

Checktheadjustmentofthedrivecontrolasfollows:

1. Withthedrivecontrolreleased,pushthesnowthrowergently

forward.Theunitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattempttopushthe snow

throwerforward.Thewheelsshouldnotturn.The unitshouldnot

rollfreely.

3. Withthedrivecontrolreleased,movetheshiftleverbackand

forthbetweenthe R2positionandtheF6positionseveraltimes.

Thereshouldbeno resistanceintheshiftlever.

4. If anyoftheabovetestsfailed,the drivecableisin needofadjust-

ment.Proceedasfollows:

5. Loosenthelowerhexbolt onthedrivecable bracket.SeeFigure

20.

6. Positionthebracketupwardtoprovidemoreslack(or downward

toincreasecabletension).

7. Retightenthelowerhexbolt.

Figure19

f

19

Figure20

Chute Control

Oncea seasonorevery25hoursofoperation,whicheverisearlier,

checkwhetherthefour-waychutecontrolTM cableshaveslackened.If

thechutedoesnotrotatefully,thechutecontrolcableswillhaveto be

adjusted.RefertoFigure21.

Toadjustthesecables,proceedasfollows:

1. Usinga 1/2"wrench,loosentheupperandlowerhexnutsfoundon

onecableadjuster.

2. Graspthe metalcablehousingandgentlypushupwardtotake

up slack(usuallynomorethan1/4-inch)inthecablebefore

retighteningbothhexnuts.

3. Repeatontheothercableadjusteruntilthechuteassemblyhas

fullrangefromleft-to-right.

Auger Control

RefertotheAssemblysectionfor instructionsonadjustingtheauger

controlcable.

Skid Shoes

RefertotheAssemblysectionfor instructionsonadjustingthe skid

shoes.

BELT REPLACEMENT

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedas

follows:

1. Topreventspillage,removeallfuelfromtank byrunningengine

untilitstops.

2. Removethe plasticbeltcoveronthefrontof the engineby remov-

ingthetwoself-tappingscrews.SeeFigure22.

3. Rolltheaugerbeltoff theenginepulley.See Figure23.

f

J

Figure21

\

2O

Figure22

f

Figure23

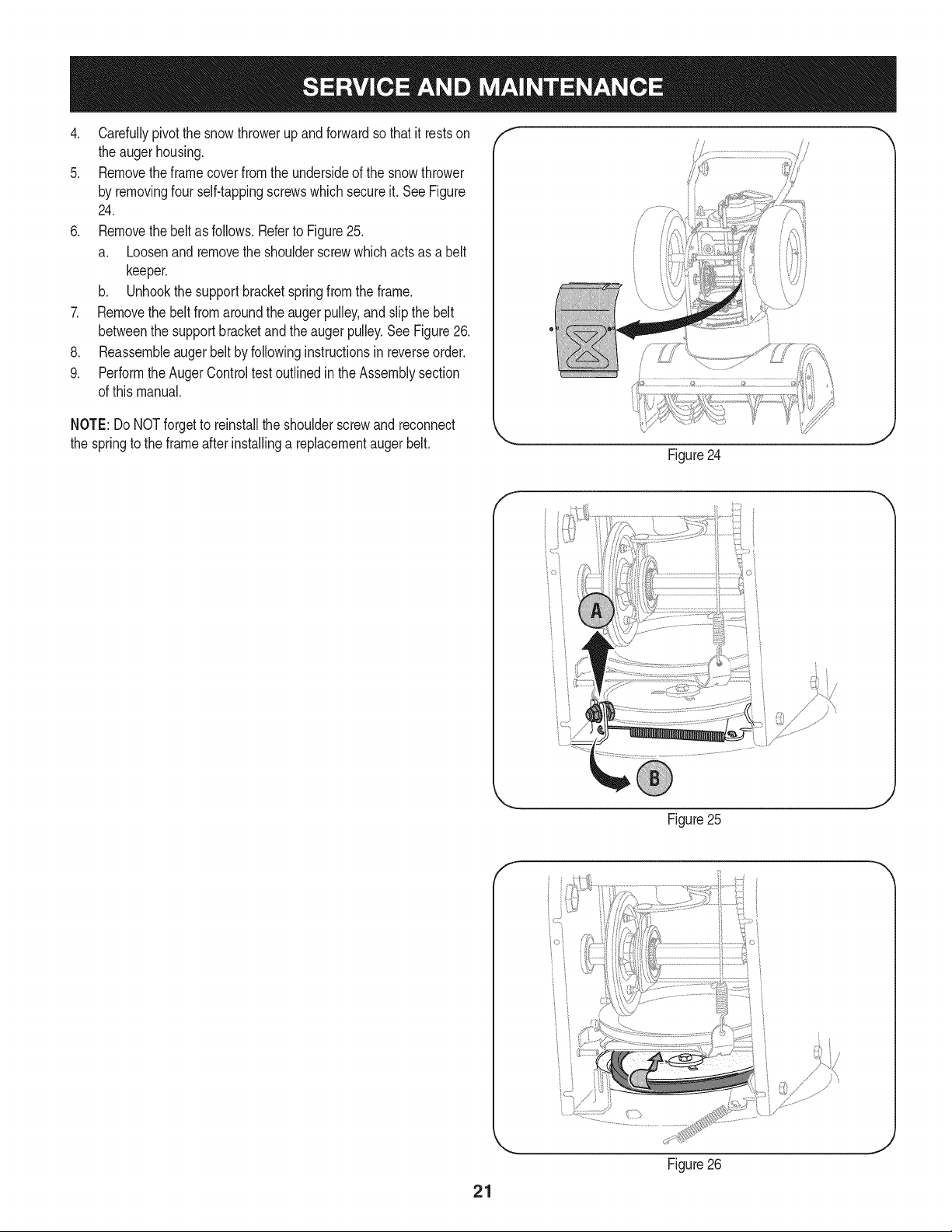

4. Carefullypivotthesnowthrowerupandforwardsothatitrestson

theaugerhousing.

5. Removetheframecoverfromtheundersideofthesnowthrower

byremovingfourself-tappingscrewswhichsecureit.SeeFigure

24.

6. Removethebeltasfollows.RefertoFigure25.

a. Loosenandremovetheshoulderscrewwhichactsasabelt

keeper.

b. Unhookthesupportbracketspringfromtheframe.

7. Removethebeltfromaroundtheaugerpulley,andslipthebelt

betweenthesupportbracketandtheaugerpulley.SeeFigure26.

8. Reassembleaugerbeltbyfollowinginstructionsinreverseorder.

9. PerformtheAugerControltestoutlinedintheAssemblysection

ofthismanual.

NOTE:DoNOTforgettoreinstalltheshoulderscrewandreconnect

thespringtotheframeafterinstallingareplacementaugerbelt.

/

Figure24

f

21

Figure25

f

Figure26

Loading...

Loading...