Page 1

OWNEirS GUIDE

• ASSEMBLY • OPERATION • MAINTENANCE •

CHIPPER-

VACUUM

Model Series

315B

Important:

Read Safety Rules

and Instructions Carefully

WARNING: This unit is equipped with an internai combustion engine and should not be used

on or near any unimproved forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester meeting applicabie local or state

laws (if any). If a spark arrester is used, it should be maintained in effective working order by

the operator.

in the State of California the above is required by law (Section 4442 of the California Public

Made ^

in

AMERICA

Resources Code). Other states may have similar laws. Federal laws apply on federal lands.

A spark arrester for the muffler is available through your nearest engine authorized service

dealer or contact the service department, P.O. Box 368022, Cleveland, Ohio 44136-9722.

IMPORTANT!

Record the Model No. and Mfg. Code which

appear on your unit in the space below. You

must have these numbers, along with the date

of purchase, in order to receive warranty or ser

vice.

MODEL NO.

SERIAL NO.

FORM NO. 770-8920K

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSON

AL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

▲

A

BEFORE AHEMPTING TO OPERATE YOUR CHIPPER-VACUUM. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL: HEED ITS WARNING.

Your chipper-vacuum was built to be operated according to the ruies for safe operation in this manual. As

n . Mprn. power equipment, careiessness or error on the part of the operator can result in serious

DANucn: injury. This unit is capable of amputating fingers and hands and throwing objects. Faiiure to observe the

foliowing safety instructions could result in serious injury or death.

SAFE OPERATION PRACTICES

i. GENERAL OPERATION

k 1. Read this owner’s guide carefully in its entirety before attempt

ing to assemble this machine. Read, understand, and foiiow aii

instructions on the machine and in the manuai(s) before opera

tion. Be compieteiy famiiiar with the controis and the proper

use of the machine before operating it. Keep this manual in a

safe place for future and regular reference and for ordering

replacement parts.

2. Your chipper-vacuum is a powerful tool, not a plaything.

Therefore, exercise extreme caution at all times. Your unit has

been designed to perform two jobs; to chip and vacuum vege

tation found in a normal yard. Do not use it for any other pur

pose.

3. Never allow chiidren under 16 to operate the unit. Children 16

years and older should only operate under close parental

supervision. Only responsible individuals who are familiar with

these rules of safe operation should be allowed to use your

unit.

4. Keep the area of operation ciear of all persons, particularly

small children and pets. Stop the engine when they are in the

vicinity of the unit. When chipping, keep work area clear of

branches or obstacles which couid cause you to stumble and

fall.

5. When feeding materiai into this equipment, be extremeiy carefui that pieces of metal, rocks, bottles, cans or other foreign

objects are not included. Personal injury or damage to the

machine couid resuit.

6. Always wear safety glasses or safety goggles, during operation

. and whiie performing an adjustment or repair, to protect eyes

from foreign objects that may be thrown from the machine.

7. Wear sturdy, rough-soled work shoes and close fitting siacks

and shirt. Shirt and slacks that cover the arms and legs and

steel-toed shoes are recommended. Do not wear loose fitting

clothes or jewelry and secure hair so it is above shouider

iength. They can be caught in moving parts. Never operate a

unit in bare feet, sandals or sneakers. Wear gloves when feed

ing materiai in the chipper chute.

8. Do not operate the unit while under the influence of alcohol or

drugs.

9. Do not overreach. Keep proper footing and balance at all

times.

10; Never place your hands or any part of your body or clothing

near or under rotating parts. Keep ciear of the discharge open

ing at all times. Never insert your hands or any part of your

body or clothing into the nozzle, chipper chute or discharge

opening as the rotating impeller can cause serious injury.

11. If it is necessary for any reason to unciog the feed intake or

discharge openings or to inspect or repair any part of the

machine where a moving part can come in contact with your

body or ciothing, stop the machine, allow it to cooi, disconnect

the spark piug wire from the spark plug and move it away from

the spark plug before attempting to unclog, inspect or repair.

12. Never operate unit without vacuum bag and discharge chute

properly affixed to unit. Large zippered end of bag must be

closed to prevent objects from being blown out.

13. Never operate unit without either the inlet nozzle or optional

hose attachment properly affixed to unit. These devices shield

the operator from accidental contact with the rotating impeller.

Never attempt to convert the unit from nozzle to hose mode or

vice versa with the engine running.

14. Never attempt to remove or empty vacuum bag when engine is

running. Shut the engine off and wait for the impeller to come

to a complete stop before removing the bag. The impeller con

tinues to rotate for a few seconds after the engine is shut off.

Never place any part of the body in the impeller area until you

are sure the impeller has stopped rotating.

15. Keep all guards and safety devices in place and operating

properly. ,

16. Do not allow an accumulation of processed material to build

up in the discharge area as this will prevent proper discharge

and can result in kick-back from the chipper chute.

17. Keep your face and body back from chipper chute to avoid

accidental bounce back of any material.

18. If the cutting mechanism strikes a foreign object or if your

machine should start making an unusual noise or vibration,

immediately stop the engine, disconnect the spark plug wire

and move the wire away from the spark plug. Allow the

machine to stop and take the following steps.

• Inspect for damage.

• Repair or repiqce any damaged parts.

• Check for any loose parts and tighten to assure continued

safe operation.

19. Muffler and engine become hot and can cause a burn. Do not

touch.

20. Do not allow leaves or other debris to build-up on engine’s

muffler. The debris could ignite and cause a fire.

21. Do not operate engine if air cleaner or cover over carburetor

air-intake is removed, except for adjustment. Removal of such

parts could create a fire hazard.

22. Only operate unit in good daylight. Do not operate unit at night

or in dark areas where your vision may be impaired.

23. Only use accessories approved for this machine by the manu

facturer. Read, understand, and follow all instructions

provided with the approved accessory.

24. If situations occur which are not covered by this manual, use

care and good judgment. Contact your dealer for assistance.

II. CHILDREN

‘Tragic accidents can occur if the operator is not alert to the pres

ence of small children. Children are often attracted to the chipping

and vacuuming activity. Never assume that children will remain

where you last saw them.

1. Keep children out of the work area and under the watchful eye

of a responsible adult other than the operator.

2. Be alert and turn the unit off if a child enters the area.

3. Never allow children under the age of 16 to operate the chip

per-vacuum.

Page 3

III. SERVICE

M. Use extreme care in handling gasoline and other fuels. They

are extremely flammable and the vapors are explosive.

a. Store fuel and oil in approved containers, away from heat

and open flame, and out of the reach of children.

b. Check and add fuel before starting the engine. Never

remove gas cap or add fuel while the engine is running.

Allow engine to cool at least two minutes before refueling.

c. Replace gasoline cap securely and wipe off any spilled

gasoline before starting the engine as it may cause a fire

or explosion.

d. Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

e. Never refuel unit indoors because flammable vapors will

accumulate in the area.

f. Never store the machine or fuel container inside where

there is an open flame or spark such as a gas hot water

heater, clothes dryer or furnace.

2. Never run your machine in an enclosed area as the exhaust

from the engine contains carbon monoxide, which is an odor

less, tasteless and deadly poisonous gas.

3. To reduce fire hazard, keep engine and muffler free of leaves,

grass, and other debris build-up. Clean up fuel and oil spillage.

Allow unit to cool at least 5 minutes before storing.

4. Before cleaning, repairing, or inspecting, make certain the

impeller and all moving parts have stopped. Disconnect the

spark plug wire and keep wire away from spark plug to prevent

accidental starting. Do not use flammable solutions to clean

air filter.

5. Keep all nuts, bolts, and screws tight to be sure the equipment

is in safe working condition. *

6. Never tamper with safety devices. Check their proper opera

tion regularly.

7. After striking a foreign object, immediately stop the engine,

disconnect the spark plug wire from the spark plug, and thor

oughly inspect the unit for any damage. Repair damage before

starting and operating unit.

8. Do not alter or tamper with the engine’s governor setting. The

governor controls the maximum safe operating speed of the

engine. Over-speeding the engine is dangerous and will cause

damage to the engine and to other moving parts of the

machine.

9. Check the vacuum bag frequently for wear. Replace if worn or

damaged.

10. Keep vacuum bag free of debris when not in use.

OWNER’S

MANUAL

SAFETY LABEL

A

Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this

manual and on the machine.

WARNING — YOUR RESPONSIBILITY

Page 4

FIGURE 2.

ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL in the engine. After assembiy,

see operation section of this manuai for proper

fuei and engine oil recommendations.

NOTE: To determine right and left hand sides of your

chipper-vacuum, stand behind and face the unit

(Refer to figure 7).

Your chipper-vacuum has been completely assembled

at the factory except for the front wheels, hub caps,

nozzle, chipper chute, support bracket and bag. A pair

of safety glasses are also included in the carton.

TO REMOVE CHIPPER-VACUUM FROM CARTON

Cut the corner of the carton. Remove ail packing

inserts and loose parts. Push down on handle to lift

front of chipper-vacuum, and roil chipper-vacuum out

of the carton. Make certain ali parts and iiterature

have been removed before the carton is discarded.

TOOLS REQUIRED FOR ASSEMBLY

(1) 3/4" Open End Wrench

(2) 1/2" or Adjustable Wrenches

(1) 9/16" Wrench

(1) Funnel

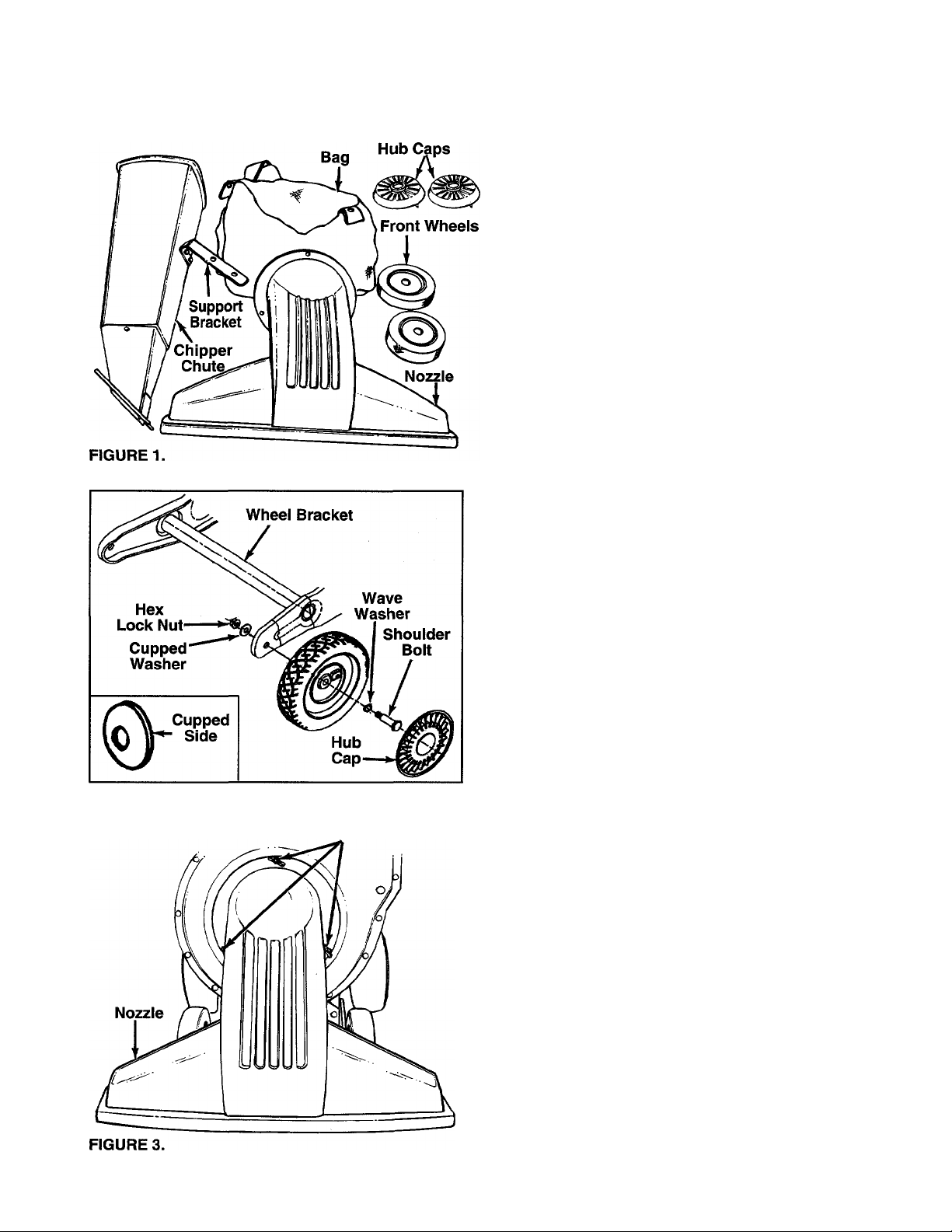

LOOSE PARTS IN CARTON (See Figure 1)

(2) Front Wheels (1) Bag

(2) HubCapst (1) Shift Knobt

(1) Nozzle (1) Tamper Plugt

(1) Chipper Chute (i) Safety Glassesf

(1) Support Bracket

tNot Shown

ATTACHING THE FRONT WHEELS

1. Tiit unit backward so that it rests on the handle

(place a piece of the carton under handle to avoid

scratches). Remove the cardboard packing

material around the wheel brackets.

2. Remove the hex lock nuts and shoulder bolts

Wing Nuts

from the front of the wheel brackets. See figure 2.

3. Place wave washer on shoulder bolt. Insert

shoulder bolt through wheel, with the head of the

shoulder bolt through the flat side of the wheel.

4. Assemble wheel to outside of wheel bracket.

Secure with cupped washer (cupped side of

washer goes against the bracket) and hex lock

nut. Tighten.

5. Aiign the four tabs on the hub caps with the four

hoies in the wheei. Press in each tab until it locks

in place. The hub cap edges must be flush with

the wheei rim when instailed properly.

AHACHING THE NOZZLE (See figure 3)

1. Remove the three plastic wing nuts from the front

of the chipper-vacuum. Place the nozzle in posi

tion over the three weld studs. Secure with the

wing nuts just removed.

2. Set unit in upright position.

Page 5

jpport

racket

FIGURE 4.

FIGURE 5.

Upper Handle washers and Nuts

Lou^ Handle

Hex Bolts, Flat

M / Lociv ,

/ Nuts (

Drive

ATTACHING THE CHIPPER CHUTE AND

SUPPORT BRACKET (See figure 4)

1. Remove the two hex lock nuts from the hex bolts

which secure the right side of the upper handle to

the lower handle. Leave bolts and washers in

place.

2. Remove three cupped washers and 5/16" hex

nuts from the weld studs beside the opening on

the right side of the chipper-vacuum.

3. Place the chipper chute in position over the weld

studs (slot goes at the bottom). Secure with

cupped washers and hex nuts just removed. Only

tighten the three nuts one or two threads for ease

of further assembly.

NOTE: Cupped side of the washer goes against the

chipper chute. See figure 2 to identify cupped side of

washer.

4. Remove the two hex bolts, flat washers and nuts

which are attached to the support bracket.

5. Attach the support bracket to the bottom of the

chipper chute loosely using the hardware

removed previously. HEADS OF THE HEX

BOLTS AND WASHERS GO TO THE INSIDE OF

THE CHIPPER CHUTE.

6. Place the support bracket over the two bolts in

the handle. Pushing UP on the chipper chute will

aid the alignment of the holes in the support

bracket with the bolts in the handle.

7. Tighten all hardware securely on the chipper

chute, support bracket and handle.

ATTACHING THE CLUTCH CABLE

The clutch cable has been assembled at the factory.

Loosen the hex nuts at the cable bracket. Hook the

“Z” end of the cable into the drive clutch handle from

the outside to the inside as shown in figure 5A. Pliers

will aid in assembly.

CLUTCH CABLE ADJUSTMENT

Adjust the hex nuts at the cable bracket so there is no

slack in the cable, but the cable is NOT tight. Do not

overtighten the cable. See figure 5B.

To check the clutch adjustment, proceed as follows.

1. Push the chipper-vacuum backward and forward

with the drive clutch handle released. It should

move freely.

If it does not, loosen both hex nuts at the cable

bracket. See figure 5B. Turn bottom nut counter

clockwise to loosen the cable.

2. Engage the drive clutch handle (hold against

upper handle), and try to push chipper-vacuum

backward and forward. The wheels should lock

up.

If the wheels do not lock up, loosen both hex nuts

at the cable bracket. Turn bottom nut clockwise to

tighten the cable.

3. Recheck adjustment. Tighten both hex nuts when

correct adjustment is reached.

Page 6

ATTACHING THE BAG

1. Place bag inside of handie assembly. Slip the

opening on the bag over the discharge chute,

making certain it is over the rib on the discharge

chute. See figure 6.

2. Place the four straps on the top of the bag over

upper handle, hooking them on studs. See figure

7. Be sure the bag goes under the drive dutch

handle.

3. Squeeze the clamp on the drawstring, and puli

the drawstring tight. Release the clamp.

INSTALLING THE SHIFT KNOB

Remove the cardboard protecting the threads. Thread

the shift knob onto the end of the shift lever.

OPERATION

CONTROLS (See figure 8)

SHIFT LEVER

The shift lever may be moved into one of eight posi

tions. Run engine with throttle in the fast position. Use

the shift lever to determine ground speed.

Forward—one of six speeds. Position number one (1)

is the slowest. Position number six (6) is the fastest.

Reverse—two reverse (R) speeds. “R” (all the way to

the right) is the faster of the two.

DRIVE CLUTCH HANDLE

Squeezing the drive clutch handle against the upper

handle engages the wheel drive. Release the drive

clutch handle to stop the forward drive.

Shift

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as

instructed in the separate engine manual packed with

your chipper-vacuum. Read instructions carefully.

NOTE: Your chipper-vacuum is shipped without oii;

however, a smaii amount of oii may be present from

the factory. Do not overfiii.

WARNING: Never fill fuel tank indoors,

with engine running or while engine is

A

TO START ENGINE

IMPORTANT: If unit shows any sign of motion with

the clutch handle disengaged, shut engine off immedi

ately. Readjust as instructed in the “Clutch Cable

Adjustment” section of the Assembly Instructions.

A

1. Attach spark plug wire to spark plug.

2. Make certain drive clutch handle is in the disen

3. Move choke lever on engine to CHOKE position.

4. Move throttle control lever on engine to FAST

5. Place one foot on the left rear wheel to prevent

6. Grasp starter handle and pull rope out slowly until

NOTE: A noise wiil be heard when finding the start of

the compression cycie. This noise is caused by the

fiaiis and fingers which are part of the shredding

mechanism faiiing into piace, and shouid be expect

ed. in addition, the fiaiis and fingers wili be noisy after

the engine is started, untii the impeiier reaches fuii

speed.

hot. Do not smoke when filling fuel tank.

WARNING: Be sure no one other than the

operator is standing near the chippervacuum while starting or operating. Do

not operate this chipper-vacuum unless

the nozzle, discharge chute and bag have

been properly installed.

gaged (released) position.

(A warm engine may not require choking.)

position.

the unit from skidding while starting.

engine reaches start of compression cycle (rope

wiirpull slightly harder at this point). Let the rope

rewind slowly.

Page 7

7. Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope

rewind slowiy. Do not let starter handle snap back

against starter.

8. Repeat instructions 6 and 7 until engine fires.

When engine starts, move choke control gradual

ly to RUN position.

TO STOP ENGINE

1. To stop engine, move throttie control lever to OFF

position.

2. Disconnect spark plug wire and ground to prevent

accidental starting while equipment is unattended.

IMPORTANT: The vacuum bag may have an air

escape located on the upper left hand side. See figure

9. The air escape can be opened if the vacuum is

operated in wet, sandy or muddy conditions.

The bag may be emptied using the large zipper as

shown in figure 9. Be certain the zipper is closed

when operating the unit.

HOW TO USE THE CHIPPER

Do not attempt to shred or chip any material other

than vegetation found in a normal yard (i.e., branches,

leaves, twigs, etc.). Material such as stalks or heavy

branches up to 3" in diameter may be fed into the

chipper chute. See figure 10.

WARNING: Material up to a maximum of

3" in diameter may be fed into the

A

chipper chute. Do not attempt to shred or

chip any material larger than 3" in diame

ter. Personal injury or damage to the

machine could result.

TO ENGAGE DRIVE

iMPORTANT: Always release the drive ciutch han-

die before moving the shift iever.

With the engine running near top speed, move shift

lever into one of the six FORWARD positions or two

REVERSE positions. Select a speed appropriate for

the conditions that exist. Use the slower speeds until

you are familiar with the operation of the chipper-

vacuum.

To engage the wheel drive, hold the drive clutch

handle against the chipper-vacuum handle. Releasing

the drive clutch handle stops the wheels from driving.

Release the drive clutch handle to slow down when

negotiating an obstacle, making a turn or stopping.

Engage slowly to prevent front wheels from lifting up.

FIGURE 10.

IMPORTANT: There is a flail screen located inside

the housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

the Maintenance section on page 9.

For best performance, it is important to keep the

chipper blades sharp. Refer to Maintenance section,

page 9. If the composition of the material being dis

charged changes (becomes stringy, etc.) or if the rate

at which the material is discharged slows down

considerably, it is iikely that the chipper blades are

dull and need to be sharpened or replaced.

ADJUSTMENTS

WARNING: Do not at any time make any

adjustment to the unit without first stop

A

HEIGHT ADJUSTMENT

The height adjustment knob is located on the right

hand side of the chipper-vacuum. See figure 11. Turn

the knob clockwise to raise the nozzle. Turn the knob

counterclockwise to lower. (Be careful not to turn

knob too far—rod could come out of ferrule.)

ping engine and disconnecting spark

plug wire.

Page 8

The best height for the nozzle will vary according to

the conditions. Adjust the height of the nozzle to find

the setting which gives the best performance for the

operating conditions. In general, raise the nozzle to

vacuum a thick layer of leaves; lower the nozzle for

smooth surfaces.

Shift Lever

6th Position

FIGURE 12.

CARBURETOR ADJUSTMENT

WARNiNG: if any adjustments are made

to the engine whiie the engine is running

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load. Do not make unnecessary adjustments.

Factory settings are satisfactory for most applications

and conditions. If adjustment is needed, refer to the

separate engine manual packed with your chippervacuum.

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

CLUTCH CABLE ADJUSTMENT

To adjust the clutch cable, refer to the “Clutch Cable

Adjustment” section of Assembly Instructions.

SHIFT RDD ADJUSTMENT

If the shift rod needs adjustment to obtain forward or

reverse correctly, proceed as follows. See figure 12.

3.

4.

5.

(e.g., carburetor), keep ciear of aii mov

ing parts. Be carefui of heated surfaces

and muffier.

Remove the bag from the unit.

Remove the hairpin clip and flat washer from the

upper end of the shift rod. Pull the ferrule out of

the hole in the shift lever. (Make certain wave

washer remains in place on the ferrule.)

Place the shift lever in 6th position (all the way to

the left).

Push down on the shift rod. Thread the ferrule up

or down the shift rod until the ferrule lines up with

the upper hole in the shift lever.

Secure ferrule to shift lever with flat washer and

hairpin clip.

MAINTENANCE

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

A

LUBRICATIDN

Wheels—Rear wheels are provided with light oil bear

ings. Place a few drops of SAE 30 oil on each bearing

once a season.

Height Adjustment Mechanism—Lubricate the pivot

points on the height adjustment mechanism once a

season using a light oil.

CLEANING

Clean the chipper-vacuum thoroughly after each use.

Wash the bag periodically with water. Allow to dry

thoroughly in the shade. Do not use heat.

ENGINE

Refer to the separate engine manual for engine main

tenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefuliy.

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specifications.

lubricating or performing any repairs or

maintenance.

Page 9

Clean the engine regularly with a cloth or brush.

Keep the cooling system (blower housing area) clean

to permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

REMOVING THE FLAIL SCREEN

If the discharge area becomes clogged, remove the

flail screen and clean area as follows.

1. Stop the engine. Make certain the chippervacuum has come to a complete stop. Disconnect

the spark plug wire before unclogging the

discharge chute.

2. Remove the vacuum bag from the unit.

3. Remove the four self-tapping screws from the

bottom of the discharge chute, and the hex bolt,

flat washer and hex nut from the top. Remove the

discharge chute assembly. See figure 13.

Discharge

Chute

Assembly

5. Clean the screen by scraping or washing with

water. Reinstall the screen.

NOTE: Be certain to reassemble the flail screen with

the curved side down as shown in figure 14.

SHARPENING OR REPLACING CHIPPER BLADES

1. Disconnect the spark plug wire and move away

from the spark plug.

2. Remove the flail screen as instructed in the previ

ous section.

3. Remove the plastic belt cover on the front of the

engine by removing the two self-tapping screws.

See figure 15.

Belt

Cover

Self-Tapping

Screws

Hex Bolt

=lat Washer

Hex Nut

Seif-Tapping

Screws

FIGURE 13.

4. Remove the two hex bolts and hex nuts which

extend through the housing. Lift the flail screen

from inside the housing. See figure 14.

1

1J1

FIGURE 15.

4. Remove the access plate by removing two hex

lock nuts. See figure 16.

5. Locate one of the chipper blades in the access

plate opening by rotating the impeller assembly

by hand. Remove the blade using a 3/16" alien

wrench on the outside of the blade and 1/2"

wrench on the impeller assembly, inside the

housing.

Page 10

6. Remove the other blade in the same manner.

Replace or sharpen blades. If sharpening, make

certain to remove an equal amount from each

blade. Reassemble in reverse order.

NOTE: Make certain blades are reassembled with the

sharp edge facing upward, as viewed from the access

plate opening.

CHANGING THE FRICTION WHEEL RUBBER

The rubber on the friction wheel is subject to wear

and should be checked after 50 hours of operation,

and periodically thereafter. Replace friction wheel

rubber if any signs of wear or cracking are found.

1. Drain the gasoline and oil from the chipper-

vacuum.

2. Tip the unit backward so it rests on the handles.

3. Remove the frame cover by removing eight self

tapping screws from underneath the chippervacuum. See figure 17.

4. Remove the gear shaft from the unit by removing

the hex bolts, lock washers and flat washers from

each side of the frame. See figure 18. Hold the

friction wheel assembly, and slide the gear shaft

out of the unit toward the right side.

5. Remove the six screws from the friction wheel

assembly (three from each side). Remove the

friction wheel rubber from between the friction

wheel plate.

6. Reassemble new friction wheel rubber to the fric

tion wheel assembly, tightening the six screws in

rotation and with equal force.

7. Slide the friction wheel assembly up onto the shift

mechanism, then slide the gear shaft back into

the unit. Reassemble in reverse order.

8. Readjust the clutch cable. Refer to adjustment

section.

BELT REMOVAL AND REPLACEMENT

WARNING: Disconnect the spark plug

A

1. Remove the plastic belt cover on the front of the

2.

3. Tip the unit backward so that it rests on the

4.

5.

wire and move away from the spark plug.

engine by removing two self-tapping screws.

Refer to figure 14.

Drain the gasoline and oil from the chippervacuum.

handles.

Remove the frame cover by removing eight self

tapping screws from underneath the chippervacuum. Refer to figure 17.

Remove the idler pulley bracket as follows. (See

figure 19.)

a. Take the tension off thé belt by pivoting the

idler pulley toward you, and line up the holes in

the idler bracket assembly. Insert a nail or simi

lar object through the holes to hold the idler

pulley in this position.

b. Remove three self-tapping screws, and lift off

the idler bracket assembly.

10

Page 11

6. Remove the hex bolt and lock washer from the

engine pulley. See figure 19. Slip the engine pul

ley off the engine shaft, and remove the belt from

the pulley.

7. Loosen the nut on the stop bolt until there is

clearance between the support bracket and the

friction wheel disc. See figure 20.

8. Slip the belt between the friction wheel and fric

tion wheel disc. Remove and replace belt.

Reassemble following instruction in reverse

order.

NOTE: The support bracket must rest on the stop bolt

after the new belt has been assembled.

Support

OFF-SEASON STORAGE

The following steps should be taken to prepare your

chipper-vacuum for storage.

1. Remove all dirt from exterior of engine and equip

ment.

2. Refer to engine manual for correct engine storage

instructions.

3. Wipe unit with an oiled rag to prevent rust (use a

light oil or silicone), especially if storing in an

unventilated or metal storage shed.

4. Store in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

OPTIONAL EQUIPMENT

Hose Attachment Kit Model 290-005 is available as

optional equipment.

Model No. -315B

Spark Plug J-8C

Air Filter Element

Air Pre-Cleaner 35881

Engine Oil (SAE 30)

Chipper Blade (Standard)

Chipper Blade (Tooled Steel)

Bag

Safety Glasses 723-0400

Vacuum Hose Kit (Optional)

33268

737-0208

(26 oz. req’d.)

781-0490

742-0544

764-0472

290-005

The only way to ensure the performance of your

product is to use original equipment parts and

accessories, which are designed and engineered to

exacting specifications. When you substitute, you take

a chance on quaiity, reliabiiity, safety and per

formance. Use originai equipment parts—See your

iocal service deaier.

11

Page 12

TROUBLE SHOOTING

PROBLEM

Engine fails to start

Loss of power;

operation erratic

Engine overheats

Too much vibration

Unit does not

discharge

POSSIBLE CAUSE(S)

1. Spark plug wire disconnected.

2. Fuel tank empty, or stale fuel.

3. Faulty spark plug.

1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Carburetor out of adjustment.

6. Dirty air cleaner.

1. Carburetor not adjusted

properly.

2. Engine oil level low.

Loose parts or damaged

impeller.

1. Discharge chute clogged.

2. Foreign object lodged in impeller.

3. Vacuum bag is full.

CORRECTIVE ACTION

1. Connect wire to spark plug.

2. Fill tank with clean, fresh fuel.

3. Clean, adjust gap or replace.'

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean

fresh gasoline.

4. Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

5. Adjust carburetor.f

6. Service air cleaner.f

1

. Adjust carburetor.f

2. Fill crankcase with proper oil.

Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration continues,

have unit serviced by an authorized service

dealer.

1. Stop engine immediately and disconnect

spark plug wire. Clean flail screen and inside

of housing. See Maintenance section of this

manual.

2. Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

3. Empty bag.

Rate of discharge

slows considerably or

composition of

discharged material

changes

Chipper blades dull.

Sharpen or replace chipper blades.

tRefer to the engine manual packed with your unit.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service dealer.

For Replacement Parts, Contact:

SERVICE DEPARTMENT • P.O. BOX 368022 • CLEVELAND, OHIO 44136-9722

Loading...

Loading...