Page 1

OUTDOOR POWER EQUIPMENT

for all seasons

.75

26" and 33"

SNOW

THROWERS

Model Numbers

315-800-000

315-860-000

315-960-000

Important:

Read Safety Rules and

Instructions Carefully

V

PRINTED IN U.S.A.

Thank you for purchasing

an American-built product.

FORM NO. 770-3960

Page 2

INDEX

Safe Operation Practices.......................................................3

Assembly Instructions...........................................................4

Operation.................................................................................9

Adjustments.........................................................................11

Lubrication............................................................................14

Instructions given with this symbol are for per

A

sonal safety. He sure to follow them.

r

♦

♦

♦

♦

♦

♦

♦

♦

For one year from the date of original retail purchase, MTD PRODUCTS INC will either

repair or replace, at its option, free of charge, F.O.B. factory or authorized service firm, any

part or parts found to be defective in material or workmanship. Transportation charges for

the movement of any power equipment unit or attachment are the responsibility of the pur

chaser. Transportation charges fot any parts submitted for replacement under this warran

ty must be paid by the purchaser u iless such return is requested by MTD PRODUCTS INC.

This warranty will not apply to an> part which has become inoperative due to misuse, ex

cessive use, accident, neglect, imaroper maintenance, alterations, or unless the unit has

been operated and maintained in accordance with the instructions furnished. This warran

ty does not apply to the engine, me tor, battery, battery chargeror component parts thereof.

Please refer to the applicable mar ufacturer’s warranty on these items.

LIMITED WARRANTY

Maintenance .........................................................................15

Off-Season Storage..............................................................18

lilustrated Parts

Parts Lists.........................................................21,23,25,27,29

Parts information...................................................BackCover

...............................................

20,22,24,26,28

♦

♦

♦

♦

♦

♦

♦

t

♦

♦

♦

♦

♦

♦

V

This warranty will not apply where the unit has been used commercially.

Warranty service is available through your local authorized service dealer or distributor. If

you do not know the dealer or distr butor in your area, please write to the Customer Service

Department of MTD.

The return of a complete unit will lot be accepted by the factory unless prior written per

mission has been extended by MID.

This warranty gives you specific

from state to state.

;gal rights. You may also have other rights which vary

♦

♦

♦

♦

♦

♦

J

Page 3

WARNING

AC

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply

with the instructions may result in personal injury.

SAFE OPERATION PRACTICES FOR SNOW THROWERS

TRAINING

1. Read this Owner’s manual carefully. Be thoroughly

familiar with the controls and proper use of the

equipment. Know how to stop the unit and dis

engage the controls quickly.

2. Never allow children to operate equipment. Never

allow adults to operate equipment without proper

instructions.

3. No one should operate this unit while intoxicated or

while taking medication that impairs the senses or

reactions.

4. Keep the area of operation clear of all persons,

especially small children and pets.

5. Exercise caution to avoid slipping or falling, espe

cially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment is

to be used and remove all door mats, sleds, boards,

wires and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting engine.

3. Do not operate equipment without wearing ade

quate winter outer garments. Wear footwear which

will improve footing on slippery surfaces.

4. Handle fuel with care. It is highly flammable.

(A) Use approved fuel container.

(B) Never add fuel to a running engine or hot

engine.

(C) Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

(D) Replace gasoline cap securely and wipe up

spilled fuel.

5. Use a grounded three wire plug-in for all units with

electric drive motors or electric starting motors.

6. Adjust collector housing height to clear gravel or

crushed rock surface.

7. Never attempt to make any adjustments while

engine is running (except where specifically recom

mended by manufacturer).

8. Let engine and machine adjust to outdoor tem

perature before starting to clear snow.

OPERATION

1. Do not put hands or feet near rotating parts. Keep

clear of discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine,

remove wire from spark plug, and thoroughly in

spect the snow thrower for any damage. Repair the

damage before restarting and operating the snow

thrower.

4. If the snow thrower should start to vibrate abnormal

ly, stop the engine and check immediately for the

cause. Vibration is generally a warning of trouble.

5. Stop engine whenever you leave the operating posi

tion, before unclogging the collector/impeller hous

ing or discharge guide, and making any repairs, ad

justments, or inspections.

6. Take all possible precautions when leaving the vehi

cle unattended. Disengage the power take-off, lower

the attachment, shift into neutral, set the parking

brake, stop the engine, and remove the key.

7. When cleaning, repairing, or inspecting, make cer

tain collector/impeller and all moving parts have

stopped. Disconnect spark plug wire and keep away

from plug to prevent accidental starting.

8. Do not run engine indoors, except when starting

engine and transporting snow thrower in or out of

building. Open doors. Exhaust fumes are dan

gerous.

9. Do not clear snow across the face of slopes. Exer

cise extreme caution when changing direction on

slopes. Do not attempt to clear steep slopes.

10. Never operate snow thrower without guards, plates,

or other safety protection devices in place.

11. Never operate snow thrower near glass enclosure,

automobiles, window wells, drop off, etc., without

proper adjustments of s iow thrower discharge

angle. Keep children and p ¡ts away.

12. Do not overload machine c< r acity by attempting to

clear snow at too fast a rate

13. Never operate machine at h

slippery surfaces. Use care

14. Never direct discharge a

anyone in iron. ^nit.

15. Disengage power to collector/impeller when

transporting or not in use.

16. Use only attachments and accessories approved by

the manufacturer of snow thrower (such as wheel

weights, counter weights, cabs, etc.).

17. Never operate the snow thrower without good

visibility or light. Always be sure of your footing and

keep a firm hold on the handles. Walk, never run.

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts, etc., at

frequent intervals for proper tightness to be sure

equipment is in safe working condition.

2. Never store machine with fuel in the fuel tank inside

a building where open flame or spark are present.

Allow engine to cool before storing in any

enclosure.

3. Always refer to owner’s guide instructions for im

portant details if snow thrower is to be stored for an

extended period.

4. Run machine a few minutes after throwing snow to

prevent freeze up of collector/impeller.

transport speeds on

in backing,

ystanders or allow

Page 4

This owner’s manual covers various

models of snow throwers. The uni

illustrated may be different thar

your unit.

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

separate engine manual for propei

fuel and engine oil recommenda

tions.

FIGURE 3.

NOTE

NOTE

ASSEMBLY

NOTE

Reference to right hand or left hand

side of machine is observed from

the operating position.

Tools Required for Assembly:

9/16" Wrench

1/2" Wrench

7/16" Wrench

or One Adjustable Wrench

Loose Parts in Carton:

(1) Handle Assembly

(1) Chute Assembly

(1) Parts taped together which include;

(1) Drive Clutch Rod Assembly

(1) Auger Rod

-------

(1) Shift Rod

(1) Chute Crank Assembly

Contents of Hardware Pack:

A

(2) Hex Bolts 3/8-16 x 2” Long

B

(3) Belleville Washers 3/8" I.D.

C

(2) Hex Nuts 5/16-18 Thread

D

(1) Belleville Washer 5/16" I.D.

E

(3) Chute Flange Keepers

F

(6) Hex Lock Nuts V4-20 Thread

G

(1) Flat Washer 3/8" I.D. x 5/8" O.D.

H

(1) Large Flat Washer

I

(1) Hex Bushing

J

(1) Cotter Pin

K

(1) Hairpin Cotter

L

(1) Compression Spring

-M

(1) Elastic Lock Nut 3/8-24 Thread

N

(2) Ignition Keys

O

(2) Hex Bolts 5/16-18 x 1%" Long*

P

(2) Hex Lock Nuts 5/16-18 Thread*

G

(1) Shift Lever

the augers are secured to the spiral shaft with

two hex bolts and hex lock nuts (see ref. nos. 40

and 50 on page 24). If you hit a foreign object or

ice jam, the snow thrower is designed so that the

hex bolts will shear. Two replacement hex bolts

and nuts are provided in the hardware pack for

your convenience. Store in a safe place until

needed.

1. Remove snow thrower and all parts from the

carton. Make certain that all loose parts and

literature have been removed before the car

ton is discarded.

Extend throttle control assembly which is at

tached to engine at rear of the snow thrower

and place on floor. Be careful not to bend or

kink control wire.

To assemble the handle, loosen one self

tapping screw and belleville washer on each

side of the unit. See figure 3. A 9/16" wrench

or adjustable wrench is required.

Page 5

Hex Bolt (A)

Belleville

Washer (B)

FIGURE 4.

Slide the slotted end of the handles under the

4.

belleville washers on the self-tapping screws

which were loosened in step 3.

Secure the upper hole in the handles with

5.

belleville washers (B) (cupped side against the

■handles) and hex bolts (A). See figure 4. Do not

tighten at this time.

6. Thread one hex nut (C) onto the eyebolt on the

chute crank assembly until there is approx

imately VA" of threads showing between the

— nut and the head of the eyebolt. See figure 5.

Place the eyebolt into the hole in the left han

7.

dle and handle panel. See figure 5. Secure

with belleville washer (D) (cupped side against

the handle panel) and hex nut (C). Tighten

securely.

Tighten securely all bolts and nuts on the han

8

dle panel and all four bolts which secure the

handles to the frame.

Grease the chute opening.

9.

Place chute assembly over chute opening,

10.

with the chute facing the front of the unit.

Place chute flange keepers (E) beneath lip of

chute assembly. Secure with hex lock nuts (F)

as shown in figure 6. Tighten with a 7/16"

wrench, then back off V4 turn to allow easier

movement.

Page 6

FIGURE 7.

11. Place hex bushing (I) into bracket beside the

chute assembly. Position the hex bushing so

the hole in the bushing is close to the chute

-------

assembly. See figure 7.

12. Place flat washer (G) on the end of the chute

crank. Insert the chute crank into the hole in

the hex bushing so that the spiral on the chute

crank engages the teeth on the chute assem

bly. Place large flat washer (H) on the end of

the chute crank. Insert cotter pin (J) into hole

in the end of chute crank. Secure by bending

the ends of cotter pin in opposite directions.

13. Assembie the throttie control to the handle

panel as follows.

A. Hold the throttle control assembly

beneath the handle panel. Turn the control

sideways and insert the lever up through

the wide portion of the slot on the handle

panel. See figure 8A.

B. After the end of the lever is through the

slot, turn and then tip the control forward

as shown in figure 8B to slide it through

the slot.

FIGURE 8.

NOTE

The lever must be all the way to the

back of the control housing as

shown in figure 8B.

C. Push the control back into the slot in the

handle panel and press in place. Be certain

the control is locked securely into the slot.

A

14.

---

Place shift lever (Q) through slot in handle

panel, making sure flared edge of shift lever

faces the detents on handle panel. Place the

hole in the end of the shift lever over the han-

-------

die panel weld bolt. See figure 9.

Page 7

FIGURE 10.

15. Place the shift rod through the slot in the bot

tom frame cover. Thread rod into ferrule. See

■figure 10.

16. Move the shifting rod up or down until the

-------

drive clutch bracket shows in the locating

slot. See figures 10 and 11.

FIGURE 11.

FIGURE 12.

17.

-----

Place the shift lever in neutral (N) position.

Screw the shift rod in or out until it fits into

the hole in the shift lever (drive clutch must

still be showing in the locating slot). When

shift rod is adjusted to the correct length, in

sert the end into the hole in the shift lever.

Secure with hairpin cotter (K) as shown in

-------

figure 12.

Page 8

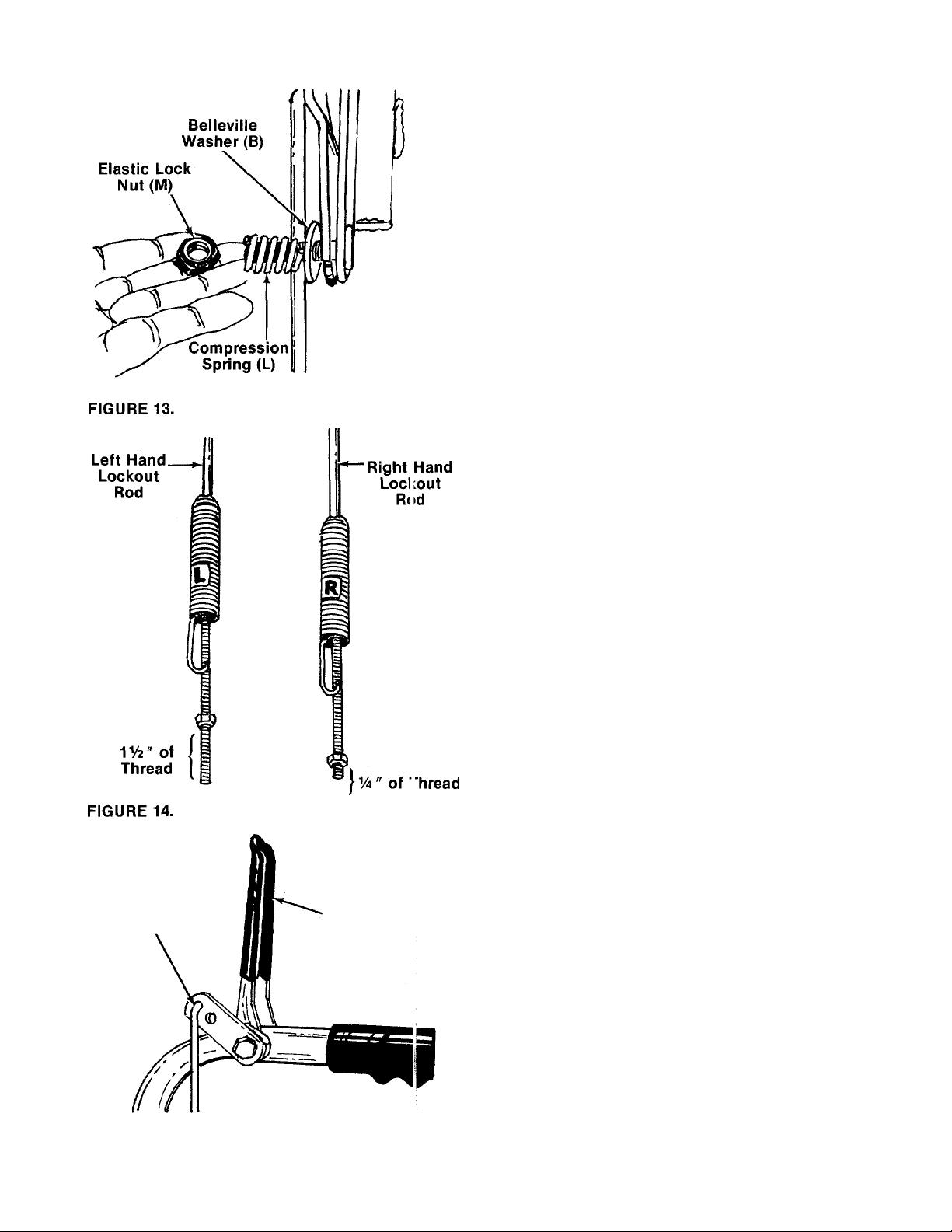

18. Secure with belleville washer (B) (cupped side

goes against shift lever), compression spring

(L) and elastic lock nut (M). See figure 13.

Tighten lock nut until compression spring

holds the shift lever into detent slot on handle

panel.

19.

The lockout rods are labeled “L” and “R” for

the left and right hand sides of the unit.

Approximate initial settings for the lockout

rods are as follows; The left hand lockout rod

for the drive clutch should have approximately

IV2 inches of thread showing below the nut.

The right hand lockout rod for the auger

clutch should have approximately Va inch of

thread showing below the nut. See figure 14.

FINAL ADJUSTMENT MUST BE MADE AS

DESCRIBED IN STEPS 21 AND 22. If the left

hand lockout rod is not adjusted correctly, the

shift lever cannot be shifted past neutral. If

the right hand lockout rod is not adjusted cor

rectly, the augers will not stop rotating.

Hook in Lockout

Rod is to the

Outside of Unit

FIGURE 15.

Clutch

Grip

20. Hook the right hand lockout rod (labeled “R”)

into the hole provided in the right hand clutch

grip (auger clutch). Hook the left hand lockout

rod (labeled “L”) to the left hand clutch grip

(drive clutch). See figure 15. The hook is to the

outside of the unit.

Page 9

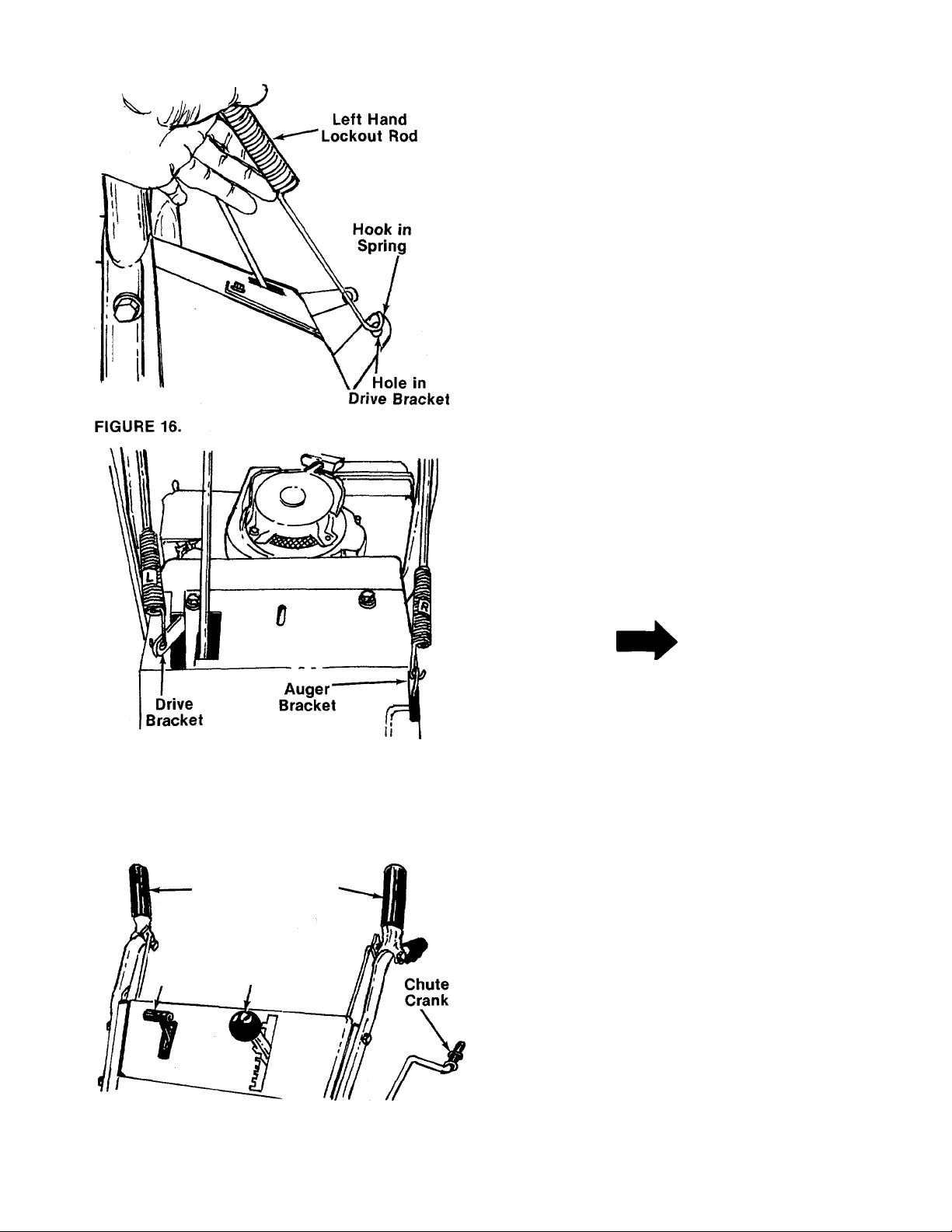

21. Swing the left hand lockout rod down and

simply hold it beside the drive bracket. Do not

pull on spring. Do not move bracket. The hook

on the end of the spring must line up with the

center of the hole in the drive bracket. See

-------figure 16.

If it does not, adjust the nut on the lockout rod

until the hook on the spring aligns with the

hole in the bracket as shown in figure 16.

Hook spring into drive bracket. See figure 17.

22. Adjust the right hand lockout rod in the same

manner as the left hand lockout rod. Refer to

Step 21. When adjustment is correct, hook the

-------

spring into the auger bracket. See figure 17.

PNEUMATIC TIRE PRESSURE

The tires are over inflated for ship

ping purposes. Check pressure and

reduce to 15 to 20 p.s.i.

FIGURE 17.

OPERATION

CONTROLS

Auger Drive

Clutch Clutch

' Throttle Shift

Control Lever

NOTE

If the tire pressure is not equal

in both tires, the unit may pull to

one side or the other.

Shift Lever (See figures 18 and 19)

The shift lever is located on the left hand side of

handle panel. The shift lever may be moved into

one of eight positions. Run engine with throttle in

the fast position. Use the shift lever to determine

ground speed.

a. Center position (N)—“NEUTRAL."

b. Forward position—One of five (5) forward

speeds. Position number one (1) is the slowest.

Position number five (5) is the fastest.

FIGURE 18.

c. Rear position—Two reverse (R) speeds. “R”

nearest the neutral (N) position is the slower of

the two.

Page 10

FIGURE 19.

Throttle Control (See figures 18 and 20)

The throttle control is located on the righ hand

side of the handle panel. It regulates the speed of

the engine.

Drive Clutch (See figure 18)

The drive clutch is located on the left handle.

Squeeze the clutch grip to engage drive. Release

to stop.

Auger Clutch (See figure 18)

The auger clutch is located on the right handle.

Squeeze the clutch grip to engage the cugers.

Release to stop the snow throwing action.

Chute Crank (See figure 18)

The chute crank is located on left hand side of the

snow thrower.

To change the direction in which snow is th rown,

turn chute crank as follows:

1. Crank clockwise to discharge to the left.

2. Crank counterclockwise to discharge o the

right.

Safety Ignition Switch (See figure 21)

The ignition key must be inserted in the s witch

before the unit wili start. Remove the ignition key

when snow thrower is not in use.

FIGURE 20.

FIGURE 21.

STARTING INSTRUCTIONS

1. Remove dipstick. Fill crankcase with oil. Oil

level must be to full mark on dipstick. Refer to

separate engine manual packed with your

snow thrower.

2. Fill fuel tank with fresh, clean regular

gasoline.

WARNING

Ai

Never fill fuel tank indoors, with en

gine running or while engine is hot.

3. Attach spark plug wire to spark plug.

4. Insert ignition key (do not turn).

5. Place shift lever in “NEUTRAL” (N) position.

6. Place throttle control in “START” (fast) posi

tion.

WARNING

AC

Never run engine indoors or in en

closed poorly vented area. Engine

exhaust gases contain carbon mon

oxide: an odorless and deadly gas.

7. Start engine, following appropriate instruc

tions:

A. Cold engine start (engine has not been run

recently).

1. Turn choke knob to “full” position. See

figure 21.

2. Push primer two (2) or three (3) times.

See figure 21.

10

Page 11

NOTE

Additional priming may be required

(for initial start only) if temperature

is below 15° F.

3. Grasp the starter rope handle and pull

out rapidly. Return rope handle slowly.

Repeat until engine starts. If engine

fails to start, repeat steps 2 and 3 as

necessary until engine starts.

4. After engine starts, turn choke gradual

ly to “OFF” position.

B. Warm engine start (engine still warm from

recent running).

1. Grasp the starter rope handle and pull

out rapidly. Return rope handle slowly.

Repeat until engine starts.

2. If engine fails to start after a number of

attempts, choke engine. Repeat step

one until engine starts. After engine

starts, turn choke knob off gradually.

Ac WARNING {

TO ENGAGE DRIVE

1. With the engine running near top speed, move

shift lever into one of the five forward posi

tions or two reverse positions. Select a speed

appropriate for the snow conditions that exist.

Use the slower speeds until you are familiar

with the operation of the snow thrower.

2. Squeeze the drive clutch grip (located on the

left handle) and the snow thrower will move.

Release it and the drive motion will stop.

NOTE

NEVER move shift lever without

first releasing the drive clutch.

ADJUSTMENTS

Ac WARNING ^

NEVER attempt to clean chute or

make any adjustments while engine

is running.

After the snow blower has been in

operation, caution should be exer

cised in the area of the muffler and

surrounding surfaces.

TO STOP ENGINE

NOTE

Run engine for a few minutes before

stopping to help dry off any mois

ture which may have accumulated

on the recoil starter.

1. Move throttle control lever to “STOP” posi

tion or pull out ignition key.

2. Remove ignition key to prevent accidental

starting.

A

Disconnect spark plug wire from

spark plug and secure it so that it

cannot accidentally contact spark

plug. Observing this precaution will

reduce the possibility of unauthor

ized starting of engine while equip

ment is unattended.

CAUTION

CHUTE ASSEMBLY ADJUSTMENT

The distance snow is thrown can be changed by

adjusting the angle of the chute assembly. The

sharper the angle, the shorter the distance snow

is thrown. See figure 22.

To adjust chute assembly, loosen the hand knob.

Pivot the top of the chute assembly to position

desired. Retighten the hand knob.

11

Page 12

SKID SHOE ADJUSTMENT

The space between the shave plate aid the

ground can be adjusted for close snow removal by

placing skid shoes in the low position. Use middle

or high position when area to be cleared is

uneven. See figure 23.

To adjust skid shoes, loosen the four hex nuts and

carriage bolts. Move skid shoes to desired posi

tion. Retighten nuts and bolts securely.

H gh

Middle

L )w

FIGURE 23.

THROTTLE CONTROL ADJUSTMENT

If adjustment becomes necessary, the tirottle

control wire assembly can be reset as follc ws:

1. Loosen, but do not remove, screw securing

throttle control wire assembly at engine. See

figure 24.

2. Move throttle control lever on handle panel to

“FAST” position.

3. Move control lever on engine to full ope i posi

tion. Retighten screw to secure throttle con

trol wire assembly.

CARBURETOR ADJUSTMENT

WARNING

Ai

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

Refer to the separate engine manual packed with

your unit for carburetor adjustment information.

DRIVE WHEELS (Model 800)

The wheels on the model 800 snow thrower may

be adjusted for three different methods of opera

tion. The adjustment is made by placing the klick

pins in one of two different holes on each side of

the unit. See figure 25.

1. Free Wheeling Operation—Place both klick

pins in the outside hole in the axle. This posi

tion allows easier movement when the engine

is not running.

2. Both Wheels Driving—Place both klick pins in

the hole in the hub next to the rim. This posi

tion is good for heavy snow as there is power

drive in both wheels.

3. One Wheel Driving —Place klick pin in the out

side axle hole on one side and in the hole in

the hub next to the rim on-the other. This posi

tion gives power drive to one wheel only, mak

ing the unit easier to maneuver.

FIGURE 24.

Hole in Hub

Next to Rim

Klick Pin

Outside Hole

in Axle

FIGURE 25.

12

Page 13

DRIVE WHEELS (Models 860 and 960)

Snow throwers model 860 and 960 are equipped

with a differential which makes the unit easy to

maneuver, it may be adjusted for two different

methods of operation. The adjustment is made by

placing the kiick pins in one of two different holes

on each side of the unit. See figure 25.

1. Differential Action —Place kiick pin in the out

side hole in the axle. This position allows easy

maneuvering when blowing light to medium

snow.

2. Straight Axle Action—Place kiick pin in the

hole in the hub next to the rim on the right

wheel. This position should be used when

blowing heavy snow or when greater traction

is needed (icy surfaces, etc.). The unit will be

more difficult to maneuver.

DRIVE AND AUGER CLUTCH ADJUSTMENTS

To adjust the drive or auger clutch, unhook the

spring from the drive or auger bracket. Refer to

steps 21 and 22 under Assembly Instructions for

proper adjustment.

SHIFT ROD ADJUSTMENT

To adjust the shift rod, place the shift lever in

neutral. Remove the cotter pin which secures the

shift rod to the shift lever. Adjust as specified in

step numbers 16 and 17 under Assembly Instruc

tions.

13

Page 14

LUBRICATION

SPECIFICATIONS:

Lubricate once a season or after every 25 h 3urs of

operation.

Oil—Use SAE 30 or equivalent.

Grease—Use automotive multi-purpose groase.

Lubricate chain once a season with enginii oil.

Grease Chute Opening Once

A Season

Engine—Remove oil fill plug and add oil until it is

to full mark on dipstick.

Change Oil—After first two (2) hours of operation

and every twenty-five (25) hours thereafter. Drain

oil from oil drain plug.

Use viscosity grade SAE 5W-30 or SAE 10W oil.

Capacity—Approximately 1V2 pints.

Differential (Models 860 and 960)

is sealed at the factory and does

not require checking. If dis

assembled for any reason, lubri

cate with 3/4 oz. of Plastilube #0.

Order part number 737-0166.

Gear case is lubricated with 4

oz. of Shell Alvania grease

EPROO (order part number

737-0168).

14

Page 15

MAINTENANCE

AUGERS

The augers are secured to the spiral shaft with two

hex boits and hex lock nuts (see Ref. Nos. 40 and

50 on page 24). if you hit a foreign object or ice

jam, the snow thrower is designed so that the hex

bolts will shear.

If the augers will not turn, check to see if the hex

bolts have sheared. Two replacement hex bolts

and hex lock nuts have been provided with the

snow thrower. For future use, order part number

710-0891 (hex bolt 5/16-18 x 1.75" long) and

712-0429 (hex insert lock nut 5/16-18 thread).

SHAVE PLATE AND SKID SHOES

The shave plate and skid shoes on the bottom of

the snow thrower are subject to wear. They should

be checked periodically and replaced when

necessary. Skid shoes and shave plate are revers

ible for longer life. The skid shoes may also be in

verted to extend their life even further.

To remove shave plate, remove the carriage boits,

lock washers and hex nuts which attach it to the

snow thrower housing. Reassemble new shave

plate, making sure heads of the carriage bolts are

to the inside of the housing. Tighten securely.

To remove skid shoes, remove the four carriage

bolts, believille washers, and hex nuts which at

tach them to the snow thrower. Reassemble new

skid shoes with the four carriage bolts, believille

washers (cupped side goes against skid shoes)

and hex nuts.

Remove the plastic belt cover on the front of

the engine by removing the three self-tapping

screws and flat washers. See figure 26.

FIGURE 26.

3. Remove the large shoulder bolt and spacer on

the right hand side of the engine puliey with

an adjustable wrench. Remove the shoulder

bolt and spacer from the idler bracket

assembly with one hand. Use the other hand

to catch the believille washer which is on the

shoulder bolt between the idler bracket and

engine plate. See figure 27.

;Belleville

Washer

BELT REMOVAL AND REPLACEMENT

Ac WARNING \

Remove the spark plug wire from

the spark plug and ground. Drain

gasoline from the fuel tank, or place

a piece of plastic film underneath

the gas cap to prevent gasoline from

leaking.

To remove and replace either the auger drive belt

or the drive belt, proceed with the following in

structions.

1. Remove the chute crank at the chute

assembly by removing the cotter pin and flat

washer.

Idler Bracket

Assembly

FIGURE 27.

4. Slip the auger drive belt (the front belt) off the

engine pulley. See figure 28.

Shoulder Bolt

Spacer

15

Page 16

Engine

Pulley

Auger

Drive

Belt

FIGURE 28.

5. Remove the top screws and lock washers

which attach the auger housing asserr bly to

the frame assembly. A 9/16" wrench is re

quired. See figure 29.

Lift Up

on Handles

(Auger Clutch

Grip Squeezed)

FIGURE 30.

7. To Remove Auger Drive Belt:

a. Remove the hex screw and belleville

washer from the center of the pulley on the

auger housing. Remove the pulley. See

figure 31. Be careful not to lose the key.

FIGURE 29.

6. To separate the auger housing from the frame

assembly, two people are required. On 3 per

son is in the operating position. Squeeze the

auger clutch grip (right hand) as you raise up

on the handles. See figure 30. The other per

son is in front of the unit. Push down cn the

housing or optional drift cutters. See figure

30. The unit will separate into two pieces.

\W

Auger Drive

Belt

Pulley

'--^Hex Screw / i

Belleville Washer y?

FIGURE 31.

b. Remove and replace auger drive belt.

c. Reassemble pulley to auger housing with

hex screw and belleville washer (cupped

side is toward the pulley). Be certain key is

in place on shaft.

8. To Remove Drive Belt:

a. Remove the cotter pin which holds the

linkage rod to the idler bracket assembly.

See figure 32.

b. Unhook extension spring from the engine

plate. See figure 32.

16

Page 17

Changing the Friction Wheel

1. Tip the snow thrower forward and let it rest on

the housing or optional drift cutters.

2. Remove the four self-tapping screws holding

the rear cover.

3. Slide out the rear cover.

4. Using two V2" wrenches, loosen and then

remove the three hex nuts and lock washers

holding the friction wheel to the friction wheel

adapter. See figure 33.

FIGURE 32.

c. Remove drive belt from the engine pulley

and bottom drive pulley.

d. Replace belt and reassemble in reverse

order.

9. Reassemble the two halves of the unit. Two

people are required.

NOTE

If the two halves do not reassemble

easily, the idler pulley and/or the

brake shoe may be behind the large

pulley.

10. Secure the two halves with the two screws

and lock washers.

11. Slip the auger drive belt over engine pulley.

12. Reassemble the large shoulder bolt, spacer

and belleville washer as shown in figure 27.

Belleville washer goes on shoulder bolt be

tween the idler bracket assembly and engine

plate (cupped side toward engine plate)

NOTE

Shoulder of the bolt must go

through both sides of idler bracket

assembly.

13. Reassemble belt cover and chute crank.

14. Remove plastic film from gas cap.

FIGURE 33.

5. Slide the friction wheel off the end of the hex

shaft. See figure 34.

NOTE

It may be necessary to strike the

friction wheel with a soft hammer to

knock it loose.

6. Assemble the new friction wheel so the

cupped side is towards the friction wheel

adapter.

7. Fasten the friction wheel to the friction wheel

adapter with the three lock washers and hex

nuts. Tighten each nut in rotation until they

are finger tight. Spin the wheel to see that it is

not cocked on the hub. Then tighten using

two V2" wrenches.

17

Page 18

A. Run engine until engine starts to falter,

then use choke to continue engine opera

tion until all fuel in tank and carburetor is

exhausted.

B. Remove fuel line at tank or carburetor and

drain any remaining gasoline from system.

FIGURE 34.

8. Replace the rear cover.

A

Check engine and snow thrower fre

quently for loose nuts, bolts, etc.

and keep these items tightened.

CAUTION

OFFSEASON STORAGE

Ac

WARNING

Drain fuel into approved container outdoors, away from open flame.

NOTE

Fuel left in engine during warm

weather deteriorates and will cause

serious starting problems.

2. Remove spark plug and pour one (1) ounce of

engine oil through spark plug hole into

cylinder. Crank engine several times to

distribute oil. Replace spark plug.

3. Remove all dirt from exterior of engine and

equipment.

4. Follow lubrication recommendations on page

14.

NOTE

When storing any type of power

equipment in an unventilated or

metal storage shed, care should be

taken to rust proof the equipment.

Using a light oil or silicone, coat the

equipment, especially any chains,

springs, bearings and cables.

t

Ac WARNING ^

Never store engine with fuel in tank indoors or in

poorly ventilated enclosures, where fuel fumes

may reach an open flame, spark or pilot light as on

a furnace, water heater, clothes dryer, etc.

If unit is to be stored over 30 days, prepare for

storage as follows:

1. Remove all gasoline from fuel tank to )revent

gum deposits from forming on these p£ rts and

causing possible malfunction of engir e.

18

Page 19

Trouble Shooting Chart

Problem

Engine fails to start

Hard starting or loss

of power

Engine overheats

Augers will not turn

Possible Cause(s)

1. Check fuel tank for gas.

2. Key not in switch on engine.

3. Spark plug lead wire dis

connected.

4. Faulty spark plug.

1. Spark plug wire loose.

2. Dirty air cleaner.

1. Carburetor not adjusted

properly.

2. Engine oil level low.

1. Bolts sheared in auger.

2. Misadjusted auger clutch

rod.

3. Foreign object jammed in

augers.

4. Auger belt broken.

Solution

1. Fill tank if empty.

2. Insert key.

3. Connect lead wire.

4. Spark should jump gap be

tween control electrode and

side electrode. If spark does

not jump, replace the spark

plug.

1. Connect and tighten spark

plug wire.

2. Service air cleaner as described

in engine manual.

1. Adjust carburetor. See engine

manual.

2. Fill crankcase with the proper

oil.

1. Replace shear bolts with bolts

provided in hardware pack.

NOTE: Do not use standard

bolts.

2. Readjust auger clutch rod. See

adjustment section.

3. Locate and remove foreign

object.

4. Replace auger belt.

Hard to shift or will

not shift

Wheels will not drive

Unit does not have

reverse

Shift rod misadjusted

1. Misadjusted drive clutch rod.

2. Klick pins not in proper place

(on units so equipped).

Sliding bracket hitting

neutral shoulder bolt.

Readjust shift rod. See adjust

ment section.

1. Readjust drive clutch rod. See

adjustment section.

2. Place klick pins in wheel hub.

Adjust nut under spring on L.H.

lockout rod.

19

Page 20

Models 800,

860 and 960

IF YOU WRITE TO US ABOUT THIS ARTICLE

OR IF YOU ORDER REPLACEMENT PARTS AL

WAYS MENTION THIS MODEL & SERIAL NO

MODEL

20

Page 21

Models 800,

860 and 960

REF.

NO.

10

11

12

13

14

15

16

17 831-0692

18

19

20

21

22

23

24 05987

25

PART

COLOR

CODE

NO.

1

2

3

05988

720-0180

738-0560

Clutch Grip Ass’y.—R.H.

Grip

Shoulder Bolt .374 Dia. x

1.53" Lg.

4

5

738-0561

741-0402

Shid. Nut 1/4-20 Thd.

Hex Flange Plastic Bearing

.38" I.D.

6

7

8

9

—

—

—

711-0677

Part of Ref. No. 17

Part of Ref. No. 17

Part of Ref. No. 17

Adjustment Ferrule

05694 Shi ft Handle As s’ y-

712-0267

736-0242

Hex Nut 5/16-18 Thd.*

Bell-Wash. .34" I.D. x .88"

O.D.

736-0105

Bell-Wash. .40" I.D. x .88"

O.D.

732-0193

712-0116

—

Compression Spring

Hex Ins. L-Nut 3/8-24 Thd.

Part of Ref. No. 17

Throttle Control Box Ass’y.

746-0500

784-5002

714-0104

749-0594

749-0342

731-0496

Throttle Control Wire

Handle Panel Ass’y.

Int. Cotter Pin 5/16" Dia.

Upper Handle—R.H. 45 720-0171

Lower Handle—R.H. 46 736-0140

Plastic Plug

Clutch Grip Ass’y.—L.H.

710-0487

Curved Carriage Bolt 5/16-18

X 2.0" Lg.

PARTS LIST FOR MODELS 800, 860 AND 960

DESCRIPTION

SNOW THROWERS

REF.

NEW

PART

NO.

26 749-0593

27

747-0461 Lockout Rod

28 749-0341

29 710-0600

30 736-0105

31 710-0555

32 05517

33 714-0507

34 736-0264

35 05522

36

05500 Drive Clutch Brkt. Ass’y.

37

710-0427

38 712-0324

39 732-0184

40 711-0374

41

05518 Auger Olutch Brkt.

42

732-0303

43 05981

44

726-0100

47

747-0416

48

735-0218

PART

NO.

COLOR

CODE

DESCRIPTION

Upper Handle—L.H.

Lower Handle—L.H.

Hex Wash. Hd. Self-Tap Scr.

5/16-24 X .50" Lg.

Bell-Wash. .40" I.D. x .88"

O.D.

Pilot Hex Scr. 3/8-16 x .88"

Lg-

Frame Cover

Cotter Pin 3/32" Dia.*

FI-Wash. .345 I.D. x .62 O.D.

X .06

Shifting Linkage Brkt.

Hex Bolt 3/8-16 X 2.0" Lg.*

Hex Ins. L-Nut V4-20 Thd.

Ext. Spring .75" O.D. x 5" Lg.

Shift Rod

Ext. Spring .38" O.D. x 3.18"

Lg-

Chute Crank Ass’y.

Push Nut 3/8" Rod

Knob 3/8" Rod

FI-Wash. .40" I.D. x .62" O.D.

Eyebolt 5/16-18 x 5.0" Lg.

Grommet

NEW

PART

*For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

(488—Mack Truck Yellow)

When ordering parts, if color or finish is important use the ap

propriate color code shown above, (e.g. Mack Truck Yellow

Finish—05487 (488).)

The engine is not under warranty by the snow thrower manufacturer. If repairs or service is needed

on the engine, please contact your nearest authorized engine service outlet. Check the “Yellow

Pages” of your telephone book under “Engines—Gasoline.”

This instruction manual covers various models

and all specifications shown do not necessari

ly apply to your model. Specifications subject

to change without notice or obligation.

21

NOTE

Find It Fast

In The

Yellow Pages

Page 22

Models 800,

IMPORTANT

860 and 960

Belts listed by Part Number are of special construction and

siould be used when replacement is necessary. The dimens ons and description given are for general reference only and

baits purchased by description and dimension generally will

o niy provide temporary service.

22

Page 23

Models 800,

860 and 960

PARTS LIST FOR MODELS 800, 860 AND 960

REF.

NO.

10

11 712-0375

12

13

14 05487 —452 Frame Ass’y.

15

16 710-0378

17 736-0217 L-Wash. 3/8" Scr. H.D.

18 710-0555

19 736-0119

20

21

22 736-0217

23

24 756-0344

25 736-0158

26

27

28 738-0129

29 756-0243

30

PART

1 710-0600

NO.

COLOR

CODE

DESCRIPTION

Hex Wash. Self-Tap Scr.

5/16-24 X .50" Lg.

731-0321 Belt Cover 32

2

714-0118

3

---

4

5

6

'

712-0267

736-0119

7 717-0522

Sq. Key V4" X 1.50" Lg.

Engine 34

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16" Scr.*

Engine Spacer Ass’y.

(Used w/Tech. Engine)

8 736-0105

Bell-Wash. .40 I.D. x .88

O.D. 37

9 738-0215

Shid. Scr. .498" Dia. x 3.00"

Lg. (800) 38 750-0227

711-0769 Stud 3/8-16 X 3.37" Lg. 39

(860 & 960)

732-0303 Ext. Spring .38 O.D. x 3.18"

Lg.

Hex Cent. L-Nut 3/8-16 Thd.

05491

710-0198

—452

Engine Brkt. Ass’y-'

Hex Sems Scr. 5/16-18 x

.75" Lg.*

736-0264

FI-Wash. .345 I.D. x .75 O.D.

X .060 46 710-0237

Hex Scr. 5/16-18 x 2.50" Lg.*

Pilot Scr. 3/8-16 X .88" Lg.

L-Wash. 5/16" Scr.*

712-0267 Hex Nut 5/16-18 Thd.*

712-0798

Hex Nut 3/8-16 Thd.*

L-Wash. 3/8" Scr. H.D.

738-0143 ShId. Scr. .498" Dia. x .340"

Lg.

V-Pulley .628 I.D. X 7.50 O.D. 52

L-Wash. for 5/8" Scr.*

712-0221 Hex Ins. Jam L-Nut 5/8-18

Thd.

05510

Brake Brkt. Ass’y.

Shid. Scr. .498" Dia. x 2.00"

Lg.

V-Pulley .875 I.D. x 10.12 O.D.

754-0194 “V”-Belt Vz" X 45.0" Lg.

SNOW THROWERS

REF.

NEW

NO.

PART

31 712-0116

756-0240

33 05531

712-0116

35

756-0240

756-0225

714-0104

36

738-0282

05493

40 747-0149

41

710-0191

42 736-0217

43 07386

44

756-0241

756-0429

45

754-0131

47

736-0242

48 05495

49

738-0281

50

736-0219

51 736-0264

737-0130

53

737-0132

54

736-0264

55 751-0360

56

710-0899

725-0954

PART

NO.

COLOR

CODE

DESCRIPTION

Hex Ins. Jam L-Nut 3/8-24

Thd.

Fl-ldler w/Flanges 3.0 O.D.

Brake Linkage Ass’y.

Hex Ins. Jam L-Nut 3/8-24

Thd.

3.0" O.D. Fl-ldler w/Flanges

(800)

Flat Idler Pulley (860 & 960)

Int. Cot. Pin 5/16" Dia.

Shid. Scr. .625 Dia. x 2.750"

Lg.

Spacer .75 O.D. x 1.00" Lg.

Blower Idler Brkt. Ass’y.

Auger Clutch Rod .31" Dia. x

10.62" Lg.

Hex Bolt 3/8-24 x 1.25" Lg.

L-Wash. 3/8" Scr. H.D.

FI-Wash.

Engine Pulley—Double

Groove (800)

Engine Pulley (860 & 960)

“V”-Belt 3/8 X 35.5 Lg.

Hex Scr. 5/16-24 X .62" Lg.*

Bell-Wash. .345 I.D. x .88

O.D. X .060

Drive Idler Brkt. Ass’y.

Shid. Scr.—.625" Dia. x .170"

Lg.

Bell-Wash. .40 I.D. x 1.12

O.D.

FI-Wash. .34 I.D. x .750 O.D.

X .05

Pipe Nipple—Vz" Pipe Thd.

X 3.00" Lg.

Hex Scr. 1/4-18 Pipe Thd.

FI-Wash. .340 I.D. x .62 O.D.

X .62

Throttle Control Wire Clamp

Hex Sems Scr. #10-32 x .62"

Lg.

Ignition Key (Not Shown)

NEW

PART

(488—Mack Truck Yellow)

*For faster service obtain standard nuts, boits and washers

iocally. if these items cannot be obtained locaily, order by

part number and size as shown on parts iist.

The engine is not under warranty by the snow thrower manufacturer. If repairs or service is needed

on the engine, piease contact your nearest authorized engine service outiet. Check the “Yeilow

Pages” of your teiephone book under “Engines—Gasoiine.”

When ordering parts, if coior or finish is important use the ap

propriate coior code shown above, (e.g. Mack Truck Yeliow

Finish—05487 (488).)

23

Find It Fast

In The

Yellow Pages

Page 24

Models 800,

860 and 960

Gearcase lubricant—4 oz. of

Shell Alvania grease, part number

737-0168.

AUGER HOUSING

24

Page 25

Models 800, 860 and 960

PARTS LIST FOR MODELS

REF. PART

NO. NO. CODE

1 09966

736-0242

2

COLOR

DESCRIPTION

Hand Knob Ass’yBell-Wash. .345 I.D. x .88 41 05136 Plastic Bushing

O.D. X .060

3 736-0231

FI. Wash. .312 I.D. x 1.125 Lg.*

O.D. X .125 46

4 712-0158

05225 —488

5

710-0260

6

7 736-0179

05951 —488

8

9 710-0276

712-0107 Hex Cent. L-Nut V2-20 Thd.

10

11 05783

12 714-0507

736-0234

13

Hex Cent. L-Nut 5/16-18 Thd. 47 05845 Bearing Hsg.—-Spiral Hsg.

Top Chute Ass’y-

Carr. Bolt 5/16-18 x .62" Lg.

FI-Wash. .53 I.D. x 1.25 O.D. 49 738-0490

X .100

Chute Ass’y. 50 710-0891 Hex Bolt 5/16-18 X 1.75" Lg.

Carr. Bolt 5/16-18 x 1.00" Lg.

Chute Flange Keeper Ass’y. 53 741-0182 Flange Brg. 1.503 I.D.

Cotter Pin 54 736-0266 FI-Wash. 1.50 I.D. x 2.00 C.D.

FI-Wash. .390" I.D. x 1.50"

O.D.

14 736-0140

FI-Wash. .385" I.D. X .62" 56 741-0184 Thrust Brg. .88 I.D. x 1.44

O.D. C.D. X .078

741-0403

15

16 05981

17 710-0371

736-0242

18

Hex Bushing

Chute Crank Ass’y. X .150

Hex L-Scr. 5/16-18 x .88" Lg. 58

Bell-Wash. .345 I.D. x .88

O.D. X .060 59 741-0217

19

756-0243

V-Pulley .875 I.D. x 10.12 60 717-0298 Complete Gear Hsg. Half—

O.D.

714-0126

20

712-0267

21

22 736-0119

05244

23

#9 Hi-Pro Key 3/16 X 3/4" Dia.

Hex Nut 5/16-18 Thd.* 61

L-Wash. 5/16" Scr.‘ 62

Bearing Hsg.—Self Aligning 63 721-0145

Brg.

24

741-0185

711-0640 Stud 3/8-16 X 2.75" Lg.

25

26 736-0105

Self Aligning Brg. .875 I.D. 65 716-0111 Snap Ring for .875" Dia.

Bell-Wash. .400 I.D. x .88 66 714-0135

O.D. X .060 Dia.

712-0267 Hex Nut 5/16-18 Thd.*

28

784-5010 Blower Hsg. Ass’y.

29

(800 & 860)

784-5011

Blower Hsg. Ass’y. (960) 05378

30 784-5038 Slide Shoe

31 736-0105

Bell-Wash. .400 I.D. x .88

O.D. x .060

32 712-0342

710-0790 Carr. Bolt 3/8-16 X .62" Lg.

33

34 738-0276

35 715-0118

05812 Blower Fan Ass’y.

36

Hex Jam Nut 3/8-16 Thd. 73 712-0429

Blower Axle 75 710-0528

Spring Pin Spiral 5/16" Dia. 76 710-0726

X 1.75" Lg. Scr. 5/16-18 X .75" Lg.

37 717-0297 Complete Gear Hsg. Half— X .150

L.H. (Incl. Bearing) 78 737-0175 Filler Plug

38 714-0135

#91 Woodruff Key V4" x 3/4" 79 784-5076

Dia.

39 05463

26" Spiral Ass’y.—L.H.

(800 & 860)

05464 26" Spiral Ass’y—R.H.

(800 & 8601

05461

33" Spiral Ass’y.—LH. (960)

05462 33" Spiral Ass’y.—R.H. (960)

}00, 860 A

NEW REF.

PART

NO.

40 712-0429 Hex Ins. L-Nut 5/16-18 Thd.

42

48 736-0250 FI-Wash. 1.06 I.D. x 1.75"

51 721-0146 CM Seal 1.50" I.D.

52

55 717-0300 Double Threaded Worm Gear

57

64

67 712-0267

68

69 05000

N

70

71

72 736-0271

74

77

ND 960 SNOW THROWERS

PART COLOR

NO.

CODE

710-0198 Hex Sems Scr. 5/16-18 x .75"

741-0244

Flange Brg. w/Flats 1.0" I.D.

C.D. X .100

Spiral Axle—26" (800 & 860)

738-0491 Spiral Axle—33" (960)

738-0275

Worm Gear Shaft

X .030

736-0291 FI-Wash. .88 I.D. x 1.40 C.D.

717-0299 Double Threaded Worm—

LH.

Sleeve Brg. .875 I.D.

R.H. (Incl. Ref. Nos. 51 &

53)

710-0376 Hex Scr. 5/16-18 x 1.00" Lg.

721-0144 Gasket

CM Seal .875" I.D.

714-0126

#9 Hi-Pro Key 3/16 x 3/4" Dia.

Shaft

#91 Woodruff Key 1/4 x W

Hex Nut 5/16-18 Thd.*t

736-0119

L-Wash. 5/16" Scr.*t

Shave Plate—26" (800 & 860)

Shave Plate—33" (960)

710-0260

Carr. Bolt 5/16-18 x .62" Lg.f

05139 Drift Cutterf

Wave Wash. 5/16" Scr.*

Hex Ins. L-Nut 5/16-18 Thd.

784-5075

Gear Hsg. Support Plate N

Hex Scr. 5/16-18 x 1.25" Lg.

Hex Wash. Hd. Self-Tap

736-0291 FI-Wash. .88 I.D. x 1.40 C.D.

Gear Hsg. Support Brkt.

DESCRIPTION

NEW

PART

N

tOptional Parts

25

Page 26

Model 800

GEAR CASE BREAKDOWN

93 ,90

26

Page 27

Model 800

PARTS LIST FOR MODEL 800 SNOW THROWER

COLOR

1EF.

NO.

1 05487 —452

2 736-0217

3 736-0163

4 741-0244 Flange Brg. 1.0" I.D.

5

6 05794

7

8 716-0102 Snap Ring for 1.00" Dia.

9 741-0301

10 710-0198 Hex Sems Scr. 5/16-18 x .75"

11

12

13 736-0119 L-Wash. 5/16" Scr.*

14 712-0267

15

16

17 714-0507

18

19

20 05522 Shifting Linkage Brkt.

21

22

23

24

25

27

28 734-1153 Wheel Ass’y. Comp. 16 x

29

30 738-0144 ShId. Scr.

32

33

34

37

38

39

40 732-0303

41

PART

NO.

CODE

DESCRIPTION

Frame Ass’yL-Wash. 3/8" Scr.*

FI-Wash. 1.03" I.D. x 1.62"

O.D. X .03

710-0258

Hex Bolt V4-20 X .62" Lg.*

Bearing Housing

712-0273

Hex L-Nut 5/16-24 Thd.

(2 Req’d.)

Shaft

Ball Brg. 25 mm x 52 mm x

15 mm

Lg-*

748-0281

05080

Friction Wheel Adapter

Friction Wheel Ass’y-

Hex Nut 5/16-18" Thd.*

05521 Sliding Linkage Brkt.

747-0151

Sliding Rod—.31" Dia. x

2.00" Lg.

Cot. Pin 3/32" Dia. x .75"

Lg-*

747-0152

Shifting Linkage Rod .31"

Dia. X 2.25" Lg.

738-0281

Shid. Scr. .625" Dia. x .170"

Lg-

732-0121

Extension Spring .73 O.D. x 68

4.31" Lg.

710-0538

736-0264

712-0375

741-0246

734-1121

Hex L-Scr. 5/16-18 x .62" Lg.*

FI-Wash. .345 I.D. x .75 O.D.

X .060

Hex Cent. L-Nut 3/8-16 Thd.

Bearing

Wheel Rim Ass’y.

4.5—L.H.

734-1152 Wheel Ass’y. Comp. 16 x

4.5—R.H. (Not Shown)

734-0808

734-0255

736-0105

738-0279

08253

741-0919

738-0281

Tire Only

Air Valve

Bell-Wash.

Drive Plate Spindle

Bearing Housing

Ball Brg. .787 I.D. x 1.85 O.D.

X .56

Shid. Scr. .625" Dia. x .170"

Lg05491

05518

—452 Engine Brkt. Ass’y.

Auger Clutch Brkt. 91

Extension Spring .38 O.D. x 93

3.18" Lg.

747-0149

Auger Clutch Rod .31" Dia. x

10.62" Lg.

NEW

PART

REF.

NO.

741-0133

42

05034 Bearing Housing

43

713-0320

45

PART

NO.

COLOR

CODE

DESCRIPTION

Ball Bearing

28 Tooth Sprocket—Hub

Ass’y.

710-0409 Hex Scr. 5/16-24 x 1.75" Lg.

46

(2 Req’d.)

738-0548 Axle—Free Wheeling

47

712-0287

48

736-0329

49

05523 Pivot Axle Brkt.

50

736-0264 FI-Wash. .345" I.D. x .75"

51

Hex Nut 1/4-20 Thd.*

L-Wash. 1/4" Scr.*

O.D. X .060

748-0184 Flange Brg.—.630" I.D.

55

750-0277 Spacer .51" I.D. x .69" O.D.

56

58

59

710-0629

750-0275

X .44

Hex Scr. 3/8-24 x 2.75" Lg.

Sprocket Hub Tubing 1.900"

Lg.

736-0242 Bell-Wash. .345" I.D. x .88

63

O.D. X .060

713-0270 #41 Chain—1/2" Pitch x 43

64

Links

713-0723 Master Link

738-0278

65

713-0199 #41 Chain 1/2" Pitch x 19

66

Sliding Support Axle

Links

713-0723

713-0193 9 and 14 Teeth Sprocket Hub

67

Master Link

Ass’y.

748-0204

05520 Chain Support Brkt.

69

712-0116 Hex L-Jam Nut 3/8-24 Thd.

70

714-0129 #9 Hi-Pro Key 3/32 x 5/8"

71

8 Teeth Sprocket

Dia.

713-0194 9 and 32 Teeth Sprocket Hub

72

Ass’y.

73 738-0280 Hex Shaft

713-0269 #420 Chain—1/2" Pitch x 37

74

Links

713-0154 Master Link

712-0896 Hex Ins. Jam L-Nut V4-28"

75

79

81

05497

714-0388

Drive Plate Mtg. Brkt. Ass’y.

#61 Hi-Pro Key 3/16 X 5/8"

Dia.

82

83

717-0302

747-0150

Aluminum Drive Plate

Drive Clutch Rod .31" Dia. x

7.38" Lg.

05500 Drive Clutch Brkt. Ass’y.

84

710-0253 Hex Scr. 3/8-16 X 1.00" Lg.

85

05502 Sliding Brkt. Ass’y.

86

710-0195 Hex Scr. 1/4-28 x .62" Lg.*

87

714-0151 Klick Pin

90

95

97

714-0104

716-0102

738-0347

736-0227

Internal Cot. Pin 5/16 Dia.

Snap Ring 1.0" Shaft

Shid. Spacer 5/8" I.D.

FI-Wash.

NEW

PART

27

Page 28

Models 860 and 9(30

.90

93 9i

‘NOTE:

If these parts are to be disassem

bled for any reason, it is necessary

to heat them after driving the spiral

pin out in order to separate as they

are treated with loc-tite.

HANDLE AND CONTROLS

28

Page 29

Models 860 and 960

PARTS LIST FOR MODEL 860 AND 960

SNOW 1

PART

lEF.

MO.

1

2

3

4

5

6

8

9

736-0217

710-0258

741-0244

715-0136

05794

716-0102

741-0301

COLOR

NO.

CODE

05487 —452

DESCRIPTION

Frame Ass’y. 46

L-Wash. 3/8" I.D.

Hex Bolt V4-20 X .62" Lg.* 47

Flange Brg. w/Flats 1.00" I.D. 48

H-Spring Pin Spiral 3/16" Dia.

X 1.25" Lg. 50

Bearing Housing 51

Snap Ring —1.00" Dia. 52

Ball Brg. 25 mm x 52 mm x

15 mm Thk. 54 710-0559

10

710-0198

Hex Sems Scr. 5/16-18 x .75"

Lg.*

11 748-0281

05080

12

13 736-0119

712-0267 Hex Nut 5/16-18" Thd.* 63

14

05521

15

16 747-0151

Friction Wheel Adapter 58 710-0629

Friction Wheel Ass’y. 59 750-0275

L-Wash. 5/16" Scr.*

Sliding Linkage Brkt. 64 713-0270

Sliding Rod —.31" Dia. x Links

2.00" Lg. 713-0723

17 714-0507

747-0152

18

Cot. Pin 3/32" Dia. x .75" Lg.*

Shifting Linkage Rod .31"

Dia. X 2.25" Lg. Links

19 738-0281

05522

20

732-0121

21

Shid. Scr. .625" Dia. x .170"

Shifting Linkage Brkt.

Extension Spring .73 O.D. x

4.31" Lg. 68

22 710-0538

736-0264

23

24 712-0375

05819

25

Hex L-Scr. 5/16-18 x .62" Lg.*

FI-Wash. .345 I.D. x .75 O.D.

Hex Cent. L-Nut 3/8-16 Thd. 71

Differential Shaft Ass’y.—

L.H. (860)

05820

Differential Shaft Ass’y.—

L.H. (960) (Incl. Ref. Nos. 5,

47 & Brg.)

26 712-0798

734-0824 Wheel Rim Ass’y. (860) 75 712-0896 Hex Ins. Jam L-Nut V4-28"

27

734-0825

28

Hex Nut 3/8-16 Thd. (860) 713-0154 Master Link

Wheel Ass’y. Comp. 16.0 x

4.80-8 (860) 79 05497

734-0808

29 712-0193

09262

30

734-0748

31

Tire Only (860)

Cone Nut 3/8-24 Thd. (960)

Wheel Rim Ass’y. (960)

Wheel Ass’y. Comp. 16.0 x

6.50 (960) 84 05500 Drive Clutch Brkt. Ass’y.

734-0275

Tire Only 16 X 6.50-8 (960)

32 738-0279 Drive Plate Spindle

08253

33

34

741-0919

734-0255

35

05034 Bearing Housing

36

37

741-0133

05491 —452 Engine Brkt. Ass’y.

38

05518

39

40 732-0303

Bearing Housing

Ball Brg. .787 I.D. x 1.85 O.D.

Air Valve

Ball Bearing

Auger Clutch Brkt.

Extension Spring .38 O.D. x

3.18" Lg.

41 747-0149

Auger Clutch Rod .31" Dia. x

10.62" Lg. 94 736-0187

748-0222 Differential Housing

42

748-0224 20 Tooth Spur Gear

43

44 748-0223

45 713-0198

9 Tooth Spur Gear

28 Teeth Sprocket

rHROWEF ts

NEW

REF.

PART

NO.

49 736-0329

53

55

56

65 738-0278

66 713-0199

67 713-0193

69

70 712-0116

72 713-0194 9 and 32 Teeth Sprocket Hub

73 738-0280 Hex Shaft

74 713-0269

78 712-0138 Hex Nut 1/4-28 Thd.

81 714-0388

82 717-0302

83 747-0150 Drive Clutch Rod .31" Dia. x

85

86

87

88

89

90 714-0143 Klick Pin 1/4" Dia. x 1.75" Lg.

91

92

93 716-0115

95

96 736-0169 L-Wash. 3/8" I.D.* (860 Only)

97

PART

NO.

COLOR

CODE

DESCRIPTION

05484 Differential Hsg. Support

Plate

738-0284

Differential Connecting Shaft

712-0287 Hex Nut 1/4-20 Thd.*

L-Wash. 1/4" Scr.*

05523

Pivot Axle Brkt.

736-0264 FI-Wash. .345" I.D. x .75" O.D.

738-0144 ShId. Scr.

736-0105

Bell-Wash.

Hex Scr. 1/4-28 x 1.75" Lg.*

748-0184 Flange Brg.—.630" I.D.

750-0277

Spacer .51" I.D. x .69" O.D.

Hex Scr. 3/8-24 x 2.75" Lg.

Sprocket Hub Tubing 1.900"

Lg.

736-0242 Bell-Wash. .345" I.D. x .88 O.D.

#41 Chain—1/2" Pitch x 43

Master Link

Sliding Support Axle

#41 Chain 1/2" Pitch x 19

713-0723

Master Link

9 and 14 Teeth Sprocket Hub

Ass’y.

748-0204 8 Teeth Sprocket

05520 Chain Support Brkt.

Hex L-Jam Nut 3/8-24 Thd.

714-0129

#9 Hi-Pro Key 3/32 x 5/8" Dia.

Ass’y.

#420 Chain —1/2" Pitch x 37

Links

Drive Plate Mtg. Brkt. Ass’y.

#61 Hi-Pro Key 3/16 X 5/8" Dia.

Aluminum Drive Plate

7.38" Lg.

710-0253

05502

710-0195

741-0305

Hex Scr. 3/8-16 X 1.00" Lg.

Sliding Brkt. Ass’y.

Hex Scr. 1/4-28 x .62" Lg.*

Sleeve Brg.

05534 Differential Tubing Ass’y.—

R.H. (860)

05637

Differential Tubing Ass’y.—

R.H.(960)

714-0104

738-0304

Internal Cot. Pin 5/16 Dia.

Differential Pin

Snap Ring .625 Shaft

FI-Wash. .62 I.D. x 1.25 O.D.

738-0347

Shid. Spacer 5/8" I.D.

07386 FI-Wash.

NEW

PART

29

Page 30

Page 31

Page 32

PARTÍ) INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service are available through the authorized .'.ervice

firms listed below. All orders should specify the model number of

your unit, part numbers, description of parts and the quar tity of

each part required.

NOTE: If any parts are found to be missing or defective upon assembly of this unit, write to advise the factory so

that immediate replacement can be made.

ALABAMA

Auto Electric & Carburetor Co.

ARKANSAS

CALIFORNIA

COLORADO

Spitzer industrial Products Co. .

FLORIDA

GEORGIA

East Poin

ILLINOIS

INDIANA

Parts & Sales Inc.

IOWA

Power Lawn & Ga

LOUISIANA

Suhren Engine C(

MARYLAND

MASSACHUSETTS

Morton B. Collins Co.

MICHIGAN

MINNESOTA

Hance Distributing Inc.

MISSISSIPPI

Biloxi Sales & Service, I

MISSOURI

NEW JERSEY

Lawnmower Parts ln(

NEW MEXICO

Spitzer Eng. & Parts

NEW YORK

Gamble Dist., Inc. . .

BIRMINGHAM

. . 2625 4th Ave.S...................

, 35233

NORTH LITTLE ROCK

. . 5301 Roundtop Drive

Box 368, Rt.4

....................

,72117

PORTERVILLE

. . 75 North D Street . . . .

93257

DENVER

. . 6601 N.

Washington St

..................

80229

JACKSONVILLE

. . 4909 Victor St.

Box 5459

..........................

32207

OPA LOCKA

. . 2351 N.W. 147th St. . .

EAST POINT

. . 2834 Church St

..................

33054

30344

LYONS

. . 8615 Ogden Ave

ELKHART

. . 2101 Industrial Pkwy..

................

60534

46516

DUBUQUE

. . 2551 J.F. Kennedy . . .

,52001

NEW ORLEANS

. . . 8330 Earhart Blvd. . .

ТАКОМА PARK

. . . 6867 New Hampshire

Ave...................................

.70118

.20912

SPRINGFIELD

. . . 300 Birnie Ave

.................

.01107

LANSING

. .. 2500 S. Pennsylvania .48910

MOUNT CLEMENS

. . . 340 Hubbard

....................

.48043

HOPKINS

. . . 420 Excelsior Ave. W.

.55343

BILOXI

. . . 506CaillavetSt.................. .39533

KANSAS CITY

. . . 3117 Holmes St

...............

.64109

ST. JOSEPH

. . . 8th and Monterey . ..

.64503

ST. LOUIS

. .. 2015 Lemay Ferry Rd. .63125

BELLMAWR

. . . 717 Creek Rd

...................

.08030

ALBUQUERQUE

. . . 1023 Third Ave. N.W. .87103

CARTHAGE

. . . West End Ave

....................

.13619

SCHOHARIE

. .. Rt. 30P.O. Box 527..

.12157

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS

AND SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service

should be handled by your nearest authorized engine service firm.

Check the yellow pages of your telephone directory under the

listing Engines—Gasoline, Briggs & Stratton or Tecumseh

Lauson.

NORTH CAROLINA

Smith Hardware Co..............................

GOLDSBORO

. 515 N. George St

GREENSBORO

Dixie Sales Company

..........................

. 335 N. Green......................

OHIO CARROLL

Stebe’s Mid-State MowerSupply . Box 366, 71 High St.. .

CLEVELAND

Bleckrie, Inc.......................................... . 7900 Lorain Ave

WADSWORTH

National Central

...................................

. 687 Seville Rd....................

YOUNGSTOWN

Burton Supply Co

................................

. 1301 Logan Ave.

Box 929

OKLAHOMA MUSKOGEE

Victory Motors, Inc...............................

. 605 S. Cherokee

OREGON PORTLAND

Kenton Supply Co................................

. 8216 N. Denver Ave. . . 97217

PENNSYLVANIA HARRISBURG

EECOInc................................................ . 4021 N.6thSt

PHILADELPHIA

Thompson Rubber Co

.........................

. . 5222-24 N. Fifth St....

PITTSBURGH

Bluemont Co

........................................

. . 11125 Frankstown Rd.

PUNXSUTAWNEY

Frank Roberts & Sons ........................

. R.D.2...................................

SCRANTON

Scranton Auto Ignition Co

..................

. . 1133-35 Wyoming Ave. 18509

TENNESSEE KNOXVILLE

Master Repair Service

........................

. 2000 Western Ave. . . . 37921

MEMPHIS

American Sales & Service, Inc. . . 3035-43 Bellbrook . . . 38116

TEXAS

Marr Brothers, Inc................................

DALLAS

.. 423 E. Jefferson

FORT WORTH

Woodson Sales Corp........................... . 1702 N. Sylvania

HOUSTON

Bullard Supply Co

...............................

. . 2409 Commerce St. . . 77003

SAN ANTONIO

Engine House Inc.................................

UTAH

A-1 Engine & MowerCo

.......................

VIRGINIA

RBI Corp

........................ ......................

WASHINGTON

Bailey’s Inc

...........................................

WISCONSIN

Automotive Supply Co

........................

. . 8610 Botts Lane

P.O. Box 17867

SALT LAKE CITY

. . 439 E. 900 So.....................

ASHLAND

.. 101 Cedar Ridge Dr. . .

SEATTLE

. . 1414 14th Ave

APPLETON

.. 123 S. Linwood Ave.

P.O. Box 798 .................... .54911

CHILTON

Horst Dist..............................................

. . 444 N. Madison

...............

................

............................

................

......................

.................

...............

................

....................

..................

27530

27402

43112

44102

44281

44501

74401

17110

19120

15235

15767

75203

76111

78217

.84111

.23005

.98122

.53014

WARRANT

The purpose of warranty is to protect the customer fro

time of manufacture. It does not provide for the unlimi

sibility of the customer. The manufacturer cannot assi

the manufacturer’s fault, it’s the manufacturer’s respor

CLAIMS AGAINSTTHE MANUFACTURER’S WARRANT'

INCLUDES:

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warrantyperiod.

3. Repair of Defects within the warranty period.

MTD PRODUCTS INC P. Э. BOX 36900

Y PARTS AND SERVICE POLICY (0783)

n defects in workmanship and materials, defects which are NOT detected at the

ed and unrestricted replacement of parts. Use and maintenance are the responime responsibility for conditions over which it has no control. Simply put, if it’s

sibility; if it’s the customer's fault, it’s the customers's responsibility.

All claims MUST be substantiated with the following

information:

1. Model Number of unit involved.

2. Date unit was purchased or first put into service.

3. Date of failure.

4. Nature of failure.

CLEVELAND, OHIO 44136

Loading...

Loading...