Page 1

Model No.

S N OW T H R O WE R

й[й1йай?^ aiFET'ií ISil

For one year from date of purchase, MTD Products Inc.,

will replace for the original purchaser, free of charge. F.O.B.

factory or authorized service firm, any part or parts found to

be defective in material or workmanship. All transportation

charges on parts submitted for replacement under this war

ranty must be paid by the purchaser. This warranty does not

include replacement of parts which become inoperative

through misuse, excessive use, accident, neglect, improper

maintenance or alterations by unauthorized persons. This

warranty does not include the engine, motor, battery, bat

tery charger or any component parts thereof. For service on

these units refer to the applicable manufacturer's warranty.

The above warranty will apply only to the original owner

and will be effective only if the wuranty card has been pro

perly processed. It will not apply where the unit has been

used commercially.

Warranty service is available through your local author

ized service dealer or distributor, UNDER NO CIRCUM

STANCES WILL THE RETURN OF A COMPLETE UNIT

BE ACCEPTED BY THE FACTORY UNLESS PRIOR

WRITTEN PERMISSION HAS BEEN EXTENDED.

314-830A

1. Know the controls and how to stop quickly—READ

THE OWNER'S MANUAL.

2. Disengage power and stop motor before cleaning dis

charge. removing obstacles, making adjustments, or

when leaving operation position.

3. Never direct discharge at bystanders гюг allow anyone

in front of machine—debris may be hidden in the snow.

4. Keep children and pets a safe distvice away.

5. Do not allow children to operate machine nor allow

adults to operate it without proper instruction.

6. Adjust height to clear ^avel or crushed rock surface.

7. 'Exercise caution to avoid slipping or falling, especi

when operating in reverse.

8. Handle gasoline with care — it is highly flammable.

A. Use approved gasoline container.

B. Never add gasoline to a running motor — fill tank

exit of doors and wipe up spilled gasoline.

C. Replace gasoline cap securely.

D. Open door if motor is run in garage — exhaust

gases are dangerous.

9. Disengage all clutches and shift into neutral before

starting motor. Keep hands, feet and clothing away

from power driven parts.

10. Use a grounded three wire extension cord for all plug

in electric units.

11. Keep machine in good operating condition and kaep

safety devices in place.

V:

MTD PRODU

PRINTED IN U.S.A.

CTS INC

• 5389 WEST 130th STREET • P. 0. BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-5524

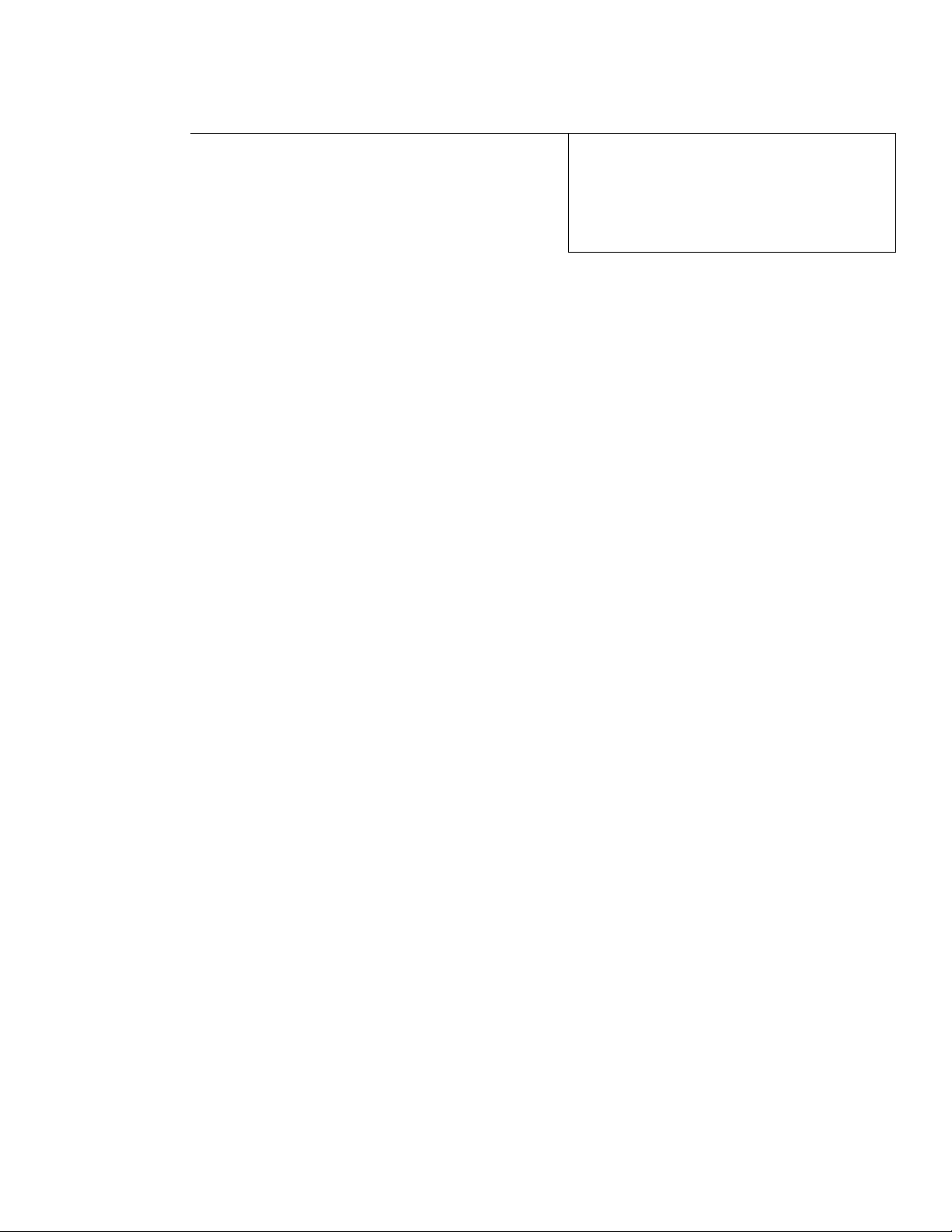

Page 2

ASSEMBLY INSTRUCTIONS

Right hand (R.H.) and left hand (L.H.) are as observed

from the operating position.

1. Assemble chrome handles {Ref. Ncs. 8 and 24) to

the frame with four hex head cap screws %-16 x %

long and four lock washers DO NOT TIGHTEN.

2. Assemble handle panel (Ref. No. 29) to the handles

with the four carriage bolts ’/i-20x 1V4 Ig. and hex

locknuts %-20 thd. Assemble handle panel so you

can read the instructions on the handle panel from

the operating position. LIFT HANDLE UP AS YOU

TIGHTEN ALL BOLTS AND NUTS ON THE HANDLE

ASSEMBLY.

3. Move the shift lever (Ref. No. 17) on the handle

panel all the way forward into No. 5 position: Use

hole marked "26". Assemble the ferrule to the end

hole in the shift lever from the R.H. side. Screw in

the shifting rod (Ref. No. 32) into the ferrule. Move

the shift lever into the reverse (R) position. Lift the

transmission arm on the rear of the frame all the

way up. Adjust the shift rod by screwing it on or

out until the lower end fits into the transmission

arm. Secure with a cotter pin (Ref. No. 141).

4. CLUTCH GRIP. Place the threaded end of the lock*

out rod (Ref. No. 31) inside the spring. (Opposite

end of the hook.) Screw on the elastic stop not *A-2D

thread approximately to 1 inch. Hook the bent

end of the rod into the eye of the clutch grip from

the right hand side. With the clutch in the released

position, hook the spring into the hole in the link

age arm. The spring and rod should be just tight

enough so the rod is not too loose. Adjust the elastic

stop nut if necessary.

5. Chute Crank. Assemble the chute crank (Ref. No.

33) into the two holes in the handle panel being

sure the rod passes through the lock bracket (Ref.

No. 23). It may be necessary to loosen the black

knob (Ref. No. 18) on the handle panel. Posh the

rod all the way through and assemble it to the uni

versal joint with a cotter pin (Ref. No. 71).

6. Remove the wing nut, washer and carriage bolt

5/16-18 x% Ig. from the chute assembly. Lift the

deflector and reassemble. If the deflector does not

pivot easily loosen the bolt and nut so it pivots free

ly. CAUTION: Release main clutch lever but do not

pry down on lever. Excessive leverage will damage

idler bracket and cause misalignment of idler pul

ley. Belt problems will result.

3« '

Page 3

*?>

FIGURE 1.

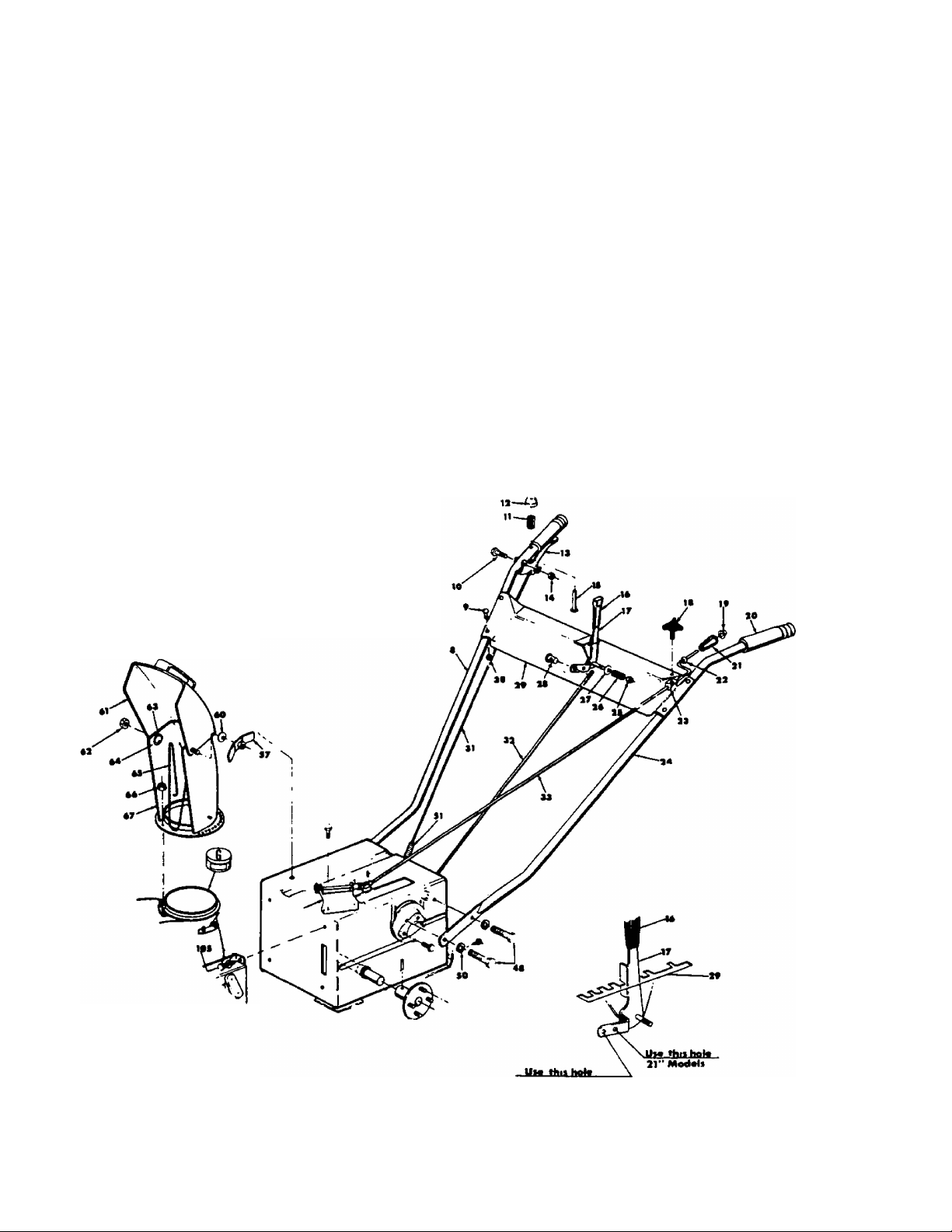

CONTROLS

Auger Clutch is located on the Left Hand side of the

frame just behind the thrower housing, (Shown in the

disengaged position.) When the handle is up, the aug

er is disengaged. WARNING: Engaging auger clutch

with main clutch already engaged will damage pins

on sprocket hob assembly. Damaged pins cause hard

engagement and clutch malfunction. Do not engage or

disengage the auger clutch without first disengaging

the main clutch. Disengaging the auger clutch allows

you to drive the snow thrower to and from the work

area without the auger turning. (See figure 2.)

Shift Lever. The shift lever determines the direction

and speed forward of the drive wheels. Always re

lease the grip clutch when shifting gears. (See figure 3.)

Chute Controls. Release the lock and turn the crank

to rotate the chute. Loosen the wing nut to adjust the

deflector. (See figure 3.)

FIGURE 3.

SKID SHOES

The skid shoes on each side of the thrower are adjust

able by loosening the bolts and nuts.

FIGURE 2.

Main Clutch, This clutch shuts off the power to the

wheels and auger. When the handle is up it is in the

disengaged position. Always shot off the main clutch

when engaging and disengaging the auger dutch.

(Shown in the disengaged position.) (See figure 1.)

Grip Clutch. The grip clutch engages and disengages

the drive wheels. To engage the clutch, squeeze the

handle and depress the button to lock it. Squeezing

the handle again will release it. (Shown in the disen

gaged position.) (See figure 3.)

low Position—Close snow removal.

Middle or High Position—Use when road is uneven.

The skid shoes and shave plate should be replaced

when worn.

The skid shoes may be tipped for better operation.

Bolt and Nut

/

FIGURE 4.

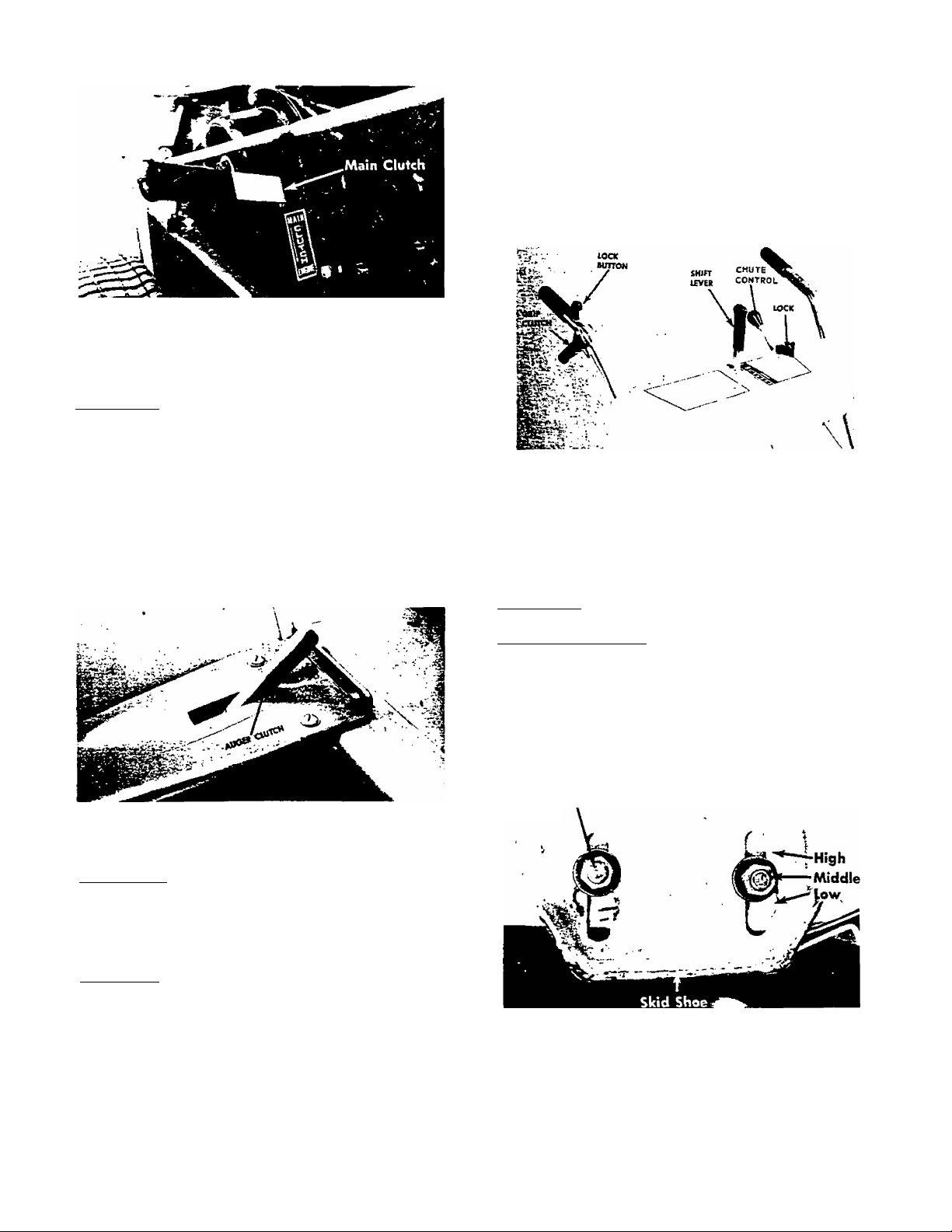

Page 4

Tip front of skid shoe

down when operat

ing in hard packed

snow.

3. Move the shift lever info number one position. (Use

the stow speeds until you are familiar with the op

eration of your snow thrower.)

4. Squeeze the grip clutch and the snow thrower will

move. Release it and it will stop. Jf

5. Never move the shift lever without releasing the »

grip clutch. The higher the forward position number c

the faster the snow thrower will move over the

ground.

6. NEVER attempt to clean the chute or make any ad

justments while the engine is running.

{ NOTE^

For traction, chains are recommended.

See page 5.

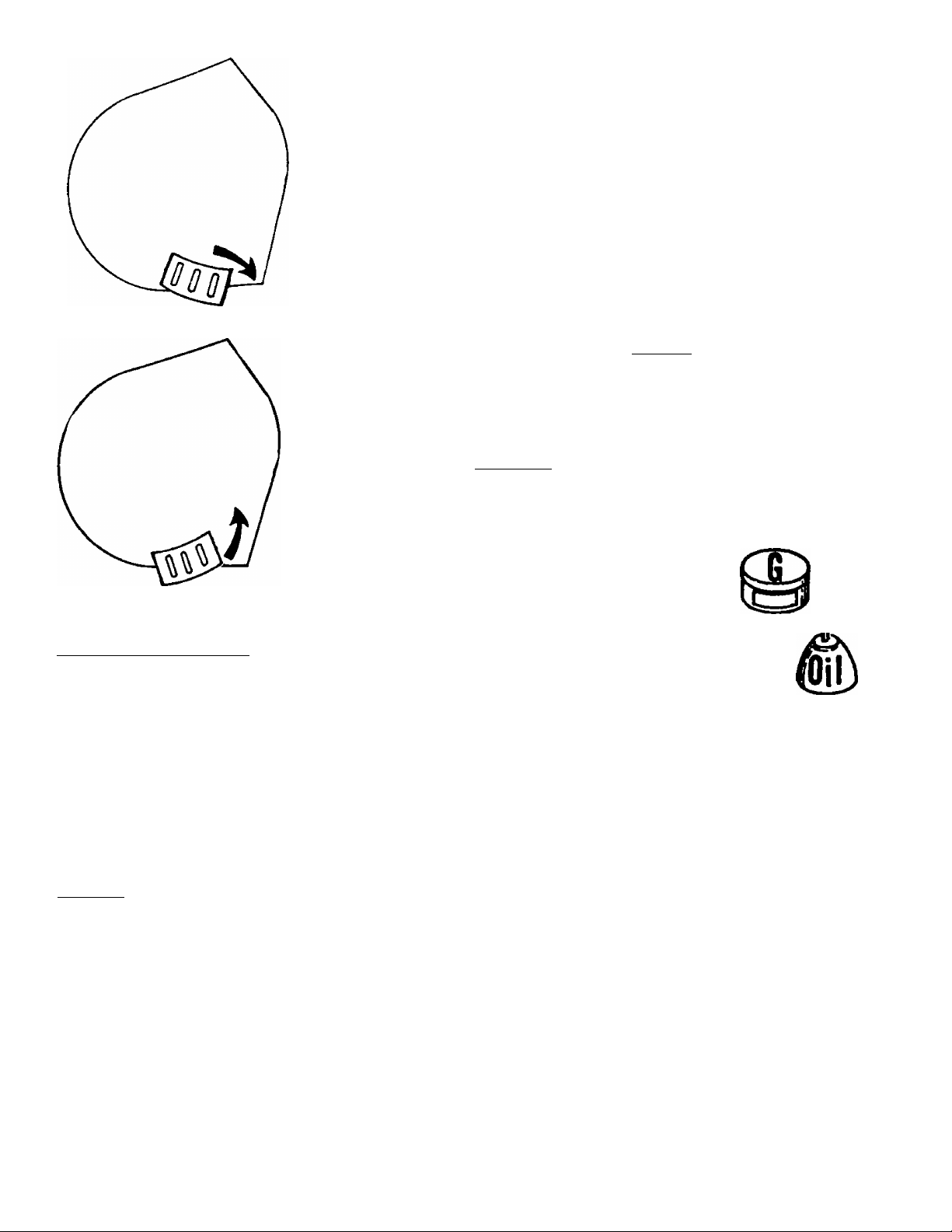

LUBRICATION

Tip front of skid shoe

up when operating in

loose stone or soft

areas.

STARTING YOUR SNOW THROWER

1. Follow your engine instructions for lubrication and

gasoline.

2. Disengage the main clutch (Lever UP).

3. Release the grip clutch and put the shift lever in

neutral position (N).

4. Start the engine in accordance with the engine

manual.

OPERATION

1. With the main dutch disengaged and with the en

gine running at near top speedy engage the auger

dutch. (See figure 2.)

2. SLOWLY engage the main dutch.

Refer to pages 11 and 12. Lubricate after each 25 hours

of operation, the parts indicated. Use multipurpose

automotive grease on parts marked

SAE 30 engine oil on parts marked

NOTE

If repairs or service is needed on the engine

or engine controls such as

the primer, choke or throt

tle control, contact your

nearest authorized engine

service outlet. Check the

'"Yellow Pages" of your

telephone book under "En-

g i nes—Gasol ine".

Fled II F«*l

ImTIw

'Yoitow Pag«*'

and

i-

Page 5

REMOVING THB ORIVE UNIT CONTAINING THE FRICTION DRIVE WHEEL

The dutch bracket must pivot freely and the dutch

linkage must be loose.

1. Remove the frame cover.

2. Remove cotter pins from linkage arm, shifting yoke

rod and shifting rod.

3. Remove the two screws from the pivot bracket as

sembly and lift the bracket up,

4. Remove the three screws holding the dutch

shaft and chain bracket out.

5. Turn and lift out the entire unit from the frame. It

may be necessary to loosen the nut on the dutch

linkage.

6. The unit can now be disassembled on a work

bench.

7. Remove five 3/7" nuts and one elastic stopnut.

8. Remove clutch fork bracket assembly and the

bevel gear housing assembly.

9. Remove three ’4" nuts on the drive wheel shaft

on the bevel pinion.

10. Pull out the clutch shaft.

11. Knock out the drive wheel shaft with a drive pin

from the opposite end of the pinion.

12. Lift out the friction wheel and fork assembly as a

unit.

13. Loosen the three 5/16" screws holding the friction

drive wheel to the friction wheel adapter.

14. Reassemble with new wheel.

NOTE

When reassembling the drive unit the

input chain pinion (Ref. No. 2,16) should

turn freely. If it turns too tightly, loosen

the bearing cap and move the bevel

gear away from the pinion slightly.

NOTE

For more traction, chains are recom

mended.

r

Tire Sizes

13.0x5.00

Chains

394-990A

PNEUMATIC TIRE PRESSURE

The tires are over inflated for

shipping purpose. Tire pressure

should be 7 to 10 psi.

NOTE: If the tire pressure is not

equal in both tires the unit may

pull to one side or the other.

C

Page 6

314-830A

>

V 22

Г.

Page 7

PARTS LIST FOR MODEL 314-830A

REF.

NO.

10

11 736-0169

13 5045

14

15 732-0249 Compression Spring

16 5107

17 713-0127 Chain w/Master Link ^41 x

18 723-0168

19

20

21 736-0264

22 710-0538

23

24

25

26

27

28

29

30

31

32

33

34

35

36

PART

NO.

1

2 712-0158

3

4

5

6 736-0179

7 736-0105

8 9966

9

37

5225

710-0260

712-0107

5223-456

5031

710-0216

5106 Eccenter

5152-456 Chain Guard Brkt. 56

748-0142

712-0107

736-0175

712-0798

736-0169

736-0300

736-0119

712-0267

5451

713-0176

738-0226

715-0118

741-0170

736-0300

710-0347

716-0121

COLOR

CODE

-456

-456

DESCRIPTION

Top Chute Ass'y.

Hex Cent. L-Nut 5/16-18 Thd.

Carriage Bolt 5/16-18x.62"

Lg*

Hex Cent. L-Nut 14-20 Thd. 42 5429-456

Chute Ass'y.

FI-Wash.

Beil-Wash.

Handle Knob Ass'y.

Chute Flange Keeper Ass'y. 46 5000-456 Shave Plate

Hex Scr. %-16x.75" Lg.*

L-Wash. %" Scr.* 1.75" Lg.*

Frame Plate Ass'y.—L.H. 49 5360

Shifting Yoke Ass'y.

40" Lg, 54

Sprocket Idler—10 Tooth

Flange Bearing .500 Dia,

FI-Wash. .33 I.D. X.750 O.D. 58

Hex Scr. w/Lock 5/16-18 x 59

.62" Lg.*

Cent, L-Nut 14-20 Thd.

Wave Wash. 14" Scr.

Hex Nut %-16 Thd.*

L-Wash %" Scr.*

FI-Wash. .39 I.D. x ,78 O.D.

L-Wash. 5/16" Scr.*

Hex Nut 5/16-18 Thd.*

Chain Guard

60 Tooth Sprocket Hub Ass'y.

Spiral Axle

Spirol Pin 5/16 Dia. x 1.75"

Lg.*

Flange Brg.

Fi-Wash. .39 I.D. x % O.D.

Hex Scr. %-16x 1.75" Lg.*

Snap Ring 1.50" Dia.

NEW

PART

N

PART

REF.

NO.

38

39 736-0119

712-0267 Hex Not 5/ 16-18 Thd.*

40

41 5038-456

43

44 5136-456

45 710-0260

47 715-0118

712-0798

50

736-0105

51

52

736-0198

53

710-0389

55

57

715-0118

712-0267 Hex Nut 5/16-18 Thd.*

60

736-0119

61

62

736-0123

63

710-0538

64

712-0287

65

736-0329

66

710-0260

67

736-0119

68

712-0267

69

70

736-0329

71

710-0289

72

73

COLOR

NO.

CODE

5240

L-Wash. 5/16" Scr.*

Thrower Paddle Ass'y.

5115-456 Spacer

Bushing

Carriage Bolt 5/16-18 x.62"

Spring Pin Spiro! 5/16 Dia. x

Bearing Housing Ass'y.

Hex Nut %-16 Thd.*

Belt Wash.

5002-456 Slide Shoe

5136 Bushing

5018-456

5136

5017-456

5136

5139-456

5239-456

FI-Wash. .75 I.D. x 1.25 O.D.

Carriage Bolt %-16 x .75" Lg.*

Spiral Ass'y.—L.H.

Bushing

Spiral Ass'y.—R.H.

Spring Pin Spiral 5/16 Dia. x

L-Wash. 5/16" Scr.*

Bushing

Hex Scr. w/Lock 5/16-18 X

Hex Nut 1/4-20 Thd.*

Carriage Bolt 5/16-18 x.62"

Lg.*

L-Wash 5/16" Scr.*

Hex Nut 5/16-18 Thd.*

Guide Blade

L-Wash. W" Scr.*

Hex Scr. 14-20 X.50" Lg.*

Auger Clutch Cover

DESCRIPTION

Yoke Brkt. Ass'y.

Spiral Hsg. Ass'y.

Lg-

1.75" Lg.

FI-Wash. ,341 I.D.

.62" Lg.

L-Wash. Vi" Scr,*

NEW

PART

N

c

Page 8

314-830A

>

Page 9

PARTS LIST FOR MODEL 314-830A

REF.

NO.

PART

NO.

1

726-0121

732-0145

2

3

4

5

6

7

8

9

10

5132

712-0107

711-0370

720-0142

5131

720-0170

726-0100

1166

11 720-0171

736-0117

12

COLOR

CODE

DESCRIPTION

NEW

PART

Push Cap Va“ Dia.—Black

Compression Spring

Clutch—Grip 39

Hex Cent. L-Nut li-20 Thd.

Clutch Grip Lock Pin

Fl-Bar Grip-Black 42

Shift—Grip

Hand Knob

Push Cap Dia.

Grip-Black 45

Knob

Fl-Wash. 47

13 5121 Chute Crank Lock 48

712-0116

U

732-0193 Compression Spring

15

736-0105

16

711-0179

17

18

19

20

21

22

23

24

25

26

.27

28

29

30

31

32

33

34

5127-456

712-0107 Hex Cent. L-Nut Vi-20 Thd.

747-0113 Lockout Rod

732-0269 Spring

711-0373

5120

712-0116

-456

5228

5061

720-0142 Fi-Bar Grip—Black

732-0185 Tension Spring

5237 7.50" Dia. Pulley-Dr. Plate

712-0375 Hex Cent. L-Nut %-16 Thd.

738-0147

754-0131

756-0137 Fl-ldler 68

710-0224

Hex Stop Nut %-24 Thd. 49

Bell-Wash.

Adj. Ferrule

Panel Assembly

Shifting Rod

Chute Crank

Hex Elastic Nut %-24 Thd.

Belt Guard Ass'y-

Idler Brkt, Ass'y-

Shid. Bolt %-16 Thd.

3V x 35.5 Belt

Hex Seif Tap Scr. #10 x .50"

Lg-*

710-0216 Hex Scr. %-16x.75" Lg.*

35

36

9755-501

Wheel Ass^y.—Comp.

734-0219 Tire—Only (12.5 x 4.50-6)

734-0210 Tube-Only (12.5x4.50-6)

10108

Rim Only

REF.

NO.

37

38

PART

NO.

736-0169

712-0798

COLOR

CODE

L-Wash. % Scr,*

Hex Nut %-16 Thd.*

DESCRIPTION

714-0143 Klik Pin-5/16" Dia, X 1.75" Lg.

40 736-0169

41

5048

L-Wash. Scr.*

Plate Ass'y.

5272 Wheel Hub Ass'y,

43

715-0118

Spring Pin Spiral 5/16 Dia. x

1.75" Lg.

44

46

50

51

52

5076

748-0151

5043

5066

711-0358

5116

711-om

715-0103

5118

Frame Cover

Flange Brg. .75 I.D.

Frame Ass'y.

Joint Brkt. Ass'y.

Joint Block

Chute Brkt. Ass'y.

Cotter Pin 3/32 X 1.00" Lg.*

Roll Pin V4 Dia. x Lg.*

Sprocket Shaft Ass'y.

53 710-0216 Hex Scr. %-16 X .75" Lg.*

54

710-0152

55

712-0287

56 736-0329

57 710-0237

736-0607 L-Wash. 5/16" Scr.*

58

Hex Scr. %-24x 1" Lg.*

Hex Nut li.20 Thd.*

L-Wash. 14" Scr.*

Hex Scr. 5/16-24 X .62" Lg.*

59 710-0442 Hex Scr. 5/16-18 X 1.50" Lg.*

710-0289 Hex Scr. 14-20 x .50" Lg.*

60

61

62

63 714-0128

64 756-0171

65

66

67

69

—

5228-

5230736-0235

736-0169

5124

710-0262

Engine

-456

Belt Guard Ass'y.

Sq. Key 14 X 1" Lg,*

3.50 Dia. Pulley .75 Bore

-456

Top Beit Guard Ass'y.

Fl-Wash.

L-Wash. %" Scr.*

Handle—R.H.

Carriage Bolt 5/16-18 x 1.50"

Lg.*

710-0606 Hex Scr. 14-20 x 1.50" Lg.*

70

71

5123 Handle—L.H.

NEW

PART

C

Page 10

314-830A

10

Page 11

ftEF.

NO.

PART

1

fex 2 711-0404

V.' 3 712-0158

" 4

5 5084

ó 736-0300

7

712-0116

714-Oni

8

9

711-0373

10

714-0111

n

12

714-0129

13

741-0131 Ball Bearing

14

712-0287

NO.

5087

5085

5138

COLOR

CODE

DESCRIPTION

Clutch Linkage

Shid. Nut 5/16-18 Thd.

Hex Cent. L-Nut 5/16-18 Thd.

Pivot Bracket Ass'y.

Linkage Arm

FI-Wash. .39 I.D. x .87 O.D.

Hex Stop Nut %-24 Thd.

Cotter Pin 3/32x 1.00'^ Lg.*

Shifting Rod

Cotter Pin 3/32 X 1.00" Lg.*

Shifting Yoke—Rod

#503 Key %" Dia,

Hex Nut 14-20 Thd.*

15 736-0329 L-Wash. 14" Scr.*

16 5034 Brg. Housing 1.38 Dia.

17

18

711-0360

710-0253

Drive Wheel Shaft

Hex Scr. %-16x 1.00" Lg.*

19 736-0169 L-Wash. %" Scr.*

20

21

22

23 736-0213

24

25

26 741-0919

27

28

29 711-0525

30

31

¿^32

:.V33

'^34 711-0363

35

36

37

38

5082 Chain Brkt. AssV-

712-0375

741-0134

Hex Cent. L-Nut %-16 Thd.

Ball Bearing .25 I.D.

Bell-Wash. .400 I.D. x .88 O.D:

5237

7.50" Dia. Pulley

717-0197 12 Tooth Sprocket

Ball Bearing .87 Dia.

10579

714-0132

Brg. Housing Ass'yHi-Pro Key #605

Drive Shaft

710-0259

736-0197

748-0198

712-0211

Sems Scr. 5/ 16-18 x .62" Lg.*

FI-Wash. .812 I.D.

Spacer

Hex Flange L-Nut %-24 Thd.

Neutral Plate

748-0227

711-0364

748-0227

714-0111

Flange Brg. .62" I.D.

Shift Sleeve

Flange Brg. .62" I.D.

Cotter Pin 3/32" Dia. x

1.00" Lg.* 104

39 5073

40 748-0166

711-0362 Clutch Shaft 106

41

736-0169 L-Wash. .38" Scr.*

42

710-0216

43

741-0131

44

45

736-0192 FI-Wash. .531 I.D. x .94 O.D. 110

46

748-0866

47

712-0200

48

736-0300

49

712-0116

50

732-0157

51

52

736-0119

53

712-0267

54

: 55

56

723-0168

57

713-0155

58

712-0116

59

715-0118

60

"TV

63

64

65

66

67

736-0198

716-0101

714-0137

738-0178

714-0129

748-0852

736-0108

■‘^51

9K62

5034 Brg. Housing 1.38" Dia. 109

5063-

5240

5106

Clutch Fork Ass'y*

Friction Wheel Adapter

Hex Scr. %-16x.75" Lg.* 107

Ball Bearing

Bevel Pinion

Hex Stop Nut 16-20 Thd.

FI-Wash. .39 I.D. x .87 O.D. 113

Hex Stop Nut %-24 Thd.

Spring

-456 Chain Idler Brkt. Ass'y.

L-Wash. 5/16" Scr.* 117

Hex Nut 5/16-18 Thd.* 118

Yoke Brkt. Ass'y.

Eccenter

Sprocket Idler—10 Tooth

#420 Chain x 40.50" Lg.

Hex Stop Nut %-24 Thd.

Spring Pin Spiral 5/16" Dia.

X 1.75" Lg.

Fl-Wash. .765 I.D.

Snap Ring .75" Dia. 126

Hi-Pro Key 3/16x%" Dia. 127

Thrower Axle 128

#503 Key %" Dia.

8-Tooth Sprocket 129

Fl-Wash. .51 I.D. x .75 O.D.

PARTS LIST FOR MODEL 314-830A

HEW

PART

REF.

NO.

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

105

108

111

112

114

115

116

119

120

121

122

123

124

125

PART

NO.

710-0170 Hex Scr. w/Lock 5/16-24 x

748-0142 Flange Brg. ,50" Dia.

715-0248 Roll Pin 3/16" Dia. X.75" Lg.*

5107 Shifting Yoke Ass'y.

732-0249

735-0114

716-0116

736-0229

5150

717-0151

748-0173

748-0172 Clutch Sleeve

748-0171

5112 Sprocket Hub Ass'y.

748-0151 Flange Brg. .75" I.D.

748-0171 Bronze Bushing

5038-456

748-0171

748-0151 Flange Bearing

736-0123

710-0538 Hex Scr. w/Lock 5/16-18 x

711-0361

748-0227

748-0167

711-0365

5077

748-0852 8-Tooth Sprocket

716-0104

736-0169

712-0711

748-0227 Flange Bearing .62 I.D.

714-0129

714-0126

736-0116

716-0106 "E"-Ring .50" Dia.

717-0288 Wheel Axle Ass'y.

710-0198 Sems Scr. 5/16-18 x.75"

5080

713-0134 #41 Chain w/ Master Link x

5033 Brg. Housing 2" Dia.

741-0133

748-0108 Flange Brg. ,50 I.D.

716-0102

710-0281 Hex Scr. '4-28 x .87" Lg.*

5079

712-0896

736-0119 L-Wash. 5/16" Scr.*

712-0267

732-0157 Spring

747-0113

732-0269

712-0324

5088

712-0116

736-0300 Fl-Wash. .39 I.D, x .87 O.D.

738-0129

748-0108 Flange Brg. .50" I.D.

713-0130 #41 Cham w/Master Link

5075 Clutch Fork Brkt. Ass'y.

748-0151

715-0118

5272

11

COLOR

CODE

DESCRIPTION

.62" Lg.*

Compression Spring

Rubber Bellow

Snap Ring .75" Dia.

Bell-Wash.

Clutch Ass'y,

Clutch Cone

Clutch Housing

Bronze Bushing

Thrower Paddle Ass'y.

Bronze Bushing

Fl-Wash. .341 I.D. x .06 O.D.

.62" Lg.

Bevel Gear Shaft

Flange Brg. .62 I.D.

Bevel Gear

Sleeve

Bevel Gear Housing Ass'y.

"E"-Ring .50" Dia.

L-Wash. -38" Scr.*

Hex Nut H-24 Thd.*

#503 Key .62" Dia.

#606 Hi-Pro Key

Fi-Wash.

Lg-*

Friction Wheel Ass'y.

23" Lg.

Ball Bearing

Snap Ring

Shift Fork

Hex Stop Nut M-28 Thd.*

Hex Nut 5/16-18 Thd.*

Lockout Rod

Spring

Hex Stop Nut '4-20 Thd.

Clutch Brkt.

Hex Stop Nut %-24 Thd.

Axle Bolt .50" Dia.

x 22" Lg.

Flange Brg. .75" I.D.

Spring Pin Spiral 5/16" Dia.

X 1.75" Lg.

Wheel Hob Ass'y.

NEW

PART

Page 12

M

LUBRICATION POINTS

Page 13

LUBRICATION POINTS

Lubricate With a Few Drops of

Light Oil (Ref. Nos. 214, 226,

Lubricate With General Pur

pose Grease (Ref. Nos. 213

and 173).

Uibricat« With a Few Drops

f Ught Oil (Ref. Nos. 204,

;02 and 201).

Lubricate With General Pur>

pose Grease (Ref. No. 197).

13

Page 14

Auger Does Not Operate, Hub

Broken on Sprocket. Roll Pin

Broken.

Defective Engine Pulley or

Misaligned Engine Pulley

Causes Belt Failure.

Do Not Pry Down on Engag

ing Lever. Excessive Leverage

Will Cause Damage to Idler

Bracket. Assembly and Mis

alignment of Idler Pulley. This

Will Result in Belt Damage.

73

O

C

00

If Augers Hits Heads of Bolts

In Housing, Bend Tips of

Auger to Cleor.

This ROLL PIN Referred to as

Shear Pin by Many Users.

Idler Must be in Alignment

With Belt, if Not. Straighten

Idler Bracket to Correct.

Added Spring Pressure Will

Reduce Idler Bracket Assem

bly Vibration and Reduce Belt

Problems. Belt "Slop" Con

Cause Belt to Break.

Chain Must Not Hit Housing

While Operating, If Chain

Hits Flange, File Clearance,

Add Spring Pressure on Idlers

to Reduce "Slap" in Chain.

tn

X

O

O

-H

Z

o

Page 15

ì

Page 16

Remove Frame Cover 5067

to Service Chains.

Unit Will Not Propell With

Damaged Friction Wheel.

Misalignment of Bevel Gear and Pinion Gear

Cause Drag on Chain. Loosen Housing and Re

align,

TROUBLE SHOOTING

Beni Shifting Fork Ccrjse Hard

Shifting of Drive Clutch. Als^

Bent Clutch Fork Assembly.

Also, Bearing Not Pressed

Firmly on Drive Wheel Shaft.

Lockr ^ too Tight on Axle

Bolt ises Drag on Chain.

Do Not Engage Auger With Main Clutch Engaged!

Engaging Auger Clutch With Main Clutch En

gaged Will (tomoge Pins on Sprocket Hub As

sembly. Damaged Pins Cause Hard Auger Clutch

Engagement and Even AUGER CLUTCH FAILURE.

of the "V" Belt to Trap Away From the En-

gitii'Pulley When Main Clutch is Disengaged

Will Also Couse Damoge to Sprockot Hub As

sembly When Auger Clutch is Engogod.

PORM NO. 770-5524

Key Must be Straight in Key

Seat for Correct and Easy

Clutch Operation.

PRINTED IN U.S.A.

Loading...

Loading...